Abstract

The world was in demand of wood products mainly for interior design, furniture making and household utilizes and at the same time agricultural residue usage was increased for making Engineering woods. Coconut is an abundant crop in Asia and coir fiber was extracted from coconut husk, as by-products. MDF was one of the by-products produced from coir reinforced with resin. In this work, the coconut coir was used to produce hybrid MDF with basalt fiber and phenol-formaldehyde resin hybridization. The panel was prepared with different coir and basalt fiber combinations by keeping a fixed resin percentage. The coir and basalt fiber percentage ranges from 40 to 75 % and 5–40 % respectively. SEM studied the morphological characteristic of the panel whereas thermal stability of the panel was evaluated through Thermo-gravimetric Analysis. The fire resistance was observed through a flammability test. The physical properties and mechanical properties were evaluated by ASTM Standards. From the investigations, the MoR and MoE have a higher value for Panel 3 with 29.14 N/mm2 and 3143 N/mm2 respectively and the internal bonding strength shows of 2.1 N/mm2 maximum values of mechanical properties. The result shows for panel 3 has 15 % and 18 % more strength for MoE and MoR respectively and IB also shows 35 % of increased value.

Keywords: Medium densityfiberboard, Coir, Basalt, DSC, TGA, Flammability

Medium densityfiberboard; Coir; Basalt; DSC; TGA; Flammability.

1. Introduction

The development of highly populated countries in the world resulted in wood usage and its products increasing year by year. At the same time, deforestation through human activities and natural calamities, global warming was asignificant challenge for humans. To overcome the above problem, the engineering woods like plywood, particle wood, MDF, laminates were introduced and produced using agricultural residue. Generally, MDF fabricated through fibers was reinforced in a resin matrix and compressed with hot pressing. In the Global market, the plywood growth rate is 8–9%, but for MDF, the growth rate was 17–20%. In recent times, the usage of MDF developed from agricultural residues were increased gradually. They were namely rice straw, wheat straw, sugarcane bagasse, empty fruit bunch fiber, soybean straw, coconut coir, etc. and even cough grass were used to prepare MDF and has good mechanical properties but low fire redardent property Nasir et al. (2019); Tsvetkov et al., 2019; Ayrilmis et al. (2011); NorulIzani et al. (2013); YuliatiIndrayani et al. (2015); AlirezaAshori et al. (2009); Philip Ye et al. (2007). The MDF was produced in hybridization form with the combination of two different fiber materials like glass fiber, rubber and sisal fiber. Here when considering about material, cost was more Khalil et al. (2010); Mohammed et al. (2017); Hassanin et al., 2016; Redwan et al. (2019); JunfengHou et al. (2015); Gillah et al. (2000). When considering the preparation of MDF, the properties of the board depending on hot pressing time, temperature, moisture content, and initial resin content Gul et al., 2017; Hong et al., 2017; Magalhã es et al., 2020.

Since 2018, India is the largest coconut harvesting country in the world. Around 75% of production are from south Indian states and the coir production was most crucial business and 2500 trillion tonnes were exported to foreign countries. At the same time, 7.5 million tonnes of coir waste is produced annually from coir industries, including short fiber, coir pith. The coir pith was used for fertilizer, whereas the short fiber was dumbed as waste. This can be used to produce the MDF board commercially.

Similarly, Basalt fiber is produced from rocks, and it has good thermal properties, sound insulation, and vibration resistance than glass fibers. Owing to good chemical resistance, basalt could be used as a replacement for carbon and glass fibers. This fiber was used in major industries of automotive, construction, shipbuilding, etc Vivek Dhand et al. (2015). In this work, the basalt fiber was chosen as hybrid reinforcement in a medium-density fiberboard with coir fiber where the phenol-formaldehyde resin was employed as the matrix. The PF resin was used for its excellent performance in bonding, water-resistance, and stability to wood panels Gardziella et al., 1985, Gardziella et al., 2000. The main purpose of using coir fiber was having around 50% of lignin, which helps to have self bonding during hot pressing and also to minimize the usage of forest woods and to utilize the agro residue especially, the coir fibre, which is abundant and has good mechanical properties and the basalt fibre has good thermal properties. Through this, the fire retardant property will be improved. These makes me helps to produce hybrid composite MDF.

2. Materials and methods

2.1. Materials

The Phenol, 40% formaldehyde solution, Glacial acetic acid, concentrated Sulphuric acid, and hexamethylenetetramine were used for preparation of resin. All these chemicals were purchased from Chenchems Private Limited, Chennai. The chopped coir fiber length ranging from 3 mm to 15 mm was bought from Central Coir Research Institute, Kerala. Similarly, the basalt fiber length of 6mm was bought from Capital Refractories India Private Limited, Mumbai.

2.2. Resin preparation

A 500 ml beaker was used for mixing 25 ml formaldehyde solution with 50 ml of glacial acetic acid and 20 g of phenol. Finally, 1ml of concentricsulphuricacid was added into the mixture and stirred continuously for 5 min. A large quantity of residue was formed and it was crushed to convert into powder form. The powder was cleaned with water continuously and the acid was removed. Then, the powder was filtered and dried in an oven.

2.3. MDF panel fabrication

Eight compositions of panels were prepared with fiber volume fractions ranging from 40% to 75% and 40%–5% forthe coir and basalt respectively. The volume of resin percentage was taken as constant with 20% of the panel. The compression molding machine was used to prepare the panel by compressing the mixed fiber with resin and the details were mentioned in Table 1.

Table 1.

Specifications of the compression molding machine.

| S.No | specification | value | unit |

|---|---|---|---|

| 1 | The capacity of the press | 25 | Ton |

| 2 | Mold size | 300 × 300 × 5 | mm3 |

| 3 | Pressing speed | 25 | mm/sec |

| 4 | Working pressure | 25 | kg/cm2 |

| 5 | Temperature | 145 | °C |

The chopped coir fiber was taken and cleaned with plain water and by using a hot air oven, the fiber was dried at room temperature to remove the dust particles for 24 h. The Chopped basalt fiber was mixed with chopped coir fiber manually according to various volume fractions. Finally, the 20% volume of resin powder was added with the fibers and mixed thoroughly. The mixed fiber and resin were taken and placed on the compression molding and compressed at 145 °C for 8 min and kept compressed for 2 h. The mixed chopped fibers with resin powder and fabricated panel were shown in Figures 1a and 1b. In this same way, 8 different proportions of the panel were prepared and the compositions listed in Table 2.

Figure 1.

(a) Mixture of fibers, (b) Prepared sample panel.

Table 2.

Volume fractions of Different Panels Prepared.

| PANEL TYPE | Volume Fractions in Percentage |

C:B:P | ||

|---|---|---|---|---|

| Coir | Basalt | PF Resin | ||

| 1 | 40 | 40 | 20 | 2:2:1 |

| 2 | 45 | 35 | 20 | 9:7:4 |

| 3 | 50 | 30 | 20 | 5:3:2 |

| 4 | 55 | 25 | 20 | 11:5:4 |

| 5 | 60 | 20 | 20 | 3:1:1 |

| 6 | 65 | 15 | 20 | 13:3:4 |

| 7 | 70 | 10 | 20 | 7:1:2 |

| 8 | 75 | 5 | 20 | 15:1:4 |

2.4. DSC analysis of phenol formaldehyde resin

The DSC analysis was carried out as per ASTM D3418 (ASTM D3418-21, 2021) standards using the Shimadzu DSC 60 plus machine with temperatures ranging from -100 °C to 500 °C. Here, 10 mg of phenol-formaldehyde powder was placed in the Standard cooling bath with liquid nitrogen and used to analyze the DSC. The powder was analyzed with the range of temperature from 0 to 200 °C and rate of heat at 25 °C/min.

2.5. Characterization of MDF panel

The panels were tested to find the physical properties like specific gravity or density and moisture content with ASTM 1037. It was important and compulsory for every sample to undergo a physical test before testing mechanical properties. The specimens to be tested were kept in the oven at 105 °C for fixed duration of 1 h to dry (Mbereyaho et al., 2020). The moisture content was calculated with the below equation

| (1) |

Where, M.C= Moisture Content, %

Wi = initial weight.

Wf = Final oven dry weight.

Similarly, the density was calculated with the specimen after oven-dry weight, next to moisture content with the equation below

| (2) |

Where ρ = density kg/m3

m = mass of the sample after oven-dry weight

l = Sample length

b = breath of the sample

h = height of the sample.

Similarly, the internal bonding strength (IB), modulus of rupture (MoR) and modulus of elasticity (MoE), were found using tensile strength perpendicular to surface and UTM with 3 points bending test respectively with ASTM D1037 (ASTM D1037-12, 2020).

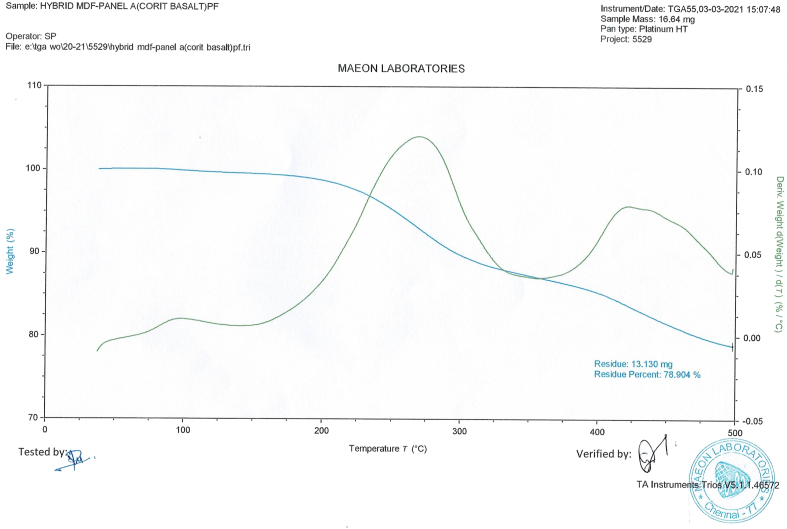

2.6. TGA analysis of hybrid MDF

The TG was analyzed through TA instrument, a model of TGA 55. The sample was heated with a range of temperature from 30 °C to 500 °C and the rate of heat at 10 °C/min and the rate of flow at 60 ml/min under nitrogen atmosphere.

2.7. Morphological study of hybrid MDF using SEM

The surface of the hybrid board is found through SEM image with the machine model of TESCAN VEGA3, and this is a tungsten heated filament and thermionic emission system that comes with the electron source. This can be used in any operation.

3. Results and discussion

3.1. Differential scanning calorimeter analysis for PF resin

The phenol-formaldehyde resin was cured under the condition of pH 7.2 and with the environmental condition using a DSC analyzer. Figure 2 shows the PF resin curing condition through a DSC graph. This shows the endothermic peak, which is due to significant mass loss in the condition of pH 7.2, the water is evaporated quickly with an increase in temperature in peak 1. This is due to the loss of water; the resin would change the state to gel between the two peaks (Qiang and Wang, 2018). When the temperature reaches peak 2, the water is completely evaporated, this is due to the endothermic effect. In between the peak 1 and 2, there was no exothermic effect because of water evaporation.

Figure 2.

DSC graph for phenol-formaldehyde resin.

3.2. Physical and mechanical properties of hybrid MDF

The moisture content was calculated from Eq. (1), and the results were shown in Figure 3. Through this, Panel 3 has a minimum value of 9 % and Panel 7 has a higher value of 14 % moisture content. This was due to coir fibers having more moisture absorption property than the basalt fiber. The agglomeration was formed when the coir fiber was increased, leading to the pores between the fibers. So, the moisture content from Panel 4–8 has increased non-linearly according to the increase in the volume of coir fibers. Generally, when the moisture content was increases, the density of the fiberboard will decreased. This will lead to absorb moisture and water and it causes instability.

Figure 3.

Moisture content for hybrid MDF

The fiber interaction, resin bonding, pressing time, and moulding pressure influenced the density for the same compositions. Hence the panel was prepared with constant press time and pressure in this work. Similarly, the volume of the resin content was also fixed as constant for all the panels. The volume of fibers was varied with different proportions, in which Panel 3 has 50 % of coir and 30 % of basalt fiber has a greater density of 835 kg/m3 and lowest value of 770 kg/m3 for panel 5 has 60 % of coir and 20 % of basalt fiber. This may be due to the interaction between the fibers through the resin bonding. The agglomerated fiber in the panel was not bonded with resin completely. The density was calculated through Eq. (2) and all panels’ density was shown in Figure 4.

Figure 4.

Density for hybrid MDF

The Bending and Internal Bonding Strength of the MDF is majorly influenced by factors that include the fiber content, nature of reinforcement of fiber, resin content, the density of the board, press time, and press temperature. The Modulus of rupture (MoR) and Modulus of Elasticity (MoE) can be calculated through bending strength, shown in Figures 5 and 6 respectively. In this, MoR and MoE have a higher value for Panel 3 with 29.14 N/mm2 and 3143 N/mm2 respectively. The inter bonding between the fiber to fiber with resin was increased more than other panels. This increases the panel strength and for Panel 8 which had the least basalt fiber volume, shows the value of MoR and MoE as 25.23 N/mm2 and 2674 N/mm2 respectively. The MoR and MoE show 15 % and 18 % greater than least volume of basalt reinforced Panel 8 compared to Most volume of basalt reinforced Panel 3 respectively. The value of MoR and MoE was directly proportional to the panel's basalt fiber percentage and density. The panel 3 has increased value because the bonding between the fibers with phenol-formaldehyde resin was more than the other panel.

Figure 5.

Modulus of rupture for hybrid MDF

Figure 6.

Modulus of elasticity for hybrid MDF

Earlier it was discussed the relation between the density and mechanical properties which was directly linked. With the same aspect, the internal bonding strength also shows the same for Panel 3 with the higher value of 2.1 N/mm2, and Panel 5 has a low value of 1.56 N/mm2 which was shown in Figure 7. The cross link between the fiber and fiber contact has increased more in the panel and also the fiber's better contact with the resin, decreasing the pores in the panel. Generally, the hot pressing made the resin bond between the fibers and the fiber, giving the panel internal strength (see Figure 8).

Figure 7.

Internal bonding strength for hybrid MDF

Figure 8.

TGA for panel 3 of Hybrid MDF.

3.3. Thermal stability using TGA

The thermal stability was observed through TGA thermo gram. There were three different stages of degradation observed in the figure. In the first stage, the temperature range from 35 °C to 203 °C and the weight loss was due to water absorption on the surface and in the inner part of the panel. The second stage of weight loss was due to evaporation of formaldehyde in the resin, water, and organic molecules and the temperature range was from 203 °C to 310 °C. The third stage of thermal decomposition, the basalt fibre provides stability and resistance to the panel.

3.4. Flammability test using UL-94HB

In horizontal flammability tests, all the panels produced the C class which is the highest rating mentioned in Table 3, indicating that they are flame spread resistance. Once the torch was removed, the hybrid MDF was found to have excellent fire resistance with minimal or no flame and smoke. When the coir and basalt fibres were mixed, they were also capable of maintaining good fire performance. This board was used as an insulating material and it cannot catch fire quickly Crossley et al., 2013; Bachtiar et al., 2019.

Table 3.

UL 94 Horizontal burn test result.

| S.No | Specimen | Horizontal burn result |

||

|---|---|---|---|---|

| Burn time | Burn length | Result | ||

| 1 | Panel 1 | No flame | Glow only | pass |

| 2 | Panel 2 | No flame | Glow only | pass |

| 3 | Panel 3 | No flame | Glow only | pass |

| 4 | Panel 4 | No flame | Glow only | pass |

| 5 | Panel 5 | No flame | Glow only | pass |

| 6 | Panel 6 | No flame | Glow only | pass |

| 7 | Panel 7 | No flame | Glow only | pass |

| 8 | Panel 8 | No flame | Glow only | pass |

3.5. SEM image for hybrid MDF

From 8 Panels are investigated for density, moisture content, MoR, MoE and IB, the Panel 3 shows superior results than other Panels. Hence, the morphological study of Panel 3 has been performed through SEM Analysis. From the SEM Micrograph in Figure 9, it can be clearly understood that fibers were good interlinkage and overlapping each other with resin throughout the panel. The strength of its constituent units, as well as their geometries and unit-to-unit bonding, determine its performance. The basalt fibers were arranged like a bunch and mixed with coir fiber, which interlocked through resin bonding and reduces the gap in the panel. This leads to reduction in moisture content and has high density. So, the scattered resin and bonding between the fibers has increased the mechanical property of Panel 3. Similarly, in Figure 10 the microscope was taken with 20 μm. The resin was layered on the fiber's surface, which shows that the resin was mixed throughout the surface of fibers in the panel and it makes the fibers to bond tightly. The arrangement of basalt fiber on the panel is seen clearly in this figure.

Figure 9.

Blended Coir and Basalt fiber in panel 3.

Figure 10.

Surface of panel 3 with 20μm.

4. Conclusion

Here, the work was concluded that the resin influences the fiber, by which compressed fiberboard with good physical and mechanical properties can be made and density also influences the mechanical properties directly. It gives a better result for the hybrid MDF. Based on the basalt fiber percentage, the properties vary from panel to panel, in which panel 3 shows 15 % and 18 % more strength than panel 8 for MoE and MoR, respectively and IB also shows 35 % of increased value. At the same time the all other panel also attains the standard requirement of medium density fiberboard.

This shows that the waste outlets of the coir industry have been used to produce the hybrid MDF, which was one of the by-products of coconut coir. In the future, the coir will be source for preparing all type of engineering wood products. At the same time, this will reduce the usage of forest sources and control deforestation in the future.

This result strongly proves that the coir and basalt fiber can be used to produce the hybrid medium density fiberboard, which can help the Engineering Wood manufacturers to produce hybrid boards using coir and basalt fiber. This hybrid board can be used commercially for many applications like interior design, furniture, etc.

Declarations

Author contribution statement

N.Pugazhenthi: Performed the experiments; Contributed reagents, materials, analysis tools or data; Wrote the paper.

P.Anand: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

Data included in article/supp. material/referenced in article.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Acknowledgements

The staff members of CCRI, Kochi.

References

- AlirezaAshori Properties of medium-density fiberboard based on bagasse fibers. J. Compos. Mater. 2009;42(18) [Google Scholar]

- ASTM D1037-12 . ASTM International; West Conshohocken, PA: 2020. Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials.www.astm.org [Google Scholar]

- ASTM D3418-21 . ASTM International; West Conshohocken, PA: 2021. Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry.www.astm.org [Google Scholar]

- Ayrilmis N., Jarusombuti S., Fueangvivat V., Bauchongkol P. Effects of thermal treatment of Rubberwood Fibers on physical and mechanical properties of medium density fiberboard. J. Trop. Forest Sci. 2011;23(1):10–16. [Google Scholar]

- Bachtiar Erik, Kurkowiak Katarzyna, Yan Libo, Kasal Bohumil, Kolb Torsten. Thermal stability, fire performance, and mechanical properties of natural fibre fabric-reinforced polymer composites with different fire retardants. Polymers. 2019;11:699. doi: 10.3390/polym11040699. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Crossley Richard, Schubel Peter, Stevenson Anthony. Furan matrix and flax fibre as a sustainable renewable composite: mechanical and fire-resistant properties in comparison to phenol, epoxy and polyester. J. Reinforc. Plast. Compos. 2013;33:58–68. [Google Scholar]

- Gardziella A., Pilato L.A., Knop A. Springer; New York, NY, USA: 1985. Phenolic Resins: Chemistry, Applications, Standardization, Safety and Ecology. [Google Scholar]

- Gardziella A., Pilato L.A., Knop A. Springer; New York, NY,USA: 2000. Phenolic Resins. [Google Scholar]

- Gillah P., Irle M., Amartey S. Development and production of laboratory-scale novel MDF panels from composite and nonwoven mattresses of sisal and wood fiber mixtures. HolzalsRoh-und Werkstoff. 2000;58:324–330. [Google Scholar]

- Gul W., Khan A., Shakoor A. Impact of hot pressing temperature on medium density fiberboard (MDF) performance. Adv. Mater. Sci. Eng. 2017;2017:1–6. [Google Scholar]

- Hassanin Ahmed H., Tamer Hamouda, ZekiCandan Ali Kilic, Akbulut Turgay. Developing high-performance hybrid green composites. Compos. B Eng. 2016;92:384–394. [Google Scholar]

- Hong Min-Kug, Lubis Muhammad AdlyRahandi, Park Byung-Dae. Effect of panel density and resin content on properties of medium density fiberboard. J. Kor. Wood Sci. Technol. 2017;45(4):444–455. 1017-0715(pISSN) [Google Scholar]

- JunfengHou, Feng Fu, Lu Keyang, Chen Lanzhen. Highly conductive fiberboards made with carbon and wood fibers. BioResources. 2015;10(4):6348–6362. [Google Scholar]

- Khalil H.A., Firdaus M., Jawaid M., Anis M., Ridzuan R., Mohamed A. Development and material properties of new hybrid medium density fiberboard from empty fruit bunch and rubberwood. Mater. Des. 2010;31:4229–4236. [Google Scholar]

- Magalhães R., Nogueira B., Costa S., Paiva N., Ferra J.M., Magalhães F.D., Martins J., Carvalho L.H. Effect of panel moisture content on internal bond strength and thickness swelling of medium density fiberboard. Polymers. 2020;13(1):114. doi: 10.3390/polym13010114. 30. PMID: 33396663; PMCID: PMC7795052. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mbereyaho Leopold, Nzayisenga Line, Tuyizere Ernest, Hagenimana Faustin. Application of African couchgrass in manufacturing of medium density fiberboard. J. Eng. Proj. Prod. Manag. 2020 [Google Scholar]

- Mohammed Y. Abdellah, Fahmy Hanan S., Abdel-Jaber G.T., Hashem A.M. Characteristic properties of glass fiber reinforced sugarcane bagasse medium density fiber board. Ciência&Tecnologia dos Materiais. 2017;29(3):97–105. ISSN 0870-8312. [Google Scholar]

- Nasir M., Khali D.P., Jawaid M., Tahir P.M., Siakeng R., Asim M., Khan T.A. A recent development in binderless fiberboard fabrication from agricultural residues: a review. Construct. Build. Mater. 2019;211:502–516. [Google Scholar]

- NorulIzani M.A., Paridah M.T., MohdNor M.Y., Anwar Umk. Properties of medium-density fiberboard (MDF) made from treated empty fruit bunch of oil palm. J. Trop. Forest Sci. 2013;25(2):175–183. [Google Scholar]

- Philip Ye X., James Julson, MonlinKuo Al Womac, Myers Deland. Properties of medium density fiberboards made from renewable biomass. Bioresour. Technol. 2007;98:1077–1084. doi: 10.1016/j.biortech.2006.04.022. [DOI] [PubMed] [Google Scholar]

- Qiang Wei, Wang Wei-Hong. Properties of phenol-formaldehyde resin modified with a silane coupling agent (KH550) Int. J. Adhesion Adhes. 2018;84:166–172. ISSN 0143-7496. [Google Scholar]

- Redwan Amamer, Haji Badri Khairiah, AzizahBahrum Study the physical properties of medium density fiberboard utilized by hybrid mixture of Efb fiber and Kenaf fiber. Al-Nahrain J. Sci. 2019;22(2):27–30. [Google Scholar]

- Tsvetkov V.E., Semochkin Y.A., Nikitin A.A. A technology for production of fiberboards based on cotton stalks. Polym. Sci. D. 2019;12(3):328–330. [Google Scholar]

- Vivek Dhand, Mittal Garima, Rhee Kyong Yop, Park Soo-Jin, Hui David. A short review on basalt fiber reinforced polymer composites. Compos. B Eng. 2015;73:166–180. ISSN 1359-8368. [Google Scholar]

- YuliatiIndrayani, Setyawati Dina, Umemura Kenji, Yoshimura Tsuyoshi. Decay resistance of medium density fiberboard (MDF) made from pineapple leaf fiber. J. Math. Fund. Sci. 2015;47(1):76–83. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supp. material/referenced in article.