Abstract

Due to the antagonism and synergy among environmental factors in the poultry house, the influence process becomes extremely complex. As a result, it is difficult to predict and evaluate the degree of such influence accurately. In this paper, we study the poultry house environment factor and its relationship with poultry production performance, using the gray relation analysis (GRA) to filtrate the main factors that influence the evaluation of the poultry house environment. Put forward using the gray relation degree (GRD) to improve the method for structuring the judgment matrix, and weights are more objective and reasonable. The evaluation index system and evaluation model are constructed through the analytic hierarchy process (AHP). It is expected that the comprehensive evaluation of the indoor environment status of the poultry house can guide the optimization of the environmental control in the poultry house and obtain better production indicators of the poultry. In this study, the experimental broiler house was enclosed in autumn. Because of the ventilation system, the indoor environment is still affected by the outdoor environment. The top 3 in the calculation of weights were outdoor environment (0.4315), indoor temperature (0.2384), and indoor air quality (0.1687), which were consistent with experience. From October 24 to 27, the environmental evaluation values of the experimental broiler house were {2.4367, 2.8149, 2.3857, 2.5669}, that is, the evaluation results were {good, good, good, good}; consistent with the expert manual judgment. The correctness and practicability of the proposed method were verified. This paper provides a scientific basis for environmental evaluation and environmental control in the poultry house.

Key words: environmental comprehensive evaluation, the gray relation degree, the analytic hierarchy process, the poultry house, the weight

INTRODUCTION

In recent years, China has put forward standardized scale livestock and poultry breeding and taken “establishment of breeding, large-scale production, improved breeding of livestock and poultry, systematization of epidemic prevention, pollution-free, and normalized supervision” as the standards to accelerate the transformation of animal husbandry. With the development of the poultry breeding industry in China, large-scale breeding has become a popular trend. Improving the level of environmental control in poultry houses, on the one hand, can improve the welfare of poultry farming. On the other hand, it can improve the productivity of poultry, so it is receiving more and more attention. Accurate evaluation of environmental conditions in poultry houses is the basis of improving environmental control levels in poultry houses.

For the past few years, the rapid development and industrialization of the “perception-based” internet of things (IoT) technology have gradually penetrated all walks of life. The agricultural IoT, including the livestock and poultry industry, has also developed rapidly, and the use of sensors has extensively promoted the development of the agricultural IoT. Livestock and poultry IoT-based environmental monitoring systems continuously monitor many different field data, such as temperature, humidity, CO2 concentration, and NH3 concentration. Some scholars have studied the influence of single environmental factors on poultry farming. Barott pointed out (Barott and Pringle, 1946) that within the range of 18 to 26°C, laying hens can maintain a balance between heat production and heat dissipation. That is, 18 to 26°C is the comfortable temperature for laying hens. (Cerci et al., 2003) believed that 16 to 25°C was a suitable environment temperature for laying hens to grow. Marsden (Marsden and Morris, 1987) showed that the most suitable environmental temperature for laying hens was 21°C, and when the temperature was higher than 30°C, the change of feed composition was not enough to offset the impact of temperature on laying hens' production. Miles (Miles et al., 2004) showed that body weight was significantly depressed by 6 and 9% for the 50 and 75 ppm concentrations of NH3 as compared with 0 ppm. Also, mortality was significantly greater at the 75 ppm NH3 concentration, 13.9% compared with 5.8% for the 0 ppm treatment. Nevertheless, the above studies are more than a few in a single environmental factor on the impact of poultry production.

Based on this kind of research, some evaluation methods for the poultry house environment have been produced in the industry. In summer, the thermal and humid environment composed of Temperature and Humidity is generally used to evaluate the environmental conditions in the houses, while in winter, the concentration of CO2 is mainly used as the monitoring index of environmental regulation. However, for the poultry farming industry, temperature, humidity, CO2 concentration, NH3 concentration, and wind speed are all key factors affecting the poultry production environment (Park et al., 2015; Zheng et al., 2020). By focusing only on a single index, a comprehensive analysis and evaluation of multiple environmental factors cannot be carried out, resulting in the cut of the organic connection between multidimensional data and the inability to mine the information contained therein.

Environmental factors are also considered a part of poultry welfare in the existing poultry welfare evaluation methods (Lay et al., 2011, Shimmura et al., 2011, Van Horne and Achterbosch, 2008). The most commonly used evaluation methods mainly include Welfare Quality (Butterworth et al., 2009) and Assurewel (Assure Wel, 2019) Welfare evaluation model. However, the existing poultry welfare evaluation system only considers part of the environmental indicators. For example, the Assurewel Welfare evaluation model only covered 2 environmental factors, NH3 and dust. On this basis, Du Xinyi (Du et al., 2020), Bai Shibao (Bai et al., 2017), Wang Qiang (Wang et al., 2016) added CO2, H2S, temperature, humidity, wind speed, and other environmental indicators to the welfare index evaluation system of the condition of the poultry house or the comprehensive environmental evaluation of the poultry house. However, the effects of indoor light, particulate matter (PM2.5, PM10), H2S, and other environmental factors on poultry farming were not considered. The selection of the above environmental indicators often depends on personal experience and preferences. Only a few environmental indicators are selected for evaluation, which affects the selection of main impact factors for comprehensive environmental evaluation. In addition, the weights of various environmental factors were fixed value in the welfare evaluation model, ignoring the differences in environmental preferences of different chicken species, and the differences in climate conditions of different geographical locations.

There are many parameters related to the environment of the poultry house, and each environmental factor interacts with each other. Based on analyzing the environmental parameters of the poultry house, it is a complex problem to evaluate the environmental status of the poultry house accurately and adjust the environment reasonably. An index system that comprehensively evaluates the poultry house's environment is needed to help us evaluate the environment of the poultry house more effectively. It is expected that the objective evaluation of the indoor environment status of the poultry house can guide the optimization of the indoor environmental control in the poultry house and obtain better production indicators of the poultry.

In cybernetics, the depth of color is commonly used to represent the clarity of information. For example, Ashby (Ashby and Pierce, 1957) calls the object with internal information unknown as a "black box." With the continuous development of information technology, people's requirements for information transparency have also increased accordingly. Therefore, we use "black" to represent information unknown, "white "to represent information clear, and "gray" to represent partial information known and partial information unknown (Ashby and Pierce, 1957). Accordingly, based on this, Ju-Long (1982)gave the following definition: we call the system with obvious information a white system, the system with unknown information a black system, and the system with partial information known and partial information unknown as a gray system.

According to the definition of the gray system (Ju-Long, 1982), the poultry house can be regarded as a typical gray system. The system input is the environmental index, and the environmental factors are coupled with each other. The system output is the production index of poultry, such as death rate, broilers weight, tibia length, egg production rate of laying hens. Gray relation analysis (GRA) places all inputs of the gray system under the same standard and studies the correlation degree between inputs and outputs, which avoids the coupling problem between inputs to a certain extent. Therefore, this paper uses the GRA method to determine the main influencing factors and evaluation indexes of environmental evaluation in the poultry house.

Analytic Hierarchy Process (AHP) decomposes complex problems into various component factors, which constitute a hierarchical structure according to the dominant relationship, determines the importance of each factor in the same level through pin-to-pair comparison, and then determines the overall ranking of the relative importance of alternatives by integrating the judgment of decision-makers (Saaty, 1994). In this study, the poultry house environment is divided into 6 parts: temperature environment, humidity environment, air quality environment, light environment, noise environment, and outdoor environment. The analysis is carried out layer by layer, and gray relation degree (GRD) is used to improve the construction of the judgment matrix, and then determine the weight of each environmental factor, and finally obtain the evaluation results.

MATERIALS AND METHODS

Animals and Experimental Conditions

Broiler chicks (Ross 308) at one d of age were obtained from Beijing Dafeng Poultry Breeding Co., Ltd. (Beijing, China) and reared in environment-controlled chambers, following the procedures described in the Ross 308 Broilers Husbandry Manual. All diets were formulated to meet the nutrient requirement for broilers suggested by National Research Council (NRC, 1994).

The experiment was conducted in an enclosed broiler house of a poultry farm in Yi County, Baoding city. The broiler house was 90 m in length, 15.26 m in width, 2.2 m in ridge length, and 3.2 m in inside height. The broiler house adopts a 3-layer H-type cage, Unit cage length × width × height: 105 cm × 80 cm × 45 cm, each layer spacing 14 cm. There are 3 rows and 4 aisles in the house, and the spacing is 1.3m. Thirty thousand healthy Ross 308 broilers were raised in the broiler house.

Routine immunization, free drinking water, regular disinfection in the broiler house. For broilers aged from 1 to 7 d, the light intensity was 30 to 60 lx for 24 h. At 9 d of age, the light intensity decreased from 1 h to 20 h and gradually decreased to 5 to 10 lx. From 12 to 30 d of age, the light duration was 20 h per d. After 30 d of age, the light duration gradually increased from 1 h to 24 h, and the light intensity remained unchanged.

There are 18 fans on the east side of the building with a total power of 36,000 W. There are 140 small Windows of 35 cm × 30 cm on the inner wall of the house. Wet curtains are set on the north, east, and west walls at the front of the broiler house, with a total area of 106 m2.

Experimental Design and Measurements

Three hundred and sixty Ross 308 experimental broilers were randomly divided into 9 groups with 4 replicates per group and ten broilers per replicate. All the broilers were raised in the middle layer of 3-layer cages.

Before the experiment, considering the unique environment of livestock and poultry breeding, and according to the shape of the sensor size, response time, sensitivity, measurement accuracy, resolution, and other inherent characteristics, careful consideration of the sensor selection. Temperature and humidity sensor selected SHT30 (Sensirion, Swiss). MH-Z19B-CO2 sensor (WeiSheng, China) was selected for CO2 monitoring. The wind speed sensor EE65-VB9 (East Qifeng Technology Co. Ltd, Beijing, China) was used for wind speed monitoring. NH3 and H2S were monitored by NE-NH3 and NE-H2S-P sensors (Nemoto Electronic Technology Co. Ltd, Shanghai, China). For the collection of PM2.5/PM10 parameters, the SDS011 laser sensor (NuoFang, China) was selected.

The sensors were deployed at the 9 (W11–W33) sampling points (Figure 1), next to the middle layer of 3-layer cages (Figure 2), and 13 environmental data, including CO2, NH3, H2S, PM2.5, PM10, wind speed, temperature, humidity, illumination, outdoor temperature, outdoor humidity, outdoor wind speed, outdoor illumination, were collected. The data collection interval was 1 h.

Figure 1.

The experimental broiler house.

Figure 2.

Sensor location.

Broilers were raised in the cage system, the weighing data of broilers were measured manually by ASC-SC73 digital weighing scale (Camry Electronic Co. Ltd, Zhongshan, China), and the individual bodyweight of broilers was measured only at 8, 14, 21, 28, 35 and 42 d of age, because it was not suitable to excessively increase the stress response of broilers during manual measurement. In order to assist in characterizing the growth and development of broilers, tibia length was also measured by the ruler at the same time. Environmental data and broiler data were measured in parallel.

The Process of Evaluation

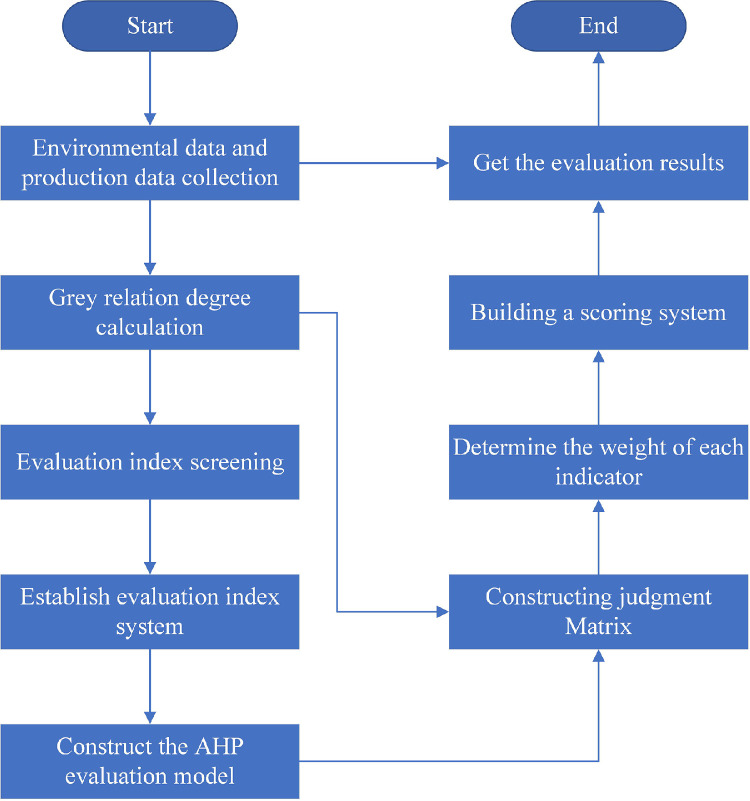

The evaluation process is shown in Figure 3.

Figure 3.

The evaluation process.

First, the evaluation index system was established: GRA method was used to find the environmental factors that had a great impact on poultry production by calculating GRD values, and the environmental factors that had a great impact were included in the environmental index system.

Second, the AHP method was used to construct the comprehensive environmental evaluation model of the poultry house. The value of GRD was used to improve the construction method of the judgment matrix.

Finally, the scoring system of each environmental factor was constructed, the actual environmental data of the poultry house was substituted into the model, the evaluation score was calculated, and the evaluation result was finally obtained.

Evaluation Index System of Environment in the Poultry House

Scientifically measuring the advantages and disadvantages of the poultry house environment status is a very complex process. Therefore, selecting a good set of evaluation indicators is particularly important (Chang et al., 2007). The evaluation index system is the basis of the evaluation model. In order to evaluate the environment in the poultry house comprehensively, the evaluation index should be selected reasonably. This study started by establishing the relationship between environmental factors and poultry production by calculating GRD value to find the relatively large impact of environmental factors on poultry production, which was included in the evaluation index system. The environmental factors that had relatively little impact on poultry production were removed to reduce the redundancy of the evaluation model.

The following conditions should be met for the selection of evaluation indicators (Li, 2015):

First, any evaluation index must meet the requirements of scientificity and operability. There should be clear logic and hierarchy among the evaluation indicators, and all aspects of the environmental characteristics of the poultry house should be comprehensively involved.

Second, consider the importance of different indicators, highlighting the poultry house's primary and secondary environmental evaluation factors, and grasping the key indicators.

Finally, each indicator is computable. That is, it is possible to determine its impact on the upper level in a certain way. The selected indicators should be comparable in the evaluation, and the evaluation value should be planned as a unified standard.

Because it is not appropriate to increase the stress response of the poultry, it is impossible to collect the production indicators of the poultry in real-time. The production indexes of poultry were collected only at 8, 14, 21, 28, 35, and 43 d of age. The GRA method is very suitable for such data is less, the primary and secondary factors are difficult to distinguish.

GRA. GRA (Chang et al., 2007; Lin and Juan, 2007; Fan et al., 2008; Tsai et al., 2008) is an analytical method of gray system theory. It is also applicable regardless of the number of samples and the regularity. The idea is to draw each factor into a sequence curve and obtain the relation degree of each factor through the similarity of its geometric shape. The closer the shape of the curve is, the greater the relation of the corresponding judged sequence is. This method is mainly used in the case of less data, difficult to distinguish the primary and secondary factors. The basic operation steps are as follows (Chen, 2005; Wu et al., 2007; Zeng et al., 2007; Wu and Chang, 2009; Pophali et al., 2011; Verma and Singh, 2013; Wu et al., 2018; Younas et al., 2019):

-

(1)

Determine the analysis sequence

Determine the reference series that reflect the characteristics of the system's behavior and the comparison series that affect the system's behavior. The data sequence reflecting the characteristics of the system's behavior is called the reference sequence and is denoted as X0, which is

| (1) |

Where k is the serial number of the environmental factor of the individual poultry house.

A data sequence composed of factors that affect system behavior is called a comparison sequence and is denoted as Xi, which is

| (2) |

In the formula above, k is the serial number of the individual broiler production factor.

-

(2)

Dimensionless processing of raw data

Due to differences in the meaning, content, and value standards of various indicators, the data dimensions are generally different, which is not convenient for a unified comparison. Therefore, to make it comparable, in applying the GRA, the data is generally nondimensionalized processing, eliminating the respective influential factors of each data and turning it into a standardized order of magnitude nondimensional data under a unified measurement scale facilitate the comparative analysis of various indicators. Therefore, the impact factor data and the reference series need to be dimensionless before the subsequent analysis. The commonly used methods of dimensionless processing mainly include normalization transformation methods, exponential transformation methods, and segmented scoring transformation methods. The most commonly used method is the normalization transformation method (Saaty, 1994). This article also chooses to use this method for dimensionless processing.

-

(3)

Calculate the absolute difference between the comparison sequence and the reference data

Calculate the absolute difference between X0 and Xi at the k-th index, denoted as ∆i(k), which is

| (3) |

-

(4)

Calculation of the GRD

The GRD is the manifestation of relation in gray theory. Relation essentially refers to the degree of difference in geometric shapes between curves. Therefore, the difference between curves can be used as a measure of the degree of relation. In the GRA, the GRD is the geometric distance between the reference sequence and the comparison sequence at each time point. The larger its value, the more significant the relation between the 2 index sequences on the corresponding indicators. The calculation formula is as follows:

| (4) |

ζi(k) is the GRD of X0 and Xi at the k-th index. minmin∆i(k) is the minimum difference of the second level. maxmax∆i(k) is the maximum difference of the second level. ρ is the resolution coefficient, 0<Ρ<1. The more effective the resolution coefficient, the larger resolution. The smaller the resolution coefficient, the smaller resolution. In this study, Ρ=0.5.

-

(5)

Calculate the GRD and arrange the order of relation

The relation coefficient is the degree of relation between the reference sequence and the comparison sequence at different points in time. Therefore, there is more than one relation coefficient, and the distribution is scattered. A unified comparison cannot be made. The GRD is the value obtained by collecting these relation coefficients through a specific method. It can reflect the degree of relation between the reference sequence and other indicators as a whole. The larger the GRD value, the stronger the relation between the reference series and the comparison series.

The calculation formula of the comprehensive GRD is:

| (5) |

Where Ri is the comprehensive GRD between the comparison sequence Xi and the reference sequence X0; ωi is the weight of GRD; N is the number of environmental factors. Ri reflects the relation between environmental factors and production indicators. The greater Ri is, the more significant the impact of environmental factors on production indicators will be.

According to the order of Ri from large to small, the main influencing factors of environmental evaluation in the poultry house can be screened. The environmental indicators that have little effect on production indicators can be eliminated in further environmental evaluation.

Improved AHP Evaluation Model

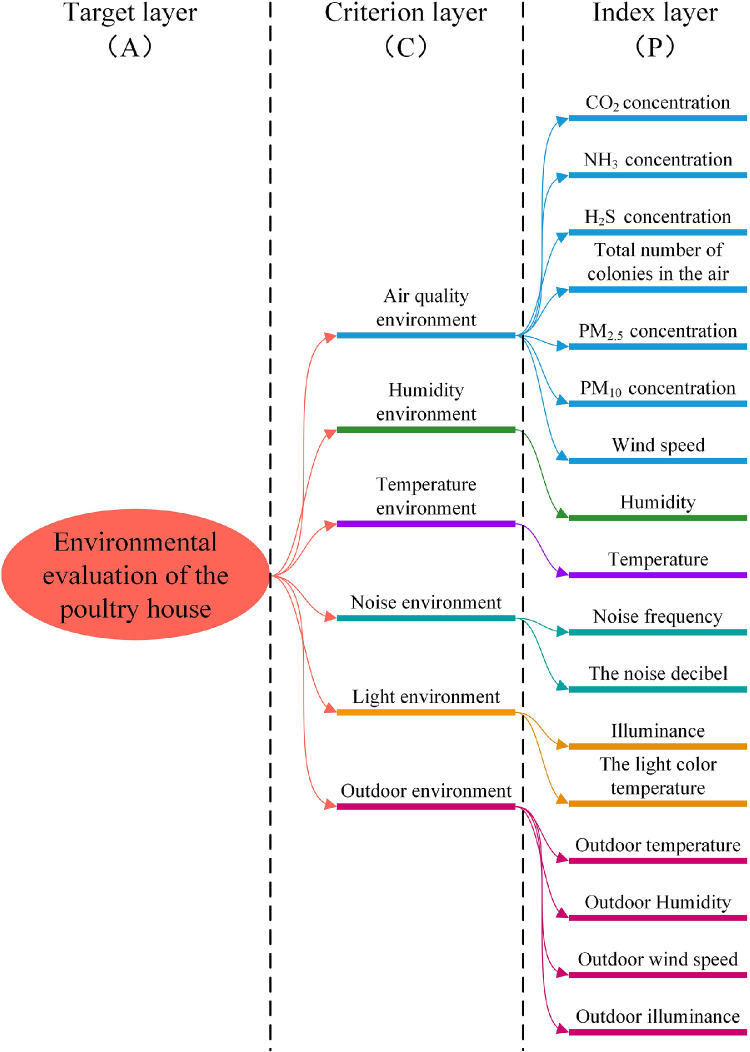

Building Hierarchical Structure Model. Each poultry house has different attributes of environmental evaluation indexes were divided, and the necessary structural levels were established. The evaluation index system of the indoor environment established in this paper is shown in the Figure 4. This index system is divided into the top layer-target layer, the middle layer-criterion layer, and the bottom layer-index layer, as shown in the Figure 4.

Figure 4.

Environmental evaluation index system.

Target layer (A): Represents the evaluation outcome, the value of environmental evaluation in the poultry house.

Criterion layer (C): According to the principles of environmental evaluation of the poultry house, the indexes related to its production indicators are the concrete reflection of the target layer. This index system selected 6 criterion layer indicators: ambient Temperature, ambient Humidity, ambient air quality, ambient noise, ambient light, and outdoor environment. Because of the ventilation system, the indoor environment is still affected by the outdoor environment. So the outdoor environment is included in the criterion layer.

Index layer (P): represents the specific environment information in a poultry house in a particular aspect and is a variety of indexes selected to reflect the direct impact on the target layer.

Construction of Judgment Matrix and Determination of Weight. After the hierarchical structure of the previous section is established, it means that the membership relationship between the upper and lower elements is determined. The elements in the upper level are used as criteria, and the elements in the lower level are compared in pairs to construct the judgment matrix (Phi-Hung et al., 2020).

Reasonable index weight plays a decisive role in the accuracy of comprehensive evaluation results (Wu et al., 2018). There are 2 methods to determine the weight: subjective empowerment and objective empowerment. Experts obtain subjective empowerment based on experience according to the economic or technical significance of the index, which is susceptible to the knowledge structure and personal experience of decision-makers. The objective empowerment is based on the information provided by the different degrees of index data, which can effectively avoid the influence of subjective factors.

At present, the AHP is used to construct the judgment matrix, and the 9-level scale method (Saaty, 1994) is often used. The 9-level scale is constructed according to the most critical and least important indices' importance. Through the pairwise comparison of evaluation indexes by experts, subjective empowerment constructs a judgment matrix, as shown in the Table 1.

Table 1.

Nine scale method (Saaty, 1994).

| Scale | Meaning |

|---|---|

| 1 | Two activities contribute equally to the objective |

| 3 | Moderate importance of one over another |

| 5 | Essential or strong importance |

| 7 | Very strong importance |

| 9 | Extreme importance |

| 2.4.6.8 | Intermediate values between the 2 adjacent judgments |

| The inverse of the scale | If activity i has one of the above numbers assigned to it when compared with activity j, then j has the reciprocal value when compared with i. |

The subjective factors of the above method have a significant influence on the evaluation results. This paper uses the GRD of each environmental factor to improve the judgment matrix construction method to overcome this shortcoming. The GRD of each environmental factor has reflected the importance of each environmental factor to the production index. The GRD of each environmental factor was compared pairwise, and the difference was mapped to the scale range. The specific methods are as follows:

At the same level, the relation degree of each environmental factor is compared. Δij is the difference between the GRD aij of environmental factor i and the GRD aj of environmental factor j. When Δij is larger than 0, that means ai is more critical than aj. The difference Δij is mapped to the 9-level scale range.

| (6) |

Therefore, the AHP uses a 9-stage scaling method, so m= 8. aij rounded to an integer. The corresponding aji is

| (7) |

The judgment matrix can be expressed as:

| (8) |

According to the judgment matrix, the eigenvalues and eigenvectors of the judgment matrix are obtained. The eigenvalues and eigenvectors satisfying RW = λmaxW are calculated. The normalization of W is the weight of each corresponding environmental factor, and λmax is the maximum eigenvalue of the judgment matrix R.

Consistency tests are required to ensure the rationality of the results. The random consistency ratio C. R. is introduced into the AHP. When C. R < 0.10, it is considered that the judgment matrix R has acceptable consistency. Otherwise, the judgment matrix should be adjusted and corrected.

Construct environmental factor scoring criteria. According to the method described in the literature (Wang et al., 2016; Bai et al., 2017) and expert opinions, the scoring table of environmental factors of the poultry in each stage of the whole cycle was established. It is important to note that environmental factors should be carefully constructed according to the breed of poultry, the type of climate in which the house is located, and the season in which the evaluation is made.

RESULTS

GRD and Environmental Evaluation Index System

According to the GRA method, the collected within 42 d of the poultry house environment parameters and GRD of poultry production indicators, the reference number listed as inner 9 sampling points to 13 environmental parameters, comparing several as inner 9 sampling points to poultry production parameters, namely the tibia length and the weight of broilers. For the convenience of data processing, we combined the data of W11–W13 into W1, W21–W23 into W2, and W31–W33 into W3. Table 2 shows the calculation results.

Table 2.

GRD calculation results of 3 sample points.

| GRD (ζi(k)) | The length of the tibia |

Body weight |

||||

|---|---|---|---|---|---|---|

| W1 | W2 | W3 | W1 | W2 | W3 | |

| CO2 | 0.763722 | 0.791259 | 0.639361 | 0.764922 | 0.732957 | 0.630619 |

| NH3 | 0.733524 | 0.810987 | 0.682188 | 0.665743 | 0.874131 | 0.763249 |

| H2S | 0.370446 | 0.415905 | 0.367046 | 0.396209 | 0.475775 | 0.406102 |

| PM2.5 | 0.742536 | 0.493806 | 0.821898 | 0.669104 | 0.46343 | 0.682214 |

| PM10 | 0.690176 | 0.49834 | 0.769281 | 0.688563 | 0.469054 | 0.660404 |

| Temperature | 0.779129 | 0.786316 | 0.770497 | 0.713192 | 0.691368 | 0.667928 |

| Humidity | 0.760571 | 0.792723 | 0.76565 | 0.745051 | 0.785198 | 0.670755 |

| Wind speed | 0.697772 | 0.563414 | 0.863939 | 0.674744 | 0.562589 | 0.757584 |

| Illuminance | 0.806233 | 0.618097 | 0.616151 | 0.747536 | 0.658269 | 0.668886 |

| Outdoor temperature | 0.773535 | 0.796534 | 0.779599 | 0.723259 | 0.729422 | 0.718689 |

| Outdoor humidity | 0.717729 | 0.714542 | 0.712538 | 0.684171 | 0.680197 | 0.655273 |

| Outdoor wind speed | 0.825536 | 0.837925 | 0.827044 | 0.79774 | 0.805959 | 0.804559 |

| Outdoor illuminance | 0.645277 | 0.64955 | 0.649213 | 0.659078 | 0.651354 | 0.658204 |

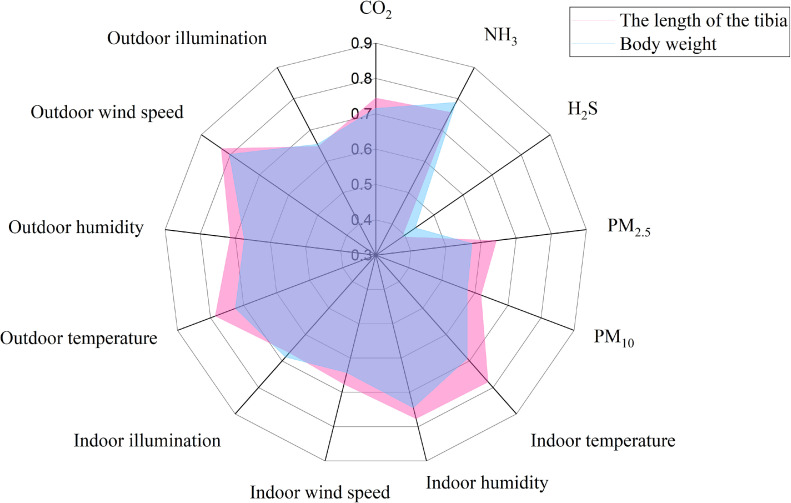

As shown in the Figure 1, the percentage of the data collection range of the 3 sample points in the entire poultry house area can be calculated according to the spacing of the sample points. Then, the comprehensive GRD weights of the measured parameters at the west gate, the middle, and the fan side can be obtained as ω1 = 0.27356, ω2 = 0.47297, and ω3 = 0.25246, respectively. According to formula 5, the GRD obtained from the 3 sampling points are weighted and summed to obtain the comprehensive GRD. The calculated results are shown in the Table 3.

Table 3.

Production index GRD calculation results.

| GRD (ζi(k)) | The length of the tibia | Body weight |

|---|---|---|

| CO2 | 0.7446 | 0.7151 |

| NH3 | 0.7565 | 0.7882 |

| H2S | 0.3907 | 0.4359 |

| PM2.5 | 0.6442 | 0.5745 |

| PM10 | 0.6187 | 0.5769 |

| Temperature | 0.7796 | 0.6907 |

| Humidity | 0.7763 | 0.7445 |

| Wind speed | 0.6755 | 0.6419 |

| Illuminance | 0.6684 | 0.6847 |

| Outdoor temperature | 0.7852 | 0.7243 |

| Outdoor humidity | 0.7142 | 0.6743 |

| Outdoor wind speed | 0.8309 | 0.8025 |

| Outdoor illuminance | 0.6476 | 0.6545 |

If the outdoor environment was considered, the order of influencing factors of broiler tibia length was as follows: outdoor wind speed> outdoor temperature> temperature> humidity> NH3> CO2> outdoor humidity> wind speed> illumination> outdoor illumination>PM2.5>PM10> NH3.

The order of influencing factors of broiler body mass was: outdoor wind speed> NH3> humidity> outdoor temperature> CO2> temperature> illumination> outdoor humidity> illumination> wind speed>PM10>PM2.5> NH3.

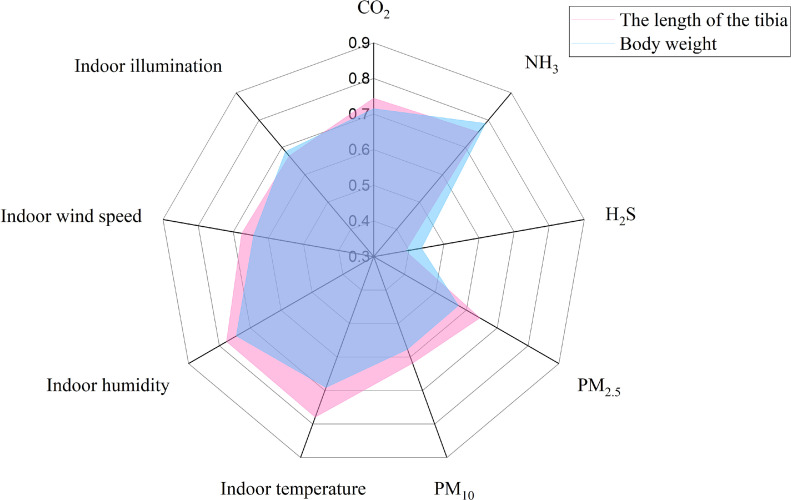

If the outdoor environment factor is taken into account, the radar diagram can be shown in Figure 5. If the outdoor environmental factors are not considered, the radar diagram can be expressed as Figure 6.

Figure 5.

GRD considering the outdoor environment.

Figure 6.

GRD without considering the outdoor environment.

In conclusion, when the outdoor environmental factors were not considered, the 4 parameters of NH3, humidity, temperature, and CO2 in the shed were the main influencing factors of broiler production, consistent with the specialist experience. However, NH3, PM10, and other parameters had a poor relation with the production indicators, so the environmental parameters with poor relation should not be considered too much in the poultry house's subsequent environmental evaluation and environmental control.

In this paper, 2 indexes of broiler production, tibia length, and weight were selected, and GRA was carried out, respectively. According to formula 5, each environmental factor's comprehensive GRD can be obtained by weighting the GRD. Because weight is more critical for broilers, ωtibia is the weight coefficient of tibia length, which is 0.4, ωweight is the weight coefficient of weight, which is 0.6. The calculation results are shown in the Table 4.

Table 4.

Comprehensive GRD calculation results of environmental indicators.

| Environmental indicators | Comprehensive GRD | Sort |

|

|---|---|---|---|

| Ignore the outdoor environment | Consider the outdoor environment | ||

| CO2 | 0.72690 | 3 | 5 |

| NH3 | 0.77552 | 1 | 2 |

| H2S | 0.41782 | 9 | 14 |

| PM2.5 | 0.60238 | 7 | 12 |

| PM10 | 0.59362 | 8 | 13 |

| Temperature | 0.72626 | 4 | 6 |

| Humidity | 0.75722 | 2 | 3 |

| Wind speed | 0.65534 | 6 | 10 |

| Illuminance | 0.67818 | 5 | 9 |

| Outdoor temperature | 0.74866 | / | 4 |

| Outdoor humidity | 0.69026 | / | 8 |

| Outdoor wind speed | 0.81386 | / | 1 |

| Outdoor illuminance | 0.65174 | / | 11 |

In the construction of the evaluation index system, the more environmental indicators are selected, the more comprehensive and accurate the evaluation results will be, but the evaluation model will become larger, and the amount of calculation will increase. The fewer environmental indicators selected, the more one-sided and inaccurate the evaluation results will be, but the evaluation model and calculation amount will be both. It is necessary to find a balance between the number of selected environmental indicators and the accuracy of evaluation model. In this study, GRD = 0.6 was taken as the threshold. Since the GRD of H2S and PM10 is less than 0.6, the influence on the production index is relatively small, and these 2 environmental factors are abandoned in the subsequent evaluation. In this experiment, the parameters such as noise and light color temperature were not collected in the poultry house, so the main factors for the current environmental evaluation in the poultry house were finally determined as CO2, NH3, PM2.5, temperature, humidity, wind speed, illumination, outdoor temperature, outdoor humidity, outdoor wind speed, and outdoor illumination.

According to the relationship and subordinate relationship among environmental indicators in the poultry house, a comprehensive evaluation model at 3 levels was established. The first layer is the target layer (A), which is the evaluation level of the indoor environment of the poultry house. The second layer is the criterion layer (C), which includes 5 indicators: indoor air quality, indoor Temperature, indoor Humidity, indoor light, and outdoor environment. The third layer is the index layer (P), including 11 selected environmental indicators, as shown in the Table 5.

Table 5.

A hierarchical structure model for environmental evaluation in the poultry house.

| Target layer (A) | Criterion layer (C) | Index layer (P) |

|---|---|---|

| Environmental evaluation of the poultry house | C1 Air quality environment | P1 CO2; P2 NH3; P3 PM2.5; P4 Wind speed |

| C2 Temperature environment | P5 Temperature | |

| C3 Humidity environment | P6 Humidity | |

| C4 Light environment | P7 Illuminance | |

| C5 Outdoor environment | P8 Outdoor temperature; P9 Outdoor humidity; P10 Outdoor wind speed; P11 Outdoor illuminance |

Constructing Judgment Matrix and Determining Weight Value

The indoor air quality in the criterion layer, as an example, contains 4 secondary indexes, and the GRD is shown in the Table 6.

Table 6.

GRD of air quality in the poultry house.

| CO2 |

NH3 |

PM2.5 |

Wind speed |

|---|---|---|---|

| P1 | P2 | P3 | P4 |

| 0.7269 | 0.77552 | 0.60238 | 0.65534 |

According to the importance of each environmental factor to the production index and formulas 6 and 7, the Ci-Pi judgment matrix of low-level indicators relative to the upper-level indicators is constructed. The judgment matrix and consistency test results are shown in the Table 7.

Table 7.

C1-Pi judgment matrix and consistency test.

| C1 | P1 | P2 | P3 | P4 | Weight |

|---|---|---|---|---|---|

| P1 | 1 | 6 | 3 | 0.2999 | |

| P2 | 2 | 1 | 8 | 6 | 0.5445 |

| P3 | 1 | 0.0556 | |||

| P4 | 2 | 1 | 0.1000 |

λmax = 4.0206, C.I. = 0.0069, R.I. = 0.89, C.R. = 0.0077<0.1.

According to Formulas 1-5, the comprehensive GRD of the air quality C1 in the criterion layer is 0.73929. Similarly, the judgment matrix and weight of the outdoor environment in the criterion layer can be obtained. The results are shown in the Table 8.

Table 8.

C5-Pi judgment matrix and consistency test.

| C5 | P8 | P9 | P10 | P11 | Weight |

|---|---|---|---|---|---|

| P8 | 1 | 3 | 5 | 0.2541 | |

| P9 | 1 | 2 | 0.0975 | ||

| P10 | 3 | 6 | 1 | 8 | 0.5915 |

| P11 | 1 | 0.0569 |

λmax = 4.0476, C.I. = 0.0159, R.I. = 0.89, C.R. = 0.0178<0.1.

According to Formulas 1-5, the comprehensive GRD of the outer environment C5 of the criterion layer is 0.77602.

Similarly, the A-Ci judgment matrix can be obtained. The results are shown in the Table 9.

Table 9.

A-Ci judgment matrix and consistency test.

| A | C1 | C2 | C3 | C4 | C5 | Weight |

|---|---|---|---|---|---|---|

| C1 | 1 | 1 | 1 | 5 | 0.1687 | |

| C2 | 1 | 1 | 4 | 0.1233 | ||

| C3 | 1 | 3 | 1 | 6 | 0.2382 | |

| C4 | 1 | 0.0383 | ||||

| C5 | 3 | 4 | 2 | 8 | 1 | 0.4315 |

λmax = 5.1305, C.I. = 0.0326, R.I. = 1.12, C.R. = 0.0291<0.1.

Because all levels have passed the consistency test, the total sorting also has satisfactory consistency. The weight values are sorted, and the results are shown in the Table 10.

Table 10.

Weight value of index layer (P) to target layer (A).

| The weight of layer C to layer A | Index layer P | The weight of layer P to layer C | The weight of layer P to layer A | Sort | |

|---|---|---|---|---|---|

| C1 | 0.1687 | P1 | 0.2999 | 0.0506 | 6 |

| P2 | 0.5445 | 0.0919 | 5 | ||

| P3 | 0.0556 | 0.0094 | 11 | ||

| P4 | 0.1000 | 0.0169 | 10 | ||

| C2 | 0.1233 | P5 | 1 | 0.1233 | 3 |

| C3 | 0.2382 | P6 | 1 | 0.2382 | 2 |

| C4 | 0.0383 | P7 | 1 | 0.0383 | 8 |

| C5 | 0.4315 | P8 | 0.2541 | 0.1096 | 4 |

| P9 | 0.0975 | 0.0421 | 7 | ||

| P10 | 0.5915 | 0.2552 | 1 | ||

| P11 | 0.0569 | 0.0246 | 9 | ||

Evaluation Criteria and Evaluation Results of Environmental Factors

According to the literature(Tan et al., 2019), the scoring criteria for environmental factors of the 4- to 7-day-old broiler houses in Yi County were established from October 24 to 27, as shown in the Table 11.

Table 11.

Evaluation criteria of environmental factors in the whole cycle broiler house.

| 1–7 d of age |

8–21 d of age |

22–42 d of age |

|||||||

|---|---|---|---|---|---|---|---|---|---|

| Environmental factors | Excellent (5 points) | Good (3 points) | Poor (1 point) | Excellent (5 points) | Good (3 points) | Poor (1 point) | Excellent (5 points) | Good (3 points) | Poor (1 point) |

| P1 CO2 (mg/m3) | <1500 | 1500–4000 | >4000 | <1500 | 1500–4000 | >4000 | <1500 | 1500–4000 | >4000 |

| P2 NH3 (mg/m3) | <6 | 6–10 | >10 | <6 | 6–10 | >10 | <6 | 6–10 | >10 |

| P3 PM2.5 (μg/m³) | <30 | 30∼100 | >100 | <30 | 30∼100 | >100 | <30 | 30∼100 | >100 |

| P4 wind speed (m/s) | 0.15–0.25 | 0.05–0.15 or 0.25–0.35 | >0.35 or <0.05 | 0.15–0.25 | 0.05–0.15 or 0.25–0.35 | >0.35 or <0.05 | 0.15–0.25 | 0.05–0.15 or 0.25–0.35 | >0.35 or <0.05 |

| P5 temperature (°C) | 35–37 | 34–35 or 37–37.5 | >37.5 or <34 | 28–34 | 26–28 or 34–35 | >35 or <28 | 24–27 | 19–24 or 27–29 | >29 or <19 |

| P6 humidity (RH%) | 60–70 | 40–60 or 70–75 | >75 or <40 | 55–65 | 40–55 or 65–70 | >75 or <40 | 45–65 | 40–45 or 65–75 | >75 or <40 |

| P7 illuminance (lx) | 15-20 | 10–15 or 20–45 | >45 or <10 | 5-8 | 2–5 or 8–12 | >2 or <12 | 5-8 | 2–5 or 8–12 | >2 or <12 |

| P81 temperature difference between the recommended and outside (°C) | 0–10 | 10–20 | <20 | 0–10 | 10–20 | <20 | 0–10 | 10–20 | <20 |

| P92 humidity difference between the recommended and outdoor (RH%) | 0%–10% | 10%–20% | >20% | 0%–10% | 10%–20% | >20% | 0%–10% | 10%–20% | >20% |

| P10 outdoor wind speed (m/s) | 0.15–0.25 | 0.05–0.15 or 0.25–0.35 | >0.35 or <0.05 | 0.15–0.25 | 0.05–0.15 or 0.25–0.35 | >0.35 or <0.05 | 0.15–0.25 | 0.05–0.15 or 0.25–0.35 | >0.35 or <0.05 |

| P11 outdoor illuminance (lx) | 4000–5000 | 3000–4000 or 5000–7000 | >7000 or <3000 | 4000–5000 | 3000–4000 or 5000–7000 | >7000 or <3000 | 4000–5000 | 3000–4000 or 5000–7000 | >7000 or <3000 |

P8 is the minimum difference between the temperature outside the poultry house and the recommended temperature inside the poultry house.

P9 is the minimum difference between the humidity outside the poultry house and the recommended humidity inside the poultry house.

The climate of different poultry houses in a geographical position has otherness, while the same poultry house is also different in the climate of 4 seasons. Therefore, the outdoor temperature and humidity cannot be reasonably divided. Therefore, replace P8 with the minimum difference between the temperature outside the room and the recommended temperature inside the room. P9 Replace with the minimum difference between the outdoor humidity and the recommended internal humidity.

According to the calculated comprehensive evaluation value, 3 environmental comprehensive evaluation grades can be delimited within the range of 5 scales, which are: poor (1, 2.3), good (2.3, 3.6), and excellent (3.6, 5).

Table 12 shows the experimental poultry house's environmental data and scoring results collected from October 24 to 27.

Table 12.

Data and scores of environmental factors of broilers aged 4 to 7 d.

| Environmental factors | October 24 |

October 25 |

October 26 |

October 27 |

||||

|---|---|---|---|---|---|---|---|---|

| Data | Score | Data | Score | Data | Score | Data | Score | |

| CO2 (mg/m3) | 1387.7 | 5 | 1495.5 | 5 | 1374.8 | 5 | 1721.0 | 3 |

| NH3 (mg/m3) | 14.2 | 1 | 17.4 | 1 | 11.9 | 1 | 13.5 | 1 |

| PM2.5 (μg/m³) | 38.8 | 3 | 47.5 | 3 | 32.3 | 3 | 19.1 | 5 |

| Wind speed (m/s) | 0.08 | 3 | 0.03 | 1 | 0.04 | 1 | 0.05 | 3 |

| Temperature (°C) | 37.7 | 1 | 36.9 | 5 | 36.4 | 5 | 37.2 | 3 |

| Humidity (RH%) | 39.1 | 1 | 38.9 | 1 | 37.9 | 1 | 43.6 | 3 |

| Illuminance (lux) | 27.828 | 3 | 19.678 | 5 | 27.444 | 3 | 10.943 | 3 |

| Outdoor temperature (°C) | 11.2 | 1 | 16.1 | 3 | 14.5 | 1 | 11.0 | 1 |

| Outdoor humidity (RH%) | 44 | 3 | 77 | 5 | 44 | 3 | 37 | 3 |

| Outdoor wind speed (m/s) | 0.25 | 5 | 0.28 | 3 | 0.28 | 3 | 0.13 | 3 |

| Outdoor illuminance (lx) | 803.7 | 1 | 3349.4 | 3 | 2119.9 | 1 | 411.8 | 1 |

From October 24 to 27, the environmental evaluation values of the experimental poultry house were {2.4367, 2.8149, 2.3857, 2.5669}, that is, the evaluation results were {good, good, good, good}; consistent with the expert manual judgment.

DISCUSSION

Applicability of GRA

Application of the GRA, the most important is determining each index weight value and production index. By selecting reasonable production indicators, reflecting the purpose of environmental evaluation in the poultry house, but also from the actual situation of poultry farming, is more objective and reasonable. In this paper, the broiler production indicators such as tibia length and body weight in broilers breeding were selected. The production indicators such as egg production rate and death rate can also be considered in the environmental evaluation of commodity laying henhouse or brooding poultry house. Environmental evaluation is to better environmental control, and better environmental control is to obtain better production indicators. However, some production indicators cannot be monitored in real-time. The GRA method is also applicable regardless of the number of samples or whether there is regularity. Therefore, in this case, the GRA method has more advantages.

Superiority of Combination of GRA and AHP

At present, there is no relevant system and standard for environmental evaluation in the poultry house. It often relies on personal experience and preferences, and only individual indicators are selected for evaluation, which affects the screening of the main influencing factors of environmental evaluation. Bai Shibao (Bai et al., 2017) used 5 environmental indexes, such as temperature, humidity, wind speed, CO2 and NH3 concentration, the comfort evaluation model was established. Compared with the evaluation of indoor environment by using a single environmental factor, the system can reflect the comfort degree of indoor environment more comprehensively. But there is no screening for the selection of evaluation indicators. Also, only using the AHP, giving scores to each index artificially for determining the weight of each environmental factor, and cannot make full use of all the information of each index. Compared with the above models, the evaluation model constructed in this paper has better versatility. The GRA method can make full use of all the information of each index, and the conclusion is clear. However, when only using GRA to evaluation, the weight of environmental indicators is often determined by artificial assignment, with solid subjectivity. The GRD improves the subjective assignment of weights in AHP, which makes the evaluation system more rigorous and scientific.

Advantages of the Method

The new method studied in this paper has several advantages as follows:

-

•

By calculating the GRD of each environmental factor and production index, the main environmental factors in the environmental evaluation system of the poultry house can be screened scientifically. The environmental factors with high GDR value should be paid more attention to when evaluating and regulating the indoor environment of the poultry house.

-

•

The method of constructing judgment matrix in AHP is improved by using GRD value, and the subjective influence of AHP evaluation model is eliminated. The evaluation result is more objective and reasonable by relying entirely on data calculation.

-

•

The results of comprehensive environmental evaluation in the poultry house can be used as the basis to judge the environmental state in the poultry house. The farmer can judge the state of the environment in the chicken house in time. When the environmental status is not ideal, the evaluation model can be used to find the environmental factors that have a great impact on the evaluation results, and the parameters are not ideal at the same time. And the corresponding adjustment can be made.

-

•

Because the environmental factors in the poultry house are coupled with each other, the adjustment of a single environmental factor will cause the change of other environmental factors. Therefore, when the single environmental factor is adjusted, the evaluation results of the evaluation model can be referred to make the comprehensive environment in the poultry house reach a more reasonable state.

Problems Needing Attention and Outlook

The combination of the GRA method and AHP is a feasible comprehensive evaluation method. Selecting reasonable production indicators can determine the improvement of production indicators caused by environmental rating and environmental control. In this study, only the influence of environmental factors on body weight and tibial length was studied, and then the evaluation model was established. In further research, we can focus on the impact of the number of different production indicators on the model, such as the welfare and behaviors of poultry. In this experiment, the total number of colonies in the air, noise frequency, noise decibel, light color temperature, and other data in environmental factors were not collected, which can be studied in the next step. Furthermore, whether the poultry house environmental evaluation model can eliminate the outdoor environmental parameters in the winter poultry house closed state still needs further research.

Different varieties of laying hens or broilers have different adaptability to the environment. The environmental preferences of laying hens or broilers of the same breed are different at different growth stages. Therefore, the index boundary value should be carefully selected and appropriately scaled in the environmental evaluation of different breeds of the poultry or poultry houses of different ages. Further research can also focus on optimizing the number and location of environmental data sampling points in the poultry house to improve the ability of data to reflect the overall natural environment in the poultry house.

DISCLOSURES

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

ACKNOWLEDGMENTS

This work is supported by the Key Research and Development Plan of Hebei Province (19226633D), the National Natural Science Foundation of China (31902209), and Hebei Provincial Special Fund for Modern Agriculture Industry Technology Innovation Teams (HBCT2018060204).

Statement: In this research on live animals met the guidelines approved by the institutional animal care and use committee (IACUC).

REFERENCES

- Ashby W.R., Pierce J.R. An introduction to cybernetics. J Oper Res Soc. 1957;10:34–36. [Google Scholar]

- Assure Wel, 2019. http://www.assurewel.org/broilers.html Accessed Aug. 2021.

- Bai S., Teng G., Du X., Du X. Design and implementation on real-time monitoring system of laying hens environmental comfort based on LabVIEW. Trans. CSAE. 2017;33:237–244. [Google Scholar]

- Barott H.G., Pringle E.M. Energy and gaseous metabolism of the chicken from hatch to maturity as affected by temperatube. J. Nutr. 1946;31:35–50. [Google Scholar]

- Butterworth A., Arnould C., Niekerk T.F. Assessment Protocol for Poultry. Welfare Quality Consortium; Lelystad, Netherlands: 2009. [Google Scholar]

- Cerci I.H., Tath P., Azman M.A., Birben N. The effect of restricted feed on feed intake, egg production and feed conversion in pullets. Indian Vet. J. 2003;80:1153–1157. [Google Scholar]

- Chang C.-W., Wu C.-R., Lin J.-Y. Developing an evaluation performance processes for Taiwan solar energy industry. J. Grey Syst. 2007;19:359–370. [Google Scholar]

- Chen W.H. A grey-based approach for distribution network reconfiguration. J. Chin. Inst. Eng. 2005;28:795–802. [Google Scholar]

- Du X., Teng G., Du X., Liu M., Wang C. Comprehensive evaluation of environmental comfort in layer poultry house using radar graph. Trans. CSAE. 2020;36:202–209. [Google Scholar]

- Fan C.K., Tsai H.-Y., Lee Y.H. The selection of life insurance sales representatives training program by using the AHP and GRA. J. Grey Syst. 2008;20:149–160. [Google Scholar]

- Ju-Long D. Control problems of grey systems. Syst. Control Lett. 1982;1:288–294. [Google Scholar]

- Li C. Evaluation of Urban Human Settlement environment in China. PhD Diss. Univ. East China Normal; Shanghai, China: 2015. [Google Scholar]

- Lay, D. C. Jr., R. M. Fulton, P. Y. Hester, D. M. Karcher, J. B. Kjaer, J. A. Mench, B. A. Mullens, R. C. Newberry, C. J. Nicol, N. P. O'Sullivan, and R. E. Porter. 2011. Hen welfare in different housing systems. Poult. Sci. 90:278–294. [DOI] [PubMed]

- Lin C.-T., Juan P.-J. Applying the AHP and GRA to location selecting for international resort parks. J. Grey Syst. 2007;19:333–350. [Google Scholar]

- Marsden A., Morris T.R. Quantitative review of the effects of environmental temperature on food intake, egg output and energy balance in laying pullets. Br. Poult. Sci. 1987;28:693–704. doi: 10.1080/00071668708417005. [DOI] [PubMed] [Google Scholar]

- Miles D.M., Branton S.L., Lott B.D. Atmospheric ammonia is detrimental to the performance of modern commercial broilers. Poult. Sci. 2004;83:1650–1654. doi: 10.1093/ps/83.10.1650. [DOI] [PubMed] [Google Scholar]

- NRC. 1994. Nutrient Requirements of Poultry. 9th rev. ed. Natl. Acad. Press, Washington, DC.

- Park J., Seok J., Lee S., Kwon O., Lee K., Heo Y., Yoon C. Ammonia and hydrogen sulfide monitoring in broiler barns and cattle barns. J. Environ. Health. 2015;41:277–288. [Google Scholar]

- Phi-Hung N., Tsai J.-F., Kumar V.A.G., Hu Y.-C. Stock investment of agriculture companies in the Vietnam Stock Exchange Market: an AHP integrated with GRA-TOPSIS-MOORA approaches. J. Asian Finance Econ. Bus. 2020;7:113–121. [Google Scholar]

- Pophali G.R., Chelani A.B., Dhodapkar R.S. Optimal selection of full scale tannery effluent treatment alternative using integrated AHP and GRA approach. Expert Syst. Appl. 2011;38:10889–10895. [Google Scholar]

- Saaty T.L. How to make a decision: the analytic hierarchy process. Eur. J. Oper. Res. 1994;48:9–26. [Google Scholar]

- Shimmura T., Bracke M.B.M., de Mol R.M., Hirahara S., Uetake K., Tanaka T. Overall welfare assessment of laying hens: comparing science-based, environment-based and animal-based assessments. Anim. Sci. J. 2011;82:150–160. doi: 10.1111/j.1740-0929.2010.00834.x. [DOI] [PubMed] [Google Scholar]

- Tan Z., Shi X., Wang F., Wang L., Wang S. Real-time monitoring and precision control of environmental parameters in multi-layer cage white feathered chicken house. China Poult. 2019;41:71–76. [Google Scholar]

- Tsai H.-Y., Huang B.-H., Wang A.-S. Combining AHP and GRA model for evaluation property-liability insurance companies to rank. J. Grey Syst. 2008;20:65–78. [Google Scholar]

- Van Horne P.L.M., Achterbosch T.J. Animal welfare in poultry production systems: impact of EU standards on world trade. World’s Poult. Sci. J. 2008;64:40–51. [Google Scholar]

- Verma R., Singh N.P. GRA based network selection in heterogeneous wireless networks. Wirel. Pers. Commun. 2013;72:1437–1452. [Google Scholar]

- Wang Q., Tong H., Shao D., Shi S., Hu Y. Analysis of broiler welfare breeding quality scoring system. China Poult. 2016;38:62–72. [Google Scholar]

- Wang Q., Tong H., Shao D., Shi S., Hu Y. Analysis of broiler welfare breeding quality scoring system. China Poult. 2016;38:69–72. [Google Scholar]

- Wu C.-R., Chang H.-Y. Evaluation of the energy fund by AHPGRA model. J. Grey Syst. 2009;21:195–208. [Google Scholar]

- Wu C.-R., Chang C.-W., Lin H.-L. Developing an AHPGR model: evaluation of hospital organization performance. J. Grey Syst. 2007;19:77–90. [Google Scholar]

- Wu D., Wang N., Yang Z., Li C., Yang Y. Comprehensive evaluation of coal-fired power units using grey relational analysis and a hybrid entropy-based weighting method. Entropy. 2018;20 doi: 10.3390/e20040215. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Younas M., Jaffery S.H.I., Khan M., Khan M.A., Ahmad R., Mubashar A., Ali L. Multi-objective optimization for sustainable turning Ti6Al4V alloy using grey relational analysis (GRA) based on analytic hierarchy process (AHP) Int. J. Adv. Manuf. Technol. 2019;105:1175–1188. [Google Scholar]

- Zeng G., Jiang R., Huang G., Xu M., Li J. Optimization of wastewater treatment alternative selection by hierarchy grey relational analysis. J. Environ. Manage. 2007;82:250–259. doi: 10.1016/j.jenvman.2005.12.024. [DOI] [PubMed] [Google Scholar]

- Zheng W., Xiong Y., Gates R.S., Wang Y., Koelkebeck K.W. Air temperature, carbon dioxide, and ammonia assessment inside a commercial cage layer barn with manure-drying tunnels. Poult. Sci. 2020;99:3885–3896. doi: 10.1016/j.psj.2020.05.009. [DOI] [PMC free article] [PubMed] [Google Scholar]