Abstract

Synthesis of metal nanoparticles using plant extracts is one of the most simple, convenient, economical, and environmentally friendly methods that mitigate the involvement of toxic chemicals. Hence, in recent years, several eco-friendly processes for the rapid synthesis of silver nanoparticles have been reported using aqueous extracts of plant parts such as the leaf, bark, roots, etc. This review summarizes and elaborates the new findings in this research domain of the green synthesis of silver nanoparticles (AgNPs) using different plant extracts and their potential applications as antimicrobial agents covering the literature since 2015. While highlighting the recently used different plants for the synthesis of highly efficient antimicrobial green AgNPs, we aim to provide a systematic in-depth discussion on the possible influence of the phytochemicals and their concentrations in the plants extracts, extraction solvent, and extraction temperature, as well as reaction temperature, pH, reaction time, and concentration of precursor on the size, shape and stability of the produced AgNPs. Exhaustive details of the plausible mechanism of the interaction of AgNPs with the cell wall of microbes, leading to cell death, and high antimicrobial activities have also been elaborated. The shape and size-dependent antimicrobial activities of the biogenic AgNPs and the enhanced antimicrobial activities by synergetic interaction of AgNPs with known commercial antibiotic drugs have also been comprehensively detailed.

Herein, we have reviewed new findings in the research domain of the green synthesis of silver nanoparticles using different plant extracts and their potential applications as antimicrobial agents covering the literature since 2015.

1. Introduction

Nanotechnology is gaining enormous attention as a new area of research dealing with the development of nanomaterials and nanoparticles (NPs) for their utilization in diverse fields such as catalysis, electrochemistry, biomedicines, pharmaceuticals, sensors, food technology, cosmetics, etc.1–3 Nanoparticles (NPs) are nanometer-sized (<100 nm) atomic or molecular scale solid particles having some excellent physical properties compared to the bulk molecules depending on their size and morphology.4,5 Among all types of NPs, metal and metal oxide nanoparticles have been thoroughly examined using science and technology due to their excellent properties such as high surface to volume ratio, high dispersion in solution, etc.6,7 Owing to these, metal and metal oxide nanoparticles display enhanced antimicrobial properties.8,9

Currently, modified or fabricated of NPs is widely utilized in industrially manufactured items e.g., cosmetics, electronics, and textiles. Furthermore, the rapid increased in the number of microbes resistant to existing antibiotic drugs that has led to the requirement of novel medicines in the form of bare NPs or in conjunction with existing antibiotics to exert a favourable synergistic effect resulted in the wide spread use of NPs in several medical fields.10,11 Nowadays, NPs have been utilized for molecular imaging to achieve profoundly resolved pictures for diagnosis. In addition, contrast agents are impregnated onto NPs for the tumour and atherosclerosis diagnosis.12–14 Furthermore, nanotherapeutic has been promoted everywhere throughout the world after the first FDA affirmed nanotherapeutic in 1990, to build up different nano-based drugs.15

At the beginning of 20th century, various physical and chemical methodologies such as chemical reduction, milling etc., have been utilized for the synthesis of NPs synthesis as well as to enhance its efficiency.16 However, these conventional techniques involve costly and toxic chemicals and cannot be considered an environmentally benign process.17 Taking into account, nowadays researchers showed great interest on the synthesis of metal and metal oxides NPs employing bio-genic route, that utilized aqueous plant extract and microbes, as they are environment-friendly, stable, clinically adaptable, bio-compatible and cost-effective.16,18 Therefore, bio-inspired technology for NPs synthesis became a significant branch in the field of nanoscience and nanotechnology.19,20 Till now, numerous metal and metal oxide NPs have been synthesized using plant extract and microbes etc.21,22 Owing to their wide availability, renewability and environment-friendly nature, in addition to their vast applications in the synthesis of NPs, plant biomass are also largely targeted by our group and others as a catalyst for chemical synthesis23,24 and biodiesel productions.25,26

Among metal NPs, silver NPs is gaining enormous interest in the research community due to their wide scope of application in microbiology, chemistry, food technology, cell biology, pharmacology and parasitology.27,28 The morphology of the silver NPs is the deciding factor of their physical and chemical properties.28 Basically, several techniques such as sol–gel method, hydrothermal method, chemical vapour deposition, thermal decomposition, microwave-assisted combustion method etc., have been utilized for the synthesis of silver NPs.29–31 Recently, bio-genic synthesis of silver NPs (AgNPs) using biomaterials such as plant extract and microbes as reducing agent and their antimicrobial activity is widely investigated.32,33 AgNPs are produced by oxidation of Ag+ to Ag0 by different biomolecules such as flavonoids, ketones, aldehydes, tannins, carboxylic acids, phenolic and the protein of the plant extracts.

UV-visible spectroscopy is a simple and widely used analytical technique to monitor the formation of AgNPs. Upon interaction with an electromagnetic field, the conducting electrons present in the outermost orbital of metal NPs collectively oscillate in resonance with certain wavelengths to exhibit a phenomenon called surface plasmon resonance (SPR). The excitation of SPR is responsible for the formation of color and absorbance in a colloidal solution of AgNPs. The SPR peaks at around 435 nm are usually taken to confirm the reduction of silver nitrate into AgNPs.34 In general, spherical NPs exhibit only a single SPR band in the absorbance spectra, whereas two or more SPR bands were observed for anisotropic particles depending on the shape.35 The absence of peak in the region 335 and 560 nm in UV-Vis spectra are sometime used as an indication of the absence of aggregation in NPs.32,36

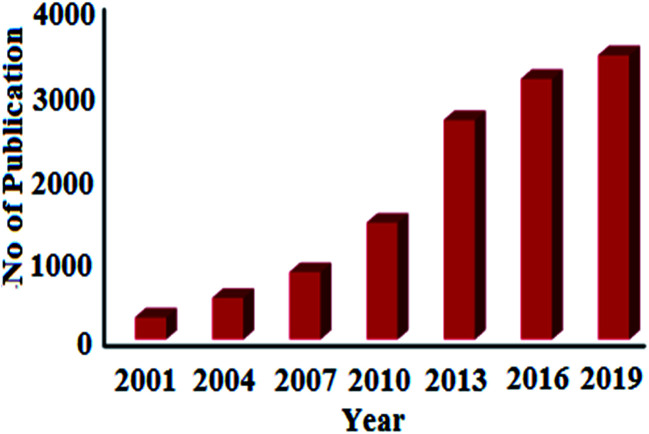

Statistical data analysis in Fig. 1 depicted the increasing trend of published research papers in the field of biogenic synthesis of AgNPs. These data were collected in September 2020 from “SciFinder Database” using the keyword “Green synthesis of silver nanoparticles”. From a meagre 259 publications in the year 2001, it has exponentially increased to 3374 publications in 2019. Thus, in this review, an attempt has been made to inspire the researchers to explore the natural resources to synthesize silver nanoparticles by diverse plants and their organs to interconnect nanotechnology with biotechnology into one, termed as nanobiotechnology. This review will also unlock ideas to utilize different paths for the production of silver nanoparticles, which can help human beings. We have comprehensively discussed the bio-genic synthesis and silver nanoparticles using various plants and their application in antimicrobial activity. We also discussed the effect of the synthesized silver nanoparticles' size and shape in antimicrobial activity towards various pathogenic bacteria. In an attempt to synthesize metals NPs one has to bear in mind that the success of NPs depends not only on the size and shape but also on stability of NPs as they have the tendency to form large aggregates that lead to precipitation, thereby reducing their efficacy.

Fig. 1. Publications per year for green synthesis of AgNPs during the period 2001 to 2019 (data collected from SciFinder Database).

2. Protocols for the biosynthesis of AgNPs

Biogenic synthesis of AgNPs is an easy single-step protocol without generating harsh and toxic chemicals; hence, they are save, economical and eco-friendly. In recent years, both plant and microbes are extensively investigated for the biosynthesis of AgNPs of varying size, shape, stability, and antimicrobial efficacy.

2.1. From plant extract

Various parts of plant such as leaves, roots, flowers, fruits, rhizomes etc., have been successfully utilized for the synthesis of AgNPs.37–39 Different parts of plant are collected from various sources, washed properly with ordinary water followed by distilled water to exclude debris and any other unwanted materials. After that, the portions are dried and ground to make powder or utilized as fresh to make the extract. To prepare the extract, the chopped pieces or the ground powder of the parts of the plant are put in deionized water or alcohol and usually heated below 60 °C for few hours as high-temperature heating long time may leads to the decomposition of phytochemicals in the biomass extract. Plant extract of different pH is added to the solutions having a different concentration of Ag salt as metal precursor followed by heating at different temperature led to the synthesis of AgNPs.40–42 This synthesis process avoids the use of chemical stabilizer as biomaterials present in the extract act as a reducing agent as well as a stabilizing agent for the synthesis of AgNPs.43,44 The progress of the formation of AgNPs can be monitored by visual color changes or using UV-Vis. Spectroscopy, where a sharp peak due to surface plasmon resonance (SPR) of AgNPs at around 430–450 nm is clearly observed.34 After successful synthesis of the AgNPs, the mixture is centrifuged at high rpm to separate the NPs followed by proper washing using solvents and dried in an oven at low temperature.45,46 The different plant parts extracts that have been successfully utilized in the green synthesis of AgNPs are given in Fig. 2.

Fig. 2. Different parts of plants used for biosynthesis of antimicrobial silver nanoparticles.

2.2. From microbes

Nowadays, the use of microbial cell for the synthesis of metal NPs has come out as a great approach. Microbial cells turn to be excellent biofactories for the synthesis of AgNPs.47,48 At first, the cultures are allowed to develop as culture suspension in disinfected distilled water having the culture medium. Then, different concentration of precursor of AgNPs is added into the cultured microbial followed by continuous mechanical stirring under dark conditions. The progress of the reaction is monitored by UV-Vis spectrophotometer. Finally, the resultant AgNPs is separated from the mixture via centrifugation at around 3000 rpm for 10–15 min.49

3. Plant-mediated biogenic synthesis of AgNPs and their antimicrobial activity

Owing to the environmental issue, biogenic synthesis of metal and metal oxide NPs is gaining immense attention from the past decades. Reported literature revealed that various plant parts such as leaf, roots, seed, fruits and stem etc., have been utilized for the biosynthesis of NPs. The synthesis of NPs is fully dependent on the biomaterials/phytochemicals present in the extract. This section aims to discuss the various plant parts extract mediated synthesis of AgNPs and their application as antimicrobial.

3.1. From leaf

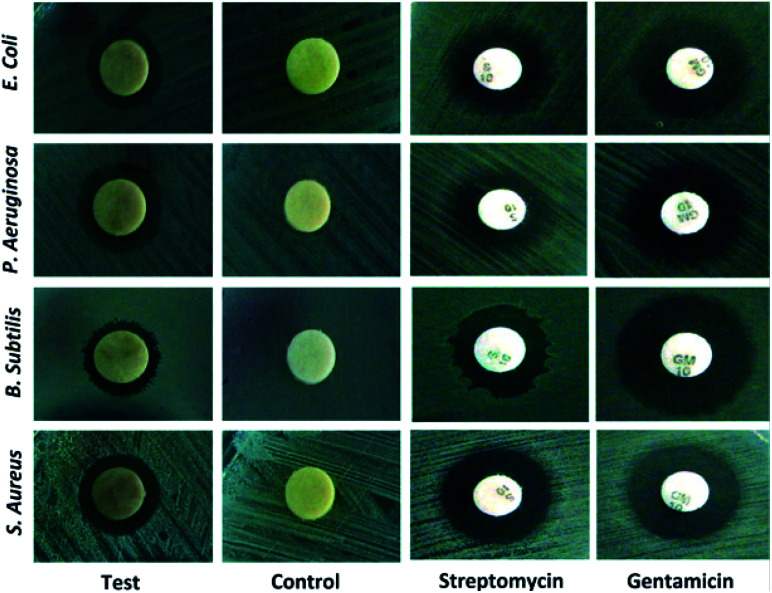

To date, a numerous number of leaves extract have been utilized for the biosynthesis of AgNPs as shown in Table 1. Skimmia laureola was reported for the synthesis of spherical AgNPs with size 38 ± 0.27 nm and tested against E. coli, K. pneumoniae, P. aeruginosa, P. vulgaris, S. aureus.50 Miri et al.51 have utilized Prosopis farcta extract for the biosynthesis of AgNPs with an average size of 10.8 nm at room temperature (RT). The antimicrobial activity of synthesized AgNPs was tested using disc diffusion method against the Gram-positive (Staphylococcus aureus (PTCC 1431), Bacillus subtilis (PTCC 1420)) and Gram-negative bacteria (Escherichia coli (PTCC 1399), Pseudomonas aeruginosa (PTCC 1074)) and compared with the control. The results showed that the inhibition diameter is increased for every tested pathogen (Fig. 3), indicates that synthesized AgNPs induces cellular damage to the bacteria's, hence can be used as nanoantibiotics. Aloe vera,52Eclipta alba,53Momordica charantia,54Leptadenia reticulata55 are also used for the production of spherical biogenic AgNPs. In another study, AgNPs were synthesized by using tea leaf extract. Bactericidal activity of the synthesized NPs was tested against S. aureus and E. coli showed that inhibition action is more effective in case of S. aureus (89% inhibition rate) compared to E. coli (75% inhibition rate). In addition, treatment of the NPs against the bacteria leads to impairment of bacterial cell–cell adhesion.56Mukia maderaspatana leave extract was utilized for the biosynthesis of AgNPs with the size range of 58–458 nm. The synthesized nanoparticle was conjugated to the antibiotic ceftriaxone to investigate the antimicrobial activity towards the human pathogens such as B. subtilis, K. pneumonia, S. typhi, S. aureus and compared with the pathogen inhibition efficiency of the free nanoparticle and the antibiotic. The result obtained revealed that the AgNPs conjugated with ceftriaxone showed highest inhibition activity compared to the others.57

Various leaf extract used for the green synthesis of AgNPs and their antimicrobial activity.

| No. | Plants | Size and shape | Test microorganisms | Ref. |

|---|---|---|---|---|

| 1 | Skimmia laureola | Spherical; 38 ± 0.27 nm | E. coli, K. pneumoniae, P. aeruginosa, P. vulgaris, S. aureus | 50 |

| 2 | Prosopis farcta | Spherical; 8–11 nm | S. aureus, B. subtilis, E. coli, P. aeruginosa | 51 |

| 3 | Aloe vera | Spherical; 70 nm | Aspergillus sp., Rhizopus sp. | 52 |

| 4 | Eclipta alba | 310 to 400 nm | E. coli, S. aureus, P. aeruginosa | 53 |

| 5 | Momordica charantia | Spherical; 11–16 nm | B. spp., S. spp., P. spp., E. coli, A. niger subsp., A. flavus subsp., P. spp. | 54 |

| 6 | Leptadenia reticulata | Spherical; 50–70 nm | S. pneumonia, K. pneumonia | 55 |

| 7 | Tea leaf | Spherical; 20 nm | S. aureus, E. coli | 56 |

| 8 | Raphanus sativus | Spherical; 6–38 nm | A. fumigatus, C. specifier, F. solani | 40 |

| 9 | Mukia maderaspatana | Spherical; 58–458 nm | B. subtilis, K. pneumonia, S. typhi, S. aureus | 57 |

| 11 | Clitoria ternatea | Spherical; 20 nm | B. subtilis, S. aureus, S. pyogenes, E. coli, P. aeruginosa, K. aerogenes | 58 |

| 12 | Solanum nigrum | Spherical; 28 nm | B. subtilis, S. aureus, S. pyogenes, E. coli, P. aeruginosa, K. aerogenes | 58 |

| 13 | Croton sparsiflorus morong | Spherical; 22–52 nm | S. aureus, E. coli, B. subtilis | 46 |

| 14 | Grewia flaviscences | Spherical; 60 nm | Bacillus, P. aeruginosa | 59 |

| 15 | Terminalia arjuna | Spherical; 8–16 nm | S. aureus, E. coli | 21 |

| 16 | Prunus yedoensis | Spherical, oval; 18–20 nm | P. acnes, S. epidermidis (skin bacteria) | 60 |

| 17 | Justicia adhatoda L. | Spherical; 5–50 nm | P. aeruginosa | 61 |

| 18 | Withania somnifera | 70–110 nm; spherical | S. aureus, P. aeruginosa, C. albicans, P. vulgaris, E. coli, A. tumefaciens | 62 |

| 19 | Pistacia atlantica | Spherical; 10–50 nm | S. aureus | 63 |

| 20 | Tectona grandis Linn | Spherical; 26–28 nm | E. coli and S. aureus | 64 |

| 21 | Ficus virens | Spherical; 4.98–29 nm | B. subtilis, S. epidermidis, E. faecalis, K. pneumoniae, V. cholerae, V. vulnificus | 65 |

| 22 | Azadirachta indica | Spherical; 250–700 nm | E. coli | 66 |

| 23 | Artocarpus altilis | Spherical; 20–50 nm | E. coli, P. aeruginosa, S. aureus, A. versicolor | 67 |

| 24 | Crotalaria retusa | Spherical; 80 nm | E. coli and S. aureus | 68 |

| 25 | Cardiospermum halicacabum | Spherical; 74 nm | P. vulgaris, P. aeruginosa, S. aureus, B. subtilis, S. paratyphi, A. solani, F. oxysporum | 69 |

| 26 | Psidium guajava | Spherical; 10–90 nm | P. aeruginosa | 70 |

| 27 | Cassia fistula | Spherical; 39.5 nm | B. subtilis, S. aureus, E. coli, P. aeruginosa, C. albicans, C. kruseii, C. viswanathii, T. mentagrophytes | 71 |

| 28 | Terminalia chebula | Spherical; 10–30 nm | E. coli, B. subtilis | 72 |

| 29 | Pedalium murex | Spherical; 20–50 nm | E. coli, K. pneumonia, M. flavus, P. aeruginosa, B. subtilis, B. pumilus and S. aureus | 73 |

| 30 | Azadirachta indica | Spherical; 34 nm | E. coli, S. aureus | 74 |

| 31 | Croton bonplandianum | Spherical; 15–40 nm | P. aeruginosa, E. coli, S. aureus | 75 |

| 32 | Tamarix gallica | Spherical; 5–40 nm | E. coli | 76 |

| 33 | Urtica dioica | Spherical; 20–30 nm | B. cereus, B. subtilis, S. aureus and S. epidermidis, E. coli, K. pneumoniae, S. marcescens, S. typhimurium | 77 |

| 34 | Ziziphus oenoplia | Spherical; 10 nm | P. aeruginosa, K. pneumoniae, E. coli, S. typhi | 78 |

| 35 | Lawsonia inermis | Spherical; 25 nm | E. coli, Pseudomonas spp., Bacillus spp., Staphylococcus spp., A. niger, A. flavus, Penicillium spp. | 79 |

| 36 | Lantana camara | Spherical; 20–200 nm | S. aureus, E. coli, P. aeruginosa, K. pneumonia | 81 |

| 37 | Jatropha curcas | Spherical; 20–50 nm | E. coli, P. aeruginosa, B. cereus, S. enterica, L. monocytogenes, S. aureus | 82 |

| 38 | Salvinia molesta | Spherical; 10 nm | S. aureus, E. coli | 83 |

| 39 | Sesbania grandiflora | Spherical; 20 nm | E. coli, Pseudomonas spp., Bacillus spp., Staphylococcus spp., A. niger subsp., A. flavus subsp., Penicillium spp. | 84 |

| 40 | Indoneesiella echioides | Spherical; 29 nm | R. rhodochrous, A. hydrophila, S. aureus, Pseudomonas aeruginosa, C. albicans | 85 |

| 41 | Phlomis | Spherical; 25 nm | S. aureus, B. cereus, S. typhimurium, E. coli | 86 |

| 42 | Hydrocotyle rotundifolia | Spherical; 7.39 nm | E. coli | 87 |

| 43 | Maclura pomifera | Spherical; 6–16 nm | S. aureus, Bacillus cereus, E. coli, P. aeruginosa, A. niger, C. albicans | 88 |

| 44 | Paederia foetida Linn. | Spherical; 5–25 nm | B. cereus, S. aureus, E. coli, A. niger | 89 |

| 45 | Atalantia monophylla | Spherical; 35 nm | B. subtilis, B. cereus, S. aureus, E. coli, P. aeruginosa, K. pneumoniae, C. albicans, A. niger | 90 |

| 46 | Talinum triangulare | Spherical; 13.86 nm | E. coli, S. typhi, B. subtilis, S. aureus, C. albicans | 91 |

| 47 | Ricinus communis | Spherical; 8.96 nm | S. aureus, P. aeruginosa | 92 |

| 48 | Erythrina suberosa | Spherical; 15–34 nm | S. aureus, P. aeruginosa, C. kruseii, T. mentagrophytes | 93 |

| 49 | Lippia citriodora | Spherical; 10–45 nm | S. aureus, B. subtilis, S. typhi, E. coli, C. albicans | 94 |

| 50 | Brassica oleracea L. | Spherical; 30–100 nm | S. aureus, E. coli, C. albicans | 95 |

| 51 | Catharanthus roseus | Spherical; 10–88 nm | E. coli, C. koseri, K. pneumonia, P. aeruginosa, and S. aureus | 96 |

| 52 | Lavandula x intermedia | Spherical; 11–47 nm | E. coli, P. aeruginosa, P. mirabilis, B. cereus, K. oxytoca, S. typhi, S. aureus, C. albicans, A. niger, F. oxysporum | 98 |

| 53 | Canna edulis | Spherical; less than 40 nm | B. cereus, S. aureus, E. coli, S. typhimurium, E faecalis, C. tropicalis, C. kruseii, C. lusitaniae, C. guilliemondii, P. chrysogenum | 99 |

| 54 | Artemisia vulgaris | Spherical; 27–53 nm | E. coli, S. aurous, P. aeruginosa, K. pneumoniae, H. influenza | 100 |

| 55 | Psidium guajava | Spherical; 25 nm | B. aryabhattai, B. megaterium, B. subtilis, A. creatinolyticus, E. coli, Alcaligenes faecalis, S. cerevisiae, A. niger, R. oryzae | 102 |

| 56 | Taraxacum officinale | Spherical; 5–30 nm | X. axonopodis, P. syringae | 104 |

| 57 | Petiveria alliacea L. | Spherical; 16.7–33.74 nm | E. coli, K. pneumoniae, S. aureus | 105 |

| 58 | Nervalia zeylanica | Spherical; 34.2 nm | S. aureus, L. brevis, P. putida, Pseudomonas sp., P. chrysogenum, P. citrinum | 106 |

| 59 | Ficus ingens | Spherical; 81.37 nm | E. coli, S. typhi, B. cereus | 107 |

| 60 | Thymbra spicata | Spherical; 70.2 nm | B. cereus, S. aureus, E. coli, S. typhimurium | 108 |

| 61 | Indigofera tinctoria | Spherical; 9–26 nm | B. pumilis, S. aureus, Pseudomonas sp., E. coli, A. fumigatus, A. niger | 110 |

| 62 | Tecoma stans | Spherical; 2–40 nm | B. subtilis, S. aureus, K. pneumoniae | 114 |

| 63 | Salvia leriifolia | Spherical; 27 nm | P. aeruginosa, E. coli, S. coagulase, C. frurdii, E. aerogenes, A. baumannii, S. marcescens, K. pneumonia, S. pneumoniae | 115 |

| 64 | Leucaena leucocephala L. | Spherical; 25–50 nm | P. aeruginosa, S. pyogenes, S. aureus, E. coli, S. typhi, B. subtilis | 116 |

| 65 | Selaginella bryopteris | Spherical; 5–10 nm | S. aureus, E. coli, A. niger | 117 |

| 66 | Galega officinalis | Spherical; 27.12 nm | E. coli, P. syringae, S. aureus | 118 |

| 67 | Camellia sinensis | Spherical; 30 nm | S. aureus, K. pneumoniae | 119 |

| 68 | Justicia spicigera | Spherical; 86–100 nm | B. cereus, K. pneumoniae, and E. aerogenes, M. phaseolina, A. alternate, Colletotrichum sp., F. solani | 120 |

| 69 | Kleinia grandiflora | Spherical; 20–50 nm | P. aeruginosa, C. albicans | 121 |

| 70 | Eucalyptus citriodora | Spherical; 17.51 nm | C. albicans, A. baumannii, E. coli, K. pneumoniae, P. aeruginosa | 122 |

| 71 | Juniperus procera | Spherical and cubic; 30–90 nm | M. luteus, B. subtilis, P. mirabilis, K. pneumoniae, C. albicans | 123 |

| 72 | Capparis zeylanica | Spherical; 23 nm | S. epidermis, E. faecalis, S. paratyphi, S. dysenteriae, C. albicans, A. niger | 124 |

| 73 | Caesalpinia pulcherrima | Spherical; 9 nm | B. cereus, B. subtilis, S. aureus, C. rubrum, E. coli, P. aeruginosa, S. typhimurium, K. pneumoniae, C. albicans, C. glabrata, C. neoformans | 126 |

| 74 | Ligustrum lucidum | Spherical; 13 nm | S. turcica | 127 |

| 75 | Aesculus hippocastanum | Spherical; 50 ± 5 nm | S. aureus, S. epidermidis, L. monocytogenes, C. renale, M. luteus, B. subtilis, B. cereus, E. faecalis, P. aeruginosa, P. fluorescens, E. coli, E. aerogenes, K. pneumonia, P. mirabilis, C. albicans, C. tropicalis, C. krusei | 128 |

| 76 | Melaleuca alternifolia | Spherical; 11.56 nm | S. aureus, methicillin-resistant Staphylococcus aureus, S. epidermidis, S. pyogenes, K. pneumoniae, P. aeruginosa, T. mentagrophytes, C. albicans | 129 |

| 77 | Carya illinoinensis | Spherical; 12–30 nm | E. coli, P. aeruginosa, S. aureus, L. monocytogenes | 130 |

| 78 | Murraya koenigii | Spherical;; 35–80 nm | E. coli, P. aeruginosa, E. faecalis, C. albicans | 131 |

| 79 | Clerodendrum inerme | Spherical; 5.54 nm | B. subtilis, S. aureus, Klebsiella, E. coli, A. niger, T. harzianum, A. flavus | 132 |

| 80 | Aspilia pluriseta | Spherical; 1–20 nm | B. subtilis, S. aureus, E. coli, P. aeruginosa, C. albicans | 133 |

| 81 | Melia azedarach | Spherical; 18 to 30 nm | V. dahliae | 134 |

| 82 | Scoparia dulcis | Spherical; 3–18 nm | P. aeruginosa, E. coli, B. subtilis, S. aureus, A. niger, C. albicans | 135 |

| 83 | Lantana trifolia | Spherical; 5 and 70 nm | E. coli, P. aeruginosa, C. albicans, S. aureus, B. subtilis | 136 |

| 84 | Mikania micrantha | Spherical; 10–20 nm | B. subtilis, E. coli, P. aeruginosa, S. pneumonia | 137 |

| 85 | Solanum nigrum | Spherical; 3.46 nm | E. coli | 138 |

| 86 | Curcuma longa L. | Spherical; 15–40 nm | S. aureus, P. aeruginosa, S. pyogenes, E. coli, C. albicans | 139 |

| 87 | Syzygium cumini | Spherical; 11–19 nm | S. aureus, A. flavus, A. parasiticus | 140 |

| 88 | Cleistanthus collinus | Spherical however not mentioned in manuscript; 30 to 50 nm | S. sonnei, P. aeruginosa, S. aureus, B. subtilis, S. dysenteriae, V. cholerae, P. mirabilis | 142 |

| 89 | Cestrum nocturnum | Spherical; 20 nm | Citrobacter, E. faecalis, S. typhi, E. coli, P. vulgaris and V. cholerae | 143 |

| 90 | Rice | Spherical; 16.5 nm | R. solani | 144 |

| 91 | Mentha aquatica | Spherical; 8 nm | P. aeruginosa, E. coli, B. cereus, and S. aureus | 146 |

| 92 | Rosmarinus officinalis | Sphere; 29 nm | S. aureus, B. subtilis, E. coli, P. aeruginosa | 147 |

| 93 | Ceropegia thwaitesii | Sphere; 100 nm | S. typhi, B. subtilis, S. aureus, S. epidermis, V. cholerae, S. epidermidis, K. pneumonia, M. luteus, P. mirabilis, P. aeruginosa, S. flexneri | 148 |

| 94 | Ziziphus jujuba | Irregular; 20–30 nm | E. coli | 149 |

| 95 | Ocimum tenuiflorum, Solanum trilobatum, Syzygium cumini, Centella asiatica and Citrus sinensis | Irregular; 28 nm, 26.5 nm, 65 nm, 22.3 nm and 28.4 nm | S. aureus, P. aeruginosa, E. coli, K. pneumoniae | 154 |

| 96 | Amaranthus gangeticus Linn | Globular-shaped; 11–15 nm | S. flexneri, B. subtilis, Sclerotinia sp. | 155 |

| 97 | Andrographis paniculata | Cubic; 40 and 60 nm | P. aeruginosa, E. coli, V. cholerae, S. flexneri, B. subtilis, S. aureus, M. luteus | 156 |

| 98 | Andrographis echioides | Cubic, pentagonal, hexagonal; 68.06–91.28 nm; | E. coli, S. aureus, S. typhimurium, M. luteus, P. aeruginosa | 158 |

| 99 | Azadirachta indica (neem) | Polydispersed; less than 40 nm | P. nitroreducens, A. unguis | 159 |

| 100 | Phyllanthus amarus | Flower-liked; 30 nm to 42 nm | E. coli, P. spp., B. spp., S. spp., A. niger, A. flavus, P. spp. | 160 |

Fig. 3. Bactericidal activity of Prosopis farcta extract mediated Ag-NPs against human pathogens. This figure has been reproduced from ref. 51 with permission from Elsevier, copyright 2015.

Clitoria ternatea and Solanum nigrum58 were also reported to synthesize very small-size AgNPs and evaluated against B. subtilis, S. aureus, S. pyogenes, E. coli, P. aeruginosa, K. aerogenes. Interestingly, among the two leaf Clitoria ternatea extract gave smaller nanoparticles, which indicated the important role of extract constituents on the size of the produced nanoparticles. In addition, AgNPs of Clitoria ternatea showed higher activity than the AgNPs of Solanum nigrum against nosocomial pathogens due to its small size. It has been well-documented in literature that smaller size NPs showed higher antimicrobial activities due to larger surface area.56Grewia flaviscences,59Prunus yedoensis,60Justicia adhatoda L,61Withania somnifera62 produced AgNPs in the range 8–100 nm which mainly are spherical. Numerous microbes such as skin bacteria are responsible for skin infection and body odor, as well as odor in feet, shoes, and/or socks mediated through the breakdown of amino acids present in sweat. Hence proper medication is required for human's wellbeing. Velmurugan et al.60 applied the synthesized AgNPs from Prunus yedoensis to treat P. acnes, S. epidermidis, a well-known skin bacteria, and found that the synthesized NPs are more effective against skin bacteria than commercial AgNPs. The biogenic AgNPs showed 18 mm ZOI (zone of inhibition) in 30 μg scale against P. acnes, whereas commercial AgNPs displayed a lower ZOI of only 12 in the same concentration.

Pistacia atlantica,63Tectona grandis Linn,64Ficus virens65 also reported for the synthesis of AgNPs and are evaluated against several microbes. Verma et al.66 reported Azadirachta indica (neem) leaf inspired synthesis of AgNPs and evaluated the effects of pH of the solution on the formation of nanoparticles as change in pH affects the shape and size of the particles by altering the charge of biomolecules, which might affect their capping as well as stabilizing abilities. They have observed that as the pH increases from 9 to 13, the absorption maximum shifts from 383 to 415 nm in the UV-spectrum and detects an increase in absorption intensity with increasing pH. This showed that pH 13 is the most favourable pH for the synthesis of AgNPs leaf extract. The shift in the peak wavelength indicates that the size of the particles increases with increasing pH of the solution. As the particles' diameter gets larger, the energy required for excitation of surface plasmon electrons decreases, as a result the absorption maximum shifted towards the longer wavelength region. Moreover, it was observed that at acidic pH i.e. pH < 7, the formation of nanoparticles is suppressed. At high pH, the bioavailability of functional groups in Azadirachta indica leaf extract promoted the synthesis of nanoparticles. However, at very high pH i.e. pH ∼13, the particles became unstable and agglomerated, when kept for overnight.

AgNPs were also recently synthesized using several leaf extract of plants such as Artocarpus altilis,67Crotalaria retusa,68Cardiospermum halicacabum,69Psidium guajava,70Cassia fistula71 and Terminalia chebula.72 In 2016, Anandalakshmi et al.73 reported Pedalium murex leaf extract mediated AgNPs. The produced NPs were tested against several microbes and displayed highest ZOI of 10.5 mm (in 15 μL mL−1 scale) against E. coli and P. aeruginosa and least activity against Klebsiella pneumoniae (8.5 mm). The shape and size of the resultant AgNPs were elucidated with the help of TEM. The TEM micrographs showed that the sizes of the particles were around 50 nm and were predominantly spherical in shape. The PXRD pattern showed fcc crystal structure. Azadirachta indica promoted synthesis of AgNPs was reported by Ahmed et al.74 The produced NPs displayed equal efficacy (9 mm ZOI) against E. coli, S. aureus whereas the plant extract show no antimicrobial activity.

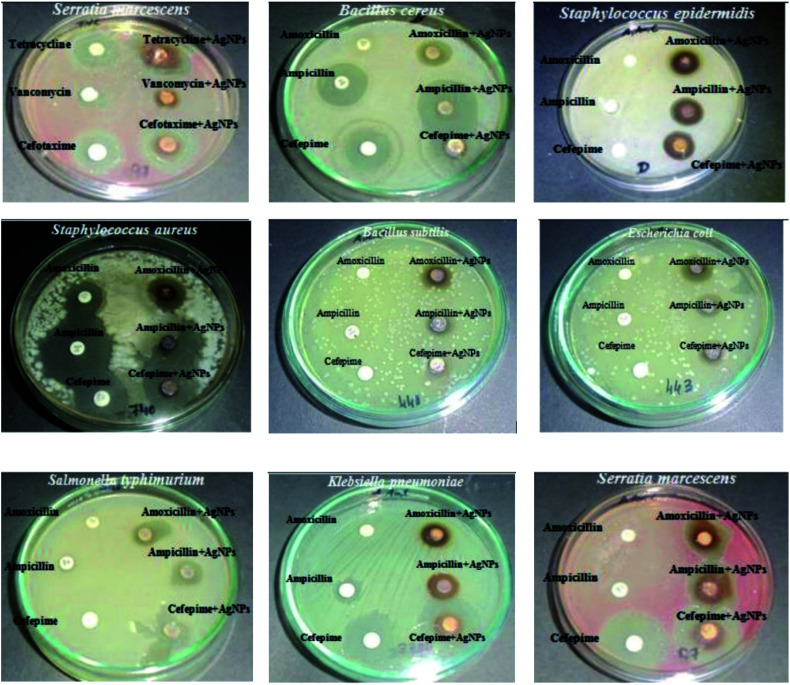

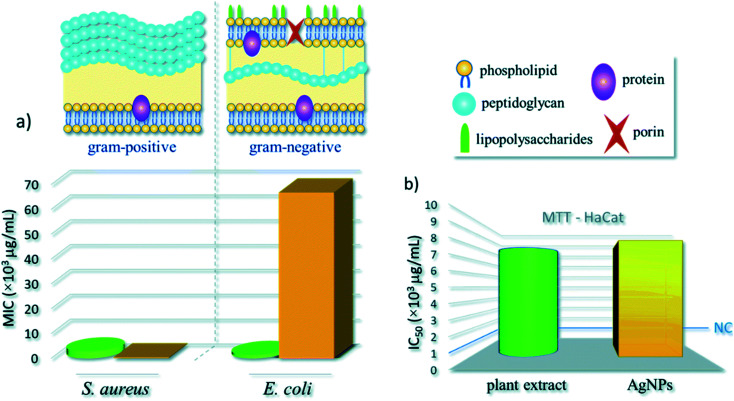

Croton bonplandianum mediated AgNPs were also found to be highy active against microbes.75 The minimum inhibitory concentrations of synthesized AgNPs were found to be 50, 45, 75 g mL−1 in case of E. coli, P. aeruginosa, and S. aureus respectively. It was concluded that Gram-negative strains of bacteria with thin cell wall such as E. coli and P. aeruginosa are more susceptible to cell wall damage compared to Gram-positive strain bacteria with a thick cell wall (S. aureus). In another work, Tamarix gallica leaf extract was used for synthesis of AgNPs. To test its activity against E. coli, three sterile filter paper discs (5 mm diameter) were impregnated with 6 μL of AgNPs produced with 5 mL of Tamarix gallica extract and 10 mL of 5 mM AgNO3 solution, López-Miranda et al. studied the green synthesis of AgNPs using and evaluated the effect of extract and AgNO3 concentration on the synthesis.76 They have observed an increase in the intensity of surface plasmon resonance (SPR) with the increase in extract concentration, which is attributed to an increasing number of AgNPs formed. Also, as the AgNO3 concentration increases, many silver ions are increasingly reduced to AgNPs. However, they have seen that the SPR band intensities are nearly independent for 5, 7, and 9 mM AgNO3, which reflected that the reaction is close to an equilibrium system because the reducing compounds and stabilizers from the extract are completely consumed, hence it is impossible to reduce a larger amount of silver ions. Henceforth, from the UV-vis analysis they concluded that the best results were obtained for the sample 0.15 g mL−1 extract with 5 mM AgNO3. The produced showed 9 mm ZOI against E. coli. Similarly, leaf extract of Urtica dioica,77Ziziphus oenoplia78 and Lawsonia inermis79 are reported for the production of AgNPs with high antimicrobial activities. In 2016, a remarkable work on the synthesis of AgNPs using Urtica dioica leaf extract that showed excellent synergistic effect with known antimicrobial drugs was reported by Jyoti et al.77 Interestingly, the synthesized AgNPs apart from showing high antimicrobial activities against several microbes, showed excellent synergistic effect in combination with antibiotics and displayed higher antibacterial effect as compared with AgNPs alone. A high 17.8 fold increase in ZOI was observed for amoxicillin with AgNPs against S. marcescens proving the synergistic role of AgNPs.77 This work provides helpful insight into the development of new antibacterial agents to fight against several new stain of microbes resistant to existing antibiotic drugs. Fig. 4 displayed the synergistic effect of AgNPs and common antimicrobial drugs. The synergistic interaction between AgNPs and antibiotic drugs has been clearly identified using UV-Vis and Raman spectrometer by McShan et al.80 The authors claimed that this synergistic interaction speed up the ejection of Ag+ from AgNPs which inturn boost its antimicrobial activities.

Fig. 4. Synergistic effect of Urtica dioica mediated AgNPs with several antibiotics. This figure has been reproduced from ref. 77 with permission from Elsevier, copyright 2016.

Recently, Manjamadha et al.81 have reported ultrasonic-assisted biosynthesis of spherical AgNPs using Lantana camara L. leaf extract. Biosynthesis of AgNPs using ultrasonication improves the reaction conditions such as reducing reaction time and enhancing the reaction rate. Bactericidal activity of the synthesized AgNPs revealed that it shows excellent antibacterial activity against Gram-positive and Gram-negative bacteria. Leaves of Jatropha curcas collected from Micro model complex, Indian Institute of Technology Delhi campus was used for the production of AgNPs.82 The transmission electron microscopy (TEM) analysis showed variation in particle shape and size (20–50 nm), whereas the diameter of NPs was found to be in range of 50–100 nm by scanning electron microscopy (SEM). Complete destruction of the microbial cell was visible using TEM examination. The synthesized NPs were tested for their antimicrobial activities and based on ZOI data, the pattern of sensitivity was observed in the order as E. coli > P. aeruginosa > B. cereus > S. enterica = L. monocytogenes > S. aureus.

Salvinia molesta,83Sesbania grandiflora,84Indoneesiella echioides85 and Phlomis86 leaf extract were also useful for the bioreduction of AgNO3 to AgNPs. An ultra-small AgNPs with an average diameter of 7.39 nm were prepared using Hydrocotyle rotundifolia.87 The synthesized AgNPs were tested for its antimicrobial property against E. coli (DH5α). The MIC value was recorded as 5 μg mL−1 and demonstrated significant growth inhibition on agar plate. Formation of spherical AgNPs using Maclura pomifera was achieved in 2017 by Azizian-Shermeh et al.88 The produced NPs (0.1 mg mL−1 concentration) displayed a very high ZOI of 23.4 ± 0.1 mm against E. coli, which is higher than Ampicillin, a well-known antibiotic drug. In the same year, Bhuyan and coworkers at National Institute of Technology Silchar reported Paederia foetida Linn. inspired AgNPs synthesis.89 The order of activities of the AgNPs against tested microbes is B. cereus > E. coli, S. aureus > A. niger. The author claimed that the AgNPs owing to their small size range (5–25 nm) could have easily penetrated the cell membrane, disturbing the metabolism, cause irretrievable damage finally leading to the microbial cell death. Au NPs has also been synthesized but has not shown any antimicrobial activity which testament the higher activity of AgNPs than that of Au NPs. Biosynthesized AgNPs from leaf extract of Atalantia monophylla,90Talinum triangulare,91Ricinus communis,92Erythrina suberosa,93Lippia citriodora,94 and Brassica oleracea L.95 are also successfully used as an outstanding antimicrobial drug.

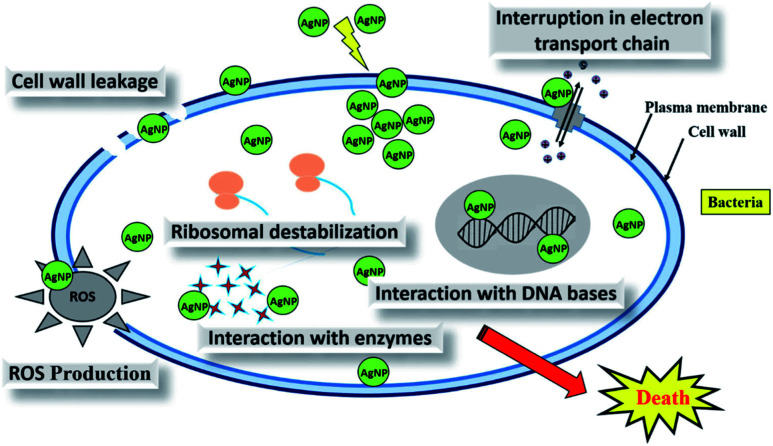

In 2017 Al-Shmgani et al. prepared AgNPs using Catharanthus roseus.96 They have used identification by color change, UV-vis spectrum, XRD, FTIR, and AFM techniques to confirm the biosynthesis of AgNPs. The leaf extract color changes from yellowish to reddish-brown after adding 2 mM AgNO3 and exposing to heat at 70 °C for 3 min indicating the formation of the NPs. AFM displays the crystalline NPs with grains sized 10–88 nm in diameter with mean size of about 49 nm. The authors claimed that synthesized AgNPs enter the cell of microbes that resulted in a disruption of adenosine triphosphate (ATP) production and DNA replication, generation of ROS and damage the cell structures as earlier observed by Sahayaraj and Rajesh.97

Spherical shape AgNPs with diameter in the range 11–47 nm (by TEM analysis) were produced using Lavandula x intermedia.98 The AgNPs were found to be most effective against E. coli among all the tested microorganisms shown in Table 1, entry 51. Interestingly, the author also observed that biogenic AgNPs showed ZOI 23 ± 0.0 mm against E. coli whereas streptomycin displayed only 20 ± 0.0 mm under the same concentration. This reflected the high antibacterial efficacy of AgNPs than that of common antimicrobial drug like streptomycin, which could promote its wide use in the future. In another work, a highly crystalline AgNPs were reported to be synthesized from Canna edulis.99 The NPs showed highest antimicrobial activity against S. typhimurium which is closely related to the finding by Sumitha et al.38

In 2017 Artemisia vulgaris mediated AgNPs were reported by Rasheed et al.100 Antimicrobial test revealed that the AgNPs exhibited significant inhibition activities against tested pathogens with the highest value being recorded against S. aureus (18 ± 0.27 mm inhibition zone). Similar to this, earlier in 2016, Thatoi et al.101 reported high activity of AgNPs against S. aureus using AgNPs synthesized from Sonneratia apetala plant extract.

Psidium guajava was applied for the production of spherical AgNPs with average dimension of 25 nm.102 The authors observed that for 100 μg mL−1Psidium guajava mediated AgNPs, the ZOI were 18.13 ± 0.02 mm and 16.92 ± 0.18 mm against A. faecalis and E. coli, respectively, whereas ZOI of 13.24–14.41 mm were recorded at the same concentration against tested Gram-positive bacteria shown in Table 1, entry 54. This finding clearly testament the higher activity of the synthesized AgNPs towards Gram-negative bacteria than the Gram-positive ones. Similar to this finding, earlier in 2013, Geethalakshmi et al. also reported the higher susceptibility of Gram-negative bacteria to silver nanoparticles compared with Gram-positive bacteria.103 Ironically, Psidium guajava mediated AgNPs is however consistently less sensitive towards tested fungi such as S. cerevisiae, A. niger and R. oryzae as compared to both Gram-positive and Gram-negative bacteria.

Taraxacum officinale leaf extract mediated AgNPs were proved to exhibit an excellent synergistic antibacterial activity with standard antibiotics (such as oxy-tetracycline, tetracycline, ampicillin, and streptomycin) and showed strong positive response against both X. axonopodis, P. syringae, a plant pathogens.104 The combined effect of tetracycline with AgNPs significantly inhibited the growth of selected phytopathogens by increasing ZOI about 40% compared to only antibiotics. The authors are of the opinion that NPs-antibiotic combination and their synergistic action would result in higher penetration in the bacterial cell membrane thereby leads to destruction of various cell organelles and death of bacteria, although the mechanism is not yet fully understood till now.

Lateef et al.105 reported that Petiveria alliacea L. mediated AgNPs showed 100% inhibition against E. coli, K. pneumoniae, S. aureus, A. fumigatus and A. flavus. But only 66.67% inhibition in A. niger. In another work, microwave-assisted synthesis of AgNPs using leaf extract of Nervalia zeylanica was reported.106 The authors observed no formation of NPs (monitored using UV-spectroscopy) even after 5 h under RT stirring of the extract and AgNO3. However, the nanoparticle formation takes place suddenly after 60 s of microwave irradiation. Ficus ingens mediated AgNPs recorded MIC value of 10 μg mL−1 on E. coli and 20 μg mL−1 on both S. typhi and B. cereus107 which is in close agreement with the earlier report of 10 μg mL−1 for E. coli. The AgNPs showed highest inhibition against E. coli and least with S. cereus. Commercial antibiotic Ciprofloxacin showed better activities than the synthesized NPs.

In general, the reduction in the size of the metallic nanoparticles is expected to increase the antibacterial activity due to significantly large surface area of the smaller nanoparticles. However, the results obtained by Erci et al.108 using Thymbra spicata leaf extract is worth discussing. In their study higher antibacterial activity of, say, AgNPs2 (average diameter 70.2 nm) in comparison to AgNPs1 (average diameter 25.1 nm) was recorded. They reasoned that this could be due to the shape of AgNPs2, which have triangles, hexagons, spheres and irregular shapes, whereas AgNPs1 exhibit mostly spherical formation. This interesting finding confirmed the shape-dependent bacterial activity of AgNPs, and support earlier reported protocol.109 The MIC of 50 μg mL−1 was recorded for S. cereus whereas, it was 100 μg mL−1 for E. coli. This finding is in sharp contrast to the work of Kavaz et al.107 mentioned earlier where Gram-negative bacteria has lower MIC than Gram-positive bacteria. However, Erci et al.108 defended their finding of the more pronounced effect of AgNPs against Gram-positive bacteria than Gram-negative bacteria based on the structural difference in cell wall composition of Gram-positive and Gram-negative bacteria. Gram-negative cell wall was covered with an outer lipid membrane (lipopolysaccharide), which is more negatively charged than Gram-positive. As is evident from the zeta value, the biogenic silver nanoparticles were also negatively charged and the electrostatic repulsion between the nanoparticles and Gram-negative bacteria hinders particle attachment and penetration into the cell37 However, this postulate is not yet fully understood. Again, as against the finding of Erci et al.108 the Gram-positive bacteria are less affected by AgNPs (produced from Indigofera tinctoria) than Gram-negative bacteria as reported by Vijayan et al.110 The authors credited the presence of large number of peptidoglycan layers on the walls of Gram-positive bacteria than Gram-negative bacteria that have to some extent prevent the nanoparticles entry to cytoplasmic membrane than Gram-negative bacteria. Hence, the true role of chemicals in the cell wall of bacteria needed to be properly investigated to understand the underlying mechanism of the cell death due to NPs.

Another interesting work on the shape-dependent activity of biogenic AgNPs was reported using Trichoderma viride extract where the authors reported a higher antimicrobial activity of penta- and hexagonal NPs than spherical NPs when the size are of similar range.111 The different shape AgNPs such as pentagonal, hexagonal and spherical were synthesized by manipulating physical parameters, temperature, pH, and reaction time. At neutral pH (7), spherical NPs were observed under all reaction conditions. Delightfully, at pH 5.0 and 9.0, rectangular and penta-/hexagonal NPs were obtained at 40 °C after 72 h of incubation. In general, longer is the reaction, bigger is the size of NPs whereas higher temperature always affords a smaller NP. It was also found that triangular shape AgNPs showed better antimicrobial activity compared to that of spherical and rod shaped as it has high percentage of facet (1 1 1) that possess a high atomic density which increases binding efficiency of Ag to sulfur containing components, whereas spherical and rod shaped particles have a high percentage of (1 0 0) facets.112,113

Recently, Tecoma stans,114Salvia leriifolia,115Leucaena leucocephala L.116 and Selaginella bryopteris117 were also reported to produced AgNPs which are mainly spherical in nature. Galega officinalis leaf extract mediated AgNPs with size-dependent activities were reported by Manosalva et al.118 AgNPs with 23 nm and 220 nm recorded MIC of 5 μL mL−1 and 30 μL mL−1 respectively against E. coli showing the higher activity of the smaller NPs. Interestingly MIC of S. aureus (a Gram-positive bacteria) is higher (50 μL mL−1) than E. coli (a Gram-negative bacteria) using 23 nm size AgNPs which implies the higher activity of AgNPs against Gram-negative bacteria.

In the year 2019, antimicrobial fabric tests on the dyed cloths were conducted using AgNPs derived from Camellia sinensis (tea leaf) extract where bleached cotton cloths were dyed using the NPs colloidal solutions. The attachment of AgNPs on the cloths was confirmed by SEM. SEM images of AgNPs with green tea extract also showed the generation of AgNPs. The AgNPs showed excellent antimicrobial activities against S. aureus, K. pneumoniae in the cotton fabric which potentially endorse the suitability of using AgNPs as an effective antimicrobial in cloths.119 Bernardo-Mazariegos et al. used DLS to measure the average hydrodynamic size and zeta potential of the AgNPs synthesized from Justicia spicigera.120 The sample with a mixture of AgNPs of different sizes gave two broad peaks and was weighted toward the larger particles (z-average size of 4.04 μm and 192 nm). The authors are of the opinion that DLS measurement may not be accurate for polydisperse samples due to its nature to respond toward larger particles. Additionally, the zeta potential was of the NPs was found to be 0.2 mV that indicated the less stability and hence, a tendency to agglomerate to form large particles.

In recent times, highly antimicrobial AgNPs were synthesized using Kleinia grandiflora,121Eucalyptus citriodora,122Juniperus procera123 and Capparis zeylanica.124 Two different shapes structure in the form of sphere and cubic are observed in SEM analysis of the AgNPs generated from Juniperus procera leaf extract. The produced NPs recorded the highest ZOI against P. mirabilis measured at 29 ± 1.3 mm. The author suggested that the high antimicrobial activity of the NPs is due to the inherent activity of the NPs coupled with the plant particulates attached to the NPs, as the plant which contain high flavonoids and polyphenols are a well-known antimicrobial by themselves.125 Small size AgNPs (9 nm) synthesized using Caesalpinia pulcherrima leaf extract were found to exhibited an MIC as low as 0.078 mg mL−1 and 0.156 mg mL−1 for K. pneumoniae and E. coli respectively. Accordingly, the AgNPs possessed maximum antimicrobial activity against K. pneumoniae and E. coli whereas only moderate effects were shown against C. xerosis, S. mutans, S. aureus, S. viridians, S. pyrogenes, S. viridians and C. diphtheriae that have higher MICs.126

Synergistic antimicrobial activity of Ligustrum lucidum mediated AgNPs and Epoxiconazole under different conjugation ratio was studied against S. turcica, a common maize pathogen.127 The antifungal activity of AgNPs was evaluated alone, and the synergistic inhibition effect was also measured at various conjugation ratios of AgNPs and epoxiconazole, where a prominent synergistic antifungal effect was observed at 8 : 2 and 9 : 1 (AgNPs/epoxiconazole) and the inhibition toxicity ratio reached as high as 1.22 and 1.24, respectively.

Aesculus hippocastanum (horse chestnut) mediated special AgNPs with size 50 ± 5 nm was reported to have highest antimicrobial activity (ZOI 20.0 ± 0.00 mm) against a Gram-negative bacteria P. aeruginosa among all the tested microorganisms listed in Table 1, entry 74.128 Interestingly, although the AgNPs have profound effects on all the tested bacteria, it have no effect against fungal strains such as C. albicans ATCC 10231, C. tropicalis ATCC 13803 and C. krusei ATCC 1424. The MIC and MBC of AgNPs for the tested microorganisms were in the range from 0.19–12.5 μg mL−1 and 1.56–25 μg mL−1.

Ramadan et al.129 studied the antiviral activity of green synthesized AgNPs and found that AgNPs greatly enhanced the antiviral activity of M. alternifolia leaf extract, which on its own has no effect on the tested viruses such as herpes simplex virus type 1 (HSV-1), and herpes simplex virus type 2 (HSV-2). In addition, the NPs showed excellent activities against several persistent skin bacteria including S. epidermis and methicillin-resistant Staphylococcus aureus (MRSA). Interestingly, tea tree oil of M. alternifolia itself showed even higher activity than the AgNPs against some tested microbes which is hardly the case in literature. In another work, Carya illinoinensis mediated AgNPs were found to be more efficient against Gram-negative (E. coli) than Gram-positive bacteria (S. aureus)130 in a similar trend reported earlier.118

Although literature revealed that bacterial cell are generally more sensitive to AgNPs, biogenic AgNPs derived from Murraya koenigii leaf extract interestingly shown highly equal activity against Gram-negative bacteria P. aeruginosa (ZOI of 18 mm) and a fungus C. albicans (18 mm ZOI).131 In 2020, several leaf extracts of plant such as Clerodendrum inerme,132Aspilia pluriseta,133Melia azedarach,134Scoparia dulcis,135 and Lantana trifolia.136 All these AgNPs are shown to exhibit an excellent antimicrobial activity against numerous common pathogenic microbes. Mikania micrantha leaf extract mediated AgNPs were also reported to show a high ZOI of 26.17 mm and 26.05 mm against B. subtilis and E. coli respectively.137

More recently, AgNPs of average size 3.46 nm were produced using Solanum nigrum plant leaf extract.138 This is one of the smallest biogenic AgNPs reported so far and NPs as small as 1.74 nm were observed. SPR bands band at 442 nm in UV-visible spectroscopy confirmed the formation of AgNPs. Interestingly, the authors observed a much prominent antimicrobial activity exerted by AgNPs compared to AuNPs and PdNPs potentially due to the more effective capping of AgNPs nanoparticles than either Au or PdNPs which results in well-dispersed small AgNPs without much agglomeration as detected by HRTEM. The authors are of the opinion that polyphenols present in Solanum nigrum extract forms a negative environment around the particles and hence create a repulsive force which overcomes the van der Waals force of attraction and prevent AgNPs agglomeration. The AgNPs showed 22 mm ZOI, while 20 mm and 19 mm ZOI are observed in Au and Pd NPs respectively against E. coli at 10 μL mL−1 concentration. However, although the authors credit the effective capping of AgNPs as a reason for its higher antimicrobial activity, it may also be due to the smaller size of the AgNPs (3.46 nm) as compared to Au (9.39 nm) and Pd NPs (21.55 nm).

Maghimaa et al.139 reported biosynthesis of AgNPs using Curcuma longa leaf extract and investigate their antimicrobial activity in AgNP coated cotton fabric. The loading of AgNPs on the cotton fabric was confirmed by SEM analysis, which was further assisted by the EDX analysis. The authors have reported that the cotton fabric loaded with AgNPs showed great resistance to the growth of pathogenic microorganisms and hence they claimed that the cotton fabric loaded with AgNPs synthesized from Curcuma longa can be used for the diverse application in the medical patient as well as in medical workers to resist microbial infection.

In 2020, green synthesis of spherical AgNPs, CuNPs and FeNPs with size 11–19, 28–35 and 40–52 nm, respectively using Syzygium cumini leaf extract was reported.140 The order of antibacterial property against methicillin- and vancomycin-resistance S. aureus, A. flavus and A. parasiticus microbes was found to be Ag- > Cu- > Fe NPs, which linearly relates with the size of the NPs, thereby reinforcing the size-dependent activity of NPs.141 In addition, the bioproduction of aflatoxins (a family of toxins produced by certain fungi that are found on agricultural crops such as maize (corn), peanuts, cottonseed, and tree nuts) in A. flavus and A. parasiticus was also significantly inhibited by AgNPs when compared with the Fe and Cu NPs. Interestingly, the pH of the plants extract reduced after the formation of NPs in all the cases. Cleistanthus collinus142 and Cestrum nocturnum143 are also known to have produced AgNPs.

In another work, rice leaf extract was utilized for the biosynthesis of AgNPs with size 16.5 nm.144 Antifungal activity of the synthesized NPs was tested against mycelium and sclerotia of R. solani, a fungus that causes sheath blight disease in rice and found that it inhibits the growth of fungus and the growth inhibition is dependent on the concentration of the AgNPs. The MIC values of AgNPs were in the range of 5–10 and 15–20 μg mL−1 towards fungal mycelium and sclerotia, respectively. Results revealed that growth inhibition at 10 μg mL−1 AgNPs is 81.7–96.7% for mycelium and 20 μg mL−1 treatment completely inhibited disease cause by R. solani. In a previous investigation, 43.3–73.6% growth inhibition of R. solani was observed at a higher concentration of 2 mg mL−1 with larger AgNPs with 40–60 nm.145

Recently, an ultra sound-assisted AgNPs of size 8 mm were synthesized using Mentha aquatica leaf extract as reducing and capping agent.146 To the best of our knowledge, this is the smallest biogenic AgNPs reported so far. The production of NPs could occur at RT, but ultrasound greatly reduced the reaction time to 10 min whereas RT took 1 h. The authors highlighted that the phenolic compounds in the Mentha aquatica leaf extract get oxidized to Quinone in an alkaline condition which provides free electrons for reduction of the Ag+ ion to Ag0 to form the desired AgNPs. Largely due to its ultra-small size, the AgNPs displayed a very low MIC of 2.2 μg mL−1 for P. aeruginosa, which showed its high efficacy against the tested microbe.

Rosemary (Rosmarinus officinalis Linn.)147 and Ceropegia thwaitesii148 leaf extract mediated AgNPs which showed consistent higher activities against Gram-negative bacteria were also reported. Interestingly, S. flexneri, S. typhi, B. subtilis, M. luteus, and P. mirabilis are more susceptible to AgNPs than E. coli148 which is not very common in literature.

In the year 2015, Gavade et al. prepared AgNPs using the leaf extract of Ziziphus jujuba under RT.149 The AgNPs have different shapes with 20–30 nm size as revealed by TEM images. The authors investigated the effect of pH on the size and stability of the NPs, and observed form UV-Visible spectroscopic graphs that absorbance value linearly increases with increasing pH increases from 4 to 9, which indicates the rate of formation of AgNPs increases from acidic to basic medium. In addition, at acidic pH, bands were wider and display red shift which is an indication of increase in particle size. However, in basic condition, bands were narrow and display blue shift due to decrease in particle size. The rapid formation of AgNPs in neutral and basic pH this may be due to the ionization of the phenolic groups present in the leaf extract.150 The slow rate of formation and aggregation of AgNPs in acidic pH could be related to electrostatic repulsion of anions present in the solution.151,152 Ironically, at basic pH there is a possibility of AgOH precipitation which need to be avoided.150 Hence, the authors concluded that the optimum condition for the preparation of AgNPs with desired size and stability was neutral medium. The NPs have a zeta potential of −26.4 mV which is an indication of its excellent stability in colloidal state as a zeta potential higher than 30 mV or lesser than −30 mV is indicative of a stable system.153 The AgNPs showed high efficacy against E. coli and found to be stable for more than 6 months probably due an excellent capping of NPs (indicated by FR-IR) and low zeta potential.

Irregular shape AgNPs of average size 28 nm, 26.5 nm, 65 nm, 22.3 nm and 28.4 nm were prepared from O. tenuiflorum, S. cumini, C. sinensis, S. trilobatum and C. asiatica, respectively.154 Among several tested microbes the highest antimicrobial activity of AgNPs synthesized by S. trilobatum and O. tenuiflorum extracts was found against Gram-positive bacteria S. aureus (30 mm ZOI) and Gram-negative bacteria E. coli (30 mm) respectively. Interestingly, C. sinensis, S. trilobatum and C. asiatica derived AgNPs consistently showed higher susceptibility towards a Gram-positive bacteria S. aureus and Gram-negative bacteria E. coli and K. pneumoniae. These findings clearly shown that some AgNPs are more sensitive towards a Gram-positive bacteria whereas some towards a Gram-negative bacteria, hence the question of selective sensitivity of biogenic AgNPs toward Gram-positive or negative bacteria still remains unsolved. Is the selectivity depending on the biomaterial capping agents attached to NPs or the size of NPs? Hence, one may need to consider the biomolecules present in the plant extract or the size of AgNPs to truly understand the selectivity.

A globular shape AgNPs were prepared using Amaranthus gangeticus Linn leaf extract in 2015 which exhibited an inhibitory activity towards Gram-positive, Gram-negative bacteria as well as fungus.155 In another work Andrographis paniculata leaf extract produced a rarely reported cubic shape AgNPs.156 Study on different shape of AgNPs is of great interest due to the shape-dependent activities of AgNPs towards microbes as noted earlier.109 The AgNPs showed a high ZOI of 21.3 ± 0.4 mm for Gram-negative bacteria P. aeruginosa with very low MIC of 3.125 μL mL−1 which testament its high antimicrobial activity. Yao et al.157 noted that the thickness of the peptidoglycan layer of other Gram-negative bacteria such as E. coli is somewhat more than P. aeruginosa, hence the author, in good agreement with Yao's work, observed a lower ZOI (16.6 ± 0.3 mm) in case of E. coli.

Elangovan et al.158 reported the biosynthesis of AgNPs having cubic, pentagonal and hexagonal shape with size range of 68.06–91.28 nm using Andrographis echioides leaf extract and investigate its bactericidal activity against several microbes. The result revealed a high ZOI in the case of E. coli (28 mm) and S. aureus (23 mm) in 100 μg mL−1 concentration of AgNPs. Azadirachta indica (neem) leaf extract was also reported for the green synthesis of polydisperse AgNPs at RT and evaluated as a potent antimicrobial agent against P. nitroreducens, a biofilm-forming bacterium and fungus A. unguis.159

While most biogenic AgNPs are spherical, a flower-like structure was reported by Ajitha et al. in 2017.160 The AgNPs showed very high activity towards bacterial culture Pseudomonas spp. (ZOI of 11 mm) even at very low AgNPs concentration (8 μL mL−1). It is worth note that the AgNPs also consistently displayed a better activity in fungal strain, Penicillium spp. than bacteria such as E. coli and Staphylococcus spp. which is hardly a case in any literature as bacteria are usually considered more sensitive to AgNPs than fungi.

3.2. From seeds

Plant seed extract also well established for the biosynthesis of nanoparticles. Till date, various seeds extract has been utilized for the biosynthesis AgNPs (Table 2, entries 1–27). Sinapis arvensis seeds mediated AgNPs was reported for more than 83% inhibition of mycelium growth of fungus N. parvum. Inductively coupled plasma spectrometry (ICP) analysis revealed complete reduction of Ag+ to Ag0 in more than 95% conversion within 50 days of reaction.161 In another work, grape seed extract was utilized for the biosynthesis of spherical and polygonal AgNPs with size ranging from 25–35 nm. Bactericidal activity of the synthesized NPs was tested against eight different ocean pathogenic bacteria; however, it showed great inhibition activity only against four bacteria such as V. alginolyticus, V. anguillarum, V. parahaemolyticus and A. punctate.162 Sumitha et al.38 reported bio-reduction of AgNO3 to AgNPs using Durio zibethinus seed extract. It is reported that saccharides present in the extract induces the bio-reduction and the amino acids present in the extract stabilized the synthesized AgNPs. Bactericidal activity was tested against different pathogenic bacteria and found that the NPs showed greater activity against S. typhimurium, S. haemolyticus and S. aureus over B. subtilis, E. coli and S. typhi. However, the synthesized NPs showed lesser inhibition compared to the drug Gentamicin against all the mentioned pathogenic bacteria even at a lower dose of Gentamicin.

Various seeds, flower, root extract used for the green synthesis of AgNPs and their antimicrobial activity.

| No. | Plants | Plant parts | Shape and size | Test microorganisms | Ref. |

|---|---|---|---|---|---|

| 1 | Sinapis arvensis | Seeds | Spherical; 1–35 nm | N. parvum | 161 |

| 2 | Grape | Seeds | Spherical and polygonal; 25–35 nm | V. alginolyticus, V. anguillarum, V. parahaemolyticus, A. punctata, E. coli, S. dysenteriae, P. Aeruginosa, S. aureus | 162 |

| 3 | Coffea arabica | Seeds | Spherical and ellipsoidal; 20–30 nm | E. coli and S. aureus | 41 |

| 4 | Durio zibethinus | Seeds | Spherical and rod shaped, 20–75 nm | S. typhi, S. typhimurium, E. coli, S. aureus, S. haemolyticus, B. subtilis | 38 |

| 5 | Pimpinella anisum | Seeds | Spherical; 3.2–16 nm | S. pyogenes, A. baumannii, K. pneumoniae, S. typhi, P. aeruginosa | 163 |

| 6 | Synsepalum dulcificum | Seeds | Spherical; 4–26 nm | P. aeruginosa and K. granulomatis, A. flavus, A. fumigatus, A. niger | 164 |

| 7 | Vigna radiata | Seeds | Spherical; 18 nm | Escherichia coli and Staphylococcus aureus | 165 |

| 8 | Dracocephalum moldavica | Seeds | Spherical; 5–50 nm | E. coli, P. aeruginosa, S. aureus, S. marcescens, S. epidermidis, B. subtilis | 166 |

| 9 | Trifolium resupinatum | Seeds | Spherical; 17 nm | R. solani, N. parvum | 167 |

| 10 | Descurainia sophia | Seeds | Spherical; 1–35 nm | A. rhizogenes, A. tumefaciens, R. solani | 168 |

| 11 | Nigella arvensis | Seeds | Spherical; 2–15 nm | S. pyogenes, B. subtilis, S. aureus, E. coli, P. mirabilis, S. typhimurium | 169 |

| 12 | Linseed | Seeds | Spherical; 10–35 nm | S. mutans, S. epidermidis, P. aeruginosa, E. coli, S. aureus, B. subtilis, A. odontolyticus, A. niger | 170 |

| 13 | Embelia ribes | Seeds | Spherical; 5–35 nm | E. coli, S. aureus | 171 |

| 14 | Melissa officinalis | Seeds | Spherical; 34.64 nm | E. coli, B. subtilis, B. vallismortis | 172 |

| 15 | Leucaena leucocephala | Seeds | Spherical; 6–25 nm | P. gigantea, E. taxodii, E. coli, S. aureus | 173 |

| 16 | Alpinia katsumadai | Seeds | Spherical; 12.6 nm | S. aureus, P. aeruginosa, E. coli | 174 |

| 17 | Myristica fragrans | Seeds | Spherical; 25 nm | Multidrug-resistant (MDR) Salmonella enterica serovar typhi (S. typhi) | 175 |

| 18 | Durio zibethinus | Seeds | Spherical; 20–75 nm | S. aureus, S. typhimurium, E. coli, B. subtilis, S. typhi, S. haemolyticus, S. aureus | 38 |

| 19 | Phoenix sylvestris L. | Seeds | Spherical; 40–50 nm | P. acnes, S. epidermidis | 176 |

| 20 | Phoenix dactylifera | Seeds | Spherical; 14–30 nm | Methicillin-resistant S. aureus | 177 |

| 21 | Tectona grandis | Seeds | Spherical; 10–30 nm | B. cereus, S. aureus, E. coli | 178 |

| 22 | Persea americana | Seeds | Spherical; 50 nm | E. coli | 179 |

| 23 | Salvia hispanica | Seeds | Spherical; 1–27 nm | E. coli, S. aureus | 180 |

| 24 | Trigonella foenum-graecum | Seeds | Spherical; 33.93 nm | E. coli, K. pneumoniae, S. aureus, S. typhi, P. aeruginosa, A. flavus, C. albicans, T. rubrum, P. notatum, T. viridiae | 181 |

| 25 | Sesame (Sesamum indicum, L.) | Seeds | Spherical; 6.6–14.80 nm | P. aeruginosa, K. pneumoniae, B. subtilis, S. aureus | 214 |

| 26 | Hibiscus cannabinus | Seeds | Spherical; 7–11 nm | S. aureus, B. cereus, E. coli | 183 |

| 27 | Carum copticum | Seeds | Spherical; 21.48 nm | P. aeruginosa, S. marcescens, C. violaceum | 184 |

| 28 | Coffea arabica | Seeds | Spherical and ellipsoidal; 20–30 nm | E. coli, S. aureus | 41 |

| 29 | Pimpinella anisum | Seeds | Irregular; 16–48 nm | E. coli, S. aureus, A. flavus, C. albicans | 185 |

| 30 | Marigold (Tagetes erecta) | Flower | Spherical; 46.11 nm | S. aureus, B. cereus, S. coli, P. aeruginosa, C. glabrata, C. albicans, C. neoformans | 188 |

| 31 | Nyctanthes arbortristis | Flower | Spherical and oval; 5–20 nm | E. coli | 189 |

| 32 | Caesalpinia pulcherrima | Flower | Spherical; 12 nm | S. aureus, C. glabrata, B. cereus, E. coli, S. typhimurium, C. albicans, C. neoformans B. subtilis, C. rubrum, Pseudomonas aeruginosa, K. pneumoniae | 190 |

| 33 | Alcea rosea | Flower | Spherical; 7.2 nm | E. coli, S. aureus | 191 |

| 34 | Argemone mexicana | Flower | Spherical; 29.34 nm | S. aureus, P. aeruginosa, E. coli, K. aerogenes | 192 |

| 35 | Turnera ulmifolia | Flower | Spherical; 32.42 nm | S. aureus, P. aeruginosa, E. coli, K. aerogenes | 192 |

| 36 | Tecoma stans | Flower | Spherical; 50–60 nm | E. coli, S. aureus | 193 |

| 37 | Moringa oleifera | Flower | Spherical; 8 nm | K. pneumonia, S. aureus | 194 |

| 38 | Syzygium aromaticum | Flower | Polydisperse; 23 nm | Staphylococcus spp. E. coli, Pseudomonas spp., Bacillus spp., A. flavus, A. niger, Penicillium spp. | 195 |

| 39 | Potentilla fulgens | Root | Spherical; 10–15 nm | E. coli, B. subtilis | 196 |

| 40 | Alpinia calcarata (ginger) | Root | Spherical; 5–15 nm | P. mirabilis, E. coli, B. cereus, S. aureus | 197 |

| 41 | Erythrina indica Lam | Root | Spherical; 20–118 nm | S. aureus, M. luteus, Escherichia coli, B. subtilis, S. typhi, S. paratyphi | 198 |

| 42 | Diospyros paniculata | Root | Spherical; 14–28 nm | P. notatum, A. flavus, A. niger, C. albicans, S. cerevisiae | 199 |

| 43 | Diospyros sylvatica | Root | Spherical; 8 nm | B. pumilis, P. aeruginosa, B. subtilis, S. aureus, K. pneumoniae, E. coli, S. pyogenes, P. vulgaris, A. niger, P. notatum, A. flavus, S. cerevisiae, C. albicans | 200 |

| 44 | Annona muricata | Root | Spherical; 15.08–33.11 nm | K. pneumonia, S. aureus | 201 |

| 45 | Cibotium barometz | Root | Spherical; 23 nm | Escherichia, S. aureus, S. enterica, P. aeruginosa | 202 |

| 46 | Diospyros assimilis | Root | Spherical; 14–28 nm | B. pumilis, B. subtilis, S. aureus, S. pyogenes, K. pneumoniae, E. coli, P. aeruginosa, P. vulgaris, A. niger, A. flavus, C. albicans, P. notatum, S. cerevisiae | 203 |

| 47 | Pelargonium endlicherianum Fenzl. | Root | Spherical; 25–80 nm | P. aeruginosa, E. coli, S. epidermidis | 204 |

| 48 | Rheum palmatum | Root | Spherical; 121 ± 2 nm | S. aureus, P. aeruginosa | 205 |

| 49 | Lepidium draba | Root | Spherical; 20–80 nm | S. aureus, B. cereus, S. typhimurium, E. coli | 207 |

| 50 | Angelica pubescens Maxim | Root | Quasi-spherical; 12.48 nm | E. coli, S. aureus, P. aeruginosa, and S. enterica | 208 |

| 51 | Phoenix dactylifera | Root | Spherical; 15–40 nm | E. coli, C. albicans | 209 |

| 53 | Arctium lappa | Root | Spherical; 21.3 nm | E. coli, A. tumefaciens, L. acidophilus, S. aureus | 210 |

| 53 | Asparagus racemosus | Root | Spherical; 10–17 nm | E. coli, S. aureus, B. subtilis, K. pneumonia, P. fluorescence, A. hydrophila, E. tarda, F. branchiophilum, Y. ruckeri | 211 |

| 54 | Lysiloma acapulcensis | Root | Spherical; 1.2 to 62 nm | E. coli, P. aeruginosa, S. aureus, C. albicans | 212 |

| 55 | Raphanus sativus | Root | Irregular; 3.2–6.0 nm | S. aureus, E. coli, C. albicans, C. glabrata, C. tropicalis | 213 |

Pimpinella anisum,163Synsepalum dulcificum,164Vigna radiate,165Dracocephalum moldavica166 leaf extracts were also successfully applied for the green synthesis of AgNPs. Vigna radiata mediated AgNPs, was found to be more susceptible towards Gram-negative bacteria E. coli (ZOI 20 mm) than Gram-positive S. aureus (ZOI 16 mm) due to the higher thickness of the peptidoglycan layer (approx. 80 nm thick) of the cell wall of Gram positive bacteria which is 10 times thicker than the peptidoglycan Gram-negative bacteria, hence is less susceptible to be destroyed by AgNPs.165

Several reported literatures revealed that the efficiency of AgNPs as antimicrobial agent is extensively dependent on the shape of the nanoparticles. The comparison of spherical, disc like and triangular shaped AgNPs as antimicrobial agent revealed the activity trend follows as spherical AgNPs > disc-like AgNPs > triangular AgNPs.65,136The highest inhibition effect of 94.1% and 84% were observed at 40 ppm concentration of AgNPs against R. solani and N. parvum respectively, using AgNPs derived from Trifolium resupinatum seeds extract.167 In a closely related study, Khatami et al. reported more than 86% inhibition of mycelium growth of R. solani at a concentration 25 μg mL−1 (or 25 ppm) of the biogenic AgNPs.168 Several plant seeds such as Nigella arvensis,169Linseed,170Embelia ribes,171Melissa officinalis172 are applied for the generation of spherical shape AgNPs. While biogenic AgNPs are reported to be more efficient antimicrobial than any other metal NPs in most of the case, it is worth mentioned that the Embelia ribes derived AgNPs is less susceptible to E. coli at showing ZOI of 20 mm against 28 mm ZOI for AuNPs at 250 μL mL−1 concentration.171 Although having small size of NPs (6–25 nm), Leucaena leucocephala mediated AgNPs displayed very low toxicity against both E. coli and S. aureus with ZOI of 18 mm and 22 mm (approx.) respectively at 1000 ppm AgNPs concentration.173Alpinia katsumadai seeds extract mediated AgNPs showed excellent activities against E. coli and S. aureus than that of P. aeruginosa,174 whereas those derived from Myristica fragrans are found to be highly sensitive to multidrug-resistant (MDR) Salmonella enterica serovar typhi (S. typhi) where a highest ZOI of 16.4 ± 0.45 was observed at 100 μg μL−1 concentration of AgNPs.175

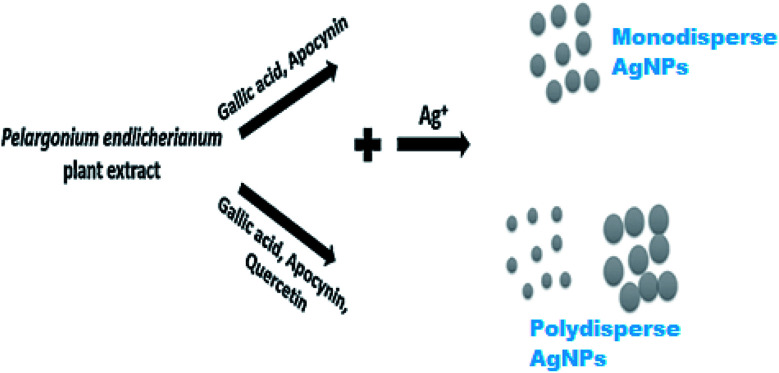

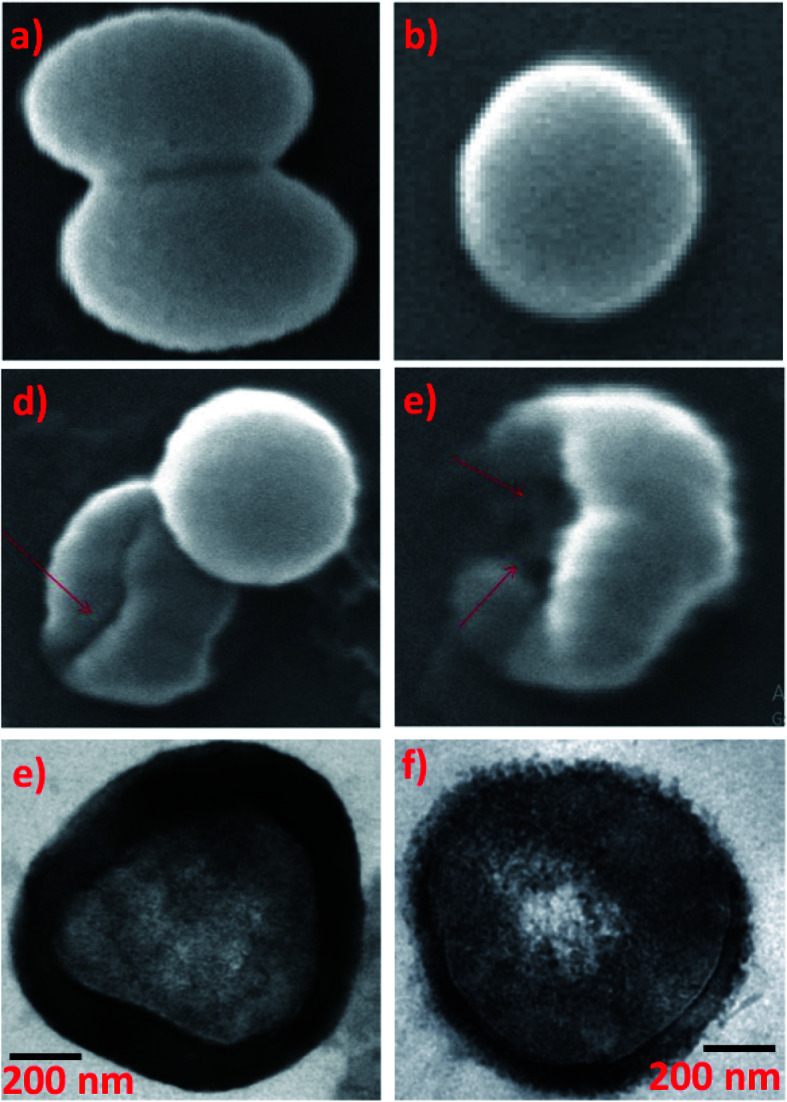

Common skin bacteria such as P. acnes and S. epidermidis are found to be highly inhibited by AgNPs synthesized using Phoenix sylvestris L. The authors also proved that AgNPs is more susceptible to the tested shin bacteria than the seeds extract as well as AgNO3 solution as can be seen from the ZOI.176 The high toxicity of Phoenix dactylifera derived AgNPs against Methicillin-resistant S. aureus is clearly seen in SEM images (Fig. 5a–d) and HRTEM images (Fig. 5e and f). Cells treated with AgNPs undergo deformities and irregular cell surface (red arrow). Attachment and penetration of NPs and deformities of the outer most layers of cell wall and cytoplasmic membrane are also clearly visible in HRTEM.177

Fig. 5. (a and b) Untreated control cells, (c and d) cells treated with 25 and 50 μg mL−1 of AgNPs respectively, SEM images; (e) untreated control cell and (f) treated with 50 μg mL−1 AgNPs TEM images. This figure has been adapted from ref. 177 with permission from Hindawi, copyright 2018.

The seeds extracts of plants such as Tectona grandis,178Persea americana,179Salvia hispanica L180 and Trigonella foenum-graecum181 produced AgNPs with high antimicrobial activities. Interestingly the size of AgNPs depends on the concentration of Persea americana extract where a small NPs was recorded at low concentration of aqueous extract, whereas high concentration results in the formation of larger NPs.179 Ironically, the AgNPs from Salvia hispanica L showed lower susceptibility towards antibiotic Ampicillin against E. coli and S. aureus although its high ZOI against E. coli (18.5 mm) and S. aureus (14.9 mm) at 7.7 μL mL−1 concentration.180

The increase in lactate dehydrogenase (LDH) and alkaline phosphatase (ALP) enzyme concentration were used as a means to visualize the change in physiology and inhibition caused to microbes such as S. aureus (263 U L−1) and S. aureus (263 U L−1) by Trigonella foenum-graecum mediated AgNPs.181 This increase in enzyme reflected that bacteria are under stress conditions due to unfavorable environment on treatment with AgNPs.182 Synergistic behavior of ampicillin with Hibiscus cannabinus seeds produced AgNPs against S. aureus, B. cereus, E. coli was investigated by Adnan et al. in 2020.183 Biogenic AgNPs that possessed high inhibitory effect on biofilms formation in P. aeruginosa, C. violaceum and S. marcescens was reported.184 The biofilms of P. aeruginosa was inhibited by 10.6, 18.8, 36.1, 62.0, and 77.6% in presence of 1, 2, 5, 10, and 15 μg mL−1 of Carum copticum mediated AgNPs respectively.

In their effort to synthesize AgNPs from Pimpinella anisum seeds extract, Zayed et al. systematically studied to influence of different parameters such as extraction solvent used, extraction temperature, solvent/plant ratio and extraction time which are crucial for the successful synthesis of AgNPs.185 Hexane, methylene chloride, 70% methanol and water were evaluated as an extraction solvent and 70% methanol was chosen as a best solvent for the fast synthesis of NPs indicated by color change of the reaction solution, whereas this color change is very slow or not visible in other solvent extracts. The high reactivity of 70% aqueous methanol extract towards the reduction of Ag+ to Ag0 NPs is due to an excellent solubility of polyphenols in the plant seeds which is efficiently washed down during the extraction process. The SPR peak intensities of both AgNPs and AuNPs increased as the extraction temperature is raised from 25 to 60 °C. This may be due to increasing the solvent's diffusion rate into plant tissues by destroying the cell structures with raising the temperature.31 They also observed increasing SPR by increasing the extraction temperature 25–60 °C but extraction at 60 to 85 °C resulted in decreasing SPR probably due to decomposition of bioreductant at high temperature. The solvent/plant ratio of 10 mL g−1 was optimized for the AgNPs synthesis. Increasing the ratio from 3–10 mL g−1 inceased the SPR due to increasing solubility of biomolecule, however above 10, SPR went down due to high dilution of the extract. The band intensity reached its maximum value with extracts prepared at 60 min, further increase in contact time caused a decrease in the band intensity. It was observed that as extraction time increases the mass transfer coefficient between the solute and solvent increases that potentially increase the amount of the extracted biomolecule from plants which enhance the formation of the NPs.186 However, prolonged extraction time resulted in the thermal decomposition and oxidation of reactive biomolecules due to prolong heating.187

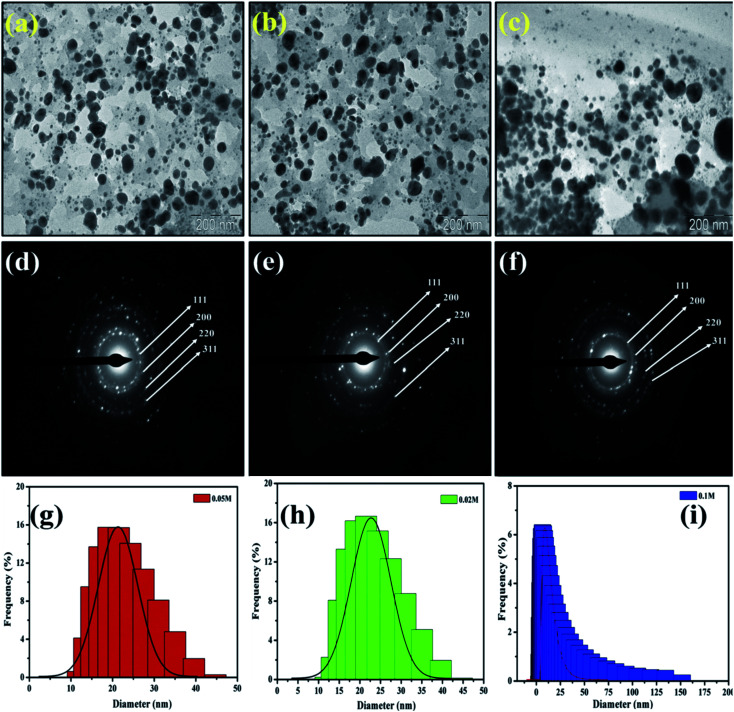

Similarly, the dried and roasted coffee (Coffea arabica) seed was employed as a reducing and stabilizing agent for the biosynthesis of AgNPs. TEM micrographs of synthesized AgNPs (Fig. 6) were revealed that the nanoparticles are spherical and ellipsoidal in structure with size ranging from (a) 10–40 nm for 0.1 M, (b) 10–50 nm for 0.05 M and (c) 20–150 nm for 0.02 M. The biomolecules that act as a capping agent around the NPs are visible in TEM images. The SAED patterns indicated that the nanoparticles are crystalline in nature with a certain d-spacing corresponds to fcc structure. The authors investigated its bactericidal activity against E. coli and S. aureus. The results revealed that AgNPs solution of 0.05 M and 0.1 M showed a high ZOI in both cases. However, ZOI is higher against E. coli.41

Fig. 6. TEM micrographs and SAED pattern of AgNPs with concentration 0.1 M (a and d), 0.05 M (b and e) and 0.02 (c and f) respectively. This figure has been reproduced from ref. 41 with permission from Elsevier, copyright 2016.

3.3. From flowers

Recently, flower extracts have been immensely utilized for the biosynthesis of NPs. There are various literatures available for the bio-reduction of AgNO3 to AgNPs (Table 2, entries 28–37). Padalia et al.188 reported the utilization of flower extract of Tagetes erecta for the bio-reduction of AgNO3 to synthesized AgNPs and investigate their bactericidal activity against both Gram-positive and Gram-negative bacteria such as S. aureus, B. cereus, S. coli, P. aeruginosa, C. glabrata, C. albicans, C. neoformans. The result obtained revealed that the bactericidal activity is greater for E. coli and P. aeruginosa compared to other pathogenic bacteria. Apart from that, the authors reported that the antifungal activity of the AgNPs along with antibiotic against the fungal strain and Gram-negative bacteria showed great activity compared to antibiotic alone. Flower extract of plants such as Nyctanthes arbortristis,189Caesalpinia pulcherrima,190Alcea rosea191 and Argemone mexicana192 were also reported from the synthesis of biogenic AgNPs. Tecoma stans flower extract was employed for the biosynthesis of spherical AgNPs with size ranging from 50–60 nm. Antimicrobial activity was tested against S. aureus and E. coli and found that ZOI is higher for S. aureus (24 mm) over E. coli (16 mm).193Moringa oleifera generated ultra-small AgNPs that showed a high ZOI of 29 mm against S. aureus.194 This is one of the highest ZOI observed at this concentration so far using biogenic AgNPs, probably due to its small size. Another exciting finding in this work is the higher antimicrobial activity of the AgNPs in Gram-positive bacteria (S. aureus) than the Gram-negative one (K. pneumonia), which is a rare case. In another work, Ajitha et al. reported the biosynthesis of polydisperse AgNPs using Syzygium aromaticum flower extract as bio-reducing as well as a capping agent. Antimicrobial activity of the synthesized NPs was explored against several microbes and found that the NPs induces cell disruption of the bacterial strain and it is maximum in case of Pseudomonas spp.195

3.4. From roots

Green synthesis of AgNPs and their application as antimicrobial using plants root extract have gained immense attention nowadays (Table 4, entries 38–54). The root extract of Potentilla fulgens was reported as a potent antimicrobial agents against E. coli, B. subtilis showing a ZOI of 9.5 ± 0.2 and 9.7 ± 0.6 respectively.196 Recently, Alpinia calcarata root extract was utilized as a bio-reducing as well as a stabilizing agent for the green synthesis of spherical AgNPs. Antimicrobial activity was tested against P. mirabilis, E. coli, B. cereus, S. aureus and the results showed that Alpinia calcarata root extract assisted synthesized AgNPs have great potential to induce cell disruption of the bacterial strain. Apart from that, the synthesized AgNPs is stable for up to six months.197 AgNPs with microbial activities were also reported to be produced from the root extract of Erythrina indica L.198Diospyros paniculate199 and Diospyros sylvatica.200

Various rhizomes, peel, tube/bulb, whole plant, petals, latex, pod and callus extract used for the green synthesis of AgNPs and their antimicrobial activity.

| No. | Plants | Plant part | Shape and size | Test microorganisms | Ref. |

|---|---|---|---|---|---|

| 1 | Bergenia ciliata | Rhizome | Spherical; 35 nm | M. luteus, S. aureus, E. aerogenes, B. bronchiseptica, A. niger, A. fumigatus, A. flavus, F. solani | 281 |

| 2 | Dryopteris crassirhizoma | Rhizome | Spherical; 5–60 nm | B. cereus and P. aeruginosa | 282 |

| 3 | Coptis chinensis | Rhizome | Spherical; 15 nm | E. coli, B. subtilis | 321 |

| 4 | Coptidis rhizome | Rhizome | Spherical; 30 nm | E. coli, S. aureus | 283 |

| 5 | Curcuma longa (turmeric) | Rhizome | Spherical; 18 ± 0.5 nm | E. coli, L. monocytogenes | 284 |

| 6 | Canna indica L | Rhizome | Spherical; 20–70 nm | S. aureus, K. pneumoniae, E. coli | 285 |

| 7 | Ferula foetida (asafoetida gum) | Rhizome | Spherical; 5.6–8.6 nm | E. coli, K. pneumoniae, C. albicans | 286 |

| 8 | Zingiber officinale (ginger) | Rhizome | Polygonal; 20–80 nm | V. anguillarum, V. alginolyticus, A. punctate, V. parahaemolyticus, V. splendidus, V. harveyi | 287 |