Abstract

This paper proposes a novel and innovative methodology to assess the degree of Circularity in one of the most resource-consuming and impactful economic activities: the building construction and/or renovation works. The proposed approach measures the ratio of circular flows in three aspects: energy, water and materials consumption; and combines them with the measure of social added value and economic value of the entire activity along its life cycle, regardless of being a new building construction or a major renovation work. The whole methodology has been developed under a life cycle perspective, incorporating into the analysis all material flows and social, environmental and economic impacts from cradle to grave, i.e., from resource acquisition to end of life treatment processes or disposal. The proposed Key Performance Indicators (KPIs) measure different and non-directly related parameters (energy, materials, social impact…) and they are both quantitative and qualitative metrics. Hence, the proposed methodology performs the indicators calculation procedure independently. The methodology has been tested with a conventional energy renovation process consisting of an installation of an External Thermal Insulation Composite System (ETICS) – one of the most prevailing façade energy retrofitting alternatives – combined with a rooftop solar PV system. In this way, a calculation example is shown and some lessons can be extracted regarding the degree circularity of current building construction and refurbishment practices. Results show that current building envelope solutions – even including an efficient rooftop PV system – are far from being considered circular: whereas a significant 51% of Energy Circularity is achieved, only a 29% and a 21% degree of Circularity is observed for the materials and social aspects, also with high payback periods – above 20 years – on the economic side. The methodology also succeeds in showing the potential for improvement and its location along the building life cycle. It is also shown that buildings behave significantly different in each of the addressed CE aspects: materials, energy and water use, social added value and life cycle cost; showing also different potential of improvement.

Keywords: Circular Economy, Sustainable Building Construction, Life Cycle Perspective, Energy balance, Materials balance, Economic Value

1. Introduction

Circular Economy (CE) is a new economic model validated by many researches (Blomsma and Brennan, 2017; Geissdoerfer et al., 2017; Ghisellini et al., 2016; Kirchherr et al., 2017; Lewandowski, 2016; Lieder and Rashid, 2016; Merli et al., 2018; Murray et al., 2017; Niero and Hauschild, 2017; Sauvé et al., 2016) and pushed by the European Union as a strategic objective (European Commission, 2015). This refers to the development of new economic models capable of having a positive impact on society in terms of natural resources depletion reduction and positive social, environmental and economic impacts. In the built environment, this concept is related to the construction of buildings and infrastructure capable of minimising material products degradation and loss of chemical and mechanical properties, keeping the materials at its highest economical and technical value, (Ellen Macarthur Foundation, 2017a). Also, according to (Niero and Hauschild, 2017), circularity refers to “keeping products, components and materials at their highest utility at all times”. This has many derivatives, among which highlight fostering dematerialisation strategies or reuse and recycling of safe materials, i.e., those that are considered healthy for humans and environment according Cradle-to-Cradle Material Health quality (Cradle to Cradle Products Innovation Institute and MBDC LLC, 2013) category. It is also worth highlighting the use of renewable energies to avoid the consumption of fossil fuels and other non-renewable resources of energy or water use reduction. Furthermore, CE also foresees the valorisation of positive economic, environmental and social impacts (Murray et al., 2017; Niero and Hauschild, 2017; Sauvé et al., 2016) which are of key importance to ensure the sustainability of CE strategies (Ghisellini et al., 2016). Circular Economy is, therefore, a research topic very prolific and focused on theoretical and some practical approaches to change economic and social dynamics (Merli et al., 2018).

The construction sector is characterised as highly intensive in the use of resources and the production of residues. According to (European Union, 2018; Huerta Carrascosa et al., 2018), the impacts of this economic sector in the EU are around: 40% of gross final energy consumption; 35% of greenhouse gas emissions; 50% of extracted material resources; 30% of water consumption; and 35% of waste production.

Therefore, the shift towards a CE paradigm in the built environment would have great impacts in terms of reduction of pressure on non-renewable resources and of residues generated. Other claimed benefits would be the reduction of energy consumption or increase in the control on scarce materials dependency, creating more resilience to face environmental and economic crisis (Huerta Carrascosa et al., 2018). The distinction between the widely-known definition of a “sustainable building”, i.e. a building that is designed and built so as to minimize negative environmental, social and economic impacts, and the new concept of “circular building” has been thrillingly debated over the recent years and according to (Kubbinga et al., 2018), circular building can be defined as:

“A building that is developed, used and reused without unnecessary resource depletion, environmental pollution and ecosystem degradation. It is constructed in an economically responsible way and contributes to the wellbeing of people and the biosphere. Here and there, now and later. Technical elements are demountable and reusable, and biological elements can also be brought back into the biological cycle.”

Therefore, the concept of circular building can be considered as complementing without overlapping the current definition of sustainable building. In light of this new concept of Circular Building, several experiences of CE principles application to buildings are appealing: for instance, (Cusenza et al., 2019) showed the viability of using Electric Vehicle second-life batteries for residential building electricity storage applications; the BAMB H2020 project (BAMB 2020, 2016) has created a framework to improve building materials reuse. (European Commission, 2020a) has also developed a white paper setting up some guidance for CE principles application to building design; and (Leising et al., 2018) have demonstrated a framework for Circular supply chain for the building sector focusing on new building, renovation and demolition projects. Also, it is of great interest the work carried out by (Westerholm, 2020), developing a Circularity checklist in different lifecycle phases of a building construction or renovation activity.

However, no comprehensive methodology for the evaluation of the Circularity in the building sector exists yet. Some initiatives are arising such as Building Circularity BC Index (Fischer, 2019), based on materials and detachability, the proposal of Circular Buildings framework to incorporate new circularity indicators to Building Research Establishment Environmental Assessment Methodology (BREEAM) (Kubbinga et al., 2018) or International Standardization Organization (ISO) works in harmonizing circular metrics through ISO/TC 323, and others are already consolidated such as Cradle to Cradle (C2C) Certification for designing safe and circular products (Cradle to Cradle Products Innovation Institute, 2016). C2C Certification Standard measures products circularity against five quality categories (Cradle to Cradle Products Innovation Institute, 2018): Material Health, Material Reutilization, Renewable Energy & Carbon Management, Water Stewardship and Social Fairness. However, this certification scheme is addressed to products and, therefore, is not addressed to measure the benefits of buildings along its construction neither in their operational stage. Other building certifications exist, such as Leadership in Energy and Environmental Design (LEED), the abovementioned BREEAM or WELL. However, these address the sustainable building rather than the Circular building, although the indicators shall be fully compatible, whenever possible to ease practitioners’ work. Last aspect worth mentioning is the importance of Business Models when implementing Circular solutions. To this end, it is important to value the economic performance of a system under a life-cycle approach in order to reflect the benefits of CE-enabled business models, which guarantee the effective implementation of CE measures.

In the case of the building and construction sector, no clear evaluation criteria have been set up nor any list of circularity indicators and system boundaries for their calculation in other aspects than the materials circularity assessment as Madaster Circularity Indicator (Madaster Services B.V., 2017) and the BAMB framework (BAMB 2020, 2016). Other frameworks as the work done by Dutch Green Building Council (Kubbinga et al., 2018) also lack clear KPI calculation procedures. This creates an important gap between knowledge and method; its filling could help reach a greater degree of implementation of the concepts of the CE and deployment of CE initiatives.

The main CE principles, in accordance with Ellen MacArthur Foundation (MacArthur et al., 2015), can be summarised under the ReSOLVE framework: Regenerate, Share, Optimise, Loop, Virtualise and Exchange. These, in the built environment are specified in (CE100 and Ellen Macarthur Foundation, 2016).

The purpose of the present work is to create a methodology to assess the degree of compliance of the aforementioned CE principles, developing a clear and unambiguous framework for holistic Circularity measurement and assessment. The developed methodology, in turn, could become a solid foundation for the development of new policies and that should provide guidance to building designers on the impacts of adopting certain circular economy measures to the circularity of a new building or a major renovation activity. The proposed CE assessment methodology is intended to be clear and unambiguous and it includes the definition of the key parameters and evaluation criteria to characterize if a building or a major refurbishment is more or less circular. Furthermore, the paper also presents the results of the application of the methodology to a test scenario, so as to show how the methodology shall be applied and how the results are outlined. Due to the absence of building retrofitting integral solutions designed under the CE principles, the proposed case-study consists on one widely used conventional retrofit solution: a modular façade external insulation, with a market size around 234 million square meters for year (Instituto Pedro Nunes (IPN) 2017), plus a rooftop PV system, an industry that “accounted for 117.000 full-time jobs and it is expected to sustain nearly 175,000 full-time jobs in 2021, with estimates of between 200,000-300,000 jobs in 2030”, according to (European Commission, 2020b). This constitutes a proper baseline for the next generation of building retrofitting solutions based on the Circular Economy to be compared with; and will also help to understand the current status of building refurbishment activities with regards to CE, helping identify the aspects with more potential for improvement.

The remainder of the paper is structured as follows:

Section 2 summarizes the System Boundaries and the Scope of the proposed framework of study.

Section 3 details the proposed methodology, the Key Performance Indicators (KPIs) and the calculation procedures used for CE assessment purposes.

Section 4 describes the test scenario, with the most relevant input data and parameters. Also, the key assumptions made are also provided.

Section 5 shows the results generated by the application of the methodology to the proposed scenario.

Section 6 provides a results analysis and gives the main conclusions extracted from it.

Section 7 lays out the main conclusions of the study.

2. System Boundaries and Scope

The evaluation of the degree of compliance of the aforementioned CE principles is a rather new concept and, therefore, there exist different approaches with varying perspectives and calculation procedures, especially for the building and construction sector. To this end, it is proposed to align the circularity methodology with the existing frameworks of building sustainability and sustainability assessment, i.e., the transversal regulations on Building Sustainability Assessment developed by CEN TC 350, the European Framework for Building Sustainability Assessment Level(s) (Dodd et al., 2020, 2017a, 2017b), and Cradle-to-Cradle certification scheme (Cradle to Cradle Products Innovation Institute, 2019). The alignment with current building sustainability European regulation guarantees the proposed approach applicability throughout European Union; the alignment with Level(s) framework guarantees the complementarity of the proposed scope with current European framework; whereas the alignment with Cradle-to-Cradle certification guarantees that circular buildings designed following the proposed approach are improving the use of circular certified products and materials. Also, taking a similar approach as proposed by BREEAM circular framework (Kubbinga et al., 2018), the proposed methodology is aligned with existing work on circular building certification.

The proposed approach focuses on the evaluation from an impact assessment and circular flow perspectives together with the business perspective evaluation. This is so because of the importance to guarantee economically viable business models that support on the mid and the long-term the economic activity of new building construction or retrofitting under the CE principles (Westerholm, 2020). The proposed framework of analysis consists on the evaluation of:

-

•

Environmental, Social and Economic impacts. The rationale is to minimise the negative environmental and social impacts while maximising the economic outcomes and the positive environmental and social impacts of a circular economy.

-

•

Circularity of flows involved in the building construction or renovation. The rationale is to maximize the circular flows, i.e., the reuse / recycling of materials or the energy self-generation.

-

•

Circularity of business model (BM) proposed to guarantee that CE principles are respected to the major extent. The only effective way of guaranteeing that the level of implementation of the CE principles is as great as possible is to align the business model with the CE-related activity.

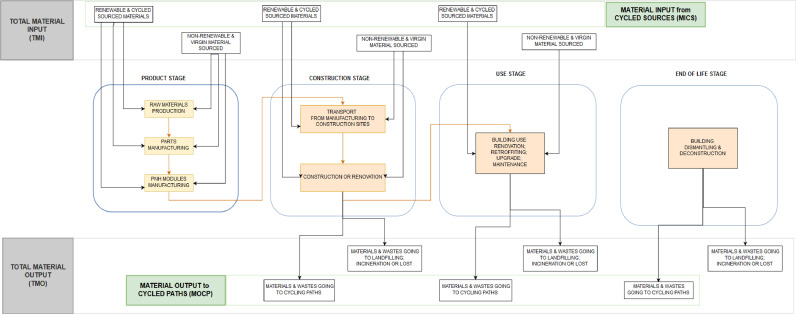

2.1. Boundaries

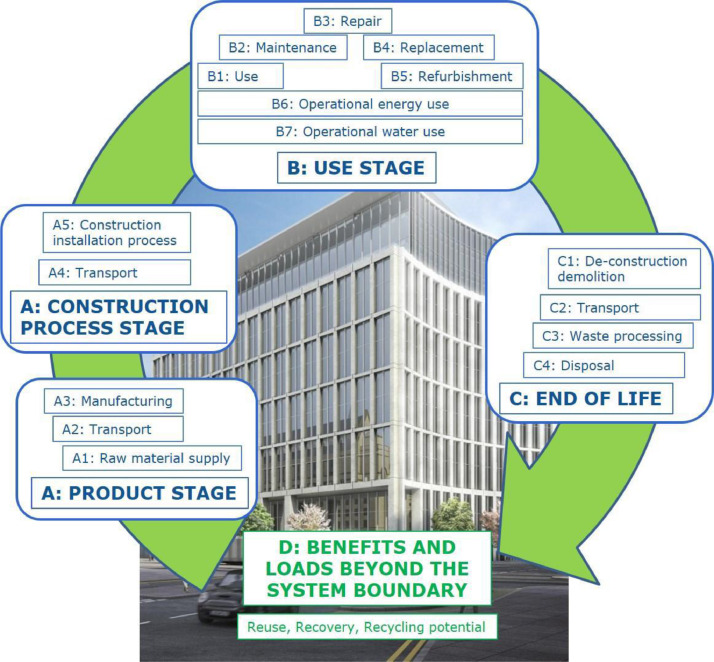

The boundaries of the analysis should cover all life cycle stages, i.e., from cradle to cradle. According with current reference normative for Sustainability assessment of buildings EN 15978 (CEN, 2011), the life cycle of a building can be phased in 4 main stages divided in several modules: A. Product stage; A. Construction stage; B. Use stage; and C. End-of-Life stage. These life cycle stages and their related sub-modules, as laid out and broken down by EN 15978 standard, are shown in Fig. 1.

Fig. 1.

Modular schematic of building life cycle stages. Source: (CEN, 2011; Dodd et al., 2017b).

The reference period of analysis shall be 50 years, aligned with LCC reference normative ISO 15686-5 (ISO, 2017). This holistic approach to the implementation of CE principles in the building construction sector is fully aligned with the proposed framework laid out in (Elia et al., 2017) (see “Fig. 1. The Circular Economy framework”).

2.2. CE evaluation strategy

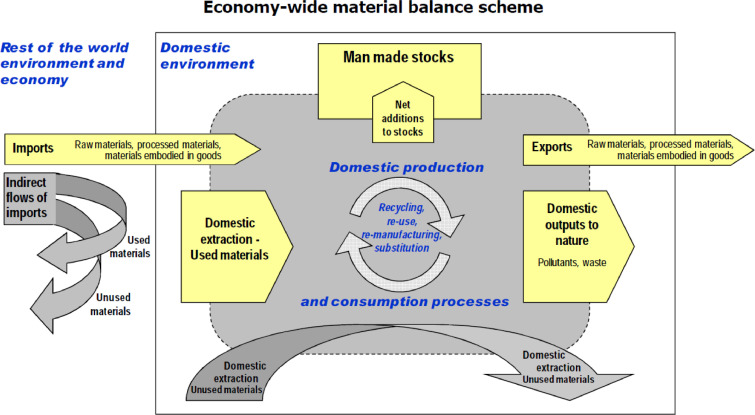

The CE evaluation strategy proposed by (Elia et al., 2017) and represented in “Fig. 3. Critical steps in the assessment of a CE strategy” consists on the steps detailed:

Fig. 3.

Material balance and flow schemes, for Economy-wide scheme. Source: (OECD, 2008).

2.2.1. Processes to monitor

First of all, the identification of the processes to monitor: materials inputs, design, production/delivery, consumption or EOL resource management. For the building and construction sector, the critical processes are located in all the four life cycle stages: i) at the product stage these critical steps are the materials inputs and manufacturing process of all building parts and components; ii) at the construction stage they are the supply chain and the building construction or refurbishment activity itself, and how different products in a building are interconnected to ensure future disassembly; iii) at the use stage there is the energy consumption and the maintenance operations, as well as the rotation of materials during buildings use phase iv) and at the end of use stage the resource and waste management activities are the most relevant processes.

2.2.2. Activities implemented

Secondly, the identification of the activities implemented: the activities with greater potential for CE measures implementation are: i) at the product stage, the design considering the ease of disassembly and the use of safe or non-toxic materials, control the use of Critical Raw Materials (CRM) and scarce materials, and promote the use of materials from cycled sources in line with Cradle-to-Cradle™ (Cradle to Cradle Products Innovation Institute, 2018); ii) at the construction stage the prioritisation of short haul or local materials – by local materials, it is considered the maximum distance of 200 km in accordance with LEED requirements (USGBC, 2019) – and components at procurement and contractor level by means of circular procurement as laid out in (Westerholm, 2020); transparency on information to ensure traceability; iii) at the use stage the use of renewable energy, the improvement of indoor comfort conditions and the development of CE business models; and iv) and at the EOL stage the fostering of business models valuing materials at their end of service life.

2.2.3. Requirements to be measured

The measurement of accomplishment of CE principles is proposed to be based on several Key Performance Indicators (KPIs). Taking as basis Level(s): A common EU framework of core sustainability indicators for office and residential buildings (Dodd et al., 2017b, 2017a), the focus of the sustainability analysis in buildings should be:

-

•

Greenhouse gas emissions along a building's life cycle.

-

•

Resource efficient and circular material life cycles.

-

•

Efficient use of water resources.

-

•

Healthy and comfortable spaces.

-

•

Adaptation and resilience to climate change.

-

•

Optimised life cycle cost and value.

The use of Level(s) framework as basis is very important because it constitutes a common EU framework for building sustainability assessment based on existing standards and intended to be used throughout the EU to inform building design under a life cycle thinking and circularity perspective. Being a public initiative, Level(s) has the potential to become a tool for building projects policies and funding mechanisms definition.

Another set of requirements come from the horizontal standardised methods for the sustainability assessment developed by the CEN TC 350. With regards to the present methodology, it is important to incorporate their main requirements:

-

•

Assessments shall be carried out considering all burdens of construction sector along all building service life.

-

•

Environmental, Social and Economic performance over the entire service life shall be quantified.

Also, the work from (Kubbinga et al., 2018), the adaptation of BREEAM building certification to the CE principles, identifies the following parameters as critical in the building construction sector:

-

•

Materials in the economy are cycled at continuous high value.

-

•

All energy is based on renewable sources.

-

•

Water is extracted at a sustainable rate and resource recovery is maximised.

-

•

Biodiversity is structurally supported and enhanced.

-

•

Human society and culture are preserved.

-

•

The health and wellbeing of humans and other species is structurally supported.

-

•

Human activities generate value in measures beyond just financial.

US Green Building Council (USGBC) is also developing standard to include circular economy based on the following 3 criteria (Hughes and USGBC, 2019): i) Upstream waste reduction; ii) Materials selection and accountability; iii) Zero waste goals. All of them included in the quantification of MCI.

2.3. Circularity Measurement pillars

Therefore, the relevant pillars to be included into a comprehensive building circularity assessment, in accordance with reference frameworks for building circularity (Cradle to Cradle Products Innovation Institute, 2019; Dodd et al., 2017a, 2017b; Kubbinga et al., 2018) are shown in Table 1 below:

Table 1.

Circular economy aspects to be evaluated in the building construction sector and alignment with existing reference frameworks.

| Circular Economy aspect | Alignment with Level(s) (Dodd et al., 2017a, 2017b) | Alignment with BREEAM (Kubbinga et al., 2018) | Alignment with Cradle-to-Cradle (Cradle to Cradle Products Innovation Institute, 2019) |

|---|---|---|---|

| Energy | GHG emissions along a building's life cycle | Energy based on renewable sources | Renewable Energy and Carbon Management |

| Materials | Resource efficient and circular material life cycles | Materials are cycled at continuous high value Health of humans is supported |

Material Health Material Reutilization or Product Circularity in version 4 |

| Water | Efficient use of water resources | Water extracted at a sustainable rate and resource recovery is maximised | Water stewardship |

| Social value | Healthy and Comfortable spaces | Health and wellbeing of humans is supported Human society preservation Biodiversity supported |

Social Fairness |

| Economic value | Optimised life cycle cost and value | Human activities generate value in measures beyond just financial | – |

This translates into the definition of five indicators that will define the degree of accomplishment of CE principles:

-

(1)

Energy circularity – in percentage – and total Life Cycle Energy Consumption (kWh of primary energy).

-

(2)

Materials circularity – in percentage – and total materials consumption (kg of materials as in the Bill of Materials (BOM)).

-

(3)

Water circularity – in percentage – and total water footprint of the building (m3).

-

(4)

Social added value – in percentage of maximum achievable social impacts.

-

(5)

Life cycle economic value – in monetary terms, EUR, USD or similar – incorporating positive and negative externalities.

The adaptation and resilience to climate change is included in the proposed framework as a transversal vector, since it is indirectly addressed with the Thermal Comfort aspect included in the Social Circularity Indicator. Also, it is included in terms of MCI and ECI, since GHG are 50% related energy production and 45% related with materials manufacturing and production (Morlet et al., 2019), and both flows and related emissions are addressed through circular indicators proposed. Furthermore, in changing climatic conditions, buildings will need to be adaptable to these changes and circular designed products will enable to modify building characteristics without negatively impacting the environment through material reuse and recycling.

The proposed methodological framework addresses the six principles of CE applicable to the built environment (CE100 and Ellen Macarthur Foundation, 2016) under the RESOLVE framework as follows:

-

•

“Regenerate”: Measure the positive impact of the solutions proposed through the quantification of renewable energy use and production as well as cycled water use with respect to overall energy and water consumption. Valorisation of upcycling materials at both product and end of life stages is also measured. The inclusion of occupants’ ‘Health and Comfort’ conditions into the social circularity assessment allows valuing the impact that the solution can have on society.

-

•

“Share”: infrastructure and appliances sharing are encouraged since they are highly impacting the energy, water and materials circularity evaluation and increase the number of circular products and solutions to be installed in a building.

-

•

“Optimise”: energy efficiency (by both passive and active solutions) and water efficiency (favouring re-circulation of water and closed cycles that allow reducing grid consumption) are highly impacting the Energy and Water circularity as they are proposed to be measured. Modularity improves the “reuse” capability of the parts and products used in the building and, therefore, highly impact the materials circularity of the building. This last aspect is also positively affected by materials efficiency measures.

-

•

“Loop”: reusable and remanufactured parts and products are highly encouraged as they significantly affect the materials, water and energy circularity assessment. For instance, a reused product will impact the energy circularity by reducing the embedded energy of the product, the water circularity by reducing the water footprint and the materials circularity by increasing the rate of cyclable materials in the Bill of Materials.

-

•

“Virtualise”: Building Information Modelling (BIM) and dynamic simulations such as those based on EnergyPlus or TRNSYS, to name but a few, are encouraged to be used as input data sources as they will improve the ease of use of the proposed methodology and the comparability of the gathered results. The benefit of replacement of products by services is reflected in the economic indicator since it reduces the required capital investments (CAPEX) and encourage the better maintenance and operation of the systems linking them to improve their performance as well as will improve results on the material, energy and water aspects by reducing replacements along service life. Also, virtual platforms for construction materials, such as Upcyclea or Madaster, will promote circular paths for materials and products embodied in buildings.

-

•

“Exchange”: better-performing materials and new products designed for its circularity, enable the exchange of materials and products between different systems, i.e., buildings, industries, or materials transformers. Also, energy services related with energy sharing and trading among different users are general enablers for circularity in all proposed aspects. In particular, the inclusion of occupants’ ‘Health and Comfort’ conditions into the social circularity assessment allows valuing the exchange of “Business as Usual” products and services by Circular Economy – based ones.

3. Methodology description

The proposed methodology consists in the calculation of five indicators: four expressed in percentual units and a fifth expressed in monetary units. Three indicators are related with the physical flows, quantifying the amount of resources consumed (being these energy, materials or water) that come from or end in cycled sources, whereas the social impact consists in a count of social measures implemented and the economic value indicator is a simplified life cycle cost analysis.

The flow analysis laid out for the evaluation of energy, materials and water circularity is aligned and compatible with the approach proposed by (Ellen Macarthur Foundation and Granta Design, 2015) and the reference standard for the assessment of the environmental performance of buildings EN 15978 (CEN, 2011). Along years material and energy flow analysis (MEFA) methodology has been used a wide recognized methodology to quantify and analyse flows within socio-economic systems (Bao et al., 2010; European Communities and EUROSTAT, 2001; Graedel, 2019; Wang et al., 2020). The proposed indicators of this paper are based on MEFA approach and adapted to measure circularity of materials, water and energy flows. For the social impact, the proposed assessment is compatible with reference normative for social performance of buildings assessment EN 16309 (CEN, 2014). Last, the simplified life cycle cost analysis is a recognized economic metric to value the externalities and to measure activities that generate value in measures beyond just financial, as claimed by (Kubbinga et al., 2018) and is also compatible with reference standard for building service life planning ISO 15686 (ISO, 2017).

3.1. Energy circularity

3.1.1. Energy Circularity Index (ECI) formulation

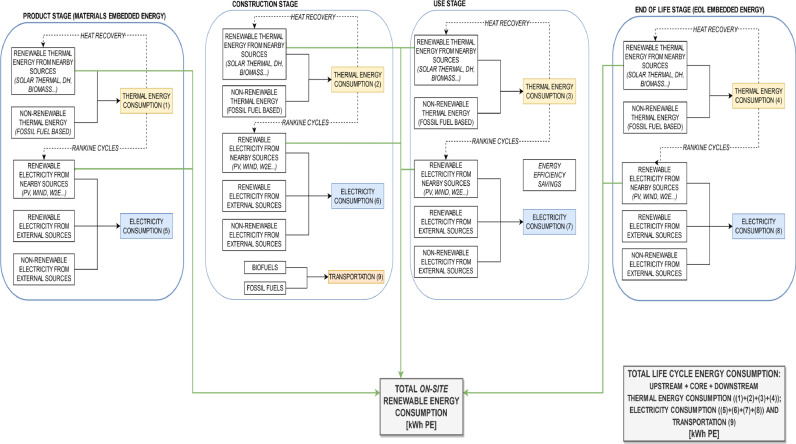

The energy consumption is intended to be expressed in primary energy, both non-renewable and renewable, so the units of calculation are kWh of primary energy (kWhPE). This allows adding up energy consumption from different sources. The degree of circularity, according to the proposed framework, is measured as the ratio of renewable energy produced on-site or nearby and energy savings to the total energy consumption (see Eqn 1). This ratio shall be calculated including all energy flows during all life cycle stages (see Figure 2).

| (1) |

Fig. 2.

Energy Flow Diagram for a Building construction or renovation.

Where , and represent the renewable energy coming from on-site generation or nearby sources, i.e., at district level; as well as from active or passive energy saving mechanisms (for instance, energy savings from improved insulation or from HVAC energy recovery) for each life cycle stage or module; and and are the total thermal energy and electricity consumption, respectively, also expressed for each life cycle stage or module.

Therefore, the proposed indicator expresses the rate of circular energy to the total embedded energy of the evaluated product or system. Hence, by “circular” energy it is considered all the renewable energy or energy savings directly attributable to the building or the district.

As shown above, the potential renewable energy flows only include the renewable energy generated on-site or nearby for material mining, product and parts manufacturing, construction of the building, operation of the building, EOL treatments and all transportation activities. These would include, therefore, solar thermal energy, biomass and biofuels energy, waste to energy (W2E) processes, on-site solar PV or wind power or even a thermal energy from a DH/DHC as long as it comes from renewable sources or waste heat. What is not considered Circular Energy is the Renewable Energy coming from the grid, i.e., due to national or utility mix.

3.2. Material circularity

3.2.1. Material Circularity Index formulation

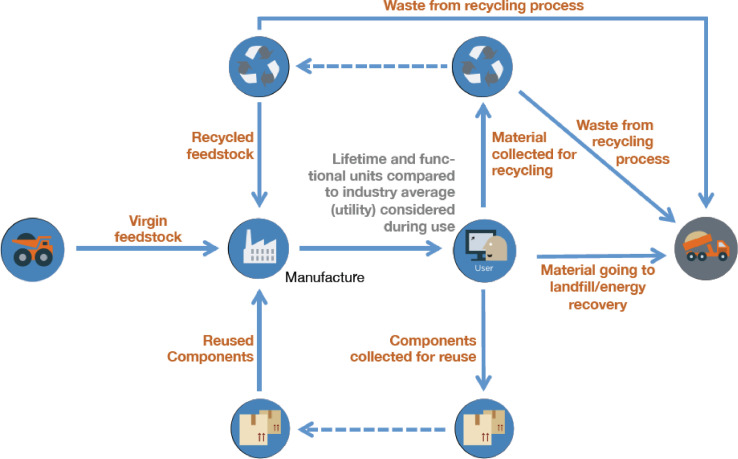

The materials use is intended to be expressed in kg of materials as in the Bill of Materials (BOM) or Bill of Quantities (BOQ). The degree of circularity, according to the proposed framework, is measured as the ratio of circular materials to the total amount of materials used, which shall be broken down by type of material and product assessed (see Eqn 2). Furthermore, materials are divided based on source of raw materials and the final path for which have been designed. Aligned with Cradle to Cradle and Ellen MacArthur circularity definition depicted in the well-known butterfly diagram (Ellen Macarthur Foundation, 2017b), two major categories have been defined:

-

•

Technical materials for technical cycle (for minerals, ores, and fuel derived products) and,

-

•

Biological materials and products designed to be reintroduced in the biological cycle (biomass and other biobased materials).

Circular Materials definition in this paper is aligned with Cradle to Cradle Certified Products Standard in version 3.1. (Cradle to Cradle Products Innovation Institute, 2018) and version 4, Draft 1 (Cradle to Cradle Products Innovation Institute, 2019) by relying on the use of related indicators whenever possible. Circular materials need to be safe for humans and environment, come from cycled sources and capable of being cyclable after their use. To discern between circular and non-circular materials, the Material Flow Analysis (MFA) will be used for building construction or major renovation process (see Figure 3). This standpoint is fully aligned with what is proposed by Ellen Macarthur Foundation and Granta Design (Ellen Macarthur Foundation and Granta Design, 2015) (see Figure 4).

Fig. 4.

Material Flow Diagram according with (Ellen Macarthur Foundation and Granta Design, 2015) approach.

The ratio of Material Circularity can be calculated as follows (Eqn 2 and Eqn 3):

| (2) |

| (3) |

Where and represent the Total Material Input and the Total Material Output to and from the building, both in kg. stands for Material Input to the building from Cycled Sources, and stands for Material Output from the building to Circular Paths, also in kg. Therefore, the Circular Materials are accounted both upstream and downstream therefore rewarding the use of recycled materials and the promotion of recycling at the end of the useful life. The MFA is the basis for Circular Material flows identification (see Figure 5).

Fig. 5.

Materials Flow Diagram for a Building construction or renovation.

This indicator computes all kind of materials, which could potentially be treated jointly under the four categories depicted in Material flow accounts statistics from EUROSTAT (EUROSTAT, 2020): biomass, metal ores, non-metallic minerals and fossil energy materials. However, for the ease of use of the methodology, it is not necessary to introduce the materials without further aggregation or sorting, although this can be done afterwards to present results post-processed in a meaningful way.

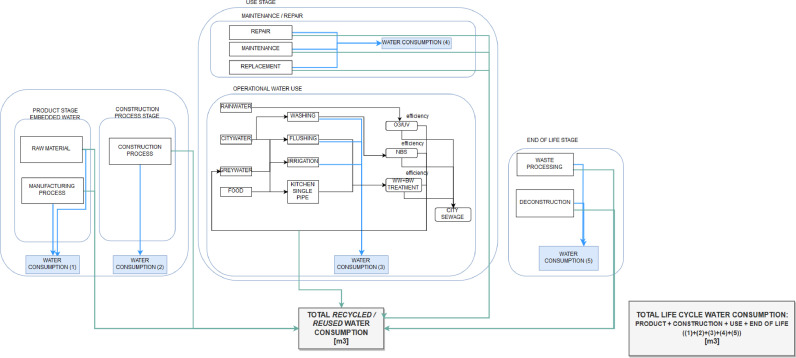

3.3. Water circularity

3.3.1. Water Circularity Index formulation

The water consumption is intended to be expressed in m3, although litres are accepted, too. The degree of circularity, according to the proposed framework, is measured as the ratio of circularly and on-site sourced water to the total amount of water consumed (see Eqn 4). This ratio should be calculated including all energy flows during all life cycle stages, as shown in Figure 6.

| (4) |

Fig. 6.

Water Flow Diagram for a Building construction or renovation.

Where , and refer to the cycled water coming from different water reutilisation or wastewater sources, namely grey water, black water or rain water, within the own building or also upstream. The total lifecycle water usage or water footprint can be calculated as the sum of water consumption in product stage (), construction stage (), use stage () and end of life stage ().

3.4. Social circularity

3.4.1. Social Circularity Index formulation

The accountancy of circularity from a social point of view requires a slightly different approach because social impact is not directly related with a physical flow as energy, water and materials usage are. This methodology proposes to align the evaluation with current normative EN 16309 (CEN, 2014). It is worth noting that this requires taking an approach both quantitative and qualitative, given that sometimes it will not be possible to obtain quantitative values for all the applicable evaluation criteria. To do so, the circularity is calculated as the number of social impacts addressed within the new building or major renovation project to the total number of potential impacts potentially addressable (see Eqn 5):

| (5) |

Where , and are the number of social impacts for which actions have been taken, whereas , and refer to the total number of impacts that could be taken care of. The total number of impacts to be addressed are shown in Table 2.

Table 2.

Summary of number of potentially addressable social impacts to be considered.

| Life Cycle Stage | Impacts requirements assessed | Reference Source |

|---|---|---|

| Product stage: A1 – A3 |

C2C Achieved Level of Certification in Social Fairness Category 0 – 5 points from None to Platinum |

Cradle to Cradle™ |

| Construction Process stage: A4 – A5 |

Social performance of buildings under construction 0 – 4 points |

LEED; Local Municipality Regulations; Cradle to Cradle™ |

| Use stage: B1 |

Assessment of social performance of buildings 0 to 13 points (1 for each criterion under “Health and Comfort”) |

EN 16309 |

| Use stage: B2 – B5 |

Assessment of social performance of buildings 0 – 4 points (same as A4 – A5) |

LEED; Local Municipality Regulations; Cradle to Cradle™ |

| End of Life stage: C1 – C4 |

Social performance of buildings under deconstruction 0 – 4 points (same as A4 – A5 and B2 – B5) |

LEED; Local Municipality Regulations; Cradle to Cradle™ |

Table 3 lays out the Evaluation Matrix for Construction (A4-5), Maintenance (B2-5) and EOL (C) stages.

Table 3.

Construction stage (A4-5), Maintenance Stage (B2-5) and EOL Stage (C) Social Assessment.

| Category | Requirement | Value (1 = yes, 0 = no) |

|---|---|---|

| SOCIAL ADDED VALUE | ||

| Impact of construction work towards neighbourhood | A plan for the Acoustic mitigation of construction works according to local ordinance has been developed and implemented | |

| A Construction Activity Pollution Prevention Plan according to EPA or local requirements been developed and implemented | ||

| Social fairness in the Construction Stage | A full social responsibility self-audit based on UN Global Compact Tool or B-Corp has been conducted | |

| Use of local workforce | Contractor based within 160 km of construction site | |

Table 4 shows an evaluation matrix for the social circularity evaluation at use stage (B1).

Table 4.

Evaluation matrix for “Health and Comfort” social impact assessment category.

| Category | Sub-category | Requirement | Value (1/0) |

|---|---|---|---|

| SOCIAL ADDED VALUE – Evaluation Matrix SIB1 | |||

| Health and comfort | Thermal comfort | PMV and PPD values are inside the range expected for a class 2 building according to the EN 15251 (CEN, 2007)? Class 2 is expected for new or refurbished buildings. PPD<10% -0.5<PMV<+0.5 |

|

| Is the operational temperature adjustable for all the building? | |||

| Is the operational temperature adjustable for specific spaces? | |||

| Is the temperature monitored in the building? | |||

| Is the humidity adjustable for all the building? | |||

| Is the humidity adjustable for specific spaces? | |||

| Is the velocity of the ventilation air adjustable for considering the indoor air quality? | |||

| Is the velocity of the ventilation air adjustable in specific spaces for considering the indoor air quality? | |||

| Indoor Air Quality | Is there any IAQ plan that includes IAQ audits every 4 years as well as operation guidelines to achieve high IAQ levels? | ||

| Can the building keep the CO2 levels under 1000 ppm at full occupancy? | |||

| Which percentage of the individual spaces has a TVOC concentration lower than 1000 ug/m3? (%) | |||

| How many of those parameters are real-time monitored: mould, VOCs, PM, CO2, CO, T and RH? (%) | |||

| Can users control the air intake and ventilation rate of the building? | |||

| TOTAL OF ADDRESSED REQUIREMENTS | X/13 | ||

3.5. Life Cycle Economic Value

The economic evaluation to be incorporated to the circularity assessment, to be consistent with all the laid-out framework, should be made under a life cycle approach. Level(s) proposal (Dodd et al., 2017b, 2017a) based on ISO 15686-5 (ISO, 2017) or EN 16627 (CEN, 2015), is adequate for this purpose, since it relates with circularity to the extent that it values and appraises the long-life lasting benefits from a certain investment thus, being able to determine if a more expensive product can provide economic benefits in the long run. It consists in the calculation of a certain Net Present Value (NPV) extended with positive and negative externalities accountancy following externalities monetisation methodologies such as KPMG True Value (KPMG International, 2014), for instance with the CO2 emissions costs or the accountancy of energy savings from energy demand reduction. The costs shall include:

-

•

CAPEX or initial investment located at construction, including acquisition costs, labour, and other expenses.

-

•

OPEX or operational expenditures located at the use stage, including utilities costs and repair, replacement and maintenance costs.

-

•

Revenues, including avoided costs or savings derived from the addressed measures as well as net incomes derived from energy sales or service fees charged to end-users.

The formulation of the Economic Value (EV) calculation is (see Eqn 6 and Eqn 7):

| (6) |

| (7) |

With the proposed approach, it is considered a “circular” flow of money the revenue stream from energy self-production or export as well as savings from reduced grid energy and water purchase and the net revenues for recovered materials and products from the building in a secondary market. Other circular flows of money would be those associated with avoided landfilling or deconstruction costs with respect to current market practices (Fischer, 2020).

3.6. Assumptions

The proposed methodology considers the following assumptions:

-

•

The product stage circularity can be calculated as the sum of embedded energy of products calculated by means of the Cradle-to-Cradle™ Certified Product Standard (Cradle to Cradle Products Innovation Institute, 2018) or Environmental Product Declarations (EPD), although monitoring is accepted and preferred, if possible. Module A2 (transportation) can be considered negligible for materials.

For the social impact, in consonance with Cradle-to-Cradle™ Certified Product Standard (Cradle to Cradle Products Innovation Institute, 2018), one point is given for each level of certification: Basic, Bronze, Silver, Gold or Platinum.

-

•

The construction stage circularity can be calculated using available information from a construction contractor or, alternatively, from consistent databases, such as BEDEC (Institut de Tecnologia de la Construcció de Catalunya (ITeC), 2020), a database of building construction products and materials publicly developed and used as reference for public procurement processes. A4 module (transportation to construction site) can be considered negligible for materials.

For the social impact, four potential impacts are considered: “acoustic mitigation of construction works” according to local regulations; the “impact of construction work towards neighbourhood” as defined in LEED (USGBC, 2019), i.e., the creation of a Construction Activity Pollution Prevention plan; the “social fairness in construction stage” as in Cradle-to-Cradle™ (Cradle to Cradle Products Innovation Institute, 2018), i.e., the performance of a self-audit based on UN Global Compact Tool or B-Corp, and the “use of local workforce” as given by Local regulations, e.g. from less than 160 km.

-

•

The use stage energy circularity should be monitored by means of electricity meters, gas meters or calorimeters whenever possible, although dynamic simulation is also a proper source of data as it constitutes a widely accepted technique recognized by existing building certification schemes such as LEED or BREEAM. The simulation methods are especially useful when the assessment is carried out during the design and construction phase, when metering is not possible. Energy bills are accepted otherwise.

The use stage materials consumption is fenced to maintenance (B2), repairs (B3), replacements (B4) and refurbishments (B5), i.e., those operations involving material use.

The use stage water circularity shall be measured using water meters whenever possible. Otherwise, calculation through water bills or water use ratios can be used.

For the social added value, the impacts in “Health and Comfort” category of EN 16309 (CEN, 2014) are to be considered.

-

•

The EOL energy and water circularity can be calculated using databases if monitoring is not possible.

For materials EOL circularity assessment MFA will be used. Module C2 (transportation to recycling or disposal facilities) can be neglected if local waste disposal or treatment facilities exist.

For the end of life stage, the “construction activity pollution prevention” as defined in LEED (USGBC, 2019) shall be used as evaluation criteria.

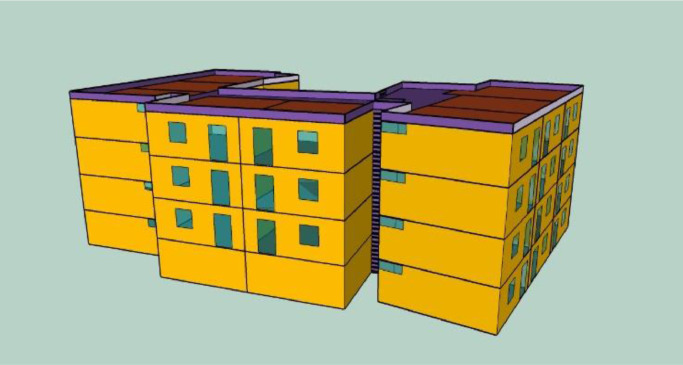

4. System description

The methodology has been tested against a scenario consisting in building energy retrofitting. The baseline scenario consists in a conventional façade energy renovation combined with a rooftop solar PV power system. The selected conventional façade retrofit alternative is an External Thermal Insulation Cladding System (ETICS), one of the most common Exterior Insulation Finish Systems (EIFS). The selected solar PV power system is a rooftop-mounted polycrystalline photovoltaics (PV) system. Both are current massively deployed alternatives for façade refurbishment and self-consumption renewable energy generation which can be used as reference of current construction standards for both residential and tertiary buildings. The use of this state-of-the-art retrofitting solution is well justified by its wide use and the fact of being based on products and solutions that are also used in new building construction. By evaluating the performance of this solution, it is expected to obtain relevant results with respect to the life cycle stages and CE pillars where more potential for improvement is found. The test scenario as it is defined includes both passive (ETICS) and active (PV system) energy consumption reduction systems. However, unlike with energy performance, there are not currently building retrofit nor new building cyclable water solutions widely used, hence, the test scenario, which is aimed at testing the “BAU” solutions does not include it.

The circular scenario is a modular ETICS system with PV integrated on its surface, developed by EU project PLUG-N-HARVEST (Plug-n-Harvest 2021, 2017).

The building from which the data has been gathered belongs to a H2020 Project Demo Site. The location of the building under study is Sant Quirze del Vallès, in the province of Barcelona. According with geographic coordinates system, it is found in:

-

•

Longitude: 2°04′51.1"E

-

•

Latitude: 41°32′07.4"N

The building is from 2003 and it consists in a U-shaped building with GF + 3F (ground floor + three floors), for residential use, except the GF that has commercial space. The building has never undergone a major renovation process. For the application of the modular ETICS solution, only the three floors of the central building are considered (see Fig. 7), because the ground floor is not qualified for installing an outer surface and the others are out of the renovation project. Each floor has two dwellings, so the residences affected by the retrofitting are six.

Fig. 7.

Test scenario building.

4.1. Input data

4.1.1. ETICS modular façade system

The South façade has 130 m2, from which 107 m2 are retrofitted with an ETICS (windows are excluded). The composing layers of the current façade are given in Table 5.

Table 5.

Composing layers of the ETICS system evaluated.

| Main Façade | ||

|---|---|---|

| Material Layer | Thickness [m] | Conductivity [W/mK] |

| Cement Board Organic Fibres | 0.008 | 1.000 |

| Ventilation Cavity | 0.050 | 0.000 |

| XPS | 0.040 | 0.045 |

| Cement Plaster | 0.003 | 1.000 |

| Clay Masonry | 0.140 | 0.870 |

| Plaster | 0.010 | 0.250 |

With these layers, the total obtained U-value – a metric expressing the thermal transmittance of a layer – of the façade is 0.68 W/m2 K. It is worth noting that the lower the U-values are, the greater the thermal insulation is. Applicable normative in Spain at the time of renovation enforced new buildings’ maximum transmittance threshold of 0.73 W/m2K. Therefore, the ETICS solution to be installed has been dimensioned to comply with the new stricter requirements. It is composed of several layers and elements: adhesive, insulation, anchors, mortar, reinforcement and coatings (priming and finishing). Although these are rather common composing layers and elements, the precise information and specification have been gathered from Fassatherm Plus EPD (EPD Registration Number: S-P-01344), an ETICS with rockwool as insulation material manufactured by Fassa Bortolo (Fassa Bortolo, 2017).

4.1.2. PV system

The rationale for the inclusion of a rooftop PV system is to equal the performance with the modular façade refurbishment product that is being developed within the project, which includes Building Integrated Photovoltaics (BIPV). Moreover, this helps improve the energy balance – and the circularity – as well as reduce CO2 footage.

The total area of PV panels considered is 53.25 m2. The PV panel area is determined as the equivalent to the area retrofitted with the Plug-and-Harvest solution and thus covered with PV panels. This ratio is estimated in order to obtain the same electricity production from a PV system installed in the roof of the building, inclined with an optimal slope (in the location under study, 38°), such as the PV system of the hypothetical conventional retrofitting featured in this test scenario, performs equally as a BIPV installed with a slope of 90°. The PV modules rated power is about 12 kWp and are from Sun Power X22 – 360W (Sunpower, 2017).

4.1.3. Bill of materials and general hypotheses

The Bill of Materials of the complete solution – ETICS plus rooftop PV system – is given below (see Table 6).

Table 6.

Bill of Materials of the ETICS system and sizing of the PV system.

| ETICS | ||

|---|---|---|

| System Layer | Material | Weight of system layer in ETICS [kg/m²] |

| Adhesive | Adhesive mortar | 4,00 |

| Insulation | Rock wool | 6,00 |

| Anchors | Polyethylene, HDPE, granulate | 0,05 |

| Anchors | Steel, low-alloyed | 0,04 |

| Base Coal | Adhesive mortar | 6,00 |

| Reinforcement | Glass fibre reinforced plastic, polyester resin | 0,18 |

| Primer | Alkyd paint, white, 60% in H2O | 0,04 |

| Finishing Layer | Limestone, milled, packed | 4,00 |

| PV system | ||

| System Layer | Material | PV modules rated power |

| PV panel | Photovoltaic cell, multi-Si | 12,09 |

The remaining general hypotheses to be used for all circularity indicators calculation are shown in Table 7.

Table 7.

General Hypotheses for Circularity Indicators calculation.

| General Hypotheses | Value | Units |

|---|---|---|

| Hypotheses of Service Life | ||

| Renovation Service Life | 50 | years |

| ETICS Service Life | 50 | years |

| ETICS coating periodicity | 15 | years |

| PV system Service Life | 30 | years |

| Inverter Service Life | 15 | years |

| PV maintenance periodicity | 1 | years |

| Hypotheses of Energy and CO2 Cost | ||

| Electricity cost | 0.13 | €/kWh |

| Price of CO2 emissions | 25.00 | €/tnCO2eq |

| CO2 emissions intensity | 0.28 | kgCO2/kWh |

| Hypotheses of Economic and Financial Analysis | ||

| Discount Rate (DR) | 3.00 | % |

| Hypotheses of Energy mix and Conversion Factors | ||

| Electricity Non-RES (kWh PE non-renewable to kWh FE) | 1.95 | |

| Electricity RES (kWh PE renewable to kWh FE) | 0.41 | |

| Natural Gas Non-RES (kWh PE non-renewable to kWh FE) | 1.19 | |

| Natural Gas RES (kWh PE renewable to kWh FE) | 0.01 | |

| Conversion factor diesel – EP | 13.02 | MWh/l |

| Hypotheses of Evaluated Renovation action | ||

| Area of retrofitted façade | 130.80 | m2 |

| Area of windows | 23.76 | m2 |

| Total Retrofitted Façade | 107.00 | m2 |

| Area of BIPV Panels | 69.60 | m2 |

| Area of equivalent rooftop PV panels | 54.00 | m2 |

| PV modules rated power | 12.00 | kWp |

4.2. Calculation methodological approach

Although the test scenario is a theoretical conventional retrofitting scenario, and therefore no monitoring data is available, all the calculation procedures are based on trustworthy and reliable sources. The calculation of the Circularity Indexes is carried out by means of a calculation engine developed as a Phyton module.

Python is an object-oriented, high-level programming language with dynamic semantics (Python Software Foundation, 2006), widely used in the engineering and scientific community for being an open-source programming language with many already developed packages and modules. For the purpose of testing the proposed methodology, inputs have been calculated by different pathways and manually inserted in the Python code that is responsible for the Circularity Indexes calculation. The results are expressed both globally – for the entire life cycle of the evaluated action – and partially, for each stage of the lifecycle. Results are printed in the Python environment console and stored in a csv file that is used to construct plots for data visualisation.

4.2.1. Energy Circularity Index

The Energy Circularity Index (ECI) has been calculated as follows:

-

•

At the product stage, embodied energy has been gathered from the ETICS system EPD; and for the PV system, PV modules and aluminium frames embodied energy are obtained from the Inventory of Carbon and Energy database by the University of Bath (Hammond and Jones, 2011), while the data concerning the inverter was collected from a study on embodied energy analysis of PV systems (Nawaz and Tiwari, 2006).

-

•

At the construction stage, data from the EPD of the ETICS system have been used. Concerning the PV system, no energy usage is considered at the construction stage other than transportation.

-

•

At the use stage, dynamic simulation with TRNSYS18 and its building type TRNBUILD, with a complete 3D modelling (see Fig. 8) and subsequent energy dynamic simulation was carried out to evaluate the energy savings and PV system simulation with TRNSYS18 was used to evaluate PV production.

-

•

At the EOL stage, it has been assumed that all the ETICS is landfilled at a disposal site and that all PV system parts are recycled in a dedicated recycling facility, both 50km away from the building site.

Fig. 8.

3D modelling of test scenario building.

4.2.2. Materials Circularity Index

The Materials Circularity Index (MCI) has been calculated using a BOM from real suppliers of ETICS and PV systems, as laid out in the previous section. Product's BOM have been obtained from product EPDs and, from small contributors without readily available EPDs, Ecoinvent database (Wernet et al., 2016), a recognised database on which renowned LCA software SimaPro relies.

4.2.3. Water Circularity Index

Since conventional retrofitting solutions do not include water management or recovery systems and the Project within this paper has been prepared in developing only integrated passive and active solutions for improved energy performance and indoor comfort, water circularity assessment is left out of the scope.

4.2.4. Social Circularity Index

Social Circularity Index (SCI) is calculated under the following hypotheses:

-

•Product Stage: level of C2C® certification of the products installed:

-

○Generic ETICS system: No C2C® certified system exist according to the Cradle-to-Cradle Certified Products Registry: 0 out of 5 points.

-

○SunPower X22 – 360 Wp. C2C® Bronze certified and Silver for Social fairness quality category under version 3.1 (SunPower Corporation, 2020): 3 out of 5 points.

-

○

-

•

Construction Stage: social aspects of building construction activities (see Table 8).

- •

-

•

EOL Stage: social aspects of building construction activities (see Table 8).

Table 8.

Construction stage (A4-5), Maintenance Stage (B2-5) and EOL Stage (C) Social Assessment.

| Category | Requirement | Value (1 = yes, 0 = no) |

|---|---|---|

| SOCIAL ADDED VALUE | ||

| Impact of construction work towards neighbourhood | A plan for the Acoustic mitigation of construction works according to local ordinance has been developed and implemented | 2/2 |

| A Construction Activity Pollution Prevention Plan according to EPA or local requirements been developed and implemented | ||

| Social fairness in the Construction Stage | A full social responsibility self-audit based on UN Global Compact Tool or B-Corp has been conducted | 0/1 |

| Use of local workforce | Contractor based within 160 km of construction site | 0/1 |

|

|

||

Table 9.

Evaluation of Social Circularity in Use Phase.

| Category | Sub-category | Requirements | Value (1 = yes, 0 = no) |

|---|---|---|---|

| SOCIAL ADDED VALUE - Evaluation Matrix | |||

| Health and comfort | Thermal comfort | PMV and PPD values are inside the range expected for a class 2 building according to the UNE 15251? Class 2 is expected for new or refurbished buildings. PPD<10% and -0.5<PMV<+0.5 |

0 |

| Is the operational temperature adjustable for all the building? | 0 | ||

| Is the operational temperature adjustable for specific spaces? | 0 | ||

| Is the temperature monitored in the building? | 0 | ||

| Is the humidity adjustable for all the building? | 0 | ||

| Is the humidity adjustable for specific spaces? | 0 | ||

| Is the velocity of the ventilation air adjustable for considering the indoor air quality? | 0 | ||

| Is the velocity of the ventilation air adjustable in specific spaces for considering the indoor air quality? | 0 | ||

| Indoor Air Quality | Is there any IAQ plan that includes IAQ audits every 4 years as well as operation guidelines to achieve high IAQ levels? | 0 | |

| Can the building keep the CO2 levels under 1000 ppm at full occupancy? | 0 | ||

| Which percentage of the individual spaces has a TVOC concentration lower than 1000 ug/m3? (%) | 0 | ||

| How many of those parameters are real-time monitored: mould, VOCs, PM, CO2, CO, T and RH? (%) | 0 | ||

| Can users control the air intake and ventilation rate of the building? | 0 | ||

|

|

|||

4.2.5. Life cycle economic value

A simplified LCC analysis has been carried out to obtain the LCC metric and the linear payback period of the proposed retrofitting solution. This LCC considers the following terms, which have been derived from installation companies and product suppliers:

-

•

Initial product acquisition costs and installation costs that, together, represent the CAPEX. These are obtained considering a retail price of 70 €/m2 and 21€/m2 of installation costs for the ETICS system and retail prices of 1548.80 €/kWp and 2915.90 € and 150 €/kWp for the PV modules, inverter and wiring, respectively, which are complemented with the installation cost of the PV system of 565 €/kWp. Installation costs include dumpster supply and removal and container rental, waste management and certifications costs.

-

•

Operation and Maintenance (O&M) and products replacement costs together represent the OPEX. 20 €/m2 have been considered for ETICS coating each 15 years and 540 €/year have been considered for PV O&M.

-

•

Operational savings and revenues. In this case, the energy savings from improved building fabrics insulation and from PV energy self-consumption, obtained by dynamic simulation and PV system performance simulation and rated at 0.13€/kWh, are considered. Cost of avoided CO2 emissions is computed by evaluating the CO2 emissions savings from reduced electricity consumption at the current grid mix (0.28 kgCO2/kWh) and the current carbon dioxide market price (25 €/tCO2).

-

•

EOL costs for deconstruction and disposal or waste treatment and revenues from material recovery and residual value. Disposal costs, including demolition, of the ETICS system are 6.61 €/m2 (cost of landfill disposal) whereas the PV system waste management cumulated revenues are assumed at 1.41 €/module according to (Latunussa et al., 2016).

5. Results

This section lays out the main results obtained from the application of the Circularity Assessment methodology described in §3 to the proposed test scenario outlined in §4.

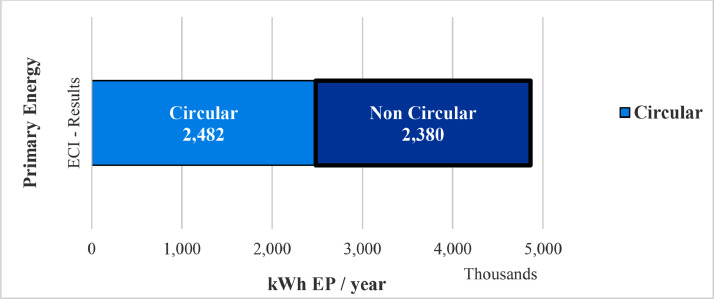

5.1. Energy Circularity Index

Obtained results for ECI for each life cycle stage and for the entire building life cycle are shown below in Table 10 and Figure 9.

Table 10.

Detailed results of the ECI calculation.

| PE Total | Circular PE | ECI | |

|---|---|---|---|

| Stage | kWh | kWh | % |

| Product (A1 – A3) | 148,570 | 24 642 | 16.59 |

| Transportation (A4) | 399,777 | 0 | 0 |

| Construction (A5) | 134 | 15 | 11.19 |

| Operation (B) | 4,278,726 | 2,456,875 | 57.42 |

| EOL (C) | 33,911 | 25 | 0.07 |

| Life Cycle | 4,861,118 | 2,481,557 | 51.05 |

Fig. 9.

ECI Results for the conventional retrofitted building – circular and non-circular energy.

5.2. Materials Circularity Index

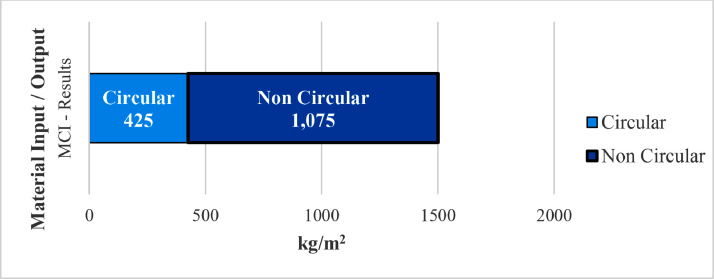

Obtained results for MCI for each life cycle stage and for the entire building life cycle are shown below in Table 11 and Figure 10.

Table 11.

Detailed results of the MCI calculation.

| TMI from cycled sources | TMO to cycled paths | TMI | TMO | MCI | |

|---|---|---|---|---|---|

| Stage | kg/m2 | kg/m2 | kg/m2 | kg/m2 | % |

| Product (A1 – A3) | 211.63 | N/A | 822.81 | N/A | 25.72 |

| Construction (A4 – A5) | 0.04 | 0 | 0.98 | 0.25 | 3.21 |

| Operation (B) | 207.71 | 6.05 | 615.12 | 22.69 | 33.51 |

| EOL (C) | N/A | 6.05 | N/A | 38.89 | 15.54 |

| Life Cycle | 419.38 | 6.05 | 1,438.92 | 61.83 | 28.75 |

Fig. 10.

MCI Results for the conventional retrofitted building – circular and non-circular material input / output.

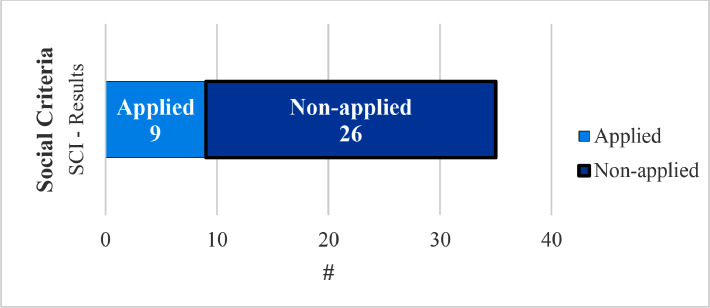

5.3. Social Circularity Index

Obtained results for SCI for each life cycle stage and for the entire building life cycle are shown below in Table 12 and Figure 11.

Table 12.

Detailed results of the SCI calculation.

| Number of Criteria | Positive Social Criteria | SCI | |

|---|---|---|---|

| Stage | # | # | % |

| Product (A1 – A3) | 10 | 3 | 30 |

| Construction (A4 – A5) | 4 | 2 | 50 |

| Operation (B1) | 13 | 0 | 0 |

| Maintenance (B2 – B5) | 4 | 2 | 50 |

| EOL (C) | 4 | 2 | 50 |

| Life Cycle | 35 | 9 | 25.71 |

Fig. 11.

SCI Results for the conventional retrofitted building – applied and non-applied criteria.

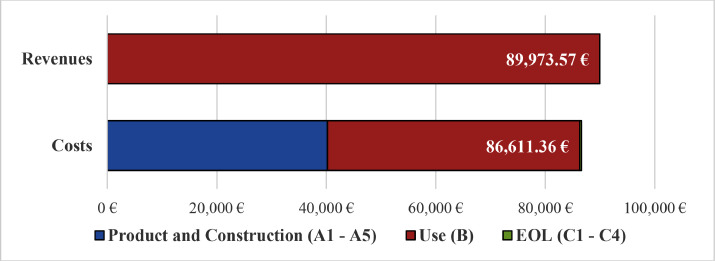

5.4. Life cycle economic value

Obtained results for LCC for each life cycle stage and for the entire building life cycle are shown below in Table 13 and Figure 12.

Table 13.

Detailed results of the LCC.

| Life Cycle Costs and Revenues [€] | Product & Construction Stage (A) | Use Stage (B) | End of Life stage (C) |

|---|---|---|---|

| One-off costs | 40,201.23 € | -19,085.26 € (PV system at year 30) | -339.74 € (ETICS dismantling at year 50) |

| Annual recurrent costs | N/A | -18,992.74 € (PV discounted annual O&M) | N/A |

| Annual recurrent revenues | N/A | 33,786.29 € (ETICS) | N/A |

| 52,402.90 € (PV) | |||

| 3,754.42 € (CO2) | |||

| Projected non-annual costs | N/A | -4,202.46 € (ETICS coating every 15 years) | N/A |

| -3,789.94 € (inverter at year 15 and 45) | |||

| Projected non-annual revenues | N/A | N/A | 29.96 € (PV valorisation at year 30 and 50) |

| Total Life Cycle Costs and Revenues | -40,201.23 € | 43,873.22 | -309.78 € |

Fig. 12.

LCC results for each life cycle stage bar plot.

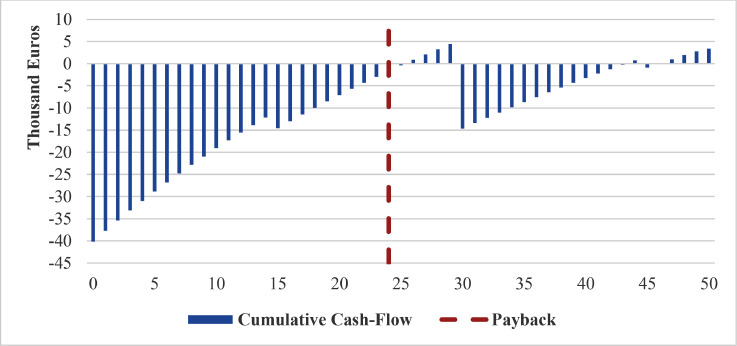

Looking at the annual cumulative cash-flow (see Figure 13), the expected payback period can be also obtained. Particularly, for the proposed scheme of costs, the payback of the investment is reached at year 25, the first year when the cumulative cash-flow is positive. However, it is also observed that investment required for PV system replacement at year 30 and ETICS system maintenance at years 30 and 45 puts the cumulative cash-flow in negative figures again and the final payback is not obtained until year 46.

Fig. 13.

Cumulative cash-flow and Payback considering Life Cycle Costs.

5.5. Overall building circularity assessment

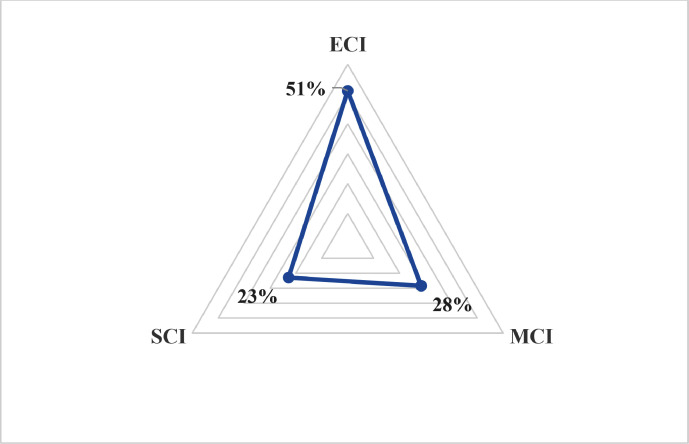

The overall Building Circularity is expressed, according to the proposed methodology, in terms of the global magnitude for each metric of the composing vectors, i.e., MWh for Energy, kg for Materials and Scoring for Social Added Value; and with the overall indexes in percentage. The results are summarised in Table 14, and plotted in a radial plot in Fig. 14.

Table 14.

Final results of Circularity Index %.

| Life Cycle Circularity [%] | |

|---|---|

| Energy Circularity Index | 51% |

| Materials Circularity Index | 29% |

| Social Circularity Index | 23% |

Fig. 14.

Circularity Indicators in a radial plot.

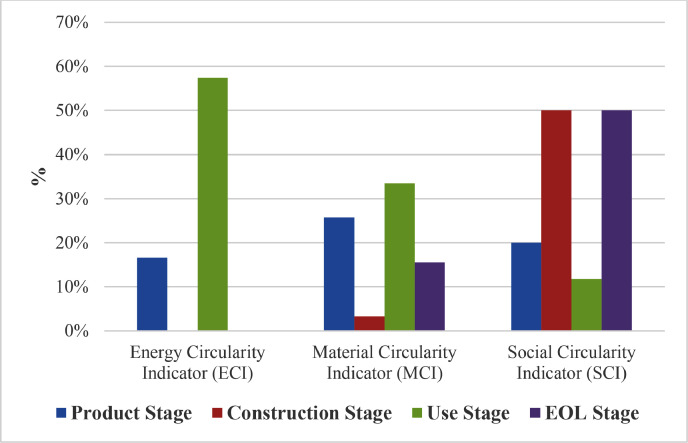

Taking a closer look to Circularity Indexes by Life Cycle Stage, the following results are obtained (see Figure 15).

Fig. 15.

Circularity Indexes by life cycle stage.

6. Discussion

Results have been obtained for four out of five Circular Economy composing vectors proposed. The water circularity index has not been calculated because the test scenario does not foresee any water circularity measures. Being only applicable at the product stage – no water is required for ETICS and PV installation – it has been considered appropriate to leave the index out of scope as C2C® certification level already includes a Water Stewardship valorisation (Cradle to Cradle Products Innovation Institute, 2016).

Regarding the first CE composing vector, energy use; the ECI obtained is about 51%. The bulk of the circularity is due to the reduction on the thermal demand with respect to the pre-refurbishment demand and to the electricity production, both at the use stage of the building. These add up to 2,456,875 kWhPE out of 4,278,726 kWhPE, an overall reduction of 57% at this stage.

Regarding the second CE composing vector, materials use; the MCI obtained is rather low: about 28%. This is because both considered products do not include any relevant principle of the circular economy guides in terms of safety for humans and environment, cyclability of resources or traceability to ensure future material cycling. Therefore, the proportion of the materials, in weight, that gets into the material cycle again, once it has served its purpose is very low. Other products, as are expected from the PLUG-N-HARVEST project are designed to increase this proportion due to the circular economy guidelines applied to the product from the early stages of design. Also, it must be noted that the use of toxic materials is not explicitly computed – although penalized in both MCI and SCI – and, therefore, overall materials performance obtained could be even lower.

Concerning the third CE composing vector, social added value; the SCI obtained is even lower: 23%. The reasons behind that are diverse: only PV modules have been selected with CE compliance purposes, the construction activities involved at the Construction Stage, Maintenance Stage and EOL Stage have been considered to be strictly compliant with the national regulation. Additionally, the social impact of this retrofit only implies the energy reduction and as a consequence, the energy bill reduction, but does not take into account other social variables. This is so because the test scenario against which the methodology has been tested is a conventional retrofitting solution and, therefore, no CE measures are envisioned beyond the strict compliance of currently enforced normative.

As with regards to Life Cycle Economic value, the overarching vector that economically values all implemented actions, the detailed CAPEX, OPEX and Revenues values show that the façade refurbishment solution does not pay for itself through the derived energy savings. Conversely, it is the good profitability of the PV system that lowers the payback period to high – but still reasonable – figures, especially considering that façade refurbishment is an action with rather low paybacks. This is so because the CAPEX of building envelopes is usually high and in many cases these renovation actions are not performed under an economical profitability perspective but with other motivation, such as the patrimonial value increase, a factor with critical importance in economic terms; building pathologies solving; or noise reduction. In this case, the electricity savings derived from PV system production counteract the negative cumulated cash-flow from the façade refurbishment. The photovoltaic technology with much lower paybacks reduces the overall payback period, somehow partially “paying” the ETICS acquisition and installation costs.

Circularity Indexes analysis by Life Cycle Stages allows identifying the areas where it is possible to improve from a CE compliance standpoint. In particular:

-

•

The ECI shows that there is not much room for energy demand reduction in the operational stage. However, even being this the stage with the highest ratio of circularity, there are still some opportunities for improvement, particularly the possibility of increasing on-site energy production is still high and it could be combined with the adoption of demand response strategies approaching to the goal of reaching net energy producing buildings instead of consumers. The other stages, i.e., the product, construction and EOL stages, remain in low or almost-zero values due to the non-circular solutions that have been used in this test scenario.

-

•

The MCI follows this premise, with low values in every stage, even in the product and EOL stages that are the main stages where this indicator applies.

-

•

The SCI is ruled a bit different, with a check points list. The use stage presents the lower values due to the fact that lowering the thermal demand is not the only action that can be performed in order to improve the social context. In this scenario, even with a lowered thermal demand, there is no action that ensure the thermal comfort inside the building, as it is considered in this indicator.

7. Conclusions

This paper presents a novel methodology to check the degree of compliance of Circular Economy (CE) principles in new building construction and refurbishment activities. The proposed evaluation methodology stems from the need of encouraging and valorising the adoption of CE measures for new or renovated buildings, which are intensive in the use of materials, energy and water along their service life, and with great potential for providing social added value. The methodology also includes the life cycle economic value assessment including the accountancy of the positive and negative externalities associated to the Energy, Materials and Water circularity assessment. The development of this methodology is of great interest to all building and construction sector stakeholders mainly due to the current lack of evaluation methodologies and indicators in this field.

Five CE composing vectors have been identified as relevant for building circularity assessment: energy consumption, materials use, water consumption, social added value and life cycle economic value. They are proposed to be treated separately due the difficulty of finding a solid approach to combine them. Thus, five independent metrics have been developed: Energy Circularity Index, Materials Circularity Index, Water Circularity Index, Social Circularity Index and Life Cycle Costing.

The methodology has been developed under a life cycle perspective, thus calculating and valorising the CE measures along the four building life cycle stages as laid out in EN 15978 and EN 16309 (CEN, 2014, 2011): product, construction, use and end of life stages.

The methodology has been tested against a conventional building energy retrofit scenario, a reference scenario of a demo site included in a H2020-funded research project. This test scenario consists in a façade retrofit solution – an ETICS – and an energy demand reduction solution – a rooftop PV system. The scenario, therefore, advises to not include the water vector into the analysis because it is not affected by the activity.

Results show that current buildings and retrofitting actions are far from being considered circular, with the highest circularity index, the Energy Circularity Index, barely surpassing 50%, which is clearly improved by the inclusion of an efficient PV system in a Southern Europe location. The remaining indexes show low circularity values, below 30%. In addition, results also show diverse potential for the adoption of CE measures along the building life cycle for each composing vector. For instance, in terms of materials use, it is mainly found in product and construction stages; whereas for energy consumption, it is during the use stage when more room for improvement is found. Concerning the social impact, results prove that it is often forgotten when designing and implementing building construction activities. Last, but not least, the economic value and linear payback of the investment is found to be rather low. New CE-enabled business models, such as Pay per Service (PPS) or Pay per Performance (PPP) might also help to reduce this gap and improve business construction and renovation activities’ profitability.

Finally, it is noteworthy to mention the potential of this methodology for regulators and policy makers. By objectively valuing the degree of compliance of Circular Economy principles during the design stages, CE measures could be valued and even included as requisites in tenders. In addition, the results here obtained set up initial basis for a database of current construction sector standards in terms of circularity of construction products and processes. Also, the authors foresee interesting synergies for building owners or end-users, as building circularity evaluation could complement current building sustainability certifications by constituting additional requirements to be included in a LEED, BREEAM, WELL or similar certification frameworks.

Credit Author Statement

Arnau González: Conceptualization, Literature Review, Methodology definition, Analysis of Results, Discussion and Conclusions and Writing – Original draft preparation.

Cristina Sendra: Literature Review, Methodology definition of materials assessment, Analysis of Results, Discussion and Conclusions and Writing - review & editing.

Antoni Herena: Methodology definition, Calculation and Analysis of Results, Discussion and Validation.

Monica Rosquillas: Calculations and Grammar and Spell checking.

Diana Vaz: Calculations.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

Funding: This research was supported by the European Union in the H2020 Framework Programme under Grant Agreement No. 768735.

Footnotes

Supplementary material associated with this article can be found, in the online version, at doi:10.1016/j.rcradv.2021.200051.

Appendix. Supplementary materials

References

- BAMB 2020, 2016. Building as Materials Banks (BAMB) [WWW Document]. URL https://www.bamb2020.eu/.

- Bao Z., Zhang S., Chen Y., Liu S., Zhang Y., Wang H. Proceedings of the 2010 International Conference on Management and Service Science, MASS 2010. 2010. A review of material flow analysis. [DOI] [Google Scholar]

- Blomsma F., Brennan G. The emergence of circular economy: a new framing around prolonging resource productivity. J. Ind. Ecol. 2017;21:603–614. doi: 10.1111/jiec.12603. [DOI] [Google Scholar]

- CE100, Ellen Macarthur Foundation . ; Cowes, Isle of Wight, UK: 2016. Circularity in the Built Environment: Case Studies. [Google Scholar]

- CEN, 2015. EN 16627 – Sustainability of construction works – Assessment of economic performance of buildings – Calculation method.

- CEN, 2014. EN 16309 — Sustainability of construction works — Assessment of social performance of buildings — Calculation methodology.

- CEN, 2011. EN 15978 — Sustainability of construction works — Assessment of environmental performance of buildings — Calculation method.

- CEN, 2007. EN 15251 Indoor environmental input parameters for design and assessment of energy performance of buildings addressing indoor air quality, thermal environment, lighting and acoustics.

- Cradle to Cradle Products Innovation Institute, 2019. Guidance for the Cradle to Cradle Certified™ Product Standard, Version 4 Draft 1.

- Cradle to Cradle Products Innovation Institute, 2018. Product certification Overview [WWW Document]. URL https://www.c2ccertified.org/get-certified/product-certification.

- Cradle to Cradle Products Innovation Institute . Cradle to Cradle Products Innovation Institute; Oakland, CA, USA: 2016. Guidance for the Cradle to Cradle Certified™ Product Standard, Version 3.1. [Google Scholar]

- Cradle to Cradle Products Innovation Institute, MBDC LLC, 2013. Material health assessment methodology 88.

- Cusenza M.A., Guarino F., Longo S., Ferraro M., Cellura M. Energy and environmental benefits of circular economy strategies: The case study of reusing used batteries from electric vehicles. J. Energy Storage. 2019;25 doi: 10.1016/j.est.2019.100845. [DOI] [Google Scholar]

- Dodd N., Cordella M., Traverso M., Donatello S. European Commission. Joint Reserach Centre (JRC); Sevilla, Spain: 2020. Level(s) – test phase analysis: Identification of horizontal themes and technical updates.https://susproc.jrc.ec.europa.eu/product-bureau//sites/default/files/contentype/product_group_documents/1581681499/20200204_Level(s)_test_phase_Outline_findings_and_proposals_Final.pdf [Google Scholar]