Highlights

This article mainly summarizes the challenges and the latest research progress of highly reversible zinc anodes in mild aqueous zinc-ion batteries and proposes corresponding recommendations.

Supplementary Information

The online version contains supplementary material available at 10.1007/s40820-021-00782-5.

Keywords: Zn-ion batteries, Zn metal anode, Dendrite, Hydrogen evolution, Corrosion

Abstract

The rapid advance of mild aqueous zinc-ion batteries (ZIBs) is driving the development of the energy storage system market. But the thorny issues of Zn anodes, mainly including dendrite growth, hydrogen evolution, and corrosion, severely reduce the performance of ZIBs. To commercialize ZIBs, researchers must overcome formidable challenges. Research about mild aqueous ZIBs is still developing. Various technical and scientific obstacles to designing Zn anodes with high stripping efficiency and long cycling life have not been resolved. Moreover, the performance of Zn anodes is a complex scientific issue determined by various parameters, most of which are often ignored, failing to achieve the maximum performance of the cell. This review proposes a comprehensive overview of existing Zn anode issues and the corresponding strategies, frontiers, and development trends to deeply comprehend the essence and inner connection of degradation mechanism and performance. First, the formation mechanism of dendrite growth, hydrogen evolution, corrosion, and their influence on the anode are analyzed. Furthermore, various strategies for constructing stable Zn anodes are summarized and discussed in detail from multiple perspectives. These strategies are mainly divided into interface modification, structural anode, alloying anode, intercalation anode, liquid electrolyte, non-liquid electrolyte, separator design, and other strategies. Finally, research directions and prospects are put forward for Zn anodes. This contribution highlights the latest developments and provides new insights into the advanced Zn anode for future research.

Supplementary Information

The online version contains supplementary material available at 10.1007/s40820-021-00782-5.

Introduction

With the sharp increase in energy demand, in response to the global challenges of the increased depletion of traditional fossil energy and associated environmental issue [1–3], many countries and regions have increased their investment in renewable energy such as solar energy, wind energy, and hydropower energy [4–6]. Although there are low- or non-carbon clean energy sources, the generation and conversion of the renewable power supply systems are intermittent, unstable, and uncontrollable, which makes energy storage and transportation difficult [7, 8]. Therefore, as a medium to regulate electricity output and improve the tolerance ability of the power grid to renewable energy, the development of ESS technology is highly essential to enable a clean energy transition [9]. Among the various ESSs, non-aqueous lithium-ion batteries (LIBs) are currently the most widely used rechargeable electrochemical devices [10, 11]. However, owing to flammable organic electrolytes and highly reactive lithium substances, the increasing concerns about the potential safety issues hinder the application of LIBs on a large scale [12–14]. Besides, the high cost and also the low abundance of lithium resources on the earth limited the long-term development of LIBs [15, 16].

Compared with traditional organic electrolytes-based LIBs, aqueous metal-ion batteries have proved promising for large-scale energy storage since the adopted aqueous electrolyte possesses the characteristic of more safety, lower cost, easier processing, and higher ionic conductivity. Currently, various aqueous metal-ion batteries have been developed, such as zinc-ion batteries (ZIBs), sodium-ion batteries (SIBs), potassium-ion batteries (PIBs), aluminum-ion batteries (AIBs), magnesium-ion batteries (MIBs), and calcium-ion batteries (CIBs) [17]. Compared to other active metals, Zn metal can be directly used as an anode due to its proper redox potential (-0.76 V vs. standard hydrogen electrode (SHE)) and excellent Zn/Zn2+ reversibility aqueous media. The high natural abundance (approximately 300 times higher than that of lithium) and good resistance to the environment allow Zn to be purchased and processed inexpensively. Very importantly, the Zn anode also has the inherent advantage of high theoretical capacity (820 mAh g−1 and 5854 mAh cm−3). Therefore, aqueous ZIBs have attracted sufficient attention [18, 19]. According to the pH of electrolytes, aqueous ZIBs can generally be divided into alkaline ZIBs and mild (neutral or mildly acidic) ZIBs. The research of zinc-based batteries traces its history back to the nineteenth century. It was not until the 1980s that Yamamoto et al. first studied rechargeable Zn–MnO2 batteries in 2 M ZnSO4 electrolyte, which created a precedent for the development of mild aqueous ZIBs [20, 21]. It has been confirmed that the substitution of mild electrolyte for alkaline electrolyte can usually exhibit better reversibility due to many advantages, such as eliminating passivation and alleviating dendrite growth on the anode surface. Thus, these reports about mild aqueous ZIBs have emerged endlessly in recent years.

As an integral part of ZIBs, it is well known that anodes are particularly important to the performance and lifespan of batteries. However, although Zn anodes have inherent advantages, as mentioned above, there are also some thorny problems, which may be devastating to ZIBs. Besides, considerable research efforts have been devoted to the cathode side, such as manganese-based and vanadium-based materials [22, 23], while the research focus on the anode side is still in the primitive stage [24]. Inadequate exploration of Zn anodes leads to a vague understanding of Zn anode failure. It remains a challenge to solve the problems of Zn dendrite growth, hydrogen evolution, and corrosion on the Zn anode side in mild aqueous ZIBs. Based on the previous reports, dendrite growth significantly reduces Zn anode’s capacity and Coulomb efficiency (CE). Large dendrites can even pierce the battery separator and cause a short circuit due to the high mechanical strength and Young’s modulus of Zn. Besides, compared with the traditional alkaline electrolyte, the weakly acidic environment provides a stronger thermodynamic trend for hydrogen evolution. The irreversible consumption of electrolytes during hydrogen evolution and corrosion impairs the long-term cycling performance of ZIBs, and the generated hydrogen increases the risk of battery splitting and electrolyte leakage. Even worse, the mutual reinforcement among these issues causes further deterioration of anode performance [25]. Therefore, in-depth study and optimization of Zn anodes are necessary for ZIBs to move toward practical applications.

To construct highly stable Zn anodes, researchers have proposed various strategies in mild aqueous ZIBs. Considering that it is essential to improve the comprehension of anode challenges and grasp the direction of anode development via recognizing diverse strategies, a detailed summary is necessary. Some previous reviews generally divided these strategies into the following categories: anode matrix modification, electrolyte optimization, and separator design. However, with an in-depth study on Zn anodes, new discoveries and novel modification strategies continue to emerge, and the previous generalizations can no longer keep pace with the latest progress, especially unable to give in-depth and clear explanations for some basic issues. Therefore, this review summarizes recent research from a broad perspective, including more comprehensive basic knowledge and the latest work on Zn anodes. At the same time, based on a large number of published studies, this work elaborates some specific mechanisms in depth, which were mentioned in other reviews but failed to give a detailed explanation, such as how the following facts profoundly affect Zn deposition: the electronic conductivity and Zn affinity of modification layer, Zn alloying, and so on.

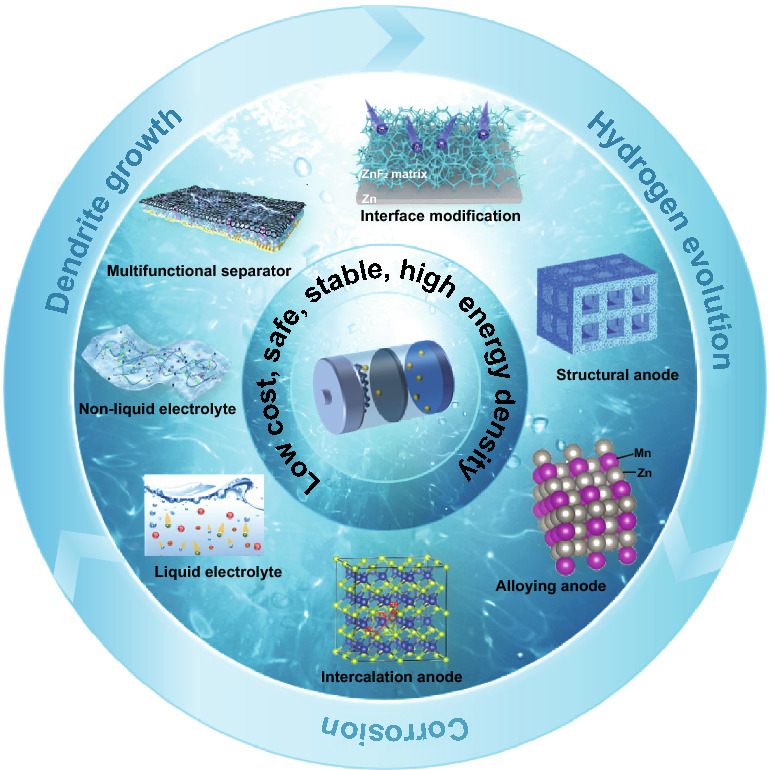

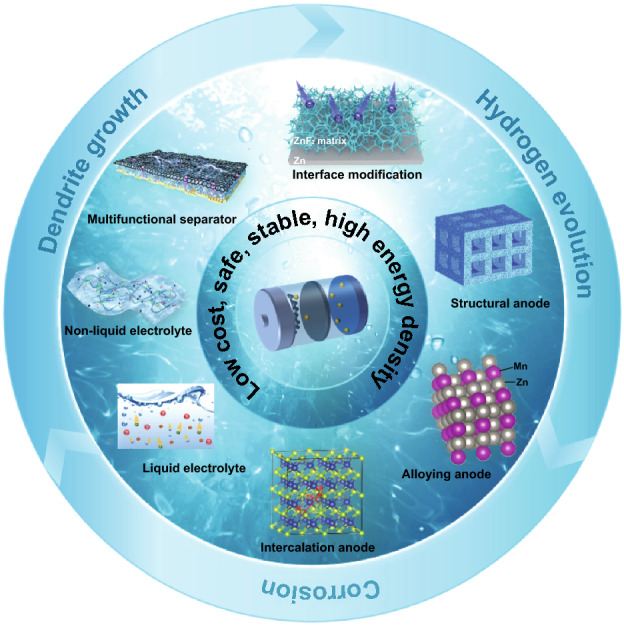

This review aims to provide a comprehensive summary of the recent development of Zn anode in mild aqueous ZIBs (as shown in Fig. 1). First, the main challenges, involving dendrite growth, hydrogen evolution, corrosion, and the interaction relationship between them, are systematically analyzed to identify Zn deposition behavior at Zn anode. Then, various latest strategies to enhance the anode performance are categorized and discussed in detail, including interface modification (redistribution of concentration field, redistribution of electric field, and regulation of surface binding energy), structural anode, alloying anode, intercalation anode, liquid electrolyte (weakening of solvation effect, suppression of 2D diffusion, formation of electrostatic shielding layer, and formation of in situ solid electrolyte interphase (SEI) layer), non-liquid electrolyte (solid-state electrolyte, hydrogel electrolyte, and other non-liquid electrolytes), separator design, and other strategies. Finally, by analyzing the latest research achievement, Zn anode’s remaining challenges and perspectives are proposed to produce more reliable aqueous ZIBs with rationally improved performance.

Fig. 1.

Schematic of strategies to enhance the performance of Zn anodes for mild aqueous ZIBs

Challenges of Reversible Zn Anode in Mild Aqueous ZIBs

The possible reactions at the anode/electrolyte interface play significant roles during the energy storage and release of ZIBs. Generally, unlike alkaline systems with zincates as charge carriers, the mild aqueous ZIBs involve the reversible plating/stripping of Zn2+ ions on anode surface accompanying the charging/discharging operations. The reaction mechanism of Zn anode can be summarized as

Discharge process:

| 1 |

Charge process:

| 2 |

Simultaneously, given that Zn has a high electrochemical activity and thermodynamical instability in mild aqueous electrolytes, leading to side reactions, there are also anode-related disadvantages, such as dendrite growth, hydrogen evolution and corrosion (Fig. 2a), which will be analyzed as follows.

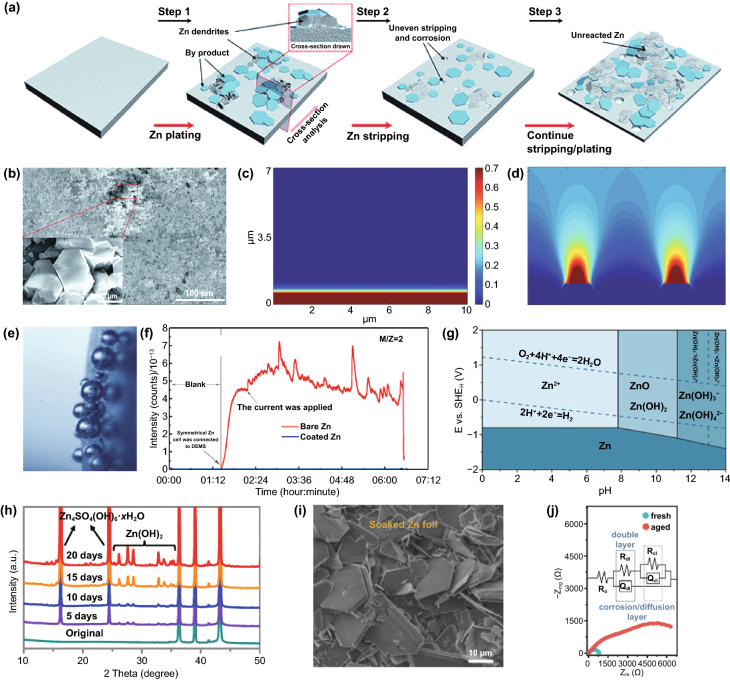

Fig. 2.

a Schematic illustration of the formation of inactive Zn; b Top-view SEM image of the Zn electrode after short circuit. Inset: flake-like dendrites [137].

Copyright 2021, Royal Society of Chemistry. Simulation of the diffusion and distribution of Zn ions along the 2D surface of the electrode with the conditions of c a flat surface and d 2 large dendritic seeds [29]. Copyright 2019, Wiley–VCH. e In situ optical microscope images of H2 gas evolution during the Zn electrodeposition process at 0.2 mA cm−2 [42]. Copyright 2019, Elsevier. f Online DEMS data for symmetrical Zn batteries with the bare Zn in 2 M ZnSO4 electrolyte, reflecting the hydrogen evolution of the anode during rest and charging/discharging process [43]. Copyright 2019, Royal Society of Chemistry. g Pourbaix diagram of ZnSO4–H2O system at 25 °C [44]. Copyright 2021, American Chemical Society. h The in situ XRD patterns of bare Zn immersed in 2 M ZnSO4 electrolyte [48]. Copyright 2021, Wiley–VCH. i SEM image of Zn foil after soaking in 1 M ZnSO4 electrolyte for 7 days [41]. Copyright 2020, Wiley–VCH. j Nyquist plots of the fresh and aged Zn electrode. The inset shows the equivalent circuit [49]. Copyright 2021, Wiley–VCH

Dendrite Growth

Currently, it is generally accepted that Zn dendrite growth is the major problem in mild aqueous ZIBs. Zn dendrites affect battery performance in several ways. On the one hand, due to the loose structure, flake-like Zn dendrites easily fall off the electrode and form “dead Zn,” thus reducing the CE and shortening the battery lifespan (Fig. 2b). On the other hand, the vertical growth of dendrites increases the thickness of the anode, and large dendrites may pierce the separator, causing a short circuit in the batteries. Even worse, faulty batteries may trigger safety incidents such as explosions or fires.

As we all know, Zn dendrites are caused by uneven deposition during the charging process. Specifically, Zn2+ ions transfer to the anode surface under the dual effect of the electric field and concentration gradient at the beginning of Zn plating, followed by acquiring electrons and nucleating [26]. Theoretically, nucleation positions should be randomly distributed on an anode surface. But the electrode surface morphology is challenging to be infinitely smooth, and there is a certain degree of roughness. In particular, due to the “tip effect,” compared to other locations, the protrusion with large curvature features higher surface charge density, which stimulates stronger local electric field intensity [27]. Furthermore, even on an infinitely smooth plane, the Zn nucleus formed earlier will act like a “protrusion” to affect the subsequent deposition of Zn2+ ions [28]. As a result, driven by the effect of electric field and concentration gradient, Zn2+ ions accelerate to accumulate and deposit on the tip (Fig. 2c, d) [29].

It can be known that many factors affect the growth of dendrites in mild aqueous ZIBs, and the connections between them are intricate. It has been proven that the Zn deposition process is affected by electrode polarization, especially concentration polarization. At a specific current density and electrode concentration, Zn2+ ions in the electrolyte continuously migrate to the anode reaction interface, where Zn2+ ions are consumed. Due to the limited migration speed, the subsequent Zn2+ ions cannot be supplemented to the reaction interface in time, resulting in a large concentration gradient perpendicular to the anode surface. The polarization caused by this concentration difference is the concentration polarization. The large concentration polarization is not conducive to the rapid transfer kinetics of Zn2+ ions. Besides, concentration polarization can lead to an increase in the overpotential on the anode surface. According to the ultra-thin electric double-layer model on the Zn surface, a large overpotential will seriously disturb the uniformity of the electric field, causes uneven Zn deposition, and destroys the stability and reversibility of the anode [20]. Therefore, the concentration polarization should be as small as possible. In addition, the current density has an important influence on the performance of the Zn anode, which can directly affect the Zn deposition rate. In the diffusion model (Eq. 3), the “Sand’s time τ” is empirically related to the transfer properties of Zn2+ ions and electrons as Eq. 3 [30]:

| 3 |

where τ is the time when Zn dendrites start to grow, and D is the diffusion coefficient. e is the electronic charge. C0 is the initial concentration of Zn salt. and are the anionic and Zn2+ mobility, respectively. J is the effective electrode current density. The smaller effective electrode current density (J) and larger Zn2+ mobility () result in a larger Sand’s time (τ), which indicates that the battery has a long lifespan before Zn dendrites grow. This can be explained by the fact that the small current density can lead to a more uniform local current density distribution and a smaller surface electric field distortion [31, 32]. Correspondingly, in a neutral/mildly acidic electrolyte, Yang et al. [29] observed that Zn dendrites gradually appeared and accelerated their growth with the increase in current density. It is proposed that a large current density will increase electrode polarization and cause uneven Zn deposition. On the contrary, a small current density is beneficial to alleviate the dendrite problem. In order to obtain a small current density, a reasonable reduction in the applied current and an increase in the specific surface area of the anode can be considered. At the same time, the capacity (the area capacity corresponding to the area of a symmetric battery or the mass load of the cathode material in an asymmetric battery) has also been found to be another critical factor affecting the growth of Zn dendrites. Large capacity will require more time to complete a single charge process, which leads to more severe dendrite formation [29]. Additionally, perfect metal manufacturing process and polished metal surface/edges can reduce anode defects [33]; the improved Zn affinity of the matrix can lower the nucleation energy barrier [34]; the high operating temperature can lead to increased diffusion coefficient, reduced concentration polarization, large nuclei size, low nucleation density, and compact growth of Zn metal [35, 36]. An appropriately low pH of the electrolyte can enable metal Zn to deposit in a hexagonal structure, instead of the inclined pyramidal structure at high pH [37]. Appropriate external pressure can offset the stress response caused by the intrinsic strain triggered by Zn deposition [38, 39]. By manipulating these factors, the problem of Zn dendrite growth can be alleviated. Based on the above analysis, the appearance of Zn dendrites in neutral or mildly acidic electrolytes largely depends on the battery configuration and charge/discharge protocol.

Hydrogen Evolution

In addition to Zn deposition, other species may be involved in side reactions on the anode, such as dissolved oxygen in the electrolyte and the electroactive materials of soluble cathodes. But the primary side reaction is the hydrogen evolution reaction (HER) caused by water (Fig. 2e, f) [40]. In fact, due to the influence of various factors such as temperature, applied voltage, electrode surface roughness, and electrolyte concentration, HER is a complicated process, which can be described as follows [41]:

Anode:

| 4 |

Cathode hydrogen evolution:

| 5 |

The hydrogen evolution at the anode occurs during the rest and operation of the battery [42, 43]. Given that the equilibrium potential of Zn2+/Zn (−0.76 V vs. SHE) is lower than that of H2O/H2 (0 V vs. SHE) in the entire pH range (Fig. 2g), the coexistence of Zn and H2O is thermodynamically unstable, which means that the two will react spontaneously and release hydrogen [44]. During the plating process, there is a competitive reaction between metal deposition and hydrogen evolution; hydrogen evolution is theoretically preferred over Zn deposition. However, according to the Tafel equation, the Zn mental anode presents a high HER overpotential, which is not conducive to hydrogen evolution kinetics; thus, the rate of HER is limited to a certain degree [45].

The mild aqueous ZIBs suffer from HER, which can irreversibly consume electrodes and electrolytes, thereby reducing battery life and CE. Also, with the gradual accumulation of hydrogen, the battery expands due to the increase in internal pressure until it bursts, ultimately causing electrolyte leakage [46]. In addition, the continuous evolution of hydrogen will cause changes in the local pH of electrolytes (Eq. 5), which is related to the formation of corrosion, exacerbating the negative effect on the battery. It is still an urgent challenge to propose an ideal strategy to solve the hydrogen evolution problem based on the above issues.

Corrosion

Simultaneously, the corrosion phenomenon accompanying the hydrogen evolution has also attracted long-term attention. Corrosion in mild systems is inseparable from HER, so electrochemical corrosion is also a thorny problem. Specifically, many micro-galvanic cells are formed at the phase interface of Zn metal/electrolyte. Zn metal at the corrosion site is dissolved due to the loss of electrons, and H2O in the neutral solution obtains electrons to generate hydrogen and OH− [47]. It has been confirmed that the continuously accumulated OH− will further react with the electrolyte to form by-products on the anode surface. However, different types of electrolytes and operating environments may have different by-products. As we all know, Zn(OH)2 and Zn4SO4(OH)6·xH2O with a hexagonal structure can be formed in ZnSO4 electrolyte (Fig. 2h), and the main reactions involved are as follows [48]:

| 6 |

Similarly, other mild electrolytes also participate in Zn corrosion and form by-products, such as TFSI-based complexes which can be formed in Zn(TFSI)2 electrolyte. Unfortunately, due to the loose structure of these by-products, they cannot act as a SEI layer to escape from the corrosion reaction (Fig. 2i) [41]. Moreover, the increased interphase impedance caused by the by-product layer restricts the diffusion of electrons/ions, which triggers a high energy barrier for Zn deposition. It severely reduces the performance of the battery (Fig. 2j) [49].

It is worth noting that dendrite growth, hydrogen evolution, and corrosion are inseparable. The three promote each other. The loose and porous Zn dendrites increase the contact area between the electrode and electrolyte, which provides more reaction sites and reduces the current density to achieve a low overpotential, leading to accelerated hydrogen evolution and corrosion. The adhesion of hydrogen bubbles on the anode surface can hinder the nucleation of Zn, resulting in an increased overpotential and uneven Zn deposition. At the same time, the accumulation of OH− anions caused by HER accelerates the corrosion process. The rough Zn surface triggered by corrosion may also further aggravate dendrite formation. The by-product layer with large curvature and irregularity also increases the contact area, accelerating the HER. Therefore, a specific anode modification strategy is usually beneficial to alleviate the three problems simultaneously.

Design and Optimization of High-performance Zn Anode in Mild Aqueous ZIBs

According to the above analysis, the anode problems, including dendrite growth, hydrogen evolution, and corrosion, hinder the commercialization of mild aqueous ZIBs. It is imperative to explore and develop efficient and stable Zn anode protection strategies. The mild aqueous ZIBs are advancing rapidly; especially in recent years, numerous novel and unique research ideas and achievements continue to emerge. This section summarizes and discusses recent developments from multiple perspectives, including interface modification, structural anode, alloying anode, intercalation anode, liquid electrolyte, non-liquid electrolyte, separator design, and other strategies.

Interface Modification

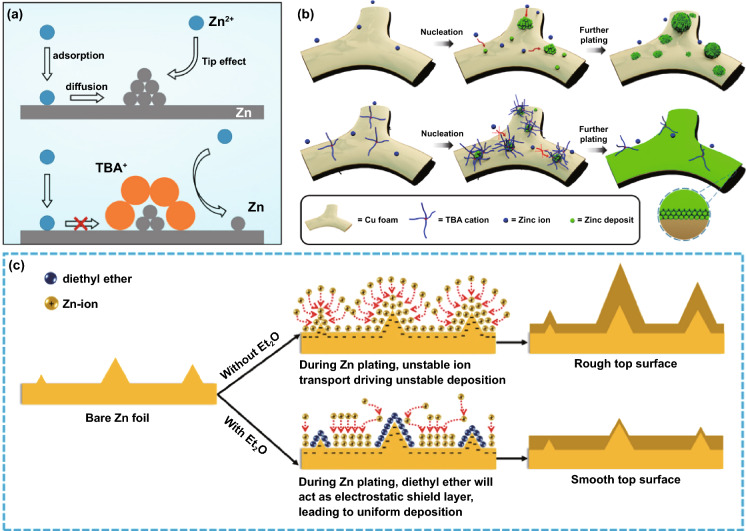

In the process of Zn2+ ion diffusion, reduction, nucleation, and Zn crystal growth, considering that dendrite growth and HER mainly occur at the anode/electrolyte interface, it seems a direct and effective strategy to construct a surface modification layer. The modified layer usually plays multiple roles, and this section focuses on redistribution of concentration field, redistribution of the electric field, and regulation of surface binding energy. These, respectively, directly manipulate the migration behavior of ions and molecules on the electrolyte side, the electron distribution on the anode side, and the nucleation barrier at the reaction interface to guide uniform Zn nucleation and growth and inhibit side reactions.

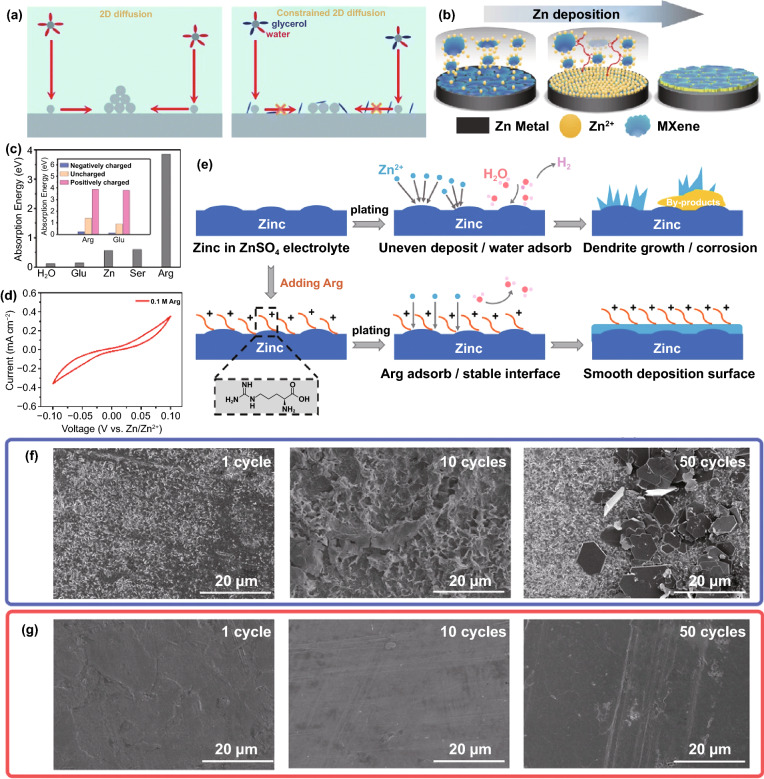

Redistribution of Concentration Field

The redistribution of concentration field mainly adjusts the spatial distribution and migration behavior of Zn2+ ions, H2O molecules, hydrated Zn2+ ions, and anions at the anode reaction interface, thereby improving subsequent Zn deposition and inhibiting side reactions. As mentioned earlier, restricting the migration behavior of Zn2+ ions during the deposition process has a profound impact on dendrite growth. Besides, it is already known that the participation of H2O molecules in the anode interface reaction will severely reduce the electrode performance. Specifically, in the electrolyte containing a large amount of free water, Zn2+ ion (0.74 Å) can be solvated to form a bulky hydrated structure [Zn(H2O)6]2+ (4.3 Å), which is not conducive to the rapid ion transfer [50]. Moreover, Zn2+ ions surrounded by H2O molecules are difficult to effectively contact the reaction interface, causing a low electrochemical reaction activity, and [Zn(H2O)6]2+ must be desolvated to participate in the subsequent reaction. Thus, there is an additional demand for energy to overcome the strong interaction between Zn2+ ions and H2O solvation sheath. Even worse, the free H2O molecules transferred from the electrolyte or generated after the desolvation process may participate in side reactions, causing hydrogen evolution and corrosion [51]. Anions in the electrolyte are also related to anode performance. On the one hand, since anions will not be solvated, they have high ion mobility and contribute a lot to ionic conductivity, but this reduces the effective ion conductivity provided by Zn2+ ions. On the other hand, anions may participate in the formation of by-products [52]. Based on the above considerations, the regulation mechanisms of modified layers, involving inhibiting the 2D diffusion of Zn2+ ions, reducing concentration polarization, reducing the degree of hydration, and restricting H2O molecules and anions from entering the anode reaction interface, are conducive to achieving uniform and rapid Zn deposition without hydrogen evolution and corrosion. Therefore, designing a suitable interface modification layer to directly redistribute concentration field is a feasible strategy to enhance the performance of Zn anodes. Generally, a modified layer has multiple interrelated means to achieve these goals. Next, the regulation mechanism of these modified layers will be described separately from the mechanical guidance of confined channels, adsorption guidance of polar groups, and directional electric field guidance of aligned dipoles.

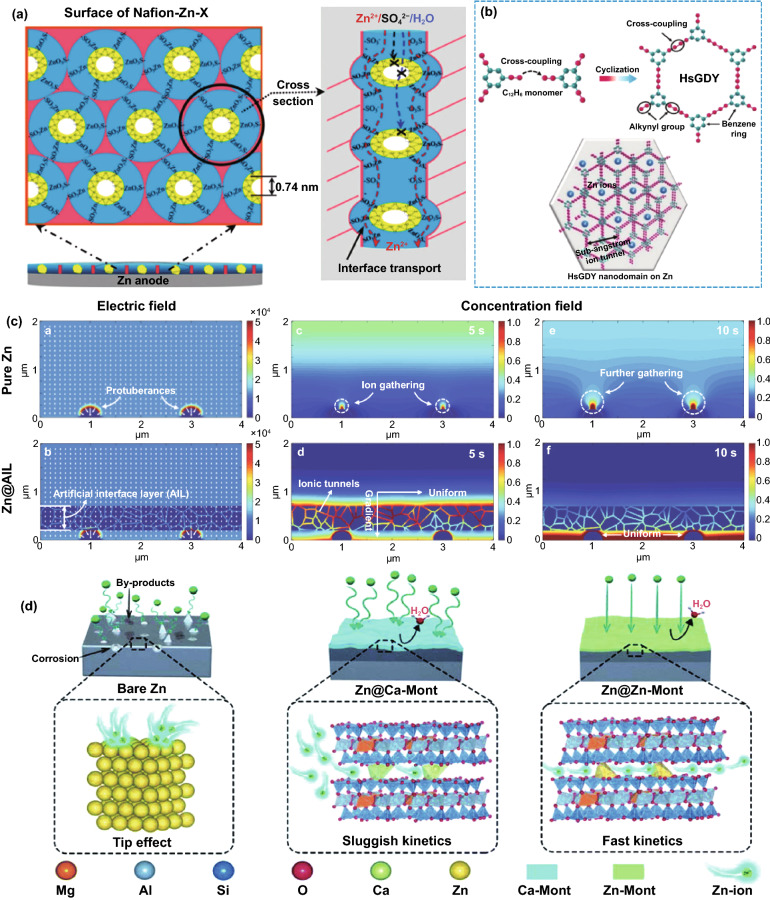

As a buffer layer that separates the active Zn from the bulk electrolyte, especially electronic insulation properties, the concentration field can generally be mechanically adjusted by constructing the confined channel, such as porous or layered structure. According to the size-selective exclusion effect, to enable the stable migration of Zn2+ ions and block other larger-sized molecules and ions, the confined channel structure should be well organized and have an appropriate channel size [53]. For instance, the Nafion–Zn-X modified layer formed by the complexation of Nafion and Zn-X zeolite (Fig. 3a) [54] or the hydrogen-substituted graphodiyne (HsGDY) layer constructed by cross-coupling of C12H6 monomer (Fig. 3b) [55] and their ion tunnels can only selectively transfer Zn2+ ions. In contrast, H2O molecules, hydrated Zn2+ ions, and SO42− ions with larger sizes cannot pass through the modified layer, so the effective mass transfer is significantly improved. Furthermore, the porous channel structure can serve as a physical barrier to inhibit the 2D diffusion of Zn2+ ions. Regardless of the initial uneven electric field on the anode surface, abundant sub-nanometer ion tunnels of HsGDY affect the migration path of Zn2+ ions (Fig. 3b): Since Zn2+ ions cannot move between tunnels, they can only be transferred along the tunnels and then nucleate and grow on the corresponding anode surface under the tunnels, rather than a thermodynamically favorable adsorption site with a low energy barrier. The inhibited 2D diffusion of Zn2+ ions promotes the formation of a uniform Zn2+ ion concentration field along with the HsGDY–Zn interface. The simulation of the concentration field well demonstrated the ion redistribution effect of the ion tunnel (Fig. 3c). It has been proved that the channel structure’s high porosity and small pore size are more conducive to accelerating the mass transfer capacity and forming a uniform Zn nucleus. The broadly and densely distributed pores ensure universal and uniform initial nucleation sites on the Zn surface. For some inorganic metal-based compounds, such as nanoporous CaCO3 [56], nanoporous SiO2 [56], kaolin [57], Zn-based montmorillonite [58, 59], and Mg–Al-layered double hydroxide (LDH) [60], they are also chemically inert and electronically insulating; therefore, the concentration field redistribution in these modified layers is mainly through their confined channel (Fig. 3d), thereby inhibiting dendrites, hydrogen evolution, and corrosion. Obviously, due to the rigid structure of these materials, the lack of mechanical flexibility is not conducive to adapting to changes in the volume of the negative electrode, resulting in limited enhancement of battery performance.

Fig. 3.

a Ion transport mechanisms in Nafion–Zn-X protective layers [54].

Copyright 2020, Wiley–VCH. b Schematic illustration of the synthesis of HsGDY and the sub-ångström ion tunnel of HsGDY; c Electric and concentration field simulation with protuberances of bare Zn and coated Zn [55]. Copyright 2020, Wiley–VCH. d Schematic illustration of the Zn deposition process on bare Zn, Zn@Ca-Mont and Zn@Zn-Mont anodes [58]. Copyright 2021, Elsevier

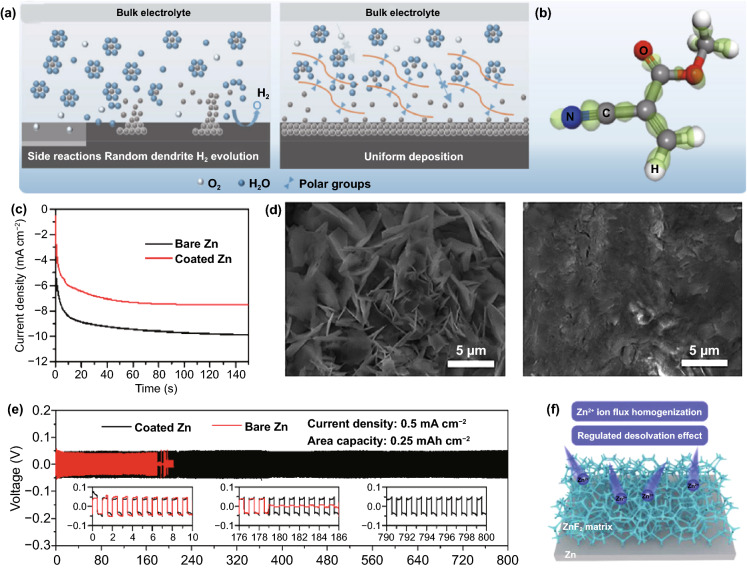

In addition to constructing intuitive confined channels to mechanically change the concentration field, many organic materials can directly and selectively manipulate the migration of Zn2+ ions to redistribute concentration field with the assistance of their specific polar groups (Fig. 4a), such as the amide group in polyamide (PA) [43], the poly(vinyl alcohol) group in poly(vinyl butyral) (PVB) [41], the carbonyl group in polyimide [49], the amide group and pyrrolidone group in polyacrylamide (PAM)/polyvinylpyrrolidone (PVP) [61], and the cyano group in cyanoacrylate [62] or polyacrylonitrile (PAN) [63]. These polar groups can donate electron pairs, which can guide coordination adsorption through strong interaction with Zn2+ ions (Fig. 4b). Due to the lower energy barrier, Zn2+ ions are transferred along the long organic chain containing polar groups, rather than freely diffused, and a large number of long chains create denser and more uniform nucleation sites for Zn deposition, which can be sensitively reflected by the variation in current versus time at a constant potential during the deposition process (Fig. 4c) [62]. At the same time, considering the electrostatic repulsion, the electronegative polar groups can block a certain amount of anion ions. It means that Zn2+ ions have a stronger driving force to gather and migrate in the modified layer than other ions or molecules. The priority and selectivity promote the rapid transfer of Zn2+ ions and the decrease in the concentration gradient, which can significantly reduce concentration polarization. As a result, stable Zn deposition and stripping can be achieved (Fig. 4d, e). Furthermore, polar groups can change the solvated structure of [Zn(H2O)6]2+ ions to lower desolvation energy. On the one hand, owing to the strong interaction between polar groups and solvated Zn2+ ions, polar groups can replace part or all of the H2O molecules; on the other hand, the N, O, and F atoms in some polar groups may fix the H2O molecules of the solvent sheath by forming hydrogen bonds, resulting in a destroyed sheath structure and reduced coordination number of Zn2+ [64–66]. The enhanced desolvation process can increase the corrosion potential and reduce the corrosion current, indicating less tendency and rate of corrosion and hydrogen evolution. In addition to organic materials, some inorganic materials can also interact strongly with Zn2+ ions, which has a similar effect on concentration field adjustment. For example, a three-dimensional (3D) interconnected ZnF2 matrix could be obtained by electrodeposition in NH4F aqueous solution [67]. Compared to bare Zn mental, the ZnF2 matrix exhibits stronger Coulomb attraction for Zn2+ ions. Coupled with the specific interconnected porous structure, the Zn2+ ion flux becomes more uniform, and the desolvation effect and transfer kinetics are enhanced (Fig. 4f). In addition, the S, O, and P atoms in ZnS, ZnO, and ZnP layers, respectively, also have strong adsorption to Zn2+ ions, which have been proven to contribute to the concentration field redistribution effect [68–70].

Fig. 4.

a Schematic diagram of the mechanism of cyanoacrylate for suppressing Zn dendrite; b The illustrations of electronic cloud distribution of cyanoacrylate monomer; c CAs of bare Zn and coated Zn at a 150 mV overpotential; d Morphology of bare Zn foil and 502-decorated Zn foil obtained from symmetric Zn cells after Zn stripping/plating for 100 cycles at 0.5 mA cm−2 for 0.25 mAh cm−2; e long-term cycling stability for the symmetrical cells at 0.5 mA cm−2 for 0.25 mAh cm−2 with the inset showing detailed voltage profile [62].

Copyright 2020, Elsevier. f Schematic illustration of the Zn@ZnF2 electrode [67]. Copyright 2020, Wiley–VCH

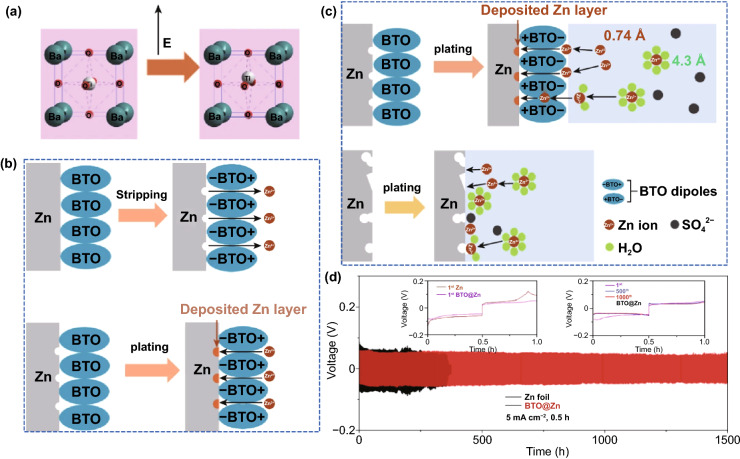

The dielectric material can respond to the external electric field in an inductive manner, producing an electric dipole moment or a change in the electric dipole moment along the direction of the electric field [71]. The directional polarization electric field of the electric dipole moment can adjust the flux of ion charge migration. Precisely, under the applied electric field, the charge in some dielectric materials can move in the microscopic range, resulting in polarization [72]. The additional electric field caused by the polarized charge can manipulate the Zn2+ ion migration. It is recently reported that perovskite-type dielectric material BaTiO3 (BTO) can be polarized by an external field [73], and the Ti ions in [TiO6]2+ deviate from the center of the symmetrical position to form an aligned electric dipole (Fig. 5a). Whether in the charging or discharging phase, the excited directional polarization electric field can induce the ordered Zn2+ ion migration (Fig. 5b). Impressively, during the plating process, the direction of the polarization electric field can be switched according to the reversal of the external electric field, which simultaneously accelerates the transfer of Zn2+ ions, repels anions, and enhances desolvation (Fig. 5c). As a result, the BTO@Zn symmetric cell exhibits decent cycling stability over 1500 h at 5 mA cm−2 with the capacity of 2.5 mAh cm−2 (Fig. 5d). Additionally, the previously reported ZrO2-modified layer can form Maxwell–Wagner polarization due to its high dielectric constant and low conductivity compared to Zn metal [74]. The polarization electric field provides controllable nucleation sites for Zn2+ ions and promotes fast ion kinetics, leading to uniform Zn deposition/stripping. Encouragingly, the types of dielectric materials are relatively abundant, which can provide more selectivity for the future design of directional polarization electric fields to redistribute concentration field.

Fig. 5.

a Schematic diagram of the Ti ion migration in the [TiO6] octahedral interstitial sites under the external electric field; b Schematic of Zn2+ ion transport during Zn stripping/plating for BTO@Zn foil; c Schematic of the mechanism of Zn2+ ion transport at the (top) BTO@Zn/electrolyte and (bottom) Zn anode/electrolyte interface during Zn plating process; d Cycling performance of the symmetric cells with Zn and BTO@Zn at 5 mA cm−2 with a capacity of 2.5 mAh cm−2. The insets reveal the detailed corresponding voltage profiles at various current densities and different cycles [73]

Redistribution of Electric Field

In addition to directly changing the flux of molecules and ions on the electrolyte side at the electrolyte/anode interface, directly regulating the electron distribution on the anode side can also manipulate the Zn deposition behavior. The redistribution of electrons can change the distribution of the electric field, mainly homogenizing the local electric field or enlarging the local electric field.

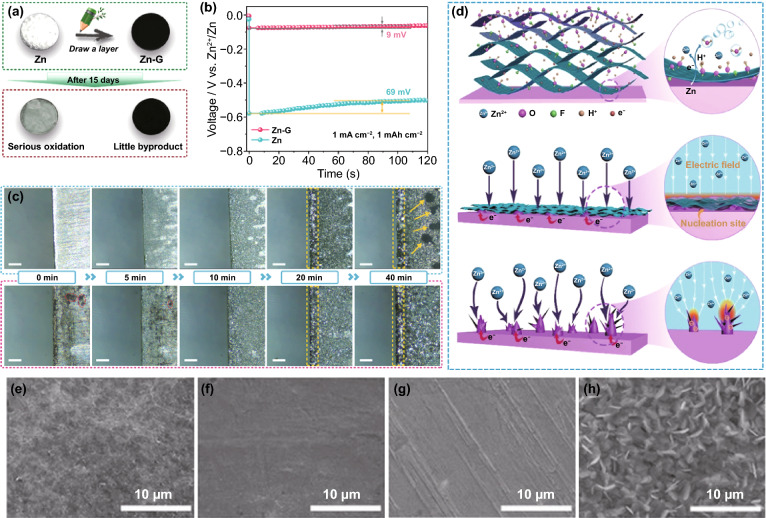

The deposition behavior of Zn2+ ions dominated by the electric field is greatly affected by the 2D diffusion around the nucleation site. According to the fundamentals of the tip effect, the uneven electric field distribution is caused by the larger local surface charge density. Therefore, the local electric field strength is closely related to the local current density. It can be known from Eq. 3 that while increasing the anode current density in pursuit of a faster battery charging rate, the local current density at the Zn deposition site should be reduced to inhibit the growth of dendrites [30]. Under the premise of a constant applied current, the modified conductive layer with a large specific surface area, such as graphene oxide (GO) [75], reduced graphene oxide (rGO) [76, 77], graphite [78], carbon nanotubes (CNT) [79], and other carbon-based materials, can distribute a part of the electronic charge of the anode, thereby having high electrochemical activity. This provides more selective nucleation sites for Zn deposition instead of converging only in the initial few hot spots for charge transfer. Thus, the local current density is significantly reduced, corresponding to a more uniform local electric field [80]. A novel and simple strategy for constructing a graphite functional interface was proposed as a proof of concept. The graphite layer was painted directly on the anode surface with the assistance of ordinary pencils (Fig. 6a) [78]. Through electrochemical tests, the nucleation overpotential (NOP) value (69 mV) of pure Zn anode was much higher than that of graphite-coated Zn anode (9 mV) (Fig. 6b). This meant that the high conductivity and large surface area of the graphite layer enabled the anode with a lower local current density, which corresponds to the characteristics of smaller Zn nuclei formation and no dendrites. This result was also proved by observing the transparent symmetrical battery through an optical microscope: Some large dendrites (dark spots marked by yellow arrows) were formed on the bare Zn surface within 40 min plating, while the graphite-coated Zn anode had a flat and smooth surface (Fig. 6c). Apart from carbon-based materials, 2D-structured MXene material with metallic conductivity as a modified layer also has a similar effect of homogenizing the local electric field (Fig. 6d) [81]. Even at the large current density, the highly conductive structure network can destroy the tip effect inside the MXene (Ti3C2Tx) layer by eliminating the uneven local electric field. Due to the lack of driving force for dendrite growth, the nucleation and growth of Zn are more uniform (Fig. 6e–h).

Fig. 6.

a Schematic illustration of the modification process and the stability in 2 M ZnSO4 electrolyte of Zn and graphite-coated Zn anode; b The voltage–time curves of Zn and Zn–G symmetric cells at 1.5 mA cm−2; c In situ optical microscope photographs of (top) Zn and (bottom) Zn–G electrodes observed by symmetric transparent cells under various deposition times [78].

Copyright 2020, Wiley–VCH. d Illustration of (top) synchronously reducing and assembling MXene layer on the Zn foil surface; Illustration of Zn plating behavior of (middle) MXene-coated Zn, and (bottom) pure Zn; SEM images of MZn-60 and pure Zn e, g before cycling, and f, h after 100 cycles at 3 mA cm−2 [81]. Copyright 2020, Wiley–VCH

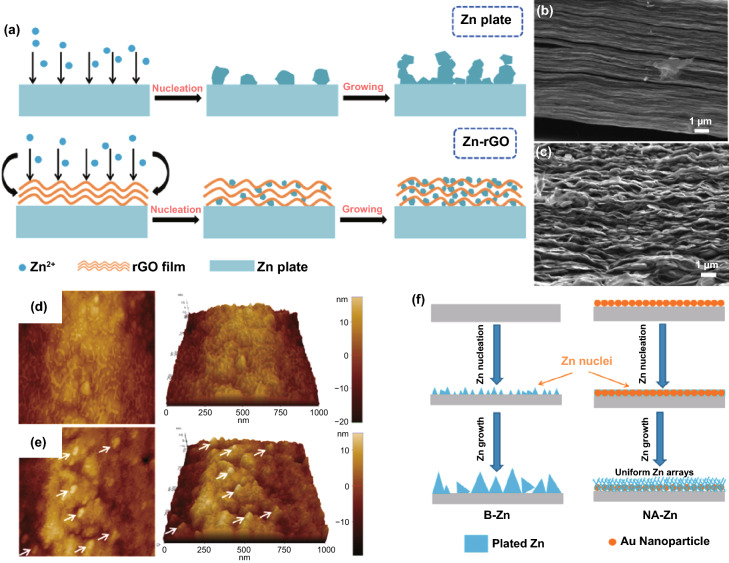

Due to the anode electron redistribution, the possible deposition sites of Zn2+ ions include the Zn metal surface, inside, and the surface of the modified conductive layer. The electrical conductivity of some modified layers is lower than that of Zn metal, and there is also generally contact resistance between them, such as ZIF-8 derived carbon [82]. Different electrical conductivity and high contact resistance result in potential change between the modified layer and Zn metal. The potential near the Zn metal surface was low (or negative) enough for Zn2+ reduction. Therefore, Zn deposition will preferentially occur at a low potential on the more conductive Zn metal surface, leading to a position-selected, bottom-up Zn deposition process [44]. However, the excellent conductive network has fast electron transfer capability for anodes modified with most carbon-based materials or MXene materials. There is almost no potential change between the modified layer and Zn metal. At a reasonable potential, Zn reduction will occur as long as it contacts the conductive network. Thus, the excellent conductive modified layer is the preferred location for Zn deposition [28]. For example, rGO with a layered structure can generate a stable electric field in which the electrolyte is fully penetrated during the plating process. The Zn2+ ions are preferentially distributed uniformly rather than aggregated; Zn is deposited on the inside and surface of the rGO layer (Fig. 7a–c) [76, 77]. It is worth noting that most of the conductive network materials are not structurally complete but have edges and defects on which Zn2+ ions will be deposited preferentially. At the same time, the Zn2+ ions transferred from the electrolyte will first contact the surface of the modified layer, suggesting that Zn deposited on the surface has a higher priority than the interior. Still, the modified layer surface cannot play the role of homogenizing the electric field. These all mean that the modified layer with a conductive network can only uniform the electric field and suppress dendrites within a certain range. Moreover, due to the increased area contact with the water in the electrolyte, the problem of side reactions at the reaction interface is still troublesome.

Fig. 7.

a Schematic illustrating the Zn plating behavior of the bare Zn and Zn/rGO anodes; cross-sectional SEM images of rGO film on Zn foil b before cycling and c after cycling [77].

Copyright 2019, Elsevier. Atomic force microscope images of d bare Zn anode and e Au-decorated Zn anode; f Schematic illustration of the Zn stripping/plating process [84]. Copyright 2019, American Chemical Society

Contrary to the strategy of homogenizing the electric field to suppress the 2D diffusion of Zn2+ ions, constructing protrusions on the metal surface to enlarge the local electric field to strengthen the 2D diffusion can also suppress dendrites, but the premise is that the protrusions are uniformly and densely distributed on the anode surface [83]. For example, a large number of Au nanoparticles (AU-NP) are constructed on the surface of Zn metal by magnetron sputtering (Fig. 7d, e) [84]. Seed crystals have high curvature and large local electric fields around them, which will preferentially become sites for Zn deposition and growth. The uniform and dense seed crystals enable the deposition of Zn2+ ions to be universal instead of growing on several loose tips on the bare Zn surface (Fig. 7f). Actually, during the Zn deposition process, the previously generated Zn nuclei also form a large local electric field to affect subsequent nucleation and growth. Therefore, adjusting the initial nucleation site is of great significance for realizing a dendrite-free anode.

Regulation of Surface Binding Energy

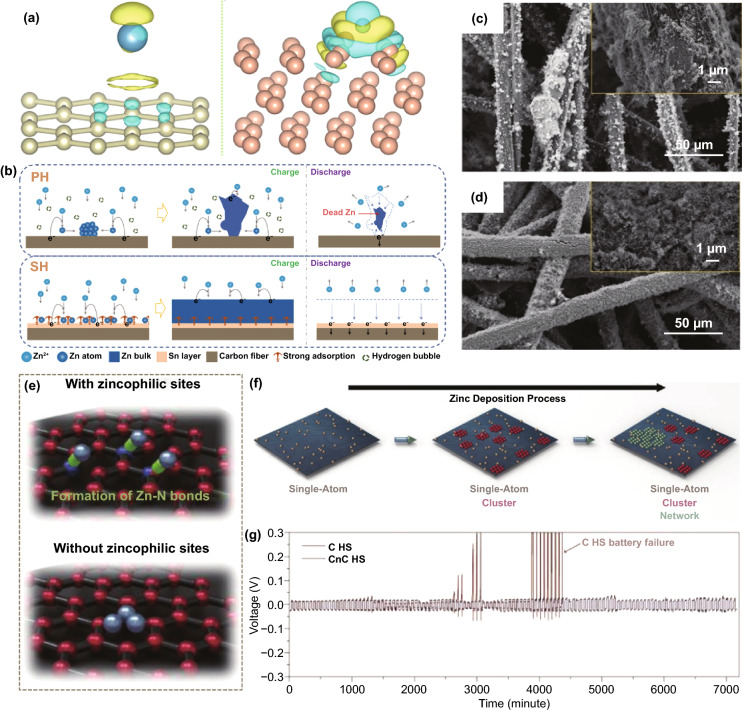

According to thermodynamics, Zn nucleation is controlled by the decrease in free energy due to phase transition and the increase in surface energy due to new interfaces. The former is the driving force for nucleation, and the latter leads to a nucleation barrier. Zn preferentially nucleates at the thermodynamically favorable adsorption sites of low energy barriers [85]. The modified material with high Zn affinity has a lower nucleation energy barrier, thus leading to a smaller nucleation overpotential, which is more conducive to Zn nucleation. The Zn affinity is evaluated by comparing the binding energy (calculated by density functional theory) of the Zn atoms attached to the modified layer and the Zn metal surface, and the larger one (more negative) has a higher Zn affinity [86]. It is reported that some metals have high Zn affinity, such as Sn, In, Ag, and Cu; they can serve as heterogeneous seeds to induce Zn nucleation and growth [87–90]. Compared with Zn metal or carbon, a well-organized Sn layer has a uniform and densely distributed zincophilic sites on the surface [87]. During the Zn nucleation process, Zn has stronger electronic interactions with these zincophilic sites (Fig. 8a), and thus, Zn preferentially nucleates uniformly at these sites. The uniformly distributed Zn nuclei also guide the subsequent uniform Zn deposition (Fig. 8b). Therefore, the zincophilic layer can significantly inhibit dendrite growth (Fig. 8c, d). Besides, it was previously proposed that the Li affinity of carbon materials can be enhanced by heteroatom doping, which can be explained by electronegativity, local dipole, and charge transfer. Similarly, the introduction of N-containing sites significantly changes the Zn affinity of graphene [50]. Widely distributed pyridine sites induce the spacious distribution of the initial Zn nuclei by forming Zn–N bonds. Lateral Zn growth leads to nearby connections to form Zn clusters, resulting in uniform Zn deposition (Fig. 8e–g).

Fig. 8.

a Interfacial charge density of (right) carbon and (left) Sn; b Schematic illustration of Zn deposition induction mechanism; SEM images of c PH and d SH after charging (inset, higher magnification) [87].

Copyright 2019, Wiley–VCH. e (top) Spacious Zn nucleation with zincophilic sites and (bottom) dense nucleation on zincophobic surface; f Schematic illustration of Zn deposition on surface with zincophilic sites; g Galvanostatic cycling performance of symmetric cells with and without zincophilic nitrogen sites [50]. Copyright 2020, Wiley–VCH

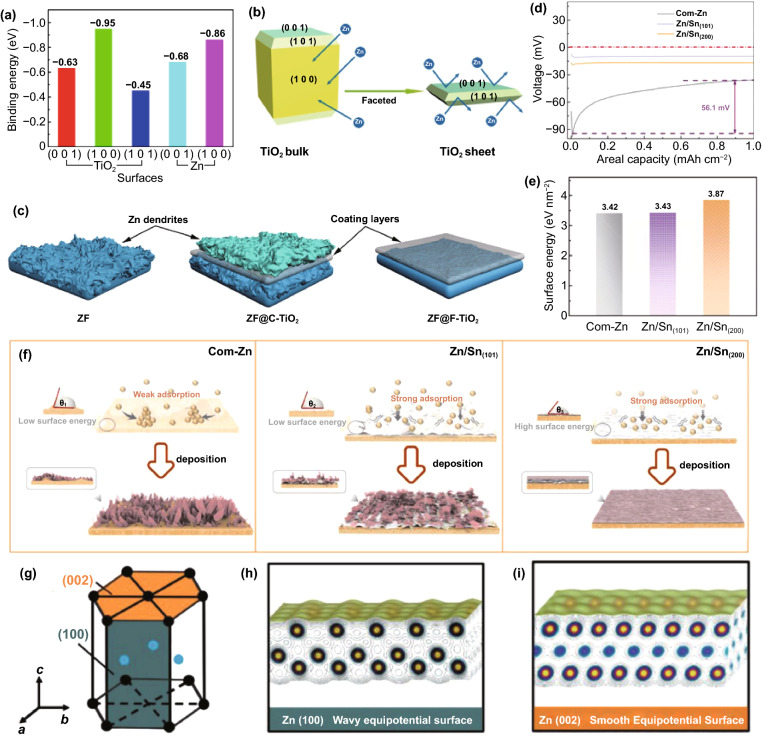

Since atoms, molecules, or ions belonging to the non-cubic crystal system have multiple crystal facets, different crystal facets have different binding energies to Zn. Thus, even in the modification layer of the same material, different exposed crystal facets have other effects on Zn nucleation. Consider as-prepared faceted TiO2 (F-TiO2) nanosheets with exposed (0 0 1) and (1 0 1) facets and commercial TiO2 (C-TiO2) with exposed (1 0 0) facets, the former with a lower Zn affinity can repel the Zn adsorption, ensuring that Zn2+ ions preferentially accumulate and nucleate on the Zn metal under the F-TiO2 nanosheets; on the contrary, the high Zn affinity of the latter leads to preferential Zn deposition on the C-TiO2 nanosheet surface (Fig. 9a, b) [86]. It is worth noting that the affinity reflects the difficulty of Zn deposition on the substrate. Providing a lower nucleation energy barrier promotes the kinetics of Zn deposition but does not necessarily change the crystal plane orientation of Zn deposition and form a Zn surface texture [91]. As the area capacity increases, it may be beyond the controllable ability of zincophilic sites to Zn deposit; Zn dendrites will still form. The restricted deposition space under the modified layer can further inhibit the large-scale dendrite growth. In contrast, the surface of the modified layer no longer has a constraining effect, and the battery is more likely to be damaged by dendrites (Fig. 9c) [86]. As a similar proof, it has recently been reported that the Sn (1 0 1) surface has a higher Zn affinity than the Sn (2 0 0) surface, and both of them are higher than commercial Zn foils (Fig. 9d). However, the Zn anode with the Sn (1 0 1) surface texture layer still exhibits rough Zn deposition morphology, while the deposition morphology on the Sn (2 0 0) surface texture layer is uniform and smooth. This is derived from the latter’s high average surface energy which may result in particularly strong capillary action, leading to better deposit “wettability” (Fig. 9e, f) [91]. According to the above analysis, the binding energy significantly influences the initial Zn nucleation behavior. At the large area capacity, the modified layer that dominates the Zn deposition with high binding energy does not necessarily play a key role in alleviating the dendrite problem or even may cause negative effects. It is worth mentioning that in the hexagonal close-packed (hcp) Zn lattice, the Zn (0 0 2) crystal surface has a smooth surface and uniform interface charge density, which is not conducive to the formation of dendrites. And such a plane with high atomic coordination has high binding energy, ensuring preferential Zn deposition at these more advantageous sites (Fig. 9g-i). During the deposition process, the surface texture of the Zn (0 0 2) planes can lead to a spontaneous reorientation of Zn crystallites and, finally, maintain the horizontal growth of the Zn (0 0 2) planes through the epitaxial mechanism. At the same time, due to the low electrochemical activity of Zn (0 0 2) planes, corrosion and H2 evolution may also be reduced [92, 93]. Therefore, adjusting the surface binding energy by constructing the modified layers and controlling their exposed crystal planes is beneficial for obtaining a stable anode interface and deeply understanding the internal mechanism of binding energy on Zn deposition.

Fig. 9.

a Calculated binding energies of Zn atom with different facets; b Schematic illustration of the interaction between Zn and anatase TiO2 with different exposed facets; c Schematic illustration of the Zn plating process with different coating layers [86]. d Voltage profiles of Zn deposition on Com–Zn, Zn/Sn (101), and Zn/Sn (200) at a current density of 1 mA cm−2 and a capacity of 1 mAh cm−2; e The calculated surface energy on different electrodes; f Schematic illustration of Zn deposition process on Com–Zn, Zn/Sn (101) and Zn/Sn (200) [91].

Copyright 2020, Wiley–VCH. g The structure of metal Zn; Surface atomic arrangement and electron equipotential plane of h Zn (100) and i Zn (002) [92]. Copyright 2021, Wiley–VCH

Structural Anode

Numerous reports have confirmed that the structural design can effectively enhance the overall performance of the ZIBs. Diversified structural design is more and more favored by subsequent research work. The modified layer strategy is mainly based on the Zn deposition of the metal anode plate, which has a limited contact area with the electrolyte. Differently, extending the contact surface to 3D space can significantly improve anode designability. Drastically increased specific surface area is the most crucial feature of structured anodes. Although this may enhance the formation of side reactions, it can effectively increase Zn nucleation sites and reduce local current density. Moreover, sufficient contact with the electrolyte and rapid charge transfer allows for lower polarization. These are conducive to obtaining a stable anode without dendrites. The reported structured anode materials, which can be roughly classified into the metallic matrix material, carbonaceous matrix material, and other matrix materials, exhibit great potential for regulating the Zn deposition behavior.

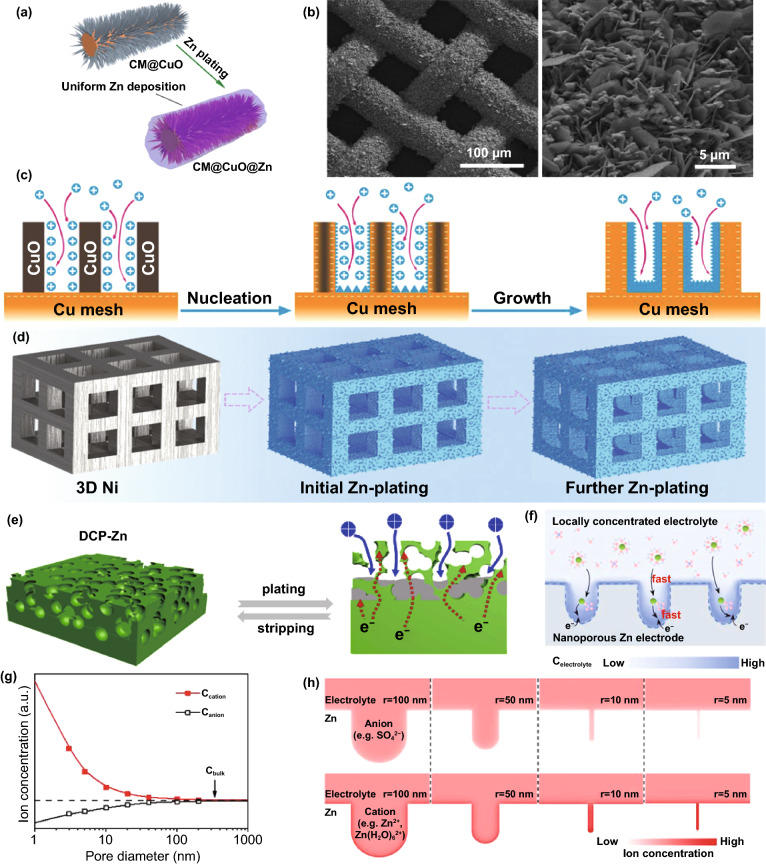

To obtain long-lifespan reversible cycle performance, the structured anode that plays a physical structural support role should have good structural stability, which puts forward high requirements for suppressing dendrites. Metal-based structured anodes, especially Cu-based materials (Cu mesh, Cu foam [94, 95], and porous Cu [96]) with excellent Zn affinity, can maintain the morphology of the structure due to their rigid properties. Zn nucleation and growth can be restricted to a specific structure through deliberate design, thereby inhibiting dendrites. Based on the unique structure and function of the Cu mesh, modifying the Cu mesh with CuO nanowires can further expand the specific surface area of the current collector and simultaneously adjust the ion distribution and electric field at the anode (Fig. 10a, b) [97]. Due to its lower nucleation energy barrier, CuO nanowires tend to selectively absorb Zn2+ ions and can be reduced to Cu nanowires to form a staggered 3D copper matrix. Zn can be uniformly deposited in the gaps of the nanowires without dendrite formation (Fig. 10c). Similarly, a 3D Ni-Zn anode with a multi-channel lattice structure was fabricated with the help of 3D printing technology (Fig. 10d) [98]. Compared with planar electrodes, 3D Ni-Zn has a larger specific surface area, which redistributes the local electric field and induces the preferential and uniform Zn deposition into the 3D microchannels, thus successfully suppressing dendrites and significantly improving the electrochemical performance of the battery. Besides, Zn itself is also designed as the main body of the 3D structure [99–101]. For example, a 3D porous Zn anode with dual channels, consisting of a continuous cavity and a conductive framework, allows ions and electrons to migrate quickly at the anode interface [99]. The unique cavity structure limits the Zn deposition position, thereby inhibiting dendrite growth (Fig. 10e). Recently, it has been proposed that nanoporous Zn electrodes (npZn) with controllable pore size can be prepared by the alloying–dealloying method. When the pore size is small enough (< 40 nm), the space charge will significantly affect the effective ion concentration of the electrolyte in the pore. Cations (Zn2+) are enriched, and anions are reduced so that interface-localized concentrated electrolytes can be achieved (Fig. 10f–h). Zn anode with a nanoporous structure can promote the uniform Zn plating and suppress side reactions [100].

Fig. 10.

a Schematic illustrations of CM@CuO@Zn; b SEM images of Zn anode using reduced CM@CuO as the host with the capacity of 5 mAh cm−2; c Schematic illustrations of the process of Zn deposition on CM@CuO and CM [97].

Copyright 2020, Wiley–VCH. d Schematic illustration of Zn deposition on the 3D Ni [98]. Copyright 2020, Wiley–VCH. e Stripping/plating performance of DCP-Zn-30 and pristine Zn foil cells with 0.1 mAh cm−2 cutoff capacity at 3–10 mA cm−2 [99]. Copyright 2020, Elsevier. f Nanoporous Zn electrode with interface-localized concentrated electrolyte; g The ion concentration at the electric double layer of nanoporous Zn metal with different pore diameters; h Surface charge densities of the cations and anions at the interface of ZnSO4 electrolyte and nanoporous Zn metal with different pore diameters ranging from 5 to 100 nm [100]. Copyright 2021, Elsevier

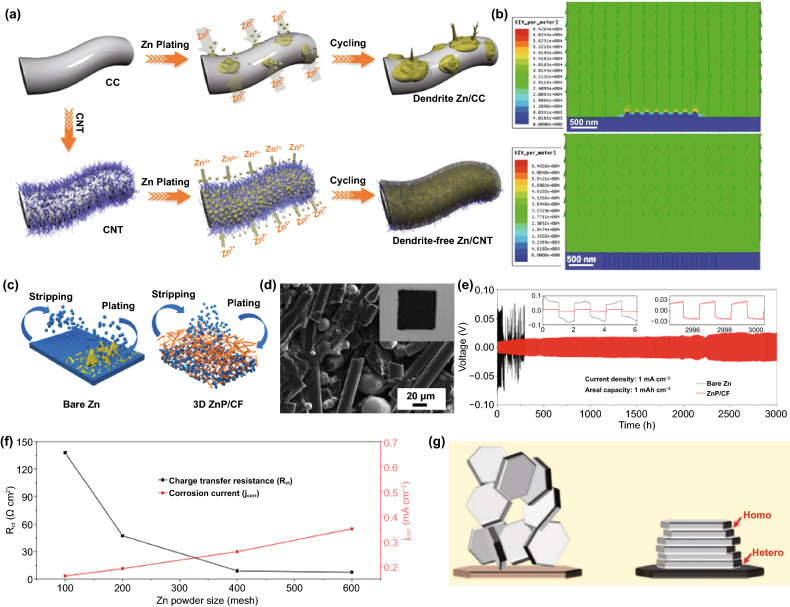

Besides, the carbonaceous matrix materials have an open 3D skeleton structure; their mechanical flexibility can sufficiently cope with the change in anode volume during cycling, particularly adaptable to shapeable anodes applied to flexible and wearable electronic devices, such as fiber-shaped Zn-ion micro-batteries [102, 103]. Up to now, several excellent research works have developed multiple carbon-based structure anodes, mainly based on highly conductive carbon fiber matrix, including carbon cloth [104], graphite felt [105], carbon nanotubes [106], etc. Impressively, the application of flexible 3D carbon nanotubes (CNT) scaffold on Zn anode has attracted much attention (Fig. 11a) [106]. The interconnected CNT formed on the carbon fiber cloth can successfully lower the energy barrier of Zn nucleation, and the uniform electric field distribution ensures the reversible plating/stripping of the dendrite-free anode (Fig. 11b). Generally, Zn on a carbon-based host is formed in situ in advance by many methods, such as electrodeposition or vapor deposition. Recently, by using a vacuum filtration process, active Zn powder can also be compounded on the carbon network to form a 3D porous Zn anode (Fig. 11c) [107]. It can be understood that point-to-point contact between Zn powder particles may form a vulnerable conductive network. During the Zn stripping process, owing to the short electron pathway, the contact points are likely to be dissolved first, and the Zn powder particles will easily lose contact with the electrode matrix and cause Zn death [108]. However, the carbon fiber skeleton can act as a binder to firmly bond the Zn powder, which can effectively reduce the capacity loss caused by Zn dissolution (Fig. 11d). Although not as large as the specific surface area of nanoscale Zn by in situ nucleation and growth, a large number of micron-scale pores between powder particles or carbon fiber skeletons in the electrode provide enough space for Zn deposition and dendrite growth, resulting in stable anode performance (Fig. 11e). The adjustable surface area of Zn powder has practical significance for commercial production. It is worth beware that the Zn charge transfer resistance decreases with the particle size of the Zn powder, implying that the smaller particle size Zn powder has a higher reactivity. Still, at the same time, it is accompanied by enhanced hydrogen evolution and corrosion reaction (Fig. 11f). Thus, the Zn powder particle size in the carbon fiber framework should be designed reasonably. Additionally, it has been reported that a similar atomic arrangement between graphene and Zn metal results in low lattice mismatch [109]. During the deposition process, Zn2+ ions will heteroepitaxially nucleate along the graphene crystal plane and grow in a strain-free state, and then Zn2+ ions continue to deposit homogeneously epitaxially on the newly formed Zn metal layer (Fig. 11g). This Zn deposition pattern that locks the crystal orientation relationship can fundamentally eliminate the growth of dendrites. The reversibility of the epitaxial Zn anode guided by the graphene substrate is greatly improved, and the CE still exceeds 99% even after 1000 cycles. Although there is a lack of strong evidence to prove that the Zn deposits on graphene sheets are oriented, this method of manipulating the anode host to control the preferential Zn deposition direction deserves further study [110].

Fig. 11.

a Schematic illustrations of Zn deposition on CC and CNT electrodes; b Models of the electric field distributions for a Zn/CC electrode (top) and a Zn/CNT electrode (bottom) after Zn nuclei formation [106].

Copyright 2019, Wiley–VCH. c Schematic diagrams of the Zn growth mechanisms on different anode structures; d SEM image of ZnP/CF composite electrode. Inset shows the optical pictures of ZnP/CF composite electrode; e Voltage profiles of the symmetric cells using Zn foil electrode and 3D ZnP/CF electrode at the current density of 1 mA cm−2 and 1 mAh cm−2; f Plots of the charge transfer resistance and the corrosion current with different particle sizes [107]. Copyright 2020, Elsevier. g Scheme illustrating the design principle of epitaxial metal electrodeposition [109]. Copyright 2019, American Association for the Advancement of Science

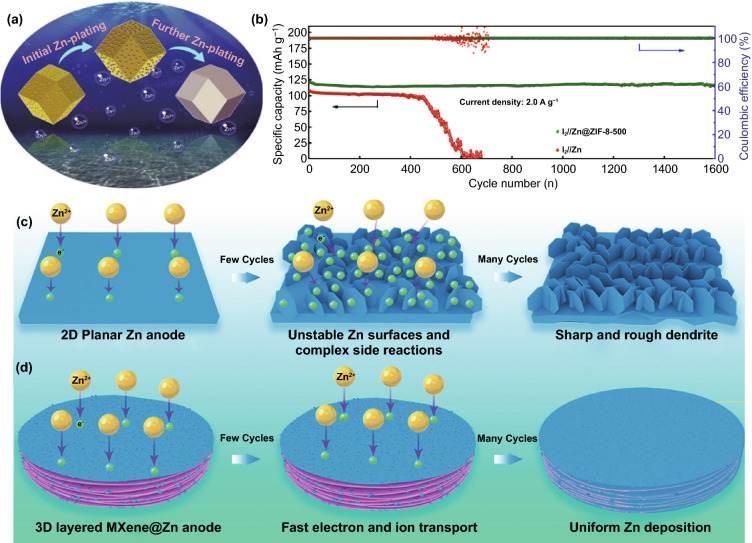

In addition to metal-based and carbon-based anode hosts, there are other types of anode hosts, such as MOF-derived material [111]: ZIF-8–500, formed by annealing treatment at 500 °C and then undergoing a thermal reduction (Fig. 12a). On the one hand, the trace amount of Zn0 in the porous framework can serve as a uniform nucleus for subsequent Zn deposition, thus alleviating the problem of Zn dendrite growth. On the other hand, the high HER overpotential can effectively slow down water decomposition. With the assistance of ZIF-8–500, the CE of the anode was close to 100%, and the Zn iodine rechargeable battery exhibited a long life of 1,600 cycles (Fig. 12b). Moreover, due to the unique layered structure and high conductivity, MXene is a suitable material for the anode host. Ti3C2Tx MXene was proven to have the effect of regulating Zn deposition behavior (Fig. 12c, d) [112]. The increased specific surface area and enhanced hydrophilicity can ensure low current density and high ion mobility, so no Zn dendrites are observed after long charge–discharge cycles. It can be investigated that the layered structure of MXene can introduce a variety of zincophilic and chemically inert seed crystals as Zn nucleation sites to induce more uniform Zn deposition, which has been similarly reported in the modification of Li metal-containing batteries [113, 114]. Recently, it was reported that MXene paper was modified with antimony (Sb) to be used as a Zn anode host. Benefiting from zincophilic Sb seeds and MXene architecture, stable battery performance can be achieved. Similarly, Cu or Ni can replace Sb as a seed crystal to modify MXene paper [115].

Fig. 12.

a Schematic illustration of the Zn plating on the ZIF-8–500 electrode; b Electrochemical performances of the I2//Zn@ZIF-8–500 full cell at a current density of 2.0 A g−1 [111].

Copyright 2019, Elsevier. Schematic of morphology evolution for c bare Zn and d Ti3C2Tx MXene@Zn anode during the stripping/plating process [112]. Copyright 2019, American Chemical Society

Alloying Anode

Alloy refers to mixing metal with other metals or nonmetals to obtain a material with metallic properties. Zn can be fused with various elements to form Zn-based alloys, classified into binary alloys, ternary alloys, and multi-element alloys according to the number of their components. In addition to Ga–In–Zn [116, 117] and Zn–Sn–Pb [118] alloys, the Zn alloys currently reported on mild aqueous Zn anodes are mainly binary alloys, such as Cu–Zn [89, 119, 120], Ag–Zn [89, 121–123], Zn–Al [124], Zn–Mn [125], Zn–Sb [115], and Zn-P [69]. The interaction between alloy components will form an alloy phase with a specific structure and composition, which can be divided into solid solution and intermetallic compound [126]. Even though the component species are the same, the alloy properties may differ due to different alloy phases formed. This greatly enriches the categories of alloys with other properties. The electrochemical alloying reaction of Zn includes a restructuring reaction and solid solution reaction [127]. Compared with the former, the latter does not require a significant phase change, resulting in less demand for additional activation energy, which means lower charge/discharge voltage hysteresis. Instead of standard Zn stripping/plating on the metal foil surface, the dealloying/alloying reactions involved in the solid solution reaction should be the mechanism that indicates the inward-transfer and reversible extraction of Zn atoms in the Zn alloy [128]. Therefore, based on the stable solution reaction, the Zn alloy anode with different alloy phases can significantly enhance the battery performance.

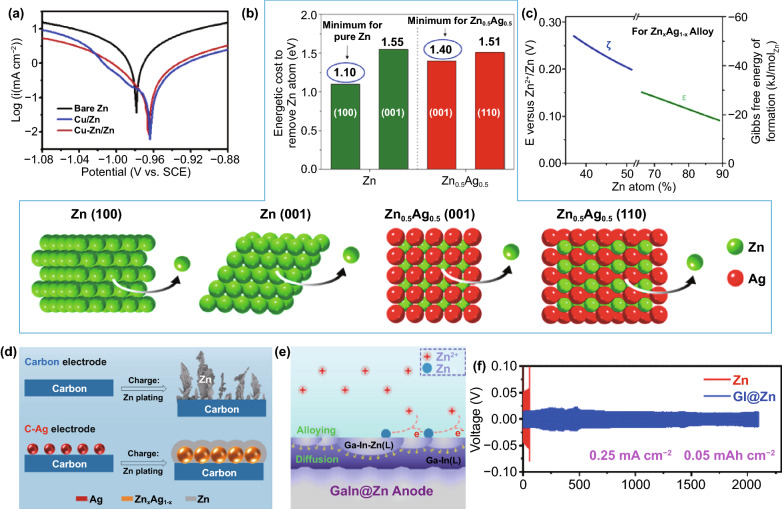

The addition of electrochemically inert metals not only changes the physical properties but also enhances electrochemical performance. Reviewing the Zn alloy anode, Cu and Ag species can improve the corrosion resistance of Zn alloys, and the corrosion potential is close to that of the pure metal introduced (Fig. 13a) [18]. However, this conclusion is affected by many factors, such as element ratio, microstructure, and the alloy phase, making it difficult to explain the detailed corrosion resistance mechanism [18, 24]. A relatively simple strategy has been proposed that the enhanced corrosion resistance of alloys can be analyzed from the perspective of energy supported by DFT (Fig. 13b) [121]. Comparing the minimum energy cost of removing Zn atoms from pure Zn and Zn0.5Ag0.5, 1.10 eV for pure Zn with 100 crystal plane is lower than 1.40 eV for Zn0.5Ag0.5 with a 001 crystal plane, implying that the Zn atoms in Zn0.5Ag0.5 have lower reactivity. The more energy cost for Zn stripping from the ZnxAg1−x alloy corresponds to a higher redox potential (Fig. 13c); thus, the ZnxAg1−x alloy has better corrosion resistance. Similarly, the alloy’s suppression strategy for dendrites can also be analyzed from the nucleation energy. Compared with pure Zn metal, ZnxAg1−x alloys have a lower nucleation energy barrier (Fig. 13c). This indicates that after Zn is reduced, it will spontaneously form an alloy phase with Ag lattice through solid solution reaction, rather than accumulating at sites containing only Zn species (Fig. 13d) [89, 121, 122]. However, excessive Zn deposition will still form a Zn layer on the alloy surface, inducing dendrite growth. Differently, liquid alloys have high fluidity and deformability and can avoid the formation of dendrites through a self-healing mechanism [116, 117]. The high Zn affinity of liquid Ga–In alloy enables the preferential formation of Ga–In–Zn ternary alloy (Fig. 13e). When the Zn species in the alloy reaches saturation, excess Zn spontaneously accumulates under the alloy layer instead of on the surface. Thus, the alloy surface can be maintained smooth, and dendrites cannot be formed on the alloy surface. Collaborating with the high HER overpotential of the alloy and the low impedance of the liquid–liquid interface, the symmetrical battery assembled by the gain anode can be cycled stably for 2000 h with a capacity of 0.05 mAh cm−2 at a current density of 0.25 mA cm−2 (Fig. 13f).

Fig. 13.

a Linear polarization curve of Cu/Zn and Cu–Zn/Zn electrode in 3 M ZnSO4 electrolyte [119].

Copyright 2020, Elsevier. b DFT simulation results showing the energetic cost of removing a Zn atom from the pure Zn metal and Zn0.5Ag0.5 alloy. Constructed models: Zn with 001 and 100 surfaces; Zn0.5Ag0.5 with 110 and 001 surfaces; c Calculated Gibbs free energy of formation at room temperature of Zn, ζ- and ε-ZnxAg1−x alloy phases and the corresponding electrochemical potential shift of Zn2+/ZnxAg1−x compared with that of Zn2+/Zn. d Schematic of Zn deposition on the (top) carbon paper substrate and (bottom) carbon paper slurry coated with Ag nanoparticles [121]. Copyright 2021, American Chemical Society. e Dendrite-free GaIn@Zn anode by alloying–diffusion synergistic strategy; f Voltage profiles of symmetric cells using bare Zn foil and GaIn@Zn at a current density of 0.25 mA cm−2 [116]. Copyright 2021, American Chemical Society

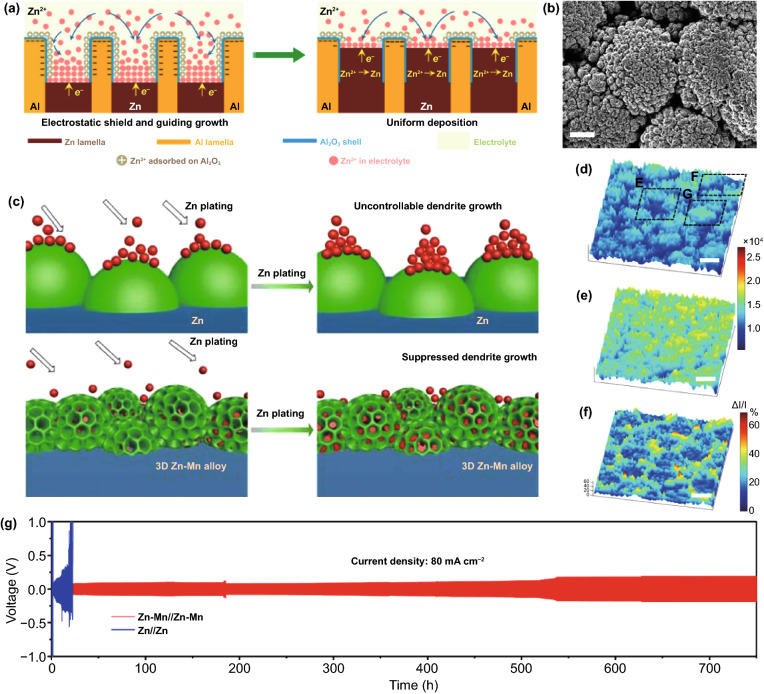

Based on the above analysis, it can be concluded that the alloy mainly suppresses side reactions and dendrite growth by increasing the HER overpotential and reducing the nucleation energy barrier. However, Zn alloys with more active metals than Zn may suffer from the competitive reaction of metal species and corrosion problems, which means that other compensable properties are needed to serve stable Zn anode. It has been proposed that the eutectic Zn88Al12 alloy with alternating Al and Zn layers can induce uniform Zn deposition by spontaneously constructing an insulating frame, which can be detailed from the two stages of Zn stripping and plating (Fig. 14a) [124]. In the initial stripping stage, since the standard equilibrium potential of Al3+/Al (−1.66 V) is lower than that of Zn2+/Zn, Al will react in preference to Zn and be converted to Al2O3. Subsequently, the dense and insulating Al2O3 passivation layer protects the anode from further oxidation so that the Al–Zn alloy anode can maintain stability. During the plating process, the positive electrostatic shielding layer formed around the plate prevents the Zn nucleation on the surface of Al2O3, thereby guiding Zn deposition in the correct position.

Fig. 14.

a Schematic illustrations of eutectic Al–Zn for uniform Zn deposition [124]. b SEM image of Zn–Mn alloy; c Schematic illustration of Zn plating processes on Zn anode and Zn–Mn anode; The images of 3D Zn–Mn alloy by in situ optical microscope before d and after e Zn plating, f was calculated by (d–e)/e = (ΔI/I); g Long-term galvanostatic cycling performance of symmetric Zn–Mn and pristine Zn cells at a current density of 80 mA cm−2 (areal capacity, 16 mAh cm−2; electrolyte, 2 M ZnSO4 in seawater) [125]

It is worth noting that the alloy preparation approaches in the laboratory mainly involve electrodeposition and chemical replacement [126], which results in a relatively single appearance of the alloy. Different microstructures of alloys containing the same element species have other effects on anode performance. By developing a reasonable preparation process, the alloy can be designed into a favorable structure to further enhance the performance of the anode. Impressively, a co-electrodeposition process of various ions has been proposed. The evolution of H2 bubbles at the solid–liquid interface can lead to the formation of a 3D anode structure [125]. Applying this strategy, the cauliflower-like 3D Zn3Mn alloy can be obtained in the solution containing Zn2+ and Mn2+ ions (Fig. 14b) [125]. The porous morphology with a large specific surface area promotes effective Zn2+ ion migration. Additionally, due to the relatively high binding energy on the alloy surface, Zn nucleation and growth are induced and regulated (Fig. 14c). During the Zn deposition process, the deposition rate in the trenches is much larger than that in the protruding area, which minimizes the formation of dendrites (Fig. 14d–f). Benefiting from these advantages, the Zn3Mn alloy anode has ultra-high reversibility. Even in the seawater-based electrolyte, despite the interference of various impurity ions, it still shows high stability and reliability (Fig. 14g). Note that this co-electrodeposition strategy can be extended to other alloy systems by adjusting the composition of the deposition solution, the applied deposition current or voltage, and the deposition time. Therefore, it is recommended that while introducing more element species to the alloy anode, the alloy structure can be designed by developing the alloy preparation process.

Intercalation Anode

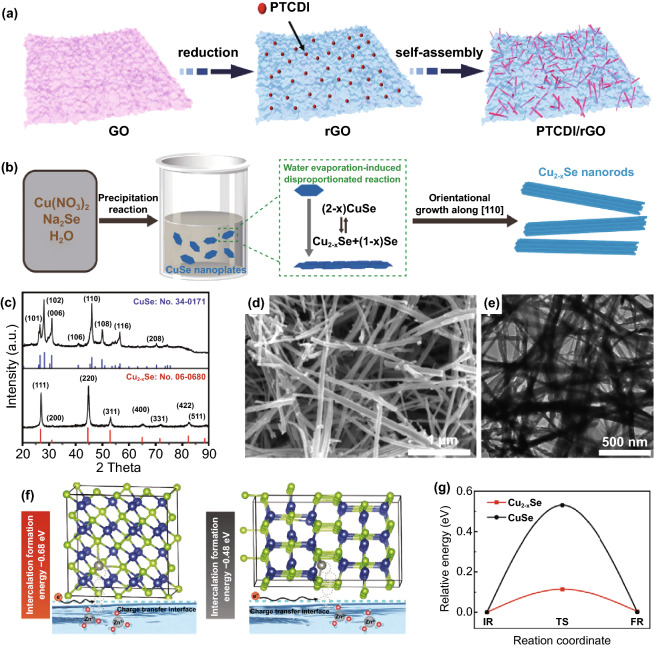

The successful application of intercalated anodes in lithium batteries has attracted more and more attention. Unlike the direct deposition/stripping of charged ions on the conventional metal anode, the lithium ions participate in battery storage and release of energy through intercalation/deintercalation on intercalation anodes [129]. Since there is no metal electrode, dendrite growth and corrosion are eliminated. This unique anode structure and its working mechanism have also inspired people to explore the application of intercalation anodes in mild aqueous ZIBs. However, there are few reports on intercalated Zn anodes, and the properties of the proposed materials are generally unsatisfactory. Due to the lack of high-performance materials and the ambiguity of the Zn storage mechanism, low energy density is one of the biggest challenges of intercalation anodes. The intercalation electrode materials that have been reported are mainly collected in Chevrel phases, transition metal oxides or sulfides, complex transition metal compounds, organic compounds, etc. [130]. There have been some reviews detailing the development of intercalation electrodes in mild aqueous electrolytes. Based on this status quo, recently, a high-rate intercalation anode (PTCDI/rGO) could be obtained by hybridizing perylene-3,4,9,10-tetracarboxylic diimide (PTCDI) and reduced graphene oxide (rGO) (Fig. 15a) [131]. During the charge and discharge, the PTCDI organic electrode provides high electron mobility and prevents the dissolution of discharge products. Besides, the porous structure caused by rGO maintains a wide range of active sites and ion diffusion paths. In addition, Yang et al. [132] proposed mixed-valence Cu2-xSe as an intercalation anode to solve the problems of Zn dendrite growth and electrolyte decomposition (Fig. 15b-e). Stable material structure, abundant cation sites, and high conductivity ensure the rapid insertion and extraction of Zn2+ ions. The low-valence copper in the electrode material is not only conducive to the generation of suitable intercalation formation energy (Fig. 15f) but also can reduce the Zn2+ ion diffusion barrier (Fig. 15g). Low-valence copper can regulate the active sites of Zn2+ ion storage and optimize the electronic interaction between active sites and intercalated Zn2+ ions. When matched with ZnxMnO2, the full battery exhibited an extremely long cycle life of over 20,000 cycles at 2 A g−1.

Fig. 15.

a Schematic illustration of preparing the PTCDI/rGO composite [131]. b Schematic illustration of the formation of the Cu2−xSe nanorods; c XRD patterns of Cu2−xSe and CuSe; SEM d and TEM e images of the Cu2−xSe nanorods; f Charge transfer process at the reaction interface and intercalation formation energy of Cu2−xSe (right) and CuSe (left); g Diffusion barrier of Zn2+ ion in Cu2−xSe and CuSe [132].

Copyright 2020, Wiley–VCH

Liquid Electrolyte

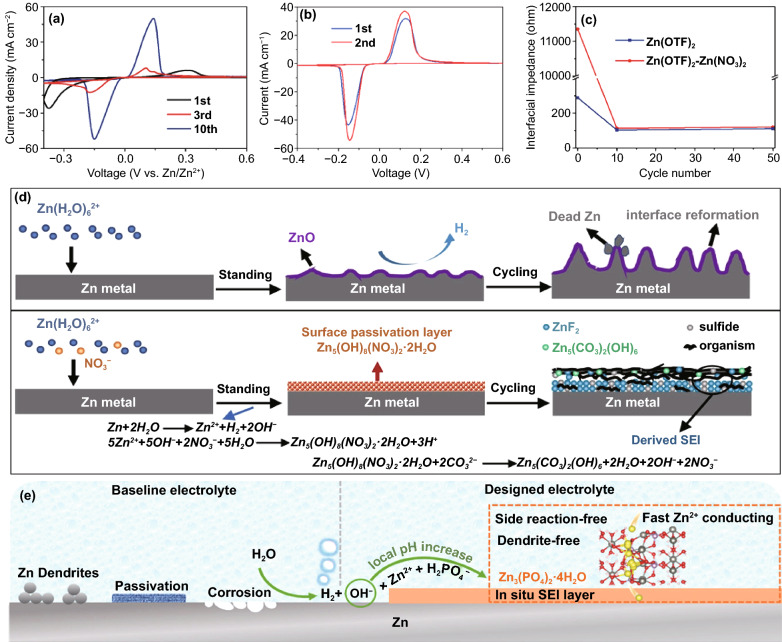

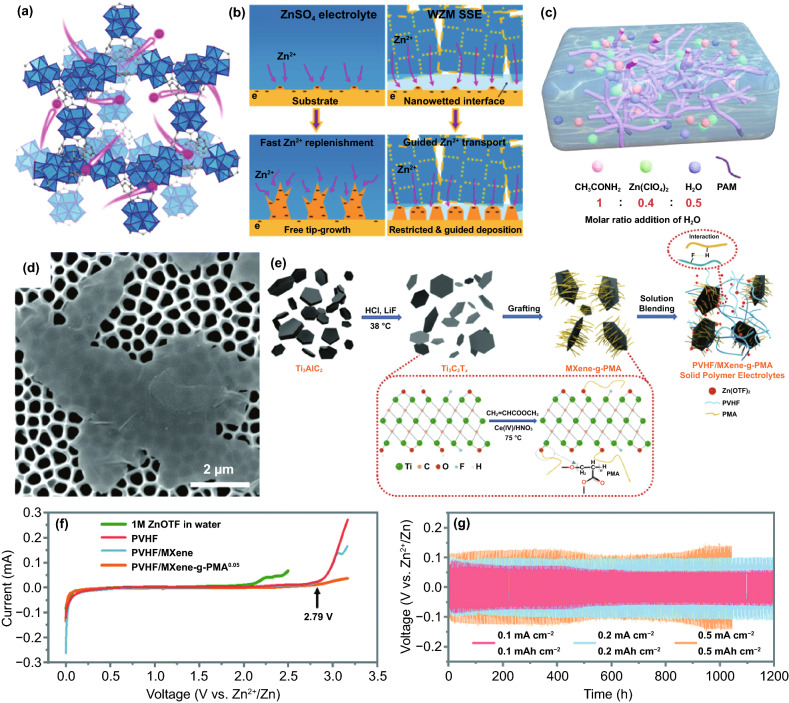

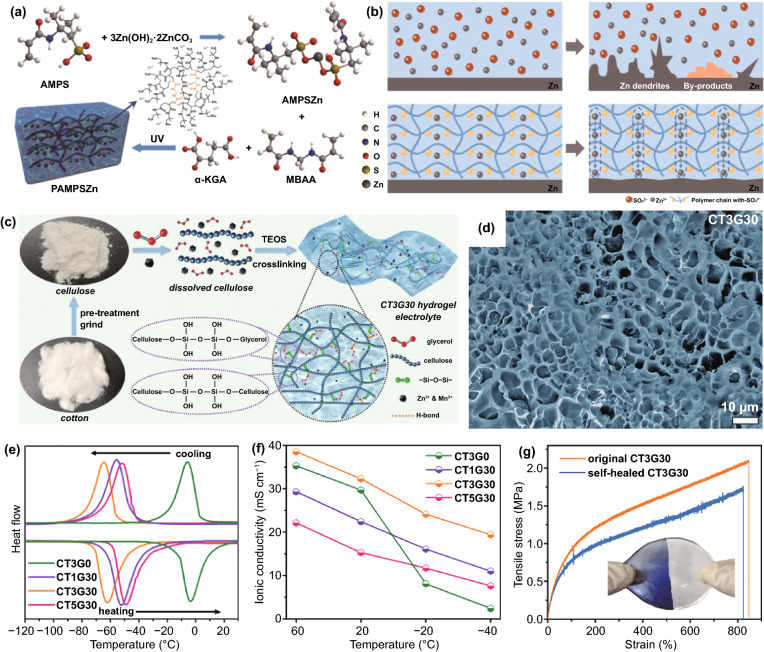

As the medium for conducting ions between the anode and cathode, the liquid aqueous electrolyte profoundly affects anode performance in mild aqueous ZIBs. A variety of modified liquid electrolytes have been proposed, which reflect different anode control strategies. This section mainly discusses the regulation strategies of liquid electrolytes on Zn deposition behavior, including weakening of solvation effect, suppression of 2D diffusion, formation of electrostatic shielding layer, and formation of in situ SEI layer.

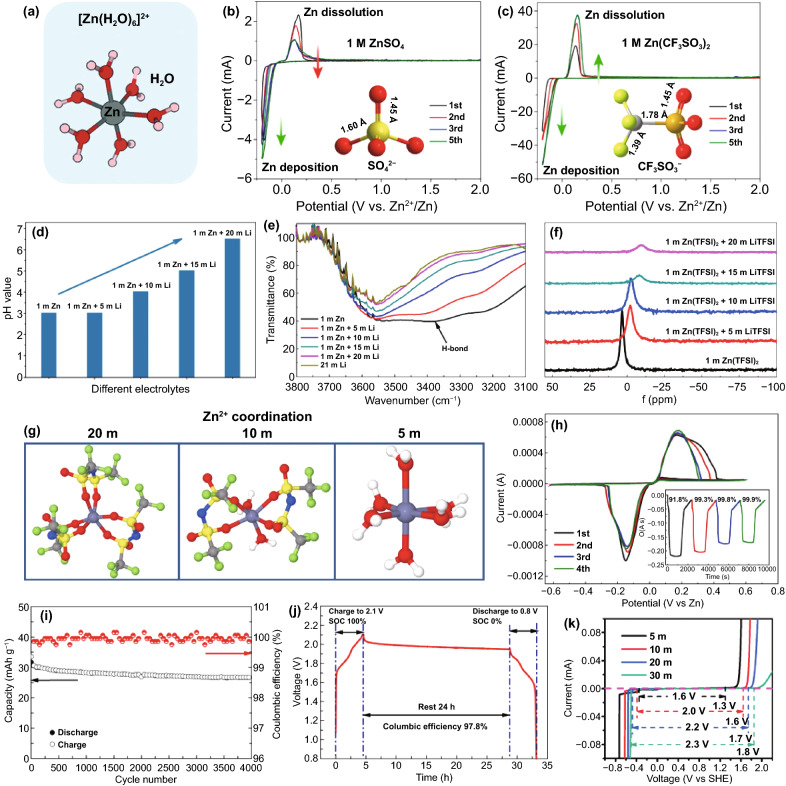

Weakening of Solvation Effect

As mentioned above, in a mild electrolyte, Zn2+ ions can cooperate with water molecules to form [Zn(H2O)6]2+ with a sheath structure, the bulky solvation structure is not conducive to the migration and deposition of Zn2+ ions, resulting in reduced battery performance (Fig. 16a). It is necessary to reduce the degree of solvation. There are various influencing factors that affect the solvation structure of Zn2+ ion in liquid aqueous electrolyte, such as species of anion salt, electrolyte concentration, and additives.

Fig. 16.

a Coordination environment of Zn2+ in water [54].

Copyright 2020, Wiley–VCH. Cyclic voltammograms of Zn electrode in aqueous electrolyte of b 1 M Zn(CF3SO3)2 and c 1 M ZnSO4 at the scan rate of 0.5 mV s−1 between − 0.2 and 2.0 V [133]. Copyright 2016, American Chemical Society. d The pH values of the electrolytes with varying LiTFSI concentrations; e The progression of FTIR spectra with salt concentration between 3,800 and 3,100 cm−1; f The change with salt concentration of chemical shifts for 17O nuclei in solvent (water); g Representative Zn2+ solvation structures in the electrolytes with 1 M Zn(TFSI)2 and three concentrations of LiTFSI (5, 10, and 20 M); h Cyclic voltammogram of Zn plating/stripping in a three-electrode cell using a Pt disk (2 mm in diameter) as the working and Zn as the reference and counter electrodes at a scan rate of 1 mV s−1. Inset: chronocoulometry curves; i Cycling stability and CE of the Zn/LiMn2O4 full cell in HCZE at 4 C rates; j Storage performance evaluated by resting for 24 h at 100% state of charge (SOC) after ten cycles at 0.2 C, followed by full discharging [134]. Copyright 2018, Springer Nature. k Electrochemical stability window of the ZnCl2 electrolyte at different concentrations [135]. Copyright 2018, Royal Society of Chemistry

Generally, in Zn salt electrolytes, anions may affect the solvation process of Zn2+ ions. The commonly reported anion salt species currently mainly involve SO42−, CF3SO3−, TFSI−, CH3COO−, NO3−, Cl−, etc. [52]. Although the most widely used SO42− anion has a stable structure and excellent compatibility with Zn anodes, it cannot effectively alleviate the solvation effect, which has become resistant to further development. It has been reported that in the Zn(CF3SO3)2 electrolyte, the bulky CF3SO3− anions with a single charge can reduce the number of water molecules in the solvent sheath around the Zn2+ ion, and the desolvated Zn2+ ion can achieve faster transfer, thereby increasing the Zn2+ ion migration and charge transfer rate (Fig. 16b, c) [133]. Therefore, a battery with a reduced solvation effect can be obtained by rationally selecting the anion species of the electrolyte.

Increasing the salt concentration in the electrolyte to reduce the contact chance of Zn2+ ions with the surrounding water seems to solve this problem effectively. As a proof of concept, Wang et al. [134] found that as the concentration of LiTFSI increases, the pH of the electrolyte gradually increases and finally stabilizes at about 7, which meant that the interaction between water and Zn2+ ions was inhibited (Fig. 16d). According to Fourier transform infrared (FTIR) spectra (Fig. 16e), the 3414 cm−1 peak, which reflected the hydrogen bond, disappeared completely at a salt concentration of 10 M, indicating that the hydrogen bond network in the water had been extensively destroyed. This phenomenon had also been confirmed in NMR (nuclear magnetic resonance) spectra (Fig. 16f). Based on molecular dynamics (MD) simulation, it could be recognized that ultra-high-concentration electrolytes containing 1 M Zn(TFSI)2 and 20 M LiTFSI completely changed the coordination environment of Zn2+ ions, in which Zn2+ ions only coordinated with TFSI−, while water molecules were surrounded by TFSI− (Fig. 16g). At the same time, the high concentration of electrolytes reduces water activity and water-induced side reactions. Hydrogen evolution and corrosion were dramatically suppressed by eliminating the step of desolvation and blocking the contact of water with the anode interface. The assembled battery not only exhibited high CE in the electrochemical test but also had a high-capacity retention rate during storage (97.8% after 24 h) (Fig. 16h–j). Similarly, Zhang et al. [135] did not observe the formation of anode by-products in the “water-in-salt” electrolyte with 30 M ZnCl2, in which the solvated structure will be converted to [ZnCl4]2−. The electrochemical stability window of the ZnCl2 electrolyte was widened along with the decrease in the hydrogen evolution potential due to the increase in concentration, which improved the CE of Zn plating/stripping as well (Fig. 16k). However, in addition to the increasing cost and reducing battery energy density, the electrolyte with an excessively high concentration exposes the characteristics of high viscosity, poor wettability, and low ionic conductivity, which limits the commercial development of Zn2+ ion batteries. Nevertheless, this strategy of applying high-concentration electrolytes still has a great practical effect. For example, appropriately increasing the electrolyte concentration is beneficial to the improvement in battery performance. We need to explore the appropriate concentration of electrolytes to achieve the optimization of comprehensive benefits.