Abstract

Background/purpose

The efficient rapid sintering technique has employed to dental zirconia ceramics for shortening the fabrication time of zirconia restorations. The purpose was to compare the optical properties of two generations of rapid sintered translucent zirconia using two dental colorimeters.

Materials and methods

Two generations of translucent zirconia ceramics, 3 mol% yttria-tetragonal zirconia polycrystal (3Y-TZP): Copran Zr-i Ultra-T (UT) and Cercon HT (HT), and 5 mol% yttria-tetragonal zirconia polycrystal (5Y-TZP): Cercon xt (XT), of different thicknesses (0.5, 0.8, and 1.2 mm; n = 5) underwent rapid sintering (RS) or conventional sintering (CS). The CIELAB values were measured on the white and black backgrounds, respectively, by digital colorimeters, shadepilot, DeguDent (DD) and Easyshade V, Vita (Vita). Translucency parameter (TP), color difference (ΔE), surface morphology, and surface roughness were evaluated.

Results

RS resulted in reduced lightness, except in the XT group. The chromaticity increased slightly after RS. Translucency decreased with increasing material thickness. ΔE values differed between both sintering processes but were clinically acceptable (ΔE < 5). Grain size of XT decreased after RS. RS did not affect the surface roughness.

Conclusion

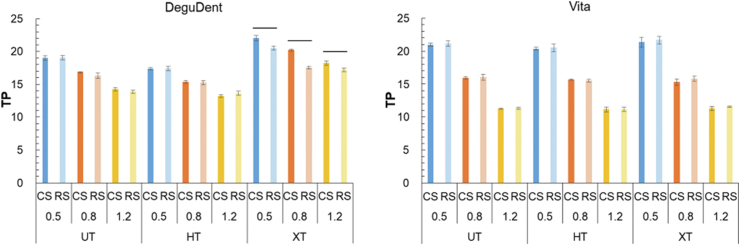

RS is a feasible method for shortening the manufacturing time of zirconia restorations. A significant difference in TP value was only in the XT group between both sintering methods as measured on DD. Color differences in rapid sintered translucent zirconia materials are imperceptible and acceptable. The specimen thickness affected more in the TP values of Vita than DD. DD has higher sensitivity to translucency and color compared with Vita.

Keywords: Zirconia ceramics, Rapid sintering, Translucency, Color difference, Colorimeter

Introduction

Zirconia ceramics have evolved in terms of esthetics, mechanical strength, chemical stability, and biocompatibility, and have gradually replaced metal alloys in dentistry.1 The classification of zirconia ceramics is commonly based on the number of stabilizers, such as yttrium oxide. Yttria-tetragonal zirconia polycrystal (Y-TZP) enhances fracture the strength and toughness due to the tetragonal-to-monoclinic phase transition characteristics.2 The general 3 mol% yttria-stabilized tetragonal zirconia polycrystal (3Y-TZP) with 5 wt% yttria, also called “high-strength zirconia,” is commonly used as a framework material for veneering porcelain as its opacity is an esthetic disadvantage.3 The translucency of 3YTZP improves when there is a decrease in alumina content, also called “high translucency zirconia,” or an increase in the yttria content. As such, 5 mol% yttria-stabilized tetragonal zirconia polycrystal (5Y-TZP) with 9 wt% yttria is referred to as “extra translucent zirconia.”4, 5, 6 The new generations of translucent zirconia are versatile and can be used for various restorations, such as esthetic anterior restorations and monolithic crown.2,7, 8, 9

Conventional sintering (CS) is a time-consuming step that requires more than 7 h with a slow heating rate and a long dwell time at high temperatures. The rapid sintering (RS) technique has resulted in better efficiency, which employs an oven with rapid heating and cooling rates to densify the zirconia ceramics in 2 h. The introduction of rapid sintered zirconia ceramics has gained the attention of dental researchers.10, 11, 12 The light transmittance of zirconia ceramics is related to their structure, as well as their grain size,2,13 density,14 and crystal phase.15,16 It has been reported that transmittance and grain size of zirconia ceramics changes when the sintering parameters, such as heating rate, sintering temperature, and dwell time, are modified. RS results in reduced grain size and increased transmission of zirconia ceramics14 or increased grain size and decreased translucency.17,18 Due to limited studies, the exact effect of sintering parameters on the optical properties of zirconia ceramics remains unclear.

CIELAB color space (also known as CIE L∗a∗b∗) is expressed as three values: L∗ for lightness and a∗ and b∗ for color. These values can be used to determine the translucency parameter (TP) color difference (ΔE), becoming the esthetic foundation of dental research and applications.19,20 In the previous studies, ΔE was considered clinically undetectable if less than 3, clinically acceptable if between 3 and 5, and clinically unacceptable if greater than 5.20,21 In dental clinics and laboratories, the digital colorimeter is relatively simple to operate compared with traditional color matching with the naked eye, which directly evaluates optical properties such as lightness, color distribution, and translucency of natural teeth or restorations.

The monolithic restorations can be manufactured in reduced preparation thickness that directly affects the optical properties of zirconia restorations.22, 23, 24 Therefore, the relationships among thickness, color, and transparency of highly translucent zirconia materials need to be explored for mastering the esthetics of zirconia monolithic restorations,25,26 especially during RS.

This study evaluated the optical properties of two generations of dental zirconia ceramics of three thicknesses that underwent RS, including L∗, a∗, b∗ values, TP, and ΔE, that measured using two commercial digital dental colorimeters. The first null hypothesis of this study is that there are no significant differences in TP and ΔE is clinically acceptable for the three commercial zirconia ceramics that underwent RS compared with CS. The second null hypothesis is that the two colorimeters show similar CIELAB color characterization for the rapid sintered zirconia ceramics.

Materials and methods

Specimens preparation

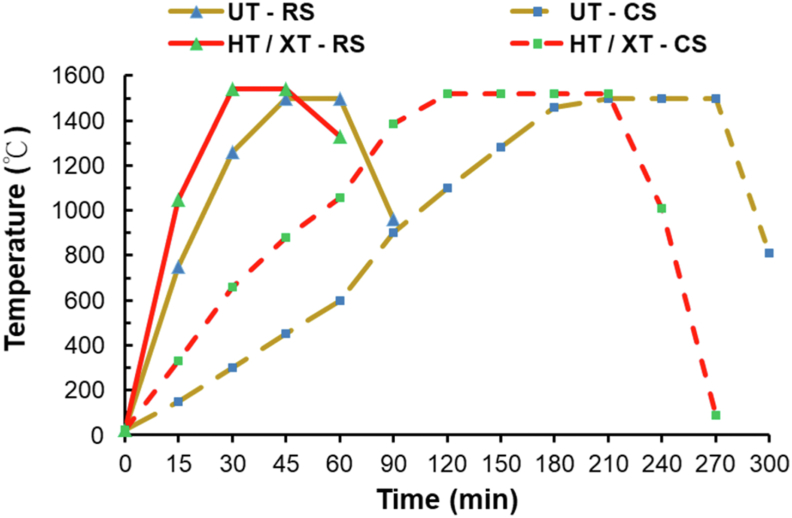

Three commercial zirconia materials were investigated as they include two grades of translucency: high translucency zirconia and extra translucent zirconia (Table 1). Disk specimens cut, then polished with grit 800 SiC grinding paper, followed by ultrasonic cleaning. CS and RS processes were performed according to the manufacturers’ instructions (Fig. 1), using a speed sintering furnace (Mihm-Vogt HT Speed, Mihm-Vogt GmbH & Co. KG, Stutensee-Blankenloch, Germany). The final dimensions of specimens were 12.0 mm in diameter and 0.5, 0.8, and 1.2 mm in thickness with the accuracy of ±0.05 mm using a digital caliper.

Table 1.

Tested materials in this study.

| Type | Brand | Code | Compositiona | Manufacturers |

|---|---|---|---|---|

| High translucency zirconia | Copran Zr-i Ultra-T | UT | 4.95–5.35% Y2O3, 0.15–0.35% Al2O3, 0.04–0.25% FeOH3, 0–0.06% Other Oxide, ZrO2 Balance | Whitepeaks Dental Solutions GmbH & Co. KG, Essen, Germany |

| High translucency zirconia | Cercon ht | HT | 5% Y2O3, 0–3% HfO2, 0–1% Al2O3 and SiO2, ZrO2 Balance | Dentsply Sinora, Milford, DE, USA |

| Extra translucent zirconia | Cercon xt | XT | 9% Y2O3, 0–3% HfO2, 0–1% Al2O3 and SiO2, ZrO2 Balance | Dentsply Sinora |

Data accords to manufacturer information.

Figure 1.

The sintering programs used in the study.

Optical properties

Before testing, two dental digital colorimeters (Vita Easyshade V, Vita zahinfabrik, Bad Säckingen, Germany (Vita) and Shadepilot, DeguDent, DeguDent GmbH, Hanau-Wolfgang, Germany (DD)) were calibrated according to the manufacturers’ instructions. Each sintered specimen (n = 5) was placed on the black (B) or white (W) backplane to measure three times. TP and ΔE (the measured values on white background) were calculated according to the following formula:

Surface morphology

The surface structures of the sintered specimens were observed by FE-SEM (JSM-6700F, JEOL, Tokyo, Japan) on a sputter-coated surface with gold at a dwell time of 30 s. The average grain size was estimated from micrographs using the linear intercept method according to ASTM E112 standard test method.

Surface roughness

The surface roughness values (Ra) of each specimen (n = 3) at three measuring locations were determined using a surface analyzer (Surfcom 50A, Tokyo Seimitsu, Tokyo, Japan) with a traverse length of 2.4 mm and a cut-off length of 0.8 mm.

Statistical analysis

Three-way and one-way ANOVA with Tukey HSD tests were used for statistical evaluations of L∗ value, TP, and grain size. The a∗ value, b∗ value, and surface roughness were evaluated with Wilcoxon/Kruskal–Wallis tests and non-parametric comparisons for all pairs using the Dunn method to determine significant differences. All tests were performed at a significance level of 0.05 using a software package (JMP14; SAS Institute Inc., Cary, NC, USA).

Results

Optical properties

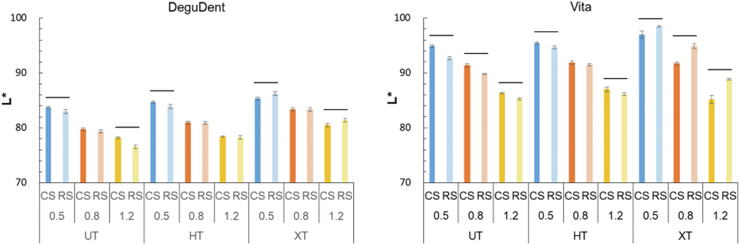

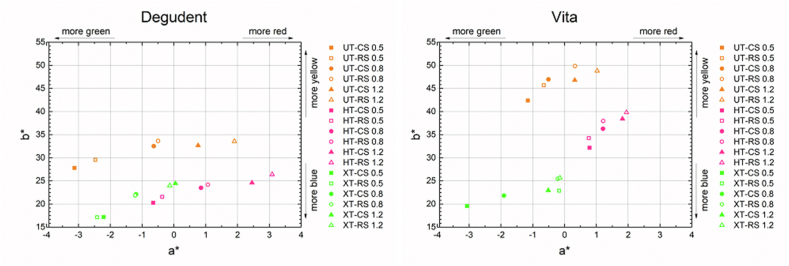

The measured L∗, a∗, and b∗ values of the sintered specimens on a white background by two colorimeters are shown in Figure 2, Figure 3. The XT group demonstrated the highest L∗ values followed by HT and UT groups. RS resulted in a reduced L∗ value, except for the XT group. The statistically significant differences were revealed among the types of materials, thicknesses, and sintering methods (p < 0.05). L∗ values obtained from DD were smaller than those obtained from Vita (p < 0.05). Regardless of the sintering method, UT and HT groups revealed greater a∗ and b∗ values, while the XT group revealed lower values. As specimen thickness increased, L∗ value decreased, a∗ and b∗ values increased. RS resulted in increased a∗ and b∗ values. DD revealed a greater range for a∗ value while Vita revealed a greater range for b∗ value, and there were similar values in the XT group.

Figure 2.

L∗ values of the zirconia specimens of different thicknesses that underwent both sintering methods measured on a white background by two colorimeters. A horizontal line above the bars indicates significant group differences (P < 0.05).

Figure 3.

a∗ and b∗ values of the zirconia specimens of different thicknesses treated with different sintering methods measured on a white background by two colorimeters.

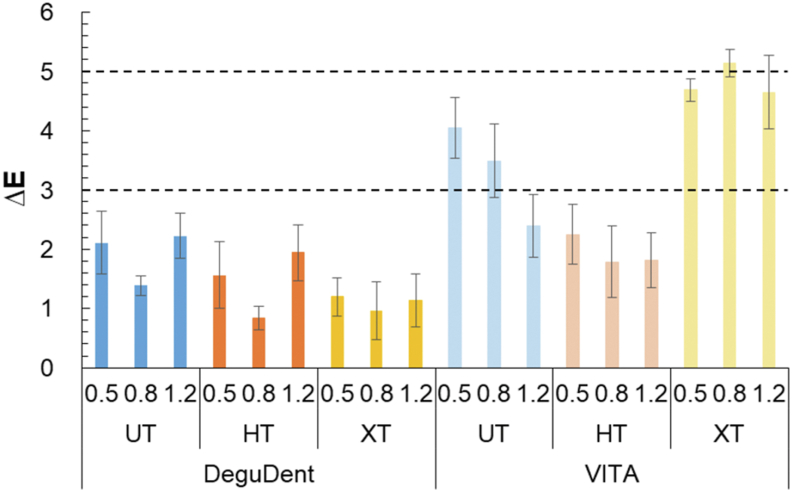

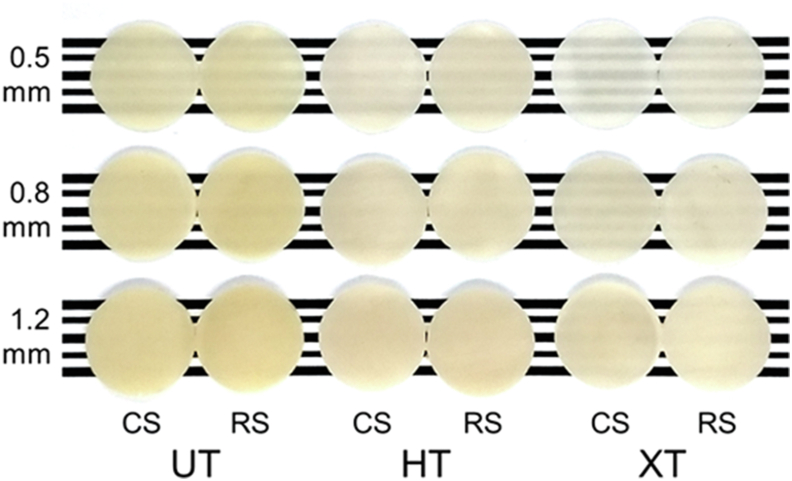

TP and ΔE values of the tested groups are shown in Figure 4, Figure 5, respectively. TP showed a downward trend with an increase in the thickness of the tested specimens (p < 0.05). TP values of the RS group were similar to those of the CS group (p > 0.05), except for the XT group on DD. The XT group showed the highest TP values with significant differences among the three materials (p < 0.05). The differences between the two sintering methods were significant on DD (p < 0.05). The thickness of the specimens affected more greatly in the TP values of Vita than DD. On DD, the ΔE values of all tested specimens in the RS and CS groups were below the clinical perceptibility threshold (ΔE < 3). On Vita, ΔE values were clinically acceptable (ΔE < 5). In terms of materials, the XT group expressed the smallest ΔE values on DD, but Vita revealed the contrasting results. The optical image for comparing the color and translucency of the tested specimens is shown in Fig. 6. The UT group was more chromatic, followed by the HT group and XT group. The perceived color and translucency of most specimens between RS and CS were difficult to distinguish from each other, only the XT group showed a slight difference with the naked eye.

Figure 4.

TP values of specimens treated with different sintering methods calculated based on the measured values from two colorimeters. A horizontal line above the bars indicates significant group differences (P < 0.05).

Figure 5.

ΔE values of the zirconia specimens underwent RS or CS, measured on two dental colorimeters.

Figure 6.

Optical image of the tested zirconia materials for the determination of the color and translucency.

Surface morphology

On SEM images, the surface of each specimen was compact without obvious pores or microcracks, and the microstructure was uniform distribution with narrow grain size. It is worth noting that in the XT group, a few larger grains were distributed in certain areas and revealed a non-homogeneous grain structure. After RS, the XT group showed the largest grain size (above 1033 nm), followed by the HT group (above 377 nm) and the UT group (less 347 nm). The average grain size increased in the UT and HT groups but decreased in the XT group, which changed approximately 10% in the RS group compared with the CS group. A significant difference between sintering conditions was only in the XT group (p < 0.05).

Surface roughness

Ra values of the specimens in the RS group were smaller (0.25–0.29) than those in the CS group (0.29–0.33), regardless of material. However, the differences were not significant (p > 0.05).

Discussion

In this study, comparing the results of three commercial zirconia ceramics, XT material that underwent RS revealed significantly lower TP values than those that underwent CS on DD. Although, ΔE values of all groups with CS and RS were clinically acceptable (ΔE < 5) no matter which colorimeter was used. This result indicated that the first null hypothesis was rejected. The similar results showed while comparing both colorimeters, the lightness of UT and HT decreased while those of XT increased, and the chromaticity increased after RS. As such, the second null hypothesis was supported.

With various zirconia ceramics, the recommended indications for dental restorations are not only based on mechanical properties but also translucency. The choice of material is crucial for manufacturing individualized dental restorations with optimal esthetic resulting in the look and feel of natural teeth. The tested 3Y-TZP zirconia ceramics contain more alumina, inhibit grain growth and diffusion during sintering.27,28 With smaller alumina grains evenly distributed in the zirconia lattice, birefringence and scattering increase due to different refractive indices of alumina and zirconia.27,29,30 Eventually, reduced light penetration makes the material less translucency. This result is consistent with the results of previous studies in which the grain size decreases after RS. It has been suggested that the inhibition of grain growth is due to shorter dwell time.10 Comparing tested 3Y-TZP zirconia ceramics (UT and HT) from different manufacturers, which had approximate grain size and equal effects of RS in optical properties. The UT material exhibited more chromatic mainly due to the compositions or proportions of added oxide coloring agents,31 which contained 0.04%–0.25% FeOH3 according to the manufacturer's instructions. The higher oxide content had a greater influence on color and lightness after sintering. The more translucent 5Y-TZP materials are higher yttria content and cubic zirconia with a larger grain size, which result in fewer grain boundaries, light scattering, and occurrence of birefringence.15,30,32 After RS, XT specimens were increased in lightness and grain size, after due to a higher final temperature than CS, which directly affects the microstructure and optical properties.1,33,34 This result is consistent with the literature.17 Also, the surface structure and roughness of the specimens was not affected significantly after RS. Thus, there was no additional light scattering, resulting in decreased translucency.

The two colorimeters used in this study have different design principles and color matching methods. Vita used the probe to touch the surface, but DD has a proper object-camera distance. To understand the differences between these two colorimeters, several tabs of Vitapan classical shade guide were also measured under the same conditions and shown (Table 2). The shade guide tabs are thicker (approximately 4–5 mm) than the tested zirconia specimens. The thickness greatly influences the translucency of ceramics. On the whole, both colorimeters presented similar values of lightness and slightly different color sensitivities on a white background. Vita showed that TP values are close to 0 because the measured values lack change on white or black backgrounds. DD demonstrated higher perceptibility in L∗, a∗, and b∗ values between black and white backgrounds, which showed also higher perceptibility in TP values even if the object is thicker. This result is consistent with the tested zirconia specimens. In a previous study, these two digital dental colorimeters were used to determine the color of full-coverage restoration inside the mouth, with no differences in optical properties.35 In this study, the two colorimeters revealed different ΔE values for RS and CS, due to different light sources, measuring modes, and imaging principles.36 Each instrument has its advantages and limitations. Past research has confirmed that in evaluations of color parameters and tooth colors, inconsistency occurs due to the lack of colorimetric equipment. It is for this reason that we used two digital dental colorimeters to evaluate the optical properties.

Table 2.

Optical properties of tabs of Vitapan classical shade guide measured under white and black background by two colorimeters.

| DeguDent | Vita | DeguDent - Vita | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Shade of tab | Background | L∗ | a∗ | b∗ | TP | L∗ | a∗ | b∗ | TP | ΔE |

| A2 | White | 78.0 | 0.8 | 20.2 | 5.8 | 79.4 | 1.1 | 18.8 | 0.0 | 2.1 |

| Black | 72.7 | 0.2 | 17.9 | 79.4 | 1.1 | 18.8 | ||||

| A3 | White | 76.0 | 1.3 | 21.7 | 5.9 | 75.3 | 2.1 | 19.4 | 0.4 | 2.5 |

| Black | 70.5 | 0.8 | 19.5 | 75.0 | 2.0 | 19.1 | ||||

| A4 | White | 69.1 | 3.2 | 24.6 | 4.9 | 69.2 | 2.0 | 27.2 | 0.2 | 2.8 |

| Black | 64.6 | 2.5 | 22.9 | 69.4 | 2.0 | 27.2 | ||||

L∗: lightness, a∗: red/green value, b∗: blue/yellow value, TP: translucency parameter, ΔE: color difference.

Natural human teeth exhibit different colors, enamel thicknesses, and levels of light transmission. In practice, the esthetics of ceramic restorations is essential. Our results confirmed that the optical properties of the three zirconia ceramics of different thicknesses are not affected significantly by RS. The RS technology is a feasible method for producing zirconia ceramic restorations. The limitations of this study are that the tested materials represent only a small fraction of the materials on the market, and the designed specimens are insufficient in clinical practice. The latest zirconia ceramics with multilayers of seamless gradient can resemble the esthetics of natural teeth for easy and rapid manufacturing of zirconia restorations. For new commercial zirconia materials, it is worth further study whether RS technology is still a feasible and suitable method for the production of zirconia restorations.

In conclusions, within the limitations of this study, the following conclusions were drawn: The lightness and grain size of high-translucency 3Y-TZP decrease after RS, while those of extra translucent 5Y-TZP increase. The translucency of extra translucent 5Y-TZP is more susceptible to RS compared with high-translucency 3Y-TZP. The color change of rapid sintered zirconia ceramics is clinically acceptable and difficult to distinguish with the naked eye. The type of colorimeter has some influence on the measurement of the transparency and color difference of zirconia ceramics. Shadepilot has higher sensitivity to translucency and color compared with Easyshade V.

Declaration of competing interest

The authors have no conflicts of interest relevant to this article.

Acknowledgements

None. No funding to declare.

Contributor Information

Chun-Chuan Yang, Email: ycc@ms.szmc.edu.tw.

Min Yan, Email: yan@csmu.edu.tw.

References

- 1.Zhang F., Inokoshi M., Batuk M., et al. Strength, toughness and aging stability of highly-translucent Y-TZP ceramics for dental restorations. Dent Mater. 2016;32:e327–e337. doi: 10.1016/j.dental.2016.09.025. [DOI] [PubMed] [Google Scholar]

- 2.Pereira G.K.R., Guilardi L.F., Dapieve K.S., Kleverlaan C.J., Rippe M.P., Valandro L.F. Mechanical reliability, fatigue strength and survival analysis of new polycrystalline translucent zirconia ceramics for monolithic restorations. J Mech Behav Biomed Mater. 2018;85:57–65. doi: 10.1016/j.jmbbm.2018.05.029. [DOI] [PubMed] [Google Scholar]

- 3.Vichi A., Carrabba M., Paravina R., Ferrari M. Translucency of ceramic materials for CEREC CAD/CAM system. J Esthetic Restor Dent. 2014;26:224–231. doi: 10.1111/jerd.12105. [DOI] [PubMed] [Google Scholar]

- 4.Zhang F., Vanmeensel K., Batuk M., et al. Highly-translucent, strong and aging-resistant 3Y-TZP ceramics for dental restoration by grain boundary segregation. Acta Biomater. 2015;16:215–222. doi: 10.1016/j.actbio.2015.01.037. [DOI] [PubMed] [Google Scholar]

- 5.Inokoshi M., Shimizu H., Nozaki K., et al. Crystallographic and morphological analysis of sandblasted highly translucent dental zirconia. Dent Mater. 2018;34:508–518. doi: 10.1016/j.dental.2017.12.008. [DOI] [PubMed] [Google Scholar]

- 6.Zhang F., Van Meerbeek B., Vleugels J. Importance of tetragonal phase in high-translucent partially stabilized zirconia for dental restorations. Dent Mater. 2020;36:491–500. doi: 10.1016/j.dental.2020.01.017. [DOI] [PubMed] [Google Scholar]

- 7.Kontonasaki E., Rigos A.E., Ilia C., Istantsos T. Monolithic zirconia: an update to current knowledge. Optical properties, wear, and clinical performance. Dent J. 2019;7:90. doi: 10.3390/dj7030090. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Camposilvan E., Leone R., Gremillard L., et al. Aging resistance, mechanical properties and translucency of different yttria-stabilized zirconia ceramics for monolithic dental crown applications. Dent Mater. 2018;34:879–890. doi: 10.1016/j.dental.2018.03.006. [DOI] [PubMed] [Google Scholar]

- 9.Kengtanyakich S., Peampring C. An experimental study on hydrothermal degradation of cubic-containing translucent zirconia. J Adv Prosthodont. 2020;12:265–272. doi: 10.4047/jap.2020.12.5.265. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Kaizer M.R., Gierthmuehlen P.C., dos Santos M.B.F., Cava S.S., Zhang Y. Speed sintering translucent zirconia for chairside one-visit dental restorations: optical, mechanical, and wear characteristics. Ceram Int. 2017;43:10999–11005. doi: 10.1016/j.ceramint.2017.05.141. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Ahmed W.M., Troczynski T., McCullagh A.P., Wyatt C.C.L., Carvalho R.M. The influence of altering sintering protocols on the optical and mechanical properties of zirconia: a review. J Esthetic Restor Dent. 2019;31:423–430. doi: 10.1111/jerd.12492. [DOI] [PubMed] [Google Scholar]

- 12.Öztürk C., Çelik E. Influence of heating rate on the flexural strength of monolithic zirconia. J Adv Prosthodont. 2019;11:202–208. doi: 10.4047/jap.2019.11.4.202. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Stawarczyk B., Özcan M., Hallmann L., Ender A., Mehl A., Hämmerlet C.H. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin Oral Invest. 2013;17:269–274. doi: 10.1007/s00784-012-0692-6. [DOI] [PubMed] [Google Scholar]

- 14.Kim M.J., Ahn J.S., Kim J.H., Kim H.Y., Kim W.C. Effects of the sintering conditions of dental zirconia ceramics on the grain size and translucency. J Adv Prosthodont. 2013;5:161–166. doi: 10.4047/jap.2013.5.2.161. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Zhang Y. Making yttria-stabilized tetragonal zirconia translucent. Dent Mater. 2014;30:1195–1203. doi: 10.1016/j.dental.2014.08.375. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Harada K., Raigrodski A.J., Chung K.H., Flinn B.D., Dogan S., Mancl L.A. A comparative evaluation of the translucency of zirconias and lithium disilicate for monolithic restorations. J Prosthet Dent. 2016;116:257–263. doi: 10.1016/j.prosdent.2015.11.019. [DOI] [PubMed] [Google Scholar]

- 17.Jansen J.U., Lümkemann N., Letz I., Pfefferle R., Sener B., Stawarczyk B. Impact of high-speed sintering on translucency, phase content, grain sizes, and flexural strength of 3Y-TZP and 4Y-TZP zirconia materials. J Prosthet Dent. 2019;122:396–403. doi: 10.1016/j.prosdent.2019.02.005. [DOI] [PubMed] [Google Scholar]

- 18.Lawson N.C., Maharishi A. Strength and translucency of zirconia after high-speed sintering. J Esthetic Restor Dent. 2020;32:219–225. doi: 10.1111/jerd.12524. [DOI] [PubMed] [Google Scholar]

- 19.Paravina R.D., Ghinea R., Herrera L.J., et al. Color difference thresholds in dentistry. J Esthetic Restor Dent. 2015;27:S1–S9. doi: 10.1111/jerd.12149. [DOI] [PubMed] [Google Scholar]

- 20.Nogueira A.D., Della Bona A. The effect of a coupling medium on color and translucency of CAD–CAM ceramics. J Dent. 2013;41:e18–e23. doi: 10.1016/j.jdent.2013.02.005. [DOI] [PubMed] [Google Scholar]

- 21.Alghazali N., Burnside G., Moallem M., Smith P., Preston A., Jarad F.D. Assessment of perceptibility and acceptability of color difference of denture teeth. J Dent. 2012;40:e10–e17. doi: 10.1016/j.jdent.2012.04.023. [DOI] [PubMed] [Google Scholar]

- 22.Kim H.K., Kim S.H. Optical properties of pre-colored dental monolithic zirconia ceramics. J Dent. 2016;55:75–81. doi: 10.1016/j.jdent.2016.10.001. [DOI] [PubMed] [Google Scholar]

- 23.Kim H.K., Kim S.H., Lee J.B., Han J.S., Yeo I.S., Ha S.R. Effect of the amount of thickness reduction on color and translucency of dental monolithic zirconia ceramics. J Adv Prosthodont. 2016;8:37–42. doi: 10.4047/jap.2016.8.1.37. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Tabatabaian F., Dalirani S., Namdari M. Effect of thickness of zirconia ceramic on its masking ability: an in vitro study. J Prosthodont. 2019;28:666–671. doi: 10.1111/jopr.12625. [DOI] [PubMed] [Google Scholar]

- 25.Tabatabaian F. Color aspect of monolithic zirconia restorations: a review of the literature. J Prosthodont. 2019;28:276–287. doi: 10.1111/jopr.12906. [DOI] [PubMed] [Google Scholar]

- 26.Matsuzaki F., Sekine H., Honma S., et al. Translucency and flexural strength of monolithic translucent zirconia and porcelain-layered zirconia. Dent Mater J. 2015;34:910–917. doi: 10.4012/dmj.2015-107. [DOI] [PubMed] [Google Scholar]

- 27.Macan J., Brcković L., Gajović A. Influence of preparation method and alumina content on crystallization and morphology of porous yttria stabilized zirconia. J Eur Ceram Soc. 2017;37:3137–3149. [Google Scholar]

- 28.Ross I., Rainforth W., McComb D., Scott A., Brydson R. The role of trace additions of alumina to yttria–tetragonal zirconia polycrystals (Y–TZP) Scripta Mater. 2001;45:653–660. [Google Scholar]

- 29.Zhang H., Li Z., Kim B.N., et al. Effect of alumina dopant on transparency of tetragonal zirconia. J Nanomater. 2012:1–5. 2012. [Google Scholar]

- 30.Stawarczyk B., Keul C., Eichberger M., Figge D., Edelhoff D., Lümkemann N. Three generations of zirconia: from veneered to monolithic. Part I. Quintessence Int. 2017;48:369–380. doi: 10.3290/j.qi.a38057. [DOI] [PubMed] [Google Scholar]

- 31.Kim H.K., Kim S.H. Effect of the number of coloring liquid applications on the optical properties of monolithic zirconia. Dent Mater. 2014;30:e229–e237. doi: 10.1016/j.dental.2014.04.008. [DOI] [PubMed] [Google Scholar]

- 32.Carrabba M., Keeling A.J., Aziz A., et al. Translucent zirconia in the ceramic scenario for monolithic restorations: a flexural strength and translucency comparison test. J Dent. 2017;60:70–76. doi: 10.1016/j.jdent.2017.03.002. [DOI] [PubMed] [Google Scholar]

- 33.Ebeid K., Wille S., Hamdy A., Salah T., El-Etreby A., Kern M. Effect of changes in sintering parameters on monolithic translucent zirconia. Dent Mater. 2014;30:e419–e424. doi: 10.1016/j.dental.2014.09.003. [DOI] [PubMed] [Google Scholar]

- 34.Yang C.C., Ding S.J., Lin T.H., Yan M. Mechanical and optical properties evaluation of rapid sintered dental zirconia. Ceram Int. 2020;46:26668–26674. [Google Scholar]

- 35.Kalantari M.H., Ghoraishian S.A., Mohaghegh M. Evaluation of accuracy of shade selection using two spectrophotometer systems: Vita Easyshade and Degudent Shadepilot. Eur J Dermatol. 2017;11:196–200. doi: 10.4103/ejd.ejd_195_16. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Chu S.J., Trushkowsky R.D., Paravina R.D. Dental color matching instruments and systems. Review of clinical and research aspects. J Dent. 2010;38:e2–e16. doi: 10.1016/j.jdent.2010.07.001. [DOI] [PubMed] [Google Scholar]