Abstract

The COVID-19 has become a global pandemic that dramatically impacted human lives and economic activities. Due to the high risk of getting affected in high-density population areas and the implementation of national emergency measures under the COVID-19 pandemic, both travel and transportation among cities become difficult for engineers and equipment. Consequently, the costly physical commissioning of a new manufacturing system is greatly hindered. As an emerging technology, digital twins can achieve semi-physical simulation to avoid the vast cost of physical commissioning of the manufacturing system. Therefore, this paper proposes a digital twins-based remote semi-physical commissioning (DT-RSPC) approach for open architecture flow-type smart manufacturing systems. A digital twin system is developed to enable the remote semi-physical commissioning. The proposed approach is validated through a case study of digital twins-based remote semi-physical commissioning of a smartphone assembly line. The results showed that combining the open architecture design paradigm with the proposed digital twins-based approach makes the commissioning of a new flow-type smart manufacturing system more sustainable.

Keywords: COVID-19 pandemic, Digital twins, Manufacturing system commissioning, Smart manufacturing, Remote semi-physical commissioning

1. Introduction

It is undeniable that COVID-19 has become a global pandemic that made a tremendous impact on human lives and economic activities. In the case of the COVID-19 pandemic, some emergency measures have been taken by the government around the world, including implementing a fourteen-day quarantine period for cross-country travels. Due to the high risk of getting affected in high-density population areas and the implementation of national emergency measures under the COVID-19 pandemic, travel among cities and countries is severely hindered. Consequently, the manufacturing sector has been dramatically affected (Shen et al., 2020).

The smart manufacturing system in the Industry 4.0 blueprint is highly interlinked with the Internet of Things (IoT) and consists of automated machines (Moghaddam et al., 2018; Wollschlaeger et al., 2017), which must be elaborately designed and validated to achieve high efficiency and sustainability. The commissioning of a new smart manufacturing system is to test system design and generate basic controls before the physical system is put into production (Hoffmann et al., 2010), which is greatly hindered by the COVID-19 pandemic. Commonly, the machine tools in a manufacturing system are provided by various suppliers practically. Since there will be differences in mechanisms, controllers, and communication interfaces to a certain extent between different machine tools, a lot of efforts are required for equipment transportation, assembly, integration, validation, testing, and debugging in the commissioning stage of a new manufacturing system.

Additionally, each piece of equipment will communicate and coordinate with others frequently. Thus, the design of the manufacturing system needs to be validated to meet the requirements of manufacturers. To validate the design accurately, it is necessary to integrate all the physical equipment and set up a unified control system to carry out the commissioning of manufacturing systems (Pellicciari et al., 2009). However, during the COVID-19 pandemic, travel and transportation among cities become difficult for engineers and equipment. Naturally, the costly integration of physical equipment distributed in different regions will be hindered, and the commissioning of the manufacturing system cannot be guaranteed within the time that was scheduled before, which will be a negative impact on the design cycle as well as the design and implementation costs of the new manufacturing system.

It is common sense that usually first the manufacturing system is physically developed and secondly commissioned onsite in the factory. However, the system commissioning process is greatly coupled with the system design/redesign process. The iteration between the system design and commissioning processes gets more and more frequent if one wants to develop a highly-automated and intelligent plant since the possibilities of design errors/flaws grow largely when the manufacturing system becomes complex. Therefore, we formerly proposed a CMCO (i.e., Configuration design-Motion planning-Control development-Optimization decoupling) design architecture (Liu et al., 2021). In the CMCO architecture, the system design scope becomes broader and includes the control dimension of the smart manufacturing system. Considering the frequent iteration between the system design and commissioning process in a complex smart manufacturing system, we considered the system control design jointly in the system commissioning phase in this paper.

The commissioning of a flow-type smart manufacturing system should be performed from three aspects: 1) static configuration of resources, e.g., assembly of multiple types of equipment; 2) dynamic operation planning, e.g., machine kinetics and workpiece logistics; and 3) controls development, e.g., field control network, sensor layout, and motion scripts. These three aspects should be consistently validated to be compatible. Inefficient commissioning may lead to a fluctuation in system operation efficiency and sustainability. Different variables (e.g., takt) and uncertainties (e.g., machine breakdowns) should be evaluated to find robust controls. The real commissioning of a flow-type smart manufacturing system with physical plants and physical controllers needs substantial cost and time. It is reported that the physical commissioning time consumes up to 25% of the time available for plant construction (Hoffmann et al., 2010). It is critical to conduct efficient commissioning of flow-type smart manufacturing systems under the COVID-19 pandemic. Computer-aided simulation tools are critical for efficient commissioning of the new flow-type smart manufacturing system. Many Virtual Commissioning (Auinger et al., 1999) and Semi-physical Commissioning (Putman et al., 2017) methods have been proposed. However, the Virtual Commissioning methods lack validation on detailed control codes, while semi-physical Commissioning methods are incapable of validating the real material flow. The advantages of reducing costs in physical commissioning cannot be expected if high-fidelity digital models are not available for virtual commissioning (Leng et al., 2020).

One promising approach is the digital twins technology, which can realize the interoperation of the physical system and cyberspace (Tao et al., 2018; Tao et al., 2018). The digital twin of the physical manufacturing system can validate the performance of design timely, avoid costly physical reconfiguration, optimize for achieving maximum efficiency, and thus cut-down commissioning cost (Zhong et al., 2015). In this paper, a new approach of digital twins-based remote semi-physical commissioning is put forward to develop flow-type smart manufacturing systems. A digital twin system is built to establish closed control loops among distributed physical equipment and virtual assemblies. Also, a decision-support kernel is proposed to enhance the efficiency of the digital twins-based semi-physical simulation model to the commissioning of flow-type smart manufacturing systems. A case of digital twins-based remote semi-physical commissioning of a smartphone assembly line is presented.

The paper is organized as follows. Based on a literature review in Section 2, a framework of digital twins-based remote semi-physical commissioning is presented in Section 3. Three key enabling techniques are detailed in Section 4, including 1) modeling the open architecture flow-type smart manufacturing system for achieving fast reconfigurability, 2) developing a digital twin system for semi-physical simulation, and 3) implementing digital twin system-based remote semi-physical commissioning. A semi-physical commissioning case of a smartphone assembly line is presented in Section 5. Then, how the proposed approach benefits the development of new manufacturing systems under the COVID-19 pandemic is discussed. Section 6 presents the conclusions.

2. Literature review

The commissioning of a manufacturing system could be categorized into Virtual Commissioning (also termed as Soft-Commissioning and Constructive Commissioning) (Auinger et al., 1999), Semi-physical Commissioning, and Physical Commissioning (also termed as Real Commissioning). Table 1 provides a comparison between three approaches of manufacturing system commissioning. Virtual Commissioning refers to the planning, debugging, and validating of the automated control components of the manufacturing systems using simulation models/tools. Semi-physical Commissioning further uses Internet of Things technology to embed the hardware to simulation models/tools for more accurately simulating the manufacturing system running state before being deployed. Physical commissioning is an inevitable process in deploying a manufacturing system in practice. Usually, conducting virtual commissioning and semi-physical commissioning in advance could reduce the time and cost required in the expensive physical commissioning phase.

Table 1.

Three approaches to manufacturing system commissioning.

| Methods | Virtual Commissioning | Semi-physical Commissioning | Physical Commissioning |

|---|---|---|---|

| Rational | Virtual plant + Virtual/Real Controller | Hardware-In-The-Loop and Reality-In-The-Loop | Physical plant + Real Controller |

| Contents | Geometric model with kinematics for the motion programming | + networking protocol + interface connectivity + control instructions | Validate and optimize all controls |

| Metric | Rapid commissioning and validation | Early validate physical equipment and cut-down the integration cost | All-dimensional improvement |

| Drawback | Lack of validation on detailed control codes | Incapable of validating the real material flow | Tremendous reconfiguration cost for eliminating errors |

| Time | Timely | Acceptable | Time-consuming |

| Cost | Low | Medium | High |

| Ref. | (Quintanilla et al., 2016) (Jain et al., 2010) (Stark et al., 2017) (Ko et al., 2013) | (Putman et al., 2017) (Liu et al., 2021) | – |

It is a common practice to let engineers work within their disciplines by using domain design tools and mitigating late integration issues by adopting the best possible PLC code or mechanical corrections without any physical system commissioning possibility (Stark et al., 2017). The virtual commissioning is realized via a simulation model/tool to enable engineers to work together before it is entirely built-in reality (Liu et al., 2012). The goal of virtual commissioning is to enable software engineers to validate essential controls and manufacturing activities earlier before the start-of-production (Reinhart and Wünsch, 2007). For instance, Ko et al. (2013) integrated a physical part model (geometric, kinematics, and motion programming) and a logical behavioral part model (corresponding to a real controller) to achieve the concurrency. Quintanilla et al. (2016) discussed the virtual commissioning of service-oriented holonic controls for the retrofit manufacturing systems. A study (Koo et al., 2011) showed the superiority of virtual commissioning on decreasing the error rate compared to physical commissioning and reducing physical commissioning time by 75%. Virtual commissioning relies on simulation to verify processes but ignores the physical interaction between the workpiece-in-process (WIP) and the system (Putman et al., 2017).

Semi-physical commissioning is a special kind of virtual commissioning with enhanced hardware-in-the-loop (virtual plant + real controllers) or reality-in-the-loop (real plant + virtual controllers) engineering analysis capabilities on the key elements of the manufacturing system. The semi-physical commissioning validates the cyber and physical interfaces simultaneously. For instance, Putman et al. (2017) proposed a cyber-physical fusion system where the physical interface can be interacted with in real-time, avoiding the expensive cost of physical implementations.

Programmable logic controllers (PLCs) are widely used in the manufacturing system due to their real-time I/O processing capabilities. Therefore, programming PLC is a critical process in manufacturing system commissioning, requiring mastering low-level control instructions and using a proper modeling tool (Ovatman et al., 2016). There exist three research focuses on how to program PLC codes efficiently. The first research focus is on enabling efficient collaboration among distributed engineers and translation between heterogeneous controllers. For instance, An et al. (2020) presented a semantic-based OntoPLC model to automatically port PLC projects among different development environments, avoiding information loss during the porting. Jain et al. (2010) proposed a collaborative development framework for the synergy of activities from distributed engineers involved in designing, implementing, operating, and diagnosing machine tools. The second research focus is on how to enable efficient reusing of best-practice control codes. Design patterns could be defined and used to enhance the reusability and modularity of the control code. For instance, Fuchs et al. (2014) defined five patterns for analyzing dependencies and encapsulations of software modules for control reuse. Nenninger et al. (Nenninger and Puchstein, 2018) defined a whole-part pattern encapsulating data and function block to enable control reuse. The third research focus is on how to enable efficient assembly and integration of different PLC modules. For instance, Stark et al. (2017) presented an architecture design approach for modularized design, simulating functional behavior, and validating the virtual prototype of the manufacturing system.

Semi-physical commissioning is conventionally implemented in small-size systems such as manufacturing units (Lee and Park, 2014). The new-generation information technology and digital twin technology allows semi-physical commissioning to large-scale systems such as production lines, workshops, and factories (Leng et al., 2019). Digital twins can prevent the vast cost in the manufacturing system reconfiguration (Renna, 2017) if the design deficiency is found in the hardware-in-the-loop simulation process. Based on the digital twins, many models of manufacturing system development are put forward in the Industry 4.0 context. Table 2 provides an overview of digital twin methods to optimize the manufacturing system design and configuration.

Table 2.

Digital twin methods to optimize the manufacturing system design and configuration.

| Model | Metric | Cases | Ref. |

|---|---|---|---|

| Manufacturing system designing | Iterative design optimization between static configuration and dynamic execution | Sheet material processing | Liu et al. (2019) |

| Process planning | Process reuse and smart evaluation | Diesel engine parts | Liu et al. (2019) |

| Machine tool modeling | Improve the stability of the machine tool | CNC milling machine | Luo et al. (2019) |

| Manufacturing system designing | A quad-play Configuration-Motion-Control-Optimization design architecture | Hollow glass processing | Liu et al. (2021) |

| Design engineering | Skin Model Shapes to bridge the gap between design and manufacturing | – | Schleich et al. (2017) |

| Reconfigurable Manufacturing system | Balancing the productivity and reconfiguration cost | Smartphone assembly | Leng et al. (2020) |

To get rid of the shortcomings of either lacking validation on detailed control codes in the virtual commissioning methods or incapable of validating the real material flow in the semi-physical commissioning methods, it is critical to establish high-fidelity digital models that could accurately reflect and validate the real-world properties of smart manufacturing systems. Therefore, a new digital twins-based commissioning approach is thereby proposed to update the manufacturing system commissioning towards a cyber-physical fusion manner.

3. Rational of digital twins-based remote semi-physical commissioning

Flow-type smart manufacturing system consists of conveyors, machining and assembling tools, storage, material handling & transportation systems, robots, and Human Machine Interface systems, which usually is a combination of standard parts and customized parts or sub-systems. Ensuring the accurate engagement of PLC code among machines is necessary to increase the commissioning efficiency of the flow-type smart manufacturing system. However, differences in the industrial control system among heterogeneous machines are significant even though all vendors claim to conform to the IEC 61131–3 and IEC 61131-10 standards, resulting in incompatibilities inside the flow-type smart manufacturing system. Therefore, the validating of interoperability among different machines in the flow-type smart manufacturing system is critical to saving the physical commissioning cost if incompatible machine tools are selected.

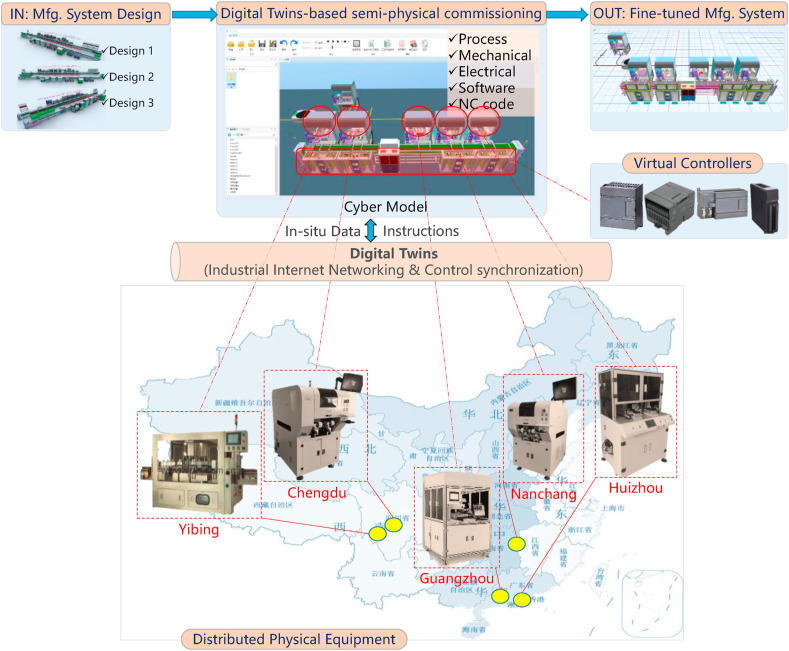

Different from the conventional semi-physical commissioning approach, the Remote Semi-physical Commissioning is proposed as a combination of hardware-in-the-loop commissioning (i.e., virtual plant + real controller) and reality-in-the-loop commissioning (i.e., real plant + virtual controller). It is a further development of Semi-physical Commissioning and is conducted online based on real-time interconnection among the digital models and physical machines distributed geographically. The online Commissioning environment could be enabled by the digital twins technology. Fig. 1 illustrates the rationale of digital twins-based remote semi-physical commissioning (DT-RSPC) to support the commissioning and integration of the entire flow-type smart manufacturing system.

Fig. 1.

The rationale of digital twins-based remote semi-physical commissioning.

The hardware controller is a prerequisite in advance, and it includes the coupling between the physical or virtual controller and the mechanical plant simulator. Utilizing digital models and a digital system, the DT-RSPC allows integrated validation of manufacturing systems for the early error-detecting and correcting during controls programming (Hoffmann et al., 2010). At the equipment level, it is critical to simulate kinetic logic and controls. The DT-RSPC extends the controller design of a flow-type smart manufacturing system to include the usage of the actors and sensors as well as communication with the Supervisory Control And Data Acquisition (SCADA) system and Manufacturing Execution System (MES), which were conventionally realized in the last stage of manufacturing system engineering. The proposed DT-RSPC could validate controls and execution engines in cyberspace rather than waiting for physical equipment placed in-situ to test. The malfunction reason and design mistakes can be quickly located in advance, and the practicability of the physical manufacturing system is validated. The warehousing and buffering of the manufacturing system could also be jointly optimized in the digital twin system (Leng et al., 2019).

The proposed DT-RSPC approach is an open architecture design-based system engineering approach extended by digital twin technologies. The open architecture design of the manufacturing system provides the standard interface to assemble various equipment. The DT-RSPC can collect remote data from distributed physical equipment to conduct online validation and adjustments of the flow-type smart manufacturing system while it does not need to gather all physical equipment from different suppliers and conduct the in-situ assembly. Since the physical commissioning will take up vast time and space, a DT-RSPC approach could shorten the integration time and reduce the debugging work after the system design.

4. Key enabling technologies

Three key enabling techniques are detailed to lay the foundation for developing a digital twin system for remote semi-physical commissioning of the flow-type smart manufacturing system.

4.1. Modelling of the flow-type smart manufacturing system

Flow-type smart manufacturing system (FSMS) is usually composed of the connected sub-systems (e.g., machine tools, industrial robots, logistics equipment, storage equipment, and conveyor) to fulfill a dedicated set of production requirements. The development of FSMS is much more standardized and easy-to-automate than other discrete manufacturing systems.

4.1.1. Modelling and assembly structuring of open architecture FSMS

Fast physical reconfigurability of FSMS is the foundation of efficient commissioning. An open architecture design (Koren et al., 2013) of reconfigurable FSMS is proposed, which is composed of a standard main-body platform together with a set of well-defined interfaces for fast removing, reinstalling, (re)configuration, upgrading, and swapping of equipment provided from different vendors (Leng et al., 2020). Three metrics characterize the Open Architecture FSMS (OA-FSMS): 1) standardized mechanical and electrical interface in the main-body platform (e.g., conveyor), 2) hot-plug adapter for quickly removing and reinstalling of equipment, and 3) platformization of adaptive modularized equipment modules and controls (Gu et al., 2009).

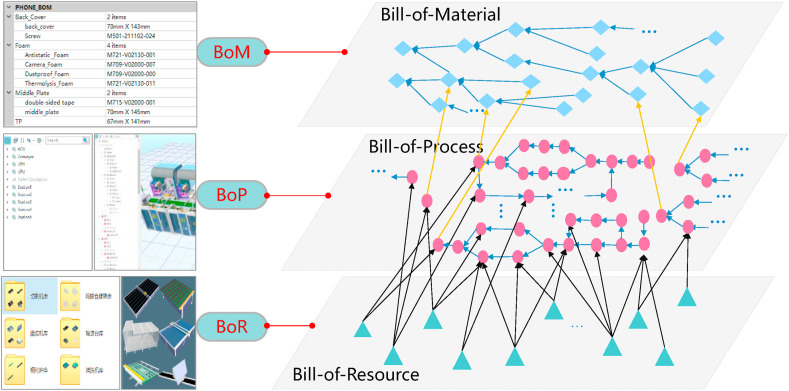

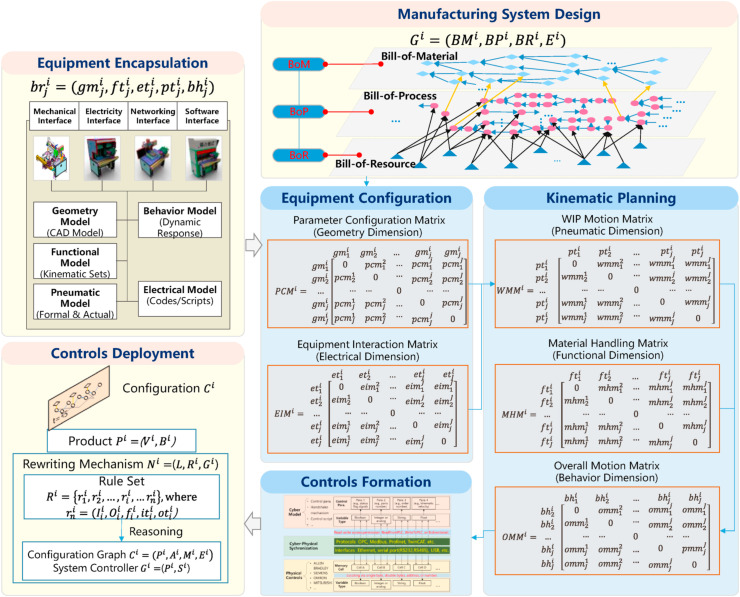

It is necessary to define a standardized structure for OA-FSMS models. As shown in Fig. 2 , the OA-FSMS could be described as a system of Bill-of-Material (BoM), Bill-of-Process (BoP), and Bill-of-Resource (BoR) (Leng et al., 2020), and thus a 3B model of OA-FSMS is defined as a directed graph . denotes a node set of BoM to be manufactured. refers to a node set of BoP to achieve the dimension or quality requirement of a manufacturing feature. denotes a node set of BoR, such as manufacturing tools and robots. stands for the relationships among different nodes. There exist four types of directed paths among different nodes in : 1) the matching relationships from to , 2) the memberships from to , 3) the process sequence relationships in , and 4) the product assembly relationships in . In another word, each process in belongs to a part in , and each resource of is assigned to a process in .

Fig. 2.

A 3B model of the flow-type smart manufacturing system.

4.1.2. Encapsulation of manufacturing resource models

One obstacle to the semi-physical commissioning is the extended time costs for the establishment of digital twin models. A formalized mechatronic model of OA-FSMS starts with the geometry CAD model of components provided by different vendors, which often results in an unstructured geometrical model. The multi-dimensional structuring of the CAD model into formalized objects (e.g., robots and machine tools) and final OA-FSMS is the critical step in creating the digital twin models. Here, the manufacturing resource model is defined as a 5-tuple:

-

●

Geometry dimension ()

Since the manufacturing equipment handles (e.g., locating and holding) workpieces during various machining processes, the geometric data of virtual equipment should be verified with the geometry of the given workpieces (Lee and Park, 2014). If the CAD model is not reasonably structured, the resulting geometrical OA-FSMS model cannot be directly used for the functional commissioning. In the worst case of the commissioning result, an OA-FSMS redesign may be necessary to provide a better geometry structure. The three-dimensional kinematic model can be identified as a geometric model based on the CAD data and enriched with additional information such as the degree-of-freedom of each moving part.

-

●

Functional dimension ()

The structured geometrical model should be encapsulated with manufacturing functions. In the functional commissioning stage, the actuator functions (e.g., translation, rotation, gripping) and sensor functions should be verified with the geometrical model, resulting in the parameterization and reconfiguration of the complete functional model.

-

●

Electrical dimension ()

The physical manufacturing system is electrically driven by control programs/scripts in the sensors and actuators. Most OA-FSMSs are controlled by PLCs, which is widely-employed industrial control technology (Lee and Park, 2014). For the electrical commissioning, the electrical I/O to the functional models should be checked and (re)configured for connection to I/O of control programs/scripts, resulting in a unified mechatronic model.

-

●

Pneumatic dimension ()

The pneumatic power enables many material handling operations in the manufacturing equipment. The pneumatic dimension is critical for ruling out malfunctions and thus should be (re)configured and checked in the commissioning process.

-

●

Behavior dimension ()

The behavior dimension simulates the dynamic features of the OA-FSMS. The behavioral performance of the manufacturing system is modeled by computation based on the control signals. For instance, within one data sampling period of the controller, the behavior model is supposed to react to the control output signals according to the configuration of the OA-FSMS and give the feedback input signal back to the controller, simulating the actual behavior of a real physical OA-FSMS (Liu et al., 2012). An essential feature of the OA-FSMS model is the coupled relationship between the behavior and the kinematics of the mechatronic parts/components. For the synchronization purpose in a digital twin system, a signal coupled relationship between the behavior dimension and the geometry/kinematic dimension is established.

4.1.3. Reference model-based rapid reconfiguration of controls

Considering the frequent iteration between the system design and commissioning process in a complex smart manufacturing system, we included the system control design content into the commissioning phase. In this paper, the commissioning of the manufacturing system directly starts from the modeling and assembling of low-level basic geometry models. If there are no similar cases/models available in the library, the commissioning requires considerable effort and expertise since it has to establish new functional, electrical, pneumatic, and behavior models based on primary geometry data.

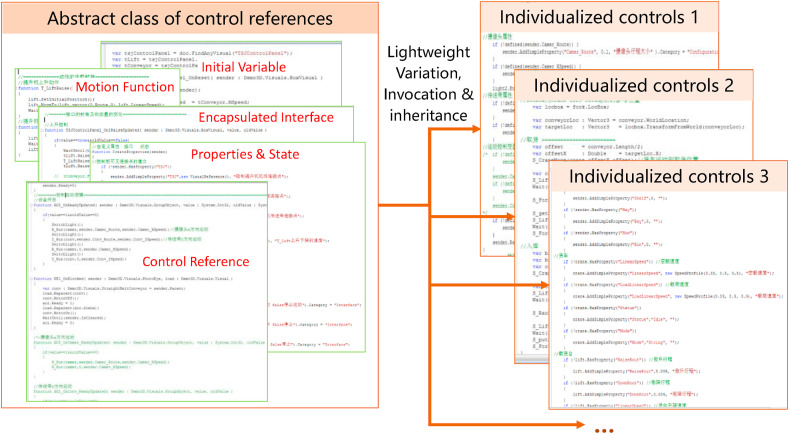

The design of sufficiently detailed models is critical in reducing debugging and correction efforts, which has undoubtedly required expertise (Hoffmann et al., 2010). The reuse of models is the foundation for implementing the fast commissioning of the OA-FSMS. Reference models on the motion planning (Cao et al., 2020) and the control scheme could be built for rapidly commissioning an OA-FSMS model. A reference model OA-FSMS for a product contains the abstracted functional behavior of mechanical parts/components. Each reference model is derived from the structured configuration knowledge of the relationship/type of manufacturing resources.

Reusing the predefined functional units allows a modularized (re)configuration of a complete OA-FSMS. A parametric adjustment of the functional component is realized based on the inheriting of reusable predefined functional models. As shown in Fig. 3 , either the geometric variants (e.g., size, scale, and location parameters) or the configuration varying in sensors and actors can be adjusted. When a new OA-FSMS commissioning project is started, the best-of-practice references help engineers extract control schemes/patterns and reuse historical control knowledge, including the definitions of the initial variable, motion function, encapsulated interface, properties & state, and control reference.

Fig. 3.

The inheriting of reusable predefined functional models.

4.2. Digital twin system for semi-physical simulation in a distributed environment

4.2.1. Digital twin system

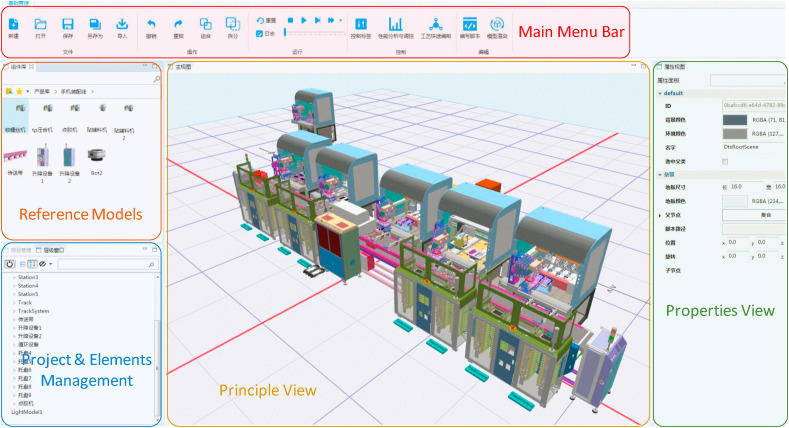

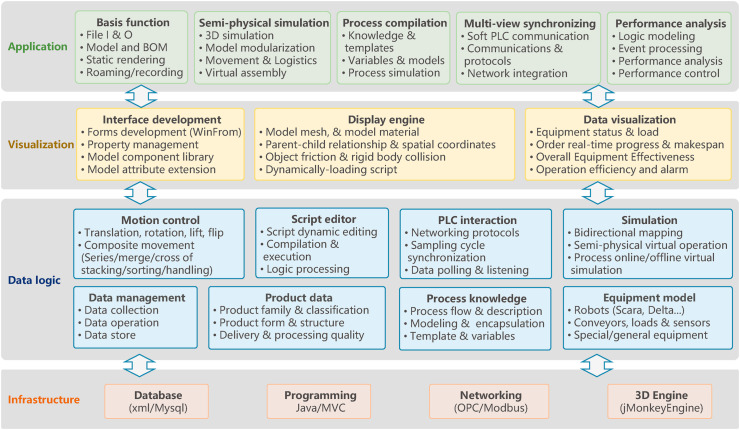

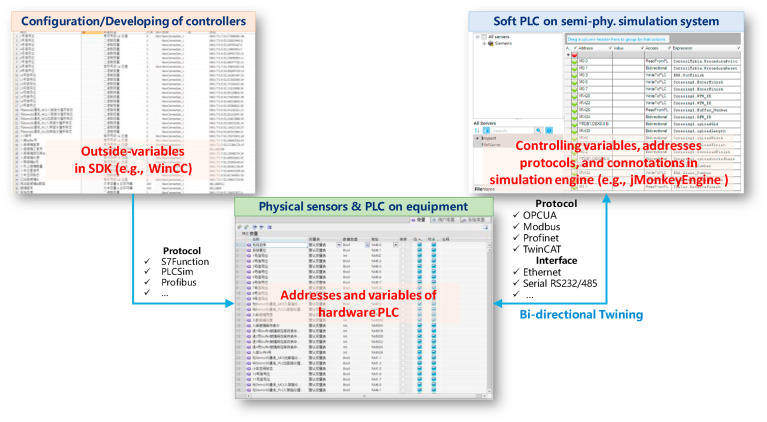

There are many useful simulation tools for manufacturing system development. However, data exchange among different engineering phases and tools remains challenging due to the lack of a generally accepted data format. It potentially causes the random error generated by repeated data entry (Hoffmann et al., 2010). Switching from virtual commissioning to semi-physical commissioning is difficult because the control functions should be connected to the physical system via the physical interface (Lee and Park, 2014). As shown in Fig. 4 , a digital twin system (DTS) has been developed based on the open-source jMonkeyEngine kernel (Java language), which is an upgrading of our formerly-proposed digital twin system that developed based on the free-to-use Unity3D kernel (C# language) (Leng et al., 2020) (Liu et al., 2021). Different from the conventional offline simulation, the digital twin system interoperates the hardware equipment with digital models through establishing the channel between the virtual/physical controllers and the execution engine so as to control both the physical equipment and the cyber model.

Fig. 4.

Digital twin system for remote semi-physical simulation in a distributed environment.

The digital twin system is used to conduct semi-physical simulation-based commissioning in a distributed environment. The digital twin implies synchronization among the physical system, simulation model, and execution engine of a smart manufacturing system (Lu et al., 2020). The synchronization between simulation models and physical equipment is realized by a mapping between the hardware Programmable Logic Controller (PLC) and soft PLC through industrial communication. Moreover, it is driven by remote data from physical equipment distributed geographically based on high-speed sampling (Hoffmann et al., 2010). Therefore, the electric and mechatronic hardware-in-the-loop commissioning of OA-FSMS can be done parallel in the digital twin system, resulting in lower debugging costs.

Fig. 5 provides an overview of the integration framework and function modules of the digital twin system, which includes four layers: infrastructure, data logic, visualization, and application. Firstly, the infrastructure layer includes a database, programming environment, networking, and 3D engine. It synchronizes the cyber model and physical object to form the hardware-in-the-loop simulation model. It includes the objectification of equipment model (e.g., loading/unloading and storage devices), moving trajectory, sensing devices, control script, and communication standard. Secondly, the data logic layer integrates the hardware-in-the-loop simulation model and control system for translating the upper-level production instructions into lower-level controller scripts/codes deployed to the physical equipment and feeding back the in-situ production information on time to the upper-level production control systems. By setting up the shared data structure, macro object, and instruction database, the communication channel between the digital twin system and the external planning system is established so that the instructions generated by the external planning system can control the operation of the device, and the results can be fed back to the external planning system in real time. Thirdly, the visualization layer includes the fusion of the 3D model and real-time data for supporting the tracking of system operation status. This layer includes a refined-parameter model library to support the rapid commissioning of process, operation, storage, and assembly. Fourthly, the application layer majorly includes the process compilation, multi-view synchronization, and performance analysis. The process of commissioning is to continually call the model in the library and deploy it to the semi-physical simulation engine according to the established planning scheme.

Fig. 5.

Integration framework of the digital twin system.

In the digital twin system, the digital model is consistent with the physical equipment in appearance, structure, behavior, state, kinematics, and dynamics (e.g., collision detection, motion trajectory, friction force, gravity, resistance, velocity, acceleration, and inertia) (Leng et al., 2020), which provides the runtime for manufacturing system commissioning. The OA-FSMS could be rapidly defined and customized in a drag-and-drop manner by combining the easy-to-use visual modeling and redevelopment IDE (integrated development environment) tool. An open data interface is established in the digital twin system to enable users: 1) to manually or automatically import control scripts, 2) to modify some functions in the process, and 3) to monitor the data flow in the breakpoint debugging manner, which significantly facilitates error troubleshooting. By supporting a drag-and-drop manipulation, the digital twin system enables the quick reconfiguration of the complex OA-FSMS model, together with its motion schemes and control scripts.

In practice, when the engineers start the simulation of the whole material flow, workers put the needed raw material in the machines to simulate the production line. Although it is difficult to coordinate the distributed workers in each simulation process, it is an effective compromise choice under the COVID-19 pandemic. Except for the simulation of whole material flow, many situations of simulation (e.g., machine kinetics inside equipment, and control compatibility) may be performed via a no-load running test manner.

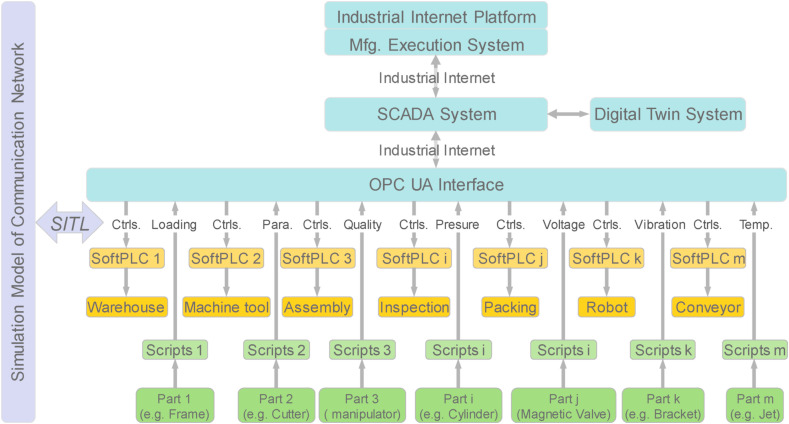

4.2.2. Distributed control in the digital twin system

Since cyber models need to interact with a physical controller, the cyber model is supposed to behave and act in the same manner as the physical equipment (Li et al., 2019). Thus, a cyber model needs to execute control programs/scripts in the same way as the inherent attributes/features of the equipment, e.g., the geometric shape and kinematics (Lee and Park, 2014). Fig. 6 illustrates the distributed control logic in the digital twin system using the REpresentational State Transfer (REST) architectural style (Battle and Benson, 2008). The remote semi-physical commissioning implies the networking of distributed equipment in a different place. Integration of a shared database with communication protocol OPC UA is adopted to overcome the obstacles between the virtual models and heterogeneous physical equipment (e.g., robot, processing center, assembly line). The data interface is established to access the internal variable data of SCADA and to enable the upper-level system (e.g., Industrial Internet Platform) to release the control variable through the external server function. The digital twin system can send messages through the communication protocol, change the variable data, and interact with the upper-level system. The communication network is mapped into a simulation model via the software-in-the-loop (SITL) manner.

Fig. 6.

Distributed control logic in the digital twin system.

In the digital twin system, the mapping between a real device and a cyber model is defined in a semantic template with mathematical language. Cyberspace includes a virtual data fusion middleware to track the discrepancies among the physical system and information system and composites a cyber-physical input to the upper-level controllers to virtualize a workpiece onto physical equipment. As shown in Fig. 7 , the operation of the virtual equipment could be directly controlled by soft PLC through a mapping relationship of the data input address, output address, and memory cache between the virtual controller and physical equipment (Leng et al., 2020). All I/O signals and interaction interfaces of each manufacturing equipment/component should be prespecified in the commissioning process. This bonding process makes sure the full interoperability of functional components/elements within the final manufacturing system.

Fig. 7.

The mapping rationale of controls in different modules of the digital twin system.

4.3. DTS-based remote semi-physical commissioning

The DTS could support the semi-physical commissioning of an OA-FSMS at both the equipment level and system level.

4.3.1. Equipment-level mechanical verification and control commissioning

The controls are usually programmed based on different programming languages, including the Instruction List, Structured Text, Function Block Diagram, and Ladder Diagram. A controller initiates the task execution of virtual equipment via output instructions and traces the machining status based on the input signals. Dealing with the validation of control programs/scripts could be realized by adopting many methods, from commissioning on the real equipment to the logic analysis (Danielsson et al., 2003).

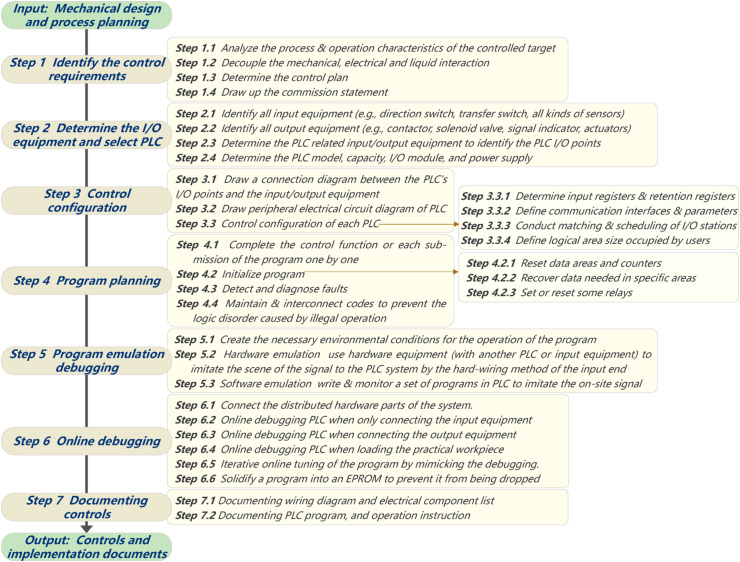

Traditional simulation methods model the operation behaviors of the machine tools with numerical codes (Lee and Park, 2014). In a distributed environment, it needs a more transparent control-programming environment to support engineers to discover the underlying hidden error. The DTS-based semi-physical simulation can detect specified mechanical behavior, geometrical/kinematics planning errors, and deviations from the specified control functions. Fig. 8 provides an overview of the semi-physical commissioning steps of equipment-level controls. The goal is to check both the theoretical and practical attributes (e.g., safety, security, liveness, and reachability) of a control code/script. A reference library of abstracted control patterns is developed in the digital twin system. If the cyber-logical model of equipment is built, the dependable control programs are generated with mature languages, such as the state diagram. Then the PLC programs are generated from those formalisms based on defining the I/O signal corresponding to the control codes/scripts. The control codes/scripts from various control developing tools of different providers are transformed into standard formats via the XML technologies as an interoperable carrier in the digital twin system. The inputted standard IEC 61131–3 codes on a soft PLC (simulated PLC, e.g., SIEMENS S7-PLCSIM) are transformed into timed automata and checked models.

Fig. 8.

Steps of equipment-level control semi-physical commissioning.

Finally, the mechanical behavior of control codes/scripts of the OA-FSMS is verified in detail in a distributed-integration manner. The twining of the operation chains from control codes/scripts are performed based on the sensors, actuators, and drives onto the mechanical components. The errors of stoppers resulted from overlooked inverse design logic, as well as inefficiencies in the workpiece flow, could be identified.

4.3.2. System-level commissioning for performance optimization

Conventional virtual commissioning is of limited capability in simulating the operation behavior of high-level controls, such as dynamic production dispatching (Berger et al., 2015). The system-level interaction of manufacturing equipment could be verified with the discrete event modeling in the digital twin system.

Fig. 9 presents a 3B model-based method for the rapid commissioning of controls. The digital twin system-based semi-physical simulation validates the correctness and efficiency of the commissioned controllers. The OA-FSMS commissioning involves three dimensions: 1) the configuration of processing equipment, material handling robot, WIP storage equipment, and energy supply device; 2) kinematic planning/verification of the equipment manipulator for handling workpiece (e.g., translation, lifting, rotating, and flipping) and WIP logistics flow among equipment; 3) the analysis of deadlock, balance, and takt consistency of the manufacturing process. The first dimension is of explicit parameter constraints in processing capacity; the second dimension is of clear rules of conciseness and combination; the last dimension is of clear performance target and the cost limit. Based on the formerly-proposed quad-play CMCO (i.e., Configuration design-Motion planning-Control development-Optimization decoupling) design architecture (Liu et al., 2021), a mathematical deduction computing model is established for supporting the OA-FSMS commissioning, as shown in Fig. 9.

Fig. 9.

A deduction computing model for commissioning the OA-FSMS.

Firstly, based on the established encapsulation library of equipment, the corresponding relationship between equipment attributes and functional requirements is easily defined. The matrix of parameter configuration and the matrix of equipment interaction could be generated as and , respectively. In variation scenarios such as product changeover and process adjustment, the WIP motion matrix could be adjusted rapidly based on BoP. Under the constraint of process priority, the material handling matrix is constructed based on the initial line balancing. Based on the matrix and of the process flow, the optional operation parameter set could be extracted. In combination with motion planning and buffer allocation computation, the kinematic planning obtains the position and posture between adjacent process equipment based on specific action types of each equipment. It outputs the matrix of the overall motion . Further, in the control formation step, the directed graph of the control structure is formed according to the control matrix based on the knowledge of the industrial interconnection rules and network optimization principles. The mathematical matrices in Fig. 9 are highly-abstracted models. “0” in the matrices represent the independent relationships between two parameters/variables. Other elements in these matrices could be different linear and nonlinear functional relationships, based on which a parameter/variable decision could be deducted by another parameter/variable decision.

Based on the hierarchy 3B model, we can realize a digital twin system-based semi-physical commissioning by following the two stages. At the initial stage of commissioning, the digital twin system generates a set of possible kinetics that realized the given goals in a knowledge-based reasoning manner. Then, the digital twin system imports the configuration on each controller of the OA-FSMS and obtains the execution kernel of system-level control. At the commissioning stage, the engineers may find errors, malfunctions, and inefficiencies. The controls need to be fine-tuned. A set of rewriting rules is obtained by computing the differences between the two controls. The equipment-level controls are sequentially and parallelly merged into the control network. By rectifying the controller with the new rule set, the digital twin system could rapidly reconfigure the control into a new one. Finally, the reference models and subclass libraries lead to the generalization and reuse of the best-practice behavioral features from the historical controls.

5. Prototype system validation and discussions

To validate the proposed digital twin system (DTS), a case of remote commissioning of a smartphone assembly line is studied.

5.1. A case of a smartphone assembly line

The smartphone assembly includes four stages, namely, welding, assembly, testing, and quality control. The smartphone assembly line comprises multiple manufacturing units, and each unit of the assembly line is constructed by multiple parallel and sequential machines and to carry out smartphone assembling cooperatively. For the WIP logistics in the smartphone assembly line, the segmental reflux method is adopted to meet the motion turnover of smartphone products.

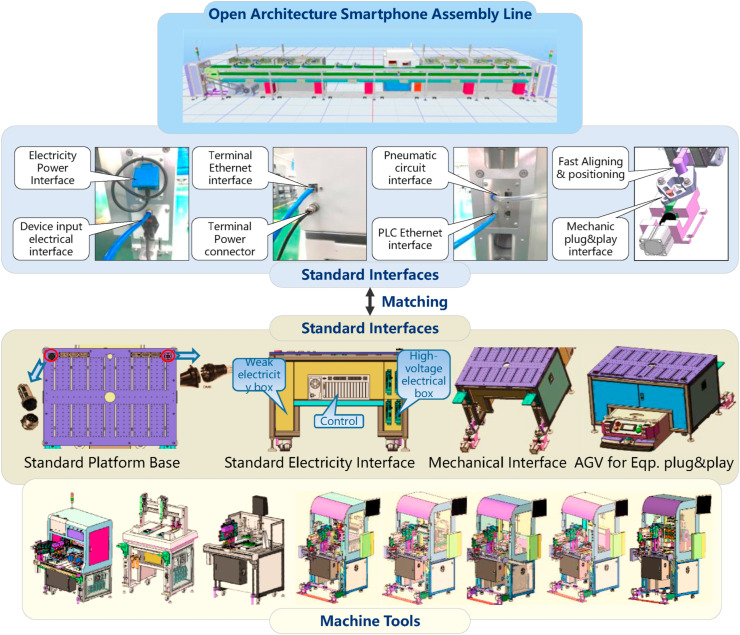

Smartphone manufacturers usually adopt non-standard and customized design modes for their automation equipment, which leads to a wide variety of dimensions, structural principles, and control interfaces of automation equipment, making it challenging to assembly the customized equipment. As shown in Fig. 10 , this research presented the open architecture design of the smartphone assembly line and built plug&play equipment, which can avoid the incompatibility issue.

Fig. 10.

The open architecture design of a smartphone assembly line.

The standardized platform of the open architecture smartphone assembly line includes a mechanical bus and an electrical bus. Firstly, the mechanical bus adopts the Universal Dock. The installation hole position and positioning slot with good commonality are arranged to realize the direct positioning and installation of individualized equipment. Secondly, the electric bus achieves highly secure wiring through partition arrangement between high and low voltage, which provides more convenience for equipment reconfiguration. The connection of low voltage control components (e.g., sensors and solenoid valves) on the lower side and the actuators on the upper side of the equipment is realized by using the plug of the serial port line and the electrical signal conversion board, which is convenient for plug&play and reduces the complexity of wiring. This OA-FSMS design method could keep the inherent topological structure and form of logistics essentially unchanged in the commissioning and reconfiguring process, making the system refactoring faster under the requirements of universality, flexibility, and modularity. The average customization time of non-standard equipment has been reduced by 22 days from 30 days, and the proportion of purchased parts/components in bulk increased from 50% to more than 75%.

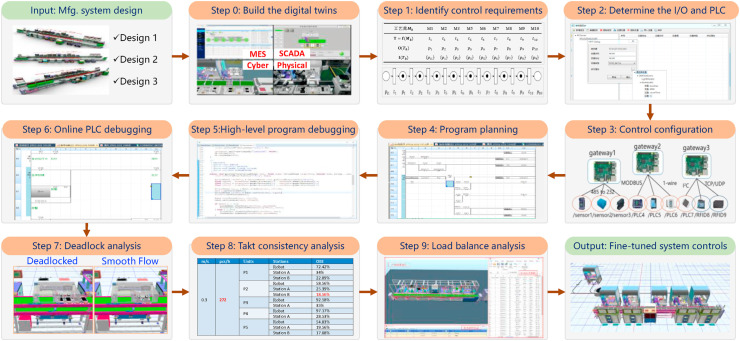

The assembly and processing methods of the smartphone are characterized by point-type processing (e.g., drilling and gluing), planar integral processing (e.g., laminating), and other processing forms with highly similar motion types. WIP logistics includes direct transmission, lifting, and flipping. For the control script of movement and action, code-level reuse is realized. Fig. 11 shows the majors steps of commissioning the smartphone assembly line. The proposed commissioning approach starts with the low-level modeling of hardware. The geometric design, system layout, and kinematic simulation model of each equipment are the input for the semi-physical commissioning. The developed control program will be supplemented by plant-specific locks, a switch-off, and parameterizations. The behavior models are created based on reference models for specific applications. The system function validation, including mechanical behavior and control functions, will end with a semi-physical simulation.

Fig. 11.

Digital twins-based remote semi-physical commissioning of the smartphone assembly line.

In semi-physical commissioning, both the physical and digital controllers are interconnected in the digital twin system simultaneously. For instance, an auto-screwdriver with its controller could be connected to a cyber assembly line model with other digital machine tools, and the cyber assembly line model in the digital twin system cannot percept any difference in the connection between the physical equipment and the digital models. The I/O lists of controllers and the I/O lists of simulation engines are interconnected via the Industrial Internet communication system or direct wiring. Each I/O has several customized features, including data type, range, and unit. The connection between the hardware PLC I/O and the software PLC I/O of the cyber model should be verified with various signal features. The virtualized assembly line model, simulating the behavior of the physical system, is supposed to react to the PLC signals precisely as physical equipment.

At the step of detailed semi-physical commissioning, the operations of manipulators are represented by concrete functional components under some prespecified rules, which are to be inspected by engineers in the detailed commissioning. About 100 function groups are built, stored, and matched in a kinematic reference library for the best-practice reuse. To simulate the operation behavior of the functional components, a simulation model includes 30 inputs and outputs on average, which are attached to the kinematics or the controllers. As shown in Table 3 , a testbed is established with 510 actuator outputs and 577 sensor inputs.

Table 3.

Statics of actuators in the smartphone assembly line.

| Equipment | X | Y | Number | Input X | Output Y |

|---|---|---|---|---|---|

| Standby Equipment | 44 | 40 | 2 | 88 | 80 |

| Double-Sided Adhesive Tape Equipment | 41 | 36 | 1 | 41 | 36 |

| TP Press Equipment | 24 | 21 | 1 | 24 | 21 |

| Fixture Circulating Equipment | 35 | 29 | 1 | 35 | 29 |

| Materials Handling Elevator | 14 | 16 | 1 | 14 | 16 |

| Positioning Equipment | 38 | 16 | 1 | 38 | 16 |

| Screening Equipment | 36 | 24 | 1 | 36 | 24 |

| Manipulator Robot | 32 | 32 | 6 | 192 | 192 |

| Workpieces Feeder | 16 | 12 | 4 | 64 | 48 |

| Auto-Screwdriving Machine | 45 | 48 | 1 | 45 | 48 |

| Sum. | 19 | 577 | 510 |

The average integrated commissioning cycle of the assembly line was reduced from 21 to 7 days. The balance analysis, deadlock analysis, and takt consistency analysis of the manufacturing process are the last key commissioning steps to improve the rationality of system design. Compared to the traditional serial design method, the digital twins support the visualization and virtual integrated debugging of dynamic behavior. The digital twin system realizes the cyber-physical synchronization and parallel control of the assembly process, thus supporting the task coordination of mechanical engineer, control engineer, and software engineer, effectively ensuring that commissioning tasks can be executed parallel. The whole line downtime rate was reduced from 5% to 2%, and the equipment failure rate has been reduced from 5‰ to 3‰. The DT-RSPC application has dramatically improved the manufacturer’s R&D capability of the production line and non-standard equipment.

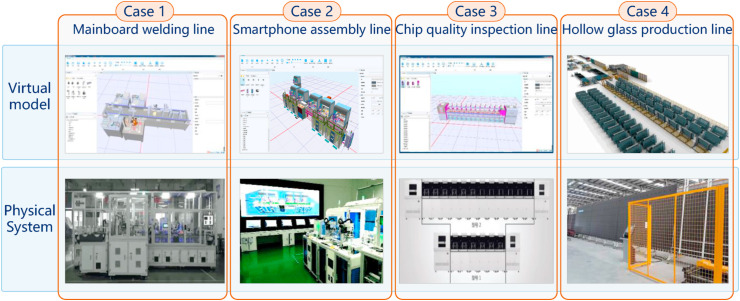

5.2. Performance evaluation of DTS

Based on the proposed DTS-driven semi-physical commissioning idea, four cases of commissioning 3C product manufacturing lines, including chip quality inspection line, mainboard welding line, smartphone assembly line, and hollow glass production line, have been studied and analyzed. As shown in Fig. 12 , the cases were conducted with two commissioning approaches. Each commissioning case had more than 500 individual control signals. The first approach is the original physical commissioning, in which the PLC is programmed, and then the program is tested afterward in in-situ commissioning on physical machines. The results were compared to those from the second approach that uses the digital twin system for semi-physical commissioning. The second approach did not execute the real physical commissioning before achieving successful semi-physical commissioning.

Fig. 12.

Four cases of DTS-driven semi-physical commissioning.

Table 4 provides an overview of the comparative results. The results showed a substantial reduction of commissioning time by 50%, 66.7%, 50%, and 41.7% in four cases, respectively, resulting from enhanced quality of control program at the start of physical commissioning. A reduction of commissioning cost by up to 60% is achieved in commissioning the smartphone mainboard welding line. Reduction of commissioning iteration times by 66.7% and 33.3% in the commissioning of the mainboard welding line and chip quality inspection line are achieved, respectively. The first reason for more efficient commissioning is because that the reference model is available in the simulation library of the digital twin system. The second reason is that the digital twins-based remote semi-physical commissioning among remote machines avoids expensive transportation and physical reconfiguration in-situ.

Table 4.

Comparative result of two commissioning approaches in four cases.

| Cases | Commissioning Time |

Commissioning Cost |

Iteration Times |

|||

|---|---|---|---|---|---|---|

| Original | DT-RSPC | Original | DT-RSPC | Original | DT-RSPC | |

| Mainboard welding line | 10 days | 5 days | 100% | 40% | 100% | 33.3% |

| Smartphone assembly line | 21 days | 7 days | – | – | – | – |

| Chip quality inspection line | 60 days | 35 days | – | – | 100% | 66.7% |

| Hollow glass production line | 180 days | 90 days | – | – | – | – |

5.3. Discussions

This research could guide engineers to develop a digital twin system for the remote semi-physical commissioning to thoroughly verify manufacturing systems based on design data and real equipment, which brings convenience for small and medium-sized enterprises under the COVID-19 pandemic. Although the detailed control parameters will be different in various cases, the proposed digital twin approach is instructive for designers from various manufacturing industries for conducting remote semi-physical commissioning. The proposed OA-FSMS (i.e., open architecture flow-type smart manufacturing system) is highly-flexible to meet the individualized requirements of manufacturing system development. The sustainability, scalability (Putnik et al., 2013), and adaptability (Gu et al., 2004) could be achieved via the OA-FSMS. The key findings in this research are that the open architecture design could greatly promote the efficiency of accommodating new configurations/controls in the DT-RSPC approach and further could promote a new paradigm of social manufacturing, in which the platform manufacturer designs the primary system architecture (similar to the operating system of a mobile phone) and then defines the mechanical and electrical interface for guiding the development of swappable equipment. In practice, by developing equipment adaptable to these standard interfaces defined by these core manufacturers (similar to the development of APPs for the Android or IOS), suppliers could participate in the OA-FSMS community to form a social ecosystem of equipment manufacturing. As the development of OA-FSMS is opened to the wild imagination of engineers, the variety of swappable equipment will be increased tremendously. Eventually, a vision of market-of-one may be achieved in a mass individualization way (Koren et al., 2015). New protection mechanisms of intellectual property will emerge in the development of OA-FSMS.

However, the commissioning function in the proposed digital twin system is in its early stage towards high-level automation and intelligence. There exist a few issues to be addressed in the future. Firstly, the decision intelligence of the proposed commissioning approach is in remarkable absence, and more artificial intelligence models and deep learning algorithms could be incorporated into the digital twin system (Lu et al., 2020). Secondly, in the distributed networking and commissioning environment, the instructions and data of the digital twin system are vulnerable to cyber-attacks, which may be resolved by introducing cyber-security defense technology such as blockchain (Leng et al., 2020, 2021). It should be noted that the blockchain itself also suffers from security issues (Leng et al., 2020), which should be carefully addressed from a systematic perspective in the implementation process.

6. Conclusions

The contribution of this paper lies in introducing the digital twins technology into remote semi-physical commissioning of flow-type smart manufacturing systems. It avoids the shortcomings of either lacking validation on detailed control codes in the virtual commissioning methods or incapable of validating the real material flow in the semi-physical commissioning methods. Based on the fundamental capability of high-fidelity hardware-in-the-loop simulation of the manufacturing system, the digital twin system could support the distributed integration of the whole smart manufacturing system via the Industrial Internet, and accurately reflect and validate the real-world properties of smart manufacturing systems. The digital twins-based semi-physical commissioning could connect virtual models with geographically-dispersed physical equipment from different vendors so that engineers can find hidden errors of controls before the manufacturing system implementation stage. Therefore, it could significantly reduce the integration time and cost required in the expensive physical commissioning phase. Besides, the proposed open architecture FSMS may lead to crowd innovation toward mass individualization. Like Wikipedia, the open architecture-based sustainable design paradigm can enhance the sharing capability of socialized design and manufacturing resources. Developing and commissioning new FSMS under the open architecture design paradigm will also become cheaper and more sustainable. However, the proposed digital twin system and its commissioning function are of limited intelligence and vulnerable to cyber-attacks in the Industrial Internet environment. Future work will be conducted in two directions: 1) incorporating more artificial intelligence algorithms into the digital twin system; 2) developing and implementing cyber-security defense mechanisms to secure the instructions and remote data.

CRediT authorship contribution statement

Jiewu Leng: Methodology, Writing – review & editing. Man Zhou: Writing – original draft. Yuxuan Xiao: Writing – review & editing. Hu Zhang: Validation. Qiang Liu: Conceptualization, Supervision. Weiming Shen: Writing – review & editing. Qianyi Su: Data curation, Software. Longzhang Li: Writing – review & editing.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by the National Key R&D Program of China under Grant No. 2018AAA0101704 and 2019YFB1706200; the National Natural Science Foundation of China under Grant No. 52075107 and U20A6004; and the Science and Technology Planning Project of Guangdong Province of China under Grant No. 2019A1515011815 and 2019B090916002.

Handling Editor: Cecilia Maria Villas Bôas de Almeida

References

- An Y., Qin F., Chen B., Rene S., Wu H. Ontoplc: semantic model of plc programs for code exchange and software reuse. Ieee Trans. Indust. Info. 2020;17(3):1702–1711. [Google Scholar]

- Auinger F., Vorderwinkler M., Buchtela G. Interface driven domain-independent modeling architecture for “soft-commissioning” and “reality in the loop”. inpp. 1999:798–805. [Google Scholar]

- Battle R., Benson E. Bridging the semantic Web and Web 2.0 with representational state transfer (Rest) Web Semant. Sci. Serv. Agents World Wide Web. 2008;6(1):61–69. [Google Scholar]

- Berger T., Deneux D., Bonte T., Cocquebert E., Trentesaux D. Arezzo-flexible manufacturing system: a generic flexible manufacturing system shop floor emulator approach for high-level control virtual commissioning. Concurr. Eng. 2015;23(4):333–342. [Google Scholar]

- Cao H., Zhou J., Jiang P., Hon K.K.B., Yi H., Dong C. An integrated processing energy modeling and optimization of automated robotic polishing system. Robot. Comput. Integrated Manuf. 2020:65101973. [Google Scholar]

- Danielsson F., Moore P., Eriksson P. Validation, off-line programming and optimisation of industrial control logic. Mechatronics. 2003;13(6):571–585. [Google Scholar]

- Fuchs J., Feldmann S., Legat C., Vogel-Heuser B. Identification of design patterns for Iec 61131-3 in machine and plant manufacturing. Ifac Proc. Vol. 2014;47(3):6092–6097. [Google Scholar]

- Gu P., Hashemian M., Nee A.Y.C. Adaptable design. CIRP Ann. - Manuf. Technol. 2004;53(2):539–557. [Google Scholar]

- Gu P., Xue D., Nee A.Y.C. Adaptable design: concepts, methods, and applications. Proc. IME B J. Eng. Manufact. 2009;223(11):1367–1387. [Google Scholar]

- Hoffmann P., Schumann R., Maksoud T.M., Premier G.C. inkuala Lumpur; Malaysia: 2010. Virtual Commissioning of Manufacturing Systems a Review and New Approaches for Simplification; pp. 175–181. [Google Scholar]

- Jain A., Vera D.A., Harrison R. Virtual commissioning of modular automation systems. Ifac Proc. Vol. 2010;43(4):72–77. [Google Scholar]

- Ko M., Ahn E., Park S.C. A concurrent design methodology of a production system for virtual commissioning. Concurr. Eng. 2013;21(2):129–140. [Google Scholar]

- Koo L., Park C.M., Lee C.H., Park S., Wang G. Simulation framework for the verification of Plc programs in automobile industries. Int. J. Prod. Res. 2011;49(16):4925–4943. [Google Scholar]

- Koren Y., Hu S.J., Gu P., Shpitalni M. Open-architecture products. CIRP Ann. - Manuf. Technol. 2013;62(2):719–729. [Google Scholar]

- Koren Y., Shpitalni M., Gu P., Hu S.J. Procedia Cirp. 2015. Product design for mass-individualization; pp. 3664–3671. [Google Scholar]

- Lee C.G., Park S.C. Survey on the virtual commissioning of manufacturing systems. J. Comput. Des. Eng. 2014;1(3):213–222. [Google Scholar]

- Leng J., Liu Q., Ye S., Jing J., Wang Y., Zhang C., Zhang D., Chen X. Digital twin-driven rapid reconfiguration of the automated manufacturing system via an open architecture model. Robot. Comput. Integrated Manuf. 2020:63101895. [Google Scholar]

- Leng J., Ruan G., Jiang P., Xu K., Liu Q., Zhou X., Liu C. Renewable and Sustainable Energy Reviews; 2020. Blockchain-empowered Sustainable Manufacturing and Product Lifecycle Management in Industry 4.0: A Survey; p. 132110112. [Google Scholar]

- Leng J., Yan D., Liu Q., Xu K., Zhao J.L., Shi R., Wei L., Zhang D., Chen X. Manuchain: combining permissioned blockchain with a holistic optimization model as bi-level intelligence for smart manufacturing. IEEE Trans. Syst. Man Cybern.Syst. 2020;50(1):182–192. [Google Scholar]

- Leng J., Yan D., Liu Q., Zhang H., Zhao G., Wei L., Zhang D., Yu A., Chen X. Digital twin-driven joint optimisation of packing and storage assignment in large-scale automated high-rise warehouse product-service system. Int. J. Comput. Integrated Manuf. 2019:1–18. [Google Scholar]

- Leng J., Ye S., Zhou M., Zhao J.L., Liu Q., Guo W., Cao W., Fu L. Blockchain-secured smart manufacturing in Industry 4.0: a survey. IEEE Trans. Syst. Man Cybern.Syst.: Systems. 2021;51(1):237–252. [Google Scholar]

- Leng J., Zhang H., Yan D., Liu Q., Chen X., Zhang D. Digital twin-driven manufacturing cyber-physical system for parallel controlling of smart workshop. J. Ambient Intell Human. Comput. 2019;10(3):1155–1166. [Google Scholar]

- Leng J., Zhou M., Zhao L.J., Huang Y., Bian Y. Blockchain security: a survey of techniques and research directions. IEEE Trans. Serv. Comput. 2020 doi: 10.1109/TSC.2020.3038641. 1-1. [DOI] [Google Scholar]

- Li M., Xu G., Lin P., Huang G.Q. Cloud-based mobile gateway operation system for industrial wearables. Robot. Comput. Integrated Manuf. 2019;58(1):43–54. [Google Scholar]

- Liu J., Zhou H., Tian G., Liu X., Jing X. Digital twin-based process reuse and evaluation approach for smart process planning. Int. J. Adv. Manuf. Technol. 2019;100(5–8):1619–1634. [Google Scholar]

- Liu Q., Leng J., Yan D., Zhang D., Wei L., Yu A., Zhao R., Zhang H., Chen X. Digital twin-based designing of the configuration, motion, control, and optimization model of a flow-type smart manufacturing system. J. Manuf. Syst. 2021;58(B):52–64. [Google Scholar]

- Liu Q., Zhang H., Leng J., Chen X. Digital twin-driven rapid individualised designing of automated flow-shop manufacturing system. Int. J. Prod. Res. 2019;57(12):3903–3919. [Google Scholar]

- Liu Z., Suchold N., Diedrich C. Intechopen; 2012. Virtual Commissioning of Automated Systems. [Google Scholar]

- Lu Y., Liu C., Wang K.I., Huang H., Xu X. Digital Twin-driven smart manufacturing: connotation, reference model, applications and research issues. Robot. Comput. Integrated Manuf. 2020;61:101837. [Google Scholar]

- Luo W., Hu T., Zhang C., Wei Y. Digital twin for Cnc machine tool: modeling and using strategy. J. Ambient Intell Human. Comput. 2019;10(3):1129–1140. [Google Scholar]

- Moghaddam M., Cadavid M.N., Kenley C.R., Deshmukh A.V. Reference architectures for smart manufacturing: a critical review. J. Manuf. Syst. 2018;49(1):215–225. [Google Scholar]

- Nenninger P., Puchstein T. 2018. Software Design Patters in Iec 61131–3 Systems: A Case Study; pp. 795–800. inieee. [Google Scholar]

- Ovatman T., Aral A., Polat D., Ünver A.O. An overview of model checking practices on verification of Plc software. Software Syst. Model. 2016;15(4):937–960. [Google Scholar]

- Pellicciari M., Andrisano A.O., Leali F., Vergnano A. Engineering method for adaptive manufacturing systems design. Int. J. Interact. Des. Manuf. 2009;3(1):81–91. [Google Scholar]

- Putman N.M., Maturana F., Barton K., Tilbury D.M. Virtual fusion: a hybrid environment for improved commissioning in manufacturing systems. Int. J. Prod. Res. 2017;55(21):6254–6265. [Google Scholar]

- Putnik G., Sluga A., Elmaraghy H., Teti R., Koren Y., Tolio T., Hon B. Scalability in manufacturing systems design and operation: state-of-the-art and future developments roadmap. CIRP Ann. - Manuf. Technol. 2013;62(2):751–774. [Google Scholar]

- Quintanilla F.G., Cardin O., Anton A.L., Castagna P. Springer; 2016. Virtual Commissioning-Based Development and Implementation of a Service-Oriented Holonic Control for Retrofit Manufacturing Systems; pp. 233–242. [Google Scholar]

- Reinhart G., Wünsch G. Economic application of virtual commissioning to mechatronic production systems. J. Inst. Eng. Prod. 2007;1(4):371–379. [Google Scholar]

- Renna P. Decision-making method of reconfigurable manufacturing systems’ reconfiguration by a Gale-Shapley model. J. Manuf. Syst. 2017:45149–45158. [Google Scholar]

- Schleich B., Anwer N., Mathieu L., Wartzack S. Shaping the digital twin for design and production engineering. Cirp Ann. 2017;66(1):141–144. [Google Scholar]

- Shen W., Yang C., Gao L. Address business crisis caused by COVID-19 with collaborative intelligent manufacturing technologies. IET Collab. Intell. Manuf. 2020;2(2):96–99. [Google Scholar]

- Stark R., Kind S., Neumeyer S. Innovations in digital modelling for next generation manufacturing system design. Cirp Ann. 2017;66(1):169–172. [Google Scholar]

- Tao F., Cheng J., Qi Q., Zhang M., Zhang H., Sui F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018;94(9–12):3563–3576. [Google Scholar]

- Tao F., Qi Q., Liu A., Kusiak A. Data-driven smart manufacturing. J. Manuf. Syst. 2018;48:157–169. doi: 10.1016/j.jmsy.2018.01.006. [DOI] [Google Scholar]

- Wollschlaeger M., Sauter T., Jasperneite J. The future of industrial communication: automation networks in the era of the Internet of Things and Industry 4.0. IEEE Indust. Electr. Mag. 2017;11(1):17–27. [Google Scholar]

- Zhong R.Y., Huang G.Q., Lan S., Dai Q.Y., Chen X., Zhang T. A big data approach for logistics trajectory discovery from Rfid-enabled production data. Int. J. Prod. Econ. 2015:165260–165272. [Google Scholar]