Abstract

Potholes are one of the most common road distresses in Kuwait especially after winter season in 2018. Pavement deterioration rate significantly increases as the pavement exposes to moisture. Paving road requires using high-quality materials. This paper aims to investigate the feasibility of using recycled asphalt pavement in hot mix asphalt (HMA) design. Questionnaires and a series of laboratory tests were conducted to analyze the effects of pores on the society and test the recycled and the regular mixtures performance to choose the best option regarding it. Marshal test portrayed that the recycled mixture has a high stability and flow. According to the tensile strength ratio test requirements which set a minimum ratio of 75%, it is recommended to reduce the proportion of recycled aggregate. The Hamburg wheel tracker (HWTD) test proved that the recycled asphalt mixture has a low rutting depth for wet and dry samples compared to the general one. On the other hand, the wet recycled mixture requires a reduction by of 20% to satisfy the specifications. The physical properties for both mixtures were compared, and the voids filled with asphalt (VFA) and voids in mineral aggregate (VMA) of the recycled mixture are lower than those in the regular mixture. The recycled mixture reveals a higher efficiency in saving costs and improving mixtures used for potholes maintenance activities. All the results proved that the mixtures consisting of recycled asphalt are most preferred since they are affordable and perform reasonably well compared to mixtures made of regular asphalt. As a future work, smaller percentages of recycled aggregate should be tested to check the robustness and sustainability of the designed recycled asphalt mixture using different tests such as Hamburg wheel tracker test (wet samples) and indirect tensile strength test. Furthermore, more experiments can be run to test other mix parameters and properties such as durability.

Keywords: Pothole, Recycled aggregate, Maintenance, Pavement, Stability, Rutting depth, Air voids

Introduction

The world is moving strongly now toward sustainable and resilient societies to reserve resources for future generations, make use of the overwhelmed waste generated and adopt renewable strategies to fight the climate change. In this direction, it is important to look carefully into circular economy (CE) concept through highlighting the importance that this theory is gaining over time as well as how this work is linked to this notion. Reike et al. (2018) highlighted three stages in the development of CE and emphasized that CE concept is old dated. They indicated that highly recognized levels of circularity had been achieved worldwide in different sciences such as energy recovery and recycling. They concluded that policymakers need to adapt more desirable and shorter loop retention options without affecting the feasibility and overall system performance. Our current work, through encouraging the recycling practice in highway materials for maintenance activities, contributed clearly to the concept of circular economy in developing countries.

Increasingly, greater attention is being paid to investigate the feasibility of using reclaimed asphalt pavement in hot mix asphalt (HMA) designs. Using high-quality mixtures made of materials with good properties would ensure designing pavement that do not deteriorate earlier than its expected lifetime. Distresses appear in pavements due to several reasons: high traffic volume, increasing the traffic load, using low quality or weak mixtures, lack of compaction, insufficient pavement thickness, less of bonds between aggregate and asphalt and water infusion contribute to pavement failure and distresses. Potholes are common distresses found throughout highways in Kuwait. These potholes have been rehabilitated by patching them with asphalt mixtures. It is worthwhile to implement a new patching mixture containing 20% recycled aggregate and polymer. Potholes are a small, bowl-shaped depression, and they occur only in the pavement surface and can deeply extend to the base course. Potholes most likely occur on roads with thin HMA surface layer. They are also related to water infiltration to the deep layers, which results in severe problems such as roughness that causes serious damages to vehicles. The key rule in pavement maintenance is the selection of the method and materials to be used based on the surrounded conditions. Potholes have the most expensive maintenance cost compared to other distresses since it can be extended to the base. Thus, it is necessary to increase the performance of the used material as well as reduce potholes maintenance cost (Biswas, 2016). According to the Public Authority for Rods and Transportation (PART), they spent about 530 million Kuwaiti dinars and requested an additional budget to complete roads repair after the winter season in 2018, which is almost twice the average annual budget (MPW, 2018). This study aims to find out the most suitable mixture in the case of potholes. To achieve the accurate results, two mixtures were prepared: One of them is the regular asphalt mixture, while the other is the recycled asphalt mixture which consists of 20% recycled aggregate. Then, a series of tests were conducted on the mixtures to assess the performance of each one, including sieve analysis, Marshall stability, Hamburg wheel tracking device, bulk density and indirect tensile strength tests. Each of them shows different important parameters that impact the mixture such as stability, tensile strength, density and air voids. The results of the study will lead us to choose the high-quality mixture that will perform well and enhance the life of pavement and delaying its failures which will also result in a lower cost of maintenance. Two questionnaires were also included in the study to have an overview of people impression of potholes, their causes and appearing in inner streets and highways and how to treat them. The results were statically analyzed through statistical tests including Chi-square, correlation and independent t tests. The study tests the problems and the solutions from the practical, theoretical and economical sides, which contributes to provide strong evidence of the feasibility of using recycled aggregate mixture and its benefits.

Literature review

HMA pavement consists of aggregates and asphalt. Aggregates support vehicle loads and ensure skid resistance, while asphalt ensures the contact between the aggregates (Obaidi et al., 2017). The main required material for the pavement’s construction is aggregates. More particularly, both asphalt concrete and conventional concrete mixtures represent a large volume at the time of production (FHWA, ‘‘Towards 2015). Both traffic and thermal loading across aged HMA layer can lead to the spread of cracks leading to the formation of bowl-formed potholes (Zborowski and Kaloush, 2011). Potholes are not the only reason of causing major problems to vehicle suspension frameworks. However, in extreme cases they may result in genuine mishaps and perpetual damage (Homji, 2005). Flexible pavement deterioration is caused by several factors such as traffic loading, climate conditions, materials quality and aging. (Biswas, 2016). Experts believe that potholes formation depends on many variables including traffic load, poor subgrade soil, poor asphalt mixture, poor drainage systems, pavement aging, high annual rainfall, inadequate pothole repair and improper thickness of pavement structure (Maher et al., 2001; Wilson and Romine, 2001; Maupin et al., 2003)). The oxidation and traffic load result in the wear of asphalt surface which lead to having cracks in old pavement structure (Hixson, 2015). Thermal cracking is one of the most critical problems of flexible flooring, particularly in areas where temperature change is critical and quick (Tarefder and Islam, 2014)). Potholes are categorized according to the depth of the hole in separate severity classifications. In the low severity category, a pothole is less than 25 mm deep, while in the moderate severity category the pothole has 25 to 50 mm depth. Finally, in high serious category, a pothole’s depth exceeds 50 mm (Miller and Bellinger, 2003). Potholes are not formed by fatigue cracks only, but also by high severe longitudinal cracks and asphalt raveling (Dong et al., 2014a, Doré and Zubeck, 2009). A pothole in flexible pavement, sized between 25 and 150 mm (0.09 to 0.93 m2), should be repaired in any weather conditions. This is the main purpose of the strategic highway research program, or SHRP. (Blaha, 1993). In summer when weather is hot and dry, the best time for the pothole patching process is achieved (Wilson and Romine, 2001)). In rainy or winter seasons, the density of potholes often indicates the efficiency of the continuous maintenance program (WSDOT Maintenance Manual April, 2017). In winter, to have an easier compaction and easier handling by the worker, aggregates should be at high-quality crushed with fewer fines and must have anti-stripping additive with the binder, while in spring, choosing the materials depends firstly on cost effectiveness and secondly on the local maintenance crew experience (Wilson and Romine, 2001)).

Repair materials—hot mixes, cold mixes, heated cold mixes and recycled mixes, are typically used for pothole patching. Hot asphalt mixes from an asphalt plant are the best materials for patching potholes (Eaton et al., 1989). Using the tack coat on the side of the pothole before placing the patching material increases the adherence of the mixture to the existing pavement surface and creating a durable patch (Prowell and Franklin, 1996). One of the most significant parameters that make a patch durable is the high-quality materials (Kuennen, 2004)). Bleeding, edge disintegration, missing patches, shoving, raveling and dishing are the most common patch disorder reported (Prowell and Franklin, 1996, Dong et al., 2014a, Maher et al., 2001, Lavorato et al. 2013; Biswas 2016). Stability, workability, durability, skid resistance, stickiness, stripping resistance and storage ability are the main properties that should be checked to gain high-quality materials (Biswas, 2016). The common properties used to repair potholes include good working cohesion, loading traffic and environmental durability, bonding, freezing and rutting potential (Maher et al., 2001). High workability of a mixture makes it less steady that leads in some cases to shoving under vehicular stacking (Rosales et al., 2007 and Pimentel 2007). Mixtures that are coated with tarps or polyethylene may have a longer storage time (Maher et al. 2001, Chatterjee et al. 2006; Pimentel, 2007). On the other hand, synthetic binder, cementation material and cold-applied bituminous material are used in the process of pothole patching (Nicholls et al., 2014).

The variability in pavement repair performance has been quite significant. As more parts of the pavement have reached or even surpassed their design life, it is essential that best repair procedures and materials are identified (Chen and Won, 2015). Many patching methods for pothole repairing depend on the repair method and facilities required for the operation: (a) throw-and-go, (b) semi-permanent, (c) spray and (d) edge seal (Maher et al., 2001; Wilson and Romine 2001; Maupin et al. 2003). Throw-and-go is the most common techniques since materials are easily used and inexpensive where materials are shoveled into an unprepared pothole, which may contain water and spoil when the pothole is filled. Compacts are left to the traffic, or a shovel compacts the material lightly (Sainz, 2016). The semi-permanent procedure is the best procedure besides full-depth replacement of the affected area. The downside is higher labor and materials cost and less productivity than spray injection and throw-and-roll (Wilson and Romine, 1994). Spray injection is most useful for maintenance transverse cracks and potholes. In this edge seal, first of all use the throw-and-roll repair, and then, potholes are being filled and compacted with a heavy vehicle. Then, a strip of asphaltic tack material along the rim of the patch is placed, interfering the pavement and the patch. Finally, put sand on the tack material in order to prevent sticking to the tires of the car. (Sainz, 2016). On average, Edmonton regularly fills 400,000 potholes and the ordinary annual pothole fixing expenditure plan is about US$ 3 million (Male, 2013). Annual United States Commission in accordance with the National Surface Transport Policy and Revenue Research Congress, for the next 50 years, about$185 billion is annually required by all levels of government to merely keep state roads, roads and bridges. In 1999, more than $1 billion in pothole and spall repair were estimated annually to be spent in the USA (Kuo et al., 1999). Today, the states pay $68 billion annually for the price of repairing highways and bridges in the USA. That's how much the United States Society of Civil Engineers (ASCE) considers that it would cost. The idea about road maintenance is joined by environmentalists and fiscal conservatives: What is there is better than new ones to be redeveloped (Pothole.info, 2010). In 2017, Saha and others studied the effect of using reclaimed asphalt pavement (RAP) on HMA. The results showed that mixtures with RAP exhibit higher resistance to rutting distress. In 2018, the effect of using RAP in warm mix asphalt and the effect of two critical factors, mixing time and temperature, were studied and the results provided a relation that allows mix designer to predict which conditions would make the hypothesis of full blending reasonable.

Extended state of the art in the subject area

A study conducted by experts in civil engineering aims to evaluate the performance of asphalt concrete made of aggregate demolition waste in Kuwait and showed that the recycled mixture satisfied all the requirements of local specifications (Aljassar et al., 2005). Shopeng and others studied the influence of using recycled aggregate in asphalt mixture in China. The results proved that the asphalt mixture performs satisfactory especially in hot and arid environments (Shaopeng et al., 2013). A recent study was also conducted to assess the performance of RAP according to its percentage in the mixture in Kuwait. The results show that adding up to RAP results in 3.6% reduction in the optimum asphalt content and saving in the virgin aggregate, while using more than 25% of RAP in the mixtures leads to a reduction in the performance of the mixture including resistance to rutting, cracking, stability and flow (Ali et al., 2020). Ghabchi and others also studied the effect of using a different amount of RSP and RAS on HMA, and the results indicated that fatigue life increased with increasing RAP content up to 25% (Ghabchi et al., 2016), while another study focuses on the gradation of the aggregate used and showed that the allowable RAP percentages for the gap gradations are lower than those for the dense gradations. The RAP also has a high rutting resistance (Gottumukkala et al., 2021)). However, changing the proportion of RAP has no significant improvement in the tensile strength ratio in the HMA. (Tassiri et al., 2021). And to ensure a durable pavement, the performance of asphalt pavement should be improved. A study reveals that substitution coarse aggregate with RAP results in significant improvement in mechanical properties and performance of HMA. Using polymer-modified bitumen binder also has an impact on improving the properties and performance of HMA (AL-GhurabiBasim & Al-Humeidawi, 2021). In general, using recycled materials in HMA such as aggregate is highly recommended because it results in benefits in terms of environmental sustainability. Recycled aggregate pavement is also an effective-cost alternative to virgin aggregate (Durrani, 2021). RAP provides sustainable benefits and has a major contribution in reducing greenhouse gas emissions and conserving the natural resources (Guangwei et al., 2021). It is proved that as RAP content increases by 20%, the energy consumption reduces by 7–10%, while CO2 emission decreases by 8–10% (Zhang et al., 2021).

Methodology

This section of the study represents the methods and tests used to reach the final results. Questionnaires were distributed to analyze the effect of potholes on the society, their causes and treatment. Statistical analysis was used to indicate the relationship between variables, if there is any. On the other hand, a prepared sample of regular asphalt mixture that is currently used in Kuwait will be compared to a recycled aggregate asphalt mixture consisting of 20 and 80% of recycled regular aggregate, respectively. A series of tests will be conducted to assess the performance of each sample and to compare the resulted parameters to find out the preferred mixture, including material collections, sieve analysis, Marshall, Hamburg wheel tracker device (HWTD), bulk density and indirect tensile strength tests.

Questionnaire methodology

The general questionnaire

This questionnaire investigates the potholes in inner streets and highways, cars malfunction due to potholes, cost of fixing it and the general impression of the quality of the potholes repair in Kuwait as shown in Fig. (1). The sample size was chosen to be 361 after the confidence level being assumed to be 92%, Z = 1.5, P = 0.5 and the confidence interval c to be within ± 0.046. The number of participants was 368, and the majority of them were females. All the responders are suffering from potholes and noticed their proliferation except one responder. Most of the responders noticed the proliferation of potholes just after the rainy season in November 2018, while 54.4% of participants in the questionnaire had an alarming frequency of facing potholes which is more than 10 potholes/day. Also, most of the responders noticed potholes in the inner streets, while only 6% of them did not face or even notice potholes there. On the other hand, 90% of responders noticed potholes in the highways which is less than those in the inner streets. Almost half of responders faced more than 10 potholes in the highways. And more than 60% of responders had at least one malfunction in their cars due to potholes in roads, most of them spent up to 200 K.D to fix their cars from responders’ view, and potholes are the number one reason of traffic disruption. Responders also noticed that potholes returned within a year after repair as a result of bad materials quality. Overall, responders described the performance of the Ministry of Public Works (MPW) in Kuwait regarding potholes repair as per Fig. 2.

Fig. 1.

Pavement maintenance questionnaire. a The probable causes of pothole. b The types of distresses cause failure of repaired pothole. c The severity of most of the potholes

Fig. 2.

Samples of regular asphalt mixture before applying on them HWTD

The pavement maintenance questionnaire

This questionnaire investigates the characteristics of the transport network, the causes of the pothole, the treatment methods and the materials used for the patching and pavement repair budget which was sent to Public Authority for Roads & Transportation, the Ministry of Public Works and Combined Group Contracting Company in March and April 2019. Questionnaires were queried from Pothole Condition in Canada and Evaluation of Maintenance Material by Biswas 2016 and made it fit the situation in the State of Kuwait.

The sample size, after careful studying, was chosen to be 368 after assuming the confidence level to be 92%, Z = 1.75, P = 0.5 and the confidence interval c to be in between ± 0.01. According to the results, potholes are most likely caused by poor drainage followed by poor asphalt mixture, while a high groundwater table has the least contribution to potholes appearing. It is also found that the edge disintegration, missing patch and raveling are the most types of distresses that may cause failure of repaired potholes. The quality of material was not determined because most of the patch mixture was not tested in the laboratory which is another factor of patch failure. According to potholes severity degree which increases with depth, low severity and moderate severity potholes are more repaired compared to the high severity. Potholes repair is also affected by seasons, and most of potholes are repaired during winter.

Marshall test

This test was undertaken to compare the air voids, stability, flow and specific gravity of each mixture. During the experiment, the plastic deformation strength of the bitumen mix is evaluated. When the whole sample is loaded at a deformation rate of 50 mm per minute, the stability of Marshall is also calculated, in which the maximum sample is loaded at a record temperature of 60 °C. (MS-2, 2014).

Tensile strength ratio (TSR) test

This test was conducted to measure the tensile strength of the wet and dry sample to calculate the ratio of the tensile strength of the saturated sample to the dry one. In the test, the resistance to wetness damage is measured by compressed mixtures of asphalt concrete. The sample is packed with a stable deformation rate of the vertical ram motion of the sample (2inches/minute) until failure.

Hamburg wheel tracker test

The values of rutting depth of each sample will be obtained during this test. The test simulates the actual repetitive loads on the road in order to detect material rutting performance on the pavement samples (Louay et al., 2017). 5600 g of aggregate was added to 288 g of bitumen, and therefore, the total weight of the regular asphalt mixture used is 5888 g, and 5600 g of aggregate was added to 257.7 g of bitumen. Therefore, the total weight of recycled asphalt mixture used is 5857.7 g.

Results and discussion

Questionnaire analysis

Chi-square test results

Firstly, two questions were selected to discover if they were significantly related to the car malfunction, and the questions are whether people noticed potholes in the (a) inner streets and (b) the highway. Secondly, two questions were selected to discover if they were related to each other, and these questions are (a) whether traffic is disruption is caused by potholes and (b) number of potholes per day. The results of the test are presented in Appendix B1, and it reveals that there is no strong relation between car malfunctions and potholes in both inner streets and highways because P value is more than 0.05. Also, the relationship between traffic disruption and number of potholes per day is very significant since P value is 0. Finally, there was no significant relationship between governorate and potholes in the highway streets because P value exceeds 0.05 unlike the relationship between governorate and potholes in the inner streets.

Independent t test results

If significance > 0.05, then the assumption of equal variances holds. On the other hand, if significance < 0.05, then equal variances are not assumed. Appendix B2 shows the results on t test. Based on the results, male participants had significantly faced more potholes per day (2.63 ± 0.715 potholes/day) compared to female (2.27 ± 0.824 potholes/day). An independent t test found this pattern to be significant, since t (75.193) = −3.341, and o is less than 0.05 and equals 0.001. The results are logical because males are more familiar with using different and far roads than females. The relation between self-driving and noticing the return of the potholes after repairing them was also studied. It is revealed that drivers who do not drive by themselves did not notice the return of the potholes after repairing them (1.47 ± 0.598) as much as those who drive by themselves (1.69 ± 0.546). The test is found to meet the pattern, where t (111.853) equals −2.919 and p value of 0.004 which is less than 0.05.

Correlation test results

This test is considered valid if the p value was found to be < 0.05 which means a strong relationship exists. First, two questions were selected to discover if they were related to each other (a) the percentage of truck traffic and (b) average number of potholes in the same network. The statistical results including the mean and standard deviation of the correlation test are shown in Appendix B3. The results proved that there is a very significant correlation between average number of potholes and the percentage of truck traffic because the significance is – 0.430 which is less than 2. Therefore, the increase in traffic has a substantial impact on potholes.

Sieve analysis test results

Sieve analysis test for regular and recycle patching mix

Aggregate sizes equal to 3/4″, 3/8″, and crushed sand were used for both the regular and recycle patching mix. The regular samples weight before entry were 5135.3 g, 3349.2 g, 1146.9 g., respectively, while for the recycle mixture, the samples weight before entry were 4893.7, 2999.4, 1020 g., respectively. The results of combined gradation for regular and recycle patching mix are shown in Appendices B4 and B5. The values of combined gradation must be close to the general specification values. As the difference between the values increases, the aggregate becomes a bit coarser. For combined gradation, values for both mixtures are close to the general ones which makes the sample accepted.

Quantity of bitumen

Values of bitumen can be calculated using the computational formula in Appendix A1, and the results are presented in following table. By finding the bitumen content, the dust–bitumen ratio can be found using Appendix A2. And to ensure having three trials for the mix, 0.5 and 1.0% will be added to the bitumen quantity in Tables 1, 2.

Table 1.

General questionnaire results

| Gender | Female | Male | ||||

| 85.9% | 14.1% | |||||

| Nationality | Kuwaiti | Non-Kuwaiti | ||||

| 93.5% | 6.5% | |||||

| Age Group | 18–25 | 25–35 | 35–45 | Above 45 | ||

| 44.6% | 19.3% | 15.2% | 20.9% | |||

| Governorate | Al-Ahmadi | Al-Farwanya | Al-Jahra | Hawalli | Kuwait City | Mubarak Al-Kabeer |

| 11.1% | 15.8% | 10.9% | 22.6% | 32.1% | 7.6% | |

| Licensed to drive | No | Yes | ||||

| 13.3% | 86.7% | |||||

| Drive yourself | No | Yes | ||||

| 20.9% | 79.1% | |||||

Table 2.

Bitumen content and ratio

| Dust–bitumen ratio | ||

|---|---|---|

| Bitumen % | Regular patching mix | Recycled patching mix |

| 4.9 | 1.29 | 1.26 |

| 5.4 | 1.17 | 1.15 |

| 5.9 | 1.07 | 1.05 |

Total weight of the mixture

The total aggregate weight in a patch can be calculated using equation in Appendix A3. The weight aggregate, crushed sand, filler and bitumen of the regular mixture after each trial 3600 g are presented in Appendix B6. The total weight of each trial is 3600 g. It is noticed that the weight of the sample decreases with trials.

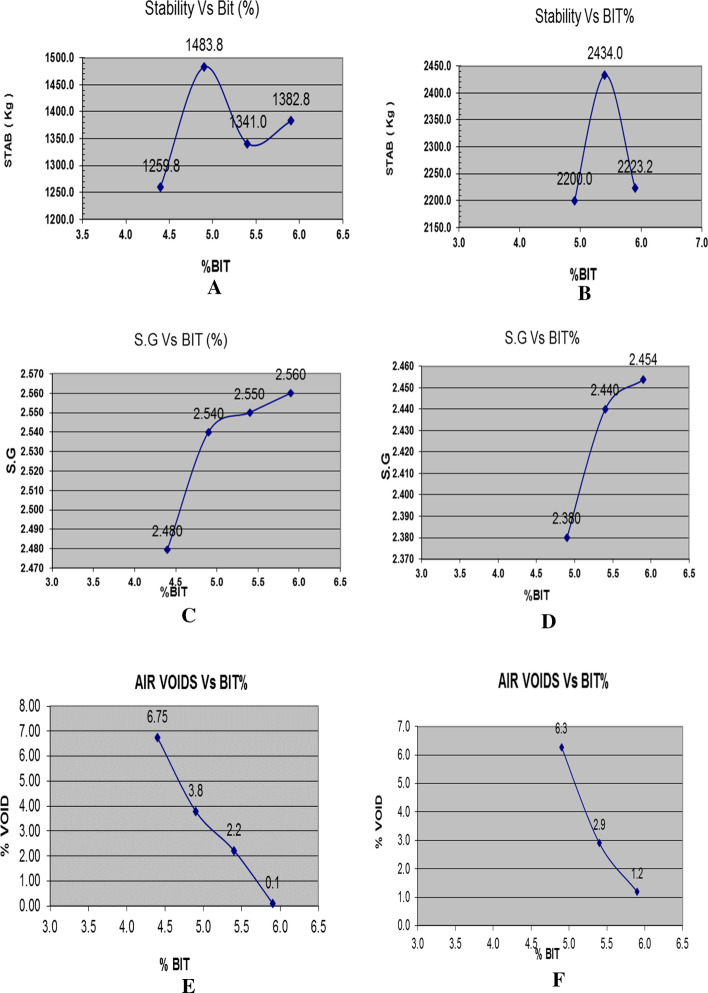

Marshall test for regular patching mix and polymer-modified bitumen

Table 3 shows the results for both regular and polymer-modified calculations, and the changes of stability, air voids, flow and specific gravity with bitumen percentage. According to the results, the polymer-modified mix has more air voids, higher values of stability and flow compared to the regular one, while the specific gravity is close to the regular mixture. Based on the values in Table 8, it is concluded that for both cases, as bitumen percentage increases, both specific gravity and flow increase, while air voids decrease. It is noticed that stability reaches its maximum value at bitumen content of 4.9%.

Table 3.

Marshall Test results

| % BIT | Stability (KN) | S.G | FLOW(mm) | Air voids% | ||||

|---|---|---|---|---|---|---|---|---|

| Regular | Recycled | Regular | Recycled | Regular | Recycled | Regular | Recycled | |

| 4.9 | 14.58 | 21.6 | 2.54 | 2.38 | 27.99 | 13.1 | 3.78 | 6.28 |

| 5.4 | 13.1 | 23.9 | 2.55 | 2.44 | 23.09 | 15.7 | 2.2 | 2.9 |

| 5.9 | 13.6 | 21.8 | 2.56 | 2.545 | 20.17 | 17.7 | 0.091 | 1.2 |

Tensile strength ratio (TSR) test results

After applying the TSR test, the average tensile strength of recycled asphalt mixture for dry and wet subset was found to be 1497 Kpa and 1038 Kpa, respectively. Therefore, the tensile strength ratio which is the ratio of dry sample tensile strength to the wet one is 69.3%, while the required percentage should exceed 75%. Therefore, the proportion of recycled aggregate should be reduced to satisfy the requirements.

Hamburg wheel tracker results

The rut depth for both regular and recycled asphalt mixtures is shown in Table 4. According to the specification of Qatar road and highway transportation, rut depth must not exceed 12.5 mm and have minimum passes of 20,000. The results show that rutting depth of the recycled asphalt mixture of dry sample reaches 0.13 mm and passed the test. On the other hand, the wet sample reaches 4.52 mm, and it did not reach 20,000 passes but only 17,952 passes. Therefore, it did not pass the test. In order to pass the test, the sample supposed to be decreased by 20%. The results show that for both wet and dry samples for recycled and regular mixture, the wet sample did not pass the test, while the dry one passed and HMA prepared using recycled aggregate has lower rut depth values. This can be explained by the fact that the amount of asphalt absorbed by recycled aggregate could strengthen the bond between asphalt and aggregate after being compacted.

Table 4.

Rut depth comparison

| Samples | ||

|---|---|---|

| Mixtures rut depth | Recycled asphalt mixture rut depth (mm) | Regular asphalt mixture rut depth (mm) |

| Wet samples | 4.52 | 7.68 |

| Dry samples | 0.13 | 1.56 |

Volumetric properties results

The following table compares the some of the volumetric properties of regular and recycled asphalt mixtures, and more properties are shown in Appendix B8. It is shown that the recycled mixture contains less voids filled with asphalt (VFA) and voids in mineral aggregate (VMA) in comparison with the regular mixture at the same bitumen content. At the maximum bitumen content which is 5.9%, the VFA is 25% lower than those in the regular mixture in Table 5.

Table 5.

Regular patching mix in bitumen

| Regular | Recycled | |||||

|---|---|---|---|---|---|---|

| 4.4% | 5.4% | 5.9% | 4.9% | 5.4% | 5.9% | |

| VFA | 48.45062 | 80.6781 | 99.00906 | 44.36872 | 70.154 | 73.8682 |

| VMA | 13.05904 | 11.5054 | 11.83517 | 11.29203 | 9.725205 | 9.281594 |

Discussion

This study is discussing the pavement deterioration solution through effective mixtures. So, it is vital to effectively discuss the outcomes and findings. Reviewing the above results and outcomes related to the mix design and testing show a number of interesting findings. Potholes’ severity degree increases with depth, and thus, they require immediate maintenance to prevent problems. The tensile strength of the wet sample calculated through the tensile strength test is 69.3% of the dry one, which did not meet the requirements. Therefore, recycled aggregate amount should be reduced to exceed the minimum limit which is 75%. While the Marshall test helped to test the stability, flow and air voids of each mixture, the results proved that the recycled mixture has a better stability and higher values of flow and air voids than the regular mixture. According to HWTD, the recycled aggregate asphalt mixture shows a low rutting depth for both wet and dry samples compared to the regular mixture. This makes the recycled mixture a better choice for pavement design. The results show that rutting depth of the recycled asphalt mixture of dry sample reaches 0.13 mm and passed the test. On the other hand, the wet sample reaches 4.52 mm, and it did not reach 20,000 passes but only 17,952 passes. Therefore, it did not pass the test. In order to pass the test, the sample supposed to be decreased by 20%. Physical properties of the recycled mixture are most preferred since the mixture contains less VMA and VFA. It is shown that the recycled mixture contains less voids filled with asphalt (VFA) and voids in mineral aggregate (VMA) in comparison with the regular mixture at the same bitumen content. At the maximum bitumen content which is 5.9%, the VFA is 25% lower than those in the regular mixture. Mixtures made of recycled aggregates perform well in maintenance activities and have a lower pavement design cost.

Maintenance of potholes

Road maintenance includes activities to maintain their construction or renovation as quickly as possible of their sidewalks, shoulders, slopes, sanitary facilities and all structures and other property within the road margins to ensure they remain strong, efficient and safe (PIARC, 1994). In the last five years, the agency's average annual paving is 5000 KD/month, and 4% of its average annual repair work is done on the potholes. (PART, 2019). According to Table 6, it is obvious that potholes with shallow depths can be monitored but not repaired automatically, while other potholes with medium depth require about 6 months to be repaired. On the other hand, the deepest potholes get repaired within least time of 24 h. It can be concluded that as depth increases, repair time decreases.

Table 6.

Timescales for repairing a pothole (Southampton, 2016)

| Depth of pothole on a road | Depth of pothole on a pavement | Timescale for repair |

|---|---|---|

| Less than 4 cm (e.g., a golf ball) | Less than 2 cm | Monitored but not repaired automatically |

| Between 4 and 7.5 cm (e.g., a tennis ball) | Between 2 and 4 cm | Within 6 months |

| More than 7.5 cm | More than 4 cm | Within 24 h |

Cost estimation

The price of asphalt mixtures varies widely among countries depending on several factors such as oil availability and its prices. Appendix 8 shows the total cost of both regular and recycled aggregates according to the local prices in Kuwait. The mentioned prices were calculated for paving a 1 km length street with 11 m width and 5 cm thickness. The total savings due to using the recycled aggregate mixture instead of the regular one reach a total value of 38 KD. Nationally, total savings cost due to using the recycled mixture instead of the regular one may be much higher than the savings in Kuwait. The value also increases as the road length increases, and this is another factor of making the recycled mixture cost-efficient and a preferred one to be used.

Conclusions

This paper shows how to improve asphalt mixtures used for potholes maintenance by providing a better alternative mixture which is the recycled aggregate asphalt mixture. After conducting several tests and questionnaires, very effective and helpful results were gained. People showed their disappointment on potholes appearing in roads, because potholes cause major damages to cars which requires an additional budget to fix them. A lot of people think that the edge disintegration, missing patch and raveling are the most types of distresses that may cause failure of repaired potholes. Not testing the patch mixture in the laboratory also contributed to patch failure. Potholes’ severity degree increases with depth, and thus, they require immediate maintenance to prevent problems. The tensile strength of the wet sample calculated through the tensile strength test is 69.3% of the dry one, which did not meet the requirements. Therefore, recycled aggregate amount should be reduced to exceed the minimum limit which is 75%. While the Marshall test helped to test the stability, flow and air voids of each mixture, the results proved that the recycled mixture has a better stability and higher values of flow and air voids than the regular mixture. According to HWTD, the recycled aggregate asphalt mixture shows a low rutting depth for both wet and dry samples compared to the regular mixture. This makes the recycled mixture a better choice for pavement designs. The results show that rutting depth of the recycled asphalt mixture of dry sample reaches 0.13 mm and passed the test. On the other hand, the wet sample reaches 4.52 mm, and it did not reach 20000 passes but only 17952 passes. Therefore, it did not pass the test. In order to pass the test, the sample supposed to be decreased by 20%. Physical properties of the recycled mixture are most preferred since the mixture contains less VMA and VFA. It is shown that the recycled mixture contains less voids filled with asphalt (VFA) and voids in mineral aggregate (VMA) in comparison with the regular mixture at the same bitumen content. At the maximum bitumen content which is 5.9%, the VFA is 25% lower than those in the regular mixture.

Mixtures made of recycled aggregates perform well in maintenance activities and have a lower pavement design cost. The previous outcomes support the decision of using the recycled mixture instead of the regular one and motivate us to conduct more studies to test other parameters and properties such as durability.

The research team faced some delays in conducting the tests due to COVID-19 regulations by Ministry of Health. Working in laboratory requires permissions, and number of labors and working hours in the laboratory have been reduced which requires additional days to apply the tests. In Kuwait, waste is not separated, so the team tried to collect aggregate demolition waste that will be used as recycled aggregate in the mixture from projects under construction which consumes a lot of time and efforts. The laboratory conditions are different than those in the field. Thus, the mixture may perform differently in the field. It is recommended to apply some in situ tests, if possible, to ensure having a good pavement mixture that performs well.

During this study, several laboratory tests were conducted and gave substantial results. Some of the results showed that the sample requires some reduction or improvement. Thus, these tests will be repeated soon after applying the recommendations to satisfy the specifications. Mixture’ performance will be assessed after that. This study provided us with some parameters of the asphalt mixture, while more important properties have not been checked. Workability, durability, skid resistance, stickiness, stripping resistance and storage ability will be checked in the following studies to have a high-quality pavement and improve it if required. On other hand, the temperature, environment and conditions in the laboratory are different than those in the field. Thus, in situ tests are required to be conducted to ensure having a good pavement. Cooperating with other researchers and experts is highly recommended and will provide us with the best results.

Acknowledgements

The author would like to thank Engineers Refah Alshammari, Reem Almahmoud, Fatemah Albusairi and Hanan Almutairi for their help in data collection and analysis.

Appendix

Appendix A: A1: computational formula

Where:

P is the approximate asphalt content of mix percent by weight of mix, a percent of mineral aggregate retained on 2.36-mm (No. 8) sieve, b percent of mineral aggregate passing the 2.36-mm (No. 8) sieve and retained on the 75 µm (No. 200) sieve, c percent of mineral aggregate passing 75 µm (No. 200) sieve, K 0.15 for 11–15 percent passing 75 µm (No. 200) sieve, 0.18 for 6–10 percent passing 75 µm (No. 200) sieve, 0.20 for 5 percent or less passing 75 micrometer (No. 200) sieve, F = 0- 2.0 percent. Based on the absorption of light or heavy aggregate, in the absence of other data, a value of 0.7 is suggested.

A2: Dust–bitumen ratio

where X = percent of mineral aggregate passing 75 µm (No. 200) sieve.

To find the total weight of the aggregate in a patch, we will take the percentages of the ¾”, 3/8″ and crushed sand in the patch and convert it into weight (gram), and then, we will add them together.

A3: Total aggregate weight in a patch

and then to calculate the weight of the patch, we will convert the approximate bitumen values from percentage to weight (gram) to add them to the fixed weight of the aggregate (3600 g).

Appendix B

See Tables 7, 8, 9, 10, 11, 12, 13 and 14.

Table 7.

Chi-square tests results

| Value | Df | Asymptotic significance (two-sided) | |

|---|---|---|---|

| Car malfunctions and potholes in the inner streets | |||

| Pearson Chi-square | 2.785a | 2 | .248 |

| Likelihood ratio | 2.642 | 2 | .267 |

| No. of valid cases | 368 | ||

| Car malfunctions and potholes in the highways | |||

| Pearson Chi-square | 9.209a | 2 | .010 |

| Likelihood ratio | 10.064 | 2 | .007 |

| No. of valid cases | 368 | ||

| Traffic disruption and number of potholes per day | |||

| Pearson Chi-square | 77.682a | 6 | .000 |

| Likelihood ratio | 25.638 | 6 | .000 |

| No. of valid cases | 368 | ||

| Governorate and potholes in the inner streets | |||

| Pearson Chi-square | 13.306a | 5 | .021 |

| Likelihood ratio | 9.113 | 5 | .105 |

| No. of valid cases | 368 | ||

| Governorate and potholes in highways | |||

| Pearson Chi-square | 7.682a | 5 | .175 |

| Likelihood ratio | 7.618 | 5 | .179 |

| No. of valid cases | 368 | ||

Table 8.

Group statistics per day and independent samples tests

| Your gender? | N | Mean | Std. deviation | Std. error mean | |

|---|---|---|---|---|---|

| Group statistics of gender and number of potholes per day | |||||

| How many potholes do you face per day? | Female | 316 | 2.27 | 0.824 | .046 |

| Male | 52 | 2.63 | 0.715 | .099 | |

| Do you drive the car yourself? | N | Mean | Std. deviation | Std. error mean | |

|---|---|---|---|---|---|

| Group statistics of self-driving and returning the potholes | |||||

| Have you ever noticed a road that was potholes and after repairing it returned potholes again? | No | 77 | 1.47 | .598 | .068 |

| Yes | 291 | 1.69 | .546 | .032 | |

| Levene’s test for equality of variances | t test for equality of means | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| F | Sig | T | Df | Sig. (two-tailed) | Mean difference | Std. error difference | 95% Confidence interval of the difference | |||

| Lower | Upper | |||||||||

| Independent samples test of gender and number of potholes per day | ||||||||||

| How many potholes do you face per day? | Equal variances assumed | 12.858 | .000 | − 3.016 | 366 | 0.003 | − 0.366 | 0.121 | − 0.604 | − 0.127 |

| Equal variances not assumed | − 3.341 | 75.193 | 0.001 | − 0.366 | 0.109 | − 0.584 | − 0.148 | |||

| Independent samples test of self-driving and returning the potholes | ||||||||||

| Have you ever noticed a road that was potholes and after repair it returned potholes again? | Equal variances assumed | 7.136 | .008 | − 3.076 | 366 | .002 | − .220 | .071 | − .360 | − .079 |

| Equal variances not assumed | − 2.919 | 111.853 | .004 | − .220 | .075 | − .369 | − .071 | |||

Table 9.

Average number of potholes and the percentage of truck traffic

| Mean | Std. deviation | N | |

|---|---|---|---|

| Descriptive statistics | |||

| AVG No. Potholes | 500.63 | 374.074 | 63 |

| % Trucks traffic | 20.760 | 21.1554 | 65 |

| AVG No. Potholes | % Trucks traffic | ||

|---|---|---|---|

| Correlations test results | |||

| AVG No. Potholes | Pearson correlation | 1 | − 0.430** |

| Sig. (two-tailed) | .001 | ||

| N | 63 | 61 | |

| % Trucks traffic | Pearson Correlation | − 0.430** | 1 |

| Sig. (two-tailed) | .001 | ||

| N | 61 | 65 | |

Table 10.

Combined gradation for the regular patching mixture

| ASTM Sieve size | Aggregate Percent Passing | Combined | Specification | ||||

|---|---|---|---|---|---|---|---|

| 3/4″ | 3/8″ | CR.S | Filler | Gradation | General | ||

| 33 | 21 | 42 | 4 | ||||

| 1 1/2″ | 37.5 mm | 100 | 100 | 100 | 100 | 100 | 100 |

| 1″ | 25.0 mm | 100 | 100 | 100 | 100 | 100 | 100 |

| 3/4″ | 19.1 mm | 94 | 100 | 100 | 100 | 98 | 100 |

| 1/2″ | 12.5 mm | 43 | 100 | 100 | 100 | 81 | 81 |

| 3/8″ | 9.51 mm | 11 | 95 | 100 | 100 | 70 | 71 |

| NO.4 | 4.75 mm | 2 | 35 | 100 | 100 | 54 | 54 |

| NO.8 | 2.36 mm | 1 | 9 | 69.44 | 100 | 35 | 39 |

| NO.16 | 1.16 mm | 1 | 4 | 38.9 | 100 | 22 | 29 |

| NO.30 | 600 μm | 1 | 3 | 25.56 | 100 | 16 | 22 |

| NO.50 | 300 μm | 1 | 2 | 16.84 | 95 | 12 | 16 |

| NO.100 | 150 μm | 1 | 2 | 10.55 | 90 | 9 | 11 |

| NO.200 | 75 μm | 1.0 | 1.1 | 5.667 | 85 | 6.3 | 7.0 |

Table 11.

Combined gradation for the recycle patching mixture

| ASTM sieve size | Aggregate percent passing | Combined | ||

|---|---|---|---|---|

| Regular 3/4″ | Recycle 3/4″ | Gradation | ||

| 80 | 20 | |||

| 1 1/″ | 37.5 mm | 100 | 100 | 100 |

| 1″ | 25.0 mm | 100 | 100 | 100 |

| 3/4″ | 19.1 mm | 94 | 99 | 95 |

| 1/2″ | 12.5 mm | 43 | 66 | 48 |

| 3/8'″ | 9.51 mm | 11 | 25 | 14 |

| NO.4 | 4.75 mm | 2 | 1 | 2 |

| NO.8 | 2.36 mm | 1 | 0 | 1 |

| NO.16 | 1.16 mm | 1 | 0 | 1 |

| NO.30 | 600 μm | 1 | 0 | 1 |

| NO.50 | 300 μm | 1 | 0 | 1 |

| NO.100 | 150 μm | 1 | 0 | 1 |

| NO.200 | 75 μm | 1.0 | 0.0 | 0.8 |

| ASTM sieve size | Aggregate percent passing | Combined | ||

|---|---|---|---|---|

| Regular 3/8″ | Recycle 3/8″ | Gradation | ||

| 80 | 20 | |||

| 1 1/2″ | 37.5 mm | 100 | 100 | 100 |

| 1″ | 25.0 mm | 100 | 100 | 100 |

| 3/4″ | 19.1 mm | 100 | 100 | 100 |

| 1/2″ | 12.5 mm | 100 | 100 | 100 |

| 3/8″ | 9.51 mm | 95 | 96 | 95 |

| NO.4 | 4.75 mm | 35 | 12 | 30 |

| NO.8 | 2.36 mm | 9 | 1 | 7 |

| NO.16 | 1.16 mm | 4 | 0 | 3 |

| NO.30 | 600 μm | 3 | 0 | 2 |

| NO.50 | 300 μm | 2 | 0 | 2 |

| NO.100 | 150 μm | 2 | 0 | 2 |

| NO.200 | 75 μm | 1.1 | 0.0 | 0.9 |

| ASTM sieve size | Aggregate percent passing | Combined gradation | ||

|---|---|---|---|---|

| Regular crushed sand | Recycle crushed sand | |||

| 80 | 20 | |||

| 1 1/2″ | 37.5 mm | 100 | 100 | 100 |

| 1″ | 25.0 mm | 100 | 100 | 100 |

| 3/4″ | 19.1 mm | 100 | 100 | 100 |

| 1/2″ | 12.5 mm | 100 | 100 | 100 |

| 3/8'' | 9.51 mm | 100 | 100 | 100 |

| NO.4 | 4.75 mm | 100 | 100 | 100 |

| NO.8 | 2.36 mm | 69.43935827 | 87 | 73 |

| NO.16 | 1.16 mm | 38.90487401 | 61 | 43 |

| NO.30 | 600 μm | 25.56456535 | 41 | 29 |

| NO.50 | 300 μm | 16.83669021 | 22 | 18 |

| NO.100 | 150 μm | 10.55017874 | 11 | 11 |

| NO.200 | 75 μm | 5.7 | 5.0 | 5.5 |

| ASTM sieve size | Aggregate percent passing | Combined | Specification | ||||

|---|---|---|---|---|---|---|---|

| 3/4'″ | 3/8″ | CR.S | Filler | gradation | General | ||

| 33 | 21 | 42 | 4 | ||||

| Recycle patching mix | |||||||

| 1 1/2″ | 37.5 mm | 100 | 100 | 100 | 100 | 100 | 100 |

| 1″ | 25.0 mm | 100 | 100 | 100 | 100 | 100 | 100 |

| 3/4″ | 19.1 mm | 95 | 100 | 100 | 100 | 98 | 100 |

| 1/2″ | 12.5 mm | 48 | 100 | 100 | 100 | 83 | 81 |

| 3/8'″ | 9.51 mm | 14 | 95 | 100 | 100 | 71 | 71 |

| NO.4 | 4.75 mm | 2 | 30 | 100 | 100 | 53 | 54 |

| NO.8 | 2.36 mm | 1 | 7 | 73 | 100 | 36 | 39 |

| NO.16 | 1.16 mm | 1 | 3 | 43 | 100 | 23 | 29 |

| NO.30 | 600 μm | 1 | 2 | 29 | 100 | 17 | 22 |

| NO.50 | 300 μm | 1 | 2 | 18 | 95 | 12 | 16 |

| NO.100 | 150 μm | 1 | 2 | 11 | 90 | 9 | 11 |

| NO.200 | 75 μm | 0.8 | 0.9 | 5.5 | 85 | 6.2 | 7.0 |

Table 12.

Weight of aggregate, crushed sand, filler and bitumen (g) for regular patching mix and total weight of the mixture

| Aggregate in size 3/4" | Aggregate in size 3/8" | crushed sand | Filler | |

|---|---|---|---|---|

| Percentage % | 33 | 21 | 42 | 4 |

| weight (g) | 1188 | 756 | 1512 | 144 |

| Bitumen content | ||||

|---|---|---|---|---|

| trail 1 | trail 2 | trail 3 | ||

| Percentage of bitumen % | 5.9 | 5.4 | 4.9 | |

| Weight of bitumen (g) | 225.7 | 205.5 | 185.5 | |

| Trail 1 | Trail 2 | Trail 3 | |

|---|---|---|---|

| Total weight of the mixture | |||

| Weight of bitumen (g) | 225.7 | 205.5 | 185.5 |

| Total weight of the mixture | 3825.7 | 3805.5 | 3785.5 |

Table 13.

Regular patching mix in bitumen

| Regular | Recycled | |||||

|---|---|---|---|---|---|---|

| 4.4% | 5.4% | 5.9% | 4.9% | 5.4% | 5.9% | |

| Pmm | 100 | 100 | 100 | 100 | 100 | 100 |

| Pb | 4.4 | 5.9 | 5.4 | 4.9 | 5.4 | 5.4 |

| Gmm | 2.6590 | 2.5580 | 2.6090 | 2.547 | 2.5150 | 2.5150 |

| Gb | 1.037 | 1.037 | 1.037 | 1.034 | 1.034 | 1.034 |

| Gse | 2.865 | 2.727 | 2.856 | 2.559 | 2.559 | 2.559 |

| Pa | 6.731854 | 2.22307 | 0.117279 | 6.2819 | 2.902584 | 2.425447 |

| Gmb | 2.480 | 2.551 | 2.555 | 2.387 | 2.442 | 2.454 |

| VFA | 48.45062 | 80.6781 | 99.00906 | 44.36872 | 70.154 | 73.8682 |

| VMA | 13.05904 | 11.5054 | 11.83517 | 11.29203 | 9.725205 | 9.281594 |

| Pbe | 2.645682 | 3.77335 | 4.755949 | 2.170286 | 2.888857 | 2.887987 |

| Pba | 1.835061 | 1.71949 | 1.215782 | 2.870362 | 2.654485 | 2.655405 |

Table 14.

Aggregates mixture prices

| Regular Asphalt Mixture Price | ||

|---|---|---|

| Bitumen price per ton = 102.060 KD | Bitumen weight 60.016 ton | Bitumen price = bitumen price per ton * bitumen weight = 6125.233 KD |

| Aggregate Price per = 11 KD | Aggregate weight = 478.175 | Aggregate price = aggregate price per * aggregate weight = 11*478.175 = 5259.925 KD |

| Aggregate weight (ton) | Aggregate weight (kg) | Aggregate volume ( | Aggregate price (KD) | Price/ | |||

|---|---|---|---|---|---|---|---|

| Calculation of recycled aggregate price | |||||||

| ¾ | G1 = 2.8 | P1 = 26.4 | 329.6 | 329,609.4 | 117.1 | 1288.5 | 11 |

| ¾ | G2 = 2.2 | P2 = 6.6 | 82.4 | 82,402.3 | 36.8 | 220.7 | 6 |

| 3/8 | G3 = 2.8 | P3 = 16.8 | 209.8 | 209,751.4 | 75.7 | 832.3 | 11 |

| 3/8 | G4 = 2.2 | P4 = 4.2 | 52.4 | 52,437.9 | 23.5 | 141.1 | 6 |

| Cr. sand | G5 = 2.6 | P5 = 33.6 | 419.5 | 419,502.8 | 158.5 | 1743.3 | 11 |

| Cr. sand | G6 = 1.8 | P6 = 8.4 | 104.9 | 104,875.7 | 57.6 | 28.8 | 0.5 |

| Filler | G7 = 2.7 | P7 = 4 | 49.9 | 49,940.8 | 18.7 | 205.9 | 11 |

| 100 | 1248.5 | 1,248,520.4 | 487.9 | 4460.71 | |||

Appendix C

See Fig. 3.

Fig. 3.

The changes with percentage of bitumen. a Stability of regular. b Stability of polymer modified. c Specific gravity of regular. d Specific gravity of polymer modified. e Air voids of regular. f Air voids of polymer modified. g Flow of regular. h Flow of polymer modified

Funding

This study was funded by Kuwait University (grant number EV 03/19).

Declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AASHTO, T. 283 Standard Test Method for the Indirect Tensile (IDT) Strength of Bituminous. American Society for Testing and Materials. Annual Book of ASTM Standards, 2010.

- AASHTO, T. 6931–07, Standard test method for the bulk density determination. American Society for Testing and Materials. Annual Book of ASTM Standards, 2010.

- Abed A, Thom N, Presti DL. Design considerations of high RAP-content asphalt produced at reduced temperatures. Materials and Structures. 2018;51(4):91. doi: 10.1617/s11527-018-1220-1. [DOI] [Google Scholar]

- AL-GhurabiBasim, S., & Al-Humeidawi, H. (2021). Evaluation of performance of hot mix asphalt contained various sizes of reclaim asphalt pavement and polymer modified bitumen. ScienceDirect.com | Science, health and medical journals.

- Ali MES, El-Badawy S, Al-Kandari JMH. Influence of recycled asphalt pavements on the performance of Kuwait asphalt concrete mixtures (Dept. C) MEJ Mansoura Engineering Journal. 2020;35:1–12. doi: 10.21608/bfemu.2020.115389. [DOI] [Google Scholar]

- Aljassar AH, Al-Fadala KB, Ali MA. Recycling building demolition waste in hot-mix asphalt concrete: A case study in Kuwait. Journal of Material Cycles and Waste Management. 2005;7:112. doi: 10.1007/s10163-005-0135-4. [DOI] [Google Scholar]

- American Association of State Highway and Transportation Officials. Theoretical Maximum Specific Gravity of Bituminous Mixtures, Test Method AASHTO T 209 – 00, Standard Specifications for Transportation Materials and Methods of Sampling and Testing, Part II – Tests, Twentieth Edition, 2000.

- ASTM D C-136. Form and Style for ASTM Standards. ASTM International, West Conshohocken, PA, (2006).

- Biswas, S. (2016). “Pothole condition in Canada and evaluation of maintenance material”.(Master’s thesis). University of Alberta, Edmonton, Canada.

- Blaha, J. R. (1993). Fabrication and Testing of Automated Pothole Patching Machine (No. SHRP-H-674). Strategic Highway Research Program, National Research Council.

- Burningham S, Stankevich N. Why road maintenance is important and how to get it done. The World Bank; 2006. [Google Scholar]

- Chatterjee, S., White, R. P., Smit, A., Prozzi, J., and Prozzi, J. A. (2006). Development of mix design and testing procedures for cold patching mixtures (No. FHWA/TX05/0–4872–1).

- Chen DH, Won M. Field performance with state-of-the-art patching repair material. Construction and Building Materials. 2015;93:393–403. doi: 10.1016/j.conbuildmat.2015.06.002. [DOI] [Google Scholar]

- Doré G, Zubeck HK. Cold regions pavement engineering. American Society of Civil Engineers Press; 2009. [Google Scholar]

- Durrani, A. (2021). nalysis of Reclaimed Asphalt Pavement (RAP) Proposed for Use as Aggregate in Microsurfacing and Chip Seal Mixes for Local Roadways Applications in Ohio.

- FHWA, ‘‘Towards sustainable pavement systems: A reference document,” U. S. Department of Transportation, Federal Highway Administration,

- Ghabchi R, Singh D, Zaman M, Hossain Z. Laboratory characterisation of asphalt mixes containing RAP and RAS. International Journal of Pavement Engineering. 2016;17(9):829–846. doi: 10.1080/10298436.2015.1022778. [DOI] [Google Scholar]

- Gottumukkala B, Kusam S, Tandom V, Muppireddy A, Mullapudi R. Restriction of RAP% in HMA based on aggregate gradation and binder properties. Civil Engineering. 2021;2:811. [Google Scholar]

- Guangwei Y, Wang K, Li J, Romero M, Liu W. Laboratory and Field performance evaluation of warm mix asphalt incorporating RAP and RAS. KSCE Journal of Civil Engineering. 2021 doi: 10.1007/s12205-021-2315-8. [DOI] [Google Scholar]

- Hixson, Russell. (2015). Edmonton laboratory testing road pothole repair methods. Journal of Commerce.

- Fragachan, J. M. (2008). Accelerated Testing Methodology For Evaluating PavementPatching Materials (Master thesis), Worcester Polytechnic Institute.

- Smith, K. L., Peshkin, D. G., Rmeili, E. H., Dam, T. V., Smith, K. D., and Darter, M. I. (1991). “Innovative materials and equipment for pavement surface repairs – volume i: summary of material performance and experimental plans,” Report No. SHRP-M/UFR-91–504, contract H-105

- Kuennen T. The pothole patching playbook: why potholes occur, how to patch them, and how to prevent them in the first place. Better Roads. 2004;74(2):30–34. [Google Scholar]

- Kuo, S-S, Carlo, L, Kuenzel, C. Evaluation of patching materials and placementtechniques for rigid pavements and bridge decks, Final Report, Florida Department of Transportation, Tallahassee; 1999.

- Mobasher B, Mamlouk M, Lin H. Evaluation of crack propagation properties ofasphalt mixtures. Journal of Transportation Engineering. 1997;123(5):405–413. doi: 10.1061/(ASCE)0733-947X(1997)123:5(405). [DOI] [Google Scholar]

- Maher, A., Gucunski, N., Yanko, W., and Petsi, F. (2001). Evaluation of pothole patching materials. Publication FHWA NJ 2001–02. FHWA, New Jersey Department of Transportation.

- Male, M. (2013). Potholes in Edmonton. MasterMaq. http://mastermaq.s3.amazonaws.com/public/Potholes%20in%20Edmonton.pdf. Accessed Apr. 5, 2013.

- Marcus, B., and Elizabeth, H. (2001). Asphalt concrete patching material evaluation. Report. Prepared for the Oregon DOT.

- Maupin Jr, G. W., Payne, C. W., and Engineer, I. (2003). Technical Assistance Report Evaluation of Spray Injection Patching. Virginia Transportation Research Council.

- Miller, J. S., and Bellinger, W. Y. (2003). Distress identification manual for the longterm pavement performance program (Fourth Revised Edition). Publication FHWA-HD-03–031. FHWA, US Department of Transportation.

- Nicholls, C., Kubanek, K., Karcher, C., Hartmann, A., Adesiyun, A., Ipavec, A., Komacka, J., and Nielsen, E. (2014). Durable pothole repairs. In transport research arena (TRA) 5th Conference: Transport Solutions from Research to Deployment. Paris, France.

- Obaidi H, Gomez-Meijide B, Garcia A. A fast pothole repair method using asphalt tiles and induction heating. Construction and Building Materials. 2017;131:592–599. doi: 10.1016/j.conbuildmat.2016.11.099. [DOI] [Google Scholar]

- Pimentel, J. M. F. (2007). Accelerated Testing Methodology for Evaluating Pavement Patching Materials (Doctoral dissertation, Worcester Polytechnic Institute, 2007).

- Pothole.info, (2010).” The pothole facts”, < https://www.pothole.info/the-facts/>.

- Prowell BD, Franklin AG. Evaluation of cold mixes for winter pothole repair. Transportation Research Record: Journal of the Transportation Research Board. 1996;1529:76–85. doi: 10.1177/0361198196152900110. [DOI] [Google Scholar]

- Dong Q, Huang BS, Zhao S. Field and laboratory evaluation of winter seasonpavement pothole patching materials. International Journal of Pavement Engineering. 2014;15(4):279–289. doi: 10.1080/10298436.2013.814772. [DOI] [Google Scholar]

- Eaton, R. A., Joubert, R. H., Wright, E. A. (1989). “Pothole primer – A public administrator’s guide to understanding and managing the pothole problem,” CRREL Special Report 81–21.

- Homji, R. (2005). Intelligent Pothole Repair Vehicle, M.S. thesis, TX A&M, College Station, TX

- Reike D, Vermeulen WJV, Witjes S. The circular economy: New or Refurbished as CE 3.0? — exploring controversies in the conceptualization of the circular economy through a focus on history and resource value retention options. Resources, Conservation and Recycling. 2018;135:246–264. doi: 10.1016/j.resconrec.2017.08.027. [DOI] [Google Scholar]

- Rosales, V. I., Prozzi, J., and Prozzi, J. A. (2007). Mixture design and performance-based specifications for cold patching mixtures. Report no. FHWA/TX-08/0–4872–2. Washington, DC: Texas Department of Transportation, Federal Highway Administration

- Saha, R., Karki, B., Berg, A., Melaku, R. S., & Gedafa, D. S. (2017). Effect of RAP on cracking and rutting resistance of HMA mixes. In Airfield and Highway Pavements 2017 (pp. 86–94).

- Sainz, M. (2016). “Pothole patching: A review on materials and methods”. (Scholarship Submission). Bradley University, Peoria, USA.

- Shaopeng W, Zhong J, Zhu J, Wang D. Influence of demolition waste used as recycled aggregate on performance of asphalt mixture. Taylor & Francis; 2013. [Google Scholar]

- Solaimanian, M., Yildirim, Y., McGinnis, R. B. (2011), and Kennedy, T. W. (2011). Annual Survey of State Transportation Officials. FHWA/TX-99/1250–3.

- Tarefder, R. A., and Islam, M. R. (2014). Measuring fatigue damages from an instrumented pavement section due to day-night and yearly temperature rise and fall in desert land of the west. In International Symposium of climatic effects on pavement and geotechnical infrastructure 2013.

- Tassiri S, Sawangsuriya A, Kanitpong K. Effects of additives on the performance properties of warm mix asphalt with reclaimed asphalt pavement. International Journal of Pavement Research and Technology. 2021 doi: 10.1007/s42947-021-00085-3. [DOI] [Google Scholar]

- Thomas, H. R., and Anderson, D. A. (2010). Pothole repair: you can't afford not to do it right. Transportation research record: Journal of Transportation Research Board, No. 1102, Transportation Research Board of the National Academies, Washington, D.C., pp. 32–40 Washington, DC, 2015.

- Wilson, T. P., and Romine, A. R. (1994). Training program — pothole repair: Pavement surface repair materials and procedures. Publication SS-20. SHRP, National Research Council.

- Wilson, T. P., and Romine, A. R. (2001). Materials and procedures for repair of potholes in asphalt-surfaced pavements-manual of practice. Publication FHWARD-99–168. FHWA, US Department of Transportation.

- Zhang Y, Cheng H, Sun L. Performance-based design of recycled hot-mix asphalt (HMA) incorporating compaction effort variable. Construction and Building Materials. 2021;303:124277. doi: 10.1016/j.conbuildmat.2021.124277. [DOI] [Google Scholar]