Abstract

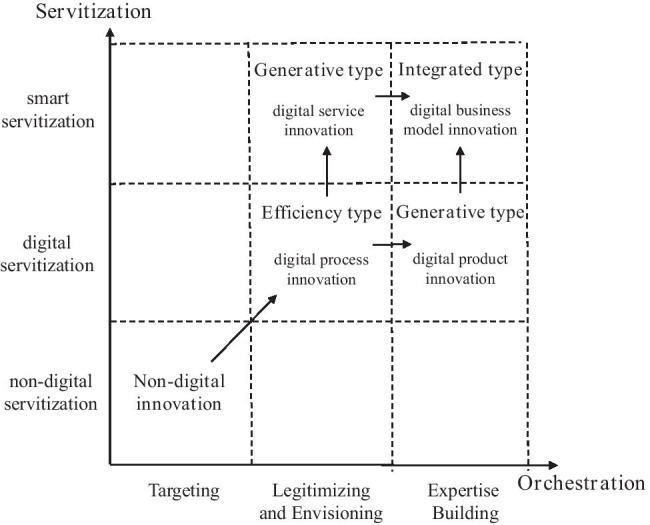

In the era of Industry 4.0, the innovative applications of the industrial internet of things continue to deepen, and the trend of digital transformation of the green manufacturing industry continues to expand. In this context, the study of digital finance innovation in green manufacturing enterprises is conducive to transforming and upgrading enterprises and national economic development. In order to review the theoretical foundations and the current state of research under this topic, this paper provides an overview of digital finance innovation in green manufacturing companies based on 296 papers published between 1900 and 2021 through bibliometric and scientific visualization methods. This paper uses HistCite to identify the most influential authors, institutions, and countries and uncover the lineage of research on digital finance innovation in green manufacturing companies. At the same time, VOSviewer is used to identify research hotspots and research clusters under the topic. Finally, on this basis, this paper classifies the types of digital innovation from the perspective of value creation. It proposes a theoretical framework for the realization path of digital finance innovation in green manufacturing enterprises based on intelligent servitization and orchestration capabilities. The findings of this paper enrich the existing innovation theory and facilitate scholars to conduct future research more effectively.

Keywords: Digital finance innovation, Green manufacturing, Bibliometric, Intelligent servitization, Orchestration capability

Introduction

With the cluster of innovative breakthroughs in new-generation digital technologies such as big data, cloud computing, artificial intelligence, and the industrial internet, digital innovation has produced profound changes to the development model of the green manufacturing industry. The global green manufacturing landscape is undergoing profound changes. On the one hand, developed countries are committed to industrial redevelopment strategies to compete for and maintain their positions at the top end of the global industrial chain. On the other hand, the green manufacturing industries of resource-intensive emerging countries are moving towards the middle and high ends, such as the dual international and domestic cycle strategy that China has begun to pursue. In this context, it is therefore essential and urgent to study digital innovation in green manufacturing.

On the other hand, COVID-19 has had a great negative impact on society and the economy. How to achieve a new round of revolution in development through the integration of new manufacturing and green development has become a realistic problem for governments of all countries. As the backbone of the economies of various countries, the importance of green manufacturing is self-evident, but under the damage of the epidemic, green manufacturing urgently needs the influx of new financial capital. With the strong support of green finance, the production efficiency of green manufacturing has been rapidly improved. In this process, governments such as China took the lead in proposing digital finance. Through the introduction of digital finance and the development of green manufacturing, new manufacturing supported by green finance has been formed.

Digital finance innovation in green manufacturing is mainly reflected in two aspects: on the one hand, new green manufacturing methods such as intelligent green manufacturing, flexible green manufacturing, and virtual green manufacturing are accelerating in popularity. Digital finance penetrates traditional manufacturing, triggers green and digital innovation, and realizes green manufacturing under the digital revolution. On the other hand, the traditional boundaries between green manufacturing and service industries are gradually blurring, and the integration of the two is becoming more and more prominent. In this context, digital technologies are having a disruptive impact on the green manufacturing industry chain, the value chain, and the innovation chain. And, every link of digital innovation has the participation of digital finance. The original factory-based green manufacturing industry will be extended upstream and downstream in the industrial chain into technology development and marketing, increasing the added value of products through digital innovation in science and technology and marketing (Nasreen et al. 2017). In this critical part of the innovation chain, it is a functional linkage model that is oriented towards market demand, with the acquisition of new technologies and product development as the core, linking multiple actors through institutional, organizational, and management innovation and realizing the value added in the whole process of innovation. The essence of digital finance innovation is to reveal the flow, transformation, and value added of knowledge and technology throughout the process, reflecting the synergy, cooperation, and value transfer of multiple participating actors in the whole process. The integration of next-generation information and digital technologies into green manufacturing has had a significant positive effect on industry development and the national economy. Scholars have studied this from different perspectives.

Regarding the definition of digital innovation, Yoo et al. (2010) define digital innovation as the production of new products through a new combination of digital and physical elements based on Schumpeterian innovation theory. Nambisan et al. (2017) propose digital innovation from a value creation perspective to create and continuously change market products, business processes, or business models caused by digital technologies. On the other hand, Edu et al. (2020) propose a definition from the perspective of IT capabilities: the ability to rely on improved IT capabilities to transform an organization’s access to new and existing knowledge, skills, customized requirements, new products or service lines, value creation, capabilities, and speed of delivery. These form the basis of digital finance innovation, which consists of two main perspectives: one is that digital finance innovation is mainly about optimizing existing products and increasing added value through services. The other is that digital innovation uses digital technology by companies to optimize various aspects of their business and ultimately improve their performance. In terms of understanding the connotation of digital innovation, Henfridsson et al. (2018) take a structural perspective. They argue that digital innovation is about capturing value by creating connections between different digital resources and that the value space is conceptualized as four layers in the digital system. Along with resource integration and collaborative activities, the link between actors and resources is becoming stronger. Nambisan (2018) states that the relationship between actors and resources in digital innovation can be better understood from an ecosystem perspective. In addition, Yoo et al. (2010) summarize the main characteristics of digital technology (programmability, the homogenization of data, the self-referential nature of digital technology), the main characteristics of digital innovation (convergence and generativity), and the types of digital innovation (distributed innovation and combinatorial innovation). In an empirical study in recent years, Khin and Ho (2018) explored the relationship between digital capabilities and firm performance using digital innovation as a mediating variable, confirming the importance of digital technology and digital orientation in enhancing firm performance. Nasiri et al. (2020) quantified digital innovation in two dimensions, business processes, and market offerings and explored the relationship between digital-related competencies and digital innovation, confirming the importance of digital humanities and collaborative, technological, and innovation competencies.

The main elements of the existing review literature are outlined in Table 1. In general, the theoretical literature on digital finance innovation is gradually improved, but the empirical literature is still in its infancy and has not yet developed a comprehensive scale. In addition, there is a lack of in-depth research into the green manufacturing industry as digital finance innovation is still a young topic that is being explored by academics across disciplines. However, the green manufacturing industry is precious to study as the most widely used and specific industry for digital innovation. Therefore, this study aims to provide an overview of past, present, and future research directions in digital innovation in green manufacturing, using bibliometric methods (Ahmad et al. 2019). The paper is structured as follows: this literature begins with an introduction that introduces the real-life context of digital innovation in green manufacturing, while we compare it with published reviews on related topics and point out the innovative nature of this study. In the second section, we describe this paper’s research instruments and methodology and describe the research design. In the third section, we describe and analyze the bibliometric results, including an analysis of publication trends, journals, authors, institutions, and countries, and a review of the research lineage. In the fourth section, we again use VOSviewer to cluster the literature and refine the core elements of each cluster. In the fifth section, we classify the types of digital finance innovation from the perspective of value creation and distill the paths to digital innovation for green manufacturing companies based on intelligent servitization and collaborative capabilities. Finally, there is a summary and outlook section where we first summarize the conclusions obtained, point out the paper’s limitations, and finally make predictions about possible future research directions.

Table 1.

Previous reviews on digital innovation

| Author | Journal | Article | Main theory contribution |

|---|---|---|---|

| Yoo et al. (2010) | Information Systems Research | The new organizing logic of digital innovation: an agenda for Information Systems Research |

(1) Defines the concept and characteristics of digital innovation (2) Introduces the organizational logic of the layered modular architecture (3) Proposes a future research agenda for information systems |

| Organization Science | Organizing for innovation in the digitized world |

(1) An introduction to the convergent and generative character of digital technologies (2) An introduction to digital technology platforms and distributed and combined innovations |

|

| Business Horizons | Digital innovation strategy: a framework for diagnosing and improving digital product and service innovation | The authors propose a management framework designed to support continuous improvement in digital innovation management, covering 5 key areas: user experience, value proposition, digital evolution scanning, skills, and improvization | |

| MIS Quarterly | Digital innovation management: reinventing innovation management research in a digital world |

(1) Challenges traditional assumptions about innovation boundaries, innovation agency, and the relationship between innovation processes and outcomes (2) Builds a framework for digital innovation management with 4 new theoretical logics: dynamic problem-solution design pairing, social cognition, technology availability, and orchestration (3) Introduces innovation research methods such as QCA |

|

| Ciriello et al. (2018) | Business & Information Systems Engineering | Digital innovation |

Based on previous literature, the authors’ understanding is presented as follows: (1) Digital innovation: from product to platform (2) Organizing digital innovation: from process to practice (3) Implementing digital innovation: from development to exploration |

| Information and Organization | Digital innovation and transformation: an institutional perspective |

(1) Identifies 3 institutions that are critical to digital transformation: digital organizational forms, digital institutional infrastructure, and digital body mechanism building blocks (2) Examine how these new transformations gain social acceptance and create value for stakeholders from an institutional perspective |

|

| Information and Organization | Recombination in the open-ended value landscape of digital innovation |

(1) Introduces the value perspective of the open approach (2) Distinguishes between use reorganization and design reorganization (3) Presents a value space framework that illustrates how value creation and value capture can take place in digital innovation |

|

| Satish (2018) | Information and Organization | Architecture vs. ecosystem perspectives: reflections on digital innovation | The authors contrast the value pathways perspective proposed by Henfridsson and propose a new perspective: a study from ecosystems, actors, value creation, and value capture |

| Information Systems Journal | Digital innovation: a review and synthesis | The authors build a theoretical framework from 7 aspects of digital innovation: inspiration, development, implementation, exploitation, external competition, and internal organization | |

| Electronic Markets | Digital innovations: embedding in organizations |

(1) Introduces the conceptual development of digital innovation (2) Delineates the categories of digital innovation (3) Describes the drivers of digital innovation (4) Describes the governance mechanisms of digital innovation |

Method

Bibliometric analysis and software

Bibliometrics is the interdisciplinary discipline of quantitative analysis of a field of knowledge through mathematical and statistical methods and is a vast body of knowledge that integrates mathematics, statistics, and bibliography. Bibliometrics focuses on describing, evaluating, and predicting the current state of knowledge and trends through the analysis of the number of literature characteristics (e.g., number of publications, number of citations) (Van Raan 1996). Scientific knowledge mapping is a comprehensive analysis method that combines traditional bibliometric methods with modern text mining techniques. The analysis of author co-citations, keyword co-occurrences, and keyword clustering enables us to tap into the research lineage, research hotspots, research frontiers, and collaborative relationships between authors, institutions, and countries in a particular research area, which helps us to grasp the changing trends and academic dialogue on the subject and thus better conduct future research.

Two visual analysis tools for bibliometrics have been chosen for this paper: VOSviewer and HistCite. VOSviewer is a bibliometric and analytical software program for building knowledge graphs developed by Van Eck and Ludo Waltman at the Centre for Science and Technology Studies (CWTS) at Leiden University in the Netherlands. The core principle of the software is to mine “co-occurrence and clustering” based on distances, draw correlation graphs (Rehman et al. 2021), and show the importance of documents, i.e., their interrelationships, through the color, size, and distribution of heavy network nodes (Eck and Waltman, 2010). HistCite is a visual tool for citation chronology. In addition to calculating the frequency of citations and outputting a list of documents, the most crucial feature of HistCite is the generation of citation chronology charts. This can help us find the source literature and uncover the succession of citations to show the research lineage under the field (Ahmad et al. 2019). The core idea is to use the Global Citation Score (GCS) and Local Citation Score (LCS) provided by the Web of Science (WoS) database as the leading indicators to measure the impact of the literature for analysis (Garfield 2009).

Research design

This bibliometric study aimed to locate the most active and influential research areas on digital innovation in manufacturers. We gathered raw data from the WoS database belonging to Thomson Reuters, which contains more than 50,000,000 publications, more than 22,000 journals, and 151 research areas (Llanos-Herrera and Merigo, 2018). The WoS database is a digital bibliometric platform internationally recognized for reflecting the level of scientific research (Merigó et al. 2015). Among these, SCIE, SSCI, and other citation index databases; Journal Citation Reports (JCR); and ESI fundamental scientific indicators are well known worldwide. By assigning a unit to each author, institution, journal, or country for each publication registered in the WoS, we aimed to provide an overview of the most productive and influential authors, institutions, and countries (Lafont et al. 2020). More specifically, the present study considers bibliographic records obtained from the WoS Core Collection. Regarding the time frame, the research included all publications from 1900 (the beginning of the standard range) to May of 2021 (2021 has not ended during the study).

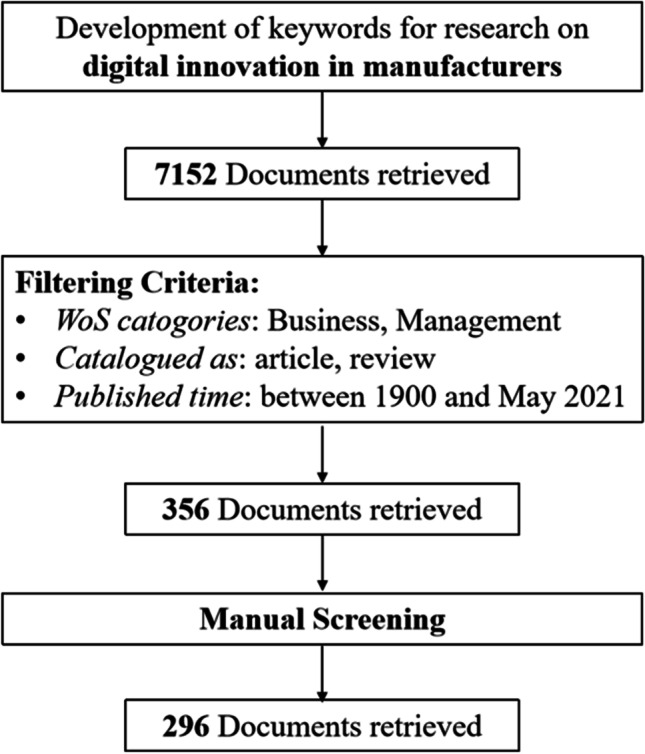

To perform a search within the WoS Core Collection database, we followed three steps. (1) The keywords are selected to filter the information. Similar to bibliometric approaches performed by other scholars (Magaly et al. 2018), our criteria for these keywords are based on existing review articles mentioned in Table 1. The search string used in the WoS Core Collection database was a combined search to return the most relevant study field in our research area: Topic = (digital innovation OR digitization OR digitalization OR Intelligent OR digital finance*) AND Topic = (manufacturer* OR Green-Manufacturing*). (2) Having identified 7152 articles, we then reduced the number of articles to 356 using the following WOS categories: business and management. The document type must be categorized as an article and review to evaluate only research studies (Merigó et al., 2015). (3) The number of results was not exceptionally high; therefore, to ensure the validity of the data, namely the retrieved literature is highly related to our aim topic, the use of different filters was envisaged by manual screening. According to the title and abstract of the article, we eliminated those which did not match the subject, like the researches on banking and insurance. In the end, the search yielded 296 results, which were used to develop the current study. Figure 1 illustrates the documents retrieval process in three steps.

Fig. 1.

Documents’ collection process

Bibliometric analysis results

Trend analysis

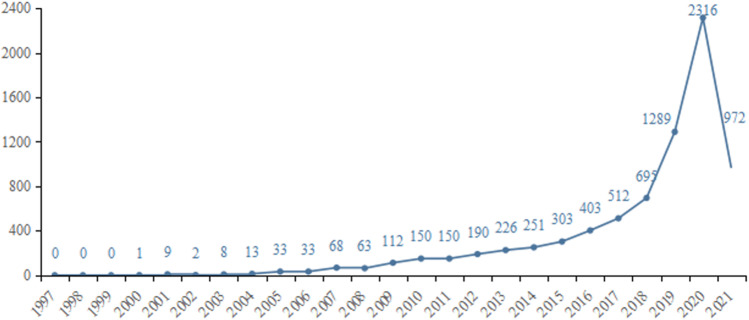

The number of publications and the frequency of citations often reflect the history and trends of a subject area and are often seen as an essential indicator of the contribution of scientific research. Based on the literature search results, we plotted the number of publications (Fig. 2) and the frequency of citations (Fig. 3) per year for research on digital finance innovation in green manufacturing. On the one hand, in terms of the number of annual publications, there has been a dramatic increase over the last 20 years, starting to exceed 100 for the first time in 2009 and reaching 1621 in 2020. Of these, the literature focusing on business and management studies shows the same pattern of growth, particularly in the last 5 years, achieving a multiplicative increase from 12 articles in 2016 to 97 articles in 2020. On the other hand, after focusing on 296 papers in the field of business and management, we derive the citation report from WoS, and looking at the annual citation frequency, as shown in Fig. 2, we can find that the citation frequency starts to increase from 2009 and achieves a multiplicative increase from 2018 to 2020. This indicates that research findings on digital finance innovation in green manufacturing are becoming more recognized in academia and increasing impact year on year.

Fig. 2.

Number of publications on “Digital innovation in green-manufacturers”

Fig. 3.

Number of annual citations

In the context of the times, it can be seen that this is closely related to human society moving from the Third Industrial Revolution to the Fourth Industrial Revolution. Since the era of automation, marked by the application of technologies such as atomic energy, electronic computers, and space technology, has moved into the era of intelligence, marked by network communication technologies, big data, cloud computing, intelligent factories, and intelligent production, digitalization and intelligence have led to a more direct and closer relationship between intelligent green manufacturing enterprises and economic development than ever before. In the post-financial crisis era after 2008, developed countries are promoting a “re-industrialization” strategy after fully recognizing the weaknesses of the country’s anti-crisis capacity due to “de-industrialization,” making use of their comprehensive technological advantages and formulating advanced green manufacturing development plans to return to the real economy from a high starting point. For example, the USA invested US $1 billion in 2012 to establish 15 Manufacturing Innovation Institutes, Germany released its Industry 4.0 Plan in 2013, and France launched its New Industrial France Strategy in 2013. Developing countries represented by China have also seized the opportunities of the times, such as Made in China 2025 released in 2015, which aims to build a green manufacturing powerhouse that will lead the world’s green manufacturing development. The strategic changes of the country lead the green manufacturing industry to undergo transformation and upgrading. In this practical context, on the one hand, some scholars use their keen insight to forecast the future development direction of the industry. On the other hand, many scholars have conducted case studies and empirical explorations based on enterprise practices, continuously refining and constructing theoretical frameworks for green manufacturing innovation and verifying and improving these theories through empirical methods to provide theoretical guidance for the digital and intelligent transformation of more enterprises.

Journal analysis

An analysis of the journals and impact factors of the published literature allows us to determine the main research areas and impact of digital finance innovation in green manufacturing. Table 2 shows the 10 journals with the highest number of publications on the topic of digital finance innovation in green manufacturing, with Journal of Manufacturing Technology Management, a journal focused on green manufacturing management, having the highest number of publications, and Technological Forecasting and Social Change having the highest H index despite having the second-highest number of publications, which shows the strong influence of this journal in the field of green manufacturing research. All 10 journals are basically of high quality with an IF of 2 or more in terms of impact factor. Among the top 5 journals in terms of the number of articles published, Technological Forecasting and Social Change, Industrial Marketing Management, and Journal of Business Research are all top journals in industrial management, with impact factors above 4. These four journals account for 31% of the total number of articles published, indicating that research in this field has a solid theoretical foundation and strong influence. Furthermore, it is clear from the nature of the journal that research into digital finance innovation in green manufacturing is a focus of the technical field and is also of interest to the fields of management, marketing, and information systems.

Table 2.

Top 10 productive and influential journals

| R | Journals | TP | %P | TLCS | TGCS | IF | 5-IF | H |

|---|---|---|---|---|---|---|---|---|

| 1 | Journal of Manufacturing Technology Management | 38 | 12.84 | 64 | 505 | 3.385 | – | 10 |

| 2 | Technological Forecasting and Social Change | 28 | 9.46 | 88 | 1316 | 5.846 | 5.179 | 17 |

| 3 | Industrial Marketing Management | 15 | 5.07 | 43 | 407 | 4.695 | 5.868 | 8 |

| 4 | Journal of Business Research | 11 | 3.72 | 33 | 157 | 4.874 | 5.484 | 7 |

| 5 | International Journal of Operations & Production Management | 9 | 3.04 | 3 | 43 | 4.619 | 5.676 | 5 |

| 6 | Journal of Business & Industrial Marketing | 9 | 3.04 | 12 | 47 | 2.497 | 2.713 | 7 |

| 7 | Technology Analysis & Strategic Management | 9 | 3.04 | 6 | 93 | 1.867 | 2.105 | 5 |

| 8 | Harvard Business Review | 7 | 2.36 | 12 | 1882 | 5.694 | 6.849 | 6 |

| 9 | Research-Technology Management | 7 | 2.36 | 39 | 210 | 2.449 | 3.677 | 3 |

| 10 | Systems Research and Behavioral Science | 7 | 2.36 | 5 | 28 | 0.731 | 1.07 | 3 |

R rank, TP total publication, %P percentage, TLCS total local citation score, TGCS total global citation score, IF impact factor 2020, 5-IF 5-year impact factor, H H index

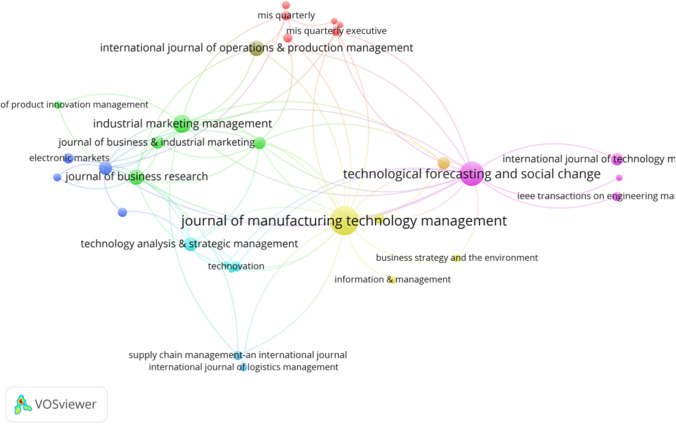

This paper further refers to by using VOSviewer to couple all journals in the literature for analysis (Fig. 4). The literature coupling analysis reflects the importance of a journal by the literature cited, with larger circles representing journals in the map indicating more significant importance. In Fig. 4, it can be found that Journal of Manufacturing Technology Management, Technological Forecasting and Social Change, Industrial Marketing Management are in the central position, followed by Journal of Business Research, International Journal of Operations & Production Management, and other journals. The top journals MIS Quarterly and Technovation are also highlighted in the map, and although these two journals have a relatively low volume of publications, they still have a high impact in terms of the citation map. The color of the circles in the map indicates the different clusters, elaborated on later in the content analysis section.

Fig. 4.

Map of co-citation analysis based on journals

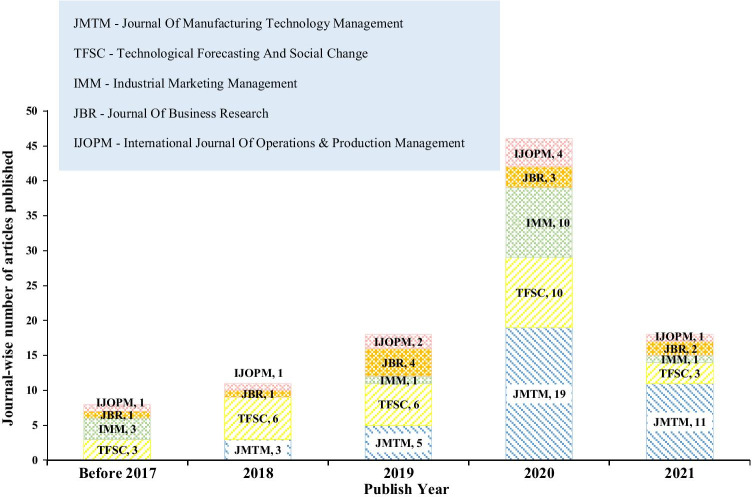

In addition, to visualize the importance that each journal places on this topic, the top 5 journals in terms of the number of articles published and the corresponding number of articles published each year are plotted in a cumulative bar chart (Fig. 5). The graph shows that the Journal of Manufacturing Technology Management and Technological Forecasting and Social Change are the top journals regarding the number of articles published each year. At the same time, the Journal of Manufacturing Technology Management and Technological Forecasting and Social Change both have the highest number of articles published each year. At the same time, Industrial Marketing Management started to focus on this topic in 2020, and the interest of each journal in the topic of digital finance innovation in green manufacturing is increasing year by year.

Fig. 5.

Journal-wise number of articles in latest years

Country analysis

Table 3 shows the number of articles published by scholars from different countries, among which the USA has 56 articles, far more than other countries, accounting for 18.92%, followed by Germany, Sweden, the UK, Finland, Italy, and China. This phenomenon is closely related to the accelerated re-industrialization and subsequent development of advanced green manufacturing technologies in developed countries, driven by the new technological and industrial revolutions since the second decade of the twenty-first century. International trends also indicate that the era of high reliance on labor in green manufacturing is coming to an end and that intelligent green manufacturing is leading the development of green manufacturing. The USA was the first to announce a national strategic plan for advanced green manufacturing in 2012, elevating advanced green manufacturing to a national strategy, followed by Germany, France, and the European Union, which also began to deepen the integration of the network economy with the real economy and promote Internet-supported intelligent green manufacturing production methods in the digital economy era. The USA was the first to begin strategic deployment, which is why it has the highest number of publications under the theme of digital finance innovation in green manufacturing. Overall, the number of articles published in developed countries is significantly higher than that in developing countries and is also closely related to the progress of strategic deployment in each country.

Table 3.

Top 10 publishing countries

| R | Country | TP | %P | TLCS | TGCS |

|---|---|---|---|---|---|

| 1 | USA | 56 | 18.92 | 50 | 1741 |

| 2 | Germany | 40 | 13.51 | 84 | 902 |

| 3 | Sweden | 34 | 11.49 | 87 | 668 |

| 4 | UK | 32 | 10.81 | 44 | 629 |

| 5 | Finland | 29 | 9.80 | 83 | 581 |

| 6 | Italy | 26 | 8.78 | 27 | 370 |

| 7 | People’s Republic of China | 23 | 7.77 | 1 | 138 |

| 8 | Switzerland | 18 | 6.08 | 36 | 304 |

| 9 | Spain | 15 | 5.07 | 3 | 408 |

| 10 | Brazil | 14 | 4.73 | 25 | 309 |

R rank, TP total publication, %P percentage, TLCS total local citation score, TGCS total global citation score

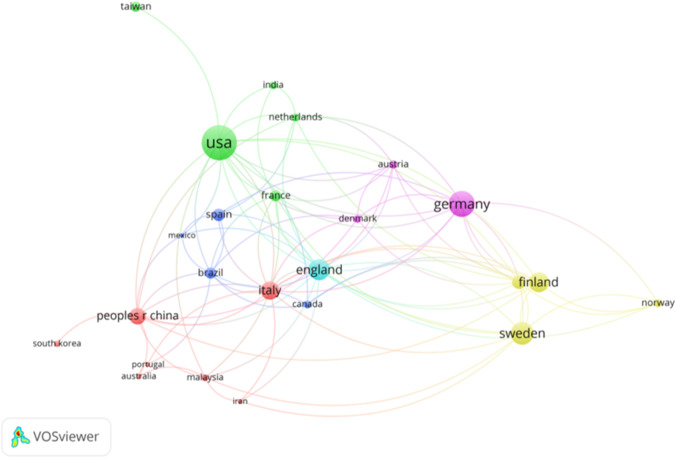

In addition, Fig. 6 shows the collaborative relationships between scholars from different countries. It can be seen that co-authorship is prevalent in the USA, Germany, Sweden, the UK, and China, and scholars are actively seeking orchestration with foreign scholars, which effectively breaks the geographical limitation of research and helps to enhance the universality of theories. Based on the number of publications and the frequency with which academics cite the literature in these countries, we can surmise that this orchestration has effectively contributed to the efficiency and quality of research output.

Fig. 6.

Map of co-authorship analysis based on countries

Author and institution analysis

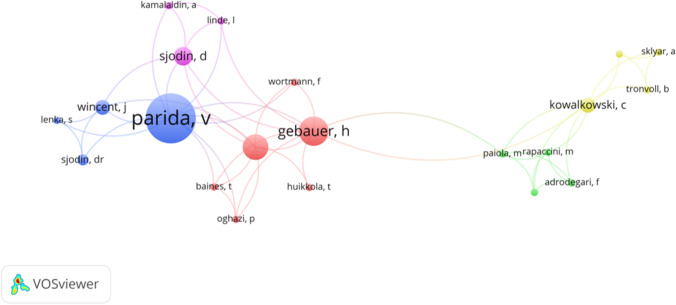

The authors of the literature influence the field to some extent, especially as scholars with more publications in high-quality journals tend to have keen insight and understanding of the field. Therefore, analyzing highly productive authors and collaborative networks can help us identify core authors, track the series of studies by that author, understand the research lineage of a topic, and capture research hotspots and research frontiers through the research content of the core author’s research team. Table 4 shows the top 10 authors and their institutions according to the number of publications. The local citation rate and the global citation rate of each author’s publications are also shown. The No. 1 author in terms of the number of articles published is Parida Vinit, whose research focuses on digitalization, servitization, and value co-creation in green manufacturing companies, with 14 co-authored articles, accounting for 4.8% of the total number of articles published, and with the highest citation rate. Of these, five have been published in the Journal of Business Research, two in Industrial Marketing Management, two in Research-Technology Management, and one in Technological Forecasting and Social Change. The second most published author is Gebauer Heiko, whose research focuses more on innovation in digital products, processes, and business models, with eight co-authored publications accounting for 2.74 of the total literature. Kohtamaeki Marko and Sjodin D ranked third and fourth, respectively, regarding the number of posts.

Table 4.

Top 5 most productive authors

| R | Author | Institution | TP | %P | TLCS | TGCS |

|---|---|---|---|---|---|---|

| 1 | Parida V | Lulea University of Technology | 14 | 4.80 | 56 | 294 |

| 2 | Gebauer H | Linkoping University | 8 | 2.74 | 22 | 109 |

| 3 | Kohtamaki M | University of Vaasa | 7 | 2.40 | 27 | 114 |

| 4 | Sjodin D | Lulea University of Technology | 5 | 1.71 | 11 | 45 |

| 5 | Kowalkowski C | Hanken School of Economics | 4 | 1.37 | 18 | 109 |

| 6 | Wincent J | Lulea University of Technology | 4 | 1.37 | 21 | 151 |

| 7 | Afum E | Dalian Maritime University | 3 | 1.03 | 1 | 8 |

| 8 | Agyabeng-Mensah Y | Dalian Maritime University | 3 | 1.03 | 11 | 193 |

| 9 | Ahenkorah E | Regent University | 3 | 1.03 | 16 | 106 |

| 10 | Diaz-Chao A | Rey Juan Carlos University | 3 | 1.03 | 1 | 8 |

R rank, TP total publication, %P percentage, TLCS total local citation score, TGCS total global citation score

In conjunction with Fig. 7, it can be seen that Kohtamaeki Marko and Sjodin D were the main collaborators of Parida Vinit and Gebauer Heiko. It is worth noting that Kohtamaeki Marko and Sjodin D have taken on more first author roles, showing that they significantly contribute to the field. In addition, the authorship of Table 4 shows that Parida Vinit, Sjodin D, and Wincent J are all from the same scientific institution, Lulea University of Technology, which has made a significant contribution and influence in the field of digital innovation in green manufacturing. We have listed the critical literature, publication dates, and journals they have worked on within Table 5 and can see that their research topics include the impact of servitization, digitalization, and related capabilities on corporate performance and business models.

Fig. 7.

Mapping of co-citation of authors

Table 5.

Major collaborative literature of Parida V, Sjodin DR, and others

| Year | Author | Title | Journal |

|---|---|---|---|

| 2015 | Parida V, Sjodin DR, Lenka S, Wincent J | Developing global service innovation capabilities: how global manufacturers address the challenges of market heterogeneity | Research-Technology Management |

| 2017 | Lenka S, Parida V, Wincent J | Digitalization capabilities as enablers of value co-creation in servitizing firms | Psychology & Marketing |

| 2018 | Sjodin DR, Parida V, Leksell M, Petrovic A | Intelligent factory implementation and process innovation: a preliminary maturity model for leveraging digitalization in manufacturing | Research-Technology Management, 2018 |

| 2019 | Kohtamaki M, Parida V, Oghazi P, Gebauer H, Baines T | Digital servitization business models in ecosystems: a theory of the firm | Journal of Business Research |

| 2019 | Sjodin D, Parida V, Kohtamaki M | Relational governance strategies for advanced service provision: multiple paths to superior financial performance in servitization | Journal of Business Research |

| 2020 | Sjodin D, Parida V, Kohtamaki M, Wincent J | An agile co-creation process for digital servitization: a micro-service innovation approach | Journal of Business Research |

| 2020 | Kohtamaki M, Parida V, Patel PC, Gebauer H | The relationship between digitalization and servitization: the role of servitization in capturing the financial potential of digitalization | Technological Forecasting and Social Change |

| 2021 | Burstrom T, Parida V, Lahti T, Wincent J | AI-enabled business-model innovation and transformation in industrial ecosystems: a framework, model and outline for further research | Journal of Business Research |

Article analysis

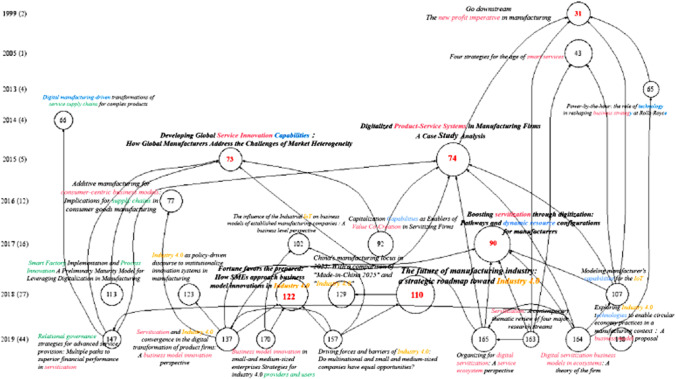

In order to identify the lineage and focus of research on digital finance innovation in green manufacturing, this study chose LCS as a measure of the importance of the literature. It used HistCite to identify the critical literature and the cross-citation relationships between the literature. Table 6 lists the top 25 papers, authors, journals, year of publication, and the number automatically generated by the software. In addition, the citation chronology chart based on LSC metrics is the most essential and distinctive visualization feature of HistCite compared to other citation bibliometric software programs. The citation chronology chart allows us to visualize the horizontal and vertical exchange between the literature under the field. Figure 6 shows the knowledge mapping of the 25 most frequently cited documents selected according to the LCS metrics. Each circle in the diagram represents one document, the size of the circle is positively correlated with the number of citations, and the arrow points to indicate the citation relationship between the documents, with the arrow pointing to the cited document and the end of the arrow to the cited document.

Table 6.

Top 40 most cited publications

| R | Date/author/journal/year | LCS | GCS |

|---|---|---|---|

| 1 |

110. Ghobakhloo M The future of manufacturing industry: a strategic roadmap toward Industry 4.0 Journal of Manufacturing Technology Management, 2018 |

26 | 173 |

| 2 |

90. Coreynen W, Matthyssens P, Van Bockhaven W Boosting servitization through digitization: pathways and dynamic resource configurations for manufacturers Industrial Marketing Management, 2016 |

23 | 118 |

| 3 |

74. Lerch C, Gotsch M Digitalized product-service systems in manufacturing firms: a case study analysis Research-Technology Management, 2015 |

20 | 107 |

| 4 |

122. Muller JM, Buliga O, Voigt KI Fortune favors the prepared: how SMEs approach business model innovations in Industry 4.0 Technological Forecasting and Social Change, 2018 |

18 | 175 |

| 5 |

43. Allmendinger G, Lombreglia R Four strategies for the age of intelligent services Harvard Business Review, 2005 |

14 | 176 |

| 6 |

129. Li L China’s manufacturing locus in 2025: with a comparison of “Made-In-China 2025” and “Industry 4.0” Technological Forecasting and Social Change, 2018 |

13 | 189 |

| 7 |

92. Lenka S, Parida V, Wincent J Digitalization capabilities as enablers of value co-creation in servitizing firms Psychology & Marketing, 2017 |

12 | 78 |

| 8 |

164. Kohtamaki M, Parida V, Oghazi P, Gebauer H, Baines T Digital servitization business models in ecosystems: a theory of the firm Journal of Business Research, 2019 |

11 | 37 |

| 9 |

165. Sklyar A, Kowalkowski C, Tronvoll B, Sorhammar D Organizing for digital servitization: a service ecosystem perspective Journal of Business Research, 2019 |

11 | 47 |

| 10 |

31. Wise R, Baumgartner P Go downstream: the new profit imperative in manufacturing Harvard Business Review, 1999 |

10 | 625 |

| 11 |

73. Parida V, Sjodin DR, Lenka S, Wincent J Developing global service innovation capabilities: how global manufacturers address the challenges of market heterogeneity Research-Technology Management, 2015 |

10 | 58 |

| 12 |

137. Frank AG, Mendes GHS, Ayala NF, Ghezzi A Servitization and Industry 4.0 convergence in the digital transformation of product firms: a business model innovation perspective Technological Forecasting and Social Change, 2019 |

10 | 83 |

| 13 |

138. Nascimento DLM, Alencastro V, Quelhas OLG, Caiado RGG, Garza-Reyes JA, et al. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: a business model proposal Journal of Manufacturing Technology Management, 2019 |

10 | 95 |

| 14 |

77. Bogers M, Hadar R, Bilberg A Additive manufacturing for consumer-centric business models: implications for supply chains in consumer goods manufacturing Technological Forecasting and Social Change, 2016 |

9 | 139 |

| 15 |

107. Hasselblatt M, Huikkola T, Kohtamäki M, Nickell D Modeling manufacturer’s capabilities for the internet of things Journal of Business & Industrial Marketing, 2018 |

9 | 21 |

| 16 |

113. Sjodin DR, Parida V, Leksell M, Petrovic A Intelligent factory implementation and process innovation: a preliminary maturity model for leveraging digitalization in manufacturing Research-Technology Management, 2018 |

9 | 40 |

| 17 |

102. Kiel D, Arnold C, Voigt KI The influence of the industrial internet of things on business models of established manufacturing companies - a business level perspective Technovation, 2017 |

8 | 69 |

| 18 |

123. Reischauer G Industry 4.0 as policy-driven discourse to institutionalize innovation systems in manufacturing Technological Forecasting and Social Change, 2018 |

8 | 68 |

| 19 |

66. Holmstrom J, Partanen J Digital manufacturing-driven transformations of service supply chains for complex products Supply Chain Management-An International Journal, 2014 |

6 | 95 |

| 20 |

147. Sjodin D, Parida V, Kohtamaki M Relational governance strategies for advanced service provision: multiple paths to superior financial performance in servitization Journal of Business Research, 2019 |

6 | 19 |

| 21 |

157. Horvath D, Szabo RZ Driving forces and barriers of Industry 4.0: do multinational and small and medium-sized companies have equal opportunities? Technological Forecasting and Social Change, 2019 |

6 | 66 |

| 22 |

170. Muller JM Business model innovation in small- and medium-sized enterprises strategies for Industry 4.0 providers and users Journal of Manufacturing Technology Management, 2019 |

6 | 27 |

| 23 |

65. Smith DJ Power-by-the-hour: the role of technology in reshaping business strategy at Rolls-Royce Technology Analysis & Strategic Management, 2013 |

5 | 48 |

| 24 |

163. Raddats C, Kowalkowski C, Benedettini O, Burton J, Gebauer H Servitization: a contemporary thematic review of four major research streams Industrial Marketing Management, 2019 |

5 | 34 |

| 25 |

196. Jerman A, Bach MP, Aleksic A Transformation towards intelligent factory system: examining new job profiles and competencies Systems Research and Behavioral Science, 2020 |

5 | 14 |

In Fig. 6, longitudinally, the 25 key papers are spread over the years 1999–2019, with an increasingly dense vein of citation relationships over the last 5 years, indicating increasing research activity in the field. In order to present the research content of each node more concisely and clearly, we have marked the titles of the literature near the nodes and distinguished the keywords in the titles with different colors. It can be found that the keywords in the title present the following four main categories: orange for Industry 4.0, IoT; red for servitization, business models, value creation, etc.; blue for dynamic capabilities, innovation capabilities, technological capabilities, etc.; and green for supply chain, relationship management, etc.

Before 2015: laying the theoretical foundations for servitization

As shown in Fig. 6, the red themes (servitization, service innovation, etc.) have always been the focus of research in these 20 years, and most of the literature with a high number of citations in the graph is also related to this branch of the theme. In addition, the pre-2015 literature provides a solid theoretical foundation and inspiration for the wealth of research that followed. On the one hand, scholars have deepened their research on the servitization of green manufacturing vertically, step by step, from servitization models to servitization strategies to digital product-service systems to the critical competencies required for servitization. On the other hand, scholars have also tried to derive new research perspectives horizontally.

No. 31 paper by Wise and Baumgartner (1999) is published in the Harvard Business Review, where the authors argue that green manufacturing success is no longer based on producing products but on providing services that capture the profits of customers at the end of the value chain, and that intelligent green manufacturing is empowering this new business model. The authors suggest that manufacturers redefine the value chain, think about green manufacturing strategies and vertical integration, and propose four service-oriented business models: embedded service, comprehensive services, integrated solutions, and distributed control. This literature emphasized the importance of servitization in green manufacturing firms and laid the theoretical foundation for later research by scholars investigating how green manufacturing industries can use digital and intelligent technologies to achieve serviced innovation and improve firm performance. After a gap of 5 years, Allmendinger and Lombreglia (2005) published No. 43 article in Harvard Business Review, proposing four business strategies for intelligent servitization: (1) embedded innovator continues to sell bundled services embedded in previous products, remaining product-centric; (2) the solutionist offers high-valued services related to the original product, providing value to the customer by expanding the range of services; (3) the aggregator focuses on data mining, enhancing the company’s ability to gain insight into opportunities through the data collection and centralized processing and analysis capabilities of the control system; and (4) the synergist pursues synergy by collaborating with other devices to contribute more valuable data and information. These four intelligent servitization strategies provide direction for the servitization transformation of green manufacturing companies in the digital intelligence era. Ten years later, Lerch and Gotsch (2015) published No. 74 paper describing the transformation path of companies based on the type of digital components and the type of services: manufacturer–IT-based service provider–pure digital service provider, providing digital (PSS). Moreover, the case study outlines three types of digital product-service systems (PSS): intelligent service delivery, intelligent product optimization, and digital brain. In the same year, core author Parida et al. (2015) and others published literature No. 73, which builds on the previous work to explore in-depth the necessary capabilities for companies to pursue servitization innovation from the perspective of corporate capabilities, summarizing four key capabilities: developing customer insights, integrating global knowledge, creating global service offerings, and digital building capabilities. Ultimately, it is emphasized that service innovation in the digital era requires green manufacturing companies to strengthen their interaction with external partners and customers, integrate internally across departments, and fully integrate internal and external resources.

Beyond 2015: theoretical construction and practical exploration in the era of Industry 4.0

The proliferation of literature after 2015 thoroughly cites the previous literature and begins to show three main branches: (1) a focus on the relationship between servitization, business models, and value creation in green manufacturing; (2) the critical competencies needed for digital innovation in green manufacturing; and (3) a focus on supply chain management and sustainability in green manufacturing in the context of digital innovation.

In 2016, Bogers et al. (2016) in literature No. 77 focused on the impact of digital green manufacturing technologies (additive green manufacturing, rapid prototyping, and 3D printing) on the logical shift in green manufacturing business models, where the authors captured that the supply chain in green manufacturing began to shift from centralized to decentralized and business models became more open, i.e., from being centered on the production of goods to being centered on the consumer. The three papers in Fig. 8 that appeared in 2017 looked at the impact of IoT on green manufacturing business models (#102), the facilitative relationship between digitization and servitization (#90), and the capabilities required for value co-creation (#92). Notably, in paper No. 90, Coreynen et al. (2016) explore three paths of servitization that green manufacturing firms can achieve through dynamic resource allocation in different digital contexts: industrial, commercial, and value servitization. Industrial servitization means that suppliers gain new knowledge by optimizing their internal business processes and translate it into value-added services for their customers. The commercialization of services means that green manufacturing companies develop customer-facing digital platforms to capture customer needs and enhance product innovation by bridging front-end and back-end processes and harnessing customer knowledge. Value servitization refers to creating new digital products using a more dynamic, disruptive, and innovative business model by leveraging integration capabilities. This is in contrast to the servitization paths proposed in papers No. 31 and No. 43, where the authors no longer limit themselves to the types of services that green manufacturing can provide, but rather refine different path options for the servitization of green manufacturing in the digital context, from the perspective of the different stages of the enterprise’s production process and value creation with other subjects, which reflects the inheritance and development of the theory. Since 2018 and 2019, various literatures have not only enriched their research methods but also worked on new perspectives, based on adequate citations of previous literature, addressing the issue of digital innovation in the context of Industry 4.0 (Nos. 110, 122, 123, 107, and 129), the issue of relational governance in digital finance innovation (Nos. 147 and 170), and the ecosystem of digital. The servitization phenomenon (Nos. 164 and 165) is examined.

Fig. 8.

Article citation relationship

This section focuses on the citation relationships of the critical literature to find the lineage of research on digital innovation in green manufacturing. In the next section, we will use VOSviewer to conduct an econometric analysis of the literature titles, abstracts, and keywords to find clusters of research under the topic and explain specifically the main elements of each research cluster.

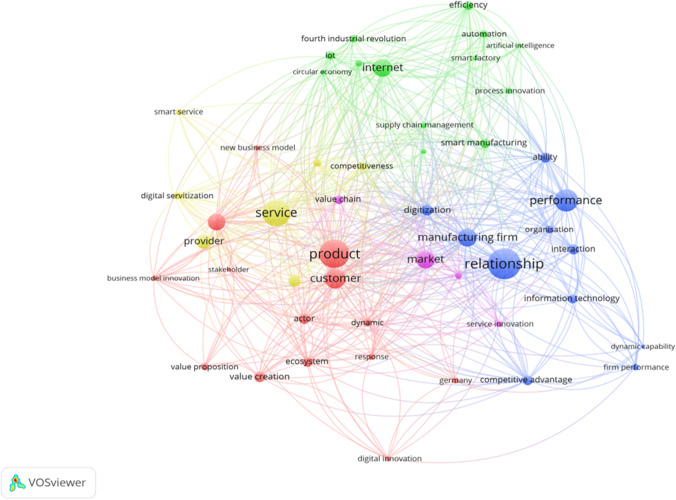

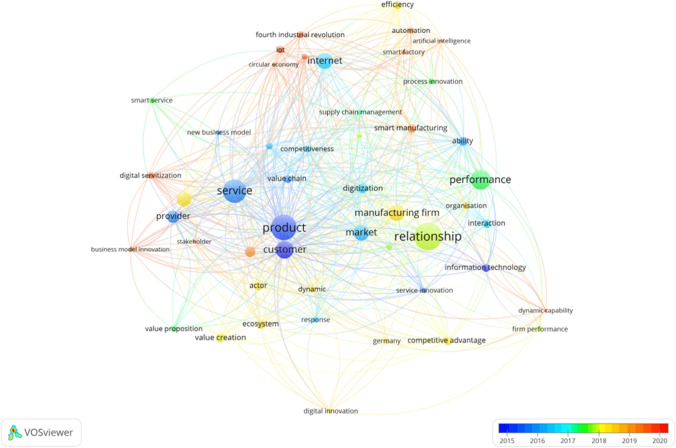

Content analysis

In order to find the branches of research under digital finance innovation in green manufacturing, we used the function of VOSviewer text analysis to perform a textual analysis of the titles and abstracts of the literature and visualize their network relationships (Fig. 9). At the same time, overlay visualization (Fig. 10), which reflects temporal changes, was plotted according to the starting time of the appearance of each keyword.

Fig. 9.

Network visualization of keywords

Fig. 10.

Overlay visualization of keywords

Cluster 1 (red): digital finance innovation, servitization, and business model

The keywords in cluster 1 consist mainly of the words corresponding to the yellow and red nodes. Table 7 shows all the keywords under this cluster, as well as the frequency of each keyword in conjunction with other keywords (total link strength), the frequency of the keyword itself (occurrences), and the average number of citations (avg. citations). According to Table 7, this cluster focuses on digital finance innovation, servitization (service, servitization, digital servitization, Intelligent service), and business models (new business model, business model innovation, value creation, value proposition, ecosystem, competitiveness). Meanwhile, according to Fig. 10, it can be seen that studies on the topic of products, suppliers, services, and consumers start the earliest, showing the darkest blue, followed by studies on ecosystems, value co-creation, and participants, which start to appear in yellow and green. In recent years, the hot topics of research have been the digitalization of services and business model innovation. These keywords are shown in red on the map and are closely related to the trends in green manufacturing, which, in the early years, focused more on the production of products and then began to focus on the relationship with suppliers and consumers. With the advancement of the servitization strategy, an ecosystem is gradually forming between the green manufacturing industry and its upstream and downstream, co-creating value with multiple entities and continuously reshaping business models. In recent years, digital and intelligent technologies have led to the convergence of digitization and servitization. From the back end of green manufacturing, companies can enhance operational performance and improve production processes through digital technologies, such as automation. The digitalization of the front end can then better enable multi-entity value co-creation by sharing information between the customer and the supply side (Coreynen et al. 2016), thus continuously promoting the intelligent transformation of green manufacturing.

Table 7.

The keywords of cluster 1

| Cluster | Label | Total link strength | Occurrences | Avg. citations |

|---|---|---|---|---|

| 1, red and yellow | Service | 199 | 50 | 62.98 |

| Product | 178 | 56 | 64.03 | |

| Customer | 143 | 35 | 62.37 | |

| Business model | 112 | 28 | 48.17 | |

| Provider | 92 | 23 | 35.56 | |

| Servitization | 77 | 18 | 28.72 | |

| Value creation | 65 | 16 | 30.37 | |

| Actor | 61 | 15 | 24.26 | |

| Ecosystem | 55 | 14 | 27.21 | |

| Digital servitization | 45 | 10 | 30.2 | |

| Response | 45 | 9 | 17.66 | |

| Value proposition | 40 | 10 | 18.1 | |

| Dynamic | 38 | 10 | 23.9 | |

| Boundary | 36 | 10 | 22.1 | |

| Intelligent service | 35 | 8 | 29.25 | |

| Competitiveness | 34 | 11 | 8 | |

| Business model innovation | 32 | 6 | 49.33 | |

| Germany | 23 | 8 | 36.25 | |

| Stakeholder | 23 | 5 | 5 | |

| New business model | 21 | 7 | 127.2 | |

| Digital innovation | 20 | 7 | 14.85 |

Under this cluster, scholars have applied different theoretical lenses to dissect value creation in digital finance innovation in green manufacturing. (1) Under the product-led logic, value creation revolves around exchange value, with green manufacturing companies more concerned with producing and acquiring products. In the process of exchange, services are defined by green manufacturing companies as an addition to the product, the understanding of which depends on the product itself and its production and delivery processes. Corporate innovation at this point comes mainly from supplier capabilities, diffusing from internal to external sources. (2) With the development of service marketing, the customer-centric marketing paradigm has advanced the evolution of the service paradigm, and products and services are gradually being differentiated. In the service-dominant logic proposed by Vargo et al., service is corporate competitiveness achieved in terms of behavior, process, and performance for the mutual benefit of stakeholders, where value is co-created by the customer and the company; i.e., the customer is involved in the production process of value. At this point in the value relationship and exchange value, use value also becomes a concern for the firm, and the innovation orientation of the firm begins to spread from external consumers to internal ones (Grieger and Ludwig 2019). In a service-led logic, green manufacturing companies can benefit from orchestration with different players in a network of players to enhance their digital finance innovation capabilities. In addition, green manufacturing companies digitize the assets of buyers and suppliers through the integration of machines, algorithms, information networks, etc., to achieve resource liquefaction and create value by fully mobilizing the resources of internal and external players to come up with new value propositions. Finally, green manufacturing companies transform customer engagement into corporate innovation capabilities by integrating resources in informal customer interactions. In this process, digital technologies need to be matched with a firm’s ability to integrate and collaborate resources to stimulate digital innovation (Goduscheit and Faullant 2018). (3) In system-led logic, value creation is derived from the interaction between products and services and the scenarios in which they are located, and corporate innovation is primarily interactive and systemic. Although service ecosystems emphasize the process of interaction and orchestration between multi-subject participants and in-service ecosystems, integration within green manufacturing firms plays a vital role in the digital finance innovation of firms. Intelligent products are equipped with monitoring, control, optimization, and autonomy functions, thus empowering companies to provide intelligent services in terms of behavior, processes, and performance. An intelligent service system is a concept that builds on intelligent products and intelligent services and refers to a system with intelligent products that integrate the resources and activities of relevant participants as boundary objects. Increasingly, green manufacturing companies are building intelligent service systems to make the transition from providing integrated solutions to providing modular solution businesses (Rajala et al., 2018) and providing intelligent services to providing platforms. This places new demands on companies’ IT capabilities, platform-related capabilities, and relationship management capabilities (front-end consumers, platform providers, and back-end service providers). The technology platform strategies of green manufacturing companies provide new avenues for orchestrating multi-actor resources in the ecosystem. The ecosystem revolves around a platform core that is simultaneously stable and homogeneous to respond to highly variable market demands using the standardized components of the platform. (4) In the theory of the firm, scholars have used resource-based view, power dependency approach, organizational identity, and transaction cost approach theories to gain insight into the dynamics of corporate decision-making in the process of digital servitization. As the boundaries of a company change from product supplier → industrializer → integrated solution provider → results provider → platform provider, the competencies required, the voice in the chain, organizational identity, investment, and the business environment are all changing. Furthermore, digital innovation makes it necessary for companies to iterate their business models and coordinate the business models of other players in the ecosystem. (5) Under the availability theory, green manufacturing companies can perceive the characteristics of their strategic goals and IoT technologies, perceive the match between the two through technology availability, and thus explore the opportunities for action in the technology to achieve their corporate goals. Differences in firms’ perceived capabilities also bring about differences in how they use digital technologies for innovation and outcomes at different stages. In the transformation of green manufacturing companies, servitization and Industry 4.0 are the two dominant trends. The former is driven by the demand side and focuses on adding value to the customer, while the latter is driven by technology and focuses on adding value to the green manufacturing process. Therefore, developed a conceptual framework linking servitization and Industry 4.0, matching nine ways of digital innovation for green manufacturing firms based on three levels of servitization (smoothing, adaptation, and replacement) and three levels of digitization (low, medium, and high). The theory of availability provides a reasonable explanation for the rationality of the framework; i.e., firms use different features of digital technology at different stages to match the level of service and ultimately achieve digital innovation at each stage of the firm’s life (Frank et al. 2019). (6) In the business model theory, scholars have focused on the fact that green manufacturing firms are revolutionizing their business models through digital technologies (e.g., artificial intelligence, 3D printing) (Burstrm et al. 2021). Some scholars have focused on the profitability of business models, such as Barua et al. (2004), who demonstrated empirically that traditional firms are using the Internet to change the way they align value with stakeholders to improve corporate performance. Gebauer et al. (2020) found through a case study that the business models of green manufacturing companies went through three dynamic stages of development, enhancing products, creating customer value, and integrating product portfolios to increase corporate revenues under a “hardware+” logic and a platform logic, respectively. Another group of scholars focused on the value creation network of business models and studied the impact of Industry 4.0 on the business models of green manufacturing companies in terms of value creation. For example, Kiel et al. (2017) found that the degree of impact of the industrial internet of things (IIoT) on the business models of green manufacturing firms was in the following order: value structure, value proposition, relationships, core competencies, partnerships, cost structure, channels, consumers, and revenue. Subsequently, Müller et al. (2018) revealed the impact of the three dimensions of Industry 4.0 (advanced digitalization of processes, Intelligent green manufacturing, and supplier-customer relationships within the value chain) on the three dimensions of the business model (value creation, value delivery, and value capture) aspects. They ranked them in order of impact: essential resources, value proposition, partners, revenue, cost, activity, and channel (Müller, 2019). Also draws consistent conclusions regarding critical partners, activities, resources, value proposition, relationships, costs, and revenues when analyzing the most advanced business models in the construction industry. When business models break through the boundaries of individual firms and the value logic shifts to a consumer-centric approach, green manufacturing firms are more likely to achieve open-mode innovation through collaboration and synergy in the ecosystem and thus optimize their business models in four ways: efficiency, complementarity, lock-in, and innovation (Bogers et al. 2016). The value logic has also changed (from mass production → mass customization → personalized production).

Cluster 2 (blue): digital finance innovation, dynamic capability, and performance

The keywords in cluster 2 consist mainly of the keywords corresponding to the blue and purple nodes. Table 8 shows specifically the keywords under this cluster, as well as the frequency of each keyword in conjunction with other keywords (total link strength), the frequency of the keywords themselves (occurrences), and the average number of citations (avg. citations). According to Table 8, this cluster focuses on digital innovation (digitization, information technology), corporate capability (ability, dynamic capability), and corporate performance and digital finance (performance, firm performance). At the same time, according to Fig. 10, the research on IT and service innovation starts first, with the darkest blue color. This is followed by studies on marketing, integration, and datafication, which appear in sky blue. In recent years, the hot topics of research have been corporate performance, competitive advantage, and dynamic capabilities, with these keywords appearing in yellow and red on the map. This indicates that green manufacturing companies are increasingly recognizing that technological innovation alone is not enough. They need to match the corresponding corporate capabilities to transform their resource and technological advantages into competitive advantages and thus achieve the ultimate goal of improving corporate performance. Therefore, in recent years, scholars have gradually started to explore what new competencies companies need to have in the context of digital servitization (e.g., digital competencies, intelligent competencies, orchestration competencies, platform competencies).

Table 8.

The keywords of cluster 2

| Cluster | Label | Total link strength | Occurrences | Avg. citations |

|---|---|---|---|---|

| 2, blue and purple | Relationship | 200 | 63 | 21.87 |

| Performance | 133 | 41 | 27.78 | |

| Manufacturing firm | 130 | 31 | 21 | |

| Market | 99 | 30 | 26.43 | |

| Digitization | 66 | 17 | 78.59 | |

| Ability | 52 | 15 | 39.93 | |

| Interaction | 52 | 15 | 48.67 | |

| Competitive advantage | 46 | 14 | 10.14 | |

| Service innovation | 43 | 8 | 20.38 | |

| Value chain | 42 | 13 | 74.31 | |

| Firm performance | 39 | 9 | 50.11 | |

| Information technology | 39 | 13 | 50.46 | |

| Organization | 32 | 11 | 5.45 | |

| China | 19 | 9 | 35.67 | |

| Dynamic capability | 14 | 5 | 2.6 |

Further reading of the literature in cluster 2 reveals that there is already literature examining how different competencies of green manufacturing firms influence firm performance in the context of digital finance innovation, where the firm’s competencies and connotations are shown in Table 9. Empirical results show that (1) the service-related capabilities of green manufacturing firms can lead to collaboration, integration, and coordination across regions and departments and with customers or partners, which, in turn, drives performance improvement (Parida et al. 2015). However, this requires the use of innovation governance strategies (SjoDin et al., 2018) and digital capabilities (Martín-Pea et al., 2019), among others, as mediating variables to unlock the benefits of servitization in green manufacturing firms. (2) In the context of digital finance innovation, companies need to digitally upgrade their existing technological capabilities, employee skills, marketing capabilities, etc. For example, the results of Nasiri et al. (2020) showed that digital workforce and orchestration capabilities show a positive relationship with corporate financial performance. Hasselblatt et al. (2018), Büchi et al. (2020), and Szász et al. (2020) confirm that green manufacturing companies with a broader and more proficient range of Industry 4.0–related technologies such as IoT tend to have better operational performance and business performance and can more take full advantage of the opportunities presented by Industry 4.0. The IT capabilities, IT systems (Zhang and Hartley 2018), and ATM technologies of these companies enable them to increase their production capacity, push the boundaries of traditional production activities, and thus improve their performance (Szalavetz, 2018). In addition, firms that are more absorptive, more entrepreneurial, and more proactive tend to more fully transform technological advantages into corporate competitiveness (Rehman, 2020). (3) Dynamic capabilities are a strong focus for scholars of enterprise capabilities. Web capabilities, orchestration capabilities, and platform capabilities can all be considered as part of dynamic capabilities. Platform capabilities refer to the ability of firms to deploy internal and external resources based on the Internet, which helps them integrate and allocate resources, share knowledge, and respond to highly variable market demands. Network capability is the ability of an organization to create internal and external interdependencies to respond to external changes. Orchestration capabilities refer to the ability of firms to set goals, legitimize them, and build corresponding expertise at different stages of development. Due to the complexity of digital technology, dynamic capabilities are essential for companies to internalize their various resources into a competitive advantage in a highly volatile environment. In addition, during internalization, the institutional environment of the organization and the learning ability of individuals determine the extent of knowledge acquisition, which is relevant in terms of the firm’s ability to develop its dynamics (Jiang et al. 2020). The dynamic capabilities of companies with a high level of digital transformation maturity often provide strategic guidance to companies in terms of process, technology, organization, and transformation (Lin et al. 2020). (4) Digital innovation capabilities, on the one hand, act as a mediating mechanism between the external environment and firm performance (Hanelt et al., 2020). On the other hand, it can also act as a direct antecedent to sales performance and customer relationship improvement (Kolbe et al. 2021). As a dependent variable for firms, digital innovation is often influenced by the capabilities mentioned earlier, such as the level of digital technology, digital analytical capabilities, and organizational variables (Saldanha et al. 2017).

Table 9.

Firm capabilities mentioned in the articles

| Firm capability | Concept | Source | |

|---|---|---|---|

| 1 | Service innovation | Service innovation strategies involve the ability to develop new service offerings that create value for customers | |

| 2 | Servitization | The process of increasing value by adding services to products | Martín-Pea et al. (2019) |

| 3 | Digitalization | Digitalization refers to the growing use of digital technology in green manufacturing | |

| 4 | Intellectual capital | Intellectual capital is an intangible resource that can generate value in the future, including human capital, relational capital, and structural capital | |

| 5 | Technology standardization capability | Technology standardization focuses on the formation of technology standards, motivation, the initial factors, the impact factors, the formation process of technology standards, and the competition and diffusion of standards at the industrial level | Jiang et al. (2020) |

| 6 | IT capability | It includes IT infrastructure flexibility, which has developed the technological base on which current and future IT applications are built, and IT technical skills, which constitute the know-how required to develop IT applications by using existing technology and to operate them either to provide a service or to make the products | |

| 7 | Absorptive capacity | ACAP refers to the ability of a firm to acquire, assimilate, transform, and exploit knowledge-based resources | |

| 8 | Digital platform capability | It represents the ability to deploy ICT-based resources in combination with other internal and external resources | |

| 9 | Network capability | It refers to the coordination of groups and individuals that share a standard structure and an expected result, the internal communication of the external knowledge, the relational skills for handling diverse individuals, and the partners’ knowledge | |

| 10 | Networking capability | The ability to develop and deploy a network to accomplish specific goals focused on the acquisition of complementary external resources | |

| 11 | Digital-related human capability | The boundless employee capabilities enable people to operate in the digital era with adaptable mindsets, skillsets, and digital know-how | Nasiri et al. (2020) |

| 12 | Digital-related collaboration capability | The bundle of firm capabilities created by digitality through collaborative activities with both external and internal partners | |

| 13 | Digital-related technical capability | The bundle of firm capabilities that facilitate technological implementation and operation in the digital era | |

| 14 | Digital-related innovation capability | The boundless firm capabilities generate new knowledge, new products and services, and new solutions through digitalization | |

| 15 | Digital innovation capability | Digital innovation is defined as creating new market offerings or changes that result from the use of digital technologies | Hanelt et al. (2021) |

| 16 | Dynamic capability | Dynamic capability is an organization’s capacity to purposefully create, extend, or modify its resource base to achieve sustainable advantages through adaptation to the changing shape of the external environment | Zeng et al. (2017) |

| Dynamic capabilities comprise 3 broad clusters: sensing opportunities (and threats), seizing opportunities, and transforming by organizing resources and renewing organizations to their relevant business model | Lin et al. (2020) | ||

| 17 | Process capability | The ability to optimize manufacturing processes with advanced technologies enables new value creation in operations, supply chain, and product life cycle | |

| 18 | Technology capability | The ability to connect intelligent machines, storage systems, and production facilities can facilitate information exchanges and data analyses to predict failures and independent configurations | |

| 19 | Organizational capability | The capabilities to implement suitable strategies in a changing environment, including intelligent manufacturing transformation and developing organizational capabilities, must include top management support and decision-making, talent, workforce training, and education and knowledge | |

| 20 | Transformation capability | The capability to transform the abstract Industry 4.0 concept into a practical application and evaluation of process systems | |

| 21 | Digitally transforming capability | The capability of executing a digital transformation strategy, including digital-savvy skills, digital intensity, and context for action and interaction | |

| 22 | Innovation capability | Innovation capability is the organization’s ability to gather information and create the knowledge needed to develop and implement new products, processes, and services | Zhang and Hartley (2018) |

| 23 | Global service innovation capability | The development of global service innovation capabilities, grouped across 4 dimensions: developing global customer insights, integrating global knowledge, creating global service offerings, and building global digitalization capabilities | Parida et al. (2015) |

| 24 | Digitalization capability | Digitalization capabilities include intelligence, connection, and analytic capabilities | |

| 25 | IoT capability | IoT capabilities are identified as digital business model development, scalable solution platform building, value selling, value delivery, and business intelligence and measurement | Hasselblatt et al. (2018) |

| 26 | Orchestration capability | Orchestration capabilities are necessary to ensure co-evolution, albeit with a different interpretation depending on the platform development stage, including targeting capability, legitimizing and envisioning capability, and expertise building capability |

Cluster 3 (green): digital finance innovation, Industry 4.0, and supply chain management

The keywords in cluster 3 consist mainly of the keywords corresponding to the green nodes. Table 10 shows specifically the keywords under this cluster, as well as the frequency of each keyword in conjunction with other keywords (total link strength), the frequency of the keywords themselves (occurrences), and the average number of references (avg. citations). According to Table 9, this cluster focuses on digital finance innovation, Industry 4.0 (artificial intelligence, process innovation, intelligent factory, intelligent green manufacturing), and supply chain management (supply chain management, circular economy, IoT). Meanwhile, according to Fig. 10, it can be seen that research about the Internet started earliest, showing sky blue. Immediately afterward, research on process innovation and supply chain management appeared, showing a green color. In recent years, the research hotspots have been topics related to intelligent green manufacturing, and these keywords appear yellow and orange on the map, which is in line with the overall transformation trend in green manufacturing. From the Internet era to the information age to the current digital intelligence era, the green manufacturing industry has constantly been using new technologies to achieve industrial upgrading and iteration.

Table 10.

The keywords of cluster 3

| Cluster | Label | Total link strength | Occurrences | Avg. citations |

|---|---|---|---|---|

| 3, green | Artificial intelligence | 20 | 5 | 12 |

| Automation | 37 | 10 | 32.5 | |

| Big data | 34 | 9 | 19.89 | |

| Circular economy | 26 | 5 | 38.8 | |

| Efficiency | 42 | 13 | 19.08 | |

| 4th industrial revolution | 27 | 10 | 13.6 | |

| Internet | 112 | 31 | 29.68 | |

| IOT | 50 | 12 | 8.75 | |

| New technology | 23 | 7 | 17.29 | |

| Process innovation | 30 | 8 | 31.25 | |

| Intelligent factory | 23 | 7 | 11 | |

| Intelligent manufacturing | 31 | 14 | 18.86 | |

| Supply chain management | 31 | 8 | 34.38 |