Abstract

This research aims to develop a fuzzy logic-based model for predicting the warp way and weft way Tearing Strength (TS) of laser engraved denim garments concerning two of the most important laser parameters such as Dots Per Inch (DPI) and Pixel Time (PT). Laser engraving is a widely used approach in garment washing factories because of its lower health hazards, time efficiency, and accuracy than other processes. However, controlling the laser parameters is very important, as if the tearing strength of the treated garments falls lower than the tolerable limit, the garment might be rejected. In this study, the fuzzy logic-based method is used to develop a prediction model to determine the Tearing Strength of the laser engraved denim. The model exhibits the exact same trend for TS as the experimental findings, i.e., TS increases with the decrement of either DPI, PT, or both. Moreover, the Mean Relative Errors (%) for warp and weft way Tearing Strength was found to be 3.34 and 3.53, respectively, which are within the acceptable limits. The coefficient of determination (R2) was found 0.98 (R = 0.99) for both the warp and weft way Tearing Strength, and the result suggested that up to 98% of total changes in warp and weft way Tearing Strength can be explained by the model. From the results, it can be evident that the principle of the proposed model can satisfactorily be used in predicting the Tearing Strength of the laser engraved denim garments, which will be beneficial for the garment washing industry by eliminating a lot of existing trial and error approach to set process parameters and thus can play an important role in increasing the productivity by process optimization.

Keywords: Laser engraving, Denim, Fuzzy logic, Modeling, Dry process, Green approach

Laser engraving; Denim; Fuzzy logic; Modeling; Dry process; Green approach.

1. Introduction

The clothing and fashion industry is one of the most expanding industries in this modern-paced world [1, 2, 3]. Both the customers and consumers are looking forward to imparting different kinds of fashion in their clothes and accessories daily. Denim is one of those items considered fashionable, not only as clothing but as essential accessories in different products, e.g., shoes. During or after the manufacturing cycle of the denim products, a value addition process is carried out to enhance the aesthetic appearance of the denim products [4]. This value-adding process comprises both the wet washes and dry processes [4, 5]. Wet washes include normal garment wash, enzyme wash, bleach wash, stone wash, etc. [4, 5, 6, 7, 8, 9, 10]. Some of these washes produce a fading effect on the treated garments, but these effects are mostly produced on the overall garment surface. On the other hand, dry processes are used to create a faded and worn-out appearance, and unlike wet washes, dry processes can produce the fading effect in a localized area on the treated garments [9, 10]. Sandblasting, hand sanding, potassium permanganate (PP) spray and sponging, hand scraping, etc., are the most common examples of the dry processes used for producing fading effects [9, 11]. Nevertheless, these traditional dry processes possessed some unavoidable drawbacks, such as health hazards for both the industry workers and the garment's end-users. Moreover, completely manual processes have a high rejection rate and lack accuracy and productivity [11, 12, 13]. To avoid these limitations of both the wet washes and dry processes, we can use an eco-friendly, low health hazardous, quicker technique with higher accuracy and efficiency to make the denim more fashionable using the laser engraving technique [11, 12, 13]. Laser systems have a vast application on textiles, including fashion designing, pleating, cutting, and modifying fabric surfaces [14]. The application of the laser technique covers the field from cutting to the decoration of the textile materials. Fading effect by laser engraving is popular; at the same time, garment decoration using laser also gained much popularity. Fabric cutting and fault detection, laser engraving or fading, laser welding of fabrics, laser marking and barcode scanning, accurate body measurement, objective evaluation of seam pucker are examples of the vast application of lasers in apparel manufacturing [15, 16]. Among the used machines, carbon dioxide laser (CO2 laser), neodymium-doped yttrium aluminum garnet laser (Nd: YAG), and diodes lasers are the most popular to achieve different types of laser treatments [17]. The CO2 laser is the most suitable and most efficient among these laser systems, especially for engraving materials like textiles. It is because textiles are not good conductors of heat and electricity. Furthermore, another important aspect is that the wavelength of the CO2 laser can easily be absorbed by the textiles [18]. Besides, CO2 is also non-toxic and relatively inexpensive, which is excellent in terms of the environmental and economic feasibility of the industry [19]. Not only in the field of textile substrate engraving, but the laser also has a wide variety of utilization in various industrial applications. For example, in the case of the machining processes like turning, drilling, milling, and grinding, different types of lasers such as CO2, Nd:YAG, and excimer lasers are used. For these applications, lasers of different mediums like solid, liquid, and gas are used prominently [20]. The other prominent application areas of laser in the industrial area include particle size measurement, diagnosis of industrial systems, tooling and alignment positioning, distance measurement, laser welding, electronic fabrication, spectroscopy, holography, monitoring of chemical dynamics, and optics. Similarly, another prominent field of laser application is material removal which mainly covers the processes like drilling, cutting, marking, and engraving. The principle of material removal is the basis of laser engraving of textile materials where the surface material of the textile substrate is gradually removed by the controlled application of CO2 laser [21, 22, 23].

Laser engraving is performed by burning the surface of the denim fabric with a laser ray [13, 24]. A laser system generates monochromatic, coherent photons in a low-divergent beam focused on the desired area of the fabric. Within a very small area, the focused region is subjected to highly intense heating [13]. The material rapidly heats as a phase shift from solid to liquid occurs, and laser energy is absorbed as heat, causing melting [11, 13]. This extreme heating of the laser system is used in a very controlled condition to engrave the denim garments. This controlled condition can be achieved by controlling the resolution or Dots Per Inch (DPI), and the Pixel Time (PT).

Several studies have already been conducted and reported the overall suitability and feasibility of the laser engraving on the textile materials [19, 25, 26, 27, 28]. The potential changes in the color and mechanical properties of the denim due to the laser engraving process have extensively been studied in previous studies [13, 18, 24, 29]. Besides, Juciene et al. studied the effect of the technological parameters of CO2 laser on the color of indigo-dyed denim [30]. The authors reported that color change () occurs antithetically in the warp and weft direction of the laser-treated samples that is significantly influenced by the presence of the beam power [30]. Moreover, both the color hue and color saturation are affected by the beam power while color brightness is affected by the laser step size [30]. In a different study on the effect of CO2 laser on indigo-dyed denim fabric, Venkatraman and Liauw found the influence of laser on color change, strength, color fastness, air permeability, and thickness of the treated denim fabrics [15]. The authors have established that the use of laser engraving technique can serve the expected aesthetic properties of the denim fabrics with a lower environmental and health hazards [15].

On the other hand, Jiang et al. studied the effect of laser engraving on Aluminium foil laminated denim. They concluded that with the increment of laser resolution and pixel time, the patterns on the treated surface become more apparent, crisp, and vice versa. Furthermore, resolution and pixel time impact the physical and mechanical properties of the treated denim [31]. Bahira G. Gabr has conducted a comparative analysis of chlorine-washed and CO2 laser faded denim [32]. The study revealed that although the air permeability of the laser-treated samples is lower than that of the chlorine-washed denim, the laser fading is suitable for tensile and seam strength [32]. In another approach, Juciene et al. studied the effect of the complex washing approach (laser treatment and industrial wet washing) on the tension properties of denim fabric. They found a reduced breaking force of the treated denim fabric due to the complex finishing where the extensibility remains unchanged [33].

All these studies revealed that the physical and color properties of the laser engraved denim products changed with the change of laser parameters like resolution and pixel time. According to Yuan et al. [34] resolution and pixel time are the two most important laser parameters to control for optimizing the process. Without controlling these parameters, the treated fabric may have a lot of degradation due to the intense laser heating [34]. The importance of controlling these parameters has also been studied. The researchers demonstrated that it is important to control these parameters to ensure a better outcome from the laser engraving process [13, 31, 35, 36, 37, 38].

Until now, among the most popular intelligent techniques of modeling, the Artificial Neural Network (ANN) model has been used to predict the color properties of the Cellulase-Treated denim fabric [39]. The ANN method has also been used as an embedded-expert system in the textile manufacturing process and used to predict textile materials' properties [40, 41].

In most research, models based on intelligent techniques like fuzzy inference system, ANN, Artificial Neuro Fuzzy Inference System (ANFIS), etc. are found to be more accurate and mature than the most prevalent models, including mathematical, statistical, and intelligent techniques-based models for predicting the properties of textile substrate [42, 43, 44, 45, 46, 47]. Mathematical and statistical methods frequently fail to address the nonlinear relationship between process parameters and textile output parameters. As a result, these models provide noisy data with a lower level of precision [48, 49, 50]. In this regard, soft modeling methods based on intelligent techniques like Artificial Neuro Fuzzy Inference System (ANFIS) or ANN can substantially address the issue with reasonable accuracy [51]. At the same time, soft modeling methods like ANN and ANFIS generally require heaps of data collection to deliver efficient prediction models, which is time-consuming and challenging in an industrial situation and is somewhat complex to utilize from the industrial point of view [47, 52]. Though ANN models usually require a huge number of datasets to operate accurately, at the same time if designed optimum, it can also demonstrate an excellent accuracy with a small amount of dataset [47]. On the other hand, fuzzy logic-based models are simple, require less data, cheaper in design cost, and are highly configurable [36, 53, 54]. Furthermore, the fuzzy logic-based model excels at property prediction, particularly with fewer datasets, which is beneficial for the industries [53]. In addition, as the primary target users of this model are the textile engineers and designers, that's why adopting a simple or in other words less complex method is more convenient as they are generally not used to using high-end technologies like neural networks. Therefore, in this current study, a fuzzy logic-based model has been developed for its better performance in terms of accuracy, suitability for the industrial process, and convenience of the target users.

Recently, Sarkar et al. modeled the complex effect of DPI and Pixel Time on fabric GSM and crease recovery angle of a laser engraved denim with the help of fuzzy logic analysis [36]. The authors concluded that fuzzy expert-based models could successfully be used to predict GSM and crease recovery angle in both warp and weft ways of the laser-treated denim [36]. In the field of textiles, fuzzy logic-based prediction models have been used to predict the fabric properties [55, 56] and color strength modeling of the dyed fabrics [54, 57]. However, until now, no significant approach has been reported to predict the laser engraved denim's physical and mechanical properties with the fuzzy expert system or ANN modeling. As it has been well established that the lasers can destroy the surface of the garments, if the laser parameters such as resolution (DPI) and Pixel Time are not well controlled, it may downgrade the essential mechanical properties, for example, Tearing Strength of the denim garments very adversely and can even affect the serviceability of that treated garments [11, 12, 13]. Therefore, incorporating a modeling-based prediction system can save a lot of material as well as man and machine hours. As a result, productivity can be significantly enhanced in addition to achieving the required properties in the final laser engraved denim. Similarly, while designing the apparel with laser engraving, the designer can easily take decision regarding the final Tearing Strength of the laser engraved denim garments without developing samples, which might be an advantageous addition to the apparel and fashion design industry. By considering the limitations of other modeling systems and the advantages of fuzzy based modeling systems over other prevailing modeling techniques, in this study, a fuzzy expert-based model have been developed. The developed model is expected to predict the final Tearing Strength of the garments regarding the controlling parameters, which the fashion and garment washing industry could use to produce faded denim by maintaining the appropriate process parameters to get the desired Tearing Strength of the final garments.

The remainder of the organization of the paper is as follows. Materials and methods that contain the entire procedure of sample preparation and testing performed to validate the model predicted results and the details of fuzzy model development are discussed before presenting the results and discussion. Afterward, the conclusion part is presented, followed by the references.

2. Materials and methods

2.1. Materials

100% cotton yarn was used to produce the denim fabrics having a mass per unit area (Grams per Square Meter, GSM) of 460, warp-faced twill (3/1), and fabric construction of 74 × 52/12 × 11, where fabric width was 55 inches. Hostapur WCTH, Germany was used as detergent for subsequent normal wash after laser treatment, and Resil AOEC, India was used as a softener.

2.2. Preparation and testing of the samples

The samples were prepared in the form of leg panels. The denim fabric used for these leg panels was sized indigo dip-dyed. The leg panels were then treated with a laser system (VAV Technology) by maintaining the desired DPI (Dots Per Inch) and Pixel Time. The samples were then washed using a regular recipe that included detergent (Hostapur WCTH, Germany) and softener (Resil AOEC, Resil, India).

The samples (leg panels) were first treated with a CO2 laser system (VAV Technology) in the desired condition. The design was generated with Adobe Photoshop CC (Version 20.0) software and the leg panels were then engraved with the laser system. A normal washing was performed after laser treatment to clean the leg panels of size particles and other dirt and dust. The desizing was performed in a liquor that contained a desizing agent, Luzyme (1.5 g/l) maintaining a material to liquor ratio of 1:10. In a laboratory-scale front-loading industrial garment washing machine (Sutlick, Singapore) the desizing process was carried out. The temperature of the wash bath was 60 °C for 10 min for the desizing whereas the pH of the wash bath was 7. Afterward, the panels were normal washed by using the same machine and liquor ratio for 5 min at 30 °C. Then the panels were rinsed (two times in cold water) and softened by using a softener. The softening process was performed in a wash bath by maintaining a liquor ratio of 1:08, containing softener, Resil AOEC (1.5 g/l), acetic acid, CH3COOH (35 gm.) at room temperature for 7 min. The pH of the wash bath was 5.5.

In a laboratory-scale hydro-extractor system (Zanussi, Roaches International Limited, England), washed and softened denim leg panels were squeezed at 200 rpm for 3–4 min to attain a wet pick-up of 70% and then dried at 70–75 °C for 20 min in a gas dryer (Fabcare, India). The physical properties of treated denim leg panels were then assessed and compared.

Following washing, all samples were conditioned for 24 h on a flat surface before being assessed in the standard atmospheric conditions of relative humidity (65 ± 2) % and temperature (20 ± 2) °C, as per BS EN 20139 and ASTM D1776. The warp way and weft way Tearing Strength of the prepared samples were determined according to ASTM D1424 – 09 (2013) with the help of an Elmendorf type tearing strength tester (ElmaTear, James Heal, UK). An average Tearing Strength of 05 samples has been recorded as the Tearing Strength for each testing condition.

Table 1 shows the process variables for both model development and laboratory trial.

Table 1.

Range of process variables.

| Process parameters | Values | ||

|---|---|---|---|

| Dots Per Inch | 15 | 20 | 25 |

| Pixel Time (μs) | 100 | 150 | 200 |

2.3. Fuzzy prediction model development

2.3.1. Structure of the fuzzy logic system

In this study, the fuzzy logic analysis system has been introduced to predict the Tearing Strength of the laser engraved denim garments. In 1965, Zadeh developed the fuzzy logic system [58], and since then, it has been exclusively used as a successful research tool in different branches of researches.

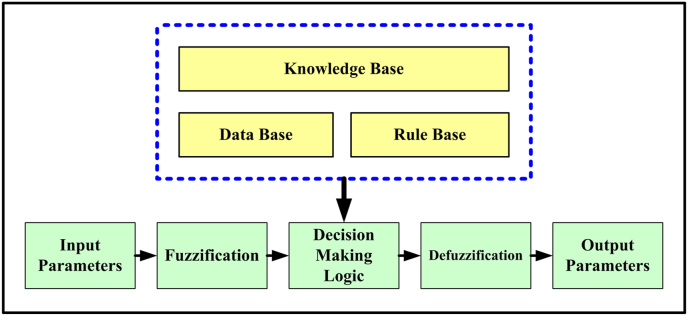

Figure 1 shows that the fuzzy logic system is comprised of four principal components [36, 56, 59]. The components are discussed below:

-

a)

Fuzzification interface: This system takes the crisp numeric input and output values. These numeric input and output values are then defined as linguistic terms in the fuzzification interface. The fuzzifier block converts all inputs and outputs into fuzzy sets, and membership functions are created. The membership functions numerically represent the degree of belonging of elements to the sets within the range of 0–1 [59–61]. Among the most used shapes of the membership functions, triangular is the simplest and most used shape [56].

-

b)

Knowledge base: Both data base and rule base constitute the rule base. if-then rules are used to represent the knowledge in a knowledge base system. These if-the statements relate the input variables and output variables [53, 61]. Fuzzy rules base is classified as Mamdani and Sugeno [50]. In this paper, Mamdani rules have been used. For example, a fuzzy model with two inputs (X and Y) and a single output (Z), which have the linguistic variables of medium and high for X and Y respectively and high for Z, then the structure of the Mamdani fuzzy inference rules is as following: - Mamdani rule: if X is medium, and Y is high, then Z is high [56].

-

c)

Decision-making logic: This executes a fundamental role as it can mimic the decision-making of human beings. Linear interpolation of the outputs between rules is one of the main strengths of the Mamdani max-min interface. That's why, in this particular study, Mamdani max-min interface is used [36, 54, 60, 61].

-

d)

Defuzzification interface: In a fuzzy inference system, the defuzzification interface is the final uni. It integrates the decision-making logic's conclusions and transforms the fuzzy output into specific, crisp numeric values [49, 50]. Eq. (i) represents the transformations of fuzzy output into a non-fuzzy crisp value Z. [60]:

| (i) |

where n represents the number of elements in the sample, refers to the position of the singleton and is the membership function of rules. A fuzzy set with a membership function that is unity at one point but zeroes in everywhere else is called a fuzzy singleton. On the other hand, A curve that defines how the points of the input space are mapped to a membership value that falls somewhere between 0 and 1 is defined as a membership function [62, 63].

Figure 1.

Basic architecture of the Fuzzy Logic System.

2.3.2. Fuzzy logic system model development

In this research, two variables such as Dots Per Inch (DPI) and Pixel Time (PT) were used as input variables and Tearing Strength (TS) as the output variable. The proposed model was then developed using a fuzzy toolbox of MATLAB (Version 9.6). For each of the input variables DPI and PT, three fuzzy linguistic sets were chosen for fuzzification: Low (L), Medium (M), and High (H). They were uniformly spaced and covered the entire input range. For the output variable TS, five output fuzzy sets were used: Very Low (VL), Low (L), Medium (M), High (H), and Very High (VH). Table 2 shows the fuzzy sets in linguistic terms along with their numerical ranges. The most used and popular parameters practiced in the industry have been extensively studied to shortlist the input parameters. The short-listed parameters were then analyzed to find out which parameters give the best results by maintaining the serviceability of the treated garments within the acceptable range. Based on the analysis and expert opinion, the final range of the parameters was selected. The selected parameters were then applied in various combinations to find out the highest and lowest values of Tearing Strength. These values have finally been used to form the range for output parameters.

Table 2.

Fuzzy sets and numeric values.

| Parameters | Range | Linguistic fuzzy sets |

|---|---|---|

| DPI (Dots Per Inch) | 15–25 | L, M, H |

| PT (Pixel Time) in (μs) | 100–200 | L, M, H |

| Tearing Strength in Warp Way (lb) | 3.2–6.9 | VL, L, M, H, VH |

| Tearing Strength in Weft Way (lb) | 3.3–7.21 | VL, L, M, H, VH |

In this study, for input-output variables, triangular-shaped membership functions are used because of their accuracy. At the same time, the Mamdani max-min inference mechanism and the center of gravity (COG) defuzzification system [50] was used.

The following functions assist in the fuzzification of the used factors -

| (ii) |

| (iii) |

| (iv) |

| (v) |

where is the first input (DPI), is the second input (PT), and are the output (TS) variables in warp and weft way showing in Eqs. (ii)–(v). Eqs. (iv) and (v) denote the output variables for warp way Tearing Strength and weft way Tearing Strength, respectively.

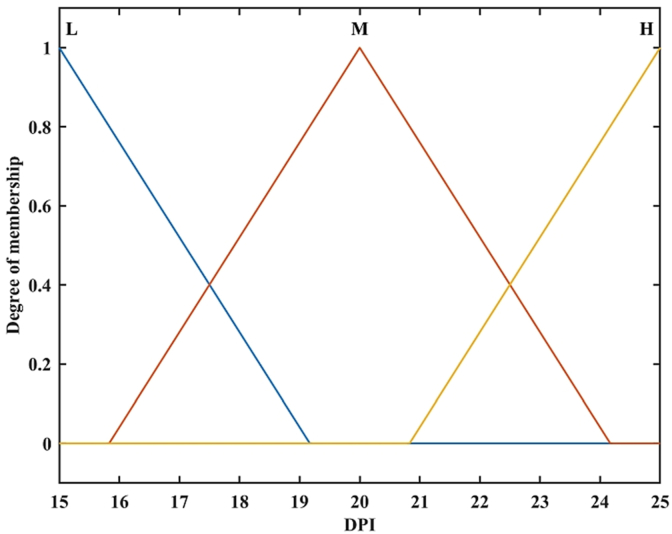

The fuzzy toolbox was used to construct prototype triangular fuzzy sets for the fuzzy variables Dots Per Inch (DPI), Pixel Time (PT), and Tearing Strength (TS). Figures 2, 3, 4, and 5 depicts the membership values.

Figure 2.

Membership functions of DPI (Dots Per Inch).

Figure 3.

Membership functions of PT (Pixel Time).

Figure 4.

Membership Function of TS (Tearing Strength) in warp way.

Figure 5.

Membership Function of TS (Tearing Strength) in weft way.

In Figures 2, 3, 4, and 5, the equally spaced triangular-shaped membership functions have been presented. The membership functions (L, M, and H for input variables and L, M, H, VL, and VH for output variables) cover the whole range of the input and output variables and, at the same time, conforms within the degree of membership between 0 and 1.

A total of nine (9) fuzzy rules were developed in this research depending on the expertise and experience of the experts. Table 3 summarizes the rules. As fuzzy rules are considered the heart of any fuzzy logic system [56], selecting a proper rule base is important for the optimum operation of the fuzzy logic-based model. In this study, the rules are formed based on the opinions of the experts. The rules are set to instruct the model in the linguistic, logical form regarding the output. For example, in Table 3, the first rule is that the output TS will be very high when the DPI is low, and the PT is low. This is the training of the model which the model uses to predict the data. The same applies to the other rules as well. Based on the entire rule base, the model operates to predict the crisp output variables based on any input combinations and vice-versa.

Table 3.

Fuzzy rules.

| Rules | Input variables |

Output variables |

|

|---|---|---|---|

| DPI | PT | TS | |

| 1 | L (Low) | L (Low) | VH (Very High) |

| 2 | L (Low) | M (Medium) | H (High) |

| 3 | L (Low) | H (High) | M (Medium) |

| 4 | M (Medium) | L (Low) | H (High) |

| 5 | M (Medium) | M (Medium) | M (Medium) |

| 6 | M (Medium) | H (High) | L (Low) |

| 7 | H (High) | L (Low) | M (Medium) |

| 8 | H (High) | M (Medium) | L (Low) |

| 9 | H (High) | H (High) | VL (Very Low) |

2.4. Validation of prediction accuracy

The prediction's accuracy has been investigated by comparing it with the laboratory experimental data. The Mean Relative Error, Coefficient of determination , and Correlation coefficient (R) was determined for the validation. Using OriginPro 2021 software, the coefficient of determination (R2) was measured and plotted.

3. Results and discussion

3.1. Fuzzy logic operation

The figures of the fuzzy logic rule viewer have been shown in Figure 6 and Figure 7, respectively, where the complete roadmap of the entire fuzzy system is presented. On the very left, for each row, the rule numbers are displayed. Whereas, across the top of the figures, the three plots displayed the antecedent and consequent of the first rules and so on for the other rules in the next rows. Every column is a variable, and each rule is a row of plots. The last plot in the last column of plots simply displays the aggregate weighted decision for the developed fuzzy system. On this particular plot, a bold vertical line displays the defuzzified output [64]. For instance, if the Dots Per Inch (DPI) is 20, and Pixel Time (PT) is 150 μs, then the Tensile Strength (TS) is 5.05 lb in the warp way direction and 5.26 lb in the weft way direction. This type of prediction can be done for every single combination within the input and output range. So, this model can be used to determine the Tearing Strength for numerous amounts of DPI and PT that can be capable of suggesting the DPI and PT for a particular TS. However, this model is a sample demonstration of how capable this method can be. But this principle with factory-specific data ranges can be used in the production stage by selecting and working with a wider range of data for any garments and fashion industry.

Figure 6.

Fuzzy rule viewer (for warp way Tearing Strength).

Figure 7.

Fuzzy rule viewer (for weft way Tearing Strength).

The developed fuzzy surfaces are shown in Figure 8 and Figure 9, proportionately. The figures explain the relationship among DPI and PT on the input side and TS on the output side. For both warp and weft way Tearing Strength, it is evident from the surface plot that with the increment of DPI and PT, the TS decreased. The figures indicate that the relation among the DPI, PT, and TS can successfully be plotted by using this model with proper details.

Figure 8.

Surface view of the TS (Tearing Strength) with DPI (Dots Per Inch) and PT (Pixel Time) (weft way).

Figure 9.

Surface view of the TS (Tearing Strength) with DPI (Dots Per Inch) and PT (Pixel Time) (warp way).

This study showed that the input parameters (DPI and PT) are affecting the output parameter (TS). If the Tearing Strength of the engraved garments decreases, the garments would become unserviceable and would be rejected. Therefore, it is important to maintain the optimal level of laser parameters to achieve the expected final tearing strength of the garments. This phenomenon concludes that this model can suggest the optimal input parameters to predict the final Tearing Strength of the garments successfully.

3.2. Analysis of experimental results

The effects of Dots Per Inch (DPI) and Pixel Time (PT) on the Tearing Strength (TS) of the treated denim garments have been depicted in Figure 10.

Figure 10.

Effect of PT (Pixel Time) and DPI (Dots Per Inch) on a) weft way Tearing Strength, and b) warp way Tearing Strength.

It can be evident that the TS decreased with the increment of DPI or PT. It is obvious because as the laser works by burning to evaporate the surface of the substrate undergoing laser treatment, more resolution or exposure for more time of the substrate under the laser would destroy the substrate's molecular bond, hence resulting in poor tearing strength [12]. It has been found that the Tearing Strength is decreased up to 54% for both the warp way and weft way as an increment of both the DPI and PT. It has also been found that the Tearing Strength in the warp way (lowest value is 3.2) decreased more than in the weft way (lowest value is 3.3) even in the same laser condition. It happens because the denim garments chosen for this specific research were warp-faced as warp-faced denim has more warp yarn exposed and suffers mostly as being treated with laser. In the previous study, a similar effect has been reported for the Tearing Strength of laser engraved denim [13]. On the other hand, the same trend of decreased tearing and tensile strength with the increment of laser parameters has also been reported in several researches, where the fabrics have been exposed to laser rays of different intensity, DPI, and PT [9, 65, 66, 67, 68].

3.3. Validation of the predicted results

By using laboratory trial data, the prediction model developed in this research has been assessed exclusively. The prediction was done by the Fuzzy Logic Expert System (FLES) model whereas the lab-scale experiment acquired the experimental results. The FLES model predicted results were then compared to the 'actual' (experimental) results. Table 4 showed the overall contrast of the actual and predicted results.

Table 4.

Comparison of actual and predicted values of Tearing Strength.

| Sl. No. | Dots Per Inch (DPI) | Pixel Time (μs) | Warp way |

Weft way |

||||

|---|---|---|---|---|---|---|---|---|

| Actual Tearing Strength (lb) | Fuzzy model predicted Tearing Strength(lb) | Relative Error (%) | Actual Tearing Strength (lb) | Fuzzy model predicted Tearing Strength(lb) | Relative Error (%) | |||

| 1 | 15 | 100 | 6.90 | 6.60 | 4.35 | 7.21 | 6.90 | 4.30 |

| 2 | 15 | 150 | 5.81 | 5.98 | 2.93 | 6.40 | 6.23 | 2.66 |

| 3 | 15 | 200 | 5.10 | 5.05 | 0.98 | 5.30 | 5.25 | 0.94 |

| 4 | 20 | 100 | 5.79 | 5.98 | 3.28 | 5.90 | 6.23 | 5.59 |

| 5 | 20 | 150 | 4.98 | 5.05 | 1.41 | 5.36 | 5.25 | 2.05 |

| 6 | 20 | 200 | 4.12 | 4.13 | 0.24 | 4.30 | 4.28 | 0.47 |

| 7 | 25 | 100 | 4.88 | 5.05 | 3.48 | 5.15 | 5.25 | 1.94 |

| 8 | 25 | 150 | 3.97 | 4.13 | 4.03 | 4.10 | 4.28 | 4.39 |

| 9 |

25 |

200 |

3.20 |

3.50 |

9.37 |

3.30 |

3.61 |

9.39 |

| Mean Relative Error (%) | 3.34 | 3.53 | ||||||

| Correlation coefficient (R) | 0.99 | 0.99 | ||||||

| Co-efficient of determination (R2) | 0.98 | 0.98 | ||||||

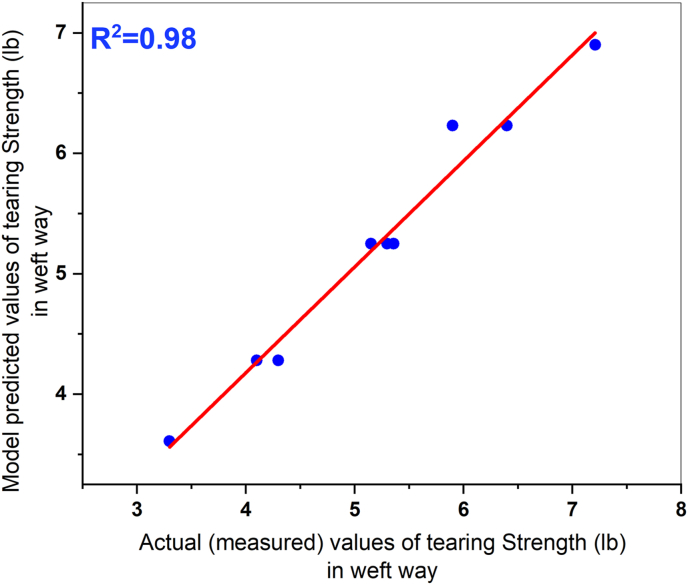

From the graphical representation (Figures 8, 9, and 10), it is already eminent that both DPI and PT have the same influence on the TS for both the measured and actual results of TS. To the best of the authors’ knowledge, until now fuzzy logic-based models have not been reported for predicting the Tearing Strength of laser engraved denim garments. Although a few researches used, the fuzzy logic models for predicting the fabric weight per unit area (GSM) and crease recovery angle of laser engraved denim have been studied [36]. The authors found that the DPI and PT affect the GSM and crease recovery angle [36]. Albeit of having different output parameters, considering the basic effect of laser, these findings are well-aligned with this current study. Furthermore, the suitability assessment of the proposed model of the present study is carried out. The correlation between the measured (experimental/actual) and predicted (FLES model) values of Tearing Strength in different treatment conditions is presented in Figure 11 and Figure 12, respectively. The Coefficient of determination (R2) was found to be 0.98 (R = 0.99) for both the warp and weft way Tearing Strength. As a result, it is reasonable to assume that the developed model has an outstanding capability to explain 98% change in the Tearing Strength of the laser-engraved garments in both the warp and weft directions. The Mean Relative Error was found 3.34% and 3.53% for warp and weft way Tearing Strength, respectively, which is less than 5% and therefore, fitted within the acceptable limit. Therefore, it can be said that both the coefficient of determination and the Mean Relative Error (%) results showed that the proposed model has excellent predictability of the Tearing Strength with the satisfactory accuracy.

Figure 11.

Correlation between actual and predicted values of Tearing Strength (TS) (warp way).

Figure 12.

Correlation between actual and predicted values of Tearing Strength (TS) (weft way).

4. Conclusions

The main objective of this study was to develop and validate a fuzzy logic-based model to predict the Tearing Strength of the laser engraved denim garments. The experimental findings, prediction by the developed model, and statistical analyses suggest that the model is well capable of fulfilling the study's primary objective.

The Coefficient of Determination, R2 was found 0.98 (R = 0.99) for both warp and weft way Tearing Strength which indicates excellent compatibility of the experimental data and data derived from the developed model. Mean Relative Error was found 3.34 % for warp way Tearing Strength and 3.53 % for weft way Tearing Strength. These results prove that the model data is extremely well aligned with the actual experimental data.

On the other hand, the developed model performs in an excellent manner and is highly customizable. Therefore, this model can be used or can be considered as a base to model any properties of the laser engraved denim garments and can eliminate the hassle of the textile washing practitioners and designers to predict the final properties of a complex process like laser engraving. In a vast scenario, this method of property prediction is material efficient that is also beneficial from the environmental pollution footprint point of view. Therefore, it can be inferred that this fuzzy logic-based model can be used as a decision-making tool in the industrial garment washing and textile manufacturing and processing sector in a quest to set proper laser parameters during engraving of the denim garments in an efficient and environment-friendly manner.

Declarations

Author contribution statement

Joy Sarkar: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Md Abdullah Al Faruque: Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Elias Khalil: Conceived and designed the experiments; Performed the experiments; Contributed reagents, materials, analysis tools or data.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

Data will be made available on request.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- 1.Al Faruque M.A., Remadevi R., Razal J., Wang X., Naebe M. Investigation on structure and characteristics of alpaca-based wet-spun polyacrylonitrile composite fibers by utilizing natural textile waste. J. Appl. Polym. Sci. 2019;137:1–9. [Google Scholar]

- 2.Al Faruque M.A., Remadevi R., Razal J.M., Naebe M. Impact of the wet spinning parameters on the alpaca-based polyacrylonitrile composite fibers: morphology and enhanced mechanical properties study. J. Appl. Polym. Sci. 2020;137:49264. [Google Scholar]

- 3.Syduzzaman M., Al Faruque M.A., Bilisik K., Naebe M. Plant-based natural fibre reinforced composites: a review on fabrication, properties and applications. Coatings. 2020;10:973. [Google Scholar]

- 4.Kashem M.A. first ed. Lucky-One Traders; Dhaka: 2015. Garments Merchandising. [Google Scholar]

- 5.Paul R., editor. Denim: Manufacturing, Finishing and Applications. Woodhead Publishing Ltd.; 2015. [Google Scholar]

- 6.Khalil E., Sarkar J., Rahman M., Solaiman M. Influence of enzyme and silicone wash on the physico-mechanical properties of non-denim twill garments. Int. J. Sci. Technol. Res. 2014;3:231–233. www.ijstr.org [Google Scholar]

- 7.Sarkar J., Khalil E., Solaiman M. Effect of enzyme washing combined with pumice stone on the physical, mechanical and color properties of denim garments. Int. J. Res. Advent Technol. 2014;2:2321–9637. [Google Scholar]

- 8.Solaiman M., Rahman M., Khalil E., Sarkar J. Consequences of enzyme rinse on physical properties of knit garments. Int. J. Res. Advent Technol. 2014;2:2321–9637. [Google Scholar]

- 9.Shamusuzzaman M., Sarkar J. Analysis of the influence of different dry processes on the properties of denim garments. Int. Conf. Mech. Eng. Renew. Energy. 2019;2019 [Google Scholar]

- 10.Gopalakrishnan P.P. Study on the influence of different garment washes on the fabric physical properties and color value. Int. Res. J. Eng. Technol. 2020;7:5688–5692. [Google Scholar]

- 11.Khalil E. Sustainable and ecological finishing Technology for denim jeans. AASCIT Commun. 2015;2:159–163. [Google Scholar]

- 12.Sarkar J., Rashaduzzaman M. Today; 2014. Laser Fading Technology: Facts and Opportunities, Bangladesh Text.https://www.textiletoday.com.bd/laser-fading-technology-facts-and-opportunities/ [Google Scholar]

- 13.Sarkar J., Khalil E., Rahman A. Technical study of the effect of CO 2 Laser surface engraving on the physical properties of denim fabric. Int. Conf. Mech. Ind. Mater. Eng. 2015:11–13. [Google Scholar]

- 14.Yuan G., Jiang S., Newton E., Fan J., Au W. 8ISS Symp. Panel Transform. 2011. Fashion design using laser engraving Technology; pp. 65–80. [Google Scholar]

- 15.Venkatraman P.D., Liauw C.M. Use of a carbon dioxide laser for environmentally beneficial generation of distressed/faded effects on indigo dyed denim fabric: evaluation of colour change, fibre morphology, degradation and textile properties. Opt Laser. Technol. 2019;111:701–713. [Google Scholar]

- 16.Nayak R., Padhye R. The use of laser in garment manufacturing: an overview. Fash. Text. 2016;3:5. [Google Scholar]

- 17.Thyagarajan K., Ghatak A. second ed. Springer US; 2011. Lasers: Fundamentals and Applications. [Google Scholar]

- 18.Ortiz-Morales M.M., Poterasu M., Acosta-Ortiz S.E., Compean I., Hernandez-Alvarado M.R. A comparison between characteristics of various laser-based denim fading processes. Opt Laser. Eng. 2003;39:15–24. [Google Scholar]

- 19.Yuan G.X., Jiang S.X., Newton E., Au W.M. Application of laser engraving for sustainable fashion design. Res. J. Text. Appar. 2013;17:21–27. [Google Scholar]

- 20.Chryssolouris G. first ed. Springer New York; New York, NY: 1991. Laser Machining. [Google Scholar]

- 21.Ready J.F. second ed. Elsevier; 1997. Industrial Applications of Lasers. [Google Scholar]

- 22.Deguchi Y. first ed. CRC Press; Boca Raton: 2012. Industrial Applications of Laser Diagnostics. [Google Scholar]

- 23.Black D.L., McQuay M.Q., Bonin M.P. Laser-based techniques for particle-size measurement: a review of sizing methods and their industrial applications. Prog. Energy Combust. Sci. 1996;22:267–306. [Google Scholar]

- 24.Özgüney A.T., Özçelik G., Özkaya K. A study on specifying the effect of laser fading process on the colour and mechanical properties of the denim fabrics. Tekst. ve Konfeksiyon. 2009;19:133–138. [Google Scholar]

- 25.Saaidin H., Tajuddin R.M. Denim casual wear with laser cut Pucuk Rebung Motif. Int. J. INTI. 2018;22:41–47. [Google Scholar]

- 26.Dudeja J.P. Laser application in apparel industry. Int. J. Adv. Sci. Technol. Eng. Manag. Sci. 2018;4:1–5. [Google Scholar]

- 27.H J., Dakuri Arjun M.N.F. Technology of industrial denim washing: review. Int. J. Ind. Eng. Technol. 2013;3:25–34. http://www.tjprc.org/view_archives.php?year=2013&id=9&jtype=2&page=2 [Google Scholar]

- 28.Jamal Z., Yadav D.N., Rani S. Application of laser Technology in fashion industry. Int. J. Home Sci. 2018;4:43–56. [Google Scholar]

- 29.na Hung O., Kan C. A Study of CO 2 laser treatment on colour properties of cotton-based fabrics. Coatings. 2017;7 [Google Scholar]

- 30.Jucienė M., Urbelis V., Juchnevičienė Ž., Čepukonė L. The effect of laser technological parameters on the color and structure of denim fabric. Textil. Res. J. 2014;84:662–670. [Google Scholar]

- 31.Jiang S.X., Yuan G., Huang J., Peng Q., Liu Y. The effect of laser engraving on aluminum foil-laminated denim fabric. Textil. Res. J. 2015;86:919–932. [Google Scholar]

- 32.Gabr B.G. Comparison among properties of chlorine washed and laser faded denim. Int. J. Text. Fash. Technol. (IJTFT) 2016;6:25–31. [Google Scholar]

- 33.Juciene M., Urbelis V.V., Juchneviciene Ž., Saceviciene V., Dobilaite V. The influence of laser treatment and industrial washing on denim fabric tension properties. Int. J. Cloth. Sci. Technol. 2018;30:588–596. [Google Scholar]

- 34.Yuan G., Jiang S., Newton E., Fan J., Au W. Application of laser treatment for fashion design. J. Text. Inst. 2012;103:48–54. [Google Scholar]

- 35.Sakib A., Islam T., Islam S., Ahmed M., Ali S. Analysis the physical properties of laser fading on denim fabric. J. Text. Eng. Fash. Technol. Res. 2019;5:4–7. [Google Scholar]

- 36.Sarkar J., Mondal M.S., Khalil E. Predicting fabric GSM and crease recovery angle of laser engraved denim by fuzzy logic analysis. J. Eng. Appl. Sci. 2020;4:52–64. [Google Scholar]

- 37.Kan C.W., Yuen C.W.M., Cheng C.W. Color fading of indigo-dyed cotton denim fabric by laser. Adv. Mater. Res. 2012;441:187–191. [Google Scholar]

- 38.Kan C. CO2 laser treatment as a clean process for treating denim fabric. J. Clean. Prod. 2014;66:624–631. [Google Scholar]

- 39.Kan C.W., Wong W.Y., Song L.J., Law M.C. Prediction of color properties of cellulase-treated 100 % cotton denim fabric. J. Text. Hindawi Publ. Corp. 2013;2013:1–10. [Google Scholar]

- 40.Haghighat E., Etrati S.M., Najar S.S. Modeling of needle penetration force in denim fabric. Int. J. Cloth. Sci. Technol. 2013;25:361–379. [Google Scholar]

- 41.Hui C.L., ng S.F. Predicting seam performance of commercial woven fabrics using multiple logarithm regression and artificial neural networks. Textil. Res. J. 2009;79:1649–1657. [Google Scholar]

- 42.Hossain I., Al Mamun A., Haque M., Uddin Z. Comparison of fuzzy intelligent model and taguchi mathematical model for the prediction of bursting strength of viscose plain knitted fabrics. Am. J. Eng. Res. 2017;6:184–193. [Google Scholar]

- 43.Unal P.G., Üreyen M.E., Mecit D. Predicting properties of single Jersey fabrics using regression and artificial neural network models. Fibers Polym. 2012;13:87–95. [Google Scholar]

- 44.Nurwaha D., Wang X.H. Comparison of the new methodologies for predicting the CSP strength of rotor yarn. Fibers Polym. 2008;9:782–784. [Google Scholar]

- 45.Hussain T., Jabbar A., Ahmed S. Comparison of regression and adaptive neuro-fuzzy models for predicting the compressed air consumption in air-jet weaving. Fibers Polym. 2014;15:390–395. [Google Scholar]

- 46.Jamshaid H., Hussain T., Malik Z.A. Comparison of regression and adaptive neuro-fuzzy models for predicting the bursting strength of plain knitted fabrics. Fibers Polym. 2013;14:1203–1207. [Google Scholar]

- 47.Sarkar J., Prottoy Z.H., Bari M.T., Al Faruque M.A. Comparison of ANFIS and ANN modeling for predicting the water absorption behavior of polyurethane treated polyester fabric. Heliyon. 2021;7 doi: 10.1016/j.heliyon.2021.e08000. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Hossain I., Choudhury I.A., Bin Mamat A., Hossain A. Predicting the colour properties of viscose knitted fabrics using soft computing approaches. J. Text. Inst. 2017;108:1689–1699. [Google Scholar]

- 49.Hatua P., Majumdar A., Das A. Modeling ultraviolet protection factor of polyester-cotton blended woven fabrics using soft computing approaches. J. Eng. Fiber. Fabr. 2014;9:99–106. [Google Scholar]

- 50.Haghighat E., Najar S.S., Etrati S.M. The prediction of needle penetration force in woven denim fabrics using soft computing models. J. Eng. Fiber. Fabr. 2014;9:45–55. [Google Scholar]

- 51.Samuel O.D., Okwu M.O., Tartibu L.K., Giwa S.O., Sharifpur M., Jagun Z.O.O. Modelling of Nicotiana Tabacum L. Oil biodiesel production: comparison of ANN and ANFIS. Front. Energy Res. 2021;8 [Google Scholar]

- 52.Hossain I., Farzana N. Prognosis of dimensional stability and mass per unit area of single Jersey cotton knitted fabric with fuzzy inference system. Tekstilec. 2019;62:166–180. [Google Scholar]

- 53.Sarkar J., Al Faruque M.A., Mondal M.S. Modeling the seam strength of denim garments by using fuzzy expert system. J. Eng. Fiber. Fabr. 2021;16:1–10. [Google Scholar]

- 54.Hossain I., Hossain A., Choudhury I.A. Color strength modeling of viscose/Lycra blended fabrics using a fuzzy logic approach. J. Eng. Fiber. Fabr. 2015;10:158–168. [Google Scholar]

- 55.Hossain I., Choudhury I.A., Bin Mamat A., Shahid A., Khan A.N., Hossain A. Predicting the mechanical properties of viscose/lycra knitted fabrics using fuzzy technique. Adv. Fuzzy Syst. 2016;2016 [Google Scholar]

- 56.Ismail A., Hossain A., Choudhury I.A. Bakar, Prediction of fabric properties of viscose blended knitted fabrics by fuzzy logic methodology. Int. Conf. Mech. Civ. Archit. Eng. 2015:100–106. [Google Scholar]

- 57.Hossain I., Hossain A., Choudhury I.A., Al Mamun A. Fuzzy knowledge based expert system for prediction of color strength of cotton knitted fabrics. J. Eng. Fiber. Fabr. 2016;11:33–44. [Google Scholar]

- 58.Zadeh L.A. Inf. Control. 1996. Fuzzy Sets; pp. 394–432. [Google Scholar]

- 59.Gopal M. second ed. Tata McGraw-Hill Education Pvt. Ltd; New Delhi: 2006. Digital Control and State Variable Methods: Conventional and Intelligent Control Systems. [Google Scholar]

- 60.Shahid M., Hossain M. Modeling the spirality of cotton knit fabric using fuzzy expert system. Turkish J. Fuzzy Syst. 2015;6:56–67. [Google Scholar]

- 61.Huang C.C., Yu W.H. Control of dye concentration, pH, and temperature in dyeing processes. Textil. Res. J. 1999;69:914–918. [Google Scholar]

- 62.Ali O.A.M., Ali A.Y., Sumait B.S. Comparison between the effects of different types of membership functions on fuzzy logic controller performance. Int. J. Emerg. Eng. Res. Technol. 2015;76:76–83. [Google Scholar]

- 63.Singal M.K., Prakash N. Fuzzy preopen sets and fuzzy preseparation axioms. Fuzzy Set Syst. 1991;44:273–281. [Google Scholar]

- 64.MathWorks Build fuzzy systems using fuzzy logic designertems using fuzzy logic designer. https://www.mathworks.com/https://www.mathworks.com/help/fuzzy/building-systems-with-fuzzy-logic-toolbox-software.html#FP484 n.d.

- 65.Dalbaşı E.S., Özçelik kayseri G., İlleez A.A. A research on the effect of various laser fading parameters on physical and surface properties of denim fabric. Opt Laser. Technol. 2019;118:28–36. [Google Scholar]

- 66.Shamsuzzaman M., Abdul Awal Z., Das D. Impact of laser intensities at various DPI and pixel time on the properties of denim garments. J. Adv. Res. Mater. Sci. 2021;77:1–13. [Google Scholar]

- 67.Du W., Zuo D., Gan H., Yi C. Comparative study on the effects of laser bleaching and conventional bleaching on the physical properties of indigo kapok/cotton denim fabrics. Appl. Sci. 2019;9:4662. [Google Scholar]

- 68.Hung O.N., Chan C.K., Kan C.W., Yuen C.W.M. An analysis of some physical and chemical properties of CO2 laser-treated cotton-based fabrics. Cellulose. 2017;24:363–381. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.