Abstract

The present study describes the manufacture of an antifungal device composed of oriental mustard flour and hydroxyethyl-cellulose (H-OMF) and evaluates its efficacity in inhibiting Aspergillus flavus growth and aflatoxin B1 (AFB1) production in almonds. Additionally, it compares the H-OMF with allyl isothiocyanate (AITC) and a freeze-dried extract of yellow mustard flour (YMF-E); such substances were previously described as antifungal. Minimum inhibitory concentration (MIC), Minimum fungicidal concentration (MFC), the H-OMF in vitro antifungal activity, and the residual fungal population, as well as the production of AFB1 in almonds were determined. AITC and YMF-E showed significant antifungal activity in vitro. Additionally, the in vitro activity of H-OMF avoided mycelial growth by applying 30 mg/L. Almonds treated with AITC (5.07, 10.13, and 20.26 mg/L) and H-OMF (2000 and 4000 mg/L) showed a reduction in the population of A. flavus and the production of AFB1 to values below the limit of detection. YMF-E showed effectiveness by in vitro methodologies (MIC and MFC) but did not show efficacy when applied in almonds. Our findings indicated that the hydroxyethyl-cellulose-based device containing oriental mustard flour might be utilised as a fumigant to increase the safety of almonds and could be extended to other cereals or dry fruits.

Keywords: natural antimicrobials, fungi, mycotoxins, food safety, AITC, Aspergillus flavus, hydroxyethyl-cellulose-based device

1. Introduction

Mycotoxins are secondary fungal metabolites produced mainly by the genera Aspergillus, Penicillium, and Fusarium [1,2,3]. Among the metabolites produced, aflatoxins (AFs) are produced by fungi of the genus Aspergillus, predominantly by two species, Aspergillus flavus and Aspergillus parasiticus, which can produce four main AFs, B1, B2, G1, and G2. According to International Cancer Research Agency (IARC), AFs are classified into group 1: carcinogens to humans. The AFB1 is the most toxic and can cause chronic liver damage, affect the immune system, growth, and malnutrition [4]. AFs are present in cereals, spices, and dry fruits such as almonds, peanuts, and oilseeds, contaminating directly pre-harvest and postharvest food [5].

Dry fruits such as almonds and nuts have beneficial effects, decreasing risk factors related to diabetes and cardiovascular diseases, with anti-inflammatory and antioxidant properties, and increasing bone health. Moreover, they are also rich in sugar and fat, mono- and polyunsaturated fats, and sterols [6,7,8]. Nevertheless, on the other hand, almonds are very susceptible to fungal growth and mycotoxin production. This fact occurs because of inadequate storage conditions, environmental issues (humidity and temperature), and high sugar content [9].

Several methods have been used to prevent fungal growth and mycotoxin production in foods. Among the strategies used are pre- and postharvest actions, which reduce the amount of contamination. Examples of pre-harvest actions are developing genetically modified cultivar lines, crop rotation, and changes in planting time, while post-harvesting methods include food drying, storage, and preservatives used [4].

Increasing interest in alternate preservation approaches for inactivating microbes and enzymes in foods has emerged from the need to ensure food safety while addressing such demands for nutrition and qualitative qualities [10]. Flavour, odour, colour, texture, and nutritional value are all critical quality characteristics. This growing demand for natural preservatives originating from plants, animals, or microorganisms has expanded the possibilities for their application [11]. Natural antimicrobials may be used alone or in combination with other innovative preservation technologies to enable the eradication of more conventional methods [12].

The use of essential oils has been investigated with great interest to the food industry due to their broad spectrum of activity, low tendency to induce resistance, and safety for consumption [13]. Plants belonging to the Brassicaceae family are rich in bioactive compounds, highlighting the glucosinolates, which in an enzymatic reaction give isothiocyanates (ITCs) [14]. Sinapis alba (yellow or white mustard) and Brassica juncea (brown or oriental mustard) are rich in glucosinolates and, in the presence of water, form ITCs’ aromatic compounds. In oriental mustard, myrosinase forms allyl isothiocyanate (AITC) from the main glucosinolate, sinigrin [15]. Concerning yellow mustard, the ITC formed is p-hydroxybenzyl isothiocyanate (ρ-HBIT) from the main glucosinolate sinalbin [16].

AITC is a volatile compound that is reported to exhibit numerous beneficial effects, including antimicrobial, anticarcinogenic, cardioprotective, and neuroprotective properties [17] and shows antifungal activity towards mycotoxigenic Aspergillus [18], Penicillium, [19], and Fusarium species [20]. Moreover, AITC is considered a GRAS (Generally Recognised as Safe) compound by the Food and Drug Administration (FDA), and the IARC has classified it as non-carcinogenic (class 3) [21].

Likewise, yellow mustard flour (YMF) has shown significant antimicrobial activity against food pathogens, such as bacteria and fungi [22,23].

In order to minimise the economic loss caused by fungi, the objectives of this work were, first, to evaluate the in vitro antifungal potential of the AITC and a freeze-dried yellow mustard flour extract (YMF-E). Then, it was to develop an antifungal device that contains hydroxyethyl-cellulose and oriental mustard flour (H-OMF) and determine its antifungal effect. Finally, it was to evaluate the efficacy of all treatments in avoiding the growth of A. flavus and preventing the production of AFB1 in almonds. These data may support a new strategy to preserve almonds and mitigate AFB1 contamination.

2. Results and Discussion

2.1. Determination of Minimum Inhibitory Concentration (MIC) and Minimum Fungicidal Concentration (MFC)

Using broth microdilution, A. flavus demonstrated sensitivity to AITC and YMF-E, as shown in Table 1. The MIC for AITC and YMF-E were 7.90 mg/L and 390 mg/L, respectively. The MFC of these compounds was previously compared with the results of MIC. AITC required a four-fold greater amount to have fungicidal effects. Regarding YMF, the quantity required was eight-fold greater than MIC. Thus, AITC was the compound that demonstrated more effectiveness against this toxigenic strain.

Table 1.

Minimum Inhibitory Concentration and minimum fungicidal concentration obtained using allyl isothiocyanate and freeze-dried yellow mustard flour extract against Aspergillus flavus ISPA 8111.

| Minimum Inhibitory Concentration/Minimum Fungicidal Concentration | ||||

|---|---|---|---|---|

| Fungi | Compounds | |||

| AITC (mg/L) | YMF-E (mg/L) | |||

| MIC | MFC | MIC | MFC | |

| Aspergillus flavus | 7.90 | 31.61 | 390 | 3130 |

MFC: minimum fungicidal concentration; MIC: Minimum inhibitory concentration; AITC: allyl isothiocyanate; YMF-E: freeze-dried yellow mustard flour extract (n = 8).

Many authors have studied the inhibition of fungal growth using natural compounds. Nielsen and Rios [24] tested the volatilisation of essential oils such as AITC against several fungi. Regarding A. flavus, the MIC was 3.5 mg/L in the gas phase. Other authors, such as Clemente et al. [25], also described the antifungal activity of AITC in a liquid medium. These authors identified that the MIC values for A. flavus, A. ochraceus, and A. niger were 6.25 mg/L, 6.25 mg/L, and 3.13 mg/L, respectively. However, MFC results were higher, ranging from 6.25 mg/L for A. niger and A. flavus strains and 25 mg/L for A. ochraceus.

Quiles et al. [26] reported MIC for several fungi strains using a concentrated extract of YMF non-autoclaved. The results ranged from 238.2 for P. camemberti to 15,000 mg/L for A. flavus, A. parasiticus, and A. carbonarius. In addition, this extract showed a fungicidal effect with MFC values ranging from 1875 mg/L against P. nordicum, P. commune, and P. brevicompactum to 15,000 mg/L towards A. flavus, A. parasiticus, and A. carbonarius.

YMF-E does not seem to have a substantial impact on Aspergillus spp., as does Penicillium spp., based on the findings reported by the other authors [11,27]. Conversely, we noticed that YMF-E had a lower MIC and MFC value in this study. Our findings, nonetheless, support previous studies since large doses are required to suppress A. flavus growth.

2.2. Oriental Mustard Flour (OMF) In Vitro Activity against A. flavus

Since the H-OMF device could not be diluted in a Potato Dextrose Broth (PDB), its antifungal activity was determined by measuring mycelial growth. Table 2 shows the in vitro antifungal effect of the H-OMF device against A. flavus during an incubation time of 7 days at 25 °C. Control samples reached a mean mycelial growth of 50 mm in diameter on the fifth day. Regardless of the incubation time, a dosage of 30 mg/L of H-OMF exhibited a fungicidal effect and inhibited visual mycelial growth. On day 3, a dosage of 25 mg/L of H-OMF reduced mycelial growth by 80%. On the fifth day, the same treatment showed a reduction by 50%. On the seventh day, this concentration provided a mycelial reduction by 26%. The dose of 12.5 mg/L of H-OMF significantly reduced mycelial growth on days 3 and 5; however, this dosage did not avoid the fungal growth. On the other hand, the concentration of 6.2 mg/L of H-OMF did not show an antifungal effect in the mycelial growth after 5 days of storage.

Table 2.

In vitro antifungal activity of oriental mustard flour antifungal device based on hydroxyethyl-cellulose (H-OMF) against Aspergillus flavus ISPA 8111.

| Mycelial Growth (mm of Diameter) after Fumigation by H-OMF | |||

|---|---|---|---|

| Treatment | Days | ||

| 3 | 5 | 7 | |

| Control | 25 ± 1.2 A | 50 ± 2.5 A | 50 ± 5.5 A |

| 30 mg/L | ND | ND | ND |

| 25 mg/L | 5 ± 1.3 B | 25 ± 3.4 B | 37 ± 5.1 B |

| 12.5 mg/L | 9 ± 0.8 C | 34 ± 2.2 C | 38 ± 4.2 B |

| 6.2 mg/L | 9 ± 1.1 C | 48 ± 1.6 A | 50 ± 6.1 A |

OMF: oriental mustard flour; ND: the mycelial growth was not detected; different capital letters represent statistical differences (p ≤ 0.05) (n = 9).

In general, only the concentration of 30 mg/L of H-OMF demonstrated a fungicidal effect; the other doses, such as 12.5 and 25 mg/L, only presented a fungistatic effect, which allowed the fungal growth during storage. Nevertheless, it should be highlighted that these concentrations also exhibited a significant difference regarding the control group. Therefore, these results suggest that H-OMF may inhibit the fungal growth in a dose-dependent manner, and concentrations higher than 30 mg/L of H-OMF might be necessary to achieve a fungicidal effect in complex matrices.

Manyes et al. [28] evaluated the capacity of AITC deposited inside a disc of sterile paper to avoid the micellar growth of A. parasiticus and Penicillium expansum. The authors demonstrated that the mycelial growth was not observed when AITC amounts greater than 50 mg were deposited in the Petri dishes’ centre inoculated with P. expansum. Concerning A. parasiticus, 25 mg was able to inhibit the mycelial growth completely. Saladino et al. [29] reported that OMF decreased the mycelial diameter growth of A. parasiticus by 48.2–60.4% when using 0.1 to 1 g of OMF incubated for 24 h. In our study, better results were found using a smaller amount of OMF, such as 0.030 g. This fact may be explained by the difference in the strains and the applied method by Saladino and colleagues.

2.3. Determination of the Fungal Population in Natural Almonds

Natural chemicals are increasingly being used to mitigate fungus development in foodstuffs. As shown in Table 3, on day 0, all treatments had significantly shown less fungal population than on days 7 and 15. All treatments of YMF-E tested did not inhibit the fungal growth when compared with the control group. However, 2000 and 4000 mg/L of H-OMF decreased the fungal population to levels below the limit of detection (LOD) (1.22 log CFU/g) on the 15th day. The same result was observed for the treatments with 5.07, 10.13, and 20.26 mg/L of AITC. Likewise, these concentrations decreased the fungal population to levels below the LOD on days 7 and 15. This fact may be explained because OMF in the presence of water was converted in AITC. However, this reaction did not occur with YMF-E. Concerning the residual fungal population, on day 0, there were no statistical differences among the control group and the treatments tested, which could suggest that antifungal compounds were slowly released over time.

Table 3.

The residual population of Aspergillus flavus ISPA 8111 in almonds treated with allyl isothiocyanate, the antifungal device of hydroxyethyl-cellulose and oriental mustard flour, and freeze-dried mustard flour extract.

| Fungal Population in log CFU/g (Mean ± SD) | ||||

|---|---|---|---|---|

| Treatment | Concentration | Days | ||

| 0 | 7 | 15 | ||

| Control | - | 5.11 ± 0.26 A | 9.24 ± 0.34 A | 10.52 ± 0.08 A |

| AITC | 5.07 mg/L | 5.10 ± 0.16 A | ≤1.22 ± 0.00 B | ≤1.22 ± 0.00 B |

| 10.13 mg/L | 5.10 ± 0.11 A | ≤1.22 ± 0.00 B | ≤1.22 ± 0.00 B | |

| 20.26 mg/L | 5.70 ± 0.51 A | ≤1.22 ± 0.00 B | ≤1.22 ± 0.00 B | |

| H-OMF | 2000 mg/L | 5.90 ± 0.20 A | ≤1.22 ± 0.00 B | ≤1.22 ± 0.00 B |

| 4000 mg/L | 5.80 ± 0.34 A | ≤1.22 ± 0.00 B | ≤1.22 ± 0.00 B | |

| YMF-E | 100 g/L | 5.60 ± 0.27 A | 8.91 ± 0.29 A | 10.31 ± 0.04 A |

| 160 g/L | 5.40 ± 0.53 A | 9.96 ± 0.10 A | 10.68 ± 0.16 A | |

| 200 g/L | 5.70 ± 0.21 A | 8.96 ± 0.17 A | 10.15 ± 0.12 A | |

AITC: allyl isothiocyanate; H-OMF: hydroxyethyl-cellulose device with oriental mustard flour; YMF-E: yellow mustard flour extract. Different capital letters represent statistical differences among treatments (p ≤ 0.05). (n = 18).

Ground yellow mustard seeds and yellow mustard seeds have been paired with meats, especially as condiments for fermented sausages [30]. White or yellow mustard (Sinapis alba) and oriental or brown mustard (Brassica juncea) are known to contain a high concentration of glucosinolates, and these substances are cleaved in the presence of moisture by myrosinase to produce ITCs and a few other minor molecules such as thiocyanates and nitriles [26]. On the one hand, the predominant glucosinolate in yellow mustard is called sinalbin, which is cleaved by myrosinase to form ρ-HBIT. Although the antifungal effect of yellow mustard is not well understood, authors have attributed it to the synthesis of ITC compounds such as ρ-HBIT [30]. On the other hand, sinigrin is the major glucosinolate molecule found in oriental mustard seeds; these are nitrogen- and sulphur-containing metabolites that serve as AITC precursors. Similarly, AITC is enzymatically synthesized when sinigrin is hydrolysed by myrosinase in a humid environment [31]. Thus, OMF may be used as a natural supply of AITC that is gradually released into the headspace of silo systems [32].

Different mechanisms of action for ITCs’ antimicrobial activity have been suggested, including regulation of sulfhydryl enzymes, inhibition of ribonucleic acid (RNA) production, partial suppression of deoxyribonucleic acid (DNA) synthesis, and inhibition of protein synthesis through the ITCs’ molecule [33]. Although the antimicrobial mechanisms of ITCs are not fully understood, it is believed that their antimicrobial action is linked to their reactivity with proteins, which may disrupt in vivo biochemical processes. In other words, the carbon of the ITC molecule (R-N=C=S) is extremely electrophilic and interacts quickly with amines, thiols, and hydroxyls. Consequently, they may readily target the thiols and amines of the amino acid structure found in proteins. However, they primarily prefer to attack the sulfhydryl groups [34].

Authors also described that ITCs’ antibacterial action is a result of their amphiphilic nature. Although most authors agree that thiocyanate moiety is a critical component of ITCs’ antibacterial action, some authors have nevertheless described that ITCs exert their influence primarily through generating oxidative stress [19,24,35].

Our research group has demonstrated the antifungal capacity of AITC against a variety of fungi, such as Aspergillus [30] and Penicillium [28].

Lopes et al. [36] and Tracz et al. [21] showed the inhibition of fungal growth at levels of 2.5 and 500 µL/L of gaseous AITC (2.53 and 506.50 mg/L considering AITC density of 1.013 kg/m3). Nazareth et al. [37] reported a reduction of A. parasiticus CECT 2681 and F. verticillioides CECT 2983 at levels below the detection limit using a single treatment of 50 µL/L (50.65 mg/L) of AITC in corn kernels stored for 150 days. Our data show that a lower concentration of AITC was necessary to achieve comparable results. This difference can be justified because food matrices and fungal strains are not the same as reported previously [37]. Quiles et al. [38] demonstrated the growth inhibition of P. verrucosum using AITC; at the concentration of 500 µL/L (506.50 mg/L), the dispositive also reduced the fungal population to undetectable levels. Our study reported concentrations lower than those required in that study, which the differences in the applied methods could justify.

The antifungal activity of AITC was also evidenced by Suhr and Nielsen [39] using essential mustard oil with 99% of AITC on pieces of bread inoculated with 106 spores/mL of Penicillium roqueforti, Penicillium corylophilum, and A. flavus. In that study, the inhibition of the fungi was observed at concentrations of 1 μL/L of AITC (99%). Quiles et al. [40] investigated the ability of AITC and OMF plus water to prevent the development of A. parasiticus in fresh pizza crust using active packaging devices for 30 days of storage. The growth of A. parasiticus was inhibited with AITC at 5 and 10 μL/L (5.07 and 10.13 mg/L, respectively) and OMF at 850 mg after 30 days. The treatment with 10.13 mg/L of AITC reduced the fungal population by more than 5 log CFU/g, and OMF at 850 mg reduced by 1.5 log CFU/g compared to the control group (8.99 log CFU/g).

Despite the differences between the studies mentioned above, this study proved that AITCs have intense antifungal activity against A. flavus, and natural compounds associated with novel devices, such as H-OMF, might be effective against mycotoxigenic strains in different types of food. Indeed, we propose that further research might be conducted to determine the fumigant potential of H-OMF in other dry fruits.

2.4. Aflatoxin Determination

To reproduce natural contamination of the almonds, A. flavus ISPA 8111 was used as an Afs’ producer. The results are shown in Table 4, and the samples were analysed from day 0 to day 15. As shown in Table 4, the treatments with H-OMF (2000 mg/L and 4000 mg/L) and AITC (5.07, 10.13, and 20.26 mg/L) reduced the production of AFB1, which could have resulted from the fungal growth inhibition. On the other hand, YMF-E (100, 160, and 200 g/L) had no effect inhibiting AFB1 production compared to the control group. Conversely, treatment with YMF-E significantly increased AFB1 production compared to the control group and over time. These results suggest that YMF-E should be avoided to prevent AFB1 production, or higher doses must be assayed.

Table 4.

Effect of allyl isothiocyanate, the antifungal device of hydroxyethyl-cellulose and oriental mustard flour, and yellow mustard flour extract treatment on aflatoxin B1 (AFB1) production by Aspergillus flavus in almonds.

| The Concentration of AFB1 in µg/kg (Mean ± SD) | |||

|---|---|---|---|

| Treatment | Concentration | Days | |

| 7 | 15 | ||

| Control | - | 36.22 ± 4.21 A | 71.67 ± 2.84 A |

| AITC | 5.07 mg/L | ≤LOD C | ≤LOD C |

| 10.13 mg/L | ≤LOD C | ≤LOD C | |

| 20.26 mg/L | ≤LOD C | ≤LOD C | |

| H-OMF | 2000 mg/L | ≤LOD C | ≤LOD C |

| 4000 mg/L | ≤LOD C | ≤LOD C | |

| YMF-E | 100 g/L | 267.38 ± 43.09 B | 276.43 ± 186.83 B |

| 160 g/L | 314.13 ± 131.49 B | 364.41 ± 77.78 B | |

| 200 g/L | 395.21 ± 143.14 B | 575.90 ± 169.61 B | |

AITC: allyl isothiocyanate; H-OMF: antifungal device of hydroxyethyl-cellulose with oriental mustard flour; YMF-E: yellow mustard flour extract; LOD: limit of detection was 0.30 µg/kg; A, B, and C: capital letters represent statistical differences among treatments at the same time point (p ≤ 0.05). The samples were previously analysed for the presence of AFB1 (n = 9).

This study may be considered the first in which a device based on hydroxyethyl-cellulose and OMF was applied to avoid the content of AFB1 in almonds. Nonetheless, the use of AITC to reduce the growth of the fungi and mycotoxin production has been studied previously by other authors. Nazareth et al. [20] evaluated the capacity of AITC to reduce the production of the mycotoxin by A. parasiticus and Fusarium poae in wheat flour. The results showed that the application of AITC in a concentration of 10 μL/L (10.13 mg/L) reduced the biosynthesis of mycotoxins entirely for 30 days. Tracz et al. [21] showed the capacity of AITC to reduce the production of mycotoxins in corn kernels in a concentration of 50, 100, and 500 μL/L (50.65, 101.30, and 506.50 mg/L, respectively), and all the treatments were capable of avoiding the production of mycotoxins. The data obtained in our study corroborate with these studies using AITC since the antimycotoxigenic effect was achieved applying concentrations lower than 20.26 mg/L.

Considering OMF’s effectiveness in reducing mycotoxin production, Quiles et al. [40] reported that pizza crust contaminated with A. parasiticus, when treated with 10 μL/L (10.13 mg/L) of AITC in filter paper and 850 mg of OMF, reduced the AFs’ (B1, B2, G1, and G2) production below the limits of quantification (≤LOQ). Hontanaya et al. (2015) evaluated the effectiveness of OMF in reducing the fungal growth of A. parasiticus and aflatoxin production in dry fruits (peanut, cashew, walnut, almond, hazelnut, and pistachio). The use of OMF reduced the aflatoxin production by 83.1–87.2%. Saladino et al. [29] used OMF (0.1, 0.5, and 1 g of flour) to derivate isothiocyanates and avoid aflatoxin production in Italian piadina contaminated with A. parasiticus. The reduction of aflatoxin production ranged from 60.5 to 89.3%. The same authors evaluated the use of isothiocyanates’ derivative from OMF and YMF by the water addition to reduce the formation of mycotoxins produced by P. expansum. The mycotoxin reduction ranged from 80 to 100%.

Recently, several authors have carried out intensive studies on the role of genes’ expression in the synthesis of AFs. Nevertheless, the regulation mechanism remains poorly recognized. Among the genes evaluated, aflR and aflS are strictly linked to the aflatoxin pathway, and their down-regulation, caused by environmental or nutritional factors, may lead the fungus to a suppressed aflatoxin production [41]. Within this frame of reference, Nazareth et al. [42] evaluated the AFB1 production and the transcriptional profile of A. flavus, applying sublethal dosages of AITC. All treatments increased the expression of genes involved in the synthesis of AFB1, although this mycotoxin has been substantially decreased because of the antifungal action. Alternatively, the findings indicated a widespread overexpression of the AFB1 gene cluster, which seems to be associated with the stressful condition induced by AITC activity. AITC also resulted in aberrant regulation of the examined genes, including those encoding critical transcription factors such as veA and laeA, which are also associated with the AFB1 production.

Overall, the device H-OMF reduced A. flavus growth and AFB1 production in the lab-scale system, demonstrating an important candidate for silo fumigation. Furthermore, this antifungal device could be scaled up to be tested in a large-scale experiment or a real silo trial due to its manufacturability. Therefore, it is also essential to note that further studies will be conducted to evaluate this antifungal device as a fumigator in 100-L scale and full-scale silos.

In a real-life situation, in order to maintain the overall quality during a longer storage time (more than 9 months), different physical barriers such as modified atmosphere packaging and refrigeration could be applied [43]. The use of low barrier packaging material combined with refrigeration on the storage conditions can maintain the quality of almonds for up to 12 months when stored at refrigeration temperature (2 °C) [43]. Therefore, due to the manufacturability of the antifungal device, it could be used in packaging based on permeable plastics or simply deposited on the bottom of storage containers.

3. Conclusions

The results obtained in this study showed the antifungal effectiveness of YMF-E, H-OMF, and AITC at in vitro assays towards A. flavus ISPA 8111, an important toxigenic fungus. Although the use of YMF-E did not show efficacy when used as a fumigant in almonds, AITC at 5.07, 10.13, and 20.26 mg/L and H-OMF at 2000 and 4000 mg/L demonstrated a remarkable ability to avoid the growth of A. flavus and AFB1 production. The AITC was slowly formed and released, inhibiting the fungal growth without contact with food. Thereby, the new device (H-OMF) based on hydroxyethyl-cellulose and oriental mustard flour could be used as a natural preservative agent to avoid fungal growth in almonds.

Comparing AITC and H-OMF, the results suggested that lower doses of AITC showed a similar antifungal and antimycotoxigenic effect as H-OMF on almonds. However, the results also demonstrated that all doses of H-OMF inhibited fungal growth and mycotoxin production, suggesting that the dose could be reduced. YFM-E was the least effective since treatments did not inhibit fungal growth and mycotoxin production.

Although AITC was more effective than H-OMF, essential oils’ compounds have a disadvantage, as they could modify the sensory characteristics of food products. On the contrary, the device (H-OMF) could gradually release the antifungal compound, avoiding this strong flavour and prolonging the safety of the stored products.

Therefore, further research should be conducted to determine the potential of AITC and H-OMF at lower concentrations, as well as the potential of YMF-E at higher dosages. Moreover, our results opened a plethora of possibilities, and further studies must be performed to determine the antifungal activity of H-OMF in different matrices such as cereals and other dry fruits. We also propose the application of this antifungal device against different types of processed almonds in association with physical barriers such as temperature and humidity control during different steps of the food chain. This association could prolong the shelf life of almonds and improve the antifungal potential of the device.

4. Materials and Methods

4.1. Chemicals

AFB1 standard solution (purity > 99%) was purchased from Sigma-Aldrich (St. Louis, MO, USA). The hydroxyethyl-cellulose was provided from Sigma-Aldrich (St. Louis, MO, USA). Methanol (99%) and formic acid (99%) used for liquid chromatography were HPLC grade and obtained from VWR Chemicals (Radnor, PA, USA). Ammonium formate was obtained from Sigma-Aldrich (St. Louis, MO, USA). Microbiological media such as PDB, potato dextrose agar (PDA), and Peptone Water were obtained from Liofilchem Products (Roseto Degli Abruzzi, Italy). YMF and oriental mustard flour (OMF) were provided by G.S. Dunn dry mustard millers (Hamilton, ON, Canada). AITC (95.1% purity) was purchased from Sigma-Aldrich (St. Louis, MO, USA).

4.2. Microorganism and Culture Conditions

The mycotoxigenic strain of A. flavus ISPA 8111 used in this study was obtained from the Institute of Food Production Science (ISPA, Bari, Italy). This microorganism was stored in sterile glycerol at −80 °C before use. Then the microorganism was grown in PDB at 25 °C, and, after growth, the PDA Petri dishes were inoculated in the dark.

4.3. Preparation of the Freeze-Dried Yellow Mustard Extract (YMF-E)

The method previously described by Quiles et al. [26] was used to extract water-soluble components with minor modifications. YMF (2 g) was homogenised in 25 mL of distilled water for 5 min at 7000 rpm using an Ultra Ika T18 basic Ultra-Turrax (Staufen, Germany). After centrifuging the extracts for 15 min at 5000× g, the supernatant was collected and deposited on polypropylene trays. Afterwards, the supernatant was freeze-dried for 72 h in a FreeZone 2.5 L Labconco (Kansas, MO, USA). The powder produced was kept at a temperature of 4 °C until its use in the antifungal activity test.

4.4. Manufacture of H-OMF Antifungal Device

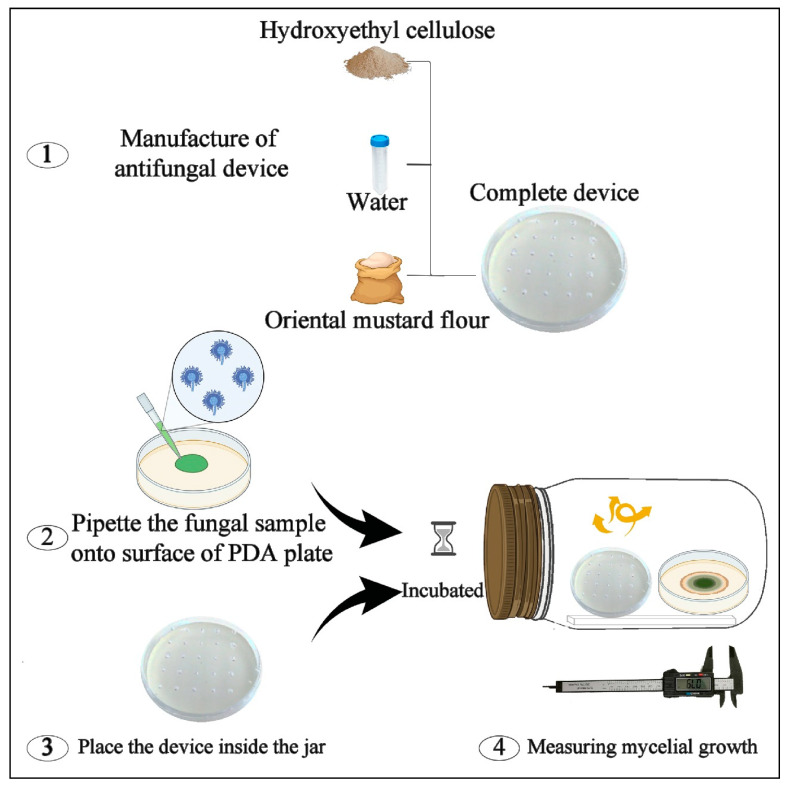

In a Petri dish, 1.5 g of hydroxyethyl-cellulose (gelling agent), 10 mL of water, and 2 or 4 g of OMF were combined to form the gel device. As illustrated in Figure 1, the lid of the Petri dish was previously punctured to allow the volatilisation of the AITC. The antifungal device was then inserted into the jars to study its antifungal effect.

Figure 1.

The small silo system used to determine the in vitro antifungal activity of mustard flour device based on hydroxyethyl-cellulose (H-OMF) against Aspergillus flavus ISPA 8111.

4.5. Determination of the Minimum Inhibitory Concentration and the Minimum Fungicidal Concentration of AITC and YMF-E

The minimum inhibitory concentration (MIC) was determined by quadruplicate, using broth microdilution in a 96-well plate according to the protocol M38-A2 of the Clinical Laboratory Standard Institute, with adaptations [44]. The fungus was first grown on PDA and incubated for 7 days at 25 °C. The fungal suspension was prepared by harvesting the spores from the surface of the plates with peptone water 0.1%. After counting the number of spores using a Neubauer chamber, the inoculum was adjusted to 2 × 104 spores/mL in a PDB medium (Liofilchem, Italy). Then, 100-μL aliquots of fungal suspension were added to each well. Different concentrations of AITC (ranging from 0.98 mg/L to 506.50 mg/L) and YMF-E (ranging from 90 to 100,000 mg/L) were added by microdilution. The microplate was filled to a final volume of 200 μL/well. The plate was incubated for 48 h at 25 °C before a visual reading was performed. Control groups were prepared with PDB and fungal suspension (positive control) and only PDB (negative control) containing 200 μL as the final volume.

The minimum fungicidal concentration (MFC) was determined after MIC determination according to the protocol described by Espinel-Ingroff et al. [45]. First, 10-μL aliquots of each well showing complete inhibition of fungal growth were withdrawn and cultured in PDA plates for 72 h at 25 °C. The negative control group was also inoculated in PDA plates and incubated for 72 h at 25 °C. The MFC was then established as the lowest dilution that yielded fewer than three colonies.

4.6. In Vitro Antifungal Activity of H-OMF against A. flavus ISPA 8111

Petri dishes (50-mm diameter) containing 6.2, 12.5, 25, and 30 mg of OMF were prepared to mix the flour with 10 mL of sterile distilled water (to improve the conversion of the glucosinolate sinigrin into AITC) and 1.5 g of hydroxyethyl-cellulose (a gelling agent). Simultaneously, Petri dishes (50-mm diameter) containing PDA were inoculated with 10 µL of A. flavus ISPA 8111 at 104 spores/mL. After, the dishes were inserted into the jars without the lids, and then the jars were hermetically closed (Figure 1). The control group did not receive any treatment. Jars were kept at 25 °C for 7 days. Finally, on days 3, 5, and 7, the inhibitory effect of H-OMF was monitored by measuring the mycelia growth diameter on a scale of mm.

4.7. Microbiological Assay with Natural Almonds

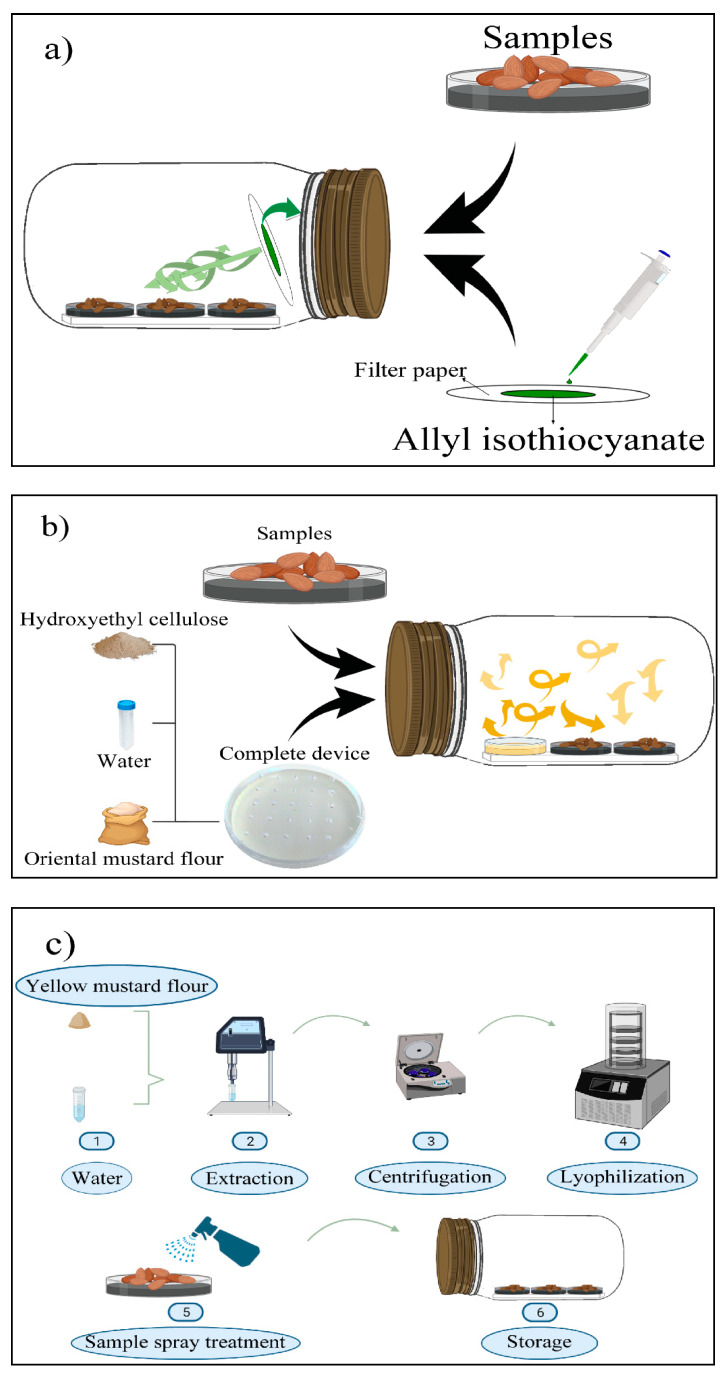

The natural almonds were autoclaved, dried at 28 °C for 24 h, contaminated with A. flavus ISPA 8111 in a concentration of 106 spores/g, and then portioned in samples of 20 g. After 24 h of incubation, three different treatments were carried out:

Filter papers (2.5 × 2.5 cm) containing AITC at 5.07, 10.13, and 20.26 mg/L (related to jar volume) were prepared and adhered to the lids of the jars (Figure 2a).

H-OMF antifungal device was manufactured by mixing 2 and 4 g of OMF with 10 mL of sterile distilled water and 1.5 g of hydroxyethyl-cellulose. The device was then placed into the jars, reaching a final concentration of 2000 and 4000 mg/L (related to jar volume) (Figure 2b). These values represented 80- and 160-folds of the minimal dose to avoid the mycelial growth of A. flavus significantly.

A spray of YMF was prepared with 0.5 (32 folds MFC), 0.8 (51.2 folds MFC), and 1 g (64 folds MFC) of YMF-E with 5 mL of sterile distilled water. The treatment was carried out by spraying the extract on the surface of almonds to reach final concentrations of 100, 160, and 200 g/L (Figure 2c).

Figure 2.

Silo system used to determine the volatile antifungal activity of: (a) allyl isothiocyanate (AITC); (b) the antifungal device based on hydroxyethyl-cellulose and oriental mustard flour (H-OMF); and (c) the spray of freeze-dried yellow mustard flour extract (YMF-E). Natural almonds were contaminated with Aspergillus flavus ISPA 8111 and stored for 15 days.

The samples were placed in 50-mm Petri dishes and transferred to 1-L glass jars. Then, the jars were hermetically closed (Figure 2). Control samples did not receive treatments. Experiments were performed in triplicate for 15 days and kept at 25 °C. Finally, the almonds were microbiologically analysed on days 0, 7, and 15.

4.8. Determination of the Fungal Population in Natural Almonds

The numbers of moulds in almonds’ kernels during storage were analysed according to Hashemi and Raeisi (2018) [46].

After incubation, 20 g of each sample were transferred to a sterile plastic bag containing 180 mL of sterile peptone water 0.1% (Liofilchem, Italy) and homogenised with a stomacher (IUL, Barcelona, Spain) for 60 s. Serial dilutions of the suspensions were performed in sterile plastic tubes with 0.1% peptone water. After that, aliquots of 0.1 mL were plated on Petri dishes containing PDA (Liofilchem, Italy), and the plates were incubated at 25 ◦C for 7 days before microbial counting. The results were expressed in a log of colony-forming unit/g of almond (log CFU/g). All analyses were conducted in triplicate.

4.9. AFB1 Extraction

The AFB1 extraction was performed using the method previously described by Huang et al. [47] with some adaptations. First, samples were ground and homogenized and 5 g were taken in Falcon tubes of 50 mL with 25 mL of methanol. Then the extract was homogenised for 3 min by Ultra Ika T18 basic Ultraturrax (Staufen, Germany) at 13,500 RPM. Next, the extracts were centrifuged at 4800× g for 5 min at 4 °C, and the supernatant was transferred and evaporated using a Büchi Rotavapor R-200 (Postfach, Switzerland). Finally, the obtained residue was resuspended in 2 mL of methanol, filtered through a 0.22-µm syringe filter, transferred to a glass vial, and injected into an LC-MS/MS system.

4.10. LC-MS/MS Analysis

The liquid chromatography system was composed of an LC-20AD pump connected to a 3200QTRAP mass spectrometer (Applied Biosystems, Foster City, CA, USA) through an ESI interface operating in positive ion mode. The established stationary phase was a Gemini NX C18 column (150 × 2.0 mm I.D, 3.0 mm) obtained from Phenomenex (Palo Alto, CA, USA). The mobile phases were solvent A (5 mM ammonium formate and 0.1% formic acid in water) and solvent B (5 mM ammonium formate and 0.1% formic acid in methanol) at a flow rate of 0.25 mL/min. The elution was carried out employing a gradient starting with 10% of B, increasing to 80% up to 1.5 min, and the proportion was kept constant until the fourth min. The ratio was again increased to 90% up to the 10th min. Phase B was then increased to 100% until the 14th min. The time interval between injections was 10 min to return to initial conditions. The injection volume of the samples was 20 µL. The nebulizer, the makeup gas, and the curtain gas were set at 55, 50, and 15 psi, respectively. Furthermore, the capillary temperature was set at 550 °C, and the ion spray voltage was set at 5500 V. Finally, the precursor-to-product ion transitions were m/z 313.3/241.3–228.5 for AFB1 [48].

4.11. Statistical Analyses

The assays were performed in triplicate (n = 9). Analysis of variance (ANOVA) was followed by Tukey’s test using the software GraphPad Prism 5. The results obtained are expressed as mean ± standard deviation. Statistical differences were considered significant if p ≤ 0.05.

Acknowledgments

The authors would like to thank the pre PhD program of the Spanish Ministry of Science, Innovation, and Universities (FPU17/06104), the pre PhD program of the University of Valencia (Atracció de Talent UV-INV-PREDOC19F1-1006684), and CAPES (Finance code 001).

Author Contributions

Conceptualization, J.M., F.B.L. and G.M.; methodology, T.M.N., R.T. and K.P.B.; software, T.M.N.; validation, T.M.N., R.T. and K.P.B.; formal analysis, T.M.N.; investigation, T.M.N. and R.T.; resources, J.M. and G.M.; data curation, R.T. and K.P.B.; writing—original draft preparation, T.M.N., R.T. and K.P.B.; writing—review and editing, T.M.N., F.B.L. and P.V.-D.; supervision, F.B.L.; project administration, G.M. and P.V.-D.; funding acquisition, J.M. and G.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Spanish Ministry of Science and Innovation, grant number PID2019-108070RB-100; Generalitat Valenciana (Prometeo Project), grant number 2018/126; and H2020-EU.4.b—Enhancing Research and Innovation Capacity of Tubitak Mam Food Institute on Management of Mycotoxigenic Fungi and Mycotoxins (MYCOTWIN) (grant number 952337).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in this article.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript: or in the decision to publish the results.

Key Contribution

This work focused on the study of the antifungal activity of bioactive compounds, especially allyl isothiocyanate (AITC), freeze-dried extract of yellow mustard flour (YMF-E), and the mixture of oriental mustard flour and hydroxyethyl-cellulose (H-OMF). AITC, YMF-E, and H-OMF showed in vitro antifungal activity against A. flavus, but only H-OMF and AITC inhibited the growth of A. flavus and prevented the production of aflatoxin B1 in almonds. The results demonstrated that H-OMF could be used as a fumigant to prevent fungal growth on nuts. Therefore, this manuscript is of interest, important from a food safety point of view, as it addresses the possibility of limiting the biosynthesis of carcinogenic aflatoxins and finding new strategies to prevent fungal growth and mycotoxin production.

Footnotes

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Anfossi L., Giovannoli C., Baggiani C. Mycotoxin detection. Curr. Opin. Biotechnol. 2016;37:120–126. doi: 10.1016/j.copbio.2015.11.005. [DOI] [PubMed] [Google Scholar]

- 2.Njobeh P.B., Dutton M.F., Koch S.H., Chuturgoon A.A., Stoev S.D., Mosonik J.S. Simultaneous occurrence of mycotoxins in human food commodities from Cameroon. Mycotoxin Res. 2010;26:47–57. doi: 10.1007/s12550-009-0039-6. [DOI] [PubMed] [Google Scholar]

- 3.Terzi V., Tumino G., Stanca A.M., Morcia C. Reducing the incidence of cereal head infection and mycotoxins in small grain cereal species. J. Cereal Sci. 2014;59:284–293. doi: 10.1016/j.jcs.2013.10.005. [DOI] [Google Scholar]

- 4.Rushing B.R., Selim M.I. Aflatoxin B1: A review on metabolism, toxicity, occurrence in food, occupational exposure, and detoxification methods. Food Chem. Toxicol. 2019;124:81–100. doi: 10.1016/j.fct.2018.11.047. [DOI] [PubMed] [Google Scholar]

- 5.Kumar P., Mahato D.K., Kamle M., Mohanta T.K., Kang S.G. Aflatoxins: A global concern for food safety, human health and their management. Front. Microbiol. 2017;7:1–10. doi: 10.3389/fmicb.2016.02170. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Alasalvar C., Salvadó J.S., Ros E. Bioactives and health benefits of nuts and dried fruits. Food Chem. 2020;314:126192. doi: 10.1016/j.foodchem.2020.126192. [DOI] [PubMed] [Google Scholar]

- 7.Aune D., Keum N., Giovannucci E., Fadnes L.T., Boffetta P., Greenwood D.C., Tonstad S., Vatten L.J., Riboli E., Norat T. Nut consumption and risk of cardiovascular disease, total cancer, all-cause and cause-specific mortality: A systematic review and dose-response meta-analysis of prospective studies. BMC Med. 2016;14:1–14. doi: 10.1186/s12916-016-0730-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Becerra-Tomás N., Paz-Graniel I., Kendall C., Kahleova H., Rahelić D., Sievenpiper J.L., Salas-Salvadó J. Nut consumption and incidence of cardiovascular diseases and cardiovascular disease mortality: A meta-analysis of prospective cohort studies. Nutr. Rev. 2019;77:691–709. doi: 10.1093/nutrit/nuz042. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Saladino F., Luz C., Manyes L., Fernández-Franzón M., Meca G. In vitro antifungal activity of lactic acid bacteria against mycotoxigenic fungi and their application in loaf bread shelf life improvement. Food Control. 2016;67:273–277. doi: 10.1016/j.foodcont.2016.03.012. [DOI] [Google Scholar]

- 10.Le Lay C., Coton E., Le Blay G., Chobert J.M., Haertlé T., Choiset Y., Van Long N.N., Meslet-Cladière L., Mounier J. Identification and quantification of antifungal compounds produced by lactic acid bacteria and propionibacteria. Int. J. Food Microbiol. 2016;239:79–85. doi: 10.1016/j.ijfoodmicro.2016.06.020. [DOI] [PubMed] [Google Scholar]

- 11.Torrijos R., de Melo Nazareth T., Quiles J.M., Mañes J., Meca G. Application of White Mustard Bran and Flour on Bread as Natural Preservative Agents. Foods. 2021;10:431. doi: 10.3390/foods10020431. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Tiwari B.K., Valdramidis V.P., O’Donnell C.P., Muthukumarappan K., Bourke P., Cullen P.J. Application of natural antimicrobials for food preservation. J. Agric. Food Chem. 2009;57:5987–6000. doi: 10.1021/jf900668n. [DOI] [PubMed] [Google Scholar]

- 13.Jamil B., Abbasi R., Abbasi S., Imran M., Khan S.U., Ihsan A., Javed S., Bokhari H. Encapsulation of cardamom essential oil in chitosan nano-composites: In-vitro efficacy on antibiotic-resistant bacterial pathogens and cytotoxicity studies. Front. Microbiol. 2016;7 doi: 10.3389/fmicb.2016.01580. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Vig A.P., Rampal G., Thind T.S., Arora S. Bio-protective effects of glucosinolates—A review. LWT-Food Sci. Technol. 2009;42:1561–1572. doi: 10.1016/j.lwt.2009.05.023. [DOI] [Google Scholar]

- 15.Nadarajah D., Han J.H., Holley R.A. Inactivation of Escherichia coli O157:H7 in packaged ground beef by allyl isothiocyanate. Int. J. Food Microbiol. 2005;99:269–279. doi: 10.1016/j.ijfoodmicro.2004.08.019. [DOI] [PubMed] [Google Scholar]

- 16.Ekanayake A., Zoutendam P.H., Strife R.J., Fu X., Jayatilake G.S. Development of white mustard (Sinapis alba L.) essential oil, a food preservative. Food Chem. 2012;133:767–774. doi: 10.1016/j.foodchem.2012.01.090. [DOI] [Google Scholar]

- 17.Williams J.R., Rayburn J.R., Cline G.R., Sauterer R., Friedman M. Effect of allyl isothiocyanate on developmental toxicity in exposed Xenopus laevis embryos. Toxicol. Rep. 2015;2:222–227. doi: 10.1016/j.toxrep.2014.12.005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Hontanaya C., Meca G., Luciano F.B., Mañes J., Font G. Inhibition of aflatoxin B1, B2, G1 and G2 production by Aspergillus parasiticus in nuts using yellow and oriental mustard flours. Food Control. 2015;47:154–160. doi: 10.1016/j.foodcont.2014.07.008. [DOI] [Google Scholar]

- 19.Tunc S., Chollet E., Chalier P., Preziosi-Belloy L., Gontard N. Combined effect of volatile antimicrobial agents on the growth of Penicillium notatum. Int. J. Food Microbiol. 2007;113:263–270. doi: 10.1016/j.ijfoodmicro.2006.07.004. [DOI] [PubMed] [Google Scholar]

- 20.Nazareth T.M., Bordin K., Manyes L., Meca G., Mañes J., Luciano F.B. Gaseous allyl isothiocyanate to inhibit the production of aflatoxins, beauvericin and enniatins by Aspergillus parasiticus and Fusarium poae in wheat flour. Food Control. 2016;62:317–321. doi: 10.1016/j.foodcont.2015.11.003. [DOI] [Google Scholar]

- 21.Tracz B.L., Bordin K., de Nazareth T.M., Costa L.B., de Macedo R.E.F., Meca G., Luciano F.B. Assessment of allyl isothiocyanate as a fumigant to avoid mycotoxin production during corn storage. LWT. 2017;75:692–696. doi: 10.1016/j.lwt.2016.10.030. [DOI] [Google Scholar]

- 22.Andini S., Araya-Cloutier C., Lay B., Vreeke G., Hageman J., Vincken J.P. QSAR-based physicochemical properties of isothiocyanate antimicrobials against gram-negative and gram-positive bacteria. LWT. 2021;144:111222. doi: 10.1016/j.lwt.2021.111222. [DOI] [Google Scholar]

- 23.Drakopoulos D., Meca G., Torrijos R., Marty A., Kägi A., Jenny E., Forrer H.R., Six J., Vogelgsang S. Control of Fusarium graminearum in Wheat With Mustard-Based Botanicals: From in vitro to in planta. Front. Microbiol. 2020;11:1595. doi: 10.3389/fmicb.2020.01595. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Nielsen P.V., Rios R. Inhibition of fungal growth on bread by volatile components from spices and herbs, and the possible application in active packaging, with special emphasis on mustard essential oil. Int. J. Food Microbiol. 2000;60:219–229. doi: 10.1016/S0168-1605(00)00343-3. [DOI] [PubMed] [Google Scholar]

- 25.Clemente I., Aznar M., Nerín C. Synergistic properties of mustard and cinnamon essential oils for the inactivation of foodborne moulds in vitro and on Spanish bread. Int. J. Food Microbiol. 2019;298:44–50. doi: 10.1016/j.ijfoodmicro.2019.03.012. [DOI] [PubMed] [Google Scholar]

- 26.Quiles J.M., Torrijos R., Luciano F.B., Mañes J., Meca G. Aflatoxins and A. flavus reduction in loaf bread through the use of natural ingredients. Molecules. 2018;23:1638. doi: 10.3390/molecules23071638. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Quiles J.M., Manyes L., Luciano F.B., Mañes J., Meca G. Effect of the oriental and yellow mustard flours as natural preservative against aflatoxins B1, B2, G1 and G2 production in wheat tortillas. J. Food Sci. Technol. 2015;52:8315–8321. doi: 10.1007/s13197-015-1876-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Manyes L., Luciano F.B., Mañes J., Meca G. In vitro antifungal activity of allyl isothiocyanate (AITC) against Aspergillus parasiticus and Penicillium expansum and evaluation of the AITC estimated daily intake. Food Chem. Toxicol. 2015;83:293–299. doi: 10.1016/j.fct.2015.06.011. [DOI] [PubMed] [Google Scholar]

- 29.Saladino F., Bordin K., Manyes L., Luciano F.B., Mañes J., Fernández-Franzón M., Meca G. Reduction of the aflatoxins B1, B2, G1and G2in Italian piadina by isothiocyanates. LWT-Food Sci. Technol. 2016;70:302–308. doi: 10.1016/j.lwt.2016.03.006. [DOI] [Google Scholar]

- 30.Luciano F.B., Belland J., Holley R.A. Microbial and chemical origins of the bactericidal activity of thermally treated yellow mustard powder toward Escherichia coli O157:H7 during dry sausage ripening. Int. J. Food Microbiol. 2011;145:69–76. doi: 10.1016/j.ijfoodmicro.2010.11.028. [DOI] [PubMed] [Google Scholar]

- 31.Bahmid N.A., Pepping L., Dekker M., Fogliano V., Heising J. Using particle size and fat content to control the release of Allyl isothiocyanate from ground mustard seeds for its application in antimicrobial packaging. Food Chem. 2020;308:125573. doi: 10.1016/j.foodchem.2019.125573. [DOI] [PubMed] [Google Scholar]

- 32.Dai R., Lim L.T. Release of allyl isothiocyanate from mustard seed meal powder. J. Food Sci. 2014;79:E47–E53. doi: 10.1111/1750-3841.12322. [DOI] [PubMed] [Google Scholar]

- 33.Turgis M., Han J., Caillet S., Lacroix M. Antimicrobial activity of mustard essential oil against Escherichia coli O157:H7 and Salmonella typhi. Food Control. 2009;20:1073–1079. doi: 10.1016/j.foodcont.2009.02.001. [DOI] [Google Scholar]

- 34.Dufour V., Stahl M., Baysse C. The antibacterial properties of isothiocyanates. Microbiology. 2015;161:229–243. doi: 10.1099/mic.0.082362-0. [DOI] [PubMed] [Google Scholar]

- 35.Troncoso R., Espinoza C., Sánchez-Estrada A., Tiznado M.E., García H.S. Analysis of the isothiocyanates present in cabbage leaves extract and their potential application to control Alternaria rot in bell peppers. Food Res. Int. 2005;38:701–708. doi: 10.1016/j.foodres.2005.02.004. [DOI] [Google Scholar]

- 36.Lopes L.F., Bordin K., de Lara G.H.C., Saladino F., Quiles J.M., Meca G., Luciano F.B. Fumigation of Brazil nuts with allyl isothiocyanate to inhibit the growth of Aspergillus parasiticus and aflatoxin production. J. Sci. Food Agric. 2018;98:792–798. doi: 10.1002/jsfa.8527. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Nazareth T.M., Corrêa J.A.F., Pinto A.C.S.M., Palma J.B., Meca G., Bordin K., Luciano F.B. Evaluation of gaseous allyl isothiocyanate against the growth of mycotoxigenic fungi and mycotoxin production in corn stored for 6 months. J. Sci. Food Agric. 2018;98:5235–5241. doi: 10.1002/jsfa.9061. [DOI] [PubMed] [Google Scholar]

- 38.Quiles J.M., de Melo Nazareth T., Luz C., Luciano, F.B., Mañes J., Meca G. Development of an antifungal and antimycotoxigenic device containing allyl isothiocyanate for silo fumigation. Toxins. 2019;11:137. doi: 10.3390/toxins11030137. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Suhr K.I., Nielsen P.V. Antifungal activity of essential oils evaluated by two different application techniques against rye bread spoilage fungi. J. Appl. Microbiol. 2003;94:665–674. doi: 10.1046/j.1365-2672.2003.01896.x. [DOI] [PubMed] [Google Scholar]

- 40.Quiles J.M., Manyes L., Luciano F., Mañes J., Meca G. Influence of the antimicrobial compound allyl isothiocyanate against the Aspergillus parasiticus growth and its aflatoxins production in pizza crust. Food Chem. Toxicol. 2015;83:222–228. doi: 10.1016/j.fct.2015.06.017. [DOI] [PubMed] [Google Scholar]

- 41.Peromingo B., Rodríguez M., Delgado J., Andrade M.J., Rodríguez A. Gene expression as a good indicator of aflatoxin contamination in dry-cured ham. Food Microbiol. 2017;67:31–40. doi: 10.1016/j.fm.2017.05.008. [DOI] [PubMed] [Google Scholar]

- 42.Nazareth T.D.M., Alonso-Garrido M., Stanciu O., Mañes J., Manyes L., Meca G. Effect of allyl isothiocyanate on transcriptional profile, aflatoxin synthesis, and Aspergillus flavus growth. Food Res. Int. 2020;128 doi: 10.1016/j.foodres.2019.108786. [DOI] [PubMed] [Google Scholar]

- 43.García-Pascual P., Mateos M., Carbonell V., Salazar D.M. Influence of storage conditions on the quality of shelled and roasted almonds. Biosyst. Eng. 2003;84:201–209. doi: 10.1016/S1537-5110(02)00262-3. [DOI] [Google Scholar]

- 44.Clinical and Laboratory Standards Institute . Reference Method for Broth Dilution Antifungal Susceptibility Testing of Yeasts. 3rd ed. Clinical and Laboratory Standards Institute; Wayne, PA, USA: 2008. Approved Standard. CLSI document M27-A3. [Google Scholar]

- 45.Espinel-Ingroff A., Cantón E., Pemán J. Antifungal susceptibility testing of filamentous fungi. Curr. Fungal Infect. Rep. 2012;6:41–50. doi: 10.1007/s12281-011-0079-1. [DOI] [Google Scholar]

- 46.Hashemi S.M.B., Raeisi S. Evaluation of antifungal and antioxidant properties of edible coating based on apricot (Prunus armeniaca) gum containing Satureja intermedia extract in fresh wild almond (Amygdalus scoparia) kernels. J. Food Meas. Charact. 2018;12:362–369. doi: 10.1007/s11694-017-9648-5. [DOI] [Google Scholar]

- 47.Huang B., Han Z., Cai Z., Wu Y., Ren Y. Simultaneous determination of aflatoxins B1, B2, G1, G2, M1 and M2 in peanuts and their derivative products by ultra-high-performance liquid chromatography-tandem mass spectrometry. Anal. Chim. Acta. 2010;662:62–68. doi: 10.1016/j.aca.2010.01.002. [DOI] [PubMed] [Google Scholar]

- 48.Quiles J.M., Saladino F., Mañes J., Fernández-Franzón M., Meca G. Occurrence of mycotoxins in refrigerated pizza dough and risk assessment of exposure for the Spanish population. Food Chem. Toxicol. 2016;94:19–24. doi: 10.1016/j.fct.2016.05.011. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data presented in this study are available in this article.