Abstract

The consumption of disposable face masks increases greatly because of the outbreak of the COVID-19 pandemic. Inappropriate disposal of wasted face masks has already caused the pollution of the environment. As made from plastic nonwoven fabrics, disposable face masks could be a potential source of microplastics for the environment. In this study, we evaluated the ability of new and used disposable face masks of different types to release microplastics into the water. The microplastic release capacity of the used masks increased significantly from 183.00 ± 78.42 particles/piece for the new masks to 1246.62 ± 403.50 particles/piece. Most microplastics released from the face masks were medium size transparent polypropylene fibers originated from the nonwoven fabrics. The abrasion and aging during the using of face masks enhanced the releasing of microplastics since the increasing of medium size and blue microplastics. The face masks could also accumulate airborne microplastics during use. Our results indicated that used disposable masks without effective disposal could be a critical source of microplastics in the environment. The efficient allocation of mask resources and the proper disposal of wasted masks are not only beneficial to pandemic control but also to environmental safety.

Keywords: COVID-19, Face mask, Microplastics, Nonwoven fabrics, Release

Graphical abstract

Used disposable face masks could release much more microplastics than the new ones because of abrasion and adsorption.

1. Introduction

The outbreak of Coronavirus Disease-2019 (COVID-19) causes global health concern(WHO, 2020b). As of the end of 2020, more than 80 million confirmed cases were reported worldwide with nearly 1.8 million cases of deaths(WHO, 2020a). Evidence suggested that wearing face masks is a feasible way to prevent infection of COVID-19(Cheng et al., 2020; Feng et al., 2020; Greenhalgh et al., 2020), which increases the demand for face masks drastically. According to media reports, China, which accounted for more than 50% of the world's mask production before the pandemic, is expected to increase its mask production in 2020 to more than 20 times 2019's level, exceeding 100 billion(KAWAKAMI, 2020). However, it may be still difficult to meet the global demands as research indicates the demand of face masks will increase 100 times globally(Stone et al., 2020).

Not only do we need to worry about the capacity of face masks, but we also need to consider the environmental issues that come with the use of face masks. Disposable face masks (DFM) could become a channel for pathogen transmission and an environmental burden as insufficient proper management(Mol and Caldas, 2020). Recently, a large number of discarded DFMs were found to be washed onto a beach in Hong Kong(Reuters, 2020). In Ile-Ife, Nigeria, wasted face masks were observed along the highway and drainage(Fadare and Okoffo, 2020). Most DFMs are made of nonwoven fabrics, which are composed of plastics such as polypropylene (PP), polyurethane (PU), polyacrylonitrile (PAN), polystyrene (PS), polycarbonate (PC), polyethylene (PE), and polyethylene terephthalate (PET)(Aragaw, 2020; Matabola et al., 2009). Plastic pollution is a global concern because of its ubiquity and nondegradable (Dong et al., 2020; Evangeliou et al., 2020; Oliveri Conti et al., 2020; Thompson et al., 2004; Xue et al., 2020). In recent years, microplastics which are mostly breakdown from large plastic wastes are recognized as emerging pollutant receiving global attention as their widely spread and potential adverse impacts(Cole et al., 2011; Rummel et al., 2017; Wesch et al., 2016; Wright et al., 2013; Zhang et al., 2018). It is possible that microplastics can be released from DFMs because of wear and tear as well as degradation in the environment(Aragaw, 2020; Fadare and Okoffo, 2020; Shruti et al., 2020). Li et al. (2021) reveals the inhalation risk of microplastics especially microfibers while wearing a mask. However, there are no actual data to describe the details of release of microplastics from DFMs to the environment.

Water is a relatively convenient medium for assessing the ability of microplastic release for DFMs. In this study, we measured the release of microplastics from different types of new and used DFMs to the environment to reveal their potentially adverse effects on the environment. The quantities and characteristics of released microplastics were identified to evaluate the influencing factors of microplastics release from the DFMs. We hope this study will alert the management to enhance the proper disposal of DFM wastes and avoid exacerbating our environment in the context of the COVID-19 pandemic.

2. Materials and methods

2.1. Sample collection

We obtained DFMs of 18 brands including medical surgical face masks, disposal medical face masks, normal disposal face masks and N95 face masks from a Chinese ecommerce platform (JD.com) by sales ranking in April and May 2020. Details of the collected DFMs were provided in Table S1. All face masks were product in 2020 after the outbreak of COVID-19. The used group of the tested masks were worn by students and staffs in our institute normally for one day before the experiment. These masks were folded, rubbed and worn through the process and kept filtering the air the user breathes in any place they went to.

2.2. Experimental setup

Deionized water (15 MΩ/cm) supplied by an ELGA Purelab water purification system (Lane End, High Wycombe, UK) was used for the experiment after filtered through a Whatman GF/C filter. All vessels used in the experiment were rinsed three times with the deionized water. Each mask was put into a 500 mL glass Erlenmeyer flask with 200 mL deionized water. Then all flasks were covered with aluminum foil and shaken on a rotary shaker at 120 rpm for 24 h. Three replicates were used for each brand and each treatment.

2.2.1. Microplastics analysis

After shaking, each face mask sample was rinsed twice with a total of 250 mL deionized water to rinse off microplastic particles that might be adsorbed on the surface. Then the rinse water and water left in the Erlenmeyer flask were filtered through a Millipore mixed cellulose esters membrane filter (0.8 μm pore size, 47 mm diameter, white gridded). The filter was then placed into a clean petri dish and air dried at room temperature.

2.3. Quantification and identification

Microplastics retained on the filter were examined under an Olympus SZ2-ILST stereomicroscope (Tokyo, Japan), and images were captured with a DigiRetina 16 digital camera. A visual assessment was performed to identify the microplastics based on their shape, color, and size. Microplastics were divided into four size categories (<100 μm, 100–500 μm, 500–1000 μm, 1000–2000 μm and >2000 μm). Typical microplastics released from the face masks were picked onto glass slides with a tweezer and identified using a Renishaw inVia Raman microscope (Wotton-under-Edge, Gloucestershire, UK) following a previous method(Zhang et al., 2017). Raman spectra were recorded from 300 to 3200 cm−1 with a laser excitation wavelength of 785 nm. The spectra of the samples were searched in the Renishaw Polymeric Materials Database and polymer types were identified based on the similarity to the spectra of standards.

2.4. Quality assurance and quality control

To avoid the contamination throughout the process, all equipment used in the sampling and laboratory analysis were pre-washed with DI water and covered with aluminum foil before use. Cotton masks, cotton laboratory coats, and clean gloves were worn during sampling and analysis. The surface of table and hands were rolled by a sticky roller to remove the particles on them. All water used in the process were filtered through a GF/C filter (1.2 μm pore size). Blank controls were produced using the same processing methods as those applied to the laboratory process. The mean number of microplastics detected in the blank controls was subtracted from the results of the experimental groups.

2.5. Data analysis

The differences of the mean abundance of microplastics among groups were analyzed by one-way ANOVA followed by Tukey's HSD test, and independent-samples t-test (homogeneous variances) or Welch's ANOVA followed by the Games-Howell test (heterogeneous variances) along with multiple comparisons and paired-samples t-test was designed to compare the difference between raw and used DFMs. A confidence level of 95% was used. The relation between microplastics released from new and used masks and their prices were analyzed using Pearson correlation analysis. Statistical analysis was performed using SPSS version 22.0 (SPSS Inc, Chicago, IL, USA).

3. Results and discussions

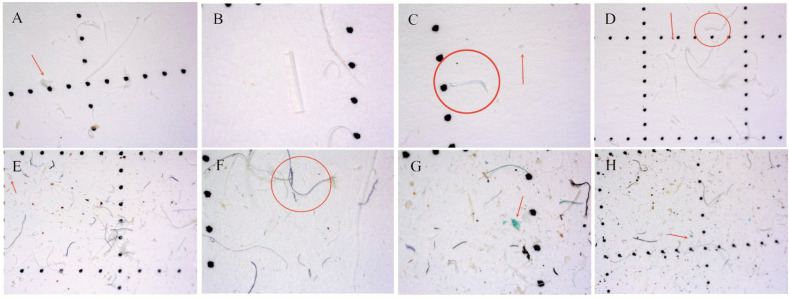

Release of microplastic fibers and fragments were found in all experimental groups after subtracting the mean microplastic detection in the blank control (4 fibers) (Fig. 1 ). It confirmed the previous speculations of release potential of microplastics from DFMs. Previous reports speculated that face masks could be a potential source of microplastics from materials, manufacturing process, and management(Aragaw, 2020; Fadare and Okoffo, 2020; Shruti et al., 2020). However, the present study firstly confirmed the release of microplastics from DFMs to the environment.

Fig. 1.

Microplastics released from new surgical medical face masks (A), new disposal medical face masks (B), new normal disposal face masks (C), new N95 face masks (D), used surgical medical face masks (E), used disposal medical face masks (F), used normal disposal face masks (G), and used N95 face masks (H). (Typical fibers are pointed out by circles and fragments are pointed out by arrows).

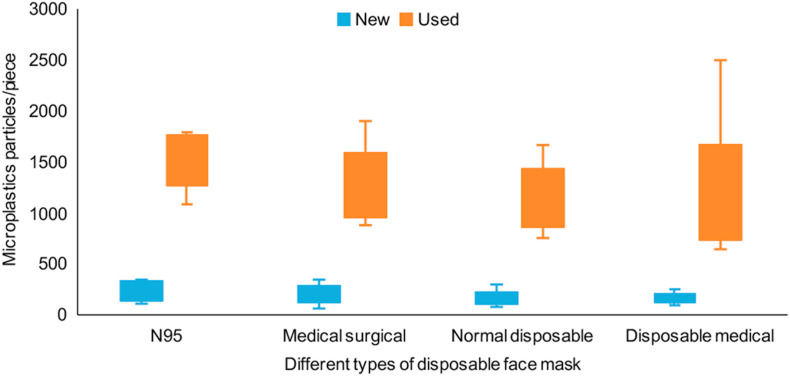

Among all types of DFMs in our experiments, average amount of microplastics released from new DFMs was 183.00 ± 78.42 and varied from 159.80 ± 46.14 to 222.17 ± 98.79 particles/piece while microplastics release from used DFMs was 1246.62 ± 403.50 and varied from 1146.04.67 ± 307.60 to 1478.00 ± 265.80 particles/piece in 24 h. For all types of the DFMs, the amount of microplastics released from used ones increased significantly than the new ones (p < 0.05) from 6.0 to 8.1 times (Fig. 2 ). However, no significant differences of release were found among different types of the DFMs.

Fig. 2.

Microplastics released from new and used disposable face masks examined in this study.

The loosely bound plastic fibers on the mask fabric were undoubtedly a significant cause of microplastics release from the DFM (Figure S1). It could be similar to the process of microfiber discharged during laundry process from the fabric(Hernandez et al., 2017; Kelly et al., 2019). UV radiation, weathering, and abrasion were essential reasons for the generation of microplastics(Khaled et al., 2018; Song et al., 2017; ter Halle et al., 2016). Daily use of DFM obviously came with exposure to radiation and wear and tear of the mask material. Li et al. (2021) also found increasing microplastics inhalation risk of the masks after different treatments for reuse such as washing and radiation. In addition, as an airborne pollutant(Dris et al., 2017), during the use of DFM, microplastics suspended in the air might also be captured on the mask, which could also enhance the release amounts.

There was no significant correlation was observed between amounts of microplastics released from new and used DFMs (Figure S2c). The capacity of the masks to release microplastics also did not correlate with their price (Figure S2a, b). It implied that the releasing of microplastic from DFMs might have no relationship with their functions and material quality. Although these DFMs were divided into four categories, during the examination we found that they all had three layers of non-woven material. The biggest difference between the different masks is in the middle filter layer, but during our experiments the masks were carried out in an unbroken state, with the middle filter layer surrounded by the front and back layers, so microplastics released from the front and back layers might have dominated, which might have led to little difference in release between the different types. In addition, although there were some differences in the grammage of the meltblown fabric for different DFMs, the main difference between them was whether or not they were treated with electrical charges (Hossain et al., 2020). This difference in charge might then have little effect when we performed a release experiment in the water.

Anyhow, once entering the environment, microplastics released from the wasted DFMs might lead to an elevated level of microplastics in the surrounding environment. As roughly calculated from our results, as the estimated production of face masks in China of 2020, more than one hundred billion of face masks could releasing more the 1.2 × 1014 microplastics into environmental within 24 h after used and discarded into the water. Even worse, the release process might be persistent.

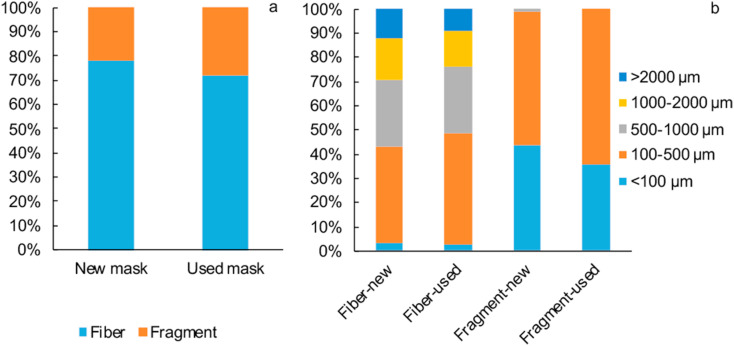

Microplastics released from the DFMs were either fibrous or fragmentary. Fibers were predominant, accounting for more than 70% of the total released microplastics (Fig. 3 a), which can be related to the fibrous structure of the fabrics (Figure S1). Microfibers were the most common and predominant shape of microplastics in the water, the air, and the organisms(Salvador Cesa et al., 2017; Wang et al., 2019). It could be released from the fabric(Hernandez et al., 2017). The main material of the DFMs was non-woven fabric. Normal non-woven fabrics in the front and back layers of DMFs could be an important source of microplastic fibers. The materials of the central layer of DFMs were meltblown fabrics, which were made from high-speed hot air drafted polymer solutions and bonded to themselves(SalehHudin et al., 2017). Although the absorption energy and deformation capability during deformation is greater, plastic nonwoven fabrics present lower stiffness and strength(Ridruejo et al., 2011). It could be a direct source of microfibers. The meltblown process could also form some plastic flakes (Figure S1), which could be the source of microplastic fragments. The higher proportion of microplastic fragments released from used face masks implied that the use process may be more beneficial for the generation of fragment microplastics. During wearing, adjustment, folding, and pull of the DFM might lead to the breakage and fragmentation of the inner materials of the fabrics because of mechanical deformation.

Fig. 3.

Morphological characteristics of microplastics released from the new and used disposable face masks: shapes (a) and sizes (b).

Medium size (100–500 μm) microplastics were predominant both in fibers and fragments, while fibers contained some large size particles (Fig. 3b). The proportions of Medium size (100–500 μm) microplastics both increased after use in fibers and fragments. Although there was a lack of specific data to support the process of microplastic generation from polypropylene nonwovens fabric, previous studies of other plastics including polyethylene, polypropylene, and polystyrene indicated that it needed time for plastic debris becoming smaller ones (Julienne et al., 2019; Weinstein et al., 2016). The use time of the DFM was limited because of health protection reasons, which might limit the time to generate smaller microplastic particles.

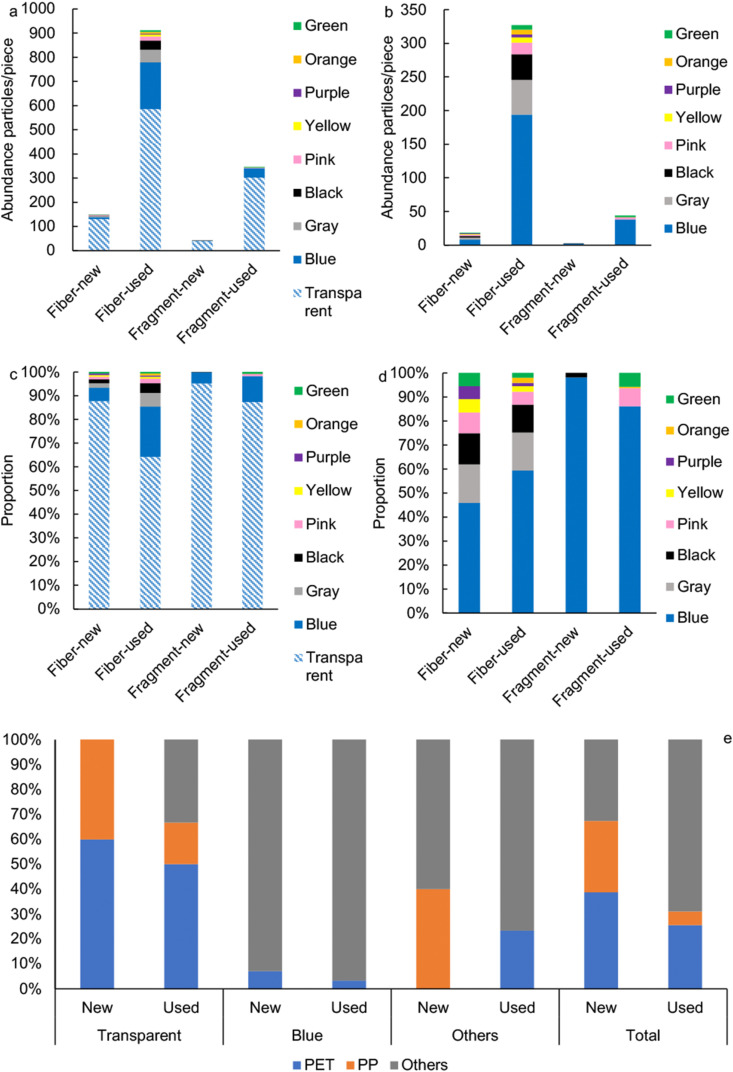

Most of the microplastics released from the masks, whether new or used, were transparent. However, the proportion of colored microplastics increased after use (Fig. 4 a and c). Among colored microplastics, blue microplastics were predominant in both fibers and fragments, the proportion of blue microplastics in colored microplastics increased after use. Although the amounts of other colors of microplastics also increased after use, the proportions of them in colored microplastics did not change appreciably or even decreased (Fig. 4b and d). PET and PP were predominant in the transparent microplastics released by the new DFMs. They might be released from the materials of the DFMs. After use, the proportion of other polymers increased for all colors of microplastics (Fig. 4e).

Fig. 4.

Abundances and proportions of microplastics in different colors released from the new and used disposable face masks: a) and c) including transparent; b) and d) colored microplastics; types of polymer in different colors of microplastics identified by Raman spectrum (e). (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

The first two predominant colors in this study, transparent and blue, were also the same as of the main colors of the fabrics that DFMs were made of. Blue fabrics generally appeared on the outer layers of the face masks. This made them more exposure to radiation and abrasion, which were favorable conditions for the production of microplastics(Song et al., 2017). Other colors of microplastics might be from the airborne microplastics during production, transport, and use. Airborne microplastics were ubiquitous and colorful(Enyoh et al., 2019). More than 10,000 microplastics could be deposited per square meter of indoor space per day and most of them were fiber(Zhang et al., 2020a; Zhang et al., 2020b). The outdoor and indoor microfiber concentration could also reach to 1.5 and 53 particles/m3, respectively in Paris(Dris et al., 2017). The breathing action acted like an air pump, enriching the airborne microplastics on the surface of the mask, which led to an increase in the release of other colored microplastics from the used masks. The results of polymer types also implied that, the microplastics released from the new DFMs were mainly their materials, PET and PP, while the use process increased the proportion of other types of polymers which might come from the airborne microplastics. However, the increasing proportion of blue microfibers still indicated that microplastics released from the masks themselves were still predominant. In any case, airborne microplastics adsorbed during the use further increased the risk of microplastic release from the masks to other environmental media, elevating the overall hazard of the masks as a source of microplastics.

As a form of medical waste, DFMs deserved stricter management and should not be casually discarded in the environment. From our results, scientific management of DFMs would be beneficial not only for pandemic control, but also for environmental microplastic risk control. The management should strictly prohibit the random disposal of DFMs outdoors and suggest citizens to collect them at home or at work and try to make them enter the medical waste recycling system. For regions where conditions were limited, they should also at least ensure that the DFMs could enter the recycling pathway for plastic products, thus preventing DFMs from entering the environment directly. In fact, even with the massive increase in mask production capacity, masks are still a limited resource in many parts of the world and optimizing the distribution of DMF was important for controlling the pandemic (Worby and Chang, 2020). And extending the use of DFM as long as possible while maintaining protection would not only ease the pressure on the supply of masks but could also be a potential way to reduce their environmental risk.

4. Conclusions

Our results indicated that used DFMs without effective disposal could be a critical source of microplastics in the environment. It was not only because of the large amount of fibers carried by the fabric material of the masks themselves, but also because of the process of use that would further promote the production and release of microplastics from the masks. In addition, the masks can act as collectors of airborne microplastics. However, during the COVID-19 pandemic, DFMs were a necessity for health care workers and public protection. The consumption of disposable face masks would continue at a high level. Therefore, effective management of DFMs at the use and waste sides would not only contribute to pandemic prevention and control, but also reduce the pressure of microplastic pollution in the environment. The management should guide the public to use and discard DFMs appropriately and provide centralized disposal options.

Credit author statement

Xianchuan Chen: Writing - Original draft preparation, Methodology, and Visualization; Xiaofei Chen: Investigation; Qian Liu: Investigation; Qichao Zhao: Writing - Review & Editing; Xiong Xiong: Supervision, Conceptualization, and Writing- Reviewing and Editing; Chenxi Wu: Supervision.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This research was funded by the National Natural Science Foundation of China (41877394), the National Key Research and Development Program of China (2018YFD0900701), and the Strategic Priority Research Program of the Chinese Academy of Sciences (XDA23040401).

Footnotes

This paper has been recommended for acceptance by Maria Cristina Fossi.

Supplementary data to this article can be found online at https://doi.org/10.1016/j.envpol.2021.117485.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

References

- Aragaw T.A. Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar. Pollut. Bull. 2020;159 doi: 10.1016/j.marpolbul.2020.111517. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cheng K.K., Lam T.H., Leung C.C. Wearing face masks in the community during the COVID-19 pandemic: altruism and solidarity. Lancet. 2020 doi: 10.1016/S0140-6736(20)30918-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cole M., Lindeque P., Halsband C., Galloway T.S. Microplastics as contaminants in the marine environment: a review. Mar. Pollut. Bull. 2011;62:2588–2597. doi: 10.1016/j.marpolbul.2011.09.025. [DOI] [PubMed] [Google Scholar]

- Dong M.T., Luo Z.J., Jiang Q.F., Xing X.L., Zhang Q.Q., Sun Y. The rapid increases in microplastics in urban lake sediments. Sci. Rep. 2020;10 doi: 10.1038/s41598-020-57933-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dris R., Gasperi J., Mirande C., Mandin C., Guerrouache M., Langlois V., Tassin B. A first overview of textile fibers, including microplastics, in indoor and outdoor environments. Environ. Pollut. 2017;221:453–458. doi: 10.1016/j.envpol.2016.12.013. [DOI] [PubMed] [Google Scholar]

- Enyoh C.E., Verla A.W., Verla E.N., Ibe F.C., Amaobi C.E. Airborne microplastics: a review study on method for analysis, occurrence, movement and risks. Environ. Monit. Assess. 2019;191 doi: 10.1007/s10661-019-7842-0. [DOI] [PubMed] [Google Scholar]

- Evangeliou N., Grythe H., Klimont Z., Heyes C., Eckhardt S., Lopez-Aparicio S., Stohl A. Atmospheric transport is a major pathway of microplastics to remote regions. Nat. Commun. 2020;11:3381. doi: 10.1038/s41467-020-17201-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fadare O.O., Okoffo E.D. Covid-19 face masks: a potential source of microplastic fibers in the environment. Sci. Total Environ. 2020;737 doi: 10.1016/j.scitotenv.2020.140279. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Feng S., Shen C., Xia N., Song W., Fan M.Z., Cowling B.J. Rational use of face masks in the COVID-19 pandemic. Lancet Respir. Med. 2020;8:434–436. doi: 10.1016/S2213-2600(20)30134-X. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Greenhalgh T., Schmid M.B., Czypionka T., Bassler D., Gruer L. Face masks for the public during the covid-19 crisis. Br. Med. J. 2020;369 doi: 10.1136/bmj.m1435. [DOI] [PubMed] [Google Scholar]

- Hernandez E., Nowack B., Mitrano D.M. Polyester textiles as a source of microplastics from households: a mechanistic study to understand microfiber release during washing. Environ. Sci. Technol. 2017;51:7036–7046. doi: 10.1021/acs.est.7b01750. [DOI] [PubMed] [Google Scholar]

- Hossain E., Bhadra S., Jain H., Das S., Bhattacharya A., Ghosh S., Levine D. Recharging and rejuvenation of decontaminated N95 masks. Phys. Fluids. 2020;32 doi: 10.1063/5.0023940. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Julienne F., Delorme N., Lagarde F. From macroplastics to microplastics: role of water in the fragmentation of polyethylene. Chemosphere. 2019;236:124409. doi: 10.1016/j.chemosphere.2019.124409. [DOI] [PubMed] [Google Scholar]

- KAWAKAMI T. NIKKEI; 2020. China to Churn Out 100bn Masks This Year in Pandemic's Wake. [Google Scholar]

- Kelly M.R., Lant N.J., Kurr M., Burgess J.G. Importance of water-volume on the release of microplastic fibers from laundry. Environ. Sci. Technol. 2019;53:11735–11744. doi: 10.1021/acs.est.9b03022. [DOI] [PubMed] [Google Scholar]

- Khaled A., Rivaton A., Richard C., Jaber F., Sleiman M. Phototransformation of plastic containing brominated flame retardants: enhanced fragmentation and release of photoproducts to water and air. Environ. Sci. Technol. 2018;52:11123–11131. doi: 10.1021/acs.est.8b03172. [DOI] [PubMed] [Google Scholar]

- Li L., Zhao X., Li Z., Song K. COVID-19: Performance study of microplastic inhalation risk posed by wearing masks. J. Hazard. Mater. 2021;411 doi: 10.1016/j.jhazmat.2020.124955. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Matabola K.P., De Vries A.R., Moolman F.S., Luyt A.S. Single polymer composites: a review. J. Mater. Sci. 2009;44:6213–6222. [Google Scholar]

- Mol M.P.G., Caldas S. Can the human coronavirus epidemic also spread through solid waste? Waste Manag. Res. 2020;38:485–486. doi: 10.1177/0734242X20918312. [DOI] [PubMed] [Google Scholar]

- Oliveri Conti G., Ferrante M., Banni M., Favara C., Nicolosi I., Cristaldi A., Fiore M., Zuccarello P. Micro- and nano-plastics in edible fruit and vegetables. The first diet risks assessment for the general population. Environ. Res. 2020;187 doi: 10.1016/j.envres.2020.109677. [DOI] [PubMed] [Google Scholar]

- Reuters . Reuters; 2020. Discarded Coronavirus Masks Clutter Hong Kong's Beaches, Trails. [Google Scholar]

- Ridruejo A., Gonzalez C., LLorca J. Micromechanisms of deformation and fracture of polypropylene nonwoven fabrics. Int. J. Solid Struct. 2011;48:153–162. [Google Scholar]

- Rummel C.D., Jahnke A., Gorokhova E., Kuhnel D., Schmitt-Jansen M. Impacts of biofilm formation on the fate and potential effects of microplastic in the aquatic environment. Environ. Sci. Technol. Lett. 2017;4:258–267. [Google Scholar]

- SalehHudin H.S., Mohamad E.N., Mahadi W.N.L., Muhammad Afifi A. Multiple-jet electrospinning methods for nanofiber processing: a review. Mater. Manuf. Process. 2017;33:479–498. [Google Scholar]

- Salvador Cesa F., Turra A., Baruque-Ramos J. Synthetic fibers as microplastics in the marine environment: a review from textile perspective with a focus on domestic washings. Sci. Total Environ. 2017;598:1116–1129. doi: 10.1016/j.scitotenv.2017.04.172. [DOI] [PubMed] [Google Scholar]

- Shruti V.C., Pérez-Guevara F., Elizalde-Martínez I., Kutralam-Muniasamy G. Reusable masks for COVID-19: a missing piece of the microplastic problem during the global health crisis. Mar. Pollut. Bull. 2020;161 doi: 10.1016/j.marpolbul.2020.111777. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Song Y.K., Hong S.H., Jang M., Han G.M., Jung S.W., Shim W.J. Combined effects of UV exposure duration and mechanical abrasion on microplastic fragmentation by polymer type. Environ. Sci. Technol. 2017;51:4368–4376. doi: 10.1021/acs.est.6b06155. [DOI] [PubMed] [Google Scholar]

- Stone T.E., Kunaviktikul W., Omura M., Petrini M. Facemasks and the Covid 19 pandemic: what advice should health professionals be giving the general public about the wearing of facemasks? Nurs. Health Sci. 2020;22:339–342. doi: 10.1111/nhs.12724. [DOI] [PMC free article] [PubMed] [Google Scholar]

- ter Halle A., Ladirat L., Gendre X., Goudouneche D., Pusineri C., Routaboul C., Tenailleau C., Duployer B., Perez E. Understanding the fragmentation pattern of marine plastic debris. Environ. Sci. Technol. 2016;50:5668–5675. doi: 10.1021/acs.est.6b00594. [DOI] [PubMed] [Google Scholar]

- Thompson R.C., Olsen Y., Mitchell R.P., Davis A., Rowland S.J., John A.W.G., McGonigle D., Russell A.E. Lost at sea: where is all the plastic? Science. 2004;304 doi: 10.1126/science.1094559. 838-838. [DOI] [PubMed] [Google Scholar]

- Wang T., Li B., Zou X., Wang Y., Li Y., Xu Y., Mao L., Zhang C., Yu W. Emission of primary microplastics in mainland China: invisible but not negligible. Water Res. 2019;162:214–224. doi: 10.1016/j.watres.2019.06.042. [DOI] [PubMed] [Google Scholar]

- Weinstein J.E., Crocker B.K., Gray A.D. From macroplastic to microplastic: degradation of high-density polyethylene, polypropylene, and polystyrene in a salt marsh habitat. Environ. Toxicol. Chem. 2016;35:1632–1640. doi: 10.1002/etc.3432. [DOI] [PubMed] [Google Scholar]

- Wesch C., Bredimus K., Paulus M., Klein R. Towards the suitable monitoring of ingestion of microplastics by marine biota: a review. Environ. Pollut. 2016;218:1200–1208. doi: 10.1016/j.envpol.2016.08.076. [DOI] [PubMed] [Google Scholar]

- WHO . WHO; 2020. Coronavirus Disease (COVID-19) Pandemic. [Google Scholar]

- WHO . WHO; 2020. WHO Director-General's Opening Remarks at the Media Briefing on COVID-19 - 21 August 2020. [Google Scholar]

- Worby C.J., Chang H.-H. Face mask use in the general population and optimal resource allocation during the COVID-19 pandemic. Nat. Commun. 2020;11 doi: 10.1038/s41467-020-17922-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wright S.L., Thompson R.C., Galloway T.S. The physical impacts of microplastics on marine organisms: a review. Environ. Pollut. 2013;178:483–492. doi: 10.1016/j.envpol.2013.02.031. [DOI] [PubMed] [Google Scholar]

- Xue B., Zhang L., Li R., Wang Y., Guo J., Yu K., Wang S. Underestimated microplastic pollution derived from fishery activities and “hidden” in deep sediment. Environ. Sci. Technol. 2020;54:2210–2217. doi: 10.1021/acs.est.9b04850. [DOI] [PubMed] [Google Scholar]

- Zhang K., Shi H., Peng J., Wang Y., Xiong X., Wu C., Lam P.K.S. Microplastic pollution in China's inland water systems: a review of findings, methods, characteristics, effects, and management. Sci. Total Environ. 2018;630:1641–1653. doi: 10.1016/j.scitotenv.2018.02.300. [DOI] [PubMed] [Google Scholar]

- Zhang K., Xiong X., Hu H.J., Wu C.X., Bi Y.H., Wu Y.H., Zhou B.S., Lam P.K.S., Liu J.T. Occurrence and characteristics of microplastic pollution in Xiangxi Bay of three Gorges Reservoir, China. Environ. Sci. Technol. 2017;51:3794–3801. doi: 10.1021/acs.est.7b00369. [DOI] [PubMed] [Google Scholar]

- Zhang Q., Zhao Y., Du F., Cai H., Wang G., Shi H. Microplastic fallout in different indoor environments. Environ. Sci. Technol. 2020;54:6530–6539. doi: 10.1021/acs.est.0c00087. [DOI] [PubMed] [Google Scholar]

- Zhang Y., Kang S., Allen S., Allen D., Gao T., Sillanpää M. Atmospheric microplastics: a review on current status and perspectives. Earth Sci. Rev. 2020;203 [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.