Abstract

Plants have complex internal signaling pathways to quickly adjust to environmental changes and harvest energy from the environment. Facing the growing population, there is an urgent need for plant transformation and precise monitoring of plant growth to improve crop yields. Nanotechnology, an interdisciplinary research field, has recently been boosting plant yields and meeting global energy needs. In this context, a new field, “plant nanoscience,” which describes the interaction between plants and nanotechnology, emerges as the times require. Nanosensors, nanofertilizers, nanopesticides, and nano‐plant genetic engineering are of great help in increasing crop yields. Nanogenerators are helping to develop the potential of plants in the field of energy harvesting. Furthermore, the uptake and internalization of nanomaterials in plants and the possible effects are also worthy of attention. In this review, a forward‐looking perspective on the plant nanoscience is presented and feasible solutions for future food shortages and energy crises are provided.

Keywords: nanocarriers, nanofertilizers, nanogenerators, nanopesticides, nanosensors, nanotoxicology, plant nanoscience

This review provides the first detailed introduction of plant nanoscience, including nanosensors, nanofertilizers, nanopesticides, nanomaterials‐mediated gene transformation, nanogenerators, and nanotoxicology. The interaction between nanomaterials and plants, as well as, the advanced application fields of nanotechnology in plants are discussed deeply to better manage the growth of plants and offer guidance for the future research and practical applications.

1. Introduction

The global population, currently 7.7 billion, is expected to rise to 9.8 billion by 2050.[ 1 ] To meet the food demand of the ever‐increasing population, it is urgent to ensure the sustainable growth of crop yields.[ 2 ] However, agriculture production is facing a series of environmental and biological challenges.[ 3 ] Therefore, it makes sense to precisely manage the limited resources and increase crop yields in a sustainable way.[ 4 ] The green revolution, which began in the 1960s, achieved the necessary increase in crop yields with low land use. However, as agricultural development becomes increasingly inefficient and unsustainable, this revolution came to an end. Instead, the second green revolution gradually emerged. This new revolution, aimed at meeting future growing food needs and achieving sustainable development, is driven by new technologies and materials.[ 5 ] Among them, nanotechnology, a fast‐growing field for processing materials at the nanoscale, stands out.[ 3 , 6 , 7 , 8 , 9 , 10 ] With the gradual penetration of nanotechnology in the field of plants, the combination of plants and nanotechnology may give birth to a new field of research, which can be called “plant nanoscience” here.

Recently, nanotechnology‐enabled sensors (namely nanosensors) play a unique role in agriculture. Nanosensors have their own unique nano‐interface, which can specially recognize the received signals and amplify the signals, providing highly sensitive, stable, and reproducible detection even at the single molecule level.[ 11 , 12 , 13 , 14 ] They can directly transfer signals released by plants into digital information on the connected electronic devices, which are time‐saving and efficient compared to traditional detection techniques.[ 4 , 15 , 16 , 17 , 18 , 19 ] Nanosensors facilitate the transition from traditional macro‐scale plant monitoring to automated micro‐scale monitoring and information acquisition, which helps to accurately mange the process of plant growth.

In addition to the real‐time monitoring of plant to achieve better agricultural production, attention should also be paid to the provision of nutrients and pest management during plant growth. However, the commonly used instantly soluble fertilizers not only have low utilization efficiency (<30%) but also cause environmental pollutions.[ 20 ] Furthermore, large amounts of chemical pesticides are lost during the application, causing the contamination of ecosystem.[ 21 , 22 ] Therefore, it is important to develop new strategies to overcome the above problems. Nanotechnology‐enabled fertilizers (namely nanofertilizers) and pesticides (namely nanopesticides) have the properties of high efficiency, durability, and biocompatibility in the application process.[ 23 , 24 , 25 , 26 ] They are excellent substitutes for traditional agrochemicals and can effectively protect plants from nutritional deficiencies and pests.[ 27 , 28 ]

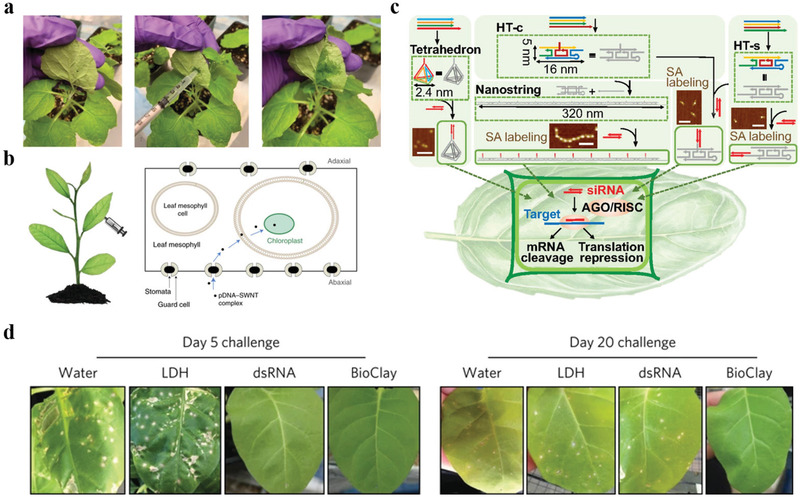

Although nanofertilizers and nanopesticides help to improve crop yields and quality, it is also necessary to solve these problems fundamentally, such as planting high‐yield plants that are naturally resistant to pests. Recently, genetic enhancement of plants has been widely employed to increase the yields and provide plants with robust resistant to biotic and abiotic stresses.[ 29 , 30 , 31 ] Plant gene transformation usually involves regulating the existing genetic material or delivering required genes to the host cells, thereby imparting new characteristics to plants.[ 32 ] Extensive studies have confirmed that nanomaterials can delivery biomolecules into animal cells, but their application in plants lags behind, mainly due to the cell wall recalcitrance to nanomaterials internalization.[ 10 , 33 , 34 , 35 , 36 , 37 ] However, some recent breakthroughs have accelerated the research process of using nanomaterials as delivery vehicles (nanocarriers) in plants.[ 38 , 39 , 40 , 41 , 42 ] Nanocarriers represent a promising way for plant genetic engineering due to their specific properties like large surface area for chemical modification and biocompatibility, protecting the loaded biomolecules from the threat of cell metabolism and degradation.[ 43 ]

As can be seen from the above comments, nanotechnology has made it possible to accurately manage plant growth processes. But for some nanotechnologies, especially nanosensors, energy supply is still a big problem because of the ongoing energy crisis. Plants are widely distributed in the environment, and it is of great interest to utilize plants to obtain sustainable energy. Besides the most common solar energy, plants can also capture the ubiquitous mechanical energy in the environment.[ 44 ] If the mechanical energy can be converted into electrical energy for use in some way, it will be very helpful to alleviate the energy crisis. The triboelectric nanogenerator (TENG), which can generate electricity based on the coupling effect of triboelectrification and electrostatic induction, has attracted great attention for low‐cost, high efficiency, high power density, and simple structure.[ 45 , 46 ] It is worth noting that plants have participated in the construction of TENG to capture the abundant mechanical energy in the environment.[ 44 , 47 , 48 , 49 ] Therefore, the combination between TENG and plant may provide new ideas for the new and green energy.

Although nanotechnologies bring us a lot of convenience, the potential toxicity from nanomaterials may cause risks for living organism and produce unknown byproducts in the environment. The study of nanotoxicology help us better understand the interactions between nanomaterials and living organism.[ 50 , 51 ] The size, surface area, morphology, concentration, and other characteristics of nanomaterials may affect the physiological processes of plants. We need to explore the uptake and transformation of nanomaterials in plants, thereby designing more efficient nanomaterials to keep the hazards of the substances at a minimum.

This review summarizes the wide applications of nanotechnology in plants in recent years around the topic of plant nanoscience, including nanosensors, nanofertilizers, nanopesticides, nanocarriers, nanogenerators, and nanotoxicology (Figure 1 ). In light of the emerging field of plant nanoscience, we emphasize the importance to view all proposed agri‐tech solutions from a systematic perspective to ensure that they are sustainable, safe, and able to cope with future food supply and energy crisis.

Figure 1.

The plant nanoscience.

2. Nanosensors for Plant Monitoring

Plants have continuous gas and fluid exchange with the environment through their leaves and roots.[ 52 ] The continuous changes of the environment directly reflect the growth status of plants, and plants can also reflect the fluctuations of their surroundings. Traditional plant phenotypic technologies, such as “3S” technologies (remote sensing (RS), geography information systems, and global positioning systems),[ 15 , 16 , 17 ] spectroscopy,[ 18 ] machine vision and digital image capture/analysis,[ 19 ] etc. These technologies are suitable for the perception of plant phenotypic information at macro‐scale such as chlorophyll and nitrogen content, canopy information, leaf area index, and pest infestation. However, critical information such as the information exchange between plants, response to environmental stress, and internal physiological signal changes at the micro‐nano scale cannot be obtained by these technologies.

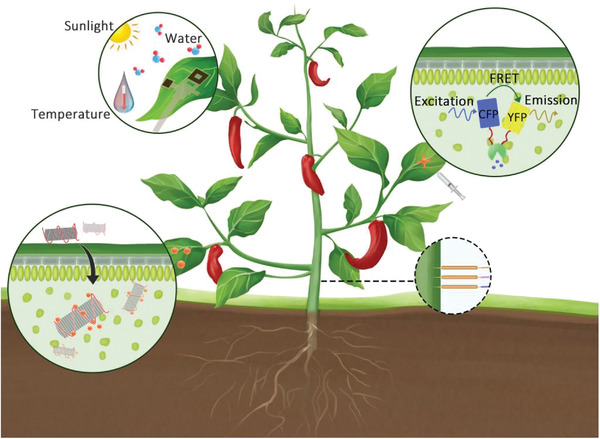

Nanotechnology, one of the most important research hotspots in the world, has great potential to enable plants to communicate with and actuate electronic devices, helping people to intuitively understand the physiological state of the plant and the dynamic changes of its surroundings.[ 4 ] Facing with the challenges of current agricultural development, nanosensors have achieved accurate, real‐time, and high spatiotemporal resolution monitoring of individual plant at the micro‐scale, and translate these signaling molecules generated by plant via optical, wireless or electrical signals, thus helping people to better control all aspects of agricultural production. As shown in Figure 2 , these smart nanosensors monitor plants and their surroundings primarily in vitro and in vivo, and their applications will be discussed in more details below.

Figure 2.

Nanosensors for plant monitoring.

2.1. In Vitro Monitoring

2.1.1. Plant Growth

When observing the process of the plant growth, the most intuitive change is the continuous change of the external shape as plant grows from the seedling. Therefore, various methods have been used for measuring the changes of circumference of plants, including manual instruments like measuring tapes or calipers, and fully automated systems like strain gauges,[ 53 ] linear potentiometers,[ 54 ] etc. But they usually have low detection accuracy, low spatial resolution of nanometer‐scale precision, and limited location, requiring regular adjustments of the frame during long‐term measurements.[ 55 ] Strain sensors are devices that convert mechanical deformations into the changes of electrical characteristics like resistance.[ 2 ] And with the current development of flexible and stretchable electronics, wearable strain nanosensors have emerged with the ability of real‐time and continuous monitoring. Although most of them are applied to monitor human motion rather than plant growth.[ 56 , 57 , 58 ] Given their unique advantages into account, it is highly desirable to make wearable strain nanosensors with high sensitivity and wide sensing range for in situ and real‐time measuring of plant growth.

The most distinctive advantage of the wearable strain nanosensor is that it can be closely attached to the surface of the plant. With the growth of the plant, a certain tension will be exerted on the nanosensor, which will make the nanosensor stretch accordingly, leading to changes in the output electrical signals. Based on this, the adhesion, flexibility, sensitivity, transparency, biocompatibility, etc., are the evaluation indexes of these wearable strain nanosensors. Especially for plants, it is necessary to consider whether can reflect the micro‐changes of plant growth at micro‐nano scale, whether they can firmly adhere to the surface of plants with abundant microstructures, whether they pose a threat to plant growth, and whether the real‐time in situ monitoring can be achieved. In existing researches, our group fabricated a flexible strain nanosensor by writing the chitosan‐based conductive ink, which was synthesized by mixing graphite nanopowder and chitosan solution, directly on cucumbers (Cucumis sativus L.).[ 59 ] Results showed that within strain from 1% to 8%, the fabricated nanosensor had a gauge factor (GF) value of 64 and can be stretched up to 60%, showing the ability to monitor plant growth. Later, the performance of the nanosensor was improved by introducing a carbon nanotube (CNT) ink, and successfully monitored the growth of another two plants (Solanum melongena L. and Cucurbita pepo).[ 2 ] This wearable strain nanosensor was directly drawn on a disposable latex glove (Figure 3a). And the synergistic reinforcement between graphite and CNT significantly improved the mechanical stability and stretchability of the nanosensor, which could respond to all strain loads from 0 to 150%, and the GF was 352 at 150% strain. This nanosensor exhibited higher spatiotemporal resolutions and sensitivity, demonstrating the two plants had a rhythmic growth pattern. Although neither of the wearable strain nanosensors have been used to continuously monitor plant growth over a long period of time, nor to validate their performance in the field. They still open up a new way for the development of wearable nanodevices in the field of plant nanoscience.

Figure 3.

Flexible and wearable nanosensors for in vitro plant growth monitoring. a) Images of the all‐in‐one wearable device for plant growth measurement. Reproduced with permission.[ 2 ] Copyright 2019, Elsevier Ltd. b) Photo of the GO‐based flexible humidity nanosensor that attached to the surface of a leaf. Reproduced with permission.[ 67 ] Copyright 2020, Elsevier Ltd. c) Schematic diagram of the multifunctional stretchable sensor on a leaf and the top view of the leaf sensor. Reproduced with permission.[ 68 ] Copyright 2019, American Chemical Society. d) The process of the vapor coating living plants with functional polymer films. Reproduced with permission.[ 69 ] Copyright 2019, American Association for the Advancement of Science. e) Photo (left), an optical microscope image (right), and the I–V characteristic (inset) of SWCNTs/graphite arrays laminated onto surface of a live leaf. Reproduced with permission.[ 72 ] Copyright 2014, American Chemical Society.

2.1.2. Environmental Factors

Plants still live in a constantly changing environment, which is sometimes not conducive to their growth.[ 60 ] Humidity level fluctuates with changes in surrounding temperature, and the opening and closing of leaf stomata in the process of photosynthesis is directly related to the change of temperature and humidity. Moreover, plants are also threatened by pests and diseases during their growth. All in all, these fluctuating environmental factors will more or less cause a series of reactions in the cells, and ultimately affect the physiological processes of plants. Plants often exhibit unique and complex responses to environmental changes, utilizing intercellular communication to integrate signals from different tissues and organs.[ 61 , 62 ] These signals usually consist of controlled production of plant hormones and rapidly spreading potential waves of cell membranes polarization, measuring these signals may provide information about fluctuating environmental factors.[ 52 , 63 ] Therefore, the use of nanosensors to communicate with plants is helpful to understand their growth mechanisms, and real‐time tracking these signals is of great significance to increase plant yields.

Of all the environmental factors, water is the most important for plant growth, because it controls the photosynthesis and transpiration process.[ 64 ] Compared with the sensors arranged in the soil or among plants, the wearable nanosensors directly attached to plants can more intuitively reflect the small changes in the water status of plants themselves, especially in the early detection. Based on this, researchers have carried out various researches. Oren et al. utilized graphene‐based on‐tape nanosensors that patterned onto the back surfaces of the leaves of maize plants to detect the changes of relative humidity (RH) on the surface of the leaves.[ 65 ] Upon irrigation, the RH of the leaves change, which is directly expressed as the change in the resistance of the nanosensor. Im et al. fabricated a flexible capacitive humidity nanosensor by depositing titanium (Ti) and gold (Au) on the polyimide (PI) film to form an interdigitated electrode.[ 66 ] The transpiration of the stoma was monitored by the nanosensor that converting plants response variation into electrical signals, which were further sent to a mobile device wirelessly in real time. Although the performance of the mentioned nanosensors are good, it will be a very meaningful innovation if they are further combined with wireless devices to realize the real‐time transmission and analysis of monitoring data. And their fabrication procedures are very complicated and time‐consuming. The long‐term stability also has not been verified. Based on this, our group proposed a convenient and effective way for the quantity production of wearable capacitive‐type humidity nanosensors by using laser direct writing technology.[ 67 ] A laser‐induced graphene interdigital electrode (LIG‐IDE) was fabricated on the PI film, and graphene oxide (GO) aqueous solution was further drop‐casted on the surface of LIG‐IDE to act as the humidity sensing material. This GO‐based flexible humidity nanosensor could be well attached to the surface of plant leaves without disturbing their normal growth, and it realized the real‐time and long‐term tracking of plant transpiration (Figure 3b). However, if the nanosensor is further combined with wireless devices to form an integrated system, and corresponding field trials are carried out, it could be more efficient for plant monitoring.

In addition to the monitoring of single environmental factors like humidity, the development of nanosensors for multi‐factor monitoring is also very necessary. Such innovative design is more time‐saving and efficient. Nassar et al. fabricated an autonomous wearable nanosensor for localized microclimate monitoring by patterning interdigitated capacitive structures of Ti/Au on PI film, and further transferred this multisensory structures onto the polydimethylsiloxane layer.[ 60 ] This device could obtain real‐time humidity and temperature levels through the continuous monitoring on the surface of plant leaves. Furthermore, the physiological changes of plant leaves are closely related to the localized microclimate. By monitoring the leaf physiology and localized microclimate simultaneously, we can establish a link between them, which is helpful to better understand the physiological changes of plants. Therefore, Zhao and coworkers developed a multifunctional leaf‐mounted nanosensor, including a copper (Cu) film acted as hydration sensing element, a Ti/Cu film acted as temperature sensing element, single‐walled carbon nanotubes (SWCNTs) acted as strain sensing element, and SU‐8 encapsulated phototransistor acted as light sensing element.[ 68 ] This multifunctional nanosensor could monitor leaf physiological and different environmental conditions continuously, and could extend with the growth of the attached leaves without disturbing the normal growth of the plant (Figure 3c).

These aforementioned nanosensors are all built on a flexible substrate to realize the detection process. Whether they can be firmly attached to the surface of the plant during long‐term use remain to be further verified. Moreover, the biocompatibility of the substrate material also needs to be considered. Based on this, Kim and coworkers demonstrated a novel concept of using biocompatible conducting polymer films as a nanosensor by directly printing the films onto living plants, which could detect deep tissue damages caused by dehydration and ultraviolet‐A exposure through non‐invasive bioimpedance spectroscopy (Figure 3d).[ 69 ] They found that the vapor‐printed nanosensor could be used as durable diagnostic handles for detecting the sources of plant stress like drought and photodamage. This study provides a good idea for the construction of nanosensors for environmental factors monitoring in the future, which will play significant roles in plant biology and precision agriculture. However, as mentioned above, these multifunctional nanosensors also should be combined with wireless devices to form integrated systems. And, they also need to conduct long‐term and field trials to verify their performance.

The release of VOCs is an important way for phytochemical resistance mechanisms. They act as secondary metabolites and can be used for plant communication with other organisms and play a crucial role in interacting with biotic and abiotic stresses.[ 70 ] Wearable nanosensors have been proven to be capable of monitoring environmental factors such as humidity, temperature, and illumination. Thus, taking advantage of the unique properties of them, they also have the potential to detect VOCs released by plants by using different sensitive materials to form different nano‐interfaces. Esser et al. utilized a mixture of SWCNTs and copper(I) complexes to fabricate a reversible chemo‐resistive nanosensor, which was able to detect ethylene at sub‐ppm concentrations from various fruits.[ 71 ] The binding of ethylene to the SWCNTs/copper(I) complexes reversibly increases the resistance of SWCNTs. However, this nanosensor is fabricated directly on a rigid substrate, which is not convenient for their application in plants. Thus, in another study, Lee et al. fabricated wearable electronic devices in situ based on the integrated arrays of SWCNTs transistors with graphitic electrodes and interconnects.[ 72 ] These devices could realize real‐time monitoring of toxic gases (dimethyl methylphosphonate vapor) by transferring and laminating directly on plant leaves (Figure 3e).

In addition to the aforementioned electrical signals that reflect the variation of VOCs content, some more intuitive colorimetric detection methods can also be used. Li and coworkers fabricated a low‐cost and integrated smartphone‐based VOC fingerprinting platform for early and non‐invasive detection of gaseous (E)‐2‐hexenal at sub‐ppm level (one of the main VOC markers emitted from tomatoes that infected by Phytophthora infestans) by using a paper‐based colorimetric sensor array.[ 73 ] In this VOC‐sensor array, 5 kinds of cysteine‐functionalized Au nanomaterials were used as plasmonic aggregative colorants and five conventional organic dyes were used for specific detection of (E)‐2‐hexenal, where the process of “signals generation‐colour changes” could be quantified by smartphones within 20 min. It also helped to diagnose tomato late blight as early as 2 days, and the diagnostic accuracy of the leaf samples collected in the laboratory or from the field was more than 95%. Inspired by this study, future nanosensors should have early high‐precision detection capabilities, and can be integrated with wireless devices to transmit monitoring data to mobile devices in real time. Moreover, if they can realize in situ monitoring in a non‐destructive and biocompatible form, it will be more conducive to their application in plants.

2.1.3. Soil Conditions

Soil is the foundation of plant growth, providing a constant supply of nutrients for plant growth. Many important ecological processes in nature are carried out in the soil, such as the transformation of pollutants. The indicators for soil quality evaluation include water content, pH, organic matter content, pollutants content, etc. Among them, the detection of various pollutants is very important, because they not only inhibit plant growth and cause great loss of crop yield, but also increase the absorption of pollutants by crops, thereby contaminating the food chain. The general steps for determining the pollutant content in soil usually include field sampling, plant tissue digestion, extraction, sample purification, etc., and the methods used are mostly mass spectrometry, chromatography, electrochemical detection, etc.[ 74 , 75 , 76 , 77 ] The complicated and time‐consuming sampling process requires expensive instruments and professional operations. Moreover, the on‐site and real‐time monitoring cannot be achieved.

Based on the above considerations, a reliable technology is needed to achieve rapid, on‐site, and real‐time assessment of pollutants in the soil. In a study, researchers designed a new type of plant nanobionic sensor for selective monitoring the arsenic content in the soil.[ 78 ] Arsenic and its compounds are serious threats to humans and ecosystems. Here, living plants are used to interface with specially designed nanomaterials as self‐powered detectors. The authors designed SWCNTs‐based near infrared (NIR) fluorescent nanosensors, which are embedded in plant tissues with no harmful effects, providing a non‐destructive method to monitor the internal dynamics of plants absorbing arsenic from the soil. This plant nanobionic approach of integrating optical nanosensors inside living plants represents a great improvement compared with traditional methods. In the future, this new type of nanobionic sensor will play an important role in soil quality monitoring, and provide ideas for the research of other nanosensors for soil condition detection. The effective assessment of soil quality will be achieved by combining portable and inexpensive electronic equipment with living plants, which is a real‐time and on‐site method.

2.2. In Vivo Monitoring

Plants possess complex signaling pathways to perceive changes in the surrounding environment. And to cope with various environmental stresses, plants reprogram their cellular transcription mechanism and metabolic responses through these signaling pathways to enhance their endurance under different stresses.[ 52 , 79 ] The signaling molecules usually can be divided into intercellular and intracellular signaling molecules according to their scope of action, and they can spread throughout the plant within seconds to trigger systemic signaling mechanisms.[ 52 , 80 , 81 ] Revealing the dynamic changes of various signaling molecules under the external environment, which is a key step in understanding how plants coordinate the activities of many cells into a multicellular whole in a dynamic environment.

Generally, the use of microelectrode‐based nanosensors to realize in situ detection is considered as non‐destructive, and their fast response time make them highly powerful tools for studying the in vivo physiological changes of plants. For another type, the genetically encoded nanosensors, which have been developed from fluorescent proteins, are able to report the changes in intracellular molecular concentration, presence and activity of proteins, several key plant hormones, metabolites, and ion dynamics through the changes in fluorescence intensity, fluorescence resonance energy transfer (FRET), or bioluminescence resonance energy transfer.[ 4 , 82 , 83 ] Although their application may be limited to specific genetically modified species and are still in the early stage of research, this situation has been alleviated with the assistance of nanomaterials. As an alternative, optical nanosensors can be widely used in plants that are currently not suitable for genetic modification.[ 52 ] Nanomaterials like SWCNTs and quantum dots (QDs), with unique optical and electronic properties, have advantages in imaging plant signaling molecules in vivo. Various delivery methods for these optical nanosensors can be performed in laboratories, and in field experiments such as needleless syringe infusion through plant leaves, topical delivery, and vacuum infiltration.[ 4 ] These aforementioned in vivo nanosensors are powerful tools for monitoring changes of signaling molecules in plants, and their specific applications will be described in detail below.

2.2.1. Metal Ions

Metal ions such as calcium (Ca2+), potassium (K+), sodium (Na+), and magnesium (Mg2+) ions are important signaling molecules in plants. Different external stimuli can cause metal ions transient increases, waves, and oscillations, which reflects the physiological changes of plants.[ 81 ] Moreover, monitoring changes in the concentration of intracellular metal ion concentrations is also important for diagnosing plant nutritional status.[ 84 ] Therefore, it is necessary to conduct studies on the dynamic changes of metal ions in plants.

The most used technology for metal ions detecting in plants mainly rely on the construction of ion‐selective microelectrode.[ 85 , 86 , 87 ] This technology can realize the noninvasively measurement of metal ions fluxes in plant root elongation zone or suspension cell. However, the detection process is complex and requires high precision of operation. Therefore, it is necessary to develop a simple and fast method. For this, Janni et al. prepared an in vivo organic electrochemical transistor sensor based on poly(3,4‐ethylenedioxythiophene):poly(styrenesulfonate) functionalized textile thread, termed as bioristor, for measuring changes of different metal ions concentrations (Na+, K+, Ca2+, and Mg2+) in the sap of drought‐stressed tomato plants.[ 88 ] The device was integrated with the stem and realized the continuously monitoring of the plant's physiological status, showing that the concentration of metal ions gradually increases within 30 h without water supply. The device can be used as a useful tool for breeding drought‐resistant tomato cultivars. However, this device is directly inserted into the stem of the plant, so the stability and biocompatibility during long‐term use, and the interaction mechanism between the nanomaterials used and the plant system need to be further investigated. In addition, the data is still transmitted by wire, which is very inconvenient for the long‐term use, thus it also needs to be integrated with wireless devices in the future.

2.2.2. Reactive Oxygen Species

Reactive oxygen species (ROS) play a variety of signal transduction roles in different organisms, which mainly includes superoxide anion (O2−), hydrogen peroxide (H2O2), carboxyl radical (—OH), and nitric oxide (NO), etc. From the toxic byproducts of aerobic metabolism, ROS have become important roles in the complex signaling network of cells.[ 89 ] The release of ROS is a quite universal and fast defense mechanism in plants, which is known to be associated with various plant pathogen interactions or environmental stresses. ROS have also been acknowledged as important regulators of plant growth, having great influences in the process of transducing hormone signals and regulating the structure of cell wall polymers.[ 90 , 91 ] Therefore, it is important to study the production of ROS and their activities between compartments in the process of plant growth.

Various technologies have been used for monitoring changes of H2O2 in plant leaves, and the mostly commonly used is fluorescent probe. However, the traditional fluorescent probe technology is time‐consuming and needs to separate plant samples. Hence, before the emergence of better H2O2 fluorescence detection technologies in plants, electrochemical methods with the advantages of simplicity, low‐cost, and high sensitivity have been widely used in the study of plant biochemical processes. For example, Ren and coworkers utilized hemoglobin (Hb) and SWCNTs modified carbon fiber ultramicroelectrode (Hb/SWCNTs/CFUME) for electrochemically in vivo monitoring the changes of H2O2 level in aloe leaves under salt stress.[ 92 ] The Hb/SWCNTs/CFUME was inserted into the center of the leaf and realized the amperometric in vivo monitoring of H2O2 due to the catalytic effect of Hb on the reduction of H2O2. In another study, Lima et al. realized the in situ monitoring of H2O2 produced in A. tequilana leaves after inoculating with bacteria by using a platinum (Pt) disc microelectrode.[ 93 ] The electrochemical results revealed the relationship between the inoculated leaves and the production of H2O2. And our group also fabricated a high‐performance ROS electrochemical nanosensor (Figure 4a).[ 94 ] Ultrathin metallic molybdenum disulfide (MoS2) nanosheets were used to fabricate freestanding paper electrode, and noble metal alloy NPs (AuPt NPs) with excellent catalytic activity were spontaneously coated on the electrode. The flexible nanosensor exhibited great mechanical properties and excellent performance in H2O2 monitoring in plant extract of aloes with the advantages of convenient, prominent selectivity and stability, and wide linear range. These electrochemical nanosensors allow in situ monitoring with high selectivity and stability, eliminating tedious data processing. However, most of them are investigated in the laboratory, and the biocompatibility of these nanosensors has not been rigorously verified. Moreover, it is necessary to develop electrochemical nanosensors that can realize in situ monitoring on living plants in the future and can be integrated with wireless devices, achieving a highly integrated, miniaturized, and portable monitoring system.

Figure 4.

Nanosensors for in vivo plant growth monitoring. a) Schematic diagram of the spontaneous growth of AuPt NPs on flexible MoS2 paper and the application in the determination of H2O2. Reproduced with permission.[ 94 ] Copyright 2020, Elsevier Ltd. b) In vivo plant sensing set‐up where a leaf infiltrated with SWCNTs was excited by a 785 nm epifluorescence microscope (left). The 20‐fold magnification view of SWCNTs inside a leaf before and after the addition of 20 µL dissolved NO solution, where three SWCNTs regions were circled (right). Reproduced with permission.[ 98 ] Copyright 2014, Nature Publishing Group. c) Photo of the stainless steel microelectrode to monitor IAA in the stem of soybean. Reproduced with permission.[ 111 ] Copyright 2019, Elsevier Ltd. d) Schematic diagram of in vivo glucose sensing and standoff imaging by QD fluorescent probe through a Raspberry Pi camera. Reproduced with permission.[ 128 ] Copyright 2018, American Chemical Society.

Although electrochemical‐based detection methods are simple and have high sensitivity, in vivo optical nanosensors are more advantageous for non‐destructive and real‐time monitoring of specific molecules, especially when we need to fully understand the dynamic changes of specific physiological processes. Especially for SWCNTs‐based in vivo optical nanosensors, which have electronic structure characteristics from metals to semiconductors with a certain energy band gap, thereby electrons transition between these energy bands to realize light absorption and emission. And they usually fluoresce in the NIR region (800–1600 nm), where chloroplast autofluorescence is minimal. Moreover, SWCNTs can be chemically functionalized, making them high sensitivity and specificity to targets. Therefore, they have unique advantages in enabling the detection of analytes with high spatiotemporal resolution down to the single‐molecule level and millisecond timescale.[ 4 , 95 , 96 ] Giraldo et al. first delivered 6,5 ss(AT)15‐SWCNTs to chloroplasts of Arabidopsis thaliana leaves by infiltrating through the leaf lamina, realizing the in vivo detection of NO, which is a key signaling molecule within chloroplasts (Figure 4b).[ 97 , 98 ] Results showed that when there was dissolved NO in vivo, the SWCNTs chiralities with emission peaks above 1100 nm exhibited a strong quenching in NIR fluorescence, exhibiting a multi‐chirality property. Therefore, the group referred to the leaves embedded with SWCNTs as nanobionic leaves, which imparted the plant leaves with novel sensing capabilities to realize biochemical detection of endogenous signaling molecules and exogenous environmental compounds. This study brought new research fields for the combination of nanotechnology and plant biology, and this, in vivo optical nanosensors can also be extended to detect other plant signaling molecules and exogenous compounds.

However, for the fluorescence responses of multi‐chirality SWCNTs with multiple NIR emission peaks, the signals observed by optical nanosensors were usually limited, and the detection accuracy may be reduced in the presence of other interfering substances.[ 98 , 99 , 100 ] Moreover, when a nanosensor is embedded into a biological sample that is complex and constantly changing, it is often difficult for them to show high selectivity in the presence of abundant interfering molecules. To solve this problem, the same group developed the ratiometric fluorescent nanosensors for in vivo sensing of H2O2 and NO in plant tissues.[ 101 ] For the H2O2 detection, the 7,6 ss(GT)15‐SWCNTs (emission = 1131 nm) were quenched in the presence of H2O2 and the 6,5 ss(AT)15‐SWCNTs (emission = 984 nm) were invariant to H2O2. For the NO detection, 7,6 ss(GT)15‐SWCNTs (emission = 1135 nm) were quenched in the presence of NO and the 6,5 polyvinyl alcohol‐SWCNTs (6,5 PVA‐SWCNTs) (emission = 1004 nm) were invariant to NO. Results showed that, in each case, there was a pair of SWCNTs fluorescence emitters, where only one responded to the target analyte and the other served as a reference signal. Such ratiometric fluorescent nanosensors has high selectivity for the target to be detected, which has advantages for specific detection in complex biological samples.

As the generation and accumulation of ROS like H2O2 is a sign of plant responses to stress, which often includes high light, high temperature, salinity, wounding, and pathogen infection.[ 89 , 102 , 103 ] Therefore, the group further how the ROS fluctuates when plants are under environmental stresses. They utilized the SWCNTs‐based ratiometric fluorescent nanosensors to continuously monitor the H2O2 signaling waveform induced by wounding in different plant cultivars and genetic variants.[ 104 ] Results showed that the H2O2 wave follows a logistic waveform, and the H2O2, electrical, and Ca2+ signaling pathways interacted to regulate the defense response of plants after wounding. In another study, Wu el al. developed a H2O2 fluorescent nanosensor based on SWCNTs functionalized with a deoxyribonucleic acid (DNA) aptamer that bound to hemin (HeAptDNA‐SWCNTs), allowing the remote in vivo monitoring of H2O2 within the plant physiological range (10–100 µM).[ 105 ] Results showed that this nanosensor could realize the real‐time monitoring of several stresses, for example, UV‐B light, high light, and pathogen‐related peptide through the change of H2O2.

These aforementioned in vivo optical nanosensors provide real‐time, efficient, and highly selective detection results. With the deepening of future researches, these nanosensors should be applied to various plant species rather than limited to model plants such as A. thaliana. And these nanosensors are still unable to measure the content changes of multiple substances at the same time, except for the most common H2O2 and NO. To detect the content of multiple substances, there needs to be certain differences between the fluorescence wavelengths of the nanomaterials. The nanomaterials currently used are still limited to SWCNTs, thereby the simultaneous detection of multiple substances is a challenge. Moreover, when nanomaterials like SWCNTs are used for optical sensing in plants, whether they have long‐term stability and whether they may pose threats to plants still need to be further investigated. Only by thoroughly studying the interaction mechanism between them and plants can the in vivo optical detection technology develop better. Last but not least, the current detection process for these optical nanosensors is done in a dark room. In field trials, sunlight will interfere with the fluorescence of the nanosensors, making them only suitable for researches in the laboratory.

2.2.3. Plant Hormones

Plants have various hormones including auxins, gibberellins, abscisic acid, cytokinins, salicylic acid, ethylene, and peptide hormones, etc. They are small organic molecules or active substances, which are induced by plant cells upon receiving specific environmental signals and can regulate plant physiological responses at very low concentrations. Thus, they play important roles in the process of plants adapting to various environmental stresses.[ 61 ] Various technologies has been used for detecting plant hormones, such as high‐performance liquid chromatography,[ 106 ] gas chromatography‐mass spectrometry,[ 107 ] fluorescence spectrometry,[ 108 ] and capillary electrophoresis (CE),[ 109 ] etc. But they can only be used in vitro, where plant samples need to undergo complex pretreatment and the procedure is time‐consuming. For in vivo detection, Hu et al. utilized Pt nanoflowers/reduced graphene oxide (rGO) modified Pt microelectrode to detect salicylic acid in plants.[ 110 ] The authors punched the stem of sunflower seedlings with a puncture needle for the insertion of microelectrodes, thereby realizing the highly sensitive and selective detection of salicylic acid in plants under different salt stresses, where the limit of detection (LOD) is 48.11 pM. Similar to this method, Li and coworkers prepared highly ordered nanopores on the surface of a stainless steel microelectrode.[ 111 ] They further utilized popcorn‐like Au nanostructures, Pt NPs and rGO nanocomposite films, and polymerized safranine T film to modify the electrode for the in vivo detection of indole‐3‐acetic acid (IAA) (Figure 4c). The microsensor realized the detection of IAA of soybean seedling stems under salt stress with high selectivity and sensitivity, and the LOD was as low as 43 pg L−1. These electrochemical nanosensors are measured by directly inserting microelectrodes into plants, the long‐term stability and biocompatibility have not been thoroughly investigated. Moreover, the whole detection process is conducted on the electrochemical workstation, and no field trial is carried out. Therefore, further investigations are needed to make these nanosensors work stably and resist the interference of environmental changes.

Optical nanosensors can also be used to detect plant hormones in vivo. QDs are promising nanomaterials with unique properties of bright fluorescence, broad excitation spectrum, tunable emissions, and good photostability, which have been widely used in biolabeling and bioimaging.[ 112 , 113 , 114 ] And the conjugation of QDs with specific ligands such as aptamers helps to realize the specific imaging of target molecules. Based on this, Liu and coworkers developed a fluorescent aptasensor by using aptamer‐functionalized QDs (zinc ion (Zn2+) doped cadmium telluride) for the in vivo determination of tomato systemin (TomSys), which is a kind of peptide hormones in plants.[ 115 ] Results showed that in the absence of TomSys, the fluorescence was quenched due to the absorption of aptamer‐functionalized QDs on the surface of GO nanosheets via the noncovalent interactions. While in the presence of TomSys, the fluorescence of QDs recovered due to the release of the aptamer‐functionalized QDs from the GO surface, and the aptamer was bound to TomSys. In addition, metal‐based fluorescent nanosensors have also been extensively developed for monitoring signaling molecules.[ 116 ] Chen et al. developed a curcumin‐Cu ion (Cu2+)‐based fluorescent nanosensor for selectively and sensitively in vivo detecting of salicylic acid.[ 117 ] Results showed that Cu2+ was first selected to bind the β‐diketone part of curcumin, resulting in the fluorescent “turn‐off” of curcumin due to the paramagnetic nature of Cu2+. Then, after the salicylic acid was introduced, the fluorescence “turn‐on” pattern was observed with high selectivity due to the affinity of salicylic acid toward Cu2+. Compared with the aforementioned electrochemical nanosensors, these fluorescence nanosensors exhibit higher selectivity and sensitivity, and the detection process can be observed more intuitively through the complex changes of fluorescence signal. However, as common problems of optical sensors mentioned above, their long‐term stability and biocompatibility in plants still need to be thoroughly investigated.

2.2.4. Other Important Molecules

In addition to the aforementioned several important signaling molecules, the dynamic changes of other molecules in plants also play important roles in assessing stresses and determining the process of plant growth and development.[ 118 ] These dynamic processes help to understand how plants perceive dynamic environmental changes and coordinate the activities of individual cells. Recently, there are increasing researchers have paid attention to exploring the metabolic process of plants, and conducting in‐depth researches on the real‐time monitoring of various metabolites of plants including adenosine triphosphate (ATP), lipid phosphatidic acid (PA), nicotinamide adenine dinucleotide phosphate (NADPH), and nicotinamide adenine dinucleotide (NADH) by using genetically encoded nanosensors.

Among them, ATP is an important product of photosynthesis and is used in the anabolism of chloroplasts, and the matching of the ATP:NADPH production and consumption in the chloroplast is a prerequisite for effective photosynthesis. Studies have demonstrated that chloroplasts can take up ATP from the cytoplasm at night to meet metabolic needs, while during the day or under stresses, chloroplasts can also export ATP to the cytoplasm.[ 119 ] Therefore, it is important to figure out the dynamic changes of the in vivo ATP in these two compartments for better plant growth. Voon et al. utilized a MgATP2−‐specific FRET‐based genetically encoded nanosensor for the measurement of intracellular compartmentation of ATP in living plants.[ 120 ] ATP is usually complexed as MgATP2− in leaves. After imaging the expression of the fluorescent ATP protein in A. thaliana seedlings, the authors revealed that the concentration of MgATP2− was higher in the cytosol than in the stroma of mature chloroplasts, which was because only immature chloroplasts needed to absorb cytoplasmic ATP for biosynthesis in the early stages of development. When the chloroplast is fully developed and able to maintain itself, it is necessary to down‐regulate the expression of ATP nucleotide transporter.

PA is an important raw material for the formation of glycerol‐phospholipids and triacylglycerol, and it acts as a significant signaling molecule that participates in regulating various fundamental plant cellular functions, especially in regulating the stomatal movement and drought or salt stress responses.[ 121 , 122 , 123 ] Therefore, Li et al. developed a genetically encoded nanosensor based on FRET (PAleon) for the monitoring of the dynamics of PA at the plasma membrane.[ 124 ] PAleon is a PA probe, which is sensitive to monitor the dynamic changes of PA in tissues when plants under abscisic acid or salt stresses. Results showed that, under the abscisic acid or salt stresses, PAleon reported a rapidly induced accumulation of PA in root tissues and guard cells without affecting the endogenous signaling system and the normal growth of plants.

NADPH and NADH are crucial energy molecules in living systems and NADH/NAD+ are a ubiquitous cellular redox couple, which are all closely related to the metabolic activities of plants. Most researches have conducted in vitro measurements by extracting these metabolites from tissues, which is time‐consuming and cannot realize the real‐time measurement of the instantaneous levels of these metabolites in different subcellular compartments. Therefore, Lim et al. developed two kinds of genetically encoded nanosensors (iNAP and SoNar) based on circularly permuted yellow fluorescent protein (YFP), realizing the dynamic monitoring of NADPH levels in NADPH pool and the NADH/NAD+ ratio in A. thaliana under light condition.[ 125 ] Results showed that in the process of photorespiration, large amounts of NADH were produced in mitochondrias under the action of glycine decarboxylase and further oxidized in peroxisomes under the action of hydroxypyruvate reductase concurrently, where the changes of NADH/NAD+ ratio in the cytosolic reflected this phenomenon. These findings confirmed the complex interactions between chloroplasts and mitochondria during photosynthesis, helping to improve the efficiency of plant photosynthesis in the future. In another study, Steinbeck and coworkers studied the subcellular redox dynamics of NADH in Arabidopsis tissues based on the genetically encoded nanosensor by using a cyan fluorescent protein and a red fluorescent protein.[ 126 ] It monitored changes in NADH/NAD+ in vivo, real‐time reflecting the effects of environmental changes (e.g., light, temperature, drought, and pest infestation) on plant metabolism. This study generated the first living Arabidopsis cytosol NADH redox atlas and observed the redox dynamics through the dark‐light transitions, respiratory inhibition, and changes of sugar supplement.

For other key plant signaling molecules like glucose, some studies have demonstrated the great potential of boric acid (BA)‐based fluorescent probes for glucose sensing, and the principle lies in the fluorescent quenching upon glucose binding to BA‐conjugated QDs.[ 127 ] Li et al. prepared ratiometric fluorescent nanosensors by using BA‐conjugated QDs (BA‐QDs) and thioglycolic acid (TGA)‐coated QDs (TGA‐QDs) to realize the in vivo glucose sensing from single chloroplast to Chara zeylanica cells and A. thaliana leaf tissues (Figure 4d).[ 128 ] In the presence of glucose, the Raspberry Pi camera system was used to image and record the visible fluorescence signal of BA‐QDs and TGA‐QDs. Results showed that the BA‐QDs fluorescence was quenched when the concentration of glucose exceeded 100 µM, while the fluorescence of TGA‐QDs remained invariant.

These genetically encoded nanosensors enable real‐time monitoring of transient, easily degradable, and low‐content metabolites, which is helpful for people to understand the dynamic changes of plant metabolic processes. But like the afore‐mentioned optical nanosensors, there are still some problems to be solved. First, the protein used should react with the specific substrate. And the gene must be able to be stably and correctly transcribed and translated in the organism without being degraded by the organism. This process is very time‐consuming and complex. Second, these sensors are difficult to apply to various plant species because of the greater differences between different species. Third, they are also difficult to measure multiple substances at the same time and their safety in plants needs to be further investigated. Finally, these sensors also need to carry out field trials.

3. Nanofertilizers for Plant Growth

Fertilizers are key to food production and still need to be used on a large scale because of the increasing food demand. Usually, plants absorb the applied nutrients inefficiently, leading to a sharp increase on farmers' costs. Nanotechnology has opened up many novel applications in the field of plant nutrition to promote plant growth, meeting the growing demand of food in the future. Its purpose is to increase the utilization efficiency of current fertilizers, either by increasing the efficiency of nutrients delivery to plants or by limiting the loss of nutrients in the environment.[ 129 ] As shown in Figure 5 , nanofertilizers can be introduced into plants via foliar or root application. And they are engineered to be target oriented, thus improving nutrients utilization efficiency, decreasing the fixation of nutrients, and reducing nutrients loss.[ 130 ] In general, depending on the role of the nanomaterials and the nutrients in use, we divide the nanofertilizers into four different categories: 1) Macronutrient nanofertilizers, 2) micronutrient nanofertilizers, 3) nanomaterials‐loaded nanofertilizers, and 4) other nanofertilizers. The first two categories of nanomaterials act as nutrients themselves for efficient uptake by plants. The third category of nanomaterials do not contain any essential plant nutrients, they often used as nanocarriers to slow release nutrients. And the last category of nanomaterials are not nutritionally required by plants, but they have been demonstrated to have positive impacts on plant growth and production.[ 130 ]

Figure 5.

Nanofertilizers for plant growth.

3.1. Macronutrient Nanofertilizers

Macronutrient nanofertilizers are composed of one or more macronutrient elements (e.g., (nitrogen) N, phosphorus (P), K, Ca, and sulfur (S)) to provide large amounts of nutrients required by plants. Global demand for macronutrient is estimated to reach 263 Mt by 2050.[ 131 ] Especially for N fertilizer, it has increased per capita food production by about 40% in the past 50 years.[ 132 ] However, these fertilizers (N, P, and K) are eventually transported into the surface and groundwater in large quantities, causing serious damages to the aquatic ecosystems.[ 129 ] Therefore, it is necessary to develop high‐efficient and eco‐friendly macronutrient nanofertilizers realize sustainable food production on the basis of protecting the ecological environment.

N, P, and K are three major nutrients for plant growth and development. Among them, N is needed by the soil in the forms of solid or liquid including anhydrous ammonia, urea, ammonium, and nitrate.[ 133 ] Different kinds of N, P, and K nanofertilizers, the fertilization method, and their growth enhancements have been listed in Table 1 , including N‐doped carbon dots, apatite nanoparticles (NPs), and monopotassium‐phosphate.[ 23 , 134 , 135 ] The diameter of these nanofertilizers are very small (<20 nm), and they have good solubility in water. They are mixed with nutrient solution or water and applied to foliar or soil, which have greatly promoted the growth rate of plants. Moreover, composite nanofertilizers which can provide different nutrients (e.g., the monopotassium‐phosphate that can provide N, P, and K nutrients) alleviate the adverse effects of abiotic stress (e.g., salt stress) on plants.

Table 1.

Currently reported macronutrient nanofertilizers

| Nanomaterial | Comparison | Plant | Concentration | Fertilization method | Growth enhancements | Ref. |

|---|---|---|---|---|---|---|

| N‐CDs | Pure water and urea | Mung bean | 0.2 mg L−1 | Nutrient solution | The growth rate of mung bean improved by 200% (average length of shoots and roots). | [134] |

| Apatite NPs | Ca(H2PO4)2 | Soybean | 21.8 mg L−1 | Soil | The growth rate and seed yield increased by 32.6% and 20.4%, and the biomass production was enhanced by 18.2% for the above‐ground and 41.2% for the below‐ground. | [135] |

| MKP | Nothing treated | Tomato | 3 g L−1 | Foliar and soil | The growth parameters of tomatoes under salt stress were improved. | [23] |

| CaO NPs | Bulk CaO and CaNO3 | Groundnut | 500 mg L−1 | Foliar | The germination and growth rate of groundnut increased. | [24] |

| S NPs | Nothing treated | Cucurbita pepo | 100–400 mg L−1 | Soil | The number of leaves and branches, height per plant, stem diameter, and healthy plant increased. | [136] |

| S NPs | Nothing treated | Tomato | 300 mg L−1 | Soil | The root and shoot growth rate increased and the effect was concentration dependent. | [137] |

Except for the above three major nutrients, Ca and S are also important macronutrients. Calcium oxide (CaO) NPs and S NPs have been utilized to mix with water and further applied to foliar and soil.[ 24 , 136 , 137 ] However, these nanofertilizers have large and uneven diameters (20–80 nm), and they are used in relatively large quantities compared to the N, P, and K nanofurtilizers (Table 1). Nevertheless, it should be noted that, although these different nanofertilizers only consist of some nontoxic elements (i.e., C, O, N, K, P, Ca, and S), more thorough investigations are still needed to ensure their safety for large‐scale and long‐trem agricultural applications.

3.2. Micronutrient Nanofertilizers

Compared to macronutrients, micronutrients provide plants with relatively small amounts of essential nutrients (<10 mg kg−1 of soil).[ 130 ] They are key elements to activate enzymes and the synthesize biomolecules involved in plant defense. Moreover, eating micronutrient‐deficient foods have adverse health effects on human health, leading to anemia, slower growth, and decreased cognitive.[ 133 ] Therefore, as well as, macronutrient nanofertilizers, it is also necessary to apply micronutrient nanofertilizers to plants, including Zn, Cu, Iron (Fe), manganese (Mn), and molybdenum (Mo).

Zn, as an essential micronutrient, is required for plants, animals, and humans. Two studies used zinc oxide (ZnO) NPs as nanofertilizers, which were purchased from different companies.[ 25 , 138 ] Their particle sizes are about 50 and 70 nm, respectively. The dissolution of these ZnO NPs in water is relatively slow. But the diameter of these ZnO NPs or their aggregates still smaller than the stomatal pore size, exhibiting the ability to penetrate and move inside plant tissues. After the NPs were attached to leaf surfaces, Zn2+ might be continuously released, providing a long‐term source of Zn that can be absorbed by plants through stomatal openings. Therefore, the application of ZnO NPs improved the growth and yield of different plants.

Fe is an important nutrient involved in chlorophyll biosynthesis and electron transfer system, and Fe deficiency can affect the normal physiological function of plants and reduce the nutritional quality.[ 139 ] Palmqvist and colleagues synthesized the maghemite (γ‐Fe2O3) NPs to serve as nanofertilizers.[ 140 ] Results showed that the drought resistance of the plants was greatly enhanced. Furthermore, the H2O2 was reduced, the growth rate of leaves and the chlorophyll content were increased. Although, the dissolution of γ‐Fe2O3 NPs is slow and the NPs form aggregates, with a hydrodynamic size of up to 500 nm. This is also conducive to the long‐term sustained absorption of iron ions (Fe3+) by plants. In another study, Liu and coworkers utilized nanoscale zero‐valent iron (nZVI) to realize soil remediation simultaneously with increasing rice production.[ 141 ] They found that nZVI with bigger size (100 nm) and lower coercivity (35.17 Oe) could greatly improve grain yield and the removal rate of pollutants in the soil. The other nZVI with smaller size and higher coercivity exhibited greater homoaggregation in soil, which have negative impacts on their performance.

Cu is another essential micronutrient for plants and microbial growth. Different Cu‐based NPs, including CuO, copper sulphide (CuS), and copper hydroxide (Cu(OH)2)) have been applied to root and foliar of different plants (Table 2 ).[ 26 , 142 ] Among them the spindle‐shaped Cu(OH)2) NPs exhibit higher dispersibility than spherical CuO and CuS NPs, thereby providing more uptake of Cu to plants. However, the CuO and CuS NPs with lower dispersibility are more persistent on the roots and continued to transport Cu to plant leaves during the application. Mn is also an important micronutrient for plants and is mainly involved in photosynthesis. The hydrodynamic radius of stable square shaped Mn NPs is about 100 nm, which can be stably dispersed in water, and the size of the dispersed particles remains within the nanoscale range. This Mn NPs‐based nanofertilizers are nontoxic even at a higher concentration, and their smaller size help plants to uptake these particles more readily.[ 143 ]

Table 2.

Currently reported micronutrient nanofertilizers

| Nanomaterial | Comparison with | Plant | Concentration | Fertilization method | Growth enhancements | Ref. |

|---|---|---|---|---|---|---|

| ZnO NPs | Nothing treated |

Rice (PR‐121) |

5 g L−1 | Foliar | The growth, yield, yield‐attributing characters, microbial counts, and the dehydrogenase enzyme activity improved. | [25] |

| ZnO NPs | ZnSO4 and untreated group | Coffee (Coffea arabica L.) | 10 mg L−1 | Foliar | The fresh weight (roots: 37%, leaves: 95%), dry weight (roots: 28%, leaves: 85%), and the net photosynthetic rate (55%) increased. | [138] |

| γ‐Fe2O3 NPs | FeCl3 | Brassica napus | 2 mg mL−1 | Soil | The H2O2 content reduced to 83 µM g−1, the malondialdehyde formation reduced to 26 mm g−1, growth rate of leaves enhanced to 50%, and chlorophyll content increased to 52. | [140] |

| nZVI | mZVI and Fe2+ | Rice | 100 mg kg−1 | Soil | The grain yield increased (47.1–55.0%), the grain PCP content decreased (83.6–86.2%), and the soil PCP removal rate increased (49.9–89.0%) after the addition of three different nZVI. | [141] |

|

Cu‐based NPs (CuO, CuS, and Cu(OH)2) |

Nothing treated |

Wheat (Triticum aestivum) |

1 mg mL−1 | Root | High‐solubility Cu(OH)2 NPs provided more uptake of Cu, while low‐solubility materials (CuO and CuS) were more persistent on the roots and continued to transport Cu to plant leaves during the 48 h depuration period. | [142] |

| CuO NPs | Nothing treated |

Maize (Zea mays L.) |

8 mg L−1 | Foliar | The plant growth grate improved by 51%. | [26] |

| Mn NPs | MnSO4 |

Mung bean (Vigna radiata) |

0.05 mg L−1 | Foliar | The root and shoot length increased by 52% and 38%, respectively, and the fresh and dry weight enhanced. | [143] |

| Mo NPs | Water treated |

Chickpea (Cicer arietinum L.) |

8 mg L−1 | Seed | The microbial activity and seed growth improved. | [296] |

3.3. Nanomaterials‐Loaded Nanofertilizers

Nanomaterials‐loaded nanofertilizers can promote plant growth to some degree, although these nanomaterials cannot be well absorbed by plants. They are used as nanocarriers for sustained delivery of nutrients, thereby increasing plant uptake efficiency of the nutrients and reducing the adverse effects of traditional fertilizers. Typical examples of this type are chitosan NPs and nano‐zeolite.

Relative to bulk chitosan, chitosan NPs combine the characteristics of chitosan and the properties of NPs like surface and interface effect, excellent physicochemical properties, highly soluble in aqueous media, and environmentally friendly, as well as, bioactive.[ 130 , 144 , 145 , 146 , 147 ] Therefore, chitosan NPs are often used as nanocarriers for loading NPK to realize the slow release of NPK fertilizers. According to literature reports, chitosan molecules in the solution are in the form of cationic polyelectrolytes, which are easy to form specific nanostructures through the electrostatic interaction with methacrylic acid (MAA).[ 148 ] Therefore, most of the chitosan NPs used as nanocarriers are formed by the polymerization of MAA in the chitosan solution (i.e., CS‐PMMA NPs).[ 148 , 149 ] For example, Abdelaziz et al. investigated the effects of CS‐PMMA NPs loaded with NPK fertilizers on the wheat grains through foliar application.[ 145 ] They found the total saccharide, K, and P contents in the wheat grains were significantly increased when compared with common fertilizers. Khailfa and colleagues used the same nanomaterial to load NPK fertilizers and evaluate their effect on garden pea plants (Pisum sativum var. Master B).[ 150 ] They found that compared with other groups, the prepared nanofertilizer could induce mitosis, and the expression of some major proteins in plants was also upregulated. The average diameter of the CS‐PMMA NPs are about 23 nm. After loading NPK, the dispersion of NPs is homogenous without any agglomeration, and it has good stability at different pH gradients. Although the slow release of NPK fertilizers with the help of chitosan NPs has been achieved, the potential impact of such systems on agriculture remains to be further explored, as their accumulation in the field may have negative effects on plants and the environment.

In general, silicon (Si) and aluminum (Al) are arranged in the 3D framework of silicon oxygen tetrahedron and aluminum oxygen tetrahedron of zeolites, respectively, forming channels and voids at nanometer scale (0.3–10 nm diameter).[ 129 ] Therefore, zeolite is a kind of material with nanostructures. Studies have shown that nano‐zeolite, as a nanocarrier of common fertilizers, can increase plant yields and reduce the use of fertilizers.[ 151 ] The nano‐zeolite is typical cubic to round in shape with the size of 90–100 nm. After loading with Fe2O3 and ZnSO4 NPs, the nano‐zeolite help to increase plant yield by slow and long‐term releasing of Fe3+ and Zn2+, greatly increasing the use efficiency of Fe and Zn.[ 152 , 153 ]

3.4. Other Nanofertilizers

In addition to the three types of nanofertilizers mentioned above, some nanomaterials that are not classified as plant nutrients also have positive impacts on plants. Although these nanomaterials themselves are not nutrient elements that required by plants, they still can promote plant growth and development. This group of nanomaterials include titanium dioxide NPs (TiO2 NPs), CNTs, and ceric dioxide NPs (CeO2 NPs).

Ti is generally not considered as an essential plant nutrient. However, some studies indicated that TiO2 NPs could improve the growth of plants by enhancing photosynthesis.[ 154 ] One study synthesized TiO2 NPs (12–15 nm) evaluated its effect on mung bean growth.[ 155 ] After the foliar application, significantly improvements were observed in shoot and root length, chlorophyll content, and total soluble leaf protein. The TiO2 NPs may adsorb to plant leaf surfaces and taken up through stomatal openings. After being absorbed by plants, the TiO2 NPs may increase the activity of phytase and phosphatase enzyme, thereby helping in native phosphorous nutrient mobilization in rhizosphere and enhancing plant metabolic activities.

Some studies have shown that CNTs have the ability to penetrate the cell walls and membranes of plants.[ 156 ] Usually at low doses, CNTs can stimulate seed germination and plant growth. Joshi et al. assessed the effects of multi‐walled carbon nanotube (MWCNT, diameter of 35 nm and lengths of 200–300 nm) on the growth and yield of oat.[ 157 ] They found that through the seed‐priming method, these MWCNT traversed the cells and enhanced the growth rate of xylem cells, chlorophyll content, and photosynthetic activity. Moreover, the MWCNT has no toxic effects on the DNA of the plants, which makes a lot of sense for its application.

Besides TiO2 NPs and CNTs, there are also many studies about the influence of CeO2 NPs on plants. The CeO2 NPs with a primary size of about 8 nm and will aggregate to about 240 nm in water. After applying to the roots or leaves of plants, they help to increase growth rate and yield.[ 158 ] Moreover, they also have better performances in inhibiting Fusarium wilt and increasing chlorophyll content in plants.[ 158 ] However, more investigations need to be conducted to examine the long‐trem effect of Ce on plant quality.

For all nanomaterials that used to enhance plant growth, the mechanism of their interaction with plants needs to be thoroughly investigated, otherwise their long‐term accumulation in plants could pose threats to animal and human health. Future researches also need to further explore the influence of size, shape, charge, and solubility of nanomaterials on their performances and plants.

4. Nanopesticides for Plant Protection

Effective pest management is necessary for agricultural production. However, it is estimated that about 90% of the applied chemical pesticides are lost during or after application due to volatilization, degradation, and photolysis, which have serious effects on food chain and human health.[ 159 , 160 ] In addition, the widespread use of pesticides has led to increased pesticide‐resistance in weeds, insects, and pathogens. Therefore, the use of pesticides should be controlled in an efficient and eco‐friendly way, and can be effectively delivered to specific sites.[ 161 ] Since nanotechnology has been proven in large amounts of experiments to improve plant growth and increase nutrient utilization efficiency, their potential in protecting plants from pests, pathogens, weeds, etc., is also gaining increasingly interests.[ 162 , 163 ] Nanopesticides, which can be defined as any pesticide formulations that contain nanomaterials with biocidal properties, have been widely studied (Figure 6 ). In general, nanomaterials itself can be directly used as pesticides, and they also can be used to protect the pesticides and enhance their delivery to the site of action. Therefore, in this section, we divide the nanopesticides into two categories: 1) Nanomaterials directly used as nanopesticideds and 2) nanomaterials used as nanocarriers for pesticides.

Figure 6.

Nanopesticides for plant protection.

4.1. Nanomaterials Directly Used as Nanopesticides

The broad spectrum of antifungal/antibacterial properties of nanomaterials allow them to be directly applied to plant seeds, leaves, and roots to against pest and pathogens. They also solve the problem of the increases in microbial resistance after the application of traditional chemical pesticides for a period of time. Among them, metal‐based NPs such as Ag, Cu, Mg, Zn, and Ti, have been extensively investigated. Besides, S and Si NPs also exhibit antimicrobial activities with low toxicity to animals and humans. In this section, a brief overview about the NPs with biocidal properties is given (also Table 3 ).

Table 3.

Currently reported nanopesticides

| Nanomaterial | Comparison with | Plant | Concentration | Application type | Targets | Growth enhancements | Ref. |

|---|---|---|---|---|---|---|---|

| Ag NPs | Nothing treated | Bermudagrass | 150 mg L−1 | Soil | Nematode | The number of nematodes reduced by 82% and 92% after 4‐ and 2‐day, respectively. | [164] |

| Ag@dsDNA@GO | Nothing treated and treated with copper (Kocide 3000) and mancozeb (Penncozeb 75DF) | Tomato | 100 mg L−1 | Soil | Xanthomonas perforans | The severity of bacterial spot disease reduced with no phytotoxicity. | [167] |

| GO‐Ag NPs nanocomposite | Pure Ag NPs and GO suspension | Wheat | 9.37 µg mL−1 | Foliar | Fusarium graminearum | The inhibition efficiency of Fusarium graminearum was threefold and sevenfold higher than pure Ag NPs (12.45 µg mL−1) and GO suspension (250 µg mL−1). | [166] |

| Ag NPs | Nothing treated | Rice | 100 mg L−1 | Foliar | Xoo | The bacterial leaf blight of rice caused by Xoo reduced and the plant biomass increased. | [165] |

| Cu3(PO4)2·3H2O nanosheets | Commercial CuO NPs | Watermelon | 10 mg mL−1 | Foliar | F. oxysporum f. sp. niveum | The Cu3(PO4)2·3H2O at a lower concentration significantly suppressed fungal disease compared with control groups. | .[ 173] |

| rGO‐CuO | Chemical fungicide (Kocide 2000) and water | Tomato and pepper | 1 mg L−1 | Seed | F. oxysporum | The rGO‐CuO NPs treated plants exhibited beneficial effects on flowering, plant height, dry weight, and the accumulation of photosynthetic pigments. | [172] |

| CuO NPs | Nothing treated | Bt‐transgenic cotton | 10 mg L−1 | Nutrient solution | Bollworm | The Bt toxin protein in the leaves and roots enhanced and the pest resistance of transgenic insecticide crops improved. | [169] |

| MgO NPs | Distilled water | Tomato | 0.7% suspension | Root | Ralstonia solanacearum | The treated tomatoes showed great inhibition of bacterial wilt. | [174] |

| Mg(OH)2 NPs | Commercial pesticide (Kocide 3000) and distilled water | Tomato | 1000 µg mL−1 | Foliar | X. alfalfae, P. syringae, and E. coli | Mg(OH)2 NPs exhibited comparable bacterial killing efficacy and reduced phytotoxicity on tomato leaves and seeds. | [175] |

| ZnO NPs | Acibenzolar‐S‐methyl, streptomycin sulfate, and nothing treated | Sweet orang | 4.14 mg per plant | Foliar | Xanthomonas citri subsp. citri | The citrus canker lesion development (38% in trials 1 and 42% in trials 2) of sweet orange that inoculated with Xanthomonas citri subsp. Citri reduced. | [176] |

| TiO2 NPs, TiO2/Zn NPs, and TiO2/Ag NPs | Nothing treated and Cu/mancozeb‐treated | Tomato | 500–800 mg L−1 | Foliar | Xanthomonas perforan | The bacterial spot disease severity of tomatoes reduced. | [177] |

| S NPs | Nothing treated | Tomato | 0.704 mg mL−1 | Foliar | Fusarium solani and Venturia inaequalis | The smaller S NPs (≈35 nm) obtained higher growth inhibition toward Fusarium solani and Venturia inaequalis. | [181] |

| S NPs | Cu NPs and chitosan NPs | Ginger | 100 µg mL−1 | Rhizome | F. oxysporum | The S NPs could be used for effective management of F. oxysporum that causes soft‐rot of gingers. | [182] |

Silver NPs (Ag NPs) is a broad‐spectrum antimicrobial agent that can affect plant pathogenic bacteria and fungi. Chemical reduction is the most commonly used method for preparing Ag NPs, which is obtained by reducing silver nitrate (AgNO3) with different reducing agents. Cromwell et al. prepared Ag NPs via the redox reaction between silver nitrate (AgNO3) and sodium borohydride, which could be used as a nematicide.[ 164 ] Besides, the green synthesis method of Ag NPs has been increasingly advocated recently, and most of them use plant or bacterial extracts to reduce AgNO3. One study has confirmed the antibacterial activity of green Ag NPs against Xanthomonas oryzae pv., oryzae (Xoo), which is the most destructive pathogen of rice.[ 165 ] The two studies demonstrate that Ag NPs can increase the activity of antioxidant enzymes of plants to activate the antioxidant system, thereby reducing the ROS caused by biotic or abiotic stresses. However, the aggregation and settling of pure Ag NPs may occur due to its strong adhesion forces between particles with high surface energy, leading to the decrease of antimicrobial activity. Thus, some measures need to be taken to stabilize Ag NPs or control the slow‐release of Ag ions. GO sheet with special surface properties, large surface area, and high water solubility, which can solve the above problems well by acting as dispersion and surfactant‐like agents.[ 166 ] This GO‐Ag NPs nanocomposite was prepared through interfacial electrostatic self‐assembly, where the Ag NPs were homogeneously attached to the surface of GO sheets and the solution of GO‐Ag NPs nanocomposite was still well distributed at a higher concentration. Due to the synergistic effect between GO and Ag NPs, they exhibited good antibacterial activity, where the inhibition efficiency against Fusarium graminearum was threefold higher than pure Ag NPs. In another, dsDNA was used as a stabilizer for further enhancing the synergistic effect and the water solubility of the nanocomposite.[ 167 ] Here, the dsDNA is beneficial to control the size and distribution of Ag NPs on the surface of GO, and avoid the aggregation of NPs at the same time. This Ag@dsDNA@GO‐based nanopesticides exhibited better inhibition efficiency against Xanthomonas perforans than pure Ag NPs and GO‐Ag NPs nanocomposite. Although these Ag NPs‐based nanopesticides exhibit no phytotoxicity, their long‐term efficacy in the field still needs to be further investigated. Whether their continuous accumulation in the field will threaten human health through the enrichment of the food chain is still unclear.

Besides Ag NPs, the antibacterial and antifungal properties of Cu ions are also outstanding.[ 168 , 169 ] Compared with bulk Cu, CuO NPs exhibit better catalytic activity and inhibition of microorganism.[ 170 ] Van et al. studied the effects of CuO NPs (30 ± 10 nm) on Bacillus thuringiensis‐transgenic (Bt‐transgenic) cotton.[ 169 ] They founs that CuO NPs could improve the expression of the Bt toxin protein both in leaves and roots even at low concentrations, thereby increasing the resistance of crops to pests. However, like pure Ag NPs, the pure CuO NPs are prone to agglomerate during use, which leads to poor antifungal activity.[ 171 ] Therefore, in another study, the researchers prepared rGO‐CuO nanocomposite through chemical precipitation method, and studied its antifungal activity against wild strains of Fusarium oxysporum.[ 172 ] With the help of rGO, the CuO NPs become more stable and more soluble in water. And the antifungal activity of the rGO‐CuO nanocomposite with smaller size of CuO NPs (5 nm) was the best. That is because the smaller NPs have a larger surface area, thereby promoting more interactions with the fungal cells as well as accelerating the release of Cu ions. Besides CuO NPs, cupric phosphate anhydrous (Cu3(PO4)2·3H2O) nanosheets also exhibit antifungal activity against F. oxysporum.[ 173 ] Moreover, compared with pure CuO NPs, the Cu3(PO4)2·3H2O nanosheets with the properties of smaller particle size, unique particle structure (nanosheets), and faster initial ions release rate, showing broad application prospects in agriculture. Therefore, the difference in particle composition and size, as well as the release rate of Cu ions, will affect the efficacy of Cu‐based nanopesticides.

Ag or Cu‐based NPs have been extensively applied to control a broad spectrum of crop diseases, but their prolonged use can lead to the development of resistance in certain plant pathogens. Thus, other metal‐based nanomaterials, such as, Mg, Zn, Ti, etc., have been extensively studied. Among them, Mg‐based NPs with the advantages of nontoxic and easy‐prepared show great potential in acting as bactericidal materials. By treating the tomato roots with MgO NPs suspension, the treated plants have a strong inhibition of bacterial wilt.[ 174 ] Moreover, this MgO NPs‐based nanopesticides are harmless to environment and low‐cost, thereby having a broader application prospect. Besides MgO, magnesium hydroxide NPs (Mg(OH)2 NPs) also exhibited comparable bacterial killing efficacy and reduced phytotoxicity on tomato leaves and seeds.[ 175 ] This study demonstrates that the Mg(OH)2 NPs have greater potential in crop protection that can replace Cu‐based fungicides, as they show comparable bactericidal efficacy and lower phytotoxicity. For Zn and Ti‐based NPs, they also play roles in pest management. ZnO NPs‐based nanopesticides could significantly reduce the citrus canker of sweet orange that inoculated with Xanthomonas citri subsp. Citri.[ 176 ] And TiO2 NPs with intrinsic photochemical activity exhibited high photocatalytic activity against X. perforans within 10 min.[ 177 ] Moreover, the TiO2 doped with Zn (TiO2/Zn NPs) performed well in the greenhouse studies, significantly reducing the bacterial spot disease severity of tomatoes.