Abstract

Papad is a crunchy wafer-like snack food consumed all over India and other Asian countries. Traditionally, sun-drying requires more drying time and reduces less moisture from papad, which absorbs more oil during frying. The current study was carried out using microwave-assisted hot air drying (MAHD) to reduce fried papad oil content. Box–Behnken design (BBD) was selected to perform 17 trials for drying of papad using MAHD along with different power levels (300, 600, and 900 W), exposure times (30, 60, and 90 s) and hot air temperatures (40, 50 and 60 °C). The fried papad characteristics were evaluated in terms of oil content, oil uptake ratio, porosity, expansion and texture using standard procedures. MAHD helped reduce higher than 30% of fried papad oil content compared to the traditional method. Scanning electron microscope (SEM) confirmed that the MAHD papad has fewer pore structures than sun dried-fried papad. Using response surface methodology (RSM), the optimized parameters of MAHD was found to be 653 W power level with an exposure time of 56 s at 43 °C of drying temperature, which reduced oil content (7.90 ± 0.02%), oil uptake ratio (1.50 ± 0.03), porosity (16.33 ± 0.29%) and expansion (7.97 ± 0.02%) of fried papad.

Keywords: Microwave-assisted hot air drying, Box–Behnken design, Oil content, Oil uptake ratio, Porosity

Introduction

Papad is a crunchy wafer prepared mostly from legume flour, which is extensively consumed in many parts of Asia, including India, because of its high nutritional benefits associated with the legumes flour (Patil et al. 2001). In India, papad making industries have a regional market where each region consumes a variety of papads such as appalam, appadam, happala and pappadam in the south region, papad in Gujrat, Maharashtra and Punjab, Bikaneri in Rajasthan and east region of India. Papad producing industries are highly competitive, where greater than 1000 local enterprises contribute nearly INR 1000 crores of India’s market. It has been increasing at a rate higher than 10% continuously, with exports growing by 30% per annum (Grorcer 2018).

Papad is consumed as a meal accompaniment after roasting or frying (Math et al. 2004). It is prepared using a combination of black gram flour or sorghum or Rice or green gram as the main ingredient by blending with other ingredients such as common salt, spices and oil. The dough of papad rolled into a spherical shape with a thickness of 0.3–2.0 mm and a moisture level of 12–16% (Math et al. 2004; Velu et al. 2008).

The essential unit operations involved in the papad-making process are mixing ingredients, kneading, cutting, shaping, drying, frying, and storage (Patil et al. 2001). Drying is an essential unit operation during the papad-making process and traditionally drying performed under open sun, which has various disadvantages associated with it. The traditional method for drying of papad is a cost-effective and time-consuming method. There is also a chance of contamination due to open drying, which affects the papad’s final characteristic (Sagar and Kumar 2010). In comparison, direct drying in a closed transparent enclosure can avoid contaminants and better quality the final dried product. MAHD is utilized in many industries like food, pharmaceutical, and chemical due to less time and area required for drying. Many investigators and industries have utilized MAHD for specific applications, and it proved to be useful over several other drying techniques (Maskan 2001; Sagar and Kumar 2010; Lavanya et al. 2017). The use of microwave drying before frying has been reported to reduce the final product’s oil content (Krokida et al. 2001; Pedreschi and Moyano 2005).

Frying is one of the vital unit operations involved during the papad making process, and it decides the final oil content in fried food products. The foods that are naturally low in fat absorb large amounts of fat during frying. Various trials were carried out to reduce the final oil content from fried products and have been extensively investigated (Gamble et al. 1987; Pinthus et al. 1993; Moreira and Barrufet 1998; Patil et al. 2001; Math et al. 2004). Several pretreatment methods were also tried to reduce oil content from fried products, such as air drying, blanching, coating, and osmotic dehydration (Patil et al. 2001; Krokida et al. 2001; Pedreschi and Moyano 2005; Izadi et al. 2015). Besides, vacuum frying is an option for reducing oil content from fried products (Garayo and Moreira 2002).

Frying is a heat and mass transfer process which releases the moisture in the form of vapour due to heat treatment and absorbs the oil, which increases the final fat content of the food product (Liu-Peng et al. 2005). Gamble et al. (1987) reported that most of the oil was absorbed during deep frying of potato chips by adhering oil due to condensation of steam at the time of removing potato chips from the fryer. The increase in pre-fry drying time leads to decrease in the moisture content with increasing final oil content of the food product. Joardder et al. (2019) reported that moisture evaporation is directly proportional to the absorption of oil into the final food product.

Overconsumption of fried products is associated with health issues such as cardiovascular disease (CVD), coronary heart disease (CHD), cancer, obesity, diabetes, and hypertension (Izadi et al. 2015). Nowadays, CVD is turning to be a leading cause of death globally. More than 80% of death occurs in India due to CVD and stroke under the age of 70 (Prabhakaran et al. 2016). According to World Health Organization (WHO), the global cause of death in 2016 due to CVD was estimated at around 17.9 million, and among these, 85% deaths occurred due to a heart attack (World Health Organization 2017).

A three-level three-factor Box–Behnken design (BBD) was applied in this study as the response surface methodology (RSM) tool. In the present study, the MAHD with different process parameters was adopted for drying of papad to reduce the final oil content from fried papad. The fried papad characteristics were evaluated in terms of oil content, oil uptake ratio, porosity, expansion, color, and hardness.

Materials and methods

Materials

Fine black gram flour of less than 60 mesh size (Krishna Bhavan Foods, and sweets, Tiruchirapalli, India) and spices, namely, asafoetida and cumin powder of the brand ‘Aachi’ (Aachi spices and foods Pvt. Ltd, Chennai, India) were purchased from the local market of Thanjavur, Tamil Nadu, India. Food grade sodium carbonate, sodium bicarbonate, and common salt was procured from ‘TATA chemicals’ Ltd. Mumbai, India. Palm oil (Ruchi Gold Oils and Food Pvt. Ltd, Mumbai, India) was used to frying papad.

Preparation of papad

The dough of papad was prepared by blending black gram flour (100 g), cumin seed powder (1.5 g), asafoetida powder (0.5 g), 2:1 of sodium carbonate: sodium bicarbonate (1 g), common salt (5 g), oil (2 ml) and water (40 ml). All the dry ingredients were mixed, and the dough was kneaded with the addition of water and oil until it turned into a soft dough. The prepared papad dough was kept for about half to 1 h at ambient conditions. The prepared dough was divided into small size balls weighing 5–6 g with the moisture content of a 32–40% dry basis (d.b). Only uniform balls (weight 5 ± 0.5 g and moisture content 32 ± 1%) were used for papad preparation. The small size of balls was flattened by papad making machine (Model no. 1239-95, AMI Engineering, Patna, India). It had two discs of circular plates with a thickness of 0.3–0.5 mm and 15 cm. The prepared papad was dried in a blackened surface under the open sun in May (summer season) with solar intensity 5.78 ± 2 kwh/m2/day and air velocity of 0.54 ± 0.12 m/s to obtain the desired moisture level 12–16%. During the drying of papad, the average recorded relative humidity and temperature were 32% and 40 ± 2 °C, respectively. The dried papad was packed in polyethylene (PE) films having a thickness of 50 microns with a water vapour permeability of 150 g/m2/24 h and stored for further analysis at ambient conditions (for 1 day). Later, the stored papad was fried by using palm oil in a deep fat fryer at 170–180 °C for 15–20 s, and after frying, the uniform samples were selected (based on frying temperature and time) and packed in PE pouches for further analysis (Patil et al. 2001; Math et al. 2004).

The dough was prepared similarly as the method mentioned above and prepared papad was dried in MAHD (Model no. PTF-2515, Enerzi microwave-assisted hot air system, Karnataka, India) at three different power levels (300, 600 and 900 W), pulsation time (30, 60 and 90 s) and temperatures (40,50 and 60 °C) to 10% moisture level with a constant air velocity of 1 m/s because there was no effect of air velocity on drying of samples (Joardder et al. 2019). The prepared raw papads were kept on the belt of MAHD with 1.28 kg/m2 of dryer load, and dried papad was fried as per the above process.

Analytical methods

The moisture content of dried and fried papad

The moisture content of the dried (Md) and the fried (Mf) papad was carried out using the oven method at 105 °C until constant weight (AOAC 2000: 934.01).

| 1 |

Oil content of fried papad

The fried papad's oil content was done in triplicate using soxhlet extraction with diethyl ether (AOAC 2000: 991.36).

| 2 |

M is the Mass of the material taken for the test; m is the Moisture % of the material. M1 is the Mass of the Soxhlet flask with extracted fat; M2 is the Mass of the empty Soxhlet flask;

Oil uptake ratio of fried papad

The oil uptake ratio was calculated according to the process given by Patil et al (2001)

| 3 |

Md is the Moisture content of dried papad (%); Mf is the Moisture content of fried papad (%).

The porosity of fried papad

The porosity of fried papad depends on its bulk and true densities. The range of bulk density is between dry solid bulk density and enclosed water density (Eq. 4). The bulk density was determined by filling a container with the crushed papad samples for a height of 15 cm at a constant rate and the content was weighed. Similarly, true density is the function of moisture content (X) and it ranges between the dry solid density (powdered papad samples) and enclosed water density (Eq. 5). Toluene displacement method was utilised instead of water displacement method for measuring true density because toluene is less absorbed by material. It has low surface tension, so that it fills even shallow dips in samples. Thus, porosity is the function of bulk and true densities (Eq. 6) (Krokida et al. 2001).

| 4 |

| 5 |

| 6 |

ρb is the bulk density (kg/m3); ρt is the true density, (kg/m3); ɛ is the porosity (%); ρw is the enclosed water density (kg/m3); ρs is the dry solid density (kg/m3); ρb0 is the dry solid bulk density (kg/m3); β’ is the volume shrinkage coefficient (–).

Expansion of fried papad

The % expansion of fried papad was calculated as per the process given by Patil et al. (2001)

| 7 |

Da is the diameter of papad after frying; Db is the diameter of papad before frying.

The color value of fried papad

The standard colour value of fried papad (L* 68.01, a* 3.02 and b* 29.62) were measured based on the control sample (market sample) and compared with MAHD fried and sun-dried fried papad. The color (∆E) value was calculated using the following formula given by Maskan (2001).

| 8 |

∆E is the total chromatic aberration value; , and = Control sample L*, a* and b* value;

L*, a*, and b* = MAHD treated sample L*, a*, and b* value.

Texture profile of fried papad

Textural properties such as brittleness, crispiness, and hardness are essential attributes that decide the acceptability of fried papad and were affected during processing and handling. The fried papad’s texture was calculated using a texture profile analyzer (TPA) of Stable Microsystems, USA. (Model TA. HD. Plus) and setting used for evaluation of fried papad texture was carried out using crisp fracture support rig (HDP/CFS*), 0.25″ spherical probe with a test speed of 2 mm/s up to 8 mm. The force (g) required to rapture the fried papad was expressed as a maximum fracture force. The texture of fried papad was identified as per the process given by Patil et al. (2001), the load value of < 350 g for brittleness, 350–450 g for crispiness > 450 g for hardness.

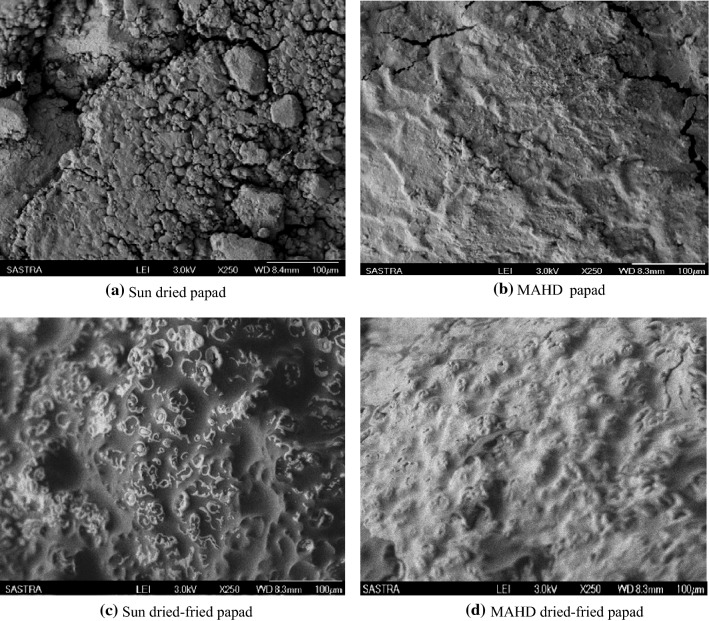

Scanning electron microscope (SEM) analysis

SEM (Model FE-JSM6701F, Hitachi, Japan) analysis was performed for dried and fried papad to identify the internal structure and pore space created by different drying methods. The samples were prepared by cutting (20 × 20 mm) small dried and fried papad pieces and mounted on the specimen holder using double side conductivity tape. The sample coating was done with gold–palladium to a thickness of about 100 Å for 30 s using a vacuum evaporator for artificial conductance. The SEM analysis was operated at 3 kV with a magnification of 250 X.

Experimental design and statistical analysis

The optimization of MAHD process variables was carried out with BBD using RSM (Rai et al. 2019; Cheng et al. 2020; Elboughdiri et al. 2020; Srikanth et al. 2020). The statistical analysis and analysis of variance (ANOVA) were performed with Design-Expert Version 10.0 (Stat-Ease, Inc. USA). Microwave power level (X1), exposure time (X2), and microwave temperature (X3) was intended as the independent variables. RSM was utilized to study the effect of process variables of MAHD on various responses such as oil content, oil uptake ratio, porosity, expansion, colour and texture. The experiment's reproducibility was evaluated to determine the experimental error, and the design included five replications of the center point. The prepared data was fitted with a quadratic equation model for predicting the optimal conditions (Rai et al. 2019; Srikanth et al. 2020), and it can be expressed as follows:

| 9 |

where Y represents the measured response associated with each factor level combination; b is an intercept; to is regression coefficient computed from the observed experimental values of Y; to is the coded levels of independent variables; to represent the interaction and quadratic terms, respectively.

ANOVA was utilized for the graphical analysis of data to obtain the interaction between the process variables and responses. The effect of process variables on responses was analyzed at 95% (P < 0.05) of confidence level. The experiment's optimization was carried out using the desirability function to find out the suitable variables on the responses.

Results and discussion

Moisture content

The moisture content of dried-fried papad is presented in Table 1. The average moisture content present in the market papad samples were around 12–16% (Math et al. 2004; Velu et al. 2008). So, in the traditional method of sun drying, the papad was dried to 13.35 ± 0.03% moisture content level. Whereas in mechanical drying such as MAHD the moisture content achieved and used in various studies was around 8–10% (Moreira and Bakker-Arkema 1989; Joardder et al. 2019). In MAHD the moisture content of papad was reduced to around 10.05 ± 0.05%. According to Joardder et al (2019) the MAHD successfully removed all sort of water from food products except chemically tight bound water. It is reported that moisture has direct effect on fried papad oil content (Patil et al. 2001; Math et al. 2004). The initial moisture content of the product and small particle size increases fried products' oil content (Moreira and Barrufet 1998; Dana and Saguy 2006) and it also has effect on other properties of fried papads (Patil et al. 2001; Math et al. 2004).

Table 1.

Effect of drying methods and moisture content after drying (Md) and after frying (Mf) of papad

| Parameter | Sun dried fried papad | MAHD fried papad | P-Value |

|---|---|---|---|

| Mean | Mean | ||

| Oil content (%) | 30.02 ± 0.25a | 9.26 ± 1.70b | 0.004 |

| Oil uptake ratio (UR) | 3.26 ± 0.09a | 1.61 ± 0.15b | 0.003 |

| Porosity (%) | 25.67 ± 0.57a | 18.00 ± 2.00b | 0.003 |

| % Expansion | 11.02 ± 0.25 a | 8.22 ± 0.56b | 0.002 |

| Color value (∆E) | 5.05 ± 0.84a | 5.26 ± 1.15b | 0.002 |

| Texture (g) | 618.78 ± 7.55a | 363.9 ± 8.03b | 0.001 |

Similar letters indicate nonsignificant difference at 5% level of significance. Md and Mf for MAHD were 10.05 ± 0.05% and 4.75 ± 0.03% and for open sun drying it was 13.35 ± 0.03% and 4.84 ± 0.05%, respectively

Response surface analysis

The fried papad characteristics with different drying methods (open sun and MAHD drying) were determined and compared using independent sample T-test (Table 1). The three levels of BBD was selected to optimize the effect of MAHD on quality parameters, namely, oil content (%), oil uptake ratio (UR), porosity (%), expansion (%), colour value (∆E) and texture (g) of fried papad. In RSM, BBD is suitable for the study of the quadratic response surfaces model, which constructs a second-order polynomial model and helps to optimize the process using a small number of experimental runs (Rai et al. 2019; Srikanth et al. 2020) and observed responses for the 17 formulations are presented in Table 2.

Table 2.

Effect of process parameters of MAHD on fried papad characteristics using Box-Behnken design

| S.N | Independent variable | Responses | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Power level (W) | Exposure time (sec) | Tempera-ture (°C) | Oil content (%) | Oil uptake (UR) | Porosity (%) | % Expansion | Color value (∆E) | Texture (g) |

|

| 1 | 300 | 30 | 50 | 11.11 ± 0.06** | 2.11 ± 0.04** | 23.67 ± 3.06** | 8.85 ± 0.04 | 4.12 ± 0.04 | 382.34 ± 9.34 |

| 2 | 900 | 30 | 50 | 9.11 ± 0.07 | 1.72 ± 0.04 | 19.67 ± 2.52 | 8.26 ± 0.03 | 4.36 ± 0.05 | 382.44 ± 5.38 |

| 3 | 300 | 90 | 50 | 10.67 ± 0.06 | 2.03 ± 0.03 | 22.67 ± 3.06 | 8.53 ± 0.05 | 4.40 ± 0.04 | 382.44 ± 6.38 |

| 4 | 900 | 90 | 50 | 8.44 ± 0.04 | 1.60 ± 0.04 | 18.33 ± 2.52 | 8.34 ± 0.05 | 4.88 ± 0.06 | 382.99 ± 7.53 |

| 5 | 300 | 60 | 40 | 9.33 ± 0.06 | 1.77 ± 0.03 | 19.33 ± 3.06 | 7.74 ± 0.02 | 3.66 ± 0.05* | 320.40 ± 5.45* |

| 6 | 900 | 60 | 40 | 7.78 ± 0.05* | 1.47 ± 0.04* | 16.00 ± 2.00* | 7.74 ± 0.03 | 3.82 ± 0.02 | 354.60 ± 7.08 |

| 7 | 300 | 60 | 60 | 10.89 ± 0.05 | 2.07 ± 0.03 | 21.67 ± 2.52 | 8.96 ± 0.04 | 6.40 ± 0.03 | 489.83 ± 7.52 |

| 8 | 900 | 60 | 60 | 8.44 ± 0.04 | 1.60 ± 0.03 | 18.67 ± 1.15 | 9.16 ± 0.06 | 6.40 ± 0.04 | 490.97 ± 6.49 |

| 9 | 600 | 30 | 40 | 8.44 ± 0.05 | 1.60 ± 0.03 | 16.33 ± 2.52 | 7.58 ± 0.05* | 3.94 ± 0.06 | 376.65 ± 5.43 |

| 10 | 600 | 90 | 40 | 8.89 ± 0.04 | 1.69 ± 0.04 | 18.67 ± 0.58 | 7.59 ± 0.04 | 4.07 ± 0.05 | 381.52 ± 6.55 |

| 11 | 600 | 30 | 60 | 8.67 ± 0.06 | 1.64 ± 0.04 | 18.67 ± 2.08 | 9.13 ± 0.03 | 6.80 ± 0.03 | 524.60 ± 8.07 |

| 12 | 600 | 90 | 60 | 8.89 ± 0.06 | 1.69 ± 0.04 | 20.00 ± 3.00 | 9.57 ± 0.06** | 6.88 ± 0.03** | 530.70 ± 7.60** |

| 13 | 600 | 60 | 50 | 8.22 ± 0.03 | 1.56 ± 0.04 | 16.67 ± 2.08 | 8.51 ± 0.03 | 5.28 ± 0.06 | 385.57 ± 6.76 |

| 14 | 600 | 60 | 50 | 8.67 ± 0.07 | 1.64 ± 0.02 | 18.67 ± 3.06 | 8.40 ± 0.04 | 5.89 ± 0.05 | 430.03 ± 9.00 |

| 15 | 600 | 60 | 50 | 8.00 ± 0.04 | 1.52 ± 0.01 | 16.33 ± 1.53 | 8.53 ± 0.03 | 6.13 ± 0.05 | 445.27 ± 7.02 |

| 16 | 600 | 60 | 50 | 8.67 ± 0.04 | 1.64 ± 0.03 | 18.67 ± 1.15 | 8.74 ± 0.03 | 6.15 ± 0.03 | 456.59 ± 5.17 |

| 17 | 600 | 60 | 50 | 8.00 ± 0.03 | 1.52 ± 0.02 | 16.33 ± 0.58 | 8.86 ± 0.04 | 6.27 ± 0.03 | 480.50 ± 8.50 |

**Maximum and *Minimum value

The significant model term is desired to obtain a good fit for a model. The experimental design presented in Table 2 was utilized to develop a mathematical equation to predict the results (Y1 and Y2). The function of variables such as microwave power level (A), exposure time (B) and hot air temperature (C) was calculated as a sum of constants using every three first-order effects (A and B, B and C and A and C), interaction effects (AB, BC, and AC) and second-order effects (A2, B2, and C2) according to Eq. 7. To access the goodness of fit for obtained results were analyzed using ANOVA and results presented in Table 3, which illustrates the reduced quadratic model in terms of coded factor and other statistical parameters. The significance of each coefficient was determined using Fisher’s F-test and P-value. The data presented in Table 3 demonstrate that the P values were < 0.05 and all the models were significant at 5% confidence level.

Table 3.

ANOVA results for all the responses of MAHD fried papad characteristics

| Response | Final equation in terms of code factors | PLOF | R2 | Adj. R2 | AP | S.D | CV | PRESS | CD |

|---|---|---|---|---|---|---|---|---|---|

| Oil content | 8.31 − 1.03 A + 0.96 A2 + 0.57 B2 | 0.18 | 0.92 | 0.81 | 8.48 | 0.44 | 4.91 | 15.13 | 0.0049 |

| Oil uptake ratio | 1.58 − 0.19 A + 0.18 A2 + 0.11 B2 | 0.18 | 0.92 | 0.81 | 8.48 | 0.083 | 4.91 | 0.54 | 0.0049 |

| Porosity | 16.40 + 0.50 A + 0.63 C + 1.55 A2 | 0.54 | 0.90 | 0.78 | 8.96 | 0.53 | 3.03 | 13.88 | 0.0080 |

| % Expansion | 8.61 + 0.77 C | 0.18 | 0.92 | 0.81 | 9.71 | 0.25 | 2.93 | 4.87 | 0.0043 |

| Color value | 5.94 + 1.37 C − 0.93 A2 − 0.58 B2 | 0.88 | 0.97 | 0.92 | 13.62 | 0.32 | 6.12 | 2.55 | 0.0002 |

| Texture | 439.59 + 75.37 C − 48.23 A2 | 0.98 | 0.92 | 0.81 | 9.81 | 27.20 | 6.42 | 10,589.58 | 0.0047 |

PLOF probability of lack of fit, AP adequate precision, S.D standard deviation; CV coefficient of variance, PRESS predicted residual error sum of squares, CD critical difference

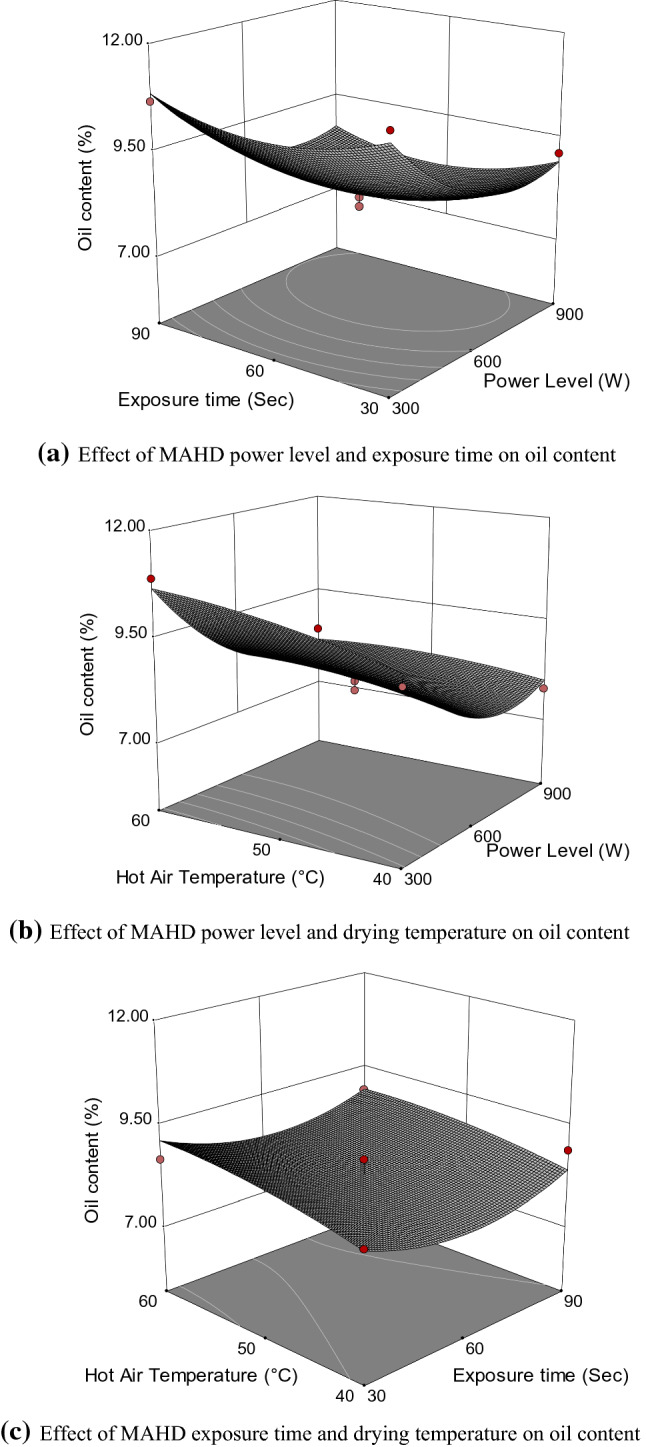

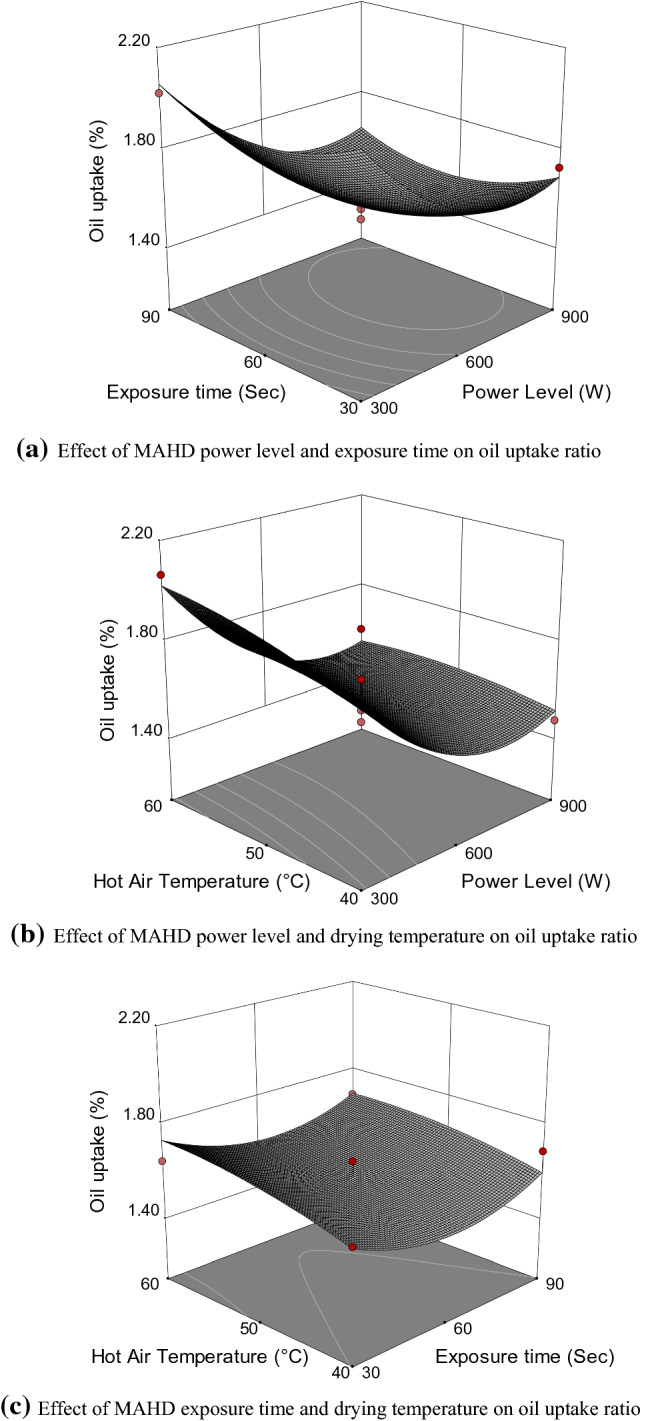

Oil content and oil uptake ratio of fried papad

The oil content of sun dried-fried papad was found to be higher (30.02 ± 0.25%) as compared to MAHD (9.26 ± 1.70%) papad and similar results were also observed for oil uptake ratio of sun dried-fried papad (3.26 ± 0.09) and MAHD papad (1.61 ± 0.15) (Table 1). In MAHD, the increase in drying time with a decrease in power level helped decrease the moisture content and pore space of dried papad, which also helped decrease the final oil content and oil uptake ratio of fried papad.

The relationship between the three variables of MAHD (power level, exposure time, and drying temperature) and fried papad response, such as oil content and oil uptake ratio, were analyzed using RSM. The maximum oil content of 11.11 ± 0.06% and oil uptake ratio of 2.11 ± 0.04 was obtained at experiment no. 1, and the minimum oil content of 7.78 ± 0.05% and oil uptake ratio of 1.47 ± 0.04 were obtained at experiment no. 6 (Table 2). The dependent and independent variables were correlated using the mathematical relationship obtained by RSM, and the polynomial equation was obtained for oil content (Y1), and oil uptake ratio (Y2) were given as follows:

| 10 |

| 11 |

The above model (Y1 and Y2) represents the quantitative effect of process variables of MAHD and their interactions on oil content and oil uptake ratio during frying of papad. The values of coefficients (A–C) are related to the effect of these variables on oil content. The F-Value (8.56) for the above models implies that the model fits the oil content and oil uptake ratio. The absolute F value becomes more substantial, and the probability value becomes smaller (P = 0.0049) when the corresponding variables would be more significant. From Table 3, the developed equations from the ANOVA analysis were modified by eliminating the terms that were not found statistically significant. The reduced quadratic model in terms of the coded factor for oil content and oil uptake ratio showed a high R2 value of 0.91 and indicated a good correlation between the experimental and predicted values for the responses.

The relationship between oil content and oil uptake ratio with process parameter of MAHD were further elucidated using response surface plot presented in Figs. 1 and 2, which shows the effect of power level (A), exposure time (B) and drying temperature (C) on oil content and oil uptake ratio of fried papad. The small circles present on response surface plots of oil content (Fig. 1a–c) and oil uptake ratio (Fig. 2a–c) indicate that the optimum level at which minimum oil content and oil uptake ratio will be observed for fried papad. It was evident from Fig. 1a, that the optimum point for oil content on fried papad was observed at 700 W of power level with exposure time of 60 s, Fig. 1b showed optimum point for oil content between 600 and 700 W of power level with drying temperature of 50 °C and Fig. 1c showed optimum point for oil content at 60 s of exposure time with drying temperature of 50 °C, and similar results were also observed for oil uptake ratio of fried papads (Fig. 2a–c). It was evident from Fig. 1 that the increase in power level from 300 to 700 W for dried papad helped to decrease the oil content, and an increase in power level from 750 to 900 W showed a negative effect indicating an increase in the final oil content of fried papad. The increase in exposure time from 30 to 60 s for dried papad showed a gradual decrease in oil content, and a further increase in exposure time up to 90 s showed an increase in the final oil content of fried papad. The increase in drying temperature from 40 to 50 °C for dried papad showed minimum oil content, and a further increase in the temperature up to 60 °C showed an increase in the final oil content of the fried papad.

Fig. 1.

Response surface graph using different process parameters of MAHD for oil content of fried papad

Fig. 2.

Response surface graph using different process parameters of MAHD for oil uptake ratio of fried papad

From Fig. 2, it was apparent that the increase in the power level from 750 to 900 W indicates a higher oil uptake ratio. Still, increases in the exposure time from 30 to 60 s showed a decrease in the final oil uptake ratio of fried papad. According to Pedreschi and Moyano (2005), the pre-drying process affects the oil transfer in fried products and decreases the final oil uptake ratio of fried products. The drying of papad with MAHD has a useful way to reduce fried papads' final oil uptake ratio.

% Porosity of fried papad

Porosity directly relates to a food product, which affects their physical properties, namely, mass diffusion coefficient, thermal conductivity and thermal diffusivity (Rahman et al. 2002). A higher porosity value of 25.66 ± 0.6% was observed for sun dried-fried papad, and MAHD fried papad showed lower porosity of 18.00 ± 2.00% (Table 1). During frying, porosity plays a vital role in the oil content and oil uptake ratio of fried papad. According to Kassama and Ngadi (2005), the properties of food, namely mechanical, textural, and sensorial, were influenced by porosity, including pore size and structure present within the food matrix. The porosity of MAHD fried papad was calculated, and it was observed that the increase in power level from 300 to 700 W leads to a decrease in the porosity of fried papad. The relationship between three variables of MAHD with porosity was analyzed using RSM, and minimum porosity of 16.00 ± 2.00% was observed at experiment no. 6, and maximum porosity of 23.67 ± 3.06% was found at experiment no. 1 (Table 2). Various researchers observed that the porosity of the product increases with loss of moisture at the time of frying and pore space fills with oil by replacing the moisture present on the food product (Pinthus et al. 1993; Dana and Saguy 2006).

Effect of process parameters on fried papad characteristics

The characteristic of fried papads evaluated in terms of expansion, color, and textural properties. The expansion of fried papad illustrates the degree of puffing. During the expansion process, the stored energy will be released, increasing radical expansion (Thymi et al. 2005). According to Velu et al. (2008), the papad prepared using mechanical sheeting (papad making machine) showed lower papad expansion due to the suddenly applied compression load, which breaks the protein-carbohydrate matrix. Sun dried-fried papad showed maximum expansion of 11.02 ± 0.25%, and MAHD fried papad showed a lower expansion of 8.22 ± 0.56%, which may be due to the difference in moisture content (Table 1). The relationship between % expansion with variables of MAHD was analyzed in RSM, and maximum expansion of 9.57 ± 0.06% was observed at experiment no. 12 and minimum expansion of 7.58 ± 0.05% were found at experiment no. 9 (Table 2).

Colour is one of the essential quality parameters directly related to the acceptability of the final product. The parameter L* indicates the lightness value; the sun-dried papad showed a lower value of L* 60.15 ± 0.26 compared to MAHD where L* was found to be 64.00 ± 0.07. The colour value of sun-dried fried papad was compared with MAHD fried papad, and results are presented in Table 1. The MAHD fried papad showed a higher ∆E value (∆E 5.26 ± 1.50) compared to sun dried-fried papad (∆E 5.05 ± 0.84). The color deterioration of sun-dried-fried papad might be due to non-uniform drying, heat spot and temperature. Moisture content is the reason for the occurrence of heat spots in the sun dried-fried papad. The relationship between variables with the MAHD fried papad’s color value showed a maximum ∆E value of 6.88 ± 0.03 at experiment no. 12, and the minimum ∆E value was observed to be 3.66 ± 0.05 at experiment no. 05 (Table 2). The ∆E value of MAHD fried papad were increased with increasing temperature and power level of MAHD. MAHD helps to evaporate the bound water present inside the dried papad which retains the colour of fried papad.

The textural properties of fried papad were illustrated in terms of hardness, crispiness, and brittleness, and the results of textural properties are presented in Table 1. The texture of sun-dried-fried papad was extremely hard, and it required a load of 618.78 ± 7.55 g to break, while MAHD fried papad was crispy and breaks at the load of 363.9 ± 8.03 g due to the difference in moisture content. Due to papad's inappropriate drying in the sun-drying method, the structure may get damaged, which requires highest breaking force. During sun drying-fried papad, the moisture may be absorbed moderately due to which papad losses brittleness and increases stiffness and toughness which can be termed as hardness (Monteiro et al. 2020). The relationship between variables and texture of MAHD fried papad is presented in Table 2, and it was observed that the suitable texture was obtained between experiments no. 13 to 17 (Table 2), which shows a crispy texture for fried papad due to the effect of power level (600 W) of MAHD. The increase in power level and temperature of MAHD increased fried papad's hardness (Table 2). The MAHD papad at 40 °C showed lower crispiness (320.40 ± 5.45 to 381.52 ± 6.55 g) and crispy texture of MAHD fried papad was observed with papad dried at 50 °C (382.34 ± 9.34 to 480.50 ± 8.50 g). Similarly, papad dried at 60 °C showed more rigid texture (489.83 ± 7.52 to 530.70 ± 7.60 g) due to the sudden evaporation of moisture from the fried papad.

Process optimization

The process optimization was done by using BBD with a desirability value of 0.994, i.e., 99%. The optimum conditions observed for the MAHD papad were power level of 653 W, exposure time of 56 s, and hot air temperatures at 43 °C. The predicted oil content, oil uptake ratio, porosity and % expansion was 7.90 ± 0.02%, 1.50 ± 0.03, 16.33 ± 0.29% and 7.97 ± 0.02%, respectively. The optimized values for texture and colour of MAHD fried papad were 381.63 ± 3.03 g and ∆E 4.57 ± 0.02. The straight line was fitted between actual and predicted responses, close to the unity slope with a high R2 value of 0.99 for all the responses.

SEM analysis

Morphological characteristic is one of the vital parameters to characterise the product quality. According to Qiu et al. (2020), the bulk density and microstructure of dehydrated products may be influenced by different drying techniques. Figure 3 shows the SEM images of dried and fried papad with sun drying and MAHD with optimized process variables. Sun-dried papad loosed microstructure compared to MAHD papad due to uneven drying temperature and slow drying period (Fig. 3a). MAHD showed a compact papad structure due to higher drying temperature and rapid evaporation of moisture (Fig. 3b). Sun dried papad showed more moisture content compared to MAHD papad. While frying, sun-dried papad showed more massive pore structure due to evaporation of moisture, which absorbed more oil compared to MAHD papad (Fig. 3c, d).

Fig. 3.

SEM analysis of dried and fried papad using different drying methods

Conclusion

This study recommends that the method for drying of papad directly influences oil content, oil uptake ratio, porosity, expansion, colour and texture of fried papad. MAHD helped reduce higher than 30% of fried papad oil content compared to traditionally dried-fried papad. The power level of MAHD has a significant effect on the reduction of oil content. MAHD also reduced the final oil uptake ratio, porosity, % expansion, and texture of fried papad. SEM images of MAHD showed fewer pore space and gaps into the internal structure of papad, which reduces the % expansion of fried papad. The MAHD method used for drying of papad will be a suitable approach for papad making industries to produce low moisture and low oil content papad, but it will increase the drying cost of the final product.

Acknowledgements

The financial assistance was provided by the Indian Institute of Food Processing Technology (IIFPT), Ministry of Food Processing Industries, Government of India, which is duly acknowledged. We would like to thank the Indian Institute of Food Processing Technology (IIFPT), Thanjavur, Tamil Nadu for supporting our research work.

Author contributions

All authors have contributed equally for writing, review and editing of the manuscript.

Funding

The work was supported by the Indian Institute of Food Processing Technology (IIFPT), Thanjavur, Tamil Nadu.

Declarations

Conflict of interest

All the authors enlisted declare that there are no conflicts of interest to disclose.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Association of Official Analytical Chemist . Official methods of analysis. 17. Rockville: AOAC international; 2000. [Google Scholar]

- Cheng M, Yuan F, Liu J, Liu W, Feng J, Jin Y, Tu L. Fabrication of fine puerarin nanocrystals by Box-Behnken design to enhance intestinal absorption. AAPS PharmSciTech. 2020;21(3):1–12. doi: 10.1208/s12249-019-1616-4. [DOI] [PubMed] [Google Scholar]

- Dana D, Saguy IS. Review: mechanism of oil uptake during deep-fat frying and the surfactant effect-theory and myth. Adv Colloid Interface Sci. 2006;128:267–272. doi: 10.1016/j.cis.2006.11.013. [DOI] [PubMed] [Google Scholar]

- Elboughdiri N, Ghernaout D, Kriaa K, Jamoussi B. Enhancing the extraction of phenolic compounds from juniper berries using the Box-Behnken Design. Washington: ACS Omega; 2020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gamble MH, Rice P, Selman JD. Relationship between oil uptake and moisture loss during frying of potato slices from cv Record UK tubers. Int J Food Sci Tech. 1987;22:233–241. doi: 10.1111/j.1365-2621.1987.tb00483.x. [DOI] [Google Scholar]

- Garayo J, Moreira R. Vacuum frying of potato chips. J Food Eng. 2002;55:181–191. doi: 10.1016/S0260-8774(02)00062-6. [DOI] [Google Scholar]

- Grorcer P (2018) Growth of Papad making in India. Magzter. https://www.magzter.com/article/News/Progressive-Grocer/Papad-Market-Growing-At-10-Exports-Rising-By-Over-30-Annually. Accessed Nov 2018

- Izadi S, Ojagh SM, Rahmanifarah K, Shabanpour B, Sakhale BK. Production of low fat shrimps by using hydrocolloid coatings. J Food Sci Tech. 2015;52:6037–6042. doi: 10.1007/s13197-014-1632-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Joardder MU, Mourshed M, Masud MH. State of bound water: measurement and significance in food processing. Cham: Springer; 2019. Bound water removal techniques; pp. 93–118. [Google Scholar]

- Kassama LS, Ngadi MO. Pore structure characterization of deep-fat-fried chicken meat. J Food Eng. 2005;66:369–375. doi: 10.1016/j.jfoodeng.2004.04.003. [DOI] [Google Scholar]

- Krokida MK, Oreopoulou V, Maroulis ZB, Marinos-Kouris D. Deep fat frying of potato strips—quality issues. Dry Technol. 2001;19:879–935. doi: 10.1081/DRT-100103773. [DOI] [Google Scholar]

- Lavanya MN, Venkatachalapathy N, Manickavasagan A. Brown rice. Cham: Springer; 2017. Physicochemical characteristics of rice bran; pp. 79–90. [Google Scholar]

- Fan L-P, Min Z, Gong-Nian X, Jin-Cal S, Qian T. The optimization of vacuum frying to dehydrate carrot chips. Int J Food Sci Tech. 2005;40:911–919. doi: 10.1111/j.1365-2621.2005.00985.x. [DOI] [Google Scholar]

- Maskan M. Kinetics of colour change of kiwifruits during hot air and microwave drying. J Food Eng. 2001;48:169–175. doi: 10.1016/S0260-8774(00)00154-0. [DOI] [Google Scholar]

- Math RG, Velu V, Nagender A, Rao DG. Effect of frying conditions on moisture, fat, and density of papad. J Food Eng. 2004;64:429–434. doi: 10.1016/j.jfoodeng.2003.11.010. [DOI] [Google Scholar]

- Monteiro RL, de Moraes JO, Domingos JD, Carciofi BAM, Laurindo JB. Evolution of the physicochemical properties of oil-free sweet potato chips during microwave vacuum drying. Inno Food Sci Emerg Technol. 2020;63:102317. doi: 10.1016/j.ifset.2020.102317. [DOI] [Google Scholar]

- Moreira RG, Barrufet MA. A new approach to describe oil absorption in fried foods: a simulation study. J Food Eng. 1998;35:1–22. doi: 10.1016/S0260-8774(98)00020-X. [DOI] [Google Scholar]

- Moreira RG, Bakker-Arkema FW. Moisture desorption model for nonpareil almonds. J Agric Eng Res. 1989;42:123–133. doi: 10.1016/0021-8634(89)90045-0. [DOI] [Google Scholar]

- Patil SJ, Singhal RS, Kulkarni PR. Screening of different hydrocolloids for improving the quality of fried papad. Eur J Lipid Sci Tech. 2001;103:722–728. doi: 10.1002/1438-9312(200111)103:11<722::AID-EJLT722>3.0.CO;2-C. [DOI] [Google Scholar]

- Pedreschi F, Moyano P. Effect of pre-drying on texture and oil uptake of potato chips. LWT-Food Sci Technol. 2005;38:599–604. doi: 10.1016/j.lwt.2004.08.008. [DOI] [Google Scholar]

- Pinthus EJ, Weinberg P, Saguy IS. Criterion for oil uptake during deep-fat frying. J Food Sci. 1993;58:204–205. doi: 10.1111/j.1365-2621.1993.tb03245.x. [DOI] [Google Scholar]

- Prabhakaran D, Jeemon P, Roy A. Cardiovascular diseases in India: current epidemiology and future directions. Circulation. 2016;133:1605–1620. doi: 10.1161/CIRCULATIONAHA.114.008729. [DOI] [PubMed] [Google Scholar]

- Qiu L, Zhang M, Ju R, Wang Y, Chitrakar B, Wang B. Effect of different drying methods on the quality of restructured rose flower (Rosa rugosa) chips. Dry Technol. 2020;38:1632–1643. doi: 10.1080/07373937.2019.1653318. [DOI] [Google Scholar]

- Rahman MS, Al-Amri OS, Al-Bulushi IM. Pores and physico-chemical characteristics of dried tuna produced by different methods of drying. J Food Eng. 2002;53:301–313. doi: 10.1016/S0260-8774(01)00169-8. [DOI] [Google Scholar]

- Rai P, Pandey A, Pandey A. Optimization of sugar release from banana peel powder waste (BPPW) using box-behnken design (BBD): BPPW to biohydrogen conversion. Int J Hydrog Energy. 2019;44:25505–25513. doi: 10.1016/j.ijhydene.2019.07.168. [DOI] [Google Scholar]

- Sagar VR, Kumar PS. Recent advances in drying and dehydration of fruits and vegetables: a review. J Food Sci Tech. 2010;47:15–26. doi: 10.1007/s13197-010-0010-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Srikanth V, Rajesh GK, Kothakota A, Pandiselvam R, Sagarika N, Manikantan MR, Sudheer KP. Modeling and optimization of developed cocoa beans extractor parameters using Box Behnken design and artificial neural network. Comput Electron Agric. 2020;177:105715. doi: 10.1016/j.compag.2020.105715. [DOI] [Google Scholar]

- Thymi S, Krokida MK, Pappa A, Maroulis ZB. Structural properties of extruded corn starch. J Food Eng. 2005;68:519–526. doi: 10.1016/j.jfoodeng.2004.07.002. [DOI] [Google Scholar]

- Velu V, Nagender A, Satyanarayana A, Rao DG. Studies on effect of sheeting methods on the expansion of papads during deep fat frying using scanning electron microscopy. J Food Process Pres. 2008;32:669–680. doi: 10.1111/j.1745-4549.2008.00207.x. [DOI] [Google Scholar]

- World Health Organization . Cardiovascular diseases (CVDs) fact sheet. Geneva: World Health Organization (WHO); 2017. [Google Scholar]