Abstract

In this research, the impacts of varying concentration of phospholipase A2 (PLA), protease and lipase enzyme-treated liquid egg white (LEW) were prepared using meringue batters. The gelling physico-chemical, and rheological properties such as rheological creep-recovery compliance behavior, color value (L*, a*, b*, ∆E*, Chroma, Hue and WI), gelling strenght, pH value, gelling index as TPA parameter and specific density of freshly prepared meringue batter were analyzed. The specific density of meringue batter of control (0.49 ± 0.01) was significantly decreased (P < 0.05) after enzyme treatments of PLA (0.39 ± 0.01), lipase (0.33 ± 0.01), and protease (0.37 ± 0.01). Also, the enzymatic treatment significantly decreased the b* values from − 0.08 ± 0.07 to − 0.76 ± 0.04, − 0.70 ± 0.06, and − 0.73 ± 0.03, respectively. The Burgers model was used to characterize rheological behavior of enzyme treated and freshly prepared meringue samples. Creep-recovery responses of samples were satisfactory (R2 > 0.99) for evaluation of creep-recovery behavior. This research points out the efficacy of lipase pre-treated LEW in meringue preparation on improving functionality such as batter density and gelling properties.

Keywords: Egg albumen, Enzymes, Meringue, Techno-functional characterization, Foammability, Structural modification, Batter rheology

Introduction

Eggs offer a moderate calorie source with protein of excellent quality and low economic cost which make eggs within reach to most of the population. Liquid egg white (LEW) contains the highest quality proteins with multifunctional characteristics such as foaming, binding, and gelling ability (Yuceer and Caner 2014). The best whipping capacity as an foaming agent of LEW popular because of its aerating characteristics (protein/sugar preparation) in solidified foamed baking products such as meringue, that consist of foam from air bubbles and made from a soft-thick dough (Schuck 2013; Vega and Sanghvi 2012). Traditional meringues made by whipping LEW with sugar until stiff and stabilizing them in the oven.

In recent years, there has been an increasing demand for novel sources of valuable egg ingredients in the food industry. The enzyme-treated liquid egg market is raising popularity, and this can be associated with the fastest growing in industrially processed egg processing industry, last decade. Different commercial enzymes (lipases, phospholipases A2-PLA, and proteases) as a processing aid are used in the treatment of egg products to enhance the functionality (Yüceer 2020b; Yüceer and Caner 2018a). Yüceer and Asik (2020) stated that the treatment of LEW using PLA improves the functional characteristics while stabilizing the structural and physical attributes of meringues produced. The proteolytic enzyme (protease) enhancing the emulsifying properties of egg white by hydrolysate the peptide bonds present in secondary structure of biologically active egg proteins (Ai et al. 2019). Also, enzymatic hydrolysis of protein improves their solubility in the product. The lipase enzyme used in albumen to degrade the residue of lipids migrated (during storage) or contaminated (in egg breaking and separating process) from yolk to albumen, which decreases the functionality of egg albumen (Yüceer and Asik 2020). Enzymatic treatment of egg proteins resulted in an improvement in technological and functional properties depending on enzyme type, pH, temperature, degree of hydrolysis, enzyme concentration, and reaction/hydrolysis time of egg protein etc. (Horimoto and Lim 2017). The consumer trends to get an innovative food product of bakery production such as meringue boost a rapid growth in the world. It is essential that, enzymes are needed to enhance the functionality in egg and egg-based applications. Recently, there are numerous studies on the characteristics of egg yolk, but there are limited publications which have addressed the use of optimum concentration of various enzymes in LEW (Daimer and Kulozik 2008, 2009; Jaekel and Ternes 2009; Kim et al. 2009; Macherey et al. 2011; Yüceer 2020a, b; Yüceer and Asik 2020). The influences of enzymes on LEW as a processing aid in meringue processing was evaluated to obtain an optimum enzyme for a better functional characteristic.

In this research the impact of PLA (0.3%), lipase (0.03%) and protease (0.5%) treatment of LEW on structural, functional and creep-recovery behavior of freshly prepared meringue’s batter samples were investigated. Thus, the primary purpose of our research, therefore, was to examine the improvement of enzymatic treatments (PLA, lipase and protease) on the physico-functional attributes of freshly prepared meringue batters from LEW such as pH, color parameters (L*, a*, b*, ∆E*, C*, °h and WI), specific density, gelling properties and rheological compliance behavior (creep-recovery).

Materials and methods

Materials

Chicken liquid egg white (LEW) were supplied from Keskinoglu Tavukculuk (Manisa, Turkey). Then, the LEW’s were arranged to four groups for experimental design: (a) control (untreated), (b) 0.3% PLA enzyme treated sample, (c) 0.03% lipase enzyme treated sample, and (d) 0.5% protease treated sample. All samples were used in preapration of meringue dough production using powdered sugar that obtained from local market.

Enzymatic treatment

The LEW was treated with phospholipase A2 enzyme, 9650 CPU/g enzyme activity (Maxapal A2™, DSM-Sanovo, Denmark) at concentration of 0.3% (v/v)) at 45 °C for 90 min (Yüceer 2020a, b).

The LEW was treated with lipase enzyme (Lipomod™ 34P, Biocatalysts Ltd., UK), 115.000 lipase U/g activity. The concentration of 0.03% (w/v) applied in the experiment. The LEW samples pH were adjusted to optimum enzyme reaction rate to 5.00 using citric acid (Tekkim Chem., Istanbul, Turkey) at 50 °C for 90 min (Yüceer and Asik 2020).

The LEW samples were treated with protease enzyme, obtained from microbial fermentation of Aspergillus oryzae (Promod™ 194SP, Wales, UK) with the activity of 200 Casein protease u/g. The pH were adjusted to optimum enzyme reaction rate to 7.00 using citric acid and the enzyme concentration was 0.5% (w/v) at 50 °C for 90 min (Yüceer and Caner 2018b). All treated/untreated (control) groups were used in the preparation of meringue batter.

Meringue batter preparation

Meringue is a cookie prepared from whipped LEW and powdered sugar. In the study, 0.2 L of LEW mixed with 350 g of powdered sugar was used as a simplest form of meringue cookies recipe to prepare a batter of meringue at room temperature. The Hobart N50CE (Hobart Foster Scandinavia A/S, Denmark) was used to mix sugar and LEW blend at 580 rpm for 90 s. to obtain soft egg white foams in first stage and mixing ended until a soft-whipped meringue batter occurs (Yüceer 2020a).

Methods

pH measurements of of meringur batter

The pH value of all prepared meringue batter samples were anaysed using Ohaus Starter pH meter (Ohaus Corporation, USA) (Yüceer 2020b). The analysis was performed in triplicate. The measurement was conducted at 20 ± 1 °C.

Color measurements of of meringur batter

The surface color values of meringue batter samples were analyzed using a colorimeter (CR-400, Konica Minolta, Japan) at 20 ± 1 °C. The reflectance colorimetric measurement values were presented to identifying surface color differences as color space CIE LAB L*, a*, b* parameters (Yüceer 2020b). In addition, Metric Hue Angle (h*), Metric Chroma (magnitude-C*), WI (Whiteness Index), and total color difference (∆E) were calculated according to Yüceer (2020a) based on color space CIELAB color difference metric (L, a, b, Delta E, Chroma, and Hue) values at following equations (Eqs. 1, 2, 3, 4):

| 1 |

| 2 |

| 3 |

| 4 |

Meringue batter density analysis

The density analysis of freshly whipped meringue batter obtained by measuring a volume of solids to weight as known a specific gravity. The volume was measured in cm3 and presented at 20 ± 1 °C. The weight per volume (specific density) was calculated according to Eq. 5and expressed as g/cm3. All measurements were conducted with three parallels.

| 5 |

Rheological measurements of meringur batter

The rheological characteristics of the meringue batter (LEW-sugar mixture foam) measurements were analyzed using a Discovery Hybrid Rheometer (DHR-2, TA Instruments, New Castle, USA) and data obtained by software (Trios Software, TA) equipped a 60 mm aluminum P -P probe geometry with 1 mm of gap. The standard procedure of creep-recovery measurements were performed according to Yüceer (2020a). In the study, the stiff peak of egg-sugar mixture foam (batter) was used in the measurement (Guadarrama-Lezama et al. 2016). The rheological behavior of meringue batter was analyzed using creep-recovery test, strain-relaxation behavior (strain sweep) and step creep (transient) phase was analysed at constant strain σ0 = 5 Pa during 180 s in the first step to obtain deformation under constant stress/force, while and recovery phase was maintained σ = 0 Pa during 360 s of recovery curve after removal the load/force at 25 °C and the stress relaxation of the sample was measured (Yüceer 2020a; Yüceer and Asik 2020). The rheological behavior results were presented in terms of creep compliance, J(t) (Pa−1) = γ/σ, where σ represents the constant stress during a creep test. The best fitted data was used as a criterion to obtain the high yield of coefficient determination R2 was 0.99 for treatments.

Gelling properties measurements

The thermal gelation of LEW is based on textural properties of protein denaturation. The LEW-gel were prepared by heating the LEW at 45 for 45 min using a dry bath incubator (FOUR E's Scientific Co, Ltd, Guangzhou, China). A texture profile analysis (TPA) of LEW gels were measured and presented as hardness value for gelling index. The TPA analysis was performed using a texture analyzer (TA.XT Plus Texture Analyzer, Stable Micro Systems, Surrey, England), equipped with 5 kg of load. The gelling strength measurement carried out using a cylindrical probe with TA-18, ½” dia ball, ss at room temperature with the following parameters: test speed of 1.0 mm/s, post-test speed of 5.0 mm/s, compression distance of 10 mm, recoverable time of 5 s, and trigger force load of 5.0 g (Yüceer 2020a).

Statistical analysis

Significant differences in samples as a result of various enzyme treatments were analyzed statistically. The obtained measurement values were analyzed by LSM-PROG GLM using a SAS statistical software (SAS 2003). Three replicates for each sample were analyzed and mean values plus standard deviations were reported. The data was calculated using a one-way analysis of variance (ANOVA) model with Tukey post-hoc comparison test was performed in comparing differences in treated/untreated samples and between groups. The differences in statistical analysis were considered as significance and defined P < 0.05 in the study.

Results and discussion

pH measurements

The pH analysis of LEW-sugar mixture (batter) was measured after whipping stage. The pH values of meringue’s batter prepared from phospholipase A2 (PLA), lipase and protease enzyme treated and untreated liquid egg white were presented in Table 1. The pH decreasement prior to enzymatic modification in lipase and protease helped to stabilizing the foam by decreasing the pH level in the meringue foam. During the study pH values ranged between 6.10 and 9.14. The expected difference was observed between the EWP samples treated with protease and lipase enzyme and those that not have the pH adjusted prior to treatment. The low pH can aid foam formation and stability in meringue production(Goldfarb 2016). According to results, the pH values of control, PLA, lipase and protease were 9.14 ± 0.19; 9.03 ± 0.12; 6.10 ± 0.20, and 7.79 ± 0.21, respectively. Yüceer (2020b) examined the use of 0.1; 0.2 and 0.3% by v/v concentrations of PLA enzyme on EWP and observed a decrease in pH values with increasing storage periods (day 45) in all treatments. The pH values of EWP samples were 9.07 ± 0.01 at the initial day (day 0) and ranged between 9.07 and 9.12 with PLA enzyme treatment as a processing aid agent. The marked differences at the end of storage in EWP samples of treated and untreated were observed in pH values. Yüceer (2020b) also found lower pH of 7.82 ± 0.11 in control samples (untreated) comparing to PLA treated eggs.

Table 1.

The pH values of meringue’s batter prepared from phospholipase A2 (PLA), lipase and protease enzyme treated and untreated liquid egg white

| Treatments | pH value |

|---|---|

| CNT* | 9.14 ± 0.19a |

| PLA | 9.03 ± 0.12b |

| Protease | 6.10 ± 0.20d |

| Lipase | 7.79 ± 0.21c |

*CNT control, PLA phospholipase A2

Results were presented as means ± standard deviations of triplicate measurements (n = 3)

a–dMeans in the same column with different lowercase letters are significantly different (P < 0.05)

Color analysis

The color parameters (L*, a*, b*, ∆E, Chroma, and Hue) of enzymes-treated and untreated freshly prepared meringue batter samples were analyzed (Table 2). According to results, the L* parameters of control, PLA, lipase and protease were 90.09 ± 0.22; 91.60 ± 0.26; 91.76 ± 0.35, and 91.94 ± 0.68, respectively. There was no significant difference (p > 0.05) was observed in the L* measurements. (Yüceer 2020a) has investigated the color parameters of meringue-batter samples treated with PLA and observed no significant difference between treated (0.1, 0.2 and 0.3%) and untreated LEW samples. The enzyme treatments led to an increase in b* parameters. This may be related to batter density (Table 2) and the air retaining capacity that is incorporated in the batter structure (Xing et al. 2015). The lower b* (3.86 ± 0.44) observed in protease treated samples. This may be related to hydrolyzation of proteins in batter system (Rao et al. 2012). Also, The differences between the treated groups L* and a* values were statistically notsignificant. The ΔE, chroma, and hue angle color parameters among the meringue batter samples were also calculated. Consequently, the ΔE color parameters were low and difficult to observe with human eye detecting points. The enzymatic treatments did not significantly affect the hue angles values of freshly prepared meringue samples. The protease treated samples had the lowest, where PLA treated samples had the highest whiteness index (WI).

Table 2.

The effect of phospholipase A2 (PLA), lipase and protease enzyme treated and untreated liquid egg albumen on batter prepared meringue’s color value changes

| Treatments | Meringue batter color values | ||||||

|---|---|---|---|---|---|---|---|

| L* | a* | b* | ∆E | Chroma | Hue | WI | |

| CNT* | 91.09 ± 0.22a | − 0.08 ± 0.07a | 4.48 ± 0.30a | 0 | 4.56 | − 5.58 | 94.23 |

| PLA | 91.60 ± 0.26a | − 0.76 ± 0.04b | 4.38 ± 0.15a | 0.79 | 4.45 | − 5.73 | 95.51 |

| Protease | 91.94 ± 0.68a | − 0.73 ± 0.03b | 3.86 ± 0.44b | 0.28 | 3.93 | − 5.25 | 92.62 |

| Lipase | 91.76 ± 0.35a | − 0.70 ± 0.06b | 4.05 ± 0.11a | 0.19 | 4.11 | − 5.78 | 93.33 |

*CNT control, PLA phospholipase A2

Results were presented as means ± standard deviations of triplicate measurements (n = 3)

a–bMeans in the same column with different lowercase letters are significantly different in each color parameter (P < 0.05)

Means with the same letters are not significantly different at (P < 0.05)

Meringue batter density

The batter specific gravity (batter density-BD), is the typical ratio of the batter weight to water weight, reflects a specific volume of final products after baking (Xing et al. 2015). The BD values of meringue’s prepared from PLA, lipase and protease enzyme treated/untreated LEW presented in Table 3. The BD of meringue batter of control (0.49 ± 0.01) was decreased significantly after treatments of PLA (0.39 ± 0.01), protease (0.37 ± 0.01) and lipase (0.33 ± 0.01). Meringue batters made using lipase enzyme were extremely lightweight. In the control group, it is observed that all enzymes used in the study decreased the BD of the batter, which may be related to foaming ability and the level of air phase that absorbs as a gas to the egg protein system (Raikos et al. 2007). Meringue is a forming of egg white protein foam (Murray 2020). Larger air bubbles in the egg protein system results in a decrease of the BD and increase in aeration of yield of foaming volume (Xing et al. 2015). The stability of meringue also shows the meringue’s ability to volume and mass (Goldfarb 2016). The lipase treated samples showed higher overrun comparing other groups. According to the result of BD, it is possible to restore the physico-functional properties of meringue with the treatment of lipase enzymes and modification of the foam structure. The control samples showed runny and flat batter structure with high density foams comparing to enzyme treated samples. Enzyme treated batters resulted a light and crisp meringue cookie (Yüceer 2020a; Yüceer and Asik 2020). This result suggested that lipase could be used in LEW to decrease the typical BD, to lighten (low density foams) the batter and increase physical stability.

Table 3.

The batter density values of meringue’s batter prepared from phospholipase A2 (PLA), lipase and protease enzyme treated and untreated liquid egg white

| Treatments | Batter density values of meringues (g/cm3) |

|---|---|

| CNT* | 0.49 ± 0.01a |

| PLA | 0.39 ± 0.01b |

| Protease | 0.37 ± 0.01c |

| Lipase | 0.33 ± 0.01d |

*CNT control, PLA phospholipase A2

Results were presented as means ± standard deviations of triplicate measurements (n = 3)

a–dMeans in the same column with different lowercase letters are significantly different (P < 0.05)

Means with the same letters are not significantly different at (P < 0.05)

Rheological behavior

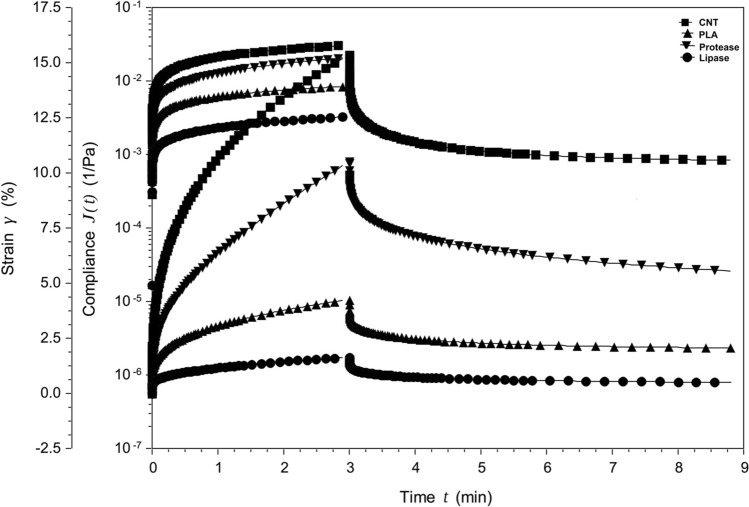

Foam is a dispersion of a gas phase as bubbles within continuous media in liquid or solid state (Nicorescu et al. 2011). A typical creep-recovery curve of meringue’s batter samples (whipped LEW/sugar mixture) prepared from different enzymes (PLA, lipase and protease) treated and non-treated liquid egg white presented in Fig. 1. The effect of enzymes on creep-recovery characteritics of meringue batter samples were best fitted to Burgers model. According to the results, it was found that lipase enzyme treated meringue batter samples exhibited the lowest creep compliance values among the enzyme treatments. The lipase treated samples exhibited an improvement in characteristics of foam aeration. All batter samples exhibited viscoelastic behavior. However, the incorporation of various enzymes significantly influenced creep-recovery behavior of meringue batters. Lipase treated meringue batter samples showed greater resistance to deformation with smaller compliance compared to PLA, protease and control samples, where PLA batter samples showed the lowest resistance to deformation amoung the treated samples. Curves from analysing data, plotted in terms of compliance vs. time, overlapped for stresses < 150 (Pa), indicating the linear viscoelastic region. The instantaneous compliance value was highest in the control sample with low stability and adoption to collapse. Protease treated samples showed the highest recovery value compared to lipase and PLA samples. The R2 values of the Burgers model for the freshly prepared meringue batter using enzyme treated-LEW samples was > 0.99. The Burger model coefficient is also the common model used in soft materials such as batters and deformation structure (Das and Ghosh 2006). This indicated the used model was satisfactory describing the stress relaxation characteristic of meringue batter samples. Also this mention the stability of meringue’s draining over time at room temperature (Goldfarb 2016). It can be suggested that lipase treated samples showed lowest creep-recovery behavior which resulted in a higher technological and production yield in cookies technological properties during cooking and storage. Lipase treated meringue batter samples exhibited a rheopectic behavior and showed an improvement in rheological behavior with a stronger structure and smaller creep strain than soft batter-foam samples (control). The stability is increased by reducing the bubble size in the foam structure (Goldfarb 2016). The influence of the lipase of the LEW on creep behavior observed a decrease in recoverable compliance and meringue batter strength, which is related to a smaller creep strain Culetu, Stoica‐Guzun, and Duta (2020). Highest compliance values were observed in nontreated samples, which is like an ideal to solid-like formation. Similar results found by Alavi et al. (2020) in the treatment of egg white with transglutaminase enzyme application. Also, the application of minimal constant shear stress (5 Pa) and removed to zero (0 Pa), resulted in a rearrangement of the hydrogen bonds during coagulation of protein aggregates in whipping (Chang et al. 1999). The lipase provided a meringue batter with superior whippablity and stability by making the foam less adoption to collapse during processing (Fig. 1). The protease treated samples showed lower compliance than control samples with a low weakening may be caused by strengthened gel network of protease (Quan and Benjakul 2019). The study results are found to be in good agreement with previous studies conducted o creep-recovery compliance on batter-dough structure (Alavi et al. 2020; Culetu et al. 2020; Mizu and Nagao 2010; O'Charoen et al. 2014; Stevenson et al. 2007; Yüceer 2020a; Yüceer and Asik 2020).

Fig. 1.

Typical creep-recovery tests of meringue’s batters prepared from different enzyme treated and non-treated liquid egg white. *CNT control, PLA phospholipase A2

Gelling properties

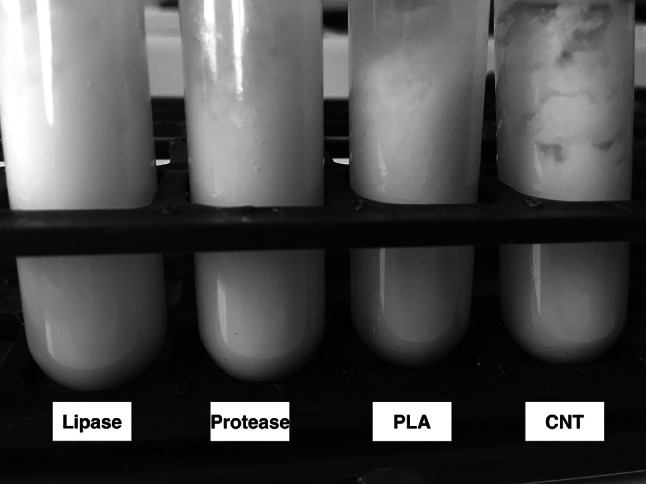

Liquid egg white as gelling agents using in many bakery products, such as angel cake, cookies, meringues, confectionery etc. The textural characteristics of LEW gels are shown in Fig. 2. The gellng index values of LEW gels prepared from PLA, lipase and protease enzyme treated and untreated LEW are pressented in Table 4. After heat treatment of LEW the samples turned into an elastic gel. Also a solidification occued in LEW proteins due to thermal denaturation (Table 4). The hardness value represented to characterising the gelling index which is relate to the the maximum force required to compress the LEW-gel sample during the first compression. The gelling index of control (41.2 ± 1.19) was decreased significantly after treatments of PLA (34.3 ± 1.32), protease (25.1 ± 1.29) and lipase (23.3 ± 1.51). The enzymatic treatmens effected the mechanical and textural properties of LEW-gel structure which is related to changing the surface hydrophobicity of albumen proteins (Wang 2009). The gelling index and BD values significantly decreased after enzymatic treatment of LEW and the dramatic decrease observed in lipase enzyme.

Fig. 2.

Visual image of meringue’s batters prepared from different enzyme treated and non-treated liquid egg white. *CNT control, PLA phospholipase A2

Table 4.

The gellng index values of meringue’s batter prepared from phospholipase A2 (PLA), lipase and protease enzyme treated and untreated liquid egg white

| Treatments | Gelling index |

|---|---|

| CNT* | 41.2 ± 1.19a |

| PLA | 34.3 ± 1.32b |

| Protease | 25.1 ± 1.29c |

| Lipase | 23.3 ± 1.51d |

*CNT control, PLA phospholipase A2

Results were presented as means ± standard deviations of triplicate measurements (n = 3)

a–dMeans in the same column with different lowercase letters are significantly different (P < 0.05)

Conclusion

This study presents the results of the application and effectiveness of three enzymes (PLA, lipase and protease) treatment on meringue batter samples. Functional, textural and physicochemical challenges were analyzed in the study. The batter density of meringue was decreased while whippability increased in all-enzyme treatments which is essential for higher volume with a crispy structure of meringue cookies. The lowest BD value obtained in lipase treated while high BD values obtained in control samples. Protease enzyme has potential to become significant breakthrough in the egg industry to preserving egg proteins deformation. The presented study highlights that, determining the effect of hydrolysis by PLA (foaming agent), lipase (stabilizing agent), protease (texture profiler) enzyme-treated LEW. Also, the results of study provide practical information to the baking industry for optimal processing conditions of meringue-based foamed applications, variety of cake decoration, mousses, pastry, wafers, dessert, masking cakes and aerated confectionery products. This study concluded that, according to overall acceptability in physico-functional properties and whipping quality, lipase treated samples is suitable for improving the stability, batter yield, functionality and rheological behavior of meringue batter with a unique structure. The enzyme treatments of LEW provide as a novel processing approach for culinary concept innovations especially in meringue production. Further studies should be conducted on inhibitory activity of bioactive substances of LEW such as ovomucoid.

Acknowledgments

Thanks to the TUBİTAK, the Scientific and Technical Council of Turkey (grant number 214O376) for supporting this research.

Authors contribution

MY conceived the designed study and project admin, MY and CC organized the whole research outlined. Manuscript drafting wrote by MY and received the final reviewed and edited manuscript with CC.

Funding

This work was financially supported by a grant from the TUBİTAK with project number 214O376.

Code availability

Not applicable.

Declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

Ethics approval was not required for this research. This study does not involve any human or animal testing.

Consent to participate

Not applicable.

Consent for publication

The Authors transfers to Springer the non-exclusive publication rights and they warrant that their contributions are original and that he has full power to make this grant.

Availability of data and material

Data available on request from the author(s). The datasets generated during the experiment that support the findings of this study are available from the corresponding author upon reasonable request.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Muhammed Yüceer, Email: myuceer@comu.edu.tr.

Cengiz Caner, Email: ccaner@comu.edu.tr.

References

- Ai M, Tang T, Zhou L, Ling Z, Guo S, Jiang A. Effects of different proteases on the emulsifying capacity, rheological and structure characteristics of preserved egg white hydrolysates. Food Hydrocoll. 2019;87:933–942. doi: 10.1016/j.foodhyd.2018.09.023. [DOI] [Google Scholar]

- Alavi F, Emam-Djomeh Z, Chen L. Acid-induced gelation of thermal co-aggregates from egg white and hempseed protein: impact of microbial transglutaminase on mechanical and microstructural properties of gels. Food Hydrocoll. 2020 doi: 10.1016/j.foodhyd.2020.105960. [DOI] [Google Scholar]

- Chang YI, Chen TC, Lee GH, Chang KS. Rheological, surface and colorbvietric properties of egg albumen gel affected by pH. Int J Food Prop. 1999;2(2):101–111. doi: 10.1080/10942919909524594. [DOI] [Google Scholar]

- Culetu A, Stoica-Guzun A, Duta DE. Impact of fat types on the rheological and textural properties of gluten-free oat dough and cookie. Int J Food Sci Technol. 2020 doi: 10.1111/ijfs.14611. [DOI] [Google Scholar]

- Daimer K, Kulozik U. Impact of a treatment with phospholipase A2 on the physicochemical properties of hen egg yolk. J Agric Food Chem. 2008;56(11):4172–4180. doi: 10.1021/jf703641e. [DOI] [PubMed] [Google Scholar]

- Daimer K, Kulozik U. Oil-in-water emulsion properties of egg yolk: effect of enzymatic modification by phospholipase A2. Food Hydrocoll. 2009;23(5):1366–1373. doi: 10.1016/j.foodhyd.2008.10.002. [DOI] [Google Scholar]

- Das S, Ghosh A. Study of creep, stress relaxation, and inverse relaxation in mulberry (Bombyx mori) and tasar (Antheraea mylitta) silk. J Appl Polym Sci. 2006;99(6):3077–3084. doi: 10.1002/app.22911. [DOI] [Google Scholar]

- Goldfarb W. Making a Balinese Meringue. International Journal of Gastronomy and Food Science. 2016;4:12–18. doi: 10.1016/j.ijgfs.2016.02.003. [DOI] [Google Scholar]

- Guadarrama-Lezama AY, Carrillo-Navas H, Pérez-Alonso C, Vernon-Carter EJ, Alvarez-Ramirez J. Thermal and rheological properties of sponge cake batters and texture and microstructural characteristics of sponge cake made with native corn starch in partial or total replacement of wheat flour. LWT Food Sci Technol. 2016;70:46–54. doi: 10.1016/j.lwt.2016.02.031. [DOI] [Google Scholar]

- Horimoto Y, Lim LT. Effects of different proteases on iron absorption property of egg white hydrolysates. Food Res Int. 2017;95:108–116. doi: 10.1016/j.foodres.2017.02.024. [DOI] [PubMed] [Google Scholar]

- Jaekel T, Ternes W. Changes in rheological behaviour and functional properties of hen’s egg yolk induced by processing and fermentation with phospholipases. Int J Food Sci Technol. 2009;44(3):567–573. doi: 10.1111/j.1365-2621.2008.01847.x. [DOI] [Google Scholar]

- Kim M-R, Shim J-Y, Park K-H, Imm B-Y, Oh S. Optimization of the enzymatic modification of egg yolk by phospholipase A2 to improve its functionality for mayonnaise production. LWT Food Sci Technol. 2009;42:250–255. doi: 10.1016/j.lwt.2008.05.014. [DOI] [Google Scholar]

- Macherey LN, Conforti FD, Eigel W, O’Keefe SF. Use of mucor miehei lipase to improve functional properties of yolk-contaminated egg whites. J Food Sci. 2011;76(4):C651–C655. doi: 10.1111/j.1750-3841.2011.02138.x. [DOI] [PubMed] [Google Scholar]

- Mizu T, Nagao K. Thermal conduction in egg albumen foam (meringue) during heating. J Jpn Soc Food Sci Technol Nippon Shokuhin Kagaku Kogaku Kaishi. 2010;57(1):20–25. doi: 10.3136/nskkk.57.20. [DOI] [Google Scholar]

- Murray BS. Recent developments in food foams. Curr Opin Coll Interface Sci. 2020 doi: 10.1016/j.cocis.2020.101394. [DOI] [Google Scholar]

- Nicorescu I, Vial C, Talansier E, Lechevalier V, Loisel C, Della Valle D, et al. Comparative effect of thermal treatment on the physicochemical properties of whey and egg white protein foams. Food Hydrocoll. 2011;25(4):797–808. doi: 10.1016/j.foodhyd.2010.09.020. [DOI] [Google Scholar]

- O'Charoen S, Hayakawa S, Matsumoto Y, Ogawa M. Effect of D-Psicose used as sucrose replacer on the characteristics of meringue. J Food Sci. 2014;79(12):E2463–E2469. doi: 10.1111/1750-3841.12699. [DOI] [PubMed] [Google Scholar]

- Quan TH, Benjakul S. Impact of salted duck egg albumen powder on proteolysis and gelling properties of sardine surimi. J Texture Stud. 2019;50(5):434–442. doi: 10.1111/jtxs.12445. [DOI] [PubMed] [Google Scholar]

- Rao Q, Rocca-Smith JR, Labuza TP. Moisture-induced quality changes of hen egg white proteins in a protein/water model system. J Agric Food Chem. 2012;60(42):10625–10633. doi: 10.1021/jf302402k. [DOI] [PubMed] [Google Scholar]

- SAS (2003) SAS User Guide Version 9.1.3. Statistical Analysis Systems Institute. Cary, NC, USA

- Schuck P. Dairy Powders. In: Bhandari B, Bansal N, Zhang M, Schuck P, editors. Handbook of foos powders process and properties. Philadelphia: Woodhead Publishing Limited; 2013. p. 450. [Google Scholar]

- Stevenson P, Mantle MD, Hicks JM. NMRI Studies of the free drainage of egg white and meringue mixture froths. Food Hydrocoll. 2007;21(2):221–229. doi: 10.1016/j.foodhyd.2006.03.009. [DOI] [Google Scholar]

- Vega C, Sanghvi A. Cooking literacy: meringues as culinary scaffoldings. Food Biophys. 2012;7(2):103–113. doi: 10.1007/s11483-011-9247-7. [DOI] [Google Scholar]

- Wang G (2009) Phospholipids oxidation and foaming enhancement of egg albumen. Ph.d. dissertation (Doktora Tezi), Iowa State University, Ames, Iowa, USA

- Xing L, Niu F, Su Y, Yang Y. Effect of egg freshness on texture and baking characteristics of batter systems formulated using egg, flour and sugar. J Sci Food Agric. 2015 doi: 10.1002/jsfa.7316. [DOI] [PubMed] [Google Scholar]

- Yüceer M. Evaluation of physicochemical properties on meringue prepared from phospholipase A2 enzyme-hydrolyzed liquid egg albumen. Eur Food Res Technol. 2020;246:1847–1856. doi: 10.1007/s00217-020-03538-4. [DOI] [Google Scholar]

- Yüceer M. Structural and rheological characterization of liquid egg white modified with phospholipase A2 enzyme. J Food Process Preserv. 2020;44(6):e14450. doi: 10.1111/jfpp.14450. [DOI] [Google Scholar]

- Yüceer M, Asik H. Texture, rheology, storage stability, and sensory evaluation of meringue's prepared from lipase enzyme-modified liquid egg white. J Food Process Preserv. 2020;44(9):e14667. doi: 10.1111/jfpp.14667. [DOI] [Google Scholar]

- Yüceer M, Caner C (2018a) New method of production meringues using enzyme modified liquid egg. Patent No. 2018/01572. Turk Patent ve Marka Kurumu

- Yüceer M, Caner C (2018b) Rheological characterization of protease treated liquid egg white. Paper presented at the the ınternational symposium on food rheology and texture, Istanbul

- Yuceer M, Caner C. Antimicrobial Lysozyme-chitosan coatings affect functional properties and shelf life of chicken eggs during storage. J Sci Food Agric. 2014;94(1):153–162. doi: 10.1002/jsfa.6322. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Not applicable.