Abstract

The food products may attract unscrupulous vendors to dilute it with inexpensive alternative food sources to achieve more profit. The risk of high value food adulteration with cheaper substitutes has reached an alarming stage in recent years. Commonly available detection methods for food adulteration are costly, time consuming and requires high degree of technical expertise. However, a rapid and suitable detection method for possible adulterant is being evolved to tackle the aforesaid issues. In recent years, electronic nose (e-nose) system is being evolved for falsification detection of food products with reliable and rapid way. E-nose has the ability to artificially perceive aroma and distinguish them. The use of chemometric analysis together with gas sensor arrays have shown to be a significant procedure for quality monitoring in food. E-nose techniques with numerous provisions are reliable and favourable for food industry in food fraud detection. In the present review, the contributions of gas sensor based e-nose system are discussed extensively with a view to ascertain the adulteration of food products.

Keywords: Adulteration, E-nose, Aroma, Chemometric analysis, Sensor

Introduction

Adulteration of food products is the incorporation of cheaper substitutes in lieu of expensive ingredients. It could be profitable for a vendor or raw material supplier. Food adulteration has become a common problem faced by food processing sector. The food standards and safety regulatory authority has prescribed the compositional standards for almost all the food products to ensure the genuineness of the product under different acts and regulations in most of the countries of the world. Unfortunately, the producers in their greed to have more money tend to adulterate food with cheaper substitutes. Adulteration with poisonous chemical like formalin and calcium carbide is widespread and regularly applied on fish (Gu et al. 2019), meat (Li et al. 2018), fruit (Pandey 2016), dairy products (Moosavy et al. 2019) that causes different types of human diseases. Other adulterants like colouring dyes, urea, and various permitted preservatives are used severely that affect several body parts of human. This can lead to various chronic illnesses like liver disorder, diarrhoea, vomiting, cancer, and heart disorder. In order to safeguard the processed food items and to ensure the acceptable level of quality, it is necessary to monitor the food product across the entire food supply chain.

There are various methods available for detecting adulteration of food like microscopic examination, differential scanning calorimetry, gas chromatography-mass spectrometry, fourier transform infrared spectroscopy, high performance liquid chromatography, nuclear magnetic resonance, sensory and chemical detection methods. Most of the techniques are costly, adulterating compound specific, and time consuming for regular uses in food industry and requires high degree of technical expertise in these fields. Consequently, real-time rapid detection methods with cheap and efficient technology for quality control and especially for rapid adulteration detection in processed foods are being commercialized. For this purpose, techniques based on e-nose, which approximately mimic human nose is widely used to deal with adulteration problems in food products.

An e-nose is expressed as an artificial olfactory system or machine olfaction used for automated simulation of the sense of smell (Al-Maskari et al. 2014). E-noses become a widespread non-destructive method to distinguish the quality of food products because they are easy to handle, cost-effective and most importantly they provide a short time analysis. An e-nose has the ability to detect the specific components of an odor and analyzes its chemical makeup to identify it (Modupalli et al. 2021). So far, various research related to food quality control have been presented focusing on the extensive use of this equipment. Persaud and Dodd (1982) gave the idea of e-nose system for aroma discrimination using chemical sensors. According to Gardner 1991 and Gardner and Shurmer 1992, an e-nose typically consists of a mechanism for chemical detection such as an electronic multisensor array system, an information-processing unit, a digital pattern-recognition algorithm system that is capable of recognising odours, and a reference-library database. Since twentieth century, e-nose technique has undergone a great deal of development and it is preferred to routine laboratory analysis. However, there is still more research needs to be done especially relating to sensor technology, processing the data, interpreting the results and validation studies. E-nose technology promises many applications including environment monitoring, quality control assessment in agricultural goods, identifying fraudulent adulteration, and spoilages. This review aims to present a brief idea about identification of food adulteration using various e-nose configurations.

E-nose system

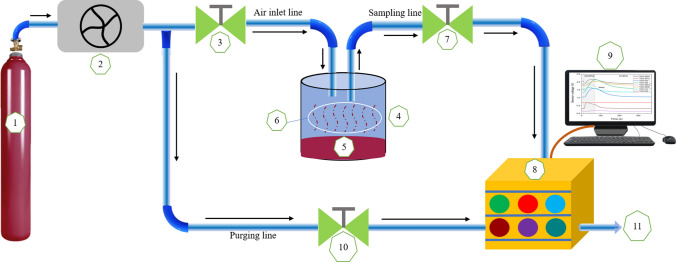

The typical block diagram of an e-nose device with nomenclature is presented in Fig. 1. The e-nose device is basically based on identification of volatile organic compounds (VOCs) generated by food samples in the output form of voltage differences detected by limited selective sensors. The apparatus mainly consists of three primary units i.e. sample delivery unit, detection unit and a computing unit. The generated VOCs in the sample container are pumped into the sensor array chamber by blowing synthetic air (99.99% pure). During e-nose measurement, the air inlet valve (part number 3 in Fig. 1) and the sampling valve (part number 7 in Fig. 1) remains open while, the purging valve (part number 10 in Fig. 1) will be closed to introduce the VOCs towards detection unit (sensor array chamber). The sensor array consists of selective and sensitive gas sensors coupled with a data acquisition card receives the analogue signal and converts it into digital signal for displaying it on the monitor. The differences in complex odours from food matrix generated as voltage response values (output) are used to classify and discriminate the quality of food products, using various pattern recognition models. Baseline correction of sensor array is necessary before each e-nose sample measurement, which can be performed by injecting the carrier gas into the sensor array compartment by opening the purge valve to push the volatiles out of the array compartment (Ghasemi-Varnamkhasti et al. 2019). While purging the sensor array chamber, the air inlet valve and sampling valve remain closed. The analysis of samples is performed using gas sensor array and pattern recognition algorithms. The normally used sensors in e-nose devices are surface acoustic waves (SAW), conducting polymers and metal oxide semiconductors (MOS) among which MOS sensors are extensively used due to its high chemical stability, low response to moisture, long life, and reasonable price (Deng 2019; Jia et al. 2019). The operational interactions between sensor coating materials and gaseous molecules influences the electrical current passing through sensor detected by a fitted transducer converting it into an electronic recordable signal to digital signal (Jia et al. 2019). The output of the digital signal is displayed by the microprocessor on computer.

Fig. 1.

Typical block diagram of an e-nose system (1. Synthetic air cylinder, 2. Blower, 3. Air inlet valve, 4. Closed sample container, 5. Sample, 6. Volatiles, 7. Sampling valve, 8. Sensor array chamber, 9. Data processing and pattern recognition, 10. Purge valve, 11. Purge outlet)

Suitable post processing methods are essential to classify and analyse the data from each sensor in the e-nose system. The most common classification and recognition methods for e-nose data are principal component analysis (PCA) (Bougrini et al. 2014), partial least square (PLS) regression (Men et al. 2014), support vector machines (SVM) (Majcher et al. 2015), linear discriminant analysis (LDA) (Cerrato Oliveros et al. 2002), principal component regression (PCR) (Hong et al. 2014), discriminant factor analysis (DFA) (Hong et al. 2011), fuzzy logic (Tohidi et al. 2018b) and artificial neural network (ANN) (Kiani et al. 2017) including probabilistic neural network (PNN) (Zakaria et al. 2011), back propagation neural network (BPNN) (Tian et al. 2019). Among these methods, PCA, LDA, PCR, PLS, DFA, SVM are regarded as linear methods while fuzzy logic, ANN and PNN, BPNN are based on nonlinear approaches. Linear chemometric tools are unsupervised learning technique to reduce the dimensions of the raw data linearly in e-nose measurement by preserving the maximum information in the new dataset and explaining the variance with classification accuracy. The nonlinear approaches are supervised learning technique and needs training of the dataset. However, once the datasets are trained well in nonlinear methods, the adulteration prediction is easier, rapid, and more consistent. Chemometric tools based on linear and nonlinear strategies are significant for separation and characterization of the examples framed by the datasets in food adulteration detection.

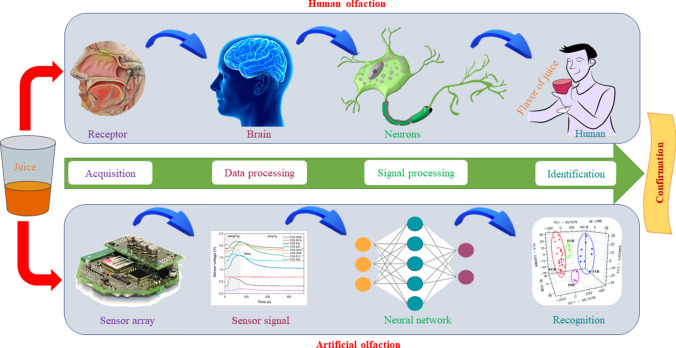

Correlation between human olfaction with e-nose

The correlation of artificial olfaction (e-nose) with human olfaction in the judgement of food quality is introduced in Fig. 2. The cycle of olfaction or smelling in people start with hair-like cilia coating the nasal cavity, called olfaction epithelium. As odorants from food molecule enters the olfaction epithelium, some chemicals in the air bind to and activate nervous system receptor on the cilia (Kauer 1991). This stimulus sends a signal to the first order neurons associated with the epithelial cells. The signal is conveyed by these neurons from the epithelium cavity to the opening of the ethmoid bone and afterward to the olfactory bulbs of the brain. This signals at that point move from the olfactory bulbs along the olfactory tracts to the olfactory territory of the cerebral cortex. The signals are interpreted based on their trademark smell which permits people to perceive the particular smell. Whereas, artificial olfaction helps in detecting odor molecules from food samples based on the selective sensor array combined with pattern recognition techniques, also known as an e-nose technique. Despite the fact that human olfaction can check the organoleptic feature of food with trained personnel, the efforts to make instrumental technique like e-noses which can make fine perception of any food products based on their aromas are being used over the past two decades by many researchers.

Fig. 2.

Correlation between human olfaction with artificial olfaction

Application in food adulteration

Detection of adulteration in various foods include fruits, alcoholic and non-alcoholic drinks, milk and dairy products, honey, meat, fish, spices, edible oils, tea, and coffee. The evolutions of e-noses in quality monitoring of foodstuffs particularly for falsification detection has been summarized below in Table 1.

Table 1.

Applications of e-nose for monitoring adulteration in food

| Category | Product | Adulteration with | Type of e-nose configuration for adulteration monitoring | Detection result to recommend best technique | References |

|---|---|---|---|---|---|

| Edible oils | Camellia seed oil and sesame oil | Maize oil | Commercial type, Airsense PEN2 (Germany) e-nose system with 10 MOS sensors | LDA: 83.6% for camellia seed oil while 94.5% for sesame oil | Hai and Wang (2006a) |

| sesame oil | Maize oil | Commercial type, PEN2 (Airsense corporation, Germany) e-nose with 10 MOS sensors | LDA: only one sample is incorrectly classified out of one hundred sixty five samples | Hai and Wang (2006b) | |

| Virgin olive oil | Sunflower oil and olive–pomace oil | Commercial type, two array chambers of Alpha MOS e-nose (FOX 3000) with 12 (6 + 6) MOS based sensors | LDA: classification accuracy > 96% and in some cases almost 100% | Cerrato Oliveros et al. (2002) | |

| Olive oil | Rapseed oil and sunflower oil | Commercial type, Fox 4000 Alpha MOS e-nose (Toulouse, France) with 3 sensor chamber each containing 6 gas sensors | PLS: correlation coefficient of 0.989 for rapseed adulteration of olive oil while, 0.990 for sunflower adulteration of olive oil | Mildner-Szkudlarz and Jeleń 2010 | |

| Olive oil | Hazelnut oil | Commercial type, Alpha MOS e-nose (Fox 4000) system with 3 chambers each containing six MOS sensors |

PCA: 96% separation of samples PLS: correlation coefficient 0.997 |

Mildner-Szkudlarz and Jeleń (2008) | |

| Argan oil | Sunflower oil | Experimental type, e-nose system with 5 MOS gas sensors | PCA: 98.81% in comestible argan oil adulteration and 98.09% in cosmetic argan oil adulteration | Bougrini et al. (2014) | |

| Soybean oil | Old frying oil | Experimental type, 8 MOS gas sensor based e-nose system | PLS: correlation coefficient of 0.843 for old frying oil adulteration of soybean oil | Men et al. (2014) | |

| Virgin coconut oil | Palm kernel olein oil | Commercial type, zNose™ (Model 7100 Electronic Sensor Technology, Newbury Park, CA, USA) e-nose with SAW sensor | PLS: correlation coefficient of 0.91 for palm olein oil adulteration of virgin coconut oil | Marina et al. (2010) | |

| Palm olein oil | palm stearin oil | Commercial type, MS-E-nose (SMart Nose300; SMart Nose, MarinEpagnier, Switzerland) | DFA: coefficient of determination for DF1 is 0.997 and DF2 is 0.966. DFA could able to discriminate below 10% adulteration level | Hong et al. (2011) | |

| Palm olein | Lard | Commercial type, zNose™ (Newbury Park, USA) based on SAW detector | ANOVA: coefficient of determination is 0.906 and Pearson’s correlation coefficient > 0.90 | Man et al. (2005) | |

| Peony seed oil | Soybean oil, corn oil, sunflower oil, rapeseed oil | Commercial type, PEN3 e-nose (Airsense analytics, Germany) with 10 MOS chemical gas sensors | LDA: soybean oil and sunflower oil can be successfully discriminated from peony seed oil | Wei et al. (2018) | |

| Milk and dairy products | Milk | Water and reconstituted milk powder | Commercial type, PEN2 e-nose (WMA Airsense Analysentechnik, Germany) with 10 MOS sensors | LDA: adulterated samples can be discriminated from milk stored for 1–4 days | Yu et al. (2007) |

| Milk | Aqueous CH2O, H2O2, NaClO | Experimental type, e-nose device based on 10 MOS gas sensors | SVM: 94.64%, 92.85%, 87.75% for aqueous CH2O, H2O2, NaClO adulteration in milk, respectively | Tohidi et al. (2018a) | |

| Milk | Detergent powder | Experimental type, e-nose system with 8 MOS sensors | SVM: 92.42% classification accuracy | Tohidi et al. (2018b) | |

| Cheese | Oscypek-like cheeses produced from ewe’s milk and cow’s milk | Commercial type, SPME-MS based e-nose | SVM: 97.9% classification accuracy | Majcher et al. (2015) | |

| Ghee | Sunflower oil and cow body fat | Experimental type, e-nose system with 8 different MOS gas sensors | PCA: 96% and 97% accuracy for sunflower oil and cow body fat adulteration of ghee, respectively | Ayari et al. (2018a) | |

| Ghee | Margarine | Experimental type, e-nose system with 8 different MOS gas sensors | PCA: 98% classification accuracy | Ayari et al. (2018b) | |

| Honey | Honey | Corn syrup and rice syrup | Commercial type, GC-Heracles e-nose (Alpha MOS, Toulouse, France) | PCA and PLS: Both the classifiers couldn’t well classified the syrup adulterations in honey | Gan et al. (2016) |

| Honey | Beetroot sugar and cane sugar | Commercial type, Cyranose 320 (Pasadena, CA, USA) e-nose system with 32 polymer sensors | LDA: 76.5% and 74.9% accuracy for stepwise LDA and direct LDA, respectively | Subari et al. (2012) | |

| Honey | Beetroot sugar and cane sugar | Commercial type, Cyranose 320 (Pasadena, CA, USA) e-nose system with 32 polymer sensors | ANN: mean absolute error of 6.9% for fusion data while 15% for e-nose separately | Subari et al. (2014) | |

| Honey | 2 different brands of sugar syrup | Commercial type, Cyranose 320 e-nose system with 32 polymer matrix sensors blended with carbon black | PNN: 92.59% classification accuracy | Zakaria et al. (2011) | |

| Alcoholic and non-alcoholic drinks | Liquor | Different geographical spirits | Commercial type, Alpha MOS based SA-Flash GC e-nose (HERACLES II, France) | DFA: 100% classification accuracy | Peng et al. (2015) |

| Italian wine | Ethanol, methanol, and other brands of wine | Experimental type, e-nose based on 4 MOS for headspace analysis | ANN: 93% of correct classification | Penza and Cassano (2004) | |

| Fruit juice | Alcohol | Commercial type, Cyranose 320 e-nose system with 32 carbon/polymer matrix sensors |

ANN, SVM: apple juice–Raki mixture, 98.33% LDA: lemon juice–alcohol mixture, 95% ANN: orange juice–vodka mixture, 96.67% KNN: sour cherry juice–alcohol mixture, 91.67% |

Ordukaya and Karlik (2016) | |

| Cherry tomato juices | Overripe tomato juices | Commercial type, PEN2 e-nose (Airsense Analytics, Schwerin, Germany) chamber with 10 MOS sensors | PCR: R2 > 0.99 for both training and prediction set of data | Hong et al. (2014) | |

| Fresh cherry tomato juice | Overripe tomato juices upto 30 per cent | Commercial type, PEN2 e-nose (Airsense Analytics, Schwerin, Germany) with 10 MOS positioned in a small chamber | SVM: 100% classification accuracy | Hong and Wang (2014) | |

| Freshly squeezed orange juice | 100% concentrated orange juice | Commercial type, FOX 3000 e-nose (Alpha MOS, Toulouse, France) equipped with 12 MOS sensors | LDA: 91.7% classification accuracy | Shen et al. 2016 | |

| Meat | Minced mutton | Pork | Commercial type, PEN2 e-nose (Airsense Corporation, Germany) with 10 different MOS sensors positioned in a small chamber | BPNN: correlation coefficient > 0.97 for both calibration and validation | Tian et al. (2019) |

| Mutton | Duck meat | Commercial type, PEN3 e-nose (Airsense Corporation, Germany) with 10 MOS sensors in sensor array | LDA: 98.2% classification accuracy | Wang et al. (2019) | |

| Lard | Chicken fat | Commercial type, zNoseTM e-nose (7100 Vapour Analysis System, Electronic Sensor Technology, Newbury Park, CA) with SAW sensor | PCA: 90% classification accuracy | Nurjuliana et al. (2011) | |

| Spices | Spice mixtures | Curry and garlic | Commercial type, e-nose (KAMINA-type, Yson GmbH) contains a chip array of 38 sensor segments based on gas sensitive doped tin oxide | PCA: 93.8% classification accuracy | Banach et al. (2012) |

| Saffron | Aroma fingerprints of saffron with yellow styles, safflower and dyed corn stigma | Experimental type, e-nose system with 6 MOS sensors (HANWEI Electronics Co., Ltd., Henan, China) | ANN: 86.87% and 100% accuracy for saffron adulteration with yellow styles-dyed corn stigma and safflower, respectively | Heidarbeigi et al. (2015) | |

| Cumin | Coriander | Experimental type, e-nose system with 6 MOS sensors | PCA: 91.68% classification accuracy | Tahri et al. (2017) | |

| Saffron | Artificially colored safflower and artificially colored yellow styles of saffron | Experimental type, e-nose system with 7 MOS sensors |

ANN: correlation coefficient of 0.95 and 0.97 for color and aroma based adulteration, respectively SVM: 100% success rate only on aroma datasets |

Kiani et al. (2017) |

Edible oils

Edible plant oils have a huge contribution in human diet for food product formulation, cooking and preservation. Some of the oils are more nutritious and have higher prices in the market due to their quality and taste. So, the vendors adulterate these expensive oils with cheaper oils, fats and sterols with similar fatty acid profile to earn profit. In some cases, adulteration of edible plant oil causes serious health issues like Spanish olive oil syndrome due to incorporating non-edible olive oil with edible one (Clemente and Cahoon 2009). Several researchers have used several techniques to detect such adulterations, but an e-nose is a trustworthy and highly sensitive technique which a consumer can ascertain the purity and authenticity of edible oils.

A number of e-nose systems have been developed to differentiate edible vegetable oils for their authenticity and identify adulteration (Table 1). Camellia seed oil and sesame oil adulteration with maize oil has been studied by Hai and Wang (2006a) using e-nose device based on 10 MOS sensors to identify the chemical vapour prints of the pure and adulterated oil samples. The range of adulteration with maize oil was from 10 to 90% with an increment of 10% (v/v) for each adulterated sample. The headspace was generated for 1 h while the data collection time was 60 s. The first 15 s data was best selected for further classification and pattern recognition based on prominent difference in mean vectors than 30 s and 60 s. PCA could not well differentiate the camellia seed adulteration with maize oil due to their overlapping characteristics while it could differentiate the sesame oil adulteration. LDA classification showed better results than PCA with an accuracy of 83.6% for camellia seed oil adulteration and 94.5% for sesame oil adulteration. The results of the training data set were poor and hence, ANN cannot be utilized to identify the adulteration of camellia seed oil, while the quantitative assurance can be done for sesame oil adulteration. In another investigation of sesame oil adulteration by maize oil by same authors (Hai and Wang 2006b) utilized the same e-nose tool and the measurement was done based on their earlier approach while, several chemometric were used to identify the adulteration in sesame oil. Excellent outcomes were achieved by LDA than PNN with just 1 example was misclassified. Fisher linear transformation with LDA and PNN was the most appropriate recognition tool for adulteration recognition in sesame oil with maize oil. BPNN and general regression neural network also showed excellent prediction percentage of sesame oil adulteration by maize oil.

The virgin olive oil and refined olive oil usually adulterated with crude hazelnut oil was inspected using a direct coupling headspace mass spectrometer chemsensor 4440 system (Gerstel, Mulheim an der Ruhr, Germany) composed of head space auto sampler and a mass spectrometer (Peña et al. 2005). Hazelnut oil contains similar types of compounds with olive oil i.e. total sterols, fatty acids chain and triglycerols and therefore, it is a challenging task to distinguish the adulteration with different olive oils by using normal testing techniques. Some other adulterants most frequently used in olive oils are olive pomace oil (Cerrato Oliveros et al. 2002), maize oil (Garrido-Delgado et al. 2018) and sunflower oil (Tsopelas et al. 2018), rapseed oil (Mildner-Szkudlarz and Jeleń 2010). Cerrato Oliveros et al. (2002) used 12 MOS sensors to generate the pattern of the VOCs present in the adulterated virgin olive oils with olive–pomace oils and sunflower oils and quantified the percentages. The level of adulteration in virgin olive oil was 5, 10, 20, 40, and 60% where as the headspace generation time during e-nose measurement was 7 min while the raw data collection was for 60 s. The LDA classification indicated satisfactory outcomes with prediction percentage more than 95% and in some cases almost 100%, while the standard BPNN algorithm accuracy is less with 87.2% accuracy compared to LDA analysis. The lowered results of the ANN can be attributed to the classification criterion used here was very strict. Mildner-Szkudlarz and Jelen (2010) studied the olive oil adulteration with rapeseed oil and sunflower oil using MOS e-nose with 3 sensor chamber each containing 6 gas sensors for detection of chemical vapour fingerprints and a headspace autosampler. The data collection was estimated for 120 s for the 10 ml headspace vials containing 2 g of oil samples. The discriminant index of 94% was attained in both the adulterated samples using PCA. Predicted correlation coefficient for PLS analysis showed 0.989 with average error of 4.414% for olive oil adulteration with rapeseed oil and 0.990% with average error of 4.203% for olive oil adulteration with sunflower oil. The same authors Mildner-Szkudlarz and Jeleń (2008) investigated the potential of techniques for volatile compound analysis coupled with alpha MOS (three sensor chambers, each containing 6 sensors) static headspace HS-100 e-nose for the detection of the adulteration of olive oil with hazelnut oil. The headspace was generated for 30 min at 35 °C while the data collection for e-nose was taken for 120 s. The e-nose data were analysed using 2D PCA. The PCA achieved 96% discrimination among the samples analysed. The PLS plot of predicted versus actual adulteration permits discriminating the adulteration in olive oil with hazelnut oil at different contents (5% to 50%, v/v, correlation coefficient 0.997 with accuracy ± 2.85%).

The application of 5 MOS sensor based e-nose technique with different feature extraction methods to detect adulteration of argan oil (comestible and cosmetic) with sunflower oil was investigated by Bougrini et al. (2014). The headspace was generated for 10 min at 32 °C. The results of pattern recognition and classification by PCA (98.81% in comestible argan oil adulteration and 98.09% in cosmetic argan oil adulteration) and DFA (97.5% in comestible argan oil adulteration and 96.4% in cosmetic argan oil adulteration) could differentiate the both the adulteration. SVM classifier achieved a success rate of 91.67% for comestible argan oil while 83.34% for cosmetic argan oil adulteration by sunflower oil. The analysis of soybean oil adulteration with old frying oil in nine different concentrations was done by Men et al. (2014) using 8 MOS sensor based e-nose with PCA and PLS classification and pattern recognition methods. During e-nose measurement, the sensors response was measured for 240 s as raw data. PCA can explain a variance of 87.19% in the data for e-nose classification of adulterated soybean oil. The adulteration level of 50% and pure soybean oil can only be well separated by PCA method. The PLS model is also used to differentiate the old frying oil from soybean oil. The correlation coefficient of 0.843 with an error of 12.099% for e-nose data also showed an effective model to predict the adulteration in soybean oil. However, the fusion data of e-nose and e-tongue is more effective in all the cases of PCA and PLS method for adulteration detection in soybean oil by old frying oil.

Marina et al. (2010) surveyed the capability of e-nose consisting of SAW sensors with subsequent classification methods such as PCA and PLS to separate the virgin coconut oil adulterated with palm kernel olein oil. The adulteration blend (w/w) was 1–10% with increment of 1% and 10–20% with 5% increment. The headspace of samples was generated at 60 °C for 10 min and data acquisition time was 12 s The separation of adulterated sample by PCA was well discriminated when the level of adulteration increased contributing 91% accuracy in the data. The PLS study with coefficient of determination (R2) value of 0.91 also indicated the potential utilization of e-nose in adulteration detection of virgin coconut oil with palm kernel olein oil. Palm olein oil usually adulterated with palm stearin oil (Hong et al. 2011) and lard (Man et al. 2005) has been studied with commercial e-nose system. According to Hong et al. (2011), PCA (PC1 98.76% and PC2 0.57%) could discriminate the adulterated samples of palm olein oil by palm stearin oil in the range of 10% to 90% proportions while those which were not classified below 10% adulterated ratios could be well discriminated by DFA (DF1 0.997 and DF2 0.966). The sample headspace used in this study was generated using a quadrupole mass spectrometer coupled with an auto sampler and 2.5 ml of sample headspace was injected in the e-nose device. The study of Man et al. (2005) with Palm olein oil adulterated with lard (mixing proportions as low as 1%) could also be identified by e-nose method with Pearson’s correlation coefficient > 0.90 in accuracy. The headspace generation used in their study using water bath at 60 °C was for 3 min while the sampling time for e-nose measurement was 5 s. Adulteration of peony seed oil with Soybean oil, corn oil, sunflower oil, rapeseed oil was investigated by Wei et al. (2018) using PEN3 e-nose with a selected array of 10 MOS sensors and chemometric techniques such as PCA and LDA. For headspace generation, the samples were heated at 80 °C for 15 min while e-nose measurement was done for 60 s. The PCA analysis could well differentiate the peony seed oil from all the four adulterants by contributing 96.72% accuracy in the e-nose dataset with partial overlapping within the four adulterant oils. The pattern recognition by LDA showed an effective discrimination of almost all the oils except a small overlapping of corn oil and rapeseed oil allowing more superior discrimination of peony seed oil adulteration with adulterant oils.

Among all the above studies, PCA, LDA, and PLS methods for e-nose data are most suitable for classification and pattern recognition to distinguish the adulteration in edible vegetable oils. These studies suggested the potential uses of e-nose coupled with multivariate analysis techniques for fraud detection in edible plant oils.

Milk and dairy products

Milk and dairy products comparatively have more demands and are expensive in terms of cost in the food market. Therefore, these are prone to adulteration through the addition of a foreign substance or by other inexpensive supplements and eliminating the vital elements. Milk can be adulterated with cheaper substitutes to rise the volume, fat content, protein content, and to prolong the shelf-life of milk.

The adulteration of skim milk with water and reconstituted milk powder was investigated by Yu et al. (2007) using an e-nose based on MOS sensors. The reconstituted milk powder used as adulterant was mixed with skim milk in various concentrations of adulteration ranging from 0 to 100% with an increment of 20% (v/v) in each adulterated sample. The protein content of the blend was prepared same to that of skim milk by homogenization with ultrasonic wave. The skim milk was as well adulterated with 5 ml, 10 ml, 15 ml, and 20 ml distilled water. The e-nose measurement was gathered every day for seven days at 20 ± 1 °C and pattern recognition was investigated using PCA and LDA. Both the models could well separate the unadulterated and adulterated milk kept up to four days. However, the PCA and LDA technique in later stages could not differentiate the pure and adulterated samples due to their overlapping characteristics as spoilage in milk was evident. The aroma profiling of raw milk with CH2O, H2O2, and NaClO was investigated by Tohidi et al. (2018a) with the developed experimental type e-nose system based on 8 selective MOS sensors. While the headspace for milk samples was generated for 720 s at 30 °C, the e-nose measurement lasts for 270 s. PCA displayed a good accuracy for e-nose data with 83%, 87%, and 97% accuracy for NaClO, H2O2, and CH2O, respectively. The discriminant accuracy rates for LDA was as low as 79.16%, 70.83%, and 66.66% for NaClO, H2O2, and CH2O, respectively. The results for SVM analysis had a good accuracy of 94.64%, 92.85%, and 87.75%, respectively. For reducing bacterial population and to assure the quality of raw milk, the use of antimicrobial agents like detergent is also a common adulteration practice. In another investigation, the blending of detergent powder as adulterant in raw milk up to the concentration level of 0.3% was examined by the same authors Tohidi et al. (2018b) using same e-nose apparatus based on the earlier approaches. The score plot of PCA explained 91% of the variations in the e-nose data. To achieve enriched grouping accuracy, linear discriminant factor and SVM approaches were employed. SVM method improved accuracy to 90%. However, the results of LDA (66.6%) grouping method did not improve on the PCA method. The separation was indistinguishable for class 0.3% adulteration in LDA. From the above studies, it can be suggested that SVM along with PCA classifier for e-nose technique is a promising tool to identify the adulteration in raw milk.

The distinctive aroma profile of pure cheeses makes them unique from other industrially processed less aroma based mislabelled chesses. An attempt on adulteration studies with solid-phase microextraction mass spectrometry (SPME-MS) based e-nose have been successfully performed by Majcher et al. (2015) for the differentiation of oscypek cheeses and oscypek-like three industrially processed cheeses produced from ewe’s milk and cow’s milk. The chemometric used was PCA, LDA, SIMCA, and SVM which allowed a successful discrimination of pure cheeses from adulterated one. PCA accounted a relatively low classification (63.59%) with only the pure oscypek cheeses formed a separate cluster while the differentiation was difficult for adulterated cheeses. LDA could correctly differentiate the pure cheeses and adulterated cheeses (up to 100% in some cases) with a small overlapping between two adulterated samples due to the false labelling of milk origin. SIMCA correctly categorized all the blends with an accuracy more than 90% except one sample for 58.3%. A 97.9% correct classification accuracy in the data for all the samples was obtained by SVM classifier.

A recent investigation on adulteration detection of pure cow ghee with sunflower oil and cow body fat was studied by Ayari et al. (2018a) using 8 MOS senor based e-nose system. The concentration levels of both the adulterants are 10%, 20%, 30%, 40%, and 50%. The data collection for e-nose measurement was 500 s and sensor purge 120 s. PCA explained 96% and 97% variance in the e-nose data for pure ghee adulteration detection with sunflower oil and cow body fat, respectively. They additionally used ANN strategy and discovered lower with 91.3% and 82.5% for sunflower oil and cow body fat adulteration, respectively. The same authors Ayari et al. (2018b) also studied adulteration of pure cow ghee with margarine using the same e-nose arrangement built on the earlier approach. PCA explained 98% variance in the e-nose data for pure ghee adulteration detection with margarine. ANN can classify with an accuracy up to 97.2%. Therefore, these studies concluded that an e-nose with PCA classification is a promising tool for the detection of adulteration in pure desi ghee.

Honey

Honey can be adulterated with cheaper substitutes such as water, syrups, and inverted sugars by fraudsters for their financial gain. The gas chromatography based e-nose technique was used by Gan et al. (2016) for corn syrup and rice syrup adulteration discrimination in honey. The adulterant samples were prepared in the concentrations of 5, 10, 20, and 40% with pure honey. The data acquisition of 84 s was used as heracles e-nose measurement and purging time was 15 s. PCA could not well classify the e-nose data for adulteration discrimination due to the complicated VOCs, although the adulterated honey was separated to some extent (52.19%). PLS model also shows poor judgement in calibration and prediction values for e-nose data in discriminating the adulterated honey as misjudgement still occurs even after the outliers were eliminated. However, spectroscopic method and electronic tongue used in their study could classify with excellent accuracy above 96% was achieved. The adulteration detection in honey with beetroot sugar and cane sugar in the concentrations of 20%, 40%, 60%, and 80% was studied by Subari et al. (2012) using Cyranose 320 e-nose apparatus. The headspace was generated at 50 °C and the raw data was collected for 40 s with purge time of 40 s. PCA showed the scattered data points for adulterated samples and could not differentiate all the adulterated honey although only pure honey made a separate cluster with 89.12% accuracy. While discriminating honey adulteration with beetroot sugar and cane sugar, LDA for e-nose data revealed better result in grouping the pure and adulterated sample with an accuracy of 76.5% for stepwise LDA and 74.9% for direct LDA method compared to the above study by Gan et al. (2016). ANN based improved level of classifier for detecting adulteration on earlier approach was studied by the same author Subari et al. (2014). The combination of e-nose and FTIR data was used as fusion data. The ‘mean absolute error’ of ANN method was found to be 6.9% for fusion of combined e-nose and FTIR while 15% for e-nose or FTIR separately confirms the successful use of ANN as a chemometric tool for adulteration detection in pure honey by e-nose technique. The adulteration of 2 dissimilar varieties of sugar syrup in honey was studied by Zakaria et al. (2011) with Cyranose 320 e-nose system. The headspace was generated at 60 °C for 10 min while data acquisition for 30 s. The LDA method achieved improved clustering behaviour compared to PCA in discriminating the adulterated honey and pure samples, whereas the PNN (92.59%) could effectively discriminate all the samples. The above studies concluded that PCA and LDA tool could not well distinguish the adulteration of honey. So, it is difficult to get the excellent classification accuracy based on e-nose data for honey adulteration. However, PNN could classify the level of falsification detection up to some degree. Since a few studies have published on the topic, so, further research needs to be done on detection of honey adulteration and more improved classification models can be applied to get better classification accuracy using e-nose system.

Alcoholic and non-alcoholic drinks

The authentication of alcoholic drinks like wine has serious concern of illegal mixing practices as dilution of ethyl alcohol, coloring and flavoring agent, mixing with water and inexpensive substitutes like sugar and starch. Different types of adulteration on alcohols have been reviewed by various researchers and highlighted that various challenges need to be elucidated with the aim to improve the confirmation of adulteration in alcohols. In this sense, an e-nose system can be utilized to understand the beverage (alcoholic/non-alcoholic) adulteration, possible detectable concentration for adulteration and how it affects the beverage qualities. Peng et al. (2015) discriminated the origin of country specific spirit by contaminating with other adulterated spirit. The authors used gas chromatography based e-nose (HERACLES II, France). The sensor preferred was best selected from the larger weighted peak with retention time. The classification models of both PCA and DFA predicted correct classification rate of 93%. However, the intersection between the samples was found to be small in PCA while the groups were distributed orderly in DFA method. Ethanol, methanol, and other brands of wine adulteration with Italian wine were studied by Penza and Cassano (2004). E-nose based on four MOS sensor system was developed for the study. The generation of headspace was done at 25 °C for 30 min and data acquisition for 2 min. The cross-validation of ANN could achieve 93.3%, 70%, and 83.3% correct classification accuracy for adulteration of red wines with methanol, ethanol, and other same colored wine, respectively and even 100% in some cases. The predicted versus actual correlation coefficient showed maximum succeeded accuracy of 0.997 and 0.921 for methanol and ethanol adulterant, individually. A well clustering of above 93% was achieved for the adulterated samples by PCA models with just one cluster is not all around separated. Neural network classifier method achieved remarkably well classification accuracy in the authentication of the intentional adulteration of wines. Ordukaya and Karlik (2016) discriminated multiple fruit juice and alcohol adulteration by using 32 polymer sensor based cyranose e-nose setup. Various classifier methods such as LDA (95%), ANN and SVM (98.33%) were used to obtain the excellent result for juice-alcohol mixture. However, for each mixture, they found different pattern recognition tools were useful to discriminate each specific adulteration. These studies successfully demonstrate the use of e-nose in detection of adulteration of alcohols using pattern recognition system based on PCA, LDA, SVM and ANN classifier models.

Fruit juices can be adulterated with overripe and concentrated fruit juices and their possible adulteration identification have been examined below. Overripe tomato juices as an adulterant blended with cherry tomato juices was inspected for their adulteration detection by Hong et al. (2014) with a PEN2 e-nose device with 10 selective MOS sensors. Prior to e-nose measurement, a pre-treatment was done by employing desiccant anhydrous sodium carbonate to improve the signal performance of array as MOS sensors are very sensitive towards water vapor. The data collection was lasted for 70 s and the purge time after each sample was 60 s. The direct e-nose measurement showed better differentiation than by desiccant employed e-nose measurement. Although the PCA achieved more than 90% of variance in the e-nose data for the pure and adulterated juices, the fusion data of e-nose and e-tongue based on ANOVA represented the best technique to differentiate the adulteration. In another study by Hong and Wang (2014), the same e-nose system was used to identify the adulteration of cherry tomato juices based on the earlier approach. PCA classified 95.40% variance in the e-nose data among all the samples. The SVM classifier achieved 100% differentiation accuracy among all the adulterated samples except the desiccant based e-nose measurement. This study also concluded that the fusion pattern recognition approach by e-nose and e-tongue was better than the sole pattern recognition by e-nose for adulteration discrimination in cherry tomato juices. New squeezed orange adulterated with 100% concentrated squeezed orange their adulteration was examined by Shen et al. (2016) utilizing a FOX3000 e-nose arrangement with an array of 12 selective MOS sensors. The concentrations of adulteration in fresh orange juice was 10, 20, and 30%. In e-nose measurement, the headspace was generated at 60 °C for 30 min while, the sampling time 45 s and purge 90 s. PCA resulted for 97.9% variance by the responses of e-nose system. However, the chemical constituents of all the pure and adulterated orange juices were relatively identical and the grouping pattern was flawless, hence an improved chemometric LDA (91.7%) was applied in this case which formed a much better cluster than PCA. The above studies on fruit juice adulteration identification by means of e-nose method shows satisfactory results derived from PCA, LDA and SVM classifiers. The performance of beverage adulteration identification and detection by multisensory e-nose device is also dependent on various headspace generations and pattern recognition method.

Meat

Aromas of meat are more vulnerable due to the lowered shelf-life stability. For quality detection of meat, aroma is the consistent indicator in meat. Basic sensory assessments are not end up being a dependable technique for the identification of adulteration in meat. Although sensors based on e-noses are sensitive to various VOCs would demonstrate a useful device in the discrimination of meat adulteration. Detection of adulteration in various meats using e-nose method was well accomplished by various researchers (Tian et al. 2019; Wang et al. 2019; Nurjuliana et al. 2011). Minced mutton was adulterated with pork and the odour fingerprint was investigated by Tian et al. (2019) using a PEN 2 (Airsense Corporation, Germany) e-nose system containing 10 selective MOS gas sensors. The minced mixer level was 0%-100% with an increment of 20% (w/w) in each adulterated sample. The headspace generation was at 25 °C for 30 min while, data collection by e-nose was 80 s. Several classification and pattern recognition techniques used were canonical discriminant analysis, PCA, stepwise LDA, MLR, PLS, and BPNN. The canonical discriminant analysis achieved an excellent clustering of pure and adulterated samples with accuracy of 93.10% for e-nose data alone. The combined fusion data for e-nose and an electronic tongue (e-tongue) were used to classify the samples and found that BPNN (R2 > 0.97) most suitably identify the adulteration of minced mutton with pork. The adulteration of mutton with duck meat was successfully studied by Wang et al. (2019) using SPME for volatile compound extraction and PEN3 e-nose system (Win Muster, 111 Germany) comprised of 10 MOS sensors. The data collection time was 60 s while, purging time to normalize the sensor signal was 300 s and chemometric used were LDA, multilayer perceptron neural network, and PLS regression analysis. Fisher LDA classifier was used to explain the total variance in the e-nose data which achieved 98.2% accuracy while multilayer perceptron network reached 96.5%. A good linear correlation was demonstrated by PLS analysis with coefficient of determination (R2) values were all more than 95% showed the possible use of e-nose as a technique to identify the adulteration of meat products. Lard was adulterated with chicken fat and their rapid halal authentication was examined by Nurjuliana et al. (2011) using commercial zNoseTM e-nose device consisted of SAW sensors. The concentrations of adulteration were 1, 5, 10, 20, 40, 60, and 80%. The total headspace generation time was for 10 min at 60 °C. The total analysis time for the e-nose measurement was 15 s. PCA was used as the only classification tool which provided an excellent clustering of all the samples with 90% variance explained in the e-nose data for splitting adulterated lard from pure lard. All the results achieved above are promising in further advancement in e-nose techniques using PCA, LDA and neural network tools for the identification of adulteration in meat.

Spices

The very often subject of adulteration in spice is a prime concern among the consumers. E-nose has received considerable attention to the researchers due to the rapid detection of adulteration in spices. The applications of 38 MOS sensor based commercial type e-nose (KAMINA, Yson GmbH) in the detection of adulteration of ‘saveloy’ and ‘sausages’ spice with an admixture of 20% concentration level of adulteration with curry leaves and garlic spice powder respectively was demonstrated by Banach et al. (2012). The headspace was generated for 1 h at 25 °C. LDA 1 (λ = 0.996) and LDA 2 (λ = 0.986) results clearly distinguished and differentiated the spices product adulterations. PCA (PC 1 = 64.1% and PC 2 = 29.7%) was also performed in order to discriminate the spice mixture adulteration. However, the authors also investigated spectrometric differentiation methods and found higher sensitivities in ion mobility spectrometry and GC–MS than e-nose technique. The detection of adulteration of saffron with safflower and corn stigma coloured with beetroot dye was demonstrated by Heidarbeigi et al. (2015). E-nose based on 6 MOS sensors successfully produced the aroma fingerprint of the genuine and adulterated saffron using two classification techniques viz. PCA and ANN. The headspace of adulterated spice was generated for 3600 s at room temperature, while the data acquisition for 180 s. PCA achieved an excellent clustering of all the samples with classification accuracy of 100% and while 86.87% and even 100% in some cases by ANN. Tahri et al. (2017) studied the adulteration of beldi cumin with Moroccan coriander in 5, 20, 50 and 70% concentration level by using 5 MOS sensor based experimental e-nose system. The sensor performance was not sufficient and hence the dataset used in this e-nose study was complex and therefore, the used e-nose system could not classify the adulteration properly. They inferred that the results found were adequately promising in evolving another e-nose arrangement for adulteration recognition in cumin with more improved consistent sensor representation as well as the improved classifier. However, their study revealed the detection of adulteration in cumin with coriander by using e-tongue technique. The saffron adulteration with artificially colored yellow styles of saffron and artificially colored safflower at levels ranging from 10 to 50% was studied by Kiani et al. (2017) using e-nose comprised of 7 MOS sensors for aroma identification. The data acquisition time for e-nose measurement was 10 s. The PCA score plot classified 95% variation in the artificially colored safflower adulteration while 99% accuracy was observed in artificially colored yellow styles adulteration. To reach the success rate up to 100% recognition of saffron, SVM classifier models were used for both training and validation where 85% of the dataset was utilized for training and the rest was utilized for testing. Therefore, the above studies suggested the use of PCA, LDA, ANN, and SVM as the best suitable tool in e-nose systems to reveal the authenticity of spices.

Conclusions and future perspectives

In recent times, numerous uses of e-nose techniques in the field of food adulteration identification were investigated by many researchers. The studies revealed that a significant improvement has been achieved with regard to efficacy, processing the data and classifier models to be employed for the detection of food adulteration. The utilization of this artificial olfaction system is gradually increasing and several vigorous advancements in e-nose are occurring for the identification of falsification in food. However, several challenges need to be solved in order to get the improved assessment to confirm the adulteration level of classification upto 100%. E-nose based on gas chromatography are increasingly used alternate e-nose instrument is gaining attention to the food industries which has the possibility to obtain information based on the aroma as well as the composition of VOCs in the tested samples. The use of SPME-MS based e-nose arrangements can decrease the investigation time for VOCs. However, compared to conventional e-nose methods these arrangements cost moderately high and unable to be used for online monitoring. Altogether, the various e-nose systems combined with proper chemometric tools has proved to be a non-destructive, reliable, and rapid technique in the detection of adulteration of food. Continuous research and development in e-noses are essential for numerous food adulteration issues.

Abbreviations

- VOC

Volatile organic compound

- SAW

Surface acoustic wave

- MOS

Metal oxide semiconductor

- PCA

Principal component analysis

- PLS

Partial least square

- SVM

Support vector machine

- LDA

Linear discriminant analysis

- PCR

Principal component regression

- DFA

Discriminant factor analysis

- ANN

Artificial neural network

- PNN

Probabilistic neural network

- BPNN

Back propagation neural network

- SPME-MS

Solid-phase microextraction mass spectrometry

Author contributions

MR implemented the idea, collected the literature, analysed the content, and wrote the manuscript; BKY conceived the idea, supervised the work and edited the manuscript.

Declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Al-Maskari S, Li X, Liu Q. An effective approach to handling noise and drift in electronic noses. In: Wang H, Sharaf MA, editors. Databases theory and applications. Springer, Cham: Lecture Notes in Computer Science; 2014. pp. 223–230. [Google Scholar]

- Ayari F, Mirzaee-Ghaleh E, Rabbani H, Heidarbeigi K. Detection of the adulteration in pure cow ghee by electronic nose method (case study: sunflower oil and cow body fat) Int J Food Prop. 2018;21(1):1670–1679. [Google Scholar]

- Ayari F, Mirzaee-Ghaleh E, Rabbani H, Heidarbeigi K. Using an E-nose machine for detection the adulteration of margarine in cow ghee. J Food Process Eng. 2018;41(6):e12806. [Google Scholar]

- Banach U, Tiebe C, Hübert T. Multigas sensors for the quality control of spice mixtures. Food Control. 2012;26(1):23–27. [Google Scholar]

- Bougrini M, Tahri K, Haddi Z, Saidi T, El Bari N, Bouchikhi B. Detection of adulteration in argan oil by using an electronic nose and a voltammetric electronic tongue. J Sens. 2014;2014:1–10. [Google Scholar]

- Cerrato Oliveros MC, Pérez Pavón JL, Garcia Pinto C, Fernández Laespada ME, Moreno Cordero B, Forina M. Electronic nose based on metal oxide semiconductor sensors as a fast alternative for the detection of adulteration of virgin olive oils. Anal Chim Acta. 2002;459:219–228. [Google Scholar]

- Clemente TE, Cahoon EB. Soybean oil: genetic approaches for modification of functionality and total content. Plant Physiol. 2009;151:1030–1040. doi: 10.1104/pp.109.146282. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Deng Y (2019) Integration technologies in gas sensor application. Semiconducting Metal Oxides for Gas Sensing. Springer, Singapore, pp 175–193

- Gan Z, Yang Y, Li J, Wen X, Zhu M, Jiang Y, Ni Y. Using sensor and spectral analysis to classify botanical origin and determine adulteration of raw honey. J Food Eng. 2016;178:151–158. [Google Scholar]

- Gardner JW. Detection of vapours and odours from a multisensor array using pattern recognition: principal component and cluster analysis. Sens Actuat. 1991;4:109–115. [Google Scholar]

- Gardner JW, Shurmer HV. Odour discrimination with an electronic nose. Sens Actuat. 1992;8:1–11. [Google Scholar]

- Garrido-Delgado R, Muñoz-Pérez ME, Arce L. Detection of adulteration in extra virgin olive oils by using UV-IMS and chemometric analysis. Food Control. 2018;85:292–299. [Google Scholar]

- Ghasemi-Varnamkhasti M, Mohammad-Razdari A, Yoosefian SH, Izadi Z, Rabiei G. Selection of an optimized metal oxide semiconductor sensor (MOS) array for freshness characterization of strawberry in polymer packages using response surface method (RSM) Postharvest Biol and Tec. 2019;151:53–60. [Google Scholar]

- Gu DC, Liu W, Yan Y, Wei W, Gan JH, Lu Y, Jiang ZL, Wang XC, Xu CH. A novel method for rapid quantitative evaluating formaldehyde in squid based on electronic nose. LWT. 2019;101:382–388. [Google Scholar]

- Hai Z, Wang J. Detection of adulteration in camellia seed oil and sesame oil using an electronic nose. Eur J Lipid Sci Tech. 2006;108(2):116–124. [Google Scholar]

- Hai Z, Wang J. Electronic nose and data analysis for detection of maize oil adulteration in sesame oil. Sensor Actuat B-Chem. 2006;119(2):449–455. [Google Scholar]

- Heidarbeigi K, Mohtasebi SS, Foroughirad A, Ghasemi-Varnamkhasti M, Rafiee S, Rezaei K. Detection of adulteration in saffron samples using electronic nose. Int J Food Prop. 2015;8:1391–1401. [Google Scholar]

- Hong X, Wang J. Detection of adulteration in cherry tomato juices based on electronic nose and tongue: comparison of different data fusion approaches. J Food Eng. 2014;126:89–97. [Google Scholar]

- Hong EJ, Park SJ, Choi JY, Noh BS. Discrimination of palm olein oil and palm stearin oil mixtures using a mass spectrometry based electronic nose. Food Sci Biotechnol. 2011;20(3):809–816. [Google Scholar]

- Hong X, Wang J, Qiu S. Authenticating cherry tomato juices—discussion of different data standardization and fusion approaches based on electronic nose and tongue. Food Res Int. 2014;60:173–179. [Google Scholar]

- Jia W, Liang G, Jiang Z, Wang J. Advances in electronic nose development for application to agricultural products. Food Anal Methods. 2019;12(10):2226–2240. [Google Scholar]

- Kauer JS. Contributions of topography and parallel processing to odor coding in the vertebrate olfactory pathway. Trends neurosci. 1991;14(2):79–85. doi: 10.1016/0166-2236(91)90025-p. [DOI] [PubMed] [Google Scholar]

- Kiani S, Minaei S, Ghasemi-Varnamkhasti M. Integration of computer vision and electronic nose as non-destructive systems for saffron adulteration detection. Comput Electron Agric. 2017;141:46–53. [Google Scholar]

- Li J, Wang M, Liu Q, Zhang Y, Peng Z. Validation of UPLC method on the determination of formaldehyde in smoked meat products. Int J Food Prop. 2018;21(1):1246–1256. [Google Scholar]

- Majcher MA, Kaczmarek A, Klensporf-Pawlik D, Pikul J, Jelen HH. SPME-MS-based electronic nose as a tool for determination of authenticity of PDO cheese, Oscypek. Food Anal Methods. 2015;8:2211–2217. [Google Scholar]

- Man YC, Gan HL, NorAini I, Nazimah SAH, Tan CP. Detection of lard adulteration in RBD palm olein using an electronic nose. Food Chem. 2005;90(4):829–835. [Google Scholar]

- Marina AM, Che Man YB, Amin I. Use of the SAW sensor electronic nose for detecting the adulteration of virgin coconut oil with RBD palm kernel olein. J Am Oil Chem Soc. 2010;87(3):263–270. [Google Scholar]

- Men H, Chen D, Zhang X, Liu J, Ning K. Data fusion of electronic nose and electronic tongue for detection of mixed edible-oil. J Sens. 2014;2014:1–7. [Google Scholar]

- Mildner-Szkudlarz S, Jeleń HH. The potential of different techniques for volatile compounds analysis coupled with PCA for the detection of the adulteration of olive oil with hazelnut oil. Food Chem. 2008;110(3):751–761. [Google Scholar]

- Mildner-Szkudlarz S, Jeleń HH. Detection of olive oil adulteration with rapeseed and sunflower oils using mos electronic nose and SMPE-MS. J Food Qual. 2010;33(1):21–41. [Google Scholar]

- Modupalli N, Naik M, Sunil CK, Natarajan V. Emerging non-destructive methods for quality and safety monitoring of spices. Trends Food Sci Technol. 2021;108:133–147. [Google Scholar]

- Moosavy MH, Kordasht HK, Khatibi SA, Sohrabi H. Assessment of the chemical adulteration and hygienic quality of raw cow milk in the northwest of Iran. Qual Assur Saf Crop. 2019;11(5):491–498. [Google Scholar]

- Nurjuliana M, Man YC, Hashim DM. Analysis of lard’s aroma by an electronic nose for rapid halal authentication. J Am Oil Chem' Soc. 2011;88(1):75–82. [Google Scholar]

- Ordukaya E, Karlik B. Fruit juice–alcohol mixture analysis using machine learning and electronic nose. IEEJ Electr Electr. 2016;11:S171–S176. [Google Scholar]

- Pandey SK. Prevailing practices of artificial ripening of mango, banana and papaya through calcium carbide in Jharkhand. Agric Eng Today. 2016;40(3):35–39. [Google Scholar]

- Peña F, Cardenas S, Gallego M, Valcárcel M. Direct olive oil authentication: detection of adulteration of olive oil with hazelnut oil by direct coupling of headspace and mass spectrometry, and multivariate regression techniques. J Chromatogr A. 2005;1074(1–2):215–221. doi: 10.1016/j.chroma.2005.03.081. [DOI] [PubMed] [Google Scholar]

- Peng Q, Tian R, Chen F, Li B, Gao H. Discrimination of producing area of Chinese Tongshan kaoliang spirit using electronic nose sensing characteristics combined with the chemometrics methods. Food Chem. 2015;178:301–305. doi: 10.1016/j.foodchem.2015.01.023. [DOI] [PubMed] [Google Scholar]

- Penza M, Cassano G. Recognition of adulteration of Italian wines by thin-film multisensor array and artificial neural networks. Anal Chim Acta. 2004;509(2):159–177. [Google Scholar]

- Persaud K, Dodd G. Analysis of discrimination mechanisms in the mammalian olfactory system using a model nose. Nature. 1982;299(5881):352–355. doi: 10.1038/299352a0. [DOI] [PubMed] [Google Scholar]

- Shen F, Wu Q, Su A, Tang P, Shao X, Liu B. Detection of adulteration in freshly squeezed orange juice by electronic nose and infrared spectroscopy. Czech J Food Sci. 2016;34(3):224–232. [Google Scholar]

- Subari N, Mohamad Saleh J, Md Shakaff A, Zakaria A. A hybrid sensing approach for pure and adulterated honey classification. Sensors. 2012;12(10):14022–14040. doi: 10.3390/s121014022. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Subari N, Saleh JM, Shakaff AYM (2014) Fusion technique for honey purity estimation using artificial neural network. In: International conference on advances in intelligent systems in bioinformatics. Atlantis Press, pp 35–40

- Tahri K, Tiebe C, El Bari N, Hübert T, Bouchikhi B. Geographical classification and adulteration detection of cumin by using electronic sensing coupled to multivariate analysis. Procedia Technol. 2017;27:240–241. [Google Scholar]

- Tian X, Wang J, Ma Z, Li M, Wei Z. Combination of an E-Nose and an E-Tongue for adulteration detection of minced mutton mixed with pork. J Food Qual. 2019;2019:1–10. [Google Scholar]

- Tohidi M, Ghasemi-Varnamkhasti M, Ghafarinia V, Bonyadian M, Mohtasebi SS. Development of a metal oxide semiconductor-based artificial nose as a fast, reliable and non-expensive analytical technique for aroma profiling of milk adulteration. Int Dairy J. 2018;77:38–46. [Google Scholar]

- Tohidi M, Ghasemi-Varnamkhasti M, Ghafarinia V, Mohtasebi SS, Bonyadian M. Identification of trace amounts of detergent powder in raw milk using a customized low-cost artificial olfactory system: a novel method. Measurement. 2018;124:120–129. [Google Scholar]

- Tsopelas F, Konstantopoulos D, Kakoulidou AT. Voltammetric fingerprinting of oils and its combination with chemometrics for the detection of extra virgin olive oil adulteration. Anal Chim Acta. 2018;1015:8–19. doi: 10.1016/j.aca.2018.02.042. [DOI] [PubMed] [Google Scholar]

- Wang Q, Li L, Ding W, Zhang D, Wang J, Reed K, Zhang B. Adulterant identification in mutton by electronic nose and gas chromatography-mass spectrometer. Food Control. 2019;98:431–438. [Google Scholar]

- Wei X, Shao X, Wei Y, Cheong L, Pan L, Tu K. Rapid detection of adulterated peony seed oil by electronic nose. J Food Sci Technol. 2018;55(6):2152–2159. doi: 10.1007/s13197-018-3132-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yu H, Wang J, Xu Y. Identification of adulterated milk using electronic nose. Sensor Mater. 2007;19:275–285. [Google Scholar]

- Zakaria A, Shakaff AYM, Masnan MJ, Ahmad MN, Adom AH, Jaafar MN, Ghani SA, Abdullah AH, Aziz AHA, Kamarudin LM, Subari N. A biomimetic sensor for the classification of honeys of different floral origin and the detection of adulteration. Sensors. 2011;11(8):7799–7822. doi: 10.3390/s110807799. [DOI] [PMC free article] [PubMed] [Google Scholar]