Abstract

Abstract

The effects of active batter coatings containing quince seed gum (QSG) and carvacrol microcapsules (CM) on oil uptake, moisture loss, lipid oxidation, texture, color and organoleptic properties of chicken nuggets during the frying process were investigated. Active coatings on the surface of nuggets reduced oil uptake and moisture loss of fried samples decreased by 33.21% and 29.64%, respectively. Antioxidant activity tests showed that oxygen radical absorbance capacity (ORAC) and DPPH radicals scavenging activity of carvacrol microcapsules were 152.23 ± 4.11 μmol TE/g, and 51.09 ± 3.32%, respectively. Investigation of primary and secondary oxidation products in the fried nugget samples showed that the peroxide value and thiobarbituric acid levels in control samples were 7.43 meq peroxide/kg and 1.35 mg MDA/kg, respectively. The results of this study showed that the highest reduction in PV and TBA were 41.85 and 37.04% for the QSG-coated samples containing 1% carvacrol microcapsules. The color of QSG-coated samples did not change significantly compared to control samples, although their hardness was reduced compared to the control samples (p < 0.05). The results showed that the use of active edible coatings made from quince seed gum and containing carvacrol microcapsules did not show any negative effects on the sensory properties of nuggets.

Graphic abstract

Keywords: Carvacrol, Malondialdehyde, Chicken nugget, Peroxide value, Deep-fat frying

Introduction

As a cooking process, frying is a common method in fast-food chains and homes for food products such as nugget, in which in direct contact with food, oil acts as a heat transfer medium, bringing its temperature to above-boiling water. This frying process causes mass and heat to be transferred quickly between the food and the oil as a heating medium. The high temperature of the oil in the process increases the outflow of water from the food and its evaporation, and subsequently, oil is absorbed by the food (Khazaei et al. 2016). Oil uptake is influenced by oil and food temperature, frying method and time, and initial food moisture content (Parimala and Soda 2012). So, any change in any of the above factors can decrease the oil uptake during the deep-fat frying process.

Application of food hydrocolloids to further maintain the moisture and prevent moisture from escaping during the deep-frying process can decrease the absorption of oil in the fried food product. Sahin et al. (2005) reported that the addition of different gum types could reduce oil uptake by 40% and moisture loss by 10% in chicken nugget samples during the deep-frying process. They also reported that hardness of the nuggets increased when the moisture value decreased during deep frying. Parimala and Sudha (2012) stated that adding guar gum with a concentration of 0.5% increases moisture retention, reduces oil absorption and improves the texture and quality of puri (Indian fried bread).

The effect of some hydrocolloids such as gellan gum, carboxymethyl cellulose and guar gum, on food quality and oil absorption during the deep-fat frying process has been studied by some researchers (Kim et al. 2011; Khazaei et al. 2016; Adedeji and Ngadi 2011). Adedeji and Ngadi (2011) studied the effects of batter formulation enriched by carboxymethyl cellulose on the nugget quality during deep-fat frying. They stated that the batter coating of batter could improve the textural and physical properties of chicken nuggets. Khazaei et al. (2016) reported that the addition of basil seed gum at 1% level could reduce oil uptake by 34.5% and moisture loss by 13.9% in shrimp samples during the deep-frying process.

The effect of strong antioxidants carvacrol and thymol on lipid oxidation and stability in meat products during deep-frying and storage has been studied in various studies (Lucera et al. 2009; Luna et al. 2010; Khazaei et al. 2016). There is no scientific literature about reducing quality loss of chicken nuggets by active batter coatings made by quince seed gum (QSG) containing carvacrol microcapsules during the deep-fat frying process. The aim of this study was to evaluate the effects of active batter coatings on oil uptake, moisture loss, lipid oxidation and quality loss of fried chicken nuggets.

Materials and methods

Material

Whole quince seeds were purchased from a local market in Tehran (Iran), and Carvacrol (99.5%) was purchased from Sigma Aldrich (St. Louis, USA). All chemicals were obtained from Merck (Germany). Fresh boneless and skinless chicken breast was purchased from a local market (Tehran, Iran).

Extraction of quince seed gum

Gum extraction from the quince seeds was performed according to the method of Jouki et al. (2014b). The gum was extracted from the seeds in several stages. Briefly, 20 g of whole quince seeds sieved and washed with its triple weight of pure ethanol for 15 min under constant stirring. Then, ethanol was removed and the seeds dried in an oven at 45 °C and the gum was extracted from whole seeds using distilled water (at ratio of 1:25), and stirred with a rod paddle blender at 1100 rpm and 60 °C for 5 min to scrape the gum layer off the seed surface. Finally, the gum was then filtered with cheese cloth and then dried using a vacuum oven at 45 °C. The extracted gum was stored in a cool, dry place until the coating solutions were prepared.

Preparation of carvacrol microcapsules

Carvacrol microcapsules were prepared according to the layer-by-layer deposition method (Raeisi et al. 2021). QSG solution (3%) and carvacrol were mixed at a ratio of 3:1 and Tween 80 as an emulsifier was added to the mixture at a rate of 1% (v/v). The mixture was stirred with a magnetic stirrer for 15 min at 700 rpm and then homogenized by an ultra-torax homogenizer at 5000 rpm for 2 min. Separation of the capsules was performed with the help of ultrasound at a power of 200 watts for 2 min. Some gum was added to the emulsion again and homogenized for 30 s. The formed emulsion was placed in a freezer at −18 °C and after 24 h transferred to a freeze dryer (Armfield FT-33, Ltd., UK) with a temperature of −49 °C and dried after 22 h (Alipoorfard et al. 2020). The prepared capsules were kept in moisture impermeable plastic bags until the day of preparation of the batter coating.

Encapsulation efficiency and particle size

The encapsulation efficiency was calculated by calculating the percentage of trapped carvacrol in the capsule relative to the initial carvacrol based on its antioxidant activity (Milani et al. 2020). The particle size of the carvacrol microcapsules was determined by dynamic light scattering (DLS) with a Zetasizer (Model ZEN3600, MALVERN, UK) at a fixed detector angle of 90° (Li et al. 2019). Briefly, sample were deionized water adjusted pH (a droplet concentration of 1:1000) and then analyzed. The results were expressed as mean diameter (nm).

Antioxidant activity of carvacrol microcapsules

The DPPH method was used to determine the antioxidant activity of carvacrol microcapsules (Jouki et al. 2014a). Briefly, 10 g of microencapsulated carvacrol powders were mixed and extracted in 90 mL methanol: water solvent mixture (80:20), and centrifuged at 4000 rpm for 15 min. Then 0.1 ml of the surface phase (supernatant) was mixed with 3.9 ml of methanolic DPPH solution (0.1 mM). The samples were kept in the dark for 30 min and then the absorbance of the samples was measured at 517 nm. The scavenging activity of DPPH radicals (%) was calculated by the following equation (Jouki and Khazaei 2010):

| 1 |

Oxygen radical absorbance capacity (ORAC)

To measure the ability of capsulated carvacrol powders for inhibition of peroxyl radical the ORAC method was used (Zhou et al. 2007). In this method, Trolox™ was employed as an antioxidant standard and fluorescein (FL) was used as a fluorescent probe. Peroxyl radicals were produced from AAPH in phosphate buffer (pH 7.4, 75 mM). Briefly, 225 μl of FL solution (81.6 nM) and 30 μl of reconstituted functional drink, blank (DMSO) or standard (Trolox™) were mixed and incubated at 37 °C for 20 min. Then, 25 μl of APPH solution (0.36 M) was added to starts the reaction. The fluorescence of the reaction mixture was measured using a multilabel plate reader (Perkin-Elmer, USA) at lex = 485 nm and lem = 535 nm every 60 s and kept at 37 °C until the reading had been declined (less than 5% of the initial reading). The results were determined by using a regression equation relating Trolox concentrations and the net area under the kinetic fluorescein decomposition curve. The results of ORAC test were expressed as μmol Trolox per equivalent (TE)/g of capsulated carvacrol powder.

Preparation of active batter coatings

To prepare batter formulation, dry ingredients (97.5% flour (wheat and corn flours in equal proportions), 1% salt, 0.5% leavening agent and 1% soy flour) were mixed with water in a ratio of 3: 5 and stirred with a hand mixer at 1000 rpm for 2 min (Sahin et al. 2005). This formulation was used as a control batter coating. In other formulations, 1% quince seed gum alone, or gum containing carvacrol microcapsules in the levels of 0.5 or 1% was used as a substitute for soy flour in the formulation.

Preparation and coating of chicken nuggets

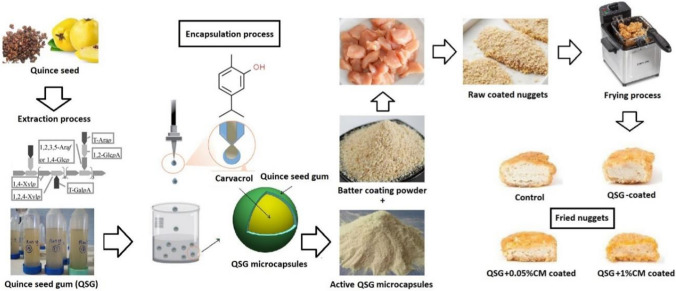

A mixture of chicken breast (88%), onion (10%), pepper (1%), and salt (0.5%) as the meat part of chicken nugget, in dimensions of 4.5 × 2.6 × 1.1 (cm) was cut using a steel mold. The nugget samples were immersed separately in the coating batter for 30 s. The nugget samples were divided into 4 groups: one group was uncoated chicken nuggets, the second group was nuggets coated with batter without carvacrol microcapsules, the third group was chicken samples coated with batter containing 0.5% carvacrol microcapsules, and the fourth group was chicken nuggets coated with batter containing 1% carvacrol microcapsules. The coated nuggets were allowed to dry in an oven at 25 °C for 5 h (Fig. 1).

Fig. 1.

Production process and application of active edible coatings made from quince seed gum (QSG) and carvacrol microcapsules (CM)

Chemical composition of nuggets

Proximate composition of chicken nuggets was measured as described by Jouki et al. (2020). Kjeldahl’s method was employed to measure the protein content. Lipid content was determined by the method of Bligh and Dyer (1959). Moisture content and crude ash of the was measured according to the method of Gharibzahedi et al. (2012).

Frying conditions

Frying of the nugget samples was performed in an electric fryer (ZDF 8802, Japan) with a volume of 5 L containing sunflower oil (Nina, Iran) at a temperature of 180 °C for 4 min. The surface oil of the samples was removed with a paper towel immediately after leaving the fryer and the fried samples were cooled to ambient temperature (25 °C).

Moisture loss and oil uptake

The moisture content of the raw and fried nugget was determined according to the method of Gharibzahedi et al. (2012), and the moisture loss (%) of the fried-nuggets was obtained by calculating the percentage difference between the moisture content of raw and fried nugget samples divided by the moisture content of fried nugget samples. The oil content was evaluated using the Soxhlet extraction method, and the oil uptake (%) of the fried-nuggets was calculated according to Eq. (2):

| 2 |

Peroxide value (PV)

After cold extraction of nugget fat, the amount of peroxide value was calculated. Briefly, 1 g of fat extracted in 25 ml of the chloroform acetic acid mixture was dissolved in a ratio of 2:3. Subsequently, 1 ml of potassium iodide saturated solution was mixed into the mixture and placed in the dark for 10 min. In the next step, 30 ml of distilled water was added and the mixture was titrated with 0.01 M in the presence of starch solution with sodium thiosulfate (Jouki et al. 2012). Finally, the peroxide value was measured as follows:

| 3 |

where S is the titration amount of sample, W is the mass of fat extracted (g), and B, F, mol equiv/L(N) are the titer of 0.01 mol equiv/ LNa2S2O3, the normality of Na2S2O3.

Thiobarbituric acid reactive substances (TBARS)

5 g of nugget sample was mixed with 15 ml of 20% TCA solution and homogenized for 1 min and then filtered using Whatman 1 filter paper. Subsequently, 2 ml of the mixture was transferred to a test tube and mixed with 2 ml of 0.02 M aqueous 2-thiobarbituric acid. Then, the mixture was placed at 90 °C for 30 min to react. After cooling, the absorbance of the nugget samples was determined at 532 nm (Jouki and Yazdi 2014). TBARS value was measured as mg malondialdehyde (MDA) /kg sample.

Texture analyses

A texture analyzer (CT3, Brookfield, USA) equipped with a 500 N load cell was used to measure the hardness of nugget samples. Nugget samples were penetrated using the double compression method and pressed up to 60% of their height. The samples were placed in the center of the probe using a 6 mm probe at a speed of 5 mm/s and a recovery time of 15 s. Texture characteristics were analyzed to evaluate the texture profile analysis values, including hardness, springiness, cohesiveness, chewiness, and gumminess (Jouki et al. 2014c; Tayyari et al. 2017).

Color measurement of fried chicken nuggets

A Minolta colorimeter (CR-400, Minolta, Japan) was used to determine the color parameters of nugget samples. Color parameters were measured as L (lightness), a (redness) and b (yellowness) and the total color difference (ΔE) was obtained using the following equation (Eq. 4):

| 4 |

where Lc, ac, and bc are the values of L, a and b color parameters for the fried control samples (Shariati et al. 2020).

Sensory evaluation

After frying, nugget samples were given to 11 trained panelists from the laboratory staff, including 6 women and 5 men (ages 25–35). Briefly, five representative nugget samples of the different treatments were individually presented in covered small porcelain dishes to each panelist. The panelists were not informed about the experimental approach and the nuggets were blind-coded with 3-digit random numbers. All evaluations were conducted in a sensory laboratory under white fluorescent light. A 5-point hedonic test score (5 = like extremely, 4 = like a little, 3 = neither like nor dislike, 2 = a little dislike and 1 = dislike extremely) was used for color, taste, smell, texture and overall acceptance (Jouki et al. 2014d).

Statistical analysis

Statistical analysis of the results was performed using SPSS software (version: 22.0, SPSS Inc.) and Duncan multiple comparison tests were used (p < 0.05) to evaluate the differences between the means. Pearson correlation test was used to make comparisons between coating treatments. A non-parametric ANOVA of Kruskal–Wallis test was employed to analyze the results of sensory evaluation.

Results and discussion

Encapsulation efficiency and particle size of carvacrol microcapsules

The encapsulation efficiency of carvacrol was 83.13 ± 1.56%, which was similar to the results reported by Sun et al. (2019) by 76.98% for pectin microcapsules, and higher than reported value by Bagis and Karabulut (2020) for gum arabic microcapsules (66.24%). As stated by Paulo and Santos (2017), the encapsulation efficiency is affected by many factors including drying methods, drying temperatures, and core and wall materials. The mean size of carvacrol-microcapsules was 5.46 ± 0.34 μm. In the layer-by-layer technique, the capsules are formed in micron range size with smooth texture. However, with the increase in the size of the capsules in millimeter dimensions, their texture become rough and gritty (Raeisi et al. 2021; Bagis and Karabulut 2020).

The particle size is an important physical characteristic that affects the texture and sensory attributes such as mouthfeel. It has been stated that the microcapsule size affects the efficiency of microencapsulation and its stability. The Larger microcapsules offer more protection against the core material compared with the smaller capsules, although they have poor dispersibility in the food product (Li et al. 2019). Therefore, there is an optimal size to not only provide good protection against bioactive compounds and achieve good shelf stability, but also have a good distribution in the food product.

Antioxidant activity of carvacrol microcapsules

The results of antioxidant activity tests showed that the oxygen radical absorbance capacity (ORAC) and DPPH radicals scavenging activity of carvacrol microcapsules were 152.23 ± 4.11 μmol TE/g, and 51.09 ± 3.32%, respectively.

Proximate composition of chicken nuggets

The results of chemical composition for raw chicken nuggets were determined. Protein, lipid, moisture, and ash contents of the chicken nuggets averaged 16.65, 2.74, 63.51, and 2.24%, respectively. Our results are in good agreement with those reported by El-Anany et al. (2020). They showed that the protein, lipid, moisture, and ash contents of the chicken nuggets averaged 18.09, 3.37, 65.76, and 1.95%, respectively.

Moisture loss and oil uptake of nuggets

The amount of fat and moisture content of nugget samples were 1.46% wb (3.83% db) and 61.21% wb, respectively (Table 1). The frying process significantly reduced the moisture content and increased the oil uptake in the nugget samples (p < 0.05). After the frying process, the fat and moisture content of the control samples reached 14.12 and 23.41%. The difference in fat and moisture content of fried samples is due to the replacement of water with oil after the evaporation process. Khazaei et al. (2016) and Kim et al. (2011) stated that the moisture is released and the food space is emptied due to heat transfer during the frying, resulting in replaced oil and increased oil content of fried food products.

Table 1.

Moisture and oil content of nugget samples before and after frying process

| Treatments | Moisture content (% wb) | Fat content (% db) | Moisture loss (%) | Oil-uptake (%) |

|---|---|---|---|---|

| Raw nuggets | 61.21 ± 1.14a | 3.83 ± 0.29c | – | – |

| Fried uncoated nuggets | 23.41 ± 0.59c | 14.12 ± 0.48a | 61.75 ± 1.33a | 271.81 ± 4.43a |

| Fried QSG-coated nuggets | 34.67 ± 0.43b | 10.76 ± 0.55b | 43.46 ± 2.31b | 181.57 ± 3.87b |

| Fried QSG + CM1-coated nuggets | 35.12 ± 0.61b | 11.02 ± 0.44b | 42.85 ± 2.68b | 188.36 ± 4.71b |

| Fried QSG + CM2-coated nuggets | 35.08 ± 0.37b | 10.91 ± 0.61b | 42.67 ± 1.90b | 186.83 ± 3.27b |

Values with the same letter in the same column are not significantly different at the 5% level. QSG Quince seed gum, CM Carvacrol Microcapsules

The application of quince seed gum significantly reduced the moisture loss of fried nugget samples (p < 0.05). The use of QSM + 1% CM (carvacrol microcapsules) reduced the moisture loss in fried nuggets by 30.81% compared to the control sample. The highest reduction in oil uptake was observed in the fried QSM-coated samples with a value of 33.21%. In our study, lower oil uptake is found during the frying due to the lower moisture loss of nugget samples. Due to the role of quince seed gum on moisture retention in the nugget matrix and closing the pores, less moisture is removed from the food during the process and due to the increased vapor pressure of the retained moisture, less oil enters the food tissue. According to the results, there was a high correlation between the rate of moisture loss and oil absorption (R2 = −93, p < 0.05).

Therefore, adding batter coating containing QSG due to increasing the moisture content of the samples and maintaining it during the frying process prevents excess oil from entering the food sample. Sahin et al. (2005) reported that the addition of different gum types could reduce oil uptake by 40% and moisture loss by 10% in chicken nugget samples during the deep-frying process. Khazaei et al. (2016) reported that using of basil gum as a hydrocolloid at a concentration of 1% reduced moisture loss by up to 13.9% in deep-fried shrimps, thereby reducing the fat uptake of the samples by 34.5%. In addition, Kim et al. (2011) showed that the use of guar gum solution at a concentration of 0.9% reduced the oil absorption in the samples of deep-fried potato strips by about 41%.

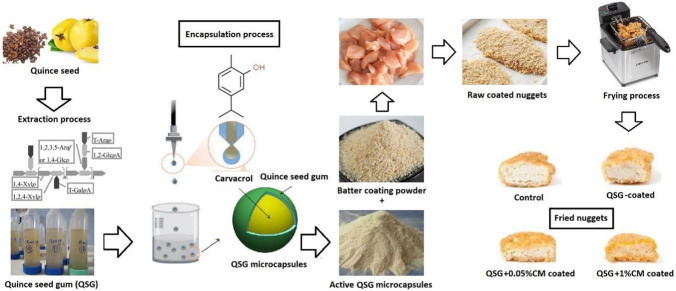

Lipid oxidation

Figure 2 shows the effect of deep frying on oxidation in nugget samples. The initial values of peroxide value and thiobarbituric acid in raw nuggets were 1.21 meq peroxide/kg and 0.59 mg MDA/kg, respectively. Similar results have been reported by some researchers (Raeisi et al. 2021; Jouki et al. 2020). To measure the oxidation of lipids in fried nugget samples, peroxide value (PV) as the primary oxidation, and thiobarbituric acid (TBA) as the secondary oxidation were evaluated. The frying process increased the peroxide value and malondialdehyde levels for all nuggets (p < 0.05). As shown by Kumar et al. (2015), in the oxidation process of lipids, hydroperoxides and oxidized unsaturated fatty acids are formed that decompose rapidly to form compounds such as aldehydes, hydrocarbons, alcohols, ketones, acids and esters.

Fig. 2.

PV (a) and TBA (b) of chicken nugget samples before and after deep-fat frying

The rate of oxidation was highest in untreated nugget samples and lowest in samples containing QSG + 1% CM (Fig. 2). Therefore, the coating of quince seed gum and carvacrol microcapsules on the nuggets reduced the oxidation during frying. Based on the results obtained in the oil absorption of samples, the reason for the decrease in oxidation in the fried coated-nugget samples could be related to reduced oil uptake. These results were expected because of the effects of QSG in reducing oil absorption and the antioxidant effects of carvacrol microcapsules. The antioxidant activity of carvacrol has been stated by many researchers (Lucera et al. 2009; Luna et al. 2010).

According to the report of Khazaei et al. (2016), the formation of secondary oxidation products occurs in the disintegration of peroxides produced at high temperatures (≥ 150 °C). Because of the high temperature of the deep frying used in this research (180 °C), an increase in these compounds is seen in the fried nugget sample. The findings of this study show that the deep-frying enhanced the peroxide value (519.11%) and malondialdehyde (128.11%) in the untreated samples. The amount of peroxide and malondialdehyde in nugget samples containing 1% carvacrol microcapsules after frying was 41.85 and 37.04% less than the control sample. These results could be related to the reduction of oil absorption due to the influence of quince seed gum and the antioxidant activity of carvacrol in inhibiting oxidation. Similar results have been previously reported in reducing lipid oxidation by reducing oil uptake due to the use of dietary hydrocolloids (Khazaei et al. 2016; Kim et al. 2011).

Texture properties

As Table 2 shows, the frying process reduces the hardness of the nugget samples. This effect can be related to the temperature of the frying process, which causes protein degradation and cell damage on the surface (Min and Ahn 2005). As Chen et al. (2008) stated, after oil uptake, the most important quality parameter to accept or reject fried products is texture, especially crispy crust. It also demonstrates that the addition of batter coating containing QSM had a significant effect on texture parameters (p < 0.05). The fried uncoated nuggets were harder than the other nugget samples. The higher hardness of these samples is probably due to the greater loss of moisture in the samples during the frying process and hardening of the samples. Among the fried nuggets, the fried uncoated-sample (control) had the highest hardness (p < 0.05). The fried samples coated with a batter containing QSM + 1% CM had the minimum required hardness (p < 0.05), which is probably due to higher moisture retention in these samples.

Table 2.

Textural properties of nugget samples before and after frying process

| Treatments | Hardness (N) | Springiness | Cohesiveness | Gumminess | Chewiness (N) |

|---|---|---|---|---|---|

| Raw nuggets | 14.43 ± 0.76a | 0.68 ± 0.03ab | 0.46 ± 0.02a | 6.21 ± 0.34a | 4.51 ± 0.48a |

| Fried uncoated nuggets | 9.13 ± 0.44b | 0.71 ± 0.03a | 0.37 ± 0.03b | 3.67 ± 0.25b | 2.37 ± 0.29b |

| Fried QSG-coated nuggets | 7.26 ± 0.51c | 0.65 ± 0.02b | 0.40 ± 0.04b | 2.88 ± 0.39c | 1.87 ± 0.33bc |

| Fried QSG + CM1-coated nuggets | 7.33 ± 0.59c | 0.69 ± 0.01ab | 0.38 ± 0.02b | 2.72 ± 0.43c | 1.94 ± 0.31bc |

| Fried QSG + CM2-coated nuggets | 6.97 ± 0.67c | 0.67 ± 0.02ab | 0.39 ± 0.03b | 2.76 ± 0.38c | 1.79 ± 0.25c |

Values with the same letter in the same column are not significantly different at the 5% level. QSG Quince seed gum, CM Carvacrol Microcapsules

Coating active batter containing quince seed gum and carvacrol microcapsules on nuggets improved chewiness and springiness. Using active coatings also decreased the cohesiveness and softness of the tissue. Choi et al. (2014) showed that the addition of makgeolli fiber to frankfurter samples can improve the texture of the product. In another study, Usawakesmanee et al. (2008) stated that the fried shrimp samples coated with 6% methylcellulose showed significantly less shear strength than the untreated shrimps. They showed that these samples retained more moisture than control samples.

Sahin et al. (2005) reported that the addition of different gum types could reduce moisture loss by 10% in chicken nugget samples during the deep-frying process and the hardness of the nuggets decreased when the moisture loss decreased. Parimala and Sudha (2012) stated that adding guar gum with a concentration of 0.5% increases moisture retention, reduces oil absorption and improves the texture and quality of puri (Indian fried bread). Han and Bertram (2017) stated that dietary fiber may reduce tissue hardness by disturbing the protein–protein and water-protein networks. In addition, Verma et al. (2010) showed that adding apple pulp to chicken nugget formulation can reduce the hardness of nugget samples and improve the texture properties by retaining more moisture.

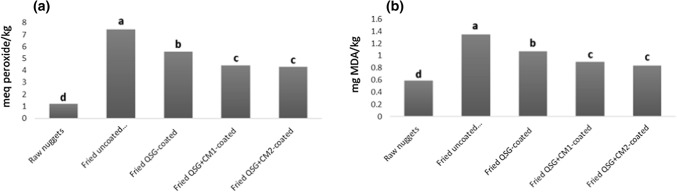

Color analysis

The effect of quince seed gum and carvacrol microcapsules on the color parameters of fried chicken nuggets is shown in Fig. 3. The L (lightness) of nugget samples decreased after frying (p < 0.05). The highest reduction in L was in the coated-nuggets with quince seed gum containing carvacrol microcapsules. The significant decrease in L values for fried nuggets may be attributed to changes in light absorption and light scattering caused by the formulation materials. Figure 3 shows the L value of the raw nuggets sample was 71.44 and after frying in the range of 62.37 for the control sample to 65.01 for the coated-nuggets with QSG-1% CM.

Fig. 3.

Color parameters of nugget samples before and after frying

The frying process also increased the redness (a) and yellowness (b) of the nugget samples. During the frying process, several reactions occur, such as Millard reactions due to sugar–protein interactions, lipid oxidation reactions, and the formation of primary and secondary oxidation products, which can lead to color changes in the fried samples. The total difference color (ΔE) of fried nuggets compared to the fried control sample is also shown in Fig. 3. In addition, samples coated with batters containing quince seed gum (QSG) and 0.5% carvacrol microcapsules had the lowest amount of changes a, b and ΔE. Improvements in physical properties such as the color of food products by treatments containing quince seed gum have also been reported in previous researches (Vaseghi et al. 2020; Jouki et al. 2014e; Khodashenas and Jouki 2020). Therefore, seed gum with unique color properties such as high transparency and minimal amount of red and yellow can improve the appearance of food products by absorbing water and reflecting light, and the adverse effects of thermal processes or chemical reactions leading to adverse color changes. At least.

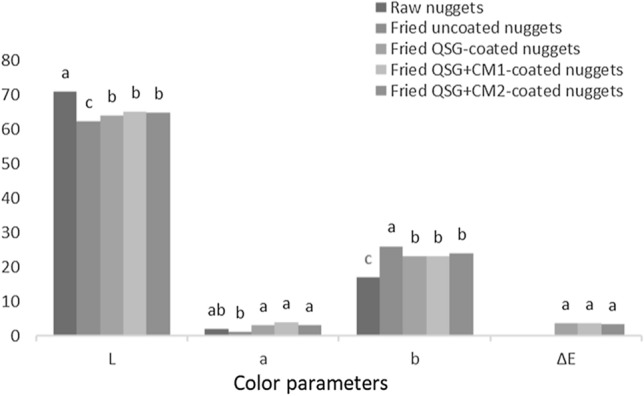

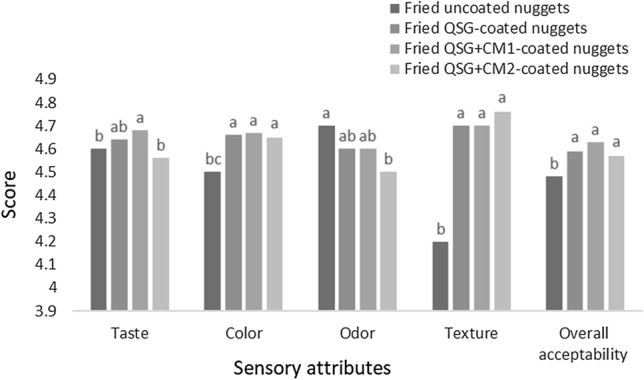

Sensory evaluation

Sensory evaluation was performed to study the effect of treatments on the sensory attributes of fried nuggets on consumer acceptance. Figure 4 shows the scores of sensory evaluations (color, odor, taste, texture and overall acceptability) of fried nuggets samples. The results of sensory evaluations showed that there was a significant difference in organoleptic attributes between different nugget samples (p < 0.05). The lowest scores of texture, taste, color and aroma among the samples were attributed to the untreated sample, which could be related to the reduction of moisture and more oil uptake of this sample during the frying process. Fried coated nuggets containing QSG + 0.5% carvacrol microcapsules have a better texture, color and taste and a higher overall acceptance score, which can be attributed to the reduction in oil uptake and moisture less in these samples.

Fig. 4.

Sensory evaluation scores of deep-fat fried nuggets

Due to the positive antioxidant effects of carvacrol microcapsules on oil oxidation in fried nugget samples, it is understandable that the taste and smell scores of the samples are higher. Also, the higher scores of nuggets coated with batter containing QSG + carvacrol microcapsules correspond to the results of texture analyses test and show that this treatment could improve the textural properties of nuggets, in addition to reducing oil absorption and oxidation. As it turned out from the results of physical tests, QSG-Coatings containing carvacrol microcapsules were able to prevent the hardening of the texture of nugget samples in the process of deep frying by retaining more water and consequently reducing oil absorption.

Conclusion

The effect of batter coatings containing quince seed gum and carvacrol microcapsules on reducing moisture loss, oil uptake, lipid oxidation, texture and color of chicken nuggets in the process of deep fat frying was investigated. The active batter coatings reduced the moisture loss and oil uptake of the nugget sample and subsequently reduced the oxidation and hardening of the nugget texture after frying. Carvacrol microcapsules along with seed gum reduced the primary and secondary oxidation rates of the samples (p < 0.05). The use of quince seed gum along with 0.5% of carvacrol microcapsules in batter coatings improved the color, texture and sensory properties of fried nugget samples.

Acknowledgements

The authors would like to gratefully acknowledge the University Research Office for funding this project.

Authors' contributions

Mohammad Jouki: Data curation, Methodology, Investigation, Writing–review & editing and Naimeh Khazaei: Formal analysis, Funding acquisition, Project administration, Software, Writing–original draft.

Funding

This work was funded by Grant (No. 32439) from the North Tehran Branch, Islamic Azad University, Tehran, Iran.

Data availability

The authors express their consent to the publication of the results and data of this article.

Code availability

All content presented in this article is approved by the authors.

Declarations

Conflict of interest

The authors declared that they have no conflicts of interest to this work.

Ethical approval

We declare no ethical issue related with this article.

Consent to participate

The authors express their consent to cooperate in this article.

Consent for publication

The authors express their consent to the publication of this article.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Adedeji AA, Ngadi MO. Microstructural properties of deep fat fried chicken nuggets coated with different batter formulation. Int J Food Prop. 2011;14:68–83. doi: 10.1080/10942910903131423. [DOI] [Google Scholar]

- Alipoorfard F, Tavakolipour JM, H, Application of sodium chloride and quince seed gum pretreatments to prevent enzymatic browning, loss of texture and antioxidant activity of freeze dried pear slices. J Food Sci Technol. 2020;57:3165–3175. doi: 10.1007/s13197-020-04265-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bagis U, Karabulut I. Efficacy of microencapsulated carvacrol in oxidative stability of sunflower oil. Euro J Lipid Sci Technol. 2020;122:2000011. doi: 10.1002/ejlt.202000011. [DOI] [Google Scholar]

- Choi YS, Kim HW, Hwang KE, Song DH, Choi JH, Lee MA, et al. Physicochemical properties and sensory characteristics of reduced-fat frankfurters with pork back fat replaced by dietary fiber extracted from makgeolli lees. Meat Sci. 2014;96:892–900. doi: 10.1016/j.meatsci.2013.08.033. [DOI] [PubMed] [Google Scholar]

- El-Anany AM, Ali RFM, Elanany AMM. Nutritional and quality characteristics of chicken nuggets incorporated with different levels of frozen white cauliflower. Ital J Food Sci. 2020;32:45–59. [Google Scholar]

- Gharibzahedi SMT, Mousavi SM, Jouki M, Ghahderijani M (2012) Analysis of physicochemical and thermo-mechanical characteristics of Iranian black seed (Nigella oxypetala Boiss). Int J Food Eng 8: Article 14. DOI: 10.1515/1556-3758.2703

- Han M, Bertram HC. Designing healthier comminuted meat products: Effect of dietary fibers on water distribution and texture of a fat-reduced meat model system. Meat Sci. 2017;133:159–165. doi: 10.1016/j.meatsci.2017.07.001. [DOI] [PubMed] [Google Scholar]

- Jouki M, Khazaei N (2010) Compare of extraction of phenolic compounds from Pistacia atlantica in different solvents. Adv Biomed Res pp: 361–365

- Jouki M, Mortazavi SA, Yazdi FT, Koocheki A. Characterization of antioxidant– antibacterial quince seed mucilage films containing thyme essential oil. Carbohydr Polym. 2014;99:537–546. doi: 10.1016/j.carbpol.2013.08.077. [DOI] [PubMed] [Google Scholar]

- Jouki M, Mortazavi SA, Yazdi FT, Koocheki A. Optimization of extraction, antioxidant activity and functional properties of quince seed mucilage by RSM. Int J Biol Macromol. 2014;66:113–124. doi: 10.1016/j.ijbiomac.2014.02.026. [DOI] [PubMed] [Google Scholar]

- Jouki M, Mortazavi SA, Yazdi FT, Koocheki A, Khazaei N. Use of quince seed mucilage edible films containing natural preservatives to enhance physico-chemical quality of rainbow trout fillets during cold storage. Food Sci Hum Well. 2014;3:65–72. doi: 10.1016/j.fshw.2014.05.002. [DOI] [Google Scholar]

- Jouki M, Rabbani M, Shakouri MJ. Effects of pectin and tomato paste as a natural antioxidant on inhibition of lipid oxidation and production of functional chicken breast sausage. Food Sci Technol. 2020;40:521–527. doi: 10.1590/fst.26419. [DOI] [Google Scholar]

- Jouki M, Tabatabaei Yazdi F, Mortazavi SA, Koocheki A, Khazaei N. Effect of quince seed mucilage edible films incorporated with oregano or thyme essential oil on shelf life extension of refrigerated rainbow trout fillets. Int J Food Microbiol. 2014;174:88–97. doi: 10.1016/j.ijfoodmicro.2014.01.001. [DOI] [PubMed] [Google Scholar]

- Jouki M, Tabatabaei Yazdi FT, Mortazavi SA, Koocheki A. Quince seed mucilage films incorporated with oregano essential oil: physical, thermal, barrier, antioxidant and antibacterial properties. Food Hydrocolloids. 2014;36:9–19. doi: 10.1016/j.foodhyd.2013.08.030. [DOI] [Google Scholar]

- Jouki M, Yazdi FT. The effect of gamma irradiation and vacuum packaging upon selected quality traits of refrigerated ostrich meat. Part 2. Colour, texture and lipid oxidation properties. Anim Sci Pap Rep. 2014;32:161–171. [Google Scholar]

- Jouki M, Yazdi FT, Khazaei N, Motamedi Sedeh F. Effects of storage time on quality characteristics of frozen turkey meat. Int J Anim Vet Adv. 2012;4:P63–67. [Google Scholar]

- Khazaei N, Esmaiili M, Emam-Djomeh Z. Effect of active edible coatings made by basil seed gum and thymol onoil uptake and oxidation in shrimp during deep-fat frying. Carbohydr Polym. 2016;137:249–254. doi: 10.1016/j.carbpol.2015.10.084. [DOI] [PubMed] [Google Scholar]

- Khodashenas M, Jouki M. Optimization of stabilized probiotic Doogh formulation by edible gums and response surface methodology: assessment of stability, viability and organoleptic attributes. J Food Sci Technol. 2020;57:3201–3210. doi: 10.1007/s13197-020-04351-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim DN, Lima J, Bae IY, Lee HG, Lee S. Effect of hydrocolloid coatings on the heat transfer and oil uptake during frying of potato strips. J Food Eng. 2011;102:317–320. doi: 10.1016/j.jfoodeng.2010.09.005. [DOI] [Google Scholar]

- Kumar Y, Yadav DN, Ahmad T, Narsaiah K. Recent trends in the use of natural antioxidants for meat and meat products. Comp Rev Food Sci Food Safety. 2015;14:796–812. doi: 10.1111/1541-4337.12156. [DOI] [Google Scholar]

- Li K, Wang B, Wang W, Liu G, Ge W, Zhang M, Yue B, Kong M. Microencapsulation of Lactobacillus casei BNCC 134415 under lyophilization enhances cell viability during cold storage and pasteurization, and in simulated gastrointestinal fluids. LWT - Food Sci Technol. 2019;116:108521. doi: 10.1016/j.lwt.2019.108521. [DOI] [Google Scholar]

- Lucera A, Mastromatteo M, Sinigaglia M, Corbo MR. Combined effects of thymol, carvacrol and grapefruit seed extract on lipid oxidation and colour stability of poultry meat preparations. Int J Food Sci Technol. 2009;44:2256–2267. doi: 10.1111/j.1365-2621.2009.02067.x. [DOI] [Google Scholar]

- Luna A, Labaque MC, Zygadlo JA, Marin RH. Effects of thymol and carvacrol feed supplementation on lipid oxidation in broiler meat. Poultry Sci. 2010;89:366–370. doi: 10.3382/ps.2009-00130. [DOI] [PubMed] [Google Scholar]

- Milani A, Jouki M, Rabbani M. Production and characterization of freeze-dried banana slices pretreated with ascorbic acid and quince seed mucilage: Physical and functional properties. Food Sci Nutr. 2020;8:3768–3776. doi: 10.1002/fsn3.1666. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Min B, Ahn DU. Mechanism of lipid peroxidation in meat and meat products-A review. Food Sci Biotechnol. 2005;14:152–163. [Google Scholar]

- Parimala KR, Sudha ML. Effect of hydrocolloids on the rheological, microscopic, mass transfer characteristics during frying and quality characteristics of puri. Food Hydrocolloid. 2012;27:191–200. doi: 10.1016/j.foodhyd.2011.07.005. [DOI] [Google Scholar]

- Paulo F, Santos, Design of experiments for microencapsulation applications: A review. Mat Sci Eng C-Mater. 2017;77:1327–1340. doi: 10.1016/j.msec.2017.03.219. [DOI] [PubMed] [Google Scholar]

- Raeisi S, Ojagh SM, Pourashouri P, Salaun F, Quek SY. Shelf-life and quality of chicken nuggets fortified with encapsulated fish oil and garlic essential oil during refrigerated storage. J Food Sci Technol. 2021;58:121–128. doi: 10.1007/s13197-020-04521-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sahin S, Sumnu G, Altunakar B. Effects of batters containing different gum types on the quality of deep-fat fried chicken nuggets. J Sci Food Agric. 2005;85:2375–2379. doi: 10.1002/jsfa.2258. [DOI] [Google Scholar]

- Shariati Z, Jouki M, Rafiei F. Flavored functional drinking yogurt (Doogh) formulated with Lactobacillus plantarum LS5, cress seed gum, and coriander leaves extract. Food Sci Nutr. 2020;8:894–902. doi: 10.1002/fsn3.1367. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sun X, Cameron RG, Bai J. Microencapsulation and antimicrobial activity of carvacrol in a pectin-alginate matrix. Food Hydrocolloid. 2019;92:69–73. doi: 10.1016/j.foodhyd.2019.01.006. [DOI] [Google Scholar]

- Tayyari F, Khazaei J, Rajaei P, Jouki M. Effects of modified atmosphere packaging systems, low temperature and storage time on the quality of fresh minimally processed pomegranate arils. Carpath J Food Sci Technol. 2017;9:16–26. [Google Scholar]

- Usawakesmanee W, Chinnan MS, Wuttijumnong P, Jangchud A, Raksakulthai N. Effect of edible coating ingredients incorporated into predusting mix on moisture content, fat content and consumer acceptability of fried breaded product. Songklanakarin J Sci Technol. 2008;30:25–34. [Google Scholar]

- Verma AK, Sharma BD, Banerjee R. Effect of sodium chloride replacement and apple pulp inclusion on the physicochemical, textural and sensory properties of low-fat chicken nuggets. LWT-Food Sci Technol. 2010;43:715–719. doi: 10.1016/j.lwt.2009.12.006. [DOI] [Google Scholar]

- Zhou K, Hao J, Griffey C, Chung H, O’Keefe SF, Chen J, Hogan S. Antioxidant properties of fusarium head blight-resistant and -susceptible soft red winter wheat grains grown in virginia. J Agric Food Chem. 2007;55:3729–3736. doi: 10.1021/jf070147a. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The authors express their consent to the publication of the results and data of this article.

All content presented in this article is approved by the authors.