Abstract

MODS, an assay for diagnosis of tuberculosis and drug-susceptibility, is based in the microscopic observation of the characteristic cords of Mycobacterium tuberculosis colonies grown in liquid media. An inverted optical microscope (100X magnification) is required to observe and interpret MODS cultures. Unfortunately, the cost of commercial inverted microscopes is not affordable in low resource settings. To perform a diagnosis of tuberculosis using the MODS assay, images with modest quality are enough for proper interpretation. Therefore, the use of a high cost commercial inverted optical microscope is not indispensable.

In this study, we designed a prototype of an optical inverted microscope created by 3D-printing and based on a smartphone. The system was evaluated with 226 MODS TB positive and 207 MODS TB negative digital images. These images were obtained from 10 sputum samples MODS positive and 10 sputum samples MODS negative. The quality of all images was assessed by a qualified technician, in terms of adequacy to interpret and classify them as positive or negative for tuberculosis.

The quality of the images was considered appropriate for MODS interpretation. All the 20 samples were correctly classified (as TB positive/negative) by reading with the prototype 3D-printed inverted microscope.

Keywords: Tuberculosis, MODS, diagnostics, microscopy, 3D printing

Introduction

Tuberculosis (TB) is still a global public health problem of high priority. Currently, an estimated 5.8 million people around the world have been newly diagnosed with TB and more than 1.5 million have died from it by 2020 [1]. Recently, cases of multi drug-resistant (MDR-) and extensively drug-resistant (XDR-) tuberculosis have been increasing, in part due to the lack of early diagnosis resulting in delayed treatment initiation [2]. Therefore, an assay for detection of MDR-TB and XDR-TB that is fast, simple and inexpensive is needed.

The Microscopic Observed Drug Susceptibility test (MODS) is a fast liquid culture assay capable of detecting TB, determine MDR-TB and XDR-TB, directly from a sputum sample in just 7–10 days with high sensitivity and specificity [3, 4, 5].

MODS consists of the culture of a sputum sample in a liquid medium, which is incubated for 7–10 days on a 24-well plate. During the growth stage, the mycobacteria present in the sample, appear suspended at the bottom of the well forming specific morphological cording patterns, which are characteristic of M. tuberculosis. The observation of these patterns is done using an inverted microscope, which is a relatively expensive piece of equipment that limits the use of this method in low resource settings [3, 4, 5]. The determination of drug susceptibility is performed by adding the different drugs of interest in different wells of the plate. The observation of cord-like patterns in a well with a certain drug confirms the growth of M. tuberculosis, which is considered evidence of resistance to that drug.

In the last years, our group has successfully developed different prototypes of low-cost inverted microscopes, which have been especially evaluated for the diagnosis of TB using the MODS assay [6, 7] as proofs of concept. However, the complexity of these devices is still a disadvantage (use of heavy material such as aluminum and image acquisition system), in addition to a still considerable cost [6, 7].

In recent years, 3D printing (cast filament manufacturing) has become a readily available consumer technology. Its ease of use and affordable cost, due to its mass production, has allowed its application in areas such as chemical instrumentation [8], microfluidics [9], biochemical analysis [10] and others.

Recent studies have demonstrated the use of devices in the transmission of digital images for remote analysis by experts [11] or remote analysis using recognition software and artificial intelligence [12, 13].

Given the great growth of this technology and its various fields of application, in this study, we show the construction and evaluation of a 3D printed inverted microscope capable of capturing images of MODS cultures using a smartphone for further interpretation and diagnostics of TB and drug susceptibility.

Methodology

Optical system and the basic principle of operation

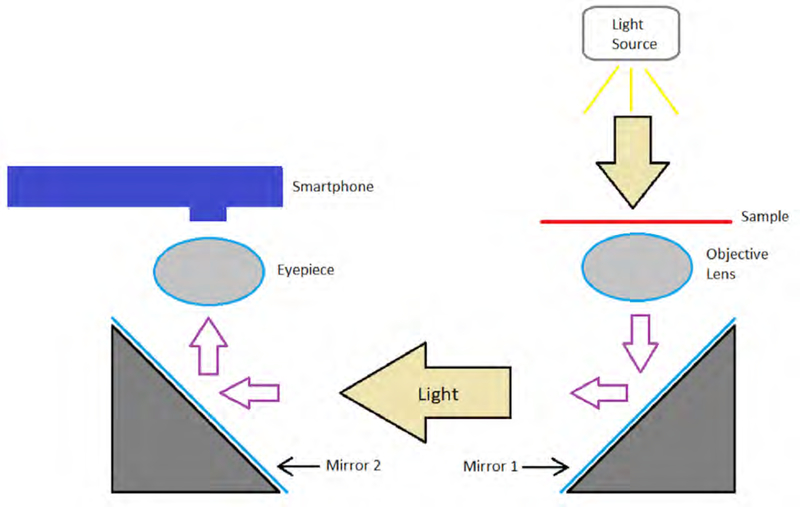

The optical system of our 3D printed microscope is based on two mirrors placed at an angle of 45 degrees to the horizontal with their reflective faces facing each other. These are simple, low-cost standard mirrors. On one of them, a 10X objective lens is placed to collect the light that passes through the sample and on the other mirror, an ocular 10X lens is placed, achieving a total 100X magnification determined by the characteristics of both lenses. The distance between the lenses (optical distance) is approximately 120 mm, a little less than that recommended by the DIN standard (160 mm). The light enters vertically on the objective lens after passing through the sample, is reflected from the first mirror horizontally to the second mirror and is again reflected vertically through the ocular lens. Finally, a smartphone is positioned in such a way that the camera’s sensor lens is aligned with the ocular lens. In this way, the smartphone serves to display and capture the images. Figure 1 shows an outline of this optical principle and its operation.

Figure 1:

Working principle. The light from the source is transmitted through the sample, passes through the objective lens and is reflected on the mirror 1 horizontally and then on the mirror 2 vertically. It then passes through the eye lens and reaches the Smartphone’s camera sensor where the image is displayed.

Prototype

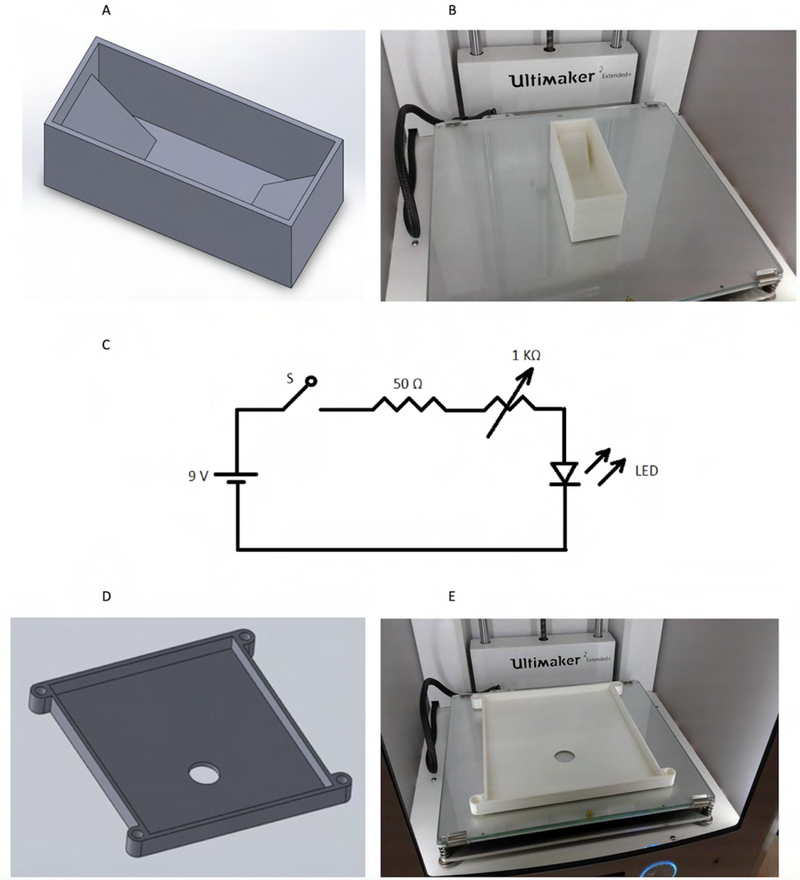

The development of the prototype is based on the optical system (Figures 2a and 2b). This prototype consists of 19 pieces designed using CAD software. CAD files are saved in STL format, the same transformed into GCODE format using the Cura software. Each piece was 3D printed with an Ultimaker 2+ Extended printer. The printing parameters for the formation of the part in GCODE format (Cura Software) are printer extruder of 0.4 mm diameter, 0.2 mm thickness of each layer, 0.6 mm thickness in the first 3 and last 3 layers (total filling), 0.8 mm thickness in the lateral layers (total filling), 20% filling in the total part, printing speed: 60 mm/s, and 120 mm/s travel speed. 2.85 mm thick Polylactic Acid (PLA) filaments from the same Ultimaker company were used.

Figure 2:

3D printed parts and lighting system circuit. (a) CAD software design of the mirror support. (b) Printed part of the holder. (c) Circuit diagram of the lighting system. (d) CAD software design of the platform for the plate support (MODS cultures). (e) Printed part of the plate holder.

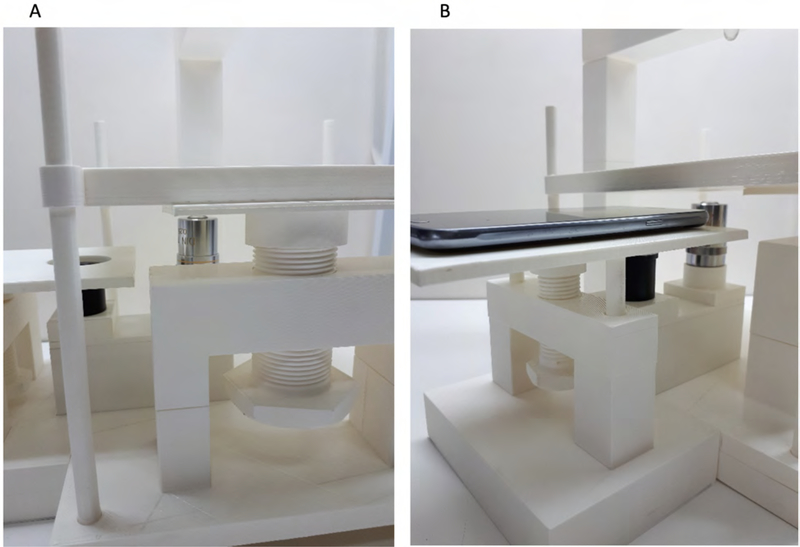

A simple and adjustable illumination system was developed, using a potentiometer and a white LED of 0.5 W power as a light source positioned 10 cm above the sample and aligned with the ocular lens. The illumination circuit is powered by a 9V DC battery. The circuit design used is simple and easy to reproduce (Figure 2c). The microscope has a platform of a size to fit a standard 24-well plate used in MODS (Figure 2d and 2e). This platform has a mechanism for manual positioning in the Z-axis that regulates the distance between the sample and the objective lens to achieve the appropriate focus. The positioning mechanism consists of a 2mm pitch screw made in 3D printing and a fixed base that serves as a support for the screw (Figure 3a).

Figure 3:

Z-positioning mechanisms for focusing. (a) 2 mm pitch screw used for Z-positioning between the target lens and the plate. (b) 2 mm pitch screw used for Z-positioning between the eyepiece lens and the Smartphone.

Above the other end of the optical system (over the ocular lens), there is a second platform that supports the smartphone for image collection. This platform also has a Z-axis positioning mechanism for adjusting the distance between the smartphone lens and the eyepiece. Similarly, this Z-axis focusing system is based on a screw of 2mm pitch made in 3D printing and a fixed base that serves as a support (Figure 3b). Two standard OEM low-cost microscope lenses were used for optical magnification. A 10X objective lens and a 10X eyepiece giving a combined 100X magnification are used. A Samsung Grand Neo Plus smartphone, with main camera of 5 MP resolution, and Android 4.4.4 operating system (Kitkat), was used to generate, view and capture the digital images. For security/biosafety reasons, the smartphone was used inside a transparent plastic zip-lock bag. After use in the readings, the smartphone was removed and cleaned with a disinfectant and a soft cloth.

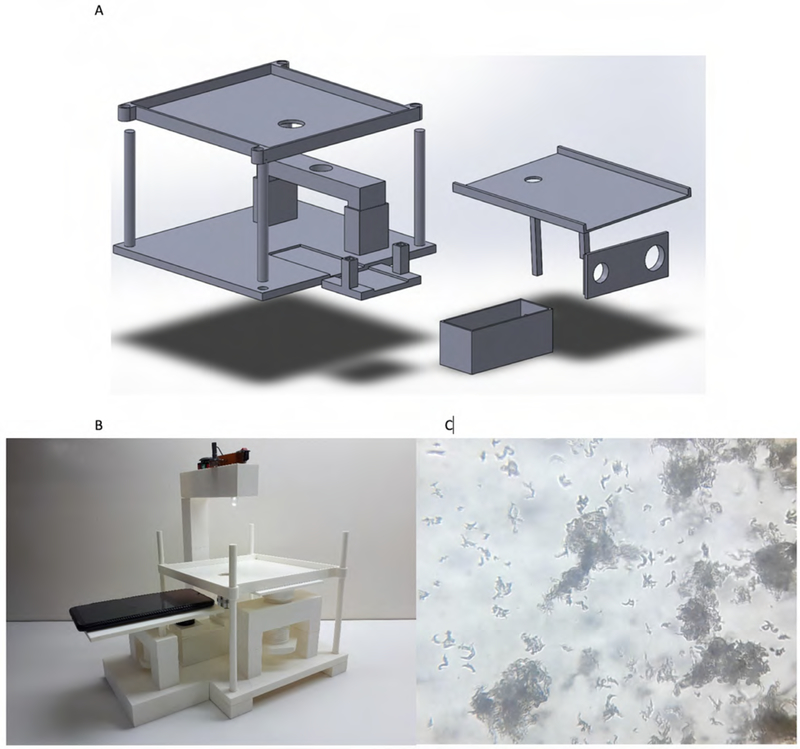

The approximate cost to build this microscope is between $70 and $100 (not considering the cost of the smartphone), which is notably less than the cost of a commercial inverted microscope. The CAD design of the microscope (Figure 4a) and the files corresponding to the elaboration of each piece are available in the web site, as well as a video tutorial about the assembly upon request to the authors. The final microscope is shown as a lightweight structure of small size, which is highly portable (Figure 4b). The quality of the images corresponding to 7–9-day MODS cultures showed appropriate details necessary for correct interpretation (Figure 4c).

Figure 4:

(a) CAD software design of some parts used in the inverted microscope assembly. (b) Inverted printed 3D microscope assembly (c) Image of a 9-day MODS culture taken with the inverted printed 3D microscope.

Validation

The validation of the prototype was carried out by digitizing images from 20 MODS cultures (10 TB MODS positive sputum samples taken at 7 days and 9 days of incubation, and 10 TB MODS negative, confirmed by standard MODS), using a Nikon Eclipse inverted microscope and the reading/interpretation was conducted by an expert technician. The processed sputum samples confirmed as MODS positive in this study, corresponded to TB patients with clinical symptoms and confirmed positive acid-fast bacilli smear. The sputum samples confirmed as MODS negative, corresponded to healthy/asymptomatic individuals. All sputum were obtained from surplus samples of another concurrent study. All digital images were visualized and captured with the Samsung Grand Neo Plus smartphone. TB positive was claimed when typical cording-shape morphology objects were observed. In contrast, non-tuberculous mycobacteria has a different morphological growing pattern (specific for each mycobacteria) [12]. Contamination and fungus growing also have a typical morphological pattern [12]. This makes MODS a highly specific test to recognize M. tuberculosis and differentiate it from non-tuberculous mycobacteria. This criteria was used for the readings using both the commercial Nikon Eclipse inverted microscope, as well as the 3D-printed inverted microscope.

A total of 114 images from 7 days positive cultures, 112 images from 9 days positive cultures and 207 images from negative cultures were obtained. All the digital images corresponding to the cultures performed are available in the following website (LINK) upon request to the authors. The quality of all the images was assessed in terms of adequate information to interpret and classify them as positive or negative for tuberculosis, as appreciated by the technician.

Results

Performance of the prototype system for local TB diagnosis

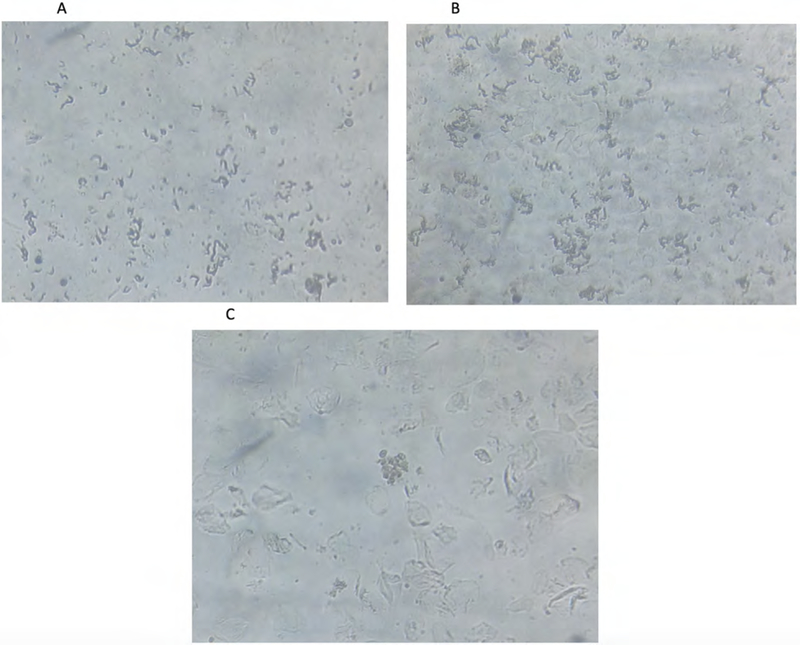

All images captured with our 3D printed inverted microscope were analyzed by a technician with experience in MODS culture interpretation. All the images showed enough high quality to be inspected and interpreted. Examples of these images corresponding to 7-day, 9-day positive cultures, and negative cultures are shown in Figures 5a, 5b, and 5c.

Figure 5:

(a) Image of a 7-day MODS positive culture in the validation stage. The image shows the characteristic strands of Mycobacterium tuberculosis. (b) Image of 9-day MODS positive culture in the validation stage. As well as the M. tuberculosis cords, but with a bigger size and more defined clusters. (c) Image of a MODS negative culture.

Of the 10 TB positive samples, all of them were classified by the expert as positive, and of the 10 negative samples, all of them were classified as negative, by reading the cultures using the 3D-printed inverted microscope.

Discussion

This study demonstrates that through 3D printing technology we can build a very low-cost inverted microscope, accessible to the public, and capable of obtaining MODS culture images with sufficient quality for a correct analysis and interpretation.

The validity of the MODS assay depends on the quality of the microscopic images and the experience of the expert who reads and interprets them. Commercial inverted microscopes have usually been used to interpret MODS cultures. In many low-resource settings, it is virtually impossible to afford a commercial inverted microscope, resulting in a major obstacle to the application of MODS and limiting the early detection of TB cases as well as the early detection of MDR-TB and XDR-TB cases.

The proposed 3D printed inverted microscope resulted highly affordable, as its cost is about $70–100. This cost comprises the OEM (generic/non-branded) lenses (10X objective and 10X eye piece), the required amount of PLA filament for printing, and the electronic components for the illumination system. We have tested a prototype for at least 4 years, under an appropriate care of use as for any laboratory-type equipment, without any functioning problem or damage, confirming that this system is highly durable. Regarding biosafety, the PLA filament used to print the microscope is inert and can be cleaned with disinfectant products without causing any damage. The smartphone evaluated in this study had a 5 Mp resolution camera, which generated images with enough quality for an appropriate reading and interpretation. Most low-cost/entry-level models of smartphones, have 5 Mp resolution cameras or more. This ensures the affordability the overall system.

The mass production of our methodology would produce even cheaper equipment and may be able to bring MODS to low resource settings. Previous studies have demonstrated the usefulness of smartphones in the transmission of digital images of MODS cultures for remote diagnosis [11], which is coupled with the development of a digital system and pattern recognition algorithms for automatic diagnosis using artificial intelligence tools with convolutional neural networks [13]. Both developments, together with the inverted microscope printed in 3D, provide a platform for the telediagnosis of tuberculosis from the analysis of digital images of MODS cultures in remote locations.

In conclusion, this study confirms that the quality of the images obtained through the 3D-printed built microscope presented here, is adequate to allow proper recognition and diagnosis of TB in MODS cultures. In this way, our study contributes modestly to the global efforts to fight against tuberculosis.

Funding

This study was funded by NIH Grant R25 TW009720-01 awarded to RO and MZ, and Google Latin American Awards 2016 awarded to MZ. PS was supported by the Wellcome Trust Intermediate Fellowship (099805/Z/112/Z).

Footnotes

Conflict of interest

All authors declared that they have no conflicts of interest.

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- 1.Global tuberculosis report 2021. Geneva: World Health Organization; 2021. Licence: CC BY-NC-SA 3.0 IGO. [Google Scholar]

- 2.Van Der Werf MJ, Langendam MW, Huitric E, Manissero D. Multidrug resistance after inappropriate tuberculosis treatment: A meta-analysis. Eur Respir J. 2012; 39(6): 1511–9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Caviedes L, Lee TS, Gilman RH, Sheen P, Spellman E, et al. Rapid, efficient detection and drug susceptibility testing of Mycobacterium tuberculosis in sputum by microscopic observation of broth cultures. The Tuberculosis Working Group in Peru. Journal of clinical microbiology. 2000;38(3):1203–8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Moore DAJ, Evans CAW, Gilman RH, Caviedes L, Coronel J, Vivar A, et al. Microscopic-observation drug-susceptibility assay for the diagnosis of TB. N Engl J Med. 2006;355(15):1539–50. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Moore DAJ, Mendoza D, Gilman RH, Evans CAW, Hollm Delgado M-G, Guerra J, et al. Microscopic observation drug susceptibility assay, a rapid, reliable diagnostic test for multidrug-resistant tuberculosis suitable for use in resource-poor settings. Journal of clinical microbiology. 2004;42(10):4432–7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Zimic M, Velazco A, Comina G, Coronel J, Fuentes P, Luna CG, et al. Development of low-cost inverted microscope to detect early growth of Mycobacterium tuberculosis in MODS culture. PLoS One. 2010;5(3):e9577. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Comina G, Mendoza D, Velazco A, Coronel J, Sheen P, Gilman RH, et al. Development of an automated MODS plate reader to detect early growth of Mycobacterium tuberculosis. J Microsc. 2011;242(3):325–30. [DOI] [PubMed] [Google Scholar]

- 8.Hartings MR, Ahmed Z. Chemistry from 3D printed objects. Nature Reviews Chemistry. 2019;3(5):305–14. [Google Scholar]

- 9.Morgan AJ, Hidalgo San Jose L, Jamieson WD, Wymant JM, Song B, Stephens P, et al. Simple and Versatile 3D Printed Microfluidics Using Fused Filament Fabrication. PLoS One. 2016;11(4):e0152023. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Zhang C, Chen C-J, Settu K, Liu J-T. Angle-Scanning Surface Plasmon Resonance System with 3D Printed Components for Biorecognition Investigation. Advances in Condensed Matter Physics. 2018;2018:1–7. [Google Scholar]

- 11.Zimic M, Coronel J, Gilman RH, Luna CG, Curioso WH, Moore DA. Can the power of mobile phones be used to improve tuberculosis diagnosis in developing countries? Trans R Soc Trop Med Hyg. 2009;103(6):638–40. [DOI] [PubMed] [Google Scholar]

- 12.Alva A, Aquino F, Gilman RH, Olivares C, Requena D, Gutiérrez AH, et al. Morphological characterization of Mycobacterium tuberculosis in a MODS culture for an automatic diagnostics through pattern recognition. PLoS One. 2013;8(12):e82809. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Lopez-Garnier S, Sheen P, Zimic M. Automatic diagnostics of tuberculosis using convolutional neural networks analysis of MODS digital images. PLoS One. 2019;14(2):e0212094. [DOI] [PMC free article] [PubMed] [Google Scholar]