Abstract

Objective:

To determine the amount of torque expressed by various self-ligating brackets and to evaluate the influence of active clip designs.

Materials and Methods:

Torque moments were measured for nine different bracket types in combination with a 0.019 × 0.025 inch stainless-steel archwire. All active brackets were measured in an open and a closed configuration to evaluate the influence of the self-ligating spring clip. In addition, slot dimensions were optically measured and compared to the torque expression.

Results:

Moments between 3.1 Nmm and 22.6 Nmm were observed at an angulation of 30° between archwire and slot. The amount of torque contributed by the spring clip of active self-ligating brackets was approximately 1 Nmm; 10 Nmm of torque was achieved with most brackets with a 20°–25° angulation between archwire and slot. The slot dimensions ranged from 0.0222 inch (0.563 mm) to 0.0241 inch (0.613 mm).

Conclusion:

The influence of the ligature or the active or passive self-ligating mechanism is minimal, and slot dimensions are far more important for the transmission of torque. The amount of torque exerted by the active spring clip is approximately 1/10th of the torquing moments recommended in the literature.

Keywords: Self-ligating brackets, Rotation, Moment

INTRODUCTION

Self-ligating brackets have become widely used in the past decade. Two main groups can be distinguished according to their ligation mechanisms: active and passive self-ligating systems. However, the differences between the two systems for the expression of torque are not clear.

Self-ligating brackets were introduced as early as 1933 by Boyd and Ford. The aim of the self-ligating mechanism was to save time since elastic ligatures were not available at the time. The main difference between the self-ligating brackets is the mechanism that closes the slot. In an active system, as for example, Speed, In-Ovation, and Quick, the ligation clip exerts a pressure on the archwire. The passive self-ligation designs, such as Damon and SmartClip, use a closing mechanism that transforms the open slot to a tube.

The manufacturers of both bracket types claim advantages for their design. The active clip should enhance the control of tooth movement. The pressure exerted on the archwire should have a double effect: enhanced rotational control and better torque expression. On the other hand, the passive design is promoted for its low friction mechanics. However, there is no clinical evidence of a superiority of one design over the other.

For a 0.019 × 0.025 inch archwire in a 0.022-inch slot, the theoretical value for torque play can be calculated from trigonometric functions as 7.3°.1 In reality, torque loss is higher because neither the dimensions of the slot nor the dimensions of the archwire are 100% precise. As measured by several authors, the dimension of the slots tends to be larger and archwires smaller than stated.2–11 Rounding and beveling of the edges of wires and brackets also contribute to an increased play.12 Thus, measured torque play in vitro can be expected to be about 15° for the above-mentioned combination. However, there are clinical factors that might influence the amount of play. One of them is the second-order angulation of the bracket to the archwire, the tip. As a bracket is angulated with respect to the archwire, the slot dimension closes and a torquing moment can be found much sooner than expected from the ideal settings.7

The frictional behavior of self-ligating brackets has been well documented in the literature.13–18 The expression of torque has been investigated less. Badawi19 showed that active self-ligating brackets had a better torque control than passive brackets and that the initial play of the archwire in the slot was less for active self-ligating brackets. Major et al.20 found that from a clinical perspective, the torque plays between active and passive self-ligating brackets were virtually indistinguishable and that the brackets did not show statistically different torque expression at angles of twist smaller than 24°.

It is the aim of the present study to evaluate the influence of active clip designs on the torquing capability of self-ligating brackets and to compare active and passive self-ligating systems.

MATERIALS AND METHODS

Five samples each of nine bracket types were evaluated for torque application: seven self-ligating brackets (Damon III, Ormco Corporation, Orange, Calif; In-Ovation R, GAC International Inc, Bohemia, NY; Oyster, Gestenco International AB, Gothenburg, Sweden; Quick, Forestadent Bernhard Förster GmbH, Pforzheim, Germany; SmartClip, 3M/Unitek, Monrovia, Calif; Speed, Strite Industries, Cambridge, Ontario, Canada; Time, American Orthodontics, Sheboygan, Wis), an esthetic ceramic bracket with a special low-friction clip (Mystique, NeoClip, GAC,) and a standard twin bracket (Mini-Mono, Forestadent) ligated with elastomeric ligatures as well as tight stainless-steel ligatures. Central incisor brackets were chosen and laser welded or bonded (ceramic and polymer brackets) to screw heads, which were mounted on the frame of the Hexapod used for the investigation (MiCos GmbH, Eschbach, Germany). A 0.019 × 0.025 inch stainless-steel wire (3M/Unitek) was fixed within a three-jaw drill chuck, which in turn was mounted on a three-dimensional force/moment sensor (FTD Nano 17, ATI, Apex, NC). The sensor itself was centrically mounted on an automated rotary disk (PRS 110, MiCos; Figure 1). Thus, with the aid of the Hexapod, the archwire could be precisely positioned within the slot of the brackets. Thereby, the archwire was centered in the open bracket until the range without torque had an equal length for palatal and buccal torque expression. Thereafter, the bracket was measured without further manipulation in the open configuration. This was immediately followed by the closed configuration measurements. In between the open and the closed configuration measurements, only the ligature was placed or the clip closed. Otherwise, the setup remained unchanged. Force moments were recorded throughout a torque application of ±30°. The crosshead speed was set at 1°/s. Torquing moments were recorded every 100 milliseconds. In addition, the Speed bracket was evaluated in combination with the 0.020 × 0.025 inch Speedwire as its special design is claimed to have superior torquing effects in combination with the active spring clip of the Speed bracket.

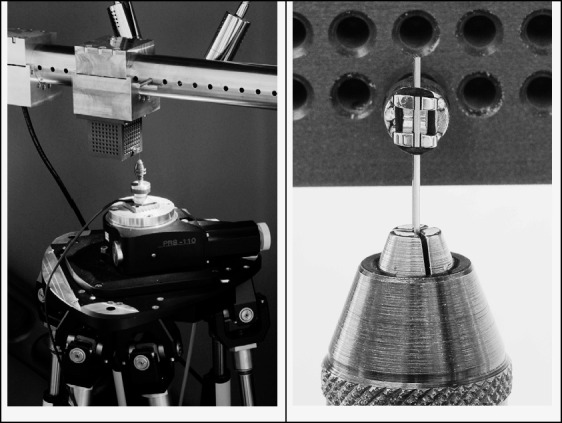

Figure 1.

Experimental setup using a Hexapod to position the wire precisely within the bracket slot and a rotary table for torque application. The detail shows the setup of the torquing mechanism.

All bracket types were measured with the closing mechanism in an open and a closed configuration. Results were evaluated for maximum torque moment at 30° torque. In addition, the level of twist needed to produce a force moment of 10 Nmm and the range of angulation without torque control in an open configuration was calculated. The torque effect of the spring clips was measured as the mean torque expression of the brackets in the closed configuration within the range without torque defined by the open configuration setup. To eliminate unwanted influences, neither the range between −1° to +1° nor the last degree of both ends of the range without torque were included for the averaging of the spring clip effect on torque expression.

Normal distribution according to the Kolmogorov-Smirnov test was found for the results of maximum torque, the range without torque being expressed and the angulation at a force moment of 10 Nmm. These results were analyzed by means of an analysis of variance using the Tukey posttest at a level of significance of P ≤ .05 with the software Prism (GraphPad, San Diego, Calif). As not all brackets showed spring clip forces within normal distribution according to Kolmogorov-Smirnov, a nonparametric analysis using multiple Mann-Whitney comparisons and two-tailed P values was calculated for buccal and palatinal torque effect of the spring clips.

In addition, the slot dimensions were measured using a light microscope (Leica M7A, Leica, Solms, Germany) in combination with a digital camera and calibrated measuring software (Leica IM 500, Leica). The dimensions of all five brackets for each bracket type were measured. The error of the method was calculated from 10 different measurements of a single MiniMono Bracket including renewed placement and digitization of the bracket and shown as a percentage deviation.

RESULTS

Figures 2–4 and Table 1 show the maximum torque value for a 30° angulation, the influence of the ligation mechanism on torque expression, the range without torque control, the amount of torque needed to exert a force/moment of 10 Nmm, and the slot width.

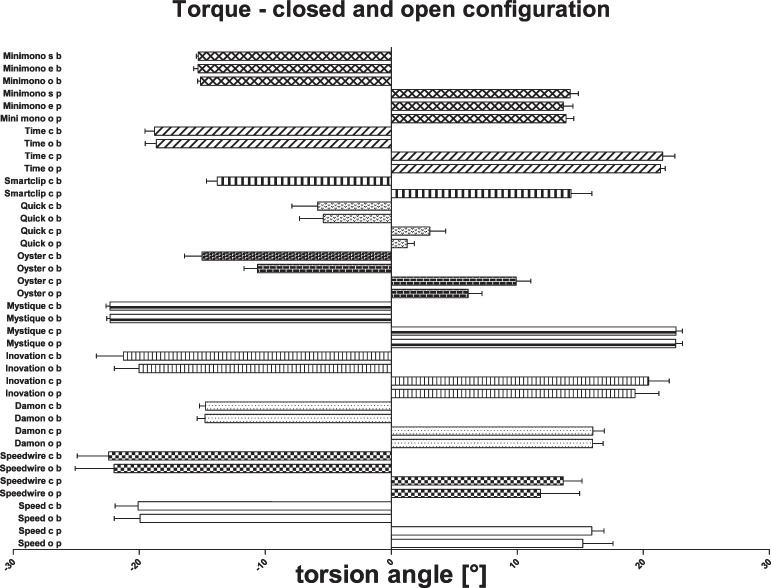

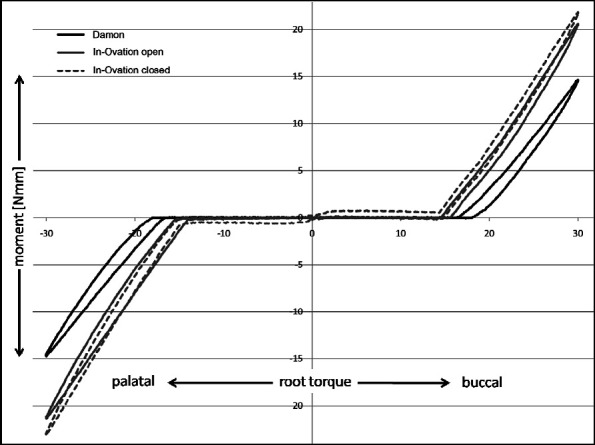

Figure 2.

Typical graphs representing passive and active self-ligating brackets. In the passive system, no torque is transmitted until the wire is in contact with the slot wall. In the active system, a small amount of force resulting in a torque of approximately 1 Nmm is exerted by the spring clip.

Figure 3.

Mean and standard deviation of palatal (p) and buccal (b) torque expression in the open (o) and closed (c) configuration. The control group (Minimono) was measured with either elastic (e) or tight stainless-steel (s) ligatures or without ligatures (o).

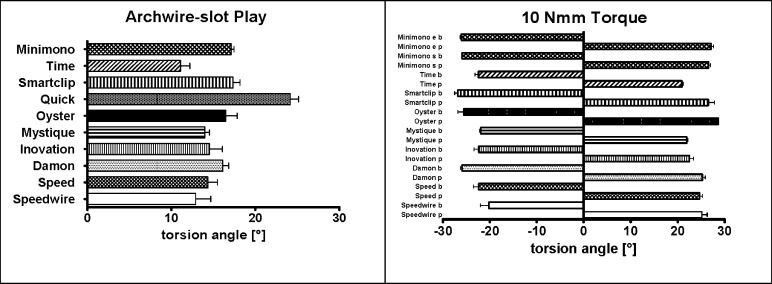

Figure 4.

Mean and standard deviation of play between archwire and slot and torsion angle expressing a couple of 10 Nmm for palatal (p) and buccal (b) root torque. The standard twin bracket was tested with elastic (e) or stainless-steel (s) ligatures.

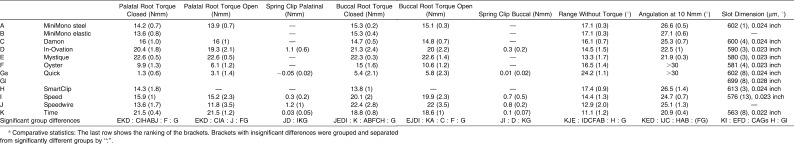

Table 1.

Mean and Standard Deviation of Maximum Torque Values for a 30° Angulation in Buccal and Palatal Root Torque in the Open and Closed Configuration, the Influence of Active Ligation Mechanism on Torque Expression, the Range Without Torque Control (Archwire-Slot Play), the Amount of Torque Needed to Exert a Palatal Root Torque of 10 Nmm, and Slot Widtha

Two of the five samples of the Mystique bracket broke before the angulation of 30° was achieved. The results for Mystique are therefore based on the remaining three brackets.

The statistical evaluation at a level of significance of P ≤ .05 revealed that in terms of maximum torque expression at 30° angulation, there was no significant difference between the open and closed configuration of the brackets (all differences <1.8 Nmm), with the exception of the Oyster bracket (difference 3.8 Nmm). There was also no difference between the ligation methods of the control group with either steel or elastic ligatures and the expression of torque by the speed bracket in combination with either the 0.019 × 0.025 inch rectangular or the 0.020 × 0.025 inch Speedwire. However, between the different brackets, significant differences were found. The lowest torque moments at 30° angulation were attained with the Quick bracket and the highest with the Mystique (NeoClip) and Time bracket, with the difference of expressed torque moment attaining approximately 20 Nmm.

Palatal root torque at 30° torsion was best expressed by the brackets Mystique, Time, and In-Ovation with values between 22.6° and 20.4°. The highest values for buccal root torque at 30° torsion were found for the brackets Speed, Mystique, and In-Ovation with expressed torque of 22.4° to 20.1°. The effect of the active spring clips was small for all active brackets. The range of angulation without expression of torque in the open configuration of the brackets can be statistically divided into four groups. The smallest range was found for the Time bracket together with Speed (Speedwire) and Mystique (11.1°–13.3°). The amount of angulation needed to express a torque moment of 10 Nmm in the closed configuration and in the direction of palatal root torque was lowest for Time, Mystique, and In-Ovation, with values between 20.9° and 22.5°. The Quick bracket and the Oyster bracket could not be evaluated, as the 10 Nmm of palatal root torque was not attained at 30° torsion.

For the microscopic measurements, a percentage deviation of 0.76% was calculated. For the slot dimensions, values between 0.0222 inch (0.563 mm) and 0.0241 inch (0.613 mm) were measured for Time and SmartClip, respectively. For the Quick bracket, two measurements were taken. One for the distance between the torquing rails and the opposing slot wall (0.0237 inch [0.602 mm]) and one between the slot walls (0.0275 inch [0.699 mm]). The 0.019 × 0.025 inch archwire had a true dimension of 0.0190 inch (0.483 mm) × 0.0246 inch (0.625 mm).

DISCUSSION

Torque application is one of the most clinically demanding tooth movements. Moments of 5–20 Nmm have been recommended to be clinically effective,21–25 but no proof for an ideal moment exists in the literature. One idea behind the design of active clips in self-ligating brackets was to increase the efficiency of the bracket for the transmission of torque. Although this assumption is commonly used by the dental companies to promote active self-ligating systems, it is not clear whether it is of clinical significance. Torque values are achieved through a combination of the passive contact of the archwire with the slot wall and the active pressure of the clip onto the archwire. A recent study showed an advantage of active over passive self-ligating brackets.19 However, as the brackets were measured with only the self-ligating mechanism closed, the difference in torque expression might have been more likely due to a variance in slot width than the actual effect of the clips. In the present study, significantly larger slot widths were found for the two passive systems compared with both active systems tested in the above-mentioned investigation. This resulted in a difference of approximately 2° in the range without torque and is probably not of clinical significance. To evaluate the effect of the clip, it is necessary to establish a baseline value of torque expression in an open configuration, which thereafter can be compared with the closed configuration. The amount of torque expression by the active clip can be measured in two ways. As torque is additive in nature, the combined moments induced by passive contact between archwire and slot wall and the moment produced by the active clip can be compared with the moment expressed from a bracket in an open configuration at equal torsion, with the difference indicating the amount of torque expressed by the active spring clip. The second method to evaluate the effect of the active spring clip, which was chosen in the present investigation, was to compare the torque moment in a closed and open configuration of the bracket within the range without torque. Both calculations resulted in small moments additionally expressed by the active clips of approximately 1 Nmm. It is questionable whether a moment at this level will have a significant influence on tooth movement, as moments 5–20 times larger are usually recommended for torquing an anterior tooth.21–25 Methodologically, testing the open and closed configuration without exchanging the wire might have induced some bias by deformation and beveling of the archwire. However, this was not found to influence torque expression in preliminary testing.

A torque level of 10 Nmm was achieved with most brackets at an angulation of the archwire to the bracket slot of 20°–25°. Only the Oyster bracket and the Quick bracket (>30°) needed more torque to express a moment of 10 Nmm. The Quick bracket showed extremely low torquing moments. This was probably due to a construction with very low torquing rails. These rails placed on the gingival slot wall on both sides of the clip aperture did not extend to a normal slot height of 0.028 inch. Therefore, the edge of the archwire under a twisting moment, like the one applied by palatal root torque, did not touch the protruding torquing rail but the slot wall. Whereas the torquing rails are at a distance from the incisal slot wall of 0.6 mm/0.024 inch, the distance between both slot walls is significantly larger with 0.7 mm/0.028 inch. This would explain the low torquing capacity of the bracket with a 0.019 × 0.025 inch archwire. To attain a reasonable torque control with the Quick bracket, larger archwires of the dimension 0.021 × 0.028 inch must be recommended.

In the present study, no torque transmission was found for the tested brackets in an open configuration and in combination with a 0.019 × 0.025 inch archwire within a range of ±11° to 17.5°. The Quick bracket even showed no torque transmission between ±24°. The discussion about prescriptions and the relevancy of their programmed torque values might become irrelevant considering these wide ranges where no torque is expressed. It has been proposed that the inadequacy of torque transmission is alleviated by the fact that mesiodistal inclination closes the slot width and increases torque expression.7 However, the clinical influence of this factor was never investigated.

Another influence on torque expression could be observed: the bracket material. The Mystique ceramic bracket (slot width 0.0228 inch) with its high stiffness displayed twice the torquing moments compared with the Oyster bracket (slot width 0.0229 inch) made of polycarbonate with an inherent lower stiffness. It is evident that polycarbonate materials are not ideal for transmitting torquing moments.

Generally the torquing capacity of all brackets was similar for buccal and palatal root torque. It is therefore not clear why this was not found for the Speed bracket with both wires. It seems that the spring clip of the Speed bracket has a strong influence on the direction of the torque expression. This is in contrast to the small torque increase measured for the clip mechanism. In addition, similar clip geometry as found for In-Ovation did not influence the direction of the torque expression. Whereas the effect can be explained by the standard deviations for the rectangular archwire, it is too strong to be neglected for the Speedwire. Probably the difference is due to the beveling of the apico-buccal edge of the archwire, which reduces the cross-sectional diameter of the opposing edges and therefore should lead to a reduction in torque expressions.

Finally, the results of the present investigation must be considered from a clinical perspective. It does not seem that the basic mechanism of active or passive self-ligation will result in clinically significant differences in torque expression. This is in agreement with earlier studies.19,20 Although there is no clinical investigation comparing the torque expression of active and passive self-ligating brackets, a recent study by Pandis et al.26 found no difference in torque expression when comparing conventional and self-ligating brackets in a clinical setup. Factors such as archwire dimension1 and material,27 on the other hand, have been shown to have greater effects on torque expression.

CONCLUSIONS

The difference between the action of active and passive self-ligating clips was not significant.

Variations in slot dimensions lead to differing torque expressions between bracket types of approximately 2° and are probably not clinically significant.

The amount of angulation needed between a 0.019 × 0.025 inch stainless-steel archwire and the bracket slot to express a torquing moment of 10 Nmm was 20°–25° for most brackets. Only the Oyster and Quick bracket needed an even greater torsion angle.

REFERENCES

- 1.Joch A, Pichelmayer M, Weiland F. Bracket slot and archwire dimensions: manufacturing precision and third order clearance. J Orthod. 2010;37:421–429. doi: 10.1179/14653121043182. [DOI] [PubMed] [Google Scholar]

- 2.Cash A. C, Good S. A, Curtis R. V, McDonald F. An evaluation of slot size in orthodontic brackets—are standards as expected. Angle Orthod. 2004;74:450–453. doi: 10.1043/0003-3219(2004)074<0450:AEOSSI>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 3.Fischer-Brandies H, Orthuber W, Es-Souni M, Meyer S. Torque transmission between square wire and bracket as a function of measurement, form and hardness parameters. J Orofac Orthop. 2000;61:258–265. doi: 10.1007/s000560050011. [DOI] [PubMed] [Google Scholar]

- 4.Gioka Ch, Eliades T. Materials-induced variation in the torque expression of preadjusted appliances. Am J Orthod Dentofacial Orthop. 2004;125:323–328. doi: 10.1016/j.ajodo.2003.02.007. [DOI] [PubMed] [Google Scholar]

- 5.Kang B, Baek S, Mah J, Yang W. Three-dimensional relationship between the critical contact angle and the torque angle. Am J Orthod Dentofacial Orthop. 2003;123:64–73. doi: 10.1067/mod.2003.55. [DOI] [PubMed] [Google Scholar]

- 6.Kusy R, Whitley J. Assessment of second-order clearances between orthodontic archwires and bracket slots via the critical contact angle for binding. Angle Orthod. 1999;69:71–80. doi: 10.1043/0003-3219(1999)069<0071:AOSOCB>2.3.CO;2. [DOI] [PubMed] [Google Scholar]

- 7.Meling T. R, Ødegaard J. The effect of second-order couple on the application of torque. Am J Orthod Dentofacial Orthop. 1998;113:256–262. doi: 10.1016/s0889-5406(98)70294-x. [DOI] [PubMed] [Google Scholar]

- 8.Meling T, Ødegaard J. On the variability of cross-sectional dimensions and torsional properties of rectangular nickel-titanium arch wires. Am J Dentofacial Orthop. 1998;113:546–557. [PubMed] [Google Scholar]

- 9.Moyers R. E. Handbook of Orthodontics 3rd ed. Chicago: Year Book Medical Publishers; 1973. [Google Scholar]

- 10.Siatkowski R. Loss of anterior torque control due to variations in bracket slot and archwire dimensions. J Clin Orthod. 1999;33:508–510. [PubMed] [Google Scholar]

- 11.Major T, Carey J, Nobes D, Major P. W. J Dent Biomech. Jun 27; 2010. Orthodontic bracket manufacturing tolerances and dimensional differences between select self-ligating brackets; p. 781321. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Sebanc J, Brantley W. A, Pincsak J. J, Conover J. P. Variability of effective root torque as a function of edge bevel on orthodontic arch wires. Am J Orthod. 1984;86:43–51. doi: 10.1016/0002-9416(84)90275-6. [DOI] [PubMed] [Google Scholar]

- 13.Franchi L, Baccetti T, Camporesi M, Barbatoc E. Forces released during sliding mechanics with passive self-ligating brackets or nonconventional elastomeric ligatures. Am J Orthod Dentofacial Orthop. 2008;133:87–90. doi: 10.1016/j.ajodo.2007.08.011. [DOI] [PubMed] [Google Scholar]

- 14.Henao S. P, Kusy R. P. Evaluation of the frictional resistance of conventional and self-ligating bracket designs using standardized archwires and dental typodonts. Angle Orthod. 2004;74:202–211. doi: 10.1043/0003-3219(2004)074<0202:EOTFRO>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 15.Henao S. P, Kusy R. P. Frictional evaluations of dental typodont models using four self-ligating designs and a conventional design. Angle Orthod. 2004;75:75–85. doi: 10.1043/0003-3219(2005)075<0075:FEODTM>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 16.Kim T, Kim K, Baek S. Comparison of frictional forces during the initial leveling stage in various combinations of self-ligating brackets and archwires with a custom-designed typodont system. Am J Orthod Dentofacial Orthop. 2008;133:187.e15–187.e24. doi: 10.1016/j.ajodo.2007.08.013. [DOI] [PubMed] [Google Scholar]

- 17.Tecco S, Festa F, Caputi S, Trainia T, Di Iorioa D, D'Attilioc M. Friction of conventional and self-ligating brackets using a 10 bracket model. Angle Orthod. 2005;75:828–832. doi: 10.1043/0003-3219(2005)75[1041:FOCASB]2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 18.Tecco S, Di Iorio D, Cordasco G, Verocchi I, Festa An in vitro investigation of the influence of self-ligating brackets, low friction ligatures, and archwire on frictional resistance. Eur J Orthod. 2007;29:390–397. doi: 10.1093/ejo/cjm007. [DOI] [PubMed] [Google Scholar]

- 19.Badawi H. M, Toogood R. W, Carey J. P. R, Heo G, Major P. W. Torque expression of self-ligating brackets. Am J Orthod Dentofacial Orthop. 2008;133:721–728. doi: 10.1016/j.ajodo.2006.01.051. [DOI] [PubMed] [Google Scholar]

- 20.Major T. W, Carey J. P, Nobes D. S, Heo G, Major P. W. Mechanical effects of third-order movement in self-ligated brackets by the measurement of torque expression. Am J Orthod Dentofacial Orthop. 2011;199:e31–e44. doi: 10.1016/j.ajodo.2010.04.029. [DOI] [PubMed] [Google Scholar]

- 21.Burstone C. J. The mechanics of the segmented arch techniques. Am J Orthod. 1966;36:99–120. doi: 10.1043/0003-3219(1966)036<0099:TMOTSA>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 22.Feldner J. C, Sarkar N. K, Sherican J. J, et al. In vitro torque-deformation characteristics of orthodontic polycarbonate brackets. Am J Orthod Dentofacial Orthop. 1994;106:265–272. doi: 10.1016/S0889-5406(94)70046-X. [DOI] [PubMed] [Google Scholar]

- 23.Jarabak J. R, Fizzel J. A. Technique and Treatment With LightWire Edgewise Appliances 2nd ed Vol I and II. St Louis, Mo: Mosby; 1972. [Google Scholar]

- 24.Reitan K. Some factors determining the evaluation of forces in orthodontics. Am J Orthod. 1957;43:32–45. [Google Scholar]

- 25.Reitan K. Effects of force magnitude and direction of tooth movement on different alveolar bone types. Angle Orthod. 1964;34:244–253. [Google Scholar]

- 26.Pandis N, Strigou S, Eliades T. Maxillary incisor torque with conventional and self-ligating brackets: a prospective clinical trial. Orthod Craniofac Res. 2006;9:193–198. doi: 10.1111/j.1601-6343.2006.00375.x. [DOI] [PubMed] [Google Scholar]

- 27.Archambault A, Major T. W, Carey J. P, Heo G, Badawi H, Major P. W. A comparison of torque expression between stainless-steel, titanium molybdenum alloy, and copper nickel titanium wires in metallic self-ligating brackets. Angle Orthod. 2010;80:884–889. doi: 10.2319/102809-604.1. [DOI] [PMC free article] [PubMed] [Google Scholar]