Abstract

The knurling design is the basis of cold-roll forming, which is related to the subsequent roll design. It is also the basis to determine the roll pass. As a typical cross-section, Z-shaped steel is widely used in automobile, household appliance manufacturing, and building structure installation. However, torsion defects often occur in the cold-roll forming of Z-shaped steel, resulting in unqualified products that are unusable. The web deflection angle is a typical factor to affect the torsion defects in the cold-roll forming of Z-shaped steel. Therefore, it is necessary to discuss the influence of web deflection on the torsion of the Z-shaped steel. The web deflection angle optimized is determined by the result. According to the theoretical calculation, the best antitorsion angle is 32°, and the conjecture is proved by experiments. Also, we obtain the forming method optimized with the least torsion. This study could provide some guidance for the design of the process flow of cold-formed Z-beam.

1. Introduction

The torsion defect of section steel is a common problem in the asymmetric section steel forming, which will seriously affect the use of section steel. Scholars, such as Cha et al., have made a series of studies on the torsion problem.1 By studying the torsion defects of cold-roll forming of asymmetric U-shaped high-strength steel, they found that the difference in longitudinal strain between the web and the vertical edge of the U-shaped steel has an important effect on torsion. They proposed to pressurize the web to improve the torsion. Tajik et al. also studied the torsion defect of asymmetric U-shaped steel and found that the long and short sides contact the rolls in the forming process inconsistently.2 It indicates that the force cannot be applied simultaneously in the thickness direction, which causes torsion. They proposed to change the shape of the roll to solve the torsion problem.

At the same time, it is also found that the synchronous change in the longitudinal strain at the edge can effectively reduce the torsion. Bidabadi et al. studied the influence of geometric factors of section steel on the torque required for channel steel forming.3 They also found that the thickness brought the greatest influence on the forming torque. The torque is closely related to the longitudinal strain of the edge, but not much to the transverse strain. Moen et al.4 considered the curling and uncoiling of the cold-formed strip. They carried out a study to predict the residual stress of the cold-roll steel member. They found that these residual stresses and strains increase nonlinearly as the thickness of the strip increases. Paralikas et al.5 studied the influence of process parameters on the quality of channel steel cold forming. They optimized the process parameters to reduce the edge longitudinal strain and weaken the redundant deformation. Davoodi et al.6 studied the influence of the material’s yield strength, strip thickness, angular increment size, flange width, and other factors on the required torque and the vertical force component of cold-roll forming. The study found that reducing the yield strength, strip thickness, and angular increment can reduce the vertical component force and required torque. Although reducing the strip width can reduce the vertical component force, it increases the overall required torque. Paralikas et al.7 studied the factors that influence the energy consumption of cold-roll forming. They found that the angle increment, frame spacing, and forming speed have the greatest impact on energy consumption. Lindgren8 studied the relationship among the longitudinal peak strain, deformation length of the U-shaped steel edge, and the yield strength of the material. Safdarian et al.9 studied the influence of forming parameters on the longitudinal strain of the edge and the longitudinal bending. They found that the longitudinal bending increased with the increase in the angle increment. The peak longitudinal strain of the edge increased with the increase in the strip thickness and angle increment. Also, the peak decreased with the increase in the frame spacing, web width, and flange width. However, it has nothing to do with the friction coefficient and forming speed.

The current torsion problems of asymmetrical steel are mainly concentrated on U-shaped steel and so forth. There has been systematic research. However, other asymmetrical steels have not been studied. There is no in-depth analysis of the influence mechanism of various factors according to the results. As a typical asymmetrical open section steel, the asymmetry of the formed product will directly cause the unbalanced force during the cold bending process and then produce torsion defects.

Based on the company’s production requirements, this study uses professional software COPRA to model and simulate Z-shaped steel with specific cross-sectional dimensions. First, it verifies that the Z-shaped steel has torsion in the roll forming. Then, we discuss the influence of the web deflection angles on the Z-shaped steel torsion. By the principle of generating torsion, the optimal web deflection angle is derived using formulas. Then, the result can be verified by simulation experiments, which proves the correctness of the derivation. It can provide experience for the actual production, reduce the reverse defects of products, improve the quality of products, and finally reduce production costs. Enterprises can further achieve good benefits.

2. Results and Discussion

2.1. Parameter Settings

The size of the section of the Z-shaped steel is as shown in Figure 1a. The various parts of the steel are named. The middle part is the web. The two curved, long sides are the leg sides, and the two curved, short sides are the flanges. The dimensions shown in Figure 1a are in millimeters.

Figure 1.

(a) Section of Z-shaped steel; (b) the knurling.

There is usually a datum in the knurling design. The datum can be a line or a point on the section. Except for the uphill or the downhill molding method,4,10 the datum keeps on the same horizontal line during the molding process. The other parts of the section are developed and designed based on this datum. The design principle of Z-shaped steel knurling in this study is to make the total torque during the forming as small as possible, to reduce the overall torsion. Therefore, the angle between the web of knurling and the horizontal line changes continuously in the forming to offset the bending moment on the legs. The center of the Z-steel web keeps on the same horizontal line in the forming. Because the flange has little influence on the forming, its influence on the torsion is not considered. Therefore, we press it in the first four passes in advance. To ensure that the torque of each part is approximately the same in the forming, the angle of inclination of the web is consistent with the bending angle of the legs. Therefore, the design of knurling is shown in Figure 1b.

The Z-shaped steel studied in this paper is S550GD + Z, which is high-strength steel for galvanized structures. It is mainly used in industrial and civil buildings,11 such as light steel keels, building decks, corrugated boards, rolling doors, and so forth. The specific performance parameters of the material are shown in Table 1. S550GD is high-strength steel with good formability and weldability. Good deformation can occur in cold rolling, while good weldability can be applied to the cold rolling forming of welded pipes.

Table 1. Performance Parameter Table of the Material S550GD.

| Young’s modulus | Poisson’s ratio | yield strength | tensile strength | elongation | |

|---|---|---|---|---|---|

| material | E (GPa) | μ | σs (MPa) | σb (MPa) | δ (%) |

| S550GD + Z | 210 | 0.3 | 550 | 700 | 18 |

2.2. Model Establishment

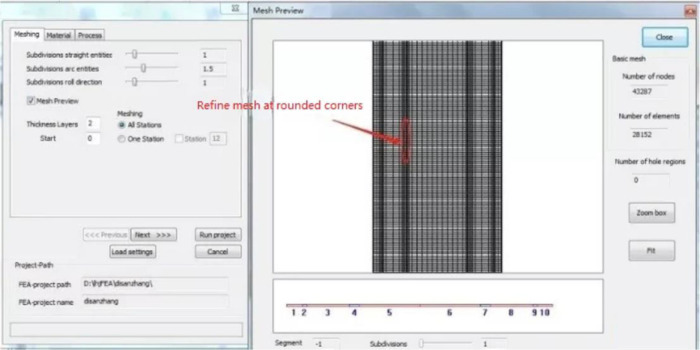

The number of cells is set to 28,152 based on the length and width of the strip, as well as the density of the required cells. The cells are 6-hedron seven entity cells with eight nodes. The cells are divided into three layers in the thickness direction so that the stress and strain changes of the different layers can be observed simultaneously. The strips at the rounded corners are individually refined to improve the simulation accuracy. Figure 2 depicts the grid division.

Figure 2.

Strip meshing.

In the cold-roll forming, the strip deforms under the influence of the roll. The roll’s distortion is minor in comparison to the strip’s deformation. In the cold-roll forming, less heat is generated. As a result, the roll has been designated as a rigid contact body. The strip is configured as a deformable contact body.12,13

Because the center of the strip should be on the same horizontal line during the forming, the displacement of the strip is limited in the Y direction. The web of the Z-steel continuously rotates during the forming of the strip. Then, there is no constraint in the X-direction. The strip moves in a constant along the Z direction, passing through the rolls to roll out the required products. Therefore, the displacement constraint is set in the Z direction. Figure 3 illustrates the specific boundary constraints.

Figure 3.

Strip boundary constraint diagram.

Cold-roll forming speed is generally 0.5∼250 m/min, and the commonly used speed range is 25∼30 m/min. The factors that affect the forming speed are generally the composition, yield strength, hardness of the strip, and so forth. The molding speed in the experiment is 25 m/min. Because the friction between the roll and the strip is sliding friction, the material used for the roll is Cr12. When a lubricant is present, the coefficient of dynamic friction between steels is typically from 0.05 to 0.1 after verification. This simulation uses a friction coefficient of 0.1.

Upper and lower roller drives, as well as coordinated upper and lower roller drives, are common driving methods. The coordinated upper and lower rollers were driven like cold rollers at the start of cold bending. Later, it was discovered that cold bending could be done without the upper shaft being driven. Furthermore, the diameters will vary greatly because of the varying shapes of the rolls. The variation in circumferential velocity is caused by the driving of the upper and lower rollers. As a result, the coordinated upper and lower rollers’ driving methods were gradually abandoned. The lower roller drive, on the other hand, frequently lacks enough friction to force the strip through the roll hole. The coordinated upper and lower rollers are normally driven on the first one or two passes and the last one or two passes in actual manufacturing. Also, using the lower roller drive, heaps and wrinkles can be avoided. As the number of passes increases, the radius of the roller normally increases by 0.5 mm.

The roll diameter includes a constant velocity circle diameter, maximum diameter, and minimum diameter. The surface speed determines the constant velocity circle diameter of the upper and lower rolls. If the speed ratio of the upper and lower rolls is 1:1, the constant velocity circle diameter of the upper and lower rolls is equal to the surface speed. The constant velocity circle of the Z-shaped steel roll is the circle formed by the rotation of the center point of the web around the driving shaft. The initial constant velocity circle diameter is 200 mm. The constant velocity circle diameter is the key to determining the roll diameter. The maximum diameter is related to the distance between the lower drive shaft and the frame. It can avoid interference. Also, two adjacent rolls should not have interference. The minimum diameter is related to the drive shaft diameter, key height, and roll thickness. The maximum and minimum diameters are defined by the actual location. The strip is made of galvanized steel with a galvanized surface. The roll gap of 0.3 mm, which is often used in industry, is utilized to prevent major surface indentation and scratches from impacting product quality.

The simulation model finally obtained using the model established in 1.2 is shown in Figure 4a. Figure 4b shows that the generated Z-shaped steel has evident torsion based on the simulation findings. Torsion is also visible in actual items. The product is placed on the ground, as indicated in Figure 4c. Torsion has led the flanges on one side of Z-shaped steel to have a particular warping height with the ground. It shows that there is torsion in the Z-shaped steel in the cold-roll forming. If the design of the roller mold is not reasonable, it will lead to excessive torsion. Then, it will fail to meet the product’s requirements.

Figure 4.

(a) Simulation results, (b) simulation model, (c) actual products; the photograph was supported by the authors of this work.

From the simulation and actual experiments, the torsion of the Z-steel mainly occurs on the web, as shown in Figure 5 below. The torsion angle θ occurs due to the twisting of the Z-steel web. It can accurately indicate torsion. The tilting height d is related to the torsion angle Φ and can intuitively reflect the torsion angle, that is, the torsion. The tilting height d here will also be affected by the rebound of the leg edges and flanges. Because it is a constant length cut from the same product, even if there is a rebound, the rebound of the product will be almost the same. It can be verified by measuring the angles between the leg edges and the flanges, also the leg edges and the webs of the two sections. As a result, the flange’s tilting height is utilized as a criterion for determining the torsion of the Z-shaped steel.

Figure 5.

Conversion diagram of the tilting height

The manufacturer’s standard for torsion-induced tilting height is no more than 12 mm for the 6-meter-long Z-steel. However, if the simulation is with a 6-meter-long Z-steel, it will severely harm the efficiency. Therefore, the strip’s length is set to be greater than 600 mm. Also, a 600-millimeter-long Z-steel is intercepted to analyze the simulation results. According to the principle of similar triangles, as shown in Figure 8, we can find the lifted height D at a length of 6 m.

Figure 8.

Simulation results of web deflection at 45°.

2.3. Control of Experimental Variables

The forming method is mainly to design and improve knurling. The design of the knurling is the basis of the cold-roll forming. It is related to the roller design and is the basis to determine the roll pass.14,15 The influence of web deflection angles on the Z-shaped steel torsion will be discussed. It is used to identify the best web deflection angle. Also, we can obtain the forming method with the least amount of torsion. This acritical intends to discuss the forming of Z-shaped steel when the web deflection angles are 45° and 32°.

The reason for choosing 45° is that the web constantly deflects during the forming. Bending the two together creates an angle between the web and the leg side. The bending angles of the leg side and the web keep consistent during the forming to guarantee that the bending moment applied on the leg side and the web is about the same. As shown in Figure 6a, it can ensure that the loading angle of α and β are uniform at each pass.

Figure 6.

(a) Schematic diagram of the loading angle. (b) Schematic diagram of torque (bending moment) in the forming process.

We can determine the web deflection angle according to the principle of Z-shaped steel torsion. The torsion defect is caused by the fact that the sum of each part’s torsion of the Z-shaped steel during the forming is not zero. Because the flange has little effect on torsion, it is still rolled in the first four passes in the forming.16,17 The design here is from the bending of the leg sides and the deflection of the web in the fifth pass. From the fifth pass to the last pass of forming, the leg sides and webs of the Z-shaped steel can be regarded as a column with a rectangular cross-section and twisted. As shown in Figure 6b, the bending angle of the bent that occurs between two joint passes during the cold-roll forming is equivalent to applying torque to twist the bent, resulting in a torsion angle. From the perspective of the overall forming process, several torques act on the bending. These torques are taken together as a combined torque. Then, from the first pass to the last pass, the bending is under the action of the combined torque. A torsion angle is generated, which is the angle required for forming.18−20 According to this principle, when designing Z-shaped steel knurling, we regard the leg sides and webs of Z-shaped steel as columns with rectangular cross-sections and twisted. From the fifth pass to the last pass, the legs are theoretically bent 90°. However, the web is also deflected. It is assumed that the web deflection angle is the bending angle of the leg, which is 90-a. To balance the torque and not produce additional torque difference, it is necessary to ensure that the torque required to bend the leg side 90-a degree is equal to the torque required to deflect the web a degree. According to the following formula,21 a can be obtained as 31.57°, rounded to 32°.

where ω is the torsion angle, T is the torque, l is the deformation length, G is the shear elastic modulus, and It is the polar moment of inertia.

Table 2 shows the distribution for the load angle used for the two web deflection angles. Figure 7 shows the corresponding knurling.

Table 2. Angle Distribution Table.

| pass | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

|---|---|---|---|---|---|---|---|---|---|

| web | 6 | 12 | 18 | 24 | 30 | 32 | 32 | 32 | 32 |

| leg side | 12 | 24 | 36 | 48 | 60 | 72 | 78 | 84 | 90 |

Figure 7.

Knurling (the left is the knurling for the web deflection of 45°, the right is the knurling for the web deflection of 32°).

Observing Figure 9, the effect of the web deflection of 32° is significantly better. We extract the different cross-sections of the final simulation results for further comparison. As shown in Figure 10, by comparison, the torsion of Z-shaped steel is significantly improved with a deflection angle of 32°. The product obtained with a web deflection angle of 45° has a lift height of 3.90 mm because of the torsion of the flange (Figure 8). The tilt height of the product with a 32° deflection angle is only 0.75 mm. The torsion improves by 84% (Figures 9 and 10).

Figure 9.

Simulation results of web deflection at 32°.

Figure 10.

Comparison of cross-sections with different web deflection angles.

We further analyze the results. As shown in Figure 11, the longitudinal strain difference in the web deflection of 45° deviates from the zero-scale line. The peak value of the longitudinal strain difference in the web deflection 45° on the path length is greater than the 32° web deflection. It indicates that the longitudinal strain difference in the two sections of the web is large. From this, it can be observed that the torsion with the deflection of 45° is greater than the deflection of 32°. It is consistent with the comparison results of the extracted warpage height. Therefore, it is more reasonable to adopt the method of web deflection of 32°. Also, it is reasonable to determine the deflection angle of the web with the principle of torque balance. However, the way that bending the leg side and deflecting the web with the same angle used for the 45° deflection is applied in the web deflection of 32°. It can provide a reference for the distribution of the forming angle.

Figure 11.

Comparison of longitudinal strain difference.

2.4. Promotion Experiment and Analysis

The above experiments have studied two ways to determine the deflection angle. After experimental verification, the torsion of Z-shaped steel is smaller when the deflection angle of the web is determined by the principle of torque balance. To further prove the optimality of determining the deflection angle by the principle of torque balance, we take 26°, 28°, 30°, 34°, 36°, and 38° that are close to 32°. The modeling and simulation experiments were with the above six deflection angles. The height of the flanges of the simulation results was measured, as shown in Figure 12.

Figure 12.

Flange uplift height under different deflection angles.

It can be seen from Figure 12 that when the deflection angle is greater than or less than 32°, the tilting height of the flange is greater than the height with the deflection angle of 32°. It indicates that the principle of torque balance is the best way to determine the deflection angle. It can provide the smallest torsion and prove the rationality of the method.

3. Conclusions

In this study, combined with the problems encountered in the processing of the enterprise, the web deflection angle is discussed. It is an essential factor affecting the torsion in the roll forming of Z-shaped steel. The main conclusions are as follows: it is verified that torsion defects exist in the roll forming of Z-shaped steel by simulation. It provides and verifies theoretical guidance for actual problems. The web deflection angle of the minimum torsion is 32° according to the torsion generation principle of the Z-shaped steel. The simulation comparison is with the typical deflection angle of 45°. It is preliminarily verified that the web deflection angle of 32° is more efficient to control the torsion defect by comparing with the web deflection angle of 45°. Taking several different web deflection angles to test, we verify the correctness of the algorithm for calculating the web deflection angle that has the minimum torsion angle in 32°. At the same time, it is proved that the deflection angle of the web of 32° is the best to control the torsion of Z-shaped steel. The conclusion drawn through the above research and analysis provides a reference for the torsion control of Z-shaped steel cold rolling.

Acknowledgments

The authors thank X.X. and H.L. for assistance with the experiments. The authors thank Dr. J.L. for his careful guidance, and thanks to R.Z. and USTB for providing the research platform.

The authors declare no competing financial interest.

References

- Cha W. G.; Kim N. Study on twisting and bowing of roll formed products made of high strength steel. Int. J. Precis. Eng. Manuf. 2013, 14, 1527–1533. 10.1007/s12541-013-0206-8. [DOI] [Google Scholar]

- Yaser T.; Hassan M. N.; Roohollah A. T. A strategy to reduce the twist defect in roll-formed asymmetrical-channel sections. Thin Wall Struct. 2018, 130, 395–404. 10.1016/j.tws.2018.05.013. [DOI] [Google Scholar]

- Bidabadi B. S.; Naeini H. M.; Tafti R. A. Experimental and Numerical Study of Required Torque in the Cold Roll Forming of Symmetrical Channel Sections. J. Manuf. Process. 2017, 27, 63–75. 10.1016/j.jmapro.2017.04.026. [DOI] [Google Scholar]

- Moen C. D.; Igusa T.; Schafer B. W. Prediction of residual stresses and strains in cold-formed steel members. Thin Wall Struct. 2008, 46, 1274–1289. 10.1016/j.tws.2008.02.002. [DOI] [Google Scholar]

- Paralikas J.; Salonitis K.; Chryssolouris G. Investigation of the effects of main roll-forming process parameters on quality for a V-section profile from AHSS. Int. J. Adv. Manuf. Technol. 2009, 44, 223–237. 10.1007/s00170-008-1822-9. [DOI] [Google Scholar]

- Davoodi B.; Naeini H. M.; Asl Y. D. Numerical and Experimental Investigation of Roll Forces and Torques in Cold Roll Forming of a Channel Section. AIP Conf. Proc. 2011, 1315, 581–586. 10.1063/1.3552510. [DOI] [Google Scholar]

- Paralikas J.; Salonitis K.; Chryssolouris G. Energy efficiency of cold roll forming process. Int. J. Adv. Manuf. Technol. 2013, 66, 1271–1284. 10.1007/s00170-012-4405-8. [DOI] [Google Scholar]

- Lindgren M. Cold roll forming of a U-channel made of high strength steel. J. Mater. Process. Technol. 2007, 186, 77–81. 10.1016/j.jmatprotec.2006.12.017. [DOI] [Google Scholar]

- Safdarian R.; Naeini H. M. The effects of forming parameters on the cold roll forming of channel section. Thin Wall Struct. 2015, 92, 130. 10.1016/j.tws.2015.03.002. [DOI] [Google Scholar]

- Zhang B.; Ding W.; Peng B. Application of downhill forming in roll forming. Forg. Stamping Technol. 2014, 39, 52–57. 10.13330/j.issn.1000-3940.2014.01.011. [DOI] [Google Scholar]

- Zhao J.; Sun K.; Gao X. Research on Direct Deformation Method of High-strength Cold-formed Thin-wall Z-beam Flexural Members. Stell Struct. 2018, 33, 51–56. 10.13206/j.gjg201805010. [DOI] [Google Scholar]

- Tu Y.Simulation of Cold Rolled Strip Temperature and Roll Temperature Field. Master’s thesis, Northeastern Univeristy, Shengyang, CHN, 2009. [Google Scholar]

- Liu H.Mechanics of materials I, 6th ed.; Higher Education Press, 2017. [Google Scholar]

- Xiao N.; Liu J.. Cold forming technology; Chemical Industry Press, 2008. [Google Scholar]

- Wang Y.; Chen H.; Wang J.; Wang X. Simulation and analysis on coil steel spring coiling process based on Marc. Comput.-Aided E 2013, 22, 427–430. [Google Scholar]

- Li G.Finite Element Analysis of Stress Process of Prestressed Anchor and Size and Material Optimization of Anchor Ring, Hefei University of Technology, 2006. https://kns.cnki.net/KCMS/detail/detail.aspx?dbname=CMFD0506&filename=2006072323.nh. [Google Scholar]

- Harms G. T.Cold Forming Technology Manual (Fine); Chemical Industry Press, 2009. [Google Scholar]

- Li Z.; Du S.. Optimization Design and Statistical Analysis of Experiments; Science Press, 2010. [Google Scholar]

- Wang C.; Luo J.; Huang Y.; Zhao R. Research on simulation and die debugging of roll forming of elevator guide tube based on COPRA. Mach. Prod. Eng. 2020, 01, 72–74. 10.19356/j.cnki.1001-3997.2020.01.019. [DOI] [Google Scholar]

- Liu F.; Song W.; Chen Y.; Jia M. Experimental study of high strength hot dip galvanizing plate S550GD+Z. Xinjiang Iron Steel 2009, 1, 9–11. 10.3969/j.issn.1672-4224.2009.01.003. [DOI] [Google Scholar]

- Shang F.Fundamentals of plastic mechanics; Xi ’an Jiaotong University Press, 2011; pp 78–90. [Google Scholar]