Abstract

3D printing, a type of additive manufacturing (AM), is a rapidly expanding field. Some adverse health effects have been associated with exposure to printing emissions, which makes occupational exposure studies important. There is a lack of exposure studies, particularly from printing methods other than material extrusion (ME). The presented study aimed to evaluate measurement methods for exposure assessment in AM environments and to measure exposure and emissions from four different printing methods [powder bed fusion (PBF), material extrusion (ME), material jetting (MJ), and vat photopolymerization] in industry. Structured exposure diaries and volatile organic compound (VOC) sensors were used over a 5-day working week. Personal and stationary VOC samples and real-time particle measurements were taken for 1 day per facility. Personal inhalable and respirable dust samples were taken during PBF and MJ AM. The use of structured exposure diaries in combination with measurement data revealed that comparatively little time is spent on actual printing and the main exposure comes from post-processing tasks. VOC and particle instruments that log for a longer period are a useful tool as they facilitate the identification of work tasks with high emissions, highlight the importance of ventilation and give a more gathered view of variations in exposure. No alarming levels of VOCs or dust were detected during print nor post-processing in these facilities as adequate preventive measures were installed. As there are a few studies reporting negative health effects, it is still important to keep the exposure as low as reasonable.

Keywords: 3D printing, additive manufacturing, diary, exposure, industry, material extrusion, material jetting, occupational, particles, powder bed fusion, vat photopolymerization, VOC

What’s Important About This Paper?

There is a lack of exposure studies on additive manufacturing in ‘real environments’ and the choice of measurement method is not obvious. This study characterized exposure and emissions from four printing methods. Exposure diaries provided information on operating processes involving additive manufacturing, moving beyond a focus only on printer emissions. The use of VOC sensors and other real-time instruments highlights that certain processes have high primary emissions, and the importance of adequate enclosures and ventilation. This work can guide future studies on exposures, risks, and exposure limits associated with additive manufacturing.

Introduction

Use of 3D printing [in this paper called additive manufacturing (AM)] has increased over the last decade. AM offers several advantages such as in-house production of relatively complex designs, customization of components and spare parts and reduced waste and logistics costs (Chua et al., 2017). AM printing methods are commonly divided into seven different categories: material extrusion (ME), material jetting (MJ), binder jetting, sheet lamination, vat photopolymerization (VP), powder bed fusion (PBF), and directed energy deposition (ISO, 2015). AM printers range in size and complexity from simple desktop printers to large industrial scale printers and a range of materials exist. The rapid expansion in use of AM has created a need for knowledge of the exposure associated with printing. There have been some published articles (House et al., 2017; Chan et al., 2018) and one conference proceeding (Johannes et al., 2016) indicating adverse health effects associated with AM. House et al. and Johannes et al. are case reports regarding asthma and exposure to ME fumes and chronic hypersensitivity pneumonitis with exposure to PBF nylon powder, respectively. Chan et al. performed a survey of AM operators using a variety of printing methods and found a high incidence of self-reported respiratory symptoms. Experimental laboratory studies on rats (Stefaniak et al., 2017a; Farcas et al., 2020) and lung cells exposed to printing emissions from ME (Farcas et al., 2019; Zhang et al., 2019) have also shown adverse effects of varying degree. Volunteers exposed to printing emissions from ME, however, showed no acute changes in inflammatory markers (Gümperlein et al., 2018). Based on the information it is imperative to evaluate the exposures, and hence risks of operating 3D printers.

The presented research focussed on printing with polymers, which is the most commonly used printing material (Statista, 2020). Printing emissions from polymeric materials have been examined in a number of studies focussing on mainly ME, but also binder jetting, VP, and PBF (Stephens et al., 2013; Afshar-Mohajer et al., 2015; Kim et al., 2015; Stefaniak et al., 2017b, 2019a; Damanhuri et al., 2019; Jeon et al., 2020). Research that includes measurements of personal exposures in real industrial occupational settings is limited. Exposure from printing polymeric materials has been assessed for ME (Du Preez, 2018; Stefaniak et al., 2019b,c) and MJ (Stefaniak et al., 2019b). Väisänen et al. (2019) evaluated exposure from different printing methods in industrial settings (ME, VP, PBF, and MJ) and similar research was done by Zisook et al. (2020). As the emission and personal exposure largely depend on differences in printing methods and related pre- and post-activities, as well as printing material, there is a need for further exposure measurements and development of appropriate measurement strategies for the specific printing methods.

The presented research had two aims:

To investigate measurement methods for use in determining exposure from AM.

To characterize the occupational exposure from AM in four different industrial facilities, which use the following printing methods to print polymeric materials: ME, MJ, VP, and PBF.

Materials and methods

The study was approved by the Swedish Ethical Review Authority (dnr 2019-03536) and informed consent was obtained from participants before partaking in the study.

Description of facilities

The study was performed at four separate industrial facilities hereafter labelled: A-PBF, B-VP, C-MJ, and D-ME after their main printing methods. Facility A-PBF also had ME printers but the main method used was PBF. The operators at the facilities performed printing, post-processing tasks, other tasks related to AM (like cleaning the room, refilling powder, repairing instrument, or packaging printed objects) and office work. Post-processing tasks were defined as manipulation of printed parts (such as sanding, grinding, melting in other components, dyeing) but also the removal of the printed objects from the powder during PBF. The printers were used to test design concepts or produce specialized spare parts to aid production lines and were not used for general production. Hence, workload and size of printed object varied due to the needs of the users of the finished product.

The facilities and their respective printing methods, number of operators, printers, and materials are described in Table 1.

Table 1.

Description of the printers and materials used at the different facilities.

| Facility (n) | Printing method | Printer make | Material/brand namea |

|---|---|---|---|

| A-PBF (n = 3) | PBF | RICOH AM S5500P, Eosint P350, Eosint P700 | Polyamide (PA12), polypropylene (PP) |

| ME | Stratasys F370 | Acrylonitrile butadiene styrene (ABS), soluble support material (QSR Support) | |

| B-VP (n = 2) | VP | Formlabs Form2 | Methacrylic acid ester-based polymer (Formlabs Black) |

| C-MJ (n = 1) | MJ | Stratasys Connex 500 Stratasys Eden 500 |

Acrylate based polymer (VeroGray™, VeroClear™), acrylic support (SUP705™) |

| D-ME (n = 1) | ME | 2 × Ultimaker3 Ultimaker 5 |

Thermoplastic polyurethane (TPU), Tough polylactic acid (Tough PLA), polyethylene terephthalate—carbon fibre- reinforced (PET-CF), polycarbonate (PC), ABS |

n, number of operators; PLA, polylactic acid.

a The materials listed were used during the period that measurements were conducted but other materials are also used in the facilities.

Facility A-PBF

In facility A-PBF, three PBF printers were placed in a smaller room (ca. 20 m2) with an adjoining room for powder handling and unpacking of printed details (ca. 20 m2). The ceiling height was ca. 3.5 m and the rooms had two doors out into the corridor, which were closed when not in use. Facility A-PBF had also three industrial sized ME printers situated in a larger room >100 m2, which was also used by other departments for e.g. storage. The ceiling height in the larger room was ca. 10.5 m but the ME printers were placed in a recess with a lower ceiling height (ca. 2.5 m). Only one ME printer was in operation during the measurement period, the other two (Stratasys F450 and Stratasys U-print) were not in use. Detailed room plans are shown in Supplementary Fig. S1 (available at Annals of Work Exposures and Health online).

In PBF, the printer was loaded with a large container filled with powder. The powder container was then heated to temperatures just below melting: 115°C for polypropylene (PP) and 175°C for polyamide 12 (PA12). Thereafter 3D objects were created by laser sintering the powder according to the specified design. After printing, objects were manually removed from the powder bed and cleaned of excessive powder. Manual removal of printed object for PA12 was done at a breakdown station with a movable local exhaust ventilation (LEV). The operator used their hands and a small brush to dig the objects out and clean the powder off. PP powder was removed within a semi-closed instrument with LEV. Used powder was collected into containers for reuse at both stations. Other post-processing tasks involved sanding objects in an enclosed glove box and sometimes objects were also dyed. Post-processing tasks of sanding down and dyeing objects were done in a separate room (Supplementary Fig. S1, available at Annals of Work Exposures and Health online). Other AM tasks involved mixing virgin powder and old powder into printer containers to reuse. This was done by manually transferring virgin powder from bags and used powder from the breakdown stations to an enclosed mixer. After that powder was dispensed by a gravity feed into containers to be put into the machine. The powder mixer had a movable LEV that was used when powder was added. For one PBF printer, powder could be automatically dispensed from a printing container into the printer using a vacuum hose. A print could take up to 12 h and prints were often run over night.

In ME, at A-PBF, a thin polymer filament was fed through a heated nozzle, which melted the plastic and deposited it on a build plate. The printed object was created by the step-wise addition of several layers of melted plastic after a design determined from a computer file. A print took anything from an hour to several hours depending on size and complexity of the object. The print temperatures for the materials used at A-PBF ranged between 210 and 250°C. Post-processing tasks for ME printing at facility A-PBF included breaking off support structures and putting the object in a warm weak caustic soda bath (70°C).

The printer rooms had mechanical ventilation. All printers at A-PBF (PBF and ME) were enclosed and had LEV.

Facility B-VP

Facility B-VP had a desktop sized VP printer in a small triangular room of ca. 10 m2 (Supplementary Fig. S1, available at Annals of Work Exposures and Health online). The ceiling height was 2.3 m and the room had one door, which was closed when not in use. During printing, a build plate was dipped into a resin-filled vat and the resin was cured layer-by-layer using a 405 nm wavelength laser (UV light), to create the object according to the pre-defined computer file. The printing temperature was ca. 30°C. The printer, along with washing and curing machines were enclosed but had no integrated exhaust and were placed on a bench with a ventilation hood above. If the print time was long, the print was usually started in the afternoon to run over night. Post-processing tasks involved rinsing the printed object off with isopropanol (IPA) and sanding/polishing down rough edges (marks from the support structure) down if necessary. IPA rinsing (ca. 15 min) had previously been done manually but was mostly done in an enclosed washing device. Sometimes extra curing took place in the curing machine, where the printed object was subjected to UV light (15–60 min at 60–80°C), but this was not done during the current study.

Facility C-MJ

Facility C-MJ had two industrial MJ printers in a room (ca. 15 m2) and an adjoining post-processing room (ca. 32 m2), which included a computer station (Supplementary Fig. S1, available at Annals of Work Exposures and Health online). The door to the printer room remained closed when not in use. The printers used liquid resin, which was deposited onto the build plate from several nozzles on a movable arm (four nozzles for the resin and four for the support material). Once on the build plate, the resin was cured using UV light. The printers operated at temperatures ranging from 30 to 60°C. Surplus resin was automatically emptied into a waste barrel. Prints took between 3 and 22 h and were often started in the afternoon to run over night. Post-processing tasks involved the manual removal of the support material and rinsing the object with water. Both printers had integrated exhausts and there was no LEV for post-processing tasks.

Facility D-ME

Facility D-ME had three desktop sized ME printers, placed next to each other on a bench behind the operator’s computer station (Supplementary Fig. S1, available at Annals of Work Exposures and Health online). The ceiling height was ca. 4 m. The printers operated on various temperatures depending on the printed material but usually ranged between 220 and 300°C. The room was divided off from a larger industrial space (ca. 70 m2). Post-processing tasks involved the manual removal of support material and sometimes sanding down of the object. Occasionally metal components were inserted into the printed objects by heating the metal component up and ‘melting it in’. The printers were enclosed with hoods but had no LEV and the room had mechanical ventilation.

Study design

All facilities were visited before the study commenced, to interview operators, make observations and initial measurements. These were used to develop the measurement strategy. The information collected during the interviews included: number of printers and frequency of use, number of exposed operators, identification of post-processing tasks and normal duration, type of material used, presence or absence of exposure-reducing measures, and use of personal protective equipment. Based on observations at the pre-visit, different measurement methods were applied across the facilities as the different printing techniques were thought to produce different exposures and emissions.

Methods and instruments

Diaries

Exposure diaries were constructed based on interviews with operators from each facility and were facility specific. During the pre-visit the most commonly performed tasks were identified at each facility and these were given corresponding number codes. There was also a code for ‘other’ where the operator was asked to specify what task was performed. The coding served two purposes—it enforced to the operators what type of information was of interest for the research and also reduced the amount of writing. Operators were asked to, each day, fill in the start and end time for each task performed and also printing material, print time and whether they had used any personal protective equipment. Operators were asked to fill in diaries for the entire measurement period (5 days). The exposure diaries were used to relate tasks to emission and exposure measurements and to get an overview of how much time was spent performing each task. Diaries are attached in Supplementary Fig. S2a–e (available at Annals of Work Exposures and Health online).

Dust

Inhalable personal dust was measured using IOM samplers connected to AirChek XR5000 pumps from SKC (SKC Inc., PA, USA) with an airflow of 2.0 l min−1. Respirable dust levels were measured using the same type of pump but with a cyclone and membrane filter (SKC Inc., PA, USA) and a different airflow (2.5 l min−1). Airflow was controlled using Drycal Defender 530 (Mesa Laboratories Inc., NJ, USA). Levels of respirable and inhalable dust were analysed gravimetrically. Filters used were MF-Millipore™ Membrane filter, 5 µm pore size, SMWP02500 (Merck, Darmstadt, Germany). IOM cassettes were plastic and the entire cassette was weighed before and after sampling. For respirable dust levels, only the filter was weighed. Filter weighing was carried out in a climate room with constant temperature and relative humidity (23 ± 1°C and 50 ± 5% relative humidity). Cassettes were conditioned for 72 h in the room prior to weighing, both before and after sampling and filters were conditioned for 16 h.

A minimum of two field blanks were taken at each facility on each measurement day and the mean weight of the blanks was subtracted from the samples collected that day. Inhalable dust was measured at facility A-PBF and C-MJ, and respirable dust was only measured at A-PBF.

Particles

Particle emissions were measured using two different condensation particle counters: P-trak Ultrafine Particle Counter 8525 and Condensation Particle Counter (CPC) 3007 (TSI Incorporated, MN, USA). The P-trak 8525 measures particles in the size range 20 nm to 1 µm, whereas the CPC 3007 measures 10 nm to 1 µm. These instruments were used at all facilities.

For particles sized 0.1–10 µm, three personal DataRAM™ pDR1000AN were used (Thermo Fisher Scientific, Waltham, MA USA). The instruments use light scattering nephelometry to measure real-time mass concentrations. A particle monitor of the type Alphasense OPC-N3 was also used. This sensor optically measures scattered light from particles in the size range 0.35–40 µm, along with temperature and humidity. DataRAM™ pDR1000AN was used for personal exposure measurements at facilities A-PBF and C-MJ and for emission measurements at B-VP, C-MJ, and D-ME. Alphasense was used for emission measurements at facility A-PBF.

Volatile organic compounds

Adsorbent tube volatile organic compound (VOC) measurements were performed according to a slightly modified ISO 16000-6:2011 method (ISO, 2011). Airflow (50–200 ml min−1) was controlled using a calibrated mass flow meter (TSI 4000, TSI Incorporated, MN, USA) and known volumes of air were pumped through adsorbent tube of Tenax TA type, to capture a wide range of VOCs (approximately C6–C20). Four tubes were sampled, in parallel and series, from each location to control for a wide concentration range and possible break through. After sampling, tubes were analysed using GC-FID/MS (Agilent Technologies 7890A and 5979C). Adsorbent VOC measurements were used for personal exposure measurements and emission measurements at all facilities.

In addition to samples on adsorbent tubes, VOC sensors (metal oxide type, ‘Aerasgard KLQ’ from S+S Regeltechnik, combined with a Tinytag View 2 datalogger) were mounted in the printing facilities during the measurement week (4–5 days). VOC sensors where placed at all facilities to gather a comprehensive measurement for the entire week including night-time/off-hours.

Isocyanates

Isocyanates were sampled using impingers filled with 10 ml of a 0.01 M dibutylamine solution in toluene, connected to SKC AirCHEK pumps with a flow of 1.5 l min−1 according to Karlsson et al. (2001). Samples were analysed using LC–MS/MS (ISO, 2013). Isocyanates were measured at facility D-ME, during printing of polyurethane-containing material [thermoplastic polyurethane (TPU)].

Measurement strategy

All measurements in the study were conducted during the same week and each facility was visited for 1 day, with the exception of facility A-PBF, which was visited for three consecutive days (for collection of dust samples only). Both exposure and emission measurements were performed. Table 2 outlines what measurements were performed at each facility and also if instruments were used to perform exposure or emission measurements or both. All AM operators at each facility filled in an exposure diary for the work-week (5 days). During the day that measurements were performed (day 1 at A-PBF), the researcher performing the measurements also recorded observations on type of task, duration, material used, and protective equipment used.

Table 2.

Overview of measurement methods applied on each of the studied printing methods.

| PBFa | VPb | MJc | MEa,,d | |

|---|---|---|---|---|

| Particles | ||||

| Respirable dust | √ | |||

| Inhalable dust | √ | √ | ||

| P-trak 8525 or CPC 3007 | √ | √ | √ | √ |

| Alphasense OPC-N3 | √ | |||

| DataRAM™ | √ | √ | √ | √ |

| Chemical emissions | ||||

| VOC—Tenax TA | √ | √ | √ | √ |

| VOC sensor Aerasgard KLQ | √ | √ | √ | √ |

| Isocyanates with impinger | √d | |||

| Observations | ||||

| Diary by employee | √ | √ | √ | √ |

| By researcher | √ | √ | √ | √ |

a Facility A.

b Facility B.

c Facility C.

d Facility D.

Personal samplers were placed in the breathing zone of the operators. Personal samplers for inhalable (A-PBF and C-MJ) and respirable dust (C-MJ) measurements were worn during the entire working day. At facilities A-PBF and C-MJ all operators also wore DataRAM™ pDR1000AN instruments for the whole working day to measure personal exposure to particles sized 0.1–10 µm. VOC samplers to measure exposure were worn during specific tasks for the duration of the task (all facilities except D-ME).

Adsorbent tube VOC and particle counting emission measurements were done at all facilities. Where possible, particle counting and VOC sampling were performed before the start of the printing activity, to represent a background and then continued during printing and post-processing tasks. Particle counters P-trak 8525 and/or CPC 3007 were used at all facilities to measure the emission of particles sized 10 nm/20 nm to 1 µm during different tasks performed by the operators. During task measurements particle counters were held in as close proximity to the operator as possible but no further away than 1 m, considered near-field. When not in use for a specific task measurement, the particle counters were stationary in strategic locations in the printer rooms or by the operators (far-field background measurements). VOC emission measurements were taken at the location of a typical operator.

Real-time mass concentration instrument DataRAM™ pDR1000AN was used at facilities B-VP, C-MJ, and D-ME to measure emissions of particles sized 0.1–10 µm during printing and were placed in the printer room, near the printers (<1 m away, near-field). At facility A-PBF, emissions of particles sized 0.35–40 µm were measured by the Alphasense OPC-N3 particle monitor, which was placed on a desk in between the printer room and the post-processing room (far-field, background). VOC sensors were placed at each facility (Supplementary Fig. S1, available at Annals of Work Exposures and Health online) at the start of the working week to assess variations in printer emissions during the week. The sensors logged continually for the duration of the measurement period.

Isocyanate samples were taken at facility D-ME during printing with TPU and samples were taken as close to the printer as possible, but outside the hood.

Results

Diaries

All operators filled in exposure diaries Mon-Fri during the measurement period, with exception for the operator at D-ME who only filled in Wed-Fri. Operators partook in a physical examination for the research study on Thursday or Friday (will be published separately), which detracted time from their normal work. The collected information from the diaries varied in detail. The operators at A-PBF, and C-MJ accounted for every minute of the working day but the operators at B-VP and D-ME focussed on print start and print finish. The data from facility A-PBF mostly reflect PBF printing. Little time was spent on ME. Table 3 describes the time distribution on tasks during the working week for each facility based on the diaries. Time distribution has varied between days and operators and therefore the range is also presented. For B-VP and D-ME, the vast majority of time was spent on work not involving interaction with the printer or the printed material, e.g. computer work. Post-processing was a time-consuming task at facility C-MJ, where the operator spent on average >60% of the working time manually sanding and scraping the printed object. At facility A-PBF, the corresponding time spent on post-processing during the week was 15% and only <1–2% at the other facilities. However, one operator at facility A-PBF spent up to 72% of the working day performing post-processing, which is reflected in the range in Table 3.

Table 3.

Time distribution on tasks during the working week for each facility based on information from the exposure diaries.

| Task | A-PBF (n = 15) | B-VP (n = 10) | C-MJ (n = 5) | D-ME (n = 3) |

|---|---|---|---|---|

| Time % (range) | Time % (range) | Time % (range) | Time % (range) | |

| Prepare/start print | <1 | 1 (<1–4) | 1 (<1–2) | 2 (<1–5) |

| Remove printed object | <1 | <1 | 1 (<1–2) | 2 (1–2) |

| Post-processing | 15 (<1–72) | 2 (<1–11) | 62 (52–82) | <1 |

| Cleaning printer | 4 (<1–21) | <1 | 6 (4–18) | <1 |

| Other AM | 7 (<1–34) | <1 | <1 | <1 |

| Other | 74 (18–97) | 97 (88–100) | 30 (9–43) | 96 (92–98) |

n, number of measurements included in the calculations. Time distribution on tasks over the working week for each facility was calculated based on all observations for all operators that week. The range reflects the individual time distributions spent on each tasks for each operator at the facility and was calculated per day. ‘Other’ is to a large extent office work but at D-ME also involved visiting production lines to discuss projects and future printing needs. ‘Other AM’ is work related to printing but outside of the other categories, e.g. cleaning room, refilling powder, and dyeing objects. Facility A—powder bed fusion (A-PBF), facility B—vat photopolymerization (B-VP), facility C—material jetting (C-MJ), and facility D—material extrusion (D-ME).

Dust

All measurements of respirable dust at A-PBF were below the limit of detection (<50 µg, corresponding to <74 µg m−3). Concentrations of inhalable dust were below the limit of detection (<90 µg, corresponding to <125 µg m−3) at facility MJ but detectable in all samples at facility PBF (range 0.1–1.9 mg m−3, median 0.2 mg m−3, 8 h average). The two highest concentrations 1.9 and 1.1 mg m−3 were obtained from the same operator on two separate days. This operator also had the highest recorded times for post-processing at the facility, i.e. 72% of the working day on the day that measured 1.9 mg m−3 (Table 3).

Particles 0.1–10 µm

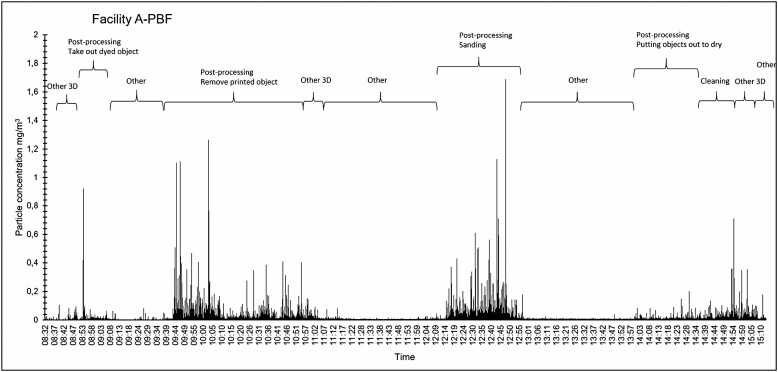

The personal sample from facility A-PBF with the highest exposure, measured with the DataRAM™, is displayed in Fig. 1. This measurement was made in parallel with inhalable dust measurements and corresponds to the day with 1.9 mg m−3. The highest peaks were found during post-processing, which included removal of the object from the powder and sanding in the glove box. Integration of the peaks showed that these tasks represented 37 and 34%, respectively, of the total exposure for the day, although they only constituted of 19 and 11% of the time. Additional particle exposure measurements with the DataRAM™ from facility A-PBF are included in Supplementary Figs S4 and S5 (available at Annals of Work Exposures and Health online). One operator mostly performed printer maintenance during the measurement day. The personal sample results from facility MJ, with the DataRAM™ showed low levels (0.0–0.1 mg m−3) with very few peaks, none >1 mg m−3 (Supplementary Fig. S6, available at Annals of Work Exposures and Health online).

Figure 1.

Concentrations of particles sized 0.1–10 µm measured by the DataRAM™ pDR1000AN at facility A-PBF. The figure has been labelled to illustrate what tasks were carried out during the measurement time. Identification of tasks is a combination of observations during the measurements and information from the exposure diary. In this figure, cleaning denotes cleaning of the printing and post-processing rooms with a vacuum cleaner and not cleaning of the printer. Other 3D reflects dyeing printed object (first mention) and refilling powder container (second two instances).

Concentrations of size 0.1–10 µm particle emissions at facilities B-VP, C-MJ, and D-ME were very low (mean 0.019, 0.001, and 0.004 mg m−3, respectively) and the maximum measured concentration was 0.183 mg m−3 (facility B-VP). Measurements of particles obtained by the Alphasense OPC-N3 particle monitor in the PBF part of facility A-PBF showed a time-bound circular pattern of particle concentrations, which was mimicked by the humidity data (Supplementary Fig. S3, available at Annals of Work Exposures and Health online).

Particles 10 nm/20 nm to 1 µm

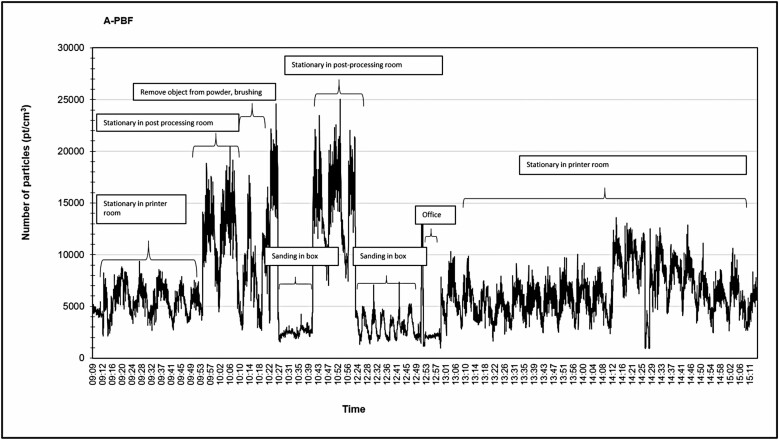

No increase in particle numbers (sizes 20 nm to 1 µm) compared with background levels (<1000–1500 pt cm−3) was seen during printing or post-processing at facility B-VP and C-MJ (Supplementary Figs S7 and S8, available at Annals of Work Exposures and Health online). At facility A-PBF, particle numbers differed between tasks and locations (Fig. 2). The particle numbers also showed a circular re-occurring pattern, which was mimicked by the Alphasense OPC-N3 particle data (Supplementary Fig. S2, available at Annals of Work Exposures and Health online). Highest peaks were found during the removal of the printed object from the powder and when the instrument was stationary in the post-processing room. Background levels at the office were ca. 2000 pt cm−3 (Fig. 2).

Figure 2.

Emissions of particles sized 10 nm to 1 µm during various AM tasks at A-PBF, measured by CPC 3007. The instrument was held as closely as possible to the operator during task measurements and placed roughly in the middle of the room during stationary measurements.

Emissions of particles in the size range 20 nm to 1 µm were found during print at facility D-ME (Supplementary Fig. S9, available at Annals of Work Exposures and Health online). Background levels before print started were between 5000 and 10 000 pt cm−3. During printing, particle numbers outside the printer ranged between 5000 and 15 000 pt cm−3 with isolated peaks at 50 000 pt cm−3. Inside the printer hood, emissions nearer 500 000 pt cm−3 were recorded. The post-processing task of inserting a heated metal bushing into the printed object, generated several peaks of 175 000–300 000 pt cm−3. Removing the support material [polylactic acid (PLA)] from the printed object did not increase emissions.

Volatile organic compound

Total volatile organic compound (TVOC) varied between the different printing techniques, during the printing process and with work tasks (Table 4). TVOC that was calculated from samples taken prior to print generally had a lower concentration than those taken during print. However, the highest concentration was measured during maintenance of the printers at facility A-PBF, where a spray can with brake cleaning was used. When comparing the different techniques, and printing materials, MJ had the highest concentration of TVOC (3200 µg m−3). The MJ and VP technique also involves washing with the solvent IPA, which is not included when TVOC is calculated, due to its low molecular weight and short retention time (TVOC is based on VOC species from C6 to C16, IPA has only C3). Concentrations of IPA and the most dominating VOC species from each technique are presented in Supplementary Table S1a–e (available at Annals of Work Exposures and Health online).

Table 4.

TVOC concentrations from different printing methods, materials, and tasks. Background and print measurements are stationary, close to the printer, while cleaning and post-processing activities are measured in the breathing zone of the operator.

| Location/method/material | TVOC (µgm−3) | ||

|---|---|---|---|

| Background | Cleaning and other AM related activities | ||

| A-PBF/PBF/PA12 | 40 | 30–90 | 18 000–99 000 |

| A-PBF/ME/ABS | 30 | 90 | — |

| B-VP/VP/Blackv4 | 60 | 140 | 180–400 |

| C-MJ/MJ/Verogray | — | 3200 | 950 |

| D-ME/ME ABS, TPU, PET-CF, TPLA, calPC | 110 | 90–100 | 70 |

ABS, acrylonitrile butadiene styrene; PC, polycarbonate; PET-CF, carbon fibre-reinforced polyethylene terephthalate; TPLA, tough polylactic acid.

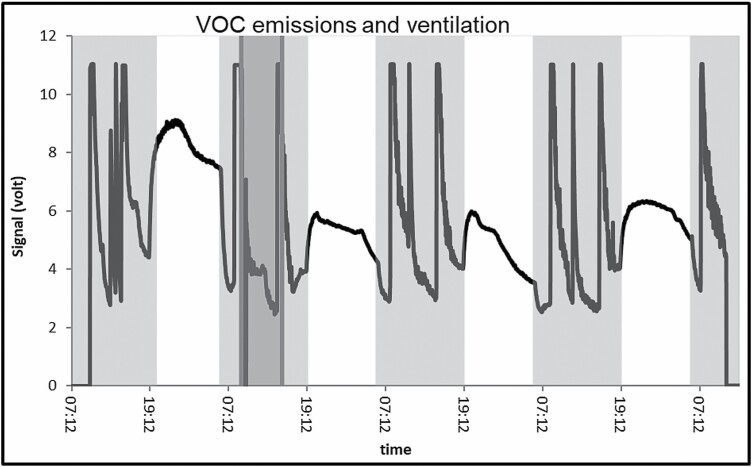

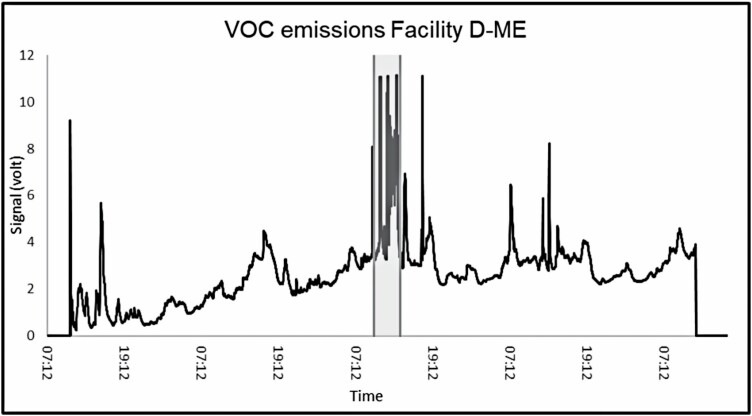

VOC sensors

Logged data from VOC sensors were retrieved from all locations, except facility A-PBF (due to instrument malfunction). Graphs which best illustrate the type and range of information that can be gained from the use of VOC sensors are displayed in Figs 3 and 4. Additional graphs are included in Supplementary Figs S10 and S11 (available at Annals of Work Exposures and Health online). At facility C-MJ, the peak signals correlated better in time with cleaning the printer than with start of print, however cleaning could not explain all peaks (Fig. 3). An increase in VOC was seen in the evening and a decrease in the morning, roughly the same time as the changes in ventilation settings occur (data show 19:00–06:00, while communication with the company gives 20:00–06:00). At facility D-ME, VOC sensor signal varied over the week but the highest signal intensity was seen during the time of other measurements (Fig. 4).

Figure 3.

A clear pattern in signal from VOC sensor at MJ is likely due to changes in ventilation settings. White field is the time between 06:00 and 19:00, dark grey field is when additional measurements were performed.

Figure 4.

Data from VOC sensor mounted close to the printers and operators computer station. The shaded area represents the day where other measurements also were carried out.

Isocyanates

The isocyanate emissions measurements made during printing of TPU at facility D-ME showed the presence of isocyanic acid. Concentrations were 0.006 mg m−3 for both samples (13 and 15 min collection times) and all other isocyanates were below the detection limit.

Discussion

Knowledge of exposure from AM in industrial environments is relatively scarce with presently some data presented for ME printing (Du Preez, 2018; Stefaniak et al., 2019b,c; Väisänen et al., 2019; Zisook et al., 2020). For other printing methods even less has been published to date (Stefaniak et al., 2019b; Väisänen et al., 2019; Zisook et al., 2020). In the present study, we contribute to this gap in knowledge by using exposure diaries to investigate how AM tasks de facto are carried out in industrial facilities and combine them with an array of measurement instruments. We used both collecting and real-time instruments for particles and VOC as one of the aims of the study was to investigate measurement methods for determining exposure from AM tasks. For the study as a whole, the entire array of instruments was proven useful as there was large variation in both emission and exposure patterns between facilities. Some instruments were however better suited to perform exposure assessment for certain printing methods. In order to perform exposure assessment for AM tasks, a variety of techniques and strategies might therefore be needed, depending on the objective of the assessment.

The use of diaries was shown to be greatly beneficial for all facilities for interpreting the collected data and putting it into perspective. Of the data that exist, our measurement results are in general agreement with previous findings i.e. the highest levels of VOCs, dust, and particles are emitted during post-processing work.

For specific substances detected, levels were low in comparison with Swedish occupational exposure limits and derived no-effect levels, however considering a mixture of different exposures can be present we still argue that the exposure should be kept as low as possible.

The facilities had already implemented preventive measures (encapsulated processes, LEVs, printers with hoods, etc.) which has likely contributed to the low concentrations of particles and VOC seen in the present study. Dissemination of the results to the facilities led to further improvements. These included a change in the timer settings for ventilation in facility C-MJ, so that the ventilation was active for longer in the afternoon, and plans for a replacement of the sanding box in A-PBF as it was a source of exposure. The latter had already been suspected as a problem by operators and employer, prior to the study. As part of the project, we also performed physical measurements on the operators to assess health effects, but this will be published separately as more operators are included from other printing facilities.

In the present study, we performed pre-visits to all facilities. These included pilot measurements and interviews with the operators, which highlighted that work with AM had the potential to produce very different exposures depending on material, print technique, and operator tasks (particularly post-processing). The pre-visit provided the foundation for the sampling strategy and had direct impact on the choice of measurement instruments. As an example, gravimetric measurements and use of the DataRAM™ to measure exposure to dust only appeared relevant at A-PBF and potentially C-MJ. Contrastingly exposure to smaller particles was more important for ME printing, where thermal degradation occurs. Information from the pre-visit was also used to tailor the exposure diaries for each facility according to the work carried out. VOC sensors were placed at each facility for the whole working week to monitor the variation in exposure due to the various emissions in AM tasks (or other sources).

Structured exposure diaries were used to characterize how operators worked with AM at the different facilities. Information on AM tasks, including printing and post-processing, were collected for five consecutive working days. Task based diaries have been previously used as a complement to risk assessments, to identify determinants of personal exposure (Bakke et al., 2009; Basinas et al., 2014; Hawley Blackley et al., 2019). The use of the diaries has showed that time spent at risk for exposure with AM work can vary extensively between printing techniques from very little interaction with printer and printed material to >60% of the working week being spent on manual post-processing. Time spent on actual printing (starting up printing and removing printed objects) was very limited and only amounted to 1–2% of the working week. Moreover, there was also variation in tasks performed within the facilities with multiple operators. At A-PBF, one operator performed most of the removing of printed objects from the powder and sanding, while another one mostly performed other tasks and instrument maintenance. Situations where most of the time is spent on work other than AM could affect the interpretation of time-integrated measurement data, with shorter high peak exposures being masked to show low 8 h averages. The added use of real-time instruments is therefore beneficial to identify such exposure peaks.

The DataRAM™ pDR1000AN was worn to measure real-time personal exposure to particles sized 0.1–10 µm, which was shown to be very useful to assess exposure for work tasks at A-PBF e.g. powder handling during post-processing. However, from Fig. 1 it is obvious that the exposure in that facility was to even larger particles, outside the range of the DataRAM™, as the parallel inhalable sampler showed an integrated exposure for that day to 1.9 mg m−3 and the integrated concentration with the DataRAM™ was 0.04 mg m−3. The emissions of particles sized 0.1–10 µm during printing (VP, MJ, and ME) and during post-processing (VP and ME) were very low and there was no considerable increase compared with the background. In these instances, the DataRAM™ had limited use as the emissions during printing and post-processing were composed of smaller particles and vapours. Use of the handheld condensation particle counters (CPC 3700 and P-trak 8525) identified emissions of smaller particles (10 nm/20 nm to 1 µm) and provided useful information, particularly during ME printing.

Our dust and particle measurement data are in general agreement with previously established research. The measurements at facility C-MJ showed no detectable levels of inhalable dust and few peaks from the worn DataRAM™. Similar results for MJ printing were found by Väisänen et al. using IOM samplers and DustTRak (Väisänen et al., 2019). Despite the low exposure, a large amount of the operator’s time was spent on manual post-processing (scraping, sanding, etc.), which could still impose a risk for sensitive individuals as the materials used in that type of printer often are respiratory and skin irritants (Borak et al., 2011). Dust measurements at facility A-PBF showed detectable levels in all samples for inhalable dust but no detectable levels of respirable dust.

There was little or no increase in particle numbers (sizes 10 nm to 1 µm) with VP and MJ printing or post-processing, which is in agreement with previous studies (Väisänen et al., 2019; Zisook et al., 2020). Here measurements of VOC might be of higher interest. For particle emissions during ME, Du Preez et al. found no appreciable change outside of the printer hood during print whereas Zisook et al. recorded numbers 4.5 times higher than background (10 000–25 000 pt cm−3) with a partially open hood (Du Preez, 2018; Zisook et al., 2020). Our results showed particle numbers slightly elevated from background (5000–15 000 pt cm−3) with isolated peaks of 50 000 pt cm−3, but with several printers operating at the same time. For ME it has been established that printing emissions vary with many factors, which can affect comparisons of research results. These include printing temperatures, filament material, infill, colour of filament, filament brand, printer brand, printing rate, and printing time (Stephens et al., 2013; Kim et al., 2015; Azimi et al., 2016; Deng et al., 2016; Steinle, 2016; Yi et al., 2016; Floyd et al., 2017; Kwon et al., 2017; Mendes et al., 2017; Stabile et al., 2017; Stefaniak et al., 2017b, 2018; Vance et al., 2017; Wojtyła et al., 2017; Zhang et al., 2017; Zontek et al., 2017; Cheng et al., 2018; Du Preez, 2018; Seeger et al., 2018; Davis et al., 2019; Gu et al., 2019; Potter et al., 2019; Zhang et al., 2019; Jeon et al., 2020; Park et al., 2020). Moreover, post-processing during ME in the form of heating metal up to insert in the printed object was a considerable source for exposure to small particles.

Measurements of nanoparticles are more difficult to interpret as there is no established level of safe exposure (Oksel Karakus et al., 2020). Because of their size, nanoparticles reach the alveolar regions and can interact with biological systems in other ways than larger particles. However, the composition of particles will vary depending on the emission source and an occupational exposure limit is difficult to establish. The Finnish institute of occupational health have established target levels of 20 000 pt cm−3 (density >6000 kg m−3) and 40 000 pt cm−3 (density <6000 kg m−3), respectively, for industry generated nanoparticles (8 h exposure time), which they have applied to AM (FIOH 2016). Maybe specific occupational exposure limits (OELs) can be developed for emissions from AM, but much more work on health effects and exposures needs to be performed.

At facility A-PBF, particle numbers differed between tasks and locations but were difficult to interpret due to the cyclic nature of the results. Väisänen et al. reported concentrations reaching up to 10 times above the background particle concentration during PBF manufacturing (Väisänen et al., 2019). In the present study, particle numbers were in a similar region during printing (4300–15 800 pt cm−3) but the background was higher (2100–9300 pt cm−3). The post-processing room and printer room are connected which could have led to particles spreading between rooms and affecting the results. Collectively, the gravimetric and real-time particle counting results suggest that there is an exposure to larger sized particles during PBF printing tasks and that removing the printed object from the powder and sanding are two main sources of exposure. These results are in agreement with measurements made by Väisänen et al. during post-processing tasks from PBF printing (Väisänen et al., 2019). Emission measurements of PM2.5 (DustTrak DRX) by Damanhuri et al. also identified powder handling pre- and post-printing as the most exposed tasks during PBF printing (Damanhuri et al., 2019).

VOC samples were collected on Tenax TA tubes during AM tasks and showed that emissions were lower during printing than during maintenance and post-processing tasks, which was expected. The presented TVOC results during printing in this study show good agreement with previous findings from industrial workplaces by Väisänen et al. (2019) although higher TVOC results were found for post-processing by Väisänen. One exception is the results from PBF, but this result reflects the use of cleaning agents during printer maintenance and not post-processing. TVOC results during ME printing were slightly lower but in the same region as emission results from university laboratory and small office (Steinle, 2016; Chan et al., 2020). Contrastingly, Zisook et al., using photoionization detector, did not find TVOC distinguishable from background for the four printing methods. Again, variations in materials, printers, and room layout can affect comparisons.

Real-time VOC instruments have been used previously in industrial AM environments but for shorter periods (Du Preez, 2018; Stefaniak et al., 2019b,c; Zisook et al., 2020). We have measured with VOC sensors of metal–oxide type but trends in VOC emissions may also be displayed in a similar fashion with photoionization detectors. We measured continuously over 5 days and could see variations in VOC emissions over the day and over the week. An example of this is displayed in Fig. 4, where the highest VOC emissions were found during the day where the other measurements took place. These results give an indication of whether the workplace assessment, which in most cases was done under a single day, was overestimated or underestimated compared with an average workday of that particular week. If VOC sensors had been placed at the facilities for an even longer period of time this would be a better indication of how reliable the actual workplace assessment may be. At facility C-MJ, a clear pattern could be seen between VOC concentrations and prints, but there was also a rapid increase in TVOC concentrations every evening at the same time, when the ventilation was turned off. This emphasizes the importance of adequate ventilation to keep levels low. The TVOC concentrations later declined, presumably as there was no additional emissions during the night.

There were several limitations with the study. Diaries were kept for 5 days to get an understanding of the variation in exposure. For practical reasons they were five consecutive days but it might have been better to choose 5 days over separate weeks (Loomis and Kromhout, 2004). It would also have been optimal to have a longer observation period but even for the short period used in the study, quality of the recorded information was lacking for some operators. The diary from facility D-ME was filled in less days than the other facilities (three instead of five), which gives the estimated times spent on each task a higher level of uncertainty. Depending on how the rooms are planned out, secondary exposure from printing or post-processing is also a possibility. The diaries alone will not provide this information so further exposure monitoring is needed to complement them.

We also used a sensor for large particles, the Alphasense OPC-N3 particle monitor at A-PBF, but data were difficult to interpret. This was also true for the results from the particle counters (P-trak 8525 and CPC 3007) at A-PBF. A time-bound, circular pattern of particle concentrations was seen throughout the working week suggesting that data may have been compromised by humidification or ventilation in the location. The PBF printer and processing room have a humidifier, which sprays out a water mist at timed intervals. These correspond well with the cyclic peaks shown and this is a likely source affecting the measurements. The measured particle numbers at A-PBF are unlikely to have been underestimated, they can however have been overestimated as the particle counters cannot differentiate between particles and mist aerosols. Despite the cyclic appearance, there are differences in particle numbers between different tasks and locations. The results support that powder handling during post-processing creates the highest particle exposure.

Particles in the size range of 10 nm to 1 µm were measured as emissions rather than as personal exposure measurements. More beneficial would have been to use real-time nanoparticle monitors that could be worn by the operators. Unfortunately, we did not have access to this kind of instrument for the study.

In future studies, it is prudent to also consider material-specific exposures further. We for instance measured isocyanates as there was printing with TPU. Low levels of isocyanic acid were detected and this has also been found by Zontek et al., printing PLA and acrylonitrile butadiene styrene (Zontek et al., 2017). In other research, printing filaments containing carbon nanotubes have been shown to release polymer particles containing the nanotubes, although no free nanotubes were observed in the air samples (Stefaniak et al., 2018). Although unfortunately outside of the scope of the present research, it would have been interesting to perform some type of particle characterization by e.g. scanning or transmission electron microscopy, TOF-SIMS, Raman spectroscopy, or particle surface measurements to further assess the exposure.

Conclusion

The presented research has shown that access to a variety of measuring instruments are needed to perform exposure assessments on AM activities due to the diversity in printing methods, materials, and tasks. Some instruments were more suitable to exposure assess certain printing methods. The use of structured exposure diaries in combination with measurement data revealed that comparatively little time is spent on actual printing and the main exposures are during post-processing. VOC and particle instruments that log for a longer period of time are a useful complement to traditional sampling as they facilitate the identification of work tasks with high emission, estimation of ventilation efficiency and give a more gathered view of variations in exposure. Little previous data have been published on exposure during industrial printing from the four printing methods. Of the data that exist, our results are in general agreement with previous findings i.e. the highest levels of VOCs and particles are emitted during post-processing work. No alarming levels of VOCs or dust were detected during print nor post-processing in these facilities, compared with the Swedish OEL, but exposure should be kept as low as possible as there is lacking knowledge of health effects.

Funding

Direct financial support was provided from two research grants: Swedish Innovation Agency (Vinnova), HÄMAT2 (dnr 2018-03336) and Swedish Research Council for Health, Working Life and Welfare (Forte) (dnr 2018-00290).

Conflict of interest

The authors declare no conflict of interest.

Data availability

The data underlying this article are available in the article and in its Supplementary Material (available at Annals of Work Exposures and Health online).

Supplementary Material

References

- Afshar-Mohajer N, Wu C-Y, Ladun Tet al. (2015) Characterization of particulate matters and total VOC emissions from a binder jetting 3D printer. Build Environ; 93: 293–301. [Google Scholar]

- Azimi P, Zhao D, Pouzet Cet al. (2016) Emissions of ultrafine particles and volatile organic compounds from commercially available desktop three-dimensional printers with multiple filaments. Environ Sci Technol; 50: 1260–8. [DOI] [PubMed] [Google Scholar]

- Bakke B, De Roos AJ, Barr DBet al. (2009) Exposure to atrazine and selected non-persistent pesticides among corn farmers during a growing season. J Expo Sci Environ Epidemiol; 19: 544–54. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Basinas I, Sigsgaard T, Erlandsen Met al. (2014) Exposure-affecting factors of dairy farmers’ exposure to inhalable dust and endotoxin. Ann Occup Hyg; 58: 707–23. [DOI] [PubMed] [Google Scholar]

- Borak J, Fields C, Andrews LSet al. (2011) Methyl methacrylate and respiratory sensitization: a critical review. Crit Rev Toxicol; 41: 230–68. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chan FL, Hon CY, Tarlo SMet al. (2020) Emissions and health risks from the use of 3D printers in an occupational setting. J Toxicol Environ Health A; 83: 279–87. [DOI] [PubMed] [Google Scholar]

- Chan FL, House R, Kudla Iet al. (2018) Health survey of employees regularly using 3D printers. Occup Med (Lond); 68: 211–4. [DOI] [PubMed] [Google Scholar]

- Cheng Y-L, Zhang L-C, Chen Fet al. (2018) Particle emissions of material-extrusion-type desktop 3D printing: the effects of infill. Int J Precis Eng Manuf Green Technol; 5: 487–97. [Google Scholar]

- Chua CK, Wong CH, Yeong WY. (2017) 1. Introduction to 3D printing or additive manufacturing. In Chua CK, Wong CH, Yeong WY, editors. Standards, quality control, and measurement sciences in 3D printing and additive manufacturing. Academic Press. ISBN: 9780128134894. [Google Scholar]

- Damanhuri AAM, Azian H, Mohd Rizal Aet al. (2019) Indoor air concentration from selective laser sintering 3D printer using virgin polyamide nylon (PA12) powder: a pilot study. Int J Integr Eng; 11: 140–9. [Google Scholar]

- Davis AY, Zhang Q, Wong JPSet al. (2019) Characterization of volatile organic compound emissions from consumer level material extrusion 3D printers. Build Environ; 160: 106209. [Google Scholar]

- Deng Y, Cao S-J, Chen Aet al. (2016) The impact of manufacturing parameters on submicron particle emissions from a desktop 3D printer in the perspective of emission reduction. Build Environ; 104: 311–9. [Google Scholar]

- Du Preez S. (2018) Exposures during industrial 3-D printing and post-processing tasks. Rapid Prototyp J; 24: 865–71. [Google Scholar]

- Farcas MT, McKinney W, Qi Cet al. (2020) Pulmonary and systemic toxicity in rats following inhalation exposure of 3-D printer emissions from acrylonitrile butadiene styrene (ABS) filament. Inhal Toxicol; 32: 403–18. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Farcas MT, Stefaniak AB, Knepp AKet al. (2019) Acrylonitrile butadiene styrene (ABS) and polycarbonate (PC) filaments three-dimensional (3-D) printer emissions-induced cell toxicity. Toxicol Lett; 317: 1–12. [DOI] [PMC free article] [PubMed] [Google Scholar]

- FIOH . (2016) Control Approach Chemical safety of 3D printing at workplaces. Finland: Finnish Institute of Occupational Health. [Google Scholar]

- Floyd EL, Wang J, Regens JL. (2017) Fume emissions from a low-cost 3-D printer with various filaments. J Occup Environ Hyg; 14: 523–33. [DOI] [PubMed] [Google Scholar]

- Gu J, Wensing M, Uhde Eet al. (2019) Characterization of particulate and gaseous pollutants emitted during operation of a desktop 3D printer. Environ Int; 123: 476–85. [DOI] [PubMed] [Google Scholar]

- Gümperlein I, Fischer E, Dietrich-Gümperlein Get al. (2018) Acute health effects of desktop 3D printing (fused deposition modeling) using acrylonitrile butadiene styrene and polylactic acid materials: an experimental exposure study in human volunteers. Indoor Air; 28: 611–23. [DOI] [PubMed] [Google Scholar]

- Hawley Blackley B, Cummings KJ, Stanton Met al. (2019) Work tasks as determinants of respirable and inhalable indium exposure among workers at an indium–tin oxide production and reclamation facility. Ann Work Expo Health; 64: 175–84. [DOI] [PMC free article] [PubMed] [Google Scholar]

- House R, Rajaram N, Tarlo SM. (2017) Case report of asthma associated with 3D printing. Occup Med (Lond); 67: 652–4. [DOI] [PubMed] [Google Scholar]

- ISO . (2011) ISO 16000-6:2011. Indoor air—Part 6: determination of volatile organic compounds in indoor and test chamber air by active sampling on Tenax TA sorbent, thermal desorption and gas chromatography using MS or MS-FID. Geneva, Switzerland: ISO. [Google Scholar]

- ISO . (2013) ISO 17734-1. Determination of organonitrogen compounds in air using liquid chromatography and mass spectrometry—Part 1: isocyanates using dibutylamine derivatives. Geneva, Switzerland: ISO. [Google Scholar]

- ISO . (2015) ISO/ASTM 52900:2015. Additive manufacturing—general principles—terminology. Geneva, Switzerland: ISO/ASTM. [Google Scholar]

- Jeon H, Park J, Kim Set al. (2020) Effect of nozzle temperature on the emission rate of ultrafine particles during 3D printing. Indoor Air; 30: 306–14. [DOI] [PubMed] [Google Scholar]

- Johannes J, Rezayat T, Wallace Wet al. (2016) Chronic hypersensitivity pneumonitis associated with inhaled exposure to nylon powder for 3-D printing: a variant of nylon flock worker’s lung disease? In D46. Case Reports in Environmental and Occupational Health. American Thoracic Society. pp. A7071–A7071. [Google Scholar]

- Karlsson D, Dalene M, Skarping Get al. (2001) Determination of isocyanic acid in air. J Environ Monit; 3: 432–6. [DOI] [PubMed] [Google Scholar]

- Kim Y, Yoon C, Ham Set al. (2015) Emissions of nanoparticles and gaseous material from 3D printer operation. Environ Sci Technol; 49: 12044–53. [DOI] [PubMed] [Google Scholar]

- Kwon O, Yoon C, Ham Set al. (2017) Characterization and control of nanoparticle emission during 3D printing. Environ Sci Technol; 51: 10357–68. [DOI] [PubMed] [Google Scholar]

- Loomis D, Kromhout H. (2004) Exposure variability: concepts and applications in occupational epidemiology. Am J Ind Med; 45: 113–22. [DOI] [PubMed] [Google Scholar]

- Mendes L, Kangas A, Kukko Ket al. (2017) Characterization of emissions from a desktop 3D printer. J Ind Ecol; 21: S94–S106. [Google Scholar]

- Oksel Karakus C, Bilgi E, Winkler DA. (2020) Biomedical nanomaterials: applications, toxicological concerns, and regulatory needs. Nanotoxicology; 15: 331–51. [DOI] [PubMed] [Google Scholar]

- Park J, Kwon OH, Yoon Cet al. (2021) Estimates of particulate matter inhalation doses during three-dimensional printing: how many particles can penetrate into our body? Indoor Air; 31: 392–404. [DOI] [PubMed] [Google Scholar]

- Potter PM, Al-Abed SR, Lay Det al. (2019) VOC emissions and formation mechanisms from carbon nanotube composites during 3D printing. Environ Sci Technol; 53: 4364–70. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Seeger S, Brödner D, Jacobi Tet al. (2018) Emissions of fine and ultrafine particles and volatile organic compounds from different filament materials operated on a low-cost 3D printer [Emissionen feiner und ultrafeiner Partikel sowie flüchtiger organischer Verbindungen beim Einsatz verschiedener Filamentmaterialien in einem “low-cost”-3D-Drucker]. Gefahrst Reinhalt Luft; 78: 79–87. [Google Scholar]

- Stabile L, Scungio M, Buonanno Get al. (2017) Airborne particle emission of a commercial 3D printer: the effect of filament material and printing temperature. Indoor Air; 27: 398–408. [DOI] [PubMed] [Google Scholar]

- Statista . (2020) Common 3D printing materials 2017–2020. Available at https://www.statista.com/statistics/560323/worldwide-survey-3d-printing-top-technologies/#statisticContainer. Accessed October 2020. [Google Scholar]

- Stefaniak AB, Bowers LN, Knepp AKet al. (2018) Three-dimensional printing with nano-enabled filaments releases polymer particles containing carbon nanotubes into air. Indoor Air; 28: 840–51. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stefaniak AB, Bowers LN, Knepp AKet al. (2019a) Particle and vapor emissions from vat polymerization desktop-scale 3-dimensional printers. J Occup Environ Hyg; 16: 519–31. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stefaniak AB, Johnson AR, du Preez Set al. (2019b) Insights into emissions and exposures from use of industrial-scale additive manufacturing machines. Saf Health Work; 10: 229–36. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stefaniak AB, Johnson AR, du Preez Set al. (2019c) Evaluation of emissions and exposures at workplaces using desktop 3-dimensional printers. J Chem Health Saf; 26: 19–30. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stefaniak AB, LeBouf RF, Duling MGet al. (2017a) Inhalation exposure to three-dimensional printer emissions stimulates acute hypertension and microvascular dysfunction. Toxicol Appl Pharmacol; 335: 1–5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stefaniak AB, LeBouf RF, Yi Jet al. (2017b) Characterization of chemical contaminants generated by a desktop fused deposition modeling 3-dimensional printer. J Occup Environ Hyg; 14: 540–50. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Steinle P. (2016) Characterization of emissions from a desktop 3D printer and indoor air measurements in office settings. J Occup Environ Hyg; 13: 121–32. [DOI] [PubMed] [Google Scholar]

- Stephens B, Azimi P, El Orch Zet al. (2013) Ultrafine particle emissions from desktop 3D printers. Atmos Environ; 79: 334–9. [Google Scholar]

- Väisänen AJK, Hyttinen M, Ylönen Set al. (2019) Occupational exposure to gaseous and particulate contaminants originating from additive manufacturing of liquid, powdered, and filament plastic materials and related post-processes. J Occup Environ Hyg; 16: 258–71. [DOI] [PubMed] [Google Scholar]

- Vance ME, Pegues V, Van Montfrans Set al. (2017) Aerosol emissions from fuse-deposition modeling 3D printers in a chamber and in real indoor environments. Environ Sci Technol; 51: 9516–23. [DOI] [PubMed] [Google Scholar]

- Wojtyła S, Klama P, Baran T. (2017) Is 3D printing safe? Analysis of the thermal treatment of thermoplastics: ABS, PLA, PET, and nylon. J Occup Environ Hyg; 14: D80–5. [DOI] [PubMed] [Google Scholar]

- Yi J, LeBouf RF, Duling MGet al. (2016) Emission of particulate matter from a desktop three-dimensional (3D) printer. J Toxicol Environ Health A; 79: 453–65. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang Q, Pardo M, Rudich Yet al. (2019) Chemical composition and toxicity of particles emitted from a consumer-level 3D printer using various materials. Environ Sci Technol; 53: 12054–61. [DOI] [PubMed] [Google Scholar]

- Zhang Q, Wong JPS, Davis AYet al. (2017) Characterization of particle emissions from consumer fused deposition modeling 3D printers. Aerosol Sci Technol; 51: 1275–86. [Google Scholar]

- Zisook RE, Simmons BD, Vater Met al. (2020) Emissions associated with operations of four different additive manufacturing or 3D printing technologies. J Occup Environ Hyg; 17: 464–79. [DOI] [PubMed] [Google Scholar]

- Zontek TL, Ogle BR, Jankovic JTet al. (2017) An exposure assessment of desktop 3D printing. J Chem Health Saf; 24: 15–25. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The data underlying this article are available in the article and in its Supplementary Material (available at Annals of Work Exposures and Health online).