Abstract

Objectives:

To investigate and compare the characteristics of commonly used types of traditional and heat-activated initial archwire by plotting their load/deflection graphs and quantifying three suitable parameters describing the discharge plateau phase.

Materials and Methods:

Forty-eight archwires (22 nickel titanium [NiTi] and 26 heat-activated) of cross-sectional diameter ranging from 0.010 to 0.016 inch were obtained from seven different manufacturers. A modified three-point wire-bending test was performed on three analogous samples of each type of archwire at a constant temperature (37.0°C). For each resulting load/deflection curve, the plateau section was isolated, along with the mean value of the average plateau force, the plateau length, and the plateau slope for each type of wire obtained.

Results:

Statistically significant differences were found between almost all wires for the three parameters considered. Statistically significant differences were also found between traditional and heat-activated archwires, the latter of which generated longer plateaus and lighter average forces. The increase in average force seen with increasing diameter tended to be rather stable, although some differences were noted between traditional and heat-activated wires.

Conclusions:

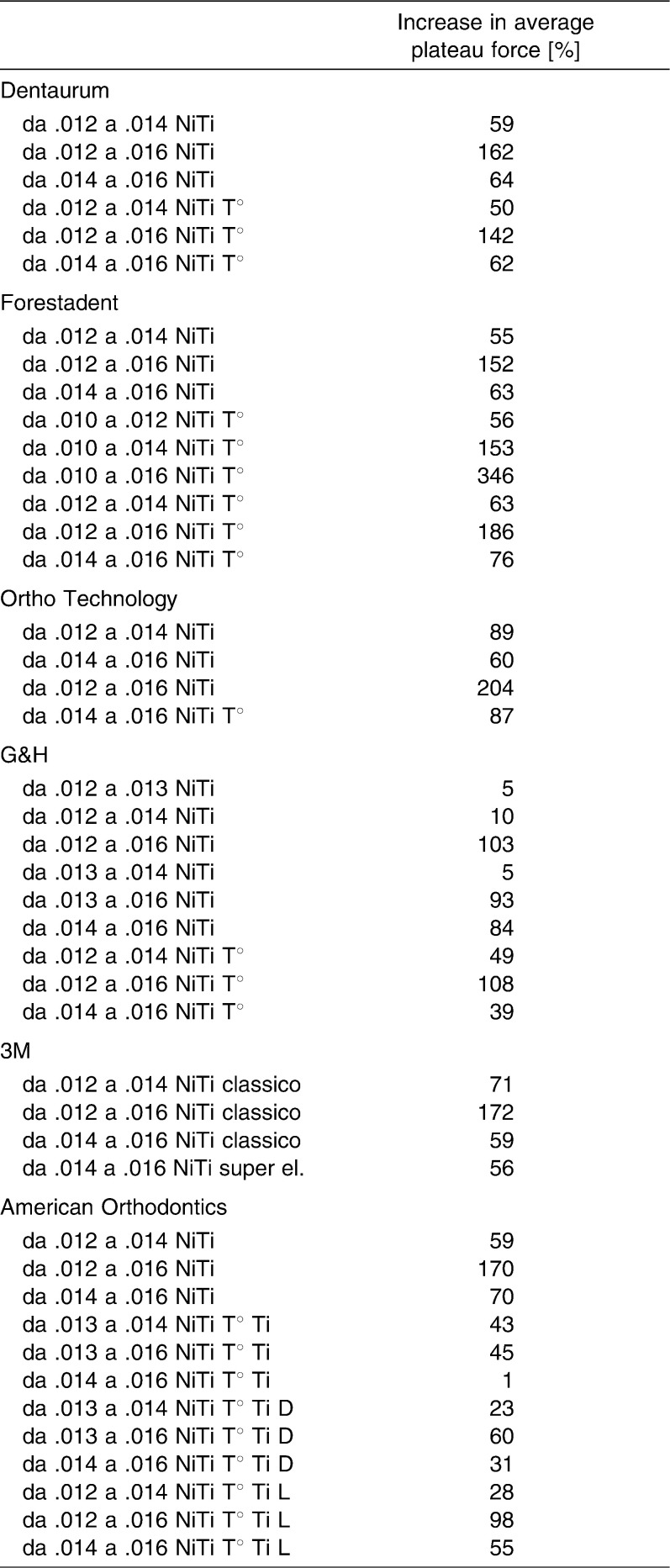

Although great variation was seen in the plateau behavior, heat-activated versions appear to generate lighter forces over greater deflection plateaus. On average, the increase in plateau force was roughly 50% when the diameter was increased by 0.002 inch (from 0.012 to 0.014 and from 0.014 to 0.016 inch) and about 150% when the diameter was increased by 0.004 inch (from 0.012 to 0.016), with differences between traditional and heat-activated wires noted in this case.

Keywords: Arch wire, Light force, Nickel titanium

INTRODUCTION

Because of their superelasticity and shape memory effect, nickel titanium (NiTi) archwires have become increasingly popular in orthodontics over the past decade. Their superelasticity is reflected in a load/deflection graph characterized by a flattish slope upon discharge, known as the plateau, which indicates that the force exerted is relatively constant in the range of tooth movement.1 This feature is linked to reversible transformation from the austenitic to the martensitic phase beyond a certain stress threshold, which is reached during activation and deactivation.2

Some alloys, if deformed in the martensitic phase and heated up to a certain transition temperature range (TTR), are able to recover their original form as they return to the austenitic phase, and therefore are said to possess shape memory. Although the first nickel titanium archwires featured this characteristic, their TTRs did not permit this property to be exploited for orthodontic purposes.3 However, thanks to the recent development of temperature-dependent (heat-activated) alloys, this shape memory characteristic can now be used to clinical effect.

Although many authors have investigated the properties of NiTi archwires,4–7 most published studies have tended to concentrate on evaluating the force exerted by various wires at specific deflections and have considered their complete behavior during the discharge phase in just a few cases.8 The aim of the present study, therefore, was to investigate the characteristics of the aforementioned plateau phase occurring during discharge, described using three parameters: the average plateau force, the plateau length, and the plateau slope. That is to say, we set out to evaluate the average force exerted by each type of archwire during tooth displacement, to discover the entity of displacement at which the average force is approximately constant, and to determine the effective degree of constancy of the plateau phase.

Furthermore, analysis was focused on the types of archwires typically employed during the first stages of orthodontic treatment by practitioners of a wide range of orthodontic techniques and philosophies.

MATERIALS AND METHODS

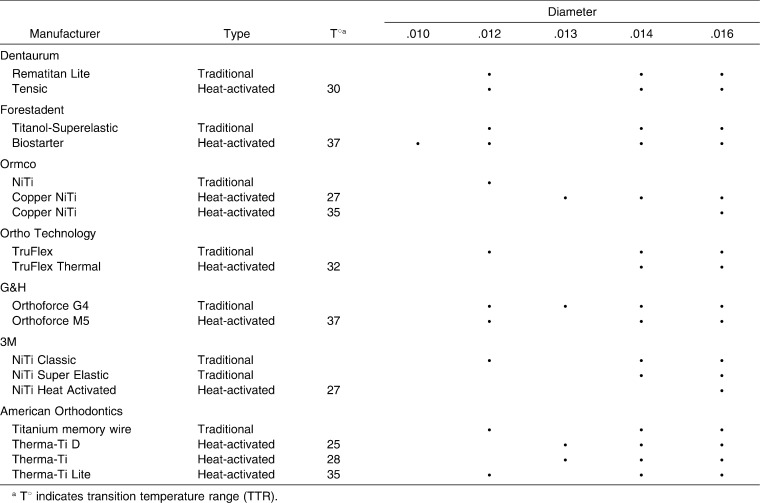

To make our study as clinically relevant as possible, numerous types of nickel titanium archwires tested were grouped into two macro-categories: traditional and heat-activated; all wires with TTRs were placed above room temperature, but close to body temperature in the latter. Of 48 archwires tested, 22 were classed as traditional NiTi wires and 26 as heat-activated, but all were circular in cross-section and had a diameter between 0.010 and 0.016 inch. The seven different manufacturers who provided the archwires in question were G&H (Franklin, Ind), Ortho Technology (Tampa, Fla), 3M Unitek (St Paul, Minn), Ormco (Orange, Calif), American Orthodontics (Sheboygan, Wis), Dentaurum (Ispringen, Germany), and Forestadent (St Louis, Mo) (Table 1). Samples of each archwire were obtained by cutting the straightest distal portion of an archwire; thus an approximate length of 5.5 cm was recovered.

Table 1.

Orthodontic Wires Tested

Means of Deflection

Tests were performed on three samples. For each sample, different wires (material and size) were tested using a three-point bending test, which commonly has been used to compare the load/deflection characteristics of NiTi archwires.9–11 However, in our experiment, so as to evaluate the samples in a condition similar to the final operating one, samples were mounted in four passive self-ligating brackets (Damon 3Mx, Ormco).12 These brackets were glued to an acrylic resin base13 in such a way as to create a 14 mm span between the internal sides of two adjacent brackets. The resin base was, in turn, placed in a Plexiglas bath filled with water kept at a constant temperature of 37.0°C. This temperature was maintained thanks to a heating pump (Julabo, Julabo Labortechnik Gmbh, Seelbach, Germany), which, to avoid potential interference caused by its vibration, was placed in a separate water bath connected to the first by a hydraulic circuit. Each archwire section was immersed in the heated water for a minimum of 60 seconds before being subjected to the testing procedure to reach thermal equilibrium. Water temperature was controlled by means of a thermocouple (Tekkal T8303, Tekkal, Milano, Italy) submerged in the test bath and monitored continuously by the same operator responsible for performing the mechanical tests.

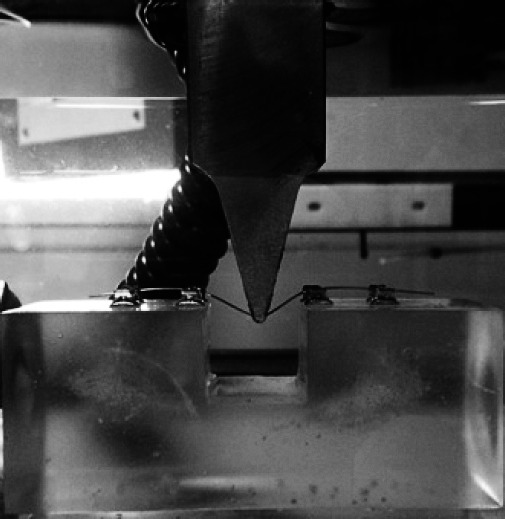

The force applied was regulated by means of an Instron 4467 dynamometer (Instron, Norwood, MA) connected to a 100 N load cell. A metal blade, with a curvature range of 1 mm at its extremity, was fixed to the load cell to deflect the archwires (Figure 1). Each wire was deflected 4 mm, at a deflection speed of 1 mm/min, and then was returned to its horizontal starting point “0” at the same speed. This degree of deflection was chosen because of its possible occurrence under clinical conditions, although some authors maintain that far smaller deflections are more authentic.14

Figure 1.

Deflection, with 1 mm blade, of mounted archwire kept in a water bath at a constant temperature of 37.0°C.

Measurements

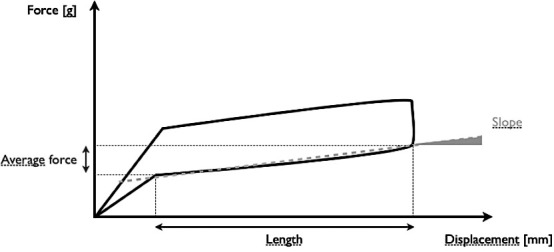

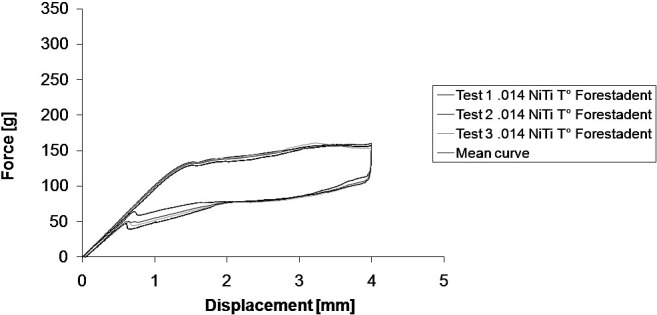

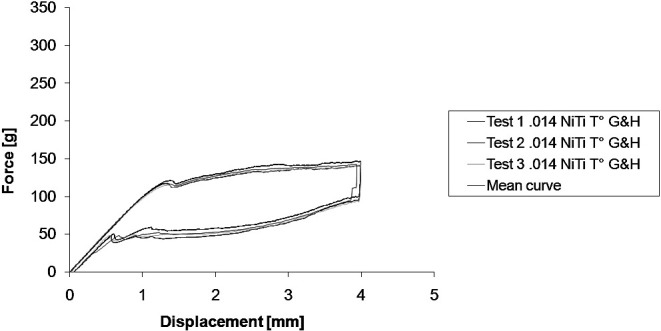

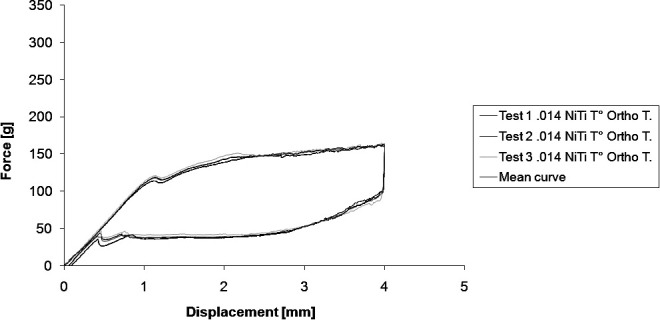

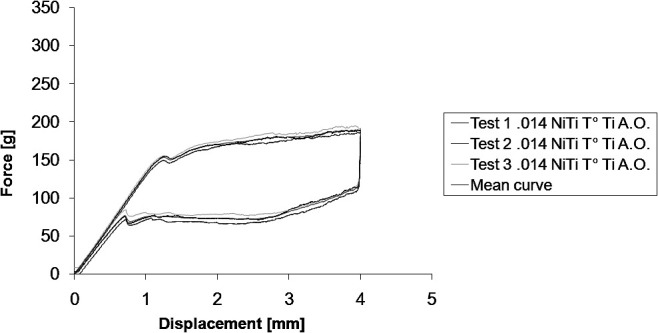

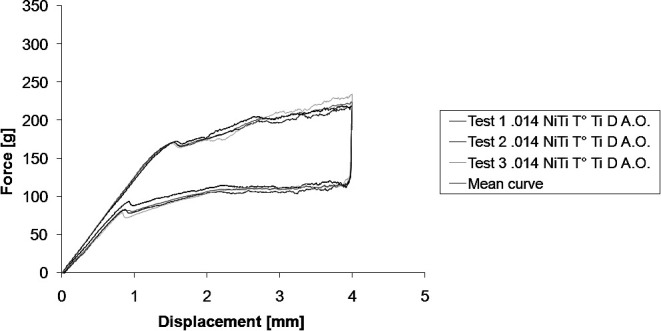

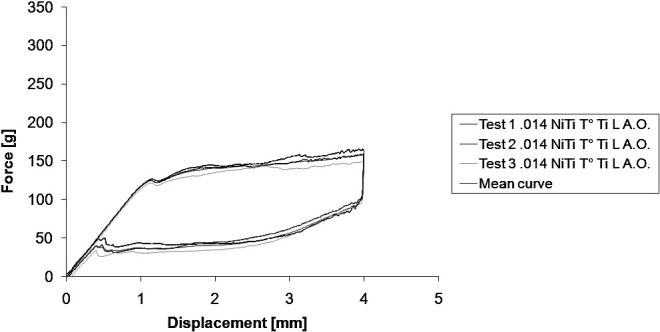

Data were gathered by means of a personal computer connected to the measuring device and were processed using Labview 8.5 (National Instruments Corporation, Austin, Tex). Data thereby collected were presented in spreadsheet form using Microsoft Excel (Microsoft Corporation, Redmond, Wash). These spreadsheets in turn were used to plot a graph for each test, showing deflection of the test strip on the x-axis, reported in mm, and the force exerted on the y-axis, reported in gram force and indicated by ”g„ on the plots. Each curve thereby obtained represented the initial loading phase, of no particular clinical relevance, and the discharge phase, which indicates the entity of the force exerted on the teeth during orthodontic treatment. Our intention was not so much to evaluate the forces expressed by certain points of deflection on the archwires, but to characterize their behavior in the plateau phase by measuring three parameters: average plateau force, plateau length, and plateau slope (Figure 2).

Figure 2.

Isolation of the discharge plateau for each graph and calculation of the three parameters chosen to characterize it: average plateau force, plateau length, and plateau slope.

The length of the plateau was used to indicate extension of the displacement range in which the force may be considered approximately constant. The average force was given by the arithmetic average of the values of force pertaining to this phase identified on the curve. The effective slope is a measure of the degree of plateau flatness; therefore, the closer the slope was to zero, the more constant was the force.

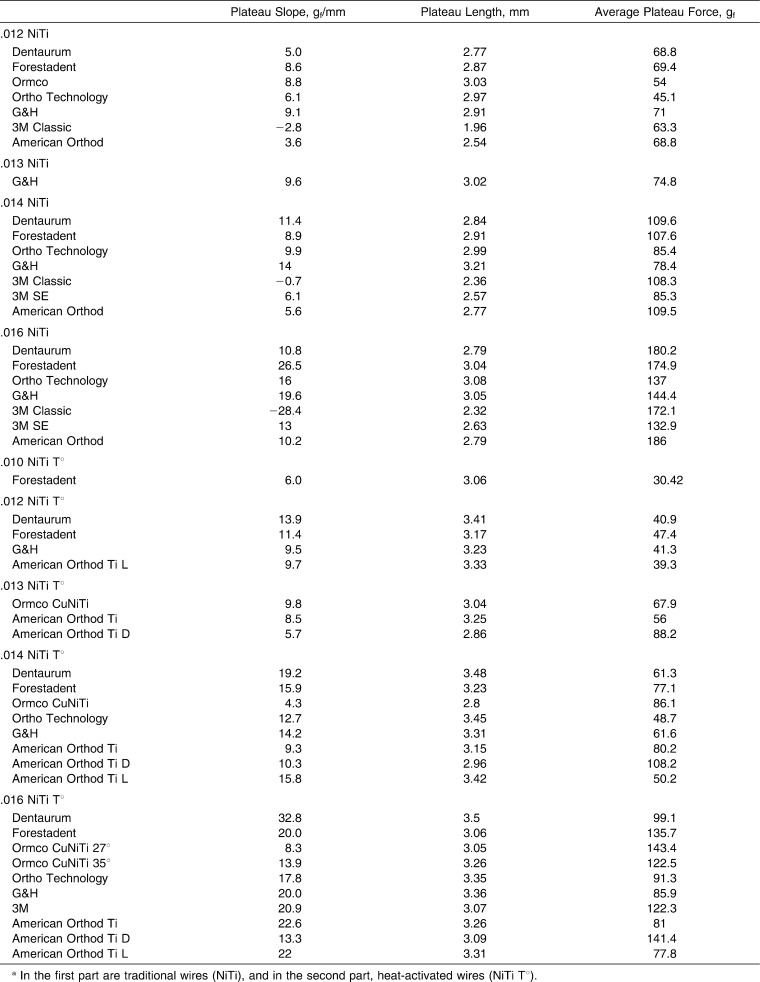

A load/deflection curve was obtained for each of the three samples of each type of wire tested. A sole operator subjectively identified and isolated the discharge plateau. This was identifiable clearly on each graph. The same operator calculated the values yielded by the three samples for each of the parameters considered (average plateau force, plateau length, and plateau slope) and for each type of wire tested. Data pertaining to each type of wire, grouped according to cross-sectional diameters, are summarized in Table 2.

Table 2.

Orthodontic Wires Grouped According to Type and Cross-Sectional Diameter (Test at 37.0°C)a

Statistical Analysis

Statistical analysis of the data was performed with the aid of analysis of variance (ANOVA), with P values < .05 considered significant. For each of the parameters considered, an internal comparison of each group of wires of the same type and diameter was made, as was a comparison of wires of different types and diameters.

RESULTS

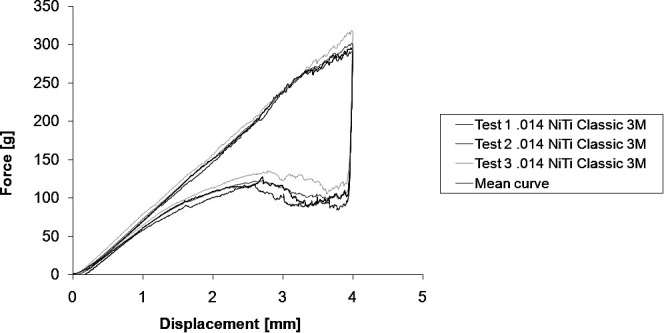

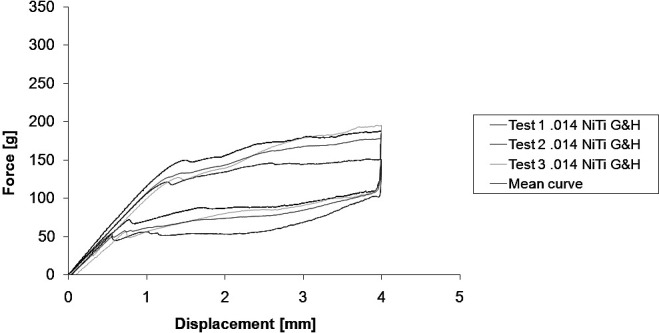

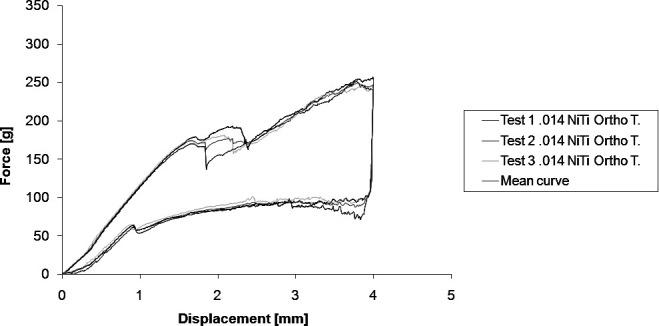

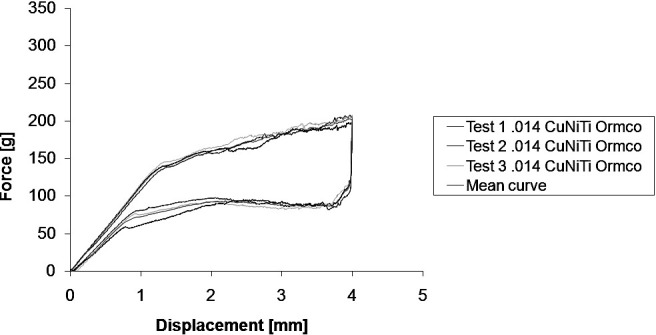

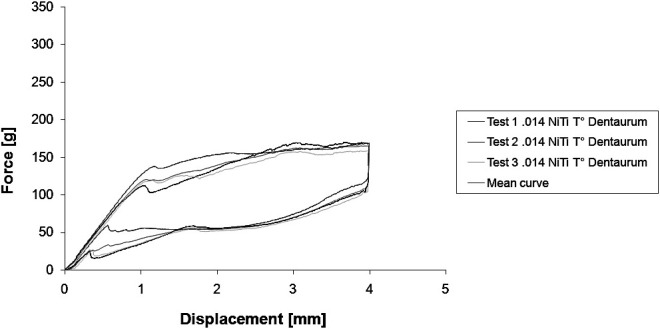

Most of the graphs plotted displayed readily identifiable plateau areas in which the force was relatively constant with a slight tendency to decrease. However, in several cases, an increase in force was seen in initial stages of the discharge phase, probably caused by a different friction coefficient between the wires and the brackets,6 resulting in negative values for slope parameters (Table 2, Figures 3 through 17).

Figure 3.

Load/deflection curve of 0.014 NiTi Classic (3M).

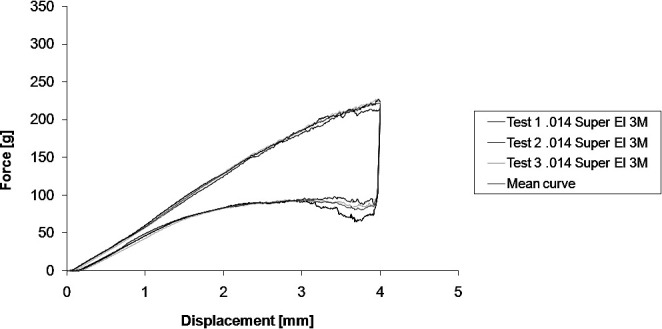

Figure 4.

Load/deflection curve of 0.014 NiTi Super Elastic (3M).

Figure 5.

Load/deflection curve of 0.014 NiTi Titanium memory wire (American Orthodontics).

Figure 6.

Load/deflection curve of 0.014 NiTi Rematitan Lite (Dentaurum).

Figure 7.

Load/deflection curve of 0.014 NiTi Titanol-Superelastic (Forestadent).

Figure 8.

Load/deflection curve of 0.014 NiTi Orthoforce G4 (G&H).

Figure 9.

Load/deflection curve of 0.014 NiTi TruFlex (Ortho Technology).

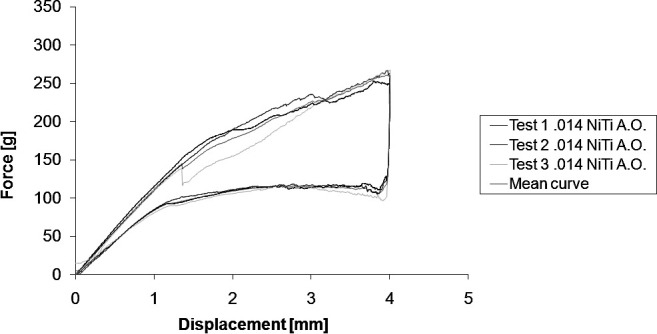

Figure 10.

Load/deflection curve of 0.014 CuNiTi (Ormco).

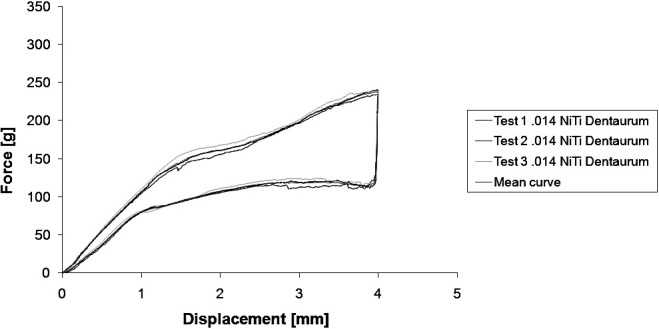

Figure 11.

Load/deflection curve of 0.014 Tensic (Dentaurum).

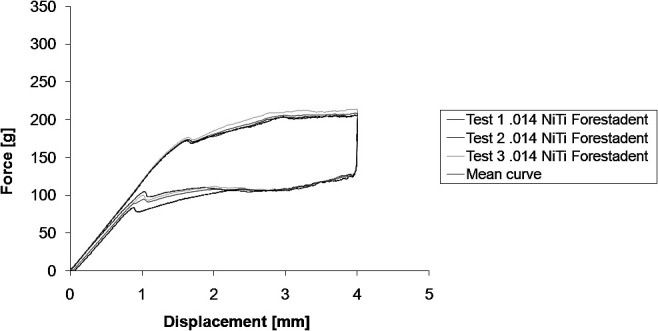

Figure 12.

Load/deflection curve of 0.014 Biostarter (Forestadent).

Figure 13.

Load/deflection curve of 0.014 Orthoforce M5 (G&H).

Figure 14.

Load/deflection curve of 0.014 TruFlex Thermal (Ortho Technology).

Figure 15.

Load/deflection curve of 0.014 Therma-Ti (American Orthodontics).

Figure 16.

Load/deflection curve of 0.014 Therma-Ti D (American Orthodontics).

Figure 17.

Load/deflection curve of 0.014 Therma-Ti Lite (American Orthodontics).

Given the sample of archwires as a whole, the average plateau force exerted ranged from roughly 30 gf to 186 gf. It is interesting to note that the minimum force measured was less than that obtained by other authors,15 who measured a minimum force of 37 gf, albeit with a 0.016 inch coaxial wire deflected by 1 mm.

Statistical analysis of these data, performed using ANOVA, revealed statistically significant differences between manufacturers regarding archwires of the same type and diameter, except for slope values yielded for 0.013 and 0.016 inch heat-activated wires. Hence, with these values excluded, the manufacturer variable has a great influence on the parameters considered.

Effect of Type of Archwire

Our analysis was focused on differences in the parameters examined between traditional and heat-activated nickel titanium archwires. Table 3 shows the mean values yielded by traditional and heat-activated NiTi wires of the same cross-sectional diameter.

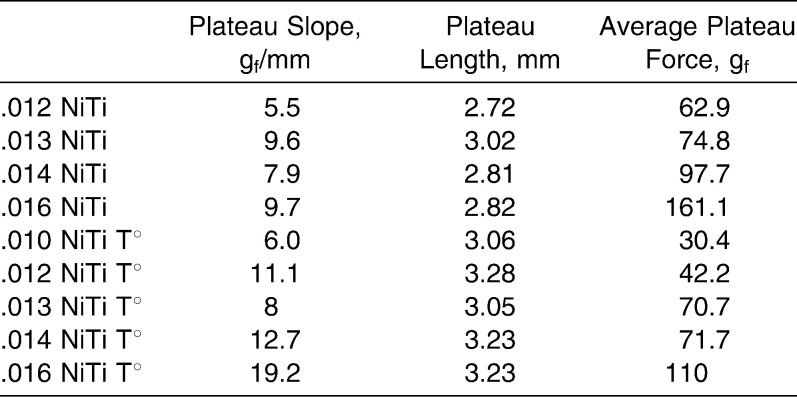

Table 3.

Mean Values Yielded by Traditional (NiTi) and Heat-Activated (NiTi T°) NiTi Wires of the Same Cross-Sectional Diameter

The decrease in average plateau force and the increase in plateau length were consistent differences between the two types of wire. In fact, ANOVA (performed on 0.012, 0.014, and 0.016 inch wires because data pertaining to 0.010 and 0.013 inch wires were insufficient for statistical purposes) showed a significant difference between the two groups regarding values for these two parameters, whereas differences in slope values were not statistically significant, except in the case of 0.012 inch wires. Table 4 shows the difference in values for each of the three parameters in a comparison of traditional and heat-activated wires of the same diameter and manufacturer.

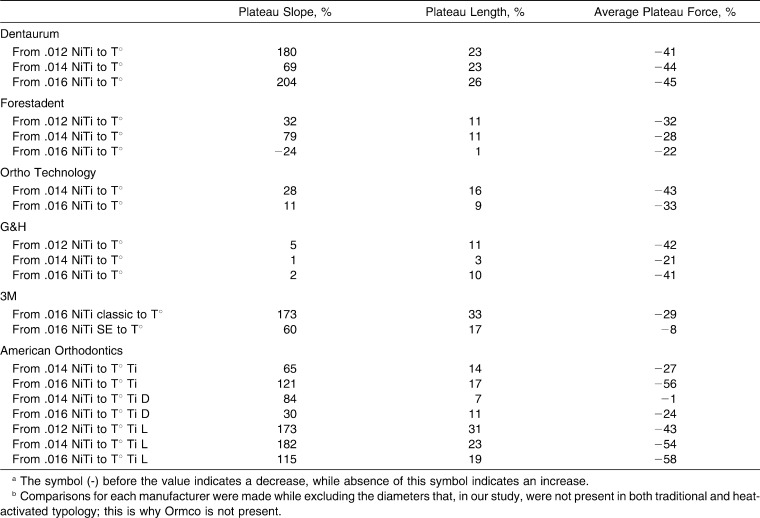

Table 4.

Comparison of Traditional (NiTi) and Heat-Activated (NiTi T°) Wires of the Same Diameter and Manufacturer for the Three Parameters Considered: Plateau Slope, Plateau Length, and Average Plateau Forcea,b

Effect of Archwire Diameter

Table 5 shows the percentage increase in average plateau force seen with increasing diameter of archwires of the same type and manufacturer (eg, Ortho Technology, from 0.012 to 0.014 NiTi, and from 0.012 to 0.016 NiTi). The trend was not constant for all wires, and differences ranging between 1% and 89% were reported. However, the average increase in plateau force observed in traditional wires was as follows:

Table 5.

Percentage increase in average plateau force seen with increasing diameter of archwires of the same type (traditional NiTi and heat-activated NiTi T°) and manufacturer

57% from 0.012 to 0.014

161% from 0.012 to 0.016

65% from 0.014 to 0.016

For heat-activated wires, the average increase was as follows:

47% from 0.012 to 0.014

134% from 0.012 to 0.016

50% from 0.014 to 0.016

It is interesting to note that the force expressed by traditional archwires shows a slightly greater tendency to increase with increasing diameter with respect to heat-activated wires, amounting to roughly 50% with a 0.002 inch increase in diameter, and 150% with a 0.004 inch increase in diameter.

DISCUSSION

The concept of optimal orthodontic forces has been discussed since the early 20th century. In particular, Schwarz defined optimal force as that which determines a change in pressure similar to capillary pressure, so that occlusion of these vessels in the compressed area of the periodontal ligament is prevented.16 This idea has been reiterated by authors such as Reitan,17 Righ et al.,18 and Proffit,19 but thus far no research has managed to quantify this ideal force applied with continuity.

Nowadays, “light continuous forces” are thought of as physiologically suitable and efficacious, but in this case, the term is used somewhat arbitrarily. In fact, no consensus whatsoever has been reached among the scientific community about what constitutes a “light” force and what does not. Thus, no concrete scientific evidence is available to quantify the optimal force for orthodontic movement,20 and clinicians must judge for themselves the most suitable force for each particular clinical situation. In this context, nickel titanium archwires have become increasingly popular in recent years because of their ability to release constant, light forces, which are considered to improve the efficiency and efficacy of treatment, especially during initial alignment and leveling phases.

In this context, the aim of our study was to evaluate and compare the behaviors of traditional and heat-activated nickel titanium archwires, with a view toward providing indications, rather than absolute values, regarding the force exerted by each, bearing in mind both the practical impossibility of defining this value in vivo21 and the fact that force values, using self-ligating brackets, are lower than those of conventional archwires.22

The method we chose for this comparison not only considered the force expressed by each wire at specific points of deflection, but aimed to characterize the behavior of each type of archwire in the discharge phase, represented as a plateau on the force/deflection graph. Characteristics of this plateau phase (average force, length, and slope) were evaluated for each wire, so each could be described from a clinical perspective. In fact, the greater the capacity of an archwire to exert more constant forces with increasing displacement, the better its performance in terms of dental movement. Particular attention was paid during our study to wires of round cross-section and small diameter (from 0.010 to 0.016 inch) to investigate the behavior of so-called light wires.

The first information emerging from this study was, according to ANOVA, the significant differences (P < .05) between archwires of the same diameter and type (traditional and heat-activated) for all parameters considered. This was true except for the slope of 0.013 and 0.016 inch heat-activated wires, depending on the manufacturer. This fact agrees with the study of Nakano et al.,6 who observed great variation in force values with different NiTi wires of the same diameter, indicating that the wires are intrinsically different and therefore can be differentiated according to their characteristics. In fact, it is important to underline that mechanical properties of NiTi alloy wires are greatly influenced by different technological parameters, such as chemical composition, heat treatment, and degree of working, which are beyond the discussion of this study but can be included in the manufacturer classification here exposed.

Moreover, a significant reduction in force and a concomitant increase in plateau length (P < .05) were noted between heat-activated and traditional wires, indicating that heat-activated archwires exert lighter, more constant forces at a greater deflection with respect to those exerted by traditional NiTi wires. In fact, our tests showed that, on average, heat-activated archwires exert a 24% lighter force and generate a 13% longer plateau than their traditional counterparts. This confirms results reported by Parvizi and Rock,23 who also recorded a greater force exerted by traditional with respect to heat-activated archwires, as well as an increase in force exerted at an increased measurement temperature.

CONCLUSIONS

Significant differences in behavior between almost all wires of equal section and type produced by different manufacturers were seen for the parameters considered (mean force, plateau length, and slope).

Comparison of traditional and heat-activated archwires of the same diameter showed that the latter exerted a significantly lighter force (∼24%) and generated a significantly longer plateau (∼13%) than the former.

On average, a 0.002 inch increase in cross-sectional diameter generated a 50% increase in plateau force (0.012 × 0.014 and 0.014 × 0.016 inch), and a 0.004 inch (0.012 × 0.016) increase in diameter resulted in an increase in plateau force of roughly 150% (differences were also noted between traditional and heat-activated wires in this case).

REFERENCES

- 1.Miura F, Mogi M, Ohura Y, Hamanaka H. The super-elastic property of Japanese NiTi alloy wire for use in orthodontics. Am J Orthod Dentofacial Orthop. 1986;90:1–10. doi: 10.1016/0889-5406(86)90021-1. [DOI] [PubMed] [Google Scholar]

- 2.Duering T. W, Melton K. N, Stockel D, Wayman C. M. Engineering Aspects of Shape Memory Alloys Part I An Introduction to Martensite and Shape Memory. London, UK: Butterworth-Heinemann; 1990. pp. 3–20. [Google Scholar]

- 3.Hurst C. L, Duncanson M. G, Nanda R. S, Angolkar P. V. An evaluation of the shape-memory phenomenon of nickel-titanium orthodontic wires. Am J Orthod Dentofacial Orthop. 1990;98:72–76. doi: 10.1016/0889-5406(90)70034-A. [DOI] [PubMed] [Google Scholar]

- 4.Andreasen G. F, Morrow R. E. Laboratory and clinical analysis of Nitinol wire. Am J Orthod. 1978;73:142–151. doi: 10.1016/0002-9416(78)90184-7. [DOI] [PubMed] [Google Scholar]

- 5.Kusy R. P. On the use of nomograms to determine the elastic property ratios of orthodontic arch wires. Am J Orthod. 1983;5:374–381. doi: 10.1016/0002-9416(83)90321-4. [DOI] [PubMed] [Google Scholar]

- 6.Nakano H, Satoh K, Norris R, Jin T, Kamegai T, Ishikawa F, Katsura H. Mechanical properties of several nickel-titanium alloy wires in three-point bending tests. Am J Orthod Dentofacial Orthop. 1999;115:390–395. doi: 10.1016/s0889-5406(99)70257-x. [DOI] [PubMed] [Google Scholar]

- 7.Pascal G, Laurence J. Stiffness in bending of a superelastic Ni-Ti orthodontic wire as a function of cross-sectional dimension. Angle Orthod. 2004;74:691–696. doi: 10.1043/0003-3219(2004)074<0691:SIBOAS>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 8.Bartzela T. N, Senn C, Wichelhaus A. Load-deflection characteristics of superelastic nickel-titanium wires. Angle Orthod. 2007;77:991–998. doi: 10.2319/101206-423.1. [DOI] [PubMed] [Google Scholar]

- 9.Tonner R. I. M, Waters N. E. The characteristics of super-elastic NiTi wires in three-point bending. Part 1. The effect of temperature. Eur J Orthod. 1994;16:409–419. doi: 10.1093/ejo/16.5.409. [DOI] [PubMed] [Google Scholar]

- 10.Tonner R. I. M, Waters N. E. The characteristics of super-elastic NiTi wires in three-point bending. Part 2. Intra-batch variation. Eur J Orthod. 1994;16:421–425. doi: 10.1093/ejo/16.5.421. [DOI] [PubMed] [Google Scholar]

- 11.Kapila S, Sachdeva R. Mechanical properties and clinical applications of orthodontic wires. Am J Orthod Dentofacial Orthop. 1989;96:100–109. doi: 10.1016/0889-5406(89)90251-5. [DOI] [PubMed] [Google Scholar]

- 12.Kasuya S, Nagasaka S, Hanyuda A, Ishimura S, Hirashita A. The effect of ligation on the load-deflection characteristics of nickel-titanium orthodontic wire. Eur J Orthod. 2007;29:578–582. doi: 10.1093/ejo/cjm068. [DOI] [PubMed] [Google Scholar]

- 13.Wilkinson P. D, Dysart P. S, Hood J. A, Herbison G. P. Load-deflection characteristics of superelastic nickel-titanium orthodontic wires. Am J Orthod Dentofacial Orthop. 2002;121:483–495. doi: 10.1067/mod.2002.121819. [DOI] [PubMed] [Google Scholar]

- 14.Kusy R. P, Dilley G. J. Elastic modulus of a triple-stranded stainless steel archwire via three and four point bending. J Dent Res. 1984;63:1232–1240. doi: 10.1177/00220345840630101401. [DOI] [PubMed] [Google Scholar]

- 15.Jeff B, Tom W. J. Force levels of nickel titanium initial archwires. J Clin Orthod. 2007;5:286–292. [PubMed] [Google Scholar]

- 16.Schwartz A. M. Tissue changes incidental to orthodontic tooth movement. Int J Orthod Oral Surg Radiog. 1932;18:331–352. [Google Scholar]

- 17.Reitan K. Clinical and histological observations on tooth movement during and after orthodontic treatment. Am J Orthod. 1967;53:721–745. doi: 10.1016/0002-9416(67)90118-2. [DOI] [PubMed] [Google Scholar]

- 18.Rygh P, Bowling K, Hovlandsdal L, Williams S. Activation of the vascular system: a main mediator of periodontal fiber remodeling in orthodontic tooth movement. Am J Orthod. 1986;89:453–468. doi: 10.1016/0002-9416(86)90001-1. [DOI] [PubMed] [Google Scholar]

- 19.Proffit W. R. Contemporary Orthodontics. St Louis, Mo: Mosby-Year Book Inc; 1999. pp. 296–325. [Google Scholar]

- 20.Yijin R, Jaap C. M, Kuijpers-Jagtman A. M. Optimum force magnitude for orthodontic tooth movement: a systematic literature review. Angle Orthod. 2003;73:86–92. doi: 10.1043/0003-3219(2003)073<0086:OFMFOT>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 21.Segner D, Ibe D. Properties of superelastic wires and their relevance to orthodontic treatment. Eur J Orthod. 1995;17:395–402. doi: 10.1093/ejo/17.5.395. [DOI] [PubMed] [Google Scholar]

- 22.Elayyan F, Silikas N, Bearn D. Mechanical properties of coated superelastic archwires in conventional and self-ligating orthodontic brackets. Am J Orthod Dentofacial Orthop. 2010;137:213–217. doi: 10.1016/j.ajodo.2008.01.026. [DOI] [PubMed] [Google Scholar]

- 23.Parvizi F, Rock W. P. The load/deflection characteristics of thermally activated orthodontic archwires. Eur J Orthod. 2003;25:417–421. doi: 10.1093/ejo/25.4.417. [DOI] [PubMed] [Google Scholar]