Abstract

Native starches have limited applications in the food industry due to their unreactive and insoluble nature. Cold plasma technology, including plasma-activated water (PAW), has been explored to modify starches to enhance their functional, thermal, molecular, morphological, and physicochemical properties. Atmospheric cold plasma and low-pressure plasma systems have been used to alter starches and have proven successful. This review provides an in-depth analysis of the different cold plasma setups employed for starch modifications. The effect of cold plasma technology application on starch characteristics is summarized. We also discussed the potential of plasma-activated water as a novel alternative for starch modification. This review provides information needed for the industrial scale-up of cold plasma technologies as an eco-friendly method of starch modification.

Keywords: Starch modification, Cold plasma, Plasma-activated water, Application, Starch properties, Industrial scale-up

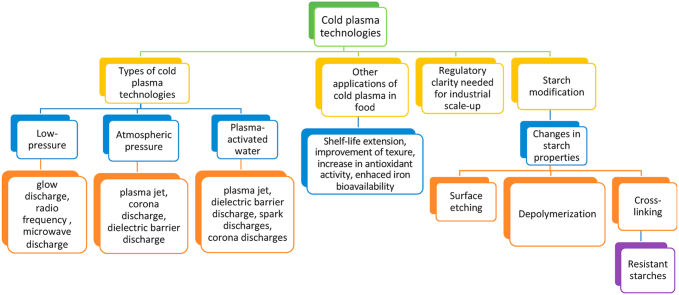

Graphical abstract

Highlights

-

•

Cold plasma technology could be an effective, sustainable alternative for starch modification.

-

•

The extent of modification of starches from different botanical sources depends on the type of cold plasma technology used.

-

•

For mainstream adoption of cold plasma modified starches, research on safety and consumer perception must be conducted.

1. Introduction

Starch is the primary energy reserve in plants and comprises two major polysaccharides: amylose and amylopectin. Amylose is mostly a linear polysaccharide made of α-(1–4)-D-glucosyl units with a few α-(1–6) linkages in larger molecular weight starches (Hizukuri et al., 1981). Amylopectin, however, is a highly branched polymer with linear chains of α-(1–4)-D-glucosyl units interconnected with α-(1–6)-linkages (Hizukuri et al., 1983). Starch is synthesized in granular form and can be obtained from seeds, roots, tubers, leaves, pollen, and even algae. Starch granules appear in various shapes such as ellipsoids, spheres, and ovals when viewed under the microscope. The diameter of starch granules can range from 0.1 μm to >100 μm depending on their botanical origin (Pérez and Bertoft, 2010). Significant starch sources for commercial applications include maize, potato, cassava, and wheat (Vamadevan and Bertoft, 2015). It is no surprise that the industrial starch market is projected to be worth 106.64 billion USD by 2022 (Rohan, 2016). This is because starch has multiple applications in both food and non-food industries.

Starch is utilized as a gelling, thickening, stabilizing, and flavor encapsulating agent in the baking, brewing, and confectionery industries (Mason, 2009). Non-food uses of starch include adhesives for the manufacture of corrugated paper boards, antifreeze, and retarding agents for concrete, as well as fermentation feedstocks for pharmaceutical products (Glittenberg, 2012). Nonetheless, in its native state, starch is highly unreactive, insoluble, and retrogrades easily. Therefore, starches must be modified to enhance their solubility, textural properties, and heat tolerance for diverse industrial applications (Laovachirasuwan et al., 2010).

Starch can be modified using physical, chemical, and biological means. Physical methods can either be thermal (heat moisture treatment, spray drying, pre-gelatinization, etc.) or non-thermal (pulsed electric field, ultrasonication, high hydrostatic pressure, cold plasma technology, etc.) and have proven to be successful in modifying starches (Zia-ud-Din et al., 2017). For example, physical processes such as pregelatinizing starches enhance these starches' thickening and water absorption capacity (Hong and Liu, 2018). The biological techniques of starch modification can either be done using genetic engineering to breed specific varieties of starch such as high amylose starches or through enzymatic conversion of these starches to achieve products like maltodextrins (Bemiller, 1997). Biological methods usually give increased yields and fewer by-products; however, they can be relatively expensive compared to physical methods (Park et al., 2017).

Chemical modification techniques are the most widely used and are reported to result in the highest efficiency. Chemical methods employed in modifying starches include cationization, acetylation, oxidation, and green solvents (Chaiwat et al., 2016; Fan and Picchioni, 2020). There is an increasing concern about the issues of environmental pollution, wastewater treatment, food safety, and the high costs involved in chemical modification methods (Chaiwat et al., 2016). While the use of ionic liquids (“green” solvents) in chemical modification may have less impact on the environment, there are issues such as poor performance in biodegradability, biocompatibility, and sustainability (Dai et al., 2013; Fan and Picchioni, 2020). Hence, physical processes are preferred over chemical methods in altering the structure and functionality of starches. It is important as a scientist to continue to explore sustainable and eco-friendly ways of starch modification, and cold plasma technology has been identified as one such method.

The term plasma was introduced by Irving Langmuir in the 1920s as the fourth state of matter in addition to solids, liquids, and gases. Prior to that, in 1816, Michael Faraday postulated the existence of the fourth state of matter which he called radiant matter (Crookes, 1881). William Crookes earlier proved the existence of plasma as “radiant matter” in a Crookes tube in 1879 (Crookes, 1879). Plasma is a fully or partially ionized gas made up of electrons, ions, free radicals, photons, UV radiation, reactive species, and molecules in their ground or excited states and carries a net neutral charge (Pankaj et al., 2018). Plasma can either be naturally occurring or artificial and makes up 99% of the visible matter in the universe. Examples of natural plasmas include the sun, Saint Elmo's fire, lightning, and the Aurora Borealis and Australis.

In contrast, examples of man-made plasmas are neon signs, fluorescent lights, and plasma pinches (Snoeckx and Bogaerts, 2017). The main objectives of this review are to discuss the different types of cold plasma setups used for plasma generation, their mode of operation, their advantages, and disadvantages, as well as how the different setups affect the morphological, physicochemical, and molecular properties of starches. The potential for plasma-activated water (PAW) as another cold plasma technology for starch modification will also be discussed. Applications of cold plasma besides starch modification will be briefly discussed. Our aim is that this review will hasten the industrial scale-up of this technology.

2. Cold plasma production

Cold plasma (also known as non-thermal plasma) is a partially ionized gas produced by applying sufficient energy (thermal, electromagnetic, or electric fields, microwave and radio frequencies) to a neutral gas at low or atmospheric pressure (Moreau et al., 2008). When the energy is applied, the free electrons naturally present in the gas pick up the energy faster than the ions. The accelerated electrons then transfer the energy to heavier gas molecules through elastic and inelastic collisions. As a result of these collisions, the gas goes through several phase reactions-ionization, excitation, and dissociation to produce several reactive species (reactive oxygen species and reactive nitrogen species), new electrons, ions, and free radicals (Milella and Palumbo, 2014). According to Milella and Palumbo (2014), the electron temperature in cold plasma is relatively high (1–10 eV), while the translational energy of the heavy particles (molecules, ions) is close to room temperature. That is because the electrons have a lighter mass than the heavy particles (Rossi, 2012). Thus, the electrons reach higher kinetic energy (temperature) faster than the heavy particles. Cold plasma is thus characterized as being in non-local thermodynamic equilibrium because of this difference in temperature between electrons and heavy particles (Snoeckx and Bogaerts, 2017).

Cold plasma requires a much lower power input, unlike thermal plasmas that need a higher power input (∼50 MW). Thermal plasmas are generated at high temperatures (4000 K- ≥ 20000 K) and pressures (≥105Pa) (Moreau et al., 2008). Thermal plasmas are fully ionized gases as all the species (electrons, ions, heavy particles) possess the same temperature. Thermal plasmas are in local thermodynamic equilibrium. The applications of thermal plasmas are diverse, a few of which include extractive metallurgy, fine powder syneresis, and coating technology (Snoeckx and Bogaerts, 2017). However, the extremely high temperatures are not suitable for treating thermally sensitive materials like starches, which is why cold plasma is a more appropriate method for starch modification and other food applications (Liao et al., 2020).

3. Generation of cold plasma at low pressure

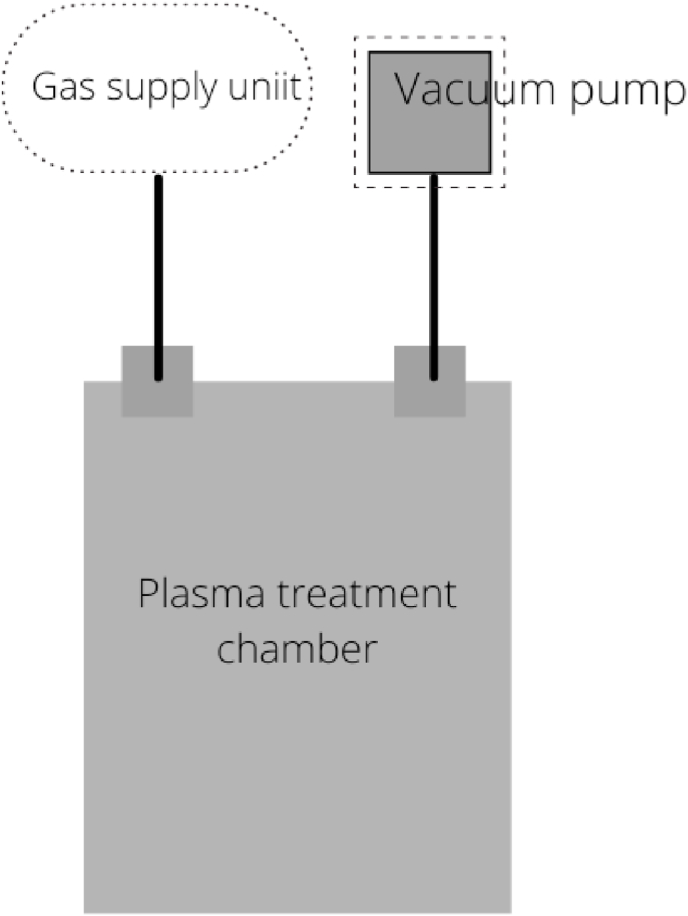

3.1. Basic setup

As mentioned earlier, cold plasma can be generated either at low pressure or atmospheric pressure. The basic setup of a low-pressure cold plasma system includes a vacuum chamber, a pumping unit that clears unwanted gases from the system, gas feeding tanks, gas controllers, pressure gauges, and electrodes that can be powered by electromagnetic generators using direct current (DC), alternating current (AC), radio frequencies or microwave frequencies. This low-pressure system can then be controlled by a microcontroller (programmable logic controller, PLC) or a personal computer (Lippens, 2007). According to Roy Choudhury (2017), the main advantage of a low-pressure plasma system is that it is easier to control the extent and composition of the critical gas atmosphere from which the plasma is generated, as it is operated in a closed vessel under vacuum. In addition, there is an even distribution of plasma inside the closed vessel (Ebnesajjad, 2014). However, low-pressure plasma systems are not suitable for continuous on-line processing and can only be conducted in batches. The vacuum equipment required for the plasma setup is expensive (Roy Choudhury, 2017). Basic low-pressure plasma systems used in starch modification as well as other food applications are outlined below:

3.2. Glow discharge cold plasma

In a glow discharge, cold plasma is obtained by applying an electric current operating at 100 V or higher through a gas over a pair or a series of electrodes (Fig. 1). This electric current could either be in the form of an alternating current (AC), a direct current (DC), low frequency (50 Hz), or radio frequency (RF) (40 kHz, 13.56 MHz). The electrons generated in this type of plasma gain sufficient energy through excitation collisions which generate photons responsible for the visible glow (Thornhill, 2007; Vaideki, 2016).

Fig. 1.

Schematic diagram of a low-pressure glow discharge plasma.

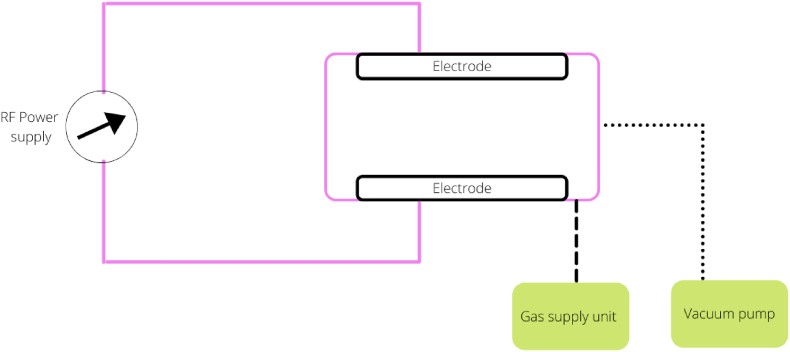

3.3. Radio frequency (RF) discharge cold plasma

Low-pressure radio frequency plasma typically operates in the radio frequency range of 1–100 MHz (Fig. 2). The power supplied from an electric field can be coupled to the plasma either capacitively (Thirumdas et al., 2017b) or inductively (Rossi, 2012). The capacitively coupled RF plasma consists of two parallel electrodes. One of the two electrodes is connected to an RF power supply while the other is grounded (Wilczek et al., 2020). As a result of the electric field created between the two electrodes, the electrons are accelerated and generate secondary electrons and positive ions through inelastic collisions with neutral gas species (Rossi, 2012; Wilczek et al., 2020). The electric current flowing into the coil induces a time-varying magnetic field in the inductively coupled RF plasma. The magnetic field also creates an induction field which causes the acceleration of electrons that produces and sustains the plasma. Inductively coupled RF plasma offers higher treatment efficiency than capacitively coupled RF plasma (Lee, 2018).

Fig. 2.

Schematic diagram of a low-pressure radio frequency plasma.

3.4. Microwave discharge cold plasma

A microwave discharge is an electrodeless plasma technique typically operated with an electromagnetic frequency of 2.45 GHz (Vaideki, 2016). A magnetron emits electromagnetic waves in a microwave discharge plasma, generating electrical discharges (Laroque et al., 2022). A waveguide directs the electromagnetic waves through a treatment chamber filled with gas electrons in this type of plasma. As a result, the electrons absorb the microwave energy and undergo ionization reactions through inelastic collisions, producing plasma. This type of plasma is more efficient in generating reactive species and has a higher electron density than a radio frequency plasma (Laroque et al., 2022). That is because the collision frequency of electrons is close to the microwave frequency. A microwave discharge plasma could be operated at low or atmospheric pressure (Thomas and Mittal, 2013). However, it is expensive to operate and not often used in starch modification (I et al., 2004).

4. Generation of cold plasma at atmospheric pressure

Plasma types that operate at atmospheric pressure include atmospheric pressure plasma jets, dielectric barrier discharge plasma systems, and corona discharge plasma systems. It could be powered using AC or DC. These systems are widely operated at a higher voltage (in kV). Atmospheric systems allow continuous type treatment of the product and do not require expensive vacuum equipment (Roy Choudhury, 2017). The most used atmospheric pressure plasma systems are discussed.

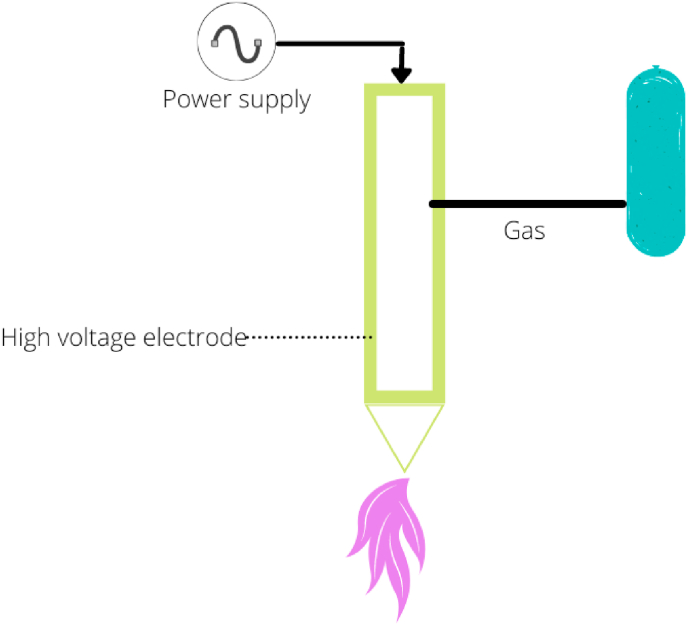

4.1. Atmospheric pressure plasma jet

According to Niemira (2012), atmospheric pressure plasma jets (APPJ) are cold plasma systems operated at atmospheric pressure. APPJ does not require air-tight vacuum chambers and is easy to build compared to low-pressure plasma systems. Different APPJ has been developed and tested on food systems, including double electrode and end-field jet, based on the type of configurations and excitation mode. APPJ with a double electrode system consists of a plasma generator with two electrodes-one ground electrode and the other connected to the power supply, airflow monitor, and gas inlet (Fig. 3). The plasma generator usually consists of an outer casing acting as a ground and an inner electrode made from stainless steel, Pyrex tube, or glass. The supplied gas is ionized by applying high voltage ranging from 2.5 kV to 60 kV between these electrodes. The gas is excited from the top and expands to the surrounding air outside the nozzle (Weltmann et al., 2009). The shape of the electrodes could be either rectangle, conical or cylindrical.

Fig. 3.

Schematic diagram of an Atmospheric pressure plasma jet system.

Gases used to produce the plasma that proved to have better preservation properties include compressed air, or a combination of argon/nitrogen and oxygen/compressed air (Surowsky et al., 2014). The selection of gas flow rate to attain the required plasma jet length greatly varies based on the design parameters of the APPJ. A single electrode APPJ (End-field jet type) was designed at the Institute of physics (Zagreb, Croatia) and consisted of a Teflon body with a copper wire placed in the capillary tube (Bursać Kovačević et al., 2016a; Elez Garofulić et al., 2015; Herceg et al., 2016). High voltage is then supplied through the copper wire. Argon was used as the source of plasma. The gas flow rate used in this Single electrode APPJ was 1.5 L/min, which is less than double electrode systems with a gas flow rate of 107 L/min (Iqdiam et al., 2020).

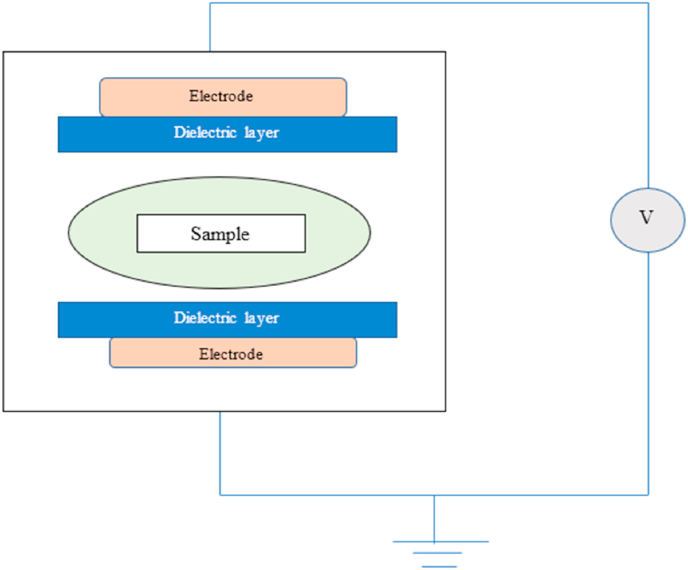

4.2. Dielectric barrier discharge

Dielectric barrier discharge (DBD) plasma consists of electrodes coated with dielectric materials such as plastic, quartz, or ceramic (Fig. 4). The electrodes are usually placed inside the closed container to prevent the escape of plasma particles, and samples are placed between the electrodes for direct treatment. Besides the coated dielectric materials, the air used in these systems acts as the barrier to the current, preventing the spark formations. These models require high voltage ignition (10 kV) (Chizoba Ekezie et al., 2017) that could be powered by AC or DC supply. Design parameters like using round-edged electrodes (Moiseev et al., 2014), selecting dielectric materials (Brandenburg, 2018), and applying higher voltage are considered to avoid arcing during plasma generation. The gases commonly used in the DBD plasma system include atmospheric air, nitrogen, argon, and helium.

Fig. 4.

Schematic diagram of a Dielectric Barrier Discharge Configuration.

4.3. Corona discharge plasma systems

Corona discharges are pulsed discharge plasma produced at atmospheric or near atmospheric pressure. When the non-uniform electric field exceeds the breakdown threshold in the limited spatial region, it forms a corona discharge (Raizer and Allen, 1997). Corona discharge plasma setup includes a high voltage supply, electrodes, and sample treatment chambers. The electrodes employed in corona discharges are often asymmetric, like a point and a plane (Turner, 2016). The corona discharge appears as a luminous glow localized around the tip of the electrode (Kim et al., 2009). Based on the type of high voltage applied to the electrodes, corona discharge could be positive (high voltage at the anode) or negative (high voltage at the cathode). Gases used to produce corona discharge typically include air, nitrogen, argon, a mixture of helium and oxygen, or argon and oxygen (Pignata et al., 2017). The samples are treated either below the electrode or channeled to the treatment chamber through hoses. Corona discharge plasma systems have been configured and tested in many ways, including the use of an air blower, cold storage system, liquid corona discharge, and cylindrical plasma reactors (Abou-Ghazala et al., 2002; Korachi et al., 2010; Timoshkin et al., 2012).

5. Plasma-activated water (PAW)

Plasma-activated Water (PAW) is highly concentrated with chemically reactive oxygen and nitrogen species (RONS). Plasma-activated water is generated by treating water with plasma devices such as the atmospheric pressure plasma (Abuzairi et al., 2018), plasma jet (Adhikari et al., 2019), DBD (Judée et al., 2018), spark or glow discharges (Lu et al., 2017) and corona discharges (Lukes et al., 2008). The composition and concentration of these species in water depend on the type of gas, applied voltage, treatment time and whether the plasma source is discharged directly into water or above water's surface (Oh et al., 2016). RONS formed at the gas phase and gas-water interface include singlet oxygen, atomic oxygen, ozone, excited and atomic nitrogen, hydroxyl radicals, superoxide, hydrogen peroxide, nitrates and nitrites ions, nitric and nitrous acid, as well as peroxynitrous acid (Thirumdas et al., 2018). The formation of these reactive species decreases the pH in water while increasing the oxidation-reduction potential (ORP) and electrical conductivity (Zhao et al., 2020). The formation of these species makes PAW useful in microbial decontamination (Lin et al., 2020), enhancing plant growth and seed germination (Judée et al., 2018) as well as starch modification (Y. Yan et al., 2020). More details on the mechanism and potential applications of PAW in food are highlighted in Thirumdas et al. (2018).

6. Recent applications of cold plasma in food processing

These next few paragraphs focus on the areas where cold plasma technology has been explored in recent times. Cold plasma and PAW are utilized in food decontamination, shelf-life extension, and seed germination (Sarangapani et al., 2017; Thirumdas et al., 2018). Cold plasma is also explored in the modification of food components, including starches, proteins (Mahdavian Mehr and Koocheki, 2020; S. Yan et al., 2020; Y. Yan et al., 2019; Bu et al., 2022), food fortification (Aditya et al., 2020), and in treatment of films (Song et al., 2019).

APPJ is used in food processing applications such as treating nuts, fruit juices, spices, and vegetables owing to its ease of access with continuous processing systems (Amini and Ghoranneviss, 2016; Bursać Kovačević et al., 2016b; Charoux et al., 2020; Dasan et al., 2017; Elez Garofulić et al., 2015; Go et al., 2019; Grzegorzewski et al., 2011; Iqdiam et al., 2020; Surowsky et al., 2014).

DBD treatment of composite films made of wheat cross-linked starch, and whey protein concentrate showed positive effects on the thermal stability, mechanical and barrier properties of composite films (Song et al., 2019). The plasma treatment of these composite films increased the oxygen-containing groups on the film surface while retaining the internal crystal structure. The grass pea protein isolate's surface electrical charge and solubility were increased by treating it with a DBD system. Cold plasma also positively affected the interfacial and emulsifying properties of the grass pea protein isolate (Mahdavian Mehr and Koocheki, 2020).

Cold plasma treatment has been shown to impact the physical properties of fortified food positively. Cold plasma was used to treat noodles fortified with mango flour by Abidin et al. (2018). The noodles treated with cold plasma were less hard and cohesive than the control samples due to increased gluten strength and improved texture with plasma treatment. Aditya et al. (2020) studied the effect of cold plasma on the fortification of coffee powder with calcium from the eggshell. The bulk density of the fortified powder decreased because of surface plasma etching. Plasma treatment enhanced the solubility of calcium in black coffee. Akasapu et al. (2020) used cold plasma to fortify rice with iron. Rice was treated in DBD plasma at 20 kV at different times. The cold plasma treated rice was then fortified with ferrous sulfate (iron). After cooking, rice treated with plasma before fortification showed higher iron bioavailability than the control rice samples. Cold plasma was used to treat brown rice grains (Park et al., 2020). This cold plasma treated rice was used in the preparation of aqueous tea infusions. The treatment increased the antioxidant activity and total phenolic contents in the brown rice-infused tea without affecting the turbidity.

7. Starch modification using cold plasma

As discussed above, it is important to modify starch to improve its functionality for various applications. Thus, the effect of low and atmospheric pressure plasma systems on various starch properties (molecular, granule morphology, crystallinity, pasting, gelatinization, and rheology) are discussed separately. Details of the operating conditions utilized for starch modification and the effects are summarized in Table 1.

Table 1.

Effect of low and atmospheric pressure plasma systems on starch properties.

| Starch | Plasma type | Operating conditions | Key findings | Reference |

|---|---|---|---|---|

| Maize, rice and potato | Low Pressure Radio-Frequency Plasma | Power: 120 W Time: 60 min Gas: Carbon dioxide and Argon Gas Flow Rate: 25 and 15 sccm |

No effect on shape of the selected starches No change in crystallinity of maize and rice starches Decrease in crystallinity of potato starch Increase in enthalpies of maize, rice and potato starches |

Okyere et al. (2019) |

| Potato | Glow plasma | Power: 270 W Time: 30,45, 60 min Gas: Nitrogen, Helium Operating pressure: 2000 Pa |

No change in morphology with Nitrogen glow treatment Decrease in crystallinity, gelatinization temperatures, and enthalpy of gelatinization of potato starch Increase in semi-crystalline lamella in the of potato |

Zhang et al. (2015) |

| Cassava | Glow plasma | Power: 270 W Gas: Helium, oxygen Time: 30, 45, 60 min Operating pressure: 2000 Pa |

Decrease in crystallinity Increase in semi-crystalline lamella thickness Decrease in enthalpy of gelatinization |

Bie et al. (2016a) |

| Corn, tapioca | Low Pressure Radio-Frequency Plasma | RF Frequency: 13.56 MHz Power: 40 and 60 W Time: 10 and 20 min Gas: Atmospheric Air |

Uneven surfaces and deposits after plasma treatment Decrease in the enthalpies of corn and increase in enthalpies of tapioca starch Increase in water binding capacity |

Banura et al. (2018) |

| Potato and Corn | Glow plasma | Voltage: 65 kV Time: 30 min Operating pressure: 1.33 Pa Gas: Ethylene |

Deposits on starch after plasma treatment | Lii et al. (2002) |

| Rice | Bell Jar type plasma apparatus | RF Frequency: 13.56 MHz Operating pressure: 0.15 mbar Time: 5 and 10 min Power: 40 and 60 W Gas: Atmospheric Air |

Formation of fissures/cavities were observed Reduction in the thermal properties Increase in peak viscosity |

Thirumdas et al. (2017b) |

| Kithul palm | Glow discharge plasma | Power: 5 and 15 W Time: 30 and 60 min Pressure: 0.2 mbar Gas: Nitrogen |

Formation of fissures after plasma treatment Increase in peak viscosity |

Sudheesh et al. (2019) |

| Maize films | Capacitively coupled Radio frequency plasma | Gap between electrodes: 3.5 cm Gas: 1-butene |

Increase in roughness of the starch films | Andrade et al. (2005) |

| Corn starch films | Glow discharge | Frequency: 13.56 MHz Pressure: < 8 Pa Voltage: −100 to −60 V Time: 10, 20 min |

Increase in roughness after treatment Appearance of small granules due to plasma coating |

de Albuquerque et al. (2014) |

| Wheat | Low-pressure radio frequency glow discharge | Power: 20–30 W Pressure: 600 mTorr Gas: Atmospheric air, oxygen Time: 4, 8, and 12 min |

Increase in roughness of the starch films No significant change in water vapor permeability |

Sheikhi et al. (2020) |

| Potato | Oxygen glow | Power: 270 W Time: 30, 45, and 60 min Gas: oxygen |

Decrease in the degree of molecular order | Zhang et al. (2014) |

| Maize | DBD | Power: 75 W Time: 1, 5, and 10 min Gas: Atmospheric air Dielectric material: quartz |

Decrease in relative degree of crystallinity, molecular weight and viscosity | Bie et al. (2016b) |

| Waxy maize starch and normal maize starch | APPJ | Power: 750 W Frequency: 25 kHz Distance from probe to sample: 14 mm Time: 1–7 min |

Etching on the surface of starch granules Increase in water binding capacity Decrease in relative crystallinity |

Zhou et al. (2019) |

| Potato | APPJ | Power: 750 W Frequency: 25 kHz Distance from probe to sample: 14 mm Time: 1–7 min |

Decrease in relative crystallinity without change in crystalline structure | Yan et al. (2019) |

| Banana | DBD | Power: 60–167 W Dielectric material used: Quartz |

Alteration in crystalline structure Increased solubility Decreased swelling power |

Yan et al. (2020) |

| Corn | APPJ | Power: 400, 600, and 800 W Time: 30 min Dimension of the chamber: 295 mm (diameter), 476 mm (height) |

Decrease in peak, trough and final viscosity No change in swelling power Increase in water soluble indexes Observation of slight fissures without significant change in overall morphology |

Wu et al. (2019) |

| Maize | APPJ (PAW) | Power: 750 W Frequency 25 kHz Time: 2min |

Decreases in swelling power Increases in solubility Increases in resistant starch content Increases in relative crystallinity Increase in gelatinization temperatures in normal maize while a decrease was observed in waxy maize |

Yan et al. (2020) |

| Corn (Normal, Hylon V, Hylon VII) | Rotatory cylindrical glass reactor (500 mL) | Power: 90 W RF Frequency: 13.56 MHz Gas: HDMSO Flow rate: 0.35 cm3/min Time: 10 min Agitation: 200 rpm |

Formation of fissures and coat deposition on granule surface Increase in absorbance ratios of 1047/1022 cm−1 Increases in enthalpy of gelatinization of high amylose corn starches only |

Sifuentes-Nieves et al. (2021) |

| Corn (Normal, Hylon V, Hylon VII) | Coaxial-DBD | Voltage: 12 kVpp Frequency: 25 kHz Dielectric material: quartz Time: 10 min Gases: Argon/HDMSO |

Starch granules covered by a thin coat due to HDMSO polymerization New vibration modes observed in 2965 (CH3 stretching), 1260 (CH3 bending in Si-(CH3)x), 840 (Si–C and CH3 rocking vibrations), and 795 cm− 1 (Si–O–Si bending vibration) Increase in absorbance ratios of 1047/1022 cm−1 |

Sifuentes-Nieves et al. (2021) |

| Rice | DBD | Voltage: 40 V Discharge distance: 12 mm Time: 2, 6, 10 min Gas: atmospheric air Input current: 0.8 A |

Changes in birefringence intensity of granules Increase in amylose content Increase in resistant starch Decreases in relative crystallinity Increase in absorbance ratios of 1047/1022 cm−1 |

Sun et al. (2022) |

| Potato | DBD | Voltage: 50 V Discharge distance: 2 mm Time: 3, 6, 9 min Input current: 1 A |

Maltese cross structure remained unchanged Decrease in intensity of FTIR band at 2871 cm−1 Occurrence of cross-links between starch molecules Decreases in relative crystallinity |

Guo et al. (2022) |

| Aria | DBD | Voltage: 7, 10, 14, and 20 kV Discharge distance: 15 mm Time: 15 min Gas: atmospheric air Average pressure: 101 kPa Frequency: 200 Hz |

Observation of particle aggregation and fissures in starch granules at 20 kV treatment Decreases in pH values due to formation of acid groups Increase in rapidly digestible starches Increase in amylose content at 20 kV, while a decrease was observed at 14 kV |

Carvalho et al. (2021) |

| Granular and non-granular waxy maize, rice and potato | Low Pressure Radio-Frequency Plasma | Power: 120 W Time: 60 min Gas: Carbon dioxide and Argon Gas Flow Rate: 25 and 10 sccm |

Decreases in short chain length of rice and maize starches (granular and non-granular) Increases in long chain length of rice and maize starches (granular and non-granular) Increases in resistant starches Occurrence of cross-linking in starch chains |

Okyere et al. (2022) |

| Mango | Novel pin to plate plasma reactor | Voltage: 170 and 230 V Discharge distance: 5 cm Time: 15and 30 min Resonant frequency: 55.51 Hz Discharge frequency: 1.5 kHz Gas: atmospheric air Duty cycle: 90 μS |

Increases in gel hydration properties Decrease in pH and turbidity Increase in % syneresis Decrease in amylose content Decrease in peak, setback, final and breakdown viscosity |

Kalaivendan et al. (2022) |

7.1. Effect of low-pressure plasma on starch properties

7.1.1. Molecular properties

Low-pressure plasma systems have proven to be effective tools in modifying the molecular properties of starches. A capacitively coupled plasma decreased the degree of rice starch hydrolysis from 91% to 87% after 60 W treatment for 10 min (Thirumdas et al., 2017b). This decrease was due to the cross-linking of rice starch chains, limiting the rate of enzymatic hydrolysis. Solid-state 13C Nuclear Magnetic Resonance (NMR) analysis of waxy starches showed that modification with plasma resulted in an increase in glucose units near α-(1,6)-glycosidic linkages (Okyere et al., 2019). Thus, plasma treatment effectively degraded the polymeric starch chain into its component glucose units.

Furthermore, Zhang et al. (2015) observed a reduction in single and double helices in glow-plasma modified potato starch after solid-state 13C NMR analysis. The authors concluded that plasma treatment induced the conversion of the starch crystallites into amorphous structures. The amylose content of kithul starch was reduced after plasma modification, which led to a subsequent decrease in the iodine binding capacity of these starches (Sudheesh et al., 2019). The hydrolysis of starch into smaller glucose units limits its ability to bind with iodine (Bailey and Whelan, 1961). Thus, the decrease observed in the iodine binding capacity was due to plasma degrading amylose into glucose units. Banura et al. (2018) and Thirumdas et al. (2017b) also reported a decrease in corn and rice starch's amylose content after plasma modification. The intensity of the H–O–H bending vibration peaks of kithul starch decreased after plasma treatment, as indicated by Fourier Transform Infrared (FTIR) analysis. The authors reported that higher plasma power levels and longer treatment times resulted in the cleavage of hydrogen bonds in starch, thus decreasing the intensity of the H–O–H bending vibration peaks (Sudheesh et al., 2019). Okyere et al. (2022) reported the ability of a radio frequency plasma to induce cross-linking in non-granular waxy maize and rice as well as granular waxy potato and rice starches as shown by Fourier Transform Infrared-Attenuated total reflectance (FTIR-ATR) analysis. The authors also reported minor changes in waxy starches' unit and internal chain structure after RF plasma modification.

Gel Permeation Chromatography with Multi-Angle Light Scattering Detection (GPC-MALS) analysis showed that the weight-average molecular weight (Mw) reduced from 4.270 × 107 to 4.716 × 106 g/mol in potato starch after oxygen glow plasma modification. The authors observed a slight decrease in the Mw of corn starch, although it was not as pronounced as that observed in potato starch. Thus, plasma resulted in the depolymerization of these starch chains. On the other hand, nitrogen and helium glow plasma induced the polymerization of potato starch (Zhang et al., 2015). In conclusion, plasma can effectively depolymerize starch granules. Also, plasma can induce cross-linking in starches depending on the treatment conditions.

7.1.2. Granule morphology

Okyere and co-authors (2019) observed no effect on the shapes of maize, rice, and potato starch granules after 120 W of treatment in a radio frequency (RF) plasma for 60 min. Similarly, the morphology of potato starch was not changed after nitrogen glow plasma treatment for 30, 45, and 60 min when observed under a normal and polarized light microscope (Zhang et al., 2015). On the other hand, deposits have been reported in starches after plasma treatment. Banura and co-authors (2018) reported the presence of uneven surfaces and deposits on corn starch granules after treatment in a capacitively coupled RF plasma (60 W, 20 min). This agrees with previous reports by Lii et al. (2002). The authors observed deposits on potato and corn starch after exposure to a glow plasma for 30 min. Also, fissures or cavities were observed in rice starch after treatment in a capacitively coupled RF plasma (60 W, 10min) (Thirumdas et al., 2017b). Sudheesh et al. (2019) also observed fissures on kithul starch granules after a low-pressure glow discharge plasma modification. Similarly, fissures were observed in maize starch after hexamethyldisiloxane (HDMSO)-RF plasma treatment (Sifuentes-Nieves et al., 2021).

When the topographic images of starch films were investigated using atomic force microscopy (AFM), an increase was observed in the roughness of these starch films. Andrade et al. (2005) observed an increase in the roughness of corn starch film (plasticized with glycerol and heated for 90 min) subjected to treatment in a capacitively coupled RF plasma. Comparably, de Albuquerque et al. (2014) reported an increase in protrusions (roughness) after treatment of corn starch film in a glow discharge helium RF plasma operated at −100 V for 10 min. Sheikhi and co-authors (2020) also reported an increase in the roughness of wheat starch film after treatment in a glow discharge plasma. The fissures, cavities, deposits, and roughness are caused by the etching mechanism of the reactive species generated during modification of starches with cold plasma (Wrobel et al., 1988; Pankaj et al., 2017; Thirumdas et al., 2017a). The effects of a low-pressure plasma on the morphology of starch depend on the treatment conditions, the plasma type, and the botanical source of starch. Data suggests that treatment with a glow discharge plasma can effectively induce fissures on starches.

7.1.3. Crystallinity

X-ray diffraction (XRD) analysis to date is the only method for assessing long-range crystalline order in starch (Warren et al., 2016). XRD has shown that the double helices in starch crystallize into A, B, or C allomorphs (Buléon et al., 1998). The A-type and B-type crystal pattern is characteristic of cereal and tuber starches, respectively (Imberty and Pérez, 1989; Popov et al., 2009), while the C-type is usually found in legumes (Buléon et al., 1998). Banura and co-authors (2018) reported minor changes in the A-type crystal pattern of corn starch after treatment in an RF plasma (60 W, 20 min). Similarly, Okyere et al. (2019) observed no changes in crystallinity after treatment of waxy maize and rice in an RF plasma unit (120 W, 60 min). On the other hand, the relative crystallinity of potato decreased from 38.48% to 33.79% after a helium glow plasma modification for 60 min (Zhang et al., 2015). A carbon dioxide-argon gas RF plasma also decreased the crystallinity of waxy potato (21.6%–16.1%) after treatment for 60 min (Okyere et al., 2019). Bie et al. (2016a) also saw a decrease in the crystallinity of cassava starch from 45.78% to 42.68% after oxygen glow plasma modification. Plasma has therefore been shown to cause the reorganization of the double helices into a less perfect crystalline structure. This is because the backbone model of starch allows for flexibility in which the longer chain segments can be reorganized (Vamadevan et al., 2013). Furthermore, breaking the hydrogen bonding network in starch during plasma treatment could also be a plausible explanation for the decreases in crystallinity (Bie et al., 2016a). We can deduce that cold plasma can effectively induce changes in the B and C type crystallinity pattern of starches more than the A-type crystalline pattern.

7.1.4. Starch gelatinization

When starch is heated in water, molecular order is disrupted inside the granules. This results in the swelling of granules, loss of birefringence, native crystallite melting, viscosity development, and solubilization (Jane et al., 1999). The occurrence of this phenomenon is termed starch gelatinization. Several authors have utilized the Differential Scanning Calorimeter (DSC) to study the gelatinization behaviors of starch after cold plasma modification. Zhang et al. (2015) observed a decrease in the gelatinization temperatures and enthalpy of gelatinization (ΔH) of potato after nitrogen and helium glow plasma modification. Bie et al. (2016a) also reported a decrease in the ΔH of cassava starch after oxygen and helium glow plasma modification. In addition, the authors suggested oxygen glow plasma as being more effective in altering the thermal properties of cassava starch. Similarly, Thirumdas et al. (2017b) reported a reduction in the thermal properties after modification of rice using an RF plasma (60 W, 10 min). Banura and co-authors (2018) reported a decrease in the enthalpies (ΔH) of corn starch after RF plasma modification.

Interestingly, the enthalpies of tapioca starch increased after RF plasma modification (Banura et al., 2018). Okyere and co-authors (2019) observed a similar increase in ΔH in maize, rice, and potato starches after RF plasma modification. Highly cross-linked starches are characterized by higher gelatinization temperatures and enthalpies due to the stability of starch crystallites (Zou et al., 2004). A degradation in the supramolecular lamellar structure results in a decrease in the gelatinization parameters (Bie et al., 2016a). The ability of cold plasma to induce any changes in the gelatinization properties of starches will essentially be determined by the botanical starch type, gas/gases employed, power, the pressure of the operating system, and the treatment time.

7.1.5. Pasting properties

The pasting properties of starches are influenced by the amylose/amylopectin ratio, the presence of lipids, granule size distribution, and the starch cultivars (Kaur et al., 2007). The Rapid Visco-Analyser (RVA), Brabender Micro-Visco-Amylograph, and rotational viscometers are widely used to study the pasting properties of starches (Wiesenborn et al., 1994). Zhang et al. (2015) investigated the pasting properties of potato starch after nitrogen and helium glow plasma modification. Plasma treatment facilitated the swelling of potato granules at a relatively lower temperature. The etching of surface granules during plasma modification would enhance the penetration of the reactive species generated from plasma into the granules. This would result in a destabilizing effect on the starches, thus, improving swelling and rupture of granules at a lower temperature. Similarly, Thirumdas et al. (2017b) observed a decrease in the pasting temperature of rice after RF plasma modification. Okyere et al. (2019) also reported a reduction in the pasting temperature of waxy potato and rice after RF plasma modification. Peak viscosities reportedly increased in waxy potato (Okyere et al., 2019), rice (Thirumdas et al., 2017b), and kithul starch after plasma treatment (Sudheesh et al., 2019). Contrarily decreases were observed in the peak viscosities of potato (Zhang et al., 2015); waxy maize and rice (Okyere et al., 2019). The degradation of the structural bonds would result in starch leaching out of the granules, causing an increase in peak viscosities (Thirumdas et al., 2017b). The decreases observed in peak viscosities might be because of the formation of starch lipid complexes induced by plasma treatment. These complexes would restrict the granules from bursting and leaching into the aqueous medium (Eliasson and Ljunger, 1988). The formation of starch lipid complexes would be more likely to occur in cereal starches since they have more lipids than tuber starches (Pérez and Bertoft, 2010). Highly cross-linked starches would also decrease peak viscosities (Thirumdas et al., 2017b). The breakdown and final viscosities increased after plasma treatment in rice (Thirumdas et al., 2017b) and kithul starch (Sudheesh et al., 2019), whereas they decreased in potato (Zhang et al., 2015); waxy maize and rice (Okyere et al., 2019). Lower breakdown and final viscosities indicate better stability for these starch pastes and a less tendency for retrogradation to set in (Han and Hamaker, 2001). In summary, cold plasma decreases the temperature at which these starches paste. However, the effects on the peak, trough, breakdown, setback and final viscosities can differ based on the plasma operating conditions.

7.1.6. Rheology

Starch is subjected to varying high temperatures and shear during processing. Hence, it is necessary to measure the rheology to fully understand the deformation and flow behavior of these starches (Lii et al., 2002). Plasma treatment (5 W-60min, 15 W-30min, and 15 W-60min) reduced the ability of kithul starch to form strong gels as indicated by the lower G' (magnitude of storage modulus) and G'' (loss modulus) values (Sudheesh et al., 2019). Similarly, Thirumdas and co-authors (2017b) reported a decrease in G′ and G″ in rice starch after plasma treatment. It can thus be inferred that plasma modification causes molecular degradation, which decreases the onset of retrogradation, resulting in starches that form softer gels.

7.2. Effect of atmospheric pressure plasma on starch properties

7.2.1. Molecular properties

Analysis of the molecular properties of starches after plasma modification can be employed using techniques such as the High-Performance Anion-Exchange Chromatography (HPAEC), GPC-MALS, High-Performance Size-Exclusion Chromatography coupled with Multi-Angle Laser Light Scattering and Differential Refractometry Detection (HPSEC-MALLS-RI), FTIR, NMR, and X-ray Photoelectron Spectroscopy (XPS) (Zhu, 2017). Guo et al. (2022) observed a decrease in intensity of the FTIR band at 2871 cm−1 in potato starch. The authors attributed this decrease to the DBD plasma treatment removing some water molecules from the starch. Yan et al. (2019) investigated the changes in short-range molecular order of microcrystalline potato starch with the FTIR after APPJ treatment. The authors reported a decrease in the ratio of absorbance at 1047/1022 cm−1. A similar decrease was observed in the band ratios of 1047/1022 cm−1 in corn starches by Bie et al. (2016b) and Zhou et al. (2019), and in aria starch by Carvalho et al. (2021). On the other hand, S. Yan et al. (2020) observed an increase in the ratio of absorbance intensity at 1047/1022 cm−1 in banana starch. Sun et al. (2022) also observed an increase in the ratio of absorbance intensity at 1047/1022 cm−1. FTIR bands at 1000, 1022, and 1047 cm−1 are sensitive to changes in starch structure (Wrobel et al., 1988). The bands at 1000 and 1047 cm−1 are much more defined in the crystalline structure of starch while that of 1022 cm−1 is more dominant in the amorphous structure (Warren et al., 2016). Thus, the band ratios at 1022/1000 cm−1 and 1047/1022 cm−1 are generally accepted as measures of short-range molecular order in starch (Bello-Pérez et al., 2005; Warren et al., 2016). A reduction in the short-range order could possibly be due to the depolymerization of the glycosidic bonds in starch (Zhou et al., 2019). On the other hand, the breakdown and release of amylose from the amorphous regions could relatively reduce the amorphous content and subsequently increase the ratio of 1047/1022 cm−1 (S. Yan et al., 2020). In addition, cold plasma treatment could induce the formation of short-range double helices and thus, increase the short-range order of the starch (Sun et al., 2022).

Furthermore, FTIR has also been used as a means of detecting cross-linking in starches. Carvalho et al. (2021) observed an increase in the areas of the C–O–C linkages in aria starch after DBD treatment (10–14 kV). Also, Wongsagonsup et al. (2014) and Deeyai et al. (2013) observed an increase in the relative areas of the C–O–C linkages in starch after plasma treatment. In addition, Wongsagonsup et al. (2014) observed a reduction in relative intensities of the OH- group protons of 50 and 100 W granular and non-granular tapioca starch after plasma treatment. This was due to cross-linking taking place in these starches resulting in the loss of OH groups (Zou et al., 2004). XPS analysis showed an increase in the O C–OH bonds in corn starch and a subsequent decrease in the C(C–H), C–O, and O–C–O bonds due to the oxidation of these bonds by plasma reactive species into carboxyl groups (O C–OH) (Bie et al., 2016b). Also, Bie et al. (2016b) reported an increase in the number average molecular weight of corn starch after plasma treatment as a result of plasma depolymerizing the chains. Sun et al. (2022) observed an increase in the molecular weight of amylose in rice starch after DBD plasma treatment. The authors attributed this increase to the polymerization of amylose chains induced by plasma treatment. Kalaivendan et al. (2022) reported an increase in the viscosity average molecular weight (MWv) of mango starches after plasma treatment (170 V). However, increasing the treatment to 230 V reduced the MWv. The authors stated that the lower treatment voltage induced the intermolecular binding of the partially depolymerized starch molecules in the adjacent chains, thereby increasing the MWv. On the contrary, at higher treatment voltage, depolymerization occurs fully inside the starch molecule and thus decreases the MWv. Carvalho et al. (2021) observed a decrease in the amylose content in aria starch after DBD treatment of up to 14 kV. They attributed this decrease to the depolymerization of aria starch into simple sugars. Interestingly, increasing the voltage to 20 kV led to increases in the amylose content. Thus, the higher treatment voltage induced polymerization of the aria starch chains. Atmospheric pressure plasma systems have been shown to depolymerize or induce cross-linking of starch molecules. This depends on several factors such as the treatment time, applied power, pressure, type of gas and the botanical source of starch.

7.2.2. Granule morphology

Scanning electron micrograph (SEM) images depicted that APPJ plasma treatment resulted in the surface etching of waxy and normal maize starch granules (Zhou et al., 2019). Similar observations were made by Wu et al. (2019) in corn starch after APPJ treatment. Wu et al. (2018) also observed cavities or fissures in banana starch as treatment intensity increased during corona electrical discharge (CED) plasma modification. DBD modification also caused cracks on the surface of banana starch (S. Yan et al., 2020), red adzuki bean starch (Ge et al., 2021a) and potato starch (Guo et al., 2022). Carvalho et al. (2021) observed the formation of fissures and particle aggregation in aria starch granules after DBD (20 kV) plasma treatment. The highly energetic species produced during plasma generation bombards the surface of the starch granule. This induces the volatilization of the starch surface (plasma etching). On the other hand, APPJ treatment at 400, 600, and 800 W did not alter the Maltese cross structure of corn starch when viewed under a polarized light microscope (Wu et al., 2019). Similarly, Guo et al. (2022) observed no changes in the Maltese cross structure of potato starch after DBD treatment. Atmospheric pressure systems can alter the surface morphology of starches without necessarily altering the highly ordered structure of these starches. Pankaj and co-authors, (2017) utilized the AFM to study the surface topography of high voltage atmospheric cold plasma (HVAC) modified films. They observed an increase in surface roughness of these modified films due to plasma etching. The authors reported that rice starch film was more susceptible to surface etching.

7.2.3. Crystallinity

The relative crystallinity (RC) of waxy (46.7%–42.0%) and normal (40.1%–35.7%) maize starch decreased after APPJ plasma treatment (Zhou et al., 2019). Similarly, the RC of potato starch decreased without a change in the crystalline structure after APPJ treatment (Yan et al., 2019). On the other hand, DBD plasma treatment altered the crystalline structure of banana starch from C-type to A-type as treatment time increased. The authors also observed a decrease in RC from 21.82% to 17.15% (S. Yan et al., 2020). Guo et al. (2022) observed a decrease in RC of potato starch after DBD plasma treatment without any changes to the B-type crystalline structure. Similarly, Sun et al. (2022) observed a decrease in the RC of rice starch after DBD plasma treatment without any changes to the A-type crystalline structure. The authors attributed this decrease to a disruption in the reorganization of the starch molecules, which could potentially reduce the perfection of the long-range crystalline structure. Depolymerization of starch chains induced by plasma treatment would also decrease the relative crystallinity, altering the crystalline structure of starch (Wongsagonsup et al., 2014).

Interestingly, Wu et al. (2018) observed an increase in the RC of banana starch after corona electrical discharge plasma treatment. The authors reported that the reactive species in plasma can induce the de-hydroxylation of the amorphous regions in starch through ether bond formation or condensation reactions. This would then cause the starch molecules to rearrange into a more perfect crystalline structure. Like low-pressure systems, atmospheric plasma can induce changes in the crystallinity of B and C-type starch more than A-type starches.

7.2.4. Starch gelatinization

Wongsagonsup et al. (2014) observed an increase in H of 50 and 100 W plasma modified granular tapioca starch. However, the gelatinization temperatures did not differ significantly from the untreated samples. Gao et al. (2019) observed an increase in the H of tartary buckwheat starch as well as an increase in the gelatinization temperatures of tartary buckwheat starch, sorghum, and wheat starch. The higher H and temperatures of gelatinization suggest the presence of longer double helices formed by untwisted ends of the external chains in amylopectin (Vamadevan et al., 2013). Highly cross-linked starches are more resistant to heat and shear damage during thermal treatment (Zou et al., 2004). Contrarily, Wu et al. (2018) reported a decrease in H of banana starch and an increase in the gelatinization temperatures after CED plasma modification. Carvalho et al. (2021) also observed a decrease in gelatinization temperature in aria starch after DBD (14 kV) treatment. Zhou et al. (2019) also observed a decrease in the H of waxy and normal maize starches. Similarly, Guo et al. (2022) observed a decrease in the H of potato after DBD plasma treatment. Depolymerization of starch chains induced by plasma treatment could lead to a reduction in gelatinization temperatures and enthalpies. Regarding starch films, HVAC plasma modified starch films had higher glass transition temperatures than the control films suggesting some degree of cross-linking taking place (Pankaj et al., 2017). Differences observed in the enthalpies and gelatinization temperatures are all based on the type of plasma setups used, the time, gas/gases, power, and pressure employed for starch modification.

7.2.5. Pasting properties

The peak viscosity of banana starch decreased from 5242 to 153 cP with an increase in DBD plasma treatment intensity. There was also a decrease in final viscosity, trough viscosity, breakdown, and setback values (S. Yan et al., 2020). Cross-links, van der Waals forces, and hydrogen bonds between the starch chains were damaged making it less viscous. Wu et al. (2019) also reported a decrease in final viscosity, trough viscosity, and peak viscosity of corn starch after treating with an atmospheric pressure jet plasma. At a higher intensity of 800 W, the viscosity significantly reduced to 410 cP, however, there was no change in the pasting temperature of the starch. The trough apparent, high pasting peak, final apparent, and setback viscosities increased after DBD treatment in aria starch when the volage was increased (Carvalho et al., 2021). However, a decrease was observed in the breakdown viscosity, suggesting that DBD treatment enhanced the stability of aria starch to heat and shear. Kalaivendan et al. (2022) observed decreases in mango starch's peak, breakdown, setback, and final viscosity after plasma treatment. The authors attributed the reduction in peak viscosity to the depolymerization of the starch chains. The decrease in breakdown, setback, and final viscosity of mango starch suggests a stabilizing effect of plasma treatment. The pasting properties of starch depend on the variety, plasma types, plasma treatment conditions, and reaction time.

7.2.6. Rheology

Modification of starches using atmospheric pressure plasma systems may form stronger or weak gels depending on the treatment conditions. Guo et al. (2022) observed a decrease in the retrogradation tendency of potato starch gels after DBD plasma treatment. Also, the authors reported a significant increase in the G′ and G′′. They attributed this increase to the formation of cross-linking in starch molecules induced by plasma treatment. Also, Wongsagonsup et al. (2014) utilized APPJ with argon as an alternative for chemical modifications of starch. The authors reported that subjecting granular tapioca starch to 50 W plasma treatment led to the formation of stronger gels. This could be attributed to the cross-linking of starch chains. However, increasing the treatment intensity to 100 W weakened the gel structure due to depolymerization. In addition, Bie et al. (2016b) observed a reduction in the viscosity of corn starch after plasma treatment. The active species in plasma induced the cross-linking of side chains which prevents starch granules from leaching into the solution (Zou et al., 2004).

7.3. Effect of plasma-activated water on starch properties

The use of PAW in modifying starches is relatively new; as such, to the best of our knowledge, there is limited information on the effect of PAW on starch properties. The relative crystallinity (RC) of waxy and normal maize starches increased after PAW treatment (Y. Yan et al., 2020). The authors suggested that hydrolysis of the amorphous regions in these starches could have led to the increase observed. Y. Yan and co-authors (2020) observed an increase in ΔH of normal maize starch after PAW modification combined with heat moisture treatment (HMT). The increase in ΔH suggests that PAW modification might have induced the formation of heterogenous crystallites (Alimi and Workneh, 2018). Thus, more energy was required to gelatinize the starches. Waxy and normal maize starches modified with PAW combined with HMT were more resistant to digestion compared to their native counterparts. Thus, PAW combined with HMT induced the formation of cross-links between the side chains of these starches, making it more difficult for the α-amylases to digest these starches (Yan et al., 2020). PAW has potential regarding starch modification. However, more research is needed to adopt this starch modification method fully.

8. Industrial scale-up of cold plasma technology for starch modification

Low and atmospheric plasma systems have proven to be effective tools in modifying starch properties. Their ability to modify starches depends on the plasma treatment conditions (power, time, gas/gases, pressure, moisture, humidity) and the botanical origin of starch. Pressure ranges of 1 to >2000Pa have been shown to effectively induce changes in the structure and functionality of starches. Treatment times ranging from 2 to 60 min can induce functional and chemical changes. Noble gases like argon and helium ionize more readily than oxygen, carbon dioxide, and air. Hence, they require much lower energy input (Thirumdas et al., 2017a; Zhu, 2017). However, there is a tradeoff due to their inability to generate reactive oxygen and nitrogen species. Thus, combining a noble gas and carbon dioxide might result in a highly functional modified starch with lower energy expenditure. In addition, combining cold plasma modification with other physical methods of starch modification (Sun et al., 2022) or enzymatic methods of starch modification (Ge et al., 2021b) could also effectively alter the starch properties. Approval of cold plasma starches to achieve GRAS status by the FDA would require enough scientific literature on its safety, and a consensus among scientific experts that the information provided in literature holds enough credibility to deem it safe. Hence more studies must be launched into the safety of plasma modified starches. Two of such studies available are shown below; An in vitro study on the effects of atmospheric cold plasma modified wheat grains on beetles (Tribolium castaneum) showed that plasma modified wheat did not negatively affect the survival or weight of these insects (Los et al., 2020). In the second study, rats fed with 5000 mg/kg or 1000 mg/kg/day of cold plasma modified edible films for 14 days did not show any signs of acute toxicity or even death (Han et al., 2016). In addition, cold plasma modified starches are resistant to digestion due to the formation of cross-links between starch molecules (Zou et al., 2004; Trinh, 2018). These cross-linked starches are stable and resistant to α-amylase digestion in the small intestine (Yeh and Yeh, 1993). Also, cold plasma modified starches can potentially be labeled without the modified starch label once enough data is obtained on its toxicity and safety. As such, the starch industry must explore the utilization of cold plasma for starch modification based on sufficient literature. A major limitation to the industrial scale-up of this technology could be the construction and design of expensive vacuum equipment. However, this can be combatted by using atmospheric cold plasma systems, that do not require a vacuum unit. In addition, there are different modes of treatment being employed by several authors for starch modification. Comparative studies optimizing the best treatment conditions for the various botanical starches would ideally hasten the industrial scale-up of this green technology. Cold plasma is successfully being employed in the medical industry (wound healing, cancer treatment), textile (finishing, printing), electronics and semiconductor industry (coating and etching) and can thus be implemented in the food industry.

9. Conclusion

Starch modification using cold plasma technology, which includes plasma-activated water, has proven to be an emerging alternative for chemical modifications. The atmospheric plasma systems have the flexibility of being used for continuous operations and production of PAW. In comparison, the low-pressure systems ensure an even distribution of plasma during modification since it is operated inside a closed vessel. Both low and atmospheric pressure plasma systems produce cross-linked starches that are more resistant to digestion. In addition, starches modified with cold plasma have good water absorption capacity and are more stable during thermal processing. The modifications in the starch properties depend on the type of gas used for plasma generation, plasma operating conditions (including power, time, pressure), and the source from which starch is obtained. We can conclude that cold plasma could be perfected and scaled up for commercial applications of starch modifications. Atmospheric pressure plasma systems might be more cost-effective for scaling up since they don't require an expensive vacuum system and offer the flexibility for continuous operations.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Conflict of interest

The authors declare no conflict of interest.

CRediT authorship contribution statement

Akua Y. Okyere: Conceptualization, Writing – original draft, Writing – review & editing, Visualization. Sasireka Rajendran: Conceptualization, Writing – original draft, Writing – review & editing, Visualization. George A. Annor: Conceptualization, Funding acquisition, Supervision, Writing – review & editing.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Contributor Information

Akua Y. Okyere, Email: okyer011@umn.edu.

Sasireka Rajendran, Email: sasi.reka@hotmail.com.

George A. Annor, Email: gannor@umn.edu.

References

- Abidin N., Rukunudin I., Zaaba S. Atmospheric pressure cold plasma (ACP) treatment a new technique to improve microstructure and textural properties of healthy noodles fortified with mango flour. J. Telecommun. Electron. Comput. Eng. 2018;10 [Google Scholar]

- Abou-Ghazala A., Katsuki S., Schoenbach K.H., Dobbs F.C., Moreira K.R. Bacterial decontamination of water by means of pulsed-corona discharges. IEEE Trans. Plasma Sci. 2002;30:1449–1453. doi: 10.1109/TPS.2002.804193. [DOI] [Google Scholar]

- Abuzairi T., Ramadhanty S., Puspohadiningrum D.F., Ratnasari A., Poespawati N.R., Purnamaningsih R.W. Presented at the 2nd Biomedical Engineering's Recent Progress in Biomaterials, Drugs Development, and Medical Devices: Proceedings of the International Symposium of Biomedical Engineering (ISBE) 2017. 2018. Investigation on physicochemical properties of plasma-activated water for the application of medical device sterilization; p. 40017. Bali, Indonesia. [DOI] [Google Scholar]

- Adhikari B., Adhikari M., Ghimire B., Park G., Choi E.H. Cold atmospheric plasma-activated water irrigation induces defense hormone and gene expression in tomato seedlings. Sci. Rep. 2019;9:16080. doi: 10.1038/s41598-019-52646-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aditya S., Gnanasekaran S., Stephen J., Radhakrishnan M. Enhancing the properties of eggshell powder by cold plasma for improved calcium fortification in black coffee. J. Food Process. Eng. 2020;43 doi: 10.1111/jfpe.13450. [DOI] [Google Scholar]

- Akasapu K., Ojah N., Gupta A.K., Choudhury A.J., Mishra P. An innovative approach for iron fortification of rice using cold plasma. Food Res. Int. 2020;136:109599. doi: 10.1016/j.foodres.2020.109599. [DOI] [PubMed] [Google Scholar]

- Alimi B.A., Workneh T.S. Structural and physicochemical properties of heat moisture treated and citric acid modified acha and iburu starches. Food Hydrocolloids. 2018;81:449–455. doi: 10.1016/j.foodhyd.2018.03.027. [DOI] [Google Scholar]

- Amini M., Ghoranneviss M. Effects of cold plasma treatment on antioxidants activity, phenolic contents and shelf life of fresh and dried walnut (Juglans regia L.) cultivars during storage. Lebensm. Wiss. Technol. 2016;73:178–184. doi: 10.1016/j.lwt.2016.06.014. [DOI] [Google Scholar]

- Andrade C.T., Simão R.A., Thiré R.M.S.M., Achete C.A. Surface modification of maize starch films by low-pressure glow 1-butene plasma. Carbohydr. Polym. 2005;61:407–413. doi: 10.1016/j.carbpol.2005.05.001. [DOI] [Google Scholar]

- I Y.-P., Liu Y.-C., Han K.-Y., She T.-C. Construction of a low-pressure microwave plasma reactor and its application in the treatment of volatile organic compounds. Environ. Sci. Technol. 2004;38:3785–3791. doi: 10.1021/es034697a. [DOI] [PubMed] [Google Scholar]

- Bailey J.M., Whelan W.J. Physical properties of starch. J. Biol. Chem. 1961;236:969–973. doi: 10.1016/S0021-9258(18)64226-7. [DOI] [PubMed] [Google Scholar]

- Banura S., Thirumdas R., Kaur A., Deshmukh R.R., Annapure U.S. Modification of starch using low pressure radio frequency air plasma. Lebensm. Wiss. Technol. 2018;89:719–724. doi: 10.1016/j.lwt.2017.11.056. [DOI] [Google Scholar]

- Bello-Pérez L.A., Ottenhof M.-A., Agama-Acevedo E., Farhat I.A. Effect of storage time on the retrogradation of banana starch extrudate. J. Agric. Food Chem. 2005;53:1081–1086. doi: 10.1021/jf048858l. [DOI] [PubMed] [Google Scholar]

- Bemiller J.N. Starch modification: challenges and prospects. Starch - Stärke. 1997;49(4):127–131. doi: 10.1002/star.19970490402. [DOI] [Google Scholar]

- Bie P., Li X., Xie F., Chen L., Zhang B., Li L. Supramolecular structure and thermal behavior of cassava starch treated by oxygen and helium glow-plasmas. Innovat. Food Sci. Emerg. Technol. 2016;34:336–343. doi: 10.1016/j.ifset.2016.03.005. [DOI] [Google Scholar]

- Bie P., Pu H., Zhang B., Su J., Chen L., Li X. Structural characteristics and rheological properties of plasma-treated starch 10. Innovat. Food Sci. Emerg. Technol. 2016;34:196–204. doi: 10.1016/j.ifset.2016.03.005. [DOI] [Google Scholar]

- Brandenburg R. Corrigendum: dielectric barrier discharges: progress on plasma sources and on the understanding of regimes and single filaments (2017 Plasma Sources Sci. Technol. 26 053001. Plasma Sources Sci. Technol. 2018;27 doi: 10.1088/1361-6595/aaced9. [DOI] [Google Scholar]

- Bu F., Nayak G., Bruggeman P., Annor G., Ismail B.P. Impact of plasma reactive species on the structure and functionality of pea protein isolate. Food Chem. 2022;371:131135. doi: 10.1016/j.foodchem.2021.131135. [DOI] [PubMed] [Google Scholar]

- Buléon A., Gérard C., Riekel C., Vuong R., Chanzy H. Details of the crystalline ultrastructure of C-starch granules revealed by synchrotron microfocus mapping. Macromolecules. 1998;31:6605–6610. [Google Scholar]

- Bursać Kovačević D., Gajdoš Kljusurić J., Putnik P., Vukušić T., Herceg Z., Dragović-Uzelac V. Stability of polyphenols in chokeberry juice treated with gas phase plasma. Food Chem. 2016;212:323–331. doi: 10.1016/j.foodchem.2016.05.192. [DOI] [PubMed] [Google Scholar]

- Bursać Kovačević D., Putnik P., Dragović-Uzelac V., Pedisić S., Režek Jambrak A., Herceg Z. Effects of cold atmospheric gas phase plasma on anthocyanins and color in pomegranate juice. Food Chem. 2016;190:317–323. doi: 10.1016/j.foodchem.2015.05.099. [DOI] [PubMed] [Google Scholar]

- Carvalho A.P.M.G., Barros D.R., da Silva L.S., Sanches E.A., Pinto C.da, de Souza S.M., Clerici M.T., Rodrigues S., Fernandes F.A.N., Campelo P.H. Dielectric barrier atmospheric cold plasma applied to the modification of Ariá (Goeppertia allouia) starch: effect of plasma generation voltage. Int. J. Biol. Macromol. 2021;182:1618–1627. doi: 10.1016/j.ijbiomac.2021.05.165. [DOI] [PubMed] [Google Scholar]

- Chaiwat W., Wongsagonsup R., Tangpanichyanon N., Jariyaporn T., Deeyai P., Suphantharika M., Fuongfuchat A., Nisoa M., Dangtip S. Argon plasma treatment of tapioca starch using a semi-continuous downer reactor. Food Bioprocess Technol. 2016;9:1125–1134. doi: 10.1007/s11947-016-1701-6. [DOI] [Google Scholar]

- Charoux Clémentine M.G., Free L., Hinds L.M., Vijayaraghavan R.K., Daniels S., O'Donnell C.P., Tiwari B.K. Effect of non-thermal plasma technology on microbial inactivation and total phenolic content of a model liquid food system and black pepper grains. Lebensm. Wiss. Technol. 2020;118:108716. doi: 10.1016/j.lwt.2019.108716. [DOI] [Google Scholar]

- Chizoba Ekezie F.-G., Sun D.-W., Cheng J.-H. A review on recent advances in cold plasma technology for the food industry: current applications and future trends. Trends Food Sci. Technol. 2017;69:46–58. doi: 10.1016/j.tifs.2017.08.007. [DOI] [Google Scholar]

- Crookes W. UK on Friday; Sheffield: 1879. On Radiant Matter. A Lecture to the British Association for the Advancement of Science. 22nd August 1879. [Google Scholar]

- Crookes W. James W. Queen & Co; Philadelphia, PA: 1881. Radiant Matter: a Resume of the Principal Lectures and Papers of Prof. William Crookes, on the 'fourth State of Matter'. [Google Scholar]

- Dai Y., van Spronsen J., Witkamp G.J., Verpoorte R., Choi Y.H. Natural deep eutectic solvents as new potential media for green technology. Anal. Chim. 2013 doi: 10.1016/j.aca.2012.12.019. [DOI] [PubMed] [Google Scholar]

- Dasan B.G., Boyaci I.H., Mutlu M. Nonthermal plasma treatment of Aspergillus spp. spores on hazelnuts in an atmospheric pressure fluidized bed plasma system: impact of process parameters and surveillance of the residual viability of spores. J. Food Eng. 2017;196:139–149. doi: 10.1016/j.jfoodeng.2016.09.028. [DOI] [Google Scholar]

- de Albuquerque M.D.F., Bastos D.C., Simão R.A. Surface modification of starch films by plasma. Macromol. Symp. 2014;343:96–101. doi: 10.1002/masy.201300199. [DOI] [Google Scholar]

- Deeyai P., Suphantharika M., Wongsagonsup R., Dangtip S. Characterization of modified tapioca starch in atmospheric argon plasma under diverse humidity by FTIR spectroscopy. Chin. Phys. Lett. 2013;30 doi: 10.1088/0256-307x/30/1/018103. [DOI] [Google Scholar]

- Ebnesajjad S. Surface Treatment of Materials for Adhesive Bonding. Elsevier; 2014. Plasma treatment of polymeric materials; pp. 227–269. [DOI] [Google Scholar]

- Elez Garofulić I., Režek Jambrak A., Milošević S., Dragović-Uzelac V., Zorić Z., Herceg Z. The effect of gas phase plasma treatment on the anthocyanin and phenolic acid content of sour cherry Marasca (Prunus cerasus var. Marasca) juice. Healthy Snacks Recent Trends Innov. Dev. Meet Curr. Needs. 2015;62:894–900. doi: 10.1016/j.lwt.2014.08.036. [DOI] [Google Scholar]

- Eliasson A.-C., Ljunger G. Interactions between amylopectin and lipid additives during retrogradation in a model system. J. Sci. Food Agric. 1988:4353–4361. [Google Scholar]

- Fan Y., Picchioni F. Modification of starch: a review on the application of “green” solvents and controlled functionalization. Carbohydr. Polym. 2020;241:116350. doi: 10.1016/j.carbpol.2020.116350. [DOI] [PubMed] [Google Scholar]

- Gao S., Liu H., Sun L., Liu N., Wang J., Huang Y., Wang F., Cao J., Fan R., Zhang X., Wang M. The effects of dielectric barrier discharge plasma on physicochemical and digestion properties of starch. Int. J. Biol. Macromol. 2019;138:819–830. doi: 10.1016/j.ijbiomac.2019.07.147. [DOI] [PubMed] [Google Scholar]

- Ge X., Shen H., Su C., Zhang B., Zhang Q., Jiang H., Li W. The improving effects of cold plasma on multi-scale structure, physicochemical and digestive properties of dry heated red adzuki bean starch. Food Chem. 2021;349:129159. doi: 10.1016/j.foodchem.2021.129159. [DOI] [PubMed] [Google Scholar]

- Ge X., Shen H., Su C., Zhang B., Zhang Q., Jiang H., Yuan L., Yu X., Li W. Pullulanase modification of granular sweet potato starch: assistant effect of dielectric barrier discharge plasma on multi-scale structure, physicochemical properties. Carbohydr. Polym. 2021;272:118481. doi: 10.1016/j.carbpol.2021.118481. [DOI] [PubMed] [Google Scholar]

- Glittenberg D. Polymer Science: A Comprehensive Reference. Elsevier; 2012. Starch-based biopolymers in paper, corrugating, and other industrial applications; pp. 165–193. [DOI] [Google Scholar]

- Go S.-M., Park M.-R., Kim H.-S., Choi W.S., Jeong R.-D. Antifungal effect of non-thermal atmospheric plasma and its application for control of postharvest Fusarium oxysporum decay of paprika. Food Control. 2019;98:245–252. doi: 10.1016/j.foodcont.2018.11.028. [DOI] [Google Scholar]

- Grzegorzewski F., Ehlbeck J., Schlüter O., Kroh L.W., Rohn S. Treating lamb's lettuce with a cold plasma – influence of atmospheric pressure Ar plasma immanent species on the phenolic profile of Valerianella locusta. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2011;44:2285–2289. doi: 10.1016/j.lwt.2011.05.004. [DOI] [Google Scholar]

- Guo Z., Gou Q., Yang L., Yu Q., Han L. Dielectric barrier discharge plasma: a green method to change structure of potato starch and improve physicochemical properties of potato starch films. Food Chem. 2022;370:130992. doi: 10.1016/j.foodchem.2021.130992. [DOI] [PubMed] [Google Scholar]

- Han X.-Z., Hamaker B.R. Amylopectin fine structure and rice starch paste breakdown. J. Cereal. Sci. 2001;34:279–284. doi: 10.1006/jcrs.2001.0374. [DOI] [Google Scholar]

- Han S.H., Suh H.J., Hong K.B., Kim S.Y., Min S.C.… Oral toxicity of cold plasma-treated edible films for food coating: cold plasma-treated edible film toxicity. J. Food Sci. 2016;81:T3052–T3057. doi: 10.1111/1750-3841.13551. [DOI] [PubMed] [Google Scholar]

- Herceg Z., Kovačević D.B., Kljusurić J.G., Jambrak A.R., Zorić Z., Dragović-Uzelac V. Gas phase plasma impact on phenolic compounds in pomegranate juice. Food Chem. 2016;190:665–672. doi: 10.1016/j.foodchem.2015.05.135. [DOI] [PubMed] [Google Scholar]

- Hizukuri S., Takeda Y., Yasuda M., Suzuki A. Multi-branched nature of amylose and the action of debranching enzymes. Carbohydr. Res. 1981;94:205–213. doi: 10.1016/S0008-6215(00)80718-1. [DOI] [Google Scholar]

- Hizukuri S., Kaneko T., Takeda Y. Measurement of the chain length of amylopectin and its relevance to the origin of crystalline polymorphism of starch granules. Biochim. Biophys. Acta BBA - Gen. Subj. 1983;760:188–191. doi: 10.1016/0304-4165(83)90142-3. [DOI] [Google Scholar]

- Hong Y., Liu X. In: Physical Modifications of Starch. Sui Z., Kong X., editors. Springer; Singapore: 2018. Pre-gelatinized modification of starch. [Google Scholar]

- Imberty A., Pérez S. Conformational analysis and molecular modelling of the branching point of amylopectin. Int. J. Biol. Macromol. 1989;11:177–185. doi: 10.1016/0141-8130(89)90065-2. [DOI] [PubMed] [Google Scholar]

- Iqdiam B.M., Abuagela M.O., Boz Z., Marshall S.M., Goodrich-Schneider R., Sims C.A., Marshall M.R., MacIntosh A.J., Welt B.A. Effects of atmospheric pressure plasma jet treatment on aflatoxin level, physiochemical quality, and sensory attributes of peanuts. J. Food Process. Preserv. 2020;44 doi: 10.1111/jfpp.14305. [DOI] [Google Scholar]

- Jane J., Chen Y.Y., Lee L.F., McPherson A.E., Wong K.S., Radosavljevic M., Kasemsuwan T. Effects of amylopectin branch chain length and amylose content on the gelatinization and pasting properties of starch. Cereal Chem. J. 1999;76:629–637. doi: 10.1094/CCHEM.1999.76.5.629. [DOI] [Google Scholar]

- Judée F., Simon S., Bailly C., Dufour T. Plasma-activation of tap water using DBD for agronomy applications: identification and quantification of long lifetime chemical species and production/consumption mechanisms. Water Res. 2018;133:47–59. doi: 10.1016/j.watres.2017.12.035. [DOI] [PubMed] [Google Scholar]

- Kalaivendan R.G.T., Mishra A., Eazhumalai G., Annapure U.S. Effect of atmospheric pressure non-thermal pin to plate plasma on the functional, rheological, thermal, and morphological properties of mango seed kernel starch. Int. J. Biol. Macromol. 2022;196:63–71. doi: 10.1016/j.ijbiomac.2021.12.013. [DOI] [PubMed] [Google Scholar]

- Kaur A., Singh N., Ezekiel R., Guraya H.S. Physicochemical, thermal and pasting properties of starches separated from different potato cultivars grown at different locations. Food Chem. 2007;101:643–651. doi: 10.1016/j.foodchem.2006.01.054. [DOI] [Google Scholar]

- Kim S.J., Chung T.H., Bae S.H., Leem S.H. Characterization of atmospheric pressure microplasma jet source and its application to bacterial inactivation. Plasma Process. Polym. 2009;6:676–685. [Google Scholar]

- Korachi M., Gurol C., Aslan N. Atmospheric plasma discharge sterilization effects on whole cell fatty acid profiles of Escherichia coli and Staphylococcus aureus. J. Electrost. 2010;68:508–512. doi: 10.1016/j.elstat.2010.06.014. [DOI] [Google Scholar]

- Laovachirasuwan P., Peerapattana J., Srijesdaruk V., Chitropas P., Otsuka M. The physicochemical properties of a spray dried glutinous rice starch biopolymer. Colloids Surf. B Biointerfaces. 2010;78:30–35. doi: 10.1016/j.colsurfb.2010.02.004. [DOI] [PubMed] [Google Scholar]

- Laroque D.A., Seó S.T., Valencia G.A., Laurindo J.B., Carciofi B.A.M. Cold plasma in food processing: design, mechanisms, and application. J. Food Eng. 2022;312:110748. doi: 10.1016/j.jfoodeng.2021.110748. [DOI] [Google Scholar]

- Lee H.-C. Review of inductively coupled plasmas: nano-applications and bistable hysteresis physics. Appl. Phys. Rev. 2018;5 doi: 10.1063/1.5012001. [DOI] [Google Scholar]

- Liao X., Cullen P.J., Muhammad A.I., Jiang Z., Ye X., Liu D., Ding T. Cold plasma–based hurdle interventions: new strategies for improving food safety. Food Eng. Rev. 2020;12:321–332. doi: 10.1007/s12393-020-09222-3. [DOI] [Google Scholar]

- Lii C., Liao C., Stobinski L., Tomasik P. Exposure of granular starches to low-pressure glow ethylene plasma. Eur. Polym. J. 2002;38:1601–1606. doi: 10.1016/S0014-3057(02)00022-8. [DOI] [Google Scholar]

- Lin C.-M., Hsiao C.-P., Lin H.-S., Liou J.S., Hsieh C.-W., Wu J.-S., Hou C.Y. The antibacterial efficacy and mechanism of plasma-activated water against Salmonella enteritidis (ATCC 13076) on shell eggs. Foods. 2020;9:1491. doi: 10.3390/foods9101491. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lippens P. In: Plasma Technologies for Textiles. Europlasma N.V., Belgium Shishoo R., editors. Woodhead publishing series in textiles; 2007. Low-pressure cold plasma processing technology. [Google Scholar]