Abstract

The ongoing COVID-19 pandemic has resulted in an unprecedented form of plastic pollution: personal protective equipment (PPE). Numerous studies have reported the occurrence of PPE in the marine environment. However, their degradation in the environment and consequences are poorly understood. Studies have reported that face masks, the most abundant type of PPE, are significant sources of microplastics due to their fibrous microstructure. The fibrous material (mostly consisting of polypropylene) exhibits physical changes in the environment, leading to its fracture and detachment of microfibers. Most studies have evaluated PPE degradation under controlled laboratory conditions. However, in situ degradation experiments, including the colonization of PPE, are largely lacking. Although ecotoxicological studies are largely lacking, the first attempts to understand the impact of MPs released from face masks showed various types of impacts, such as fertility and reproduction deficiencies in both aquatic and terrestrial organisms.

Keywords: Microplastic, Mask, Protective equipment, Pollution, Characterization techniques

Graphical abstract

1. Introduction

Since it entered the market in the 50's, plastic has brought many economic and social benefits. However, the excessive use of disposable products has caused an exponential increase in the amount of plastic waste globally (Benson et al., 2021a; Torres and De-la-Torre, 2021a). Therefore, plastics are gradually becoming a global environmental threat. Plastics are one of the most used materials due to their excellent versatility, malleability, and ability to provide solutions to a wide variety of needs in today's society. In 2019, plastic production reached 368 million tons, the most common being polypropylene (PP), followed by polyethylene (PE) in all its versions (PlasticsEurope, 2020). Plastic waste in the environment can be transported by rivers, storms, strong winds, or dumped directly into terrestrial or aquatic ecosystems. The interactions of these residues with environmental conditions could lead to their physical damage (e.g., fragmentation) and changes in their physicochemical properties (e.g., crystallinity, glass transition temperature (Tg)) due to mechanical abrasion, photolytic, chemistry, or biological degradation (Ganesh Kumar et al., 2020), giving rise to new types of micropollutants, such as microplastics (MPs) (plastics smaller than 5 mm) and nanoplastics (PNPs) (plastics smaller than <1 μm) (Akhbarizadeh et al., 2021a, Akhbarizadeh et al., 2020; Takdastan et al., 2021). MPs are cataloged as primary or secondary. Primary MPs/PNPs are manufactured in micro/nano-size, while secondary ones are derived from the degradation of larger plastics (Cole et al., 2011). They are ubiquitous in all environments of the world (Gela and Aragaw, 2022), causing great concern for the environment (Hajiouni et al., 2022; Wang et al., 2019) and human health due to their small size, large specific surface area, and strong biological penetration (Xu et al., 2019). Research has shown that MPs/PNPs are capable of adsorbing and transporting external contaminants, such as heavy metals, polycyclic aromatic hydrocarbons (PAHs), pesticides, among others (Rahman et al., 2021). The type of polymer, size, and environmental conditions affect the absorption of these pollutants (Torres et al., 2021). In addition, based on the morphology, size, and concentration, MPs can cause ecotoxicological consequences to multiple organisms (Aragaw and Mekonnen, 2021a; Rochman et al., 2019). For instance, ingestion of MPs around 70 μm in size and various polymer types can cause intestinal damage to Danio rerio after 10 days of exposure (Lei et al., 2018). In the oyster Crassostrea gigas, small polystyrene MPs (2–6 μm) decreased the oocyte number and sperm velocity in exposed individuals, possibly altering their fecundity (Sussarellu et al., 2016).

The ongoing COVID-19 pandemic has led to the excessive use of personal protective equipment (PPE), such as face masks, gloves, face shields, among others, in order to prevent the transmission of the virus (Ardusso et al., 2021; Benson et al., 2021a). The most widely used type of PPE is the disposable surgical face masks due to their low cost and effectiveness. In most countries, the use of face masks in public places is mandatory (De-la-Torre et al., 2021a). In the United States, KN95 mask production increased from 45 million to 180 million per month in 2020 (Statista, 2021), adding to global plastic production. Due to inadequate management and disposal, PPE items have already become a new threat to the environment. This new waste category has been evidenced on beaches (De-la-Torre et al., 2021b; Rakib et al., 2021; Ardusso et al., 2021), rivers (Cordova et al., 2021), and urbanized areas (Ammendolia et al., 2021; Torres and De-la-Torre, 2021b).

Face masks and gloves are the most commonly used PPE since the pandemic began. In particular, surgical face masks are manufactured using non-woven fabric forming technology for disposal after use (Aragaw, 2020). The micro- and nanofiber mat is produced through electrospinning, but the specific composition, components, and manufacturing conditions vary from brand to brand (De-la-Torre and Aragaw, 2021; Fadare and Okoffo, 2020). The most used material for its production is polypropylene (PP), but polyurethane (PU), polyacrylonitrile (PAN), polystyrene (PS), polycarbonate (PC), polyethylene (PE), and polyethylene terephthalate (PET) are also used (Chellamani et al., 2013). These fabrics, in contact with ultraviolet light and sand, facilitate the release of micro/nanoparticles (De-la-Torre and Aragaw, 2021; Fadare and Okoffo, 2020; Kutralam-Muniasamy et al., 2022) It is estimated that a mask under ambient conditions of a coastal ecosystem can release around 173,000 microfibers per day (Saliu et al., 2021). Likewise, Sullivan et al. (2021) reported that masks exposed to water released some heavy metals such as lead, cadmium, and antimony. On the other hand, the gloves are manufactured with latex or natural rubber, nitrile, foil, vinyl, neoprene, etc. (Preece et al., 2020). In addition, to improve the physical, mechanical, and chemical properties of this PPE type, substances (e.g., plasticizers, stabilizers) are commonly added during their manufacture which may be easily released from gloves throughout aging and may contaminate the aquatic environment (Jędruchniewicz et al., 2021). Given recent reports and investigations about the prevalence of PPE items polluting the marine environment as an unprecedented form of plastic pollution, and the recognition of face masks as important sources of MPs/PNPs in the marine environment, it is imperative to evaluate the effect of weathering conditions and aging on the structural, physical, and chemical properties of PPE items, as well as their consequences. Thus, the present paper integrates and reviews the current knowledge regarding PPE pollution, degradation of PPE items, and their subproducts, such as MPs/PNPs and chemical compounds.

2. PPE pollution, sampling methods, and main challenges

Environmental pollution with PPE has been expected due to their excessive use and weakening of solid waste management systems. It was estimated that ~3.5 million metric tons (MT) of face masks ended up in landfills worldwide in the first year of the pandemic (Patrício Silva et al., 2021a). Nevertheless, a significant amount may leak into the oceans and natural environments, which is estimated between 0.15 and 0.39 million MT per year (Chowdhury et al., 2021). The first observations of PPE pollution were presented to the public by news outlets, shared on social media, or displayed by NGOs, such as OceansAsia (Stokes, 2020). However, recent scientific publications provided further detail and analysis of the abundance, distribution, sources, and evolution of PPE pollution in aquatic environments (Table 1 ). On the other hand, other researchers have begun to use mathematical models to quantify the impact of the pandemic on plastic discharge. In this way, Peng et al. (2021) estimated that more than eight million tons of PPE were generated worldwide during the pandemic, and about 25,000 tons of PPE waste entered the ocean.

Table 1.

Summary of the studies quantifying PPE in coastal sites.

| Country | City | Sampling type | Total area covered per sampling campaign (m2) | Number of sampling campaigns | Total PPE | Mean PPE density (PPE m−2) | Most abundant PPE | Ref. |

|---|---|---|---|---|---|---|---|---|

| Argentina | – | Transectsa | 474,719 | 1 | 43 | 7.21 × 10−4 | Face masks (48.8%) Gloves (48.8%) |

(De-la-Torre et al., 2022) |

| Perú | – | Transectsa | 1,179,727 | 1 | 489 | 6.60 × 10−4 | Face masks (94.5%) | |

| Perú | Lima | Transectsa | 110,757 | 12 | 138 | 6.42 × 10−5 | Face masks (87.7%) | (De-la-Torre et al., 2021b) |

| Morocco | Agadir | Transectsa | 282,374 | 16 | 689 | 1.13 × 10−5 | Face masks (96.8%) | (Ben-Haddad et al., 2021) |

| Morocco | Tetouan | Transectsa | 17,789 | 5 | 321 | 1.20 × 10−3 | Face masks (100%) | (Mghili et al., 2021) |

| Iran | Bushehr | Transectsa | 43,577 | 4 | 2382 | 1.72 × 10−2 | Face masks (66.2%) | (Akhbarizadeh et al., 2021b) |

| Bangladesh | Cox's Bazar | Transectsa | 516,683 | 12 | 29,254 | 3.16 × 10−4 | Face masks (97.8%) | (Rakib et al., 2021) |

| Kenya | Kwale and Kilifi | Transectsb | – | 1 | – | 0.00–5.6 × 10−2 | – | (Okuku et al., 2020) |

| Ethiopia | Bahir Dar | Transectsa | 119,850 | 12 | 221 | 1.54 × 10−4 | Face masks (93.7%) | (Aragaw et al., 2022) |

| Chile | Nationwide | Quadrants | – | 1 | 17 | 6.00 × 10−3c | –c | (Thiel et al., 2021) |

| Brazil | Sao Paulo | – | – | – | 178 | – | Face masks (100%) | (Gallo Neto et al., 2021) |

The length and number of transects varied per site, aiming to cover the whole beach area.

Standing stock surveys.

Only face masks were counted.

Initially, (Okuku et al., 2020) surveyed 24 beaches along the Kenya coast through standing stocks procedure. The surveys were carried out 100 days after the first COVID-19 case was reported in Kenya. COVID-19 related items accounted for about 0.43% of all the litter found, with densities ranging from 0.00 to 3.8 × 10−2 PPE m−2 in urban beaches and from 0.00 to 5.6 × 10−2 PPE m−2 in remote beaches. These findings were attributed to the possible lack of compliance with public beach closures in rural or remote areas. A few months later, Cordova et al. (2021) reported the unprecedented occurrence of COVID-19 related items in two river outlets discharging into Jakarta Bay, Indonesia. PPE items (mean of 780 items day−1) represented 15–16% of all the litter items collected and were composed of different types of face masks, respirators, hazmat suits, gloves, and face shields. Riverine litter monitoring was carried out between March and April 2020. Interestingly, in a previous survey (between March and April 2016), no PPE items were found in the two river outlets, which confirms the influence of the pandemic on solid waste generation and pollution. In Brazil, 178 face masks were found between April and October 2020 in several sites as part of several marine wildlife monitoring activities (Gallo Neto et al., 2021). The relevancy of these findings is that one of the necropsied penguins (Spheniscus magellanicus) had ingested a face mask, which is assumed as the cause of death. This is not the only case of wildlife interaction with PPE items. Hiemstra et al. (2021) reviewed the reports and photographic evidence of PPE entrapment, ingestion, entanglement, and other sorts of interactions across social media and news outlets. A long list of impacted animals from different taxa is displayed, although many could remain unreported.

Tracking the drivers of PPE pollution in beach areas could be a tough task, although the main source is obvious. Beachgoers and visitors are, without doubt, the ones bringing and improperly discarding the highest amounts of PPE. For instance, this became evident in Morocco, where the occurrence of PPE items was almost null during lockdown (the population was not allowed to enter beach areas) and suddenly increased just after the beaches reopened to the public (Ben-Haddad et al., 2021). Several studies tried to investigate the drivers of PPE pollution by assigning and comparing the main activity (e.g., recreational, aquatic sports, fishing, etc.) carried out in each site. The majority agreed that recreational activities are the ones driving more PPE than others (De-la-Torre et al., 2021b; Rakib et al., 2021), probably attributed to the number of visitors to this type of beach. To this end, we believe that encouraging and/or enforcing the use of reusable PPE items (mainly cloth face masks) in beach areas is imperative to reduce the number of littered PPE significantly.

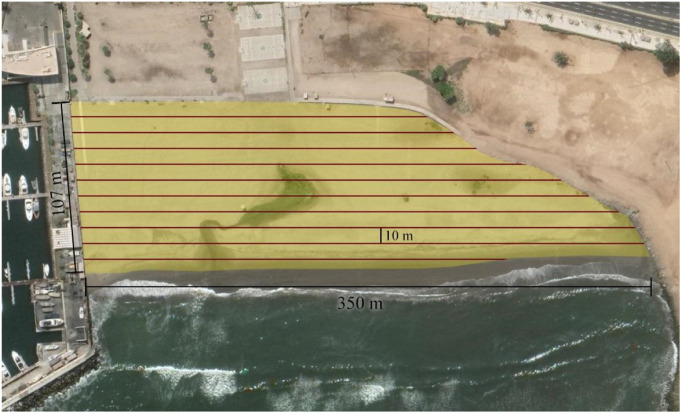

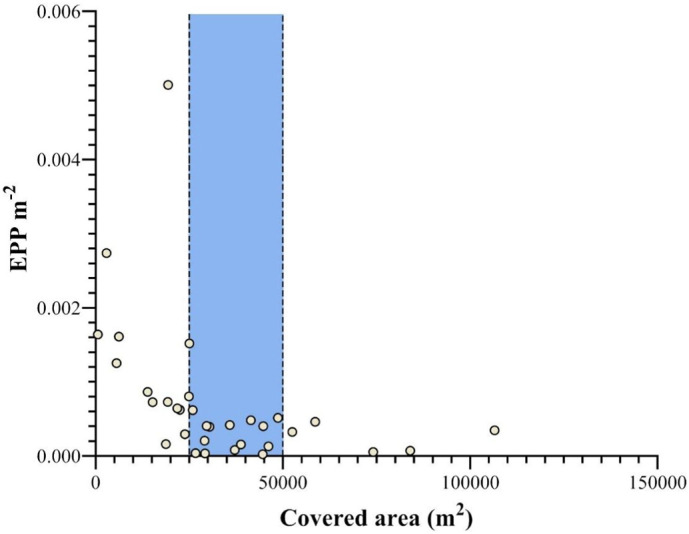

The emerging field of PPE monitoring lacked standard sampling procedures that would make studies comparable worldwide. However, later studies followed the transect-based methodology used by De-la-Torre et al. (2021b). This sampling procedure consists of determining a sampling area within each beach (mostly aiming for the entirety of the beach) and, subsequently, a number of transects parallel to each other (separated by 8–10 m) enough to cover the selected area (Fig. 1 ). Litter monitoring is carried out by walking along the transects once and visually identifying PPE items. The benefit of this methodology is that the sampled area is well defined and ignores sampling bias due to unevenly distributed litter across the beach. Thus far, this methodology has been applied in Perú, Argentina, Bangladesh, Iran, and Morocco. Their overall results are shown in Table 1. However, after applying this methodology in a nationwide study including 36 sampling sites with covered areas ranging from a few hundred meters squared, a nonlinear inverse correlation (sampled area vs. PPE density) was observed (Fig. 2 ). This is mainly because a very small covered area with a few PPE items translates into a relatively high PPE density (number of PPE per m2), which could bias the interpretation of the results in terms of PPE density and statistical analysis. In this sense, we suggest the covered areas to range from around 25,000 to 50,000 m2 per sampling site.

Fig. 1.

Map of a sand beach displaying the sampling area (yellow area) and appropriate transects parallel to each other (red lines) separated by 10 m, as described by De-la-Torre et al. (2021b). (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.)

Fig. 2.

Scatter plot of sampled area vs. PPE density from 36 sites along the coast of Peru. The Blue region indicates the suggested range of covered area (from 25,000 to 50,000 m2) to avoid bias. Spearman correlation: p ≤ 0.0001, r = −0.6698. The data was obtained from (De-la-Torre et al., 2022). (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.)

Due to lockdown and travel restrictions (which may vary across countries), complying with scheduled sampling campaigns has become quite difficult. Particularly, obtaining a comprehensive overview of PPE pollution in terms of abundance and distribution is key but challenging at the same time. Many long-term marine litter monitoring projects were compromised or momentarily stopped due to the COVID-19 pandemic (Thiel et al., 2021). Some studies may need specific permission from the local government authorities in order to complete the monitoring schedule (Ben-Haddad et al., 2021) but being granted such permission may not always be successful. Given the current monitoring challenges that researchers may encounter, citizen science projects have been regarded as suitable initiatives for obtaining reliable and well-distributed litter data while engaging with the general public (Oturai et al., 2021). This approach may be exceptionally useful in the context of the COVID-19 pandemic (Ammendolia and Walker, 2022). The first demonstration of PPE monitoring using a readily available technological tool was carried out by Ammendolia et al. (2021). In their study, the spatial distribution of different types of PPE items was recorded in the city of Toronto using the georeferencing mobile application “Marine Debris Tracker” (https://debristracker.org/). This tool was initially developed as part of a citizen-science initiative. Thus, providing a great opportunity for PPE monitoring under the current scenario (Ammendolia and Walker, 2022).

3. Degradation and subproducts

Before the COVID-19 pandemic, the presence of plastic debris in different environmental matrices had become a concern due to their low rate of degradation, ubiquity, and high fragmentation into the smaller particles (meso/micro/nanoplastics) could be potentially dangerous to wildlife and humans (Kumar et al., 2021). Moreover, during aging of this plastic debris and their respective fragmentation due to exposure to the weathering conditions (e.g., UV-light, temperature) can leach other emerging pollutants (e.g., plasticizers, antioxidants, UV stabilizers, lubricants, dyes) and be a vector for other pollutants such as heavy metals, persistent organic pollutants (POPs), pesticides, and polycyclic aromatic hydrocarbons (PAHs) (Agboola and Benson, 2021; Hüffer et al., 2018; Ricardo et al., 2021; Torres et al., 2021). As previously mentioned, there has been a substantial increase in the production and use of PPE for slowing down the transmission rate of the virus SARS-CoV-2 in human beings (Ardusso et al., 2021; Patrício Silva et al., 2021a; Peng et al., 2021). However, due to the improper disposal of this new type of waste, there have been negative implications for the terrestrial and aquatic environments, as well as wildlife, in the short and medium-term, as a result of the increase in pollution triggered by plastic debris (Hiemstra et al., 2021; Patrício Silva et al., 2021b).

Plastics undergo environmental weathering through abiotic and biotic processes. The former refers to the physical and/or chemical changes that occur due to abiotic factors, such as sunlight, temperature, wind, and mechanical forces, while the latter is driven by organisms through physical (chewing, biting, etc.) and biochemical processes (Zhang et al., 2021). The degradation process of plastic debris can last up to hundreds of years depending on its physicochemical properties and the surrounding environmental condition. During this process, there are changes in their properties, such as crystallinity, hydrophobicity, functional groups, mechanical properties, among others (Ali et al., 2021). In particular, when plastic debris is in contact with the aquatic environment, the hydrophobicity of plastic material begins to change due to the formation of dissolved organic matter layers on their surface, which is essential to the adherence and growth of microbial communities present in the water column (e.g., bacteria, single-celled algae, and fungi), forming the so-called plastisphere (Arias-Andres et al., 2018; De Tender et al., 2017; Rummel et al., 2017). It is well known that this microcosm or plastisphere can influence the aging processes, vertical transport and migration of plastic debris, enrichment or dissemination of harmful microorganisms, and the sorption and release of contaminants by plastic debris (He et al., 2022; Rummel et al., 2017). In the case of PPE (in particular, face masks) in aquatic ecosystems, they can be a potential refuge for pollutants and to facilitate enrichment and spread of antibiotic resistance genes (ARG) in the environment due to lateral gene transfer (LGT) between unilateral and/or multicellular microorganisms, causing antibiotic-sensitive microorganism to evolve resistance (Zhou et al., 2021). According to Zhou et al. (2021), face masks can be a base substrate to ARG processes between aquatic microorganisms and accelerate this transfer. In a previous work, we suggested that the architecture of the face masks (microscopy meshing) could influence the preferential growth of some microorganism communities during the first stages of formation as in the topography or texture of the biofilm.

3.1. Chemical degradation

Weathering of plastics causes irreversible changes in their chemical characteristics. For instance, photodegradation of synthetic polymers exposed to incident UV light induces chain scission reactions (Gewert et al., 2018). The chemical changes occurring in the polymer backbone can be evaluated by FTIR spectroscopy, Raman, and X-ray photoelectron spectroscopy (XPS). In polyolefins (e.g., PE, PP), UV light causes the oxidation of the polymer structure, which appears in the IR regions ranging from 3300 to 3500 cm−1 and 1610–1800 cm−1 (Almond et al., 2020; Grigoriadou et al., 2018). For instance, Ainali et al. (2021) reported the occurrence of new peaks around 3300–3500 cm−1 and 1650–1860 cm−1 in PP and HDPE, attributed to the occurrence of hydroxyl/hydroxyperoxide and carbonyl groups, respectively, after 45 days of exposure to UV light. These results are consistent with PE and PP exposed to different environments (land, water, and ocean) for 23 weeks (Q. Chen et al., 2021), confirming the formation of ketone and oxygen-containing functional groups due to polyolefin polymer chain scission (Resmeriță et al., 2018). While the studies aforementioned conducted experiments with pristine pieces of plastic, this type of chemical change is also expected in face masks. Saliu et al. (2021) analyzed the surgical face masks exposed to the experimental conditions specified in Table 2 by μFTIR. Unlike pristine face masks, weathered face masks displayed broad peaks around 3400 cm−1 assigned to hydroxyl groups and various overlapping carbonyl groups around 1720 cm−1. Furthermore, a surgical mask picked up from a beach presented very similar additional peaks, suggesting that these experimental conditions may represent chemical degradation in the environment. It should be noted, however, that directly analyzing plastics extracted from the environment without any cleaning treatment could lead to erroneously assigning additional hydroxyl and carbonyl peaks to chemical degradation (Sandt et al., 2021). This is due to the possible contamination of plastics with organic matter rich in oxygen-containing groups (e.g., lipids, polysaccharides). Hence, plastics extracted from the environment must be sufficiently cleaned before being analyzed by spectroscopic techniques.

Table 2.

Summary of the experimental conditions and MP release from experimental studies.

| Type of mask | Experimental conditions | Quantification technique | MP release | Ref. |

|---|---|---|---|---|

| Disposable surgical | Virgin face mask was placed in an aqueous solution and shaken for 24 h. | Laser in-situ scattering and transmissometry analyzer (particle detection range 1–500 μm) | 483,888 MPs per mask | (Z. Wang et al., 2021) |

| Virgin face mask was UV-light irradiated, placed in an aqueous solution, and shaken for 24 h. | 1,566,560 MPs per mask | |||

| Virgin face mask was UV-light irradiated, placed in an aqueous solution in the presence of sand, and shaken for 24 h. | 16,001,943 MPs per mask | |||

| Disposable surgical | Virgin face mask was placed in an aqueous solution and stirred for 24 h. The face mask was then dried, and the experiment was repeated 2 more times | Metallographic microscopy (40× and 100× magnification) Scanning electron microscopy (SEM) (1000× and 10,000× magnification) |

116,600 MPs per mask | (Shen et al., 2021) |

| Virgin face mask was placed in an aqueous solution in the presence of alcohol and stirred for 24 h. The face mask was then dried, and the experiment was repeated 2 more times | 147,000 MPs per mask | |||

| Virgin face mask was placed in an aqueous solution in the presence of detergent and stirred for 24 h. The face mask was then dried, and the experiment was repeated 2 more times | 168,800 MPs per mask | |||

| Disposable surgical (7 types) | Virgin face mask was UV-irradiated (10 h at 65 °C, repeated 15 times), placed in an aqueous solution, and stirred for 24 h. | Stereomicroscope | 61 MP per mask (1–5 mm) 117,400 MP per mask (25–500 μm) |

(Saliu et al., 2021) |

| Disposable surgical | Virgin face mask was placed in an aqueous solution and exposed to shear damage using a kitchen chopper (2 min), | Stereomicroscope Flow cytometry |

28,000 MP per mask (0.1–5 mm) 2.1 × 1011 MP per m2 of treated fabric (0.1–100 μm). |

(Morgana et al., 2021) |

| Disposable surgical (3 types) and N95 | Virgin face masks were placed in an aqueous solution and stirred for 24 h. | Stereomicroscope | 183 MPs per mask | (X. Chen et al., 2021) |

| Worn (24 h of usage) face masks were placed in an aqueous solution and stirred for 24 h. | 1246.6 MPs per mask | |||

| Disposable surgical (8 brands) and N95 (2 brands) | Virgin face masks were placed in a glass bottle, 100 mL was added and stirred for 3 min, and the leachate was extracted. The procedure was repeated 10 times. | Field-emission SEM Atomic force microscopy (AFM) |

2.23 × 103 MPs per mask (>1 μm) 2.43 × 109 MPs per mask (<1 μm) |

(Ma et al., 2021) |

| Disposable surgical | Virgin face masks were placed in soil and exposed to the environment (sun and rain) for 30 days. The masks were then rubbed 120 times inside a closed chamber lined with filter paper. | Digital microscope | 1.01 × 105 MPs per mask | (Rathinamoorthy and Balasaraswathi, 2021) |

| Virgin face masks were placed in soil and exposed to the environment (sun and rain) for 30 days. Then, masks were placed in water (freshwater or marine) and rubbed continuously for 15 min. | 1.64 × 104–6.61 × 104 MPs per mask |

On the other hand, XPS is an essential technique to identify the changes in the compositions and state chemicals, group functionals, and elements adsorbed on the plastic surface (Kim et al., 2021; Mao et al., 2020). In this way, Mao et al. (2020) studied the aging mechanism of PS with UV irradiation under different conditions (air, pure water, and seawater) and the effect of aging on heavy metal adsorption. In the case of plastic particles, this technique shows the changes in the binding energy (BE) of the different atomic orbitals from the chemical elements that comprise the surface of plastic particles, which are influenced by their chemical structure, changes in the surface oxidation due to aging processes of MPs/PNPs, and adsorption and/or interactions with other compounds, like heavy metals such as Cd (A. Yu et al., 2021), Pb (Fu et al., 2021), and Cu (Qiongjie et al., 2022), among others. Yan et al. (2021) studied the changes in the surface chemistry of face masks (i.e., N95, 3 M) upon the heat treatment for their reusing. These authors informed no change in the surface chemistry of the different types of face masks by dry or steam heat treatment.

The wettability of a liquid indicates its ability to interact with another liquid or solid. This property is evaluated by measuring the contact angle. A lower contact angle (≤90°) indicates greater wettability and vice versa (Sarkar et al., 2020). Environmentally degraded polyolefins in contact with water generally exhibit greater wettability than pristine ones, probably due to the formation of polar groups on their surface (Waldman and Rillig, 2020). Previous studies have demonstrated a notorious increase in the wettability of PP plastics after several weeks exposed to different environments (Q. Chen et al., 2021), likely due to the formation of oxygen-containing groups. To the best of our knowledge, no previous study has evaluated the wettability of PPE samples from the environment or after experimental treatments. This property is relevant to understanding the ability of littered plastics, particularly PPE, of interacting with external environmental contaminants and serving as suitable substrates for biofilm formation (Bhagwat et al., 2021; Torres et al., 2021). These characteristics of PPE are still poorly understood and have been suggested as a research priority in this field of research (De-la-Torre and Aragaw, 2021). The degree of crystallinity refers to the number of aligned polymer chains that make up a polymer matrix. The parts where polymer chains are aligned with one another are called crystalline regions (lamellae), and the remaining parts lacking a specific ordering (mostly entangled polymer chains) are called amorphous regions (Drioli and Giorno, 2016). This property highly influences the chemical, optical, thermal, and mechanical properties of plastic materials, including its fracture mechanism (Crawford and Quinn, 2017; Julienne et al., 2019). This property has been investigated in plastics exposed to weathering conditions, generally showing a time-dependent behavior. For instance, LDPE and HDPE plastics (degree of crystallinity of 34% and 45.4%, respectively) exposed to UV light displayed an increase in the degree of crystallinity after the first 10–20 days of exposure but decreased back to near the initial values (33.2% and 46.6%, respectively) after 60 days (Ainali et al., 2021). This behavior is attributed to the chain scission in PE molecules and later crystallization of unchained segments within the polymer matrix. Q. Chen et al. (2021) and X. Chen et al. (2021) demonstrated the influence of the different types of aquatic environments (freshwater, estuary, and ocean) on the changes in the degree of crystallinity after exposure time. They reported that PE plastics exposed to either of the aquatic environments (+UV light) results in an increased degree of crystallinity (after 11 weeks), which continued increasing until 23 weeks of exposure. Conversely, PP plastics showed a slight increase after 11 weeks but later decreased below the degree of crystallinity at time 0. For PE, it was observed that the degree of crystallinity was positively correlated to the salinity of the medium (freshwater < estuary < ocean), suggesting that salinity could promote the crystallization of segmented chains. In our previous study (De-la-Torre et al., 2022), we reported a notorious decrease in the crystallinity of PP-based face masks recovered from the environment compared to pristine ones through X-ray diffraction (XRD). However, cotton-polyester face masks displayed little variation in the intensity of their XRD patterns. Although the time the analyzed face masks were exposed to natural environmental conditions is unknown, our results provided preliminary evidence of the changes in crystallinity in PPE exposed to the environment. Hence, further research is needed concerning the degree of crystallinity and thermal stability of different PPE items under controlled environmental conditions.

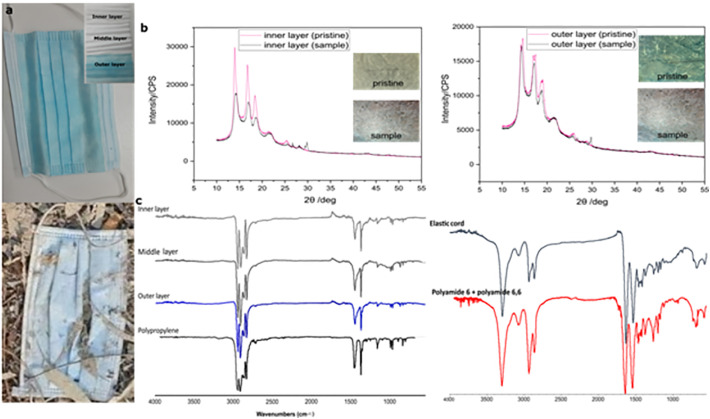

Fig. 3, Fig. 4 showed an example of the characterization techniques used for identifying PPE commonly employed during the current COVID-19 pandemic. The photographs of pristine and sample surgical face masks were exhibited (Fig. 3a). It can be seen in (Fig. 3b) that intensities of peaks characteristic of PP in 2θ angles of 14°(110), 17°(040), and 18.6°(130) and minor signals at 21–22° and 25.6° (Li et al., 2019). The intensities of diffraction peaks of 110, 040, and 130 segments of crystal planes of polymers decreased in the outer layer from the sample compared to pristine material. On the other hand, the XRD pattern of the inner layer from the sample face mask did show a slight difference in the intensity of peaks than the pristine face mask. ATR-FTIR spectrums of layers and cord composed of the sample face mask were presented in Fig. 3c. FTIR spectra from three layers of the sample showed characteristic bands of PP, and the FTIR spectrum from the cord sample exhibited signals typically representative of Polyamide 6 and Polyamide 6,6 mixes.

Fig. 3.

(a) Photograph of pristine and sample surgical face masks. (b) XRD spectra of pristine and sample surgical face masks, and (c) ATR-FTIR spectra of layers and cord compound the sample surgical face mask.

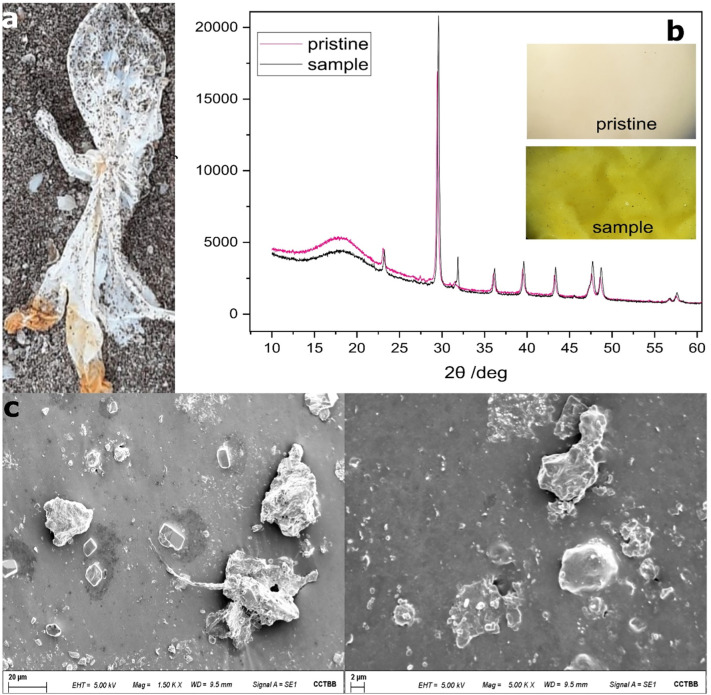

Fig. 4.

(a) Photograph of a glove found in coastal areas. (b) XRD spectra of pristine and sample gloves, and (c) SEM micrograph at 1500 and 5000× of sample gloves.

On the other hand, the photograph of a glove found in the coastal area was presented in Fig. 4a. The XRD pattern of pristine and sample gloves was exhibited in Fig. 4b. Both spectra exhibited a broad amorphous region of natural rubber that is visible at 2θ = 18.13 (Parvathi et al., 2021), and characteristic peaks of CaCO3 were also identified in both spectra (Lee et al., 2012). The intensity of the amorphous region decreased in the sample compared to pristine material. Finally, SEM images of gloves show small micro-voids, cavities, and particles (crystals) adhered to their surface.

3.2. Physical degradation

Chemically degraded plastics display downgraded physical properties, which may result in changes in their mechanical properties (Speight, 2011) or structure, commonly observed as cracking or embrittlement of the material (Chamas et al., 2020). The mechanical properties of plastics refer to their reaction (behavior) to an applied force. For instance, Rajakumar et al. (2009) reported a dramatic decrease in the elongation at break (maximum stretch before breaking) and tensile strength (maximum load supported before breaking) of PP film after 70 days of natural weathering regardless of the season. With reduced mechanical properties and embrittlement of the plastic material, fragmentation will likely occur under natural conditions. The fragmentation mechanism of degraded plastics is dependent on their chemical properties. Julienne et al. (2019) demonstrated that LDPE and PP plastics experimentally exposed to UV irradiation displayed differentiated crack propagation. The distinctive crack propagation pathways of each type of plastic were associated with their crystalline morphology rather than the degree of crystallinity, thus providing insights concerning the formation of secondary MPs. SEM micrographs of experimentally degraded surgical face masks showed the breakage of loosely attached fibers and rough surfaces that exacerbated at longer exposure time (Saliu et al., 2021; Z. Wang et al., 2021). Similarly, face masks and gloves recovered from the urban and marine environment displayed microfiber fragmentation and the formation of cracks and micro-voids, respectively (Akarsu et al., 2021; De-la-Torre et al., 2022). This suggests that PPE, especially face masks, are highly susceptible to fragmentation and may act as a source of MPs into the environment. The studies investigating this behavior under controlled conditions are reviewed in Section 3.3.

Finally, Yan et al. (2021) studied the impact of heat and steam treatment on the protection surgical masks (N95, WDR, and 3 M) using a group of characterization techniques such as XRD, XPS, Raman, SEM, and near-edge X-ray absorption fine structure spectroscopy (NEFAXS). Moreover, these authors also evaluated the angle of contact of mask materials after and before each treatment. According to the results of these authors, they suggested that applied steam treatment in surgical face masks may generate an increase of crystallinity, a decrease of elasticity, a change of surface adsorption to the fibers, and higher structural damage to sample polymers.

3.3. Release of contaminants

We previously discussed the knowledge gaps concerning PPE pollution in the marine environment and proposed several research questions (De-la-Torre and Aragaw, 2021), many of which have been partially addressed in recent studies. One of the main concerns is the release of MPs (mostly in the form of microfibers) from face masks and PPE items in general. Under different experimental setups and evaluated variables, this issue has been investigated with great interest. Table 2 summarizes the main methodology and quantification techniques carried out in the recent literature, as well as the concentration of MPs released per face mask. These studies combine simple and low-cost techniques, such as the use of a stereomicroscope, and advanced equipment, such as scanning electron microscopy (SEM) and/or atomic force microscopy (AFM), to quantify MPs. In general terms, optic microscopy is used to visually identify MPs of larger fractions, and more sophisticated techniques are applied for smaller MPs (e.g., <100 μm) or even nanoplastics (PNPs) (<1 μm). Combining both quantification methods is pivotal to understanding the MPs particle size distribution leached by face masks. Also, all of the consulted studies reporting differentiated size ranges agree that the smaller MPs fractions are the most abundant by several orders of magnitude (Ma et al., 2021; Morgana et al., 2021; Saliu et al., 2021). Interestingly, Ma et al. (2021) went a step forward and evaluated the bioaccumulation potential of MPs released by disposable face masks. This experiment was carried out by exposing face mask MP leachates to multiple organisms (rotifer Brachionus rotundiformis, copepod Parvocalanus crassirostris, shrimp Penaeus vannamei, scallop Chlamys nobilis, and juvenile grouper Epinephelus lanceolatus), all of which effectively ingested MPs. While this study provides an interesting overview of the interaction between face mask-associated MPs and aquatic organisms, ecotoxicological studies are largely lacking. However, recently, Sun et al. (2021) studied the chronic toxicity of MPs released from PP-face masks on marine copepod Tigriopus japonicus. These authors reported that copepods ingested the MPs release from the PP-face mask generating an important decline in the fecundity of this marine species (Sun et al., 2021). In terrestrial organisms, this type of study has only been carried out on earthworms and springtails, resulting in the inhibition of organism reproduction and other impacts (Kwak and An, 2021). Furthermore, the human health effects of PPE-associated MPs are still largely unexplored (De-la-Torre et al., 2021a; Kutralam-Muniasamy et al., 2022).

Similar to commercial plastic products, face masks include a number of additives and chemicals that could potentially leach into the environment. However, this has been poorly investigated in contrast with MP release and the number of studies is fairly limited. For instance, Sullivan et al. (2021) determined that the leachates of several disposable face masks contained organic chemicals, surfactants, dyes, and plastic oligomers, as well as potentially harmful heavy metals (Cd and Pb). More recently, X. Wang et al. (2021) determined the presence of phthalate esters plasticizers (most commonly di-methyl phthalate, di-n-butyl phthalate, di-ethyl phthalate, di-isobutyl phthalate, and di(2-ethylhexyl) phthalate) in disposable face masks and estimated daily intake values from face mask usage that exceed tolerable concentrations (Jin et al., 2021). Bussan et al. (2021) determined the levels of heavy metals present in 24 surgical and KN95 face masks using ICP-MS. These authors informed that the concentrations for six elements (Cr, Ni, As, Cd, Hg, and Tl) were below the detection limit; in contrast, detectable concentration levels were observed for Cu, Sb, and Pb. Moreover, the same authors also informed the potential leaching of Pb and Sb from face masks and how heavy metals may interact with humans through their saliva and depending on the time of use of face masks that contained these metals. In specific cases, like Argentina, where antiviral face masks impregnated with Ag and Cu nanoparticles were popularized, the environmental threat posed by their incorrect disposal is more pronounced (Ardusso et al., 2021). The main concern is the possible leaching of metal nanoparticles from commercial products (e.g., face mask and antiviral textiles) since they could negatively impact aquatic environments due to their high reactivity and a possible alteration of the ecotoxicological profile of MPs/PNPs on organism aquatics (Forero-López et al., 2022). Regardless, significantly more research is needed in this sense, which must be accompanied by ecotoxicological studies to better understand the environmental implications of incorrect PPE disposal. Furthermore, studies concerning the adsorption of external contaminants on MPs/PNPs derived from weathered PPE items are necessary to be conducted and compared with conventional MPs/PNPs (Torres et al., 2021).

4. Strategies to decrease PPE pollution

Since the outbreak of COVID-19, improper disposal of PPE waste has resulted in an unprecedented glut of plastic waste into the aquatic and terrestrial environments, prompting concerns that this could potentially aggravate MPs/PNPs pollution globally (Benson et al., 2021a; Fadare and Okoffo, 2020). As previously mentioned, the introduction of face masks into the aquatic environment can result in the release of millions of MPs/PNPs, pollutants (e.g., toxic metals, phthalates), or can serve as a base for deposition and growth of microorganisms or algae. Hence, it is necessary to implement environmental management strategies in order to safeguard the stability of marine ecosystems and human health. L. Li et al. (2021) and S. Li et al. (2021) suggest the implementation of specific garbage containers for PPE, as well as providing guidance for tourists to properly dispose of their wastes, and beach disinfection procedures. These strategies must be accompanied by continuous waste generation monitoring and control (Hatami et al., 2022). Further, authorities should work on public awareness concerning the negative impact of PPE in the environment and provide guidelines for their correct disposal, as well as promote reusable alternatives (Aragaw, 2021a). These strategies aim to prevent PPE and other types of wastes from entering the marine environment, as well as limit the amount of waste generated (Aragaw, 2021b). However, other conservation actions, such as beach clean-ups, may also contribute to preserving coastal environments free from marine litter (Battisti et al., 2020).

On the other hand, some authors have implemented different technological strategies to mitigate the plastic pollution generated by PPE waste (in particular, face masks), such as employing a Ni(OH)2/NiCl2 hybrid catalyst to catalytic carbonization of face mask waste (R. Yu et al., 2021) or through a method co-hydrothermal liquefaction (Co-HTL) with Spirulina platensis grown in wastewater (L. Li et al., 2021). Other authors have developed antiviral/antibacterial biodegradable cellulose textiles for manufacturing face masks with the aim of making woven environmentally friendly and bioprotective materials with the potential to minimize MPs pollution (Deng et al., 2022). Alshabanah et al. (2021) have synthesized thermoplastic polyurethane (TPU) nanofibers impregnated with ZnO and CuO nanoparticles or personal protection applications to supply or improve the antiviral properties of the textiles polymer. However, the problem is also short-term due to the concern about the indiscriminate disposal of PPE (mainly face masks). For this reason, some researchers have proposed the conversion of disposable face masks as carbon powders that can be applied as an anode in sodium-ion batteries (Lee et al., 2022), which is an exciting and innovative development to mitigate plastic pollution from PPE. However, other researchers have proposed implementing a process system to produce renewable fuels from PPE waste (Zhao et al., 2022). Different processes have been employed to treat PPE waste, such as incineration, which is economically feasible but can emit large amounts of greenhouse gases (GHGs) and toxic substances, contributing to climate change (Fang et al., 2020; Klemeš et al., 2020; Zhao et al., 2022). Another process is optimized pyrolysis for mixed medical waste (Aragaw and Mekonnen, 2021b; Fang et al., 2020), a technique with high economic viability and technical feasibility but unknown environmental performance (Zhao et al., 2022).

All strategies have been attractive due to innovation and advances in new materials and processes designed to decrease the plastic pollution from PPE in the environment. However, the possible negative repercussions in the environment in the long-term must be taken into account from these materials waste during their development. For example, the excessive use of additives during the synthesis or modification in the cellulosic materials to confer physicochemical and antiviral properties may change their biodegradability or release chemical compounds in the environment from cellulosic debris (Forero-López et al., 2022; Truchet et al., 2021). Moreover, in developing countries, deficits in final PPE waste disposition and Municipal Solid Waste (MSW) management have been accentuated during this pandemic. The volume of plastic waste generated during the COVID-19 pandemic considerably outweighs the capacity of waste management facilities, particularly in most developing countries (Benson et al., 2021b). The poor waste management infrastructures and other flaws prove that plastic recycling processes (both mechanical and chemical pathways) are challenging to implement in these countries, further complicating the plastic pollutant landscape.

5. Conclusions

The widespread abundance of PPE items has put into perspective the impact of the COVID-19 on marine plastic pollution. This unprecedented type of pollution has raised concerns due to its impact on marine biota and the release of MPs/PNPs and chemical pollutants. To this date, several studies have quantified PPE pollution in the marine environment, their impact on biota (e.g., ingestion and entanglement), and experimentally evaluated the release of MPs/PNPs. However, not much is discussed concerning the degradation of PPE items upon entering the marine environment. In the present paper, we have reviewed and discussed the studies investigating PPE pollution and degradation of synthetic polymers commonly found in PPE items, as well as the MPs/PNPs release mechanisms. We have provided methodological recommendations for further monitoring programs to take into account, as well as identifying research gaps, and possible strategies to mitigate PPE pollution.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The corresponding author is thankful to Universidad San Ignacio de Loyola for financial support. This work was funded by Agencia Nacional de Promoción Científica y Tecnológica (ANPCyT-PICT 2019-2241-) granted to MDFS and ADFL, Argentina.

References

- Agboola O.D., Benson N.U. Physisorption and chemisorption mechanisms influencing micro (nano) plastics-organic chemical contaminants interactions: a review. Front. Environ. Sci. 2021;9:167. doi: 10.3389/FENVS.2021.678574/BIBTEX. [DOI] [Google Scholar]

- Ainali N.M., Bikiaris D.N., Lambropoulou D.A. Aging effects on low- and high-density polyethylene, polypropylene and polystyrene under UV irradiation: an insight into decomposition mechanism by Py-GC/MS for microplastic analysis. J. Anal. Appl. Pyrolysis. 2021;158 doi: 10.1016/J.JAAP.2021.105207. [DOI] [Google Scholar]

- Akarsu C., Madenli Ö., Deveci E.Ü. Characterization of littered face masks in the southeastern part of Turkey. Environ. Sci. Pollut. Res. 2021;1–11 doi: 10.1007/s11356-021-14099-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Akhbarizadeh R., Dobaradaran S., Amouei Torkmahalleh M., Saeedi R., Aibaghi R., Faraji Ghasemi F. Suspended fine particulate matter (PM2.5), microplastics (MPs), and polycyclic aromatic hydrocarbons (PAHs) in air: their possible relationships and health implications. Environ. Res. 2021;192 doi: 10.1016/J.ENVRES.2020.110339. [DOI] [PubMed] [Google Scholar]

- Akhbarizadeh R., Dobaradaran S., Nabipour I., Tajbakhsh S., Darabi A.H., Spitz J. Abundance, composition, and potential intake of microplastics in canned fish. Mar. Pollut. Bull. 2020;160 doi: 10.1016/j.marpolbul.2020.111633. [DOI] [PubMed] [Google Scholar]

- Akhbarizadeh R., Dobaradaran S., Nabipour I., Tangestani M., Abedi D., Javanfekr F., Jeddi F., Zendehboodi A. Abandoned COVID-19 personal protective equipment along the Bushehr shores, the Persian Gulf: an emerging source of secondary microplastics in coastlines. Mar. Pollut. Bull. 2021;168 doi: 10.1016/j.marpolbul.2021.112386. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ali S.S., Elsamahy T., Koutra E., Kornaros M., El-Sheekh M., Abdelkarim E.A., Zhu D., Sun J. Degradation of conventional plastic wastes in the environment: a review on current status of knowledge and future perspectives of disposal. Sci. Total Environ. 2021;771 doi: 10.1016/J.SCITOTENV.2020.144719. [DOI] [PubMed] [Google Scholar]

- Almond J., Sugumaar P., Wenzel M.N., Hill G., Wallis C. Determination of the carbonyl index of polyethylene and polypropylene using specified area under band methodology with ATR-FTIR spectroscopy. E-Polymers. 2020;20:369–381. doi: 10.1515/EPOLY-2020-0041/MACHINEREADABLECITATION/RIS. [DOI] [Google Scholar]

- Alshabanah L.A., Omran N., Elwakil B.H., Hamed M.T., Abdallah S.M., Al-Mutabagani L.A., Wang D., Liu Q., Shehata N., Hassanin A.H., Hagar M. Elastic nanofibrous membranes for medical and personal protection applications: manufacturing, anti-COVID-19, and anti-colistin resistant bacteria evaluation. Polymers (Basel) 2021;13:3987. doi: 10.3390/POLYM13223987. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ammendolia J., Saturno J., Brooks A.L., Jacobs S., Jambeck J.R. An emerging source of plastic pollution: environmental presence of plastic personal protective equipment (PPE) debris related to COVID-19 in a metropolitan city. Environ. Pollut. 2021;269 doi: 10.1016/j.envpol.2020.116160. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ammendolia J., Walker T.R. Citizen science: a way forward in tackling the plastic pollution crisis during and beyond the COVID-19 pandemic. Sci. Total Environ. 2022;805 doi: 10.1016/J.SCITOTENV.2021.149957. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aragaw T.A. The macro-debris pollution in the shorelines of Lake Tana: first report on abundance, assessment, constituents, and potential sources. Sci. Total Environ. 2021;797 doi: 10.1016/J.SCITOTENV.2021.149235. [DOI] [PubMed] [Google Scholar]

- Aragaw T.A. Microplastic pollution in African countries' water systems: a review on findings, applied methods, characteristics, impacts, and managements. SN Appl. Sci. 2021;3:629. doi: 10.1007/s42452-021-04619-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aragaw T.A. Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar. Pollut. Bull. 2020;159 doi: 10.1016/j.marpolbul.2020.111517. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aragaw T.A., De-la-Torre G.E., Teshager A.A. Personal protective equipment (PPE) pollution driven by the COVID-19 pandemic along the shoreline of Lake Tana, Bahir Dar,Ethiopia. Sci. Total Environ. 2022;820 doi: 10.1016/J.SCITOTENV.2022.153261. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aragaw T.A., Mekonnen B.A. In: Microplastic Pollution. Muthu S.S., editor. Springer; Singapore, Singapore: 2021. Distribution and impact of microplastics in the aquatic systems: a review of ecotoxicological effects on biota; pp. 65–104. [DOI] [Google Scholar]

- Aragaw T.A., Mekonnen B.A. Current plastics pollution threats due to COVID-19 and its possible mitigation techniques: a waste-to-energy conversion via pyrolysis. Environ. Syst. Res. 2021;10:8. doi: 10.1186/s40068-020-00217-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ardusso M., Forero-López A.D., Buzzi N.S., Spetter C.V., Fernández-Severini M.D. COVID-19 pandemic repercussions on plastic and antiviral polymeric textile causing pollution on beaches and coasts of South America. Sci. Total Environ. 2021;763 doi: 10.1016/j.scitotenv.2020.144365. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Arias-Andres M., Klümper U., Rojas-Jimenez K., Grossart H.P. Microplastic pollution increases gene exchange in aquatic ecosystems. Environ. Pollut. 2018;237:253–261. doi: 10.1016/J.ENVPOL.2018.02.058. [DOI] [PubMed] [Google Scholar]

- Battisti C., Poeta G., Romiti F., Picciolo L. Small environmental actions need of problem-solving approach: applying project management tools to beach litter clean-ups. Environments. 2020;7:87. doi: 10.3390/environments7100087. [DOI] [Google Scholar]

- Ben-Haddad M., De-la-Torre G.E., Abelouah M.R., Hajji S., Alla A.A. Personal protective equipment (PPE) pollution associated with the COVID-19 pandemic along the coastline of Agadir,Morocco. Sci. Total Environ. 2021;798 doi: 10.1016/J.SCITOTENV.2021.149282. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Benson N.U., Bassey D.E., Palanisami T. COVID pollution: impact of COVID-19 pandemic on global plastic waste footprint. Heliyon. 2021;7 doi: 10.1016/j.heliyon.2021.e06343. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Benson N.U., Fred-Ahmadu O.H., Bassey D.E., Atayero A.A. COVID-19 pandemic and emerging plastic-based personal protective equipment waste pollution and management in Africa. J. Environ. Chem. Eng. 2021;9 doi: 10.1016/j.jece.2021.105222. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bhagwat G., O’Connor W., Grainge I., Palanisami T. Understanding the fundamental basis for biofilm formation on plastic surfaces: role of conditioning films. Front. Microbiol. 2021;12:1615. doi: 10.3389/FMICB.2021.687118/BIBTEX. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bussan D.D., Snaychuk L., Bartzas G., Douvris C. Quantification of trace elements in surgical and KN95 face masks widely used during the SARS-COVID-19 pandemic. Sci. Total Environ. 2021;151924 doi: 10.1016/J.SCITOTENV.2021.151924. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chamas A., Moon H., Zheng J., Qiu Y., Tabassum T., Jang J.H., Abu-Omar M., Scott S.L., Suh S. Degradation rates of plastics in the environment. ACS Sustain. Chem. Eng. 2020;8:3494–3511. doi: 10.1021/acssuschemeng.9b06635. [DOI] [Google Scholar]

- Chellamani K.P., Veerasubramanian D., Vignesh Balaji R.S. Surgical face masks: manufacturing methods and classification. J. Acad. Ind. Res. 2013;2:320–324. [Google Scholar]

- Chen Q., Wang Q., Zhang C., Zhang J., Dong Z., Xu Q. Aging simulation of thin-film plastics in different environments to examine the formation of microplastic. Water Res. 2021;202 doi: 10.1016/J.WATRES.2021.117462. [DOI] [PubMed] [Google Scholar]

- Chen X., Chen X., Liu Q., Zhao Q., Xiong X., Wu C. Used disposable face masks are significant sources of microplastics to environment. Environ. Pollut. 2021;285 doi: 10.1016/J.ENVPOL.2021.117485. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chowdhury H., Chowdhury T., Sait S.M. Estimating marine plastic pollution from COVID-19 face masks in coastal regions. Mar. Pollut. Bull. 2021;168 doi: 10.1016/J.MARPOLBUL.2021.112419. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cole M., Lindeque P., Halsband C., Galloway T.S. Microplastics as contaminants in the marine environment: a review. Mar. Pollut. Bull. 2011;62:2588–2597. doi: 10.1016/j.marpolbul.2011.09.025. [DOI] [PubMed] [Google Scholar]

- Cordova M.R., Nurhati I.S., Riani E., Nurhasanah, Iswari M.Y. Unprecedented plastic-made personal protective equipment (PPE) debris in river outlets into Jakarta Bay during COVID-19 pandemic. Chemosphere. 2021;268 doi: 10.1016/j.chemosphere.2020.129360. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Crawford C.B., Quinn B. Microplastic Pollutants. Elsevier; 2017. Plastic production, waste and legislation; pp. 39–56. [DOI] [Google Scholar]

- De-la-Torre G.E., Aragaw T.A. What we need to know about PPE associated with the COVID-19 pandemic in the marine environment. Mar. Pollut. Bull. 2021;163 doi: 10.1016/j.marpolbul.2020.111879. [DOI] [PMC free article] [PubMed] [Google Scholar]

- De-la-Torre G.E., Dioses-Salinas D.C., Pizarro-Ortega C.I., Fernández Severini M.D., Forero-López A.D., Mansilla R., Ayala F., Jimenez Castillo L.M., Castillo-Paico E., Torres D.A., Mendoza-Castilla L.M., Meza-Chuquizuta C., Vizcarra J.K., Mejía M., Valdivia De La Gala J.J., Sayra Ninaja E.A., Siles Calisaya D.L., Flores-Miranda W.E., Eras Rosillo J.L., Espinoza-Morriberón D., Gonzales K.N., Torres F.G., Rimondino G.N., Ben-Haddad M., Dobaradaran S., Araga T.A., Santillán L. Binational survey of personal protective equipment (PPE) pollution driven by the COVID-19 pandemic in coastal environments: abundance, distribution, and analytical characterization. J. Hazard. Mater. 2022;426 doi: 10.1016/j.jhazmat.2021.128070. [DOI] [PMC free article] [PubMed] [Google Scholar]

- De-la-Torre G.E., Pizarro-Ortega C.I., Dioses-Salinas D.C., Ammendolia J., Okoffo E.D. Investigating the current status of COVID-19 related plastics and their potential impact on human health. Curr. Opin. Toxicol. 2021;27:47–53. doi: 10.1016/J.COTOX.2021.08.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- De-la-Torre G.E., Rakib Md., Jahan Refat, Pizarro-Ortega C.I., Dioses-Salinas D.C. Occurrence of personal protective equipment (PPE) associated with the COVID-19 pandemic along the coast of Lima,Peru. Sci. Total Environ. 2021;774 doi: 10.1016/j.scitotenv.2021.145774. [DOI] [PMC free article] [PubMed] [Google Scholar]

- De Tender C., Devriese L.I., Haegeman A., Maes S., Vangeyte J., Cattrijsse A., Dawyndt P., Ruttink T. Temporal dynamics of bacterial and fungal colonization on plastic debris in the North Sea. Environ. Sci. Technol. 2017;51:7350–7360. doi: 10.1021/ACS.EST.7B00697/SUPPL_FILE/ES7B00697_SI_001.PDF. [DOI] [PubMed] [Google Scholar]

- Deng C., Seidi F., Yong Q., Jin X., Li C., Zhang X., Han J., Liu Y., Huang Y., Wang Y., Yuan Z., Xiao H. Antiviral/antibacterial biodegradable cellulose nonwovens as environmentally friendly and bioprotective materials with potential to minimize microplastic pollution. J. Hazard. Mater. 2022;424 doi: 10.1016/J.JHAZMAT.2021.127391. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Drioli E., Giorno L. Encyclopedia of Membranes. Springer Berlin Heidelberg; Berlin: 2016. Encyclopedia of membranes. [DOI] [Google Scholar]

- Fadare O.O., Okoffo E.D. COVID-19 face masks: a potential source of microplastic fibers in the environment. Sci. Total Environ. 2020;737 doi: 10.1016/j.scitotenv.2020.140279. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fang S., Jiang L., Li P., Bai J., Chang C. Study on pyrolysis products characteristics of medical waste and fractional condensation of the pyrolysis oil. Energy. 2020;195 doi: 10.1016/J.ENERGY.2020.116969. [DOI] [Google Scholar]

- Forero-López A.D., Fabiani M., Lassalle V.L., Spetter C.V., Fernandez-Severini M.D. Critical review of the characteristics, interactions, and toxicity of micro/nanomaterials pollutants in aquatic environments. Mar. Pollut. Bull. 2022;174 doi: 10.1016/j.marpolbul.2021.113276. [DOI] [PubMed] [Google Scholar]

- Fu Q., Tan X., Ye S., Ma L., Gu Y., Zhang P., Chen Q., Yang Y., Tang Y. Mechanism analysis of heavy metal lead captured by natural-aged microplastics. Chemosphere. 2021;270 doi: 10.1016/J.CHEMOSPHERE.2020.128624. [DOI] [PubMed] [Google Scholar]

- Gallo Neto H., Gomes Bantel C., Browning J., Della Fina N., Albuquerque Ballabio T., Teles de Santana F., de Karam e Britto M., Beatriz Barbosa C. Mortality of a juvenile Magellanic penguin (Spheniscus magellanicus, Spheniscidae) associated with the ingestion of a PFF-2 protective mask during the COVID-19 pandemic. Mar. Pollut. Bull. 2021;166 doi: 10.1016/J.MARPOLBUL.2021.112232. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ganesh Kumar A., Anjana K., Hinduja M., Sujitha K., Dharani G. Review on plastic wastes in marine environment – biodegradation and biotechnological solutions. Mar. Pollut. Bull. 2020;150 doi: 10.1016/J.MARPOLBUL.2019.110733. [DOI] [PubMed] [Google Scholar]

- Gela S.M., Aragaw T.A. Abundance and characterization of microplastics in main urban ditches across the Bahir Dar City,Ethiopia. Front. Mar. Sci. 2022;10 doi: 10.3389/fenvs.2022.831417. [DOI] [Google Scholar]

- Gewert B., Plassmann M., Sandblom O., Macleod M. Identification of chain scission products released to water by plastic exposed to ultraviolet light. Environ. Sci. Technol. Lett. 2018;5:272–276. doi: 10.1021/ACS.ESTLETT.8B00119/SUPPL_FILE/EZ8B00119_SI_001.PDF. [DOI] [Google Scholar]

- Grigoriadou I., Pavlidou E., Paraskevopoulos K.M., Terzopoulou Z., Bikiaris D.N. Comparative study of the photochemical stability of HDPE/Ag composites. Polym. Degrad. Stab. 2018;153:23–36. [Google Scholar]

- Hajiouni S., Mohammadi A., Ramavandi B., Arfaeinia H., De-la-Torre G.E., Tekle-Röttering A., Dobaradaran S. Occurrence of microplastics and phthalate esters in urban runoff: a focus on the Persian Gulf coastline. Sci. Total Environ. 2022;806 doi: 10.1016/J.SCITOTENV.2021.150559. [DOI] [PubMed] [Google Scholar]

- Hatami T., Rakib M.R.J., Madadi R., De-la-Torre G.E., Idris A.M. Personal protective equipment (PPE) pollution in the Caspian Sea, the largest enclosed inland water body in the world. Sci. Total Environ. 2022;824 doi: 10.1016/j.scitotenv.2022.153771. [DOI] [PMC free article] [PubMed] [Google Scholar]

- He S., Jia M., Xiang Y., Song B., Xiong W., Cao J., Peng H., Yang Y., Wang W., Yang Z., Zeng G. Biofilm on microplastics in aqueous environment: physicochemical properties and environmental implications. J. Hazard. Mater. 2022;424 doi: 10.1016/J.JHAZMAT.2021.127286. [DOI] [PubMed] [Google Scholar]

- Hiemstra A.F., Rambonnet L., Gravendeel B., Schilthuizen M. The effects of COVID-19 litter on animal life. Anim. Biol. 2021;71:215–231. doi: 10.1163/15707563-bja10052. [DOI] [Google Scholar]

- Hüffer T., Weniger A.K., Hofmann T. Sorption of organic compounds by aged polystyrene microplastic particles. Environ. Pollut. 2018;236:218–225. doi: 10.1016/j.envpol.2018.01.022. [DOI] [PubMed] [Google Scholar]

- Jędruchniewicz K., Ok Y.S., Oleszczuk P. COVID-19 discarded disposable gloves as a source and a vector of pollutants in the environment. J. Hazard. Mater. 2021;417 doi: 10.1016/j.jhazmat.2021.125938. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jin L., Griffith S.M., Sun Z., Yu J.Z., Chan W. On the flip side of mask wearing: increased exposure to volatile organic compounds and a risk-reducing solution. Environ. Sci. Technol. 2021;55:14095–14104. doi: 10.1021/ACS.EST.1C04591/SUPPL_FILE/ES1C04591_SI_001.PDF. [DOI] [PubMed] [Google Scholar]

- Julienne F., Lagarde F., Delorme N. Influence of the crystalline structure on the fragmentation of weathered polyolefines. Polym. Degrad. Stab. 2019;170 [Google Scholar]

- Kim T., Park K., Hong J. Understanding the hazards induced by microplastics in different environmental conditions. J. Hazard. Mater. 2021;127630 doi: 10.1016/J.JHAZMAT.2021.127630. [DOI] [PubMed] [Google Scholar]

- Klemeš J.J., Fan Y.Van, Jiang P. The energy and environmental footprints of COVID-19 fighting measures – PPE, disinfection, supply chains. Energy. 2020;211 doi: 10.1016/j.energy.2020.118701. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kumar M., Chen H., Sarsaiya S., Qin S., Liu H., Awasthi M.K., Kumar S., Singh L., Zhang Z., Bolan N.S., Pandey A., Varjani S., Taherzadeh M.J. Current research trends on micro- and nano-plastics as an emerging threat to global environment: a review. J. Hazard. Mater. 2021;409 doi: 10.1016/J.JHAZMAT.2020.124967. [DOI] [PubMed] [Google Scholar]

- Kutralam-Muniasamy G., Pérez-Guevara F., Shruti V.C. A critical synthesis of current peer-reviewed literature on the environmental and human health impacts of COVID-19 PPE litter: new findings and next steps. J. Hazard. Mater. 2022;422 doi: 10.1016/J.JHAZMAT.2021.126945. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kwak J.Il, An Y.J. Post COVID-19 pandemic: biofragmentation and soil ecotoxicological effects of microplastics derived from face masks. J. Hazard. Mater. 2021;416 doi: 10.1016/J.JHAZMAT.2021.126169. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lee G., Eui Lee M., Kim S.-S., Joh H.-I., Lee S. Efficient upcycling of polypropylene-based waste disposable masks into hard carbons for anodes in sodium ion batteries. J. Ind. Eng. Chem. 2022;105:268–277. doi: 10.1016/J.JIEC.2021.09.026. [DOI] [Google Scholar]

- Lee S.-H., Seo J., You K.-S., Nam S.-Y., Ahn J.-W. 5th Asian Particle Technology Symposium. Research Publishing Services; 2012. Calcium ion extraction from blast furnace slags for the synthesis of pure calcium carbonate polymorphs by accelerated carbonation; pp. 509–526. [DOI] [Google Scholar]

- Lei L., Wu S., Lu S., Liu M., Song Y., Fu Z., Shi H., Raley-Susman K.M., He D. Microplastic particles cause intestinal damage and other adverse effects in zebrafish Danio rerio and nematode Caenorhabditis elegans. Sci. Total Environ. 2018;619–620:1–8. doi: 10.1016/j.scitotenv.2017.11.103. [DOI] [PubMed] [Google Scholar]

- Li D., Xin Y., Song Y., Dong T., Ben H., Yu R., Han G., Zhang Y. Crystalline modification of isotactic polypropylene with a rare earth nucleating agent based on ultrasonic vibration. Polymers (Basel) 2019;11:1777. doi: 10.3390/POLYM11111777. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li L., Huang J., Almutairi A.W., Lan X., Zheng L., Lin Y., Chen L., Fu N., Lin Z., Abomohra A.E.F. Integrated approach for enhanced bio-oil recovery from disposed face masks through co-hydrothermal liquefaction with Spirulina platensis grown in wastewater. Biomass Convers. Biorefinery. 2021 doi: 10.1007/S13399-021-01891-2/TABLES/3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li S., Ding J., Zheng X., Sui Y. Beach tourists behavior and beach management strategy under the ongoing prevention and control of the COVID-19 pandemic: a case study of Qingdao,China. Ocean Coast. Manag. 2021;215 doi: 10.1016/J.OCECOAMAN.2021.105974. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ma J., Chen F., Xu H., Jiang H., Liu J., Li P., Chen C.C., Pan K. Face masks as a source of nanoplastics and microplastics in the environment: quantification, characterization, and potential for bioaccumulation. Environ. Pollut. 2021;288 doi: 10.1016/J.ENVPOL.2021.117748. [DOI] [PubMed] [Google Scholar]

- Mao R., Lang M., Yu X., Wu R., Yang X., Guo X. Aging mechanism of microplastics with UV irradiation and its effects on the adsorption of heavy metals. J. Hazard. Mater. 2020;393 doi: 10.1016/J.JHAZMAT.2020.122515. [DOI] [PubMed] [Google Scholar]

- Mghili B., Analla M., Aksissou M. Face masks related to COVID-19 in the beaches of the Moroccan Mediterranean: an emerging source of plastic pollution. Mar. Pollut. Bull. 2021;113181 doi: 10.1016/J.MARPOLBUL.2021.113181. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Morgana S., Casentini B., Amalfitano S. Uncovering the release of micro/nanoplastics from disposable face masks at times of COVID-19. J. Hazard. Mater. 2021;126507 doi: 10.1016/j.jhazmat.2021.126507. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Okuku E., Kiteresi L., Owato G., Otieno K., Mwalugha C., Mbuche M., Gwada B., Nelson A., Chepkemboi P., Achieng Q., Wanjeri V., Ndwiga J., Mulupi L., Omire J. The impacts of COVID-19 pandemic on marine litter pollution along the Kenyan Coast: a synthesis after 100 days following the first reported case in Kenya. Mar. Pollut. Bull. 2020;111840 doi: 10.1016/j.marpolbul.2020.111840. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Oturai N.G., Bille M., Clausen L.P.W., Hansen S.F., Syberg K. Strength in numbers: how citizen science can upscale assessment of human exposure to plastic pollution. Curr. Opin. Toxicol. 2021;27:54–59. doi: 10.1016/J.COTOX.2021.08.003. [DOI] [Google Scholar]

- Parvathi K., Al-Maghrabi M.A., Subburaj M., T. Ramesan M. Natural rubber and copper alumina nanocomposite-based flexible elastomer-inorganic hybrid systems. Polym. Compos. 2021;42:4586–4595. doi: 10.1002/PC.26170. [DOI] [Google Scholar]

- Patrício Silva A.L., Prata J.C., Duarte A.C., Barcelò D., Rocha-Santos T. An urgent call to think globally and act locally on landfill disposable plastics under and after covid-19 pandemic: pollution prevention and technological (bio) remediation solutions. Chem. Eng. J. 2021;426 doi: 10.1016/J.CEJ.2021.131201. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Patrício Silva A.L., Prata J.C., Mouneyrac C., Barcelò D., Duarte A.C., Rocha-Santos T. Risks of COVID-19 face masks to wildlife: present and future research needs. Sci. Total Environ. 2021;148505 doi: 10.1016/j.scitotenv.2021.148505. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Peng Y., Wu P., Schartup A.T., Zhang Y. Plastic waste release caused by COVID-19 and its fate in the global ocean. Proc. Natl. Acad. Sci. U. S. A. 2021;118 doi: 10.1073/PNAS.2111530118/-/DCSUPPLEMENTAL. [DOI] [PMC free article] [PubMed] [Google Scholar]

- PlasticsEurope . 2020. Plastics - The Facts 2020. Madrid. [Google Scholar]

- Preece D., Lewis R., Carré M.J. A critical review of the assessment of medical gloves. Tribol. Mater. Surf. Interf. 2020;15:10–19. doi: 10.1080/17515831.2020.1730619. [DOI] [Google Scholar]

- Qiongjie W., Yong Z., Yangyang Z., Zhouqi L., Jinxiaoxue W., Huijuan C. Effects of biofilm on metal adsorption behavior and microbial community of microplastics. J. Hazard. Mater. 2022;424 doi: 10.1016/J.JHAZMAT.2021.127340. [DOI] [PubMed] [Google Scholar]

- Rahman A., Sarkar A., Yadav O.P., Achari G., Slobodnik J. Potential human health risks due to environmental exposure to nano- and microplastics and knowledge gaps: a scoping review. Sci. Total Environ. 2021;757 doi: 10.1016/j.scitotenv.2020.143872. [DOI] [PubMed] [Google Scholar]

- Rajakumar K., Sarasvathy V., Thamarai Chelvan A., Chitra R., Vijayakumar C.T. Natural weathering studies of polypropylene. J. Polym. Environ. 2009;17:191–202. doi: 10.1007/S10924-009-0138-7. [DOI] [Google Scholar]

- Rakib M.R.J., De-la-Torre G.E., Pizarro-Ortega C.I., Dioses-Salinas D.C., Al-Nahian S. Personal protective equipment (PPE) pollution driven by the COVID-19 pandemic in Cox's Bazar, the longest natural beach in the world. Mar. Pollut. Bull. 2021;169 doi: 10.1016/j.marpolbul.2021.112497. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rathinamoorthy R., Balasaraswathi S.R. Disposable tri-layer masks and microfiber pollution – an experimental analysis on dry and wet state emission. Sci. Total Environ. 2021;151562 doi: 10.1016/J.SCITOTENV.2021.151562. [DOI] [PubMed] [Google Scholar]

- Resmeriță A.M., Coroaba A., Darie R., Doroftei F., Spiridon I., Simionescu B.C., Navard P. Erosion as a possible mechanism for the decrease of size of plastic pieces floating in oceans. Mar. Pollut. Bull. 2018;127:387–395. doi: 10.1016/J.MARPOLBUL.2017.12.025. [DOI] [PubMed] [Google Scholar]

- Ricardo I.A., Alberto E.A., Silva Júnior A.H., Macuvele D.L.P., Padoin N., Soares C., Gracher Riella H., Starling M.C.V.M., Trovó A.G. A critical review on microplastics, interaction with organic and inorganic pollutants, impacts and effectiveness of advanced oxidation processes applied for their removal from aqueous matrices. Chem. Eng. J. 2021;424 doi: 10.1016/J.CEJ.2021.130282. [DOI] [Google Scholar]

- Rochman C.M., Brookson C., Bikker J., Djuric N., Earn A., Bucci K., Athey S., Huntington A., McIlwraith H., Munno K., Frond H.De, Kolomijeca A., Erdle L., Grbic J., Bayoumi M., Borrelle S.B., Wu T., Santoro S., Werbowski L.M., Zhu X., Giles R.K., Hamilton B.M., Thaysen C., Kaura A., Klasios N., Ead L., Kim J., Sherlock C., Ho A., Hung C. Rethinking microplastics as a diverse contaminant suite. Environ. Toxicol. Chem. 2019;38:703–711. doi: 10.1002/etc.4371. [DOI] [PubMed] [Google Scholar]

- Rummel C.D., Jahnke A., Gorokhova E., Kühnel D., Schmitt-Jansen M. Impacts of biofilm formation on the fate and potential effects of microplastic in the aquatic environment. Environ. Sci. Technol. Lett. 2017;4:258–267. doi: 10.1021/ACS.ESTLETT.7B00164/SUPPL_FILE/EZ7B00164_SI_001.PDF. [DOI] [Google Scholar]

- Saliu F., Veronelli M., Raguso C., Barana D., Galli P., Lasagni M. The release process of microfibers: from surgical face masks into the marine environment. Environ. Adv. 2021;4 doi: 10.1016/j.envadv.2021.100042. [DOI] [Google Scholar]

- Sandt C., Waeytens J., Deniset-Besseau A., Nielsen-Leroux C., Réjasse A. Use and misuse of FTIR spectroscopy for studying the bio-oxidation of plastics. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2021;258 doi: 10.1016/J.SAA.2021.119841. [DOI] [PubMed] [Google Scholar]

- Sarkar M., Hasanuzzaman M., Gulshan F., Rashid A. Reference Module in Materials Science And Materials Engineering. Elsevier; 2020. Surface, mechanical and shape memory properties of biodegradable polymers and their applications. [DOI] [Google Scholar]

- Shen M., Zeng Z., Song B., Yi H., Hu T., Zhang Y., Zeng G., Xiao R. Neglected microplastics pollution in global COVID-19: disposable surgical masks. Sci. Total Environ. 2021;790 doi: 10.1016/j.scitotenv.2021.148130. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Speight J.G. Handbook of Industrial Hydrocarbon Processes. Elsevier Inc.; 2011. Handbook of industrial hydrocarbon processes. [DOI] [Google Scholar]

- Statista Production volume of N95 masks in the United States in January 2020 and winter 2020(in millions) [WWW Document] 2021. https://www.statista.com/statistics/1135072/us-n95-mask-production/ Madrid.

- Stokes G. OceanAsia; 2020. No Shortage Of Masks At The Beach - OCEANS ASIA [WWW Document]https://oceansasia.org/beach-mask-coronavirus/ [Google Scholar]

- Sullivan G.L., Delgado-Gallardo J., Watson T.M., Sarp S. An investigation into the leaching of micro and nano particles and chemical pollutants from disposable face masks - linked to the COVID-19 pandemic. Water Res. 2021;196 doi: 10.1016/j.watres.2021.117033. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sun J., Yang S., Zhou G.-J., Zhang K., Lu Y., Jin Q., Lam P.K.S., Leung K.M.Y., He Y. Release of microplastics from discarded surgical masks and their adverse impacts on the marine copepod Tigriopus japonicus. Environ. Sci. Technol. Lett. 2021 doi: 10.1021/ACS.ESTLETT.1C00748. [DOI] [Google Scholar]

- Sussarellu R., Suquet M., Thomas Y., Lambert C., Fabioux C., Pernet M.E.J., Goïc N.Le, Quillien V., Mingant C., Epelboin Y., Corporeau C., Guyomarch J., Robbens J., Paul-Pont I., Soudant P., Huvet A. Oyster reproduction is affected by exposure to polystyrene microplastics. Proc. Natl. Acad. Sci. U. S. A. 2016;113:2430–2435. doi: 10.1073/PNAS.1519019113/-/DCSUPPLEMENTAL. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Takdastan A., Niari M.H., Babaei A., Dobaradaran S., Jorfi S., Ahmadi M. Occurrence and distribution of microplastic particles and the concentration of di 2-ethyl hexyl phthalate (DEHP) in microplastics and wastewater in the wastewater treatment plant. J. Environ. Manag. 2021;280 doi: 10.1016/J.JENVMAN.2020.111851. [DOI] [PubMed] [Google Scholar]

- Thiel M., de Veer D., Espinoza-Fuenzalida N.L., Espinoza C., Gallardo C., Hinojosa I.A., Kiessling T., Rojas J., Sanchez A., Sotomayor F., Vasquez N., Villablanca R. COVID lessons from the global south – face masks invading tourist beaches and recommendations for the outdoor seasons. Sci. Total Environ. 2021;147486 doi: 10.1016/j.scitotenv.2021.147486. [DOI] [Google Scholar]

- Torres F.G., De-la-Torre G.E. Historical microplastic records in marine sediments: current progress and methodological evaluation. Reg. Stud. Mar. Sci. 2021;46 doi: 10.1016/J.RSMA.2021.101868. [DOI] [Google Scholar]

- Torres F.G., De-la-Torre G.E. Face mask waste generation and management during the COVID-19 pandemic: an overview and the Peruvian case. Sci. Total Environ. 2021;786 doi: 10.1016/J.SCITOTENV.2021.147628. [DOI] [Google Scholar]

- Torres F.G., Dioses-Salinas D.C., Pizarro-Ortega C.I., De-la-Torre G.E. Sorption of chemical contaminants on degradable and non-degradable microplastics: recent progress and research trends. Sci. Total Environ. 2021;757 doi: 10.1016/j.scitotenv.2020.143875. [DOI] [PubMed] [Google Scholar]

- Truchet D.M., Forero Lopez A.D., Ardusso M.G., Rimondino G.N., Buzzi N.S., Malanca F.E., Spetter C.V., Fernández-Severini M.D. Microplastics in bivalves, water and sediments from a touristic sandy beach of Argentina. Mar. Pollut. Bull. 2021;173 doi: 10.1016/j.marpolbul.2021.113023. [DOI] [PubMed] [Google Scholar]

- Waldman W.R., Rillig M.C. Microplastic research should embrace the complexity of secondary particles. Environ. Sci. Technol. 2020;54:7751–7753. doi: 10.1021/ACS.EST.0C02194. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang J., Liu X., Li Y., Powell T., Wang X., Wang G., Zhang P. Microplastics as contaminants in the soil environment: a mini-review. Sci. Total Environ. 2019;691:848–857. doi: 10.1016/j.scitotenv.2019.07.209. [DOI] [PubMed] [Google Scholar]

- Wang X., Okoffo E.D., Banks A.P., Li Y., Thomas K.V., Rauert C., Aylward L.L., Mueller J.F. Phthalate esters in face masks and associated inhalation exposure risk. J. Hazard. Mater. 2021;127001 doi: 10.1016/J.JHAZMAT.2021.127001. [DOI] [PubMed] [Google Scholar]

- Wang Z., An C., Chen X., Lee K., Zhang B., Feng Q. Disposable masks release microplastics to the aqueous environment with exacerbation by natural weathering. J. Hazard. Mater. 2021;417 doi: 10.1016/j.jhazmat.2021.126036. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Xu M., Halimu G., Zhang Q., Song Y., Fu X., Li Y., Li Y., Zhang H. Internalization and toxicity: a preliminary study of effects of nanoplastic particles on human lung epithelial cell. Sci. Total Environ. 2019;694 doi: 10.1016/j.scitotenv.2019.133794. [DOI] [PubMed] [Google Scholar]

- Yan S., Stackhouse C.A., Waluyo I., Hunt A., Kisslinger K., Head A.R., Bock D.C., Takeuchi E.S., Takeuchi K.J., Wang L., Marschilok A.C. Reusing face covering masks: probing the impact of heat treatment. ACS Sustain. Chem. Eng. 2021;9:13545–13558. doi: 10.1021/ACSSUSCHEMENG.1C04530/SUPPL_FILE/SC1C04530_SI_001.PDF. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yu A., Sun X., Tang S., Zhang Y., Li M., Wang X. Adsorption mechanism of cadmium on polystyrene microplastics containing hexabromocyclododecane. Environ. Technol. Innov. 2021;24 doi: 10.1016/J.ETI.2021.102036. [DOI] [Google Scholar]

- Yu R., Wen X., Liu J., Wang Y., Chen X., Wenelska K., Mijowska E., Tang T. A green and high-yield route to recycle waste masks into CNTs/Ni hybrids via catalytic carbonization and their application for superior microwave absorption. Appl. Catal. B Environ. 2021;298 doi: 10.1016/J.APCATB.2021.120544. [DOI] [Google Scholar]