Abstract

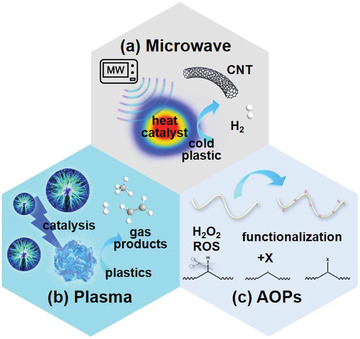

Microplastics are an emergent yet critical issue for the environment because of high degradation resistance and bioaccumulation. Unfortunately, the current technologies to remove, recycle, or degrade microplastics are insufficient for complete elimination. In addition, the fragmentation and degradation of mismanaged plastic wastes in environment have recently been identified as a significant source of microplastics. Thus, the developments of effective microplastics removal methods, as well as, plastics recycling strategies are crucial to build a microplastics‐free environment. Herein, this review comprehensively summarizes the current technologies for eliminating microplastics from the environment and highlights two key aspects to achieve this goal: 1) Catalytic degradation of microplastics into environmentally friendly organics (carbon dioxide and water); 2) catalytic recycling and upcycling plastic wastes into monomers, fuels, and valorized chemicals. The mechanisms, catalysts, feasibility, and challenges of these methods are also discussed. Novel catalytic methods such as, photocatalysis, advanced oxidation process, and biotechnology are promising and eco‐friendly candidates to transform microplastics and plastic wastes into environmentally benign and valuable products. In the future, more effort is encouraged to develop eco‐friendly methods for the catalytic conversion of plastics into valuable products with high efficiency, high product selectivity, and low cost under mild conditions.

Keywords: catalytic conversion, degradation, microplastics, plastic waste, recycle

The emerging microplastics issue has received enormous amount of attentions recently as the adverse impacts on living things. The developments of catalytic conversion of microplastics and plastic wastes into harmless matters and valuable chemicals give the promising route for not only building a microplastics‐free environment but also constructing the circular economy mode.

1. Introduction

Microplastics (MPs), defined as plastic debris with diameters smaller than 5 mm,[ 1 , 2 ] are regarded as an emerging environmental contaminant and have received enormous amounts of attention due to their potential adverse impacts on living things. Depending on their sources, MPs are classified as primary and secondary MPs. As shown in Figure 1 , primary MPs are plastic particles designed and produced intentionally for a given application, such as, micro‐sized plastic microspheres, fragments, and microfibers pervasively applied in personal care products or synthetic textiles. In contrast, secondary MPs are unintentionally formed from the gradual fragmentation of mismanaged plastic wastes by photolysis, abrasion, and/or microbial decomposition. Whether intentionally or unintentionally produced, MPs with varied shapes, including beads, foams, fibers, and films,[ 3 , 4 , 5 ] have been detected in air,[ 6 ] aquatic systems,[ 7 , 8 , 9 , 10 ] river and ocean sediments,[ 11 ] and soil.[ 3 , 12 ] The fast release of MPs with their combined high resistance against degradation results in a rapid accumulation of these particles in the natural environment.[ 13 , 14 ] It is predicted that the total mass of plastic debris cumulated in ocean could increase to ≈250 million metric tons (Mt) by 2025, which is an order of magnitude higher than in 2010.[ 15 ] The light and small nature of MPs lead to their easy transportation with wind and water flow in environment. As a consequence, MPs have been found worldwide both close to human habitation and in remote areas far away from human activities. After long‐term exposure to MPs, the chronic toxicity including impaired reproduction and malnutrition can be caused, posing a threat to biota and humans. Further, due to the relatively large specific surface area of MPs, heavy metals,[ 16 ] and persistent organic pollutants (POPs)[ 17 , 18 ] are prone to adhere and accumulate on the surface of MPs and then migrate in environment. It has been reported that the concentrations of POPs adsorbed onto the MPs can be 10[ 6 ] higher than that in the ambient environment.[ 19 ] Thus, further transfer and accumulation of these hazardous POPs carried MPs in the food chain lead to serious potential threats to human health. The level of concern around MPs is so great, governments globally are legislating against the production of primary MPs.[ 20 ]

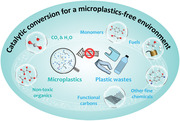

Figure 1.

Pathways of the generation of MPs and concept to build a MPs free environment. a) Generation of primary MPs. b) The end‐of‐life of plastic products. c) Generation of secondary MPs plastic wastes. d) Chemical degradation of the existing environmental MPs. e) Rational plastic wastes managements to alleviate the generation MPs from the key source.

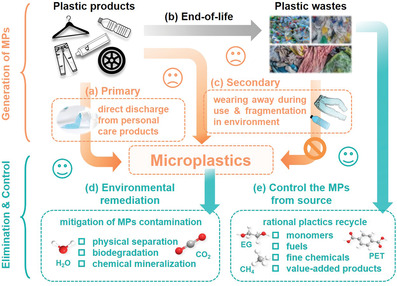

To understand the development trends and subject areas of research related to MPs, we analyzed the publications published from 2004, when the concept of microplastics was first proposed by Thompson et al.[ 21 ] to November of 2021 by using “microplastic” or “micro‐plastic” or “micro‐sized plastic” as keywords. We obtained 4692 records from Web of Science Core Collection (WoSCC) database. As shown in Figure 2 , the number of the published papers on MPs research have increased exponentially in the last 10 years, and about 65.72% (3261 items) of the total publications were published in the most recent 3 years, reflecting that this topic is of critical importance.

Figure 2.

The number of annual publications and keywords (insert) on MPs research in Web of Science Core Collection (WoSCC) database from 2004 to November of 2021. (Insert created using wordle.net.)

The articles (83.65%) and reviews (10.17%) account for the majority of the papers (a sum of 4402 papers). We summarized the most prevalent keywords from these papers and the insert of Figure 2 illustrates the frequency visualization of keywords among these identified papers. The larger size of these keywords indicates that the more papers have been published concerning such topics. The most frequently used keywords are microplastics, health, environment, marine, analysis, degradation, and soil. There are many high‐quality reviews focusing on the hot spots mentioned above. Ganesh et al. reported an overview of degradability of typical synthetic plastics in the marine environment and highlighting the degradation resistance of MPs and their long‐term toxic effects on marine organisms.[ 22 ] Ivleva et al. reviewed the methods of analysis for aquatic MPs, uptake of MPs in aquatic organisms, and toxicity effects on these aquatic organisms.[ 1 ] Elkhatib et al. compared the sampling, processing, identification and quantification technologies of MPs in several studies.[ 23 ] Chamas et al. discussed the environmental effects on degradation rates of MPs with respect to their shape, size, and chemical composition.[ 24 ] Guo et al. gave an overview on the MPs’ sorption behaviors on heavy metals and POPs in marine environment.[ 25 ] In previous studies, researchers focused on the understanding of the characterization of MPs in natural environments especially in marine and soil, as well as, their impacts to health of living things. Taking into account the rapid accumulation of MPs and severe contamination of these pollutants in the environment, pioneering researchers began to emphasize the importance of developing efficient strategies to mitigate MPs contamination. Even though researchers have discovered the insufficient nature of traditional technologies in practical application for MPs removal, reviews mostly focused on summarizing traditional physical methods rather than discussing the potential alternatives and their challenges. Meanwhile, the mismanaged plastic wastes in environment are also worth considering, since they can degrade and gradually fragmented into MPs. Physical separation via waste water treatment plants (WWTPs) remains the primary mechanism of removing MPs. Unfortunately, the sludge from physical separation is often recycled for landfill or agricultural applications, leading to MPs re‐entering the water system. Taking the sludge used for agriculture in North America as an example, there are 4.4 × 104 to 3.0 × 105 tons of MPs that return to environment per year.[ 26 ] Subsequently, MPs can return to water systems again through soil erosion or surface runoff. Thus, emerging methods that permanently degrade and remove MPs are critical to remediating the environment. Hence, it is an urgent need to review the recent advanced technologies for transformation of MPs into non‐toxic matter or recycling plastic wastes into valuable products. On the other hand, researchers proved the relationship between MPs and plastic wastes that plastic wastes in landfills and environment are potential sources for MPs releasing under weathering, light radiation, and microorganisms.[ 27 , 28 , 29 ] Unfortunately, less than 9% of the total plastic wastes were recycled due to the high cost, low productivity of current recycle approaches. Thus, the development of efficient and green methods to catalytic convert plastic wastes into valorized chemicals is significant, since it can not only prevent the release of MPs but also reclaim raw materials for plastics industry. In summary, the two strategies jointly contribute to create a green and sustainable MPs‐free environment by eliminating MPs existing in environment and preventing the generation of MPs from the significant potential source.

In this critical review, we take a holistic approach to managing, mitigating, and remediating MPs from the environment. First, we highlight the recent innovations on transforming MPs into environmental‐friendly products and reveal their underlying mechanisms and challenges to directly alleviate the potential health risk for living organisms. Second, we focus on the recycling strategies of plastic wastes, which is highly important to suppress the release of secondary MPs by potentially yielding new fine chemicals or fuels. Novel catalytic methods such as, photocatalysis, catalytic advanced oxidation process (AOP), and biodegradation (enzymatic catalysis) open the door to convert MPs and plastic wastes into non‐toxic products or valuable products (monomers, fuels, or other value‐added fine chemicals). Advanced catalyst design is significant to promote the development of these methods, where the product selectivity, conversion efficiency, reaction rate can be further optimized. The overall aim of this review is to inspire innovation for green and efficient catalytic strategies targeting on MPs contamination elimination and plastic wastes recycling to comprehensively build a MPs‐free environment.

2. Sources, Fate, and Impacts of Microplastics

Plastics are high molecular weight synthetic polymers produced by polymerization of various types of monomers derived mainly from fossil feedstocks. Nowadays, plastics are an essential type of material in our society due to their light‐weight, relatively low price, excellent moldability, and durability. The global production of plastics continuously increases during the last decades and this figure increased to 367 Mt in 2020 from 2 Mt in 1950.[ 30 ] However, the overuse of plastics has caused serious MPs contamination.

Primary MPs are continuously released into nature through the use of micro‐sized plastics‐contained products in our daily lives. For instance, polyethylene (PE) particles with size between 70 and 400 µm have been frequently used as exfoliators in facial cleaners and toothpaste.[ 31 ] About 0.74 to 4.8 g of PE microbeads (diameters smaller than 1000 µm) were added to 100 mL of body and facial scrub, which result in 15.2 mg MPs release into the sewage system per person per day.[ 32 ] Laundry of textiles based on polyester (PET) polyamide (PA) and other kinds of chemical microfibers has also been known as an important source of primary MPs as well. It was reported that >1900 fiber‐based MPs were produced by washing of a single garment.[ 2 ]

The release of secondary MPs is mostly derived from the littered plastic wastes. Based on the lifetime statistics, the majority of plastic products are used for short‐term applications. About 40% of plastic products have a lifetime shorter than one month or for disposable uses. To date, the cumulative mass of virgin plastics on the earth has reached to 8300 Mt, with 6300 Mt ending up as waste.[ 33 ] Unfortunately, only 9% and 12% of the total plastic wastes end up in recycle and incineration, while 79% of plastic wastes have been landfilled or directly enter in nature environment.[ 34 ] Landfilling with characteristic of facility was considered as major option for plastic wastes managements in the past years. Geyer et al. estimated that the sum of plastic wastes accumulated in landfills or natural environment globally were around 4900 Mt (60% of all plastics ever produced) and this number will reach to roughly 12 000 Mt by 2050.[ 33 ] Although it seems that the landfill treatment is the easiest and most economical method, the buried plastic waste can lead to greater impacts by constantly releasing secondary MPs due to several physical or chemical degradation effects. The chemical composition of secondary MPs is more various than primary MPs, since many categories of plastics are used in our lives. Secondary MPs can be released by wearing of tires (synthetic rubber), which can be carried by stormwater runoff and enter water systems.[ 35 ] The use and disposal of PE, PA, and polypropylene (PP) fibers during fishing and other water activities also release a large amount of secondary MPs.[ 36 ] Meanwhile, the chemical composition of secondary MPs will change during weathering, since the generation of oxygen‐containing groups and unsaturation bonds on the polymer chain.[ 24 ] As the result, the slightly changed density and hydrophilicity of secondary MPs can influence the MPs removal efficiency in WWTPs, which is discussed in later sections. Due to the breakdown of plastics triggered by physical wear and chemical degradation, secondary MPs possess wider size distribution with the range of millimeters to nanometers. It has been reported that numerous smaller‐sized MPs (<500 µm) and even nanoplastics (NPs, <1 µm) could be released during the secondary degradation and fragmentation of primary and secondary MPs.[ 13 , 37 , 38 ] Even worse, compared with bulk plastics, smaller‐sized MPs are more difficult to clean and more hazardous.[ 39 , 40 , 41 , 42 ]

Water systems are the mostly heavily polluted area by MPs.[ 15 ] Su et al. reported that the abundance of MPs in the surface water samples of Taihu Lake is about 6.80 × 106 items km−2, which is the highest among all the known data about freshwater lakes worldwide.[ 43 ] Fibrous microplastics account for a major part of 48–84% of MPs pollutants. Sources and abundance of MPs in Qinghai Lake, the largest inland lake in China, were investigated by Wu et al.[ 4 ] In this study, the abundance of MPs in surface water and inflowing rivers were up to 7.58 × 105 items km−2 and 0.31 × 105 items km−2, respectively. It was also identified that PE and PP are the main chemical component of these MPs. He et al. indicated that the average abundance of MPs in shallow and deep soils in the suburbs of Shanghai were 78.00 and 62.50 items kg−1 respectively.[ 3 ] It was also indicated that the fibers (53.33%) and fragment (37.58%) were the dominant morphologies of MPs. Zhang et al. investigated the abundance of MPs in sediment samples from the Qiantang River and Hangzhou Bay, in which the microplastic abundance of 0.23 and 0.18 particles gsediment −1 were detected, respectively.[ 44 ] Micro‐Fourier transform infrared spectroscopy analysis identified that PE‐MPs accounted for 60% of the total items of MPs. Owing to the low density and small size of MPs, wind, precipitation, surface runoff, and riverine transport result in the worldwide migration of MPs. As the final destination of all kinds of pollutants from the land, ≈15–51 trillion MPs, equivalent to 93 000–236 000 tons in weight, have been accumulated in the ocean since 2015.[ 45 ] As previously projected under the current production and waste of plastics, the total amount of plastic wastes and MPs accumulated in ocean could increase by an order of magnitude from 2010 levels by 2025.[ 15 ] Moreover, Kane et al. found a high MPs abundance of up to 1.9 × 107 items m−2 in “hot spots” created by ocean current.[ 46 ] In addition, the presence of MPs has been found at both the proximity of human habitats and remote areas far away from human activities. MPs pollution is also a serious problem in Mariana Trench, where the MPs abundance was reported to be about 2200 pieces L−1 (6.20 pieces gsediment −1) at depths of 5108–10 908 m.[ 47 ] MPs pollution also exists in drinking water. Based on the statistics reported by Craver et al., the concentrations of MPs with particle size between 1 and 500 µm in drinking water could be as high as 5505 items L−1.[ 23 ]

Although ingestion of MPs does not directly lead to acute fatal effects on organisms, chronic toxicity could be triggered by long‐term exposure to MPs.[ 48 ] Sussarellu et al. pointed out that the intake and transfer of polystyrene (PS) MPs in blood can cause reproductive disruption in marine filter feeders.[ 49 ] It should be noted that the shape, size, surface charge, dose, and other factors of MPs play a critical role on inducing biological toxicity.[ 50 ] Au et al. reported that fibers PP‐MPs were more toxic than PE‐MPs particles on significantly declining of the food egestion of Hyalella azteca.[ 51 ] Zhang et al. proved that intestinal inflammation was easily induced by the activation of TLR4 signaling when exposed at a high‐concentration of PE‐based MPs.[ 52 ] During the photodegradation and biodegradation of MPs in environment, different functional groups (e.g., —COOH and —NH2) can be introduced onto their surfaces and thus alter their surface charge. Kim et al. found that the PS NPs could be internalized by alveolar cells, and the positively charged NPs could result in the activation of apoptotic signaling.[ 38 ] To give the as‐manufactured plastics certain application, various additives such as low molecular organics, polymers, and heavy metal complexes are used as plasticizers, flame retardants and colorants and incorporated into plastics. Unfortunately, most of the additives such as, bisphenol A, di‐2‐ethylhexyl phthalate, and heavy metal complexes are known to be toxic.[ 53 , 54 ] Thus, the additives leaching from MPs can also impose toxicity to biota and human. As previously mentioned, the relatively high specific surface area and small particle size of the MPs resulted in the adherence and accumulation of heavy metals[ 16 ] and POPs[ 17 , 18 ] on the surface of MPs, which then further migrate in the environment with MPs. Toxic elements such as, cadmium (Cd), lead (Pb), mercury (Hg), and arsenic (As), as well as, polycyclic aromatic hydrocarbon (PAHs) and polychlorinated biphenyls (PCBs) have been detected on the surface of MPs samples obtained from various environments.[ 25 ] Turner et al. showed that the concentrations of Pb encountered in MPs was up to 17 500 µg gMPs −1 in the sediment of beaches in southwest England.[ 16 ] PAHs and PCBs carried by MPs were detected with remarkably high concentrations of 13 708 and 7554 ng gMPs −1 by Taniguchi et al. in the coast of the state of São Paulo.[ 55 ] In addition, MP particles can also act as carriers of foreign species and thus transporting the potentially pathogenic microorganisms in the environment.[ 56 , 57 , 58 ] Due to the accumulation effect, concentrations of these hazardous matters can be 1 million times higher than those in the ambient environment,[ 19 ] which results in the enhanced toxicity triggered by the ingestion of MPs.[ 59 , 60 , 61 ] Hence, it is highly essential to develop efficient solutions for tackling the MPs issue.

3. Current Management Approaches of Microplastics

Due to the heavy use of plastic microbeads as additives in personal care products and the release of microfibers during laundry of synthesized textiles, municipal wastewater contains a large number of MPs. Before entering the environment, waste water is treated in WWTPs. Although WWTPs are regarded as reliable filters to trap all kinds of pollutants existing in the municipal water, it has been reported that the effluent from WWTPs is actually a key outlet for releasing MPs to our natural environment.[ 19 , 23 , 40 ] Due to the lack of effective MPs removal technologies in WWTPs, numerous MPs can pass through traditional WWTPs and enter the natural water systems. Moreover, MPs that are removed by waste water treatment are mainly retained in the sludge, which is mostly directly landfilled or further processed as farmland fertilizer. These MPs can still return to water systems through soil erosion or surface runoff.[ 26 ] Due to the comprehensive natural forces of wind, rainfall, and snowfall, MPs now widely existing globally.[ 62 , 63 ] Mechanical collection of the MPs already existing in the environment by trawl or automatic collectors is helpful to purify the natural water bodies, yet is highly time‐consuming and is far away from being efficient and effective. Rational regulation of MPs in WWTPs is therefore of great importance to block MPs from further migration into the environment.

3.1. Water Waste Treatment Plants and Microplastic Removal Efficiency of Each Step

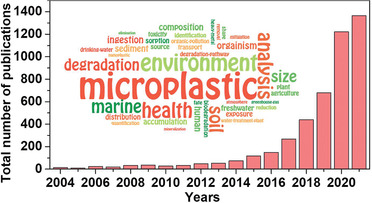

A typical waste water treatment process in WWTPs comprises four stages: Preliminary treatment, primary treatment, secondary treatment, and tertiary treatment (Figure 3 ).

Figure 3.

Removal of MPs at different WWTP steps: a) Preliminary treatment. b) Primary treatment. c) Secondary treatment. d) Tertiary treatment. e) Land application.

The first step of WWTPs is a so‐called “pre‐treatment” process, comprising a preliminary and a primary treatment step (Figure 3a). At the first stage of the entire process, rags, sticks, and other large items are trapped during the preliminary treatment process to avoid their damage to pumps and interference of membranes in the subsequent purification processes. It typically comprises coarse screening (6–150 mm), fine screening (less than 6 mm), and grit removal steps. Large flocs of fat, oil, and grease contained in wastewater can be helpful to trapping MPs during preliminary treatment.[ 64 ] Thus, the suspended or floating MPs are removed along with other insoluble impurities affording an ≈35–59% MPs removal efficiency at this stage.[ 19 , 65 ] Subsequently, a portion of the remaining MPs are removed by gravity separation and surface skimming operations in primary clarifiers (Figure 3b), where the relatively heavier MPs can settle down or be trapped in sludge flocs, while the floating lighter MPs are trapped by the grease during surface skimming. As a result, about 50–98% of the MPs can normally be removed after primary treatment.[ 66 ] During the pre‐treatment process, the removal efficiency of MPs is influenced by several characteristics of the MPs, including their size, chemical compositions and morphology. Dris et al. indicated that the concentration of the relatively larger MPs with particle size of 1–5 mm was significantly reduced from 45% in the influent to 7% in the effluent during pre‐treatment process.[ 67 ] Murphy et al. found that the lighter PE‐MPs floating on the water surface can be easily removed in the skimming process, while the heavier polyvinyl chloride (PVC) and polyethylene terephthalate (PET) MPs can be separated by settling or being captured by sludge flocs.[ 40 ] It is worth noting that the concentration of fibrous MPs in waste water are markedly reduced in the pre‐treatment effluent, which could be ascribed to the long‐shaped fibrous MPs are more prone to be removed by coagulation trapping and following gravity separation.[ 68 ] However, it has been reported that fibrous MPs remain to be the largest fraction after this stage.[ 64 , 69 ] In addition to the retention by pre‐treatment, the decrease of particle size of MPs in effluent could be ascribed to the fragmentation of large items by the physical forces through sand abrasion or water turbulence.[ 70 ] This phenomenon leads to the newly generated smaller sized MPs debris passing through pre‐treatment and proceeding to secondary treatment.

The next step of WWTPs is the secondary treatment, where the remaining suspended solids and dissolved organic pollutants in the water can be further removed by the combined use of the activated sludge and the clarification tank (Figure 3c). Aside from being captured by sludge, the microorganisms in the activated sludge can enhance the MPs removal efficiency. Due to growth of biofilms on the surface of MPs, the relative densities of MPs are normally dramatically altered, which facilitates the sinking and subsequent separation of suspended MPs.[ 71 , 72 ] It is known that there are a few bacteria, such as, Bacillus, Rhodococcus, and Nocardia asteroids, that are capable of degrading MPs,[ 73 , 74 , 75 ] however, the low biodegradation rates and short contact times between activated sludge and MPs result in negligible effect on the degradation of MPs in secondary treatment. The overall MPs removal efficiency is 86–99.8% relative to the pre‐treatment effluent accompanied with decrease of the MPs’ average size.[ 71 , 72 ] Sun et al. reported the MPs with diameters larger than 500 µm were completely removed in this stage and the remaining ones were predominantly smaller than 190 µm.[ 19 ] Talvitie et al. revealed that only 8% MPs in the secondary effluent are larger than 300 µm in diameters.[ 76 ] Similar to the pre‐treatment stage, MPs undergo the continuous fragmentation under the comprehensive physical and biological factors. Although the formation of biofilms on the surface of MPs can facilitate the sedimentation of the MPs, the altered surface wetting properties and their relative densities might lead to MPs escape from skimming and settling processes.[ 19 ] For many WWTPs, the secondary effluent is discharged into water environment after disinfection, causing the leakage of large amounts of fibrous MPs and smaller‐sized (i.e., <300 um) MPs which accumulate in the environment. As indicated in a report, a high MPs removal efficiency of 98% was achieved for a secondary WWTP serving 650 000 people in Scotland. However, the daily seepage amount of MPs (corresponding to the 2% remaining) into the environment was estimated to be 65 million pieces.[ 40 ] In a separate report, the estimated median value of the amount of MPs discharged from WWTPs with an average annual efflux of 5 × 107 m3 per year was 200 000 particles per day.[ 77 ]

Tertiary treatment, also called as advanced treatment, is the final stage of the whole process, which is frequently adopted to produce high quality drinking water (Figure 3d). Typically, gravity filtration, sand filtration, disc filters, dissolved air flotation, biologically active filters, membrane bioreactors (MBRs), and other advanced treatments can be applied to decrease the concentration of suspended solid impurities, organic pollutants, heavy metals, and pathogens in water.[ 69 ] Based on these separation techniques, it has been reported that a high MP removal efficiency of 98–99.9% can be delivered. It is interesting to note that the fibrous MPs are difficult to remove in this process. By employing a sampling device with multiple mesh screens (500, 190, and 100 µm) to collect MPs from tertiary effluent, Ziajahromi et al. found that the MPs smaller than 190 µm are the majority of the residual MPs in tertiary effluent.[ 78 ] Meanwhile, the fibrous MPs have been proved to be the major species (54.5–88.9%) in tertiary effluent, which is thought to arise as these high‐aspect‐ratio materials are able to pass through the pores of filter or membranes longitudinally.[ 39 , 65 , 69 , 78 ]

Despite the relative high MPs removal efficiency in WWTPs, the remaining MPs are extremely difficult to be removed by using currently available technology. Development of more advanced techniques to reduce the amount of MPs in the effluent of WWTPs is urgent to avoid their further migration into the environment. In the next sections, we will discuss the recent progresses to regulate MP based on several advanced techniques.

3.2. Physical Trapping Methods

3.2.1. Coagulation

In current water plants, coagulation is frequently used during the advanced treatment to produce drinking water of high quality. The coagulants, for example, ferric sulfate or aluminum sulfate, used in this procedure triggers the aggregation of the suspended particulate matters into flocs[ 19 , 65 ] which subsequently sediment and can be conveniently separated from water. The hydrogen bonding and/or electrostatic interactions between the coagulants and suspended solids are the key to ensure good separation efficiency during this process.

To investigate the efficacy of MP removal via coagulation, Ma et al. studied a Fe‐based salt (FeCl3·6H2O) as coagulant to remove PE MPs at pH 7.0 in a lab‐scale simulated drinking water treatment.[ 79 ] This process was not very efficient with only 13% MPs with diameters <0.5 mm able to be removed at a relative high Fe salt concentration of 2 mmol L−1 (≈112 mg L−1 Fe), where the doses of Fe commonly applied for coagulation of other impurities in drinking water treatment were ≈20 mg L−1. The authors believed that some MPs trapped in unstable flocs were not efficiently settled, which could be ascribed to the weak interaction between the coagulant and the surface of pristine plastic.[ 71 ] By simply adding 15 mg L−1 polyacrylamide (PAM) to the FeCl3.6H2O, an excellent MP removal efficiency of 90.91% ± 1.01% was achieved. The authors speculated that, due to static interactions between the anionic PAM and cationic Fe‐based flocs, more stable and dense flocs were formed and the escape of MPs from them was therefore effectively avoided.

In addition to the use of additives, the surface properties of MPs is a significant aspect influencing the MPs removal efficiency of coagulation.[ 80 ] For instance, the changes of surface chemistry and roughness of MPs during the weathering processes in the natural environment could impact MPs affinity for coagulants and flocculants. Lapointe et al. evaluated the coagulation efficiencies in removing pristine and weathered MPs.[ 81 ] In this study, PE and PS microspheres and polyester microfibers were the main subjects during the aluminum salts‐based coagulation (alum concentration of 0.063 mmol L−1). For the pristine MPs removal, a superior removal efficiency of polyester microfibers of 99% and residual MPs of 5 microfibers L−1 were delivered, while the removal efficiencies of PE and PS microspheres was 82% (residual of 90 MPs L−1) and 84% (residual of 80 MPs L−1), respectively. This phenomenon can be not only attributed to the stronger adsorption bridging effects between the fibrous polyester MPs and flocs, but also ascribed to the enhanced surface attachment of flocs resulting from the presence of abundant C = O bonds at the ester group. For the weathered MPs in environment, the photo‐oxidation effect and the attachment of natural organic matter (biofilm or POPs) can introduce oxygen‐containing groups (hydroxyl and carboxylic acid groups) and unsaturated bonds (vinyl groups). Thus, these newly formed groups could promote interactions between the coagulant and MPs by acting as anchoring sites. As a consequence, the removal of weathered PE was remarkably increased to 99%, compared to the 82% of pristine PE.

In summary, the development of advanced and green additives to stabilize the flocs, as well as, the extra oxidation steps (e.g., UV and ozone) to boost the interaction between flocs and MPs are critical to enhance the MPs removal efficiency during coagulation process.

3.2.2. Membrane‐Based Filtration

Due to key advantages of a high separation efficiency and compact plant size, filtration techniques such as, microfiltration (MF), ultrafiltration (UF), reverse osmosis (RO), dynamic membranes (DM), and MBRs, have been shown to be feasible to produce high quality water from primary or secondary effluent.[ 82 , 83 ] By using the asymmetric membranes with micrometer or nanometer‐sized pores, the impurities including bacteria, protozoa, viruses, and the suspended solids can be effectively removed. Although UF and RO have exhibited the good efficiency for MPs removal in WWTPs, millions of MPs still remained in the effluent after these treatments.[ 78 ]

Dynamic membrane technology has been studied extensively as a promising candidate in advanced water treatment process.[ 84 , 85 ] Different from traditional filtration approaches that use membranes with micrometer or nanometer‐sized pores to retain the tiny solids, DM technology uses a newly formed cake layer on supporting membrane through filtration, which serves as a secondary barrier to trap the impurities debris. Since the DM is fully composed of the solid impurities from the wastewater, the use of extra chemical agents can be avoided and the possibility of introducing secondary pollutants can be therefore circumvented. Typically, the low filtration resistance and low trans‐membrane pressure (TMP) during DM filtration make it feasible to be applied under a gravity‐driven mode without the use of pumps. By utilizing a gravity‐driven lab‐scale DM filtration protocol, Xu et al. attempted to purify synthetic wastewater composed of tap water and diatomite particles.[ 86 ] The pore size of the supporting membrane is 90 µm, while the sizes of 90% of the diatomite particles are in a range of 1–90 µm. After 20 min of treatment, the turbidity of the synthetic wastewater was significantly reduced from 195 to 1 nephelometric turbidity unit, indicating a high removal efficiency of these micro‐sized MPs by DM technology. In addition, the TMP during DM filtration is significantly lower than UF and OR, resulting in overall lower energy consumption.

Recently, membrane technologies have been further modified by coupling with other techniques, overall exhibiting higher MPs removal efficiency. MBR, a heterogeneous reaction system composed of a biological reactor and a membrane system, has been developed for advanced wastewater treatment.[ 87 ] First, the influent enters the bioreactor and undergoes a biodegradation process. Here, biological‐activated sludge with high biomass concentration and relative long solid retention time allows for an efficient removal of refractory organic pollutants. Subsequently, a semi‐crossflow filtration system is utilized to separate the mixed suspension, where the suspend solids are intercepted by membrane and concentrated in the retentate. With the synergy of the bio‐reaction processes and porous membranes, the MBR exhibited superior performance for treatment of MPs in contaminated wastewater. Talvitie et al. reported a MBR set‐up by integrating a biodegradation tank with a membrane filtration tank composed of 20 submerged flat‐sheet membrane units with effective membrane area of 8 m2 and pore size of 0.4 µm.[ 88 ] By applying this technique, the concentration of MPs in a primary effluent in WWTPs was reduced significantly from 6.9 to 0.005 MP particles L−1, indicating a remarkably high elimination rate of 99.9%. It is noteworthy that the biological reactor permitted the degradation of organic impurities adhered onto MPs, which is beneficial to enhance the accuracy of qualitative analysis of the separated MPs. Similar to the biological process in secondary treatment, it is commonly believed that the biodegradation of chemical inert MPs is limited during the MBR process. Although filtration technique is highly promising for MPs removal in tertiary treatment, membrane fouling and abrasion are the main challenges of this technique, which often lead to the decay of purification efficiency.[ 64 , 70 ]

3.2.3. Adsorption

Adsorption has also been frequently applied to absorb pollutants such as, heavy metals and organic contaminants in water. Ion exchange, π–π interactions, hydrophobic interactions and hydrogen‐bond interactions between the absorbents and contaminates are responsible for the adsorption performance. Recently, this method has also been employed to mitigate MPs in water treatment process. Yuan et al. investigated the adsorption efficiency of PS MPs by using 3D reduced graphene oxide (3DRGO).[ 89 ] In this study, PS microspheres with an average diameter of 5 µm were used as MP samples. Because of the strong π–π interaction between 3DRGO and PS‐MPs, an excellent adsorption capacity of 617.28 mgPS g3DRGO −1 was obtained under the mild experimental conditions (pH 6, 26 °C). It should be noted here, it is expected a sp2‐rich MPs would adsorb strongly on RGO. Given sp3‐rich MPs such as, PP and PE dominate the total amount of MPs in the environment,[ 4 ] the study would benefit from a broader focus on different polymers than do not experience π–π stacking. Streb et al. fabricated a functional nanoparticle composite by loading water‐immiscible polyoxometalate ionic liquid (POM‐IL) onto magnetic Fe2O3@microporous SiO2 core‐shell particles (defined as magnetic polyoxometalate‐supported ionic liquid phases, magPOM‐SILP).[ 90 ] The magnetic Fe2O3 core facilitated a facile separation and recycling of absorbent. Specifically, the POM‐IL was synthesized by the combination of the lacunary‐Keggin cluster anion ([α‐SiW11O39]8−) with the tetra‐n‐heptyl ammonium cation (O7 ( = (n‐C7H15)4N+), where the presence of Q7 endows a high hydrophobicity of POM‐IL. Thus, the water‐immiscible POM‐IL allowed a fast attachment of PS beads (with diameter of 1 and 10 µm, concentration of 1 g L−1) on the surface of these particles due to the hydrophobic interactions between POM‐IL layer and the PS (Figure 4a–c). As a result, a complete removal of PS beads in 5 mL deionized water within 24 h was quantified by dynamic light scattering (Figure 4d,e). Moreover, the MPs removal performance of larger volumes of water (50 mL) was also studied, where the absorbent delivered an over 90% MPs removal efficiency equivalent to an excellent removal capacity of 900 mgPS gmagPOM‐SILP −1. In addition, this novel magnetic absorbent opened up a new avenue to overcoming the challenge of absorbent separation in practical water treatment applications by circumventing the time consuming conventional filtration.

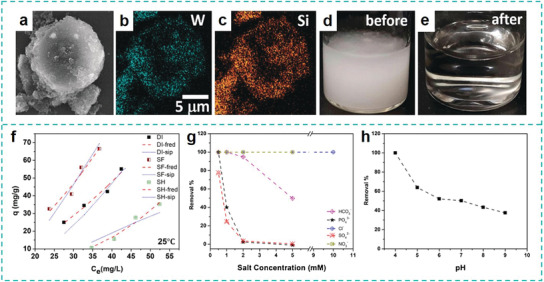

Figure 4.

Capturing MPs through adsorption. a–c) SEM and EDX elemental mapping images of 10 µm PS beads absorbed onto the magPOM‐SILP. d,e) optical images of PS contaminated water before and after treatment. Reproduced with permission.[ 90 ] Copyright 2020, Wiley‐VCH. f) Nanoplastics adsorption isotherm curves of Zn‐Al LDH at 25 °C in distilled water (DI), synthetic freshwater(SF), and synthetic hard water (SH). g) MPs removal efficiency in the presence of competitive anions. h) MPs removal efficiency under different pH. Reproduced with permission.[ 91 ] Copyright 2020, Elsevier.

Although MPs attract wide spread attention, nano‐sized plastics, NPs, also widely exist. NPs have a higher removal resistance in current water treatment processes and are even more hazardous to the ecosystem. To enhance the adsorbing efficiency of NPs, Darbha et al. designed a type of double‐layered Zn‐Al hydroxide (Zn‐Al LDH) to adsorb PS particles with diameters smaller than 1 µm from aqueous solution.[ 91 ] The surface properties of MPs existing in the natural environment are dramatically altered to be more negatively charged due to oxidation. Thus to mimic this effect, PS NPs were pretreated by coating with anionic surfactant.[ 25 ] This system is characterized by a superior anionic exchange capacity (AEC ≈ 3 meq g−1) and thus has strong adsorption ability for the anionic contaminants. Moreover, partial substitution of the trivalent Al ion by the divalent Zn ion affords a positively‐charged surface of LDH facilitating its sorption of anionic species. Based on the adsorption isotherm curves (Figure 4f), the maximum adsorption capacity toward PS NPs was calculated as 164.49 mgPS gZn‐Al LDH −1, 162.62 mgPS gZn‐Al LDH −1, and 53.2 mgPS gZn‐Al LDH −1 in deionized water (DI), synthetic freshwater (SF), and synthetic hard water (SH), respectively. The authors pointed out that to avoid the competitive absorptions and reduction of adsorption capacity by anions such as HCO3 −, PO4 3−, and SO4 2−, these ions in water should be removed in prior to the addition of Zn‐Al LDH (Figure 4g). In addition, the performance of this adsorbent under basic condition was unsatisfactory, which is related to the decreased zeta potential of Zn‐Al LDH resulting from deprotonation of hydroxyl groups (Figure 4h). Therefore, it is challenging to directly apply this system in a complex water system with varied unknown anions.

In addition to research works mentioned above, various absorbents such as, Fe3O4‐CNT and Zr‐MOFs‐based foam have been developed and delivered superior performance in other typical MPs (i.e., PE, PET, PMMA, PVDF, and PA) removal.[ 92 , 93 ]

In general, MPs removed during the multi‐stage wastewater treatment processes remain in the sludge. This MPs rich sludge is often further processed either as landfilled or used as farmland fertilizer (Figure 3e).[ 94 ] Although a series of treatments are applied to remove harmful matter before the application in agriculture, the presence of MPs is ignored.[ 95 ] Thus, unfortunately, no matter how many developments have been done, these strategies mentioned above based on simple physical separation cannot permanently address the pollution of environmental MPs, as the lack of rational treatment to recycle or completely eliminate the separated and collected MPs debris and particles.

3.3. Chemical Degradation Approaches

This re‐introduction of physically separated MPs into the environment has led to the development of chemical strategies to degrade, and thus permanently remove MPs. In this process, catalysts play significant roles to generate reactive oxygen species (ROSs) and thus trigger the degradation of MPs.

3.3.1. Advanced Oxidation Processes

AOPs are known as a powerful method to eliminate organic pollutants through generating ROSs with high standard reduction potentials, such as, sulfate radical (SO4 •−, E 0 = 3.1 V vs NHE) and hydroxyl radical (•OH, E 0 = 2.7 V vs NHE).[ 96 , 97 , 98 ] Due to their strong oxidation capability, a large variety of pollutants including dyes, antibiotics, and POPs have been effectively degraded or mineralized by this technique.[ 99 ] As a unique type of organic pollutant, MPs are obviously more challenging to be degraded due to their considerably higher molecular weights (MWs) compared to other low MW organic pollutants as mentioned above. A few pioneer works reported recently are ambitious to degrade MPs via this protocol. Though previous works have proved the ROSs generated via AOPs could destroy the surface structure of MPs particles,[ 100 ] the investigations of AOPs in MPs pollutants degradation are extremely rare.

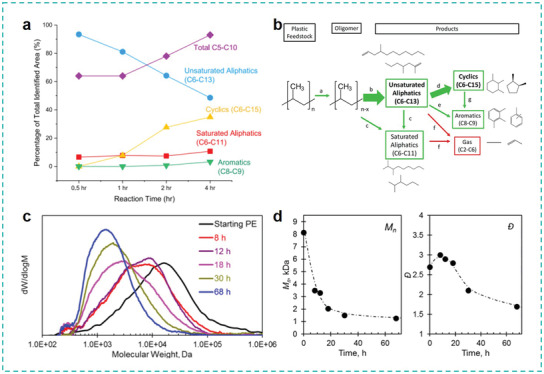

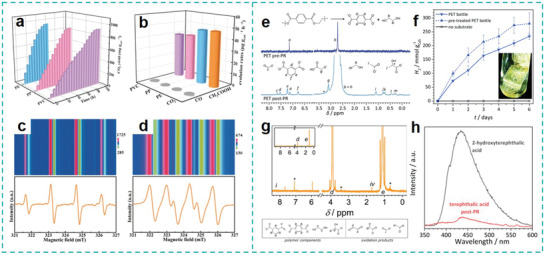

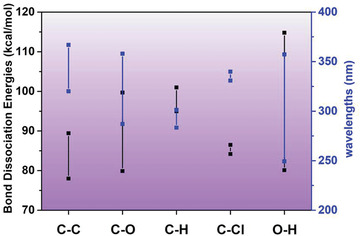

Wang et al. were the first to use SO4 •−‐based AOPs (SR‐AOPs) to degrade MPs. In their report, a helical‐shaped, N‐doped carbon nanotube catalyst encapsulated with manganese carbide nanoparticles (Mn@NCNTs) was fabricated for SR‐AOPs reaction, while PE beads (Figure 7b) obtained from a few commercial facial cleansers were used as MP samples.[ 101 ] Under a hydrothermal (HT) condition created in an autoclave, the PE‐MPs beads first generated cracks, fused into a thin polymer film and then progressively developed into a film with a large amount of cavities as evidenced by SEM analysis (Figure 5a–c). A remarkable 54 wt% weight loss of MPs was achieved by this method after reaction for 8 h at 160 °C (Figure 5d). The decay of MPs removal efficiency in the first three cycles was slight, indicating the outstanding stability of Mn@NCNTs in the SR‐AOPs system. From the perspective of the reaction mechanism, the authors verified that the presence of SR‐AOPs is indispensable, which continuously supplies the free radicals (SO4 •− and •OH) to oxidize MPs particles into small molecules and then mineralizing them into CO2 and H2O. A hydrothermal condition plays a crucial role in this process as well: The generated bubbles and vapor mechanically shear the PE‐beads causing chain scission of the macromolecules and triggering the degradation process; meanwhile, the generation of ROSs is also effectively accelerated given that the activation of peroxymonosulfate (PMS) can be heat‐driven. The authors proposed that the mechanism of this process is as such: The C—C bond of PE backbone is first broken into two hydrocarbon radicals under a HT conditions. Subsequently, when further decomposition of the hydrocarbon radicals occurs, the lower‐weight molecules are generated and are further converted into new shorter‐chain hydrocarbon radicals via the β‐scission and hydrogen abstraction routes, induced by other hydrocarbons. Finally, these intermediates radicals are attacked and ultimately mineralized by the SO4 •− and •OH generated from SR‐AOPs system. In this manner, the highly persistent PE was degraded into environmentally‐benign intermediates such as low hydrocarbon length aldehyde, ketone, and carboxylic acids, which were biodegradable and could be utilized as carbon sources for algae growth. As the SR‐AOPs reaction progress, these intermediates were degraded into low molecular weight organics and further mineralized into CO2 and H2O. Although the relatively harsh reaction conditions (high pressure and high temperature) is not feasible to be directly applied in the WWTPs for MPs removal, this interesting piece of work provides a good example to demonstrate to which extent the chemical degradation process is strengthened to break down the highly persistent C‐C bond based macromolecules.

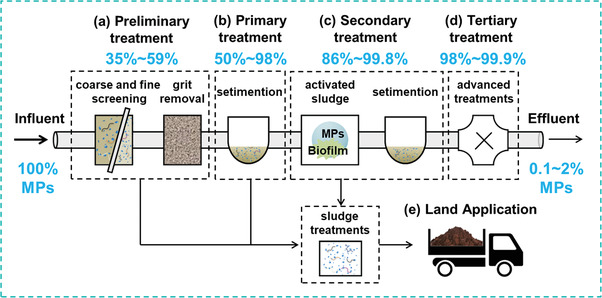

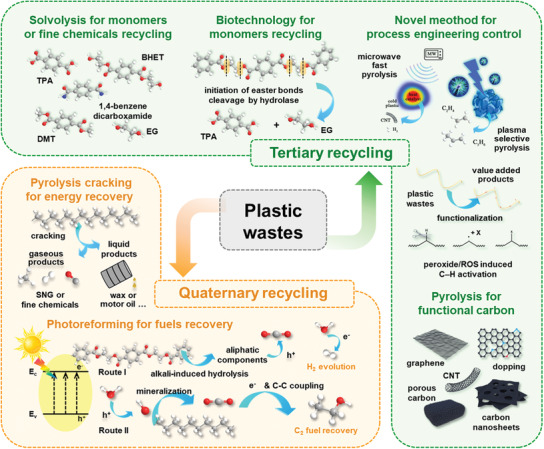

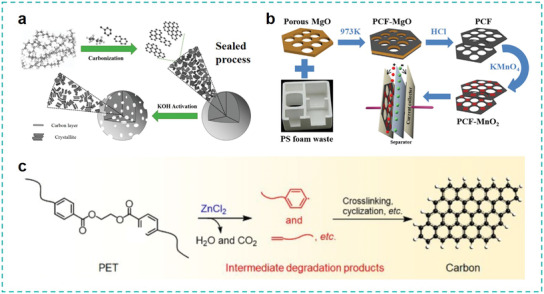

Figure 7.

Typical plastic wastes managements using chemical approaches. Tertiary recycling: Solvolysis for monomers or fine chemicals recycling, biotechnology for monomers recycling, novel strategies for process engineering control, pyrolysis for functional carbon materials. Quaternary recycling: Pyrolysis cracking for energy recovery, photo‐reforming for fuels recovery.

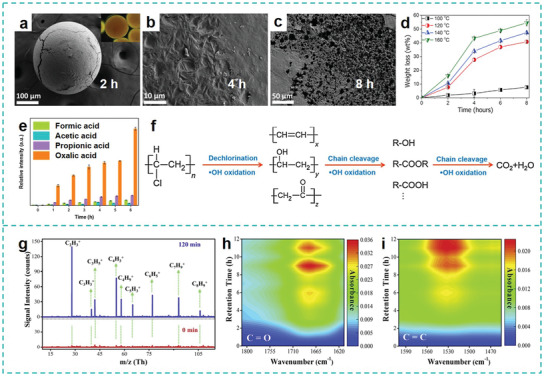

Figure 5.

AOPs and photocatalytic for MPs degradation. a–c) SEM images of MPs after 2, 4, and 8 h of degradation. d) Weight loss of MPs under different temperature. Reproduced with permission.[ 101 ] Copyright 2019, Elsevier. e) Evolution of organic intermediates during the electro‐fenton treatments. f) Mechanism of degradation of PVC. Reproduced with permission.[ 108 ] Copyright 2020, Elsevier. g) Mass spectra obtained by HPPI‐TOFMS during the photodegradation of PS. DRIFTS study of PS at different time intervals: h) C = O signal, i) C = C signal. Reproduced with permission.[ 112 ] Copyright 2020, Elsevier.

Alternatively, EAOPs based on Fenton or Fenton‐like chemistry (electro‐Fenton, EF) are most frequently utilized to generate ROSs (such as •OH) and decontaminate the persistence organic pollutants (POPs), which are featured as versatility, superior efficiency, excellent environmental compatibility and sustainability.[ 102 ] During this process, the cathode material plays the key role in determining the degradation efficiency of the system: Hydrogen peroxide (H2O2) is generated in situ on the cathodes by reducing O2 via a two‐electron oxygen reduction reaction and is subsequently converted into •OH.[ 103 , 104 , 105 , 106 , 107 ] Gao et al. designed a heterogeneous TiO2/C cathode in a EF‐like system for degrading PVC‐based MPs in a Na2SO4 electrolyte (0.05 m, pH 3.0), where a graphite electrode and Ag/AgCl electrode were used as the counter electrode and reference electrode, respectively.[ 108 ] At the end of the reaction, the original smooth surface of PVC‐MPs was destroyed by showing a number of large holes according to SEM characterization. After potentiostatic electrolysis at −0.7 V under 100 °C for 6 h, a dechlorination and degradation efficiency of 75% and 56 wt% were obtained, respectively, through quantitative analysis of the concentration of Cl− in the electrolyte and weight loss of the PVC MPs. The evolution of organic intermediates (e.g., formic acid, acetic acid, propionic acid, oxalic acid) during the EF treatments further proved the destruction of PVC into small organics (Figure 5e). The input of electrons in such EF‐like systems continuously boosts the generation of catalytic species. By characterizing the chemical structures of degrading intermediates and residual material in the electrolyte, the authors proposed the reaction mechanism of dechlorination and degradation process as depicted in Figure 5f. First, the direct electrons transfer from TiO2/C cathode to the PVC MPs gives rise to the dechlorination under heating conditions. Meanwhile, the attack of oxidative •OH toward PVC MPs results in the formation of oxygen‐containing groups such as C = O and O—H, combined with the release of liquid shorter‐chain intermediates. Subsequently, the vulnerable hydrocarbon species are prone to be oxidized into small molecular weight organics and finally mineralized to CO2 and H2O. Given the advantages of the relative mild conditions under 100 °C and −0.7 V (vs Ag/AgCl), such an EF‐like technology is promising for potential applications in WWTPs to purify the MPs‐contaminated water bodies.

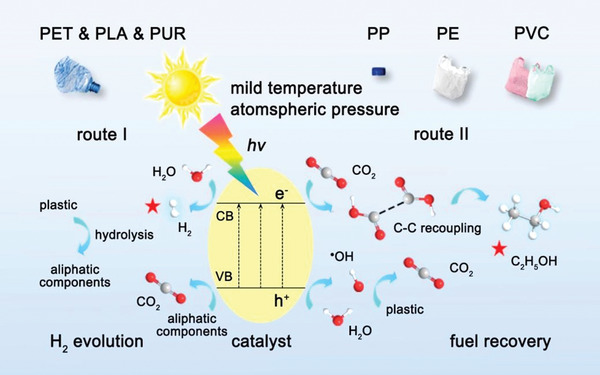

3.3.2. Photocatalysis

Photocatalysis is a well‐established environmentally‐friendly technique exploiting free and inexhaustible solar energy. In recent years, this technique has gained significant applications in water purification because of its high degradation efficiency of antibiotics, pesticides, and dyes.[ 109 ] The mechanism of photocatalytic degradation process can be attributed to the interaction between ROSs (e.g., hydroxyl (•OH), superoxide (O2 •−)) generated on the surface of semiconductors and the organic substrate, which breaks the chemical bonds of organic pollutants leading to their complete mineralization toward CO2 and H2O. Meanwhile, the photo‐excited holes (h+ VB), generated by transfer of electrons from the valance band to the conduction band, are capable to directly oxidize the organics into CO2 and H2O.

TiO2 is a classical photo‐catalyst capable of oxidizing organic contaminants with high efficiency. It also has several advantages, including low toxicity, cheap price and excellent acid and alkali‐resistance.[ 110 , 111 ] In recent years, the TiO2‐based materials have been extensively studied in photocatalytic degradation of MPs. Due to a relatively high band gap of 3.2 eV, a TiO2‐catalzyed photo reaction is often performed under UV irradiation. Zhang et al. synthesized a TiO2 film as catalyst to degrade PS microspheres and PE powder at solid‐state under UV irradiation.[ 112 ] As the essential part of the photocatalytic system, the TiO2 films were fabricated by dropping TiO2 nanoparticles (P25) dispersed in a mixture of water, ethanol and Triton X‐100 (TXT) on the conduction side of FTO glass and further calcined at 450 °C in air. The PS spheres solution with diameter of 400 nm was dropped on the TiO2 films and was subsequently dried for photodegradation experiment. During the annealing process, TXT served as the morphology‐directing agent to adjust the surface properties, electrical properties and porous sizes distribution. Therefore, the Triton X‐100 based TiO2 (TiO2‐TXT) film delivered superior hydrophilicity, specific surface area as well as the separation and transfer of photogenerated electron‐hole pairs. Under UV irradiation with wavelength of 365 nm, continuous fragmentation of original structures was observed and an almost complete mineralization (98.40%) of 400 nm‐PS spheres was achieved by TiO2‐TXT catalyst within 12 h, proving the effectiveness of this protocol. The excellent mineralization efficiency of TiO2‐TXT film was mainly ascribed to two aspects: 1) The unique surface hydrophilicity could improve the interaction between PS MPs and TiO2; 2) the enhanced charge carrier generation and separation could accelerate the generation of •OH and O2 •−, which act as the significant role in the degradation process. In addition to the oxidation degradation triggered by ROSs, photo‐excited holes also contributed toward oxidizing and mineralizing MPs into CO2 and H2O. Further measurements by high‐pressure photon ionization‐time of flight mass spectrometry and in situ diffuse reflectance infrared Fourier transform spectroscopy revealed that PS were degraded into multiple intermediates including styrene, benzene, toluene (Figure 5g) based on the presence of their corresponding characteristic signals of functional group (i.e., C = O and C = C) (Figure 5h,i). Meanwhile, the degradation of PE also presented marked change in morphology and chemical bonds, suggesting the feasibility and potential of this method in degrading various MPs contaminations.

To fill the knowledge gap in the underlying effect of operating parameters such as pH and temperature during degradation process, González et al. investigated the degradation behaviors of HDPE primary MPs with the presence of a newly designed C, N‐doped TiO2 catalyst,[ 113 ] which absorb light with wavelength of 428 nm, within the range of visible light. All the experiments were performed by adding HDPE and photocatalyst in water inside a batch‐type container placed in a closed reaction chamber equipped with a LED lamp emitting visible light. Optical images illustrated the different destroyed morphologies of the PE microbeads under various pH value and temperature. Under 0 °C and pH 3, a maximum mass loss of ≈72% was delivered within 50 h. Thus, the authors presumed that a synergetic effect of the low temperature and high H+ ion concentration exist on PE MPs photocatalytic degradation. On one hand, it is prone to form more hydroperoxide (—CH2—HCOOH—CH2‐) n at low pH, where the high concentration of H+ ions could serve as the promoter to boost the relevant reaction. Subsequently, two new free oxy and hydroxyl radicals ((—CH2—HCO•—CH2—) n and •OH, respectively) were formed via the splitting of hydroperoxide, since the O−O bond was vulnerable to cleavage. These hyperactive radicals efficiently abstract protons from other polymer chains, playing a crucial role for PE degradation. Moreover, the high zeta potential of TiO2 nanoparticles at low pH could prevent their agglomeration and result in a good dispersion of the catalyst; the strong interaction between the well‐dispersed colloidal nanoparticles and MPs guaranteed efficient photodegradation. On the other hand, the low temperature was also favored for the degradation process. Smaller MPs particles could be formed by the fragmentation of MPs beads at 0 °C, which allowed the fast degradation through the enlarged interface between the MPs and semiconductors.

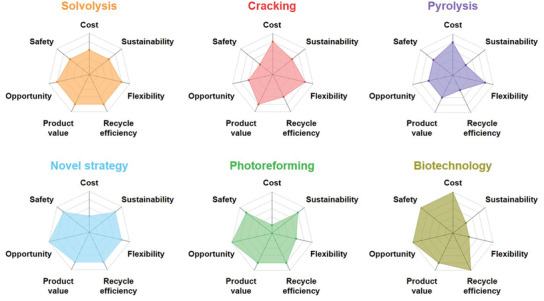

3.4. Overview of Current Microplastics Removal Strategies

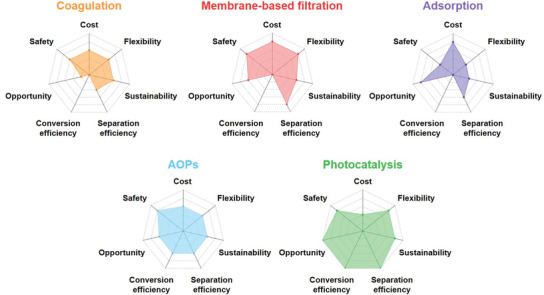

With so many potential avenues for MP removal, accurately assessing the strengths and weaknesses is critical for each approach (Figure 6 ). Particularly, these approaches have been compared from seven aspects: Cost, safety, flexibility, sustainability, separation efficiency, conversion efficiency, and opportunity. Cost depends on the fabrication of the key materials (i.e., membrane, absorbent, and catalyst) and energy consumption during the whole process. Safety hinges on whether the toxic chemical agents are used and toxic intermediate products are generated. Flexibility: The stability of performance in practical application under various environment factors including pH, temperature, and the presence of distractions such as, other anions and organic pollutants. Sustainability is estimated from two aspects: 1) The structure and performance stability and recyclability of the key materials in the long‐term application; 2) the treatment time and experimental condition (i.e., high temperature, high press, electricity, and UV‐light). To highlight the difference between physical trapping and chemical degradation, the removal efficiency is further distinguished as separation efficiency and conversion efficiency. Chemical degradation approaches can not only separate MPs from water body but also convert them into non‐toxic matters, while MPs collected by physical trapping methods are likely to return to the environment. Overall, opportunity is the summary and outlook of these approaches in practical application.

Figure 6.

Comparison of the general performance metrics for current MPs removal strategies.

Although coagulation and adsorption can deliver good capacity (≈90% efficiency) for MPs separation, the regeneration of coagulants and adsorbents will lead to the release of MPs into environment. Meanwhile, no one can guarantee that the leakage of organic coagulating additives and micrometer sized adsorbents will not seriously threaten the ecosystem. As the most reliable methods, membrane‐based filtration can exhibit higher efficiency than coagulation and adsorption. The flexibility of membrane‐based filtration makes it able to be coupled with other techniques and deliver enhanced efficiency. For instance, an amazing MPs removal efficiency of 99.9% could be delivered by the MBR. For the practical applications, the management and maintenance should be improved to avoid the membrane fouling and abrasion, which is essential to guarantee the sustainable purification efficiency. Although these traditional technologies are relatively developed and have delivered good MPs removal efficiencies, they can only separate the MPs from water system rather than eliminate the contaminants, which cannot completely solve the MPs issue.

As with the mitigation strategies for other persistent pollutants or greenhouse gases, chemical catalytic conversion is the most promising strategy for permanent removal of contaminants, either via elimination or upcycling into valuable products.[ 114 , 115 , 116 ] The developments of chemical degradation of MPs through AOPs and photocatalytic degradation have given the promising alternatives of traditional technologies for thorough eradication of MPs by converting them into non‐toxic matter. Meanwhile, the development of physical‐chemical coupling approaches can be promising to further improve MPs removal efficiency by evoking a synergistic effect. More efforts should be invested to develop versatile catalysts for MPs mitigation. For instance, the incorporation of photocatalytic sites into membrane will trap MPs and deliver excellent in situ catalytic degradation performance through the shorten path of ROSs transfer and attacking. It can not only efficiently separate MPs from water but also converts MPs into non‐toxic matters rather than leaving them to accumulate and return to environment. In the near future, the combination of developed physical methods and emerging catalytic conversion approaches is essential to guarantee the overall low cost and MPs degradation efficiency in large scale water treatment applications (such as, WWTPs).

Due to rapid migration in aquatic environment, ingestion by aquatic organisms and risk to human through drinking water, MPs in water are of great concern to researchers. Previous studies always took importance on removing MPs in water, while MPs in soil were generally identified as one of the sources of MPs in water.[ 1 , 19 , 42 , 93 ] However, Li et al. reported MPs in soil can be also ingested by plants during growth.[ 59 ] Therefore, the removal or separation of MPs from soil (especially soil in landfill with high concentration of MPs) will become an important research hot pot in the future. Commonly, density separation is the most measured for the extraction of MPs in soil, where the soil sample is added into a salt solution with defined density, and then shaken, stirred, aerated, and settled.[ 1 ] Taking into account the cost and environmental effect, saturated sodium chloride (NaCl, ρ = 1.2 g cm3) solution is the most authoritative extraction medium and widely used in trace analysis and large‐scale practical applications for extracting MPs from sand or stones of soil parts (ρ = ≈2.6 g cm3). Besides, calcium chloride (CaCl2, ρ = 1.3 g cm−3), sodium iodide (NaI, ρ = 1.8 g cm−3), zinc chloride (ZnCl2, ρ = 1.6 g cm−3), and sodium polytungstate (SPT, 3Na2WO4·9WO3·H2O, 1.4–3.1 g cm−3) solutions have been also applied to separate certain categories of MPs. In the future development, it will be promising to design coupling strategy including density separation and the as‐mentioned physical or chemical methods for MPs remediation in aqueous systems (i.e., membrane filtration, photocatalytic degradation, and AOPs in Section 3) to achieve the separation and/or degradation of MPs in soil.

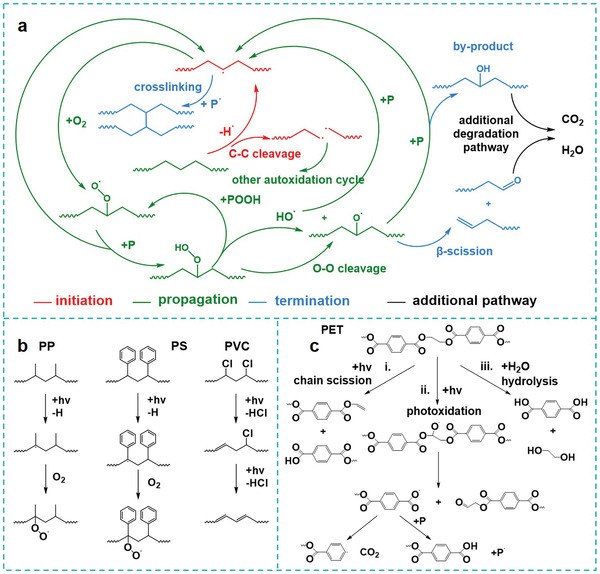

4. Rational Recycling Protocols of Plastic Wastes to Eliminate Microplastics

The plastic wastes in the environment are a critical issue. Numerous MPs can be released through the corrosion of mismanaged plastic wastes by sun radiation, wind and other environmental factors. Although landfill is conducted as the major management strategy for plastic wastes, the gradual release of MPs and toxic additives pose potential treats to environment. Thus, the traditional landfill is destined to be phased out in the future. Although plastic wastes could be eliminated by incineration, greenhouse gas emission is one of the most non‐ignorable impacts. The content of combustible carbon of each ton of this category of waste is ≈79%, corresponding to significant greenhouse gas emission of about 2.9 tons of CO2.[ 117 ] Apart from the emissions of CO2, other harmful gases such as CO, NO, SO2 can be also released during open burning, accompanied by a large amount of ashes migrating and suspending in the atmosphere, bringing significant harm to the ecological environment.[ 6 ] In this context, recycling is regarded as the ideal and ultimate solution for solving the current MPs issue and ensuring a sustainable use of plastics from the long run. Recycling 1 ton of plastic wastes for reuse rather than producing virgin materials can save up to ≈130 million kJ of energy.[ 118 ] Moreover, recycling of plastic wastes can also effectively reduce the greenhouse gas emission. In 2014, 3.17 million tons of plastic wastes were recycled meaning that ≈3.2 million tons of CO2 were saved, equivalent to the gas emissions of 670 000 cars on the road in a year.[ 117 ] Unfortunately, the recycle rate of plastic wastes to raw materials was low, especially for the secondary (recycled) plastics wastes.[ 33 , 119 ] The following sections describes approaches to recycle macroscale plastic wastes such that they are not naturally converted into dangerous MPs via erosion or other degradation mechanisms.

4.1. Typical Plastic Wastes Recycling Technologies

Typically, recycling of plastics includes four well‐known categories: Primary, secondary, tertiary, and quaternary recycling. Primary recycling is an in‐plant mechanical recycling strategy, which directly incorporates the scrap materials into prime‐grade products without any pretreatment such as, purification, physical separation, or chemical depolymerization, representing closed loop recycling. In secondary recycling, mixed plastic waste streams are sorted, fragmented, extruded and manufactured into new plastic products, which is also classified as mechanical recycling. With proper control over processing conditions, the degradation of physical properties in first several cycles can be suppressed.[ 120 ] Nevertheless, the gradual thermo‐oxidative or hydrolytic scission of polymers can give rise to the decrease of quality and loss of performance, which limits the sustainability of the mechanical recycling. Several types of polymers (e.g., polyurethane) cannot be recycled mechanically. For tertiary recycling, chemical approaches are mainly involved to recover plastic wastes into oil/hydrocarbon components or high‐purity monomers by chemical bonds scissions, which can be reused as raw materials and incorporated into plastic production lines. Meanwhile, chemical recycling is a “trash to treasure” approach to upgrade plastic wastes into value‐added products. Additionally, the chemical reclamation strategy develops an extra feedstock source from disposed plastic wastes rather than the consumption of crude oil, which opens up a new avenue to relieving the crude oil crisis. Therefore, chemical recycling is considered as an attractive alternative to the traditional plastic waste management, where the “kill several birds with one stone” strategy possesses economic effectiveness and environmental friendliness. Quaternary recycling, also named as energy recovery, aims to obtain multicarbon products featured with high‐yielding heating values mainly by combustion of the plastic waste. Nevertheless, this protocol still faces several technical challenges, especially the emission of greenhouse gas and heavy metal containing ash.

Rational management of the plastic waste, especially through efficiently recycling and avoiding their leakage into the environment is undoubtedly a major pathway of cutting down the generation of the secondary MPs. In the below section, we briefly discuss the technical advances of mechanical recycling, and more detailed discussions can refer a few excellent reviews.[ 121 , 122 ] Given the high potential of obtaining high‐quality monomers or valuable chemicals from plastic wastes and achieving a close‐loop of material regeneration, as illustrated in Figure 7 , we will focus on the current tertiary and quaternary recycling strategies. The mechanisms, challenges, and opportunities of these techniques will be highlighted.

4.2. Mechanical Recycling

For mechanical recycling robust collection and separation technologies of plastic wastes are essential to obtain reasonably clean raw materials from the complex waste steams which are frequently contaminated by food, dyes, and other plastic impurities. Typically, a combination of several automated and/or manual processes are adopted to achieve this goal, including near infrared, X‐rays, density, electrostatics, melting point, hydrocyclons, selective dissolution, and manual sorting are used to enhance the efficiency of sorting.[ 122 ] Recently, fluorescence marker has emerged as an advance technique to facilitate fast sorting process. Maris et al. used rare earth based compounds as fluorescent dye for plastic marking, where the marked polymers can be facilely separated under spectroscopic detection. Nevertheless, the safety of such markers have not been fully discussed/understood yet.[ 123 ] Subsequently, plastics are grinded into small flakes, which further undergo sink/float methods, air elutriation, and heat discoloration for optical separation. The advantages of cheap, large‐scale, solvent‐free, and applicable to many polymers make extrusion the most frequently used mechanical recycling approach. Heat and rotating screws in the extruder lead to the thermal softening or plasticization of waste plastics, and the plastic melt further through the temperature‐controlled barrels resulted in the fabrication of fixed cross‐section extrudate. It is worth noting that free radical reactions induced thermal degradation and chain scission are accelerated by the excessive temperatures and high screw speeds, sometimes leading to the formation of downgrade or even un‐processable polymers.[ 124 ] Although mechanical recycling is currently the foremost plastic recycling strategy, the recycled products are often suffered from reduced viscosity and mechanical properties, which are only applicable for low‐quality applications. Because of their lowered grade, the mechanical recycled plastics are more susceptible to environmental factors, resulting in a more rapid release of MPs into the environment.

To improve the quality of mechanical recycling, thermal, light stabilizers, and/or antioxidant are used to suppress free radical reactions during mechanical recycling. However, the presence of stabilizers complicates mechanical recycling process. For instance, carbon black is widely used as reinforcing filler and UV protector in polymers, while aesthetic requirement of the products cannot fully satisfied.[ 125 ] Phenols (i.e., commercial Irganox 1010) can stabilize hydrogen bonding and trap alkyl peroxy radicals, while the migration of antioxidants and potential carcinogenicity is also a concerning issue.[ 126 ] To this context, development of eco‐friendly plastic stabilizers are highly encouraged.[ 127 ] A few recent examples have emerged on such aspect. For example, Iyer et al. studied the mechanical performance of LDPE extruded with a claimed low cost antioxidant derived from natural agro‐wastes,[ 126 ] which effectively suppress the embrittlement of the plastics. Deeper understanding of the migration mechanism and potential toxicity of these stabilizers over several recycling life‐cycles are urgently needed.

The down‐grade of recycled plastic is characterized by the much reduced molecular weights. Therefore, the use of chain extenders to further enhance the molecular weights of the products is a cost‐effective, straightforward, and highly efficient protocol. Upon using chain extenders, the reactive end‐groups (two or more) can be conveniently jointed together by forming covalent bonds and hence significantly enhances the chain length. Oxazolines, lactams, hydroxyls, carboxylic acids, and organic phosphites and phosphates are the widely investigated the chain extenders.[ 122 , 128 ] By using triphenyl phosphite, Cavalcanti et al. successfully enhanced the viscosity of the recycled PET through their carboxyl and hydroxyl terminal groups.[ 129 ] It should be noted that the potential migration and toxicity of chain extenders, where the unreacted short oligomers or other molecules may leach into packaged products. Thus, most of existing chain extenders are not suitable for food‐grade plastics production.[ 122 ] More risks during the repeated extrusions could also be triggered by the limited thermal stability of chain extenders.[ 130 ]

Furthermore, various inorganic fillers, plasticizers, and compatibilizers have also been studied to minimize degradation during the mechanical recycling of plastics.[ 131 , 132 , 133 ] Given the relatively short production cycle and low cost of this technique, mechanical recycling remains a key protocol in the plastic recycling system. The future development should definitely focus on a progressive enhancement of the quality and eco‐impacts of the end‐products.

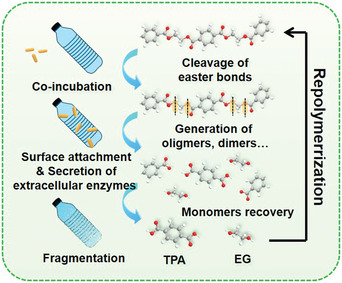

4.3. Solvolysis of Plastic Wastes for Monomers

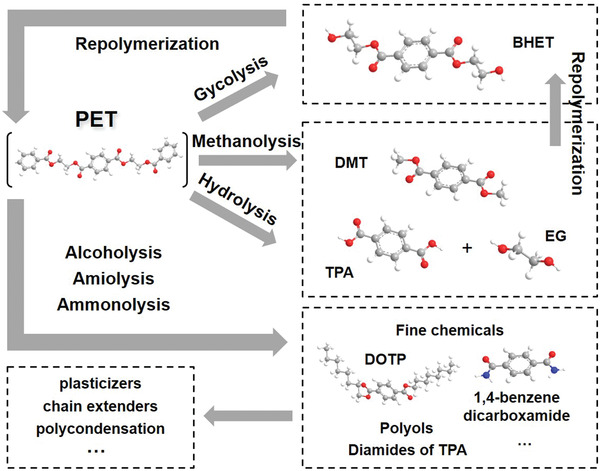

Monomer recycling, breaking MPs down into their own starting materials for reuse, has been regarded as one of the most efficient strategies to construct the circular economy system by potentially avoiding further exploration of the fossil feedstock and also ensuring high quality of the regenerated plastics. Various chemical depolymerization approaches for monomer recovery have been investigated and utilized thus far. Solvolysis is known as the most well‐established solution to yield high purity monomers for polymerization or other fine chemicals and reused for industrial manufacture. Since the ester bonds in polyesters, mostly referring to PET, are prone to depolymerize by a number of nucleophilic reagents, such as, water, alcohol, and amines, different products can be recovered through glycolysis, hydrolysis, methanolysis and so on as shown in Figure 8 . With respect to the products via solvolysis, terephthalic acid (TPA), dimethyl terephthalate (DMT), and bis(hydroxyethyl)terephthalate (BHET) can be reused as precursors to re‐make PET, while other products such as, dioctyl terephthalate (DOTP) and 1,4‐benzene dicarboxamide can be used as plasticizer or chain extender for industrial chemistry.

Figure 8.

Overview of solvolysis for monomers and fine chemicals recovery of PET. Color code: C, gray; O, red; N, blue; H, White.

4.3.1. Glycolysis for Bis(hydroxyethyl)Terephthalate Recycling

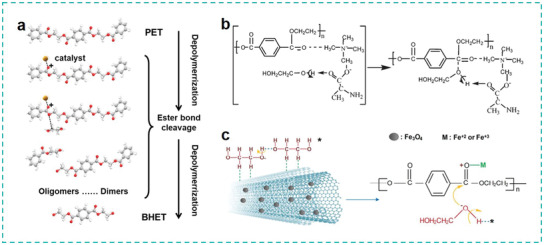

Among these strategies, glycolysis is the most classical industrial process for recycling PET wastes, which is conducted at 180–250 °C with the presence of catalyst and excess glycol as solvent.[ 134 ] Since using BHET rather than TPA or DMT as precursor for PET production can circumvent an intermediate process step, recovering high purity BHET from waste PET becomes the primary goal. Ethylene glycol (EG) is the most frequent used regent for PET depolymerization, where the depolymerization pathway is shown in Figure 9a. Typically, the ester bonds of PET are activated by the interaction between Lewis acid‐like catalyst and the carbonylic oxygen resulting in that more electrons are dragged toward carbonylic oxygen atom. Subsequently, more partial positive charges are introduced toward the carbonylic carbon, which enhances the electrophilicity of carbon atom. The more electrophilic carbonylic carbon are more vulnerable to be attacked by the lone pair electrons of nucleophilic EG, which lead to the cleavage of ester bonds through the formation of new C—O bonds between carbonylic carbon and oxygen of the EG and break of the exiting C—O bonds of the PET. As the consequence, the continuous ester bonds cleavage give rise to the depolymerization of PET into BHET. However, the conversion of oligomers and dimers into BHET is reversible, meaning that when the monomers accumulation reaches a certain amount, the depolymerization reaction can shift backward. This phenomenon leads to the increasing amount of dimers and oligomers at the expense of the BHET.

Figure 9.

Gycolysis of PET with different catalyst for BHET recycling. a) Pathway of the conversational transition metal salt catalyzed depolymerization of PET. Color code: C, gray; O, red; H, White; metal, Yellow. b) Mechanism of [N1111][Ala] boosted glycolysis of PET. Reproduced with permission.[ 138 ] Copyright 2012, Royal Society of Chemistry. c) Mechanism of the Fe3O4 MWCNT catalyzed glycolysis. Reproduced with permission.[ 144 ] Copyright 2016, Royal Society of Chemistry.

In order to enhance the BHET selectivity, metal salts, ionic liquids, and heterogeneous catalysts have been applied as catalyst during the depolymerization of PET. Typically, the performances of metal acetate employed as homogenous catalyst in glycolysis have been extensively studied. However, the immiscibility of PET with the polyols leads to the limited glycolysis kinetics. In this context, Liu et al. developed a ultrafast glycolysis with maximum depolymerization efficiency of 100% and BHET yield of 83% were delivered at 190 °C within 1 min by using Zn(OAc)2·2H2O as catalyst and DMSO as cosolvent.[ 135 ] The authors speculated that hydrogen bond between DMSO and PET played a key role in PET dissolution. However, the toxic DMSO, as well as, transition metal ions (Zn2+, Co2+, Mn2+) existing in the liquid residue can lead to the secondary pollution. To circumvent this problem, the non‐toxic sodium carbonate was studied by López‐Fonseca et al. as the green candidate for PET glycolysis, which exhibited a BHET yield of 80% at 196 °C within 1 h.[ 136 ] Ionic liquids (ILs) are also a category of efficient catalyst for the conversion of PET into BHET, where the ILs can be easily separated from the final products. In 2009, Wang et al. first employed a neutral ionic liquid catalyst, 1‐butyl‐3‐methylimidazolium chloride ([bmim]Cl) for PET glycolysis. Interactions between cation and carbonyl oxygen, anion, and hydroxyl group of EG, respectively, could facilitate the nucleophilic attack on the carbonyl of PET and thus boosted glycolysis process. As the consequence, the maximum performances of 100% PET conversion and 70% BHET selectivity were delivered at 195 °C and 1 atm within 8 h.[ 137 ] Later, Wang et al. developed acid tetramethylammonium alanine ([N1111][Ala]) achieving an outstanding glycolysis efficiency of 100% PET conversion and 74.3% BHET selectivity at 170 °C and 1 atm within 50min.[ 138 ] The authors indicated the mechanism of the [N1111][Ala] catalyzed degradation, where the H‐bonds formed between EG and [Ala]−, [N1111]+, and PET, as well as, [N1111]+ and [Ala]− led to the disconnection of long chain of PET and the acceleration of glycolysis (Figure 9b). In the last few years, various IL catalysts comprised of metal halide or metal acetate anions (i.e., Fe, Co, Cu, Zn) and [bmim] cation were studied,[ 139 , 140 ] which exhibited superior selectivity for BHET (>80% within 1 h) as well as, the recyclability than metal‐free ILs. More recently, choline formate ([Ch][For]) and choline acetate ([Ch][OAc]) with less toxicity were developed to circumvent the utilization of toxic imidazolium cations, which delivered competitive glycolysis activity (>80% in 3h).[ 141 ] Further investigations will mainly focus on the development of novel catalysts possessing the merits of high activity, selectivity, environment friend, and recyclability.

Heterogeneous catalysts have been also studied to boost the transesterification reaction between PET and EG, which possess the advantage of the ease of separation. Shukla et al. utilized β‐zeolite and γ‐zeolite as first examples of heterogeneous catalysts for PET glycolysis, which exhibited similar efficiency of fully PET conversion and ≈65% BHET selectivity at 196 °C within 8 h.[ 142 ] In order to enhance the separation from final products, magnetic catalysts have been developed. Kim et al. reported an efficient glycolysis of PET by first using EG as regent and superparamagnetic γ‐Fe2O3 nanoparticles as catalyst, affording a high yield (>90 wt%) of BHET within 1 h at 300 °C with the catalyst dosage of 5 wt%.[ 143 ] The HPLC measurement shown that the BHET monomer account for the main glycolysis product. The superiority of γ‐Fe2O3 was further indicated by using ZnO, Mn3O4, and CeO2 as catalyst in the same glycolysis condition. Meanwhile, benefiting from the excellent thermal and chemical stability of the as‐synthesized γ‐Fe2O3 catalyst, the BHET transformation capacity of first 10 runs was not affected, which further proved the reusable of the catalyst. ElMetwally et al. designed a Fe3O4‐boosted MWCNT catalyst to enhance the BHET selectivity.[ 144 ] As a result, a remarkably 100 wt% yield of BHET was achieved within 2 h at 190 °C by using the Fe3O4/MWCNT catalyst, where the catalyst could be conveniently recycled and its performance was steady after 8 glycolysis cycles. Importantly, the remarkably reduced processing temperature was beneficial for saving the energy input. The mechanism of the Fe3O4‐boosted MWCNT catalyst was illustrated in Figure 9c: Fe3O4 served as a Lewis acid‐like catalyst to trigger the scission of ester bonds, while the presence of MWCNT facilitated hydrogen bonding between with EG and an increase of the electronegativity of hydroxyl functional groups of EG. Thus, the depolymerization reaction was significantly promoted by the facilitated ester bonds cleavage.

Apart from EG, diethylene glycol, propylene glycol, dipropylene glycol, and other dihydric alcohols have been studied as solvents for PET glycolysis. However, the utilization of appropriate catalyst to promote the transesterification reaction between PET and EG for enhancing BHET selectivity is still the primary consideration for glycolysis, which could be ascribe to the BHET is the desirable precursor to re‐make PET in accordance with the concept of circular economy.