Abstract

Between increasing public concerns over climate change and heightened interest of niche market beef on social media, the demand for grass-fed beef has increased considerably. However, the demand increase for grass-fed beef has raised many producers’ and consumers’ concerns regarding product quality, economic viability, and environmental impacts that have thus far gone unanswered. Therefore, using a holistic approach, we investigated the performance, carcass quality, financial outcomes, and environmental impacts of four grass-fed and grain-fed beef systems currently being performed by ranchers in California. The treatments included 1) steers stocked on pasture and feedyard finished for 128 d (CON); 2) steers grass-fed for 20 mo (GF20); 3) steers grass-fed for 20 mo with a 45-d grain finish (GR45); and 4) steers grass-fed for 25 mo (GF25). The data were analyzed using a mixed model procedure in R with differences between treatments determined by Tukey HSD. Using carcass and performance data from these systems, a weaning-to-harvest life cycle assessment was developed in the Scalable, Process-based, Agronomically Responsive Cropping Systems model framework, to determine global warming potential (GWP), consumable water use, energy, smog, and land occupation footprints. Final body weight varied significantly between treatments (P < 0.001) with the CON cattle finishing at 632 kg, followed by GF25 at 570 kg, GR45 at 551 kg, and GF20 478 kg. Dressing percentage differed significantly between all treatments (P < 0.001). The DP was 61.8% for CON followed by GR45 at 57.5%, GF25 at 53.4%, and GF20 had the lowest DP of 50.3%. Marbling scores were significantly greater for CON compared to all other treatments (P < 0.001) with CON marbling score averaging 421 (low-choice ≥ 400). Breakeven costs with harvesting and marketing for the CON, GF20, GR45, and GF25 were $6.01, $8.98, $8.02, and $8.33 per kg hot carcass weight (HCW), respectively. The GWP for the CON, GF20, GR45, and GF25 were 4.79, 6.74, 6.65, and 8.31 CO2e/kg HCW, respectively. Water consumptive use for CON, GF20, GR45, and GF25 were 933, 465, 678, and 1,250 L/kg HCW, respectively. Energy use for CON, GF20, GR45, and GF25 were 18.7, 7.65, 13.8, and 8.85 MJ/kg HCW, respectively. Our results indicated that grass-fed beef systems differ in both animal performance and carcass quality resulting in environmental and economic sustainability trade-offs with no system having absolute superiority.

Keywords: beef sustainability, beef systems, carcass quality, grass-fed beef, greenhouse gases, life cycle assessment

Lay Summary

Between the influence of the “food elite” on social media and increasing public concerns over climate change, consumer demand for grass-fed beef has increased considerably. Although many consumers perceive grass-fed beef as more environmentally friendly than grain-fed beef, there is a dearth of research available to address these consumer claims. In order to answer both consumer and producer concerns, we performed an experiment that evaluated the environmental footprint (i.e., water, land, greenhouse gasses, and energy), beef quality, and economic outcome of four beef cattle production systems on the West coast. The four systems included conventional beef finished on grain for 128 d, steers grass-fed for 20 mo, steers grass-fed for 20-mo with a 45-d grain finish, and steers grass-fed for 25 mo. We found that varying grass-fed and grain-fed production systems resulted in different environmental effects. The conventional system produced the lowest greenhouse gas footprint but required the highest energy input. The grass-fed for 20 mo used the least amount of water but produced the greatest greenhouse gas. In conclusion, this study illustrated the complexities underpinning beef sustainability; no system resulted in absolute economic, meat quality, and environmental superiority.

Is West coast grass-fed beef better for the environment than conventional grain-fed beef or is it just consumer hype?

Introduction

With increasing concerns over the environmental impacts of conventional beef, grass-fed beef is now viewed by many consumers as a more sustainable alternative (McCluskey et al., 2005; Xue et al., 2010; McCluskey, 2015). This evolving consumer ideology has resulted in a steady increase in demand for grass-fed beef, with retail sales of labeled fresh grass-fed beef in the U.S. growing from $17 million in 2012 to $272 million in 2016 (Nielsen Retail Measurement Services, 2017). To meet these demands, producers have begun to utilize a grass-fed beef option (beef that has been fed grass for the entirety of its lifecycle as per USDA definition; USDA-FSIS, 2019) in their current production systems. However, unlike conventional beef production (beef that is finished in a feedyard for over 60 d) that produces a consistent product, grass-fed beef performance and carcass quality varies significantly depending on region, resource availability, and forage quality (Berthiaume et al., 2006; Scaglia et al., 2012; Duckett et al., 2013). The different production systems lead to variations in quality grade, weight, and dressing percentage (DP; Neel et al., 2007; Kim et al., 2012; Schmidt et al., 2013) that result in varying economic and environmental impacts (Pelletier et al., 2010; Cruz et al., 2013; Stanley et al., 2018). Therefore, to accurately address the economic outcomes and environmental impacts of grass-fed beef, animal performance and carcass quality parameters need to be empirically evaluated on a regional basis.

One of the most effective ways to determine a production system’s environmental impact is to use life cycle assessment (LCA; Tedeschi et al., 2015; Notarnicola et al., 2017). Despite continued interest in grass-fed beef’s environmental impacts, only a few grass-fed beef LCA have been completed. Moreover, no LCA has modeled grass-fed beef production in the Western USA. In an LCA performed in Michigan that modeled the finishing phases of conventional beef and intensely managed grass-fed beef, grass-fed beef’s global warming potential (GWP) on a per kilogram basis was 57% greater (excluding soil carbon sequestration) than conventional beef (Stanley et al., 2018). Similarly, in an LCA that modeled beef production in the Midwest, the GWP per kilogram for grass-fed beef production was 30% greater than that of conventional beef (Pelletier et al., 2010). Although these LCA provide insight into grass-fed beef production and environmental impacts, the management practices and input parameters modeled in these studies are substantially different from those associated with grass-fed beef systems in the Western United States (Cruz et al., 2013). Furthermore, these studies included relatively few environmental impact categories, limiting the scope of analysis as well as the opportunity to assess potential trade-offs between various impacts.

California, with a Mediterranean climate, over 39 million people, the highest number of farmer’s markets (USDA, 2012) and the 4th largest cattle industry in the country (NCBA, 2020) is set to become a leader both in grass-fed beef production and demand. Therefore, there is a pressing need to evaluate the performance and economic characteristics of grass-fed production systems currently being utilized by ranchers in the Western United States. Only by using a whole systems approach can both the economic feasibility and the relationship between product quality and environmental impact of grass-fed beef production be characterized. In order to address consumer, producer, and other scientific concerns, the present study sought to 1) determine the performance, carcass qualities, and economic returns of four grass-fed and conventional beef systems currently being utilized by Western ranchers and 2) combine the live animal performance (from weaning to harvest) along with carcass data to build the first-ever empirically derived, multi-impact factor LCA for grass-fed beef production systems in the Western United States.

Materials and Methods

Animal protocol

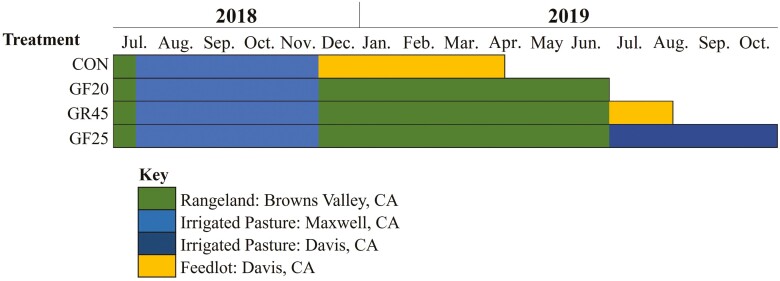

The weaning, animal health protocol, and study design for this project were approved by the Institutional Animal Care and Use Committee at the University of California-Davis (UCD; protocol #20560). In June 2018, cows and calves at the University of California Sierra Foothill Research and Extension Center (Browns Valley, CA) were fenceline weaned (fenceline contact between calf and dam) for 45 d to minimize animal stress and to monitor calf health as described by Price et al. (2003). At weaning, Angus and Angus-Herford cross steer calves were allocated to one of four treatments: 1) steers stocked on pasture then finished in a feedyard (CON), 2) steers grass-fed for 20 mo (GF20), 3) steers grass-fed for 20 mo with a 45-d grain finish (GR45), and 4) steers grass-fed for 25 mo (GF25; Figure 1). All treatments were designed based on current beef production systems in California. After being fenceline weaned, steer calves were stratified by weight (average initial body weight was 284 SD 27.57 kg) and randomly assigned to treatments. In the beginning of the trial, there were 22 steers per treatment, but these numbers were reduced over time due to pinkeye infection that were treated with antibiotics as per IACUC protocols. For grass-fed cattle to be harvested at a natural plant, cattle were required to be on grass for 100% of their lifespan and were never to be treated with antibiotics or administered any type of hormone. Therefore, antibiotic-treated cattle were removed from the study as per natural program agreements. After pinkeye animals were treated, the number of cattle remaining in each treatment was as follows: 21 cattle in CON, 18 in GF20, 13 in GR45, and 16 in GF25. After weaning, steers were transported to summer flood irrigated pasture located in Maxwell, CA, that were irrigated bimonthly beginning the second week of July through the second week of November. Steers were rotated between two pastures throughout the grazing season. Irrigated pasture included a mix of annual grasses (predominantly Cynodon dactylon and Sorghum halepense), and clover (25% to 30% Medicago and Trifolium). After the summer–fall grazing season ended in late November, steers were transported to their designated feeding locations. Steers in the CON treatment were taken to the feedyard of UCD located at Davis, CA where they were housed in a group pen. At the feedyard animals were fed a starter ration for 14 d, followed by an intermediate ration for 14 d and finished on a high-energy corn-based ration for 100 d (Table 1). Steers in the GF20, GR45, and GF25 treatments were shipped from Maxwell, CA, to the Sierra Field Research Station Browns Valley, CA, to graze winter–spring foothill rangeland. Cattle were rotated between three large-scale paddocks once every month. Rangeland forage species composition was typical of California native rangelands consisting of a mixture of grasses (e.g., Bromus and Avena spp.) and forbs (e.g., Erodium, Medicago, and Trifolium spp.). At the end of the winter–spring grazing season cattle in the GF20 treatment were harvested. Steers in the GR45 treatment were taken to the feedyard at UCD. While in the feedyard steers were fed a starter ration for 7 d, intermediate ration for 10 d, and finished on a high-energy corn diet for duration of the 45-d grain period (Table 1). Steers in the GF25 treatment were transported to irrigated University of California-Davis owned, flood irrigated pasture in Davis, CA. The pasture at UCD consisted of a 50:50 mixture of perennial grasses (Cynodon dactylon and Sorghum halepense), and clover (25% to 30% Medicago polymorpha and Trifolium dubium). Cattle were rotated between two paddocks every 2 wk. Cattle land occupation values (head/hector/month) for all the systems are listed in the Supplementary Material. Cattle in the GF20 and GF25 treatments followed USDA Food Safety and Inspection Services labeling guidelines (USDA-FSIS, 2019). Cattle in the CON and GR45 treatments were harvested at a large scale commercial packing house in Fresno, CA and steers in the GF20 and GF25 systems were harvested at a natural and organic beef packing house in Merced, CA. To adhere to natural standards none of the steers were implanted. Steers in the CON and GR45 treatment were fed an ionophore to replicate commercial feeding systems in CA. Although cattle in the GR45 treatment received an ionophore, the cattle present in these systems were still representative of niche market beef production typical sold at farmers markets.

Figure 1.

Timeline of grass-fed and conventional beef treatments from weaning to harvest. CON, steers stocked on pasture then finished in a feedyard; GF20, steers grass-fed for 20 mo; GR45, steers grass-fed for 20 mo with a 45-d grain finish; GF25, steers grass-fed for 25 mo.

Table 1.

Composition of feedyard diets for CON and GR45 treatments1

| Item | Feedyard rations2 | ||

|---|---|---|---|

| Starter | Intermediate | Finishing | |

| Ingredient | % Dry matter basis | ||

| Rolled corn | 41.0 | 51.1 | 72.0 |

| Distillers grains | 20.0 | 20.0 | 6.00 |

| Fat | 1.50 | 2.0 | 3.00 |

| Molasses | 8.00 | 7.00 | 3.00 |

| Alfalfa hay | 15.0 | 10.0 | 5.00 |

| Wheat hay | 12.0 | 8.00 | 6.00 |

| Calcium carbonate | 0.82 | 1.15 | 1.80 |

| Urea (45 N) | 0.35 | 0.40 | 1.40 |

| Magnesium oxide | 0.00 | 0.00 | 0.20 |

| Rumensin | 0.02 | 0.02 | 0.50 |

| Beef trace salt | 0.32 | 0.32 | 0.32 |

CON, steers stocked on pasture then finished in a feedyard for 128 d; GR45, steers grass-fed for 20 mo with a 45-d grain finish.

For CON starter, ration was fed for 14 d, followed by the intermediate ration for 14 d and finishing ration for 100 d. For GR45 stater, ration was fed for 7 d, the intermediate ration for 10 d, and finishing ration for 28 d.

Performance and carcass quality analysis

The average daily gain was determined for each animal as the slope of the linear regression of body weight by days of age. At the end of the feeding period, steers were weighed after 18 h of feed withdrawal and then transported to slaughter. All carcasses were chilled for 48 h and separated between the 12th and 13th ribs. The USDA Quality and Yield Grades (USDA, 2016) were assigned to each carcass by trained personnel. Carcass characteristics were evaluated as follows: hot carcass weight (HCW), percentage of kidney, pelvic, and heart fat (KPH), longissimus dorsi muscle area at the 12th to 13th rib, body fat depth at ¾ of the width of the longissimus dorsi muscle, and marbling score. DP, yield grade (YG), and quality grade were calculated using standard equations (Boggs et al., 1998). Strip loins (LDM, Institute Meat Purchasing Specification number 180) from the right sides of each of 12 carcasses were collected, vacuum packaged, and stored under dark conditions at 4 °C for 14 d.

Feed analysis

To collect pasture/rangeland samples, a quarter meter square (50 cm × 50 cm) of PVC pipe was randomly thrown into the pasture. Forage samples were collected from the square by cutting the plant matter on the ground. This process was repeated 30to 100 times along the cross-section of the given pasture. Pasture/rangeland samples were taken every 30 d for the duration of the project. Feedyard samples were collected from the mixer wagon every 14 d. After each collection, feed samples were combined and sub-sampled in triplicate and frozen at −35 °C. Samples were thawed and dry matter was determined by oven drying at 100 °C for 12 h. For composition analysis, feed samples were ground to pass a 1-mm screen (Wiley mill, Arthur Gill Thomas Co., Swedesboro, NJ) and dried at 55 °C for 15 h before undergoing proximate analysis. Dietary ME values were calculated using equations published by the NRC (2016).

Cost of production

Cost analysis was based on UC Davis input costs, livestock advisor estimates, and UC Extension Costs studies (Table 2). The purchase price of steers was based on Shasta Livestock Auction (Cottonwood, CA) prices for the month of June over a 3-yr consecutive period (2016 to 2018). Pasture/rangeland rental costs were determined based on negotiated prices between UC Davis and landowners. Maxwell pasture was leased for $0.20 per kg of gain and UC land price was based on $30 animal unit monthly. Although mortality loss in the present study was zero, to be consistent with other UC extension cost studies death loss was considered 2% of initial purchase price. Feed costs and markup were based on 2019 market conditions for central CA feedyards. Transportation, management, and harvest costs were based on UC Agriculture and Natural Resource cost studies (Forero et al., 2017a, 2017b). As per previous cost studies, time needed to haul, gather, feed, check, and move cattle to new pastures were considered individual owner expenses and were not included in costs (Forero et al., 2017a, 2017b). Water charges, fertilizer, irrigation, and fence repair were included in the pasture rental costs. Interest on operating costs was calculated on cash costs (weaning cattle purchased) and was calculated at 5.0% annual interest amortized over a 2.5-yr period. All harvesting and marketing costs were based on the University of California Agriculture and Natural Resource (UCANR) cost and return study (Forero et al., 2017a, 2017b). As with previous cost studies, the present study costs were calculated on a per head basis. An account for each treatment are presented in Table 2.

Table 2.

Operating and overhead cash costs for beef systems from weaning to harvest

| Item | Treatment1 | |||

|---|---|---|---|---|

| CON | GF20 | GR45 | GF25 | |

| Purchase price, $/hd | 845 | 845 | 845 | 845 |

| Operating inputs, $/hd | ||||

| Irrigated pasture | 61.0 | 61.0 | 61.0 | 161 |

| Rangeland | – | 150 | 150 | 150 |

| Salt/mineral | – | 12.5 | 12.5 | 17.5 |

| Veterinary/medical | 16.9 | 12.7 | 13.5 | 14.4 |

| Death loss (2% of purchase price) | 1.25 | 16.9 | 16.9 | 16.9 |

| Brand inspection | 1.00 | 1.25 | 1.25 | 1.25 |

| Checkoff | – | 1.00 | 1.00 | 1.00 |

| Harvest costs | – | 100 | 100 | 100 |

| Cut and wrap | – | 525 | 695 | 662 |

| Marketing costs | – | 35.0 | 35.0 | 35.0 |

| Stock trailer | 2.40 | 24.0 | 24.0 | 36.0 |

| 1-ton pickup truck | 80.3 | 185 | 207 | 257 |

| ATV | 5.25 | 13.65 | 13.65 | 18.9 |

| Feedlot yardage | 469 | – | 154.8 | – |

| Feed costs | 40.3 | – | 13.95 | – |

| Net operating costs, $/hd | 655 | 1,140 | 1,500 | 1,470 |

| Cash overhead costs, $/hd | ||||

| Interest on operating loan | 21.2 | 60.0 | 65.0 | 94.6 |

| Insurance (liability) | 22.0 | 22.0 | 22.0 | 22 |

| Total cash overheads, $/hd | 43.2 | 82.0 | 87.0 | 117 |

CON, steers stocked on pasture then finished in a feedyard for 128 d; GF20, steers grass-fed for 20 mo; GR45, steers grass-fed for 20 mo with a 45-d grain finish; GF25, steers grass-fed for 25 mo.

Statistical analysis

All statistical analyses were performed in R. The study was a completely randomized design with individual animals treated as the experimental unit. Performance data and carcass components were analyzed in a GLM procedure with model containing treatment as the fixed effect. Differences between treatments were determined by Tukey Honest Significance Difference using an α-level of 0.05.

LCA assumptions and system boundaries

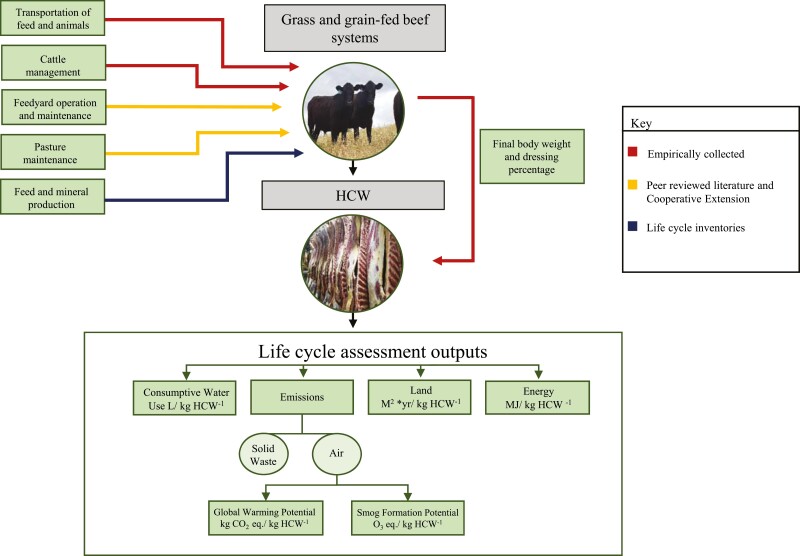

In order to determine the environmental impacts of each of the beef production systems, an attributional cradle-to-gate LCA was performed using a Scalable, Process-based, Agronomically Responsive Cropping Systems LCA (SPARCS-LCA) model framework (Marvinney and Kendall, 2021). This is a deterministic LCA model framework constructed in Microsoft Excel. System boundaries included the stocker and finishing (pasture, rangeland, and feedyard) phases. Animal performance, herd management practices, transportation, feed inputs, and machinery usage were empirically based. Figure 2 shows the schematic of the main components of the LCA for the four different beef systems examined. This LCA was produced following International Organization for Standardization (ISO) 14040 standards. Because harvest and post-harvest operations typically contribute a minimal percentage of total water, GHG, and energy use to the life cycle environmental footprint of beef production (Asem-Hiablie et al., 2019), these operations and impacts were excluded from this analysis. Emissions from equipment manufacture, infrastructure, and other long-term capital investments are also generally excluded from LCA system boundaries and so were not included (Lupo et al., 2013).

Figure 2.

An overview of the four treatments LCAs including inputs and outputs of phases, source of data, and impacts measured.

For this application, SPARCS-LCA model was parametrized with input quantities specific to each phase of the California beef production life cycle on a per head cattle per month basis to generate an input table. Each item in this table was assigned one or more reference inventories obtained from Ecoinvent and U.S. professional databases via GaBi ts v6 software (PE International, 2019), and the input quantity multiplied by the environmental flow values from the life cycle inventory (LCI). These values were multiplied by characterization factors obtained from TRACI v3.1 (USEPA, 2017) for particular environmental impacts to produce reference impacts by life cycle phase on a per head per month basis (see Supplementary Material). Impact categories were calculated on a per head basis each month for each system and subsequently divided by the total time the animal spent in each system (stocker, range, irrigated pasture, and feedyard) to determine total environmental impact per steer. Although the mortality rate in this trial was zero, to accurately represent the four beef systems, mortality was set at 2% for the stocking phase and 2% for the finishing phase (Stackhouse-Lawson et al., 2012). The total for each phase was adjusted by the mortality of the succeeding phases to obtain the total for the production system per finished animal. After impact per steer and mortality rate were incorporated, per steer impact was divided by steer HCW to determine environmental impact per kg of HCW produced.

The following impact categories were reported: GWP on a 100 yr time horizon, freshwater use, energy use, smog formation potential, and land occupation, based on characterization factors obtained from TRACI 3.1 (USEPA, 2017). We accounted for greenhouse gas production (e.g., methane [CH4], carbon dioxide [CO2], and nitrous oxide [N2O]) from enteric ruminal fermentation, manure storage and handling, feed production, transportation, and on-farm energy use. In order to more easily compare results to previous and future beef LCA, the functional unit of reporting was set as 1 kg of HCW.

Enteric CH4, manure CH4, and N2O emission

Carbon dioxide, methane, and nitrous oxide emissions from transportation and on-site manure, enteric, and fuel combustion as well as upstream industrial processes (for which sulfur hexafluoride and PFC emissions were also considered) were accounted for in calculation of GHG impacts. Biogenic carbon dioxide from soil and livestock respiration was treated as carbon neutral in GHG impact calculation, while methane from manure and enteric emission was treated separately from non-biogenic methane as per IPCC guidelines (2014). Greenhouse gases were converted to CO2 equivalents (CO2 eq) using 100-yr GWPs: CO2 = 1, CH4 = 34, N2O = 298 (IPCC, 2014).

Enteric fermentation was based on IPCC 2006, Tier 2 methodology (2014). Gross energies (bomb calorimeter-derived total heat of combustion energy contents) were calculated using feed ingredients and animal characteristics from on-farm data for all four systems. Dry matter intake (DMI, kg/d) was calculated using NRC (2016). The DMI required for maintenance was determined by the NEm requirement divided by the NEm content of the diet and the DMI required for BW gain was the NE required to meet the ADG goal divided by the NEg content of the diet. Both NEm and NEg were determined by the shrunk weight of the animal and the rate of gain as reported by NRC (2016). Default CH4 conversion factors (Ym) of 3.0% of gross energy intake were used for grain-systems and 6.5% gross energy intake for grass systems were consistent with other cattle LCA analysis (Stackhouse-Lawson et al., 2012; Stanley et al., 2018).

Manure CH4 and N2O emissions were calculated using the Agriculture module of the State Inventory Tool produced by the US Environmental Protection Agency (USDA, 2019). All formulas in the tool were based on IPCC (2014) Tier 2 methodology. The Agriculture module calculated CH4 emissions for manure management by first calculating total volatile solids (VS; Mg animal/mass/d) produced by the state’s livestock. For cattle, animal population was multiplied by the VS rate (kg/head/yr) for total VS produced. For calves and all other livestock, animal population was multiplied by the typical animal mass (kg) by the VS rate, and number of days per year to obtain the total annual VS produced. This value was multiplied by maximum potential methane emissions, and the weighted CH4 conversion factor, resulting in m3 CH4. The total volume (m3) CH4 emitted was converted into CO2 equivalents by multiplying by density of CH4 (0.678 kg/m3 CH4) and GWP of CH4 (34). To estimate N2O emissions from manure management, the Ag module first calculated the total K-nitrogen excreted. For cattle, animal population was multiplied by the K-nitrogen excretion rate (kg/head/yr) for total K-nitrogen excreted. Next total K-nitrogen was separated into dry and liquid systems and multiplied by the corresponding emission factor. For this trial, all cattle in the system were housed and drylots so the drylot emission factor of 0.2 kg N2O–N kg per N was used. Finally, total kg N2O emissions are converted to million MT on a CO2 equivalence by multiplying by the GWP of N2O (IPCC, 2014).

Stored manure from the scraping of feedyard pens was composted and sold to farmers, primarily orchard growers. Since the compost was not used for cattle feed, we did not allocate the emissions from the manure compost to any of the beef systems. Soil N emissions from feed production (i.e., synthetic fertilizer) were accounted for in feed emissions. This trial utilized established CA pastures and no synthetic fertilizer or manure was applied to any of the rangelands or pasturelands used in this study. Pastures in this study had been used for cattle production for the last 50 yr with little change in management practices over that time. Animals in this study were not intensively managed and minimal rotational grazing occurred. With no change in grazing management practices and little to no local carbon sequestration grazing research, soil carbon sequestration was not considered in this assessment.

Emissions from freight transport of feed and mineral inputs as well as the movement of cattle between locations were calculated based on transport distance and total mass and referenced with truck freight transport inventory data obtained from the Ecoinvent LCI database via GaBi ts v6 (PE International, 2019). Transport distances were calculated based on specific source location data were available, and based on spatially weighted mean distances where specific source locations were not available (e.g., local alfalfa production). Emissions from feed production were calculated using the SPARCS-LCA model parametrized with input data from UCANR cost and return studies for alfalfa produced in the Sacramento Valley growing region; and obtained from the US Professional LCI database via GaBi ts v6 (PE International, 2019) in the case of other feed components including corn, tallow, CDS, and DDGs. Fuel consumption was based on empirical data were available and calculated based on vehicle operation time using vehicle type-specific data from the California Air Resources Board (CARB) OFFROAD model (2007). Emissions from on-farm vehicle use were calculated from fuel-specific LCI data for agricultural equipment operation taken from the EcoInvent LCI database via GaBi ts v6 (PE International, 2019).

Water and energy use

Consumptive water use included animal water intake, irrigation of crops and pastures, and feedyard water use. Based on Beckett and Oltjen (1993), consumptive water included only water that had the potential to be developed and/or diverted for human use. Therefore, rainfall was not included in this assessment. Water intake for all cattle was based on weight, temperature, and stage of production (NRC, 2016) California feedyard managers provided total feedyard water usage for cattle in the feedyard treatments. Pasture irrigation demand was obtained from University of California cooperative extension economic cost and return analysis (Stewart and Macon, 2020).

Feedyard mill water and energy use was obtained from Wiedemann et al. (2017). Fuel and energy use for pasture and feed crop management as well as transportation was calculated from Cost and Return studies (Long et al., 2015; Stewart and Macon, 2020), empirical data, and LCI data (see Supplementary material) obtained from GaBi ts v 6.0 (PE International, 2019). Energy use for irrigation pumping was calculated after Marvinney and Kendall (2021) based on pump efficiency and energy use data from industry sources (Goulds Water Technology, 2019).

Smog and land occupation calculations

Smog formation potential was calculated using TRACI 3.1 characterization factors (USEPA, 2017). Land occupation was calculated as area × occupation time, and reported in units of m2 yr, as per Ecoinvent and US Professional LCI databases accessed via GaBi TS v6 (PE International, 2019).

Results

Cattle performance and carcass characteristics

Cattle performance

While stocked on irrigated pasture in Maxwell, CA, from July to November, all steers gained 0.40 kg/d (SD 0.07). When the grass-fed treatments (GF20, GR45, and GF25) were moved to Browns Valley, CA, rangeland, steers gained on average 0.61 kg/d (SD 0.10) from late November to mid-June. However, between the months of December and March, there was limited rainfall and persistent cloud cover. During this period, rangeland forage species remained dormant and stocked steers (GF20, GR45, and GF25) lost 18 kg (SD 5.0). During spring, forage quantity improved and cattle on grass (GF20, GR45, and GF25) rebounded and gained 1.95 kg/d (SD 0.12) for the duration of the grazing season (late Marth though early June). Cattle in the GF25 treatment gained 0.79 kg/d (SD 0.13), while on irrigated pasture in Davis, CA. Overall, forage nutritive value was greater for the Davis irrigated pasture compared to the irrigated pasture in Maxwell (Table 3). While in the feedyard, CON cattle gained 2.02 kg/d (SD 0.19) and GR45 gained 1.60 kg/d (SD 0.35).

Table 3.

Composition of feedyard diets for CON and GR45 treatments

| Item | Grass diets | Grain diets | |||

|---|---|---|---|---|---|

| Irrigated pasture Maxwell, CA | Rangeland Browns Valley, CA | Irrigated pasture Davis, CA | Feedyard ration for CON | Feedyard Ration for GR45 | |

| Days in system | 201 | 151 | 134 | 128 | 45.0 |

| Analyzed dietary composition, % | |||||

| DM | 34.5 | 35.5 | 27.9 | 86.3 | 88.3 |

| CP | 10.7 | 9.13 | 12.7 | 14.8 | 16.0 |

| NDF | 60.5 | 59.5 | 53.2 | 26.7 | 29.5 |

| ADF | 39.3 | 41.0 | 36.0 | 17.4 | 19.5 |

| Ash | 10.7 | 10.3 | 11.2 | 6.24 | 6.17 |

| EE | 2.67 | 2.83 | 2.25 | 6.83 | 6.74 |

| Ca | 0.47 | 0.43 | 0.55 | 0.68 | 0.63 |

| P | 0.23 | 0.19 | 0.19 | 0.31 | 0.39 |

| Mg | 0.25 | 0.13 | 0.43 | 0.25 | 0.21 |

| K | 1.90 | 1.15 | 1.85 | 0.90 | 0.92 |

| S | 0.29 | 0.10 | 0.27 | 0.16 | 0.23 |

| Calculated energy, Mcal kg DM1 | |||||

| ME | 2.38 | 2.26 | 2.52 | 3.33 | 3.37 |

| NEm | 1.50 | 1.39 | 1.62 | 2.30 | 2.33 |

| NEg | 0.90 | 0.81 | 1.02 | 1.60 | 1.62 |

Dietary ME, NEm, and NEg values were calculated using the NRC (1996) equation.

Steer final weights varied across treatments (P > 0.001; Table 4). The CON steers finished with the highest final body weight (FBW) at 632 kg (SD 44) and GF20 finished with the lowest FBW of 283 kg (SD 26). There was no difference for FBW between GR45 and GF25 treatments (P = 0.38) with FBW of 551 (SD 39) and 570 kg (SD 29), respectively. Hip height of animals at harvest did not differ across treatments (P = 0.41), as such frame size was not considered a factor for differences in FBW.

Table 4.

Effect of post-weaning treatment on animal performance and carcass characteristics

| Item | Treatment1,2 | P-value | |||||||

|---|---|---|---|---|---|---|---|---|---|

| CON | SD | GF20 | SD | GR45 | SD | GF25 | SD | ||

| Final hip height, cm | 133 | 3.41 | 132 | 2.92 | 133 | 3.38 | 133 | 3.67 | 0.48 |

| Initial body weight, kg | 283 | 26.4 | 283 | 25.9 | 287 | 30.9 | 283 | 30.4 | 0.97 |

| Final body weight3, kg | 632c | 43.5 | 478a | 26.2 | 551b | 39.6 | 570b | 25.1 | <0.0001 |

| Average total gain, kg | 343c | 27.5 | 195a | 20.0 | 286b | 38.6 | 263b | 28.5 | <0.0001 |

| HCW, kg | 372c | 25.0 | 230a | 13.8 | 303b | 22.1 | 292b | 15.9 | <0.0001 |

| Dressing percent, % | 61.8d | 1.20 | 50.2a | 1.12 | 57.5c | 2.08 | 53.4b | 1.57 | <0.0001 |

| KPH4, % | 2.89c | 0.07 | 1.06a | 0.16 | 1.65b | 0.25 | 1.30b | 0.18 | <0.0001 |

| Back fat, cm | 1.17c | 0.27 | 0.44a | 0.06 | 0.74b | 0.16 | 0.66b | 0.11 | <0.0001 |

| LM5 area, cm | 79.7b | 7.13 | 65.0a | 6.73 | 68.4a | 6.99 | 65.0a | 5.99 | <0.0001 |

| LM length, cm | 13.3b | 0.21 | 12.9a | 0.21 | 13.1b | 0.20 | 14.2a | 0.23 | <0.0001 |

| LM depth, cm | 7.06c | 0.59 | 6.03a | 0.63 | 6.41ba | 0.60 | 6.08a | 0.56 | <0.0001 |

| LM length:depth ratio | 1.89a | 0.21 | 2.32b | 0.20 | 2.05a | 0.20 | 2.35b | 0.23 | <0.0001 |

| Marbling score6 | 421c | 45.8 | 285a | 49.9 | 341b | 45.9 | 333b | 61.4 | <0.0001 |

| Yield grade | 2.86c | 0.52 | 1.45a | 0.28 | 2.37b | 0.41 | 2.14b | 0.34 | <0.0001 |

| Quality grade7 | 7.04c | 0.57 | 3.94a | 1.39 | 5.30b | 0.75 | 4.81b | 0.91 | <0.0001 |

CON, steers stocked on pasture then finished in a feedyard; GF20, steers grass-fed for 20 mo; GR45, steers grass-fed for 20 mo with a 45-d grain finish; GF25, steers grass-fed for 25 mo.

Means with different superscripts indicate differences within treatments, determined by Tukey HSD.

FBW does not include 4% shrink.

Kidney, pelvic, and heart fat.

Loin muscle.

100 = Practically devoid00; 300 = Slight00; 400 = Small00; 500 = Modest00; 700 = Slightly Abundant00; 900 = Abundant00 (USDA, 2016).

Standard (−, 0, and +), 1, 2, and 3; Select (−, 0, and +), 4, 5, and 6; Choice (−, 0, and +), 7, 8, and 9; Prime (−, 0, and +), 10, 11, and 12.

Carcass characteristics

HCW followed the same pattern as FBW with CON having the heaviest HCW of 372 kg (SD 25), weighing 69 to 142 kg heavier than other treatments (Table 4; P < 0.05). The GF20 treatment finished with the lowest HCW (P < 0.05), with carcasses weighing 230 kg (SD 14). There was no difference between GF25 and GR45 treatments in HCW (551 ± 16 vs. 570 kg±22, respectively; P > 0.05). DP differed between all treatments (P < 0.001). For the CON treatment, DP was 61.8%, followed by the GR45 (57.5%), then GF25 (53.4%), and GF20 having the lowest DP (50.3%). KPH differed between CON and all other treatments (P < 0.05) with the highest KPH of 2.89% and GF20 having the lowest KPH of 0.65%. Between GF25 and GR45 KPH did not differ (P > 0.05), with KPHs valued at 1.30% and 1.65%, respectively.

As expected, back fat was greater for the CON treatment (11.7 mm) than all other treatments (P < 0.05). Back fat was lowest for GF20 at 4.40 mm (P < 0.05) but was not different between GF25 and GR45 (6.60 vs. 7.40 mm, respectively; P > 0.05). Marbling scores and quality grade were greater for CON compared to all other treatments (P < 0.05) with a marbling score of 421 and quality grade of 7.04. Cattle in the GR20 had the lowest marbling score (P < 0.05) and quality grade (P < 0.05) when compared with all other treatments with a marbling score of 285 and a quality grade of 3.95. The GR45 finished with a marbling score of 341 and a quality grade of 5.30 and the GF25 finished with a marbling score of 333 and a quality grade of 8.81. There was no difference in marbling score (P > 0.05) or quality grade (P > 0.05) when comparing the GF25 and GR45.

YG did not differ between CON and GR45 treatments (P > 0.05) with YGs of 2.86 and 2.78, respectively. YG for the GF20 was lower compared to all other treatments (P < 0.05) with an YG value of 1.45. YG for GF25 was different from all other treatments at 2.14 (P < 0.05). Longissimus muscle (LM) area was different for CON compared to all other treatments (P < 0.05) with an LM area of 79.7 cm2. No difference in LM area was observed between GF20, GR45, and GF25 (P < 0.05) with LM areas ranging from 65.0 to 68.4 cm2. When evaluating the shape of the LM using the length to depth (L:D) ratio a significant difference was observed for the grain-fed steers (CON and GR45) compared to the grass-fed only treatments (GF20 and GF25) with grain-finished treatments having a smaller L:D ratio (P < 0.05). Grass-finished treatments with a greater L:D ratio demonstrates that the LM were more oblong in shape than grain-finished treatments.

Financial analysis

Without marketing or processing costs (i.e., cut and wrap and harvesting) the CON produced both the lowest cost per steer and lowest breakeven of $4.00 per kg of HCW (Table 3). When marketing and harvesting costs were included cost per steer for the CON treatment increased to a breakeven of $6.01 per kg of HCW. The cost per steer was lowest for the GF20 with and without harvesting and marketing costs. However, with the lowest harvest weight and the lowest DP, the breakeven prices were highest for the GF20 treatment at $6.11 per kg of HCW without and $8.98 per kg of HCW with marketing and processing. Compared to the CON treatment, the breakeven per steer without and with marketing and harvesting costs were greater for both the GR45 treatment and the GF25. Breakeven prices for the GR45 and GF25 treatments were greater than the CON, but less than the GF20. The breakeven without processing and marketing for the GR45 was $5.29 and with processing and marking $8.02. The breakeven without processing and marketing for the GF25 was $5.60 and with processing and marking $8.33.

Life cycle assessment

Energy

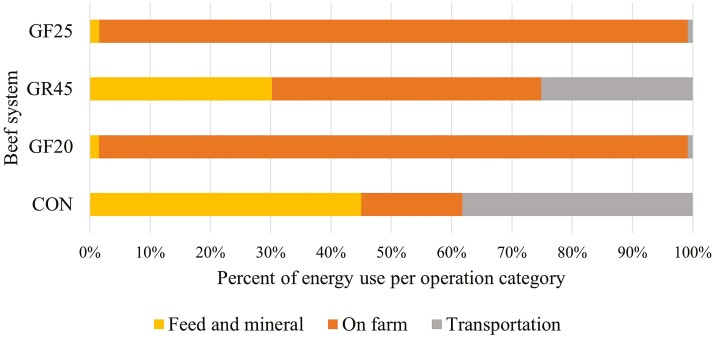

The energy footprint was largest for CON at 18.7 MJ kg per HCW, followed by GR45 at 13.8 MJ kg per HCW, then GF25 at 8.85 MJ kg per HCW, and GF20 with the lowest energy footprint at 7.65 MJ kg per HCW (Table 4). The energy footprints for the CON and GR45 treatments were greater than the grass-fed treatments due to increased transportation and farming inputs needed to produce and deliver their feedyard rations. The GF25 system produced a slightly greater energy value compared to GF20 due to the increased energy demands for irrigating pasture. Treatment energy use by operational category is represented in Figure 3.

Figure 3.

Proportion of energy use per beef system. CON, steers stocked on pasture then finished in a feedyard; GF20, steers grass-fed for 20 mo; GR45, steers grass-fed for 20 mo with a 45-d grain finish; GF25, steers grass-fed for 25 mo.

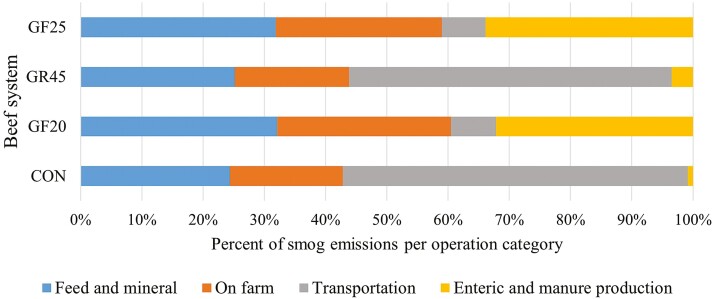

Smog formation

The smog formation potential was highest for the CON (0.15 O3 eq kg per HCW) followed by GR45 (0.08 O3 eq kg per HCW), with the GF20 (0.01 O3 eq kg per HCW) and GF25 (0.01 O3 eq kg per HCW) resulting in substantially smaller smog formation impacts (Table 4). The lower smog footprint of the 100% grass-fed system was expected due to lower transportation and production inputs (i.e., feed production) compared to the conventional system. Treatment smog emissions by operational category is represented in Figure 4.

Figure 4.

Proportion of smog emissions per beef system. CON, steers stocked on pasture then finished in a feedyard; GF20, steers grass-fed for 20 mo; GR45, steers grass-fed for 20 mo with a 45-d grain finish; GF25, steers grass-fed for 25 mo.

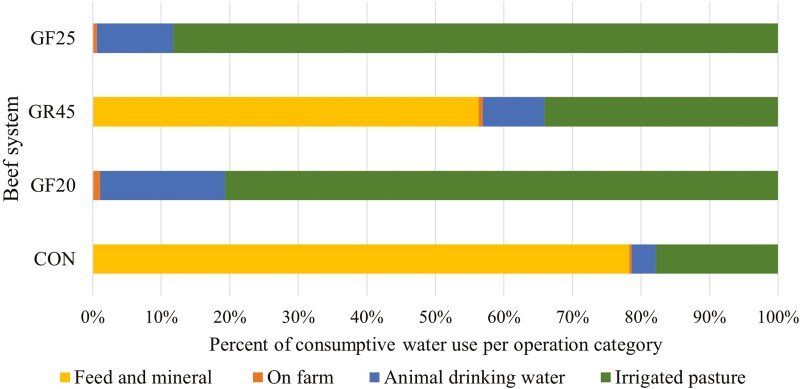

Consumptive water use

The GF25 treatment resulted in the largest water footprint of 1,210 L kg per HCW, followed by CON with a water footprint of 910 L kg per HCW, then GR45 at 664 L kg per HCW, and finally GF20 with the lowest water footprint of 465 L kg per HCW. The GF25 system resulted in higher water usage than the GF20 system due to the use of irrigated pasture during the finishing phase. Breakdown of water use per operation category for each system is provided in Figure 5.

Figure 5.

Proportion of consumptive water use per beef system. CON, steers stocked on pasture then finished in a feedyard; GF20, steers grass-fed for 20 mo; GR45, steers grass-fed for 20 mo with a 45-d grain finish; GF25, steers grass-fed for 25 mo.

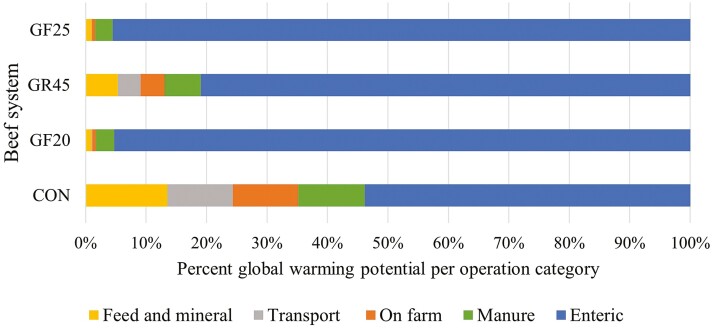

Global warming potential

The CON beef systems resulted in the lowest GWP of 4.79 CO2eq kg per HCW (Table 4). Within this system, enteric methane accounted for 54% of emissions, followed by feed and mineral emissions at 14% and on farm energy and total transportation and manure emissions all at 11% (Figure 6). When compared to the CON system the GWP for GF20 was 40% greater at 6.74 CO2 eq kg per HCW (Table 4). The GWP value was greater for the GF20 system principally due to the increase in enteric methane production and decreased harvest weight and DP. Breakdown of GWP per operation category for each system is provided in Figure 6.

Figure 6.

Proportion of GWP per beef system. CON, steers stocked on pasture then finished in a feedyard; GF20, steers grass-fed for 20 mo; GR45, steers grass-fed for 20 mo with a 45-d grain finish; GF25, steers grass-fed for 25 mo.

NAAU: .

Land occupation rate

Land occupation rate was lowest for the CON system at 1.28 m2 yr kg per HCW (Table 4). In comparison, due to the large amount of rangeland required, the GF20 required the greatest land occupation rate at 11.3 m2 yr kg per HCW, followed by GF25 at 9.82 m2 yr kg per HCW, then GR45 at 9.64 m2 yr kg per HCW. For a more comprehensive view on land occupation rate, land occupation was subdivided into irrigated pasture, rangeland, and farmland and mining (Table 5). When comparing irrigated pasture, land occupation for GF25 was 0.08 m2 yr kg per HCW. This was 400% greater than the CON system at 0.02 m2 yr kg per HCW. The GF20 had the largest rangeland land occupation rate of 10.5 m2 yr kg per HCW followed by the GF25 at 8.25 m2 yr kg per HCW and the GR45 at 7.95 m2 yr kg per HCW (Table 5). As expected, the CON and GR45 systems required considerably more farmland and mining land compared to the grass-fed systems due to commodity production at 0.81 and 1.10 m2 yr kg per HCW, respectively. The GR45 system had a slightly greater farmland and mining land occupation rate compared to the CON system due to the greater in weights of the cattle and the lower gain to feed ratio.

Table 5.

Grass and grain-fed system production costs and breakevens from weaning to harvest

| Treatment1 | Per head cost, without processing and marketing, $hd1 | Per head cost, with processing and marketing costs, $hd−1 | Breakeven without processing and marketing costs, $kg−1 of HCW | Breakeven with processing and marketing costs, $kg−1 of hot HCW |

|---|---|---|---|---|

| CON | 1,543 | 2,320 | 4.00 | 6.01 |

| GF20 | 1,405 | 2,066 | 6.11 | 8.98 |

| GR45 | 1,601 | 2,431 | 5.29 | 8.02 |

| GF25 | 1,635 | 2,432 | 5.60 | 8.33 |

CON, steers stocked on pasture then finished in a feedyard; GF20, steers grass-fed for 20 mo; GR45, steers grass-fed for 20 mo with a 45-d grain finish; GF25, steers grass-fed for 25 mo.

Discussion

Cattle performance and carcass quality

FBW, DP, and yield and quality grade

In the present study, GF20 and GF25 finished weights (478 and 570 kg, respectively), were similar in performance to previous grass-fed studies completed in the Eastern United States, where animals finished between 400 and 559 kg (Brown et al., 2009; Scaglia et al., 2012, 2014; Schmidt et al., 2013). In comparison to a grass-fed beef study performed in California by Cruz et al. (2013), the GF25 finished weight was 45 kg lower. Although breed, age of harvest, and location were similar between the two Californian grass-fed beef studies, weather and nutritional logistics were different. In the California Mediterranean climate, the majority of rainfall occurs during the late fall-winter to early spring, with high forage nutrition available on rangelands between February and May (George et al., 2001). In Cruz et al. (2013), despite the ample rainfall in December (NOAA, 2013), to avoid a decrease in nutritional plane during the winter, steers on rangeland were supplemented with alfalfa hay for a 40-d period. In our study, due to delayed rains and persistent overcast, rangeland nutrition remained poor throughout the entire winter resulting in an 18 kg weight loss for grass-fed steers between the months of November and March.

The discrepancies between previous and the present studies reveal a number of potential vulnerabilities and resilience issues associated with grass-fed beef systems. In the West where droughts and fire continue to be an issue, inclement weather could damage pasture or rangeland, jeopardizing a rancher’s ability to steadily produce grass-fed beef. One option for ranchers is to harvest grass-fed cattle early. When steers were harvested at an early age of 20 mo, FBW was less than other treatments at 478 kg, but still heavier than other grass-fed beef systems in the East (Brown et al., 2009). If harvesting cattle early is not feasible, a combined grass-fed and short-term grain-finished program may be a possible alternative. When 20 mo grass-fed steers were placed in the feedyard for a 45 d period, cattle gained 73 kg (1.62 kg/d). The total weight gain resulted in similar harvest weights compared to cattle that were finished on grass for an additional 5 mo in the GF25 treatment (P = 0.38). The ability to move cattle off rangeland into a confined feeding operation, even for a short period of time, may help add resilience to niche market/ farmers market beef programs.

Studies have shown grass-fed beef DP range from 49% to 60%, (Brown et al., 2009; Scaglia et al., 2012, 2014; Schmidt et al., 2013; Stanley et al., 2018) with one study producing a DP of 62% (Schmidt et al., 2013). Although some grass-fed cattle have produced DPs over 60%, most studies have shown cattle that are 100% grass-fed yield lower DPs compared to conventional cattle (Brown et al., 2009; Kim et al., 2012; Scaglia et al., 2012). Our study was no exception, with all grass-fed treatments resulting in lower DP compared to CON (P > 0.05). Increasing days on feed improved grass-fed cattle DP, with cattle in the GF25 treatment dressing 3% units greater compared to GF20 at 53%, (P > 0.05). Interestingly, although animals in the GF25 and GR45 treatments were fasted for the same amount of time and finished at similar weights, GR45 had a 4% units greater DP at 57% (P < 0.05). This suggests that differences in DPs may be a result of diet and the subsequent effects on muscle and organ development. Cruz et al. (2013) determined that grass-fed steers resulted in heavier rumen weights compared to conventional steers (P < 0.05) likely linked to increased ruminal papillae length (most noted in calf development in dairy) which would result in reduced DP. In addition, digestibility is lower and particulate passage rates of high fiber diets are slower than those of concentrate diets which results in greater gut fill at the time of harvest for grass-fed cattle, even with adequate feed withdrawal periods (Demment and Van Soest, 1985). Thereby, more fibrous diets with slower rates of digestibility and passage may result in an inflated live weight at times of harvest as compared to grain-finished animals, and this is reflected in the lower DP of these cattle.

Consistent with other studies (Brown et al., 2009; Schmidt et al., 2013; Scaglia et al., 2014), the grass-fed treatments resulted in lower quality grades and marbling scores compared to the CON treatment (P < 0.05). Although marbling score is an indicator of carcass quality, a greater marbling score does not necessarily correlate with greater consumer satisfaction (Platter et al., 2003), especially with consumers who prefer grass-fed beef (Miller, 2020). In one study when consumers were asked to choose a steak based on marbling, more consumers in Chicago preferred low marbling steaks compared to consumers residing in San Francisco, suggesting consumer perception for marbling is depended on region (Killinger et al., 2004). In addition, studies have shown that grass-fed beef consumers prefer grass-fed beef compared to conventional beef because they believe grass-fed beef is healthier partially due to its lower fat content (McCluskey et al., 2005; Xue et al., 2010). Therefore, it remains to be determined if the grass-fed beef with lower quality grade negatively affects the marketability of the product or sustainability of the system.

Ribeye size and shape

Consumers prefer larger ribeye size, with larger ribeye steaks selling faster than smaller ribeye steaks (Sweeter et al., 2005; Leick et al., 2011), indicating that ribeye size affects consumer purchasing decisions. Conventionally, fed beef had the largest LM area of 79.71 cm2 (P < 0.05). No difference in LM size was observed for the GF20, GR45, and GF25 treatments (64.95 to 68.43 cm2; P > 0.05). Several researchers observed smaller LM areas for grass-fed animals as compared to grain fed animals (Berthiaume et al., 2006; Kerth et al., 2007; Roberts et al., 2009; Cruz et al., 2013); however, no study has yet to report differences in LM shape. The present study demonstrated that the CON treatment had a lower length to width ratio, a rounder shape, compared to the GF20 and GF25 treatments. Interestingly, although the GR45 treatment had been on pasture for 20 mo, after 45 d on grain in a feedyard setting the LM shapes were not statistically different than the CON (P > 0.05), and were different from the 100% grass-fed treatments (P < 0.05). Currently, it is unknown if consumers would evaluate ribeye shape when making purchasing decisions. However, with continued consumer interest in grass-fed beef production (McCluskey, 2015), ribeye shape may be a factor in purchasing decisions in the years to come.

Financial durability

Treatment breakeven costs were 40% to 50% greater for all grass-fed and GR45 treatments as compared to conventional beef production (Table 5). Despite the greater costs of production, grass-fed treatment breakevens with processing costs were still 40% to 50% less than the 2019 USDA national average direct to consumer whole carcasses prices ($15.93 kg per HCW, USDA-AMS, 2019). In terms of total net return, breakeven multiplied by kg of beef produced was far greater for the GF25 and GR45 compared to the GF20, therefore both the GF25 and GR45 in this trial were more profitable treatment compared to the GF20. Although all three non-conventional beef systems had the potential to be profitable, during the trial we encountered several obstacles that could hinder long-term financial successes for our grass-fed beef production systems.

Representing current California grass-fed beef production systems, both GF20 and GF25 steers were 100% naturally raised. In order to stay compliant with the natural program, animals were never given hormones or antibiotics throughout the animal’s lifecycle. Unfortunately, during the fall of 2018, 20 steers in the present study were infected with pinkeye in one or both eyes. Pinkeye can have devastating losses on any type of beef operation, with cattle producers regarding pinkeye as one of the most troubling diseases affecting their cattle (George, 1990; Whittier et al, 2009). Following veterinary animal protocols steers were treated with antibiotics to reduce animal discomfort and prevent blindness, then removed from the 100% grass-fed treatments. The removal of these animals from the natural program was not accounted for in our financial analysis, however removing animals from a natural beef program would have profound financial implications for producers, not only due to the veterinary costs and performance loss, but also loss from not being able to sell the cattle at a natural/grass-fed premium.

Life cycle assessment

Energy

Similar to other LCA, in the present study feed and mineral production was the largest contributor to energy demand for conventional beef production (Pelletier et al., 2010; Rotz et al., 2015; Asem-Hiablie et al., 2019). However, in contrast to these LCA, our beef system required the transportation of feedstuffs (i.e., corn) from the Midwest to California. This high transportation energy input resulted in a greater energy input for the CON cattle (16.6 MJ kg per HCW, feedyard only) compared to other LCA performed in the Midwest and Panhandle (Rotz et al., 2015; 13.7 MJ kg per HCW).

Less energy was required to produce grass-fed steers (7.65 MJ kg per HCW for GF20 and 8.58 MJ kg per HCW for GF25) compared to treatments finished in the feedyard (18.7 MJ kg per HCW for CON and 13.8 MJ kg per HCW for GR45). Similarly, Pimentel and Pimentel (2008) and Koknaroglu et al. (2007) determined that grass-fed systems were less energy-intensive compared to the fossil fuel demanding conventional beef systems. However, Pelletier et al. (2010) demonstrated that grass-fed production in the Midwest (33.8 MJ kg per HCW; assuming 53% DP) was more energy-intensive than conventional beef production (19.5 MJ kg per HCW; assuming 62% DP). Unlike the present study, cattle were intensively managed on fertilized pastures and required large amounts of hay during winter, resulting in a high energy footprint (Pelletier et al. 2010). Our results highlight regional disparities between grass-fed beef production systems, and illustrate how grass-fed beef systems are not necessarily directly comparable due to local conditions and logistics.

Smog formation potential

Of the top 10 cities in the country with the worst air quality, 6 are Californian (American Lung Association, 2020). Agricultural activities are a major source of California NOx emissions (a major component of smog formation; Almaraz et al., 2018), and the smog formation potential impact is an important metric to evaluate California beef sustainability. Our model determined the GF20, GF25, and the GR45 produced 93%, 92%, and 50% fewer smog emissions than did the CON system (Table 6). However, as most of the grain used was grown elsewhere and transported to California, most of the smog-forming potential occurred outside the state. If our study had utilized nitrogen application on pastures, NOx emissions would have been substantially higher, resulting in greater local smog formation potential. Although smog has not commonly been examined in prior beef LCA work, an LCA comparing photochemical ozone creation potential (POCP), a precursor to smog, determined that grass-fed systems produced lower POCP values compared to the conventional system (Battagliese et al., 2015). The greater POCP emissions for the conventional beef system was due to greater feed inputs (i.e., corn and corn silage) compared to the grass-fed system.

Table 6.

Environmental impact factors for treatments on a kg of HCW−1 basis1

| Impact factor3 | Treatment2 | |||

|---|---|---|---|---|

| CON | GF20 | GR45 | GF25 | |

| GWP, CO2 eq.4 | 4.91 | 6.90 | 6.82 | 8.53 |

| Consumptive water, L | 933 | 465 | 678 | 1,250 |

| Land occupation rate, m2 per yr | 1.28 | 11.3 | 9.64 | 9.82 |

| Energy, MJ | 18.7 | 7.65 | 13.8 | 8.85 |

| Smog formation, O3 eq.5 | 0.15 | 0.01 | 0.08 | 0.01 |

Envionmental impacts based on weaning to harvest.

CON, steers stocked on pasture then finished in a feedyard; GF20, steers grass-fed for 20 mo; GR45, steers grass-fed for 20 mo with a 45-d grain finish; GF25, steers grass-fed for 25 mo.

All impact factors based on the functional unit kg per HCW.

GWP, carbon dioxide equivalent.

Ozone equivalent.

Consumptive water use

Grass-feeding for 25 mo (GF25) had the highest water footprint requiring 1,254 L/kg HCW for the stocker and finishing phase, 150% greater than the CON system. This result was similar to those of Capper (2012) who used a deterministic model to determine that grass-fed beef systems required 132% more water than did conventional beef systems. In our present study, the water footprint of CON was within range of those found previously, where conventional beef’s water footprint for the stocker and finishing phases ranged from 683 to 5,341 L kg per CW (based upon on Rotz assessment that cow-calf portion of beef’s lifecycle was responsible for 30% of the conventional beef water footprint; Rotz et al., 2015). In the CON system, feed was responsible for 96% of total water consumption, and drinking water was responsible for 3% of water consumption for the CON steers. This proportion of water consumption for the CON system was nearly identical to Beckett and Oltjen (1993) who determined for the entire conventional beef lifecycle, including cow–calf production feed was responsible for 96% of water use and drinking water was responsible for 3%. In both the present study and the Beckett and Oltjen study, feed water represented a large percentage of water use due to the high amount of irrigation required to grow feed.

In contrast to the GF25 system, the GF20 system (465 L kg per HCW) did not utilize irrigated pasture during the finishing phase, resulting in a water footprint 50% lower than the CON system and 63% lower than the GF25 system. This finding was consistent with Battagliese et al. (2015) who determined that conventional beef production used more water compared to non-irrigated, grass-fed beef operations. Although the GF20 system produced the lowest water footprint, the system also resulted in the lowest harvest weight and quality grade. In order to improve quality grade without compromising water footprint, placing cattle in the feedyard for 45 d (GR45), improved quality grade (P < 0.05) while only slightly increasing the consumptive water use (678 L kg per HCW).

Global warming potential

In this study, GWP for the CON system was 4.91 kg CO2 eq kg per HCW which were similar to Stackhouse-Lawson et al. (2012) who modeled California Angus conventional beef systems, resulting in a GWP of 4.95 kg CO2 eq kg per HCW (for stocker and finishing phases only). Our CON GWP value was also similar to conventional beef production systems in Alberta where the GWP for the stocker and finishing phases of beef production was 4.40 kg CO2 eq kg per HCW (Beauchemin et al., 2010). The greater GWP values for California beef production systems compared to the Alberta system may be due to increased transportation and feed input emissions associated with producing beef in California. However, it is important to note both the Beauchemin et al. (2010) and Stackhouse-Lawson et al. (2012) studies used the 4th edition IPCC greenhouse gas equivalent of 25 for CH4 which is lower than the 5th edition IPCC CH4 equivalent value of 34 that was used in the present study.

The GF25 system GWP was 174% greater at 8.53 CO2 eq kg per HCW compared to CON (Figure 3), similar to results that found that grass-fed beef systems resulted in a carbon footprint over 167% greater than conventional beef systems (Capper, 2012). The principal reason for greater GWP in grass-fed beef was due to increased enteric methane production from the high forage diets and increased days on feed. Though the GF20 cattle GWP was still greater than the CON system at 6.90 CO2 eq kg per HCW, the GWP was 30% less than the GF25 system (Figure 2). Despite the GF25 system producing a greater DP and heavier harvest weight, these factors did not offset the increased methane emissions from increased days on feed. Interestingly, compared to the GF20 system, when cattle were moved to the feedyard in the GR45 treatment, GWP decreased slightly, producing a GWP of 6.87 CO2 eq kg per HCW. The present study is the first to demonstrate that finishing cattle on grain for a short period of time after being grass-fed for an extended period of time results in not only increased carcass quality, but also a lower carbon footprint.

Even though our grass-fed systems resulted in greater carbon footprints compared to our grain-finished systems, some studies have shown the ability for grass-fed beef systems to sequester carbon, offsetting grass-fed beef cattle’s GHG enteric methane production (Pelletier et al., 2010; Stanley et al., 2018). In Stanley et al. (2018), when conventional and grass-fed finishing phases were compared and carbon sequestration was not considered, the grass-finished system GWP was 158% greater than the conventional beef systems. In contrast, when carbon sequestration was factored into the model, the grass-fed system produced a net negative GWP of −6.65 CO2 eq kg per HCW (Stanley et al., 2018). Similarly, using soil organic carbon sequestration rates for US pastures undergoing improvement or transition to management intensive grazing systems (Phetteplace et al., 2001), Pelletier et al., (2010) determined that grass-fed beef systems in the Midwest produced 15% fewer emissions compared to conventional beef. Despite both studies factoring in soil sequestration, no previous study has accounted for decreasing soil organic carbon sequestration rates over time, therefore it is unknown how long each of these grass-fed systems would be able to continue to sequester carbon. Regarding potential soil sequestration in the California Rangelands, the addition of livestock manure application to rangelands has shown to increase soil organic carbon (Owen et al., 2015). However, in a review by Conant et al. (2001), when improved grazing practices were implemented, less than half the studies demonstrated an increase in soil organic carbon. In the cases where soil carbon did increase, they occurred in relatively warm and moist climates that possessed specific mineralogy enabling for the retention and stabilization of carbon (Conant et al, 2001; Buckley Biggs and Huntsinger, 2021). Furthermore, in a study modeling California rangeland soil carbon levels from 1750 to present day determined rangelands with light to moderate grazing resulted in a continual decrease in soil organic carbon (Ryals et al., 2015). It has been hypothesized that the soils slowly released carbon as they transition from perennial to annual grasslands over multi-decadal timescales (Ryals et al., 2015). Therefore, without real time soil carbon measurements, we cannot infer that the grass-fed systems in our study either contributed to soil carbon loss or gain.

Land occupation rate

Previous LCA have determined that grass-fed systems require greater land space compared to conventional beef systems (Pelletier et al., 2010; Tichenor et al., 2017; Stanley et al., 2018). Our studies were consistent with these findings with GF20 and GF25 systems requiring substantially greater land, 11.25 and 9.82 m2 yr kg per HCW, respectively, compared to CON, 1.28 m2 yr kg per HCW. However, the grass-fed systems in our study required an even greater amount of land compared to previous grass-fed beef LCA (Pelletier et al., 2010; Stanley et al., 2018). This greater demand for land occupation required by the GF20, GF25, and GR45 was principally due to cattle management strategy and the type of land they utilized. Unlike Stanley et al. (2018) who utilized high quality pasture throughout the finishing phase for grass-fed beef, the present study utilized rangeland. Rangeland is an essential part of cattle’s lifecycle in the west, but due to lower nutritive value rangeland requires lower stocking rates compared to pastureland (George et al., 2001). For reference, in the present study, when cattle were on rangeland (GF20, GR45, and GF25), they required approximately 0.41 ha/mo. In comparison, when the GF25 cattle were moved to irrigated pasture, land occupation was decreased to 0.07 ha/mo. By moving cattle from rangeland to either irrigated pasture (GF25) or to the feedyard (GR45), the total land footprint decreased (Table 6), demonstrating that finishing cattle on irrigated pasture or feedyards resulted in more beef production with fewer land resources. However, unlike pastureland or cropland, that can be utilized to produce a variety of food sources, rangeland cannot be used to grow crops and is most efficiently used by ruminants. When land footprint was evaluated by type of land, CON had the greatest farmland and mineral footprint at 0.81 m2 yr kg per HCW and the GF20 had the lowest footprint at 0.01 m2 yr kg per HCW (Table 7). In contrast, GF20 had the highest rangeland footprint at 10.5 m2 yr kg per HCW, while CON had a 0 m2 yr kg per HCW footprint. These disparities in land footprints demonstrate the importance of incorporating land type into environmental assessments because not all land can be utilized in the same manner. However, despite the type of land occupation, grass-fed beef’s large land footprint does present an issue. If the U.S. beef supply chain converted to 100% grass-fed beef, current grass resources could only support 27% of the current beef supply (Hayek and Garrett, 2018). Therefore, to maintain food security while meeting consumer demands there needs to be a balance between conventional and grass-fed beef systems.

Table 7.

Land occupation for beef systems from weaning to harvest1

| Treatment2 | Cattle land occupation, m2 per yr per kg HCW | ||

|---|---|---|---|

| Irrigated pasture | Rangeland | Farmland and land for mining | |

| CON | 0.02 | 0.00 | 0.81 |

| GF20 | 0.04 | 10.5 | 0.01 |

| GR45 | 0.03 | 7.95 | 1.10 |

| GF25 | 0.08 | 8.25 | 0.01 |

Land occupation measured using the standard ISO 14040 LCA functional unit

CON, steers stocked on pasture then finished in a feedyard; GF20, steers grass-fed for 20 mo; GR45, steers grass-fed for 20 mo with a 45-d grain finish; GF25, steers grass-fed for 25 mo.

Conclusion

The varying grass-fed and grain-beef production systems resulted in systematic and proportional trade-offs. In the CON system, despite having the lowest GHG footprint, it had the highest energy and smog footprints. Water use in the GF20 system was substantially lower compared to GF25, but the GF20 cattle had the lowest quality grade, lowest HCW, and highest breakeven costs. Trade-offs were also observed for land occupation, with the GF20 system resulting in the highest land footprint (due to the large amount of rangeland required) but required minimal cropland. In terms of animal performance compared to the CON all systems (GF20, GF45, and GF25) resulted in lower DPs, lower HCWs and lower quality grades. This decrease in performance illuminates one of the greatest impediments of producing grass-fed beef. The increased days on feed and decreased HCW resulted in higher costs per kg of HCW for the GF45 and grass-fed systems. However, with the continuing increase in demand for niche market beef, producers may be able to overcome this financial obstacle.

In conclusion, our study demonstrated that nuances of grass-fed and grain-fed beef production result in varying economic, animal performance, and environmental trade-offs rather than being system absolutes. Furthermore, we underscored the importance of obtaining system specific performance data to accurately depict environmental impacts of beef production. For example, in the GF20 system if an average grass-fed DP of 55% (Schweihofer, 2013) was used instead of our empirically derived 50.2%, the GWP for GF20 would have decreased by 10%, resulting in an inaccurate GWP. This highlights why grass-fed beef systems are not interchangeable and to accurately assess the performance and environmental impacts of these systems, they should be evaluated on a regional and management strategy basis. Finally, our study illustrated the complexities underpinning environmental sustainability, for no beef system resulted in a systematically lower environmental footprint. In future we plan to further investigate the sustainability and productivity of these grass-fed and grain-fed beef systems by evaluating palatability, food safety, and beef nutrition.

Supplementary Material

Acknowledgment

This research was made possible by the James Beard Scholarship Program.

Glossary

Abbreviations

- AUM

animal unit monthly

- CO2 eq

carbon dioxide equivalent

- DP

dressing percentage

- FBW

final body weight

- GWP

global warming potential

- HCW

hot carcass weight

- KPH

kidney, pelvic, and heart fat

- LCA

life cycle assessment

- LD

longissimus dorsi muscle

- POCP

photochemical ozone creation potential

- REA

longissimus dorsi muscle area at the 12th to 13th rib

- VS

volatile organic solids

Conflict of interest statement

The authors declare no conflict of interest.

Literature Cited

- Almaraz, M., Bai E., Wang C., Trousdell J., Conley S., Faloona I., and Houlton B. Z.. . 2018. Erratum: agriculture is a major source of NOx pollution in California (Science Advances DOI:10.1126/sciadv.aao3477). Sci. Adv. 4:1–8. doi: 10.1126/SCIADV.AAU2561 [DOI] [PMC free article] [PubMed] [Google Scholar]

- American Lung Association . 2020. Most polluted cities. [accessed September 21, 2020] https://www.stateoftheair.org/city-rankings/most-polluted-cities.html.

- Asem-Hiablie, S., Battagliese T., Stackhouse-Lawson K. R., and Alan Rotz C.. . 2019. A life cycle assessment of the environmental impacts of a beef system in the USA. Int. J. Life Cycle Assess. 24:441–455. doi: 10.1007/s11367-018-1464-6 [DOI] [Google Scholar]

- Battagliese, T., Andrade J., Vinas R. R., Stackhouse-Lawson K., Rotz A., and Dillon J.. . 2015. Submission for verification of eco-efficiency analysis under NSF Protocol P352, Part B U.S. beef—phase 2 eco-efficiency analysis. BASF; 1–35 p. [Google Scholar]

- Beauchemin, K. A., Henry Janzen H., Little S. M., McAllister T. A., and McGinn S. M.. . 2010. Life cycle assessment of greenhouse gas emissions from beef production in western Canada: A case study. Agric. Syst. 103:371–379. doi: 10.1016/j.agsy.2010.03.008. [DOI] [PubMed] [Google Scholar]

- Beckett, J. L., and Oltjen J. W.. . 1993. Estimation of the water requirement for beef production in the United States. J. Anim. Sci. 71:818–826. doi: 10.2527/1993.714818x [DOI] [PubMed] [Google Scholar]

- Berthiaume, R., Mandell I., Faucitano L., and Lafrenière C.. . 2006. Comparison of alternative beef production systems based on forage finishing or grain-forage diets with or without growth promotants: 1. Feedlot performance, carcass quality, and production costs. J. Anim. Sci. 84:2168–2177. doi: 10.2527/jas.2005-328 [DOI] [PubMed] [Google Scholar]

- Boggs, D. L., Merkel R. A., and Doumit M. E.. . 1998. Live cattle evaluation, grading, and pricing. In Boggs, D. L., Merkel R. A., and Doumit M. E., editors. Livestock and carcasses. An integrated approach to evaluation, grading, and selection, 5th ed. Dubuque (IA): Kendall/Hunt publishing company; p. 113–143. [Google Scholar]

- Brown, K. R., Anderson G. A., Son K., Rentfrow G., Bush L. P., Klotz J. L., Strickland J. R., Boling J. A., and Matthews J. C.. . 2009. Growing steers grazing high versus low endophyte (Neotyphodium coenophialum)-infected tall fescue have reduced serum enzymes, increased hepatic glucogenic enzymes, and reduced liver and carcass mass. J. Anim. Sci. 87:748–760. doi: 10.2527/jas.2008-1108 [DOI] [PubMed] [Google Scholar]

- Buckley Biggs, N., and Huntsinger L.. . 2021. Managed grazing on California Annual Rangelands in the context of state climate policy. Rangel. Ecol. Manag. 76:56–68. doi: 10.1016/j.rama.2021.01.007 [DOI] [Google Scholar]

- California Air Resources Board (CARB) OFFROAD . 2007. Mobile source emissions inventory program. Sacramento (CA). [Google Scholar]

- Capper, J. L. 2012. Is the grass always greener? Comparing the environmental impact of conventional, natural and grass-fed beef production systems. Animals (Basel). 2:127–143. doi: 10.3390/ani2020127 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Conant, R. T., Paustian K., and Elliott E. T.. . 2001. Grassland management and conversion into grassland: Effects on soil carbon. Ecol. Appl. 11:343–355. doi: 10.1890/1051-0761(2001)011[0343:GMACIG]2.0.CO; [DOI] [Google Scholar]

- Cruz, G. D., Acetoze G., and Rossow H. A.. . 2013. Case study: Carcass characteristics of angus steers finished on grass or grain diets at similar quality grades. Prof. Anim. Sci. 29:298–306. doi: 10.15232/S1080-7446(15)30236-9 [DOI] [Google Scholar]

- Demment, M. W., and Van Soest P. J.. . 1985. A nutritional explanation for body-size patterns of ruminant and nonruminant herbivores. Am. Nat. 125:641–672. doi: 10.1086/284369 [DOI] [Google Scholar]

- Duckett, S. K., Neel J. P., Lewis R. M., Fontenot J. P., and Clapham W. M.. . 2013. Effects of forage species or concentrate finishing on animal performance, carcass and meat quality. J. Anim. Sci. 91:1454–1467. doi: 10.2527/jas.2012-5914 [DOI] [PubMed] [Google Scholar]

- Forero, L. C., Ingram R., Stackhouse J., Stewart D., and Sumner. D. A.. 2017a. Sample costs for beef cattle finished on grass 20 head northern Sacramento valley. Davis, CA: University of California Cooperative Extension. [Google Scholar]

- Forero, L. C., Stackhouse J., Stewart D., and Sumner D. A.. . 2017b. Sample costs for beef cattle: yearling/ stocker cattle in northern Sacramento valley. Davis (CA): University of California Cooperative Extension. [Google Scholar]

- George, L. 1990. Managing bovine pinkeye in beef calves. Calif. Agric. 44. doi: 10.3733/ca.v044n02p11 [DOI] [Google Scholar]

- George, M., Bartolome J., McDougald N., Connor M., Vaughn C. and Markegard G.. . 2001. Annual range forage production. Oakland (CA): University of California; 1–9 p. http://ucanr.edu/repository/a/?a=114175 [Google Scholar]

- Goulds Water Technology . 2019. Goulds water technology: a xylem brand. Turbine Catalog: Performance Curves. [accessed May 24, 2019] http://goulds.com/turbine-catalog/. [Google Scholar]

- IPCC. 2014. Climate change 2014: synthesis report. Contribution of working groups I, II and III to the fifth assessment report of the intergovernmental panel on climate change, Core Writing Team, Pachauri R.K., and Meyer L.A., editors. Geneva (Switzerland): IPCC; 151 pp. http://www.ipcc-nggip.iges.or.jp/public/2006gl/index.htm [Google Scholar]

- Hayek, M. N., and Garrett R. D.. . 2018. Nationwide shift to grass-fed beef requires larger cattle population. Environ. Res. Lett. 13. doi: 10.1088/1748-9326/aad401. [DOI] [Google Scholar]

- Kerth, C. R., Braden K. W., Cox R., Kerth L. K., and D. L. Rankins, Jr. 2007. Carcass, sensory, fat color, and consumer acceptance characteristics of Angus-cross steers finished on ryegrass (Lolium multiflorum) forage or on a high-concentrate diet. Meat Sci. 75:324–331. doi: 10.1016/j.meatsci.2006.07.019 [DOI] [PubMed] [Google Scholar]

- Killinger, K. M., Calkins C. R., Umberger W. J., Feuz D. M., and Eskridge K. M.. . 2004. Consumer visual preference and value for beef steaks differing in marbling level and color. J. Anim. Sci. 82:3288–3293. doi: 10.2527/2004.82113288x [DOI] [PubMed] [Google Scholar]

- Kim, Y. S., Fukumoto G. K., and Kim S.. . 2012. Carcass quality and meat tenderness of Hawaii pasture-finished cattle and Hawaii-originated, mainland feedlot-finished cattle. Trop. Anim. Health Prod. 44:1411–1415. doi: 10.1007/s11250-012-0080-x [DOI] [PubMed] [Google Scholar]

- Koknaroglu, H., Ekinci K., and Hoffman M. P.. . 2007. Cultural energy analysis of pasturing systems for cattle finishing programs. J. Sustain. Agric. 30:5–20. doi: 10.1300/J064v30n01_03 [DOI] [Google Scholar]

- Leick, C. M., Behrends J. M., Schmidt T. B., and Schilling M. W.. . 2011. Consumer selection of constant-weight ribeye, top loin, and sirloin steaks. Meat Sci. 87:66–72. doi: 10.1016/j.meatsci.2010.09.004 [DOI] [PubMed] [Google Scholar]

- Long R, Leinfelder-Miles M., Putnam D., Klonsky K., and Stewart D.. . 2015. Sample costs to establish and produce alfalfa hay in the Sacramento valley and northern San Joaquin Valley flood irrigation. Davis (CA): University of California Cooperative Extension. [Google Scholar]

- Lupo, C. D., Clay D. E., Benning J. L., and Stone J. J.. . 2013. Life-cycle assessment of the beef cattle production system for the northern great plains, USA. J. Environ. Qual. 42:1386–1394. doi: 10.2134/jeq2013.03.0101 [DOI] [PubMed] [Google Scholar]

- Marvinney, E., and Kendall A.. . 2021. A scalable and spatiotemporally resolved agricultural life cycle assessment of California almonds. Int. J. Life Cycle Assess.:1123–1145. doi: 10.1007/s11367-021-01891-4 [DOI] [Google Scholar]

- McCluskey, Jill. 2015. Changing food demand and consumer preferences. SE Washington State University Paper prepared for Agricultural Symposium Federal Reserve Bank of Kansas City July 14–15, 2015. [accessed September 23, 2020] https://www.kansascityfed.org/~/media/files/publicat/rscp/2015/mccluskey-paper.pdf?la=en [Google Scholar]

- McCluskey, J., Wahl T. I., Li Q., and Wandschneider P. R.. . 2005. U.S. grass-fed beef: marketing health benefits. J. Food Distrib. Res. 36:1–8. doi: 10.22004/ag.econ.27758 [DOI] [Google Scholar]

- Miller, R. 2020. Drivers of consumer liking for beef, pork, and lamb: A review. Foods. 9:25. doi: 10.3390/foods9040428 [DOI] [PMC free article] [PubMed] [Google Scholar]

- National Cattlemen’s Beef Association (NCBA) . 2020. Industry statistics. [accessed January 9, 2020] https://www.ncba.org/beefindustrystatistics.aspx.

- National Oceanic and Atmospheric Administration (NOAA) . 2013. California Nevada River Forecast Center. Northern California (CA): Monthly Precipitation Summary Water Year. [accessed January 9, 2020] https://www.cnrfc.noaa.gov/monthly_precip_2013.php. [Google Scholar]

- Neel, J. P., Fontenot J. P., Clapham W. M., Duckett S. K., Felton E. E., Scaglia G., and Bryan W. B.. . 2007. Effects of winter stocker growth rate and finishing system on: I. Animal performance and carcass characteristics. J. Anim. Sci. 85:2012–2018. doi: 10.2527/jas.2006-735 [DOI] [PubMed] [Google Scholar]