Abstract

Objective:

To determine the effect of coating on the properties of two esthetic orthodontic nickel-titanium wires.

Materials and Methods:

Woowa (polymer coating; Dany Harvest) and BioForce High Aesthetic Archwire (metal coating; Dentsply GAC) with cross-section dimensions of 0.016 × 0.022 inches were selected. Noncoated posterior regions of the anterior-coated Woowa and uncoated Sentalloy were used for comparison. Nominal coating compositions were determined by x-ray fluorescence (JSX-3200, JOEL). Cross-sectioned and external surfaces were observed with a scanning electron microscope (SEM; SSX-550, Shimadzu) and an atomic force microscope (SPM-9500J2, Shimadzu). A three-point bending test (12-mm span) was carried out using a universal testing machine (EZ Test, Shimadzu). Hardness and elastic modulus of external and cross-sectioned surfaces were obtained by nanoindentation (ENT-1100a, Elionix; n = 10).

Results:

Coatings on Woowa and BioForce High Aesthetic Archwire contained 41% silver and 14% gold, respectively. The coating thickness on Woowa was approximately 10 µm, and the coating thickness on BioForce High Aesthetic Archwire was much smaller. The surfaces of both coated wires were rougher than the noncoated wires. Woowa showed a higher mean unloading force than the noncoated Woowa, although BioForce High Aesthetic Archwire showed a lower mean unloading force than Sentalloy. While cross-sectional surfaces of all wires had similar hardness and elastic modulus, values for the external surface of Woowa were smaller than for the other wires.

Conclusions:

The coating processes for Woowa and BioForce High Aesthetic Archwire influence bending behavior and surface morphology.

Keywords: Coating, Nickel-titanium wire, Three-point bending test, Hardness, Nanoindentation test

INTRODUCTION

Esthetic archwire (wire) is highly desirable to complement esthetic brackets in clinical orthodontics.1 The first esthetic transparent nonmetallic orthodontic wire contained a silica core, a silicone resin middle layer, and a stain-resistant nylon outer layer and was marketed as Optiflex by Ormco.2 Fallis and Kusy subsequently developed an esthetic wire containing S2 glass fibers (Owens Corning, Toledo, Ohio) embedded in a polymeric matrix formed from (bisphenol A–diglycidylether methacrylate and triethylene glycol dimethacrylate.3 Another research group has also developed a fiber-reinforced polymer wire.4 Although these polymer-based esthetic wires have an excellent appearance, they have not been clinically popular because of their brittle character. On the other hand, metallic archwires coated with polymer materials, such as Teflon and epoxy resin, have also been developed.5,6 Recently, coating technology for metallic biomedical materials based on a plasma-immersion ion-implantation technique has been developed,7 and ion-implanted wires specially intended for improving the friction with brackets have been marketed for clinical orthodontics, although these products are not tooth colored.8–10 Elayyan et al.6 have performed a randomized clinical trial of epoxy resin–coated nickel-titanium wire and reported that retrieved coated wire produced lower force values (three-point bending test) than as-received coated wire and that 25% of the coating was peeled off within 33 days in vivo.

Recently, new esthetic nickel-titanium wires with tooth color, Woowa (Dany Harvest, Seoul, South Korea) and BioForce High Aesthetic Archwire (Dentsply GAC, Islandia, NY), have been introduced in clinical orthodontics. Woowa has a double-layered coating structure (inner layer: silver and platinum coating; outer layer: special polymer coating). BioForce High Aesthetic Archwire has a proprietary, low-reflectivity rhodium coating that presents a white appearance.

The purpose of this study was to investigate the effects of these different coatings on the mechanical properties of the aforementioned two commercially available esthetic orthodontic nickel-titanium wires. Three-point bending and nanoindentation tests were performed to study their mechanical properties, which were compared with those for noncoated wires. The wire surfaces were characterized by a scanning electron microscope (SEM) and an atomic force microscope (AFM). It was hypothesized that the esthetic coatings do not affect the mechanical properties.

MATERIALS AND METHODS

Materials

Two as-received esthetic nickel-titanium wires, Woowa (Dany Harvest) and BioForce High Aesthetic Archwire (Dentsply GAC), with a cross-section dimension of 0.016 × 0.022 inch were used in this study. Two noncoated as-received nickel-titanium wires, the noncoated posterior regions of the anterior-coated Woowa and Sentalloy (Dentsply GAC) with the same cross-section dimensions, were used for comparison. Communications with the manufacturer revealed that BioForce High Aesthetic Archwire and Sentalloy have the same composition and are made by similar manufacturing procedures. The only difference is the heat treatment procedure, and the different heat treatment conditions in each region (anterior and posterior) of the BioForce High Aesthetic Archwire yield different force levels between the anterior region and posterior region. The posterior regions from all wires were used for all experiments. Nominal compositions of the wire coatings were determined by x-ray fluorescence (XRF; JSX-3200, JOEL, Tokyo, Japan).

Scanning Electron Microscopy and Atomic Force Microscopy

For studying the cross-sections of the wires, each specimen was encapsulated in epoxy resin (Epofix, Struers, Copenhagen, Denmark), and the surface was ground and polished using a series of silicon carbide abrasive papers and a final slurry of 0.05-µm alumina particles. All specimens were sputter coated with gold and examined by an SEM (SSX-550, Shimadzu, Kyoto, Japan) operating at 15 kV.

The external surfaces of the wires were examined with an AFM (SPM-9500J2, Shimadzu) to characterize the surface morphology. Values of average surface roughness (Ra) were calculated by software supplied with the AFM (n = 5).

Three-Point Bending Test

A three-point bending test was carried out for the specimen wires (n = 5). The span size for the wire segments, 12 mm, was chosen in accordance with ANSI/ADA Specification No. 32.11 All samples were loaded with the same protocol on a universal testing machine with a 20-N load cell (EZ Test, Shimadzu) at room temperature (25°C). Each wire was first loaded to a deflection of 3 mm (loading process) and then unloaded (unloading process) at a rate of 0.5 mm/min. The unloading force (ie, the load measured at a deflection of 1.5 mm during the unloading process) was compared between coated and noncoated wires of the same type.

Nanoindentation Test

The cross-sectional surfaces and external surfaces of the wires were examined with a nanoindentation apparatus (ENT-1100a, Elionix, Tokyo, Japan). For analysis of the cross-sectional surface, each specimen was encapsulated in epoxy resin (Epofix), and the surface was ground and polished using the same series of silicon carbide abrasive papers and final slurry of 0.05-µm alumina particles that were employed to prepare the SEM specimens. All specimens were fixed to the specimen stage with adhesive resin (Superbond Orthomite, Sun Medical, Shiga, Japan), and all nanoindentation testing was carried out at 28°C using a Berkovich indenter with a peak load of 20 mN. Each test consisted of three segments: 10 seconds for loading to the peak value, a hold period of 1 second at the peak load, and 10 seconds for unloading. The maximum depth of indentation and the hardness and elastic modulus were calculated by software that was supplied with the nanoindentation apparatus, using equations in ISO Standard 14577.12

Statistical Analysis

A statistical analysis was performed using PASW Statistics (version 18.0J for Windows, IBM, Armonk, NY) to examine the effect of coating on surface roughness, unloading force, hardness, and elastic modulus between the coated and noncoated specimens of the same wire type. The data were examined for the normality of distribution with the Kolmogorov-Smirnov test and the equality of variances with the Levene test. Because each data set did not meet the required criteria for parametric analysis, the Mann-Whitney U-test was applied to determine whether a significant difference existed between the groups (P < .05).

RESULTS

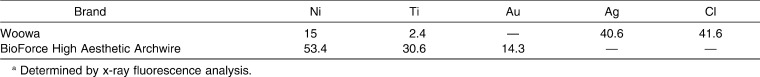

Nominal compositions of the wire coatings obtained by XRF are summarized in Table 1. The XRF analyses suggest that the coating on Woowa contained 41% silver and 42% chlorine and that the coating on BioForce High Aesthetic Archwire contained 14% gold beside nickel and titanium. The XRF analyses were unable to detect rhodium, which the manufacturer reports as being incorporated in the coating on BioForce High Aesthetic Archwire.

Table 1.

Composition of the Wire Coatings (wt %)a

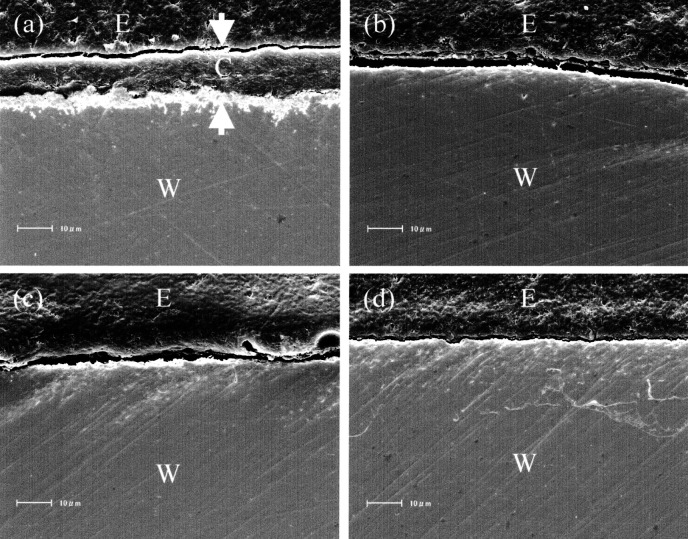

Figure 1 shows representative SEM photomicrographs for cross-sectioned wires. The coating layer on Woowa had a uniform thickness of approximately 10 µm, but no coating layer could be observed on the surface of the BioForce High Aesthetic Archwire at the SEM magnification employed.

Figure 1.

Scanning electron microscope photomicrographs of the external surface of (a) Woowa, (b) noncoated Woowa, (c) BioForce High Aesthetic Archwire, and (d) Sentalloy. Original magnification 1000×. C indicates coating layer; E, epoxy resin; and W, wire.

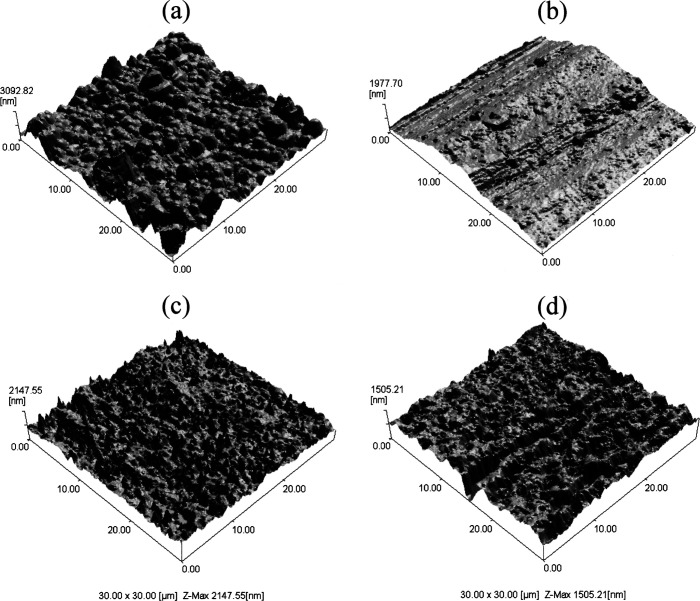

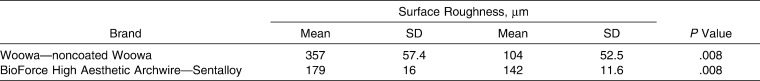

Figure 2 shows representative three-dimensional images obtained with the AFM for the external surfaces of the four wires examined, and Table 2 shows the average surface roughness (Ra) values, where each row presents the comparisons between the coated and noncoated wires of the same type. The surface of Woowa was rougher (357 µm) than the noncoated Woowa (104 µm, P = .008). Also, the surface of BioForce High Aesthetic Archwire was rougher (179 µm) than Sentalloy (142 µm, P = .008).

Figure 2.

Three-dimensional images for external surfaces of four wires obtained with atomic force microscope (AFM). (a) Woowa. (b) Noncoated Woowa. (c) BioForce High Aesthetic Archwire. (d), Sentalloy.

Table 2.

Average Surface Roughness (Ra Values) for the Four Wires

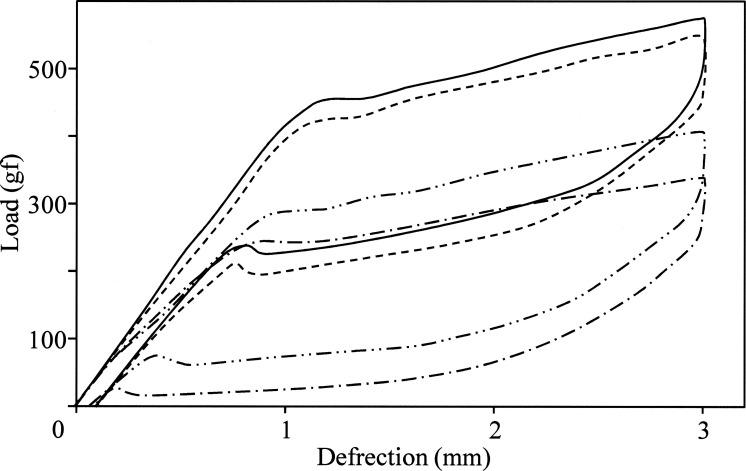

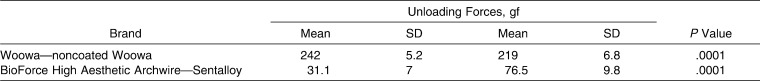

Figure 3 shows representative load-deflection curves for the four nickel-titanium wires. Unloading forces at a deflection of 1.5 mm for the four nickel-titanium wires are summarized in Table 3, where each row again presents the comparison between the coated and noncoated wires of each type. The coated portion of Woowa and the noncoated posterior part of this wire showed a considerably higher mean load than the BioForce High Aesthetic Archwire and Sentalloy. Woowa produced a significantly higher unloading force value than the noncoated Woowa (P = .0001). In contrast, BioForce High Aesthetic Archwire produced significantly lower unloading force value than Sentalloy (P = .0001). All wires exhibited superelastic behavior at room temperature.

Figure 3.

Representative load-deflection curves of four wires. Woowa, continuous line; noncoated Woowa, dashed line; BioForce High Aesthetic Archwire, dashed-dotted line; Sentalloy, dashed double-dotted line.

Table 3.

Average Unloading Forces at a Deflection of 1.5 mm for the Four Nickel-Titanium Wires

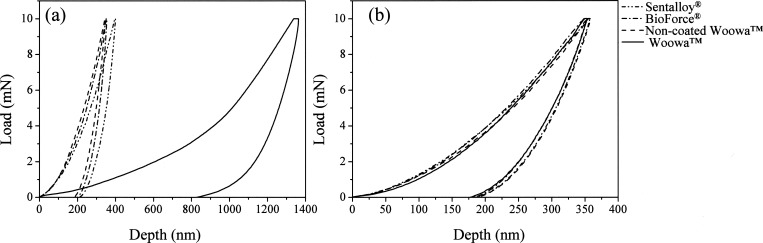

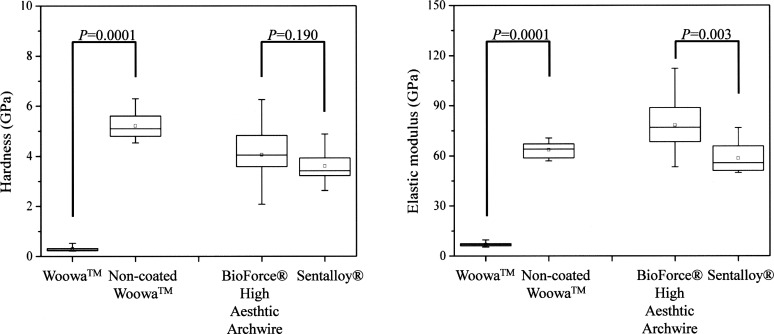

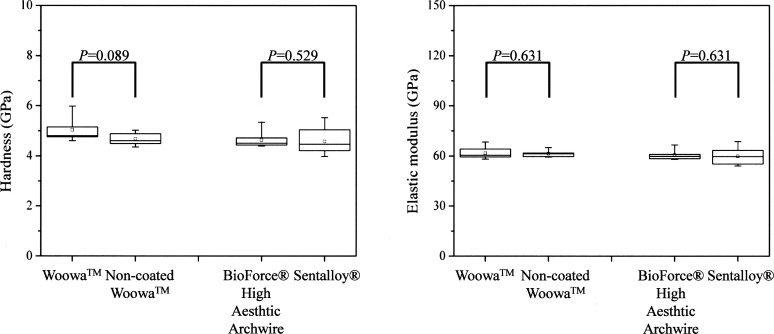

Figure 4 shows representative loading-unloading curves for the nanoindentation testing obtained from the external surfaces and cross-sections of the four nickel-titanium wires. The values of the maximum depth of indentation for the external surface (coating layer) of Woowa were much greater than those obtained for the other wires. All wires showed similar loading-unloading curves for the cross-sectioned surfaces. Figures 5 and 6 show the hardness and elastic modulus of each wire for the external surface regions and cross-sectional surface regions, respectively. The hardness (P = .0001) and elastic modulus (P = .0001) of the external surface region for Woowa were significantly lower than the values for the noncoated Woowa. There was no significant difference in the average hardness (P = .190) between BioForce High Aesthetic Archwire and Sentalloy, although the elastic modulus of the external surface region for BioForce High Aesthetic Archwire was significantly higher than for Sentalloy (P = .003).

Figure 4.

Representative loading-unloading curves of each wire obtained by nanoindentation testing. (a) Comparison of the external surfaces. (b) Comparison of the cross-sectioned surfaces. Woowa, continuous line; noncoated Woowa, dashed line; BioForce High Aesthetic Archwire, dashed dotted line; Sentalloy, dashed double-dotted line.

Figure 5.

Mechanical properties at the external surface of each wire obtained by nanoindentation testing.

Figure 6.

Mechanical properties for cross-sectioned surface of each wire obtained by nanoindentation testing.

DISCUSSION

This study used XRF analyses to obtain information about the compositions of the wire coatings. From private communications with the manufacturers, silver, platinum, and a specific polymer (parylene) were used for coating Woowa, and gold and rhodium were used for coating BioForce High Aesthetic Archwire. The parylene polymer generally has chlorine in the structure, and the XRF analyses showed reasonable results that the surface region of Woowa contained 41% silver and 42% chlorine. In contrast, 14% gold was detected at the surface for BioForce High Aesthetic Archwire, and rhodium was not detected, which may be due to its amount being less than the XRF detection limit.

It was found that application of the coating layer on Woowa and BioForce High Aesthetic Archwire affected the three-point bending behavior. Woowa with a thick (10 µm) coating produced a significantly higher unloading force value than the noncoated Woowa, although the coating layer of Woowa, which contained parylene, had a very low elastic modulus. On the other hand, BioForce High Aesthetic Archwire produced significantly lower unloading force values than Sentalloy did. This may be attributed to different heat treatment conditions for the wires before rhodium plating and a thermal effect during the rhodium plating procedure. There was only one previous study that reported the mechanical properties (three-point bending) for epoxy-coated nickel-titanium wire, although a different device and different conditions for the three-point bending test were used.6 This study reported that the as-received coated nickel-titanium wire with a diameter of 0.016 inch produced 51–61 gf during the unloading process, and these unloading forces are similar to those found for BioForce High Aesthetic Archwire and Sentalloy in the present study. On the other hand, the starting nickel-titanium wire for Woowa may have been intentionally processed by the manufacturer to produce a higher mean load for clinical use.

Friction between the bracket and the wire during tooth movement is one of the primary issues in clinical orthodontics, since the efficiency of tooth movement is greatly influenced by this friction.8,13–15 Surface roughness and hardness of the wire influence its frictional properties,13–15 and surface coating the orthodontic wire should influence its roughness and hardness. Mixed results have been reported about the relationship between surface roughness and frictional force. Saunders and Kusy13 reported that there is little correlation between surface roughness and friction. In contrast, a recent study showed that there was a positive correlation between bracket slot roughness and friction resistance.15 The surfaces of Woowa and BioForce High Aesthetic Archwire were rougher than the surfaces of the corresponding noncoated wires (Table 2), and the external surface region of Woowa had significantly lower hardness and elastic modulus than values for the noncoated Woowa (Figure 5). Therefore, the coating layers on Woowa and BioForce High Aesthetic Archwire might influence their frictional characteristics. However, further research is needed to prove this hypothesis. On the other hand, the hardness obtained for the external surface region of the BioForce High Aesthetic Archwire showed similar values to the noncoated Sentalloy nickel-titanium wire.

The maximum depth of indentation for the external surface (coating layer) of the BioForce High Aesthetic Archwire was approximately 370 nm (0.37 µm). From private communication with the manufacturer, the coating layer of the BioForce High Aesthetic Archwire mainly consisted of gold and rhodium and is approximately 0.5 µm in thickness. The thickness was too small for the coating to be detected at moderate SEM magnification (Figure 1). This thin metallic coating layer for the BioForce High Aesthetic Archwire might be expected to have mechanical properties that are similar to those for the near-surface layer of nickel-titanium wires (Sentalloy and noncoated Woowa). However, further research is needed to prove this hypothesis.

CONCLUSIONS

Under the conditions in this study, the following conclusions can be drawn:

The coating process for Woowa influences its three-point bending behavior.

The coating process for BioForce High Aesthetic Archwire might influence its three-point bending behavior.

The surface of the parylene coating layer on Woowa had rougher morphology and much lower hardness, but the bulk portion of the coated wire had similar mechanical properties compared with the noncoated wire.

The surface of the coating layer on BioForce High Aesthetic Archwire had rougher morphology and similar hardness compared with the noncoated wire.

Acknowledgments

The authors thank the Dany Harvest Co Ltd and Dentsply GAC for providing information about the Woowa and BioForce High Aesthetic Archwire.

REFERENCES

- 1.Brantley W. A. Orthodontic wires. In: Brantley W. A, Eliades T, editors. Orthodontic Materials Scientific and Clinical Aspects. Stuttgart, Germany: Thieme; 2001. pp. 77–104. [Google Scholar]

- 2.Talass M. F. Optiflex archwire treatment of a skeletal class III open bite. J Clin Orthod. 1992;26:245–252. [PubMed] [Google Scholar]

- 3.Fallis D. W, Kusy R. P. Variation in flexural properties of photo-pultruded composite archwires: analyses of round and rectangular profiles. J Mater Sci Mater Med. 2000;11:683–693. doi: 10.1023/a:1008903224180. [DOI] [PubMed] [Google Scholar]

- 4.Imai T, Watari F, Yamagata S, Kobayashi M, Nagayama K, Nakamura S. Effects of water immersion on mechanical properties of new esthetic orthodontic wire. Am J Orthod Dentofacial Orthop. 1999;116:533–538. doi: 10.1016/s0889-5406(99)70185-x. [DOI] [PubMed] [Google Scholar]

- 5.Husmann P, Bourauel C, Wessinger M, Jäger A. The frictional behavior of coated guiding archwires. J Orofac Orthop. 2002;63:199–211. doi: 10.1007/s00056-002-0009-5. [DOI] [PubMed] [Google Scholar]

- 6.Elayyan F, Silikas N, Bearn D. Ex vivo surface and mechanical properties of coated orthodontic archwires. Eur J Orthod. 2008;30:661–667. doi: 10.1093/ejo/cjn057. [DOI] [PubMed] [Google Scholar]

- 7.Sridharan K, Anders S, Nastasi M, Walter K. C, Anders A, Monterio O. R, Ensinger W. Nonsemiconductor application of PIII&D. In: Anders A, editor. Handbook of Plasma Immersion Ion Implantation and Deposition. Weinheim, Germany: Wiley-VCH; 2004. pp. 553–637. [Google Scholar]

- 8.Kusy R. P, Tobin E. J, Whitley J. Q, Sioshansi P. Frictional coefficients of ion-implanted alumina against ion-implanted beta-titanium in the low load, low velocity, single pass regime. Dent Mater. 1992;8:167–172. doi: 10.1016/0109-5641(92)90076-o. [DOI] [PubMed] [Google Scholar]

- 9.Wichelhaus A, Geserick M, Hibst R, Sander F. G. The effect of surface treatment and clinical use on friction in NiTi orthodontic wires. Dent Mater. 2005;21:938–945. doi: 10.1016/j.dental.2004.11.011. [DOI] [PubMed] [Google Scholar]

- 10.Cobb N. W, Kula K. S, Phillips C, Proffit W. R. Efficiency of multi-strand steel, superelastic Ni-Ti and ion-implanted Ni-Ti archwires for initial alignment. Clin Orthod Res. 1998;1:12–19. doi: 10.1111/ocr.1998.1.1.12. [DOI] [PubMed] [Google Scholar]

- 11.American National Standard/American Dental Association Specification No32 Orthodontic wires. Chicago, Ill: American Dental Association, Council on Scientific Affairs; 2000. [Google Scholar]

- 12.ISO 14577-1 Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part 1 Test Method. Geneva, Switzerland: International Organization for Standardization; 2002. [Google Scholar]

- 13.Saunders C. R, Kusy R. P. Surface topography and frictional characteristics of ceramic brackets. Am J Orthod Dentofacial Orthop. 1994;106:76–87. doi: 10.1016/S0889-5406(94)70024-9. [DOI] [PubMed] [Google Scholar]

- 14.Muguruma T, Iijima I, Brantley W. A, Mizoguchi I. Effects of a diamond-like carbon coating on the frictional properties of orthodontic wires. Angle Orthod. 2011;81:143–150. doi: 10.2319/052110-276.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Doshi U. H, Bhad-Patil W. A. Static frictional force and surface roughness of various bracket and wire combinations. Am J Orthod Dentofacial Orthop. 2011;139:74–79. doi: 10.1016/j.ajodo.2009.02.031. [DOI] [PubMed] [Google Scholar]