Abstract

Today, the world faces an enormous increase in plastic waste pollution caused by the emergence of the COVID-19 pandemic. Plastic pollution has been already one of the greatest threats to our planet before the Coronavirus outbreak. The disposal of millions of personal protective equipment (PPE) in the form of face masks has significantly contributed to the generation of plastic waste and has exacerbated plastic pollution. In an attempt to mitigate pollution caused by the excess PPE waste, an innovative way was developed in this research to reduce pandemic-generated wastes by using the shredded face mask (SFM) fibers as an additive to hot mix asphalt (HMA) to enhance rutting resistance. Rutting or permanent deformation is one of the major distresses of asphalt pavement. Since the SFM behaves as a semi-liquid between 115.5 and 160 °C, which is in the range of HMA mixing and paving temperature, it can function as a binding agent to glue the aggregates. When the pavement is cooled down to ambient temperature, the hardened SFM can provide stability and stiffness to HMA. Based on the results of this study, the modified mixes exhibited excellent resistance to permanent deformation under the Asphalt Pavement Analyzer (APA), as rutting depth values were reduced from 3.0 mm to 0.93 mm by increasing the SFM content from 0% to 1.5%. From the rutting test results and premature distress mechanism study, the appropriate addition of SFM modifiers could improve the high-temperature properties of HMA that can be used to strengthen high-compression and shearing zones in the pavement structure.

Keywords: Asphalt pavement rutting, Fatigue, Face masks, Perpetual pavement, Plastics

Graphical abstract

1. Introduction

The COVID-19 pandemic has created serious health, financial, and environmental issues worldwide (Garel and Petit-Romec, 2020). It is uncertain when and how this pandemic will end (Yong, 2021). During the current pandemic, there has been a sharp increase in the use of Personal Protective Equipment (PPE) compared to pre-pandemic time (Maderuelo-Sanz et al., 2021). This is mainly because of the implemented mandatory requirements for wearing PPE, especially face masks (Rowan and Laffey, 2021). One of the effective health campaigns against the Coronavirus virus is using face masks, which has led to the necessity of face masks as part of the global public health initiative to avoid the spread of the virus (Royo-Bordonada et al., 2020). Compound annual growth of 20% for the supply of facial and surgical masks is estimated from 2020 to 2025 (Ilyas et al., 2020). This trend will continue.

Though the use of face masks is incredibly needed, the disposal of the face mask is threatening the environment (Boroujeni et al., 2021). A large amount of discarded face masks is generated globally on a daily basis. It was estimated that 129 billion face masks were generated in 2020 monthly (Prata et al., 2020). Another estimation showed that over 6.68 billion (approximately 206,470 tons) face masks were used globally daily due to the COVID-19 pandemic (Saberian et al., 2021a). Masks made from lightweight materials can easily be moved around by wind and rain, even if they are dumped in bins or sent to landfills. This is why the used face masks are ubiquitous in our cities, parks, parking lots, and local areas. Ultimately, the used face masks can easily find their way to rivers and oceans, threatening marine life (Kilmartin-Lynch et al., 2021b). It has been reported that more than 1.56 billion masks entered oceans in 2020 (Lee et al., 2021). Also, reports state that the number of face masks in oceans will be more than the number of jellyfish in the near future. Therefore, the microplastic issues have already been worsened due to the entering of the used PPE, including face masks, into the oceans (Kilmartin-Lynch et al., 2021a; Torresa and De-la-Torreb, 2021).

The disposable surgical face masks, which are mainly made of polypropylene (PP), are the most commonly used masks (Kwak and An, 2021). In addition, since disposable face masks are mainly made of non-biodegradable plastics, these single-use masks will take as long as 450 years to break down in the environment (Saberian et al., 2021a). To alleviate these critical environmental issues, we must take advantage of sustainability principles to collaborate on used face mask disposal to reduce the environmental risks. A potential option would be the adoption of used face masks for large-scale civil and construction projects. The effects of polypropylene in HMA have been already studied to some extent. Othman (2010) used PP as a coating material to evaluate the long-term aging of HMA. The PP additive has managed to counteract the effect caused by the long-term aging of HMA. It was also observed that the coating method could significantly enhance the tensile strength and fracture energy under the aged and unaged conditions since the inclusion of polypropylene could improve the surface roughness and the mechanical properties of the aggregates. Hamedi et al. (2018) used PP in HMA as an antistripping additive. The test results indicated that the use of PP improved the resistance of asphalt mixtures in both wet and dry conditions. The investigation of the effect of PP in HMA on rutting resistance has rarely been found. The effects of PP fibers on the properties of asphalt binders were studied by Kathari (2016). It was observed that the incorporation of PP fibers decreased the thermal sensitivity and increased resistance to permanent deformation at high temperatures. However, little research has been conducted to investigate the effect of PP in HMA on rutting resistance. More recently, two research have been conducted on the repurposing of single-use face masks for civil engineering applications, concrete application (Kilmartin-Lynch et al., 2021b), and road base and subbase application (Saberian et al., 2021a). Another potential application of adopting single-use face masks in civil engineering can be the asphalt application to modify the quality, performance, and properties of asphalt, which is the main aim of the current study.

In highway construction, asphalt binder is used to bind mineral aggregates (sand, gravel, rock, filler, etc.) that form pavement surfaces. Asphalt binder is influenced by a variety of factors, including temperature swings, solar radiation, oxidation, and average daily traffic (ADT) (Zhang et al., 2020). As a result, road surfaces are prematurely losing viability due to the physical stresses on the asphalt binder. Therefore, the asphalt binder needs to be rejuvenated. Some types of fresh asphalt binder also require modification to comply with the pavement requirements (Roberts et al., 1996).

In terms of pavement structure, one of the challenges facing many asphalt roads today is to control rutting in pavements due to traffic volume, tire pressure, and axial load (Saberian et al., 2020a; Saberian et al., 2021b). This pattern often emerges in the first few years after the service area is opened (Suo and Wong, 2009). There are three forms of rutting in asphalt pavements: structural rutting, wheel path wear and densification, and asphalt concrete instability (permanent deformation) (Saberian et al., 2018; Saberian et al., 2021c). The latter two types of rutting are illustrated in Supplementary Fig. 1(a) and Supplementary Fig. 1(b), respectively. The most severe type of rutting is asphalt concrete instability rutting, as shown in Supplementary Fig. 2 (Wang, 2016). The rutting of the pavement layers is a cumulative deformation that has persisted for years, which can be caused by the aggregate particle shape, toughness, and angularity of coarse and fine aggregates. It also can be caused by an incorrect asphalt binder and mix design, for instance, a binder that does not meet AASHTO M320 (AASHTO, 2017), or AASHTO M332 (AASHTO, 2020) specifications, a poorly designed mix, or a mix with a high percentage of asphalt binder. To look at it in another way, such a poor pavement has the characteristics of densification and lateral deformation, or differently, it looks like a depression in the wheel paths and erosions on the edges (Khan et al., 2013).

Rutting contributes to the deterioration and hydroplaning propensity of pavement (Fontes et al., 2010). Rutting can also lead to major failures of the pavement structure (Saberian et al., 2020b; Suo and Wong, 2009). As a result, the rutting has a negative effect on the safety of pavements and can harm the lives of the commuters on the roads (Dhir OBE et al., 2019). Rutting is an important parameter for structural evaluation and selection criterion for new pavements (FHWA and NAPA, 2001). Research has found that both inappropriate selection of asphalt binder and aggregates, such as less crushed sides of coarse aggregate and uncrushed gravel, can contribute to rutting (Li et al., 2021). Manufactured sand is better than natural sand. For asphalt binder rutting, the ratio of dynamic shear modulus to the sine of the phase angle, |G*|/sinδ, is used as a parameter in the performance grading (PG) standard. This parameter is measured using an oscillation test in the linear viscoelastic (LVE) range. However, in pavements, the deformations that occur during rutting are substantially higher and involve non-linear viscoelastic (NLVE) behaviors (Salim et al., 2019). Improving asphalt binder selection criteria can improve rutting, as the Superpave design method has suggested, which has been used in the US in the last 20 years. As traffic volumes, traffic flows, and pressures have increased recently, the likelihood of tires causing rutting and cracking has increased (Xu and Huang, 2012). Some modifiers, such as polymers and some plastics, can make the asphalt binder stiffer to make it less susceptible to stress cracking and make the asphalt binder become softer to resist better to the stiffness changes at service temperatures (Speight, 2015). Therefore, different types of residual plastic wastes have been recently used as asphalt binders for increasing the effectiveness and improving the performance of asphalt (Almeida et al., 2021; Veropalumbo et al., 2021). Some waste plastics, including polyethylene, polypropylene, and polystyrene, do not produce any toxic gas during heating; if sprayed on hot aggregate at 160 °C, they tend to create a film covering the aggregates to form plastics coated aggregates, resulting in a better raw material for the construction of flexible pavements. (Rajasekaran et al., 2013; Sarkar et al., 2016). It has also been reported that the adoption of plastics as asphalt binders can improve the engineering properties of flexible pavements (i.e., Marshall stability, water resistance, and resistant to crack propagation) (Esfandabad et al., 2020; Haider et al., 2020; Needhidasan and Agarwal, 2020). Therefore, the recycling and repurposing of COVID-19 generated wastes, including single-use face masks, solid waste plastics, and industrial by-products (such as asphalt shingles, glass, and ash), will not only reduce the environmental issues and provide added financial values, but also can be considered for asphalt applications, where they may be an ingredient in HMA.

2. Significance of the research

To mitigate the spread of the pandemic's deleterious environmental effects, rigorous partnerships and collaborations are needed across all disciplines. This study explores the possibility of using face masks to convert them to an additive for hot mix asphalt (HMA) to modify the mechanical properties of asphalt pavement, therefore opening an avenue to reduce the increased PPE pollutions. In this research, a series of experiments on the volumetric properties of Superpave specimens and rutting were conducted on the blends of different percentages of the shredded face masks (SFM) added to the normal HMA mixes for pavement applications. This study attempts to evaluate the improvements in the modification of asphalt due to the addition of SFM.

The specific objectives of the current study can be summarized as follows:

-

•

To evaluate the effects of SFM on the rutting of the modified flexible pavement.

-

•

To determine the effect of the inclusion of SFM in the modified mixture from the Superpave test.

3. Materials and methods

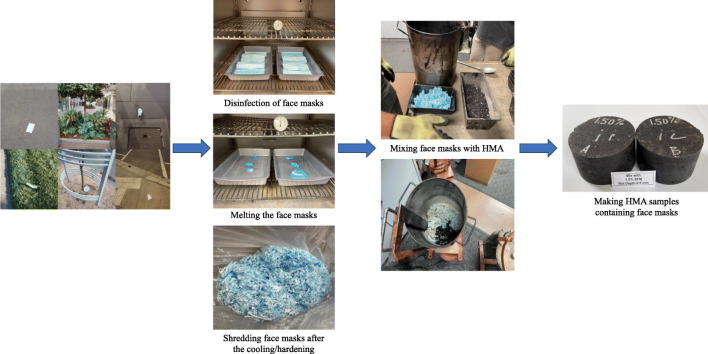

3.1. Preparation of the single-use face masks as HMA modifier

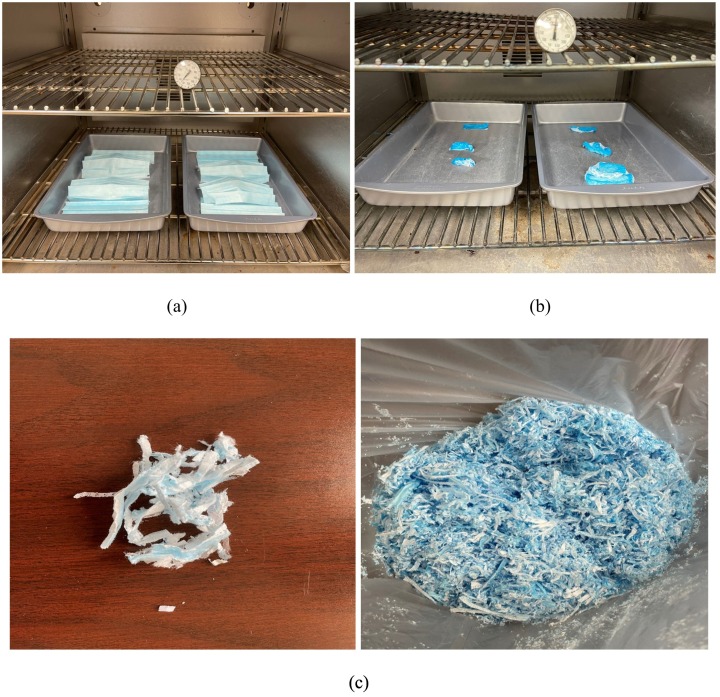

In this study, shredded single-use face masks were used as a modifier for the hot mix asphalt. The physical properties of the face masks were evaluated through a series of experiments, and the results are outlined in Supplementary Table 1. However, since this study was conducted on new masks, to simulate the disinfection process and observe the physical changes of the treated face masks, the masks were disinfected by placing them in the oven at a temperature of 70 °C for 60 min (Xiang et al., 2020). Then, the nose metal strips and ear-loops were removed from the face masks prior to use. To evaluate the behavior of the face masks in the HMA mixture, the main process of the sample preparation of masks started at this point by placing the face masks in an oven at 160 °C for 10 min to melt the face masks. Then, the melted face masks were removed from the oven and cooled at room temperature to be hardened. It should also be mentioned that the face masks started melting at 115.5 °C after 10 min in the oven. Fig. 1 (a and b) shows views of the face masks in the oven for the disinfection process and the liquefying process. Then, the cooled and hardened face masks were shredded into small pieces to a size of 40 mm × 5 mm using a paper shredder. Considering the fiber was melted under the mixing temperature acting as a binder and uniform size of the SFM, the effect of the size under this situation is neglected (Fig. 1(c)).

Fig. 1.

(a) Disinfection of face masks in the oven, (b) melted/semi-liquefied face masks at 160 °C temperature in the oven, and (c) shredded face masks after the cooling/hardening process to be added in the HMA mixes as a modifier.

3.2. Hot mix asphalt composite materials

In this research study, Superpave PG 64-22 asphalt was used. The performance graded (PG) system is a methodology for evaluating the performance of asphalt binder materials. It was created in the early 1990s as part of the strategic highway research program (SHRP). The Superpave performance grading (PG) standard assigns a performance grade to asphalt binders that vary by 6 °C depending on the ambient environmental temperatures (Clayton et al., 2009). PG64-22 is an asphalt binder Performance Grade (PG) determined by two factors: traffic and pavement temperature. Adjustments are made to the PG grade of asphalt binder based on traffic circumstances and volume, with the goal of extending the pavement's design life. This asphalt grade is used for the high pavement design temperature of 64 °C and low pavement design temperature of minus 22 °C.

Two specimens for each combination were prepared for this research. Coarse aggregate, fine aggregate, Reclaimed Asphalt Pavement (RAP), having 5.2% asphalt binder, and 7.6% asphalt content (AC) were chosen for the control mix design. Crushed stone manufactured sand, natural sand, and baghouse fines were also used. The same mix was used for different contents of SFM. Table 1 shows the aggregate gradation for RS 4.75A surface mix (control). RAP has been utilized for paving in hot mix asphalt (HMA) blends since the 1930s. The option of using the old asphalt binder in the new mixes, in contrast to the recycled aggregate or crushed portland concrete, reduces the needed (new) asphalt content, makes the use of RAP for HMA combinations more cost-effective (Huang et al., 2005). To guarantee that the aggregate in the RAP had identical features as the new one, the RAPs were sampled from the same geographic region. RAP sources were approved by the NCDOT (the North Carolina Department of Transportation) and blended with asphalt binder PG 64-22. A total of seven HMA mixes incorporating different proportions of SFM (i.e., 0% (control mix), 0.25%, 0.5%, 0.75%, 1%, 1.25%, and 1.5% by weight of the mixtures) were considered for testing in this study. Supplementary Fig. 3 shows the mixing of SFM with the asphalt binder for preparing the HMA mixes. It is worth mentioning that during the mixing process, the uniformity of the SFM dispersion in the mixes was controlled by observing the SFM with light color.

Table 1.

Aggregate gradation for RS 4.75A surface mix.

| Material | 78 M | UCLa base | Man. sanda | N sanda | BgHs finesa | RAP | Blend | Control points |

|---|---|---|---|---|---|---|---|---|

| Percent (MDa) | 5.0 | 32.1 | 30.0 | 15.0 | 2.5 | 15.4 | 100 | |

| Percent (JMFa) | 5.0 | 35.0 | 30.0 | 15.0 | 15.0 | 100 | ||

| Sieves (mm) 50.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100 | |

| 37.5 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100 | |

| 25.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100 | |

| 19.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100 | |

| 12.5 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100 | 100 |

| 9.5 | 93.0 | 97.0 | 100.0 | 100.0 | 100.0 | 97.0 | 98 | 95–100 |

| 4.75 | 37.0 | 86.0 | 100.0 | 100.0 | 100.0 | 84.0 | 90 | 90–100 |

| 2.36 | 13.0 | 70.0 | 87.0 | 100.0 | 100.0 | 70.0 | 78 | |

| 1.18 | 4.0 | 48.0 | 61.0 | 99.0 | 100.0 | 59.0 | 60 | 30–60 |

| 0.600 | 3.0 | 34.0 | 43.0 | 90.0 | 100.0 | 48.0 | 47 | |

| 0.300 | 2.0 | 20.0 | 26.0 | 43.0 | 100.0 | 33.0 | 28 | |

| 0.150 | 1.0 | 13.0 | 5.0 | 7.0 | 96.0 | 14.0 | 11 | |

| 0.075 | 1.0 | 11.6 | 2.1 | 3.3 | 94.0 | 7.8 | 8.4 | 6.0–12.0 |

| Ign.Furn.Corr.Factora | ||||||||

| Agg.Bulk Dry.S.G.a | 2.435 | 2.543 | 2.592 | 2.656 | 2.520 | 2.605 | 2.578 | |

| Agg. Effective S.G.a: 2.584 | ||||||||

| Agg. Apparent S.G.a | 2.626 | 2.649 | 2.719 | 2.682 | 2.548 | 2.653 | 2.672 | |

UCL: unclassified dry screenings containing 3/8″ size rock; N Sand: natural sand; Man. Sand: manufactured sand; BgHs Fines: baghouse fines; MD: mix design; JMF: job mix formula; Ign.Furn.Corr.Factor: ignition furnace correction factor; Agg.Bulk Dry.S.G: aggregate bulk dry specific gravity; Agg. Effective S.G.: aggregate effective specific gravity; Agg. Apparent S.G.: aggregate apparent specific gravity.

3.3. Mix design

As mentioned earlier, seven samples were prepared with the specification of RS 4.75 A with the same mixed formula as that of the Superpave mix PG 64–22. One is the control mix with no SFM and the other six contain 0.25%, 0.50%, 0.75%, 1.00%, 1.25%, and 1.50% SFM. The diameter and thickness of the specimens were 150 mm and 75 mm, respectively. The optimum asphalt content and RAP were 7.6% and 15.4% for all mixtures, respectively. %VTM, %VFA, %VMA were found to be 5.0%, 76.0%, and 21.2% for all mixtures, respectively. Table 2 summarizes the mix properties for N design, which is the number of gyrations specified to reach the target density of the mix, and it is based on the estimated field density in the middle of its service life. Table 3 shows Superpave volumetric properties RS 4.75A. The composing materials were mixed at approximately 160 °C and immediately compacted under the Superpave gyratory compactor (SGC).

Table 2.

Mix properties of N.

| % Asphalt Binder-Total Mix | 7.0 | 7.5 | 8.0 | 8.5 | |

| Gmba@ Ndesa (or Nmaxa) | 2.188 | 2.200 | 2.211 | 2.222 | |

| Max. Specific Gravity (Gmma) | 2.338 | 2.322 | 2.307 | 2.291 | |

| % Voids-Total Mix (VTM) | 6.4 | 5.3 | 4.2 | 3.0 | |

| % Solids-Total Mix | 93.6 | 94.7 | 95.8 | 97.0 | |

| % Effective Binder Content (Pbea) | 6.9 | 7.4 | 7.9 | 8.4 | |

| Dust to PbeRatio (P.075/Pbe) | 1.22 | 1.14 | 1.06 | 1.00 | |

| By volume of Effective Pba | 14.6 | 15.8 | 16.9 | 18.1 | |

| % Solids by Vol. of Agg. Only | 79.0 | 78.9 | 78.9 | 78.9 | |

| % Voids in Mineral Agg. (VMA) | 21.1 | 21.1 | 21.1 | 21.1 | |

| % Voids Filled w/Binder (VFA) | 69.2 | 74.9 | 80.1 | 85.8 | |

| %Gmm@ Ninia6 | 87.2 | 88.0 | 88.8 | 89.8 | |

| % Gmm@ Ndes50 | 93.6 | 94.8 | 95.8 | 97.0 | |

| % Gmm@ Nmax | 98.5 | ||||

| Sand Equivalent: | 58.4 | Pbin RAP | 5.2 | ||

| C. Agg. Angularity: | 100/100 | Pbfrom RAP | 0.8 | ||

| F. Agg. Angularity: | 47.2 | Pbaa | 0.1 | ||

| ASH% | |||||

| TSRa% | 83.8 | ||||

| Ign. Furn. Calib.a | 0.29 |

Gmb: bulk specific gravity of compacted mixture; Ndes: the number of gyrations specified to reach the target density of the mix and it is based on the estimated field density in the middle of its service life; Nmax: the number of gyrations based on an estimate of the final density expected in the field at the end of its service life after years of further densification by traffic; Nini: The number of gyrations used as a measure of mixture compactability during construction; Pbe: effective asphalt content, percent by the total mass of mixture; Gmm: maximum specific gravity of paving mixture (no air voids); Pb: asphalt content, percent by the total mass of mixture; Pba: absorbed asphalt, percent by mass of aggregate; TSR: tensile strength ratio; Ign. Furn. Calib.: ignition furnace calibration.

Table 3.

Superpave volumetric properties RS 4.75A.

| Control Mix | 0.25% SFM | 0.50% SFM | 0.75% SFM | 1.00% SFM | 1.25% SFM | 1.50% SFM | |

|---|---|---|---|---|---|---|---|

| Diameter (mm) | 150.00 | 150.00 | 150.00 | 150.00 | 150.00 | 150.00 | 150.00 |

| Thickness (mm) | 75.00 | 75.00 | 75.00 | 75.00 | 75.00 | 75.00 | 75.00 |

| Dry Mass in Air | 2897.92 | 2890.80 | 2891.80 | 2891.20 | 2892.55 | 2892.45 | 2894.75 |

| SSD Mass in Air | 2899.60 | 2892.15 | 2893.6 | 2893.50 | 2894.70 | 2894.45 | 2896.2 |

| Bulk Sp. Gravity | 2.213 | 2.193 | 2.195 | 2.191 | 2.192 | 2.192 | 2.197 |

| % Air Voids | 4.53 | 5.40 | 5.40 | 5.50 | 5.45 | 5.45 | 5.25 |

| %VTM | 5.0 | ||||||

| %VFA | 76.0 | ||||||

| %VMA | 21.2 | ||||||

| %AC | 7.6 | ||||||

3.4. Equipment employed

For laboratory and field use applications, there is a wide range of asphalt concrete accelerated testing equipment for evaluating the permanent deformation (rutting). For example, Hamburg-type wheel tracking equipment can be used for wet or dry rutting resistance testing (Walubita et al., 2020), while wheel tracking equipment developed by the French LCPC is widely used in Europe with two prismatic specimens (beam shape) (Bodin et al., 2011). The Asphalt Pavement Analyzer (APA), as shown in Supplementary Fig. 4, developed by PTI, is widely used in the United States with growing international use (Uzarowski et al., 2010). A series of laboratory tests were performed on HMA mixes for evaluating the performance of rutting resistance of HMA mixes containing SFM. All the tests were performed in NCDOT approved laboratories. The testing method was established by the American Association of State Highway and Transportation Officials and the American Society for Testing and Materials. In this project, Asphalt Pavement Analyzer (APA) and Superpave tests were conducted. Four replicate samples were prepared for each mix design, and the average results were provided.

The APA chamber temperature was set at 64 °C, the wheel loading condition was 100 lbs. (45 kg), and the hose pressure was 100 psi (689 kPa). APA machine was set at 60 cycles per minute. Samples were subjected to 8000 cycles in the APA. Rut depth measurements were collected at seating loads of 0, 25, 4000, and 8000 cycles in this study.

4. Results and discussion

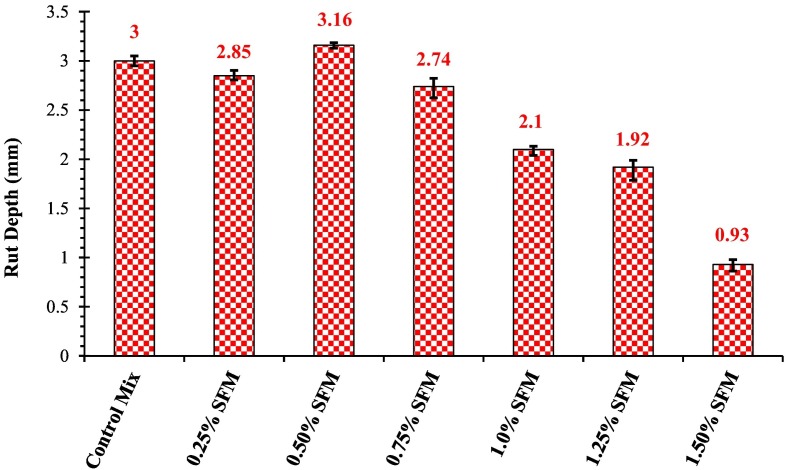

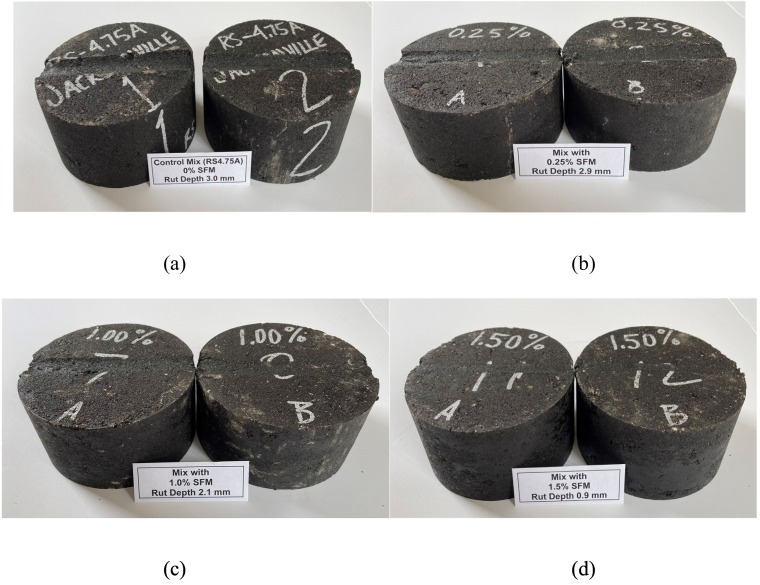

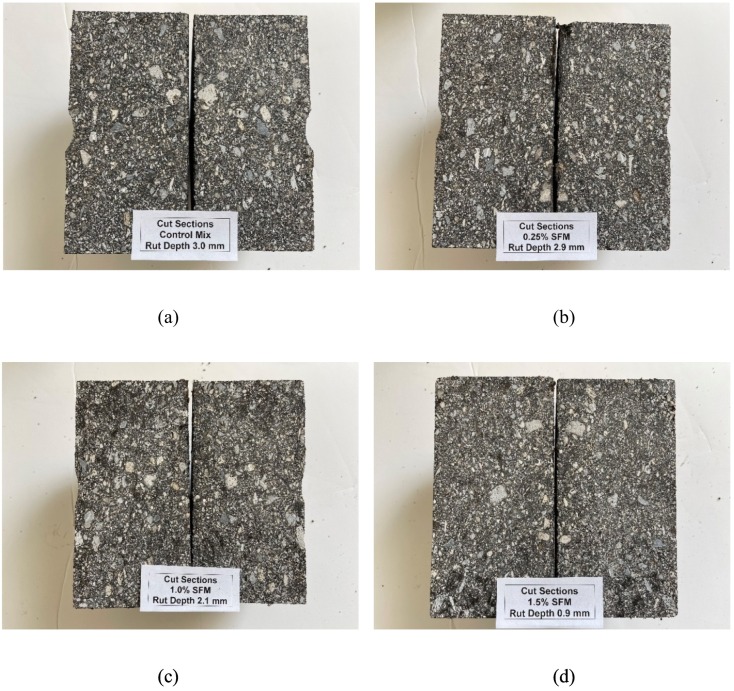

Fig. 2 shows the comparison between the control mix and the different percentages of SFM mix specimens in a bar chart. As seen from the figure, the adoption of shredded face masks (SFM) has improved the rutting resistance of hot mix asphalt. At 0.5%, the rutting showed a higher value (3.16 mm). It might be due to the testing error that does not affect the interpretation of the overall results and its trend. The rutting depth of the control sample was observed at 3.0 mm; however, by increasing the SFM content from 0.5% to 1.5%, the rutting depth reduced from 3.16 mm to 0.93 mm, which is lower than the control mix and lower than the maximum specification requirements for local traffic pavement and interstate highway pavement. It should be mentioned that the maximum rut depth is 4.5 mm (≥ 30 million ESALs) for interstate highway pavement in the US, and for local traffic pavement, it is 11.5 mm (≤ 0.3 ESALs). The mix design incorporating 1.5% SFM provided the lowest rut depth at 0.93 mm, which is a remarkable result. Therefore, it can be concluded that the melted SFM functioned like an asphalt binder to bind the aggregates and reduce the rut depth. Generally, it can be argued that the mixtures containing SFM are more resistant to the wheel loads. This can be explained by the increase in the stiffness of the mixes and improved adhesion between the aggregates by the incorporation of SFM. As indicated earlier, the soft PP masks melted under the mixing temperature and hardened under ambient temperature, thus enhancing the adhesion between aggregate particles. Considering the best SFM content of 1.5% in HMA in this study, for constructing one kilometer of pavement with a thickness of 50 mm asphalt, approximately 2.7 tons of face masks (about 180,000 face masks) will be used. Fig. 3 shows a view of the specimens including 0%, 0.25%, 1.0%, and 1.50 SFM after the rutting test with rutting depth.

Fig. 2.

Comparison of the rut depth between the control mix and mixes with SFM.

Fig. 3.

(a) Control mix (RS4.75A) 0% SFM with rut depth of 3.0 mm; (b) mix with 0.25% SFM with rut depth of 2.9 mm; (c) mix with 1.0% SFM with rut depth of 2.1 mm; and (d) mix with 1.5% SFM with rut depth of 0.9 mm.

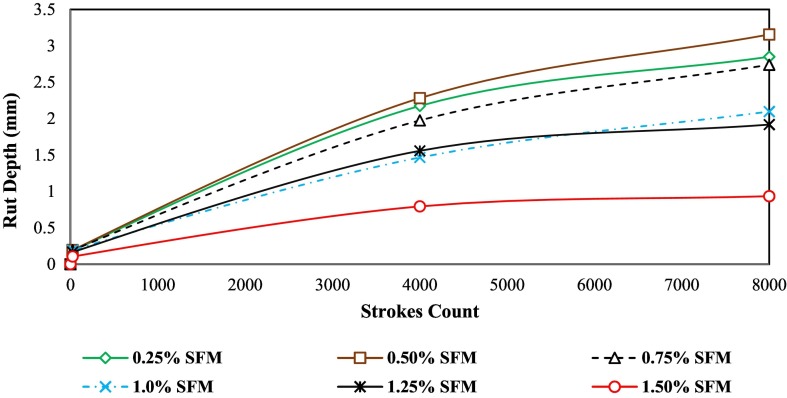

Fig. 4 provides the results of rut depths of different SFM mix specimens at 0, 25, 4000, and 8000 cycles. The rutting test results and research by others (e.g., Othman, 2010) suggest that using SFM modified HMA to mitigate thermal sensitivity-related cracking might be worthy of additional research. In the next step of the study, the gradations will be adjusted with coarser nominal particle size to investigate if the SFM-modified HMA can be used as the maximum strain layer of perpetual pavement, which is an asphalt pavement designed and constructed to last longer than 50 years without the necessity for major structural rehabilitation/reconstruction and requiring only time to time surface renewal in response to distress confined to the top of the pavement (Lee et al., 2020), as shown in Supplementary Fig. 5. Top-down cracking becomes prevalent due to the increase in heavy traffic (Hu and Walubita, 2008; Walubita et al., 2011; Faruk et al., 2016). From the rutting test results, it is reasonable to suggest that SFM may reduce the top-down cracking, and the function of SFM-modified HMA on top-down cracking is an area worth investigating (Supplementary Fig. 6). Therefore, the incorporation of SFM may lead to mitigating the HMA distresses in a wide range of temperatures (Supplementary Fig. 7).

Fig. 4.

Rut depth of the mixes with varied SFM additions under APA test.

The HMA cylinders were cut using a circular saw with a diamond blade to observe the appearance of the cut surfaces of the control sample and samples with SFM fibers. It was observed from the cut sections that there was no SFM fiber residue was identified. This indicated that the SFM fiber was melted and mixed with the aggregates under mixing temperature at approximately 160 °C (320 °F). Fig. 5 shows the images of cut sections of selected HMA specimens.

Fig. 5.

Cut sections of (a) control mix (RS4.75A) 0% SFM; (b) mix with 0.25% SFM; (c) mix with 1.0% SFM; and (d) mix with 1.5% SFM.

5. Conclusions and recommendations for future work

The COVID-19 pandemic has created severe environmental impacts globally. One of the serious environmental issues is the daily utilization of billions of polypropylene single-use face masks around the world. In this preliminary study, the effects of shredded face masks in the hot mix asphalt were evaluated for the first time. The potential application of SFM in HMA and the rutting performance of HMA mixes incorporating SFM were proved through a series of Asphalt Pavement Analyzer (APA) laboratory tests. It was observed that the rutting depth was reduced by increasing the SFM content, which can be attributed to the melted SFM acting as an asphalt binder in binding the aggregates. The mixes with 0%, 0.25%, 0.50%, 0.75%, 1.0%, 1.25%, and 1.5% SFM in HMA meet the requirements for S4.75A mix type.

This study shows that the mixes with different SFM percentages had good resistance against rutting, while the result was outstanding for the mix containing 1.5% SFM. A very low rut depth (0.93 mm) of the sample was obtained, implying that the incorporation of SFM in the HMA mix, which increased the stiffness of the mixes and improved the adhesion between the aggregates, can provide more resistance to the pavement subjected to the traffic load.

This study proposed a new approach for reducing pandemic generated waste by recycling the used face masks in HMA. It opened a new avenue for sustainable asphalt pavement development and added knowledge in this area. The results obtained from this study can provide the industry and government agencies with valuable references for future efforts in developing sustainable ways for the pavement industry.

In the future study, an increased content should be considered, and its effect on rutting will be evaluated to determine the optimum addition of SFM for rutting correction. The mechanism of the promising results from the preliminary study needs to be further investigated with the focus on the interface zones of fine and coarse aggregates within 0–100 μm and micro-hardness changes. For future works, it is also recommended to conduct more tests to assess the feasibility of using SFM for asphalt mixtures, such as tensile strength, moisture susceptibility, modulus, and distribution of SFM fibers in asphalt mixtures for quality control. Chemical composition or micro-level by microscopy is also suggested for further mechanism study. In addition, since top-down cracking has been recognized as one of the distresses in asphalt pavements due to the increase in heavy traffic, the subsequent research can also explore if the SFM-modified HMA can help reduce and retard top-down cracking. The possibility of the SFM on mitigating the HMA distresses at various temperature ranges should be assessed.

CRediT authorship contribution statement

George Wang: conceptualization, writing – review and editing, resources, validation, supervision, coordinating; Jie Li: conceptualization, writing – review and editing, analysis, supervision; Mohammad Saberian: writing – review and editing, analysis; Md. Hasibul Hasan Rahat: methodology, validation, testing; Carol Massarra: methodology, validation, investigation; Chelsea Buckhalter: methodology, validation, investigation, analysis; Jodi Farrington: writing – review and editing, analysis; Tony Collins: testing, analysis; Jeff Johnson: testing, analysis.

Declaration of competing interest

With regards to the declaration of interest, we hereby confirm that our work has not been published previously, that it is not under consideration for publication elsewhere, that its publication is approved by all authors, and that, if accepted, it will not be published elsewhere in the same form, in English or in any other language, including electronically without the written consent of the copyright holder.

Acknowledgements

The authors would like to acknowledge the technical support from ST Wooten Corporation, Asphalt Center, especially Mr. Everett Thornton. We also thank the Unit of Materials and Test of the Department of Transportation of North Carolina. The research team appreciates the technical information on the face masks provided by Dr. Harry Ploehn and technical support by Mr. Andrew Wilson of the College of Engineering and Technology of East Carolina University.

Editor: Damia Barcelo

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.scitotenv.2022.154118.

Appendix A. Supplementary data

Supplementary material

References

- AASHTO . American Association of State Highway and Transportation Officials (AASHTO); 2017. AASHTO M 320 - Standard Specification for Performance-Graded Asphalt Binder. [Google Scholar]

- AASHTO . American Association of State Highway and Transportation Officials (AASHTO); 2020. AASHTO M 332 - Standard Specification for Performance-graded Asphalt Binder Using Multiple Stress Creep Recovery (MSCR) Test. [Google Scholar]

- Almeida A., Capitão S., Estanqueiro C., Picado-Santos L. Possibility of incorporating waste plastic film flakes into warm-mix asphalt as a bitumen extender. Constr. Build. Mater. 2021;291 [Google Scholar]

- Bodin D., Grenfell J.R., Collop A.C. Road Materials and Pavement Design. Vol. 10. 2011. Comparison of small and large scale wheel tracking devices. 2009 - Issue sup1: Special Issue on Asphalt Materials (ICAM 2009—China) [Google Scholar]

- Boroujeni M., Saberian M., Li J. Environmental impacts of COVID-19 on Victoria, Australia, witnessed two waves of coronavirus. Environ. Sci. Pollut. Res. 2021;28:14182–14191. doi: 10.1007/s11356-021-12556-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Clayton T., Peterson T., Binders P.G. Taking the Mystery out of the Numbers. 08. Colorado Asphalt Pavement Association (CAPA); 2009. pp. 1–4. no. 2. [Google Scholar]

- Dhir OBE R.K., Brito J.D., Silva R.V., Lye C.Q. Sustainable Construction Materials, Recycled Aggregates. Woodhead Publishing Series in Civil and Structural Engineering; 2019. 12 - Use of recycled aggregates in road pavement applications; pp. 451–494. [Google Scholar]

- Esfandabad A.S., Motevalizadeh S.M., Sedghi R., Ayar P., Asgharzadeh S.M. Fracture and mechanical properties of asphalt mixtures containing granular polyethylene terephthalate (PET) Constr. Build. Mater. 2020;259 [Google Scholar]

- Faruk A.N.M., Liu W., Lee S.I., Naik B., Chen D.H., Walubita L.F. Traffic volume and load data measurement using a portable weigh in motion system: a case study. Int. J. Pavement Res. Technol. 2016;9(3):202–213. [Google Scholar]

- FHWA, NAPA . Vol. 128. 2001. HMA Pavement Mic Type Selection Guide. Information Series 128. 2001 National Asphalt Pavement Association and Federal Highways Administration Information Series. [Google Scholar]

- Fontes L.P., Trichês G., Pais J.C., Pereira P.A. Evaluating permanent deformation in asphalt rubber mixtures. Constr. Build. Mater. 2010;24(7):1193–1200. [Google Scholar]

- Garel A., Petit-Romec A. Investor rewards to environmental responsibility: evidence from the COVID-19 crisis. J. Corp. Finan. 2020;68 [Google Scholar]

- Haider S., Hafeez I., Jamal, Ullah R. Sustainable use of waste plastic modifiers to strengthen the adhesion properties of asphalt mixtures. 2020;235:117496. [Google Scholar]

- Hamedi G.H., Azarhoosh A.R., Khodadadi M. Effects of asphalt binder modifying with polypropylene on moisture susceptibility of asphalt mixtures with thermodynamically concepts. Period. Polytechn. Civ. Eng. 2018;62(4):901–910. [Google Scholar]

- Hu X., Walubita L.F. Modelling tensile strain response in asphalt pavements: bottom-up and/or top-down fatigue crack initiation. Road Mater. Pavement Des. 2008;10(1):125–154. [Google Scholar]

- Huang B., Li G., Vukosavljevic D., Shu X., Egan B.K. Laboratory investigation of mixing hot-mix asphalt with reclaimed asphalt pavement. Transp. Res. Rec. 2005;1929(1):37–45. [Google Scholar]

- Ilyas S., Srivastava R.R., Kim H. Disinfection technology and strategies for COVID-19 hospital and bio-medical waste management. Sci. Total Environ. 2020;749 doi: 10.1016/j.scitotenv.2020.141652. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kathari P.M. Rheological properties of polypropylene reinforced asphalt binder. Transp. Infrastruct. Geotechnol. 2016;3:109–126. [Google Scholar]

- Khan S., Nagabhushana M.N., Tiwari D., Jain P.K. Rutting in flexible pavement: an approach of evaluation with accelerated pavement testing facility. Procedia. Soc. Behav. Sci. 2013;104:149–157. [Google Scholar]

- Kilmartin-Lynch S., Roychand R., Saberian M., Li J., Zhang G. Sci. Total Environ. 2021. Application of COVID-19 single-use shredded nitrile gloves in structural concrete: case study from Australia. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kilmartin-Lynch S., Saberian M., Li J., Roychand R., Zhang G. Preliminary evaluation of the feasibility of using polypropylene fibres from COVID-19 single-use face masks to improve the mechanical properties of concrete. J. Clean. Prod. 2021;296 doi: 10.1016/j.jclepro.2021.126460. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kwak J.I., An Y.J. Post COVID-19 pandemic: biofragmentation and soil ecotoxicological effects of microplastics derived from face masks. J. Hazard. Mater. 2021;416 doi: 10.1016/j.jhazmat.2021.126169. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lee S.I., Carrasco G., Mahmoud E., Walubita L.F. Alternative structure and material designs for cost-effective perpetual pavements in Texas. J. Transp. Eng. B Pavements. 2020;146(4) [Google Scholar]

- Lee S.B., Lee J., Tsang Y.F., Kim Y.M., Jae J., Jung S.C., Park Y.K. Production of value-added aromatics from wasted COVID-19 mask via catalytic pyrolysis. Environ. Pollut. 2021;283 doi: 10.1016/j.envpol.2021.117060. [DOI] [PubMed] [Google Scholar]

- Li Y., Hao P., Zhao C., Ling J., Wu T., Li D., Liu J., Sun B. Anti-rutting performance evaluation of modified asphalt binders: a review. J. Traffic Transp. Eng. (Engl. Ed.) 2021;8(3):339–355. [Google Scholar]

- Maderuelo-Sanz R., Acedo-Fuentes P., García-Cobos F.J., Sánchez-Delgado F.J., Mota-López M.I., Meneses-Rodríguez J.M. The recycling of surgical face masks as sound porous absorbers: preliminary evaluation. Sci. Total Environ. 2021;786 doi: 10.1016/j.scitotenv.2021.147461. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Needhidasan S., Agarwal S.G. A review on properties evaluation of bituminous addition with E-waste plastic powder. Mater. Today Proc. 2020;22(3):1218–1222. [Google Scholar]

- Othman A. Impact of polypropylene application method on long-term aging of polypropylene-modified HMA. J. Mater. Civ. Eng. 2010;22(10) doi: 10.1061/(ASCE)MT.1943-5533.0000105. [DOI] [Google Scholar]

- Prata J.C., Patrício Silva A.L., Walker T.R., Duarte A.C., Rocha Santos T. COVID-19 pandemic repercussions on the use and management of plastics. Environ. Sci. Technol. 2020;54(13):7760–7765. doi: 10.1021/acs.est.0c02178. [DOI] [PubMed] [Google Scholar]

- Rajasekaran S., Vasudevan R., Paulraj S. Reuse of waste plastics coated aggregates-bitumen mix composite for road application—green method. Am. J. Eng. Res. 2013;2(11):1–13. [Google Scholar]

- Roberts F.L., Kandhal P.S., Brown E.R., Lee D.Y., Kennedy T.W. 1996. Hot Mix Asphalt Materials, Mixture Design and Construction. [Google Scholar]

- Rowan N.J., Laffey J.G. Unlocking the surge in demand for personal and protective equipment (PPE) and improvised face coverings arising from coronavirus disease (COVID-19) pandemic – implications for efficacy, re-use and sustainable waste management. Sci. Total Environ. 2021;752 doi: 10.1016/j.scitotenv.2020.142259. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Royo-Bordonada M.A., García-López F.J., Cortés F., Zaragoza G.A. 2020. Face masks in the general healthy population. Scientific and ethical issues. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Saberian M., Li J., Nguyen B., Wang G. Permanent deformation behavior of pavement base and subbase containing recycle concrete aggregate, coarse and fine crumb rubber. Constr. Build. Mater. 2018;178:51–58. [Google Scholar]

- Saberian M., Li J., Nguyen B.T., Boroujeni M. Experimental and analytical study of dynamic properties of UGM materials containing waste rubber. Soil Dyn. Earthq. Eng. 2020;130 [Google Scholar]

- Saberian M., Li J., Perera S.T.A.M., Ren G., Roychand R., Tokhi H. An experimental study on the shear behaviour of recycled concrete aggregate incorporating recycled Tyre waste. Constr. Build. Mater. 2020;264 [Google Scholar]

- Saberian M., Li J., Kilmartin-Lynch S., Boroujeni M. Repurposing of COVID-19 single-use face masks for pavements base/subbase. Sci. Total Environ. 2021;769 doi: 10.1016/j.scitotenv.2021.145527. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Saberian M., Li J., Perera S.T.A.M., Zhou A., Roychand R., Ren G. Large-scale direct shear testing of waste crushed rock reinforced with waste rubber as pavement base/subbase materials. Transp. Geotechn. 2021;28 [Google Scholar]

- Saberian M., Perera S.T.A.M., Li J., Zhu J., Wang G. Effect of crushed glass on the shear behavior of recycled unbound granular aggregates incorporating crumb rubber. Int. J. Pavement Res. Technol. 2021 [Google Scholar]

- Salim R., Gundla A., Zalghout A., Underwood B.S., Kaloush K.E. Relationship between asphalt binder parameters and asphalt mixture rutting. J. Trapsotption Res. Rec. 2019;2673(6):431–446. [Google Scholar]

- Sarkar D., Pal M., Sarkar A.K. Study on plastic coated overburnt brick aggregate as an alternative material for bituminous road construction. Adv. Mater. Sci. Eng. 2016;2016:1–8. [Google Scholar]

- Speight J.G. Chapter 9: Asphalt Technology, Asphalt Materials Science and Technology. Elsevier; 2015. pp. 361–408. [Google Scholar]

- Suo Z., Wong W.G. Non-linear properties analysis on rutting behaviour of bituminous materials with different air void contents. Constr. Build. Mater. 2009;23(12):3492–3498. [Google Scholar]

- Torresa F.G., De-la-Torreb G.E. Face mask waste generation and management during the COVID-19 pandemic: an overview and the peruvian case. Sci. Total Environ. 2021;786 [Google Scholar]

- Uzarowski L., Prilesky H., Berube E., Henderson V., Rizvi R. Proceedings of the 55th Annual Conference of the Canadian Technical Asphalt Association (CTAA): Edmonton, Alberta, November, 2010. 2010. Evaluation of mechanistic properties of hot-mix asphalt containing recycled asphalt shingles for use in the Pacific Northwest Coastal Region. Canadian Technical Asphalt Association, 2010 Conference. [Google Scholar]

- Veropalumbo R., Russo F., Oreto C., Biancardo S.A., Zhang W., Viscione N. Verifying laboratory measurement of the performance of hot asphalt mastics containing plastic waste. Measurement. 2021;180 [Google Scholar]

- Walubita L.F., Jamison B.P., Das G., Scullion T., Martin A.E., Rand D., Mikhail M. Search for a laboratory test to evaluate crack resistance of hot-mix asphalt. Transp. Res. Rec. 2011;2210(1):73–80. [Google Scholar]

- Walubita L.F., Fuentes L., Prakoso A., Rico Pianeta L.M., Komba J.J., Naik B. Correlating the HWTT laboratory test data to field rutting performance of in-service highway sections. Constr. Build. Mater. 2020;236 [Google Scholar]

- Wang G.C. Woodhead Publishing; 2016. The Utilization of Slag in Civil Infrastructure Construction. [Google Scholar]

- Xiang Y., Song Q., Gu W. Decontamination of surgical face masks and N95 respirators by dry heat pasteurization for one hour at 70°C. Am. J. Infect. Control. 2020;48(8):880–882. doi: 10.1016/j.ajic.2020.05.026. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Xu T., Huang X. Investigation into causes of in-place rutting in asphalt pavement. Constr. Build. Mater. 2012;28(1):525–530. [Google Scholar]

- Yong E. How the pandemic now ends - Delta has changed the pandemic endgame. The Atlantic, August 12, 2021. 2021. https://www.theatlantic.com/health/archive/2021/08/delta-has-changed-pandemic-endgame/619726/?utm_source=email&utm_medium=social&utm_campaign=share

- Zhang H., Zhu C., Wei C., Duan H., Yu J. Handbook of Functionalized Nanomaterials for Industrial Applications. Micro and Nano Technologies. 2020. Chapter 27 - Application of functionalized nanomaterials in asphalt road construction materials; pp. 865–907. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary material