Abstract

This study developed biomechanical models for hand breakaway strength that account for not only grip force but also hand-handle frictional coupling in generation of breakaway strength. Specifically, models for predicting breakaway strength for two commonly-used handle shapes (circular and rectangular handles) and varying coefficients of friction (COF) between the hand and handle were proposed. The models predict that (i) breakaway strength increases with increasing COF and (ii) a circular handle with a 50.8mm-diameter results in greater mean breakaway strength than a handle with a rectangular cross-section of 38.1 by 38.1mm for COFs greater than 0.42. To test these model predictions, breakaway strengths of thirteen healthy young adults were measured for three frequently-encountered COF conditions (represented by three glove types of polyester (COF=0.32), bare hand (COF=0.50) and latex (COF=0.74) against an aluminum handle) and for the two handle shapes. Consistent with the model predictions, mean breakaway strength increased with increasing COF and was greater for the circular than rectangular handle for COFs of 0.50 and 0.74. Examination of breakaway strength normalized to body weight reveals that modification of COF and handle shapes could influence whether one can hold his/her body using the hands or not (thus must fall), highlighting the importance of considering these parameters for fall prevention. The biomechanical models developed herein have the potential to be applied to general handle shapes and COF conditions. These models can be used to optimize handle design to maximize breakaway strength and minimize injuries due to falls from ladders or scaffolds.

Keywords: Ladder Injury, Handle Design, Hand Grip, Friction

1. Introduction

Falls account for one third of construction fatalities according to the US Bureau of Labor Statistics (BLS, 2009). Falls from a ladder, roof and scaffold are the leading cause of disabling falls to lower levels and the second leading cause of fatal falls to lower levels (BLS, 2009). Every year, more than 20,000 American workers get injured by falls from ladders (Christensen and Cooper, 2005). Fatal injuries due to falls from a ladder have increased by 55% one year to the next (BLS, 2004). The direct compensation and medical treatments associated with falls to lower levels cost American businesses $5.3 billion/year (LibertyMutual, 2010).

Hands are the only interface available to arrest the body once a fall has been initiated. If a person was to begin to fall, the ability for the hand to hold onto a fixed object and arrest the falling body provides the primary means of preventing injury. Thus, quantification and understanding of a person’s maximum hand force to hold onto a rail or ladder rung (i.e., breakaway strength) are needed to develop measures to prevent ladder fall injuries. Previous studies on power grip strength do not predict breakaway strength, because power grip strength addresses only the voluntary finger flexion strength, but not the frictional coupling between a hand and handle (Rajulu, 1993; Young et al., 2009). Empirical evidence exists that frictional coupling affects a person’s force exertion capability in push, pull, and twist (Seo et al., 2008; Seo et al., 2008; Young et al., 2009; Seo et al., 2010). In addition, different hand-handle coupling due to different handle shapes has also been shown to affect force exertion capability (Fothergill et al., 1992; Kong et al., 2007; Kong et al., 2008; Young et al., 2009). These previous studies, however, are empirical and do not provide detailed biomechanical description of how both finger flexion strength and hand-handle frictional coupling contribute to breakaway strength. This gap in knowledge imposes an obstacle in improving handle and ladder designs to increase breakaway strength for people and reduce ladder fall-related injuries and fatalities.

The objective of this study was to develop and evaluate biomechanical models that take into account both finger flexion strength and frictional coupling for predicting breakaway strength. The models allow quantitative assessment of the relative contributions of voluntary gripping and frictional coupling on breakaway strength as well as prediction of breakaway strength for varying coefficient of friction (COF) and handle shapes. Specifically, two biomechanical models were developed to predict breakaway strengths for circular and rectangular handles for varying COFs. The models predict that (i) breakaway strength increases with increasing COF and (ii) a circular handle results in greater mean breakaway strength than a rectangular handle for the dimensions investigated for COFs greater than 0.42. The two predictions were evaluated by empirically-measured breakaway strengths for three COFs and two handle shapes. In addition, the model for the circular handle was further evaluated for the model assertion that the ratio of friction to normal force increases with increasing COFs. Lastly, to gauge people’s ability to hold their body using the hand, breakaway strength normalized to body weight was examined.

2. Biomechanical models

Biomechanical models for breakaway strength are proposed based on that of Seo et al (2010). Breakaway strength for a circular handle is computed as the sum of both normal forces and friction forces at the contact between the phalanges and handle in the pulling direction (Figure 1a). Maximum normal forces are determined by the finger flexion strength, whereas friction forces can be up to COF multiplied by normal forces. Breakaway strength for a circular handle is expressed as follows, assuming maximum friction force.

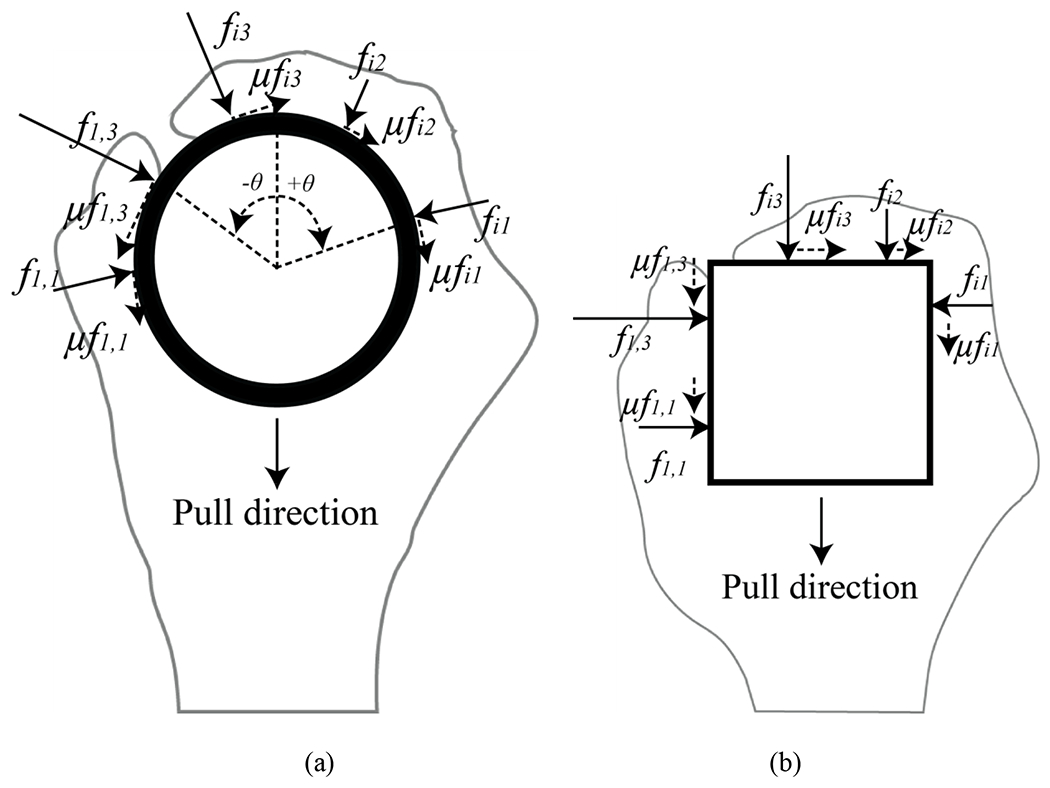

Figure 1.

Biomechanical models of breakaway strength for both circular handle (a) and square handle (b). fij is normal force for i-th finger and j-th phalanx, μ is COF, and θij is the angle between a vertical line and fij (positive for fij that is on the right half of the handle the four fingers’ knuckles contact, negative for fij that is on the left half). Friction force can be up to COF × fij. The thumb, index, middle, ring, and little fingers are i=1, 2, 3, 4, and 5, respectively. Proximal, middle, and distal phalanges are j=1, 2, and 3, respectively. The arrows representing phalanx forces are scaled to show not only the directions but also the magnitudes of normal and friction forces used for the model when COF is 0.5.

| (1) |

where fij is normal force for i-th finger and j-th phalanx, μ is COF, and θij is the angle between the pulling direction and fij (positive for fij that is on the right half of the handle the four fingers’ knuckles contact, negative for fij that is on the left half, Figure 1a). The proximal, middle, and distal phalanges are j=1, 2, and 3, respectively. The thumb, index, middle, ring, and little fingers are i=1, 2, 3, 4, and 5, respectively.

Similarly, a biomechanical model of breakaway strength for a rectangular handle is illustrated in Figure 1b. The hand posture for grasping a medium-size rectangular handle (38.1mm×38.1mm cross-section) was observed and adopted for the model. In this posture, only phalanx normal forces on the top surface and friction forces on the side surfaces contribute to breakaway strength. The breakaway strength for a rectangular handle is expressed as follows, assuming maximum friction force.

| (2) |

where all notations are same as in Eq. 1.

Using these models (Figure 1, Eqs. 1 and 2), breakaway strengths were predicted for various COFs, handle shapes, hand sizes/strengths. The prediction was performed for the circular handle diameter of 50.8mm and the rectangular handle cross-sectional dimension of 38.1mm×38.1mm that satisfy OSHA 1910.27 fixed ladder standards and represent ladder rungs that are frequently encountered at workplaces. The diameter of 50.8mm was specifically chosen to match the dynamometer size available for measuring phalanx force (3.2 Procedure). Breakaway strengths were predicted for COFs from 0.32 to 0.74 to represent frictional conditions commonly encountered at workplaces (OSHA, 2003; Fix8, 2011). The model used the 5th, 50th, and 95th percentile hand size data (White, 1971; Clauser et al., 1972; NASA, 1978) and maximum normal force data for each phalanx from the literature (Amis, 1987). For the circular handle, the hand location that results in the maximum predicted breakaway strength was used.

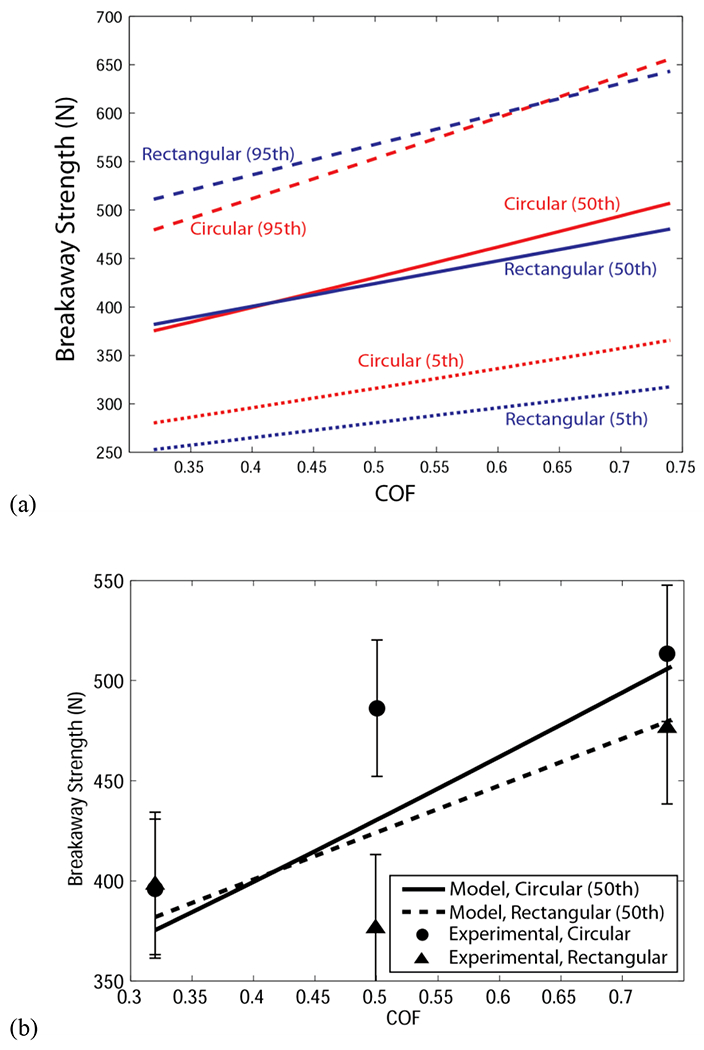

The model results are summarized in Figure 2a. The models predict that (i) breakaway strength increases with increasing COF; and (ii) mean breakaway strength for the circular handle is greater than that for the rectangular handle for COF greater than 0.42. For a wide range of people with various hand sizes and strengths (from 5th to 95th percentile), the COF condition for which breakaway strength is higher for the circular than rectangular handle varies depending on the hand size/strength. For the 95th percentile individual, breakaway strength is greater for the circular than rectangular handle for COF higher 0.63. For the 5th percentile individual, breakaway strength is greater for the circular than rectangular handle for all COF examined. Empirical evaluation of the models was performed only for the predictions made for an average individual (50th percentile).

Figure 2.

a) Predicted breakaway strengths for different hand sizes/strengths (5th, 50th, 95th percentile), handle shapes (circular and rectangular) and COFs (0.32 to 0.74). b) Comparison of predicted and experimental mean breakaway strengths. Empirically-observed breakaway strengths are for COFs=0.32, 0.50, and 0.74. Experimentally, breakaway strength increased with increasing COF (p<.001). Also, the circular handle resulted in greater mean breakaway strength than the rectangular handle for COF greater than 0.42 (p=.01). Error bars represent ± one standard error.

3. Empirical evaluation of the models

An experiment was conducted to evaluate the two model predictions stated above. Specifically, the effects of 3 COFs (simulated by 3 gloves) and the 2 handle shapes (circular and rectangular handles) on a person’s breakaway strength were investigated. In addition, to further evaluate the circular handle model regarding the assumed maximum friction force, friction force relative to normal force that subjects used were examined.

3.1. Participants

Thirteen right-handed young healthy adults (9 males and 4 females) of mean height of 170.5 (SD=9.4) cm, weight 69.0 (SD=13.5) kg, and age 25.0 (SD=4.3) years participated in the experiment. The non-dominant hand was tested because people typically use the dominant hand for main tasks (e.g., painting, reaching for something) while holding onto a ladder/scaffold with the non-dominant hand. No subjects had history of neuromuscular disorders. All procedures were approved by the Institutional Review Board. All participants gave informed consent.

3.2. Procedure

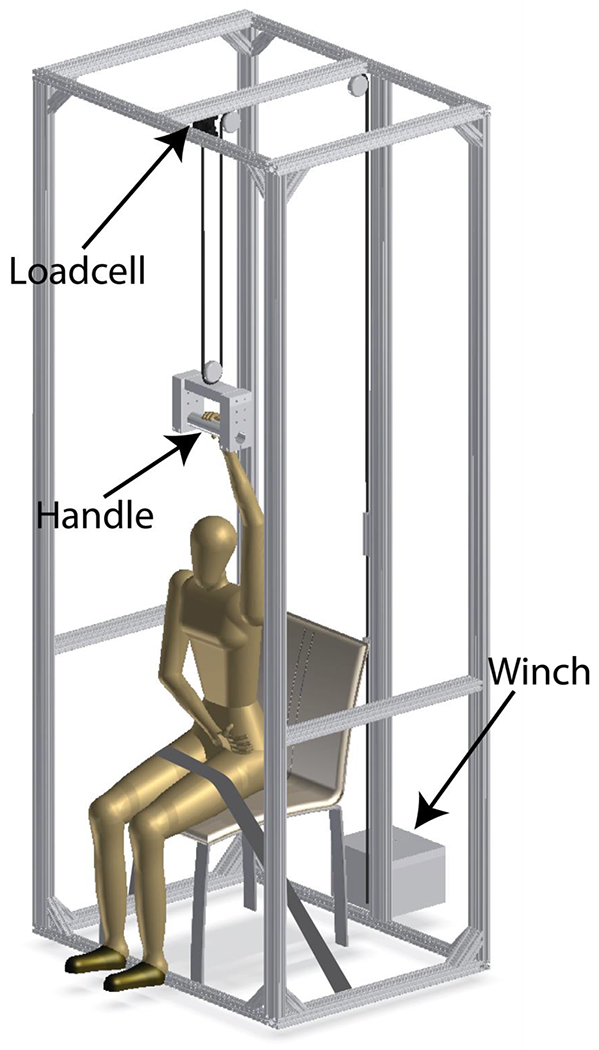

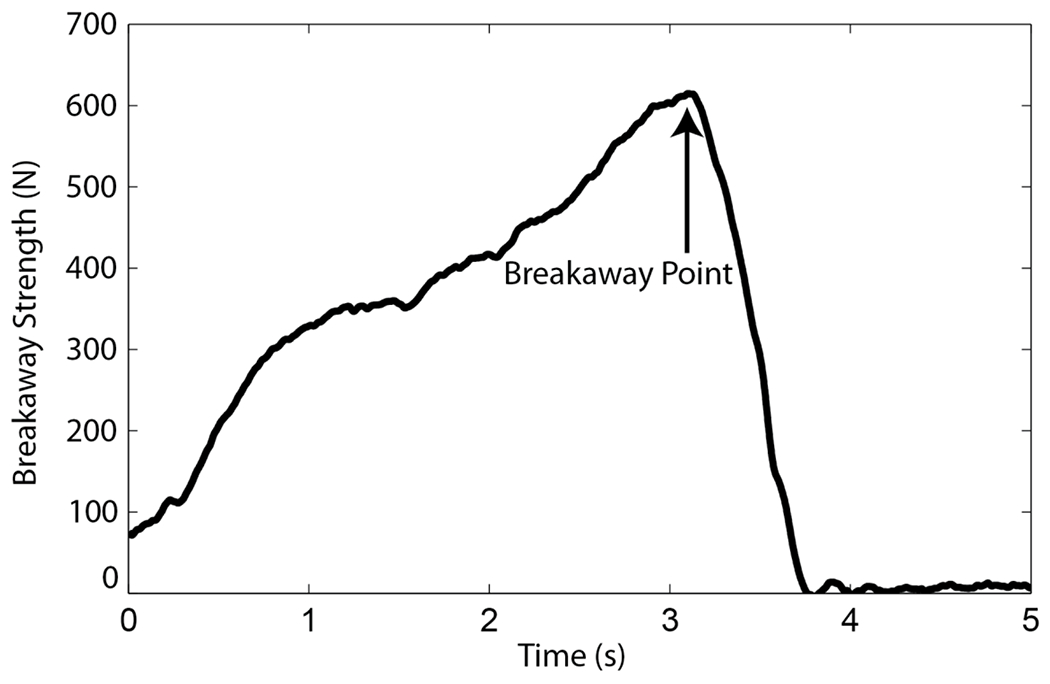

Subjects were seated and strapped down to a fixed chair, with their non-dominant hand grasping an overhead aluminum handle (Figure 3). Subjects were instructed to hold onto the handle as long as they could while the handle was raised up at 7 cm/s. The speed of handle movement was chosen not to jerk subjects’ arm. The initial upper limb posture was approximately 160° shoulder flexion without ab/adduction, 10° elbow flexion and 0° wrist flexion. As the handle was raised, the upper limb was fully stretched and breakaway of the hand from the handle occurred. The procedure of holding onto the handle while the handle moved away from the body was chosen to focus our investigation on the effect of hand-handle coupling on breakaway strength and limit the influence of upper limb posture on breakaway strength (Chaffin et al., 1983; Daams, 1993). The handle was attached to a pulley whose chain was connected to a winch on one end (to raise the handle) and to a fixed load cell on the other end (to record hand force). Data from the load cell (SM-1000, Interface Inc. Scottsdale, AZ) were sampled at 1 kHz. Breakaway strength was determined as the highest hand force recorded (Figure 4). One measurement of breakaway strength took approximately 5 seconds.

Figure 3.

Experimental setup. The handle moved up via a winch. Breakaway strength was measured by the load cell connected to the handle

Figure 4.

Time course of hand force. Breakaway strength is determined as the peak hand force.

Three gloves were used to vary COF. The following three gloves (Figure 5) that are frequently encountered at workplaces were used (OSHA, 2003; Fix8, 2011): (1) the polyester glove (HD55080/FACP, West Chester, Inc., Monroe, OH), (2) the bare hand, and (3) the latex glove (HD30503/L3P, West Chester, Inc. , Monroe, OH). These three gloves had COFs against aluminum of 0.32, 0.50, and 0.74 (SD=0.06, 0.08, and 0.12), respectively. COFs were experimentally determined as the maximum ratio of shear to normal forces when the thumb tip in the three glove conditions slipped on a horizontal aluminum surface while maintaining normal force of 50 N. In addition to the COFs, the two handle shapes (50.8mm-diameter circular handle and 38.1mm×38.1mm cross-section rectangular handle as in the model prediction) were tested.

Figure 5.

The polyester glove (a) and latex glove (b) are commonly used at workplaces to protect workers’ hand (OSHA, 2003; Fix8, 2011). These gloves can change the coefficient of friction available at the hand-handle interface and thus may affect workers’ capability to hold onto a ladder rung

Breakaway strength was measured twice for each condition (3 glove conditions×2 handle shapes). The 6 conditions were tested in a random order. Minimum of 2 min breaks were given between consecutive exertions to prevent muscle fatigue.

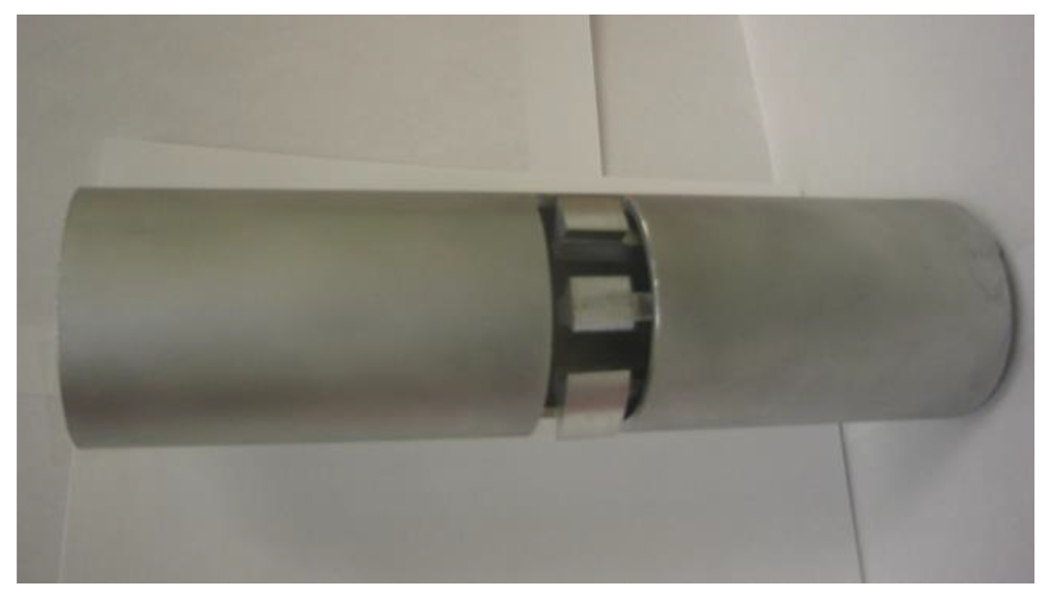

To further evaluate the circular handle model, friction force relative to normal force during pull was recorded using a custom-made dynamometer (Figure 6) (Enders and Seo, 2011). The subjects were instructed to perform an isometric pull exertion on the dynamometer for 5 seconds using the same posture and holding strategy as in the breakaway strength test. Subjects were instructed to apply 50% of their perceived breakaway strength to reduce muscle fatigue and to avoid the fingers moving across the three measuring contact pads (Figure 6). Muscle recruitment patterns for 50% maximum voluntary contraction (MVC) are reported to be a similar scaled-down version of those for 100% MVC (Valero-Cuevas, 2000). Thus, the ratio of shear to normal forces on each phalanx is expected to be similar between 100% and 50% of breakaway strength. Measurement of friction force relative to normal force for each phalanx was repeated for five fingers and three COFs in a randomized order.

Figure 6.

A custom-made circular dynamometer for measuring normal force and friction force of each phalanx

3.3. Analysis

To evaluate the two model predictions, repeated measures analysis of variance (ANOVA) was performed to determine if subjects’ breakaway strength significantly varied with the two within-subject factors of glove and handle shape (SPSS Inc., Chicago, IL; v17). In addition, experimental data were compared to the predicted mean breakaway strength using one-sample two-tailed t-test for each condition. To further evaluate the circular handle model, repeated measures ANOVA was performed to determine if the ratio of friction to normal force varied for glove condition. The level of significance was .05. Lastly, to examine the subjects’ ability to hold their body using the hand, breakaway strength normalized by each subject’s body weight was examined for individual subjects across the COF and handle shape conditions.

4. Results

4.1. Evaluation of the model predictions

The glove, handle shape, and their interaction significantly affected the subjects’ breakaway strength (p≤.01; Figure 2b, Figure 7). Breakaway strength increased as COF increased, consistently with the model prediction (Figure 7). The circular handle resulted in greater mean breakaway strength than the rectangular handle for COFs of 0.50 and 0.74, as predicted by the models (Figure 2b). The experimental data were not significantly different from the predicted mean breakaway strengths for all 6 conditions (p>.1).

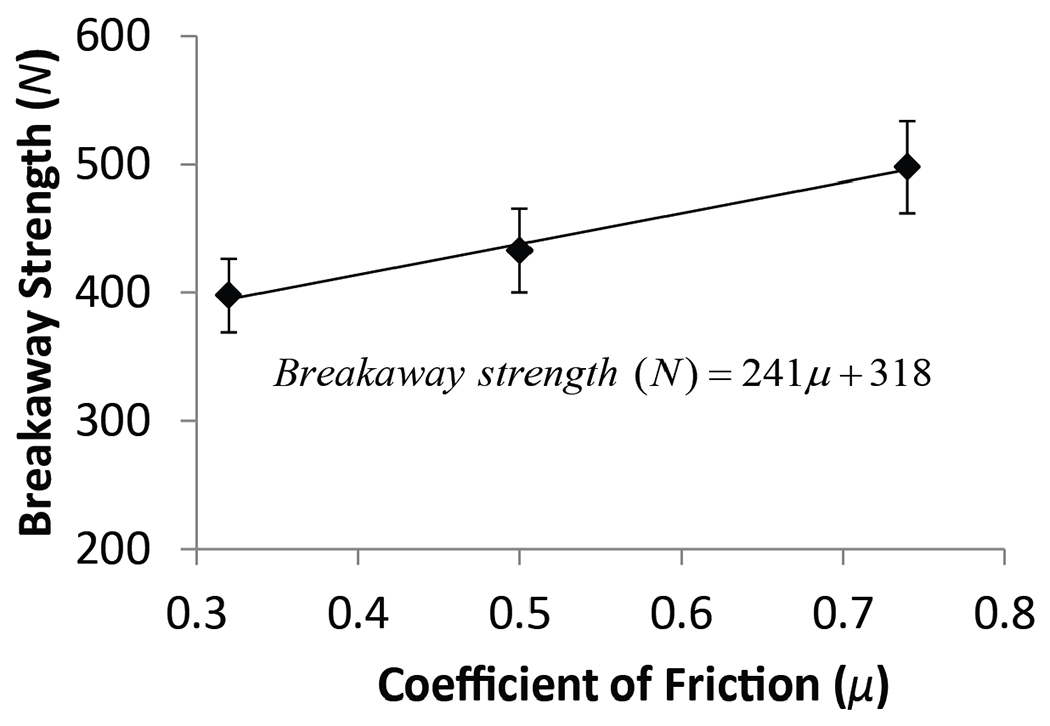

Figure 7.

The linear relationship between the coefficient of friction and breakaway strength (shown in mean ± SE, pooled for the two handle shapes). The coefficients of frictions were 0.32, 0.50, and 0.74 for the polyester glove, bare hand, and latex glove, respectively.

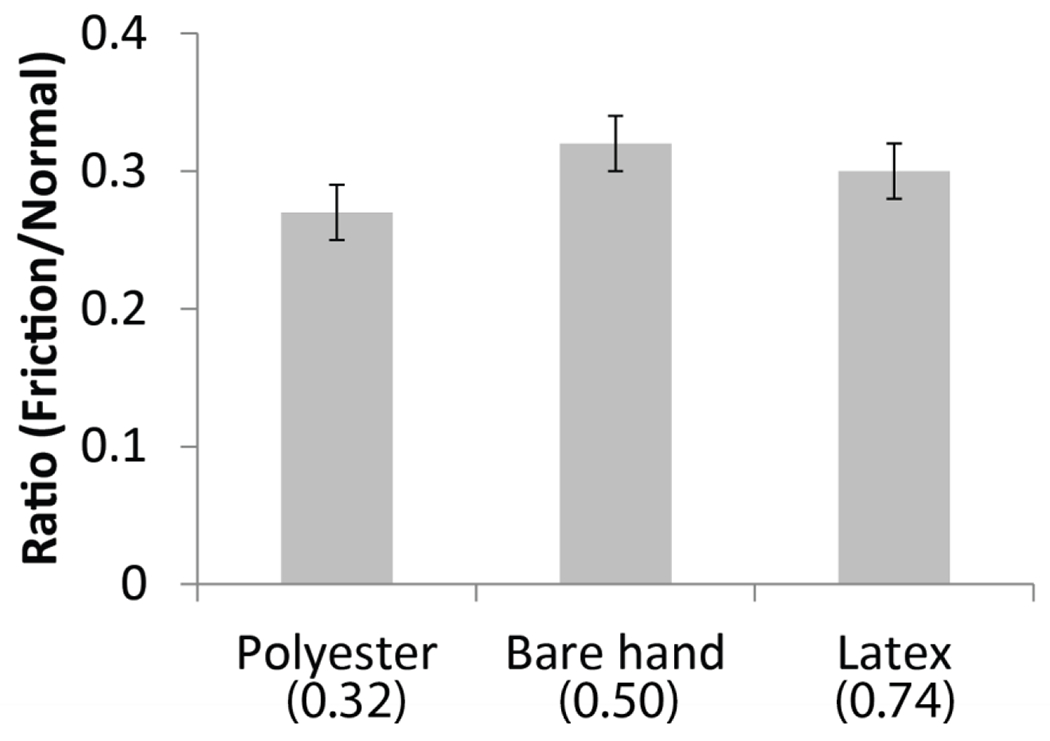

4.2. Further evaluation of the circular handle model

Friction force relative to normal force significantly varied for glove (p=.01; Figure 8). The friction force relative to normal force tended to increase as COF increased. The ratio of friction force to normal force was significantly greater for the bare hand (p=.04) and latex glove (p=.002) than the polyester glove. The ratios of friction to normal forces were not as high as COFs.

Figure 8.

The mean ratio of friction force to normal force on the phalanges during 50% pull (phalanges and fingers pooled). Error bars represent ± one standard error.

4.3. Normalized breakaway strength

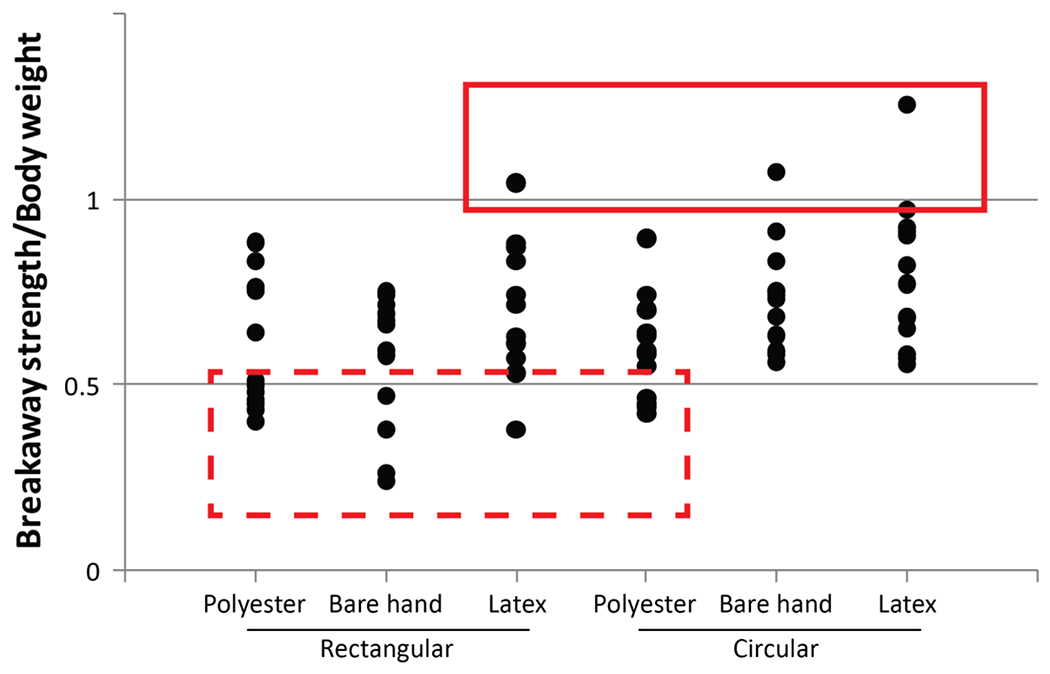

Breakaway strengths normalized by body weight are shown across the COF and handle shape in Figure 9. For the rectangular handle with COFs of 0.32, six out of the 13 subjects would not be able to hold their body even with the two hands. For the circular handle with COFs of 0.50 and 0.74, all subjects would be able to hold their body with two hands, while the strongest subject may be able to hold his body with one hand.

Figure 9.

Breakaway strengths normalized by subjects’ body weights. The normalized breakaway strengths increased with increasing COF and for the circular handle compared to the rectangular handle. Dots in the solid box represent one subject who would be capable of supporting his body with one hand in three out of six COF/handle shape conditions. Dots in the dashed box represent subjects who would not be able to support their body even with two hands in the given COF/handle shape conditions assuming equal bilateral strengths.

5. Discussion

5.1. Model prediction #1: Breakaway strength increases with increasing COF

The model prediction that breakaway strength increases with increasing COF at the hand-handle interface for both handle shapes (Eq. 1, 2, Figure 2b) was supported by the experiment. Breakaway strength increased 9% and 25%, as COF increased from 0.32 (polyester glove) to 0.50 (bare hand) and to 0.74 (latex glove), respectively (Figure 2b, Figure 7). The models explain that hand-handle frictional coupling is accountable for 39% of a person’s breakaway strength for the latex glove condition, whereas for the polyester glove condition, hand-handle frictional coupling is responsible for only 21% of the person’s breakaway strength (pooled for both handle shapes). These findings illustrate that the hand-handle frictional coupling is an important factor in estimating breakaway strength.

5.2. Model prediction #2: Mean breakaway strength is greater for the circular than rectangular handle for the bare hand and latex glove.

The model prediction that mean breakaway strength is greater for the circular than rectangular handle for COF greater than 0.42 was supported by the experiment (Figure 2b). As with the previous study reporting the shape effect on breakaway strength produced in the direction parallel to the long axis of handles (Young et al., 2009), the present study demonstrates that breakaway strength perpendicular to the handle’s long axis is also dependent on handle shape.

The biomechanical models explain that the handle shape effect on breakaway strength is related to the handle geometry-defined phalanx force directions. For instance, for the 50th percentile hand size/strength, the model explains that the contribution of the distal phalanges of the 2nd to 5th digits to breakaway strength for the circular handle, (Eq 1; Figure 1a), is greater than that for the rectangular handle, fi3 (Eq 2; Figure 1b), when 0<θi3<35.5° for COF=0.32, 0<θi3<53.1° for COF=0.50, and 0<θi3<73.0° for COF=0.74 (i=2 to 5). The simulated distal phalanx locations for the four fingers range from 9° to 19° depending on the three COF conditions, indicating that the same distal phalanx force results in greater breakaway strength for the circular than rectangular handle. Similar results can be found for not only the distal but also middle phalanges of the four fingers as well as for all phalanges of the thumb that generate the majority of force during grip (Amis, 1987). It should be noted that difference in breakaway strength for the circular and rectangular handles depends on the hand size/strength as described in our model results (Figure 2a). For different hand sizes, the COF at which breakaway strength becomes greater for the circular than rectangular may change.

5.3. Further evaluation of the circular handle model

The model assertion that the friction force to normal force ratio at the hand-handle contact increases with increasing COFs was supported by the experimental data (Figure 8). The subjects used greater friction force relative to normal force across all phalanges for the high COF than low COF conditions. This finding further demonstrates that high COF allows greater friction force, which results in greater breakaway strength as illustrated in section 5.1. The observed ratios of friction force to normal force were not as high as COFs, possibly because the ratios were measured during submaximal pulling. Subjects may have been cautious not to allow hand-handle slip during submaximal pulling, whereas slip is inevitable during breakaway.

5.4. Other factors for breakaway strength

Measured breakaway strengths deviated from the predicted the most for the bare hand condition (Figure 2b). For the circular handle and bare hand combination, the mean measured breakaway strength was greater than the model prediction. One possible explanation is that less obstructed tactile sensitivity for the bare hand may have allowed the subjects to use greater hand-handle frictional coupling, compared to the glove conditions. Obstructing tactile sensory information by use of gloves can result in decreased maximal grip force, increased muscular effort, and inefficient grip force control (Kinoshita, 1999; Willms et al., 2009). Similarly, in the present study, the subjects applied greater friction force relative to normal force for the bare hand than the two glove conditions (Figure 8), indicating greater use of frictional coupling between the hand and handle.

For the rectangular handle and bare hand combination, the mean measured breakaway strength was smaller than the model prediction. This smaller than predicted breakaway strength may be due to pain that finger skin may have experienced around the edge of the rectangular handle. Subjects anecdotally reported that the rectangular handle caused pain at their fingers, when they used the bare hand. Both the gloves may have acted as a cushion between the fingers and the rectangular handle, whereas for the bare hand condition, subjects may have felt pain and released their hand earlier, resulting in reduced breakaway strength.

5.5. Functional implications

The present study provides evidence that manipulation of COF and handle shapes may contribute to reduction of injuries related to falls from ladder/scaffolds. Breakaway strength normalized by body weight increased with increasing COF and for the circular than rectangular handle (Figure 9). Six out of the 13 subjects would not be able to support their bodies with two hands for the polyester glove and rectangular handle combination (Figure 9 bottom box). If they used the bare hand or latex glove and the circular handle, all subjects would be able to support their bodies with two hands. Even the strongest subject would not be able to support his body with one hand, unless the high COF and/or circular handle is used (Figure 9 top box). The present study suggests that high COFs and the circular handle can increase breakaway strength over body weight, and thus reduce the rate of ladder fall injuries.

5.6. Limitations

While this study demonstrates the benefits of the proposed biomechanical models, there are limitations and areas for improvement that may be addressed in the future work. First, the models assume all five fingers’ full contribution to breakaway strength. In the model, the thumb contributes to approximately 20% of breakaway strength. Although the thumb was visually observed to be in contact with the handle during breakaway, it is possible that the thumb was about to lose contact with the handle and did not produce much force to the handle at breakaway. Actual forces on each phalanx at breakaway are currently unknown and warrant further investigation.

Second, the present findings are for vertical fixed ladders, not for inclined ladders. The present study’s modeling approach can be applied to rectangular handles with different orientations to find that breakaway strengths for the rectangular handles may vary up to 9%, if ladders are tilted up to 45°. The ladder tilt angle is recommended to be less than 15° by OSHA 1910.27 fixed ladder standards, thus less than 9% changes in breakaway strength may be expected for inclined ladders.

Third, only aluminum handles, not wooden handles, were tested for only three types of glove conditions. As the present study shows after examining a wide range of COF, breakaway strength depends on the COF. Thus, the wooden handle with different glove conditions would change the COF and affect breakaway strength accordingly.

Lastly, a caution is needed when applying the present study’s results into actual fall arrest scenarios. The present study measured breakaway strength as an instantaneous maximum force. To arrest an actual fall, the duration of such hand force generation may be critical. In addition, the present study measured breakaway strength while the handle was moving away from the hand at 7 cm/s. In a rapid fall, a person’s ability to rapidly build up grip force may limit breakaway strength. Nevertheless, the present study’s findings provide important information on the effects of COF and handle shape on breakaway strength and potential fall arrest mechanisms.

6. Conclusion

This study proposed biomechanical models for breakaway strength. The experimental results support the model predictions that (i) breakaway strength to hold onto a handle increases with increasing COF and (ii) breakaway strength is greater for the circular handle than for the rectangular handle for COFs greater than 0.42. The proposed biomechanical models can be used as a platform to predict breakaway strength for various handle shapes and COF conditions. Furthermore, improved biomechanical understandings of factors associated with breakaway strength such as COF and handle shapes can help improve design of ladders and scaffolds to reduce injuries due to fall from elevation.

Acknowledgments

This work was supported by funds from NIOSH UIC ERC T42 OH008672.

Footnotes

Conflict of interest statement

None of the authors has a potential conflict of interest (e.g., consultancies, stock ownership, equity interests, patent-licensing arrangements) related to the manuscript or the work it describes.

References

- Amis A, 1987. Variation of finger forces in maximal isometric grasp tests on a range of cylinder diameters. Journal of biomedical engineering 9(4), 313–320. [DOI] [PubMed] [Google Scholar]

- BLS, 2004. Census of Fatal Occupational Injuries Summary. U.S. Department of Labor, Bureau of Labor Statistics.Washington D.C. [Google Scholar]

- BLS, 2009. Census of Fatal Occupational Injuries. U.S. Department of Labor, Bureau of Labor Statistics.Washington, D.C. [Google Scholar]

- Chaffin DB, Andres RO, Garg A, 1983. Volitional postures during maximal push/pull exertions in the sagittal plane. Human Factors 25(5), 541–550. [DOI] [PubMed] [Google Scholar]

- Christensen T, Cooper N, 2005. Attacking Ladder Falls--One Rung at a Time. Occupational Hazards 67(11), 39–41. [Google Scholar]

- Clauser CE, Tucker PE, McConville JT, Churchill E, Laubach LL, Reardon J, 1972. Anthropometry of air force women. Aerospace Medical Research Laboratory, Aerospace Medical Division. [Google Scholar]

- Daams BJ, 1993. Static force exertion in postures with different degrees of freedom. Ergonomics 36(4), 397–406. [DOI] [PubMed] [Google Scholar]

- Enders L, Seo NJ, 2011. Phalanx force magnitude and trajectory deviation increased during power grip with an increased coefficient of friction at the hand-object interface. Journal of Biomechanics In press. [DOI] [PubMed] [Google Scholar]

- Fix8, 2011. General Handling Gloves, Retrieved Nov, 2011 (http://www.fix8.co.uk/products/PPE+%26+Safety+Equipment/Safety+Gloves/General+Handling+Gloves).

- Fothergill DM, Grieve DW, Pheasant ST, 1992. The influence of some handle designs and handle height on the strength of the horizontal pulling action. Ergonomics 35(2), 203–212. [Google Scholar]

- Kinoshita H, 1999. Effect of gloves on prehensile forces during lifting and holding tasks. Ergonomics 42(10), 1372–1385. [DOI] [PubMed] [Google Scholar]

- Kong Y-K, Lowe BD, Lee S-J, Krieg EF, 2008. Evaluation of handle shapes for screwdriving. Applied Ergonomics 39(2), 191–198. [DOI] [PubMed] [Google Scholar]

- Kong YK, Lowe BD, Lee SJ, Krieg EF, 2007. Evaluation of handle design characteristics in a maximum screwdriving torque task. Ergonomics 50(9), 1404–1418. [DOI] [PubMed] [Google Scholar]

- LibertyMutual, 2010. Workplace Safety Index. Liberty Mutual Research Institute for Safety. [Google Scholar]

- NASA, 1978. Anthropometric source book, vol. 1: Anthropometry for designers; vol. 2: A handbook of anthropometric data; vol. 3: Annotated bibliography. NASA Reference Publication 1024, Houston, TX. [Google Scholar]

- OSHA, 2003. Personal Protective Equipment (OSHA 3151-12R 2003). [Google Scholar]

- Rajulu SL, 1993. A comparison of hand grasp breakaway strengths and bare-handed grip strengths of the astronauts, SML III test subjects, and the subjects from the general population [microform] / Sudhakar L. Rajulu [and] Glenn K. Klute. National Aeronautics and Space Administration, Office of Management, Scientific and Technical Information Program, Washington, D.C. :. [Google Scholar]

- Seo NJ, Armstrong TJ, Chaffin DB, Ashton-Miller JA, 2008. The effect of handle friction and inward or outward torque on maximum axial push force. Human Factors 50(2), 227–236. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Seo NJ, Armstrong TJ, Chaffin DB, Ashton-Miller JA, 2008. Inward torque and high-friction handles can reduce required muscle efforts for torque generation. Human Factors 50(1), 37–48. [DOI] [PubMed] [Google Scholar]

- Seo NJ, Armstrong TJ, Young JG, 2010. Effects of handle orientation, gloves, handle friction and elbow posture on maximum horizontal pull and push forces. Ergonomics 53(1), 92–101. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Valero-Cuevas FJ, 2000. Predictive modulation of muscle coordination pattern magnitude scales fingertip force magnitude over the voluntary range. Journal of Neurophysiology 83(3), 1469–1479. [DOI] [PubMed] [Google Scholar]

- White RM, 1971. The Body Size of Soldiers: US Army Anthropometry-1966. ARMY NATICK LABS MA CLOTHING AND PERSONAL LIFE SUPPORT EQUIPMENT LAB. [Google Scholar]

- Willms K, Wells R, Carnahan H, 2009. Glove attributes and their contribution to force decrement and increased effort in power grip. Human Factors 51(6), 797–812. [DOI] [PubMed] [Google Scholar]

- Young JG, Woolley C, Armstrong TJ, Ashton-Miller JA, 2009. Hand-Handhold Coupling: Effect of Handle Shape, Orientation, and Friction on Breakaway Strength. Human Factors 51(5), 705–717. [DOI] [PubMed] [Google Scholar]