Abstract

The production of coalbed methane (CBM) wells varies greatly in the Qinshui Basin, North China. Analyzing the primary factors controlling the CBM well productivity is essential to improve their development efficiency. Based on the geological conditions and production data of CBM wells in the Zheng zhuang area, the principal component analysis (PCA) method was used to classify the drainage types and screen the key factors influencing the production of gas and water. The drainage types of the CBM wells in the study area can be divided into four categories. The gas production shows an increasing trend with the increase of the comprehensive score of the PCA. The key controlling factors of productivity for CBM wells can be summarized by the gas-bearing property, permeability, groundwater fluid potential, and burial depth. The impact of burial depth on CBM well productivity is manifested in its control of gas content and permeability. The groundwater flows to a low fluid potential area, which leads to a high water production and a small pressure drop. The gas production shows a positive correlation with post-fracturing permeability. The gas content is a key factor for controlling the critical desorption pressure, critical gas production pressure, and pressure drop at the gas breakthrough point. High gas content is a prerequisite for the high productivity of CBM wells.

1. Introduction

Coalbed methane (CBM) is the term given to natural gas of an unconventional form in the adsorption state found in coal deposits or coal seams.1−3 The exploitation of CBM plays a vital role in improving the current energy structure, alleviating gas disasters, and restraining the greenhouse effect.4 The Qinshui Basin is the most important development base of CBM in China.5−7 Although over 4000 CBM wells have been drilled and installed in the southern Qinshui Basin, the average mean daily gas production of gas from a single well is less than 500 m3 in China. The gas and water production performance of the CBM wells in the southern Qinshui Basin varies significantly from one well to another, hence showing a significant variability in the production of gas and water. Therefore, it is important to solve the productivity bottleneck of these wells.

The CBM productivity of a well is controlled by many complicated geological and engineering factors. The geological factors reflect the reservoir properties, strata permeability, and desorption and adsorption characteristics of the coal reservoir, including gas content, porosity, thickness of the coal seam, permeability, burial depth, coal structure, in situ stress, hydrogeological conditions, and geological structures.6,8−10 The engineering factors are mainly concerned with drilling and completion methods, reservoir reconstruction techniques, well pattern deployment methods, drainage system, and stimulation measures.11

Commercial exploitation of CBM is an important milestone in the history of the global oil and gas industry. Several countries have been successful in developing their CBM resources. In the United States, commercial production began in the Black Warrior Basin, San Juan Basin, and Powder River Basin.7,12,13 Six geological basins including Bowen, Sydney, Gunnedah, Surat, Cooper, and Gloucester host the majority of coal seam gas resources in Australia. Twenty-nine percent of Australia’s LNG nameplate capacity is in three east coast facilities that are supplied primarily by coal seam gas.14 Since 2002, the Lower Cretaceous Mannville Group coals in the central Alberta Plains have been the focus for CBM production in Canada.15 Over the past 25 years, China has developed its substantial CBM resources and realized commercial exploitation in several basins and regions, such as Qinshui, Ordos, Junggar, Tuha, and western Guizhou. The CBM well productivity in China is still significantly lower than that in some other countries, such as Australia and the United States.16 Many researchers have studied the primary factors influencing the productivity of wells in different CBM basins or blocks. Meng et al. used the gray relational analysis to isolate the primary driver of the productivities of CBM wells of medium rank in the Liulin area, North China.11 The factors controlling the productivity of CBM were classified into groups, namely, geological and fracturing engineering parameters. Liu et al. found that geological factors, and in particular the influence of faults, the structural curvature of coal seams, and gas content, play key roles in regulating long-term gas production in the Hancheng block, southeast Ordos Basin, China.17 Peng et al. proposed that hydrological conditions and the sealing ability of the roof are two key factors affecting the production of CBM wells in the Shizhuangnan block of the southern Qinshui Basin, North China.18 Tao et al. analyzed the geological and engineering factors affecting the production of gas in the Fanzhuang block of the southern Qinshui Basin based on comparative analysis, quantitative analysis, and gray system theory.19 Lv et al. determined that hydraulic fracturing can guarantee the high productivity of CBM wells during the first couple of months following the development of a high-rank CBM field.20 By analyzing the production characteristics of CBM wells in the Fenn and Corbett Creek areas of Canada, Gentzis et al. described the effect of horizontal drilling technology on gas production.21 The multibranched horizontal well was successfully applied to the CBM development in the Alberta basin in western Canada, the San Juan basin in the United States, and the Bowen/Sydney basins in Australia. The branches allow the well to achieve maximum productivity in a short period of time by minimizing the single-water drainage stage.22−24

In the drainage process, there may be correlations among the controlling factors of CBM well productivity. This may lead to identifying an overlap of information by the single factor analysis. In this article, the drainage types of the Zheng zhuang area of the Qinshui Basin were classified by the principal component analysis (PCA) method based on the geological conditions and production data of the CBM wells. The key factors regulating the productivity of CBM wells were comprehensively analyzed to provide theoretical support for improving the productivity in this area.

2. Status of CBM Development in the Zheng Zhuang Area

The Zheng zhuang area is in the west of the Sitou fault in the southern Qinshui Basin and has a northwest-trending monocline with small-scale normal faults and several internal secondary folds. The Zheng zhuang area contains over 1000 vertical CBM wells and is the most important development area in China at present, as well as being the first area in China to commence the commercial exploitation of CBM. The main CBM production layer in this area is coal seam no. 3 of the Lower Permian Shanxi formation (Figure 1). The no. 3 coal seam has a relatively stable structure and belongs to anthracites. The thickness of the no. 3 coal seam in the study area ranges from 2.40 to 7.35 m, with an average of 5.39 m. The burial depth of the no. 3 coal seam decreases from north to south, ranging from 383.05 to 1336.9 m. The gas content of the no. 3 coal seam in the study area ranges from 1.49 to 31.44 m3/t, with an average of 19.44 m3/t.25−27 According to production data for 708 vertical CBM wells that have been in active production for over 1000 days, the production of gas and water varies significantly under the influence of geological and engineering factors. The mean daily production of gas ranges between 0 and 2432.78 m3/d, with a mean of 333.41 m3/d (Figure 2). The mean daily production of water fluctuates between 0.18 and 47.99 m3/d, with a mean of 3.49 m3/d (Figure 3). The development effect of CBM in the Zheng zhuang area is poor, and 74.86% of the CBM vertical wells have a mean daily gas production of less than 500 m3/d.

Figure 1.

Contour map showing the content of gas in coal seam no. 3 and the stratigraphic column of the coal-bearing PermoCarboniferous strata in Zheng zhuang, Qinshui Basin, northern China. (a) Position of Qinshui Basin in northern China. (b) Position of Zheng zhuang in southern Qinshui Basin. (c) Contour map showing the gas content of coal seam no. 3 and the locations of wells in Zheng zhuang. (d) Stratigraphic column of the coal-bearing strata.

Figure 2.

Average gas production of vertical CBM wells in the Zheng zhuang area.

Figure 3.

Average water production of vertical CBM wells in the Zheng zhuang area.

Analyzing the drainage records of these 708 CBM wells, it is found that most of them display an interruption phenomenon during the drainage process. The principal causes for the drainage interruption are equipment failure and the artificial shutdown of the wells. These interruptions cause reservoir damage and have a serious impact on the productivity of the wells. In this article, the research purpose is to analyze the geological and engineering factors of productivity for CBM vertical wells. Thus, 151 wells that have experienced a single interruption time of less than 24 h were selected to determine the factors required to eliminate the effect of drainage interruption on productivity. As shown in Figure 1c, the gas and water production data also display significant difference.

3. Drainage Type Classification of CBM Wells

The productivity of CBM wells is affected by many geological and engineering factors, and there may be correlations among these factors, leading to an overlap of the information. PCA is a form of multivariate analysis for transforming many indicators into relatively few principal components without a reduction in the original information. The PCA method can decrease the dimensionality of the variable space and overcome the challenge of an overlap of information between evaluation indices.28,29 Based on the geological and engineering parameters of CBM wells in the study area, the controlling factors of productivity for these wells were extracted. Then, the drainage type of CBM wells was classified by synthesizing gas and water production data and the comprehensive scores obtained by PCA.

In combination with the collected data for the CBM wells, 10 factors, including burial depth, coal seam thickness, gas content, porosity, permeability, static fluid level, water head height, gas production pressure, pressure drop at the gas breakthrough point, and pressure drop rate, were prepared for the PCA. The gas production pressure is the flowing bottomhole pressure (FBHP) under the continuous migration of CBM from the coal seam to the wellbore. The pressure drop is the difference between the initial FBHP and the gas production pressure and refers to the ratio of pressure drop to the corresponding drainage time.

In this study, 66 CBM vertical wells with complete parameters and production data were chosen from the 151 CBM wells with a single interruption time of less than 24 h. The variable coefficient of coal seam thickness is 9.12% and shows little dispersion, indicating that the coal seam distribution in the study area is stable (Table 1). Therefore, the parameter of coal seam thickness is excluded for the PCA. The variable coefficients of the other factors are all greater than 10%, indicating that the reservoir parameters and drainage systems among the different CBM wells vary greatly (Table 1).

Table 1. Influence Factor Statistics of Gas and Water Production of CBM Wells in the Study Area.

| change characteristics of factor | burial depth (m) | thickness of coal seam (m) | gas content (cm3/g) | porosity (%) | permeability (10–3 μm2) | static fluid level (m) | height of water head (m) | gas production pressure (MPa) | pressure drop at gas breakthrough point (MPa) | pressure drop rate (MPa/d) |

|---|---|---|---|---|---|---|---|---|---|---|

| maximum | 877.50 | 7.05 | 28.20 | 8.89 | 2.72 | 310 | 954.94 | 4.82 | 6.82 | 0.29 |

| minimum | 543.40 | 4.20 | 7.61 | 2.12 | 0.08 | 0 | 480.00 | 0.03 | 1.03 | 0.00 |

| average | 678.98 | 5.60 | 21.73 | 6.32 | 0.86 | 101.51 | 711.38 | 2.50 | 3.68 | 0.05 |

| variable coefficient | 0.11 | 0.09 | 0.24 | 0.24 | 0.66 | 0.86 | 0.13 | 0.40 | 0.39 | 1.09 |

4. Results

The calculation process of PCA was completed by SPSS 24.0 (Figure 4). The correlation matrix of influence factors of gas and water production is shown in Table 2. According to the results of eigenvalue and cumulative variance proportion (Table 3), four components were selected with an eigenvalue greater than 1. The cumulative variance contribution rate of these four components explains 83.91% of the total variance, which indicates that these four components reflect the majority of the influence factor information. Table 4 shows the loading of each parameter for the four principal components. The first principal component (PC1) describes 31.94% of the database variability and mainly contains information about gas content, gas production pressure, and pressure drop at the gas breakthrough point. The second (PC2) describes 24.25% of the database variability and has strong positive loadings for porosity and permeability. The third (PC3) mainly colligates information about the static fluid level and the water head height. The fourth (PC4) describes 11.85% of the database variability and has strong positive loadings for burial depth (Figure 5).

Figure 4.

Flow chart illustrating the process used in the application of PCA within the classification of CBM wells in the current study.

Table 2. Correlation Matrix of Influence Factor Statistics of Gas and Water Production.

| influence factor | burial depth | gas content | porosity | permeability | static fluid level | water head height | gas production pressure | pressure drop at gas breakthrough point | pressure drop rate |

|---|---|---|---|---|---|---|---|---|---|

| burial depth | 1.000 | 0.163 | 0.156 | –0.082 | 0.282 | 0.244 | 0.282 | 0.176 | 0.177 |

| gas content | 1.000 | 0.187 | 0.141 | 0.298 | 0.262 | 0.762 | –0.582 | –0.256 | |

| porosity | 1.000 | 0.879 | –0.101 | 0.236 | 0.155 | 0.012 | 0.038 | ||

| permeability | 1.000 | –0.184 | 0.203 | 0.104 | –0.022 | 0.038 | |||

| static fluid level | 1.000 | –0.283 | 0.209 | –0.601 | –0.275 | ||||

| height of water head | 1.000 | 0.331 | 0.075 | 0.073 | |||||

| gas production pressure | 1.000 | –0.616 | –0.232 | ||||||

| pressure drop at gas breakthrough point | 1.000 | 0.570 | |||||||

| pressure drop rate | 1.000 |

Table 3. Eigenvalue and Cumulative Variance Proportion of Different Factors.

| component | eigenvalue | variance contribution (%) | cumulative variance contribution (%) |

|---|---|---|---|

| 1 | 2.87 | 31.94 | 31.94 |

| 2 | 2.18 | 24.25 | 56.19 |

| 3 | 1.43 | 15.87 | 72.06 |

| 4 | 1.07 | 11.85 | 83.91 |

| 5 | 0.64 | 7.07 | 90.97 |

| 6 | 0.41 | 4.54 | 95.52 |

| 7 | 0.26 | 2.92 | 98.43 |

| 8 | 0.09 | 0.99 | 99.42 |

| 9 | 0.05 | 0.58 | 100.00 |

Table 4. Loading of Each Drainage Parameter in the Four Principal Components.

| principal

component |

||||

|---|---|---|---|---|

| factors | PC1 | PC2 | PC3 | PC4 |

| burial depth | 0.095 | 0.013 | –0.011 | 0.938 |

| gas content | 0.850 | 0.120 | 0.114 | 0.151 |

| porosity | 0.067 | 0.961 | 0.072 | 0.129 |

| permeability | 0.039 | 0.965 | 0.108 | –0.096 |

| static fluid level | 0.441 | –0.107 | –0.761 | 0.311 |

| water head height | 0.274 | 0.128 | 0.789 | 0.238 |

| gas production pressure | 0.862 | 0.064 | 0.209 | 0.225 |

| pressure drop | –0.848 | 0.003 | 0.362 | 0.239 |

| pressure drop rate | –0.557 | 0.048 | 0.265 | 0.450 |

Figure 5.

Component loadings of the PCA correlation analyses.

Based on the PCA method, the principal components are enumerated and their scores are calculated. Then, the comprehensive score of each CBM well can be calculated by eq 1.

| 1 |

where F is the comprehensive score, k is the number of principal components, fi is the score of each principal component, and Vi is the variance contribution of each principal component.

The comprehensive score F represents the characteristics of gas and water production of a CBM well. Thus, the drainage type of a CBM well can be classified according to the comprehensive score. The basic method of CBM development is reservoir depressurization by dewatering. Thus, the production of CBM well includes gas and water. The geological and engineering parameters affect not only gas production but also water production. The ratio of the average gas production to the average water production (Pg/Pw) can represent the production status of gas and water in the drainage process. The higher the value of Pg/Pw, the higher the gas production per unit of water production. Based on the relationship between the comprehensive scores obtained by the PCA and the Pg/Pw of a CBM well, the CBM wells in the study area are divided into four drainage types (Figure 6). The comprehensive score of type I is higher than 0.54, and the value of Pg/Pw is higher than 3000. The comprehensive score of type II ranges from 0 to 0.54, and the value of Pg/Pw ranges from 4.32 to 3637.96. The comprehensive score of type III ranges from −0.6 to 0, and the value of Pg/Pw is within the range of 0–586.43. The comprehensive score of type IV is less than −0.6, and the value of Pg/Pw ranges from 0 to 0.17, with an average of 0.05. As shown in Figure 5, the gas production per unit of water production increases with the increasing comprehensive score of a CBM well. The average gas production of CBM wells for type I is much higher than that for type IV. Hence, with the increasing comprehensive score of CBM wells, the average gas production presents an obvious increasing trend.

Figure 6.

Relationship between the comprehensive scores obtained by PCA and the ratio of the average gas production to the average water production.

5. Discussion

As outlined above, four principal components of the influence factors of productivity for CBM wells were extracted by PCA. In each principal component, the absolute value of the component loading reflects the contribution to the principal components. The key controlling factors are the high absolute value of the component loadings of the drainage parameters. In order to facilitate the analysis, the four principal components (PC1 to PC4) are first defined as the controlling factors of gas-bearing property, permeability, groundwater fluid potential, and burial depth, respectively.

5.1. Controlling Factors of Burial Depth

The burial depth of no. 3 coal seam for the CBM wells with a mean gas production greater than 1000 m3/d is mainly distributed between 550 and 750 m (Figure 7). The gas content of the no. 3 coal seam with a depth of burial less than 1000 m increases with the increasing depth of burial. The main reason for the transition of gas production with the depth of burial is the change in the in situ stress with depth and the effects of the in situ stress on coal reservoir permeability.

Figure 7.

Correlation between gas production and depth of the no. 3 coal seam.

The in situ stress state is the principally located stress transition and tension zone with the burial depth ranging from 580 to 820 m, which is beneficial for the development of reservoir fractures. The coefficient of lateral stress (λ), defined as the ratio between the mean horizontal in situ stress and vertical stress, is used to describe the variations in in situ stresses. The average horizontal stress is less than the overburden stress with λ < 1. The coal reservoir is in an extensional state and has s a relatively high permeability.30,31 For values of λ < 1, the permeability increases rapidly with decreasing λ (Figure 8). The λ fluctuates with the increasing depth, with λ less than 1 for burial depths ranging from 575 to 775 m (Figure 9). Thus, the physical properties of no. 3 coal seam over this burial depth range are beneficial for a high gas production.

Figure 8.

Relationship between the coefficient of lateral stress and permeability.

Figure 9.

Relationship between the coefficient of lateral stress and burial depth.

5.2. Hydrogeological Conditions

Hydrogeological conditions control the productivity of CBM wells in two ways: (1) they control the migration and accumulation of CBM, and (2) they affect the gas production capacity. The amount of water production affects the rate of reservoir pressure decline and the desorption of CBM. The CBM wells with a high production of water in the study area are usually characterized by a low gas production (Figure 10). The pressure drop funnel of CBM wells with a high production of water is difficult to expand, leading to a low production of gas. The wells with a mean production of water greater than 6.0 m3/d in fact hardly produce gas.

Figure 10.

Relationship between mean production of water and mean production of gas from CBM wells in the study area.

According to the hydrochemical test results of the water produced from CBM wells collected in the study area, the water is classified as a Na–HCO3 type (Figure 11). The results indicate that the produced water comes from the coal seam and there is no leaking recharge phenomenon.

Figure 11.

Pipe diagrams of coalbed water chemical characteristics in the study area.

The water production of CBM wells is affected by groundwater fluid potential and coal reservoir permeability. The hydraulic head can be obtained by the following equationwhere H is the hydraulic head, Hc is the burial depth of no. 3 coal seam, HL is the burial depth of the initial working fluid, and h is the altitude of no. 3 coal seam, all in meters.

It can be seen from eq 2 that there is an obvious correlation between the hydraulic head and the initial working fluid, which is the reason for their high component loading in PC3. The path of groundwater flow is from high to low fluid potential. The CBM wells located in areas of high fluid potential usually produce more water, which leads to a long drainage depressurization time and poor gas production (Figure 12).

Figure 12.

Relationship between water production and hydraulic head of no. 3 coal seam.

The flow of groundwater of no. 3 coal reservoir always follows the path of the decreasing hydraulic head. This results in the coal seam water flowing from the southwest to the north and east of the study area. The hydraulic head gradually decreases from Well block Z3 to Well block Z1, and the mean water production also shows an obvious trend of Well block Z1 > Well block Z2 > Well block Z3 in the drainage process. The coal seam water converges to the location of low fluid potential, resulting in a good gas production in Well block Z3 and poor gas production in Well block Z1 (Figure 13).

Figure 13.

Hydraulic head and groundwater flow path of no. 3 coal seam in the study area.

5.3. Controlling Factors of Permeability

Permeability is the main parameter reflecting the flow capacity of the coal seam fluid, which determines the migration efficiency of CBM and affects the extension of drainage depressurization. The logging porosity and permeability data were used in the PCA. Because the permeability is obtained by the relationship between coal permeability and porosity, the permeability shows an exponential relationship with logging porosity (Figure 14). As a result, PC2 has strong positive loadings for porosity and permeability. However, the hydraulic fracturing technique is applied in the reservoir stimulation and the permeability is improved after hydraulic fracturing. The gas production has a positive correlation with the post-fracturing permeability (Figure 15), showing that petrophysical properties of coal reservoirs can be substantially improved by hydraulic fracturing.

Figure 14.

Relationship between porosity and permeability of no. 3 coal seam in the study area.

Figure 15.

Correlation between post-fracturing permeability and gas production.

5.4. Controlling Factors of Gas-Bearing Properties

PC1 has strong positive loadings for gas content and gas production pressure and negative loadings for pressure drop, which indicates that these three factors are major contributors for PC1 and are interrelated.

5.4.1. Effect of Gas Content on the Productivity of CBM Wells

There are 24 high-productivity wells (mean gas production > 1000 m3/d) in the study area, 22 of which are located in the area with gas content greater than 16 m3/t (Figure 1c). Although the gas content is not the decisive factor in controlling the productivity of CBM wells, it is difficult for CBM wells to display a high gas production under low gas content.

5.4.2. Effect of Gas Production Pressure on the Productivity of CBM Wells

The gas production pressure for the examined wells ranges from 0.03 to 4.09 MPa, with a mean of 2.45 MPa. The gas production pressure is positively correlated with gas production (Figure 16), which indicates that the gas production pressure has a key effect on the productivity of CBM wells.

Figure 16.

Relationship between gas production pressure and gas production of CBM wells in the study area.

The critical desorption pressure is generally greater than the actual gas production pressure, but there is a good positive linear correlation between them. The CBM wells with a high critical desorption pressure and gas production pressure have an earlier gas production time in the drainage process, which can result in good production levels. According to the linear fitting relationship shown in Figure 17, the gas production pressure of a CBM well can be used to estimate the critical gas production pressure during the drainage process. The gas production pressure is therefore crucial for the drainage system formulation.

Figure 17.

Relationship between gas production pressure and critical desorption pressure.

5.4.3. Effect of Pressure Drop on the Productivity of CBM Wells

The pressure drop is negatively correlated with the maximum and mean gas production. The smaller the pressure drop, the easier it is for a CBM well to produce gas (Figure 18). The CBM wells will experience a much greater time for drainage, under the condition of the coal reservoir existing in a high-pressure-drop area.

Figure 18.

Relationship between the pressure drop at gas production pressure and gas production of CBM wells.

5.4.4. Interrelation of Gas-Bearing Property Factors

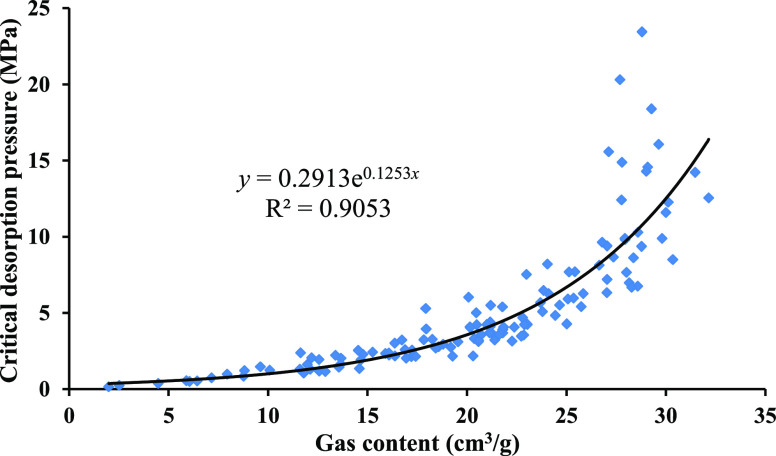

Based on the correlation matrix of influence factor statistics of gas and water production, the gas content has an apparent correlation to gas production pressure, and the correlation coefficient between pressure drop and gas production pressure has the maximum value among the influence factors. Gas content is the key factor in controlling the critical desorption pressure, the critical desorption pressure showing an exponential relationship with the gas content (Figure 19). There is an obvious linear relationship between the gas production pressure and the critical desorption pressure; thus, the gas content is also a key factor in controlling the gas production pressure. In conclusion, the gas content is a key controlling factor for PC1, with a higher gas content leading to the CBM well showing a higher productivity.

Figure 19.

Relationship between gas content and critical desorption pressure.

6. Conclusions

-

1

Based on the PCA method, four components were selected for reflecting the majority of the influence factors of gas and water production in the Zheng zhuang area. Four drainage types are divided, and the Pg/Pw of a CBM well presents an obvious increasing trend with the increasing comprehensive score obtained by the PCA.

-

2

The main reason for the transition of gas production with burial depth is the change of in situ stress with depth and the controlling effect of in situ stress on coal reservoir permeability. The groundwater that flows to a low fluid potential area leads to a high water production and a small pressure drop. The gas production displays a positive correlation with the post-fracturing permeability. The gas content is the key controlling factor in the gas-bearing properties, with a higher gas content leading to the CBM well showing a higher productivity.

Acknowledgments

This work was supported by the Natural Science Foundation of Shandong Province, China (ZR2020QD040), and the Key Laboratory of Coalbed Methane Resources and Reservoir Formation Process of the Ministry of Education (China University of Mining and Technology) (no. 2021-003).

The authors declare no competing financial interest.

References

- Mohamed T.; Mehana M.. CoalBed Methane Characterization and Modeling: Review and Outlook; Energy Sources Part A, 2020. [Google Scholar]

- Tao S.; Pan Z.; Tang S.; Chen S. Current status and geological conditions for the applicability of CBM drilling technologies in China: A review. Int. J. Coal Geol. 2019, 202, 95–108. 10.1016/j.coal.2018.11.020. [DOI] [Google Scholar]

- Zhang X.; Wu C.; Liu S. Characteristic analysis and fractal model of the gas-water relative permeability of coal under different confining pressures. J. Pet. Sci. Eng. 2017, 159, 488–496. 10.1016/j.petrol.2017.09.057. [DOI] [Google Scholar]

- Li P.; Zhang X.; Li J.; Zhao J.; Huang J.; Zhang S.; Zhou S. Analysis of the Key Factors Affecting the Productivity of Coalbed Methane Wells: A Case Study of a High-Rank Coal Reservoir in the Central and Southern Qinshui Basin, China. ACS Omega 2020, 5, 28012–28026. 10.1021/acsomega.0c03540. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chen S.; Tang D.; Tao S.; Yang Y.; Chen L. Current status and key factors for coalbed methane development with multibranched horizontal wells in the southern Qinshui basin of China. Energy Sci. Eng. 2019, 7, 1572–1587. 10.1002/ese3.366. [DOI] [Google Scholar]

- Zhang J.; Liu D.; Cai Y.; Pan Z.; Yao Y.; Wang Y. Geological and hydrological controls on the accumulation of coalbed methane within the No. 3 coal seam of the southern Qinshui Basin. Int. J. Coal Geol. 2017, 182, 94–111. 10.1016/j.coal.2017.09.008. [DOI] [Google Scholar]

- Qin Y.; Moore T. A.; Shen J.; Yang Z.; Shen Y.; Wang G. Resources and geology of coalbed methane in China: a review. Int. Geol. Rev. 2018, 60, 777–812. 10.1080/00206814.2017.1408034. [DOI] [Google Scholar]

- Chen S.; Tao S.; Tian W.; Tang D.; Zhang B.; Liu P. Hydrogeological control on the accumulation and production of coalbed methane in the Anze Block, southern Qinshui Basin, China. J. Pet. Sci. Eng. 2021, 198, 108138. 10.1016/j.petrol.2020.108138. [DOI] [Google Scholar]

- Hu Q.; Liu S.; Sang S.; Fang H.; Tripathy A.; Yan L.; Qin M.; Mao C. Numerical analysis of drainage rate for multilayer drainage coalbed methane well group in Southern Qinshui basin. Energy Explor. Exploit. 2020, 38, 1535–1558. 10.1177/0144598720946494. [DOI] [Google Scholar]

- Zhang X.; Wu C.; Wang Z. Experimental study of the effective stress coefficient for coal permeability with different water saturations. J. Pet. Sci. Eng. 2019, 182, 106282. 10.1016/j.petrol.2019.106282. [DOI] [Google Scholar]

- Meng Y.; Tang D.; Xu H.; Gan Q.; Yan T.. Identifying the Key Factor of Medium-Rank Coalbed Methane Productivity with Gray Relational Analysis: a Case Study in Liulin Area, Ordos Basin, China; Energy Sources Part A, 2020. [Google Scholar]

- Moore T. A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. 10.1016/j.coal.2012.05.011. [DOI] [Google Scholar]

- Flores R. M. Coalbed methane: From hazard to resource. Int. J. Coal Geol. 1998, 35, 3–26. 10.1016/s0166-5162(97)00043-8. [DOI] [Google Scholar]

- Salmachi A.; Rajabi M.; Wainman C.; Mackie S.; McCabe P.; Camac B.; Clarkson C. History, Geology, In Situ Stress Pattern, Gas Content and Permeability of Coal Seam Gas Basins in Australia: A Review. Energies 2021, 14, 2651. 10.3390/en14092651. [DOI] [Google Scholar]

- Gentzis T. Review of Mannville coal geomechanical properties: Application to coalbed methane drilling in the central Alberta Plains, Canada. Energy Sources, Part A 2009, 32, 355–369. 10.1080/15567030802466110. [DOI] [Google Scholar]

- Tao S.; Chen S.; Pan Z. Current status, challenges, and policy suggestions for coalbed methane industry development in China: A review. Energy Sci. Eng. 2019, 7, 1059–1074. 10.1002/ese3.358. [DOI] [Google Scholar]

- Liu Y.; Tang D.; Li S.; Xu H.; Tao S.; Zhao J.; Geng Y.; Fan H. Productivity subarea of CBM field and its key controlling factors: A case study in the Hancheng pilot test area, southeastern Ordos Basin, China. Energy Explor. Exploit. 2019, 37, 102–124. 10.1177/0144598718798091. [DOI] [Google Scholar]

- Peng C.; Zou C.; Zhou T.; Li K.; Yang Y.; Zhang G.; Wang W. Factors affecting coalbed methane (CBM) well productivity in the Shizhuangnan block of southern Qinshui basin, North China:Investigation by geophysical log, experiment and production data. Fuel 2017, 191, 427–441. 10.1016/j.fuel.2016.11.071. [DOI] [Google Scholar]

- Tao S.; Tang D.; Xu H.; Gao L.; Fang Y. Factors controlling high-yield coalbed methane vertical wells in the Fanzhuang Block, Southern Qinshui Basin. Int. J. Coal Geol. 2014, 134–135, 38–45. 10.1016/j.coal.2014.10.002. [DOI] [Google Scholar]

- Lv Y.; Tang D.; Xu H.; Luo H. Production characteristics and the key factors in high-rank coalbed methane fields: A case study on the Fanzhuang Block, Southern Qinshui Basin, China. Int. J. Coal Geol. 2012, 96-97, 93–108. 10.1016/j.coal.2012.03.009. [DOI] [Google Scholar]

- Gentzis T.; Goodarzi F.; Cheung F. K.; Laggoun-Défarge F. Coalbed methane producibility from the Mannville coals in Alberta, Canada: A comparison of two areas. Int. J. Coal Geol. 2008, 74, 237–249. 10.1016/j.coal.2008.01.004. [DOI] [Google Scholar]

- Clarkson C. R. Production data analysis of unconventional gas wells: review of theory and best practices. Int. J. Coal Geol. 2013, 109, 101-146. 10.1016/j.coal.2013.01.002. [DOI] [Google Scholar]

- Wight D. Unconventional drilling methods for unconventional reservoirs. Bull.—Houst. Geol. Soc. 2006, 48, 41. [Google Scholar]

- Ham Y.; Kantzas A.. Development of coalbed methane in Australia: unique approaches and tools. CIPC/SPE Gas Technology Symposium 2008 Joint Conference; Society of Petroleum Engineers, 2008.

- Zhang X.; Wu C.; Wang Z.; Xu D. Postfracturing permeability prediction for CBM well with the analysis of fracturing pressure decline. Energy Sci. Eng. 2019, 7, 3111–3123. 10.1002/ese3.483. [DOI] [Google Scholar]

- Huang S.; Liu D.; Cai Y.; Gan Q. In situ stress distribution and its impact on CBM reservoir properties in the Zhengzhuang area, southern Qinshui Basin, North China. J. Nat. Gas Sci. Eng. 2019, 61, 83–96. 10.1016/j.jngse.2018.11.005. [DOI] [Google Scholar]

- Huang W.; Lei M.; Qiu Z.; Leong Y.-K.; Zhong H.; Zhang S. Damage mechanism and protection measures of a coalbed methane reservoir in the Zhengzhuang block. J. Nat. Gas Sci. Eng. 2015, 26, 683–694. 10.1016/j.jngse.2015.06.034. [DOI] [Google Scholar]

- Boudenne J.-L.; Parinet J.; Demelas C.; Manasfi T.; Coulomb B. Monitoring and factors affecting levels of airborne and water bromoform in chlorinated seawater swimming pools. J. Environ. Sci. 2017, 58, 262–270. 10.1016/j.jes.2017.05.022. [DOI] [PubMed] [Google Scholar]

- Geng X.; Qi M.; Liu J.; He C.; Li Y. Application of principal component analysis on water fooding efect evaluation in natural edge-bottom water reservoir. J. Pet. Explor. Prod. 2020, 11, 439–449. 10.1007/s13202-020-01055-4. [DOI] [Google Scholar]

- Huang S.; Liu D.; Cai Y.; Gan Q. In situ stress distribution and its impact on CBM reservoir properties in the Zhengzhuang area, southern Qinshui Basin, North China. J. Nat. Gas Sci. Eng. 2019, 61, 83–96. 10.1016/j.jngse.2018.11.005. [DOI] [Google Scholar]

- Chen S.; Tang D.; Tao S.; Xu H.; Li S.; Zhao J.; Cui Y.; Li Z. Characteristics of in-situ stress distribution and its significance on the coalbed methane (CBM) development in Fanzhuang-Zhengzhuang Block, Southern Qinshui Basin, China. J. Pet. Sci. Eng. 2018, 161, 108–120. 10.1016/j.petrol.2017.11.042. [DOI] [Google Scholar]