Abstract

Sound environmental management to control marine plastic pollution requires a careful assessment of environmental costs and benefits of replacing single-use plastics with their biodegradable counterparts. This research employs the standard life cycle assessment (LCA) approach to assess and compare the environmental impact of plastic straws made from polypropylene (PP), and its biodegradable alternatives made from polylactic acid (PLA) and paper (PA) in the United States. Eight environmental impact categories, not including marine litter, were analyzed and a composite relative environmental impact index (REI) was derived for quantitative comparison. The results show that US daily consumption of disposable drinking straws (500 million straws daily) may carry significant environmental burdens regardless of straw types, with the feedstock manufacture stage of the life cycle creating most of the contribution. The REI index values were 2.4 for PP straws, 6.4 for PLA straws, and 5.1 for PA straws with landfill and 3.2 for PP straws, 6.8 for PLA straws, and 4.9 for PA straws with incineration. A sensitivity analysis did not show much change in REI with increasing marine litter rate, demonstrating that replacing PP straws with PLA or PA straws for controlling marine plastic pollution would come with environmental costs in other categories. The trade-off can be quantitatively represented by the difference in REI between PP straws and PA or PLA straws. Our analysis also indicates close-loop recycling can greatly reduce the environmental impact of PP straws, serving as a technological development to control plastic pollution. While disposable straws were used as a case study in this work, the findings are extensive to other single-use products.

Keywords: Marine litter, Paper straw, Plastic waste, Polylactic acid, Polypropylene, Single-use plastics

1. Introduction

Environmental pollution caused by anthropogenic use and disposal of plastics has attracted increasing concerns and become a global issue (Agamuthu et al., 2019; Bucci et al., 2020; Waldschlager et al., 2020). According to the Center for International Environmental Law (2019), a total of 8300 million metric tons (MT) of petroleum-based plastics have been produced by the end of 2015. Approximately 6300 million metric tons of plastic waste have been generated, around 9% of which were recycled, 12% incinerated, and 79% accumulated in landfills or the natural environment (Geyer et al., 2017). Because petroleum-based plastics are biologically nondegradable, they are easily accumulated in the environment, especially in the oceans (Jepsen and de Bruyn, 2019; Li et al., 2021; Tessnow-von Wysocki and Le Billon, 2019). In 2010, 192 coastal countries generated 275 million MT of plastic waste, 99.5 million MT of which came from coastal regions (within 50 km of the coast) and 4.8 to 12.7 million MT entered the ocean (Jambeck et al., 2015). Plastic debris including microplastics can cause serious threats to marine animals, birds, and potentially human health (Danopoulos et al., 2020; Gouin, 2020; Kuhn et al., 2018).

As a single-use item, plastic drinking straws are construed as one of the largest contributors to plastic waste in the oceans and coastal zones in the United States and around the globe (Borenstein, 2018; Gibbens, 2019). It is estimated that there are up to 8.3 billion plastic straws contaminating the world’s beaches and about 7.5 million of plastic straws reside in America’s coastline (Borenstein, 2018). Because of their small size and low weight, most plastic straws are not recycled and thus can enter the environment as a waste. An international movement on eliminating disposable plastic straws has received strong support from the public, industries, and governments (Wagner and Toews, 2018). Many large companies and local governments have already taken actions to reduce the consumption and disposal of plastic straws. For example, Starbucks phased out plastic straws from all of its stores in 2020 (Gibbens, 2019). The European Union (EU) has been taking action on single-use plastics including straws since 2014 and requires all of its member states to ban disposable plastic straws by 2021 (Hogue, 2018). Some US cities such as Seattle and Miami Beach have already opted to ban plastic straws. New York City, Hawaii, and California have pending plastic straw ban legislation underway (Gibbens, 2019). However, it is almost impossible to completely remove disposable drinking straws from our daily life because of normal drinking habits and sanitation requirement (Caverly, 2019).

Drinking straws in the US are usually made of polypropylene (PP), which is produced from petroleum or natural gas. The PP plastic straws are nondegradable, and if released into the environment the plastic waste can eventually be broken into microplastics or nanoplastics that have even higher environmental risks (Weinstein et al., 2016). In fact, PP is one of the most commonly reported plastic debris in surface waters worldwide (Kim et al., 2020; Waldschlager et al., 2020). Alternative materials, which are biologically degradable, are used to replace PP for disposable straws. A popular alternative is paper; paper (PA) drinking straws have already been used in many places in the world (Urquhart, 2019). Biodegradable plastics derived from natural biomass also have been proposed to replace PP for drinking straws. Among them, polylactic acid (PLA) is one of the most commonly used bio-based plastics for drinking straws (Chen et al., 2020), even though the biodegradability of PLA in natural environments is not a scientific consensus (Nazareth et al., 2019).

Switching to paper or biodegradable plastic alternatives would be straight forward if marine plastic pollution was the only environmental impact for drinking straws. However, evaluation of environmental impact of drinking straws throughout the whole life cycle of the product reveals other environmental concerns (Chitaka et al., 2020; Zanghelini et al., 2020; Viera et al., 2020). Therefore, it is critical to evaluate and compare the environmental impacts of different straws using the cradle-to-grave life cycle assessment (LCA) approach. LCA is a systematic tool for identification and quantification of environmental impacts associated with all the stages of a product’s life from raw material extraction through materials processing, manufacture, distribution, use, repair and maintenance, and disposal or recycling. The International Organization for Standardization (ISO) has established principles and guidelines in ISO 14040 for conducting LCA of a product (ISO, 2006). Recently, a few LCA studies comparing the environmental impacts of disposable drinking straws have been reported for several countries and regions, to include South Africa (Chitaka et al., 2020), Brazil (Zanghelini et al., 2020), EU (Herberz et al., 2020), and Malaysia (Moy et al., 2021). In particular, Rana (2020) compared LCA results of three single-use drinking straws (plastic, paper, and bioplastic) in terms of energy demand and global warming potential in the US though no further analyses on other impact categories were reported. These LCA studies generally attempted to reveal full environmental burdens of plastic straws and their non-plastic alternatives, thereby better informing the decision-making of drinking straw usage. They differ in their respective results, partly due to different system boundaries and input data. For example, Zanghelini et al. (2020) performed LCA of six different drinking straws including plastic, stainless steel, glass, paper, bamboo and jute in Brazil and concluded that plastic drinking straws have better environmental performance in climate change emission compared with paper disposable straws. In contrast, Chitaka et al. (2020) reported higher climate change emissions of plastic straws than paper ones due to the use of coal for polypropylene production in South Africa. These studies also emphasized the general lack of impact assessment inventory method for marine litter, especially the proper weighting factor that may influence decision making. Effects of plastic marine pollution mostly are reported at the conceptual level whereby a robust LCA method is not readily available (Wilcox et al., 2016).

The objective of this study is to conduct an environmental impact trade-off analysis for functional replacement of disposable PP drinking straws with the alternative PLA, and PA straws to control marine plastic pollution at the national scale of the United States using the cradle-to-grave LCA approach. We examined eight environmental impact categories plus marine litter impact and developed a composite relative environmental impact index (REI) to evaluate the environmental trade-off. Specifically, our analysis attempted to address the following questions (i) which stage in the life cycle of these straws carries the highest environmental burden? (ii) how does uncertainty in marine litter rate change the trade-off analysis? and (iii) which alternative, PLA or PA straws, would be more environmentally sound to replace PP straws? We also evaluated how recycling of plastic straws as an end-of-life waste management strategy would change the environmental impact. Findings of this study can improve our understanding of the potential environmental impacts of PP, PLA, and PA straws and thus inform the decision-making of disposable straws in the US.

2. Material and methods

2.1. LCA goal and scope

The LCA goal is to compare the environmental impacts of total daily beverage consumption using single-use straws in the US when considering PP, PLA, and PA as three material alternatives for the straw. The ISO 14040 standard is closely followed. All of the straws are disposable and have the same functionality. In the US, most of the disposable drinking straws are made of PP with a daily consumption of about 500 million (Gibbens, 2019). For comparison, the functional unit of PP, PLA, and PA straws was set as the number of disposable drinking straws used per day in the US. The required mass input for each type of straws was determined based on their individual weight (Table 1).

Table 1.

Functional unit and required mass input of disposable drinking straws.

| PP straw | PLA straw | PA straw | |

|---|---|---|---|

|

| |||

| Weight (g/straw) a | 0.52 | 0.81 | 1.15 |

| Functional unit (no./d) | 500,000,000 | 500,000,000 | 500,000,000 |

| Mass input (kg/d) | 260,000 | 405,000 | 575,000 |

After Chitaka et al. (2020) and Rana (2020).

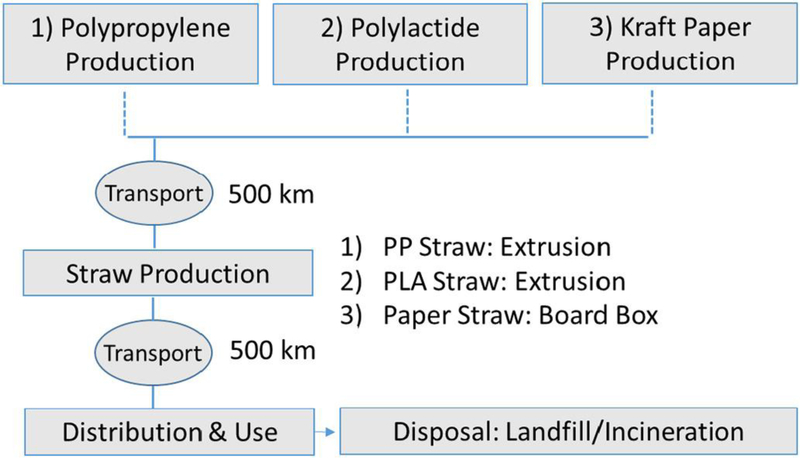

The geographic boundary of the study is limited to raw material production, transport, straw production, distribution, use, and disposal in the US (Fig. 1). All production, use, and disposal are assumed to occur in the same calendar year. The modes of transportation, distribution, use, and disposal of the three types of the straws are assumed to be the same for comparison (Fig. 1).

Fig. 1.

Life cycle stages and boundaries of different drinking straws.

In the US, PP and PLA straws are produced by extruding PP and PLA resins, respectively (Hischier, 2007). The raw material PP is mainly extracted from crude oil and natural gas (Hischier, 2007), while PLA is a starch-based polymer made from renewable resources like corn starch, tapioca roots, or sugarcane (ETH et al., 2007). PA straws are made to food grade Kraft paper, which is mainly produced from pulpwood (Hischier, 2007). The transport of feedstock materials and final product is assumed to be 500 km each using diesel trucks. Since the dimensions of the three types of straws are similar, their packaging methods and patterns should also be similar and would not affect the comparison of the environmental impact.

At the end of life, all the disposable straws would have the same method of disposal. Plastic waste is generally managed in three ways: recycling, incineration, and landfill, with unmanaged waste going into the environment. Currently, the majority of municipal solid waste in the US is disposed to landfills (USEPA, 2021). For comparative LCA, landfill emissions are modeled to vary with straw materials; other landfill emission parameters were kept the same. To test the effect of the waste management method, incineration was considered as an alternative disposal method. Waste to energy conversion was not considered in the incineration analysis. Capital goods, energy consumption, land, and labor are not included.

2.2. Life cycle inventory

The primary input and output of the raw material production were obtained from three LCA databases: GaBi database, Ecoinvent database, and US Life Cycle Inventory (USLCI) database. The PLA production LCA data were based on the eco-profile for Ingeo PLA produced from corn by NatureWorksTM (Vink, 2007). The PA production data were based on a series of processes in the USLCI database including foresting, logging, pulp extraction, and paper production. Data of the extrusion of PP and PLA straws were obtained from Ecoinvent database. There are no data available on the production of straws from paper, however, it is similar to carton box production (Rana, 2020). The main input and output of carton box production from the Ecoinvent database were thus used as the alternative in this study. Sensitivity analysis showed that the LCA results are not sensitive to the straw production processes because their relatively low energy input and emissions. The life cycles of the three types of drinking straws were modeled using the GaBi Software (Educational Version).

2.3. Environmental impact assessment

The life cycle impact assessment (LCIA) was based on CML-IA, a database that contains characterization factors for life cycle impact assessment (Guinée, 2002). The analysis focused on eight impact categories from outputs of GaBi, including global warming potential (GWP), acidification potential (AP), eutrophication potential (EP), ozone depletion potential (ODP), freshwater toxicity potential (FTP), human toxicity potential (HTP), terrestrial toxicity potential (TTP), and abiotic depletion of fossil (ADF). Marine litter impact was not available in GaBi modeling and a tradeoff analysis of environmental impacts with marine litter was developed separately.

These LCIA categories of each type of drinking straws were first calculated assuming 100% of the used straws were sent to landfills; this was used as the baseline scenario for further analysis. Each LCIA category was compared to determine whether the alternative straw options would have lower environmental impact than the PP straw. A contribution analysis by stage was performed for the four stages of life cycle, including raw material manufacturing (Feedstock), straw production (Extrusion), packaging and transportation (Transportation), and wastes disposal (Landfill or Incineration) as shown in Fig. 1. Additional alternatives were created to investigate the effect of waste management. In one alternative, all straw waste was assumed to be incinerated. In another set of alternatives, close-loop recycling of PP straws was included by assuming 10%, 25%, 50%, 75%, and 90% of PP straws were recycled and reused for production.

To allow for direct comparison of the environmental impacts among the three straw types, a relative environmental impact index (REI) was calculated as follows:

| (1) |

where i represents straw type; j denotes impact category; and EI is the environmental impact value of each straw type under each category obtained from GaBi application. Dividing the environmental impact value by the maximum among the three straw types under each category serves as internal normalization so the REI value for any category would fall between 0 and 1. Summation of REI under all categories for a straw type represents integration of all the GaBi environmental impacts with equal weight assigned to all categories.

This internal normalization method also allows for an understanding of trade-off with the marine litter impact. Because the impact of plastic pollution on marine life is dependent on the quantity of plastic in the marine environment (Wilcox et al., 2018), we evaluated straw litter impact by the flux of plastic straws or equivalent entering the marine environment and its subsequent degradation. With the base case of 100% landfill, we conducted a sensitivity analysis by assuming a straw marine leakage rate of up to 20% of total straw consumed to evaluate the resulting changes in other impact categories. The REI was calculated using the maximum impact value of a category for 100% landfill in Eq. (1). In other words, only Ei,j changes with marine liter rate while max(Ei)j is kept the same with 100% landfill to allow for evaluation of change in REI. We also used literature values of degradation rate in the ambient marine environment to derive a relative marine impact factor of the PP, PLA, and PA straws. With the same internal normalization procedure in Eq. (1), the actual leakage flux is not needed for calculating the relative marine litter impact index because the same propensity for marine litter of all straw types is assumed.

3. Results and discussion

3.1. Landfill and incineration comparison

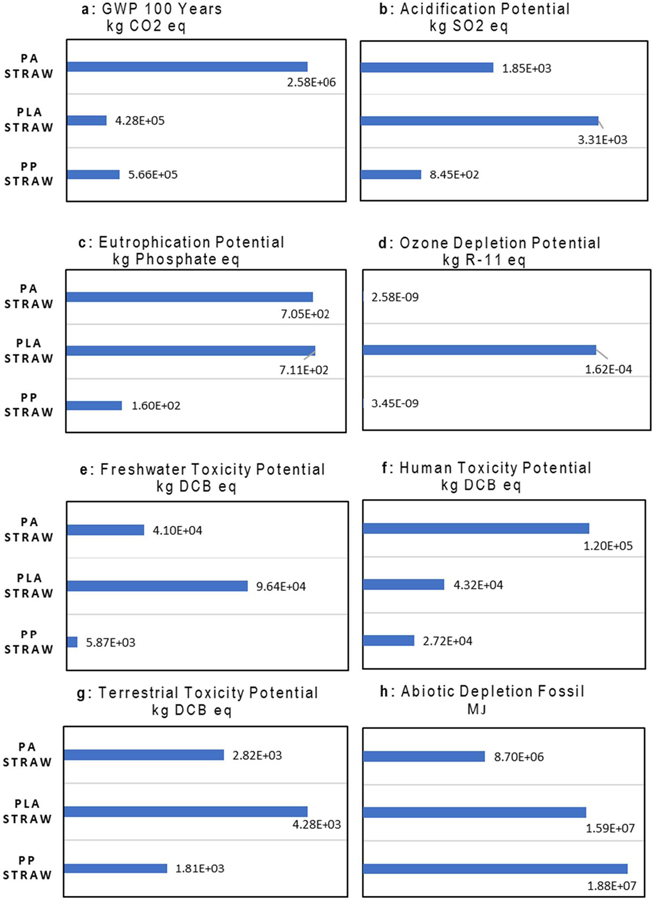

Landfilling is the most widely used method for the disposal of non-recyclable solid waste globally including the United States (Nanda and Berruti, 2021). Fig. 2 shows the LCA results of the three types of drinking straws ending up in landfills, with the percentage of contribution from four key stages in their life cycle including feedstock manufacturing (i.e., producing PP resins, PLA resins, or paper sheets from natural resources), straw extruding, transportation, and disposal listed in Table 2. Overall, the results indicate that US daily consumption of disposable straws (PP or the alternatives) comes with substantial environmental burdens for all impact categories except for ozone depletion potential (ODP). These results are consistent with the findings of previous studies that revealed significant environmental impacts of single-use items, especially disposable plastic products (Dhaliwal et al., 2014; Garrido and del Castillo, 2007; Zanghelini et al., 2020). Interestingly, PP straws tend to create less or comparable impacts among all these categories except for the abiotic depletion of fossil (ADF). In other words, almost all the PLA and PA impact potentials (except GWP of PLA, ODP of PA, and ADF of PLA and PA) are larger than for PP straws.

Fig. 2.

Environmental burdens of disposable drinking straws of eight impact categories. All the used straws are assumed to be disposed in landfill.

Table 2.

Percentage contributions from the key stages of the life cycle to the environmental impact of disposable drinking straws. All the used straws are assumed to be disposed in landfill.

| Impact category/straw type | Feedstock | Extrusion | Transportation | Landfill | |

|---|---|---|---|---|---|

|

| |||||

| Global warming potential (GWP) | PP | 80% | 13% | 4% | 3% |

| PLA | 59% | 26% | 9% | 6% | |

| PA | 63% | 8% | 2% | 27% | |

| Acidification potential (AP) | PP | 72% | 13% | 10% | 6% |

| PLA | 89% | 5% | 4% | 2% | |

| PA | 65% | 16% | 10% | 9% | |

| Eutrophication potential (EP) | PP | 48% | 7% | 14% | 31% |

| PLA | 82% | 2% | 5% | 11% | |

| PA | 56% | 4% | 7% | 31% | |

| Ozone depletion potential (ODP) | PP | 88% | 10% | 0% | 2% |

| PLA | 100% | 0% | 0% | 0% | |

| PA | 57% | 38% | 5% | 5% | |

| Freshwater toxicity potential (FTP) | PP | 93% | 2% | 3% | 1% |

| PLA | 99% | 0% | 0% | 0% | |

| PA | 13% | 85% | 1% | 0% | |

| Human toxicity potential (HTP) | PP | 80% | 13% | 5% | 2% |

| PLA | 80% | 13% | 5% | 2% | |

| PA | 84% | 12% | 2% | 1% | |

| Terrestrial toxicity potential (TTP) | PP | 76% | 3% | 1% | 20% |

| PLA | 84% | 2% | 1% | 13% | |

| PA | 76% | 5% | 1% | 18% | |

| Abiotic depletion of fossil (ADF) | PP | 92% | 5% | 2% | 1% |

| PLA | 85% | 9% | 3% | 3% | |

| PA | 56% | 30% | 8% | 7% | |

Specifically, the global warming potentials (GWP) of PP, PLA, and PA straws were 5.66E+05, 4.28E+05, and 2.58E+06 kg CO2 eq, respectively (Fig. 2a), consistent with findings of other LCA studies about PLA’s lower carbon footprint and energy consumption than plastics (Ghomi et al., 2021). Greenhouse gas emission from manufacturing feedstock contributed 80% for PP straw, 59% for PLA straw, and 63% for PA straw, much higher than that of the other three stages (Table 2). Acidification potentials (AP) were 8.45E+02, 3.31E+03, and 1.85E+03 kg SO2 eq for PP, PLA, and PA straws, respectively (Fig. 2b). Again, significant AP was linked with manufacturing feedstock (65–89%). Eutrophication potentials (EP) were 1.60E+02, 7.11 + E02, and 7.05E+02 kg phosphate (P) eq for PP, PLA, and PA straws, respectively (Fig. 2c). Manufacturing feedstock (48–82%) and end-of-life landfill (11–31%) are the two largest contributing steps. Ozone depletion potentials (ODP) were limited with only PLA straws being noticeable (1.62E-04 kg R-11 eq), which correlated with feedstock manufacturing (Fig. 2d). Freshwater toxicity potentials (FTP) were 5.87E+03, 9.64E+04, and 4.01E+04 kg DCB eq for PP, PLA, and PA straws, respectively (Fig. 2e). The largest contribution came from feedstock manufacturing for PP and PLA straws (93–99%) and from straw extrusion for PA straws (85%). Human toxicity potentials (HTP) were 2.72E+04, 4.32E+04, and 1.20E+05 kg DCB eq for PP, PLA, and PA (Fig. 2f), largely attributable to feedstock manufacturing (80–84%) and straw extrusion (12–13%). Terrestrial toxicity potentials (TTP) were 1.81E+03, 4.28E+03, and 12.82E+03 kg DCB eq for PP, PLA, and PA (Fig. 2g), primarily from feedstock manufacturing (76–84%) and landfill disposal (13–20%). Abiotic depletion fossil (ADF) with landfill was 1.88E+07, 1.59E+07, and 8.70E+06 MJ for PP, PLA, and PA straws, respectively (Fig. 2h). Manufacturing feedstock contributed significantly with 92% for PP straws, 86% for PLA straws, and 56% for PA straws, for which 30% also came from the extrusion process (Table 2).

It is worth noting that, for the potentials of abiotic depletion of natural resources, we only evaluated fossil fuel (ADF), which is the only category that exhibited lower values for PP straws than PLA and PA straws (Fig. 2). This may not be a fair comparison because PP resins are synthesized directed from petroleum while PLA resins and PA sheets are derived from plant biomass that depletes other natural resources in the upstream production in association with agriculture practices such as water consumption and fertilizer applications. As a result, the lower ADF of PLA and PA than that of PP does not necessarily mean that PLA and PA would deplete less natural resources than PP.

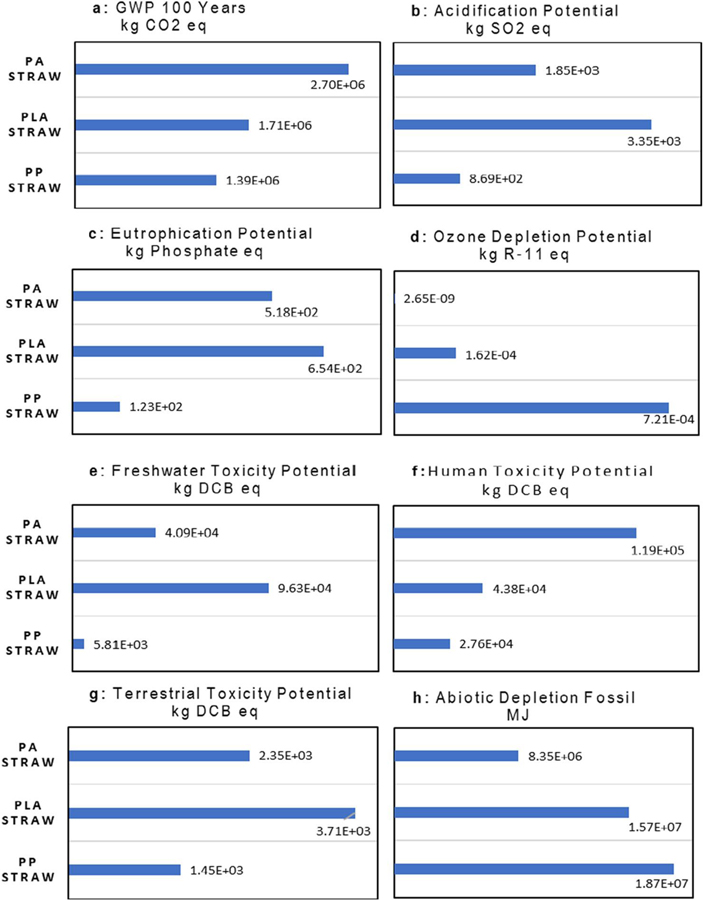

Incineration is another commonly used management strategy for non-recyclable solid waste (Margallo et al., 2015). To test the effect of disposal methods on the environmental impact of the three types of drinking straws, the end-of-life disposal was reevaluated with the assumption that all the used straws are incinerated. Fig. 3 shows the LCA results of the three types of drinking straws with disposal option as incineration, and Table 3 compares the results with landfill (Fig. 2) along with the percentage of contributions from the four key stages in their life cycle. The results indicated that the daily consumption of disposable straws for incineration carries a similar environmental impact pattern with landfill. In other words, for incineration (Fig. 3) PLA and PA straws showed higher impact potentials in six of the eight categories (ODP and ADF are the exceptions) than that of PP straws. On the impact category level, switching the waste management option from landfill to incineration does not cause major changes to AP, FTP, HTP, and ADP (within 1–4% change). However, substantial increase in GWP (2.5 times increase for PP and 4 times increase for PLA) and ODP (>100 times increase for PP and 7.9 time increase for PLA) as well as notable reduction in EP (by 8–27%) and TTP (by 13–20%) were observed. For example, straw incineration increased GWP of PP, PLA, and PA straws to 1.39E+06, 1.71E+06, and 2.70E+06 Kg CO2 eq, respectively (Fig. 3a). There also were corresponding changes in the percent contributions from the final end-of-life waste disposal (Table 2, Table 3). These changes are consistent with the fact that incineration increases air emissions of pollutants but reduces the leakage from the landfill site to terrestrial and aquatic ecosystems (Nanda and Berruti, 2021).

Fig. 3.

Environmental burdens of disposable drinking straws of eight impact categories. All the used straws are assumed to be incinerated.

Table 3.

Percentage contribution of the four key stages in the life cycle to the environmental impact of disposable drinking straws. All the used straws are assumed to be incinerated.

| Impact category/straw type | Incineration: landfill ratioa | Feedstock | Extrusion | Transportation | Incineration | |

|---|---|---|---|---|---|---|

|

| ||||||

| Global warming potential (GWP) | PP | 2.46 | 33% | 5% | 2% | 60% |

| PLA | 4.00 | 15% | 7% | 2% | 77% | |

| PA | 1.05 | 60% | 8% | 2% | 30% | |

| Acidification potential (AP) | PP | 1.03 | 70% | 12% | 10% | 8% |

| PLA | 1.01 | 88% | 5% | 4% | 3% | |

| PA | 1.00 | 65% | 16% | 10% | 9% | |

| Eutrophication potential (EP) | PP | 0.77 | 63% | 9% | 18% | 10% |

| PLA | 0.92 | 89% | 3% | 5% | 3% | |

| PA | 0.73 | 77% | 6% | 10% | 6% | |

| Ozone depletion potential (ODP) | PP | >100 | 0% | 0% | 0% | 100% |

| PLA | 7.90 | 13% | 0% | 0% | 88% | |

| PA | 1.03 | 56% | 37% | 5% | 7% | |

| Freshwater toxicity potential (FTP) | PP | 0.99 | 94% | 2% | 3% | 0% |

| PLA | 1.00 | 99% | 0% | 0% | 0% | |

| PA | 1.00 | 13% | 85% | 1% | 0% | |

| Human toxicity potential (HTP) | PP | 1.01 | 79% | 13% | 5% | 3% |

| PLA | 1.01 | 79% | 13% | 5% | 3% | |

| PA | 0.99 | 85% | 12% | 2% | 1% | |

| Terrestrial toxicity potential (TTP) | PP | 0.80 | 95% | 3% | 1% | 0% |

| PLA | 0.87 | 97% | 2% | 1% | 0% | |

| PA | 0.83 | 91% | 6% | 1% | 1% | |

| Abiotic depletion of fossil (ADF) | PP | 0.99 | 93% | 5% | 2% | 1% |

| PLA | 0.99 | 87% | 9% | 3% | 1% | |

| PA | 0.96 | 58% | 31% | 8% | 3% | |

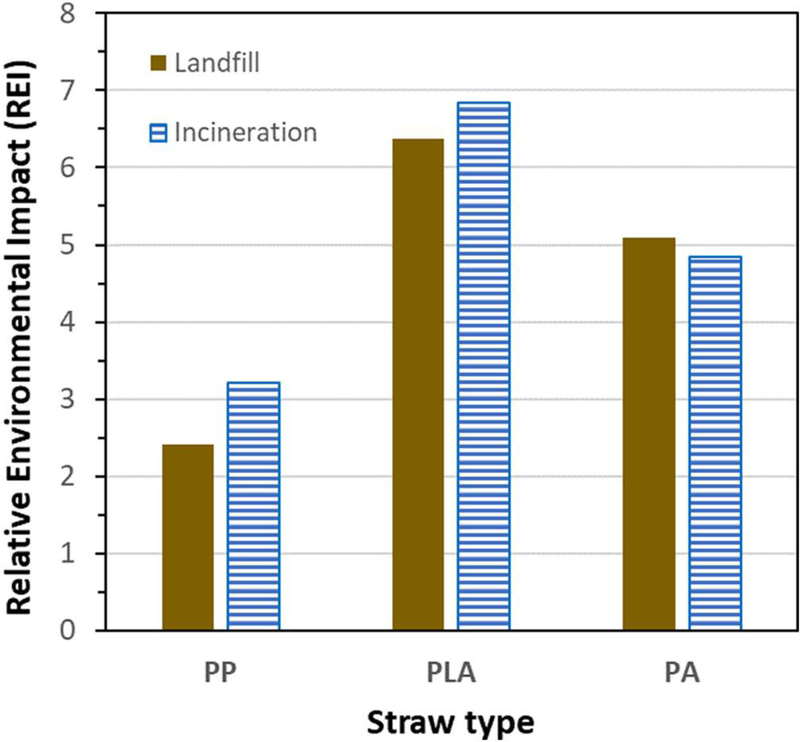

3.2. Composite relative impact index and marine litter

While category specific comparison identifies the absolute value of each impact category among PP, PLA, and PA straw LCA, the composite REI combining all eight categories as a single score allowed for more direct comparison of the relative environmental impacts among the three types of straws (Fig. 4). The REI values were 2.4 for PP straws, 6.4 for PLA straws, and 5.1 for PA straws with landfill and 3.2 for PP straws, 6.8 for PLA straws, and 4.9 for PA straws with incineration, indicating that the environmental impacts for PP straws are substantially less than that for PLA and PA straws no matter whether the end-of-life disposal option is landfill or incineration (Fig. 4). Between the two candidates for replacing plastic drinking straws, the LCA analysis demonstrates that REI value for PLA straws was about 30–40% more than for PA straws. This suggests that PA straws should be a better candidate for consideration if PP straws are indeed to be phased out. This could also be the case for other single-use plastic items such as disposable cups and take-out containers.

Fig. 4.

Relative environmental impact as REI of PP, PLA, and PA straws under 100% landfill or incarnation scenarios.

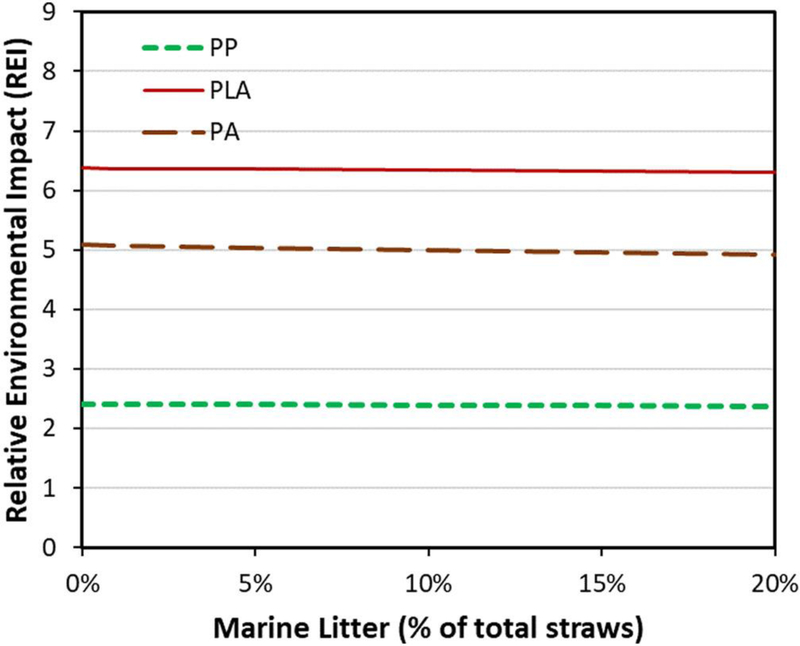

It is important to note that the above analysis assumes that no straws enter the marine environment during the end-of-life stage (100% landfill or incineration). We thus conducted a sensitivity analysis assuming that up to 20% of total straws consumed could be leaked into the ocean as marine litter. The result indicates that the associated impact values for the eight categories (data not shown) and the REI decreased with increasing marine litter rate, however the changes were very minimal (Fig. 5). This is mostly because the feedstock manufacture stage accounted for the highest percentage of contribution to the impact categories and thereby REI (Table 2). The insensitive nature of REI with changing marine litter rate suggests that the trade-off for the proposed replacement of PP straws by PLA and PA straws for abatement of marine plastic pollution can be quantitatively represented by the difference of REI values between PP straws and PA or PLA straws (Fig. 4) or scaled from category specific analyses (Fig. 2, Fig. 3).

Fig. 5.

Sensitivity analysis of the relative environmental impact as REI of PP, PLA, and PA straws under varying marine litter rate. The 100% landfill scenario was used as the base condition.

The above sensitivity analysis of marine litter rate and its influence on changes in other environmental impacts needs to be understood further in a context of marine litter impact. We must admit that our current knowledge of plastic litter impacts on marine life and human health is still at the conceptual level for LCA analysis (Wilcox et al., 2016, Wilcox et al., 2018) due to the paucity of data to establish a quantitative relationship between marine litter rate or plastic leakage flux, fate and transport of plastic waste in the marine environment, and the extent to which a species’ population may be affected. Uncertainties associated with ingestion of micro- or nano-plastics by a wider range of organisms and its subsequent cumulative impacts on marine organisms and human health further warrant the need of additional research (Waldschlager et al., 2020). Existing attempts to assess effects of marine litter impact of straws in the context of LCA focused on physical threat to marine life via entanglement and ingestion (Chitaka et al., 2020; Woods et al., 2019). Therefore, we estimated the number of straws entering the marine environment, and their degradation in the marine environment based on the existing literature. While the exact flux of marine litter of disposable straws in the United States is not known, Jambeck et al. (2015) used 2% litter rate in the coastal zone for calculation of marine plastic debris and noted that the annual input (in 2010) of plastic waste into the marine environment was equivalent to 1.7 to 4.6% of the total plastic waste generated from all coastal countries in the world. This percentage is well within the range of marine litter in our sensitivity analysis. Jambeck et al. (2015) further noted that the United States, ranked 20th by the mass of mismanaged plastic waste, had about 0.04–0.11 million MT of plastic debris entering the coastline per year. According to the International Coastal Cleanup 2017 Report (Conservancy, 2017), a total of 1417.32 MT of plastic debris were collected in the 2016 coastal cleanup in the US. These plastic debris contained 125,973 plastic straws and stirrers, yielding about 89 plastic straws (counting stirrers as straws) per MT plastic waste. Taking the plastic debris flux to the US coastline in Jambeck et al. (2015), one may obtain a straw leakage flux of 3.6–9.8 million straws per year. This rate is far less than 1% of 500 million straws consumed per day (Table 1), further validating that the environmental trade-off between PP straws and PLA or PA straws can be quantitatively represented by the difference of REI values between PP straws and PA or PLA straws (Fig. 4) or scaled off from category specific analyses (Fig. 2, Fig. 3).

Regarding degradation of straws in the marine environment, plastic and paper represent the two extremes in the spectrum with plastic being non-degradable and paper being the complete marine degradable material (Chamas et al., 2020; Chitaka et al., 2020). PLA, albeit hydrolysable, is much more resistant to degradation under the ambient marine environment than with compost or landfill (Chamas et al., 2020; Teixeira et al., 2021). Chamas et al. (2020) further indicated that the degradation rate of PLA was not significantly higher than for PP due to lack of thermal energy for depolymerization in the marine environment. However, there are also reports demonstrating that UV light, wave action, and marine sediment may accelerate PLA degradation with about 20–100% weight loss within a year (Beltran-Sanahuja et al., 2020; Teixeira et al., 2021). Given their tendency to float in seawater and thus slow degradation, PLA straws may still pose similar physical threats to marine life, albeit not as persistent as PP straws, after released into the marine environment. If marine litter impact is treated as a category as in Eq. (1), it is reasonable to assign marine litter category REI as 1 for PP straws, 0 for PA straws, and about 0.5 for PLA straws. Adding these marine litter REI values to the composite REI in Fig. 4 still would not make the REI value of PP straws larger than for PLA or PA straws. For the landfill option, a weighting factor of 2.7 or 4.5 would be needed for marine litter impact to break even with REI between PP straws and PA or PLA straws, respectively.

While the real benefit of replacing PP straws with one comprised of PLA and PA to control plastic straws related marine litter lies primarily in the environmental value endowed by the society, such management and policy decisions should be made with a careful consideration of all the LCA impacts. Our results demonstrate that the use of alternative disposable straws, which are commonly considered as the ‘greener’ replacements for controlling marine plastic pollution, would come with a trade-off for more impacts to the environment in other categories, supporting comparative LCA studies between plastic products and their paper and/or degradable counterparts (Boonniteewanich et al., 2014; Muthu et al., 2009). The reason for greater environmental impacts from PLA and PA straws in other categories are perhaps associated with much higher total pollutant emissions in manufacturing PLA and PA straws than PP straws, especially considering lower weight of a PP straw (0.52 g) than a PLA straw (0.81 g) and a PA straw (1.15 g). The LCA results of the percentage contribution of the straw life cycle reveal that the biggest contributors among the eight impact potentials come mostly from the production of feedstock materials (Table 2, Table 3). In the case of PP straws, the impacts would be through production of PP resins from natural gas and crude oil. Zanghelini et al. (2020) also found that raw material acquisition (as PP polymer chain) is the main driver for all impact categories of the life cycle of PP straw in Brazil. In contrast, the production of polypropylene is significantly more carbon-intensive in South African whereby coal is the primary energy source for electricity generation (Chitaka et al., 2020). Herberz et al. (2020) further noted that a single-use plastics ban would decrease plastic marine pollution in the EU by 5.5% accompanied with an increase in emissions contributing to marine aquatic toxicity by 1.4%. These authors concluded that single-use products made from plastic or other materials are all harmful to the environment, consistent with findings of this study.

3.3. End-of-life plastic straw management strategy

Today a large number of plastic straws are still being used and recycling is perhaps the most environmentally safe waste management option. Sensitivity analysis of plastic straw recycling in looping back to feedstock (Fig. 6) indicates that all the eight impact categories decrease almost linearly with the increase of PP straw recycling rate. When the recycling rate reaches 90%, the values of the eight categories decrease 70%–87%. These results confirm that recycling can greatly reduce the environmental impact of disposable PP drinking straws.

Fig. 6.

Effect of recycling rate on impact ratio of PP drinking straws with the base condition being 100% landfill of used plastic straws.

Although plastics recycling seems to be the most effective waste management strategy for disposable plastic drinking straws, the actual recycling rate may be low in both the US and around the globe (Geyer et al., 2017; USEPA, 2021). In the United States, plastic waste generation has increased dramatically since the 1980s, reaching about 32.4 million metric tons in 2018 (USEPA, 2021). About 75% of these plastic wastes reached landfills while 16% were combusted for energy recovery. In contrast, plastic recycling has remained at about 9% since 2010 though item specific waste recycling can be as high as 30%. The US plastics recycling rate is comparable to a global average of 9% recycling of 6300 million metric tons plastic wastes produced as of 2015 (Geyer et al., 2017). This low recycling rate is likely due to limitations in traditional plastics recycling technology, which involves mostly mechanical means for secondary melting and remolding of plastic waste into other forms of plastics, normally in lower grade. These recycled plastics will eventually face final disposal. Difficulties associated with high cost of sorting plastics by resin type, especially when materials are mixed during collection, further limit the mechanical or manual separation at a material recovery facility. Given the small sized and light weighted nature of PP straws, traditional recycling technology does not seem to be feasible or sufficient in meeting environmental management goals.

Advanced recycling techniques, called feedstock recycling, employ chemical means to completely breakdown plastics into its chemical components and then be polymerized back into fresh plastics, thereby closing the loop of the plastics life cycle with nearly infinite resource recovery (Lee and Liew, 2021). These recycling methods, albeit still requiring large scale industry level implementation, offer great potential in meeting environmental management goals (Fig. 6). Given the current 9% recycling rate, there is ample room for improvement of plastic waste recycling. In addition, a variety of microbial and fungal species also have been identified with enzymatic activity on various polymers including PP (Lee and Liew, 2021), though such techniques are still in their early stage of development. Given the environmental cost for replacing PP with PLA and PA in straws and further development needs of advanced recycling technology, a well-designed straw waste management strategy should continue to rely on education and outreach programs to raise environmental awareness and to change social norms of littering habits to model a lifestyle and behavior for protection of human health and the environment.

4. Conclusions

Advocating the use of paper or PLA straws as alternatives of plastic straws requires a holistic evaluation of the environmental costs and benefits. This LCA study concludes that replacing PP straws by PLA and PA straws for abatement of plastic marine pollution in the United States would come with more environmental costs in other impact categories. The composite relative environmental impact index developed in this study, which is insensitive to varying marine litter rate, provides a direct means for such comparison and trade-off analysis. Findings of this study should also be applicable to other single-use items, especially disposable plastics. Focused data collection programs are strongly needed for future LCA studies to establish a quantitative relationship between marine litter rate, fate and transport of plastic debris in the marine environment, and the extent to which a species’ population may be affected.

Acknowledgements

The authors would like to than Dr. D.E. Meyer for providing constructive review of an early version of the manuscript. The research presented was not performed for or funded by EPA and thus not subject to EPA’s quality system requirements. The views expressed in this article are those of the authors and do not necessarily reflect the views or policies of the U.S. Environmental Protection Agency.

Footnotes

Declaration of competing interest

The authors, Angela Gao and Yongshan Wan, hereby declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Agamuthu P, Ragossnig AM, Velis C, 2019. Publishing impactful interdisciplinary wasterelated research on global challenges: circular economy, climate change and plastics pollution. Waste Manag. Res. 37, 313–314. [DOI] [PubMed] [Google Scholar]

- Beltran-Sanahuja A, Casado-Coy N, Simo-Cabrera L, Sanz-Lazaro C, 2020. Monitoring polymer degradation under different conditions in the marine environment. Environ. Pollut. 259. [DOI] [PubMed] [Google Scholar]

- Boonniteewanich J, Pitivut S, Tongjoy S, Lapnonkawow S, Suttiruengwong S, 2014. Evaluation of carbon footprint of bioplastic straw compared to petroleum based straw products. Energy Procedia 56, 518–524. [Google Scholar]

- Borenstein S, 2018. Science says: amount of straws, plastic pollution is huge. https://phys.org/news/2018-04-scienceamount-straws-plastic-pollution.html Accessed April 2021.

- Bucci K, Tulio M, Rochman CM, 2020. What is known and unknown about the effects of plastic pollution: a meta-analysis and systematic review. Econ. Appl 30. [DOI] [PubMed] [Google Scholar]

- Caverly IT, 2019. Water, water everywhere, but not a straw to drink: how the Americans with disabilities act serves as a limitation on plastic straw bans. Iowa Law Rev. 105, 369–397. [Google Scholar]

- Chamas A, Moon H, Zheng JJ, Qiu Y, Tabassum T, Jang JH, Abu-Omar M, Scott SL, Suh S, 2020. Degradation rates of plastics in the environment. ACS Sustain. Chem. Eng 8, 3494–3511. [Google Scholar]

- Chen HP, Wang YH, Sun X, Peng YK, Xiao L, 2020. Mixing effect of polylactic acid microplastic and straw residue on soil property and ecological function. Chemosphere 243. [DOI] [PubMed] [Google Scholar]

- Chitaka TY, Russo V, von Blottnitz H, 2020. In pursuit of environmentally friendly straws: a comparative life cycle assessment of five straw material options in South Africa. Int. J. Life Cycle Assess. 25, 1818–1832. [Google Scholar]

- Conservancy O, 2017. In: Conservancy O (Ed.), International Coastal Cleanup 2017 Report Washington, DC. [Google Scholar]

- Danopoulos E, Jenner LC, Twiddy M, Rotchell JM, 2020. Microplastic contamination of seafood intended for human consumption: a systematic review and meta-analysis. Environ. Health Perspect. 128. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dhaliwal H, Browne M, Flanagan W, Laurin L, Hamilton M, 2014. A life cycle assessment of packaging options for contrast media delivery: comparing polymer bottle vs. glass bottle. Int. J. Life Cycle Assess. 19, 1965–1973. [Google Scholar]

- ETH V, Da G, Jj K, Rj W, Rp OC, 2007. ORIGINAL RESEARCH: the eco-profiles for current and nearfuture NatureWorks® polylactide (PLA) production. Ind. Biotechnol. 3, 58–81. [Google Scholar]

- Garrido N, del Castillo MDA, 2007. Environmental evaluation of single-use and reusable cups. Int. J. Life Cycle Assess. 12, 252–256. [Google Scholar]

- Geyer R, Jambeck JR, Law KL, 2017. Production, use, and fate of all plastics ever made. Sci. Adv. 3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ghomi ER, Khosravi F, Ardahaei AS, Dai YQ, Neisiany RE, Foroughi F, Wu M, Das O, Ramakrishna S, 2021. The life cycle assessment for polylactic acid (PLA) to make it a low-carbon material. Polymers-Basel 13. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gibbens S, 2019. A brief history of how plastic straws took over the world. National Geographic; Accessed April, 2021 https://www.nationalgeographic.com/environment/article/news-plastic-drinking-straw-history-ban. [Google Scholar]

- Gouin T, 2020. Toward an improved understanding of the ingestion and trophic transfer of microplastic particles: critical review and implications for future research. Environ. Toxicol. Chem. 39, 1119–1137. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Guinée J, 2002. Handbook on Life Cycle Assessment Operational Guide to the ISO Standards. Springer; Netherlands. [Google Scholar]

- Herberz T, Barlow CY, Finkbeiner M, 2020. Sustainability assessment of a single-use plastics ban. Sustainability-Basel 12. [Google Scholar]

- Hischier R, 2007. Life Cycle Inventories of Packaging and Graphical Paper, Final Report Ecoinvent Data v2.0 No. 11. Swiss Centre for Life Cycle Inventories, Dübendorf, CH. [Google Scholar]

- Hogue C, 2018. EU moves closer to the last (plastic) straw. Chem. Eng. News 96 18–18. [Google Scholar]

- ISO, 2006. ISO 14040: Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization, Genève, Switzerland: ISBN 978–970-580–48992-48991. [Google Scholar]

- Jambeck JR, Geyer R, Wilcox C, Siegler TR, Perryman M, Andrady A, Narayan R, Law KL, 2015. Plastic waste inputs from land into the ocean. Science 347, 768–771. [DOI] [PubMed] [Google Scholar]

- Jepsen EM, de Bruyn PJN, 2019. Pinniped entanglement in oceanic plastic pollution: a global review. Mar. Pollut. Bull. 145, 295–305. [DOI] [PubMed] [Google Scholar]

- Kim YN, Yoon JH, Kim KH, 2020. Microplastic contamination in soil environment - a review. Soil Sci. Annu. 71, 300–308. [Google Scholar]

- Kuhn S, van Oyen A, Booth AM, Meijboom A, van Franeker JA, 2018. Marine microplastic: preparation of relevant test materials for laboratory assessment of ecosystem impacts. Chemosphere 213, 103–113. [DOI] [PubMed] [Google Scholar]

- Law CFIE, 2019. Plastic & Health: The Hidden Costs of a Plastic Planet (February 2019).

- Lee A, Liew MS, 2021. Tertiary recycling of plastics waste: an analysis of feedstock, chemical and biological degradation methods. J. Mater. Cycles Waste Manage. 23, 32–43. [Google Scholar]

- Li PH, Wang XD, Su M, Zou XY, Duan LL, Zhang HW, 2021. Characteristics of plastic pollution in the environment: a review. Bull. Environ. Contam. Toxicol. 107, 577–584. 10.1007/s00128-020-02820-1. [DOI] [PubMed] [Google Scholar]

- Margallo M, Taddei MBM, Hernandez-Pellon A, Aldaco R, Irabien A, 2015. Environmental sustainability assessment of the management of municipal solid waste incineration residues: a review of the current situation. Clean Techn. Environ. Policy 17, 1333–1353. [Google Scholar]

- Moy CH, Tan LS, Shoparwe NF, Shariff AM, Tan J, 2021. Comparative study of a life cycle assessment for bio-plastic straws and paper straws: Malaysia’s perspective. Processes 9. [Google Scholar]

- Muthu SS, Li Y, Hu J-Y, Mok P-Y, 2009. An exploratory comparative study on ecoimpact of paper and plastic bags. Bioeng. Inform. 1, 307–320. [Google Scholar]

- Nanda S, Berruti F, 2021. Municipal solid waste management and landfilling technologies: a review. Environ. Chem. Lett. 19, 1433–1456. [Google Scholar]

- Nazareth M, Marques MRC, Leite MCA, Castro ÍB, 2019. Commercial plastics claiming biodegradable status: is this also accurate for marine environments? J. Hazard. Mater. 366, 714–722. [DOI] [PubMed] [Google Scholar]

- Rana K, 2020. Plasticless: A Comparative Life-cycle, Socio-economic, and Policy Analysis of Alternatives to Plastic Straws. Michigan Technological University, Houghton, MI: MS Thesis. [Google Scholar]

- Teixeira S, Eblagon KM, Miranda F, Pereira MFR, Figueiredo JL, 2021. Towards controlled degradation of poly(lactic) acid in technical applications. C-J. Carbon Res. 7. [Google Scholar]

- Tessnow-vonWysocki I, Le Billon P, 2019. Plastics at sea: treaty design for a global solution to marine plastic pollution. Environ. Sci. Policy 100, 94–104. [Google Scholar]

- Urquhart K, 2019. CANADIAN-MADE PAPER STRAWS an Ontario company is bringing its drinking straws made of Canadian pulp to market. Pulp Pap. Can. 120, 24–25. [Google Scholar]

- USEPA, 2021. Plastics: material-specific data. US Environmental Protection Agency; Accessed April 2021 https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/plastics-material-specific-data. [Google Scholar]

- Viera JSC, Marques MRC, Nazareth MC, Jimenez PC, Castro IB, 2020. On replacing single-use plastic with so-called biodegradable ones: the case with straws. Environ. Sci. Policy 106, 177–181. [Google Scholar]

- Vink ET, Glassner DA, Kolstad JJ, Wooley RJ, O’Connor RP, 2007. The eco-profiles for current and near-future NatureWorks polylactide (PLA) production. Ind. Biotechnol. 3 (1), 58–81. [Google Scholar]

- Wagner TP, Toews P, 2018. Assessing the use of default choice modification to reduce consumption of plastic straws. Detritus 4, 113–121. [Google Scholar]

- Waldschlager K, Lechthaler S, Stauch G, Schuttrumpf H, 2020. The way of microplastic through the environment - application of the source-pathway-receptor model (review). Sci. Total Environ. 713. [DOI] [PubMed] [Google Scholar]

- Weinstein JE, Crocker BK, Gray AD, 2016. From macroplastic to microplastic: degradation of high-density polyethylene, polypropylene, and polystyrene in a salt marsh habitat. Environ. Toxicol. Chem. 35, 1632–1640. [DOI] [PubMed] [Google Scholar]

- Wilcox C, Mallos NJ, Leonard GH, Rodriguez A, Hardesty BD, 2016. Using expert elicitation to estimate the impacts of plastic pollution on marine wildlife. Mar. Policy 65, 107–114. [Google Scholar]

- Wilcox C, Puckridge M, Schuyler QA, Townsend K, Hardesty BD, 2018. A quantitative analysis linking sea turtle mortality and plastic debris ingestion. Sci. Rep.-Uk 8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Woods JS, Rodder G, Verones F, 2019. An effect factor approach for quantifying the entanglement impact on marine species of macroplastic debris within life cycle impact assessment. Ecol. Indic. 99, 61–66. [Google Scholar]

- Zanghelini GM, Cherubini E, Dias R, Kabe YHO, Delgado JJS, 2020. Comparative life cycle assessment of drinking straws in Brazil. J. Clean. Prod 276. [Google Scholar]