Abstract

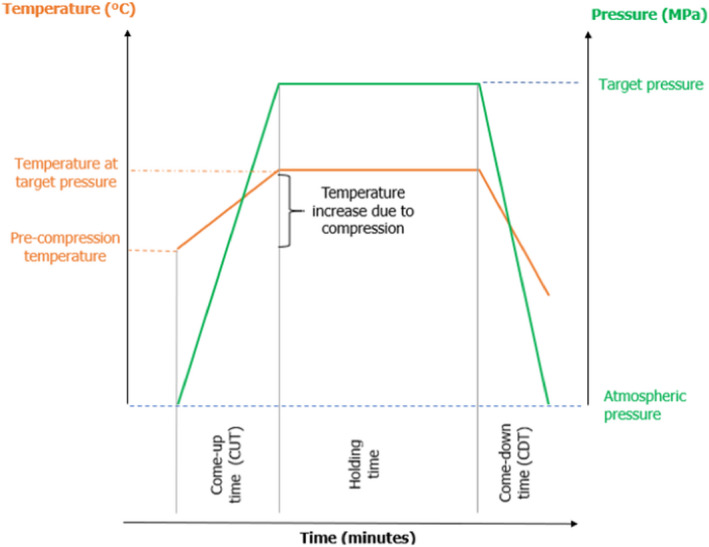

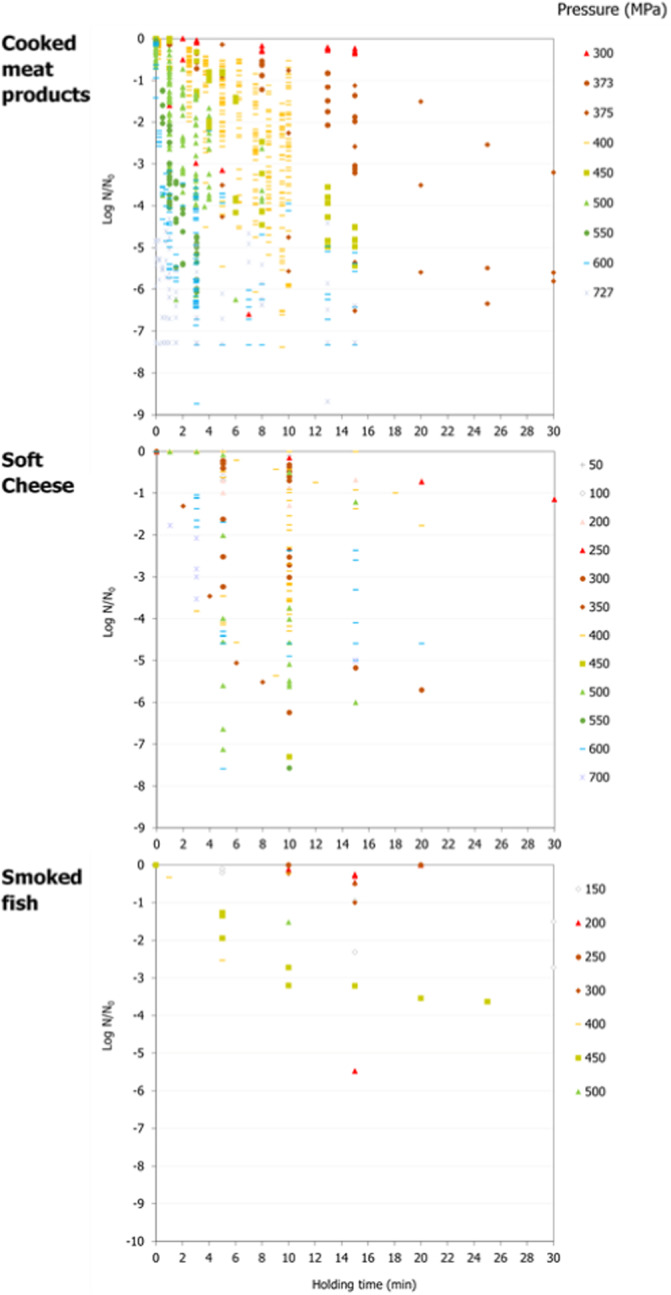

High‐pressure processing (HPP) is a non‐thermal treatment in which, for microbial inactivation, foods are subjected to isostatic pressures (P) of 400–600 MPa with common holding times (t) from 1.5 to 6 min. The main factors that influence the efficacy (log10 reduction of vegetative microorganisms) of HPP when applied to foodstuffs are intrinsic (e.g. water activity and pH), extrinsic (P and t) and microorganism‐related (type, taxonomic unit, strain and physiological state). It was concluded that HPP of food will not present any additional microbial or chemical food safety concerns when compared to other routinely applied treatments (e.g. pasteurisation). Pathogen reductions in milk/colostrum caused by the current HPP conditions applied by the industry are lower than those achieved by the legal requirements for thermal pasteurisation. However, HPP minimum requirements (P/t combinations) could be identified to achieve specific log10 reductions of relevant hazards based on performance criteria (PC) proposed by international standard agencies (5–8 log10 reductions). The most stringent HPP conditions used industrially (600 MPa, 6 min) would achieve the above‐mentioned PC, except for Staphylococcus aureus. Alkaline phosphatase (ALP), the endogenous milk enzyme that is widely used to verify adequate thermal pasteurisation of cows’ milk, is relatively pressure resistant and its use would be limited to that of an overprocessing indicator. Current data are not robust enough to support the proposal of an appropriate indicator to verify the efficacy of HPP under the current HPP conditions applied by the industry. Minimum HPP requirements to reduce Listeria monocytogenes levels by specific log10 reductions could be identified when HPP is applied to ready‐to‐eat (RTE) cooked meat products, but not for other types of RTE foods. These identified minimum requirements would result in the inactivation of other relevant pathogens (Salmonella and Escherichia coli) in these RTE foods to a similar or higher extent.

Keywords: High‐pressure processing, microbial inactivation, food, milk, ready‐to‐eat products, safety concern

Summary

Following a request from the European Commission, the Scientific Panel on Biological Hazards (BIOHAZ) was asked to provide a scientific opinion on the efficacy and safety of high‐pressure processing (HPP) of food. It was clarified that high‐pressure homogenisation and multipulsed HPP are out of scope of the assessment. HPP was considered a non‐thermal treatment (with product temperature < 45°C during the treatment) to be applied at different points in the food processing and preservation chain aiming to achieve microbial inactivation, particularly of pathogenic vegetative bacteria, to improve food safety.

In Term of Reference 1 (ToR1), EFSA was requested to assess the efficacy and microbiological and chemical safety of the use of HPP when applied to relevant foodstuffs. This ToR consisted of three subquestions.

ToR1a provides an overview of the foods to which HPP is or could be applied along with the processing conditions (e.g. pressure, time, temperature). The food categories/foods to increase microbiological food safety were considered, placing the focus on those foods that are being commercially subjected to HPP in the EU. A literature search and questionnaire were used. The latter consisted of questions related to the products being treated using HPP along with their processing conditions (for establishments) as well as the relative importance and recommendations for HPP (for equipment providers). Competent authorities (CA) were asked to provide information about evaluations of the impact of HPP on food safety. It was concluded that almost all types of food can be treated with HPP, although low moisture food is not usually treated with this technology due to low microbial inactivation when the water content is below 40%. The relative importance of the food type being treated with HPP in comparison to other food types for which HPP is used was ranked based on the information obtained from the questionnaire. Within the industrial context, pressures of between 400 and 600 MPa are most often applied for microbial inactivation, with common holding times ranging from 1.5 to 6 min.

ToR1b focused on listing the food intrinsic and extrinsic factors that may influence the efficacy of HPP. Only the impact in terms of reduction (log10 units) of vegetative microorganisms has been covered, as non‐thermal HPP treatment does not inactivate spores. A literature search was conducted, and it was concluded that the main intrinsic (i.e. food related) factors that influence the efficacy of HPP of foodstuffs in terms of microbial reduction of vegetative microorganisms are the water activity (aw) and pH of the food. The main extrinsic (i.e. processing related) factors are the target pressure and the holding time. The type of microorganisms, taxonomic unit and strain and the physiological state of the microorganisms to be inactivated also affect the efficacy of HPP. The efficacy of HPP in different food matrices is variable due to the interactions between the intrinsic factors which makes it difficult to predict the efficacy of HPP in a complex food matrix thereby necessitating validation in real foods.

ToR1c required an evaluation of the potential chemical and microbiological food safety risks in HPP‐treated food compared to untreated food or food submitted to treatments, routinely applied to these foods with the purpose to increase microbiological food safety, if any. The microbiological food safety risks are referring to a physiological, biochemical or genetic effect on a pathogen that could result in an increased risk (e.g. potential activation of spores or prion infectivity), compared to other treatments routinely applied to these foods (e.g. thermal pasteurisation). The potential chemical food safety concerns addressed include the formation of process contaminants and food contact materials (FCM). The whole duration of the shelf‐life of the foods was considered. Information provided through the questionnaire, related to the awareness of any food safety problems originating from food subjected to HPP, was considered together with information retrieved using specific literature searches. It is judged 99–100% certain (almost certain), that HPP of food will not present any additional microbial food safety concerns to consumers when compared to other treatments routinely applied to these foods. It is judged, with more than 95% certainty, that mycotoxins and process contaminants evaluated in the scientific opinion will not present an increased concern due to HPP‐treated food intake compared to conventional food. It was also concluded that the use of HPP does not give rise to additional chemical food safety concerns from FCM in HPP‐treated food compared to food treated under similar temperature and time (T/t) conditions without HPP.

In ToR2, EFSA was requested to assess the efficacy of HPP when applied to raw milk and raw colostrum from ruminants. It was clarified that raw milk and colostrum from ruminants refer to cow, sheep, goat, camel and/or buffalo. This ToR consisted of three subquestions.

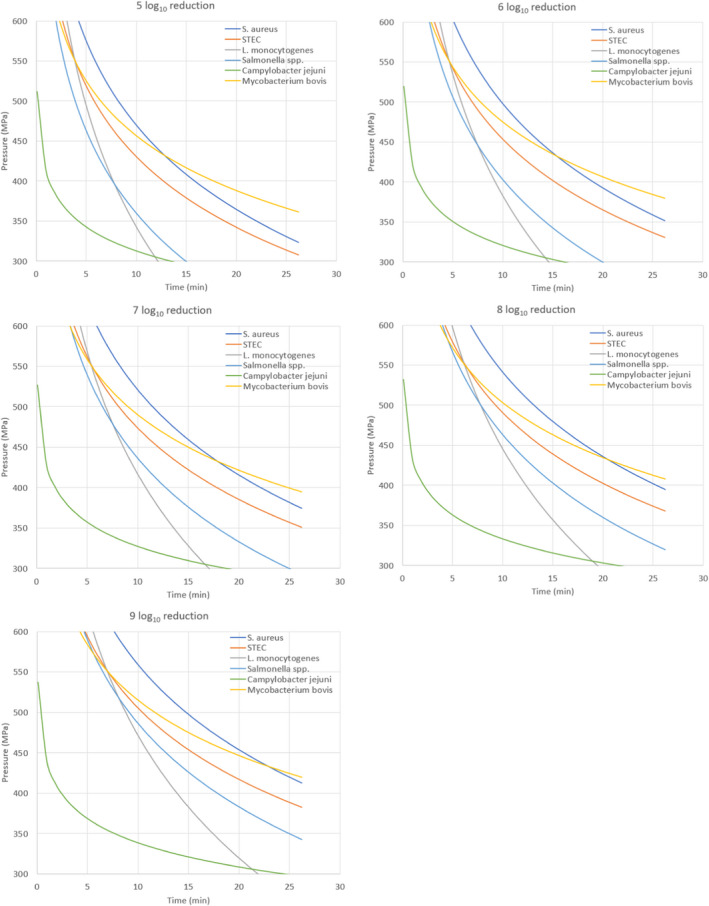

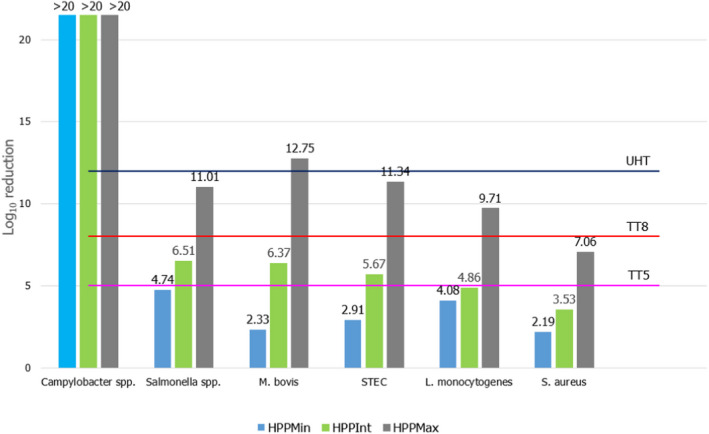

ToR2a focused on recommending minimum requirements as regards time and pressure of the HPP, and other factors if relevant, for the control of Mycobacterium spp., Brucella spp., Listeria monocytogenes, Salmonella spp. and Shiga toxin‐producing Escherichia coli (STEC), to achieve an equivalent efficacy to that of pasteurisation. The requestor clarified that other relevant pathogens may be added. Based on a previous scientific opinion (EFSA BIOHAZ Panel, 2015) and using food‐borne outbreak (FBO) data, it was concluded that the relevant additional hazards to be reduced by thermal pasteurisation of raw milk/colostrum from ruminants are Campylobacter spp., tick‐borne encephalitis virus (TBEV) and Staphylococcus aureus. The end point in the assessment is the raw milk/colostrum for direct human consumption and the minimum T/t requirements for thermal pasteurisation of milk according to EU legislation (i.e. at least 72°C for 15 s, at least 63°C for 30 min or equivalent) were applicable as reference condition. Thermal pasteurisation of milk according to these legal requirements is expected to result in more than 10 log10 reductions of most of the pathogens (i.e. STEC, L. monocytogenes, Salmonella spp., S. aureus and Campylobacter spp.), while lower reductions are expected for Brucella spp. and M. bovis (using Mycobacterium avium subsp. paratuberculosis (MAP) as surrogate) and even lower for TBEV for which there is a significant lack of data. HPP cannot achieve equivalent log10 reductions to those achieved by thermal pasteurisation of milk according to these legal requirements, but target pressure–holding time (P/t) combinations can be identified that achieve lower log10 reductions (i.e. 5, 6, 7 and 8 log10 reductions) as pasteurisation performance criteria (PC) recommended by international agencies. For STEC, L. monocytogenes, Salmonella spp., S. aureus and Campylobacter spp., it is judged 99–100% certain (almost certain) that the PC of 8 log10 reduction is achieved using thermal pasteurisation of raw milk and by HPP treatment of raw milk/colostrum by using defined P/t combinations. For example, by using 600 MPa – 8 min, 550 MPa – 10 min and 500 MPa – 15 min for S. aureus, the most HPP resistant of these biological hazards. For M. bovis, it is judged 95–99% certain (extremely likely) that the PC of 5 log10 reduction is met using thermal pasteurisation of milk. This 5 log10 reduction can be achieved with 99–100% certainty (almost certain) by HPP treatment of raw milk/colostrum using, e.g. 600 MPa – 2.5 min, 550 MPa – 4.5 min and 500 MPa – 7.5 min. For B. melitensis and TBEV, minimum HPP requirements could not be set due to the lack of data. The most stringent HPP condition currently used industrially (600 MPa for 6 min), based on the information collected, would achieve the PC (i.e. 5 logs for M. bovis and 8 logs for S. aureus, STEC, L. monocytogenes, Salmonella spp. and Campylobacter spp.), except for S. aureus as this HPP condition would achieve 6 log10 reductions.

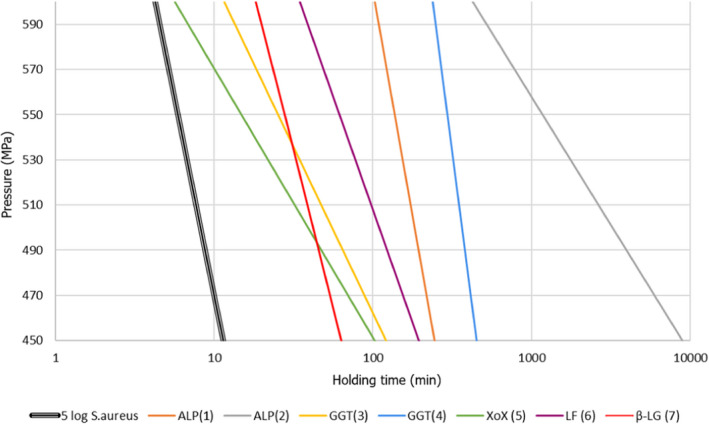

ToR2b gives an overview of appropriate indicators to verify the efficacy of HPP, either as part of the validation and verification in the HPP facility and/or in the end‐product on the market. A literature search was conducted, and the screening considered whether the record contained information about the effect of HPP on an inherent milk/colostrum component that could serve as an indicator for pasteurisation. Raw milk/colostrum of all animal and human milk was considered, although the focus was on ruminant milk/colostrum. It was concluded that alkaline phosphatase, the endogenous milk enzyme that is widely used to verify adequate thermal pasteurisation of cows’ milk, is relative pressure resistant and its use would be limited to that of an overprocessing indicator, while inactivation of other milk enzymes (γ‐glutamyltransferase or xanthine oxidase) or denaturation of some whey proteins (β‐lactoglobulin, lactoferrin) would occur at HPP processing conditions closer to those necessary for the 5 log10 inactivation of S. aureus. Nevertheless, based on available evidence, it is judged 90–95% certain (very likely) that none of the evaluated indicators can currently be proposed as an appropriate indicator to be used under the technologically and commercially feasible HPP conditions applied by the industry (400 and 600 MPa for 1.5–6 min).

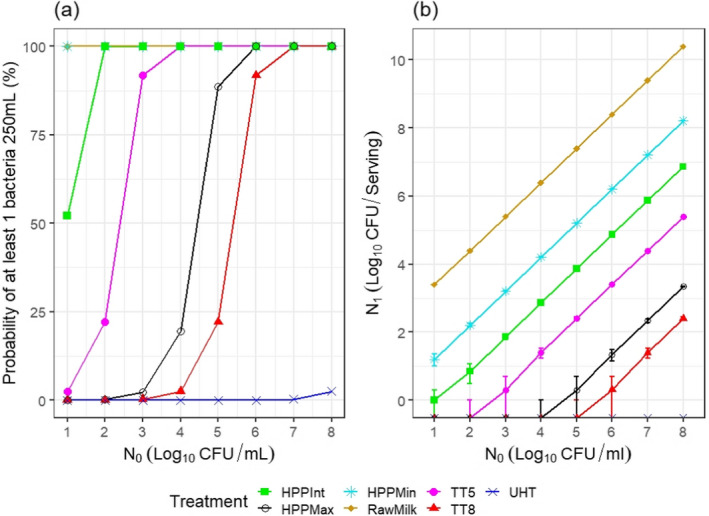

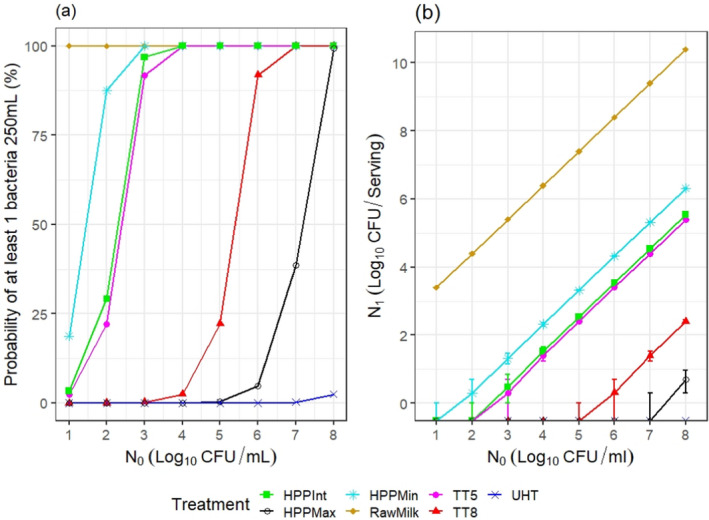

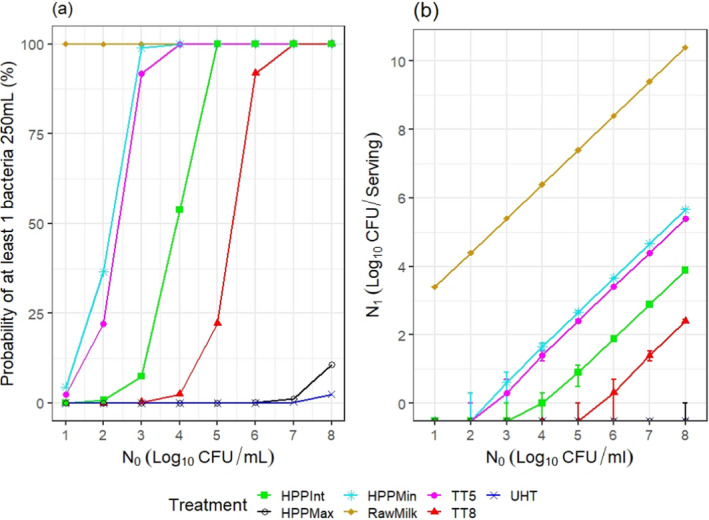

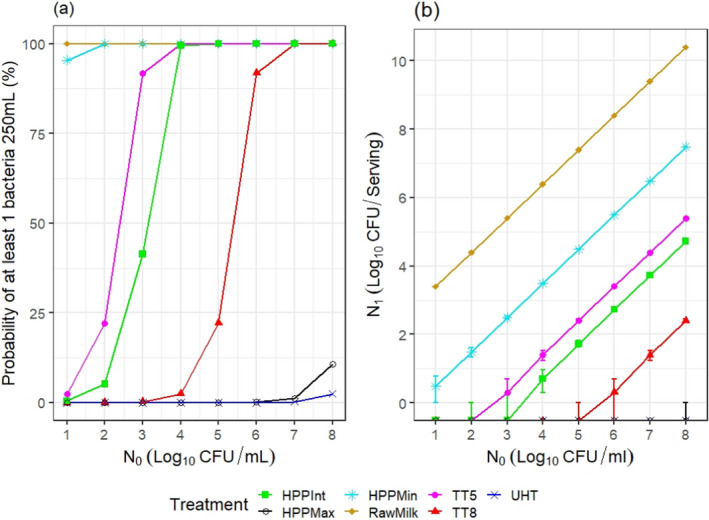

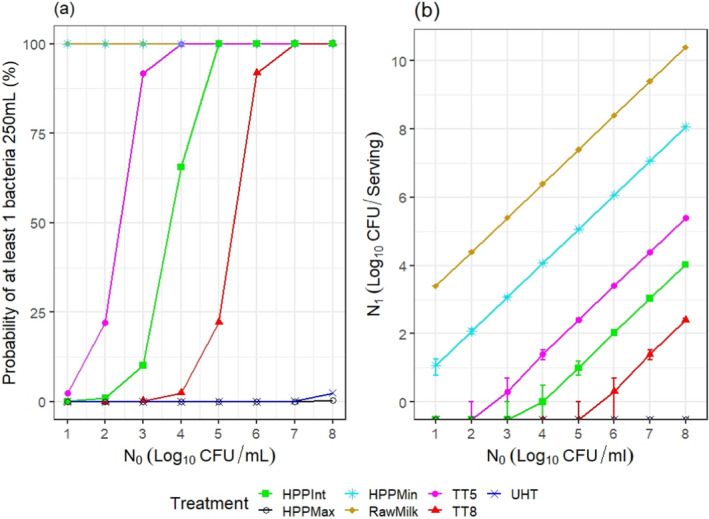

ToR2c provides a comparative assessment of the risk to human health that could derive from the consumption of HPP‐treated vs. raw vs. pasteurised vs. ultra‐high temperature (UHT)‐treated milk or colostrum. A comparative assessment was undertaken of the relative levels of exposure to selected pathogens from the consumption of the four types of milk, for those pathogens for which it was possible to estimate the log10 reductions resulting from both HPP and thermal treatments. A model was used to estimate the level of contamination in a serving of 250 mL of milk and the probability of a serving being contaminated (carrying at least one CFU), immediately after treatment. The batch to be treated was considered to be contaminated, although, for each pathogen, scenarios of fixed theoretical levels of initial contamination ranging from 1 to 8 log10 CFU/mL were assumed. It was concluded that even the most stringent HPP condition used industrially (600 MPa for 6 min) would lead to less log10 reductions compared to UHT milk (considered to achieve 12 log10 reductions), except for Campylobacter spp. The impact of these reductions on the relative levels of exposure depend on the initial contamination levels. Even the least stringent HPP condition used industrially (450 MPa for 5 min) leads to a lower probability of exposure to contaminated servings to all pathogens than raw milk. Comparative assessments could not be made for pathogens in colostrum and for Brucella spp. or TBEV in milk due to lack of HPP and/or thermal inactivation data. When comparing to thermally pasteurised milk, considering the minimum and maximum PC recommended by international agencies (i.e. 5 and 8 log10 reductions), the HPP conditions assessed (500 MPa – 5 min, 600 MPa – 3 min or 600 MPa – 6 min) as well as the initial contamination levels of milk have an impact on the outcome of the comparative exposure assessment. For all relevant pathogens, except for S. aureus, present in milk at initial contamination levels below 5 log10 CFU/mL, the most stringent HPP condition used industrially would lead to such high log reduction that more than 99 out of 100 servings would not be contaminated. The public health significance of a small number of surviving bacteria after HPP could not be estimated due to lack of data.

In ToR3, EFSA was requested to assess the efficacy of HPP when applied to foods known to cause human listeriosis. First, the ready‐to‐eat (RTE) foods were identified considering those known to be associated with human listeriosis in the EU based on previous scientific opinions (EFSA BIOHAZ Panel, 2018, 2020b) and FBO data, and relevant to be treated by HPP. The RTE foods identified were within the categories of cooked meat products, soft and semi‐soft cheese, fresh cheese and smoked or gravad fish. Frozen vegetables are currently not treated with HPP because of its detrimental effects on the structure of the product.

Furthermore, this ToR consisted of two subquestions.

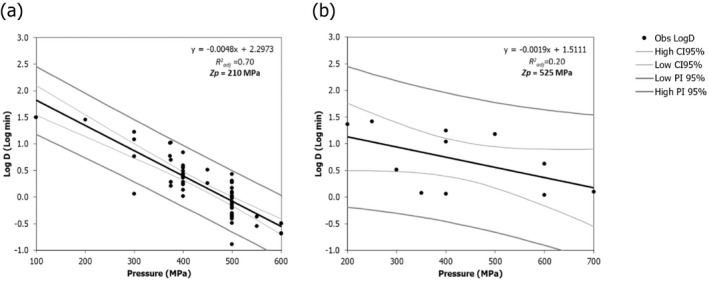

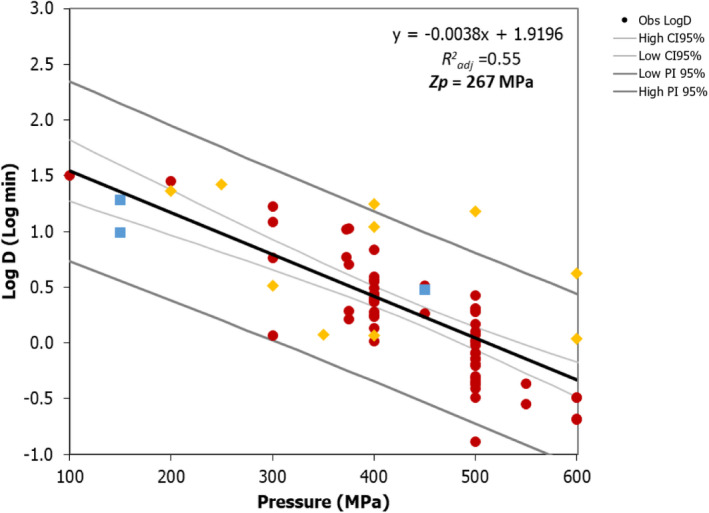

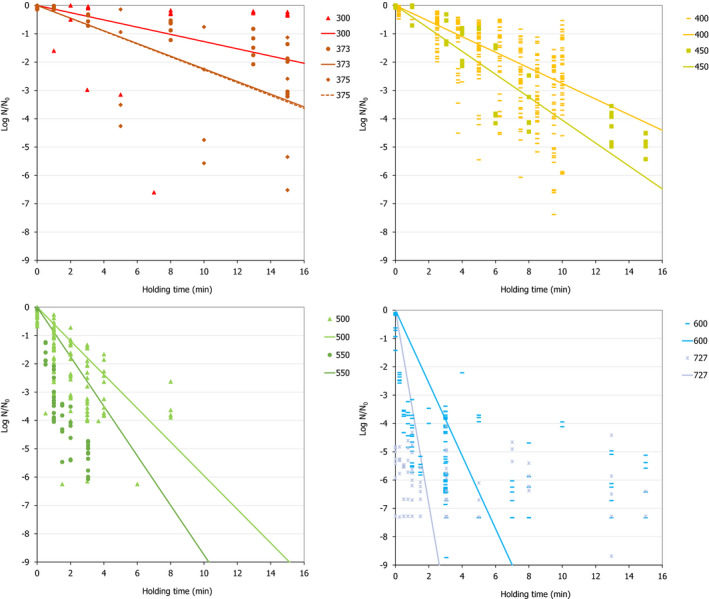

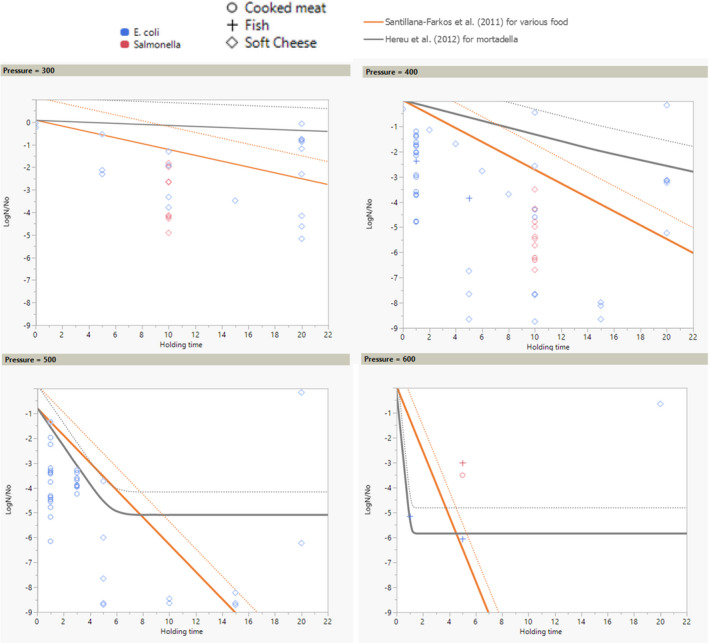

ToR3a focused on recommending minimum requirements as regards of time and pressure of the HPP, and other factors if relevant, to reduce significantly L. monocytogenes levels and assuming that the parameters influencing the growth of L. monocytogenes remain unchanged. The minimum HPP requirements to reduce L. monocytogenes in the selected RTE food categories were estimated through the calculation of the equivalent P/t combinations required for achieving a target log10 reduction, in the form of isoreduction plots. The model developed by Santillana Farakos and Zwietering (2011) including pressure and time was used. This model was built through a meta‐analysis of literature data for Listeria spp. in various food treated at 200–700 MPa. Minimum requirements to reduce L. monocytogenes levels by specific log10 reductions could be identified when HPP is applied to RTE cooked meat products. For example, a reduction of more than 2 log10 could be achieved on RTE cooked meat products applying 600 MPa‐2.3 min, 550 MPa‐3.4 min and 500 MPa‐5.0 min while more than 5 log10 reductions could be achieved by extending the holding times and by applying 600 MPa‐4.7 min, 550 MPa‐6.9 min and 500 MPa‐10.1 min. For the other types of RTE foods, generic minimum HPP requirements could not be set and specific validation studies following international guidelines are needed for each specific food.

ToR3b required an assessment of the efficacy on other relevant pathogens when applying the identified minimum requirements. From FBO data, Salmonella spp. and pathogenic E. coli were identified as the most important relevant hazards (i.e. apart from L. monocytogenes), in the above listed foods known to be associated with human listeriosis. The microbial reduction for these other two pathogens was assessed from data gathered through a literature search. It was concluded that, in the RTE foods considered, these pathogens are generally more sensitive to HPP than L. monocytogenes and it is judged 66–90% certain (likely) they will be inactivated to a similar or higher extent than L. monocytogenes.

It is recommended that future research on the impact of intrinsic factors on the efficacy of HPP treatments should consider interactions of different components and these studies should be undertaken in real food matrices. Further, it is recommended to perform an in‐depth analysis on the effect of HPP treatments on inherent compounds in milk or colostrum for which a significant effect is found at P/t combinations intended to be used for pasteurisation. Studies on pathogen behaviour in milk and colostrum during storage after HPP should be performed. Further research is required on HPP inactivation of L. monocytogenes and other relevant pathogenic bacteria for RTE foods (as smoked and gravad fish and soft/semi‐soft cheese) from a quantitative perspective which could facilitate the construction of a suitable predictive model to set the generic minimum requirements for HPP to assure the food safety of these food products.

1. Introduction

1.1. Background and Terms of Reference as provided by the requestor

High pressure processing (HPP), also referred as high‐hydrostatic pressure processing (HHP) or ultra‐high‐pressure processing (UHP) is a non‐thermal technique of food preservation that inactivates pathogens and vegetative spoilage organisms. HPP subjects liquid and solid foods usually to pressures of about 400 to 600 MPa at refrigeration or mild process temperatures (< 45°C). It has minimal effects on taste, texture, appearance or nutritional value (Muntean et al., 2016).

HPP is applied mainly to pre‐packed juices, sauces, dips, fishery products, meat products and ready‐to‐eat meals (RTE). There is also an increasing interest for the use of HPP of milk as an alternative for pasteurisation.

HPP is not specifically regulated at EU level. Overall food safety requirements such as good hygiene practices (GHP), procedures based on the Hazard Analysis and Critical Control Point (HACCP) principles, traceability and labelling requirements apply. HPP is considered as processing within the meaning of Regulation (EC) No 852/20041, and standalone establishments carrying out HPP on products of animal origin are subject to approval. Clarification on the implementation of hygiene requirements in case of HPP have been recently introduced under section 9.6 of the Guidance document on the implementation of certain provisions of that Regulation.2

The efficacy of HPP treatments will be dependent on the pressure applied, the holding time and temperature, the characteristics of the food and the target microorganism. Some possible food safety concerns have been described in scientific literature.

The European Commission funded research on HPP for example under the FP6 a project called “Hipster” and under FP7 a project called “High Tech Europe”, from which the internet portal is available at respectively https://hipster‐project.eu/ and https://www.foodtech‐portal.eu/index.php?title=Categorv:Technology_Sheet.

Apart from an overall assessment on the efficacy and safety of HPP of the food categories described above, it is appropriate to provide a more detailed assessment on the use of HPP for two specific purposes: as an alternative for pasteurisation and ultra‐high temperature (UHT) treatment of raw milk and raw colostrum, and for the control of Listeria monocytogenes in RTE foods.

When raw milk, colostrum, dairy or colostrum‐based products undergo heat treatment, such treatment must comply with the requirements in point II. 1 of Chapter II to Section IX of Annex III to Regulation (EC) No 853/20043. Specifically, these products need to be pasteurised achieving certain requirements (i.e. at least at 72°C for 15 s or at least at 63°C for 30 min or any other combination of temperature‐time (T/t) conditions to obtain an equivalent effect) or be subjected to UHT treatment. There is an increasing demand to allow HPP as an alternative treatment because it is expected to keep the properties closer to those of raw milk and colostrum.

L. monocytogenes contamination of RTE foods continues to be of public health concern in the EU. This was illustrated by EFSA in its recent scientific opinion on the risks to public health from consumption of RTE foods contaminated with L. monocytogenes.4 An increasing trend was found of the notified incidence rate of confirmed human invasive listeriosis cases in the EU/EEA over 2008‐2015 for the elderly (> 75 years old) and females between 25 and 44 years old (probably related to pregnancies). This increase likely resulted from an increased proportion of persons with underlying health conditions but may also have been caused by the rise in consumption of RTE foods and an improved surveillance in some Member States. The RTE foods typically associated with human listeriosis, such as smoked fish, heat‐treated meat and soft and semi‐soft cheese, continue to be of public health significance. However, yet unconsidered RTE food categories of plant‐derived origin, under certain conditions, can also support growth and have the potential to contribute to the burden of disease. The EU summary report on trends and sources of zoonoses, zoonotic agents and food‐borne outbreaks in 20185 and a recent L. monocytogenes outbreak due to frozen vegetables6 seem to confirm these conclusions. An ongoing EFSA opinion on L. monocytogenes in frozen fruit, vegetables and herbs, blanched during processing,7 primarily addresses control options during processing and consumption.

EFSA is asked to deliver a scientific opinion on the efficacy (reduction of the levels of food‐borne pathogens) and safety of HPP of food. Quality issues and organoleptic properties are not part of this mandate.

More specifically, EFSA is asked:

ToR1. To assess the efficacy and microbiological and chemical safety of the use of HPP when applied to relevant foodstuffs, and in particular:

To provide an overview of the foods to which HPP is or could be applied along with the processing conditions (e.g. pressure, time, temperature).

To list the intrinsic and extrinsic factors that may influence the efficacy of HPP.

To evaluate the potential chemical and microbiological food safety risks in HPP‐treated food compared to untreated food or food submitted to treatments, routinely applied to these foods with the purpose to increase microbiological food safety, if any (e.g. pasteurisation of juices).

ToR2. To assess the efficacy of HPP when applied to raw milk and raw colostrum from ruminants, and in particular:

To recommend minimum requirements as regards time and pressure of the HPP, and other factors if relevant, for the control of Mycobacterium spp., Brucella spp., L. monocytogenes, Salmonella spp. and Shiga toxin‐producing Escherichia coli (STEC), to achieve an equivalent efficacy to that of pasteurisation;

To propose appropriate indicators to verify the efficacy of HPP, either as part of the validation and verification in the HPP facility and/or in the end‐product on the market;

If data allow, to provide a comparative assessment of the risk to human health that could derive from the consumption of HPP‐treated vs. raw vs. pasteurised vs. UHT‐treated milk or colostrum.

ToR3. To assess the efficacy of HPP when applied to foods known to cause human listeriosis (e.g. RTE smoked or gravid fish, soft and semi‐soft cheese and cooked meat products and (blanched) frozen vegetables such as peas or corn that are consumed without prior cooking) and in particular:

To recommend minimum requirements as regards time and pressure of the HPP, and other factors if relevant, to reduce significantly L. monocytogenes levels (e.g. by a certain log reduction or reduction of the probability of illness per serving), and assuming that the parameters influencing the growth of L. monocytogenes remain unchanged (e.g. shelf‐life and storage conditions);

To assess the efficacy on other relevant pathogens when applying the minimum requirements identified in a.

1.2. Interpretation of the Terms of Reference

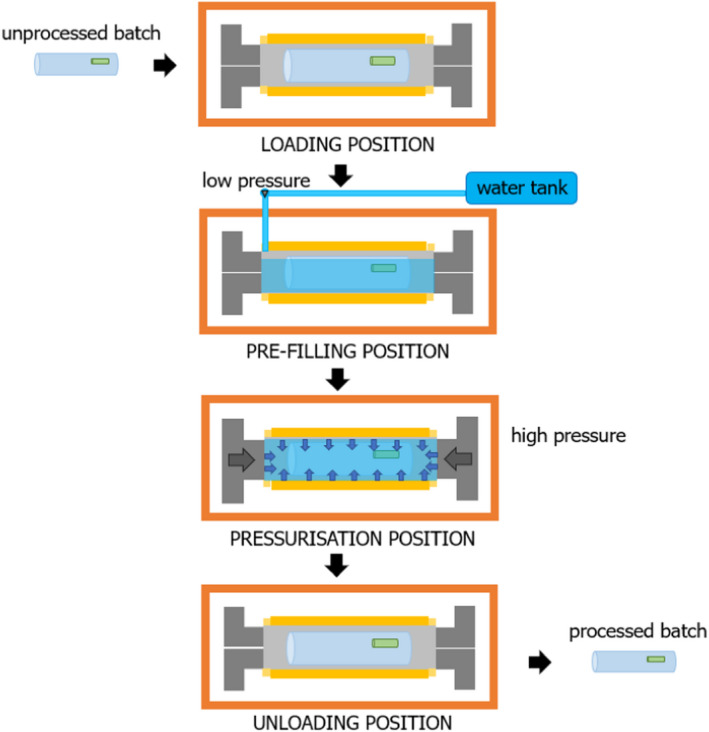

HPP is a non‐thermal treatment in which foods are subjected to isostatic pressures. Traditionally, this is an in‐batch process that can be applied to both solid and liquid prepacked foods. Pressure is transmitted rapidly and uniformly in an isostatic manner so that all parts of the food are subjected to the same pressure simultaneously. It was clarified with the requestor that high‐pressure homogenisation (HPH; also called dynamic high‐pressure homogenisation, dynamic‐HPH) is out of the scope of the assessment. HPH is based on the same principles as the homogenisation process used in the dairy industry for reducing the size of fat globules, but it works at higher pressures (100–400 MPa). Not only pressure, but the combined action of other physical effects (such as cavitation, shear stress, turbulence, impingement and temperature, that may increase due to friction) causes inactivation of vegetative microorganisms (Patrignani and Lanciotti, 2016).

Multipulsed HPP (mpHPP) treatment, with few exceptions, is more effective than the classical or single‐pulsed HPP (spHPP) treatment for inactivation of microorganisms in fruit juice, dairy products, liquid whole egg, meat products and sea foods (Buzrul, 2015). However, it is not likely to be applied commercially because it is a longer application and may significantly increase the wear and tear of the equipment and reduce the quality of the food (Buzrul, 2015; Colussi et al., 2018; Balakrishna et al., 2020), and for this reason, it is outside the scope of this assessment.

This scientific opinion will consider the HPP as a non‐thermal treatment and will not consider treatments causing an increase in product temperature above 45°C. Depending on the food composition, the temperature increase of the product might range from 2–3°C/100 MPa (in aqueous phase) to 8.7–9.7°C/100 MPa (in oil phase) (Rasanayagam et al., 2003; Patazca et al., 2007). The compression heating, which causes a (quasi)adiabatic increase of temperature, is completely reversible upon pressure release, but the temperature of the product does not return to the initial value, due to the heat transfer within the high‐pressure chamber and temperature equilibration during holding time (particularly for longer pressure holding times) (Ghafoor et al., 2020). As such, applications are excluded using either heat‐assisted HPP (referred to in this document as high‐pressure thermal processing or HPTP) (Sevenich and Mathys, 2018) or HPP where the maximum temperature of the product during the treatment exceeds 45°C, in which microbial inactivation may result partly or entirely from thermal energy.

Apart from its common application as a preservation technology, HPP has been applied in many other food technology processes and in the development of new products. These include but are not limited to freezing, enzyme control, cold gelatinisation of starch, protein unfolding, shucking of shellfish, enhancing mass transfer phenomena and even for promoting microbial growth under mild processing conditions, thus enhancing fermentation processes and reducing fermenting time (Barba et al., 2015; Ghafoor et al., 2020). The processing parameters (i.e. level of pressure, temperature and holding time) differ according to the targeted applications (Ghafoor et al., 2020). Within the food industry context, the main reason to apply HPP to a food matrix is the non‐thermal inactivation of pathogenic and spoilage vegetative microorganisms (Sevenich and Mathys, 2018) to increase microbiological safety and microbial shelf‐life of the processed food with, in general, minimal impact on thermally sensitive compounds (e.g. nutrients and vitamins) and sensory attributes. This scientific opinion will focus on the use of HPP for microbial inactivation, particularly of pathogenic vegetative bacteria, with the aim of improving food safety. Quality issues and sensory properties, as well as nutritional aspects are out of scope.

HPP can be applied at different points in the food processing and preservation chain. It can be applied to intact or minimally processed raw materials or products (e.g. milk, fruit juices, smoothies, dips, sauces) and as a final lethal in‐package treatment to reduce the potential recontamination of the food after the primary lethal treatment (e.g. thermal pasteurisation, cooking), due to post‐process handling, e.g. slicing of cooked meat products, preparation of RTE meals, etc. This is usually referred to as post‐lethality treatment. When HPP is applied to achieve pathogen inactivation as a control measure, it has to be integrated within the HACCP plan, as such, the efficacy of HPP has to be validated by demonstrating that the HPP conditions applied achieve the target inactivation of the relevant microorganism in the specific food product.

For most of the conventional HPP applications, foods are packaged before treatment (in‐package HPP), which is a discontinuous batch‐based process. For liquid food, semicontinuous production processing can be applied using equipment with small to medium vessels working in parallel followed by aseptic packaging (bottling). The liquid food is then in direct contact with the equipment parts (piston, vessel, plugs and seals). More recently, the so‐called ‘in‐bulk HPP’ has been developed using a large vessel (similar to in‐pack HPP). In this case, liquid food is processed in a flexible plastic bag with a volume and size similar to the vessel, allowing no direct contact with the steel parts of the equipment, followed by ultra clean/aseptic packaging (Tonello‐Samson et al., 2020).

Specifically, for ToR1a, the food categories/foods that are treated with HPP worldwide with the purpose to increase microbiological food safety will be considered, placing the focus on those foods that are being commercially processed by HPP in the EU.

For ToR1b, as the non‐thermal HPP treatment will be considered, for evaluating the factors that may influence the efficacy of HPP, only the impact on vegetative microorganisms will be covered, as this treatment does not inactivate spores.

For ToR1c, the microbiological food safety risks are not those for which the efficacy (pathogen reduction) is being evaluated. Instead, it is referring to a physiological, biochemical or genetic effect on a pathogen that could result in an increased risk e.g. potential activation of spores (germination) or prion infectivity (due to conformational change of prion proteins), compared to the food that was not HPP treated, as opposed to the risk reduction that is normally the goal of HPP treatment. The potential concerns will be contextualised to account for the potential food safety risks that are not exclusive of HPP. The whole duration of the shelf‐life of the foods is to be considered in the assessment of the potential chemical and microbiological food safety risks.

For ToR2, raw milk and colostrum from ruminants refer to cow, sheep, goat, camel and/or buffalo. For ToR2a, other relevant pathogens may be added, e.g. Campylobacter. The end point in the assessment is the raw milk or colostrum for direct human consumption. Its further use for other dairy products (e.g. for cheese or yoghurt production) is out of the scope of this scientific opinion. The efficacy of the processing conditions is of relevance (not the post‐processing contamination) considering the minimum time and temperature requirements for thermal pasteurisation of milk from legislation are applicable (as reference condition) to recommend minimum requirements as regards time and pressure of the HPP for the control of the relevant pathogens. UHT treatments will be considered only in ToR2c, where a comparative assessment will be undertaken of the relative levels of exposure to selected pathogens [or probability of illness, if data allow] from the consumption of pasteurised, UHT or HPP‐treated milk or colostrum.

For ToR3, the requestor clarified that the assessment should focus on ‘foods known to cause human listeriosis in the EU’, not on foods that could potentially cause listeriosis (based on the risk factors associated with the processing conditions, exposure to contamination, growth supporting characteristics, etc.) but have no recorded cases/outbreaks in the EU to date.

The ToRs have been translated into assessment questions (AQs). These are for ToR1 as follows:

AQ1/What are the (broad) food categories for which there is evidence that HPP could in principle be applied with the purpose of increasing microbiological food safety, focusing on those foods that are being commercially processed by HPP? What are the processing conditions (e.g. pressure, time, temperature) and packaging applied by the industry?

AQ2/What are the intrinsic (i.e. food‐related) and extrinsic (i.e. processing‐related) factors that may influence the efficacy of HPP in terms of reduction (log10 units) of vegetative microorganisms when applied to foodstuffs?

AQ3/What are the potential microbiological food safety concerns in HPP‐treated food compared to untreated food or food submitted to treatments, routinely applied to these foods, with the purpose of increasing microbiological food safety (e.g. thermal pasteurisation of milk)?

AQ4/What are the potential chemical food safety concerns through formation of process contaminants in HPP‐treated food compared to untreated food or food submitted to treatments, routinely applied to these foods with the purpose of increasing microbiological food safety?

AQ5/What are the potential chemical food safety concerns through food contact materials (FCM) in HPP‐treated food compared to untreated food or food submitted to treatments, routinely applied to these foods with the purpose of increasing microbiological food safety?

For ToR2, the AQs have been formulated as:

AQ6/What log10 reduction of Mycobacterium spp., Brucella spp., L. monocytogenes, Salmonella spp. and STEC (or other relevant vegetative pathogens) is achieved by thermal pasteurisation of raw milk and raw colostrum from ruminants according to the legal requirements?

AQ7/What are the minimum requirements of HPP (i.e. time and pressure and any other relevant factor) of raw milk and raw colostrum from ruminants to achieve an equivalent efficacy (in terms of log10 reduction) to that of thermal pasteurisation for the control of the pathogens deemed relevant according to AQ6?

AQ8/Which inherent components of the milk or colostrum could be used as appropriate indicators to verify the efficacy of HPP of raw milk and raw colostrum from ruminants, either as part of the validation and verification immediately after such treatment (e.g. in the processing plant) and/or in the end‐product on the market, considering the minimum requirements as defined in AQ7?

AQ9/What are the relative levels of exposure [or probability of illness, if data allow] for the pathogen(s) to be defined per serving through the consumption of industrially HPP‐treated milk or colostrum in comparison to raw vs. thermally pasteurised vs. UHT‐treated milk or colostrum [according to the legal requirements] [considering that the batch to be treated is contaminated]?

For ToR3, the AQs have been formulated as:

AQ10/What are the minimum requirements of HPP (i.e. time and pressure and any other relevant factor) when applied to the food categories known to be associated with human listeriosis to reduce significantly L. monocytogenes levels by specific log10 reductions, assuming that the parameters influencing the subsequent growth of L. monocytogenes remain unchanged (e.g. product characteristics, shelf‐life and storage conditions)?

AQ11/What is the efficacy (log10 reduction) on other relevant pathogens when applying the minimum requirements of HPP identified in AQ10?

1.3. Additional information

1.3.1. Approach to answer the ToRs

The approach to answer the ToRs was defined in advance and is described in the protocol (Annex A). It covers both the problem formulation (i.e. what the assessment aims to address) and which methods will be used for addressing the problem. The problem formulation (‘what’) includes the clarification of the mandate (see further refined in Section 1.2) and consists of the steps (1) translation of the mandate into scientifically answerable AQs, (2) definition of the subquestions (SQs) of each AQ and their relationship (conceptual model) and (3) the selection of the approach for the assessment. The planning of the methods for conducting the assessment (‘how’) consists of (1) specifying the evidence needs and the methods for answering each SQ, including uncertainty analysis and (2) the methods for integrating evidence across SQ and addressing of the remaining and overall uncertainty. Protocol development followed the draft framework for protocol development for EFSA’s scientific assessments (EFSA, 2020).

The SQs can be found below; their relationship can be found in the protocol.

SQ1 (for AQ1)/What are the (broad) food categories for which there is evidence that HPP could in principle be applied with the purpose of increasing microbiological food safety, focusing on those foods that are being commercially processed by HPP?

SQ2 (for AQ1)/What are the processing conditions (e.g. pressure, time, temperature) and packaging applied by industry?

SQ3 (for AQ2)/What are the intrinsic (e.g. food‐related) and extrinsic (e.g. processing‐related) factors that may influence the efficacy of HPP in terms of reduction (log10 units) of vegetative microorganisms when applied to foodstuffs?

SQ4 (for AQ3)/What are the potential microbiological food safety concerns in HPP‐treated food compared to untreated food or food submitted to treatments, routinely applied to these foods with the purpose to increase microbiological food safety?

SQ5 (for AQ4)/What is the effect of HPP‐treated foods, if any, on the levels of specific contaminants compared to untreated or conventionally treated foods?

SQ6 (for AQ4)/What would be the contributions of these levels to the total exposure to the specific contaminants?

SQ7 (for AQ5)/What is the effect of HPP, if any, on the migration potential (including diffusivity and partitioning effects) of FCM substances during the treatment, compared to migration from the FCM with the same food/simulant, t/T/surface area (SA), etc. but without HPP?

SQ8 (for AQ5)/What is the chemical effect of HPP, if any, during the treatment on the number and nature of reaction/degradation products (non‐intentionally added substances, NIAS) in/from the FCM?

SQ9 (for AQ5)/What is the effect, if any, on the morphology, physical and chemical properties of the treated FCM (‘permanent’ change) that may influence migration to the food after the HPP treatment?

SQ10 (for AQ5)/Does HPP affect the characteristics of the food and so impact its potential to elicit migration?

SQ11 (for AQ6)/What are the relevant pathogens to be reduced by thermal pasteurisation of raw milk and raw colostrum from ruminants?

SQ12 (for AQ6)/What are the thermal inactivation parameters for the control of the pathogens deemed relevant according to SQ11 in raw milk and raw colostrum from ruminants?

SQ13 (for AQ6)/What log10 reduction of the pathogens deemed relevant according to SQ11 is achieved by thermal pasteurisation of raw milk and raw colostrum from ruminants using the minimum legal requirements?

SQ14 (for AQ7)/What are the relevant factors that affect the efficacy of HPP (in terms of log10 reduction of the pathogens deemed relevant according to SQ11) of raw milk and raw colostrum from ruminants?

SQ15 (for AQ7)/What is the most resistant pathogen considering the pathogens deemed relevant according to SQ11 when treating raw milk and raw colostrum from ruminants using HPP?

SQ16 (for AQ7)/What are the minimum requirements of HPP (relevant factors from SQ14) of raw milk and raw colostrum from ruminants to achieve an equivalent efficacy to that of thermal pasteurisation for the control of the pathogens deemed relevant according to SQ11?

SQ17 (for AQ8)/Which inherent components of the milk or colostrum could be used as appropriate indicators to verify the efficacy of HPP of raw milk and raw colostrum from ruminants, either as part of the validation and verification immediately after such treatment (e.g. in the processing plant) and/or in the end‐product on the market, considering the minimum requirements as defined in SQ16?

SQ18 (for AQ9)/What are the relative levels of exposure [or probability of illness, if data allow] for the pathogen(s) to be defined per serving through the consumption of industrially HPP‐treated milk or colostrum [conditions as being used by industry from SQ2] in comparison to raw vs. thermally pasteurised vs. UHT‐treated milk or colostrum [according to the minimum legal requirements] [considering that the batch to be treated is contaminated]?

SQ19 (for AQ10)/What are the most relevant foods known to be associated with human listeriosis in the EU and that are relevant to be treated with HPP (i.e. there is evidence of use)?

SQ20 (for AQ10)/What are the relevant factors that affect the efficacy of HPP (in terms of log10 reduction of L. monocytogenes) in the RTE foods identified in SQ19?

SQ21 (for AQ10)/What are the minimum requirements of HPP (e.g. time, pressure) according to the relevant factors related to food (from SQ20) when applied to the foods identified in SQ19 to reduce significantly L. monocytogenes levels by specific log10 reductions, assuming that the parameters influencing the subsequent growth of L. monocytogenes remain unchanged (e.g. product characteristics, shelf‐life and storage conditions)?

SQ22 (for AQ11)/ What are the other relevant pathogens (apart from L. monocytogenes) in the foods identified in SQ19?

SQ23 (for AQ11)/ What is the efficacy (log10 reduction) on other relevant pathogens identified in SQ22 when applying the minimum requirements of HPP identified in SQ21 according to the relevant factors related to food (from SQ20)?

2. Data and methodologies

2.1. Questionnaire on the commercial use of HPP of foods

A questionnaire on the commercial use of HPP in foods with the purpose to increase microbiological food safety was sent on 24 November 2020 through the European Commission WG on food hygiene to the competent authorities (CA) in each Member State (MS). Part of the questionnaire was to be filled by the CA and they were requested to forward the other part of the questionnaire to the establishments using HPP in their country. The questionnaire addressed to establishments has also been shared for information with the members of the Advisory Group on the Food Chain and Animal and Plant Health (a body gathering representatives of stakeholders) and the EFSA stakeholders. The questionnaire for the equipment providers has been sent to Hiperbaric, JBT‐Avure Technologies, Multivac/Thyssenkrupp – Uhde High Pressure Technologies, and Stansted Fluid Power on 11 December 2020.

The questionnaires can be found in Appendix A, together with a summary of the replies. It consists of general questions related to the products being treated using HPP along with their processing conditions (for establishments) as well as relative importance and general recommendations for HPP (for equipment providers), and the validation process of the HPP treatment (for establishments and equipment providers). CA were also asked to provide information about past and current evaluation of the impact of HPP on food safety. A question was also included on expected important technological changes in the near future (for CA, establishments and equipment providers) and in‐bulk treatment using a batch system (for equipment providers).

A specific question was included on the food microbiology/hygiene and asked about the awareness of any microbiological food safety problems originating from food subjected to HPP (for CA, establishments and equipment providers).

Also, specific questions related to food contaminants and FCM were included (for CA, establishments and equipment providers), further detailed in Sections 2.2.4 and 2.2.5, respectively.

2.2. Efficacy and microbiological and chemical safety of the use of HPP when applied to relevant foodstuffs

2.2.1. Overview of the food categories to which HPP is being applied for food safety reasons

The strategy for conducting the literature searches and screening is provided in Appendix B. A general search was conducted in Web of ScienceTM Core Collection (2010–present) as described in Appendix B.1 to retrieve review papers, book sections and books summarising information about the food products being treated with HPP worldwide with the purpose of increasing microbiological food safety. As clarified in the ToR, this scientific opinion only considers the HPP as a non‐thermal treatment. Therefore, the search excluded all the studies focused on heat‐assisted HPP or using HPP with an initial fluid temperature such that, due to pressure‐associated temperature increase, the maximum temperature of the product during the treatment exceeds 45°C.

The records were screened for information about the use of HPP of food products only with the aim of increasing food safety in three steps: screening of (1) titles, (2) abstracts and (3) full‐text documents to further identify records to be excluded based on criteria related to report and study characteristics considering whether the record contains info about the use of HPP of food products only to improve food safety. Selected full‐text documents were screened to extract the relevant information needed to answer AQ1.

Replies to the general questions provided through the questionnaire were also considered and summarised (see Section 2.1) to provide an overview of the food categories to which HPP is being applied for food safety reasons along with the processing conditions used by industry.

2.2.2. Food intrinsic and extrinsic factors that may influence the efficacy of HPP

The records retrieved as described in Section 2.2.1 were screened in two steps for relevant information on HPP inactivation of microorganisms for bacteria considering the vegetative form only (as non‐thermal HPP does not inactivate spores): screening of title and abstract (Ti/Ab) and further at full text level. The reference lists of these documents were further screened for additional relevant information. Studies were considered eligible when they fulfilled the following criteria: (i) report inactivation of above‐mentioned microorganisms by HPP at temperatures < 45°C, (ii) deal with bacterial pathogens or non‐pathogens, since their inactivation may be influenced by the same factors, (iii) be conducted in food or in laboratory media.

2.2.3. Potential microbiological food safety concerns in HPP‐treated food

Information provided through the questionnaire related to the awareness of any microbiological food safety problems originated from food subjected to HPP was considered (see Section 2.1). The following examples were provided: spore activation leading to more rapid and more complete germination and outgrowth, prion activation by conversion of normal form to amyloid form and the induction of virulence or of toxin gene expression.

With respect to the literature search of relevant information, eligible studies should report on microbiological concerns which are generated or increased specifically by HPP treatment. They should fulfil the following criteria: (i) deal with the effect of HPP on food‐borne pathogens including vegetative and/or spore‐forming bacteria, viruses, mycotoxin‐producing moulds, protozoa or prions, (ii) report an increased or new risk, or a physiological, biochemical or genetic effect on a pathogen that could result in an increased risk, compared to the food that was not HPP treated, as opposed to the risk reduction that is normally the goal of HPP treatment. A two‐step strategy was followed to retrieve relevant studies: (i) the records from Section 2.2.1 were screened first using the Ti/Ab, and then at full‐text level to identify specific HPP‐associated concerns.

Subsequently, a targeted search was conducted with specific search strings for each specific concern identified as specified in Appendix B.2: (i) focusing on spore activation/germination with HPP (97 records), (ii) related to prions (38 records) and (iii) induction of virulence and toxin gene expression (25 records). With respect to records about these specific searches, the results were narrowed down in several steps: (i) records meeting the eligibility criteria based on Ti/Ab were first selected, and then (ii) full papers were further screened.

2.2.4. Potential chemical food safety concerns in HPP‐treated food through formation of process contaminants

An extensive literature search has been performed with the aim to retrieve information reporting or reviewing chemical changes related to contaminants during the HPP compared to non‐treated or conventional processes. To search for different types of publications providing information on chemical contaminants during HPP, two databases were used; search queries used in individual databases and the subsequent screening to retrieve potentially relevant studies can be found in Appendix B.3. The records were screened for relevance in two levels: (i) The retrieved articles were screened first at Ti/Ab level for information on chemical substances that are modified or produced due to HPP and (ii) the selected records were screened at the full‐text level for information that is related to contaminants.

In addition, in the questionnaires (see Section 2.1), a question on the awareness of studies on the effect of HPP on the potential formation or degradation/modification of contaminants in foods during and after HPP treatment was included.

2.2.5. Potential chemical food safety concerns in HPP‐treated food through food contact materials

In order to retrieve information on the effect of HPP on the packaging and ultimately on the migration potential of substances from packaging to food or food simulants, (i) questionnaires were developed and sent to the CA, the establishments using HPP and the equipment providers (see Section 2.1) as well as to the EFSA FIP FCM Network, (ii) expert knowledge from a representative of the US Food and Drug Administration (US‐FDA) was considered through a technical hearing held on 14 October 2020 and (iii) a general literature search was conducted.

In the questionnaires, questions specific to FCM were included such as special considerations or technical requirements on the properties of FCM, awareness of studies on the effect of HPP on FCM including the potential formation of new reaction/degradation products and the migration of substances into food during and after HPP treatment, and whether there are types of foods for which HPP has an adverse effect or for which HPP is not suitable or recommended.

The literature was searched in two databases, covering the period from 1990 to 9 October 2020 as described in Appendix B.4. It considered English primary articles. Reviews, books and conference proceedings were also included, but no conclusions were drawn from them, without recourse to an evaluation of the original papers (without applying the 1990 cut‐off date).

The selection for inclusion/exclusion of studies was performed based on a three‐step strategy. First, the identified records were screened by title and abstract and classified according to a conceptual framework of the factors that determine the identity and quantity of chemicals migrating from FCM. Second, the selected records were screened as full text to further identify records to be included/excluded based on criteria related to report characteristics and study characteristics. Third, the included records were evaluated to address the main question: ‘What is the effect of HPP treatment on the food packaging and ultimately on chemical migration to food?’.

2.3. Efficacy of HPP when applied to raw milk and raw colostrum from ruminants

2.3.1. Minimum HPP requirements for the control of pathogens in raw milk and raw colostrum to achieve an equivalent efficacy to thermal pasteurisation

2.3.1.1. Additional hazards to be reduced by thermal pasteurisation of raw milk and raw colostrum from ruminants

The previous scientific opinion by the BIOHAZ panel on the public health risks related to the consumption of raw drinking milk (EFSA BIOHAZ Panel, 2015) was consulted for the selection of the hazards to be reduced by thermal pasteurisation of raw milk/raw colostrum from ruminants. Data on ‘strong and weak’ evidence food‐borne outbreaks (FBOs) at EU/EEA level from 2008 to 2019 implicating milk as the food vehicle (i.e. the food (or foodstuff) that is suspected of causing human cases) were extracted from the EFSA zoonoses database and the available epidemiological evidence summarised, including the causative agent and number of outbreaks. Further information in other data elements, such as ‘more food vehicle information (fboVehicleInfo)’ and ‘contributory factors (fboFactor)’, was consulted, when available (reported as free text). More information about the reporting on FBOs can be found in the technical report titled ‘Zoonoses, antimicrobial resistance and food‐borne outbreaks guidance for reporting 2020 data’ (EFSA, 2021b).

2.3.1.2. Relevant factors to describe the requirements of HPP of raw milk and raw colostrum from ruminants

A literature search was performed to identify the relevant factors determining the effect of HPP in raw milk and raw colostrum from ruminants. The search is described in Appendix B.5 and the screening process was undertaken in two steps: screening of (1) Ti/Ab and (2) full text to further identify records to be excluded based on criteria related to report characteristics (e.g. not in English) and study characteristics. The search also included literature reviews using the same string as described in Appendix B.1 as well as relevant references from WG member’s knowledge. A record was excluded when the study dealt with laboratory media experiments, unless it could help in identifying (qualitatively) a relevant factor. A study was considered eligible when:

included a challenge test, e.g. the pathogen was inoculated to a target concentration and under controlled conditions;

done in milk or colostrum, for which, experimental information (preferably from quantitative perspective) such as the following is provided: strain and its physiological state, the origin (species) of raw milk/colostrum and related factors (e.g. fat and antimicrobial compounds) and HPP technological conditions; and

provided inactivation data such as log10 reduction, kinetic parameter (e.g. inactivation rate) and/or mathematical model(s) about log10 reduction or inactivation rate.

Data were extracted using predefined tables. Besides raw milk/colostrum‐related factors and HPP technological conditions, other relevant issues were collected when available: microbial strain (and conditions for preparing the inoculation culture), and analysis (method and media, time and conditions after HPP that may overcome sublethal damage with a consequent overestimation of the efficacy of the treatment).

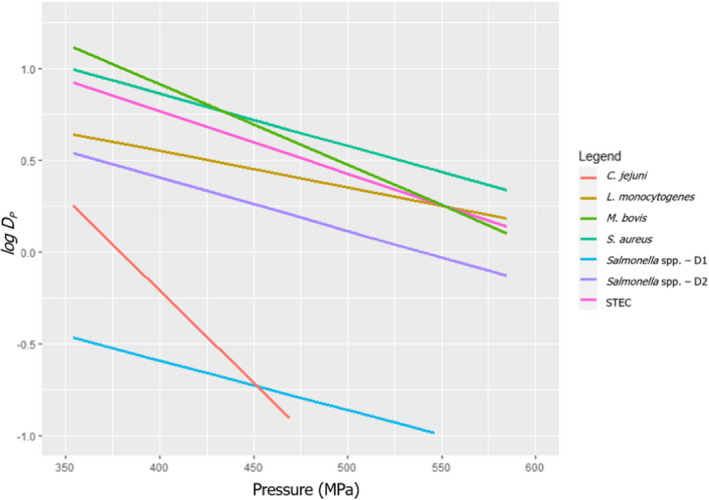

2.3.1.3. Most resistant pathogen when treating raw milk and raw colostrum from ruminants using HPP

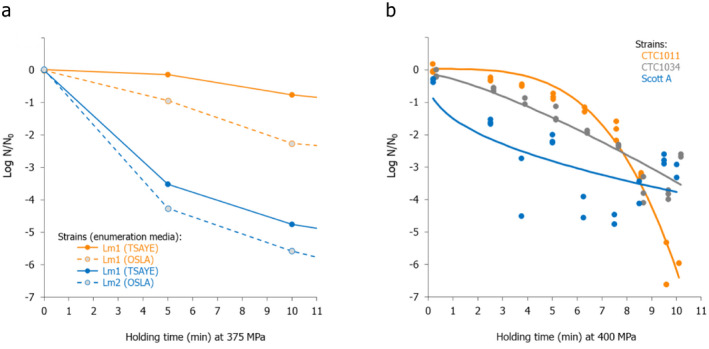

The most resistant pathogens to be considered when treating raw milk/colostrum from ruminants using HPP were identified by means of a literature review aimed at capturing the pathogen‐specific log10 reductions in comparable conditions (i.e. time/pressure, media), scientific evidence in terms of log10 reductions (ideally the decimal reduction time at a given target pressure, Dp‐value) of pathogens when raw milk or previously heat‐treated milk is treated by using HPP.

The search is described in Section 2.3.1.2. It included records of milk from other species should limited data be available when considering only cows’ milk. After preliminary screening of Ti/Ab, studies were retained if the pathogen‐specific parameters were reported and were obtained from HPP treatment of milk/colostrum. An MS Excel spreadsheet containing the data used for modelling is made available through the Knowledge Junction under 10.5281/zenodo.5998538.

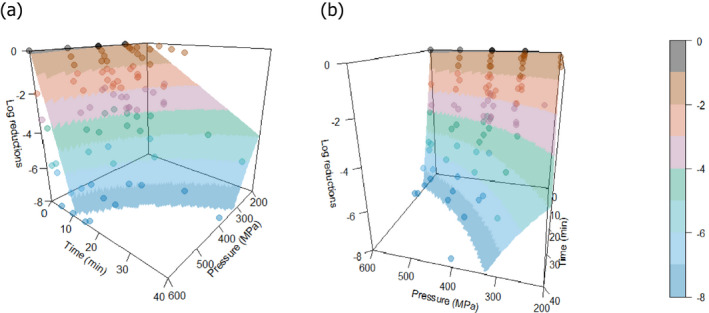

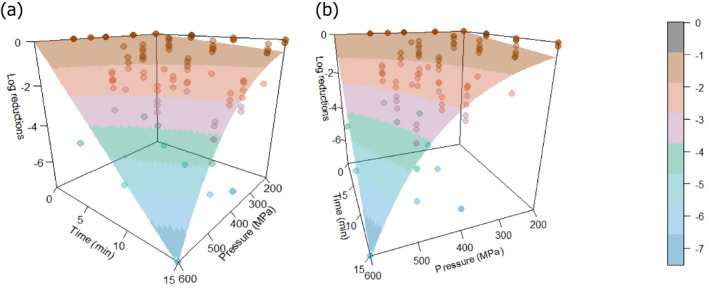

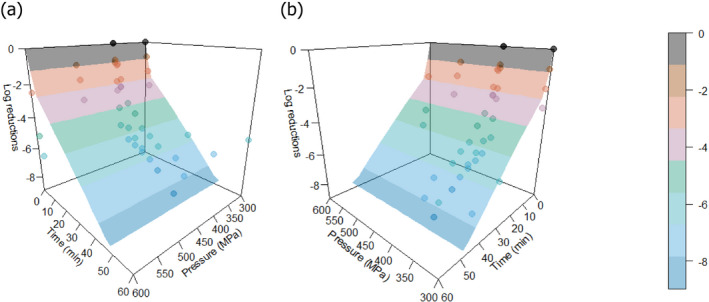

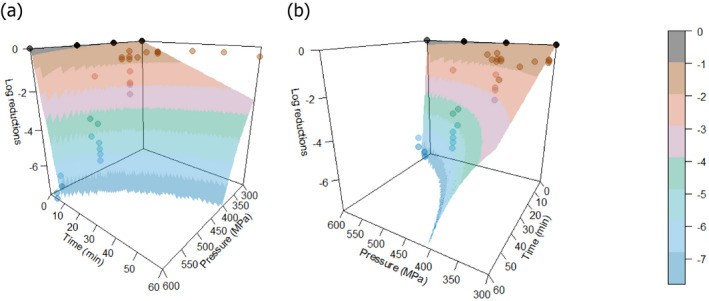

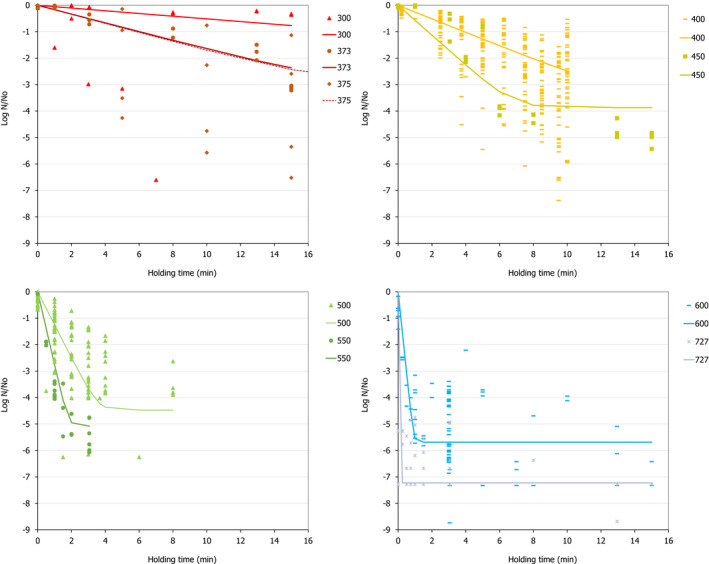

A global modelling approach, with a log‐linear (single inactivation phase) or a biphasic primary inactivation model (Cerf, 1977), both encompassing a Bigelow secondary model term for the impact of pressure on microbial inactivation, was fitted to the log10 reduction (logR), data extracted from the relevant literature studies.

The following inactivation models were used:

- Log‐linear model

(1) -

Biphasic model

(2) where: is the decimal reduction time or D‐value (min) at the reference pressure (Pref) of 600 MPa, zp is the change in pressure (MPa) required for 10‐fold change of the Dp‐value, f is the fraction (0–1) of the sensitive subpopulation and k1 and k2 the inactivation rates (i.e. ln(10)/D) of the sensitive and resistant to pressure subpopulations. Fitting of the equations was performed by means of nls regression in R version 4.0.5. (R Core Team, 2021).

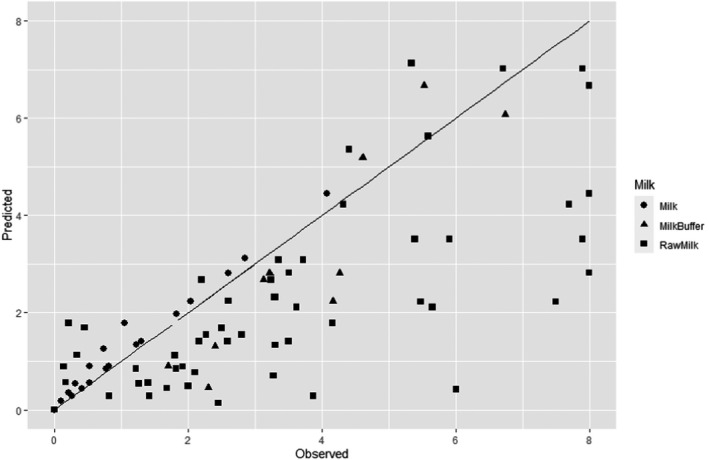

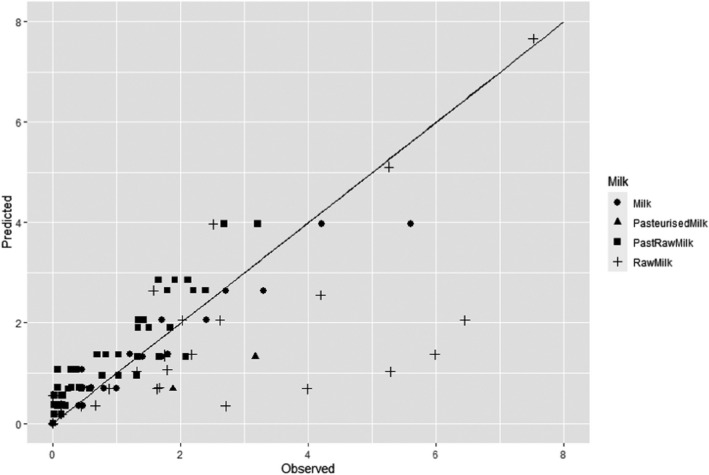

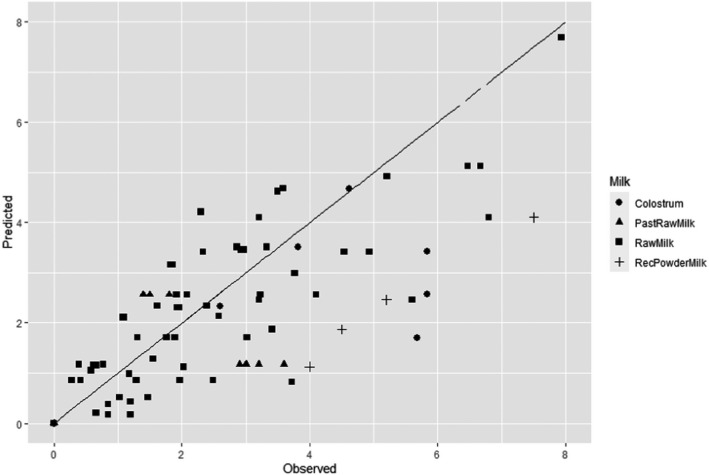

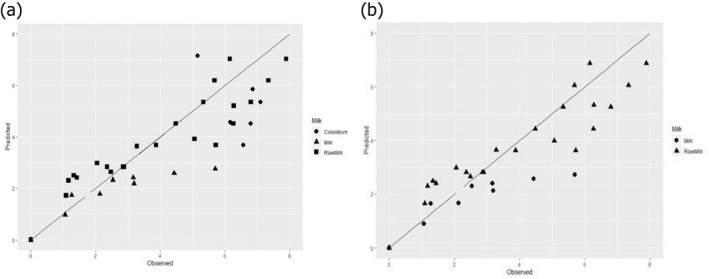

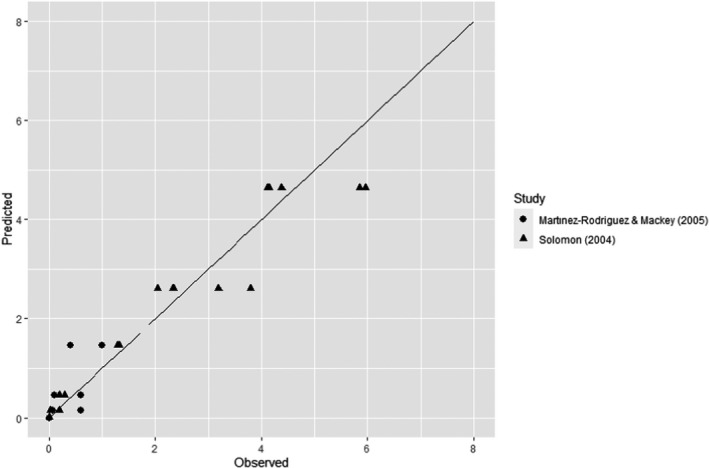

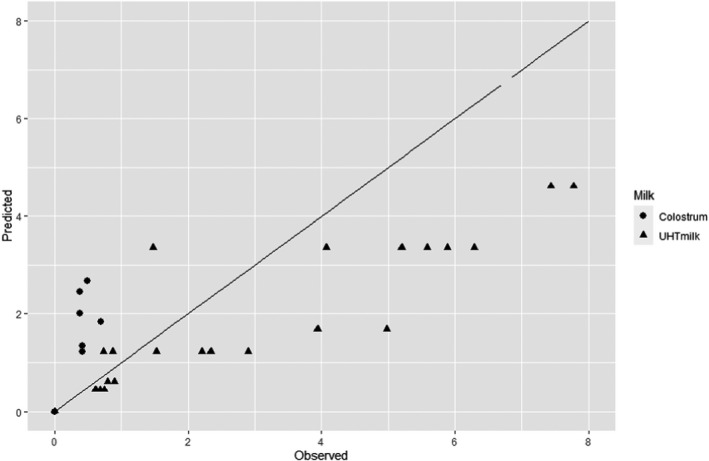

The Root Mean Square Error (RMSE) and the % of predicted log10 reductions within and outside the Acceptable Prediction Zone (APZ) were used as the goodness‐of‐fit criteria. The APZ was defined as a range ± 1 log10 from the 100% accurately predicted value, i.e. the value that makes the difference between prediction and observation equal to 0.

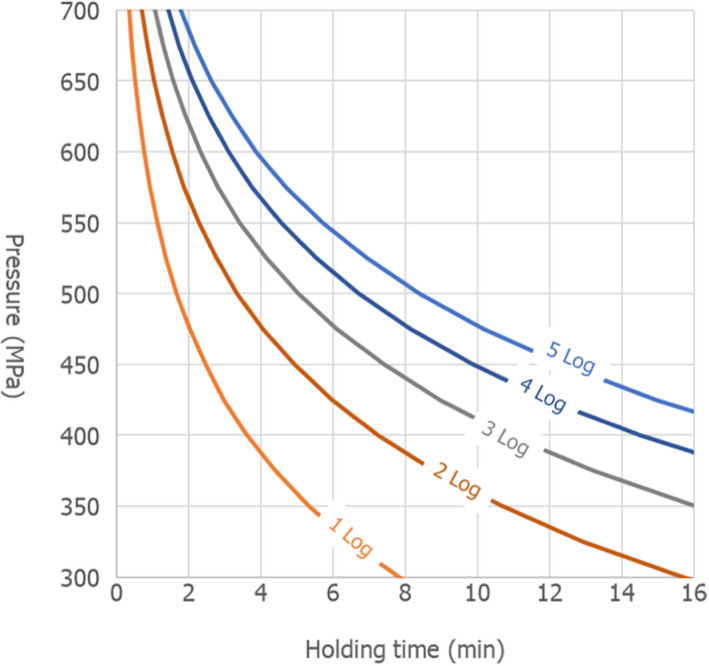

The global modelling aimed to: (i) describe the combined effect of pressure (MPa) and holding time (min) on the inactivation (expressed as log10 reduction) of relevant hazards in raw milk and colostrum, (ii) assist in ranking the relevant hazards based on their resistance to pressure via plotting of the dependency of their log Dp‐values on pressure (MPa) and (iii) to calculate the equivalent pressure–holding time (P/t) combinations for achieving specific (target) log reduction of the (most resistant) hazard to pressure, in the form of isoreduction plots.

2.3.1.4. Minimum requirements of HPP of raw milk and raw colostrum from ruminants to achieve an equivalent efficacy to that of thermal pasteurisation

Data gathered from the studies retrieved from the search described in Section 2.3.1.2 were used to evaluate the HPP treatment conditions needed to achieve the equivalent log10 reduction of thermal pasteurisation. The aim was to identify the log10 reductions reached in raw milk/colostrum for a specific pathogen when different HPP processing conditions (P/t combinations) were applied.

In order to identify the HPP conditions resulting in an equivalent efficacy to that of thermal pasteurisation, performance criteria (PC) normally recommended by international agencies have been considered. This was done by first carrying out a literature review aimed at identifying the pathogen‐specific thermal inactivation parameters (DT and/or zT‐values and/or time to specific log10 reductions) or log10 reductions achieved by thermal pasteurisation (65°C for 30 min and 72°C for 15 s).

The strategy for conducting the literature searches and screening to retrieve records reporting those pathogen‐specific thermal inactivation parameters or log10 reductions in raw milk or colostrum is provided in Appendix B.6. A study was considered eligible for the evaluation of the impact of temperature on the relevant hazards (as outcome of Section 2.3.1.1) when it reported on the thermal treatment of milk or colostrum (from any species), considering that: (i) priority was given to cows’ milk but milk from other animal species was also considered if the evidence for some of the pathogens was scarce (population); (ii) a heat treatment needs to be conducted (intervention) and the thermal inactivation parameters and/or log10 reductions of the hazards reported (outcome); (iv): industrial, pilot or laboratory conditions were used (setting). When data for the estimation of the log10 reductions of the relevant pathogens in milk and colostrum were not available, evidence for surrogate microorganisms was used. This is the case for Mycobacterium avium subsp. paratuberculosis (MAP), which was considered adequate to serve as surrogate for M. bovis for the scope of this scientific opinion. Knowing that the resistance of MAP to thermal and HPP treatments is higher than M. bovis, the assessment based on MAP data could be considered as a worst‐case scenario. For STEC, the evidence was used considering the entire body of evidence for any E. coli strain subjected to HPP treatment.

When the log10 reductions were not reported, or reported for T/t combinations different from the minimum legal requirements of 63°C for 30 min or 72°C for 15 s, the log10 reduction achieved by thermal pasteurisation under the conditions of interest was estimated from the DT‐ and zT‐values as follows:

| (3) |

where t is the time (in s), the milk is held at Tref (i.e. 72°C or 63°C) and DTref is the DT‐value for a specific pathogen at Tref (i.e. 72°C or 63°C). The pathogen‐specific DTref is derived from:

| (4) |

Where is the DT‐value for a specific pathogen recorded at temperature TX (selected out of those, for which the corresponding values are also available in the literature) and zT is the pathogen‐specific thermal resistance constant.

The evidence gathered by the literature review was then used to evaluate, for each relevant hazard, whether the specific log10 reductions proposed by international agencies (i.e. 5, 6, 7 and 8 log10 reductions, here in called PC) are achieved using the minimum legal requirements for thermal pasteurisation. If the target log10 reductions were achieved (or exceeded), pathogen‐specific HPP equivalent conditions were derived, when data allowed for, for each PC. If none or only some of the target log10 reductions were achieved, HPP equivalence was assessed based on the log10 reductions that are estimated to be achieved by the minimum legal pasteurisation requirements (T/t conditions), according to the thermal inactivation parameters of the hazard.

2.3.2. Appropriate indicators to verify the efficacy of HPP treatments on raw milk or raw colostrum

A search was conducted to retrieve records dealing with HPP of milk or colostrum (see Appendix B.5). If another reference was potentially relevant from the reference list of the reviewed papers, it was retrieved and screened. The screening considered whether the record contained information about the effect of HPP on an inherent milk/colostrum component that could serve as an indicator for pasteurisation. Raw milk/colostrum of all animal and human milk was considered, although the focus was on ruminant milk/colostrum. Records were discarded when the effect of HPP was evaluated on previously heat‐treated milk, in which the natural properties of the components could be altered, or on other dairy products (e.g. cheese, yogurt or milk mixed with other ingredients).

The screening of the relevance of each study (appropriateness to answer AQ8) was performed at full‐text level. Data were extracted from the selected records using predefined tables compiled with information at the record level including the following questions:

Was the study performed using raw ruminant milk/colostrum?

Was the inherent milk compound evaluated as an indicator to assess HPP pasteurisation‐like treatments?

Did the study consider HPP conditions within the range for industrial applications of pasteurisation‐like HPP treatments (i.e. temperature < 25°C, pressure < 600 MPa and time < 15 min)?

Did the study contain quantitative data, in the range proposed for the pasteurisation‐like HPP treatments, that would allow the estimation of the effect of HPP on the compound?

Did the study include kinetic data expressed as Dp, zp or similar, easily comparable with lethality parameters determined for pathogen microorganisms?

Did the study compare the effect of HPP on the compound itself with the effect on a target microorganism?

Did the study include data about the stability of the effect on the compound caused over time after the treatment?

The information extracted from the selected records was appraised in a narrative way to determine which of the compounds could be suitable to determine if HPP is applied correctly as a pasteurisation method. The following criteria were applied:

Quality of the literature support considering the number of records appraised and the quality of the retrieved studies (based on the number of affirmative answers to questions for the record‐appraisal).

Is the effect of HPP on the compound significant in the range of HPP conditions (P/t) according to SQ16?

Is the effect similar for milk/colostrum from all ruminant species?

Does the effect remain stable after the treatment and shelf‐life?

Has the effect been compared/validated with any of the target pathogens from SQ11?

Is the method of analysis used feasible for a Critical Control Point (CCP) monitoring/HACCP validation purpose?

For a better evaluation of the potential indicators, when the data provided by the records were adequate (e.g. at least three or more pressure and holding times for the same matrix) the P/t conditions necessary to reduce 90% of the initial concentration/activity of the compound were estimated and compared with the conditions necessary to achieve 5 log10 reduction of the most resistant pathogen as described in Section 2.3.1.3. Decimal reduction time at a given target pressure (Dp) was recorded, either as reported by the authors or, when not available, estimated by fitting the reduction of the concentration (e.g. whey proteins) or activity (enzymes) expressed as log10 (Cf/C0), where C0 is the initial concentration/activity of the compound and Cf is the residual concentration/activity after applying the HPP treatment. The linear regression for each case was estimated in MS‐Excel. The Dp (in min) was calculated as the inverse of the estimated inactivation rate (k) defined by the slope of the curve. A secondary linear model was fit to the log10 transformed Dp values vs. pressure (P) to derive the pressure resistant constant (zp) as the inverse of the slope of the linear regression.

2.3.3. Comparative assessment of the risk to human health from the consumption of HPP‐treated milk or colostrum

The comparative exposure assessment of the risk to human health from the consumption of HPP‐treated milk or colostrum was done by estimating the probability of contaminated servings immediately after treatment to the relevant pathogens through the consumption of four types of milk, i.e. raw milk, thermally pasteurised milk, UHT milk and industrially HPP‐treated milk. The batch to be treated was considered to be contaminated, although different initial contamination levels were established through different scenarios.

The comparison was carried out for the pathogens for which it was possible to estimate the log10 reductions resulting from both HPP and thermal treatments. A model was used to estimate the colony forming units (CFUs) in milk after thermal or HPP treatment. For purpose of comparison, two outputs were generated:

the variability in the level of contamination in a serving (with serving size of 1 cup of ~ 250 mL) after processing as described using the location parameters of the distribution (5th, 50th (median) and 95th percentiles); and

the probability of at least one CFU being present in that serving.

The model assumed for each pathogen, scenarios of fixed theoretical levels of initial contamination (N0) ranging from 1 to 8 log10 CFU/mL. The rationale for evaluating these scenarios was to ease comparisons across the outputs and to evaluate to what extent the outcome is dependent on the initial contamination levels.

From the initial level of contamination and assuming the bacteria are homogeneously distributed in milk, the probability of at least 1 CFU being present after processing, P(N1 > 0), was estimated as:

| (5) |

where P(N1 = 0) the theoretical probability of observing 0 CFU derived from a Poisson distribution of rate = λ × V, where V is the consumption unit of interest (250 mL). The microbial contamination was assumed to be randomly and homogeneously distributed in the milk system without aggregation of cells, because of the liquid (homogenous) character of the milk. Thus, the distribution of cells in milk was assumed to follow a Poisson distribution. When the distribution of cells would be heterogeneous, e.g. due to clumping of cells, another distribution such as the negative binomial distribution, may be more appropriate (Jongenburger et al., 2012).

The residual level of contamination in a serving of milk after heat treatment was estimated as:

| (6) |

where logR is the log10 reduction assumed to be achieved by thermal pasteurisation for a minimum (TT5, log R = 5) and maximum scenario (TT8, log R = 8) of log10 reductions. For UHT treatment, log R = 12 was assumed.

Raw milk was assumed to receive any processing or heat treatment (logR = 0) and therefore:

For HPP‐treated milk, the pathogen‐specific log10 reductions achieved when considering the minimum, maximum and an intermediate HPP processing conditions for milk reported to be applied by the industry were informed through the questionnaire (minimum = 450 MPa for 5 min, maximum = 600 MPa for 6 min, intermediate = 600 MPa for 3 min). More stringent conditions were not considered because these were outside the range of commonly applied conditions by the industry. The parameter log R (the predicted mean log10 reductions) in Equation 6 was informed through the global modelling described in Section 2.3.1.3.

For the four types of milk and all pathogens, the theoretical location parameters of the distributions describing the level of contamination in log10 CFU per serving (N1) after the thermal or HPP treatment (or no treatment for raw milk) were extracted to prepare a graph with the cumulative distributions, describing, for all scenarios (in terms of initial level of contamination N0), the variability in the number of bacteria per serving under the assumption that bacteria are homogeneously distributed in milk:

| (7) |

2.4. Efficacy of HPP when applied to foods known to be associated with human listeriosis

2.4.1. Most relevant foods known to be associated with human listeriosis in the EU

The aim was to retrieve information on the RTE foods known to be associated with human listeriosis in the EU and that are relevant to HPP either because they are already commercialised after HPP, or the literature provided some evidence that they are technologically appropriate to be treated by HPP. The previous scientific opinions by the BIOHAZ panel on (i) the L. monocytogenes contamination of RTE foods and the risk for human health in the EU (EFSA BIOHAZ Panel, 2018) and (ii) the public health risk posed by L. monocytogenes in frozen fruit and vegetables including herbs, blanched during processing (EFSA BIOHAZ Panel, 2020b), were reviewed for relevant information.

Data on ‘strong and weak evidence’ FBO from 2008 to 2019 at EU/EEA level were extracted from the EFSA zoonoses database. The data related to L. monocytogenes (as causative agent) were used to summarise the number of outbreaks and number of human cases for the reported food vehicles. When available, further information about the food vehicle was taken from the data element ‘more food vehicle information (fboVehicleInfo)’ (reported as free text). Also, the multicountry outbreaks (2012–2021 period) were screened for evidence that the causative agent was L. monocytogenes.

To complement this information, relevant documents on FBOs associated with L. monocytogenes in different RTE foods occurring in EU countries were identified and reviewed. These documents included scientific papers, book chapters, non‐peer review papers, regulations, guidance documents from (inter)national authorities and scientific opinions. The reference list of these documents was further screened to identify additional relevant publications until reaching a coverage of the subject considered sufficient.

2.4.2. Relevant factors to describe the requirements of HPP of the most relevant foods known to be associated with human listeriosis in the EU

A literature search was performed to identify the most relevant factors determining the effect of HPP in the selected most relevant foods known to be associated with human listeriosis in the EU and are relevant to be treated with HPP (Section 2.4.1). The search is described in Appendix B.7 and the screening process was undertaken in two steps: screening of (1) Ti/Ab and (2) full text to further identify records to be excluded based on criteria related to report characteristics (e.g. not in English) and study characteristics. A record was excluded when the study dealt only with laboratory media experiments, unless they could help in identifying (qualitatively) a relevant factor. A study was considered eligible when it:

included a challenge test, e.g. L. monocytogenes was inoculated at known level and controlled conditions;

was performed in a real food matrix (most relevant RTE foods from Section 2.4.1), for which, experimental information (preferably from a quantitative perspective) such as the following is provided: strain and its physiological state, food type and related factors (pH, aw, fat content, preservatives) and HPP technological conditions; and

provided inactivation data such as log10 reduction, kinetic parameters (e.g. inactivation rates or Dp‐values) and/or mathematical model(s).

Data were extracted using predefined tables. Besides food‐related factors and HPP technological conditions, other relevant information was collected when available: microbial strain (history and conditions for preparing the inoculation culture) and experimental approaches (method and media, time and conditions after HPP that may overcome sublethal damage with a consequent overestimation of the efficacy of the treatment).

2.4.3. Minimum HPP requirements to reduce L. monocytogenes levels in foods known to be associated with human listeriosis

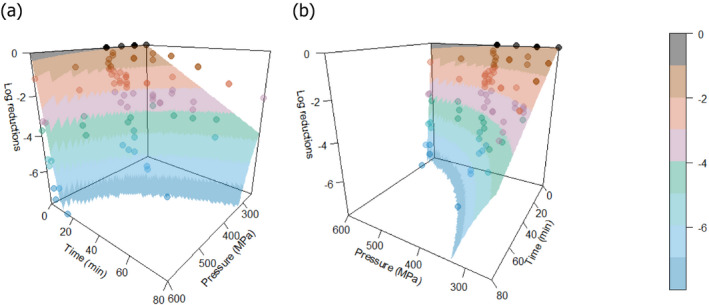

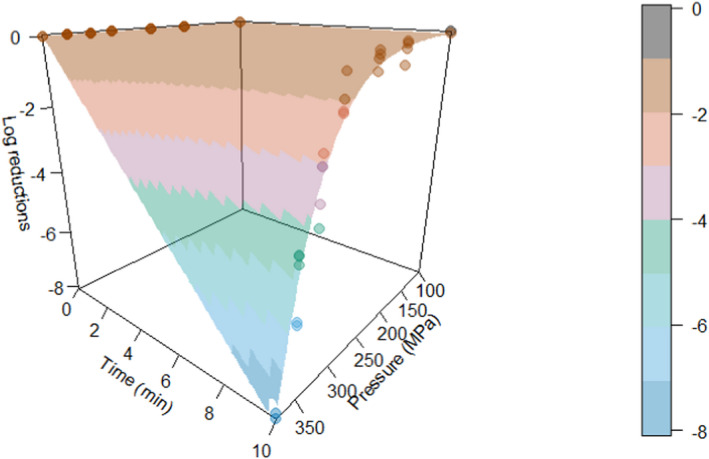

The minimum HPP requirements to reduce L. monocytogenes in the selected RTE food categories were estimated through the calculation of the equivalent P/t combinations required for achieving a given log10 reduction (PC), in the form of isoreduction plots.

Data gathered from the studies retrieved from the search described in Section 2.4.2 were used to evaluate the HPP treatment conditions associated with a given log10 reduction. An MS Excel spreadsheet containing the data used in the model is made available through the Knowledge Junction under 10.5281/zenodo.5998538.

When directly available, the reported log10 reduction result was retrieved or digitalised from figures. In some cases, the log10 reduction (in log10 units) was calculated from the reported concentrations as Equation 8:

| (8) |

where N0 and N are the concentrations (CFU/g) of the pathogen before and after HPP, respectively. In most cases, N0 refers to the inoculation level used (Ni) in the challenge test. In studies dealing with inactivation kinetics, N0 usually refers to the concentration (CFU/g) of the pathogen after a HPP treatment with only a pressure come‐up time (CUT) and no holding time (i.e. a cycle of pressure increase until the target pressure is reached, immediately followed by pressure release).

Two different approaches were followed:

-

a

Modelling the collected data in order to obtain a mathematical model describing the combined effect of pressure (MPa) and holding time (min) on the inactivation (log10 reduction) of L. monocytogenes in the selected RTE foods.

First, attempts were made to fit a polynomial model including linear, quadratic and interaction terms of HPP parameters (pressure, holding time and initial fluid temperature) to the overall log10 reduction data for each type of RTE food included in the assessment. Secondly, the classical two‐step (primary and secondary) modelling approach was applied using the retrieved studies providing inactivation kinetic data. The decimal reduction time at a given target pressure (Dp) was recorded, either as reported by the authors or, when not available, it was estimated by fitting the primary inactivation model to the log10 reduction data. The log‐linear model without (Equation 9) or with tail (Equation 10) was used to fit the inactivation curve at each target pressure (Hereu et al., 2012b). The statistical significance of the tail was tested by comparing the fit of Equations 9 and 10 through an F‐test (van Boeijen et al., 2008; Santillana Farakos and Zwietering, 2011) and when a more complex model (i.e. with tail) was statistically significant (p < 0.05), the inactivation parameters estimated with Equation 10 were used.

| (9) |

| (10) |

where log10(N/N0)i is the log10 reduction at time zero of the HPP (no holding time, when the data for a cycle of pressure come‐up immediately followed by the pressure release were not available, the inoculum level before HPP treatment was used); log10(N/N0)res is the maximum log10 reduction achieved associated with the occurrence of a resistant tail; kmax is the inactivation rate expressed in natural logarithm per unit of time and t is the holding time at the target pressure (P).

The Dp (in min) was calculated as the inverse of the estimated inactivation rate (Equation 11).

| (11) |

A secondary linear model fit to the log10 transformed Dp values vs. pressure (P) was applied to derive the pressure resistant constant (zp), i.e. the parameter expressing the dependence of pressure resistance on pressure changes, as the inverse of the slope of the linear regression. The 95% confidence interval (CI) and prediction interval of the linear regression were estimated in MS‐Excel and the goodness‐of‐fit parameters with the JMP® statistical software (JMP®, Version 14, SAS Institute Inc., Cary, NC, 1989–2019).

The global regression approach nesting the primary and secondary models as in Section 2.3.1 was used to fit the entire set of log10 reduction data.

-

b

Use of predictive models available in the literature.