Abstract

Background: E-cigarette designs, materials, and ingredients are continually evolving, with cotton wicks and diverse coil materials emerging as the popular components of atomisers. Another recent development is the use of nicotine salts in e-liquids to replicate the form of nicotine found in cigarette smoke, which may help cigarette smokers to transition to e-cigarettes. However, scientific understanding of the impact of such innovations on e-cigarette aerosol chemistry is limited.

Methods: To address these knowledge gaps, we have conducted a comparative study analyzing relevant toxicant emissions from five e-cigarettes varying in wick, atomiser coil, and benzoic acid content and two tobacco cigarettes, quantifying 97 aerosol constituents and 84 smoke compounds, respectively. Our focus was the potential for benzoic acid in e-liquids and cotton wicks to form aerosol toxicants through thermal degradation reactions, and the potential for nickel–iron alloy coils to catalyze degradation of aerosol formers. In addition, we analyzed e-cigarette emissions for 19 flavor compounds, thermal decomposition products, and e-liquid contaminants that the FDA has recently proposed adding to the established list of Harmful and Potentially Harmful Constituents (HPHCs) in tobacco products.

Results: Analyses for benzene and phenol showed no evidence of the thermal decomposition of benzoic acid in the e-cigarettes tested. Measurements of cotton decomposition products, such as carbonyls, hydrocarbons, aromatics, and PAHs, further indicated that cotton wicks can be used without thermal degradation in suitable e-cigarette designs. No evidence was found for enhanced thermal decomposition of propylene glycol or glycerol by the nickel–iron coil. Sixteen of the 19 FDA-proposed compounds were not detected in the e-cigarettes. Comparing toxicant emissions from e-cigarettes and tobacco cigarettes showed that levels of the nine WHO TobReg priority cigarette smoke toxicants were more than 99% lower in the aerosols from each of five e-cigarettes as compared with the commercial and reference cigarettes.

Conclusions: Despite continuing evolution in design, components and ingredients, e-cigarettes continue to offer significantly lower toxicant exposure alternatives to cigarette smoking.

Keywords: electronic cigarettes, nicotine salts, cotton wicks, HPHCs, NiFe coil, carbonyls, cigarette smoke toxicants

Introduction

Over the past 15 years, e-cigarettes have emerged into widespread use as credible alternatives to tobacco cigarettes. Vaping may offer a means of increasing adult cessation of combustible tobacco cigarettes, although there is also the risk of enhanced youth transition to combustible tobacco products (Stratton et al., 2018). In reviewing the scientific evidence base on e-cigarette safety, Public Health England have concluded that vaping carries lower risks than smoking (Public Health England, 2019). Consistent with this, studies of aerosol chemistry demonstrate substantial reductions in toxicant emissions in comparison to combustible tobacco cigarettes (Margham et al., 2016). In contrast, other reviews have concluded that the absolute risks of vaping cannot yet be determined unambiguously, noting evidence for DNA damage and mutagenesis from some aerosol components (Stratton et al., 2018), adverse events in the pulmonary, oral, gastrointestinal, and other bodily systems (Seiler-Ramadas et al., 2020), dependence arising from e-cigarette use, as well as hazards from battery explosions and incidence of fatalities associated with ingestion of e-liquids.

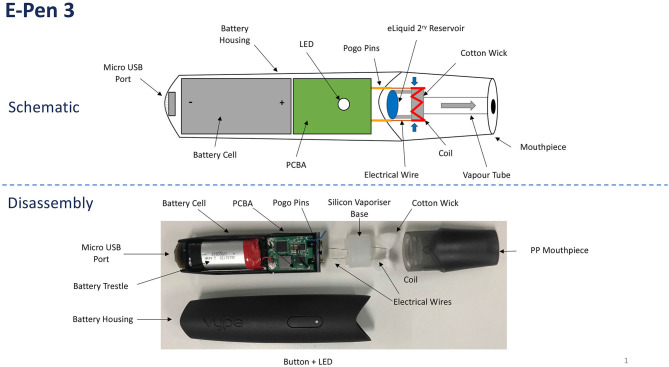

Given the relatively short time since their emergence, it is unsurprising that e-cigarettes continue to evolve in composition and performance (Malek et al., 2018). Despite the inevitable product diversity, however, all e-cigarettes share common attributes and performance traits. E-cigarettes comprise a reservoir of liquid (“e-liquid”), a transport system (“wick”) that carries the e-liquid from the reservoir to a heating (“coil”) zone (“atomiser”), a battery that supplies power to the coil, controlling electronics, and a mouthpiece, shown schematically in Figure 1. When activated, an e-cigarette functions by heating the e-liquid to its boiling point. The resulting gases are drawn away from the heated atomiser by the airflow created by the vaper's puff. The combination of rapid cooling, small particulate nucleation sites in the gas stream, and the presence of a supersaturated vapor causes the gases to condense into an aerosol cloud (“vapor”).

Figure 1.

Schematic and image of the ePen3 device.

The e-liquid generally comprises glycerol (VG; boiling point [BP], 290°C) and/or propylene glycol (PG; BP, 188°C) as aerosol formers, plus a number of optional components including water as a viscosity controller; flavors for consumer appeal; and nicotine, the chief addictive agent in tobacco cigarettes and likely reason for how some smokers have switched from combustible cigarettes to e-cigarettes. Many studies have characterized the chemical composition of e-liquids and e-cigarette aerosols with considerable focus on their low-level toxicants. Several comprehensive integrated chemical studies have measured e-cigarette emissions of up to 142 analytes (Lauterbach and Laugesen, 2012; Lauterbach et al., 2012; Tayyarah and Long, 2014; Flora et al., 2016; Margham et al., 2016), identifying significantly lower levels of toxicants in e-cigarette aerosols than in cigarette smoke. By contrast, other studies have found much higher levels of toxicants, particularly VG and PG thermal decomposition products, in overheating and dry-wicking e-cigarette designs (Farsalinos and Gillman, 2018), demonstrating the need for careful thermal management in e-cigarettes.

A recent development in e-cigarette design has been the replacement of unprotonated nicotine in some e-liquids by nicotine salts. Nicotine is a di-basic compound (Clayton et al., 2013a,b) that reacts with acids in solution to form weak salts. Nicotine in tobacco and cigarette smoke is predominantly present in the mono-protonated form, complexed with multiple organic acids (John et al., 2018). Use of nicotine salts in e-cigarettes is proving popular with vapers, perhaps because the salts more faithfully mimic the chemical form of nicotine in cigarette smoke and are claimed to offer a “less harsh” experience during vaping (Strongin, 2019). Several organic acids have been tested for use in e-liquids (Bowen and Chenyue, 2015), but commonly used salts include nicotine benzoate and lactate. At e-cigarette operating temperatures, however, organic acids are often thermally unstable (Moldoveanu, 2010). In particular, polycarboxylic acids such as citric and tartaric acids thermally degrade to form toxic anhydrides. Benzoic acid (BA) is one of the more stable organic acids, but it also potentially decarboxylates at temperatures around 500°C, forming benzene or phenol (Moldoveanu, 2010). To our knowledge, only one study has examined toxicant formation from organic acids in an e-cigarette, reporting degradation of BA to benzene in a tank system used at possibly unrealistically high-power settings, however, benzene formation was not observed with a much lower powered cartomizer device (Pankow et al., 2017).

A further area of e-cigarette product evolution is the atomiser, which traditionally comprises a wick to transport the e-liquid from the reservoir to an electrically heated metal coil. The amount of e-liquid in the wick is critical in dictating the temperatures reached within the atomiser when the coil is heated (Chen et al., 2018). For example, temperatures of 145–334°C were recorded for an atomiser operating a conventional wicking process (typical of e-cigarette use) with a 100% PG test liquid (BP, 188°C); however, temperatures of 110–185°C were measured under extremes of wick loading (fully wet to fully dry) with an artificially fully wettened coil, while temperatures of 322–1,008°C were measured under artificial liquid-free conditions intended to replicate dry wicking.

The wick often comprises multiple strands of silica or cotton—two materials with significantly different properties. Cotton can transport e-liquid more efficiently to the coil, facilitating greater aerosol delivery to the vaper; however, it is less thermally stable than silica and may degrade if the coil temperature exceeds the decomposition threshold of cotton. In terms of chemical composition, cotton predominantly (>99%) comprises cellulose (Corradini et al., 2009; Liu, 2018), which when heated may liberate volatile organic compounds (e.g., aldehydes, acids, and esters) even at temperatures as low as 180°C during char formation steps (Yang and Freeman, 1993). As temperatures increase to 350°C and higher, aromatic compounds evolve from solid cellulosic char substrates, and benzene, toluene, naphthalene and anthracene are released from the char (Hajaligol et al., 2001). Polycyclic aromatic hydrocarbons (PAHs) are also pyrolysis products of cellulose at 300–650°C and may be formed via low-temperature mechanisms (McGrath et al., 2003). Above 600°C, carbon monoxide (CO) forms (Hajaligol et al., 2001). These observations are from cellulose-degradation experiments conducted under slow-heating conditions that are orders of magnitude slower than the temperature dynamics inside an e-cigarette atomiser. Reaction time and heating rate are critical parameters in thermal decomposition events; therefore, e-cigarette conditions are likely to be less favorable to thermal decomposition processes. Nevertheless, given the possibility of aromatic and PAH compound formation at the e-cigarette operating temperature range, it is important to test whether they are formed with commercial e-cigarettes.

Lastly, the atomiser coil, which commonly comprised an alloy such as nichrome (NiCr) in early e-cigarettes, now can comprise of kanthal, nickel–iron (NiFe), stainless steel or pure metals such as nickel or titanium. Notably, metal catalysis has been suggested to enhance the thermal decomposition of PG and VG (Jensen et al., 2017), PG and VG may interact with various metal surfaces (Tuma et al., 2013), and the coil material has been shown to affect PG decomposition in a heated flow reactor (Saliba et al., 2018). These observations suggest that some coil materials may interact with the e-liquid, degrading the aerosol formers in the atomiser. Despite this possibility, it is currently unclear whether metal coil materials influence toxicant production from e-liquids to any significant extent under real-world usage conditions.

Paralleling the changes in e-cigarette design, regulatory lists of toxicants are also evolving in response to evidence of toxicants in e-cigarette aerosols. As part of e-cigarette pre-launch product registration and reporting requirements in Europe, the Tobacco Product Directive now stipulates chemical emissions testing for multiple priority compounds, including acetaldehyde, acrolein, and formaldehyde (EU, 2014). Dependent on several factors, reporting of diethylene glycol, ethylene glycol, diacetyl, pentane-2,3-dione, and tobacco-specific nitrosamines (TSNAs) emissions may also be required. Metals including aluminum, chromium, iron, nickel, and tin are also stipulated for reporting, as well as lead and mercury if present in the e-cigarette device (UK Emissions Testing Guidance, 2016).

The US FDA has established a list of more than 90 Harmful and Potentially Harmful Compounds (HPHCs) in tobacco products (FDA, 2012), and recently sought public comment on the proposal to add a further 19 compounds to the list (FDA, 2019). Among these compounds, glycidol, a probable human carcinogen (IARC, 2000), which is a thermal decomposition product of VG (Laino et al., 2011; Sleiman et al., 2016). Ethylene glycol has been found in e-liquids (Hutzler et al., 2014) and has adverse respiratory effects on inhalation. Diethylene glycol, when identified in e-liquids and aerosols, is thought to arise as a contaminant of the VG or PG stocks used by e-liquid manufacturers (Varlet et al., 2015); it may induce severe and irreversible acute toxic affects (Sanina, 1968; Health Council of the Netherlands, 2007; Australian Government Department of Health and Ageing, 2009; Schep et al., 2009; California Poison Control System, 2012; Devoti et al., 2015), and has been identified by the Californian EPA as a reproductive toxicant if ingested (Borghardt et al., 2018). According to the National Institute for Occupational Safety and Health (NIOSH), the remaining 16 toxicants (acetic acid, acetoin, acetyl propionyl, benzyl acetate, butyraldehyde, diacetyl, ethyl acetate, ethyl acetoacetate, furfural, VG, isoamyl acetate, isobutyl acetate, methyl acetate, n-butanol, propionic acid, and PG) have adverse respiratory effects. At present, however, there are few data on the emissions of these 19 additional HPHCs, and validated analytical methods for their quantification are not widely available.

It is of considerable interest to compare e-cigarette toxicant emissions with those of combustible cigarettes. Previous comparisons of this kind have largely focused on per-puff measurements, due to the differences in usage patterns between cigarettes and e-cigarettes. As estimates for puffs per day from e-cigarettes (e.g., mean 163 ± 138, median 132 Dautzenberg and Bricard, 2015), and combustible cigarettes (estimates of average values of 14 cigarettes per day with puffs/cigarette around 10) are broadly comparable this approach appears reasonable. However, additional factors may be important to consider, such as compensatory behavior amongst vapers. For example, Dawkins et al. (2018) examined the effects of differing e-liquid nicotine concentrations and device power levels on e-cigarette consumption. They identified evidence for compensatory behaviors amongst vapers where use of a lower nicotine concentration e-liquid may be associated with higher number and duration of puffs as well as formaldehyde exposure. Similarly, Farsalinos et al. (2018) identified compensatory puffing patterns and nicotine self-titration, resulting in a change in puffing patterns (puff number and duration) when vapers change the power settings of an e-cigarette device. These observations suggest that it is also important to consider differences in toxicant emissions as a function of nicotine delivery when comparing emission data from e-cigarettes and combustible cigarettes of differing nicotine content.

The purpose of the present study was to understand whether recent developments in e-cigarette product design influence aerosol emissions, particularly those that may arise from use of two thermally sensitive materials: cotton and BA, and a relatively new coil material, NiFe. In addition, two modern e-cigarette designs have been quantitatively characterized for emissions of the FDA's proposed 19 additional HPHCs, in order to understand this poorly understood area of aerosol chemistry. We contextualize the emissions against values for smoke yields from two cigarettes, a commercial cigarette and a reference product, as well as background air/method baseline values from the measurement laboratory. We also examined the impact of comparing emissions data per-puff and per-mg of nicotine to understand the potential impact of compensatory puffing behavior that might occur when vapers use differing nicotine content e-cigarettes.

Methods

Test Products

Cigarette Comparators

For comparison, two cigarette products were used: Kentucky reference 1R6F (Jaccard et al., 2019), a king-size cigarette with US-style blended tobacco (ISO tar yield, 9.3 mg) and a cellulose acetate filter; and Benson & Hedges Skyblue (Japan Tobacco International), a king-size commercial cigarette with US-style blended tobacco (length, 83 mm; circumference, 24.2 mm; weight, 0.82 g; ISO tar yield, 8.7 mg) and a 21 mm cellulose acetate filter with 30 mm filter tipping and 36% filter ventilation. The cigarette paper of Benson & Hedges Skyblue (B&H Skyblue) is banded: the air permeability is 87 mL/min/cm2 between bands and 6.72 mL/min/cm2 on the bands.

E-Cigarette Devices

Two e-cigarette devices were tested: Vype ePen2 (Nicoventures Trading Ltd., Blackburn, UK) and Vype ePen3 (Nicoventures Trading Ltd.). Vype ePen2 consists of a reusable section containing a 650-mAh rechargeable battery and an actuation button, a disposable flavor cartridge and a mouthpiece cover. It uses a silica rope wick, and an NiCr coil. The device comes with two power settings (high, 4.4 W; and low, 2.8 W); the high-power setting was used in this study.

Vype ePen3 has a different design to the ePen product used in an earlier study (Margham et al., 2016) and is shown schematically in Figure 1. It comprises a “closed system” e-cigarette with a rechargeable battery and a flavored e-liquid pod of 2-mL capacity. The device measures 121 × 26 × 12 mm and weighs 39 grams with a full pod. The e-cigarette is powered by a 650-mAh battery, which is connected to a coil with resistance of 1.95–2.36 ohm, resulting in a power output of 5.9 W. The battery electronics has a protect circuit board (PCB) to protect against short-circuiting, low or high charging voltage, over current, and over charging. The PCB stops battery power to the coil after 8 s, thereby limiting dry-puff events, and causes the device to automatically power off after 10 min of inactivity. The coil is made from a NiFe alloy whose resistance is strongly temperature dependent. The 5.9 W power rating of the device was delivered at the operating temperature and resistance, with device electronics monitoring power as a function of voltage. The device uses a cotton wick to transport e-liquid to the heated coil.

The device was tested for electrical safety performance and was compliant with the essential requirements of the following applicable CE marking European Directives: 2014/30/EU Electromagnetic Compatibility (EMC) Directive 2011/65/EU; and Annex II Amendment (EU) 2015/863 Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment (RoHS). Conformity was assessed in accordance with the following harmonized EMC standards: Requirements for Household Appliances, Electric Tools and Similar Apparatus, Part 1 Emission (EN55014-1 and CISPR 14-1) and Part 2 Immunity (EN55014-2 and CISPR 14-2); and Product Family Standard for Aftermarket Electronic Equipment in Vehicles (EN 50498). Conformity was also assessed in accordance with the following harmonized RoHS standards: Technical Documentation (EN 50581, IEC 63000); and Determination of Certain Substances (IEC/EN 62321-1). In addition, the device was certified for low-voltage electrical safety within the IECEE CB Scheme: Household and Similar Electrical Appliances—Safety, Part 1 General Requirements (IEC 60355-1).

A fully charged ePen3 battery provides ~200 puffs (based on an 80-mL, 3-s puff taken once every 30 s), which matches the liquid capacity of the pod under these testing conditions.

E-Liquids

Five e-liquids with two variants of tobacco-style flavor (“Blended Tobacco” and “Master Blend”) of different compositions were used in this study (Table 1). PG, VG, nicotine, and water were of pharmacopeia standard purity. The flavor compounds were a minimum of food grade and their safety in an inhalation context was evaluated by following Product Stewardship principles (Costigan and Meredith, 2015), and (Costigan and Lopez-Belmonte, 2017). In all cases, the compound flavors accounted for up to 1% of the e-liquid formulation.

Table 1.

E-liquid composition of the study products.

| E-cigarette description | PG % (w/w)* | VG % (w/w) | Water % (w/w) | Nic % (w/w) | BA level | Flavor type |

|---|---|---|---|---|---|---|

| ePen2 18 mg/mL Nic BT | 25.00 | 48.22 | 25 | 1.78 | 0 | Blended Tobacco |

| ePen3 18 mg/mL Nic BT | 54.00 | 34.22 | 10 | 1.78 | 0 | Blended Tobacco |

| ePen3 12 mg/mL Nic Low BA | 54.25 | 34.57 | 10 | 1.18 | Low | MasterBlend |

| ePen3 18 mg/mL Nic Medium BA | 54.73 | 33.5 | 10 | 1.77 | Medium | MasterBlend |

| ePen3 30 mg/mL Nic High BA | 56.06 | 31.2 | 10 | 2.74 | High | MasterBlend |

BA, benzoic acid; Nic, nicotine.

Reported propylene glycol content also includes % content of flavor compounds and benzoic acid.

Blended Tobacco (BT) was tested in ePen2 and ePen3, which differ in coil and wick type, and operating power. Due to the differences in e-cigarette wicks between ePen2 and ePen3, the same PG/VG ratio cannot be used in both products. This is because the silica wick of ePen2 had inferior wicking properties toward high viscosity liquids compared to those of the cotton wick in ePen3. Hence the e-liquid water content was higher in the ePen2 e-liquid than in ePen3, to reduce the liquid viscosity to functional levels. Comparison of the aerosol chemistry between these two products therefore reflects the potential effects of three factors: (1) silica vs cotton wicks; (2) differences in PG/VG/water ratios; and (3) differences in coil power, where ePen3 > ePen2.

Master Blend (MB) was tested in three ePen3 e-liquids differing only in nicotine and BA content (which was increased by substitution with VG in the formulation): 12 mg/mL nicotine with low levels of BA; 18 mg/mL nicotine with medium levels of BA; and 30 mg/mL nicotine with high levels of BA. Comparison of the aerosol chemistry among these three products therefore reflects the combined influence of increasing nicotine/BA content and ratio, and small changes (~10%) in VG content (from 32.1 to 34.5% in the formulation).

Comparison of the aerosol chemistry between ePen3 Blended Tobacco (18 mg/mL nicotine) and ePen3 Master Blend (18 mg/mL nicotine with medium BA) also provides insight into the influence of BA, together with the effect of a small change in VG level and flavor type.

Puffing Conditions

Prior to testing, the commercial and reference cigarettes were marked with the standard butt length as specified in ISO 4387 (2000). Cigarettes were conditioned and tested under a conditioned laboratory environment of 22 ± 2°C and 60 ± 5% relative humidity as specified in ISO 3402 (1999). Tobacco cigarettes were smoked on a rotary or a linear smoking machine using “Canadian Modified” conditions (55-mL puff volume, 2-s puff duration, 30-s interval, vents blocked) (ISO 20778, 2018).

E-cigarette samples were puffed in a dedicated e-cigarette room under a conditioned laboratory environment of 22 ± 2°C and 60 ± 5% relative humidity as specified in ISO 3402 (1999). Puffing of e-cigarettes was carried out on a linear smoking machine using an automated e-cigarette activation system and puffing parameters set out in the CORESTA Reference puffing method CRM81 (CORESTA, 2015) and ISO 20768 (2018) (55-mL puff volume, 3-s puff duration, 30-s interval, square wave puff profile, no ventilation blocking).

Emissions Analysis

Cigarette smoke toxicants and e-cigarette emissions were measured by using Labstat standard methods, as described previously (Margham et al., 2016). The 19 additional HPHCs proposed by the FDA were measured in e-cigarette aerosol using the following methods. Aromatic flavourants were determined in emissions from e-cigarettes by using Labstat method TMS-00175. In brief, e-cigarette aerosol was generated by an automated constant volume linear smoking machine and target compounds were trapped on a 44-mm glass fiber filter disc (pad) followed by a cryogenic (≤-35°C) trap (impinger) containing 20 mL of acetonitrile. The pad was folded, placed in a 25-mL amber glass vial, combined with the impinger solution and extracted for 30 min by using a platform shaker. A 5-mL aliquot of the extract was added to 50 μL of internal standard (ISTD) solution. The sample was then analyzed by gas chromatography–mass spectrometry (GC-MS).

Propionic acid was determined in e-cigarette aerosol by using Labstat method TMS-00177. In brief, e-cigarette aerosol was generated and emissions were trapped on a pad and impinger as described for TMS-00175. The pad was combined with the impinger solution and an internal standard solution (Anisole) and extracted by using a platform shaker. The extract was analyzed by selective ion monitoring (SIM) GC-MS using a WAX-type capillary column.

Acetic acid was determined in e-cigarette aerosol by using Labstat method TMS-00115A. In brief, e-cigarette aerosol was generated by using a linear smoking machine and emissions were collected on a 44-mm Cambridge filter pad. The pad was extracted with 20 mL of 0.1% H3PO4 by shaking for 45 min. The extract was then analyzed by HPLC-UV using a C18 column with detection at 210 nm. Owing to a lack of established methods applicable to smoke analysis, not all of the additional HPHCs were evaluated for the comparator cigarettes.

For all analyses, 50 puffs of ePen3 or ePen2 were used per collection, which is half the puff number used in previous studies (Margham et al., 2016), because ePen3 delivers approximately twice as much aerosol mass per puff. Air/method blank determinations were also conducted in order to identify background contaminants and analytical artifacts. In all cases 5 replicates were measured per observation.

Accelerated Aging Tests for Metal Emissions

Metal emission measurements were conducted to examine the potential for benzoic acid in the e-liquids to corrode the metallic elements of the e-cigarettes, and increase aerosol metal emissions. Metal corrosion by acids is a time-sensitive phenomenon, and therefore we conducted accelerated aging tests where sealed cartomisers containing unflavoured e-liquids and various levels of benzoic acid and nicotine were stored at 40°C/75% RH for 3 months prior to testing. The accelerated conditions were selected to offer a means of reproducing typical shelf-life times for e-cigarettes. After aging the cartomisers were allowed to stabilize at laboratory testing conditions prior to measurements being made. Comparator cigarettes were not subject to accelerated aging conditions prior to testing.

Data Treatment and Analysis

For measurable analytes, data were reported as mean ± SD. To facilitate comparisons between e-cigarette aerosol and cigarette smoke, the data were treated as follows. We compared data both on a per-puff basis, where measurements per collection were divided by the puff number, and per-nicotine where we divided the toxicant emission values by the average nicotine emission value. Where values were less than the limit of detection (<LOD) or limit of quantification (<LOQ), we imputed a value of LOD/2 or the midpoint between LOD and LOQ, respectively, as described previously (Margham et al., 2016). Comparisons were made based on mean per-puff data using the derived values for <LOD and <LOQ values where necessary. Comparisons were only made where the overall per collection mean (based on derived values) for a given analyte was above the LOQ for at least one product.

We calculated the percent reduction in emissions from all five e-cigarettes relative to smoke from both cigarettes except where both e-cigarette and cigarette mean values were <LOQ. Percent reductions above 99.9% were reported as >99.9%.

Because the results of the percent reductions were sensitive to the imputed values used in the calculations, we assessed the magnitude of errors that might arise from use of the midpoint approach, by comparing the percent reductions estimated by this method with those obtained by using two “boundary condition” approaches.

An “upper boundary” estimate approach, where <LOQ values are imputed as the LOQ, and <LOD values are imputed as the LOD, reflecting the maximum possible concentrations of an unquantifiable compound that may be present in the analyzed sample.

A “lower boundary” estimate approach, where values <LOD are imputed as zero, and values <LOQ are imputed as the LOD, reflecting the minimum possible concentrations of an unquantifiable compound that may be present in the analyzed sample.

The impact of the three imputation strategies on the calculated percent reductions was assessed for the nine cigarette smoke analytes prioritized for reduction by the World Health Organizations Tobacco Product Regulation advisory group (WHO TobReg) (Burns et al., 2008).

Statistical comparisons are made between test product and blank emission yields on a per puff basis. When comparing between test products, Generalized Linear Models (GLMs) are used with post-hoc Tukey adjustment with an alpha of 0.05. Alternatively, when comparing multiple test products to the air blank yield, GLMs are used with Dunnett's control adjustment with an alpha of 0.05. When two yields are evaluated (test product or air blank), independent samples t-tests are used for the statistical comparison.

Statistical comparisons are also made on a per milligram of nicotine basis. This was done by taking the average nicotine per puff value of each of the products and divide the constituent measurement per puff by the average mg of nicotine per puff. Comparisons are made between the reference products and test products. These comparisons do not include blanks, as nicotine was not measured in the blanks. When comparing the test products and reference products, GLMs are used with post-hoc Tukey adjustment with an alpha of 0.05.

Results

Overall, the aerosols from five e-cigarette variants (Table 2) and mainstream smoke from two conventional cigarettes (Table 3) were analyzed for 97 and 84 potential toxicants, respectively, together with air/method blanks as a control. The data in Tables 2, 3 are presented on a per-puff basis, however we also present the data for those quantified analytes on a per-nicotine basis in Table 4. Table 5 presents the results of the accelerated aging study of metals emissions. Below, we describe the findings for each group of analytes.

Table 2.

Per-puff emissions of components from the e-cigarettes and air/method blank.

| Aerosol constituent | Unit | LOD | LOQ | Air/method blank | ePen2 18 BT | ePen3 18 BT | ePen3 MB 12 Low BA | ePen3 MB 18 Medium BA | ePen3 MB 30 High BA | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | Mean | SD | Mean | SD | ||||

| Carbon monoxide | μg/puff | 10.50 | 34.99 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| ACM, water, and nicotine | |||||||||||||||

| Water | μg/puff | 3.83 | 12.75 | BDL | BDL | 1,014 | 144.0 | 1,090 | 36.00 | 1,068 | 82.00 | 1,058 | 32.00 | 1,104 | 78.00 |

| Nicotine | μg/puff | 0.13 | 0.45 | BDL | BDL | 39.60 | 5.20 | 149.0 | 35.40 | 130.8 | 20.60 | 168.4 | 11.40 | 256.0 | 50.00 |

| ACM | μg/puff | 7.14 | 23.70 | BDL | BDL | 3,583 | 756 | 8,838 | 250 | 8,692 | 529.2 | 8,758 | 277.3 | 8,818 | 819.4 |

| Triacetin, humectants, menthol | |||||||||||||||

| Propylene glycol | μg/puff | 0.24 | 0.80 | NQ | NQ | 690.0 | 150.0 | 3,760 | 140.0 | 3,880 | 240.0 | 3,860 | 100.0 | 3,980 | 380.0 |

| Menthol | μg/puff | 0.24 | 0.81 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Diethylene glycol | μg/puff | 0.24 | 0.80 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Triacetin | μg/puff | 0.24 | 0.80 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Glycerol | μg/puff | 1.44 | 4.80 | NQ | NQ | 1,676 | 392.0 | 2,960 | 200.0 | 3,120 | 220.0 | 2,900 | 120.0 | 2,780 | 320.0 |

| Pad ethylene glycol | μg/puff | 0.05 | 0.17 | BDL | BDL | BDL | BDL | BDL | BDL | 0.32 | 0.30 | BDL | BDL | 0.30 | 0.26 |

| Impinger ethylene glycol | μg/puff | 0.05 | 0.17 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Pad glycidol | μg/puff | 0.11 | 0.36 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Impinger glycidol | μg/puff | 0.11 | 0.36 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| PAHs | |||||||||||||||

| Naphthalene | pg/puff | 10.07 | 33.56 | 56.40 | 11.00 | 90.40 | 13.00 | 85.20 | 8.80 | 97.20 | 20.80 | 81.00 | 8.00 | 87.00 | 4.40 |

| 1-Methylnaphthalene | pg/puff | 6.07 | 20.24 | 52.60 | 16.20 | 62.00 | 14.00 | 65.20 | 14.20 | 73.20 | 29.60 | 52.40 | 10.80 | 49.20 | 8.20 |

| 2-Methylnaphthalene | pg/puff | 4.55 | 15.18 | 64.60 | 19.60 | 68.00 | 12.60 | 72.80 | 18.40 | 90.40 | 24.80 | 66.60 | 6.80 | 67.20 | 7.60 |

| Acenaphthylene | pg/puff | 4.55 | 15.18 | 23.80 | 6.40 | 28.80 | 9.00 | 24.00 | 4.60 | 19.48 | 2.94 | NQ | NQ | NQ | NQ |

| Acenaphthene | pg/puff | 9.60 | 32.00 | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ |

| Fluorene | pg/puff | 4.72 | 15.72 | 42.20 | 10.00 | 44.20 | 7.00 | 50.20 | 9.20 | 52.40 | 13.00 | 41.20 | 10.60 | 38.00 | 4.40 |

| Phenanthrene | pg/puff | 3.58 | 11.94 | 262.0 | 20.00 | 262.0 | 18.00 | 286.0 | 28.00 | 274.0 | 34.00 | 260.0 | 18.00 | 256.0 | 16.00 |

| Anthracene | pg/puff | 4.63 | 15.43 | 18.12 | 3.50 | 23.80 | 4.00 | 26.20 | 4.60 | 20.60 | 3.00 | 24.00 | 4.80 | NQ | NQ |

| Fluoranthene | pg/puff | 3.94 | 13.13 | 102.4 | 13.40 | 102.4 | 13.00 | 110.8 | 15.20 | 102.8 | 19.80 | 94.20 | 13.80 | 91.20 | 16.00 |

| Pyrene | pg/puff | 9.43 | 31.44 | 282.0 | 42.00 | 290.0 | 50.00 | 280.0 | 60.00 | 252.0 | 54.00 | 236.0 | 40.00 | 244.0 | 48.00 |

| Benzo(a)anthracene | pg/puff | 7.30 | 24.35 | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | BDL | BDL | BDL | BDL |

| Chrysene | pg/puff | 4.68 | 15.58 | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ |

| Benzo(b)fluoranthene | pg/puff | 16.90 | 56.34 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Benzo(k)fluoranthene | pg/puff | 11.86 | 39.52 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Benzo(e)pyrene | pg/puff | 6.96 | 23.19 | BDL | BDL | NQ | NQ | BDL | BDL | BDL | BDL | BDL | BDL | NQ | NQ |

| Benzo(a)pyrene | pg/puff | 10.63 | 35.42 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Perylene | pg/puff | 11.36 | 37.86 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Indeno(1,2,3-cd)pyrene | pg/puff | 10.12 | 33.73 | BDL | BDL | NQ | NQ | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Dibenz(a,h)anthracene | pg/puff | 12.39 | 41.31 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Benzo(g,h,i)perylene | pg/puff | 10.12 | 33.73 | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | BDL | BDL | NQ | NQ |

| Benzo(c)phenanthrene | pg/puff | 5.38 | 17.92 | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ |

| Cyclopenta(c,d)pyrene | pg/puff | 8.11 | 27.03 | NQ | NQ | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Benzo(j)aceanthrylene | pg/puff | 10.37 | 34.56 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Volatiles | |||||||||||||||

| 1,3-Butadiene | ng/puff | 5.70 | 19.01 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Isoprene | ng/puff | 8.12 | 27.06 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Acrylonitrile | ng/puff | 6.40 | 21.34 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Benzene | ng/puff | 3.41 | 11.37 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Toluene | ng/puff | 12.23 | 40.78 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Ethylbenzene | ng/puff | 2.88 | 9.61 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Ethylene oxide | ng/puff | 7.18 | 23.98 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Vinyl chloride | pg/puff | 131.5 | 438.3 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Propylene oxide | ng/puff | 3.12 | 10.40 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Furan | ng/puff | 5.63 | 18.75 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Vinyl acetate | ng/puff | 2.19 | 7.29 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Nitromethane | ng/puff | 1.70 | 5.66 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Tobacco-specific nitrosamines | |||||||||||||||

| NNN | pg/puff | 9.85 | 32.82 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| NAT | pg/puff | 19.51 | 65.04 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| NAB | pg/puff | 5.36 | 17.85 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| NNK | pg/puff | 15.05 | 50.18 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Carbonyls | |||||||||||||||

| Formaldehyde | ng/puff | 5.49 | 18.30 | NQ | NQ | 268.0 | 148.0 | 52.80 | 10.80 | 179.0 | 244.6 | 109.4 | 25.60 | 123.3 | 17.83 |

| Acetaldehyde | ng/puff | 9.95 | 33.17 | NQ | NQ | 230.0 | 134.0 | NQ | NQ | 100.6 | 169.6 | NQ | NQ | 34.12 | 7.30 |

| Acetone | ng/puff | 6.31 | 21.03 | 88.60 | 26.80 | 135.8 | 36.60 | 111.0 | 17.00 | 140.8 | 10.80 | 176.8 | 25.40 | 170.3 | 19.44 |

| Propionaldehyde | ng/puff | 4.84 | 16.13 | NQ | NQ | 96.20 | 71.00 | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ |

| Acrolein | ng/puff | 9.28 | 30.92 | BDL | BDL | 346.0 | 200.0 | BDL | BDL | BDL | BDL | NQ | NQ | NQ | NQ |

| Isobutyraldehyde | ng/puff | 1.65 | 5.51 | NQ | NQ | 164.0 | 35.20 | 506.0 | 78.00 | BDL | BDL | 5.66 | 10.82 | BDL | BDL |

| Methyl Ethyl Ketone | ng/puff | 5.13 | 17.09 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| 3-Buten-2-one | ng/puff | 6.21 | 20.70 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| n-Butyraldehyde | ng/puff | 3.51 | 11.71 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Crotonaldehyde | ng/puff | 6.23 | 20.75 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Glycolaldehyde | ng/puff | 7.45 | 24.84 | BDL | BDL | 60.20 | 39.20 | NQ | NQ | 35.20 | 22.00 | 33.20 | 6.80 | BDL | BDL |

| Acetoin | ng/puff | 6.73 | 22.43 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Glyoxal | ng/puff | 2.52 | 8.40 | BDL | BDL | 18.76 | 9.54 | NQ | NQ | 45.20 | 86.60 | 14.78 | 7.36 | 38.33 | 7.59 |

| Methylglyoxal | ng/puff | 1.54 | 5.12 | BDL | BDL | 73.20 | 34.20 | 36.40 | 11.60 | 135.0 | 163.4 | 83.40 | 19.20 | 145.9 | 20.47 |

| 2,3-Butanedione | ng/puff | 1.74 | 5.80 | BDL | BDL | NQ | NQ | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| 2,3-Pentanedione | ng/puff | 3.51 | 11.71 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| 2,3-Hexanedione | ng/puff | 3.81 | 12.71 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| 2,3-Heptanedione | ng/puff | 4.68 | 15.61 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Phenolic compounds | |||||||||||||||

| Hydroquinone | ng/puff | 12.44 | 41.47 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Resorcinol | ng/puff | 3.29 | 10.98 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Catechol | ng/puff | 5.14 | 17.13 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Phenol | ng/puff | 5.15 | 17.17 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| p-Cresol | ng/puff | 2.06 | 6.86 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| m-Cresol | ng/puff | 1.13 | 3.77 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| o-Cresol | ng/puff | 1.54 | 5.15 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Aromatic flavourants | |||||||||||||||

| Methyl acetate | ng/puff | 72.00 | 240.00 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Ethyl acetate | ng/puff | 60.00 | 200.00 | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ |

| 1-Butanol | ng/puff | 60.00 | 200.00 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Isobutyl acetate | ng/puff | 60.00 | 200.00 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Furfural | ng/puff | 84.00 | 280.00 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Isoamyl acetate | ng/puff | 96.00 | 320.00 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Benzyl acetate | ng/puff | 60.00 | 200.00 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Ethyl acetoacetate | ng/puff | 4.80 | 16.00 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Acids | |||||||||||||||

| Acetic acid | ng/puff | 284.00 | 946.00 | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL |

| Propionic acid | ng/puff | 36.00 | 120.00 | BDL | BDL | 154.81 | 14.60 | NQ | NQ | BDL | BDL | BDL | BDL | BDL | BDL |

ACM, aerosol collected matter; BDL, below detection limit; LOD, limit of detection; LOQ, limit of quantification; NAB, nitrosoanabasine; NAT, nitrosoanatabine; NNK, 4-N-nitrosomethylamino)-1-(3-pyridyl)-1-butanone; NNN, nitrosonornicotine; NQ, not quantified; PAH, polycyclic aromatic hydrocarbon. BT, Blended Tobacco, MB, MasterBlend.

Table 3.

Cigarette smoke emissions per-puff, and puff numbers from 1R6F and B&H Skyblue.

| Smoke constituent | Unit | Air blank | B+H Skyblue cigarette | Ky1R6F reference cigarette | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LOD | LOQ | Mean | SD | LOD | LOQ | Mean | SD | LOD | LOQ | MS | SD | ||

| CO | |||||||||||||

| Puff count | per cig | 10.00 | 0.00 | 8.50 | 0.900 | 9.30 | 0.400 | ||||||

| CO | mg/puff | 1.59E−02 | 5.30E−02 | NQ | NQ | 1.92E−02 | 6.39E−02 | 2.765 | 0.153 | 1.64E−02 | 5.47E−02 | 2.892 | 0.075 |

| NFDPM, water, and nicotine | |||||||||||||

| Puff count | per cig | 10.00 | 0.00 | 8.30 | 0.300 | 9.70 | 0.400 | ||||||

| Water | mg/puff | 6.38E−03 | 2.13E−02 | BDL | BDL | 7.68E−03 | 2.56E−02 | 1.663 | 0.253 | 6.57E−03 | 2.56E−02 | 1.629 | 0.103 |

| Nicotine | mg/puff | 2.24E−04 | 7.48E−04 | BDL | BDL | 2.70E−04 | 9.02E−04 | 0.210 | 0.013 | 2.31E−04 | 9.02E−04 | 0.210 | 0.010 |

| NFDPM | mg/puff | 1.19E−02 | 3.95E−02 | BDL | BDL | 1.43E−02 | 4.76E−02 | 3.145 | 0.398 | 1.23E−02 | 4.07E−02 | 2.990 | 0.144 |

| Triacetin, humectants, menthol | |||||||||||||

| Puff count | per cig | 10.00 | 0.00 | 8.30 | 0.300 | 9.70 | 0.400 | ||||||

| Propylene glycol | mg/puff | 4.00E−04 | 1.33E−03 | BDL | BDL | 4.82E−04 | 1.61E−03 | 0.002 | 0.000 | 4.13E−04 | 1.38E−03 | 0.049 | 0.003 |

| Menthol | mg/puff | 4.07E−04 | 1.36E−03 | BDL | BDL | 4.90E−04 | 1.63E−03 | BDL | BDL | 4.20E−04 | 1.40E−03 | BDL | BDL |

| Diethylene glycol | mg/puff | 4.00E−04 | 1.33E−03 | BDL | BDL | 4.82E−04 | 1.61E−03 | BDL | BDL | 4.12E−04 | 1.37E−03 | BDL | BDL |

| Triacetin | mg/puff | 4.01E−04 | 1.34E−03 | BDL | BDL | 4.84E−04 | 1.61E−03 | 0.123 | 0.012 | 4.14E−04 | 1.38E−03 | 0.162 | 0.008 |

| Glycerol | mg/puff | 2.40E−03 | 7.99E−03 | BDL | BDL | 2.89E−03 | 9.63E−03 | 0.046 | 0.004 | 2.47E−03 | 8.24E−03 | 0.164 | 0.006 |

| Pad ethylene glycol | mg/puff | 8.41E−05 | 2.80E−04 | BDL | BDL | 1.01E−04 | 3.38E−04 | BDL | BDL | 8.67E−05 | 2.89E−04 | BDL | BDL |

| Impinger ethylene glycol | mg/puff | 8.41E−05 | 2.80E−04 | BDL | BDL | 1.01E−04 | 3.38E−04 | BDL | BDL | 8.67E−05 | 2.89E−04 | BDL | BDL |

| Pad glycidol | mg/puff | 1.80E−04 | 6.00E−04 | BDL | BDL | 2.17E−04 | 7.23E−04 | 0.001 | 0.002 | 1.86E−04 | 6.19E−04 | BDL | BDL |

| Impinger glycidol | mg/puff | 1.80E−04 | 6.00E−04 | BDL | BDL | 2.17E−04 | 7.23E−04 | BDL | BDL | 1.86E−04 | 6.19E−04 | BDL | BDL |

| PAH | |||||||||||||

| Puff count | per cig | 10.00 | 0.00 | 8.80 | 0.700 | 9.60 | 0.300 | ||||||

| Naphthalene | ng/puff | 1.50E−02 | 4.99E−02 | 2.26 | 0.55 | 1.91E−02 | 6.36E−02 | 173.9 | 13.52 | 1.75E−02 | 5.83E−02 | 139.3 | 10.83 |

| 1-Methylnaphthalene | ng/puff | 9.04E−03 | 3.01E−02 | 2.66 | 0.53 | 1.15E−02 | 3.83E−02 | 126.7 | 8.864 | 1.05E−02 | 3.51E−02 | 106.6 | 1.146 |

| 2-Methylnaphthalene | ng/puff | 6.78E−03 | 2.26E−02 | 3.26 | 0.67 | 8.62E−03 | 2.87E−02 | 132.5 | 9.091 | 7.91E−03 | 2.64E−02 | 115.5 | 1.458 |

| Acenaphthylene | ng/puff | 6.78E−03 | 2.26E−02 | 0.51 | 0.10 | 8.62E−03 | 2.87E−02 | 20.45 | 0.795 | 7.91E−03 | 2.64E−02 | 19.48 | 2.292 |

| Acenaphthene | ng/puff | 1.43E−02 | 4.76E−02 | 0.31 | 0.04 | 1.82E−02 | 6.06E−02 | 10.09 | 1.114 | 1.67E−02 | 5.56E−02 | 8.563 | 0.500 |

| Fluorene | ng/puff | 7.02E−03 | 2.34E−02 | 0.97 | 0.19 | 8.93E−03 | 2.98E−02 | 37.95 | 3.864 | 8.19E−03 | 2.73E−02 | 34.48 | 1.771 |

| Phenanthrene | ng/puff | 5.33E−03 | 1.78E−02 | 0.65 | 0.10 | 6.78E−03 | 2.26E−02 | 20.45 | 2.045 | 6.22E−03 | 2.07E−02 | 20.21 | 1.042 |

| Anthracene | ng/puff | 6.89E−03 | 2.30E−02 | 0.18 | 0.04 | 8.77E−03 | 2.92E−02 | 10.16 | 1.170 | 8.04E−03 | 2.68E−02 | 10.52 | 0.625 |

| Fluoranthene | ng/puff | 5.86E−03 | 1.95E−02 | 0.24 | 0.03 | 7.46E−03 | 2.49E−02 | 13.75 | 1.364 | 6.84E−03 | 2.28E−02 | 12.29 | 0.729 |

| Pyrene | ng/puff | 1.40E−02 | 4.68E−02 | 0.29 | 0.07 | 1.79E−02 | 5.96E−02 | 11.01 | 1.170 | 1.64E−02 | 5.46E−02 | 9.917 | 0.563 |

| Benzo(a)anthracene | ng/puff | 1.09E−02 | 3.62E−02 | NQ | NQ | 1.38E−02 | 4.61E−02 | 3.580 | 0.489 | 1.27E−02 | 4.23E−02 | 3.292 | 0.198 |

| Chrysene | ng/puff | 6.96E−03 | 2.32E−02 | 0.07 | 0.02 | 8.85E−03 | 2.95E−02 | 3.966 | 0.409 | 8.12E−03 | 2.71E−02 | 3.750 | 0.104 |

| Benzo(b)fluoranthene | ng/puff | 2.52E−02 | 8.38E−02 | BDL | BDL | 3.20E−02 | 1.07E−01 | 1.648 | 0.170 | 2.93E−02 | 9.78E−02 | 1.313 | 0.073 |

| Benzo(k)fluoranthene | ng/puff | 1.76E−02 | 5.88E−02 | BDL | BDL | 2.25E−02 | 7.48E−02 | 0.732 | 0.023 | 2.06E−02 | 6.86E−02 | 0.605 | 0.059 |

| Benzo(e)pyrene | ng/puff | 1.04E−02 | 3.45E−02 | NQ | NQ | 1.32E−02 | 4.39E−02 | 0.919 | 0.108 | 1.21E−02 | 4.03E−02 | 0.753 | 0.081 |

| Benzo(a)pyrene | ng/puff | 1.58E−02 | 5.27E−02 | NQ | NQ | 2.01E−02 | 6.71E−02 | 1.852 | 0.193 | 1.84E−02 | 6.15E−02 | 1.719 | 0.125 |

| Perylene | ng/puff | 1.69E−02 | 5.63E−02 | BDL | BDL | 2.15E−02 | 7.17E−02 | 0.289 | 0.058 | 1.97E−02 | 6.57E−02 | 0.271 | 0.022 |

| Indeno(1,2,3-cd)pyrene | ng/puff | 1.51E−02 | 5.02E−02 | BDL | BDL | 1.92E−02 | 6.39E−02 | 0.663 | 0.094 | 1.76E−02 | 5.86E−02 | 0.624 | 0.033 |

| Dibenz(a,h)anthracene | ng/puff | 1.84E−02 | 6.15E−02 | BDL | BDL | 2.35E−02 | 7.82E−02 | 0.114 | 0.019 | 2.15E−02 | 7.17E−02 | 0.114 | 0.024 |

| Benzo(g,h,i)perylene | ng/puff | 1.51E−02 | 5.02E−02 | BDL | BDL | 1.92E−02 | 6.39E−02 | 0.491 | 0.055 | 1.76E−02 | 5.86E−02 | 0.433 | 0.044 |

| Benzo(c)phenanthrene | ng/puff | 8.00E−03 | 2.67E−02 | NQ | NQ | 1.02E−02 | 3.39E−02 | 0.690 | 0.061 | 9.33E−03 | 3.11E−02 | 0.589 | 0.055 |

| Cyclopenta(c,d)pyrene | ng/puff | 1.21E−02 | 4.02E−02 | BDL | BDL | 1.54E−02 | 5.12E−02 | 1.580 | 0.182 | 1.41E−02 | 4.69E−02 | 1.396 | 0.323 |

| Benzo(j)aceanthrylene | ng/puff | 1.54E−02 | 5.14E−02 | BDL | BDL | 1.96E−02 | 6.55E−02 | 0.123 | 0.022 | 1.80E−02 | 6.00E−02 | 0.107 | 0.007 |

| Volatiles | |||||||||||||

| Puff count | per cig | 10.00 | 0.00 | 8.40 | 0.700 | 9.20 | 0.500 | ||||||

| 1,3-Butadiene | μg/puff | 1.90E−02 | 6.33E−02 | NQ | NQ | 2.26E−02 | 7.54E−02 | 10.31 | 0.726 | 2.07E−02 | 6.88E−02 | 9.978 | 0.500 |

| Isoprene | μg/puff | 2.70E−02 | 9.01E−02 | 0.39 | 0.05 | 3.22E−02 | 1.07E−01 | 83.10 | 5.476 | 2.94E−02 | 9.80E−02 | 86.20 | 5.000 |

| Acrylonitrile | μg/puff | 2.13E−02 | 7.11E−02 | NQ | NQ | 2.54E−02 | 8.46E−02 | 2.321 | 0.202 | 2.32E−02 | 7.72E−02 | 2.478 | 0.283 |

| Benzene | μg/puff | 1.12E−02 | 3.73E−02 | 0.20 | 0.02 | 1.33E−02 | 4.44E−02 | 8.512 | 0.679 | 1.22E−02 | 4.06E−02 | 8.652 | 1.043 |

| Toluene | μg/puff | 4.08E−02 | 1.36E−01 | 0.92 | 0.12 | 4.86E−02 | 1.62E−01 | 12.38 | 1.429 | 4.43E−02 | 1.48E−01 | 13.59 | 1.848 |

| Ethylbenzene | μg/puff | 9.60E−03 | 3.20E−02 | 0.18 | 0.03 | 1.14E−02 | 3.81E−02 | 1.238 | 0.155 | 1.04E−02 | 3.48E−02 | 1.293 | 0.130 |

| Ethylene oxide | μg/puff | 2.39E−02 | 7.93E−02 | BDL | BDL | 2.85E−02 | 9.44E−02 | 1.905 | 0.119 | 2.60E−02 | 8.62E−02 | 1.946 | 0.228 |

| Vinyl chloride | ng/puff | 4.38E−01 | 1.46E+00 | BDL | BDL | 5.21E−01 | 1.74E+00 | 9.595 | 1.155 | 4.76E−01 | 1.59E+00 | 11.09 | 0.543 |

| Propylene oxide | ng/puff | 1.04E+01 | 3.47E+01 | BDL | BDL | 1.24E+01 | 4.13E+01 | 115.1 | 8.095 | 1.13E+01 | 3.77E+01 | 215.3 | 13.26 |

| Furan | μg/puff | 1.87E−02 | 6.27E−02 | NQ | NQ | 2.22E−02 | 7.46E−02 | 6.155 | 0.702 | 2.03E−02 | 6.81E−02 | 5.989 | 0.696 |

| Vinyl acetate | ng/puff | 7.30E+00 | 2.43E+01 | BDL | BDL | 8.69E+00 | 2.89E+01 | 77.50 | 12.14 | 7.93E+00 | 2.64E+01 | 62.39 | 7.174 |

| Nitromethane | ng/puff | 5.67E+00 | 1.89E+01 | BDL | BDL | 6.75E+00 | 2.25E+01 | 27.98 | 4.048 | 6.16E+00 | 2.05E+01 | 49.46 | 9.565 |

| Tobacco–specific nitrosamines | |||||||||||||

| Puff count | per cig | 10.00 | 0.00 | 8.60 | 0.800 | 9.30 | 0.400 | ||||||

| NNN | ng/puff | 1.64E−02 | 5.47E−02 | BDL | BDL | 1.91E−02 | 6.36E−02 | 9.105 | 2.116 | 1.76E−02 | 5.88E−02 | 22.69 | 1.398 |

| NAT | ng/puff | 3.25E−02 | 1.08E−01 | BDL | BDL | 3.78E−02 | 1.26E−01 | 17.79 | 3.488 | 3.50E−02 | 1.17E−01 | 26.13 | 1.828 |

| NAB | ng/puff | 8.93E−03 | 2.98E−02 | BDL | BDL | 1.04E−02 | 3.46E−02 | 2.186 | 0.407 | 9.60E−03 | 3.20E−02 | 2.667 | 0.344 |

| NNK | ng/puff | 2.51E−02 | 8.36E−02 | BDL | BDL | 2.92E−02 | 9.73E−02 | 9.093 | 2.023 | 2.70E−02 | 8.99E−02 | 20.97 | 1.075 |

| Carbonyls | |||||||||||||

| Puff count | per cig | 10.00 | 0.00 | 8.10 | 1.000 | 9.10 | 0.500 | ||||||

| Formaldehyde | μg/puff | 1.37E−01 | 4.57E−01 | NQ | NQ | 1.69E−01 | 5.65E−01 | 5.235 | 0.852 | 1.51E−01 | 5.03E−01 | 4.879 | 0.319 |

| Acetaldehyde | μg/puff | 2.49E−01 | 8.29E−01 | NQ | NQ | 3.07E−01 | 1.02E+00 | 177.4 | 16.91 | 2.73E−01 | 9.11E−01 | 158.9 | 5.385 |

| Acetone | μg/puff | 1.58E−01 | 5.26E−01 | BDL | BDL | 1.95E−01 | 6.49E−01 | 65.68 | 6.667 | 1.73E−01 | 5.78E−01 | 62.31 | 3.187 |

| Propionaldehyde | μg/puff | 1.21E−01 | 4.03E−01 | BDL | BDL | 1.49E−01 | 4.98E−01 | 15.43 | 1.728 | 1.33E−01 | 4.43E−01 | 13.74 | 1.319 |

| Acrolein | μg/puff | 2.32E−01 | 7.73E−01 | BDL | BDL | 2.86E−01 | 9.54E−01 | 15.93 | 1.358 | 2.55E−01 | 8.49E−01 | 14.51 | 1.099 |

| Isobutyraldehyde | μg/puff | 4.13E−02 | 1.38E−01 | BDL | BDL | 5.10E−02 | 1.70E−01 | 6.272 | 0.815 | 4.54E−02 | 1.51E−01 | 5.000 | 0.747 |

| Methyl ethyl ketone | μg/puff | 1.28E−01 | 4.27E−01 | NQ | NQ | 1.58E−01 | 5.28E−01 | 17.41 | 1.605 | 1.41E−01 | 4.70E−01 | 15.93 | 0.769 |

| 3-Buten-2-one | μg/puff | 1.55E−01 | 5.17E−01 | BDL | BDL | 1.92E−01 | 6.39E−01 | 7.988 | 0.741 | 1.71E−01 | 5.69E−01 | 7.462 | 0.385 |

| n-Butyraldehyde | μg/puff | 8.78E−02 | 2.93E−01 | BDL | BDL | 1.08E−01 | 3.61E−01 | 4.469 | 0.506 | 9.65E−02 | 3.22E−01 | 3.802 | 0.352 |

| Crotonaldehyde | μg/puff | 1.56E−01 | 5.19E−01 | BDL | BDL | 1.92E−01 | 6.41E−01 | 5.321 | 0.654 | 1.71E−01 | 5.70E−01 | 4.484 | 0.242 |

| Glycolaldehyde | μg/puff | 1.86E−01 | 6.21E−01 | BDL | BDL | 2.30E−01 | 7.67E−01 | 7.222 | 0.778 | 2.05E−01 | 6.82E−01 | 6.220 | 0.934 |

| Acetoin | μg/puff | 1.68E−01 | 5.61E−01 | BDL | BDL | 2.08E−01 | 6.92E−01 | 2.864 | 0.321 | 1.85E−01 | 6.16E−01 | 1.495 | 0.176 |

| Glyoxal | μg/puff | 6.30E−02 | 2.10E−01 | BDL | BDL | 7.78E−02 | 2.59E−01 | 0.631 | 0.099 | 6.92E−02 | 2.31E−01 | 0.897 | 0.148 |

| Methylglyoxal | μg/puff | 3.84E−02 | 1.28E−01 | BDL | BDL | 4.74E−02 | 1.58E−01 | 1.840 | 0.198 | 4.22E−02 | 1.41E−01 | 1.868 | 0.154 |

| 2,3-Butanedione | μg/puff | 4.35E−02 | 1.45E−01 | 0.24 | 0.17 | 5.37E−02 | 1.79E−01 | 19.01 | 0.988 | 4.78E−02 | 1.59E−01 | 17.58 | 0.879 |

| 2,3-Pentanedione | μg/puff | 8.78E−02 | 2.93E−01 | NQ | NQ | 1.08E−01 | 3.61E−01 | 3.321 | 0.222 | 9.65E−02 | 3.22E−01 | 2.813 | 0.121 |

| 2,3-Hexanedione | μg/puff | 9.54E−02 | 3.18E−01 | BDL | BDL | 1.18E−01 | 3.92E−01 | NQ | NQ | 1.05E−01 | 3.49E−01 | NQ | NQ |

| 2,3-Heptanedione | μg/puff | 1.17E−01 | 3.90E−01 | BDL | BDL | 1.45E−01 | 4.82E−01 | BDL | BDL | 1.29E−01 | 4.29E−01 | BDL | BDL |

| Phenolic compounds | |||||||||||||

| Puff count | per cig | 10.00 | 0.00 | 8.13 | 0.365 | 9.42 | 0.512 | ||||||

| Hydroquinone | μg/puff | 1.35E−01 | 4.51E−01 | BDL | BDL | 1.67E−01 | 5.55E−01 | 14.939 | 0.467 | 1.44E−01 | 4.79E−01 | 11.78 | 0.818 |

| Resorcinol | μg/puff | 3.95E−02 | 1.32E−01 | BDL | BDL | 4.85E−02 | 1.62E−01 | 0.343 | 0.054 | 4.19E−02 | 1.40E−01 | 0.308 | 0.061 |

| Catechol | μg/puff | 1.21E−01 | 4.03E−01 | BDL | BDL | 1.49E−01 | 4.96E−01 | 15.519 | 0.466 | 1.28E−01 | 4.28E−01 | 11.82 | 0.644 |

| Phenol | μg/puff | 1.43E−01 | 4.78E−01 | BDL | BDL | 1.76E−01 | 5.88E−01 | 3.276 | 0.165 | 1.52E−01 | 5.07E−01 | 1.595 | 0.218 |

| p-Cresol | μg/puff | 2.07E−02 | 6.91E−02 | BDL | BDL | 2.55E−02 | 8.50E−02 | 1.526 | 0.087 | 2.20E−02 | 7.34E−02 | 0.865 | 0.095 |

| m-Cresol | μg/puff | 4.51E−02 | 1.50E−01 | BDL | BDL | 5.55E−02 | 1.85E−01 | 0.634 | 0.034 | 4.79E−02 | 1.60E−01 | 0.360 | 0.042 |

| o-Cresol | μg/puff | 1.84E−02 | 6.14E−02 | BDL | BDL | 2.26E−02 | 7.55E−02 | 0.792 | 0.049 | 1.95E−02 | 6.51E−02 | 0.409 | 0.046 |

NFDPM, nicotine-free dry particulate matter; BDL, below detection limit; LOD, limit of detection; LOQ, limit of quantification; NAB, nitrosoanabasine; NAT, nitrosoanatabine; NNK, 4-N-nitrosomethylamino)-1-(3-pyridyl)-1-butanone; NNN, nitrosonornicotine; NQ, not quantified; PAH, polycyclic aromatic hydrocarbon.

Table 4.

Toxicant to nicotine ratios calculated for the analytes providing quantifiable values from the e-cigarettes in this study.

| Parameter per mg nicotine | ePen2 18 BT | ePen3 18 BT | ePen3 MB 12 Low BA | ePen3 MB 18 Med. BA | ePen3 MB 30 High BA | Ky1R6F | B&H Skyblue | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mean | SD | mean | SD | mean | SD | mean | SD | mean | SD | mean | SD | mean | SD | |

| Water (mg) | 25.66 | 3.6 | 7.31 | 0.24 | 8.16 | 0.63 | 6.29 | 0.19 | 4.31 | 0.30 | 7.75 | 0.56 | 7.92 | 1.11 |

| ACM/NFDPM (mg) | 63.99 | 15.46 | 51.00 | 1.44 | 57.31 | 3.37 | 44.72 | 1.43 | 29.14 | 2.76 | 14.22 | 0.92 | 14.97 | 1.76 |

| Propylene glycol (mg) | 17.44 | 3.78 | 25.28 | 0.90 | 29.71 | 1.83 | 22.97 | 0.62 | 15.54 | 1.51 | 0.23 | 0.01 | 0.01 | 0.00 |

| Glycerol (mg) | 42.38 | 9.94 | 19.82 | 1.33 | 23.79 | 1.73 | 17.26 | 0.71 | 10.85 | 1.22 | 0.78 | 0.01 | 0.22 | 0.02 |

| Pad Ethylene glycol (mg) | BDL | BDL | BDL | BDL | 0.002 | 0.002 | BDL | BDL | 0.001 | 0.001 | BDL | BDL | BDL | BDL |

| Naphthalene (ng) | 2.29 | 0.33 | 0.57 | 0.06 | 0.74 | 0.16 | 0.48 | 0.05 | 0.34 | 0.02 | 660.85 | 65.14 | 829.71 | 88.12 |

| 1-Methylnaphthalene (ng) | 1.57 | 0.35 | 0.44 | 0.10 | 0.56 | 0.23 | 0.31 | 0.06 | 0.19 | 0.03 | 505.17 | 14.33 | 603.98 | 51.14 |

| 2-Methylnaphthalene (ng) | 1.72 | 0.32 | 0.49 | 0.12 | 0.69 | 0.19 | 0.40 | 0.04 | 0.26 | 0.03 | 547.74 | 17.47 | 631.68 | 54.72 |

| Acenaphthylene (ng) | 0.73 | 0.23 | 0.16 | 0.03 | 0.15 | 0.02 | NQ | NQ | NQ | NQ | 92.52 | 11.92 | 97.53 | 9.87 |

| Fluorene (ng) | 1.12 | 0.18 | 0.34 | 0.06 | 0.40 | 0.10 | 0.24 | 0.06 | 0.15 | 0.02 | 163.53 | 7.64 | 180.56 | 19.22 |

| Phenanthrene (ng) | 6.62 | 0.47 | 1.92 | 0.19 | 2.10 | 0.26 | 1.54 | 0.11 | 1.00 | 0.07 | 95.92 | 5.19 | 97.68 | 11.48 |

| Anthracene (ng) | 0.60 | 0.10 | 0.18 | 0.03 | 0.16 | 0.02 | 0.14 | 0.03 | NQ | NQ | 49.82 | 2.75 | 48.46 | 6.33 |

| Fluoranthene (ng) | 2.59 | 0.33 | 0.74 | 0.10 | 0.79 | 0.15 | 0.56 | 0.08 | 0.36 | 0.06 | 58.48 | 3.81 | 65.83 | 8.46 |

| Pyrene (ng) | 7.31 | 1.27 | 1.88 | 0.40 | 1.93 | 0.24 | 1.41 | 0.19 | 0.96 | 0.19 | 47.01 | 2.90 | 52.55 | 7.08 |

| Formaldehyde (ug) | 6.80 | 3.73 | 0.35 | 0.07 | 1.37 | 1.87 | 0.65 | 0.15 | 0.48 | 0.07 | 23.16 | 2.22 | 25.37 | 5.75 |

| Acetaldehyde (ug) | 5.83 | 3.38 | NQ | NQ | 0.77 | 1.30 | NQ | NQ | 0.13 | 0.03 | 753.87 | 41.62 | 852.17 | 62.13 |

| Acetone (ug) | 3.44 | 0.93 | 0.74 | 0.11 | 1.08 | 0.08 | 1.05 | 0.15 | 0.67 | 0.08 | 295.48 | 18.21 | 315.00 | 18.88 |

| Propionaldehyde (ug) | 2.43 | 1.79 | NQ | NQ | NQ | NQ | NQ | NQ | NQ | NQ | 64.95 | 5.26 | 73.84 | 1.93 |

| Acrolein (ug) | 8.74 | 5.04 | BDL | BDL | BDL | BDL | NQ | NQ | NQ | NQ | 68.68 | 4.52 | 76.76 | 4.14 |

| Isobutyraldehyde (ug) | 4.15 | 0.89 | 3.40 | 0.52 | BDL | BDL | 0.03 | 0.06 | BDL | BDL | 23.64 | 3.03 | 29.97 | 0.91 |

| Glycoaldehyde (ug) | 1.52 | 0.99 | NQ | NQ | 0.27 | 0.17 | 0.20 | 0.04 | BDL | BDL | 29.60 | 5.49 | 34.92 | 4.99 |

| Glyoxal (ug) | 0.47 | 0.24 | NQ | NQ | 0.35 | 0.66 | 0.09 | 0.04 | 0.15 | 0.03 | 4.24 | 0.61 | 3.03 | 0.45 |

| Methylglyoxal (ug) | 1.85 | 0.86 | 0.24 | 0.08 | 1.03 | 1.25 | 0.49 | 0.11 | 0.57 | 0.08 | 8.88 | 0.67 | 8.97 | 1.83 |

NQ, not quantified; BDL, below detection limit.

Table 5.

Per-puff metals emission data from e-cigarettes, obtained after accelerated aging at 40°C/75% RH for 3 months, and tobacco reference cigarette.

| Air/method blank and vapor | Air/method blank values | ePen3 18 BT | ePen3 MB 12 Low BA | ePen3 MB 18 Medium BA | ePen3 MB 30 High BA | Ky1R6F reference cigarette | Ky1R6F reference cigarette | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aerosol/Smoke constituent | Unit | LOD | LOQ | Mean | SD | Mean | SD | Mean | SD | Mean | SD | Mean | SD | LOD | LOQ | Mean | SD |

| Puff count | 25 | 25 | 25 | 25 | 8.80 | 0.20 | |||||||||||

| Coil metals | |||||||||||||||||

| Nickel | ng/puff | 0.25 | 2.17 | NQ | NQ | NQ | NQ | BDL | BDL | NQ | NQ | NQ | NQ | 0.32 | 1.08 | NQ | NQ |

| Iron | ng/puff | 0.33 | 1.09 | 3.55 | 1.43 | 2.71 | 0.93 | 1.30 | 0.42 | 1.94 | 0.81 | 4.58 | 0.68 | 0.64 | 2.13 | 4.05 | 0.53 |

| Other metals | |||||||||||||||||

| Aluminum | ng/puff | 0.39 | 1.29 | 4.15 | 3.02 | NR | NR | 7.66 | 1.28 | 8.13 | 1.06 | 3.36 | 0.39 | NR | NR | NR | NR |

| Arsenic | ng/puff | 0.07 | 0.23 | NQ | NQ | BDL | BDL | BDL | BDL | BDL | BDL | NR | NR | 0.10 | 0.33 | 0.86 | 0.02 |

| Cadmium | ng/puff | 0.04 | 0.14 | NQ | NQ | BDL | BDL | BDL | BDL | BDL | BDL | BDL | BDL | 0.19 | 0.62 | 10.12 | 0.15 |

| Chromium | ng/puff | 0.06 | 0.19 | 1.62 | 0.81 | 1.81 | 0.33 | 1.19 | 0.21 | 1.16 | 0.14 | 1.54 | 0.36 | 0.15 | 0.51 | NQ | NQ |

| Copper | ng/puff | 0.18 | 0.60 | NQ | NQ | BDL | BDL | BDL | BDL | NQ | NQ | NQ | NQ | 0.28 | 0.93 | 3.49 | 0.20 |

| Lead | ng/puff | 0.03 | 0.11 | NQ | NQ | NQ | NQ | BDL | BDL | 0.13 | 0.17 | 0.12 | 0.04 | 0.52 | 1.74 | 3.20 | 0.10 |

| Manganese | ng/puff | 0.23 | 0.76 | NQ | NQ | BDL | BDL | NQ | NQ | NQ | NQ | NQ | NQ | NR | NR | NR | NR |

| Molybdenum | ng/puff | 0.11 | 0.36 | 0.54 | 0.38 | 0.44 | 0.17 | 0.55 | 0.20 | 0.37 | 0.09 | NQ | NQ | NR | NR | NR | NR |

| Zinc | ng/puff | 0.70 | 2.34 | 2.30 | 0.87 | NQ | NQ | NQ | NQ | 3.34 | 0.39 | 9.18 | 2.54 | 2.00 | 6.70 | 38.0 | 1.00 |

| Mercury | |||||||||||||||||

| Puff Count | 50 | 25 | 25 | 25 | 10.50 | 0.60 | |||||||||||

| Mercury | ng/puff | 0.04 | 0.14 | BDL | BDL | BDL | BDL | NQ | NQ | NQ | NQ | NQ | NQ | 0.08 | 0.27 | 0.37 | 0.04 |

NR, not reported; NQ, not quantified; BDL, below detection limit.

Nicotine, Aerosol Mass, CO, and Water Emissions

The nicotine per-puff yields from the ePen3 samples were 3–7 times higher as compared with ePen2, depending on the nicotine concentration of the e-liquid. Nicotine per-puff emissions from ePen2 were 81% lower than those from both cigarettes. Due to the different nicotine concentrations of the ePen3 e-liquids, the percentage difference in nicotine emissions between the ePen3 samples and the two cigarettes varied from 38% lower to 22% higher.

Aerosol collected matter (ACM) per puff was, on average, 2.4 times higher from the ePen3 aerosol samples than from ePen2. The per-puff ACM yield from ePen2 was 15–20% higher than the cigarette tar yield. In contrast, the per-puff ACM yields from all e-Pen3 variants were 176–196% higher. ePen2 per-nicotine ACM yields were significantly higher than from the ePen3 samples with at least 18 mg/mL nicotine. The cigarette per-nicotine emissions were not significantly different from each other, but were significantly lower than the corresponding ACM emissions from all of the e-cigarettes.

The CO emissions from all e-cigarettes were below the detection limit (BDL) and therefore >99% lower than those from either cigarette. The air/method background values for this group of analytes were all BDL.

Water emissions per-puff were comparable among all e-cigarette samples. The per-puff water emissions from all five e-cigarettes were consistently 32–39% lower than those from the two cigarettes. Per-nicotine water emissions from the ePen2 sample were significantly higher than from the ePen3 samples due to the lower nicotine emission from ePen2. Per-nicotine water emissions from the two combustible cigarettes were not significantly different from each other, but were significantly lower than from ePen2 and higher than ePen3 30 mg/mL.

Triacetin, Humectants, Menthol

Air/method background levels of menthol, diethylene glycol, triacetin, ethylene glycol, and glycidol were all BDL. Background levels of PG and VG were detected but too low to quantify (i.e., <LOQ), which may reflect ambient contamination from repeated device testing in the e-cigarette laboratory.

Emissions of menthol, diethylene glycol, triacetin, and glycidol were BDL for all five e-cigarettes. Ethylene glycol emissions were quantifiable from two e-cigarettes but BDL with the other samples.

All e-cigarette aerosols contained considerable quantities of PG and VG. Per-puff emissions of PG were 6 times higher from the ePen3 samples than from ePen2, reflecting both the higher proportion of PG in the ePen3 e-liquids and the 2–3-fold higher per-puff ACM from ePen3 samples as compared with ePen2. Per-nicotine PG emissions from the two combustible cigarettes were not significantly different from each other, but were significantly lower than those from any of the e-cigarettes. ePen2 PG/nicotine was significantly lower than from all ePen3 variants, except for ePen3 30 mg/mL high BA.

In comparison to the B&H Skyblue cigarette, per-puff VG emissions from the five e-cigarettes were between 3,500 and 6,750% higher, and PG emissions were between 32,000 and 183,000% higher. VG and PG emissions were also higher from the e-cigarettes than from the 1R6F cigarette, but to a lesser degree: VG emissions were 900–1,800% higher and PG emissions were 1,300–8,000% higher. Per-nicotine VG emissions from the two combustible cigarettes were not significantly different from each other, but were significantly lower than from any of the e-cigarettes tested in this study. ePen2 VG/nicotine was significantly higher than from all ePen3 variants. Per-nicotine VG from the ePen3 products with a nicotine loading below 30 mg/mL were statistically equivalent.

Glycidol was not detected in any of the e-cigarette aerosols, but was quantified in B&H Skyblue cigarette smoke but not in 1R6F smoke. The per-puff emissions from the e-cigarettes were at least 95% lower than those from the B&H Skyblue cigarette. The relative emissions of diethylene glycol and ethylene glycol from e-cigarettes and cigarettes could not be calculated because these analytes were not detected in sufficient numbers of samples.

Polycyclic Aromatic Hydrocarbons

Among the 23 PAHs analyzed, 18 were either not detected in the e-cigarette aerosols or detected at extremely low levels not significantly different to the air/method blank, indicating that these compounds are not generated by the five e-cigarettes tested. For example, benzo(b)fluoranthene, benzo(k)fluoranthene, benzo(a)pyrene, perylene, dibenz(a,h)anthracene and benzo(j)aceanthrylene were BDL for all air/method blanks and e-cigarette samples. Cyclopenta(c,d)pyrene was <LOQ in the air/method blank, but not detected in any of the e-cigarette samples. Benzo(a)anthracene was <LOQ for air/method blank and three e-cigarette samples, and BDL for two of the ePen3 samples. Benzo(g,h,i)perylene was also <LOQ for air/method blank and four e-cigarette samples, but BDL for one ePen3 sample. Benzo(c)phenanthrene, acenaphthene and chrysene were <LOQ for all tested samples. 1-methylnaphthalene, 2-methylnaphthalene, fluorene, acenaphthylene, phenanthrene, fluoranthene, and pyrene were quantified in most or all samples, including the air/method blank, but their levels did not differ significantly between the e-cigarette samples and the air/method blank sample.

The per-puff levels of four PAHs were higher in e-cigarette aerosols than in air/method blanks. Indeno(1,2,3-cd)pyrene and benzo(e)pyrene were BDL for the air/method blank and almost all e-cigarette samples, but indeno(1,2,3-cd)pyrene was <LOQ for ePen2 and benzo(e)pyrene was <LOQ for ePen2 and one ePen3 sample. Anthracene emissions from ePen3 (18 mg/mL, BT) were significantly higher than the air/method blank (p <0.05); all other e-cigarette aerosols were not significantly different to the air/method blank. Naphthalene was significantly (up to 70%) higher in all five e-cigarette aerosols than in the air/method blank (p < 0.005).

Overall, on a per-puff basis, levels of PAHs were significantly higher in cigarette smoke than in the e-cigarette aerosols. Across all PAHs and e-cigarettes, per-puff levels were, on average, 98.8% lower in e-cigarette aerosol than in smoke from B&H Skyblue (range 94.5% [dibenz(a,h)anthracene] to >99.9% [multiple PAHs]). Similarly, per-puff PAH levels were, on average, 98.7% lower in aerosol from e-cigarettes than in smoke from 1R6F (range 94.5–99.9%). Expressed as a ratio to nicotine all of the PAH emissions from the e-cigarettes were substantially lower (mean 98.7%, range 84% with pyrene to >99.9% for multiple PAHs) than from both combustible cigarettes. Quantifiable per-nicotine PAH emissions had a tendency to decrease across the e-cigarettes as nicotine emissions increased (i.e., from ePen2 to increasing ePen3 nicotine content), but differences between ePen2 and ePen3 were not always significant.

Volatile Compounds

None of the volatile organic toxicants examined were detected in the air/method blank or e-cigarette aerosols; all measurements were BDL for the five test products. In contrast, quantifiable levels of all volatile toxicants were detected in smoke from the two tobacco cigarettes. Consequently, the levels of these compounds in the aerosols from the e-cigarettes were, on average, 99.4% lower than those from the B&H Skyblue cigarette on a per-puff basis (range 97–>99.9%), and 99.6% lower than those from 1R6F (range 98.3–>99.9%).

Tobacco-Specific Nitrosamines

Tobacco-specific nitrosamines (TSNAs) emissions both in the air/method sample and all e-cigarette aerosols were BDL. By contrast, all four TSNAs were quantified in the smoke from 1R6F and B&H Skyblue cigarettes. Emissions of TSNAs from all e-cigarette samples were therefore ~99.9% lower than those from the two tobacco cigarettes.

Carbonyls and Dicarbonyls

Among 18 carbonyls evaluated, emissions of methyl ethyl ketone, 3-buten-2-one, n-butyraldehyde, crotonaldehyde, acetoin, and 2,3-pentanedione were BDL for the air/method blank and all e-cigarette samples. These six compounds were quantified in both cigarette smoke samples, and thus their levels were, on average, >99.9% lower in e-cigarette aerosols than in cigarette smoke.

2,3-Heptanedione was not detected in e-cigarette aerosols, the air/method blank, or the cigarette smoke samples. 2,3-Hexanedione was detected but not quantifiable in the cigarette samples, and not detected in any of the other samples.

Formaldehyde was not quantifiable in the air/method blank, but was quantified in all e-cigarette aerosol samples. Formaldehyde levels per-puff were higher in the ePen2 than in the ePen3 aerosol samples (p = 0.03), but were much higher in the two cigarette smoke samples. In comparison to B&H Skyblue cigarette smoke, levels of formaldehyde were, on average, 97.2% lower in the e-cigarette aerosols (range 94.9–99%). Similarly, the e-cigarettes had, on average, 97% lower formaldehyde emissions as compared with 1R6F (range 94.5–98.9%). Per-nicotine emissions from the two combustible cigarettes were not significantly different from each other, but were significantly higher than from any of the e-cigarettes tested in this study. Per-nicotine formaldehyde emissions from ePen2 were significantly higher than from all ePen3 samples other than the 12 mg/mL low BA sample. All ePen3 variants were not statistically different from each other.

Acetaldehyde was not quantifiable in the air/method blank or two e-cigarette samples (ePen3 [18 mg/mL, BT] and ePen3 [18 mg/mL, Medium BA]), but was quantified in aerosol from ePen2, ePen3 (12 mg/mL, Low BA) and ePen3 (30 mg/mL, High BA). Both per-puff and per-nicotine levels were significantly higher (p < 0.05) in the ePen2 sample than in all ePen3 samples except for ePen3 (12 mg/mL, Low BA), where high levels of variance were observed. The cigarette smoke samples contained substantially higher levels of acetaldehyde than any other carbonyl, and the acetaldehyde content of the e-cigarette aerosols was >99.9 lower than the smoke from both combustible cigarettes on both a per-puff and per-nicotine basis.

Acetone was quantified in the air/blank samples and in all e-cigarette aerosols. Acetone emissions were higher in the e-cigarettes than the air/method blank for ePen2 and most ePen3 samples (p < 0.05), although emissions from the ePen3 BT (18 mg/mL) sample were not significantly different from the air/method blank (p > 0.05). Per-puff emissions from ePen3 BT 18 mg/mLwere lower than from those of the other ePen3 samples (p < 0.05) except for ePen3 (12 mg/mL Low BA). On a per-nicotine basis the e-cigarette acetone emissions were not significantly different to each other, but were significantly lower than those from both combustible cigarettes (which were not significantly different to each other). In comparison to cigarette smoke, acetone emissions from the e-cigarettes were, on average, 99.6–99.8% lower than those from B&H Skyblue and 1R6F cigarette smoke on a per nicotine or per-puff basis, respectively.

Propionaldehyde was detected but not quantifiable in the air/method blank or ePen3 aerosol samples, but was quantified in the ePen2 sample. On average, propionaldehyde emissions were 99.8% lower from the e-cigarettes than from the two tobacco cigarettes.

Acrolein was not detected in the air/method blank or two of the ePen3 aerosol samples. The other two ePen3 samples showed non-quantifiable levels. The ePen2 aerosol had substantially higher and quantifiable (albeit variable) levels of acrolein than the ePen3 samples (both per-puff and per-nicotine). B&H Skyblue acrolein emissions were significantly higher than from 1R6F; both cigarette smoke emissions were significantly higher than from the e-cigarettes. Acrolein per-puff emissions were 98.2% lower (88% on a per-nicotine basis) from ePen2 than from cigarette smoke; on average, ePen3 samples were >99.9% lower from than from cigarette smoke.

Isobutyraldehyde was detected but not quantified in the air/method blank. Regarding the e-cigarettes, it was not detected in two ePen3 samples, but was quantified in the emissions of the other two ePen3 samples and ePen2. Isobutyraldehyde levels per-puff were significantly higher in emissions from ePen3 (18 mg/mL, BT) than in those from ePen2 (18 mg/mL, BT), which were in turn significantly higher than those from the other ePen3 samples. Per nicotine emissions from ePen2 and ePen3 18 mg BT were significantly higher than from the other e-cigarettes. Per nicotine emissions from B&H were significantly higher than from 1R6F. In comparison to cigarette smoke, e-Pen2 isobutyraldehyde emissions were an average of 97% lower per-puff and 84% lower per-nicotine, and ePen3 emissions were 91–99.9% lower per-puff and 87–99.9% lower per-nicotine.

Glycolaldehyde was not detected in the air/method blank, but was detected in most of the e-cigarette aerosol samples. Levels were generally higher from ePen2 than from the ePen3 samples. Glycolaldehyde was not detected in one ePen3 sample and <LOQ in another; the other two ePen3 samples had quantifiable levels that were not significantly lower than those of the ePen2 sample (p > 0.05). E-cigarette emissions of glycolaldehyde were, on average, 99.5% lower as compared with cigarette smoke.

Glyoxal and methylglyoxal were not detected in the air/method blank, but were detected at quantifiable levels in all e-cigarette aerosol samples except for ePen3 (18 mg/mL, BT) aerosol, where glyoxal was detected but not quantifiable. Quantifiable glyoxal emissions from the e-cigarettes were not significantly different to each other. Methyl glyoxal emissions were higher (although not statistically significant) from ePen3 (30 mg/mL, High BA) than from ePen2, ePen3 (18 mg/mL, BT), or ePen3 (18 mg/mL, Medium BA) samples (p > 0.05). Methyl glyoxal emissions from ePen3 (18 mg/mL, Medium BA) were higher than those from the ePen3 (18 mg/mL, BT) sample, but not statistically significant (p > 0.05). However, methylglyoxal emissions did not differ significantly between ePen2 and ePen3 (18 mg/mL, BT). Relative to cigarette smoke, glyoxal levels from e-cigarettes were, on average, 96.1% lower than those from B&H Skyblue (range 92.8–99.1%) and 97.3% lower than those from 1R6F (range 95–99.4%). Methylglyoxal levels were, on average, 94.9% lower from e-cigarettes than from either tobacco cigarette (range 92.1–98.0%).

2,3-Butanedione (diacetyl) was not detected in the air/method blank or in any sample other than the ePen2 aerosol, where it was not quantifiable. Diacetyl emissions from the e-cigarettes were, on average, >99.9% lower than those from the two cigarettes.

Phenolic Compounds

None of the seven phenols measured were detected in the air/method blank, or in any of the e-cigarette aerosol samples (all BDL). By contrast, phenols were quantified in both cigarette smoke samples. Consequently, levels of the phenols in the e-cigarette aerosols were, on average, 99.8% lower than those in cigarette smoke (range 99.5–>99.9%).

Aromatic Flavourants

Among the 10 flavourants tested, methyl acetate, 1-butanol, isobutyl acetate, furfural, isoamyl acetate, benzyl acetate, ethyl acetoacetate, and acetic acid were not detected in any of the e-cigarette aerosols or the air/method blank (all BDL). Ethyl acetate was detected, but not quantified in the air/method blank and all e-cigarette aerosol samples. Propionic acid was not detected in the air/method blank or in most of the e-cigarette samples; however, it was detected at sub-quantifiable levels in the ePen3 (18 mg/mL, BT) aerosol and at quantifiable and substantially higher levels in the ePen2 aerosol.

Metals

Metals emissions from the e-cigarettes were measured after the cartridges containing e-liquids were stored at 40°C/75%RH for 3 months, in an accelerated aging test. The data from this exercise are presented in Table 5.

Of particular interest are the e-cigarette emissions of Ni and Fe, as they constitute the major components of the coil. The data in Table 5 show nickel emissions are <LOQ for all samples, including cigarette smoke. With the iron emissions, the e-cigarette samples were not significantly different from the air/method blank values or the cigarette smoke iron emission.

Of the other metals examined, with aluminum and molybdenum the e-cigarette emissions were not significantly different to the air/method blank values; cigarette smoke emissions were not measured for these metals. Arsenic, copper and mercury cigarette smoke emissions were quantifiable, whereas all e-cigarette emissions were <LOQ or <LOD. Manganese emissions from the e-cigarettes were also <LOQ or <LOD but the cigarette smoke emissions were not measured. Chromium e-cigarette emissions were not significantly different to the air/method blank, which was higher than the cigarette smoke emission level. Cadmium cigarette smoke emissions were 10 ng/puff, but all e-cigarette emissions were <LOD. Lead emissions from two e-cigarettes were quantifiable, but not significantly different to the air/method blank values; cigarette smoke emissions were 25 times higher. Zinc emissions from the 30 mg/mL nicotine high BA sample were significantly higher than from the other e-cigarettes which were not significantly different to the air/method blank level or <LOQ; cigarette smoke emissions were four times higher than from the high BA e-cigarette emission.

Discussion

In this study, we quantified 97 analyte emissions from five e-cigarettes, and 84 analyte emissions from two tobacco cigarettes. Some of these analytes, including many of the additional HPHCs recently proposed by the FDA, have not previously been quantified in e-cigarette aerosols to our knowledge.

Relevance of Air/Method Blank Measurements to E-Cigarette Emissions Testing

Recent studies have demonstrated the importance of recording baseline measurements to check for contamination when quantifying low-level emissions from e-cigarettes (Tayyarah and Long, 2014; Margham et al., 2016; Wagner et al., 2018). In particular, Margham et al. (2016) demonstrated that contamination from laboratory air and analytical methodology equipment and reagents can lead to background “blank sample” levels of some toxicants that are statistically indistinguishable from those measured in e-cigarette emissions. Such artifacts severely confound both the identification and accurate quantification of e-cigarette aerosol constituents. It is therefore essential to follow basic scientific good practice by conducting measurements of background air/method samples under identical conditions to those used for e-cigarette aerosol measurements if accurate data are sought.