Abstract

Objective:

To evaluate the force extension relaxation of different manufacturers and diameters of latex elastics subjected to static tensile testing under dry and wet conditions.

Materials and Methods:

Sample sizes of 15 elastics from American Orthodontics (AO) (Sheboygan, Wis), TP (La Porte, Ind), and Morelli Orthodontics (Sorocaba SP, Brazil) were used. Equivalent medium force products were tested—3/16, 1/4, and 5/16 inch lumen size from each manufacturer—making a total of 1080 specimens. An apparatus was designed to simulate oral environments during elastics stretching. Forces were read after 1, 3, 6, 12, and 24 hour periods using the Emic Testing Machine (Emic Co., Sao Paulo, Brazil) with 30 mm/min cross-head speed and load cell of 20 N (Emic Co). Kruskal-Wallis and Dunn's tests were used to identify statistical significance.

Results:

Statistical differences between AO and the other brands were noted for all testing times. Significant variation in mechanical properties was observed in latex elastics from Morelli. Relationships among loads at the 0 hour time period were as follows: Morelli>AO>TP for 3/16 elastics (P = .0016), 1/4 elastics (P = .0016), and 5/16 elastics (P = .0087).

Conclusion:

Significant differences in force extension relaxation were noted for elastics from these manufacturers. Force relaxation over the 24 hour time period was AO>Morelli>TP for 3/16 elastics, AO>TP>Morelli for 1/4 elastics, and TP>AO>Morelli for 5/16 elastics. The force decay pattern showed a notable drop-off of forces during 0 to 3 hours, a slight increase in force values from 3 to 6 hours, and a progressive force reduction over 6 to 24 hours.

Keywords: Elastomers, Extension testing, Force degradation, Latex elastics, Orthodontics

INTRODUCTION

Latex elastics have been used for interarch mechanics and other intraoral elastic purposes.1 Advantages of latex elastics include their high flexibility, relatively increased force, low costs, and greater ability to return to their original dimensions after substantial deformation compared with nonlatex elastics.2 It is easy for patients themselves to change the elastics and maintain good oral hygiene.2 These auxiliaries, made from natural rubber, are replaced on a daily basis, but concern associated with their use pertains to the force relaxation of these materials.3

Natural rubber is an elastomer with a structure formed by a three-dimensional reticulate structure by cross-links. Its elastic properties depend on irregular twisted arrangements of long molecular chains linked together at certain points by covalent bonds between different atoms, such as sulfur with carbon atoms.2,4 When latex elastic loads a certain force beyond its stress limit, fatigue begins at the weak points brought by its inside or surface lack of homogeneity.2,4,5 Simultaneously, friction between molecular chains also causes dynamic fatigue.2,4 Physical and chemical properties of latex cause orthodontic elastics to undergo fatigue creep and force relaxation, which result in force decay that is accentuated under the oral environment.2,4,6

Clinicians using orthodontic elastics need to know the force magnitude applied to teeth at a given elastic extension and how this force declines over time.4,7 As a consequence of fatigue, authors suggested the use of 40% more than optimal force at the commencement of elastic application to compensate for the initial loss.8 Nonetheless, this proposal is empirical, and a survey that analyzes force-elongation characteristics, force degradation, and material disposal is necessary. In any comparison between latex elastics, the nearly instantaneous force at a given extension and the force relaxation rate over different periods for a 24 hour evaluation are assessed.7 Material properties of the different brands evaluated in this study under a laboratory-simulated oral environment could assist in the development of clinical guidelines for latex elastics of different diameters.

The hypothesis tested in this study was that there was no difference among elastics from different brands as a consequence of manufacturer and time extension variables. The purpose of this study was to evaluate the force degradation of different brands and diameters of latex elastics occurring during different times until 24 hours of extension.

MATERIALS AND METHODS

Orthodontic elastics made from natural rubber (latex) supplied by three manufacturers were subjected to static tensile testing: American Orthodontics (AO) (Sheboygan, Wis), TP (La Porte, Ind), and Morelli Orthodontics (Sorocaba SP, Brazil). Elastics of three sizes—3/16, 1/4, and 5/16 inch lumen—were tested. Fifteen specimens from each elastic type were tested under dry conditions and immersed in water conditions at 1, 3, 6, 12, and 24 hours, making a total of 1080 elastics. They were within their expiration dates and were stored in sealed plastic packages in a cool and dark environment.

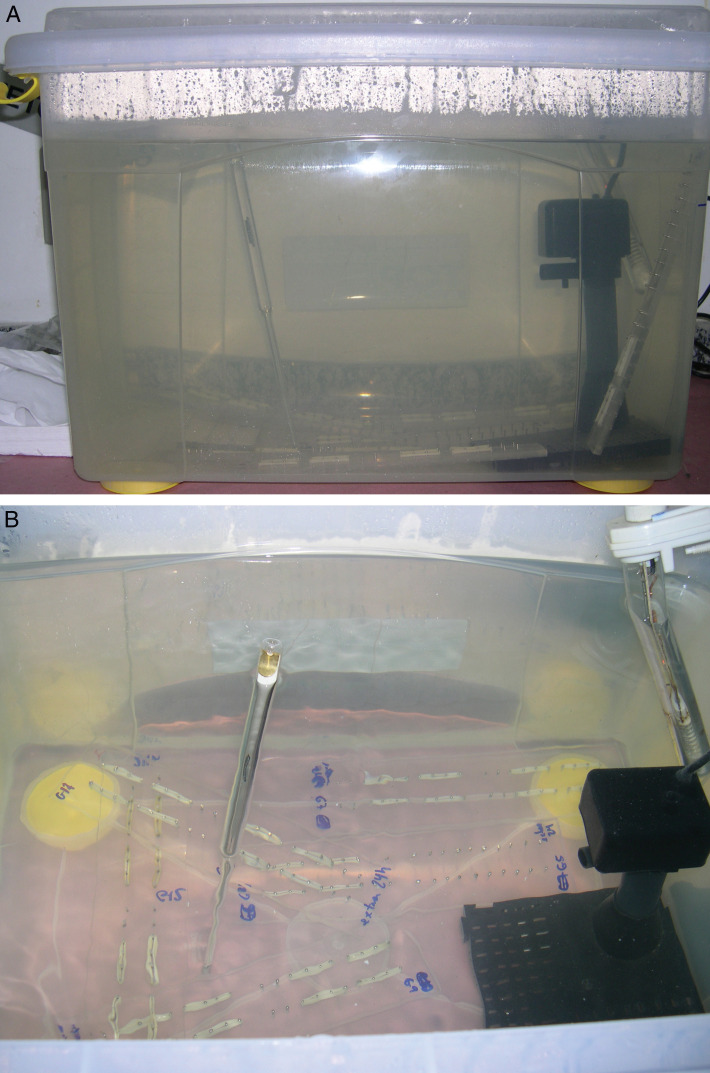

A special apparatus was designed to simulate oral environments of temperature and humidity. The apparatus consisted of a plastic tank with 15 gallons of deionized water maintained at 37°C by a water heater with an accuracy of ±0.5°C (Magic Heater, 7 Stars Co., Shanghai, China) and a submersible water bomb (Better Bomb, Better Co., São Paulo, Brazil) with a capacity of circulation of 60 gallons/h (Figure 1). The water bomb was placed on the top of a cylinder and plastic base. The tank was sealed to prevent any type of alteration in temperature, which was checked by an accurate thermometer.

Figure 1.

(A) Water tank. (B) View of tank apparatus: (a) water heater, (b) water bomb, and (c) thermometer.

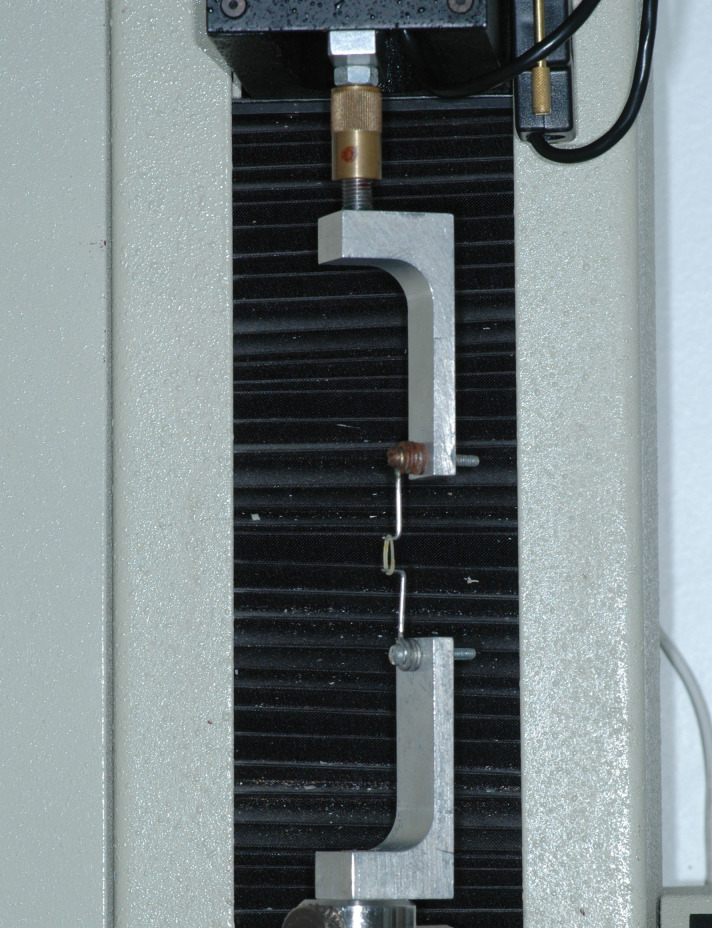

Elastics were mounted between stainless steel pins on an acrylic board at a 30 mm distance at regular intervals of 1 minute. Materials remained stretched for 1, 3, 6, 12, and 24 hour periods in the water tank before force measurements were taken. Each elastic band was carefully transferred to the setup extension testing mounted in the universal Emic DL500 MF testing machine (Emic Co., Sao Paulo, Brazil) in the same sequence intervals in which the elastics were mounted on the acrylic boards. Cross-head speed was 30 mm/min, and the calibrated load cell capacity was 20 N (Emic Co.). Extension force magnitudes of the elastics (when stretched at a distance of 30 mm) were recorded immediately after they were removed one-by-one from the boards (Figure 2). Tensile readings were recorded in gram force (gf) with duration of 1 minute for each elastic band.

Figure 2.

Elastic testing Emic DL 500 machine.

A pilot study investigated the variability in elastic samples and estimated the stability of temperature maintenance in the water tank. Five latex elastics of each diameter were tested statically, and force measurements were gathered over the same periods.

Sample size calculations were completed with Graphpad Prism 5.0 (Graphpad Inc., La Jolla, Calif), and a sample-size calculation required input of the following variables: estimated standard deviation (SD) (7%), desired power (80%), minimum detectable difference desired (10%), and number of comparisons (6). The estimated SD used was the maximum seen in the pilot study for percentage of initial force. Output from these calculations led to selection of a sample size of around 15 specimens.

Descriptive statistics were used as medians and percentage of extension force reduction. Repeated-measures Kruskal-Wallis analysis was used to compare the effects of time intervals and different manufacturers. Dunn's test was used to identify statistically different groups when Kruskal-Wallis indicated a statistical difference.

RESULTS

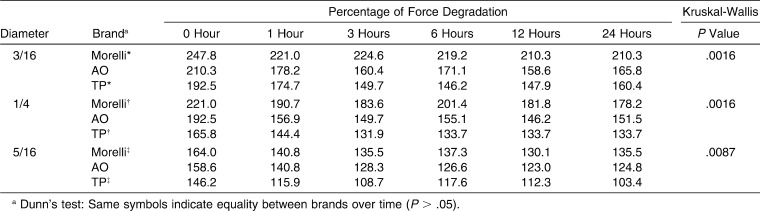

Table 1 shows the maximum extension force for elastic extension of 30 mm before and after immersion in water for 1 to 24 hours. For force extension relaxation from 1 hour through 24 hours, no consistent similarities were noted between AO and TP or Morelli elastics. Morelli elastics maintained the greatest loads for 1/4 and 5/16 elastics. TP elastics maintained greater loads than AO elastics for 3/16 and 1/4 elastics, except at 6 hours. For 5/16 elastics, AO showed greater loads than TP, except during a period from 6 to 12 hours. In a general summary, the relationships among loads over the 24 hour time period were as follows: AO<Morelli<TP for 3/16 elastics, AO<TP<Morelli for 1/4 elastics, and TP<AO<Morelli for 5/16 elastics (Table 1).

Table 1.

Median Extension Force (gf), Kruskal-Wallis and Dunn's Results

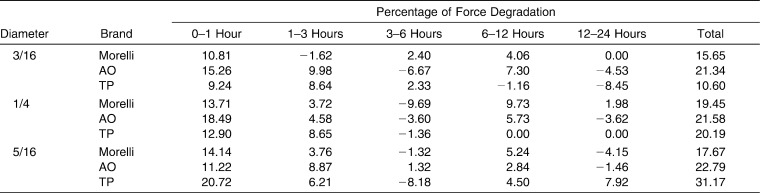

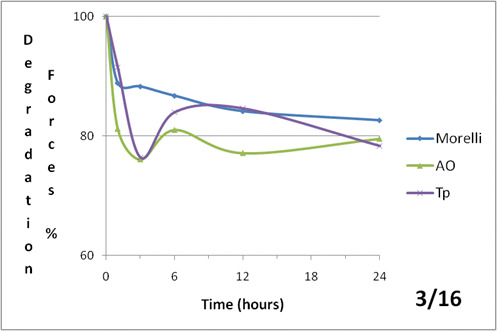

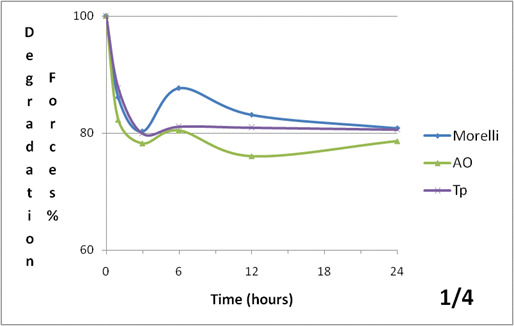

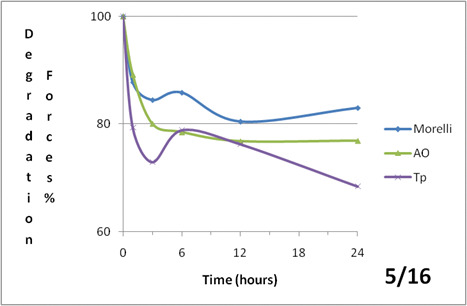

Because of the wide range of variation in extension forces, decreases over time were compared by percentages of force extension relaxation. Degrading effects are recorded as the amount of force extension remaining after immersion in the water tank. Degrading percentages for AO, TP, and Morelli median descriptive statistics are included in Table 1. The force relaxation pattern is illustrated in Figures 3, 4, and 5, where a notable drop-off of forces is shown until 3 hours and an elongated curve from 3 to 12 hours with a slight decrease from 6 hours, followed by a more stable pattern at 12 to 24 hours in some groups (Figures 3, 4, and 5). At the 24 hour time interval, force extension relaxations of 3/16 elastics were 10.6% (TP), 15.65% (Morelli), and 21.34% (AO); of 1/4 elastics 19.45% (Morelli), 20.19% (TP), and 21.58% (AO); and of 5/16 elastics 17.67% (Morelli), 22.79% (AO), and 31.17% (TP) (Table 2).

Figure 3.

Force decay (%) over time (hours) of 3/16 inch medium elastics of each brands (Morelli, AO and Tp).

Figure 4.

Force decay (%) over time (hours) of 1/4 inch medium elastics of each brands (Morelli, AO and Tp).

Figure 5.

Force decay (%) over time (hours) of 5/16 inch medium elastics of each brands (Morelli, AO and Tp).

Table 2.

Percentage of Extension Force Degradation Over Time

Overall, statistically significant differences were observed among AO and the other brands at different observation intervals. The Kruskal-Wallis test was used among different groups and times. Further analysis showed significant differences among 3/16 elastics (P = .0016), 1/4 elastics (P = .0016), and 5/16 elastics (P = .0087). Multiple comparisons by Dunn's test did not show differences between Morelli and TP elastics (P > .05) (Table 1).

DISCUSSION

Comparison among extension force/extension relaxation of different manufacturers of elastics was performed by using percentage of force relaxation rather than actual force generated because of the great numbers of force extension values.9 Although rates of force degradation in this study were greater, patterns of degradation for 1/4 elastics were similar to those for latex elastics measured by Kersey, who reported 17% force degradation at 24 hours9 for 20 mm with the statically stretching method. However, acceptability of the range from 20 to 30 mm simulates intermaxillary mechanics; variability in stretching distance could have contributed to the difference between studies. Other comparisons could not be performed because a match across brands, lumen size, time period, and distention was not evaluated in this study.

A statistical difference in general patterns of extension force was noted among different diameters, with significant influence of brands and time. Results seemed to vary according to the elastic brands in each internal diameter group. Large initial fall-off of force in elastics subjected to immersion matched the findings of other studies2,4 and could be observed during the period from 0 to 3 hours. The first hour fall-off averaged from 15.26% to 20.72% for 3/16 (AO>Morelli>TP), 1/4 (AO>TP>Morelli), and 5/16 inch elastics (TP>Morelli>AO). An elongated open downward curve characterized elastics patterns during the period from 3 to 12 hours. The curve showed negative degradation until 6 hours and gradual degradation from 6 to 12 hours (Figures 3, 4, and 5). Further investigation is needed to determine the causes of the ascending force during the period from 3 to 6 hours and for TP 3/16 elastics from 12 to 24 hours. Although water immersion and temperature are significant in the degradation force because of inference in secondary elastics bond sites,1 perhaps transitory hardening of material could explain the force increase. After 12 hours, force extension relaxation became slower, except for TP 3/16 elastics, and force values followed a straighter line where the graph covers a range of forces more appropriate for most clinical applications. At 24 hours, degradation ranged from 10.60% to 31.17% with different patterns among the 3/16 (AO>Morelli>TP), 1/4 (AO>TP>Morelli), and 5/16 inch lumen (TP>AO>Morelli). These comparisons of brands at different times were not evaluated in any other previous study, and differences between elastics could be explained by the characteristics of each manufacturer. However, Morelli elastics could exhibit slower degradation patterns, along with significant variability in force delivery. A nonparametric distribution was shown by the normality tests, and great variability could be associated with deficiencies in standard patterns of material, leading to reduction of the effectiveness of tooth movement (Figures 6 and 7).

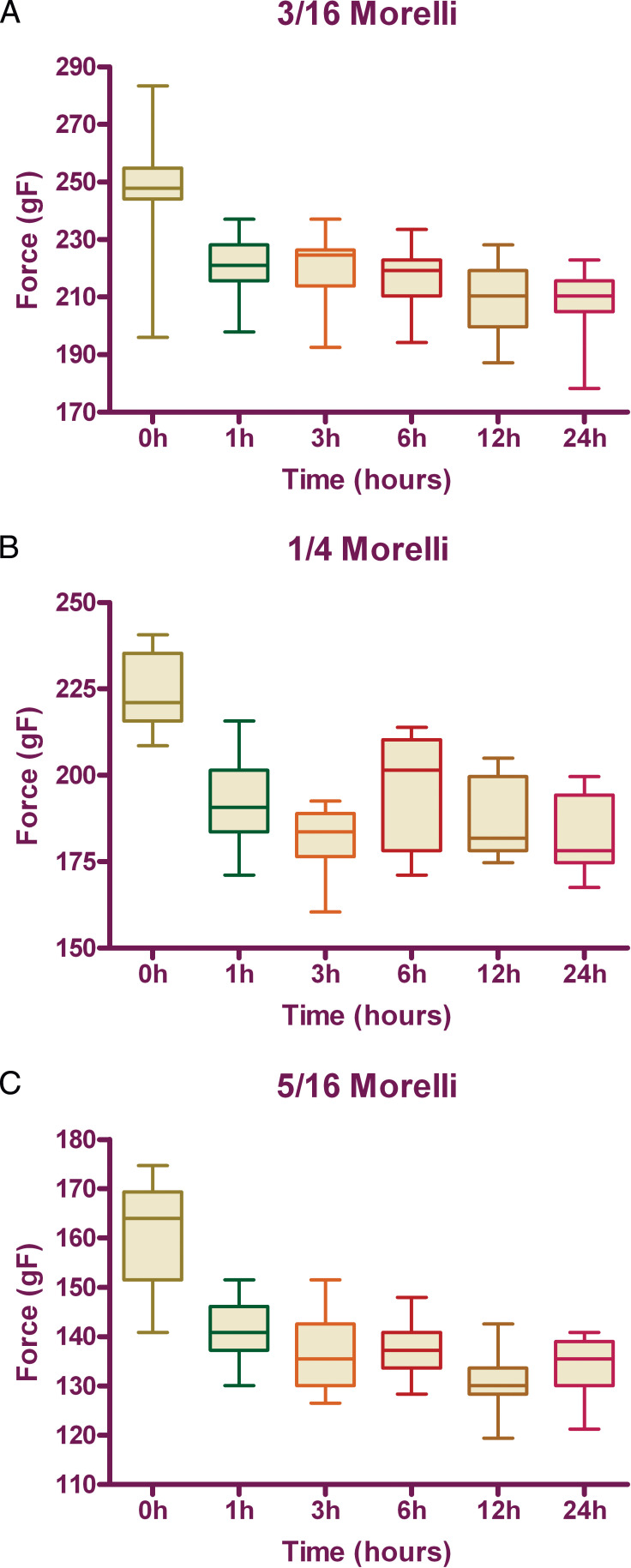

Figure 6.

Box plots of medians (gf) for each elastic size: 3/16 (A), 1/4 (B), 5/16 (C) in different time periods (hours).

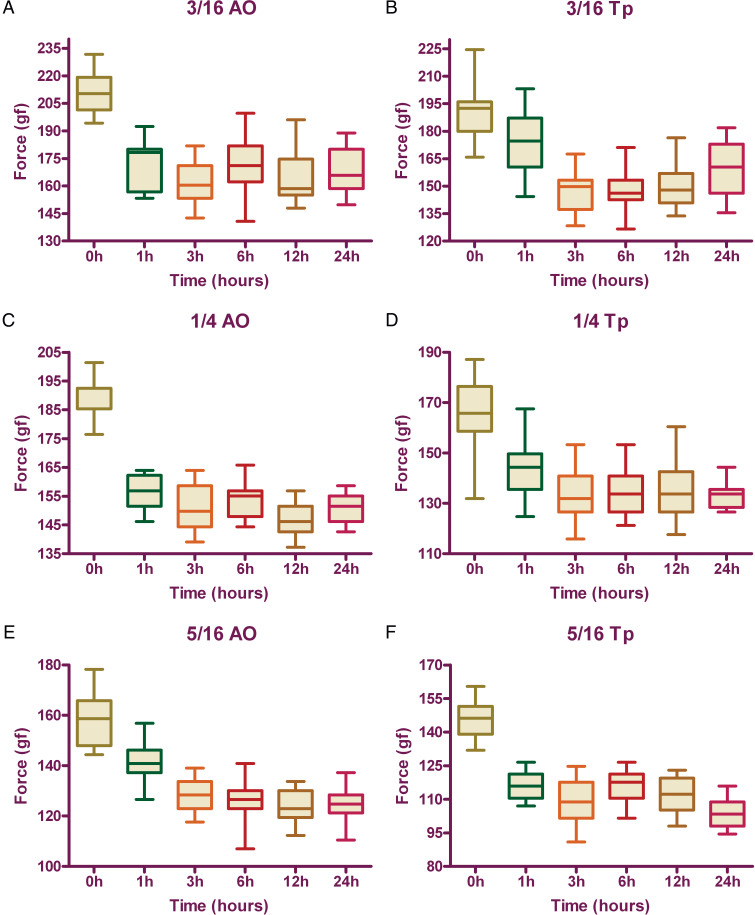

Figure 7.

Box plots of medians (gf) in different time periods (hours) of AO and Tp: 3/16 (A,B), 1/4(C,D) and 5/16 (E,F) elastics.

Force extension relaxation was not evaluated in periods longer than 24 hours because of clinical trends.2,4,10 In clinical practice, patients usually are required to discard the elastics after 1 day of use; most change the elastics at every meal.2 More frequent changes could be observed in hyperdivergent facial patients, in whom any type of elastics relaxation could result in increased vertical forces and undesirable extrusion results.3 Even during the nighttime, periods longer than 24 hours were not exceeded. Liu et al.11 suggested that force relaxation was remarkably stable after 1 day of elastics usage because structural changes, caused by repeated stretching, were not cumulative. Furthermore, the elongation force reduction was relatively small, averaging from 2% to 6% over the second day of clinical use, and remained relatively constant for a few days.2 Other studies confirmed that after 24 hours, force degradation could be considered nonsignificant.8,12,13

Different extensions in wet tests were described as ranging from 20 to 40 mm, as suggested by Bales,14 because these distances represent the range of elastic extensions in common clinical use and are similar to those of other studies from 20 through 50 mm.12,13,15 Other authors considered values of forces provided by manufacturers as standard patterns of loads and employed extensions at two or three times the internal diameter of the elastics as references.1,7,9 However in general, the manufacturer's values could not be considered reliable in many cases, once great variability was seen within samples.9 Forces generated at three times diameter extension were larger than the manufacturer's values and were two times smaller than the manufacturer's specified loads.7 Thus, in this study, 30 mm of extension was employed instead of manufacturers' internal diameter load values.

The intraoral environment exerts greater effects on the elastic.3 This occurs because the oral cavity includes a wide array of potent aging factors such as pH fluctuations, temperature,7 and enzymatic and microbial action.3 However much in vitro approaches underestimate the extent and severity of intraoral agents, some variables could be reproduced. These variables consist of time, load, temperature, humidity, and stretching, which could characterize alterations in polymer chain conformation during tensile loading.2 Artificial saliva was not employed because its high viscosity made impossible the circulation of heated saliva in the tank, resulting in significant temperature variations.

Fifteen samples of each elastic type were tested through sample size calculations for variation factors of materials and methods. Most previous studies used smaller samples as a limitation of their methods because limited time was available to transfer each elastic from the measuring boards, together with the time required to measure force at that testing machine.2,4,10,16 The method designed for this study allowed larger samples because the water tank was built beside the testing machine and could be opened to assess any given elastic at any time. Moreover, the elastics were stretched one-by-one on measuring boards with the same regular interval used by the testing machine to assess force values. Thus, no difference in stretching time was noted between the first and the fifteenth elastic of each board.

On the other hand, the method suffered from a major weakness: it failed to allow for the collection of continuous data because the force was only periodically recorded; thus noncontinuous data were used to construct the force relaxation curves, inducing some unavoidable approximation. Nevertheless, this limitation was in general agreement with the approach of other studies.3

Some authors have tested orthodontic elastics in a cycled environment in an attempt to better simulate conditions in the mouth of an orthodontic patient.9 Nevertheless, other studies defended the concept that the force decay rate was similar to that of statically tested elastics after the first hour.9 In most cases, the choice of the number of cycles per minute was relatively arbitrary and was made by the authors to reflect a balance between the higher frequency of opening seen during chewing and the lower frequency seen at other times.9 Meanwhile and despite the expense of cycle apparatus design and fabrication, this study tested orthodontic elastics in a static environment and maintained accordance with most works.2,4,9,10

CONCLUSIONS

The hypothesis tested was rejected for AO elastics, because significant differences in 3/16, 1/4, and 5/16 elastics were noted when compared with TP and Morelli elastics at all times.

Most force extension relaxation was shown to occur within the first 3 hours after extension, regardless of the size and manufacturer of the elastics.

The force relaxation pattern showed a negative degradation until 6 hours and a gradual degradation from 6 to 12 hours. Further investigation in secondary elastics bond sites could help to determine the causes of the ascending force.

After 12 hours, force extension relaxation became slower in many groups, which could be explained by a range of forces more appropriate for most clinical applications.

REFERENCES

- 1.Kersey M. L, Glover K, Heo G, Rabound D, Major P. W. An in vitro comparison of 4 brands of nonlatex orthodontic elastics. Am J Orthod Dentofacial Orthop. 2003;123:401–407. doi: 10.1067/mod.2003.22. [DOI] [PubMed] [Google Scholar]

- 2.Wang T, Zhou G, Tan X, Dong Y. Evaluation of force degradation characteristics of orthodontic latex elastics in vitro and in vivo. Angle Orthod. 2007;77:688–693. doi: 10.2319/022306-76. [DOI] [PubMed] [Google Scholar]

- 3.Gioka C, Zinelis S, Eliades T, Eliades G. Orthodontic latex elastics: a force relaxation study. Angle Orthod. 2006;76:475–479. doi: 10.1043/0003-3219(2006)076[0475:OLE]2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 4.Kanchana P, Godfrey K. Calibration of force extension and force degradation characteristics of orthodontic latex elastics. Am J Orthod Dentofacial Orthop. 2000;118:280–287. doi: 10.1067/mod.2000.104493. [DOI] [PubMed] [Google Scholar]

- 5.Hanson M, Lobner D. In vitro neuronal cytotoxicity of latex and nonlatex orthodontic elastics. Am J Orthod Dentofacial Orthop. 2004;126:65–70. doi: 10.1016/j.ajodo.2003.07.006. [DOI] [PubMed] [Google Scholar]

- 6.Eliades T, Eliades G, Silikas N, Watts D. C. In vitro degradation of polyurethane orthodontic elastomeric modules. J Oral Rehabil. 2005;32:72–77. doi: 10.1111/j.1365-2842.2004.01366.x. [DOI] [PubMed] [Google Scholar]

- 7.Russel K. A, Milne A. D, Khanna R. A, Lee J. M. In vitro assessment of the mechanical properties of latex and non-latex orthodontic elastics. Am J Orthod Dentofacial Orthop. 2001;120:36–44. doi: 10.1067/mod.2001.114642. [DOI] [PubMed] [Google Scholar]

- 8.Andreasen G. F, Bishara S. Comparison of elastic chains with elastics involved with intra-arch molar to molar forces. Angle Orthod. 1970;40:151–154. doi: 10.1043/0003-3219(1970)040<0151:COACWE>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 9.Kersey M. L, Glover K. E, Heo G, Major P. W. A comparison of dynamic and static testing of latex and nonlatex orthodontic elastics. Angle Orthod. 2003;73:181–186. doi: 10.1043/0003-3219(2003)73<181:ACODAS>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 10.Beattie S, Monaghan P. An in vitro study simulating effects of daily diet and patient elastic band change compliance on orthodontic latex elastics. Angle Orthod. 2004;74:234–239. doi: 10.1043/0003-3219(2004)074<0234:AIVSSE>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 11.Liu C. C, Wataha J. C, Craig R. G. The effect of repeated stretching on the force decay and compliance of vulcanized cis-polyisoprene orthodontic elastics. Dent Mater. 1993;9:37–40. doi: 10.1016/0109-5641(93)90103-w. [DOI] [PubMed] [Google Scholar]

- 12.Bishara S. E, Andreasen G. F. A comparison of time related forces between plastic alastiks and latex elastics. Angle Orthod. 1970;40:319–328. doi: 10.1043/0003-3219(1970)040<0319:ACOTRF>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 13.Bell W. R. A study of applied force as related to the use of elastics and coil springs. Angle Orthod. 1951;21:151–158. doi: 10.1043/0003-3219(1951)021<0151:ASOAFA>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 14.Bales T. R, Chaconas S. J, Caputo A. A. Force-extension characteristics of orthodontic elastics. Am J Orthod. 1977;72:296–302. doi: 10.1016/0002-9416(77)90215-9. [DOI] [PubMed] [Google Scholar]

- 15.Hixon E. H, Aasen T. O, Arango J, Clark R. A, Klosterman R, Miller S. S, Odom W. M. On force and tooth movement. Am J Orthod. 1970;57:476–489. doi: 10.1016/0002-9416(70)90166-1. [DOI] [PubMed] [Google Scholar]

- 16.Bertl W. H, Droschl H. Forces produced by orthodontic elastics as a function of time and distance extended. Eur J Orthod. 1986;8:198–201. doi: 10.1093/ejo/8.3.198. [DOI] [PubMed] [Google Scholar]