Abstract

Designing bioelectronic devices that seamlessly integrate with the human body is a technological pursuit of great importance. Bioelectronic medical devices that reliably and chronically interface with the body can advance neuroscience, health monitoring, diagnostics, and therapeutics. Recent major efforts focus on investigating strategies to fabricate flexible, stretchable, and soft electronic devices, and advances in materials chemistry have emerged as fundamental to the creation of the next generation of bioelectronics. In this review, we summarize contemporary advances and forthcoming technical challenges related to three principal components of bioelectronic devices: (i) substrates and structural materials, (ii) barrier and encapsulation materials, and (iii) conductive materials. Through notable illustrations from the literature, integration and device fabrication strategies and associated challenges for each material class are highlighted.

Keywords: flexible bioelectronics, materials chemistry, bioresorbable, soft electronics, encapsulation, extensible conductors

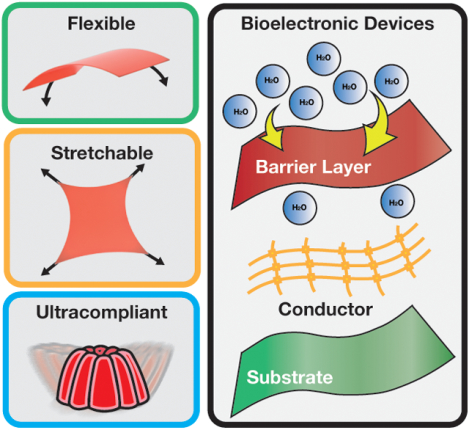

Graphical Abstract

Flexible, stretchable and soft electronics interfaced with the human body hold immense potential to unlock a variety of diagnostic, therapeutic, and health monitoring applications. Materials chemistry plays a crucial role in determining the interaction and integration of these devices with biological systems. Recent progress in materials chemistry-enabled bioelectronics is presented and challenges, opportunities, and future research directions are highlighted.

1. Introduction

Reliable interfacing of flexible, stretchable, and soft electronics with the human body could advance a wide range of medical technologies such as chronic brain-computer interfaces,[1–6] implantable electrophysiological sensors,[7–10] active drug delivery systems,[11–16] wearable health monitoring devices,[17–24] and electrical stimulatory therapeutic devices.[25–33] Electronic devices with flexible and compliant form factors permit conformal integration with tissues in the human body, which are often soft, curvilinear, and dynamic.[34–36] While the prospects for biomedical applications are promising, transforming flexible electronics from laboratory curiosities into robust and reliable medical devices creates new challenges in fabrication and deployment. Advances in materials chemistry and polymer science contribute to the design of flexible electronic devices for biomedical applications.[37–40] Decades of research in flexible bioelectronics have standardized materials and processing techniques that serve as cornerstone technologies within the bioelectronics scientific community. This has included advances in the processing and integration of traditional electronics materials,[41–46] the design of novel biocompatible polymer substrates,[47–52] and investigating intrinsically flexible and stretchable organic electronics.[53–58] Furthermore, novel materials and new fabrication techniques enable new form factors and increase the parameter space for both mechanical and electrical properties, and structural adaptability. Here we discuss how materials chemistry can accelerate progress in bioelectronics in three specific areas: (1) substrate and structural materials, (2) packaging and barrier layers, and (3) flexible and stretchable conductors. We will examine contemporary instances of materials development, process design, and implementations of flexible bioelectronics systems, with an emphasis on implantable devices, through a lens of materials chemistry. Furthermore, we will present emerging challenges, bottlenecks, and opportunities for innovation in the field.

1.1. Defining Key Terms in Flexible Electronics

Terms such as flexibility, stretchability, mechanical compliance, softness, and extensibility are often used interchangeably. However, precisely defining this beforehand will clarify the forthcoming technical discussion. As such, this article will assign bioelectronic devices as flexible, stretchable, or ultracompliant roughly based on the intrinsic mechanical properties of the structural materials. These classifications, albeit artificial, facilitate discussions on the role of materials chemistry in flexible bioelectronic devices.

Mechanical flexibility and compliance are interchangeably defined as the inverse of stiffness, a parameter that refers to the ability of a body to resist deflection or deformation and can be expressed as the ratio of applied force to the deformation.[74,75] While a material can be subject to varying modes of deformation, flexibility specifically refers to the ability of a material to undergo bending.[76] In the context of bioelectronics, the minimum bending radius and bending stiffness can be valuable measures of flexibility that provides direct insight into the ability of a film to conform to topographically complex curvilinear targets. The minimum bending radius of a film rb,min is dependent on the elastic modulus of the material and the thickness of the film, given by:[75,77]

| (1) |

The bending stiffness of a film is:

| (2) |

where E is the Young’s modulus of the material, h is film thickness, σy is yield strength, and ν is the Poisson’s ratio. “Flexible bioelectronics” will refer to inextensible devices with an effective elastic modulus typically between 0.1–100 GPa and bending stiffness on the order of 10−9–10−15 N m2.[78] With the broad range of possible bending stiffnesses, this class of devices are useful in a variety of applications such as intracortical probes, conformal neural probes, retinal implants, cochlear implants, etc.[79–81]

The term “stretchability” is somewhat vaguer in the context of bioelectronics, sometimes referring to the ability for a system to accommodate strain without failure in the elastic regime and other times expanding the requirement to include plastic regime.[82–84] Concluding an effort to define stretchability in the context of electronics, Lipomi states “stretchable electronics comprise materials and devices that accommodate strain, or do not accommodate strain, depending on your perspective, by a variety of mechanisms: elastic deformation, plastic deformation, strain‐evolved formation of buckles, and even formation of cracks”.[85] In this article, we will define “stretchable electronics” as devices that are able to withstand a non-zero strain that is useful to its intended application prior to device and/or material failure. They are typically extensible devices whose effective elastic moduli lie between 0.1–100 MPa. Extensibility of materials is similarly understood as the extent to which a material can be stretched before failure and can be quantified by the percent elongation at failure. Stretchable devices can be deployed in mechanically dynamic applications such as cardiac sensors, wearable devices, and peripheral nervous interfaces.[86–90]

Lastly, softness broadly refers to the property of low mechanical modulus materials to deform under small, applied stresses. Unlike flexibility, softness extends beyond elastic deformation by bending, encompassing low modulus polymeric materials, such as viscoelastic hydrogels and supramolecular networks with mesoscale organization. In this article, devices based on such materials will be discussed under the title of “ultracompliant bioelectronics”. Furthermore, “ultracompliant electronics” comprise devices with elastic moduli between 0.1–100 kPa. Ultracompliant devices are most useful in forming seamless interfaces with soft tissues such as the brain.[91–94]

1.2. Guidelines for Designing Implantable Flexible Bioelectronics

Implantable flexible bioelectronic devices present unique additional design constraints compared to wearable devices. Implantable flexible bioelectronic devices will ideally be composed of non-toxic biocompatible materials to promote integration of the device with the biological environment.[34,95,96] Biocompatibility is used as an all-encompassing term to describe materials that do not induce severe foreign body and inflammatory responses, and are able to function in their intended application without causing harm to local tissue or overall human health.[97,98] Strategies commonly employed to improve biocompatibility of implantable devices involve the following: (i) using non-toxic, biologically derived, or biomimetic materials, (ii) engineering the surface chemistry and topography to camouflage the device, improve biointegration, and minimize the consequences of bio-fouling; (iii) target localized release of drugs or other bioactive compounds to manage the inflammatory response.[99–106]

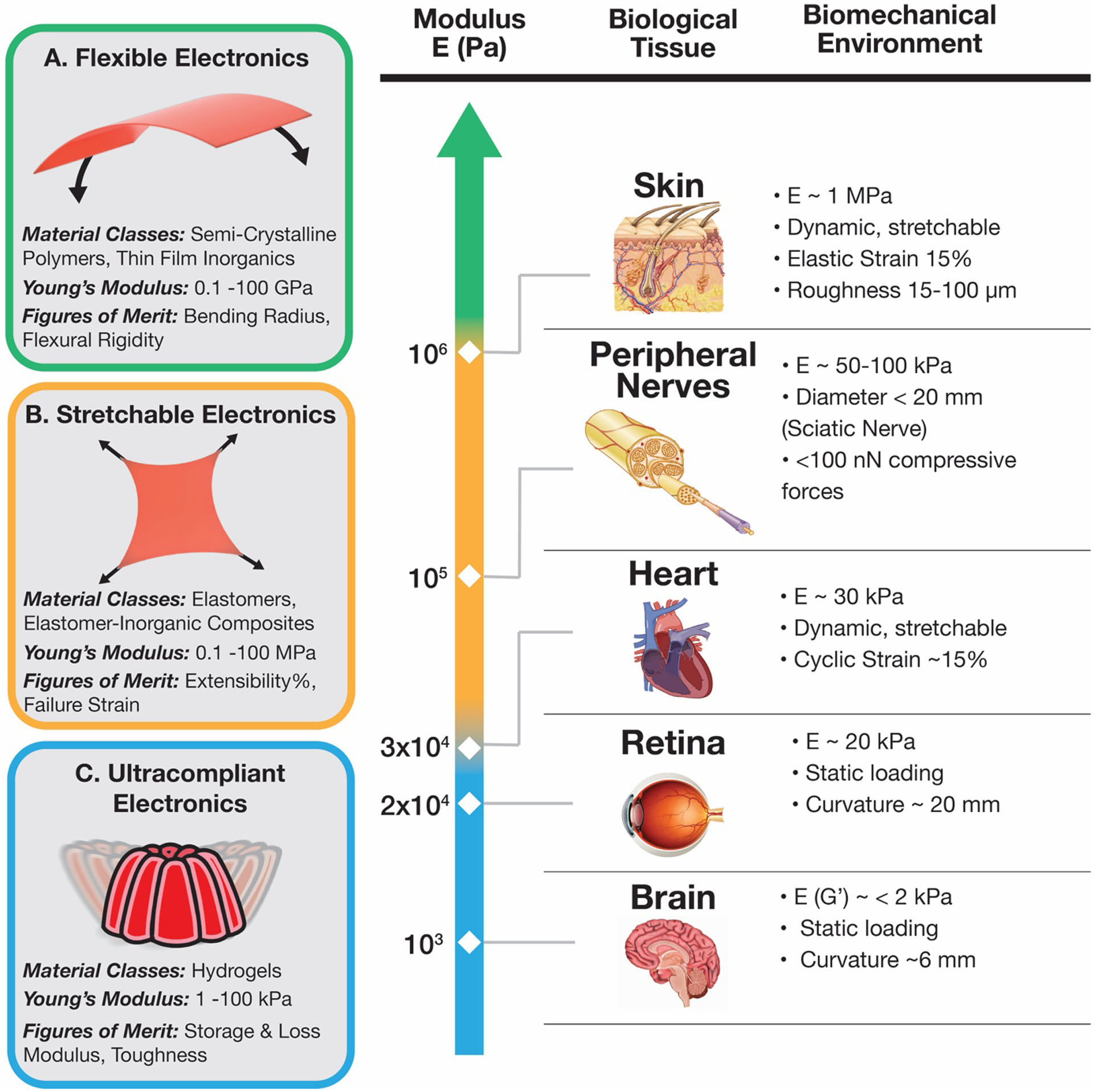

In addition to managing in vivo responses to implanted devices, it is also imperative to understand the mechanical environment of the biological environment at site of tissue integration. As illustrated in Figure 1, various organs exhibit different mechanical environments, such as elastic modulus, extensibility, dynamic versus static loading condition, etc. A holistic picture of these conditions should greatly influence the materials selection and device design of the bioelectronics. For instance, a long-term device meant to conformally contact heart tissue must be a fatigue resistant, stretchable device that can withstand several thousand cycles of loading per operational day.[107–110] A conformal neural interface, on the other hand, can be made of ultrathin flexible materials that don’t need to be stretchable or fatigue resistant.[111–113]

Figure 1.

(Left) The mechanical description and figures of merit of three regimes of bioelectronics devices: A. flexible electronics (0.1–100 GPa),[41] B. stretchable electronics (0.1–100 MPa),[39] and C. ultracompliant electronics (1–100 kPa).[59] (Right) A biomechanical description of target organs and loading conditions for mechanically compliant bioelectronics deployment: skin,[60] peripheral nerves,[61–64] heart,[65–67] retina,[68,69] and brain.[70–72] Reproduced with permission.[73] Copyright 2017, Elsevier.

A final consideration that requires additional thought and planning in all implantable bioelectronics applications is designing for processability and practicality. While there might be several attractive materials for use in bioelectronics for their interesting mechanical or functional properties, they must be amenable to integration with microelectronics processing techniques or propose the development of novel device integration methods. Furthermore, practical challenges such as interfacing devices with input and output data and power transmission cables must be considered from an early stage in the design process.[114–116]

2. Substrates and Structural Materials for Flexible Bioelectronics

Substrates are structural elements that provide mechanical integration for device components, such as logic elements, electrodes, traces, and interconnects. Active devices and supporting components are often composed of micropatterned thin film architectures <1 μm in thickness, while substrate materials are of macroscopic dimensions and are often >100 μm in thickness.[54] Thus, the substrate often dictates the mechanics, form factor, and toxicity profile of the overall device.

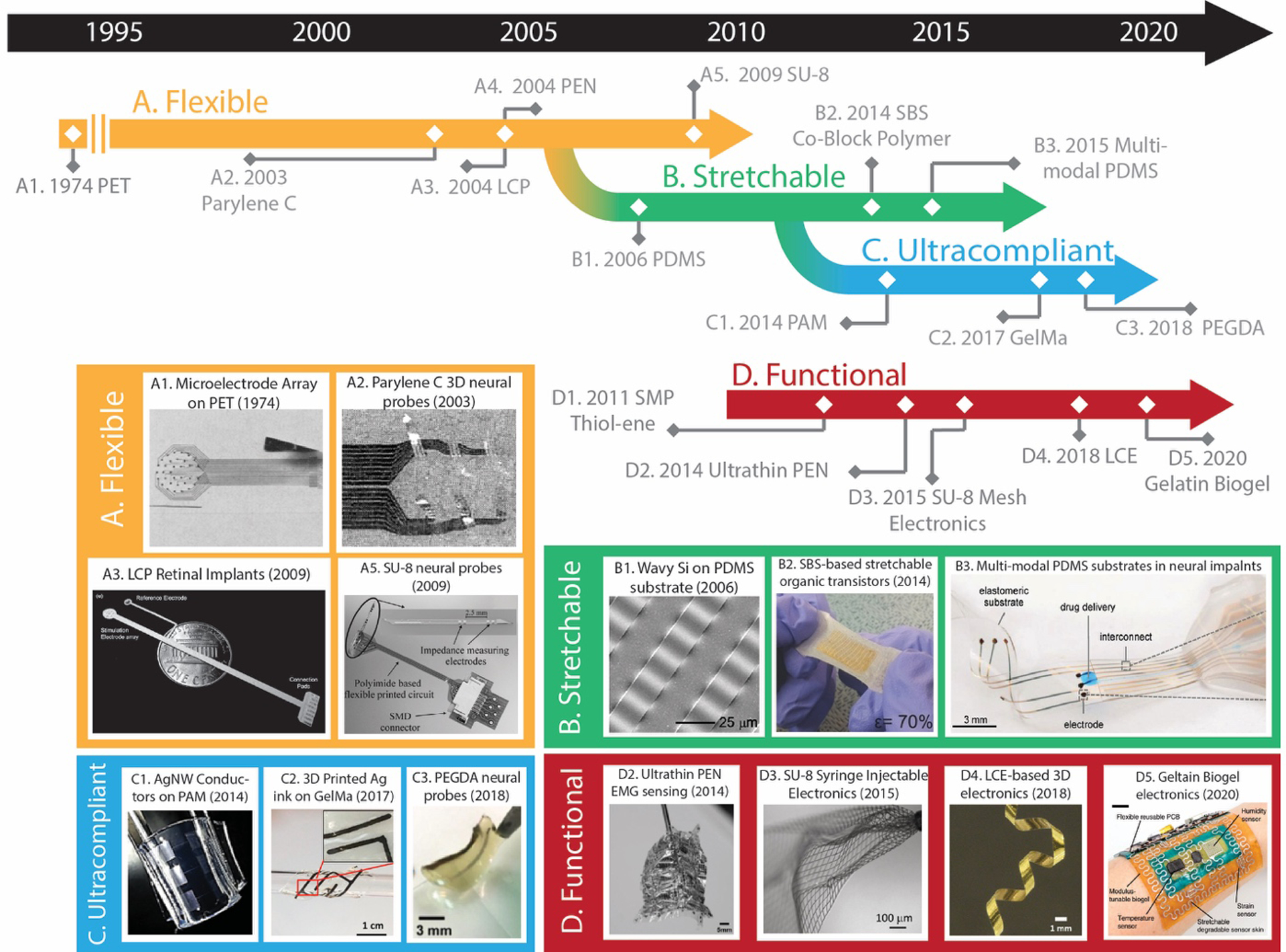

In the following discussion on substrates, the materials will be classified into the four following categories, employing definitions presented in Section 1.1 and Figure 2: (i) flexible substrates, (ii) stretchable substrates, (iii) ultracompliant substrates, and (iv) structurally adaptive substrates. Figure 2 represents a non-exhaustive survey of a trend towards softer and more compliant substrates for bioelectronic devices. Using this chronological perspective, this section will utilize a bottom-up approach to summarizing trends in this domain. This sub-topic will review chemical composition, then macromolecular networks and polymer processing, and then finally microstructural aspects of materials that are commonly used as substrates and structural materials in bioelectronic devices.

Figure 2.

Timeline outlining the evolution of mechanically compliant substrates in bioelectronics towards softer devices designed to maximize biological integration. Substrate materials are roughly classified into four categories – A. Flexible, B. Stretchable, C. Ultracompliant, and D. Structurally Adaptive. Key advances from each category have been presented on the timeline and select examples have been featured through the following pictures: A1. Polyethylene Terephthalate (PET). Reproduced with permission.[117] Copyright 1974, Springer Nature. A2. Parylene C. Reproduced with permission.[118] Copyright 2003, IEEE. A3. Liquid crystal polymers (LCPs). Reproduced with permission.[119] Copyright 2009, Association for Research in Vision and Ophthalmology. A5. SU-8 epoxy. Reproduced with permission.[120] Copyright 2009, Elsevier. B1. Stretchable Si on PDMS. Reproduced with permission.[121] Copyright 2006, The American Association for the Advancement of Science. B2. Organic transistors on styrene-butadiene-styrene (SBS). Reproduced with permission.[122] Copyright 2014, John Wiley and Sons. B3. Muti-modal PDMS electronic dura mater. Reproduced with permission.[123] Copyright 2015, The American Association for the Advancement of Science. C1. Silver nanowires on polyacrylamide. Reproduced with permission.[124] Copyright 2014, American Chemical Society. C2. Printed silver flakes on gelatin methacrylate (GelMa). Reproduced with permission.[125] Copyright 2017, Elsevier. C3. Transfer printed polyethylene glycol-dopamine (PEGDA). Reproduced with permission.[126] Copyright 2017, John Wiley and Sons. D2. Ultrathin 1 μm polyethylene napthalate (PEN). Reproduced with permission.[127] Copyright 2014, IEEE. D3. Syringe injectable SU-8. Reproduced with permission.[128] Copyright 2015, Springer Nature. D4. Morphing electronics on a liquid crystal elastomer. Reproduced with permission.[129] Copyright 2019, American Chemical Society. D5. Transient devices on gelatin biogels. Reproduced with permission.[130] Copyright 2020, Springer Nature.

2.1. Flexible Substrate Materials in Bioelectronics

This section focuses on thin films of high modulus inextensible polymers (1–10 GPa, <250 μm), such as Parylene C, polyesters, polyimides, and SU-8, and their use as substrates in bioelectronics. The commercial availability of such polymers and compatibility with microelectronics processing techniques has accelerated progress in flexible bioelectronics. With early bioelectronic implants typically comprising rigid bulk inorganic components and packaging, flexible substrates significantly improved mechanical matching across the biotic-abiotic interface.[131–134] These materials offer exceptional processability as they are amenable to thin film processing, patterning, molding, etching, and other diverse types of subtractive and additive fabrication techniques.[47,135–137] Here, we briefly highlight contemporary and historical examples of polymers as substrate materials in flexible bioelectronic devices.

2.1.1. Polyesters

Polyesters have found wide use as substrate materials in flexible bioelectronics, ranging from the crude early demonstrations of flexible multielectrode arrays for medical applications in the 1970s, to intricate devices with active on-board electronics for applications in conformal cardiac sensors.[109,117] As a widely used commercial and industrial polymer, the infrastructure surrounding polyester processing can be leveraged to engineer these materials as substrates for flexible bioelectronic devices.[28,159,160]

Polyethylene terephthalate (PET) and polyethylene naphthalate (PEN) are two aromatic thermoplastic polyesters commonly used as substrates in flexible bioelectronic devices.[109,160–162] PET and PEN both feature ester links between monomers with aromatic groups in the polymer backbone which confer chemical stability and produce stable semi-crystalline hydrophobic domains that resist biodegradation. One versus two aromatic rings in PET and PEN, respectively, has a direct impact on the glass transition temperature (Tg,PET = 75–85 °C; Tg,PEN = 114–125 °C), crystallinity, and therefore also the Young’s modulus (EPET = 2.95 GPa; EPEN = 5.5 GPa).[163] As thermoplastics, PET and PEN are manufactured through a combination of molten extrusion and cold rolling to produce films of desired thicknesses.[164,165] As a result, it can be more challenging to integrate pre-rolled polyesters with microelectronics manufacturing methods compared to polymer substrates that can be deposited or spin coated. However, the thermal and chemical stability of polyesters have encouraged researchers to develop several approaches to implement PET and PEN as substrates for bioelectronics.

PET is a versatile thermoplastic that has been successfully in implemented in a variety of systems that utilize differing substrate thicknesses (1–50 μm) and processing methods. A 1974 study demonstrated the use of a relatively thick PET film (50 μm) in an early prototype of a multielectrode array for a flexible cochlear implant.[117] More recently, ultrathin PET substrates (1–3 μm) have also been successfully integrated for a range of wearable and in vivo applications. Lee et al. presented the fabrication of an ultraflexible multielectrode array on 1.5 μm PET substrates for in vivo cardiac monitoring in 10-week old rats.[109] Traces are deposited using thermal evaporation through a shadow mask and passivated with a Parylene-C insulation layer. In addition to engineering an extremely low bending radius (<10 μm) in their ultrathin PET film, the authors utilized a patterned adhesive polyvinyl acetate (PVA) hydrogel to improve electrode interfacial adhesion and create a highly conformal contact with the cardiac tissue. As a result, the ultrathin device with PVA coated electrodes showed stable signal amplitudes of 8 mV with a 0.1 mV noise level, in contrast to uncoated electrodes showing fluctuating signal amplitudes from 5–7 mV with a 1.5 mV noise level. Sung et al. designed a wireless implantable controlled release system on PET substrates for delivery of neurotherapeutics directly to the cerebral cortex (Figure 3, A-i,ii).[159] The device features SU-8 drug reservoirs with nominal volumes of 1.5 nL capped with Au membranes, Ti conductive traces to deliver 1.1 mA cm−2 DC current to electrochemically dissolve the Au, and an SU-8 passivation layers, all fabricated on a PET film 25 μm in thickness. (Figure 3, A-iii). PET substrates were specifically selected in this application as a result of its compatibility with UV adhesive-based bonding and to provide necessary flexibility and handling for deploying the device into the subdural space.

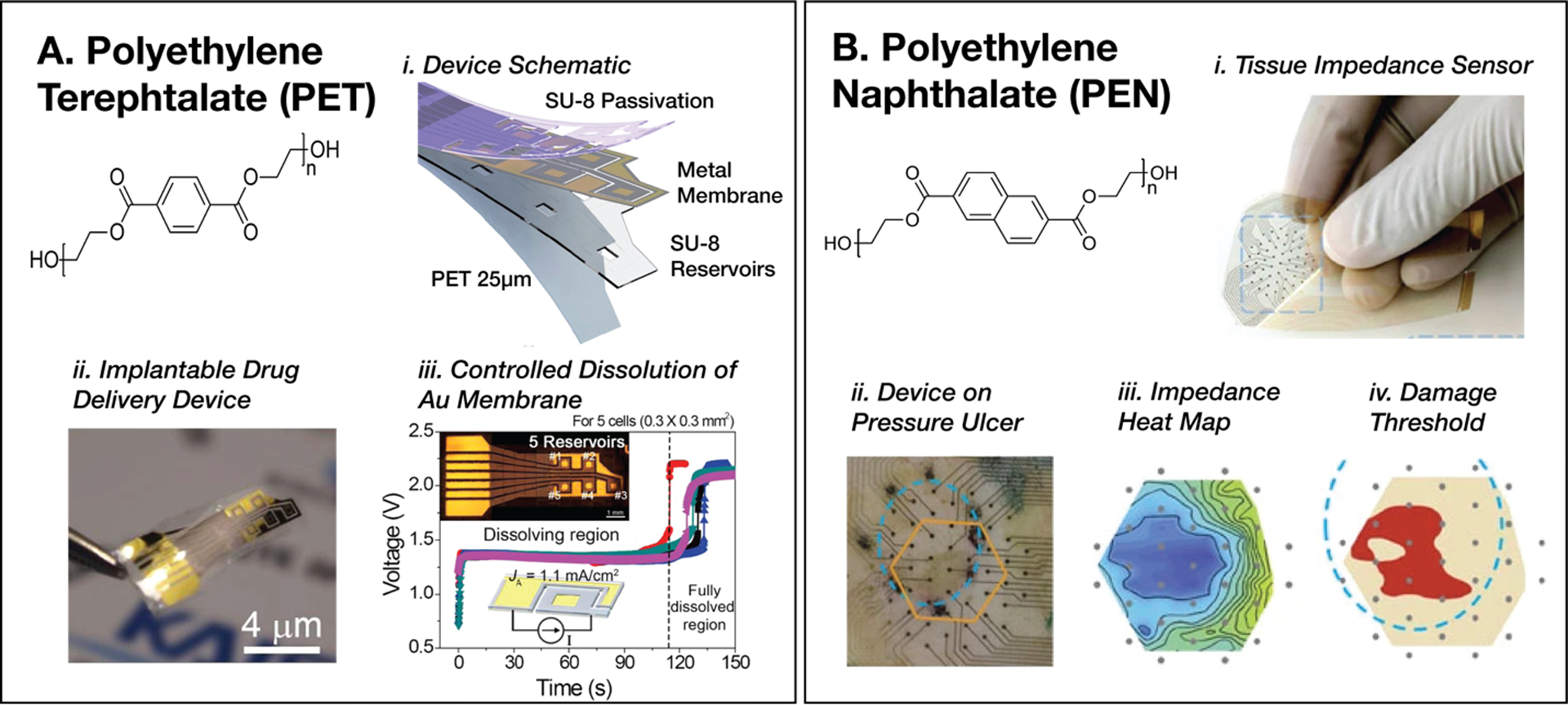

Figure 3.

A. Polyethylene terephthalate (PET)-based bioelectronic device for controlled drug delivery within the cerebral cortex (i, ii). Demonstration of temporal control over dissolution of a gold membrane to release the drug (iii). Reproduced with permission.[159] Copyright 2018, Elsevier. B. Inkjet-printed impedance sensors on polyethylene napthalate (PEN) substrates for early detection of pressure ulcers in mice. Reproduced with permission.[168] Copyright 2015, Springer Nature.

Similar to PET, PEN has also been widely used as a substrate for bioelectronics for its thermal and chemical stability, especially in cases that benefit from its higher Young’s Modulus compared to PET. Someya et al. and Fuketa et al. integrated 100 μm and 1 μm thick PET films respectively with patterned metal thin film conductors and organic semi-conductors to fabricate wearable sensors.[127,161] These examples also illustrate the compatibility of PEN substrates with manufacturing techniques, such as laser cutting and micromachining for feature and form-factor definition.

PEN substrates have also been used for inkjet printing and 3D printing of functional inks containing nanomaterials such as gold, silver, and carbon nanoparticles.[160,166,167] Inkjet printing of gold nanoparticles described by Khan et al. was used to fabricate a flexible impedance sensing electrode array to detect pressure ulcers in rat models (Figure 3, B).[168] PEN served as a reliable substrate that could undergo 1000 twist cycles without damage to the device.

2.1.2. Polyimides

Polyimides are commercially available polymers that have been used extensively as substrates in flexible bioelectronics due to the combination of chemical stability and compatibility with many existing microfabrication processes.[169,170] By definition, polyimides contain imide (-R1CO-NR2-COR3-) groups in the polymer backbone. Delocalized electrons in the imide group help to confer thermal and chemical resistance as a result of stable delocalized electronic configuration.[169,171] Polyimides are commodity materials used in adhesives, electronic device insulation and packaging, and flexible printed circuit boards.[172] Polyimides can be prepared using aliphatic or aromatic monomers (Figure 4). Polyimides with aromatic groups such as poly(4,4’-oxydiphenylene pyromellitimide) (PMDAODA PI) or Kapton and biphenyltetracarboxylic dianhydridde/para-phenylenediamine (BPDA-PPD) or U-Varnish are of particular interest as substrate materials in bioelectronics.[173] Although most polymers used in bioelectronics are aromatic or semi-aromatic as a result of superior thermal and chemical resistance, aliphatic polyimides are becoming materials of interest for optoelectronics applications due to their higher optical transparency (~90%) compared to commercial polyimides such as Kapton (~70%).[174,175]

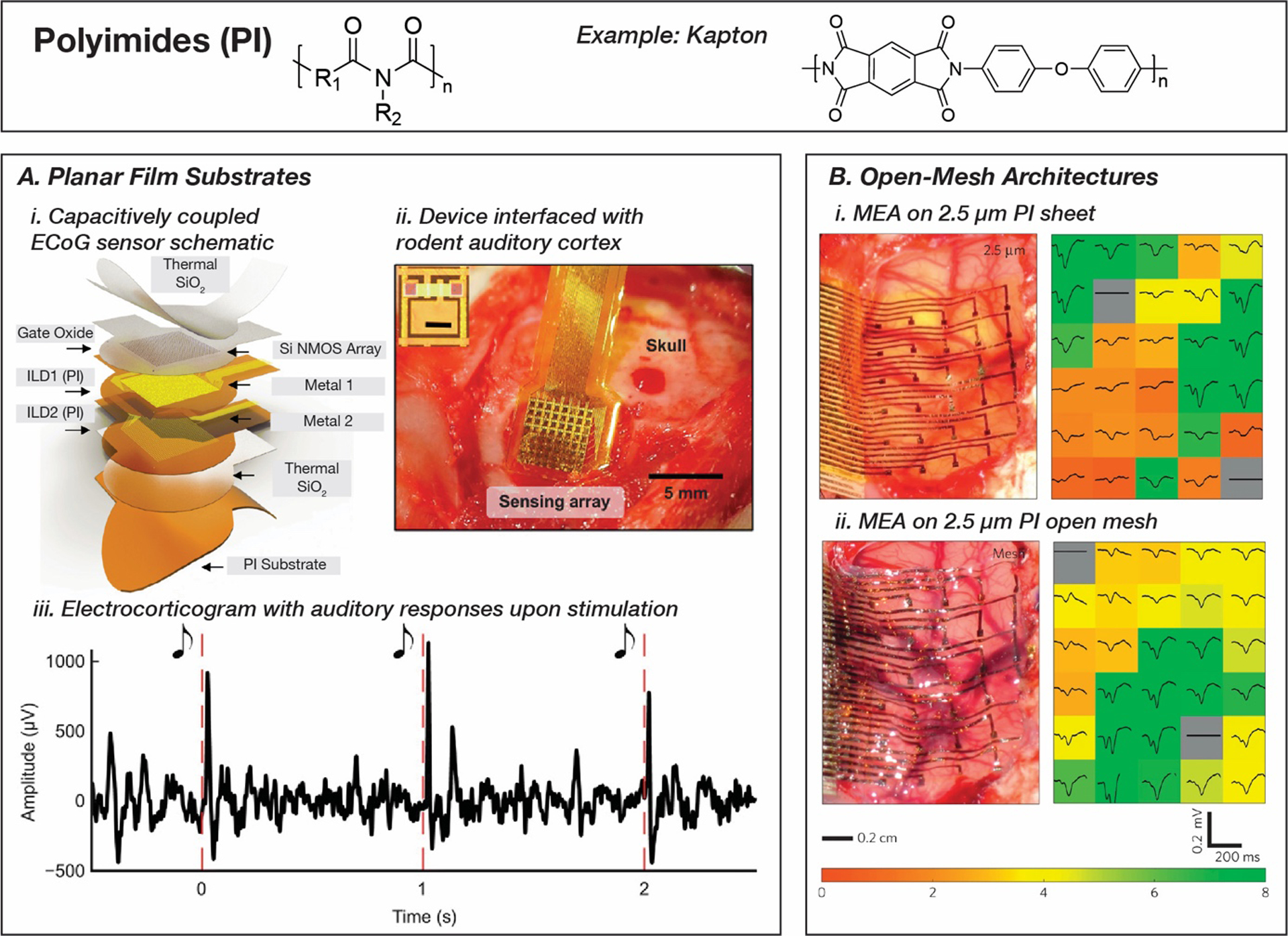

Figure 4.

Polyimide-based bioelectronic implants for electrophysiology. A. Capacitively-coupled neural sensors capable of high density 1008 channel electrodes for multiplexed electrocorticograms on a polyimide substrate. Reproduced with permission.[185] Copyright 2020, The American Association for the Advancement of Science. B. Open-mesh architectures using etched polyimide substrates capable of highly conformal recordings with improved signal-to-noise ratio compared to complete films. Reproduced with permission.[112] Copyright 2010, Springer Nature.

In addition to its chemical and thermal resistance, polyimide is biocompatible, strongly bonds photoresists to facilitate photolithography, and is compatible with etching techniques.[170,176] Furthermore, polyimides are thermosets that can be produced as liquid polymer precursors that can be solution processed at room temperature (drop casted, spin coated, and molded) and baked to produce irreversibly cured polymer films.[177–179] As a result, polyimides have been used as substrates in early instantiations of cochlear implants, an early example of implantable bioelectronic devices.[180] In this study, microfabrication processes were optimized and standardized for polyimide substrates, including spin-coating on Si handling wafers, photopatterning, and the use of tantalum adhesion layers for metallization.

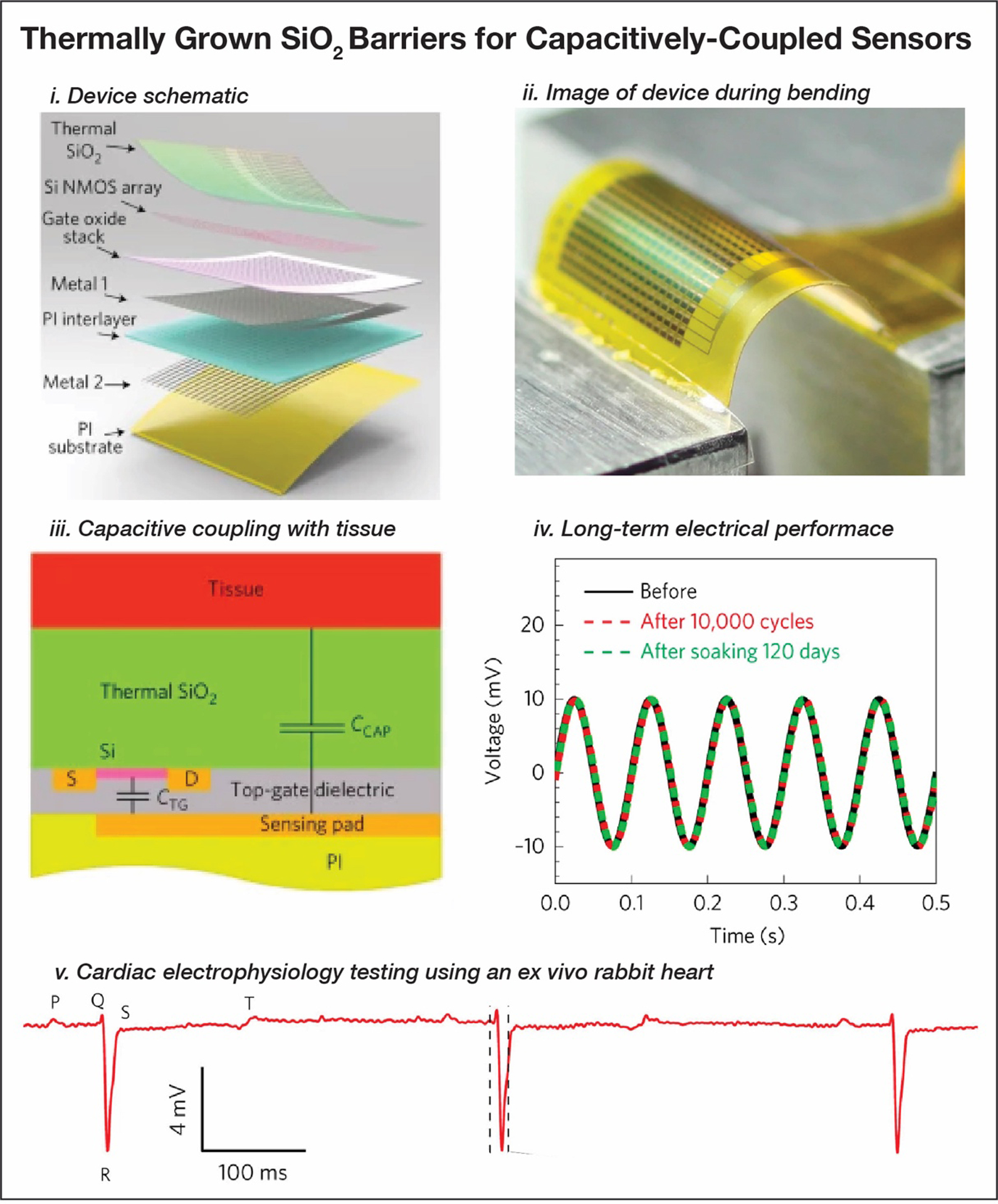

More contemporary examples exploit polyimides for their compatibility with nanofabrication methods to design complex implantable devices in cardiac and neural sensing applications.[181–183] Silicon nanomembrane transistors were integrated with a 288-electrode array for on-board amplification and multiplexing on flexible polyimide substrates to measure cardiac electrophysiology.[182] Multilayer architectures use two thin (~1.5 μm) spin-coated PI 2545 (HD Microsystems, NJ, USA) intermediary insulation layers and a Kapton (DuPont, DE, USA) polyimide substrate 12.5 μm in thickness bonded the to the device using a plasma activated silicone adhesive. When interfaced with a porcine heart, the device can map the cardiac wavefront with 800 μm resolution and signal-to-noise ratios (SNR) of ~34 dB. As one of the first instances of Si-based devices in implantable systems, this project highlights the potential of leveraging silicon-based microfabrication technology for robust yet flexible bioelectronic devices. Recently, a similar fabrication scheme was used to design a capacitively-coupled 396-node cardiac sensor and a 1008-node electrocorticography (ECoG) sensor that allowed for a completely encapsulated device without any exposed electronic components for long-term electrophysiology monitoring and high resolution (~400 μm) mapping (SNR ~42 dB) (Figure 4, A).[184,185]

Polyimides are amenable to micropatterning which can be used to create porous ordered mesh networks as substrates, improving the conformability of bioelectronic devices.[112,186,187] This is possible through a variety of techniques, such as dry etching using reactive ions, conventional photopatterning, and laser cutting. Seminal work in this field was reported by Kim et al. where photolithographic techniques were employed to pattern and metallize 2 μm thick Kapton PI films, followed by dry etching of PI to pattern the substrate into a mesh (Figure 4, B).[112] Dissolvable silk films were used as a temporary stiffener to deploy the devices in in vivo applications. A hemispherical mechanical model to estimate minimum adhesion energy per unit area showed that the polyimide mesh required a 10× lower adhesion energy compared to a film of the same thickness (γsheet = 29 mJ/m2, γmesh = 2.4 mJ/m2, thickness = 2.5 μm). An in vivo demonstration of the structures on a feline visual cortex showed that the mesh-based devices had the highest mean signal amplitude and the lowest error (VRMS,mesh = 5.7±3), suggesting that compliant electrodes are in closer contact with neural tissue compared to the unpatterned sheet devices (VRMS,sheet 76μm = 5.2±3.9,VRMS,sheet 2.5μm = 5.2±3.9).

2.1.3. Liquid Crystal Polymers

Liquid crystalline polymers (LCP) are highly crystalline polymer networks whose use as substrates in flexible bioelectronics evolved from their use as packaging materials in microelectronic devices. LCP are unique thermoplastics composed of low molecular weight aromatic subunits called mesogens that can self-assemble and align into liquid crystals upon heating or dissolution.[188–190] Crystalline domains confer chemical and thermal stability (Tdeg ~380°C), comparatively large elastic moduli for polymers (E~10 GPa), and low water absorptivity (moisture absorption <0.04wt%).[119,142] These properties, in addition to research suggesting that commonly used commercial LCP films are biocompatible for in vivo applications, have made them compelling for use in bioelectronics.[191–193]

LCP have been used as substrates for various devices including neural interfaces and retinal prosthetics.[194] Lee et al. used LCP as a substrate for peripheral neural interfaces to record from the sciatic nerve of murine subjects (Figure 2, A3). Multi-electrode arrays are fabricated on LCP by depositing Ti/Au metal stacks using sputtering and then patterning using wet etching.[195] Conformal retinal prosthetics have also been prepared using electronics integrated with LCP-based substrates.[119,196] Rabbits implanted with surrogate devices showed no adverse effects after 2.5 years post-implantation.[193] Lastly, LCP substrates can be integrated with ultrathin Si-based radio frequency integrated circuits to enable more sophisticated functions including in vivo wireless communication.[192]

Aligned and crystalline networks in LCP produce some challenges for use in flexible bioelectronics. First, aligned polymer chains generate robust, yet highly anisotropic mechanical properties. For example, the anisotropy ratio of tensile strength and elastic modulus of commercial 1-mm thick Vectra A950 films are and respectively.[197,198] However, using modified film extrusion processes, biaxial LCP films that have polymer chains orientation equally distributed in two perpendicular directions (−45° and +45°) exhibit isotropic mechanical properties.[199] The high melting point of LCPs coupled with the low viscosity of LCP melts limit their processing into films to extrusion-based methods (Velctra A-950: Tm =280°C, melt viscosity η = <100 Pa s).[142,200] As a result, most reports that use LCPs as substrates in bioelectronic devices use commercially available films with thicknesses greater than 25 μm. This lower limit of thickness bounds the flexibility of LCP-based devices and prevents their use from applications requiring high conformability. Dry etching and laser based-thinning can reduce the thickness of LCP substrates for applications where thicknesses <25 μm are required.[143,201]

2.1.4. Epoxies

Epoxies are widely used as photoresists in microelectronics fabrication but have also gained traction as a substrate material in flexible electronics.[202–205] Commercially available SU-8 photoresist contains a UV-activated photoacid generator that protonates epoxide groups on multifunctional oligomers and yields highly cross-linked networks.[145] The resulting polymer is mechanically robust and thermally stable with a Young’s Modulus up to E ~ 5 GPa and shows no detectable structural degradation at temperatures up to 380°C.[206] In photolithography, the non-crosslinked polymer can easily be dissolved with an SU-8 developer like 1-methoxy-2-propanol acetate. SU-8 films of a broad range of thicknesses (0.2–300 μm) can be fabricated by spin coating precursors with varying viscosities.[207,208] In addition to the favorable processing capabilities and mechanical properties, demonstrations of the biocompatibility of SU-8 implants have made it a compelling material for bioelectronics.[209–211]

Flexible bioelectronic devices fabricated on bulk SU-8 substrates have been extensively investigated for diverse applications, including peripheral and cortical nerve interfaces. Photopatterned SU-8 with thin-film gold electrodes was used to fabricate grooved microprobes aimed at channeling the regrowth of sciatic nerves in a rat model.[204] This structure measured nervous impulses for 51 weeks in vivo with a signal-to-noise ratio (SNR) >2 and no indication of adverse inflammatory reactions. SU-8-based cortical probes exploit the robust in-plane mechanical properties combined with out-of-plane flexural compliance to accommodate insertion forces without buckling.[212] Altuna et al. presented a multimodal device capable of microfluidic drug delivery into the brain in addition to measuring neural responses (Figure 5, A-i,ii,iii).[203] Devices deployed in vivo can detect local field potentials and single cell activity in conjunction with localized delivery of precise drug volumes within the brain of murine subjects (Figure 5, A-iv).

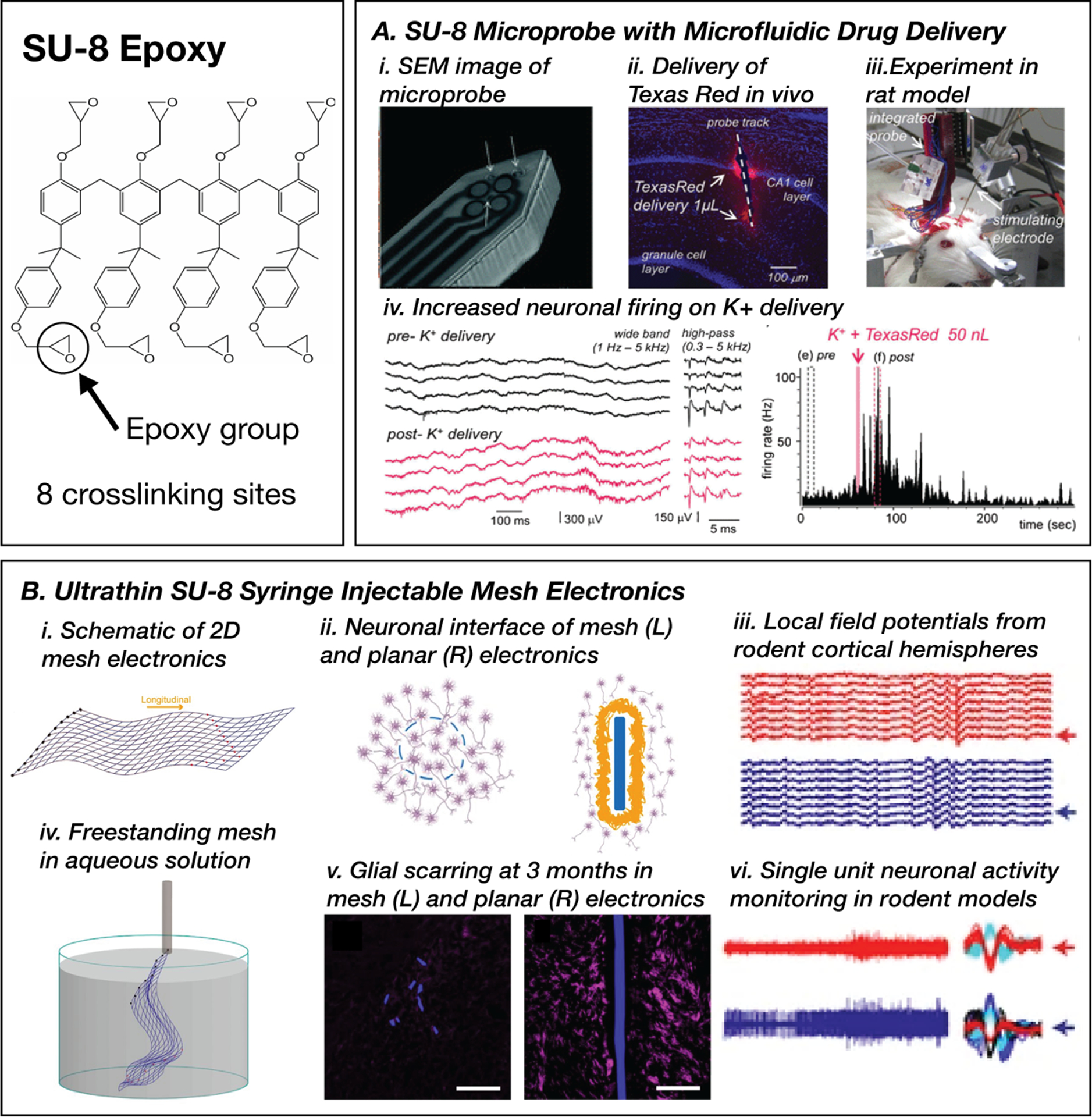

Figure 5.

SU-8 epoxy substrates for flexible neural interfaces. A. A neural probe photopatterned with microfluidic channels for simultaneous drug delivery and electrophysiology (i, iv), demonstrated through increased neural activity on the delivery of potassium ions(iv).Reproduced with permission.[203] Copyright 2012, Elsevier. B. Photopatterned syringe-injectable mesh electronics (i, ii) deployed in murine brains that promote biointegration (ii), reduce glial scarring (v), and can record field potentials (iii) and single neuronal activity (vi). Reproduced with permission.[214] Copyright 2017, National Academy of Sciences. Reproduced with permission.[215] Copyright 2016, Springer Nature.

Photo-definable features of SU-8 lend itself to the manufacturing of substrates with complex features. Ultra-thin SU-8 films (300–400 nm) can be photo-patterned to create porous substrates with over 90% free space (Figure 5, B-i).[213] These structural elements with bending stiffnesses as low as 0.104 nN-m (compared to 3000 nN-m for standard 25 μm polyimide thin films) can be compressed and delivered through a needle with a diameter as low as 100 μm (Figure 5, B-ii).[214] Porous SU-8 substrates support the integration of passive sensors for measuring local field potentials and mapping single neurons in the cortex of mice with limited detectable chronic immune response for 12 months.[128,214,215] Mesh-based multielectrode arrays record stable signals with low background noise and RMS amplitudes of VRMS = 300 μV and stable recordings from spikes for >6 months. “Syringe-injectable electronics” use several features of SU-8 substrates, including precise film thicknesses, facile patterning, and heterogeneous integration with thin film electronics. The ability to deploy such devices through a syringe offers a minimally invasive implantation technique through a stereotaxic injection. When combined with extreme miniaturization, patterned mesh SU-8 substrates can enable exciting new concepts in electrophysiological recording.

One of the major challenges in implementing SU-8 as substrates in flexible electronics is poor adhesion with metallic interconnects when deposited using conventional deposition methods. This challenge can be overcome through the use of adhesive layers and different deposition methods like ion implantation.[202] While there are several challenges and limitations in using SU-8, it stands uniquely among other substrate materials as a high-aspect ratio photoresist that is capable of precise direct photopatterning. Additionally, the demonstration of SU-8 mesh electronics makes the interesting proposition of using patterned substrates to create viscoelastic flexible bioelectronic devices that can be implanted using minimally invasive approaches.

2.1.5. Parylene C

A material developed broadly for packaging applications such as microelectronics insulation, implant coatings, and food encapsulants, Parylene C possesses several properties that make it attractive for bioelectronics.[216–223] Parylene C is a chlorinated member of a larger family of poly(p-xylylene) polymers that are typically synthesized using chemical vapor deposition (CVD).[216] Parylene synthesis schemes produce vapors by subliming solid dipara-xylylene precursors at ~150 °C.[224] At ~700 °C and 0.1 torr, dimers pyrolyze into the vapor-phase monomer para-xylylene. When this gas encounters a substrate, it forms a semi-crystalline conformal transparent layer of poly(p-xylylene). Highly crystallinity and dense packing in Parylene C produce Young’s moduli in the range of EPara-C = 1–3 GPa for both thin and bulk films alike. Parylene C films have been used as substrates for flexible electronics with thicknesses ranging from several nm to 100 μm.[148] The extensibility of Parylene C is typically limited to εyield = ~4% with εfailure = ~25–200% at σyield = 60–80 MPa.[149,225] Parylene C is attractive for use in bioelectronics because it features robust mechanical properties, facile processing and integration with photolithography and etching, and has an established record of low toxicity.[226,227]

Parylene C can be fabricated by micromachining and thermoforming to create both 2D and 3D structural elements for bioelectronics.[228–232] Highlighted in Figure 2, A2, Parylene was used in one of the earliest demonstrations of flexible neural probes with 3D form factors by Suzuki et al. in 2003 through micromachining.[118] This study processed Parylene using dry etching and sacrificial layers to release Parylene structures and create structural pillars used as probes for multi-channel recording from the brain. More recently, a dry-etching technique was utilized to pattern kirigami designs into Parylene substrates that allowed over 800% strain (Figure 6, A).[233] 10-channel platinum multielctrode arrays on kirigami patterned Parylene C can record electrocardiograms of a beating mouse heart with a stable signal amplitude of VRMS~4 mV. Thermoforming has been extensively used to anneal and fix Parylene based devices into form factors for specific applications including sheaths and tubes for neural interfaces and curved surfaces for retinal implants.[234–237] Hara et al. built on previous literature on sheath designs of cortical probes to demonstrate device viability in chronic applications.[238] A signal-to-noise ratio >5.5 was observed that increases over a 22-week post-implantation period as the device integrated with surrounding neurites.

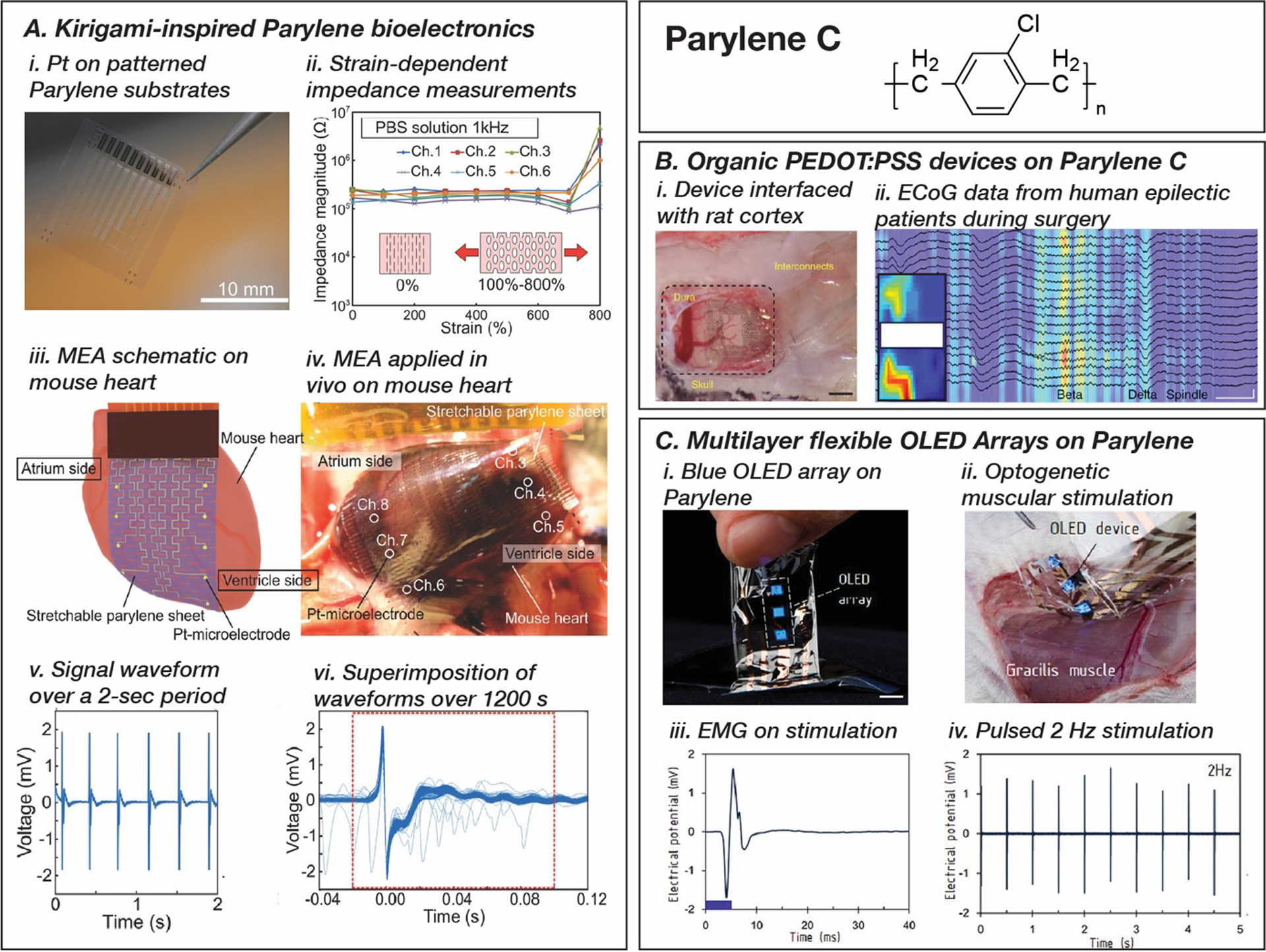

Figure 6.

Parylene C based bioelectronics for implantable applications. A. Laser cut Parylene C substrates for kirigami enabled stretchable multielectrode arrays for electrophysiological monitoring (i, ii, iii, iv), capable of high-resolution electrocardiography (v, vi). Reproduced with permission.[135] Copyright 2018, John Wiley and Sons. B. 265 PEDOT:PSS electrode array on 2 μm Parylene C to record neural activity from human epileptic patients. Reproduced with permission.[220] Copyright 2015, Springer Nature. C. Flexible blue organic light emitting diode (OLED) on Parylene C substrates (i) for optogenetic muscular stimulation (ii) and electromyogram recording (iii, iv). Reproduced with permission.[248] Copyright 2020, National Academy of Sciences.

Beyond conventional inorganic thin-film flexible devices, Parylene C can serve as a substrate for organic bioelectronics.[227,239–243] An organic electrochemical transistor array of doped poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) was fabricated on Parylene C substrates using photolithographic patterning methods and used to measure cortical activity in vivo from human epileptic patients (Figure 6, B).[220] Additionally, with a growing interest in bio-optoelectronics, Parylene C became an obvious choice as a substrate for optical devices given its transparent optical properties in addition to robust mechanical and dielectric properties (Figure 6, C).[244–247] In 2020, Kim et al. exploited recent advances in organic semiconductors to fabricate a Parylene C-based flexible array of organic light-emitting diodes with an in vivo demonstration of optogenetic stimulation of the sciatic nerve in mouse models.[248]

A major challenge of fabricating inorganic thin-film electronics on Parylene C involves its thermal instability during deposition and patterning processing as a result of its thermoplastic nature and low oxidative degradation temperatures (Tdeg ~125°C).[222,249] This can result in the formation of bubbles, cracks, and damage during the manufacturing process. However, if needed, high temperature stable varieties of Parylene such as Parylene HT can be explored as substrates.[235]

2.2. Stretchable Substrate Materials in Flexible Bioelectronics

Elastomers have gained traction as structural materials for medical devices owing to their mechanical flexibility (E < 10 MPa), extensibility(εyield > 10%, typically well over 100%), and facile processability.[54,250,251] As designing stable biological interfaces with low mechanical impedance mismatch has become important, the role of elastomers has become prominent because of the intrinsic stretchability of several biological tissues.

However, the use of elastomers for implantable bioelectronics as a stretchable substrate is relatively recent due to technical challenges when integrating rigid electronic components with compliant substrates. The last two decades have seen a tremendous rise in the utilization of stretchable substrates to enable a wide range of biological applications such as dynamic bioelectronic cardiac patches, conformal wearable devices, and soft central and peripheral nervous interfaces.[35,252–254] The recent success of stretchable bioelectronics suggests that integrating elastomers with high performance electronic components will continue to grow as commercialization becomes imminent.[34,255,256]

2.2.1. Silicone-based Elastomers

Silicones are named after their inorganic silicon-oxygen backbone, with organic functional groups attached to each Si. Polydimethylsiloxane (PDMS), the most common variety of silicone in bioelectronics, has two methyl groups that are bonded to each Si atom in the polymer backbone (Figure 7). Silicones such as PDMS exhibit thermal stability, chemical resistance in physiological solutions, and dielectric properties (Resistivity ρPDMS = 4×103 Ω-m, dielectric constant εPDMS=2.3–2.8, degradation temperature Tdeg=400–650°C), which are attributed to electron delocalization along the backbone and Si-O bond energies of 452 kJ mol−1 compared to 348 kJ mol−1 in C-C bonds.[257–260] PDMS resists enzymatic biodegradation pathways due to its partial inorganic character.[261] As a result, dozens of medical devices that use silicones have been approved by the FDA including shunts, catheters, contact lenses, soft tissue implants, and stimulation leads.[262,263]

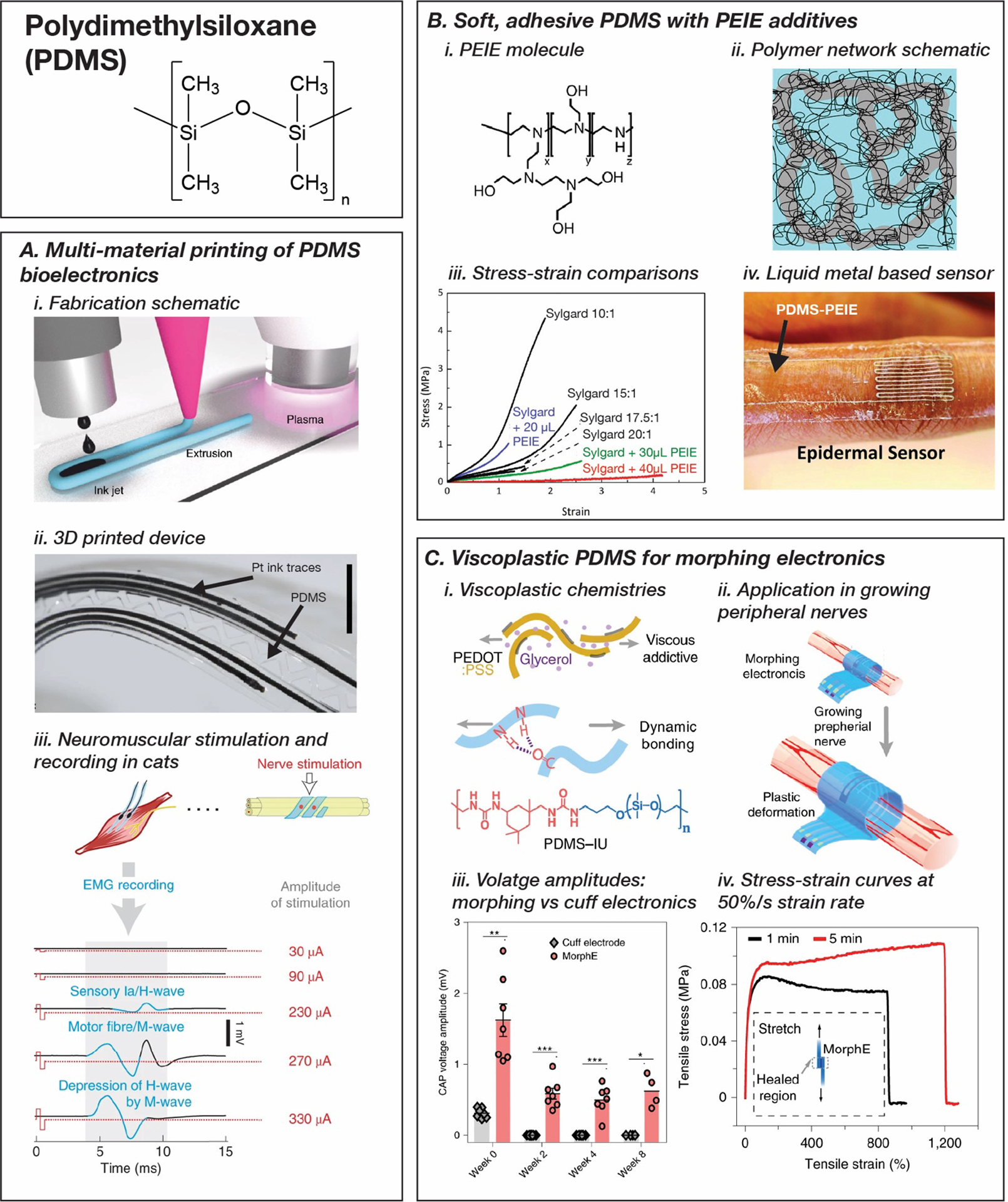

Figure 7.

Polydimethylsiloxane (PDMS) and PDMS derivatives for wearable and implantable bioelectronics. A. 3-dimensional printing strategies for PDMS substrates and platinum nanoparticle inks to form in situ stretchable conductors to rapidly prototype electrode arrays (i, ii) for neuromuscular stimulation and recording. Reproduced with permission.[271] Copyright 2020, Springer Nature. B. Ethoxylated polyethylenimine (PEIE) additive in PDMS elastomers to produce softer and stickier elastomers for wearable devices. Reproduced with permission.[273] Copyright 2016, John Wiley and Sons. C. Viscoplastic PDMS derivatives and plasticized PEDOT:PSS conductors for morphing electronics in regenerating peripheral nervous interfaces (i, ii, iv), with superior signal-to-noise performance compared to fixed cuff electrodes (iii). Reproduced with permission.[276] Copyright 2020, Springer Nature.

Commercial PMDS silicones (e.g., Sylgard, Ecoflex, and Silbione) are widely used as structural materials in stretchable bioelectronic devices.[264–266] Silicone can be processed into 2D and 3D deterministic architectures and combined with inorganic thin films to confer stretchability to flexible bioelectronic devices.[121,267–270] Minev et al. micropatterned PDMS substrates for use as synthetic electronic dura mater capable of simultaneous electrical measurements and microfluidic drug delivery in neural interfaces for up to 6 weeks.[123] These devices were fabricated using soft lithography for patterning drug microchannels, plasma-activated covalent bonding for assembly, and thermal evaporation and stencil printing for patterning conductors.

The versatility of silicones was further demonstrated by Afanasenkau et al. in their demonstration of a multi-material 3D printing approach utilized to simultaneously print silicone elastomers and Pt conductive inks that form conductive composites in situ (Figure 7, A).[271] At a physiologically estimated maximum operational strain of 20%, the printed devices showed a 10-fold increase in impedance at 20 kΩ compared to the unstrained composite, still being conductive enough to retain device functionality. Through this technique, several neuromuscular interfaces with unique form factors were reported with applications including spinal cord stimulation and recording, sciatic nerve recording, and electromyogram recording.

Materials chemistry has played an important role in designing modified silicone-based materials to overcome limitations of commercial PDMS. Commercial silicones suffer from poor adhesiveness that impacts devices both during processing and deployment.[272] Jeong et al. designed and synthesized soft, stretchable, and adhesive PDMS by adding small volumes (20–40 μL in 10 g of PDMS) of ethoxylated polyethyleneimine (PEIE) with PDMS precursors prior to curing (Figure 7, B). PEIE additives induce heterogeneity and increase sol content, thereby reducing the modulus to EPDMS+PEIE = 24 kPa from EPDMS = 1 MPa and increasing the force of interfacial adhesion forces to Fad,PDMS+PEIE = 1.2 N compared to Fad,PDMS < 0.1 N (Sylgard 184).[273] Compared to PDMS, PEIE-modified silicones increase mechanical compliance and adhesion which can improve integration with ultrafine tissue targets and reduce subsequent fibrous capsule formation in vivo.[102] Silicones can also be modified with photoactive groups to achieve photocrosslinkable analogues. Choi et al. reported a new class of photocrosslinkable silicones that use urethanes with pendant methacrylate groups as photoactive groups.[274] Photocrosslinkable silicones were originally designed as materials for high resolution nanometer scale patterning and soft lithographic molding. However, photocrosslinkable silicones could also be used as structural materials with micron-scale features for stretchable bioelectronics.

Devices interfaced with regenerating or growing tissue can experience small stresses and rates of strain (~1 mm/day) over long periods of time as the tissue expands. Conventional silicone elastomers are too stiff to operate in this context.[275] However, this can be addressed through engineering an increased viscoelastic response in PDMS elastomers. This was accomplished by designing a chemically modified PDMS with isophorone bisurea (IU) and 4,4′-methylenebis(phenyl urea) (MPU) and blending PDMS-IU with PDMS-IU0.6-MPU0.4.[276–278] By balancing the dynamic bonding of IU and hydrogen bonding of MPU, the PDMS blend is capable of a Young’s modulus of 0.4 MPa at a strain rate of 50% s−1. This material was integrated with a plasticized PEDOT:PSS conductor for stable chronic neuromodulation and nerve growth monitoring tested on the sciatic nerve of fast growing rats over a period of 4 weeks (140% increase in nerve diameter) (Figure 7, C).

2.2.2. Block Copolymer-based Elastomers

Block copolymer (BCP)-based elastomers are polymer networks with physical crosslinks that have been used in medical devices, such as catheters, drug delivery systems, and materials for regenerative medicine.[279–284] Polystyrene-based ABA triblock polymers are a prominent example of this molecular architecture, in which polystyrene A blocks flank a central B block with variable composition.[285] Typically, the middle block chain is composed of an aliphatic monomer, resulting in two rigid hydrophobic polystyrene blocks linked by a flexible polymer chain. However, any reasonable combination of A and B blocks that are immiscible with one another can serve as ABA triblocks. Populations of ABA triblocks self-assemble into rigid domains of A blocks that serve as physical crosslinks with flexible interstitial phases that are rich in B blocks.[286,287] BCP-based elastomers possess tunable mechanical and viscoelastic properties that can be optimized by varying the volume fraction and lengths of the A and B blocks. This controls the morphology and volume fraction of the rigid microdomain blocks, ϕm, of the physically crosslinked species, A.[285,288] The higher volume fraction of the rigid microdomains understandably produces elastomers with higher elastic moduli.[289] For instance, ABA triblocks composed of polystyrene (A) and polybutadiene (B) can be modulated to form both viscous polymer lubricants and robust physically crosslinked elastomeric polymer networks by varying ϕm.[255–257] Polymer networks with physical crosslinking expands the range of processability to include casting, extrusion, electrospinning, and molding.[284,290–293] The combination of processability and unique mechanical properties makes them useful as substrates in bioelectronics.

In Figure 2 B2, we see an early use of BCP-based elastomers, specifically poly(styrene-b-butadiene-b-styrene) (SBS), as a substrate for a highly stretchable transistors for wearable tactile sensing applications.[122] The authors employ electrospinning to cast a film of the SBS elastomer, and all device elements, including the Au nanosheet conductor, PH3T polymeric semiconductor, and PEG-based ionic dielectric, were integrated using a stamp transfer printing technique.[122] This work demonstrates a robust integration technique for fabricating devices on BCs. Molina-Lopez et al. demonstrated the versatility of processing BCP-based elastomers by fabricating a multilayer inkjet-printed synaptic transistor arrays on a styrene-ethylene-butylene-styrene (SEBS) substrate for use as low voltage (~1 V) wearable devices.[294] The ionic nature of these transistors closely mimic the synaptic behavior of neurons, making them exciting devices for neural interfaces and neuromorphic processing. BCP networks with physical crosslinks exhibit significant hysteresis compared to elastomers with chemical crosslinks.[284] This can be an undesired characteristic for stretchable electronic systems that experience dynamic loading conditions. Proposed solutions for this issue involve chemically crosslinking the BCP to create more rigid anchors in the polymer network.[295,296]

2.3. Ultracompliant Substrate Materials in Flexible Bioelectronics

Matching the modulus of the substrate at the tissue-device interface is a dominant principle when designing devices for seamless integration with excitable tissue.[297,298] In many instances, the mechanics and chemistry of electronically excitable soft tissues are dominated by the extracellular matrix.[299–303] Therefore, integrating active electronic components to materials that mimic this native environment could ostensibly offer advantages. Specifically, integrating sensors, traces, and other active components on ultracompliant substrates, such as hydrogels, is an important step in this evolution.[59] Hydrogels have been used extensively as coatings for rigid silicon-based neural implants and 1D recording wires to modulate the chemistry at the tissue-device interface, but to date have seldom been used as structural materials.[304–310] Hydrogels are challenging to process into mechanically robust electronic devices since they are fundamentally incompatible with many microfabrication strategies that require vacuum, elevated temperature, or exotic organic solvents.[311–313] New concepts in materials processing strategies and heterogeneous integration catalyzed recent advances in hydrogel-based bioelectronics.[314–320]

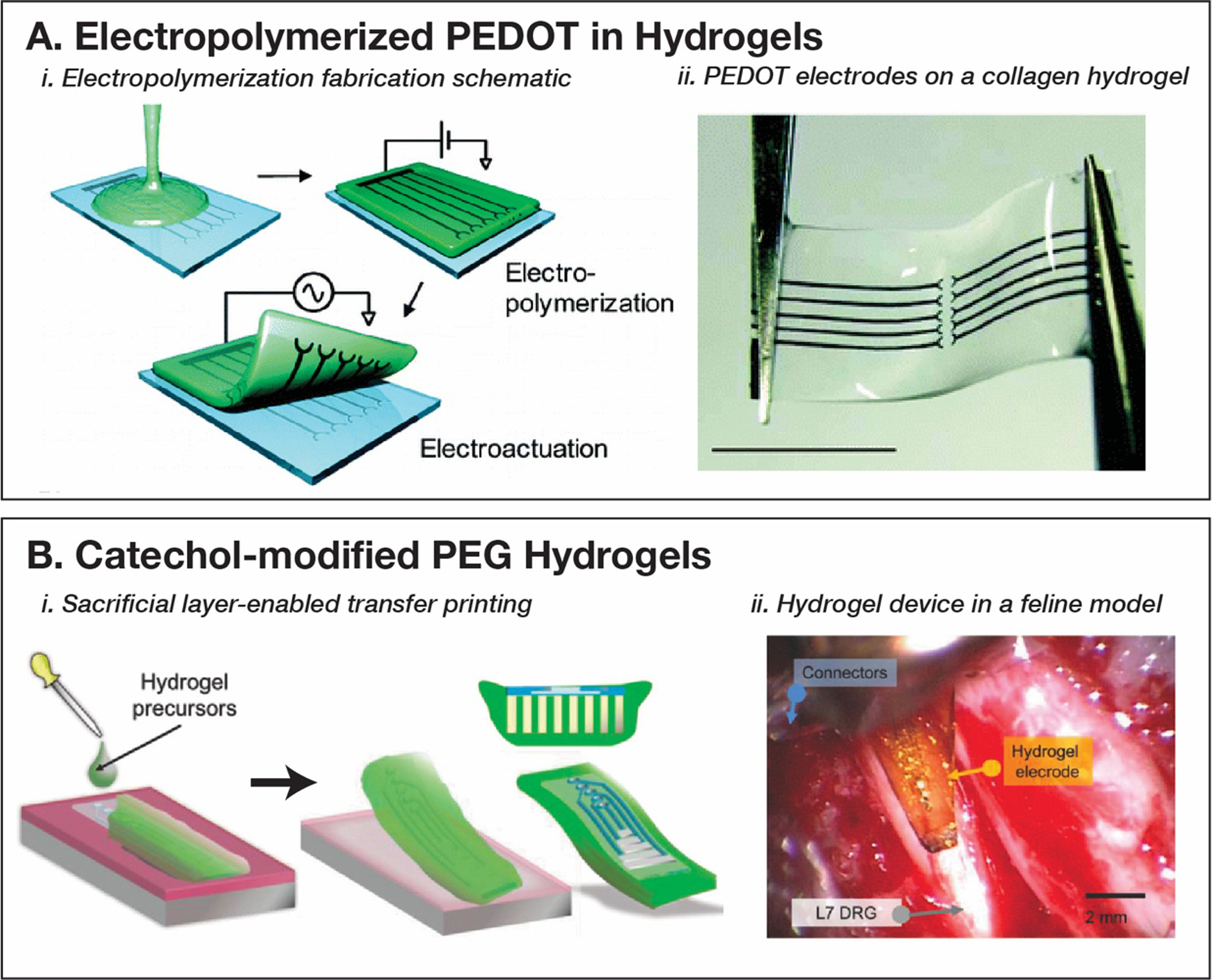

With the development of intrinsically conductive polymers capable of electropolymerization, such as PEDOT, in situ polymerization of conductive traces within hydrogel substrates has been explored. Sekine et al. electropolymerized PEDOT on a microfabricated Pt pattern within a newly crosslinked agarose network (Figure 8, A-i).[321] Repeated electrochemical actuation using the same set-up is employed to peel off the hydrogel easily. This simple technique is generalizable to any crosslinkable hydrogel (Figure 8, A-ii). Ido et al. improve the conductivity of PEDOT electrodes in hydrogel-based networks by pre-polymerizing PEDOT on Pt traces in acetonitrile, a solvent system that is optimized for electropolymerization as opposed to hydrogel processing.[322] This can be followed by casting the hydrogel and PEDOT solution and following the same procedure laid out previously. These procedures have been used to fabricate advanced electronic tissue engineering platforms and wearable sensors.[323]

Figure 8.

A. Electropolymerization technique for patterning PEDOT polymer electrodes in hydrogel matrices. Reproduced with permission.[321] Copyright 2010, American Chemical Society. Reproduced with permission.[322] Copyright 2012, American Chemical Society. B. Catechol-modified polyethylene glycol hydrogels (PEGDA) substrates for peripheral nerve interfaces in feline models fabricated using an aqueous phase transfer printing technique. Reproduced with permission.[126] Copyright 2018, John Wiley and Sons.

Another important development that enabled the fabrication of such hydrogel-based devices was an aqueous phase transfer printing process developed by Wu et al.[324] They demonstrated a versatile technique to transfer print microfabricated metal traces from wafers with water-soluble sacrificial layers to aqueous pre-swollen hydrogels. This is done by photopatterning the metal traces on a polyacrylic acid (PAA) sacrificial layer. Hydrogel precursors are then cast and cured on the substrate before releasing the sacrificial layer.

This method was adapted by Huang et al. to fabricate a multielectrode array on polyethylene glycol-dopamine (PEG-Dopa) hydrogels for a peripheral nerve interface (Figure 8, B).[126] As a widely used hydrogel system for a variety of biomedical applications, PEG-based hydrogels are a natural choice for use in bioelectronics.[325–328] The catechol motifs found in dopamine improve interfacial adhesion with Parylene C insulating layers, thus facilitating transfer printing.[329,330] Multi-electrode arrays fabricated using this technique were used as peripheral nerve interfaces to record from the dorsal root ganglia in feline models.

2.3.1. Tough Hydrogels

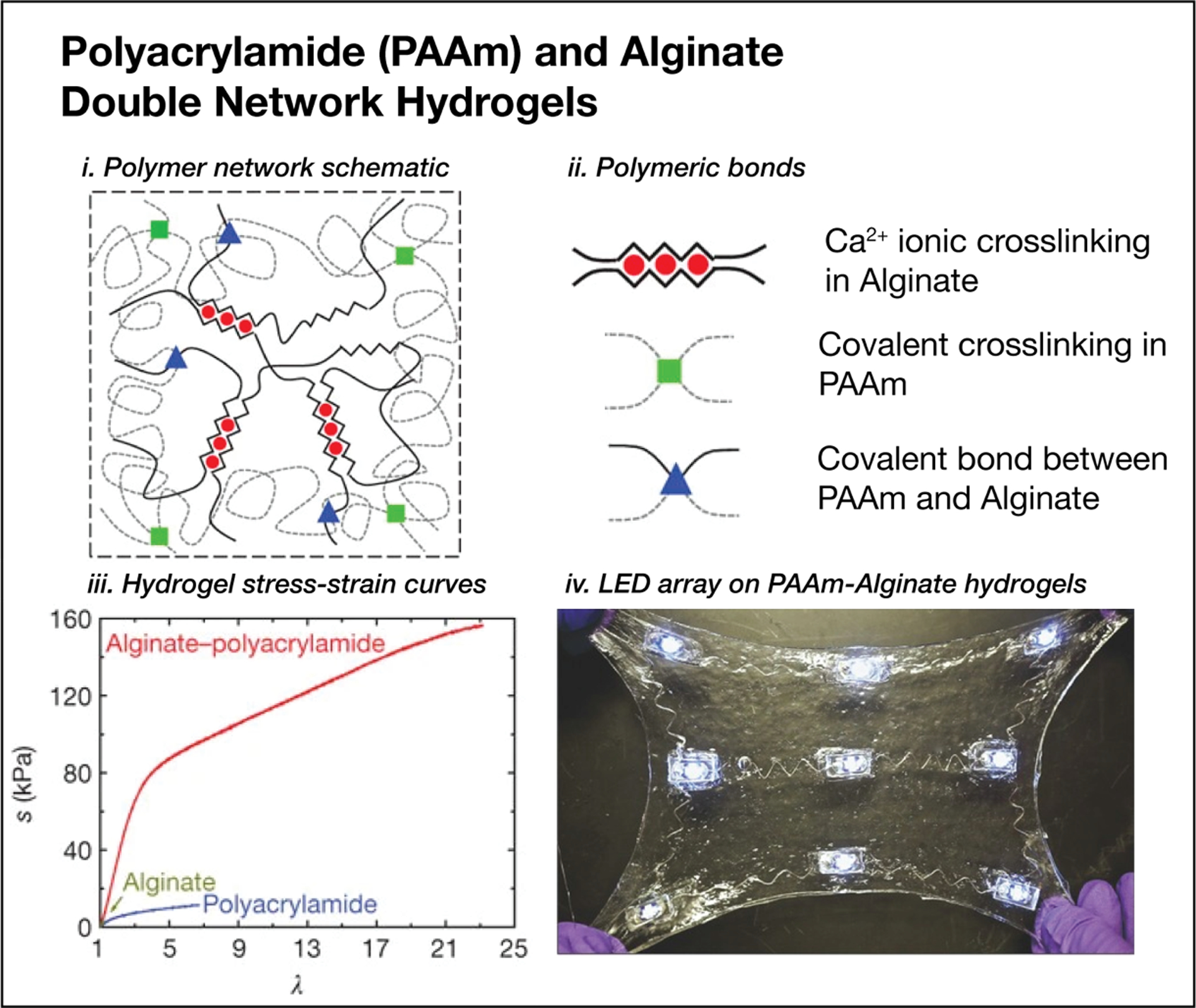

Most hydrogel networks have polymer fractions of ϕ2 < 0.1 and therefore exhibit small elastic moduli because of the volumetric dilution of crosslinks. The molecular topology endows networks with mechanical compliance at the expense of toughness with tensile toughness on the order of 10 J m−2 compared to 10,000 J m−2 for typical silicone-based elastomers.[157,331] The typical brittle properties of hydrogels limit extensibility and therefore bound the potential use as structural materials for flexible bioelectronic devices. However, the toughness of hydrogels can be increased by incorporating interpenetrating double networks. For example, polyacrylamide (PAAM) and alginate double network hydrogels exhibit maximum strains of εmax >2000% and fracture energies of ~9000 J m−2 (Figure 9, i–iii).[157] This toughness is a result of the combination of a covalently crosslinked network polyacrylamide providing stability by remaining intact on deformation and the mobile ionically crosslinked alginate that reversibly unzips on deformation.

Figure 9.

Polyacrylamide (PAAm) and alginate double network tough hydrogels for ultracompliant, stretchable, and adhesive electronics. (i, ii, iii) Reproduced with permission.[157] Copyright 2012, Springer Nature. (iv) Reproduced with permission.[158] Copyright 2016, John Wiley and Sons.

Lin et al. demonstrated the use of the PAAM-Alginate double network (DN) hydrogel-based hybrid electronic and diffusive drug delivery devices demonstrated as a proof-of-concept for wound healing applications (Figure 9, iv).[158] The conductive traces are preformed titanium wire that is bent into serpentine structures to enable stretchability. Additionally, they demonstrate a rigid-island based strategy to bond conventional electronic components to the hydrogel substrate where the electronic components are encapsulated by PDMS and bonded to the hydrogel with a silanized glass slide as an intermediary structure. This method is a promising steppingstone in designing hydrogel-based stretchable electronics. Beyond Ti wires, conductive elements could include transfer printed metal films, electrodeposited conducting polymers, or other structures, such as 3D printed colloidal metals.

Other approaches to develop tough hydrogels have involved innovation in supramolecular polymer networks, nano-clay hydrogel composites, and other combinations of interpenetrating networks.[332–335] While these strategies have resulted in materials with promising properties for application in bioelectronics, there has yet to be broad adoption of tough hydrogels as structural materials in flexible bioelectronic devices, with a few notable exceptions.[29,336,337]

2.4. Structurally Adaptive Substrates for Bioelectronics

2.4.1. Biodegradable Polymers

Flexible bioelectronic devices fabricated on transient substrates have several compelling advantages as medical implants. In principle, transient devices can be implanted and resorbed within the body without the need for secondary extraction surgeries as in the case for non-degradable systems. To date, transient electronics have been integrated with naturally derived materials such as silk fibrion, cellulose, gelatin, and collagen, and synthetic polymers such as poly(lactic-co-glycolic acid (PLGA), polyurethanes, and poly(1,8-octanediol-co-citrate) (POC).[130,338–342] These polymers possess a range of varying mechanical properties and degradation characteristics engineered for unique applications. A common trait of all biodegradable polymers in implantable electronics is that their degradation by-products must be non-toxic to prevent an inflammatory response.[343–347]

Biologically Derived Biodegradable Polymers

Silk fibroin is a high molecular weight protein isolated from the cocoon of the Bombyx mori that is solution processable into various form factors and exhibits tunable mechanical properties, degradation characteristics, and crystallinity thus making it an attractive choice as a structural material for transient bioelectronics.[348–356] The crystallinity and β-sheet content can be tuned by processing treatments and post-processing conditions, such as treatment with methanol.[357–360] Crystalline methanol treated films deposited using a layer-by-layer technique are brittle with a mechanical modulus of 6–8 GPa, ultimate tensile strength of 100 MPa, and exhibit slower degradation kinetics compared to their amorphous silk fibroin counterparts.[361–363] The high tensile strength of silk films allows for them to serve as ultrathin substrates in flexible bioelectronic devices that are intended to conform to curvilinear tissues.[364,365] On the other hand, an acetone solvent induced sol-gel transition can be used to fabricate transparent silk fibroin hydrogels with compressive moduli ranging from 0.4 to 11.5 kPa.[366] Lastly, silk has served as a particularly unique material in soft electronics as it has been demonstrated that cross-linking in silk can be controlled by electron-beam radiation.[367,368] This has allowed silk to be directly exploited as a lithographic resist that can be processed using only water.[367]

Biologically derived structural polymers such as gelatin and collagen can processed into films and used as substrates in bioelectronics.[369–373] Through the use of additives such as glycerol, citric acid, and glucose, Baumgartner et al. process tough gelatin biogels that can accommodate strains of up to εmax = 300%. Conductive zinc traces were defined through laser patterning to fabricate a wearable sensor capable of monitoring a number of different parameters such as temperature, humidity, and strain.[130] Mammalian collagen-based glutaraldehyde cross-linked hydrogels have also been used as substrates.[374] The extent of crosslinking is controlled to demonstrate tunable degradation properties, and a transfer printing method is optimized to fabricate multilayer device stacks on collagen-based substrates.

Synthetic Biodegradable Polymers

Aliphatic polyesters such as polylactic acid (PLA) and poly (lactic-co-glycolic acid) (PLGA) were among the first synthetic polymers investigated as biodegradable substrates for potential applications in bioelectronics. From extensive characterization in drug delivery applications, modulation of degradation profiles of PLA and PLGA is well understood and has been extended to biodegradable electronics applications.[341,375,376] PLA substrates have been used to fabricate bioresorbable stents with integrated bioelectronic sensing of temperature and arterial blood flow.[377] Transfer printing methods have been developed to fabricate complex Si-based semi-conductor devices on PLGA substrates.[378] Transient silicon nanomembrane devices have been used for high resolution spatial mapping of cortical activity, monitoring intercranial pressure in rats, and wireless bioresorbable cardiac pacemakers.[379–381]

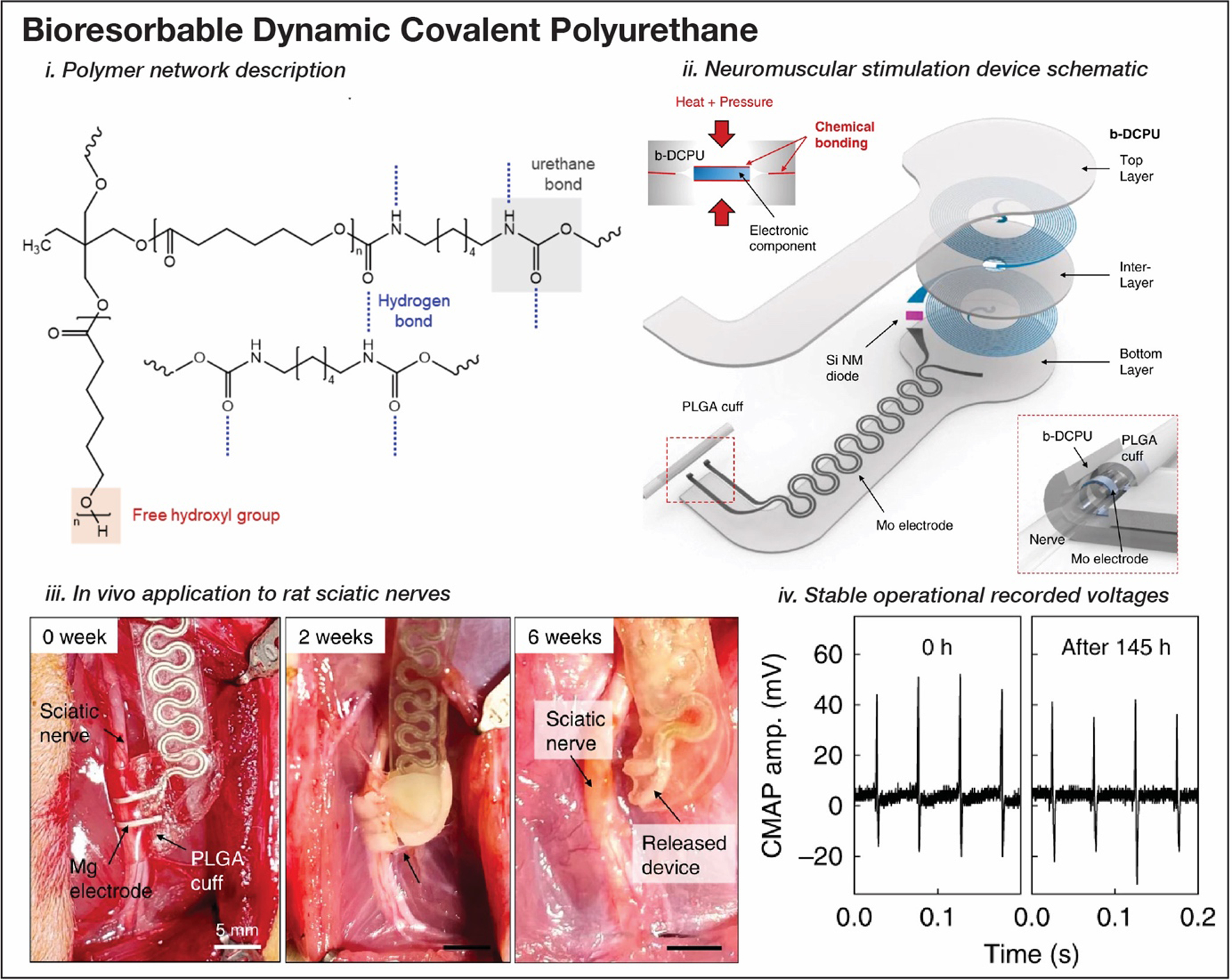

Biodegradable elastomers have also garnered interest as substrate materials for bioresorbable electronics. Poly(1,8-octanediol-co-citrate) (POC) is one such biodegradable elastomer initially developed for tissue engineering applications that has been explored as a substrate for bioelectronics.[382–385] Silicon nanomembranes linked into functional devices can be transferred to POC for use in stretchable pH sensors and wearable electrophysiological sensors.[386] More recently, Choi et al. developed a bioresorbable dynamic covalent polyurethane (b-DCPU) elastomer for use as a substrate in an electronic stimulation device for neuromuscular regeneration (Figure 10).[340] Thermally activated dynamic bonding of the polymer network enables robust self-adhesion (~500 J m−2), and with inorganic device components, such as Si, Mo, SiO2, and Mg (>850 J m−2), facilitates facile processing of stable devices. Additionally, with a controllable elastic modulus between 0.5–3.8 MPa and yield and failure strains of 25% and 170% respectively, b-DCPU devices are able to withstand the dynamic environment around the sciatic nerve in mice. The device reliably stimulates and records in vivo for ~30 days, with complete bioresorption within 6 weeks.

Figure 10.

Bioresobable dynamic covalent polyurethane (b-DCPU)-based neuromuscular stimulation device for peripheral nerve regeneration (i, ii), tested in vivo on growing rat sciatic nerves (iii), with stable operational voltages for over 145 hours (iv). Reproduced with permission.[340] Copyright 2020, Springer Nature.

2.4.2. Mechanically Adaptive Polymers

Stiffness tuning or softening polymers are a compelling choice as substrates in applications requiring the insertion of bioelectronics into soft tissue, as in the case of cortical probes. As described previously, soft neural probes with comparable mechanical properties to cortical tissue show lower inflammatory response and glial scarring compared to stiffer implants.[387–393] However, soft cortical probes must be able to withstand the insertion forces without buckling. Considering the insertion of a cortical neural interface where forces up to ~12–40 mN are needed to penetrate the dura mater of the brain, a material capable of undergoing a stiff-soft-transition offers unique advantages with a rigid regime during insertion and soft regime during operation within the brain.[394–398] This problem has been tackled using several approaches, including hydration-induced softening, rapidly dissolving stiffeners, shape memory polymer transitions, and stiff nanofiber and hydrogel composites.[399–405]

A seminal breakthrough towards designing materials capable of significant change in mechanical modulus was reported by Capadona et al.[406] Bioinspired nanocomposites of stiff cellulose nanofibers (1.43 GPa) in a soft poly(vinyl acetate) (PVAc) matrix undergo a chemically regulated transition from 4200 MPa to 1.6 MPa upon hydration. Specifically, sulfate groups are introduced onto cellulose nanofiber surface in order to mediate their interaction through competitive hydrogen-bonding with solvent molecules. This material has been investigated for use as substrates for neural probes, showing that the softening material shows significantly lower neuroinflammatory response and improved proximity of neural cells in chronic use post-implantation in comparison to stiff materials.[394,407] While this material has shown great promise as an adaptable substrate for neural probes, it presents challenges in integration with microfabrication strategies as it is incompatible with typical wet chemicals and temperatures exceeding 100 °C. However, Hess-Dunning et al. presented a microfabrication strategy involving utilizing a conformal Parylene C protective coating prior to proceeding with standard microfabrication methods.[408] Multielectrode arrays fabricated using this procedure were implanted in the primary motor cortex of rats and showed stable recording capability of neural responses (mean SNR ~4) over a period of 16 weeks.

An alternate approach towards designing mechanically adaptable polymers has been through softening shape memory polymer (SMP) networks on the exposure to elevated body temperatures. The highly selective thiol-ene chemistry has been utilized to design shape memory polymers capable of such mechanical transitions.[409,410] A similar thiol-ene/acrylate polymer system was engineered by Ware et al. in 2012 for use as a biocompatible softening substrate for responsive neural interfaces.[411–415] This thiol-ene/acrylate polymeric system is composed of tricyclodecanedimethanol diacrylate and 1,3,5-triallyl-1,3,5-triazine-2,4,6(1H,3H,5H)-trione monomers that are polymerized under UV light in the presence of a photoinitiator, 2,2-dimethoxy-2-phenylacetophenone. As a result of challenges in using conventional electronics processing techniques with this SMP as a substrate, a transfer-by-polymerization method was used to transfer metallic traces from a glass-Parylene C substrate by exploiting the weak adhesion of Parylene C on glass, followed by laser micromachining to define the form factor. Ware et al. illustrated a reduction in elastic modulus from 1 GPa to 18 MPa upon heating to the physiological temperature of 37 °C. Through successful recording of brain activity for 4 weeks in mice, Ware et al. demonstrated a unique approach to solving the challenge of designing probes stiff enough to be inserted into soft tissue while remaining highly compliant post-implantation.[416]

2.4.3. Adaptive Liquid Crystal Elastomers

Liquid crystal elastomers (LCEs) are a unique class of LCP that possess a combination of stretchability and polymer chain self-organization that can be used more for shape-changing functional bioelectronics (Figure 2, D4). LCEs are crosslinked polymeric networks with mesogen groups as side chains that confer smectic arrangements.[417–421] Some LCEs possess the unique capability of pre-programmed field-responsive shape change based on the alignment of the polymer chains during the processing of the LCE film.[422–428] In addition to this active functionality, LCEs still possess the high thermal and chemical resistance and mechanical robustness of conventional LCP.[429] Kim et al. showed the first instance of stimulus-responsive 3D electronics systems that are based on LCE substrates by demonstrating a morphing helical antenna.[129] To achieve this, the LCE precursors were photopolymerized after aligning azobenzene-dye molecules to program the shape change. The 3D transformation of the structure occurs through an order-disorder transition at temperatures below the cross-linking temperature. Similar processing methods were used to fabricate helical LCE-based multichannel cables integrated with a 16-channel nerve cuff electrode array for peripheral nerve interfaces and deployable cortical probes.[430]

As a material with rapidly growing interest for applications not just in bioelectronics but also soft robotics, there is significant progress being made towards processing and patterning methods of LCEs. While early applications of LCEs utilized techniques such as mechanical loading or magnetic fields to align the polymer chains within the LCE network, Ware et al. demonstrate a unique materials chemistry that enables highly sensitive photoalignment of defined volumes within the LCE polymer network.[431] Since this work, voxelated LCEs have been utilized for the 3D printing of structures capable of programmable shape change.[432,433] Additionally, a similar platform has also been used to engineer LCE films with localized domains with varying stiffnesses.[434] There is significant opportunity in utilizing the progress in processing LCEs to designing unique functional and adaptive bioelectronics.[435]

3. Packaging and Barrier Layers for Flexible Bioelectronics

3.1. Overview of Technical Challenges

Implantable electronic devices require appropriate insulation from the external environment to maintain reliable function. Liquid water, dissolved oxygen, ions, water vapor, and other small molecules can diffuse through barrier layers or defects in barrier layers, accumulate near sensitive electronic components, and ultimately contribute to device failure. Oftentimes, it is the performance of the barrier and packaging layers that determines the functional lifetime of implantable electronic devices.[78,436,437] Packaging strategies and materials for barrier layers for implantable electronics can be informed from innovations in more mature industries such as consumer electronics.[438,439] However, flexible electronics intended for use in biomedical applications afford significant additional challenges. Implanted devices may be continuously exposed to mechanically dynamic environments, elevated temperatures, and aqueous solutions with high concentrations of highly mobile and potentially debilitating ions such as sodium.[440–442] Furthermore, chronically implanted devices are subject to enzymatic reactions and other biological milieu that can contribute to additional failure modes.[443] Additionally, barrier layers of implantable electronics must encapsulate the entire device. From a materials chemistry perspective, the ideal barrier layer is composed of a material(s) that is (i) insulating, (ii) impermeable to moisture and ions through highly conformal and low defect density films with negligible diffusivities, (iii) stable in the presence of proteins and other biomolecules, (iii) highly mechanically compliant, interact (or not) with the surroundings in the desired manner, and lastly, (iv) able to maintain these properties over the functional lifetime of the device.

There have been a variety of materials and combinations thereof that have been investigated as barrier layers for flexible and stretchable bioelectronics. Materials that have been tested include metallic thin films like Al and Ti, ceramic oxides and nitrides like SiO2, Al2O3, HfO2, Si3N4, and TiN, and organic polymers like Parylene C, polyimide, and a variety of dielectric elastomers.[182,217,444–451] These materials have been used both on their own and in composites in attempts to protect electronic devices from contaminants found in the physiological environment. The rigid materials (inorganic oxides, nitrides, and metals) achieve a desired flexural modulus through the use of ultrathin layers that enable flexibility but not stretchability. On the other hand, the mechanical properties of the organic barrier layers are determined by the intrinsic properties of the polymer, allowing for both flexibility and stretchability. Rapid soak tests to evaluate water and ion penetration have shown that ultrathin ceramic layers perform significantly better than commonly used polymeric barrier layers. In the next few sections, the advantages and drawbacks of each of these materials will be presented, in an effort to highlight the importance for careful materials selection based on the application of the bioelectronic system and the immense scope for innovation in flexible and stretchable barrier layers.[452,453]

3.2. Techniques to Measure Barrier Layer Performance

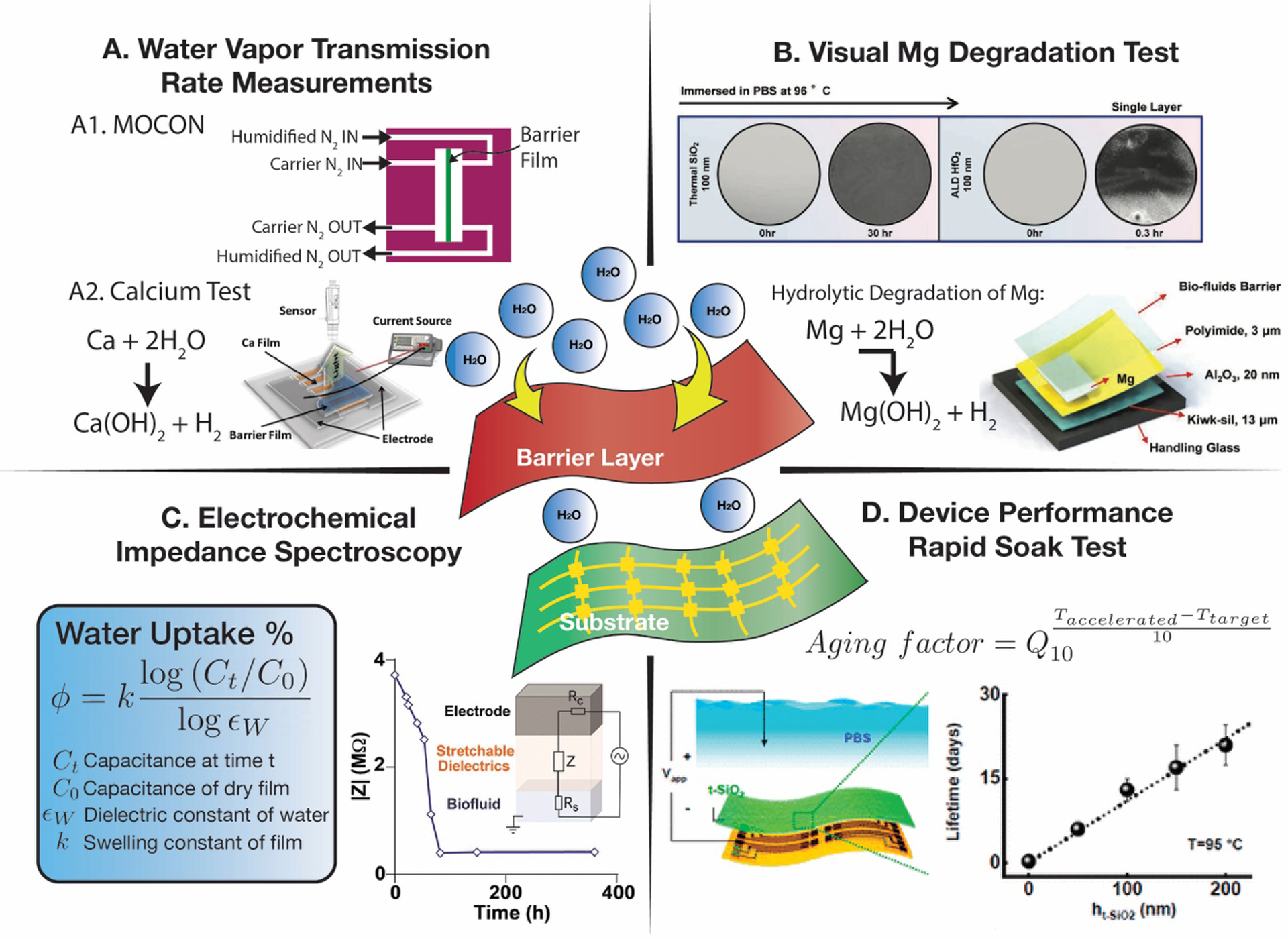

Several standardized methods have been established to evaluate the performance of barrier layers (Figure 11). For flexible barrier layers in bioelectronics, a common method for the evaluation of barrier function involves soak tests in a solution of phosphate-buffered saline (PBS), to mimic typical ionic concentrations of biofluids. Often, these tests are performed in an accelerated format at higher temperatures to extrapolate the characteristics of the barrier layers at long timescales. The Arrhenius relationship can be leveraged to estimate true operational time to failure from the accelerated soak tests by calculating the acceleration factor.[469–471]

| (3) |

where Q10, Taccelerated, and Ttarget refer to the quantity by which the reaction rate increases for a 10°C increase in temperature, the accelerated temperature at which the test is conducted, and the target operational temperature of the device.

Figure 11.

Schematic describing the four primary techniques to evaluate barrier layer performance. A. Water vapor transmission rate determination using the Ametek MOCON platform or a calcium test, B. Visual degradation studies using dissolvable metals such as magnesium, C. Electrochemical impedance spectroscopy to determine water uptake or delamination, and D. Device performance rapid soak tests at elevated temperatures. A1, calcium test. Reproduced with permission.[481] Copyright 2016, Elsevier. B, visual Mg degradation test. Reproduced with permission.[463] Copyright 2017, John Wiley and Sons. C, electrochemical impedance spectroscopy. Reproduced with permission.[449] Copyright 2020, American Chemical Society. D, rapid soak test. Reproduced with permission.[450] Copyright 2018, American Chemical Society.

Another common qualitative approach researchers have used involves depositing the barrier layer over arrays of metals that are known to have high reactivity with water, such as Mg or Ca.[450,472] The arrays are then subject to aqueous conditions and monitored optically over time. This method, while qualitative, provides a simple visual way to characterize barrier performance.

The method described above can be modified to provide quantitative information on the Water Vapor Transmission Rate (WVTR), one the most common metrics measured in g m−2 day−1 used to evaluate barrier layers.[473] Commonly referred to as the ‘Ca Test’, the electrical conductivity or optical transmittance can be measured to precisely measure very small rates of water vapor permeation.[474] A more common method for measuring WVTR requires specialized instrumentation (Ametek MOCON, Minnesota, USA) that uses precise moisture sensors to measure the permeation of water vapor through barrier layers. Although these devices are widely used in the electronics packaging community, they are limited by their minimum measurable WVTR of ~10−3 g m−2 day−1.[475] Apart from the Ca test, multiple research groups have created their own experimental set-ups to measure ultra-low WVTR (lower than 10−6 g m−2 day−1) values by employing tritiated water that can be mapped using a scintillation counter.[476,477] While WVTR values are an important metric to evaluate biofluid barrier, in practice, the same material can show a wide range of WVTRs because the fabrication method and defect densities will greatly determine fluid permeation.

The temporal evolution of insulating properties of barrier layers can be evaluated during soak tests by measuring the electrical properties of test structures.[455,478,479] Electrochemical Impedance Spectroscopy (EIS) is valuable tool to evaluate multiple aspects of barrier layer function because of its sensitivity to changes in dielectric properties. By modeling the system as a combination of resistors and capacitors, the EIS spectrum can provide information on barrier function and the degree of delamination between the substrate and barrier layer.[480] The percentage of water uptake can be described through the following relationship:

| (4) |

where Ct, C0, ∊W, and k refer to capacitance at time t, capacitance of the dry film, dielectric constant of water, and swelling constant of the film respectively.

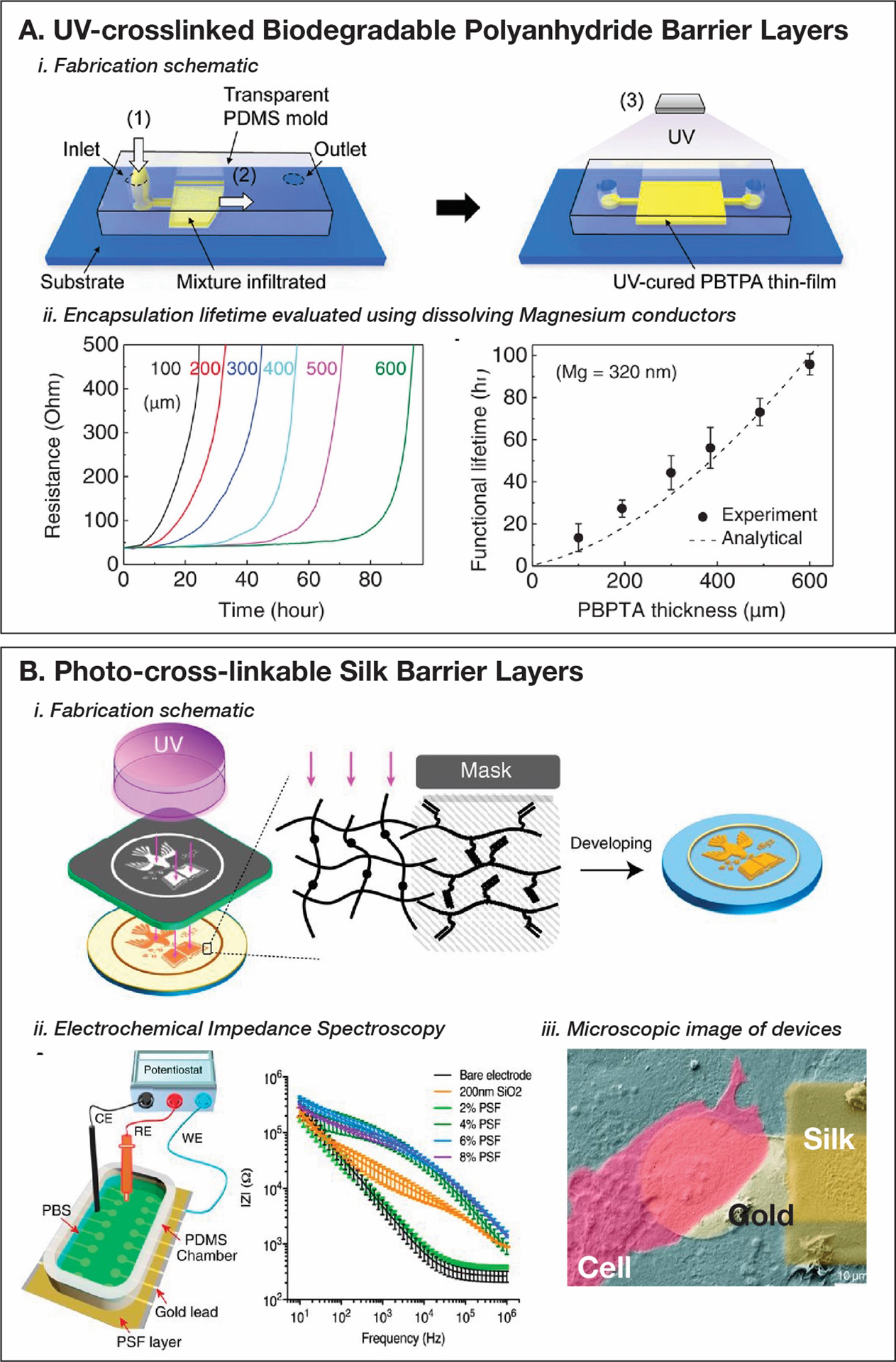

3.3. Polymeric Barrier Layers

High-performance polymeric barrier layers for use in flexible bioelectronics is a region of active investigation. Polymers typically have a significantly lower flexural rigidity than inorganics and can be designed with intrinsic stretchability, making them a promising candidate for barrier layers. High-modulus inextensible plastics such as polyimide, Parylene C, SU-8, and LCPs demonstrate superior barrier function compared to low-modulus amorphous elastomeric polymers such as PDMS, styrene-ethylene-butylene-styrene (SEBS), and polyisobutylene (PIB). However, several of these materials continue to find successful use in applications that play to the material strengths. A wide variety of organics have been used and tested as barrier layers including several of the polymers discussed under the section entitled Substrates and Structural Materials. However, even the gold standards of polymeric barrier layers (i.e. LCP and Parylene C) fall short in barrier function in comparison to many inorganic materials including oxides and nitrides (e.g. SiO2, Al2O3, and SiN3).[78,436,437] In this section, we present a discussion on the different types of polymeric barrier layers, their advantages and shortcomings, and most importantly, opportunities for designing the next generation of this important class of materials.

3.3.1. Flexible Polymers as Barrier Layers

Inextensible high-modulus polymers derive their barrier functionality from the packing density of the polymer chains within a film, with a greater density corresponding to lower diffusivity of moisture and ions across the barrier.[482–486] Notably, the high mechanical modulus and inextensible nature of polymers can also be attributed to the polymer chain packing within a polymer network. The packing of polymer chains is predominantly controlled by two parameters: crystallinity and crosslinking density.[487–489] Among the common inextensible polymeric barriers that will be discussed in this article, Parylene C, polyimides, and LCPs are crystalline in nature, and SU-8 is amorphous but highly crosslinked.[490,491] The crystallinity in polyimides, Parylene C, and LCPs arises from the ordering of long linear polymer chains, with rigid aromatic components contributing to increased alignment and crystallinity.

Poly(4,4-oxydiphenylene-pyromellitimide) (PMDA-ODA; Kapton, Dupont Wilmington DE, USA) is a polyimide used as a structural material for flexible electronics, but less often as a barrier layer due to its susceptibility to hydrolytic degradation.[492,493] In contrast to Kapton polyimides, biphenyltetracarboxylic bianhydride/para-phenylenediamine (BPDA-PPD; PI2611, U-Varnish-S) is a polyimide that is more commonly used as a barrier layer. PI2611 (HD Microsystems, NJ, USA) films (9 μm in thickness) have WVTR of 6 g m−2 day−1.[456] Devices encapsulated in BPDA-PPD can operate for up to 12 months in vivo and >20 months in vitro.[493–495]

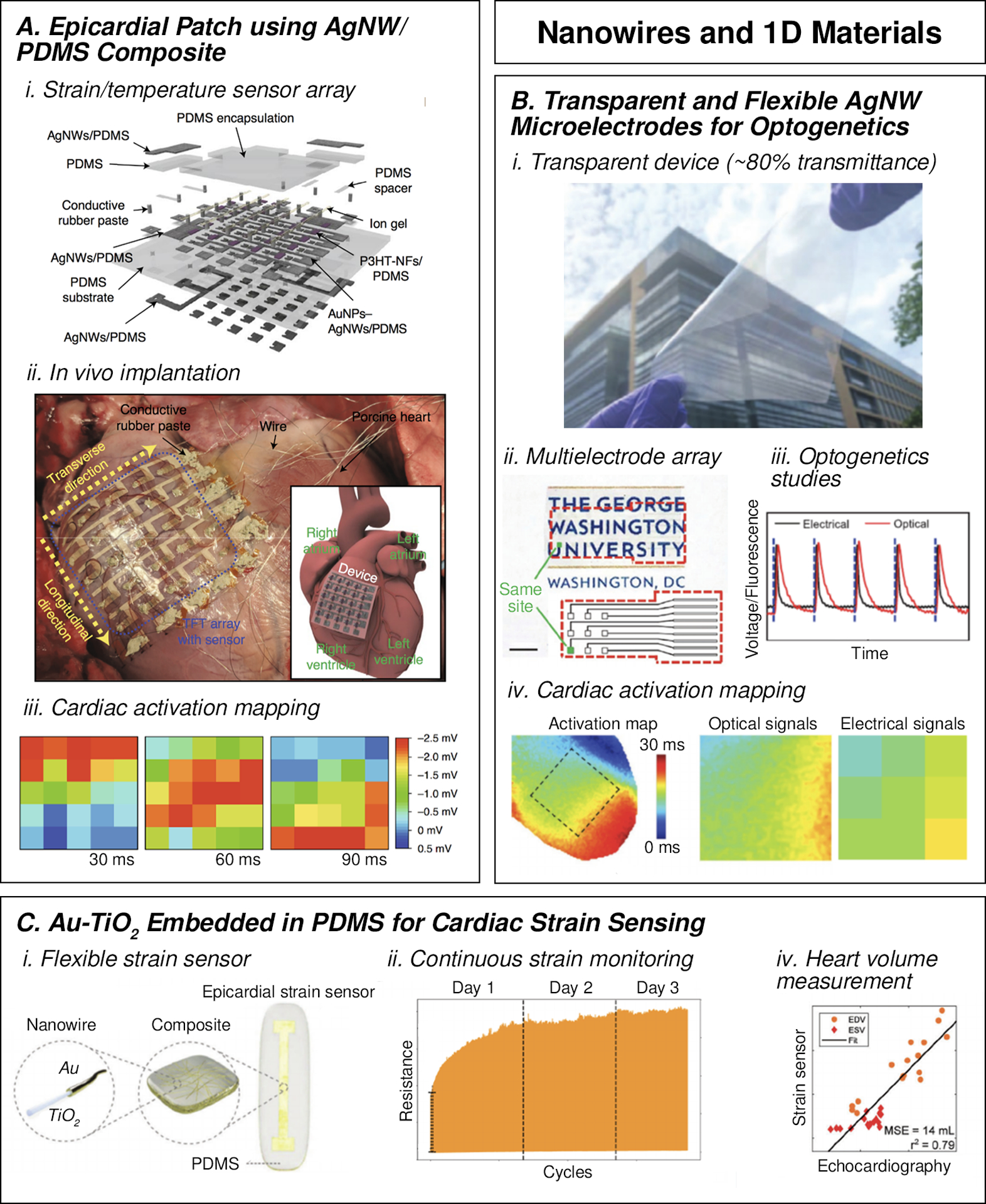

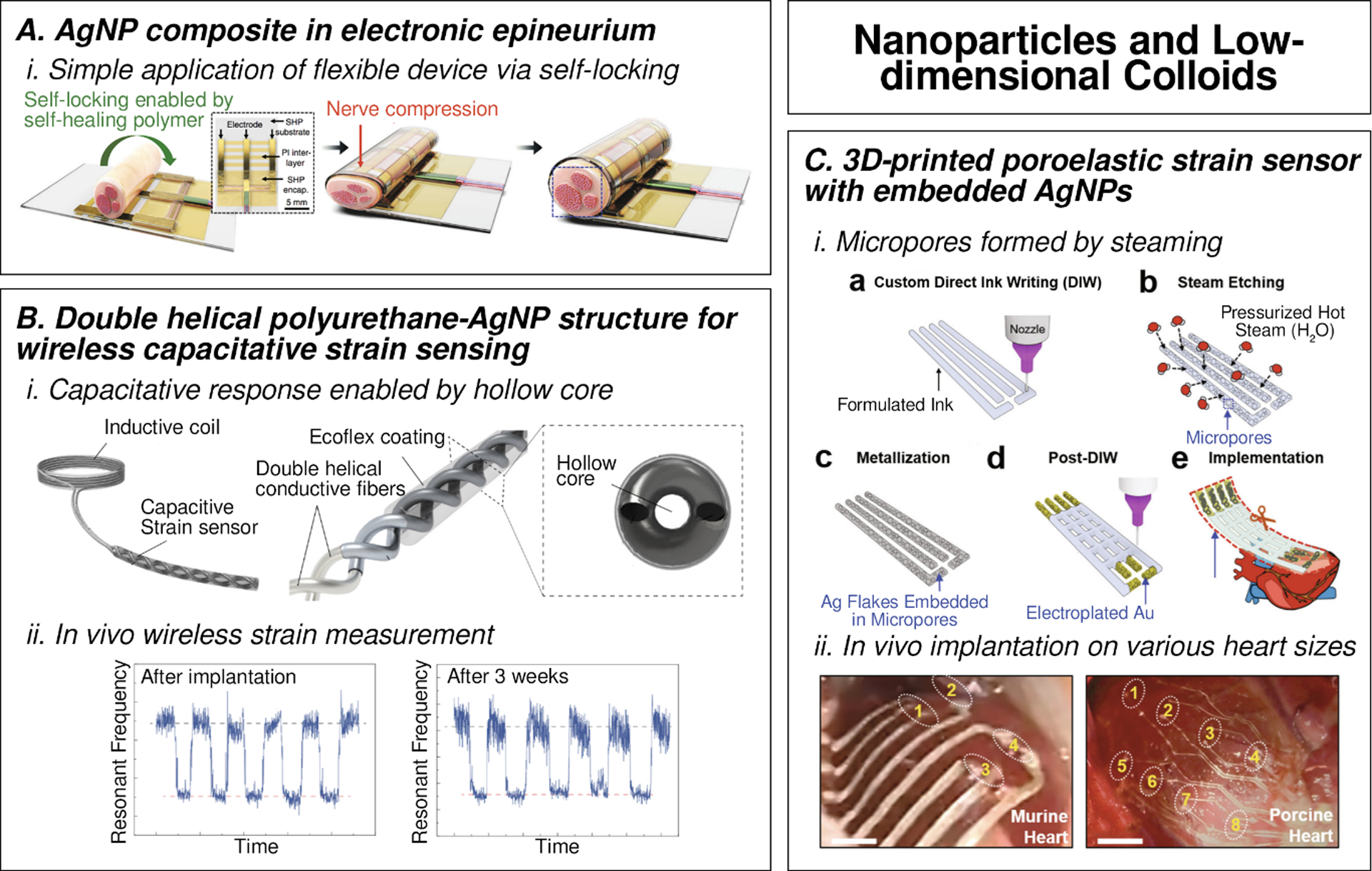

Parylene C films show a greater degree of crystallinity than Kapton or PI2611 with a WVTR as low as 0.08 g m−2 day−1.[496] This increased crystallinity is attributed to alignment of chlorinated para-xylylene monomers. Approximately 70–90% of neural implants encapsulated in Parylene C barrier layers retain function after 29 weeks in an in vitro soak test as measured by EIS (10% decrease in relative impedance).[455] Additionally, accelerated testing of Parylene C suggests that devices can maintain function for >1 year in physiological buffers at 37°C. With a lower WVTR than PI, Parylene C encapsulated devices promise more stable device for long-term use. Other accelerated lifetime tests have also shown that a 10 μm thick Parylene C encapsulated devices have retained function for 117 days at 75 °C, indicating around a 4.5-year lifetime at physiological temperatures.[454] However, the major roadblock in implementing Parylene C-based encapsulation is its poor adhesion with several substrates and metals commonly used in bioelectronics.[249,497] Techniques such as silanization, O2 plasma treatment, mechanical interlocking, and annealing improve adhesion and reduce risk of delamination between layers.[149,498–500]