Abstract

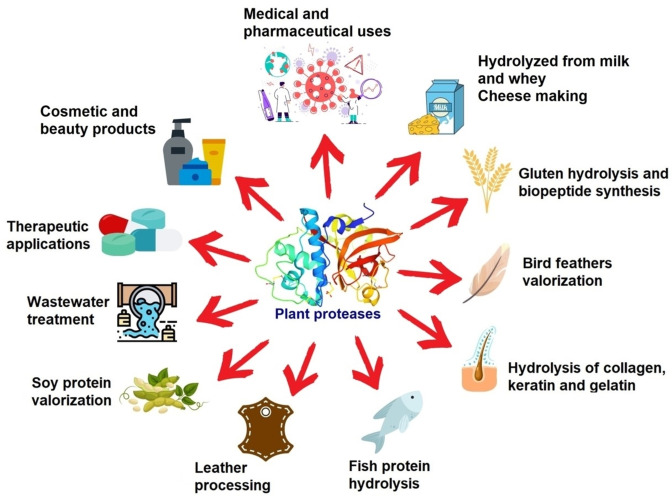

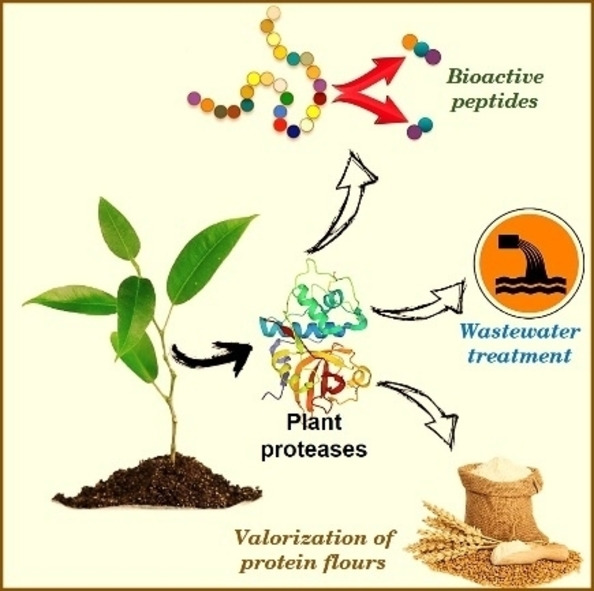

An updated review of emerging plant proteases with potential biotechnological application is presented. Plant proteases show comparable or even greater performance than animal or microbial proteases for by‐product valorization through hydrolysis for, for example, cheese whey, bird feathers, collagen, keratinous materials, gelatin, fish protein, and soy protein. Active biopeptides can be obtained as high added value products, which have shown numerous beneficial effects on human health. Plant proteases can also be used for wastewater treatment. The production of new plant proteases is encouraged for the following advantages: low cost of isolation using simple procedures, remarkable stability over a wide range of operating conditions (temperature, pH, salinity, and organic solvents), substantial affinity to a broad variety of substrates, and possibility of immobilization. Vegetable proteases have enormous application potential for the valorization of industrial waste and its conversion into products with high added value through low‐cost processes.

Keywords: application of plant proteases, by-product valorization, hydrolysis, plant proteases production, sustainability

Plant proteases are increasingly used in industrial applications. Potential application fields are continuously broadening, ranging from the production of bioactive peptides to the treatment of liquid effluents, including the recovery of by‐products with high protein content and many other interesting applications which are reviewed.

1. Introduction

Proteases (also called proteinases, or proteolytic enzymes) are enzymes able to hydrolyze the peptide linkages in proteins. In biological environments, proteases are essential for the normal cellular metabolism, including mitochondrial process. [1] Proteases also play a vital role during various biochemical processes, controlling the size, structure, and composition of key proteins. [2]

From an economic perspective, the research of new proteases is in continuous growth because they represent 60 % of all commercialized enzymes in the world. The overall protease enzyme's market has been estimated above 3 billion US$, showing a compound annual growth rate (CAGR) of 6.1 % by 2024. [3] Nowadays, the industrial applications of proteases cover a wide range of industries, such as leather and detergent industries, food technology and pharmaceutical manufacturing. [4]

The proteases can be classified attending the following criteria:

The catalyzed reaction; according to this category the proteases are included in hydrolases (group 3), and subgroup 4 (hydrolases of peptide bonds). Subclass 3.4 can be also subdivided into exo‐ or endopeptidases. The first ones hydrolyze external peptidic linkages (amino‐terminal or carboxyl‐terminal), meanwhile, the endopeptidases hydrolyze the internal peptide bonds in the protein. [5]

Nature of the active site; following this criterion the proteases are classified within seven categories: cysteine endopeptidases (also known as thiol proteases), serine endopeptidases, aspartic endopeptidases (first called acid proteases), glutamic endopeptidases, metalloendopeptidases, threonine endopeptidases, and peptidases with unknown action mechanism. They are grouped if a covalent complex between the enzyme and the substrate is generated during the enzymatic mechanism (cysteine, threonine, and serine endopeptidases) or not (aspartic, glutamic, and metalloendopeptidases). The formation of the covalent enzyme‐substrate complex can be understood considering if the nucleophile is an amino acid in serine, threonine, and cysteine proteases, meanwhile, in other peptidases, the nucleophile is activated by water molecules. [6]

Structure‐based evolutive relationships; where the proteins that share sufficient sequence homology (amino acidic sequence) are included within the same family, while a clan is integrated by families with a common ancestor protein. The MEROPS database (http://merops.sanger.ac.uk/index.htm ) contains 244 families and 55 clans. The names of clans and families are designed with basis on the letters S, C, T, A, G, M, and U, in concordance with the specific catalyst mechanism. Some clans contain families with different mechanisms, which are designed with the letter “P”. [7]

Proteases are found from prokaryotes to complex organisms (plants and animals). The type of protease, as well its functional properties, directly depend on its particular function and the organism conditions of the host. [6] Proteases are involved in the physiology of the plants during their entire cycle life (chloroplast photoinhibition, defense mechanisms, photomorphogenesis, and seed germination, among others) The most abundant type of protease in plants is cysteine (CPs), followed by serine proteases (SPs) and aspartic proteases (APs).

In the cysteine proteases, the nucleophile is the sulfhydryl group of a cysteine residue and the proton donor is a histidine residue (a feature shared with serine proteases). They are active over a wide range of temperatures and pHs. The thiol group of the enzyme has to be in the reduced form for catalytic activity. Thus, the cysteine proteases require a rather reducing environment to be active. Most cysteine proteases have molecular weights between 25 and 30 kDa, and show an optimum pH of 5 to 8. According to the MEROPS database, CPs are divided into ten clans: CA, CD, CE, CF, CH, CL, CM, CN, CO, and C−, and to date, plant CPs have been described as belonging to five of these clans (CA, CD, CF, CO, and CE). The structure of these proteases reveals an α‐helix and a β‐barrel‐like separated from the active site (Cys‐25 and His‐159), which are located at each side of a groove and are well conserved in all members of the family.

Plant CPs play an important role in protein mobilization and defense against biotic and abiotic agents. Plants CPs are inhibited by Iodoacetamide (IAA) and p‐chloromercury benzoate (PCMB). [8]

Plant SPs have a Ser residue as the nucleophile. The catalytic mechanism involves a proton donor in addition to the serine that carries the nucleophile. In 4 clans, the proton donor is a histidine residue; with a third residue present: aspartate in 3 clans and another histidine in the fourth one. In the other 2 clans, the proton donor is a lysine residue and a third catalytic residue is not required. In one of these, there is a Ser/His catalytic dyad. Three clans, (SA, SB, and SC) share a catalytic triad of serine (S) aspartate (D), and histidine (H) in different orders (e. g., HDS (SA), DHS (SB), and SDH (SC)).

Plant SPs are involved in numerous physiological processes, such as microsporogenesis, pathogen attack, and specialization of tissues. They have a molecular weight between 20 and 120 kDa (most of them lies within the 60–80 kDa range). The optimum conditions for their highest activity are alkaline medium (pH: 7–11), and temperature up to 50 °C. Some exceptions are Ara12 from A. thaliana, RSIP from maize, and C1 from soybean, showing an optimum pH between 3.5 and 6.5. [9] Furthermore, diisopropyl‐fluorophosphate and phenylmethylsulfonyl fluoride are serine peptidase inhibitors.

Plant aspartic proteases are found in seeds, flowers, and leaves, differing from cysteine and serine proteases the nucleophile is an activated water molecule rather than the nucleophilic side chain of an amino acid. According to the MEROPS database, APs are grouped in AA (A1, A3, A11, and A12 families) and AD clan (A22 family), being most of them belonging to the A1 family. The primary structure of APs contains a signal sequence at the amino terminus for translocation, a prosegment responsible for correct folding and stability, and a plant‐specific insert (PSI, also known as swaposin domain). PSI contain about 100 amino acids, being responsible for the vacuolar transport of the enzyme. Regarding the second structure, APs mainly contain β‐sheets with a biloval conformation. [10]

Most of APs have two aspartic residues, which are responsible for the activity of the enzyme, being inhibited by pepstatin A. The active site is formed by two Asp residues responsible for water activation. APs exhibit high specificity towards the cleavage at peptide bonds between hydrophobic amino acid residues. The majority of APs are active in acidic conditions, showing an optimum pH of 4–6.5 and a temperature up to 55 °C. APs show a molecular weight range of 35–65 kDa. The enzyme mass depends on whether the PSI fragment was removed by proteolysis previous to activation (heterodimeric) or not (monomeric). The majority of plant APs are heterodimeric with a mass from 35 to 51 kDa.

Plant proteases have been traditionally used for decades; highlighting papain, bromelain, ficin, and actinidin (see Table 1). Over recent decades, new plants have emerged as a valuable raw source of proteases with competitive commercial potential. Table 2 shows emerging serine and aspartic endopeptidases isolated from plants with industrial applications reported in recent years. Proteases derived from plants are gaining attention due to their high proteolytic activity and affinity for specific substrates, remarkable stability over a wide range of operating conditions (pH: 4–10 and temperature up to 60 °C), and low cost associated with the raw source.

Table 1.

Traditional plant proteases with industrial applications.

|

Protein |

Source |

pH[a] |

Temp[a] [°C] |

Molecular weight [kDa] |

Uses |

Ref. |

|---|---|---|---|---|---|---|

|

Papain |

Carica papaya (fruit, root and leaves) |

5–9 |

65 |

23.4 |

• Meat tenderization: connective tissue and myofibrillar proteins hydrolysis. • Dairy industry: production of semisoft cheese or cream cheese), protein hydrolysates production. • Baking industry: reduction of the allergenic protein content of cereals. • Animal feed: bioactive peptides production. • Brewing and wine industry: protein aggregates solubilization. • Bioethanol production: deflocculating agent. • Tooth whitening and biomedicine: tissue repairing of venous ulcers and antibacterial activity. |

[14] |

|

Bromelain |

Ananas comosus (stem and juices) |

5–10 |

70 |

28–32.5 |

• Meat tenderization: myofibrillar proteins hydrolysis. • Fish industry: biopeptides hydrolysates production. • Alcohol production: protein aggregates solubilization. • Animal feed: protein degradation in ruminant feed degradation. • Textile industry: protein solubilization. |

[15] |

|

|

|

|

|

• Biomedicine: blood coagulation, fibrinolysis, antibacterial activity, tissue recovering, anti‐inflammatory agent. |

|

|

|

Ficin |

Ficus carica |

8 |

60 |

23.8 |

• Meat tenderization: myofibrillar proteins hydrolysis. • Milk clotting. • Bioactive peptides production. • Synthetic fibers hydrolysis. • Biomedicine: Production of active antibodies fragments by proteolysis, hemostatic. • Brew industry: protein extraction from barley and malt. • Meat tenderization: myofibrillar proteins hydrolysis. |

[16] |

|

Actinidin |

Actinidia deliciosa (Kiwi fruit) |

6 |

40 |

24.5 |

• Chicken and fish protein hydrolysis. • Alcohol production: protein aggregates solubilization. |

[17] |

[a] Optimal pH or temperature.

Table 2.

Emerging serine and aspartic plant endopeptidases with industrial applications reported in recent years.

|

Protease type |

Name |

Source |

pH[a] |

Temp[a] [°C] |

Molecular weight [kDa] |

Uses or activity |

Ref. |

|---|---|---|---|---|---|---|---|

|

Serine |

Milii |

Latex of Euphorbia milii |

9.0 |

35 |

80 |

Molluscicidal agent and antithrombic drugs |

[18] |

|

Wrightin |

Wrightia tinctoria latex |

7.5–10 |

70 |

58 |

Food industry |

[19] |

|

|

Carnein |

Latex of Ipomea carnea |

6.5 |

65 |

80 |

Brewing wine |

[20] |

|

|

Neriifolin |

Euphorbia neriifolia latex |

9.5 |

50 |

94 |

Dairy industry |

[21] |

|

|

Dubiumin |

Solanum dubium Fresen |

11.0 |

70 |

66 |

Milk‐clotting |

[22] |

|

|

Milin |

Euphorbia mill |

8.0 |

60 |

51 |

Milk‐clotting |

[23] |

|

|

Religiosin |

Ficus religiosa |

8.0–8.5 |

50 |

43 |

Milk‐clotting |

[24] |

|

|

LGP (Latex glycoprotein) |

Synadenium grantii |

7–8 |

37 |

34 |

Casein hydrolysis |

[25] |

|

|

Aspartic |

Asteraceae |

Silybum marianum flowers |

4.5–6.8 |

37 |

27 |

Casein hydrolysis |

[26] |

|

Purified extract (APs) |

Centaurea calcitrapa |

5.1 |

52 |

45–67 |

Milk‐clotting |

[27] |

|

|

Protein extract (APs) |

Ficus racemosa latex |

4.5–6.5 |

60 |

45–70 |

Dairy industry |

[28] |

|

|

Arctiumisin |

Arctium minus (Hill) Bernh |

7.0–8.2 |

50 |

30 |

Bioactive peptides production |

[29] |

|

|

Cardosin |

Cynara cardunculus latex |

5.5 |

– |

55 |

Milk‐clotting |

[30] |

|

|

Onopordosin |

Onopordum acanthium |

2.5 |

30 |

47 |

Bovine milk‐clotting |

[31] |

[a] Optimal pH or temperature.

This work provides an update and critical review of the production techniques, isolation procedures, and immobilization of plant proteases. Emerging applications of plant proteases are discussed in detail, including valorization of products and waste from the food industry (e. g., bird feathers, fish, dairy, gluten, soy), hydrolysis of keratinous materials, organic chemistry, water remediation, biopeptide production, and therapeutic uses. These applications could provide new alternatives for the use of plant proteases to enhance the feasibility of the food and biomedical industries.

1.1. Catalytic Mechanism

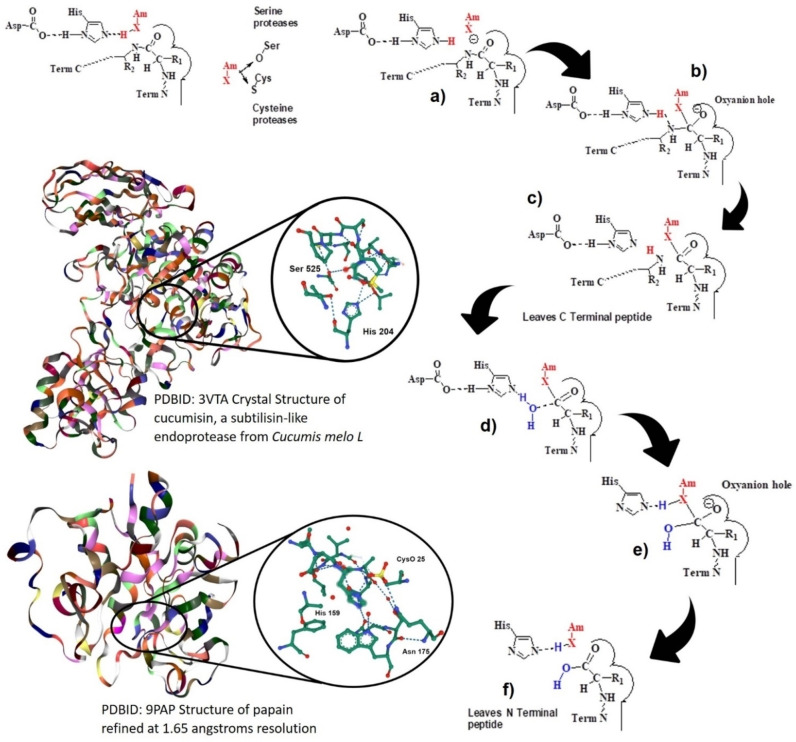

As previously mentioned, the most abundant plant proteases are cysteine proteases, followed by serine proteases and then aspartic proteases. The catalytic mechanism for these major plant proteases is described below. Figure 1 shows the mechanism for the serine/cysteine protease catalyzed protein hydrolysis reaction. The mechanism of action of serine proteases is related to a catalytic triad where the acidic Asp is required to stabilize the positively charged His, which enhances the nucleophilicity of the serine oxygen. In the case of cysteine proteases, the Asp is not needed and the catalytic site is a dyad Cys‐His. [11] The nucleophilic attack occurs by the negatively polarized X (O or S) (Figure 1a), resulting in a tetrahedral intermediary where the negatively charged X is bound to the oxyanion hole (Figure 1 b). Protonation of the NH‐ breaks the bond with the release of the product 1 (C‐terminal peptide (Figure 1c)) and formation of the acyl intermediate, which is attacked by catalytic water (Figure 1d). A second intermediate is formed (Figure 1e). Finally, product 2 is released (N‐terminal peptide) and the active site is regenerated (Figure 1f).

Figure 1.

Mechanism of protein hydrolysis catalyzed by plant serine/cysteine proteases.

Aspartate proteases are different: the catalytic site is a dyad with two Asp. With water present, the reaction involves three main steps: 1. Nucleophilic attack by an activated water molecule with a first transition state and formation of a tetrahedral intermediate. 2. Nitrogen protonation. 3. Fission of the scissile bond and release of the products with new C‐ and N‐terminal peptides. [11] Figure 1 includes the PDB figure for papain (https://www.rcsb.org/structure/9pap) and cucumisin (https://www.rcsb.org/3d‐view/ngl/3vta).[ 12 , 13 ]

2. Production of Plant Proteases

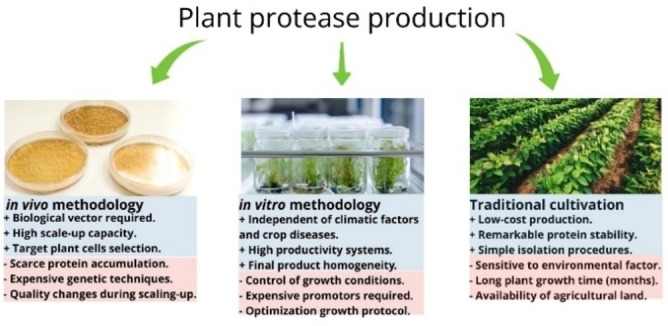

During the two last decades, new strategies have been developed to decrease the cost and the growth time of plants. The plant proteases can be obtained in vivo (using a biological vector to express a specific vegetable protein), through in vitro cultures (employing cell, tissues, and organs), or directly from vegetable biomass (latex, flowers, fruits, roots) using traditional cultivation. From an overview, in vivo and in vitro strategies involve higher costs compared to protein production from crops protein. However, they ensure continuous production of protease with standard parameters. On the other side, proteases derived from traditional crops are more affordable from an economic perspective. However, the homogeneity of target protease depends on the plant response to changes in climatic conditions, modifications in mineral concentrations in the soil, or the presence of other plants. Besides, other factors need to be considered to analyze the feasibility of large‐scale plant protease production, for example, availability of agricultural land for cultivation, labor costs, and plant growth time. [4] Figure 2 summarizes the main advantages and disadvantages of plant protease production using in vivo and in vitro methodology, and traditional cultivation.

Figure 2.

Methodologies for plant protease production.+Advantages, ‐Disadvantages.

2.1. In vivo Protease Production

Protease production via in vivo methodology is a complex process, which can also involve post‐translational modifications (proper folding, glycosylation, phosphorylation) of the proteins to enhance their proteolytic activity and stability. The proteins produced through in vivo strategy (also known as heterologous proteins) are grouped within three categories according to their application: therapeutic proteins, reagents proteins for research and proteins with various industrial uses. A gene or cDNA encoding desired protein and an efficient biological vector with the capacity to transcribe the transgene into the desired protein are required by in vivo methodology. [32] Thus, the target protease can be expressed and isolated.

The requirements for the application of a viable expression system on a large scale are high productivity, easy handling and maintenance, and inexpensive and simple post‐processing. [46] The use of plants as expression systems has exhibited a growing interest in recent years considering its following advantages: low‐cost production compared to mammalian cell culture and microbial fermentation, targeted cells selection (seed, tubers) to express the desired protein, and affordable scale‐up capacity (cultivation of more plants). [33] Furthermore, plants as expression systems show a low risk of contamination with human pathogenic microorganisms.

In contrast, the main limitations of plants as expression systems are low level of protein expression/biomass production ratio, low level of accumulation of expressed protein, changes in protein quality during scale transition from laboratory to agricultural scale, and long production periods (months or even years). [34] The protein accumulation can be increased using promoters to transcribe sequences encoding recombinant proteins, protein fusion to increase product stability, or targeting specific subcellular sites and tissues.[ 33 , 34 ]

The in vivo protein production demands in advance extensive research at laboratory scale to determine the optimum vector and procedures to achieve a feasible protein accumulation yield in the plant, including the use of genetic engineering techniques, thus increasing the protein production cost.[ 35 , 36 ] In consequence, the application of in vivo methodologies in plants is frequently reserved for the production of therapeutic or reagent proteins with high added‐value, whose commercial prices permit the use of complex and expensive genetic techniques.[ 34 , 37 ] An extensive recompilation of genetic technique used for in vivo methodology is presented by Desai et al. [34]

Aspartic, cysteine, and serine proteases have been successfully produced using in vivo methodology from a broad variety of tissues, such as seed (Arabidopsis thaliana, rice, and barley), leaves (tomato and potato), and flowers (cardoon). Cardosin A (Cynara cardunculus) is an aspartic protease whose accumulation in pistils tissue has been increased through in vivo production. In this way, the proteases show higher milk‐clotting activity and their specificity could be also enhanced to the substrate target (k‐casein). [38] Regarding cysteine proteases, papain, bromelain and ficin have been produced through in vivo techniques, showing an optimum activity at 65 °C and a slight enhance in their thermal stability compared with the isolated from crops. In the case of serine proteases, taraxilisin (M. pomifera) and cucumisin (Cucumis melo) increased their specificity (myofibrillar proteins) through in vivo methodologies.[ 39 , 40 ]

In summary, the use of in vivo techniques for plant protease production is applied to improve their specificity, thermal stability and activity. However, the methodologies are reserved for proteases with a wide reported characterization, cases in which the use of complex genetic procedures is feasible.

2.2. In vitro Protease Production

In vitro cell culture methodology has emerged as an attractive alternative, allowing the relative homogenization of large batch of proteases with competitive costs for the production of traditional plant proteases, for instance; papain, bromelain, ficin, and cardosin. The grown of cells and tissues in vitro is independent of climatic factors, crop diseases, heterogeneity in source material, pesticides, remote geographical location and economic problems associated with unstable cultivation policies. [41]

The application of bioreactors for tissue and cell suspension culture grown exhibits major advantages, such as high ratio extract protein volume/amount of biomass in the medium, and rigorous control of environmental conditions. Controlling these variables contributes to obtaining homogeneous compounds and reduces erratic variations due to climatic and seasonal factors. These advantages contribute to achieving a feasible yield in the elaboration of plant proteases whose production by traditional plant agriculture is not economically viable.

The in vitro tissue culture can be carried out using genetically modified plants to maximize the protease volumetric productivity. Relevant grown culture parameters are the selection of transgenic cell lines, temperature and pH, oxygen demand, and bioreactor type (stirred‐tank, pneumatic, wave, membrane, and scale‐down). [42] In recent years, there has been a growing interest by roots culture (also known as “hairy roots”), which offer in contrast to normal roots, high genetic stability, and fast growth rates. These benefits are especially important for recombinant protein production, phytoremediation, enhanced secondary metabolite production, and plant breeding. [43] The in vitro methodologies can be distinguished into two categories: (i) micropropagation and somatic embryogenesis and ii) callus and cell suspension cultures.

2.2.1. Micropropagation and Somatic Embryogenesis

The micropropagation techniques make it possible to reduce the growth periods of large volumes of clonal plants from years to months, producing pathogen free specimens. Micropropagation methodology has been successfully applied to Ficus carica, Carica Papaya, Taxus canadensis, Coleus forskohlii, Hypericum perforatum, and Catharanthus roseus. Micropropagation can be carried out using nodal explants, shoot tips, or leaf segments, which are immersed within a specific growth media. BAP (6‐benzylaminopurine) and NAA (naphthaleneacetic acid) are commonly used as regulators to promote shoot proliferation, thus increasing the enzyme production rate. [44]

The costs associated to regulators compounds are crucial to scale up of micropropagation techniques to produce high‐quality roots. An optimized growth medium is required for each particular enzyme according to the explant types in order to achieve a feasible yield. [45] Specific protocols have been developed for the production of commercial proteases on a large scale. Regarding papaya, the micropropagation is performed using shoots immersed in agar medium with low concentration of IBA (indole‐3‐butyric acid). Once the induction stage was accomplished, the root development is carried out using vermiculite medium with MS (Murashige and Skoog) under aerated conditions. In the case of bromelain, its proteolytic activity could be increased when the medium consists of ANA (α‐naphthaleneacetic acid) and 0.5 ppm of BA (benzyladenine) at 24 °C in 16 h light/8 h dark photoperiod using nodus callus. [41]

On the other hand, somatic embryogenesis process makes it possible to achieve massive propagation using ovular tissue, immature zygotic embryos, mature zygotic embryos, anthers, apical meristems or stems. 2,4‐Dichlorophenoxyacetic acid and adenine hemisulphate are growth regulators commonly used to promote the multiplication of healthy plants, which are after transplanted to the field. [46] The Morishige and Skoog medium (inclusive in combination with kinetin and indolebutyric acid) is broadly used for the cultivation of plant cell culture.[ 45 , 46 ] As mentioned for micropropagation techniques, a specific protocol for plant production using somatic embryogenesis is also required to achieve an efficient large‐scale performance. The application of solvents and regulators with low ecotoxicity and competitive purchase cost is a continuous challenge to achieve sustainable plant production through micropropagation and somatic embryogenesis.

2.2.2. Callus and Cell Suspension Cultures

Callus and cell suspension favor the synthesis of a specific metabolite through the control of growth conditions (temperature, pH, and regulators concentration). Only the specimens with major induction capacity are selected to be transferred into the growth medium, where the callus formation begins. This represents a significant advantage in terms of culture periods compared to micropropagation, ensuring the continuous availability of enzymes with high homogeneity levels.

Callus and cell suspension cultures methodologies have been successfully applied for the production of cardosin (Cynara cardunculus) and silymarin (Silybum marianum L.). [47] The protocol used during growth periods has a predominant effect on proteolytic activity.[ 48 , 49 ] Fernandez and Pomilio optimized the growth protocol for bromelain production from Ananas comosus, observing that protease obtained through callus culture exhibited higher specific activity compared to those obtained from traditional cultivation. [41] In the case of Ficus carica, Dini et al. documented the production of a protein extract using cell cultures with dermatological applications. [50] The authors observed that the specific activity of the extract is sensitive to the concentration of regulators in the medium. The correct selection of regulators and growing conditions is crucial to achieve a high yield of the target enzyme or protein extract. Protein‐free media can be also used for metabolites production, containing only salts, sugars, and specific growth‐regulating hormones. This strategy involves a low cost of production and contamination risk. [51]

The cell suspension cultures using large‐scale bioreactors commonly show a high protein accumulation/amount of biomass ratio. The use of bioreactors for plant cells cultivation overcomes the problems associated with climatic and seasonal factors, showing a simplified purification process when the product is secreted into the extracellular medium. On the other hand, cell suspension cultures require the application of promotors systems (similar to those used in micropropagation and somatic embryogenesis), and rigorous control of the healthy specimens and growth conditions. [52]

2.3. Protein Obtained Directly from Plants

The main benefit of traditional cultivation is its low‐cost production, without the need to employ complex genetic engineering techniques. Similar to in vivo methodology, the production of proteases from crops is sensitive to environmental conditions changes (floods or droughts), fertilizers, and land‐use patterns (crops rotation), which can affect the homogeneity of the product. Furthermore, the long growing periods between planting and harvesting must be taken into account for the techno‐economic evaluation.

Protein extracts can be obtained from different plant organs (roots, fruits, flowers, peels, or latex) as is indicated in the work of Sun et al. The authors carried out extensive comparative analysis on proteolytic activity among 90 plant resources, using casein as substrate at pH from 3.0 to 10.5. [53] Remarkable proteolytic activity (1 % casein substrate) was observed in that extracts derived from kiwifruit (28.8 U g−1), broccoli (16.9 U g−1), ginger (16.6 U g−1), leek (32.7 U g−1), and red pepper (15.8 U g−1). The authors noted that there are promising plants with potential for the production of proteases.

Numerous proteases present in the latex of plants belonging to families such as Caricaceae (mexicain, papain, clycylendopeptidase), Moraceae (ficain, ficain P I, macluralisin), Asclepiadaceae (funastrains CII and CI, morrenains BI and BII, Morrenain O II, asclepain CI), Asteraceae (taraxalisin), Convolvulaceae (carnein), Apocynaceae (cryptolepain, ervatamins A, B, C, heynein, philibertain G I), and Euphorbiaceae (euphorbains Y‐1, Y‐2, Y‐3, P, La1, La2, La3 Lc, T1, T2, T3, T4, milin) have been identified. [54] Serine and cysteine proteases obtained from latex are stable in a broader range of pH and temperature compared with aspartic proteases. However, APs have fewer inhibitors. Table 3 shows the common properties of PPs isolated from laticifers plants.

Table 3.

|

Protease |

Molecular weights [kDa] |

Stability range |

Optimal conditions |

Common inhibitors |

||

|---|---|---|---|---|---|---|

|

pH |

Temp. [°C] |

pH |

Temp. [°C] |

|||

|

Serine |

33–117 (majority 60–80) |

2.5–11 |

<80 |

5.2–10 |

40–75 (most of them 60–70) |

Diisopropyl fluorophosphate (DFP), Phenylmethanesulfonyl fluoride (PMSF), Pamidinomethanesulfonyl fluoride (APMSF), Chymostatin and Ciethyl pyrocarbonate (DEPC). |

|

Aspartic |

45–60 |

4.0–7.5 |

<70 |

4.5–6.5 |

60 |

Pepstatin A |

|

Cysteine |

21–29 |

3–12 |

<80 |

7–9 |

60 |

Iodoacetamide (IAA), p‐chloromercury benzoate (PCMB), sodium tetrathionate, mercuric chloride, transepoxysuccinyl‐ l‐leucylamido‐(4‐guanidino)butane (E‐64). |

Flowers are also a suitable source of PPs.[ 55 , 56 , 57 ] For example, Cardosin and cyprosins proteases obtained from fresh flowers (Cynara cardunculus) have been traditionally used on cheese elaboration (optimum temperature 65 °C and pH 5–7). In recent years, peel and kernel (food processing wastes) have been considered valuable vegetable protease sources. Within this context, Mehrnoush et al. optimized the extraction and purification of serine protease from mango peel using an aqueous two‐phase polyethylene glycol/dextran system, reaching 97.3 % yield under optimal conditions (8000 g mol−1 of polyethylene glycol (PEG) and 4.5 % of NaCl at pH 7.5). [58] The proteases showed to be active for azocasein hydrolysis, indicating that mango peel could be an effective source of natural enzymes considering the large amounts of peel and kernel generated during mango processing.

Seeds and rhizomes of plants are important cysteine storage and play an important role during germination. [62] Research on the extraction of proteases from seeds and rhizomes focused on the obtention of new enzymes for milk‐clotting. Cysteine proteases obtained from traditional cultivation show particular specificity towards casein substrate and they commonly present stability higher than 75–80 % over a wide range of pH (4–10) and temperature (60–70 °C).[ 63 , 64 , 65 ]

As mentioned previously, plant latices are an extremely interesting source of proteases due to their easy extraction, high enzymatic activities, and relatively simple purification processes. These proteases protect ripening fruits against plant pathogens such as insects and fungi and most belong to the cysteine and serine proteases family, only one is a member of an aspartic proteases and none is a metalloprotease (at least for now). Table 4 shows the main structural facts of the most important Serine proteases found in plant latices.

Table 4.

Some serine proteases in plant latices.

|

Protease |

Plant |

MW [kDa] |

Isoelectric point |

pH; T [°C] opt. |

|---|---|---|---|---|

|

Macluralisin |

Maclura pomifera |

65 |

– |

8.5; 58 |

|

Taraxalisin |

Taraxacum officinale |

65 |

4.5 |

8; 40 |

|

Euphorbain L, Y1, Y2, Y3, P La1, La2, L3, Lc, T1, T2, T3, T4 |

Euphorbia, different |

33–74 |

4.5–7 |

5.5–8.3 |

|

Hevains A, B, L |

Hevea brasilensis |

58–80 |

4.3–6.9 |

6–7 |

|

Parthenain |

Parthenium argentatum |

63 |

6.3 |

7–8 |

|

Ficin E Other A, B and C |

Ficus elastica |

50 |

3.7 |

6 |

|

Carnein |

Ipomoea carnea ssp fistulosa |

80.2 |

6.5 |

60 |

|

Artocarpin |

Artocarpus heterophyllus |

79.5 |

6.3 |

8; 60 |

|

Milin |

Euphoris milii |

51.4 |

7.2 |

8; 60 |

Some of the serine proteases have homology with subtilisin‐like proteases. Subtilisin‐like proteases (or subtilases) are serine peptidases present mostly in plants. Plant subtilisins (plant SBTs) are homologs of the bacterial subtilisins that were first identified in the Carlsberg and BPN strains of Bacillus subtilis. [66] Macluralisin's N‐terminal sequence shares 30 % homology with the sequence of subtilisin‐like proteinase K from Tritirachium album whereas Taraxalisin's has 40 % of its residues identical to those of Subtilisin Carlsberg. Subtilisin Carlsberg from B. licheniformis (also known as subtilisin A, subtilopeptidase A, alcalase Novo), was discovered by Linderstrøm‐Lang and Ottensen while studying the conversion of ovalbumin to plakalbumin. The similarity of catalytic and binding site geometries for subtilisin and chymotrypsin, despite their different tertiary structures, gave rise to the notion of convergent molecular evolution. Studies about these enzymes have been crucial in understanding the mechanism of serine protease activity. [67]

Protease B from the latex of E. supina Rafin is a Cucumisin‐like serine protease, whereas Carnein's N‐terminal sequence showed a high degree of identity with that of Subtilisin‐like serine protease. Cryptlepain and Milin sequences do not match with any sequence of known plant serine proteases.

Latex cysteine proteases are in the range from 21 to 29 kDa in molecular weight, are stable in the range 3–12 of pH and up to 80 °C. The manuscript from Domsalla and Melzig presents a complete description of properties of several latex proteases. [54] Here some of them are presented in Table 5.

Table 5.

Cysteine proteases from plant latices.

|

Protease |

Plant |

MW [kDa] |

Isoelectric point |

pH; T [°C] opt. |

|---|---|---|---|---|

|

Ervatamin A |

Ervatamia coronaria |

27.6 |

8.37 |

8–8.5; 50–55 |

|

Ervatamin B |

Ervatamia coronaria |

26 |

9.35 |

6–6.5; 50–55 |

|

Ervatamin C |

Ervatamia coronaria |

23 |

9.54 |

7.5–8; 50 |

|

Funastrain CII |

Funastrum clausum |

23.6 |

>9.3 |

9–10; up to 70 |

|

Asclepain S |

Asclepias speciosa Torr. |

– |

– |

7–8; 65–75 |

|

Calotropins DI DII |

Calotropis gigantea |

23.8‐24.2 |

9.60 |

|

|

Araujiain HI, HII and HIII |

Araujia hortorum |

24.03 |

>9.3 |

8–9.5; 60 |

|

Papain |

Carica papaya |

23.43 |

8.75 |

5.5–7 |

|

Caricain |

Carica papaya |

23.28 |

11.7 |

7 |

Ervatamin C has a similarity of 66 % to Ervatamin B and 50 % to Papain. Funastrain CII shows remarkable stability of its caseinolytic activity. The N‐terminal sequence of it shows a high degree of homology with Asclepain F. Another group is the Morrenains BI, BII, and OII. Asclepain CI is the major purified protease from latex of stems of Scarlet milkweed Asclepias crussasiva L. and shows a high identity with Funastrain CII (87 %) and Asclepain F (86 %). Araujiain HI, HII, and HIII show partial homology (36–48 %) with other plant cysteine proteinases.

There is an important group of proteases: papain‐like cysteine proteases (PLCP). Papain‐like cysteine proteases genes belong to a large multigenic family with 31, 43, 40, 26, 40, and 24 PLCP family members were identified in Arabidopsis, rubber, cassava, castor, poplar, and grapevine, respectively, divided into 9 subfamilies based on structural characteristics. [68]

Homology in plant proteases is very heterogeneous: from no homology at all to up to 90 % homology. Within this context, besides the examples cited above, ficins are glycoproteins and have high homology with bromelain. [16]

Table 6 presents a comparison of the activity of different latex proteases with some of the more recognized plant proteases. In general, the characterization is performed using a model reaction with a model substrate (azo) casein, (azo) collagen, or (azo) albumin. A typical reaction with casein involves 100 μL of enzyme solution added to 900 μL of substrate solution (2 % casein in 10 mm. Tris‐Cl buffer pH 8.0) incubated at 50 °C for 20 min. The reaction is terminated by the addition of an equal volume of 10 % chilled trichloroacetic acid (TCA). One protease unit is defined as the amount of enzymes that release 1 μmol of tyrosine per mL per minute under the above assay condition. The specific activity is expressed in unit of enzymes activity per milligram of protein. Other ways of determining proteolytic activity have been used. For example, to 10 mL solution containing 1 % (w/v) casein, 0.05 m acetate, 0.05 m phosphate, and 5.0×10 m EDTA 0,05 mL of enzyme were added. Two‐milliliter aliquots were removed at 0, 10, 20, and 30 minutes and added to 3.0 mL of 5 % trichloroacetic acid solution. One unit of activity is defined as a change of 0.001 in absorbance at 280 nm in one minute.

Table 6.

Examples of degree of hydrolysis (%) or Units mg−1 protein for different proteases with casein, whey concentrate, or milk as substrates.

|

Protease |

Protein |

pH |

Temperature [°C] |

Reaction time |

Degree of hydrolysis |

|

|---|---|---|---|---|---|---|

|

Reference |

Enzyme |

|

|

|

|

|

|

[71] |

Papain |

Whey concentrate |

7 |

37 |

0.2–24 h |

13.3–22 % |

|

|

Commercial Papain |

|

|

|

|

10 U mg−1 |

|

[72] |

Actinidin |

Whey concentrate |

– |

15–70 |

5 h |

3.7–15 % |

|

[73] |

Bromelain |

Casein 1 % |

5.1 |

35 |

30 min |

41.7 U mg−1 |

|

|

Commercial bromelain |

|

|

|

|

3–15 U mg−1 |

|

[69] |

From latex |

|

|

|

|

|

|

|

Euphorbia synudenium |

Casein 2 % |

8 |

50 |

20 min |

9.44 U mg−1 |

|

|

Carica papaya |

Casein 2 % |

8 |

50 |

20 min |

0.935 U mg−1 |

|

|

Calotropis gigantea |

Casein 2 % |

8 |

50 |

20 min |

0.618 U mg−1 |

|

|

Calotropis procera |

Casein 2 % |

8 |

50 |

20 min |

0.82 U mg−1 |

|

|

Plumberia Rubera |

Casein 2 % |

8 |

50 |

20 min |

1.03 U mg−1 |

|

|

Ficus religiosa |

Casein 2 % |

8 |

50 |

20 min |

2.17 U mg−1 |

|

[74] |

Bromelain 5 % |

Cow milk |

6 |

45 |

340 min |

22.6 % |

|

[74] |

Papain 5 % |

Cow milk |

6 |

45 |

340 min |

17 % |

|

[70] |

Araujia hortorum latex |

Casein 1 % |

8 |

45 |

2 min |

12.8 U mg−1 |

|

|

Araujiain |

Casein 1 % |

8 |

45 |

2 min |

77.9 U mg−1 |

From the reference of Borde et al. it is clear that the specific activity for different latex proteases is heterogeneous in casein hydrolysis and from 0.61 to 9.44 U mg−1 latex. [69] However, the purified enzymes have very high activity, reaching 77.9 U mg−1 for araujiain. [70]

Depending on the source of the protease and its degree of purity, the enzymatic activity can range from less than 1 U mg−1 to about 80 U mg−1. However, the values depend on the experimental conditions and the additives (cysteine, group 2 ions, metal ions, other).

3. Isolation and Purification of Plant Proteases

Isolation and purification of proteases involve consecutive steps that could lead to loss of product yield. Nowadays, the industry demands efficient downstream process for enzymes purification, highlighting the following requirements: application of mild conditions, easy scale‐up, low material costs and minimization of protein denaturation.

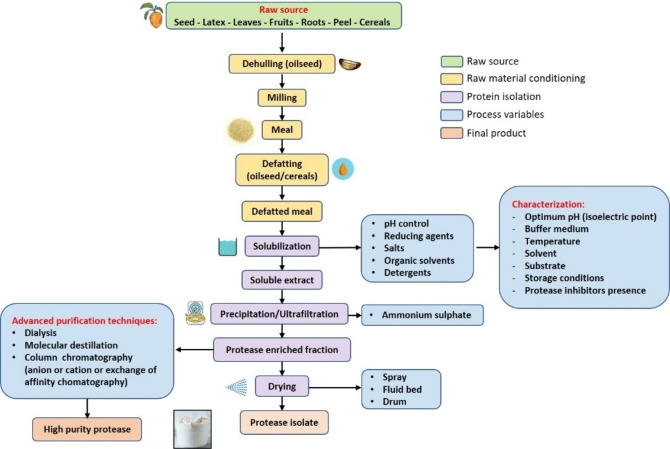

From an economic as well as an environmental perspective, an effective extraction method contributes to favor the commercial possibilities of emerging proteases. There is a continuous development of isolation and purification techniques to achieve sustainable plant proteases production. The amount of protein required, the degree of final purity of the product, whether loss of activity is acceptable, time required for isolation and purification costs should be considered to design a feasible isolation process before scaling up. When the protease extract is obtained from crops, additional considerations should be taken into account, such as plant species, seasonal and environmental variations, application of fertilizer during growth stage, structure and properties of raw material (leaves, seed, roots, latex, and fruits, among others), and previous processing. [75] Figure 3 shows the general procedure for isolation and purification of plant proteases.

Figure 3.

Plant protease purification methodologies.

The first stage of protease isolation process involves the disruption of the tissues where the proteases are accumulated during milling procedure. In the case of seeds, the previous dehulling is required to achieve a feasible homogenization of raw material powder. [76] An extra pre‐treatment of raw material is the defatting of the flours. This stage is only performed for oilseed and cereals, which have high level of fat/oil. [40]

Once the material was conditioned, the solubilization process is performed, obtaining an extract with the target protease in a soluble form. The efficiency of the solubilization process and the distribution coefficient predominantly depend on material composition (protein, lipids, carbohydrates, pigments, fibers, polyphenols, gums, polysaccharides among other compounds), solvent buffer, extraction time, pH, ionic strength, reducing agents, and temperature. [77] During the solubilization process, rigorous control of operating conditions is required to prevent protein denaturation and functional adverse reactions. For most plant proteases, the extraction is carried out at pH between 4 and 9 because solubilization at extreme basic pH could produce the racemization of amino acids.

The protein solubility on the selected solvent is a key parameter. Commonly, previous studies at laboratory scale are developed before scaling‐up, considering the large volume of solvents required and their large‐scale handling. [16] The solvents or buffers used in proteases extraction generally are high purity quality with remarkable costs associated. Consequently, a preliminary techno‐economic assessment of solvent recovery design should be carried out. The solvent selection also depends on raw material sources. Proteases obtained from oilseeds and legumes generally present a considerable solubility in aqueous media, whereas cereal proteases exhibit the opposite behavior. During the extraction step, surfactants, salts, or organic solvents (ethanol) are usually used to increase the solubility of cereal proteases. [75]

Acetate or citrate buffers are commonly used during aspartic proteases extraction to increase their activity and stability. [78] On the other hand, tris(hydroxymethyl)aminomethane buffer is broadly used on serine and cysteine protease extraction. Also reducing agents could be used to improve the cysteine proteolytic activity, for instance, dithiothreitol (DTT). Ethylendiaminetetraacetic acid (EDTA) and polyvinylpyrrolidone (PVP) are commonly used as chelating agents, preventing protein oxidation and tannin‐protein aggregation during isolation processing. [55] In recent years, there is a growing interest in protease extraction using neutral polymers, such as dextrose and PEG. The application of neutral polymers is efficient when flowers and leaves are used as raw materials. The process is commonly carried out at low temperature (4 °C) using buffer (Tris‐HCl) at pH from 6 to 8, with short contact time (30–60 s). After blending, filtration and subsequent centrifugation stages are performed. [79]

Once the soluble extract is obtained, the clarification step is performed to separate the protease from unwanted material using precipitation, ultracentrifugation, or ultrafiltration techniques. Ultrafiltration shows higher performance than precipitation, obtaining a final product with better functional quality and higher proteolytic activity. On the other hand, the application of ultrafiltration methodology involves higher cost and membrane maintenance compared to other technologies. [80] Precipitation is performed through several methods, such as isoelectric precipitation, organic solvents applications, addition of salts (reducing ionic strength), or use of exclusion polymers.

Isoelectric precipitation is the predilect technique due to its low operating cost. In contrast, this methodology could modify the protease solubility when concentrated acids or alkalis are used, generating the partial protease denaturation by local extreme pH values. [81] In the case of vegetable protease, pigments, carbohydrates, fibers, and lipids are removed from protein extract using a mixture of water/alcohol. The application of organic solvents should be restricted to prevent protein denaturation and the modification of the active site. Another concentration methodology is heat coagulation, which is scarcely used in view of the high level of denaturation achieved during the processing. The use of heat coagulation is reserved for protein extracts with nutritional applications or to increase the selective denaturalization of specific proteins.

Isolation methods by adding salts are scarcely used because of the high cost associated with salt recovery. These methods show comparable performance to isoelectric precipitation, with low denaturation rate. [82] The use of specific salts introduces modifications of the ionic strength of the medium, resulting in alterations in protein solubility without heating, thus conserving the properties of the final product.

Three‐phase partitioning system (TPP) provides a simple and effective protein purification. This technique also can be applied to complex mixtures, involving the blending of crude plant extract with ammonium sulfate ((NH4)2SO4), in combination with organic solvent, commonly tert‐butanol (t‐BuOH). During the procedure, three phases are formed: aqueous phase (rich in carbohydrates and polar compounds) and solvent layer (rich in pigments, lipids, fibers, and nonpolar compounds), while the proteins are selectively partitioned as a precipitate. [83]

After the protease‐enriched fraction was obtained, the drying is carried out. Rigorous temperature control is carried out at this stage to avoid denaturation of the protein. Most vegetable proteases are stable at temperatures up to 70 °C. Drying methods used on an industrial scale are drum drying, spray drying and fluidized bed drying. Spray drying is broadly used owing to its high efficiency to produce protease preparations without denaturalization. However, irreversible aggregation could occur during the process, in which the protein‐enriched solution is atomized and dried with flow hot air. In contrast, during drum drying, the protein extract is applied as a thin layer on a hot surface. This methodology produces the evaporation of large amount of water using short contact periods. [84]

Pre‐concentrated enzymes can be further subjected to affinity chromatographic, size‐exclusion, and ion‐exchange (anionic or cationic) procedures. These techniques are used when a high purity protein preparation is required, for example for biopharmaceutical industry or small quantities production.

4. Plant Protease Applications

4.1. Traditional Applications of Proteases (Cheese Making, Meat Tenderizing, Detergents, Food and Beverages)

Vegetable proteases have been used in manufacturing processes for decades, such as cheese‐making, dairy industry, meat tenderization, brew industry, tanning of leather, and peptide production. An enormous application field of plant proteases is based on hydrolysis of protein‐based substrate from vegetal and animal origin.

4.1.1. Leather Industry: Tanning

Conventional leather processing involves consecutive unit operations (soaking, liming, hair removal, deliming, bating, degreasing, and pickling) where harmful chemicals are used (lime, solvents, sodium sulfide, and ammonium salts). The effluents from leather factories generate serious pollution problems when they are discharged without the correct treatment.

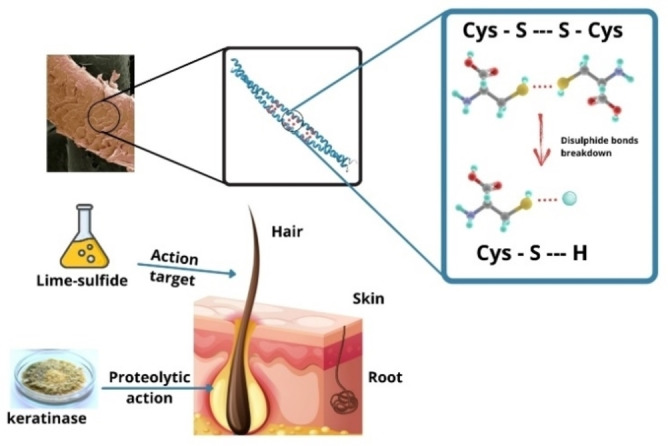

Within this context, plant proteases are an eco‐friendly alternative to replace the use of sodium sulfide for dehairing and tanning leather. [85] The mechanism of hair removal using enzymes is a complex process and currently is not fully understood. Sodium sulfide acts over the hair shaft outside the skin, reducing the S−S bond and increasing protein solubilization. Proteases dehairing act over the active sites of the basement membrane and the specific cells of the outer root sheath and follicle bulb (see Figure 4). Collagen is the most abundant protein found in skin and hides, followed by globular proteins and other fibrous proteins. [86] The glycoconjugates proteins, including glycoprotein (GPs), proteoglycan (PGs), and glycosaminoglycan (GAGs) play an important role in forming collagen fibrils and fixation of hairs in hair follicles. Enzymes attack the glycosidic bonds of GAGs chains and the link between the core protein and GAG. [87] Recently was proposed that enzymes attack β‐1,4‐bonds between N‐acetylglucosamine moieties in the glycosylation of serine and threonine (non‐coiled head structure of the keratin filaments), causing the de‐assembling of the root. [88]

Figure 4.

Lime‐sulfide and keratinase action during leather dehairing stage.

High collagenase activity is undesirable in order to obtain leathers with substantial‐quality. [89] A keratinolytic/caseinolytic activity (K/C) ratio lower than 0.5 is required to prevent leather degradation, this requirement is satisfied by plant proteases. In addition, plant proteases show remarkable stability under the operative conditions of leather processing (temperature: 30–50 °C, pH: 4–8, and high salt concentration). [90]

Few reports of vegetable proteases in leather tanning are found in the literature. However, proteases extracted isolated from different plants (Apocynaceae, Bromiliaceae, Anana comosus and Euphorbia nivulia) have shown potential to partially substitute the environmentally toxic lime‐sulfide treatment.

Lopéz et al. investigated the application of peptidases from Calotropis procera latex (CpLP) and Cryptostegia grandiflora latex (CgPL), plants belonging to the Apocynaceae family, for dehairing process. [91]

The latex was submitted to centrifugation and dialysis process to obtain protein enriched‐fraction. The dehairing tests were performed at 25 °C for 24 h at a pilot scale with 0.05 % w/v enzyme. Keratin azure and epidermis substrates were used (hide powder azure (HPA) and azocollagen as keratin, and Elastin‐Congo Red as elastin substrates). CpLP showed twice the proteolytic activity on all substrates compared to CgPL, except Elastin‐Congo Red, which the activity was not detected. In contrast, CgPL showed an elastin activity of 0.12 U mg−1. CpLP exhibited the following activities: 13.4 U mg−1 keratin azure, 36.3 U mg−1 epidermis, 93.0 U mg−1 HPA, and 403.3 U mg−1 azocollagen. From these results, it can be inferred that CpLP presented the highest ratio of keratinolytic/collagenolytic activities.

The activity of CpLP was enhanced by adding sodium sulfite (optimum conditions: 0.05 % w/v enzyme, 0.6 % w/v sodium sulfite at 30 °C for 24 h) without damaging the collagen layer of skin (incomplete depilation was reached using only CpLP). This synergistic effect was based on the activation of cysteine peptidases and the cleavage of keratin disulfide bonds promoted by sodium sulfite.

Proteolytic extract derived from Agave americana serine protease has been isolated and tested on leather liming. Bouhlel et al. optimized the extraction and purification of protease of Agave americana (PPA). [92] The protein‐enriched fraction was initially obtained from leaves using Tris‐HCl buffer (pH 7.8), incubated at 4 °C overnight using CaCl2 as activity stabilizer agent, and subsequent centrifugation. The purification of PAA was carried out using ammonium sulfate precipitation at the level of 80 %, followed by ethanol fractionation and finally, gel filtration coupled to HPLC system. PPA (with a molecular weight of 35 kDa) showed to be stable up to 70 °C and pH from 6.5 to 8.5, exhibiting the highest activity at 60 °C. Wool remotion from sheepskin essays using PPA at 40 °C for 24 h were performed. The authors observed that PPA efficiently unhaired the sheepskin (no major data was reported).

The use of crude bromelain derived from Anana comosus for cowhide pieces dehairing was also studied. The crude extract showed a casein activity of 4.71 U mL−1 casein at pH 4.5. [93] The extract was immersed in sodium acetate buffer solution (pH 4.5) with cowhide using an enzyme concentration of 100 % w/v of skin distilled water. After 24 h, around 50 % hair was removed, probably due to the reaction process was limited by the enzyme diffusion through the skin matrix.

In recent work, the potential application of Carica papaya (Cp) and Vasconcellea quercifolia (Vq) obtained, using simple procedures, from latex on the dehairing process was documented. [94] The activity of both protease extracts was measured using HPA, keratin azure, and elastin‐congo red epidermis substrate under eco‐friendly conditions (35 °C and pH 8), and compared to commercial dehairing enzyme. Cp showed the double of keratinolytic activity (10 keratin/casein units) compared to Vq and the commercial dehairing enzyme (5 keratin/casein units). However, an excessive keratinolytic activity could contribute to skin damage. Besides, three enzymes had a similar collagen activity (around 2300 HPA/casein unit). The result most notable was observed in elastinolytic activity, where Cp and Vq exhibited lower values (20 and 10 elastin/casein activity, respectively) than those the commercial dehairing enzyme (98 elastin/casein activity). In this way, the hide treated with Cp and Vq shows higher softness and flexibility. Regarding epidermis activity, Cp and Vq showed almost 70 % of that of the commercial enzyme activity, indicating that the dehairing process was less efficient. Comparing both plant proteases, Cp was more efficient than the Vp preparation, producing hair‐free hides with clean pores and without significant damage on the grain surface. Moreover, cowhide treated with Vq was rougher than that treated with Cp. Further studies are required to understand the relationship between the different substrate activities (all increased with temperature) to improve the efficiency of the dehairing process using Cp and Vq.

Another protein extract with promising results is those derived from Euphorbia nivulia. [95] This protease preparation is stable between pH 5 to 8 and up to 60 °C (75 % residual activity), showing high compatibility with metal ions, detergents, oxidizing agents, surfactants, and organic solvents. A preliminary dehairing study was performed at 30 °C and pH 7 for 18 h without sodium sulfate. The results indicated that the protease extract completely removed of fine hairs of goat hide (no major data was reported). Only a few reports with quantitative data of plant proteases on the unhairing process are found in literature CpLP and Cp are the most promising plant proteases. However, supplementary researches are needed to understand the crucial relationship between the selectively towards keratin, collagen, and elastin substrates in the skin to develop a potential enzyme procedure substitute of lime‐sulfide treatment.

4.1.2. Hydrolysis of Protein‐Based Substrates

A huge amount of waste rich in protein substrates is wasted in the fishing, dairy, food, and bakery industries. Plant proteases have emerged as an affordable technology to valorize these wastes via hydrolysis in order to obtain high value‐added products such as bioactive peptides. An updated review of the hydrolysis of cheese whey, keratinous materials from poultry feathers (keratin, collagen, and gelatin), gluten and soy and legume proteins, and fish is provided in the next section.

4.1.2.1. Dairy Industry: Valorization of Cheese Whey, Milk Hydrolysates, and Milk‐Clotting

Cheese production has grown at a rate of 3 % per year in the last 15 years, reaching a production volume around of 180–190 million tons/year. [96] Cheese production involves the generation of several byproducts, one of the most abundant is cheese whey (CW). An average of 90 % of the mass of milk used in cheese making is extracted in form of the whey and approximately half of total volume is discarded without the treatment required, thus generating serious pollution problems and environmental concerns. The discharge of these effluents into bodies of water without the necessary treatment has a negative impact on aquatic life due to dissolved oxygen depletion. [97]

The wastewater whey volume also depends on the animal milk used, with cow‘s milk showing the highest effluent compared to sheep and goat milk (Table 7). Milk coagulation can produce two types of whey. Acid whey (pH <5) is obtained from fermentation or addition of organic or mineral acids, and sweet whey (pH 6–7), which is produced during the addition of proteolytic enzymes like chymosin. [98] Table 8 shows the protein composition of acid and sweet whey, respectively.

Table 7.

Volume of whey generated and yield to cheese for milks from cow, goat, sheep and camel. [100]

|

Parameter |

Milk |

|||

|---|---|---|---|---|

|

Cow |

Goat |

Sheep |

Camel |

|

|

Cheese yield (kg/100 kg milk) |

9.86 |

14.78 |

9.84 |

10.12 |

|

Whey volume (L L−1) |

0.873 |

0.822 |

0.873 |

0.834 |

Table 8.

Protein composition of acid and sweet whey. [96]

|

Protein |

Sweet whey[a] |

Acid whey[b] |

|---|---|---|

|

β‐Lactoglobulin (β‐Lg) |

46 % |

44 % |

|

Peptide fraction |

30 % |

40 % |

|

α‐Lactalbumin (α‐La) |

16 % |

11 % |

|

Immunoglobulin (IgG) |

5 % |

3 % |

|

Others |

4 % |

3 % |

[a] pH 6.5, [b] pH 3.5.

Cheese whey is a heterogeneous mixture of different proteases: β‐lactoglobulin (β‐LG), α‐lactalbumin (α‐LA), immunoglobulins (Igs), bovine serum albumin (BSA), lactoferrin (Lf), and peptide‐fraction. Cheese whey also can contain lactoperoxidase (LP), proteose‐peptone, and glycomacropeptide (GMP). The composition of whey depends on procedures used for casein removal from milk. The studies related to the kinetics of hydrolysis have been focus on the major substrates (β‐LG and α‐LA). A simplified mechanism has been proposed with satisfactory reproducibility of experimental data adopting the Michaelis–Menten model. First, the plant protease bond to the substrate forming an intermediate in equilibrium with milk protein and the enzyme. Then, the enzyme cleaves the protein chain according to the nature of its active site. The hydrolysis β‐LG and α‐LA occur simultaneously. [99] It was also found that the kinetic of whey protein is sensitive to enzyme concentration, the composition of whey, pH, and temperature.

Approximately 55 % of the total organic and inorganic compounds in milk are retained in cheese whey, which make it an attractive raw material for the production of economically valuable products.

Based on the absence of any toxic agent, the following approaches have been used for cheese whey valorization: prebiotic galacto‐oligosaccharides from lactose, generation of bioethanol, production of high‐grade lactose for pharmaceutical purposes and hydrolysates production, protein concentrates, lactose and organic acids, among others. Cheese whey is also used in sports drinks, nutritional products, and high protein preparation. [101]

Cheese whey valorization appears as a huge field of application for plant proteases. Plant proteases, especially cysteine, are selective to casein substrates and many of them have been traditionally used for milk‐clotting. The use of plant proteases for cheese whey hydrolysis permit to obtain hydrolysates with functional properties (emulsifiers and foaming agents), nutritional foods and bioactive peptides with beneficial properties. [40] Madureira et al. reviewed the main biological properties of whey proteins and peptides, including benefit on the immune system (e. g., antimicrobial, immunomodulation, and cytomodulation activities), on the cardiovascular system (e. g., antihypertensive, antioxidant, and antithrombotic activities), on the nervous system (e. g., opioid agonists and antagonists) and on the gastrointestinal system, (e. g., anti‐appetitive and mineral‐binding vectors).[ 102 , 103 ]

The obtention of biopeptides for health care through whey protein hydrolysis using is gaining interest. Especially plant proteases isolated through simple procedures represent an affordable technology to obtain these biopeptides. Protein extracts from melon fruit (Cucumis melo), trompillo berries (Solanum elaeagnifolium), and citrus flowers (Citrus aurantium) have been tested for the production of bioactive peptides with the capacity to inhibit angiotensin‐converting enzyme (ACE) for hypertension treatment. [104] It has been observed that enzymatic crude extract from trompillo and melon fruit are selective towards β‐Lg and α‐La hydrolysis in sweet whey (pH 6.5, 60 °C, 5 : 95 (v/v) enzyme/substrate ratio). Trompillo almost completely degraded β‐Lg and α‐La after 24 h, whereas, only 30 % β‐Lg was hydrolyzed by melon proteases at the same time.

Lactoferrin (Lf), bovine serum albumin (BSA), and immunoglobulin (IgG) are minimally hydrolyzed for both enzymes. The similar enzymatic behavior exhibited by both plant protease extracts (trompillo and melon) may be attributed to the high concentration of serine proteases in each extract. On the other hand, citrus proteases showed minimum hydrolysis of sweet whey, while they exhibited higher bioactivity for acid whey, favoring the degradation of Lf, BSA, α‐La, and IgG under the same test conditions (no quantitative hydrolysis data was reported). This enzymatic behavior can be understood in view of the fact that citrus proteases have optimal proteolytic activity under acidic conditions (3.0–4.5). The ACE ‐ inhibitory activity of peptide sequences derived from CW hydrolysis using melon, trompillo, and citrus flower proteases was in the range of 85–90 %, 75–80 %, and 32–43 %, respectively. The results indicated that these proteases show potential for the production of hydrolysates for hypertension treatment.

Promising results were also documented using Maclura pomifera proteases latex. [105] The enzymatic preparation (also called pomiferin) showed a caseinolytic activity of 14.1 U mL−1, with a protein concentration of 1.5 mg mL−1. Ucas is an enzyme unit (caseinolytic unit) defined as the amount of protease producing an increment of one absorbance unit per min. The extract exhibited the highest proteolytic activity towards whey hydrolysis at 45 °C and pH 6. A linear correlation was observed between the hydrolysis time and the enzyme dissolution from 30 to 45 °C. When no dissolution was performed (10 (v/v) enzyme/substrate) the reaction took place almost instantly. Meanwhile, when the factor dissolution was 20 the reaction time was between 40 (45 °C) and 190 s (30 °C). Pomiferin hydrolyzed milk protein into small peptides (19–25 kDa), which exhibited antioxidant activity and ACE‐inhibitory activity of 57 % and 11 %, respectively. Thus, milk hydrolysates could be used for therapeutic applications.

In literature, a few reports of milk hydrolysates production using vegetable enzymes at pilot scale were found. Tavares et al. investigated the valorization of cow whey using selective filtration techniques (from ultrafiltration to nanofiltration), in combination with hydrolysis using proteolytic enzymes from Cynara cardunculus aqueous extracts. [106] The optimal hydrolysis conditions were: enzyme/substrate ratio of 1.6 % v/v, pH 5.2, 55 °C, and incubation time of 7 h. The results indicated that 87 % of α‐La was hydrolyzed, while no degradation of β‐Lg was registered. The final products of the process were a bioactive peptide concentrate, an hydrolysates fraction with molecular weight lower than 3 kDa and β‐Lg rich fraction, containing 73, 43, and 91 % w/w protein, respectively. All these fractions were low in lactose and salt. Furthermore, the small peptide fraction showed potential antihypertensive activity (ACE‐inhibitory activity of 710 μg mL−1 according to the IC50 method).

Highly hydrolyzed milk protein also could be used ingredients for infant preparations and therapeutic baby foods. From a nutritional perspective, the absorption of milk proteins hydrolysates and short‐chain peptides in the gastrointestinal tract is better compared to the absorption of high‐molecular‐weight proteins contained in milk. Thus, milk hydrolysates contribute to reducing the residual antigenicity (amount of undigested protein with the capacity to interact with antibodies) in foods. [107] In general, hydrolysates products are between 103 to 106 times less antigenic than the native proteins. [108]

Antimicrobial peptides are another valuable product derived from milk hydrolysis. These peptides commonly contain from 12 to 50 residues, including at least two positively charged residues and a remarkable proportion of hydrophobic residues (generally >50 %). The cationic side chains of basic residues (e. g., arginine, lysine, and histidine) interact with the negatively charged membranes cell of bacteria, including lipopolysaccharide. In comparison to traditional antibiotics to treat microbial infections, antimicrobial peptides derived from casein and milk hydrolysis show the capacity to attack target cells rapidly over different types of bacteria. [109] The peptides derived from bovine milk hydrolysis employing root latex proteases of Jacaratia corumbensis (Caricaceae family) have been shown potential antimicrobial. [110] The proteases exhibited high proteolytic activity (2.5 ⋅ 10−4 U mg−1) at room temperature and pH 7.6, leading to the formation of hydrolysates peptides, which were consecutively purified. The hydrolysates obtained after 2 h hydrolysis showed efficient antimicrobial activity against Enterococcus faecalis, Bacillus subtilis, Escherichia coli, Pseudomonas aeruginosa, Klebsiella pneumoniae and Staphylococcus aureus. The antimicrobial test was performed following the Minimum Inhibitory Concentration method (MIC). From the study was obtained a MIC of 50 mg mL−1 for all bacteria previously cited, except for Staphylococcus aureus, with a value of 40 mg mL−1 (107 Colony Forming Units/mL).

Similar therapeutic uses could be reached from hydrolysates obtained using proteases from Araujia hortorum (Asclepiadaceae). These proteases have simple and economic procedure extraction and high caseinolytic activity.[ 111 , 112 ] Quiroga et al. studied the synthesis of peptides in aqueous‐organic media catalyzed by proteases from Araujia hortorum latex at pH 9. [113] The activity of enzymatic preparation in 50 % (v/v) ethyl acetate, 50 % (v/v) hexane, 50 % (v/v) propanone and N,N‐dimethylformamide was 1.96, 7.84, 9.52, and 40.9 Ucas mg−1 of protein, respectively. The protease extracts were selective for generating short peptides, especially Z−Ala−Phe−OMe, which could be used in therapeutic applications.

The composition of milk hydrolysates peptides, and consequently their potential uses, depends on protease nature and reaction conditions, as well the composition of raw material. Table 9 shows the composition of cow, goat, sheep, and camel milk. Cows are the main source of milk worldwide, meanwhile, small ruminants (sheep and goat) produce around 3.5 % of the world's milk. In some cases, sheep and goat milk are suitable alternatives for persons with cow milk allergies. Furthermore, goat milk contains larger proteins, smaller fat globules, and shorter fatty acids than cow milk. On the other hand, sheep milk is rich in proteins and minerals (e. g., calcium, phosphate, and magnesium), showing higher amount of polyunsaturated fatty acids (PUFA) and conjugated linoleic acids (CLAs) compared to goat milk. [114] Camel milk exhibits less amount of lactose and higher level of β‐CN, α‐La, and serum albumin compared to cow milk. Besides, camel milk is rich in iron, magnesium, riboflavin (vitamin B2), folic acid (vitamin B9), vitamin B11, vitamins C and D, and fatty acids. Furthermore, caseins represent between 75–80 % of the total protein of camel milk.[ 114 , 115 ]

Table 9.

|

Compound [g/100 g] |

Milk |

|||

|---|---|---|---|---|

|

Cow |

Goat |

Sheep |

Camel |

|

|

Moisture |

87.9 |

87.6 |

82.9 |

86.9 |

|

Fat |

3.7 |

4.3 |

6.1 |

4.1 |

|

Lactose |

4.7 |

4.1 |

4.8 |

4.1 |

|

Protein |

3.4 |

3.7 |

5.5 |

3.4 |

|

Casein |

3.0 |

2.4 |

4.7 |

2.1 |

|

Ash |

0.7 |

0.8 |

0.9 |

0.7 |

|

Minerals [mg/100 g] |

|

|||

|

Potassium |

145.0 |

185.0 |

138.0 |

60 |

|

Calcium |

112.0 |

130.0 |

197.5 |

117 |

|

Phosphorous |

91.0 |

109.0 |

141.0 |

51.5 |

|

Sodium |

42.0 |

39.5 |

39.0 |

69 |

|

Magnesium |

11.0 |

14.5 |

19.5 |

14.2 |

|

Zinc |

0.40 |

0.43 |

0.60 |

Trace |

|

Iron |

0.10 |

0.06 |

0.10 |

0.39 |

|

Copper |

Trace |

0.04 |

0.10 |

Trace |

|

Vitamins [mg/100 g] |

|

|||

|

Vitamin A |

37.0 |

54.3 |

64.0 |

35.4 |

|

Riboflavin |

0.20 |

0.17 |

0.30 |

0.57 |

|

Vitamin E |

0.08 |

0.04 |

0.11 |

0.07 |

|

Thiamin |

0.04 |

0.06 |

0.07 |

0.04 |

|

Retinol |

35.0 |

0.04 |

64.0 |

27.0 |

|

Carotenoids |

16.0 |

Trace |

Trace |

Trace |

|

Folic acid |

8.5 |

1.0 |

6.0 |

8.7 |

|

Vitamin C |

1.0 |

1.3 |

4.6 |

4.5 |

|

Vitamin D |

0.2 |

0.15 |

0.2 |

0.5 |

|

Vitamin B12 |

0.50 |

0.06 |

0.66 |

0.85 |

|

Fatty acids [g/100 g] |

|

|||

|

C16 : 0 |

27.9 |

28.2 |

25.9 |

29.8 |

|

C18 : 0 |

12.2 |

8.8 |

9.6 |

12.9 |

|

C18 : 2 (n‐6) |

1.4 |

3.2 |

3.2 |

3.1 |

|

C18 : 3 (n‐3) |

1.0 |

0.42 |

0.80 |

1.4 |

|

Total SFA[a] |

68.7 |

68.7 |

64.2 |

58.9 |

|

Total PUFA[b] |

4.0 |

3.7 |

4.8 |

4.5 |

|

Total CLAs[c] |

1.1 |

0.70 |

1.6 |

3.1 |

[a] SFA=saturated fatty acids, [b] PUFA=polyunsaturated fatty acids, [c] CLAs=conjugated linoleic acids.

The protein content and vitamin composition of camel milk have encouraged the production of small bioactive peptides with, antioxidant and antimicrobial properties. Al‐Shamsi et al. explore the enzymatic hydrolysis of camel milk hydrolysates using bromelain and papain. [116] The protein hydrolysis was performed at 50 °C under constant stirring in a water bath using an enzyme/substrate ratio of 1 : 100 (wt/wt) at neutral pH. After 6 h of reaction, a hydrolysis degree of 24 % and 40 % was reached using bromelain and papain, respectively. The biopeptides (<14 kDa) showed notable antioxidant improvement compare to the camel milk source. DPPH (2,2‐diphenyl‐1‐picrylhydrazyl), ABTS (2,2‐azinobis 3‐ethylbenzthiazoline‐6‐sulfonic acid) radical scavenging, and ferrous Iron‐Chelating activity activities were increased 50 % and 33 %, 4.75 and 11.75 times, and 21 % and 2 %, using bromelain and papain, respectively. Similar observations were reported by Wali et al., who isolated specific antioxidant peptides produced during camel milk hydrolysis using papain. [117] The optimal conditions reported were: pH 5.8, 50 °C and an enzyme concentration of 5 kU g−1 protease. In addition, the isolated peptides showed comparable ABTS radical scavenging activity to the results reported by Al‐Shamsi et al. [116]

Cheese production is considered one of the most important activities in the dairy industry. About 80 % of world cheese production (20 million tons) is derived from cow‘s milk. [121] Cheese manufacturing from milk is a complex process, being enzymatic coagulation, the first step. [122] During milk clotting, caseins are separated as a coagulum and the whey is released (fat trapped in the gel network). Plant proteases have been traditionally used for milk clotting in cheesemaking manufacturing. [122] The presence of enzymes in coagulants preparation determines the final gel firmness, curd draining properties, moisture content, texture, and flavor of the final product. The catalytic mechanism of most plants extracts with milk‐clotting activity initiate with the hydrolysis of the casein micelle‐protective protein (k‐CN), in particular with the breakdown of the Phe105‐Met106 peptide bond. The glycomacropeptide (f106‐169, hydrophilic portion) is then released from the casein micelle surface, decreasing the electrostatic and steric repulsion between the micelles, thus causing casein aggregation and clot formation. The clot formation is commonly observed when 70–80 % of κ‐CN is hydrolyzed. The milk‐clotting activity depends on protease type or extract composition, specificity, and optimum conditions (enzyme concentration, pH, temperature, and calcium ions). Commonly, calcium ions are added to the milk in the form of CaCl2 (10–40 g CaCl2 100 kg−1 milk) to favor the formation of the gel matrix. [122]

A paramount parameter of enzymatic coagulation is the milk‐clotting/proteolytic activity ratio (MCA/PA). Proteases with high values of MCA/PA ratio favor the production of cheese with suitable textural and flavor features. In contrast, proteases with a low MCA/PA ratio are associated with weak curds, higher protein losses in the whey, soft texture, and bitter cheeses.[ 10 , 122 ] Industrial milk coagulation traditionally is carried out at 32–37 °C and pH 6.3‐6.8 using the chymosin enzyme. [10] Crude extracts from kiwifruit, melon mesocarp and ginger rhizome exhibited a higher MCA/PA ratio than chymosin, favoring the rheological properties of the final product. [104] Table 10 shows the milk‐clotting activity and the MCA/PA ratio of crude extracts and plant purified enzymes in comparison with the chymosin enzyme. The higher MCA/PA ratio shown by different plant proteases compared to chymosin represent their potential to be applied for milk coagulation at an industrial scale. In the case of Bromelia penguin, their extracts are able to hydrolyze selectively the κ‐CN in the Phe105‐Met106 peptide, leading to the formation of amino para‐kappacasein fragment (F1‐105 κ‐CN) and glycomacropeptide (F106‐169 κ‐CN). In contrast, cardosin A and B are selective towards the hydrophilic sections αs1‐CN (Phe23‐Phe24, Phe153‐Tyr154, and Typ164‐Tyr165) and β‐CN (Leu127‐Thr128, Leu165‐Ser166, and Leu192‐Tyr193).

Table 10.

Milk‐clotting activity and the MCA/PA ratio of plant preparations in comparison with chymosin enzyme.[ 122 , 124 , 125 ]

|

Enzyme or extract |

Milk‐clotting activity (MCA) |

MCA/PA[a] |

Optimum conditions |

|

|---|---|---|---|---|

|

T [°C] |

pH |

|||

|

Crude extracts | ||||

|

Kiwifruit mesocarp (A. deliciosa) |

2.7 U mg−1 |

5 (104) |

40 |

7 |

|

Rhizome (Z. officinale) |

2.3 U mg−1 |

3.2 (162) |

60 |

7 |

|

Melon mesocarp (C. melo) |

1.5 U mg−1 |

2.5 (208) |

40 |

7 |

|

Cardoon flowers (C. cardunculus) |

61 IMCU mL−1 |

NA |

50 |

6.5 |

|

Fruit mesocarp (B. pinguin) |

2.59 U mg−1 |

1.3 (162) |

50 |

7–9 |

|

Purified enzymes | ||||

|

Cardosin A (C. cardunculus) |