Abstract

Objective:

To compare the frictional behavior of several self-ligating brackets with that of normal brackets both with and without tipping force-moments and in combination with different archwire dimensions.

Materials and Methods:

The resistance to sliding (RS) of seven self-ligating brackets, a conventional bracket, and a ceramic bracket with a low-friction clip were evaluated in combination with three different archwires and tipping force-moments of 0 and 10 Nmm. The center of rotation for the measurements was set within the center of the bracket or with a 10-mm offset. Resistance to sliding was measured using an Instron 3344 at a cross-head speed of 10 mm/min at a temperature of 36°C.

Results:

Without a tipping moment, RS increased with the active self-ligating brackets with increasing archwire size. No RS was found for any of the passive self-ligating brackets. The 10-Nmm tipping moment resulted in more RS and was similar for all bracket and archwire combinations. RS was approximately doubled when the center of rotation was located at the bracket rather than with a 10-mm offset.

Conclusions:

RS between brackets and archwires is highly dependent on the experimental setup. Different setups can result in contradictory results. Almost 1 N of traction force is lost in RS when a moment of 10 Nmm is placed at a rotational center 10 mm from the bracket.

Keywords: Self-ligating brackets, Friction, Force-moment, Resistance to sliding

INTRODUCTION

Self-ligating brackets have become very popular over the course of the last decade. Effective ligation is important, as it ensures that forces generated between the archwire and the brackets are transmitted to the tooth. In later stages of treatment, when single teeth or groups of teeth are slid along the archwire by traction from elastics or coil springs, the ligation maintains the existing alignment. As a consequence, the control of the archwire in the slot is always coupled with resistance to sliding (RS) arising in the mechanical system.1

Friction is represented by the formula Friction = μxF, in which μ represents the coefficient of friction for the material combination and F the force perpendicular to the contacting surfaces. Mathematically the size of the surfaces in contact is irrelevant.

In order to move a tooth along an archwire the applied force needs to overcome the RS within the system, which was estimated2 at approximately 50% of the total force applied to a tooth. This is especially critical in situations in which large, slot-filling archwires are used.3 Consequently, higher force levels from inter- and intramaxillary elastics or coil springs are needed to bring about tooth movement on full-size archwires.

These forces, however, can overpower the archwire and result in unwanted distortion and deformation of the wire, leading to unwanted side effects on the teeth. One solution with which to eliminate friction is the use of closing loops in the archwire to avoid sliding mechanics. However, the placement of loops is time consuming, accurate activation is not easy, and the patient may experience soft tissue irritation as well as hygiene issues. In view of this, sliding mechanics, although sensitive to RS, are often preferred. When considering the overall RS, parameters other than friction, such as binding and notching, play a more important role.2 Binding is defined as that part of RS that occurs when the archwire is angulated in the slot without becoming plastically deformed. Notching occurs mainly in coated archwires, when the coating is damaged and a consequent indentation interferes with sliding. It has been shown that binding outplays friction with angulations as small as 3°. With angulations of 7° between the archwire and slot, more than 94% of the RS is caused by binding.4 It has also been shown5 that binding is not only sensitive to the angulation but is also directly proportional to the stiffness of the archwire.

It was the goal of this study to investigate the RS of seven self-ligating brackets, a conventional stainless-steel twin bracket with elastic ligatures, and a ceramic bracket with an unconventional low-friction ligation clip when combined with different archwire dimensions with and without a tipping force-moment. In addition, the influence of two locations of the center of rotation for the application of the tipping moment was evaluated.

MATERIALS AND METHODS

Static RS was measured for seven self-ligating systems, a ceramic bracket with a low-friction clip, and a control bracket in combination with three archwires and tipping moments of 0 and 10 Nmm. In the setup using a tipping moment of 10 Nmm (which was chosen to simulate a canine retraction with a small powerhook) the groups were subdivided according to the placement of the center of rotation (CR) of the couple. The CR was either placed within the center of the bracket or at an offset of 10 mm (Figure 1). The direction of the tipping moment simulated a distal tip of the crown, as seen in canine retraction. Three passive self-ligating brackets—Damon III (Ormco Corporation, Orange, Calif), SmartClip (3M/Unitek, Monrovia, Calif), and Oyster (Gestenco International AB, Gothenburg, Sweden)—were compared to four active self-ligating brackets—In-Ovation R (GAC International Inc, Bohemia, NY), Quick (Forestadent, Pforzheim, Germany), Speed (Strite Industries, Cambridge, Ontario, Canada), and Time (American Orthodontics, Sheboygan, Wis)—and a ceramic bracket with a special polyoxymethylene acetyl polymer ligation (Mystique, NeoClip [GAC International]). The control bracket was a conventional twin bracket (MiniMono, Forestadent) in combination with an elastic ligature (Power chain, Ormco). All brackets were upper canine brackets (tooth 13) with a 0.022-inch slot. Three straight stainless-steel archwire sizes were selected: an 0.016-inch and two rectangular stainless-steel wires with dimensions of 0.016 × 0.022 inches and 0.019 × 0.025 inches (3M/Unitek). In addition, the Speed system was also evaluated in combination with the 0.020 × 0.025-inch Speedwire. As the wire geometry of the Speedwire is unique to the Speed system, it was not tested with all brackets. Each group consisted of 10 bracket-archwire combinations, resulting in a total of 560 measurements.

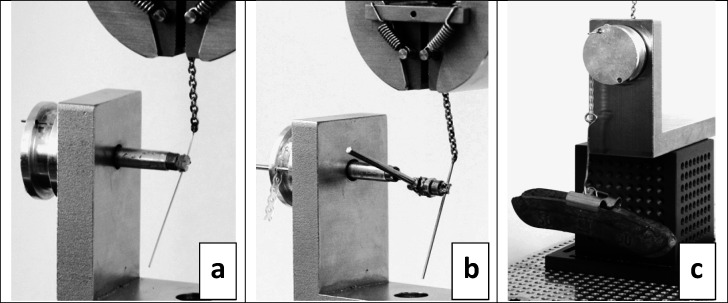

Figure 1.

Experimental setup for testing of RS with 0- and 10-Nmm force-moment. The moment was induced by a lever arm of 10 mm and a lead weight of 100 g. The center of rotation was placed within the bracket (a) and 10 mm from the bracket (b). Configuration “a,” without the lead, was used for testing without an applied moment. For all setups, the wire was attached to a stainless-steel chain, which was found to be essential in order to eliminate all undesired RS from torque or minimal malalignment. (c) Close-up view of the generation of the moment.

An Instron 3344 (Instron Corp, Wilmington, Del) with a static load cell of 100 N (Instron static load cell 100 N, calibrated according to ISO7500-1; Instron Corp) was used for the measurements, which were taken at a temperature of 36°C (±1°C). The temperature in the air chamber was controlled at ±1°C by a Julabo FS 18 thermostat (Julabo, Seelbach, Germany). The cross-head speed was set at 10 mm/min, and a sliding distance of 8 mm was measured. The initial peak value was recorded as static RS. The measurements were taken in the dry state without lubricants.

The data were statistically analyzed for means and standard deviations as well as significant differences between the bracket types with a nonparametric Kruskal-Wallis and a Dunn's posttest using the software Prism (GraphPad, San Diego, Calif).

RESULTS

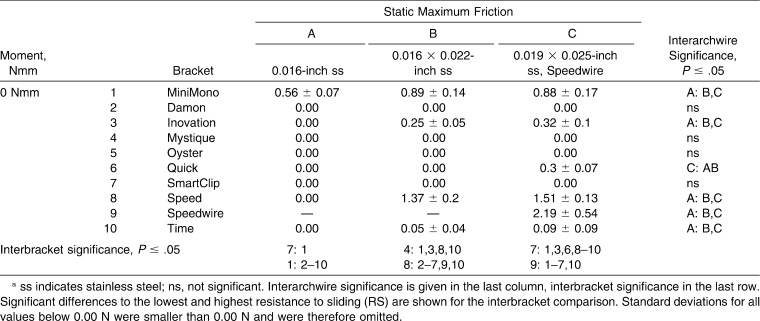

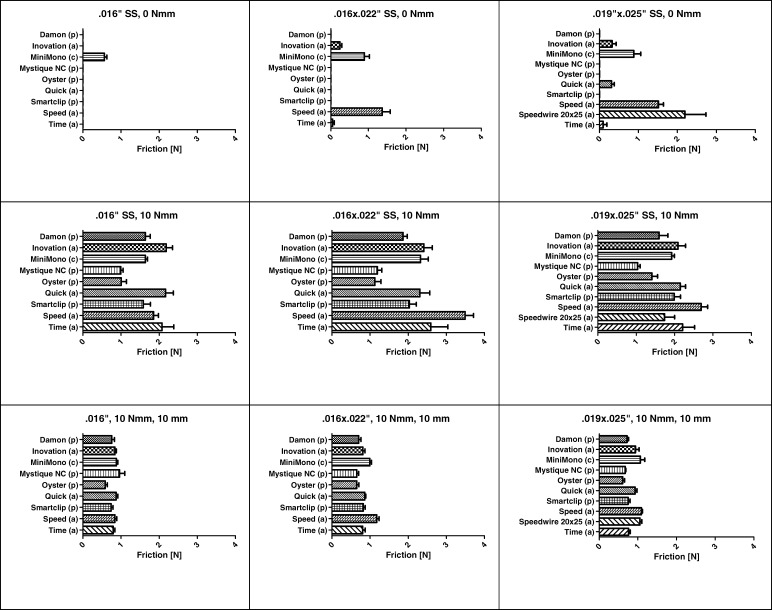

Tables 1–3 and Figures 2 and 3 give an overview on the RS. Only the conventional bracket and an 0.016-inch archwire with a ligated elastomeric module showed a substantial RS, even without a force-moment. All other systems, whether passive or active, did not show any clinically relevant RS. When an 0.016 × 0.022-inch archwire was used, the conventional bracket as well as all active self-ligating brackets, with the exception of Quick, showed RS. All brackets, except the passive self-ligating systems, showed RS with the 0.019 × 0.0250-inch archwire. The differences between those brackets showing RS and those that didn't were highly significant.

Table 1.

Frictional Forces for All Brackets and Archwires Without Moment and Offseta

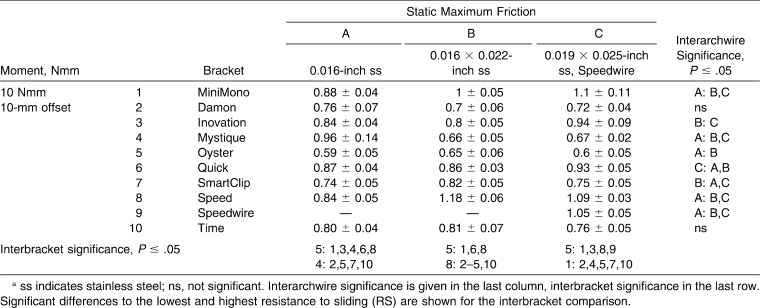

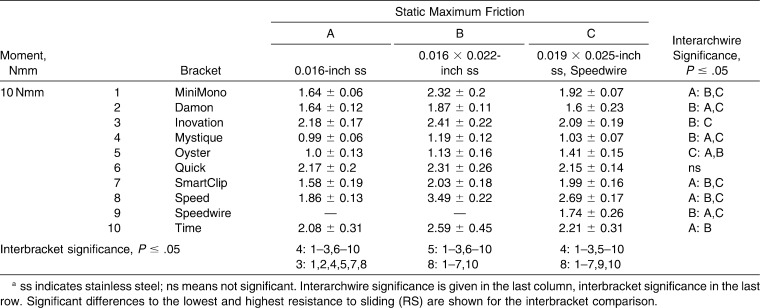

Table 3.

Frictional Forces for All Brackets and Archwires Applying a Moment of 10 Nmm With a 10-mm Offseta

Figure 2.

Results from testing of RS without a tipping moment (row 1), with a tipping moment of 10 Nmm (row 2), and with an additional offset of 10 mm for the center of rotation (row 3). a indicates active self-ligation; p, passive self-ligation; and c, conventional/control bracket.

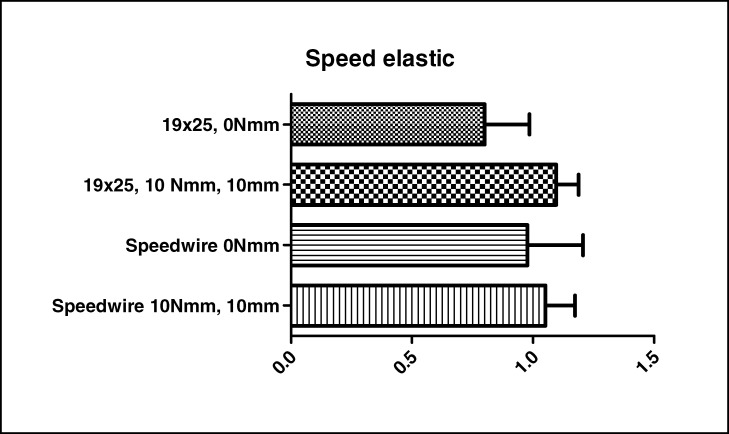

Figure 3.

Results from testing of RS of the Speed bracket with an open clip and an elastic ligature.

Table 2.

Frictional Forces for All Brackets and Archwires Applying a Moment of 10 Nmm Without an Offseta

When a force-moment of 10 Nmm was placed at the center of the bracket, many of the differences seen between the bracket systems and archwire sizes without a force-moment were no longer evident. Similar RS was found for all brackets and archwires. Two unconventional, passive self-ligating brackets, Oyster and Mystique/NeoClip, showed significantly lower RS than did all other systems for all archwire dimensions.

When the force-moment of 10 Nmm was placed 10 mm away from the center of the bracket, there was also little variations between the brackets. However, the RS was approximately half.

DISCUSSION

The newly developed bracket systems, with their supposedly reduced RS and their potential advantages, have been frequently and sometimes controversially debated in the current literature.1–3,5–10 Many of the discrepancies in the results can be attributed to the different testing designs. Some authors used an experimental setup in which the archwire was pulled straight through the bracket slot without any angulation, torque, or force-moment applied. This approach was also used as a comparison for the force-moment measurements in the present study. An optimal experimental design would ensure no contact between the archwire and the slot wall as long as the tested archwires did not fully engage the bracket slot. When there is no contact, RS should be zero with any passive self-ligating bracket, regardless of the archwire type or bracket material. RS measured under these circumstances was due to experimental flaws due to incorrect alignment of the archwire within the bracket slot.5–8 With the use of a stainless-steel chain almost all unwanted effects of malalignment, angulation, or torque between the bracket slot and the archwire were eliminated in the present study. The chain allowed the archwire to align itself perfectly within the bracket slot. This resulted in minimal RS for all passive self-ligating brackets. As binding and notching were eliminated in this setup, RS recorded for the remaining bracket-archwire combinations could be attributed mainly to friction arising through contact of the archwire and the ligation mechanism. With a small-sized archwire, as is used in the alignment stage, there was no difference between active and passive self-ligating systems. Only the elastomeric ligatures applied pressure to the archwire, causing relevant friction. However, with increasing archwire dimensions the active clips came into greater contact with the archwires, and friction increased. All active systems showed friction in combination with a 0.019 × 0.025-inch archwire. The Speed bracket showed almost twice the friction of a conventional bracket combined with an elastomeric module. Even the use of the specially developed Speedwire did not lower the friction.

Therefore, it must be concluded that within this experimental setup, low friction can be achieved with the use of passive self-ligating brackets or the combination of low-dimension archwires and active self-ligating appliances. The first setup represented two clinical situations: (1) a well-aligned dental arch with a single malaligned tooth or only a few malaligned teeth, as, for example, is noted in the case of canine displacement, and (2) retraction of the anterior segment of teeth on a heavy archwire in an extraction case. In both situations, well-aligned brackets in the buccal segments should allow for better sliding of the archwire. To date, no clinical advantage of low self-ligating systems has been found in the literature.7

A second experimental setup with fixed angulations between archwire and bracket slot was thoroughly evaluated by Kusy and coworkers.8–10 This setup was not tested in the present study. The results from the literature, however, showed that with angulations as low as 3° binding accounts for approximately 75% of the total resistance to sliding, with friction playing only a minor role. The clinical situation represented in this setup is the initial stage of alignment with several malaligned teeth. Clinically, no advantage of self-ligating brackets has been found.11–15

The third experimental setup, using a defined tipping moment of the bracket to the archwire, primarily represents the clinical situation of a tooth sliding along the archwire, but to date, this setup has not been well investigated.10,16,17 In the present investigation a tipping moment of 10 Nmm was chosen, and the CR was placed either at the bracket or 10 mm from the bracket. The resulting RS was essentially similar for all archwires and brackets. However, it is not clear why two brackets, the Oyster and Mystique/NeoClip brackets, showed markedly less RS with all archwires. Whereas the decreased RS might be attributed to a lower frictional coefficient for the Oyster bracket, ceramic brackets such as the Mystique bracket usually show higher RS, in combination with stainless-steel archwires, than do traditional brackets.18–20 However, in earlier studies10,21 using a similar experimental setup with a tipping moment of 30 Nmm, ceramic brackets were also found to express less RS than self-ligating stainless-steel brackets.

The traditional setup, using defined tipping moments with the CR placed at the bracket, seems to be problematic. As the CR in the clinical situation is not located at the bracket, but rather within the root of the tooth, the pressure exerted by the mesial and distal borders of the slot on the archwire is significantly reduced. It is true that a couple can be applied anywhere on the tooth, inducing the same tipping reaction. However, the angulation of the bracket to the archwire, and therefore its resistance to sliding, will vary according to the distance between the CR of the tooth and the center of the bracket. The same reasoning also applies for different bracket widths and leads to less RS with wider brackets than with narrow brackets.22 In the modified experimental setup with a CR positioned 10 mm from the bracket, an RS of around 1 N was found for most brackets. This is only half the friction found with the “traditional” setup. If the relative levels of the RS are compared, the modified setup showed only slight differences between the brackets and archwires tested. It is interesting that the Speed bracket in combination with the rectangular archwires showed higher RS in the passive configuration than with an applied moment. These results were confirmed in repeated series after checking for errors in the experimental setup. To further investigate these results, an additional setup with an open clip configuration and an elastic ligature was evaluated. The results are shown in Figure 3. As expected, the Speed bracket with an elastic ligature showed a smaller RS without the application of a moment. It was concluded that the unexpected results were due to the nickel-titanium clip. Manual sliding in the passive configuration was less smooth than when a couple of 10 Nmm was applied 10 mm from the bracket midpoint. Therefore, a strong binding component from the clip in the passive configuration was suspected.

It is also interesting to look at the frictional force in relation to the applied moment. A 1-N retraction spring applied to a tooth with its center of rotation 10 mm apical to the bracket would create a tipping moment of 10 Nmm to that tooth. RS of approximately 1 N was shown in the modified tipping moment setup. Under these circumstances, the distal pull of the coil spring of 1 N would hardly be sufficient to induce any tooth movement, except tipping until the bracket comes into contact with the archwire. This implies that the functional release of binding plays an important role in orthodontic tooth movement.22–24 It would also explain why tooth movement in clinical studies has been found11,13,24 to be very similar, regardless of the bracket type. Direct conclusions applied from in vitro studies to the clinical situation should not be drawn, as too many factors apart, from the materials, will influence the overall treatment progression.

CONCLUSIONS

Active and passive self-ligating brackets showed different behavior with regard to their resistance to sliding. The influence of the experimental setup, however, was paramount.

As soon as the brackets were not passively aligned to the archwire, the differences were minimal between active and passive self-ligating brackets or brackets ligated with elastomeric ligatures, as were the differences related to archwire size.

REFERENCES

- 1.Hamdan A, Rock P. The effect of different combinations of tip and torque on archwire/bracket. Eur J Orthod. 2008;30:508–514. doi: 10.1093/ejo/cjn017. [DOI] [PubMed] [Google Scholar]

- 2.Kusy R. P, Whitley J. Q. Friction between different wire-bracket configurations and materials. Semin Orthod. 1997;3:166–177. doi: 10.1016/s1073-8746(97)80067-9. [DOI] [PubMed] [Google Scholar]

- 3.Ehsani S, Mandich M. A, El-Bialy T. H, Flores-Mir C. Frictional resistance in self-ligating orthodontic brackets and conventionally ligated brackets. Angle Orthod. 2009;79:592–601. doi: 10.2319/060208-288.1. [DOI] [PubMed] [Google Scholar]

- 4.Thorstenson G. A, Kusy R. P. Resistance to sliding of self-ligating brackets versus conventional stainless steel twin brackets with second order angulation in the dry and wet (saliva) states. Am J Orthod Dentofacial Orthop. 2001;120:361–370. doi: 10.1067/mod.2001.116090. [DOI] [PubMed] [Google Scholar]

- 5.Tecco S, Tetè S, Festa F. Friction between archwires of different sizes, cross-section and alloy and brackets ligated with low-friction or conventional ligatures. Angle Orthod. 2008;79:111–116. doi: 10.2319/101107-487.1. [DOI] [PubMed] [Google Scholar]

- 6.Gandini P, Orsi L, Bertoncini C, Massironi S, Franchi L. In vitro frictional forces generated by three different ligation methods. Angle Orthod. 2008;78:917–921. doi: 10.2319/090607-420.1. [DOI] [PubMed] [Google Scholar]

- 7.Miles P. G. Self-ligating vs conventional twin brackets during en-masse space closure with sliding mechanics. Am J Orthod Dentofacial Orthop. 2007;132:223–225. doi: 10.1016/j.ajodo.2007.04.028. [DOI] [PubMed] [Google Scholar]

- 8.Articolo L. C, Kusy R. P. Influence of angulation on the resistance to sliding in fixed appliances. Am J Orthod Dentofacial Orthop. 1999;115:39–51. doi: 10.1016/S0889-5406(99)70314-8. [DOI] [PubMed] [Google Scholar]

- 9.Thorstenson G. A, Kusy R. P. Effect of archwire size and material on the resistance to sliding of self-ligating brackets with second-order angulation in the dry state. Am J Orthod Dentofacial Orthop. 2002;122:295–305. doi: 10.1067/mod.2002.126156. [DOI] [PubMed] [Google Scholar]

- 10.Thorstenson G. A, Kusy R. P. Comparison of resistance to sliding between different self-ligating brackets with second-order angulation in the dry and saliva states. Am J Orthod Dentofacial Orthop. 2002;121:472–482. doi: 10.1067/mod.2002.121562. [DOI] [PubMed] [Google Scholar]

- 11.Scott P, DiBiase A, Sherriff M, Cobourne M. Alignment efficiency of Damon3 self-ligating and conventional orthodontic bracket systems: a randomized clinical trial. Am J Orthod Dentofacial Orthop. 2008;134:470.e1–470.e8. doi: 10.1016/j.ajodo.2008.04.018. [DOI] [PubMed] [Google Scholar]

- 12.Fleming P, DiBiase A, Sarri G, Lee R. Efficiency of mandibular arch alignment with 2 preadjusted edgewise appliances. Am J Orthod Dentofacial Orthop. 2009;135:597–602. doi: 10.1016/j.ajodo.2007.06.014. [DOI] [PubMed] [Google Scholar]

- 13.Pandis N, Poychronopoulou A, Eliades T. Self-ligating vs conventional brackets in the treatment of mandibular crowding: a prospective clinical trial of treatment duration. Am J Orthod Dentofacial Orthop. 2007;132:208–215. doi: 10.1016/j.ajodo.2006.01.030. [DOI] [PubMed] [Google Scholar]

- 14.Miles P. G, Weyant R. J, Rustveld L. A clinical trial of Damon2 vs conventional twin brackets during initial alignment. Angle Orthod. 2006;76:480–485. doi: 10.1043/0003-3219(2006)076[0480:ACTODV]2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 15.Miles P. G. SmartClip versus conventional twin brackets for initial alignment: is there a difference? Aust Orthod J. 2005;21:123–127. [PubMed] [Google Scholar]

- 16.Reicheneder C. A, Baumert U, Gedrange T, Proff P, Faltermeier A, Muessig D. Frictional properties of aesthetic brackets. Eur J Orthod. 2007;29:359–365. doi: 10.1093/ejo/cjm033. [DOI] [PubMed] [Google Scholar]

- 17.Bednar J. R, Gruendeman G. W, Sandrik J. L. A comparative study of frictional forces between orthodontic brackets and arch wires. Am J Orthod Dentofacial Orthop. 1991;100:513–522. doi: 10.1016/0889-5406(91)70091-A. [DOI] [PubMed] [Google Scholar]

- 18.Angolkar P. V, Kapila S, Duncanson M. G, Nanda R. S. Evaluation of friction between ceramic brackets and orthodontic wires of four alloys. Am J Orthop Dentofacial Orthop. 1990;98:499–506. doi: 10.1016/0889-5406(90)70015-5. [DOI] [PubMed] [Google Scholar]

- 19.Pratten D. H, Popli K, Germane N, Gunsolley J. C. Frictional resistance of ceramic and stainless steel orthodontic brackets. Am J Orthod Dentofacial Orthop. 1990;98:398–403. doi: 10.1016/S0889-5406(05)81647-6. [DOI] [PubMed] [Google Scholar]

- 20.Kusy R. P, Whitley J. Q. Friction between different wire-bracket configurations and materials. Semin Orthod. 1997;3:166–177. doi: 10.1016/s1073-8746(97)80067-9. [DOI] [PubMed] [Google Scholar]

- 21.O'Reilly D, Dowling P. A, Lagerstom L, Swartz M. L. An ex vivo investigation into the effect of bracket displacement on the resistance to sliding. Br J Orthod. 1999;26:219–227. doi: 10.1093/ortho/26.3.219. [DOI] [PubMed] [Google Scholar]

- 22.Tidy D. C. Frictional forces in fixed appliances. Am J Orthod Dentofacial Orthop. 1989;96:249–254. doi: 10.1016/0889-5406(89)90462-9. [DOI] [PubMed] [Google Scholar]

- 23.Hixon E. H, Aasen T. O, Clark R. A, Klosterman R, Miller S. S. On force and tooth movement. Am J Orthod. 1970;57:476–478. doi: 10.1016/0002-9416(70)90166-1. [DOI] [PubMed] [Google Scholar]

- 24.Miles P. G. Self-ligating vs conventional twin brackets during en-masse space closure with sliding mechanics. Am J Orthod. 2007;132:223–225. doi: 10.1016/j.ajodo.2007.04.028. [DOI] [PubMed] [Google Scholar]