Abstract

The COVID-19 pandemic is one of the most severe supply chain disruptions in history and has challenged practitioners and scholars to improve the resilience of supply chains. Recent technological progress, especially industry 4.0, indicates promising possibilities to mitigate supply chain risks such as the COVID-19 pandemic. However, the literature lacks a comprehensive analysis of the link between industry 4.0 and supply chain resilience. To close this research gap, we present evidence from a systematic literature review, including 62 papers from high-quality journals. Based on a categorization of industry 4.0 enabler technologies and supply chain resilience antecedents, we introduce a holistic framework depicting the relationship between both areas while exploring the current state-of-the-art. To verify industry 4.0’s resilience opportunities in a severe supply chain disruption, we apply our framework to a use case, the COVID-19-affected automotive industry. Overall, our results reveal that big data analytics is particularly suitable for improving supply chain resilience, while other industry 4.0 enabler technologies, including additive manufacturing and cyber-physical systems, still lack proof of effectiveness. Moreover, we demonstrate that visibility and velocity are the resilience antecedents that benefit most from industry 4.0 implementation. We also establish that industry 4.0 holistically supports pre-disruption resilience measures, enabling more effective proactive risk management. Both research and practice can benefit from this study. While scholars may analyze resilience potentials of under-explored enabler technologies, practitioners can use our findings to guide industry 4.0 investment decisions.

Keywords: Industry 4.0, Supply chain risk management, Supply chain resilience, Supply chain disruption, Digital supply chain, Literature review

1. Introduction

Even before the COVID-19 pandemic, supply chains (SCs) were under pressure. Increasingly complex supply networks, globalization, and external effects (e.g., natural disasters and political interventions) have repeatedly led to supply chain disruptions (SCDs) over the last few years (Fan and Stevenson, 2018, Lechler et al., 2019). Nevertheless, no recent event has revealed the vulnerability of supply chains as the COVID-19 outbreak did at the beginning of 2020 (Govindan, Mina, & Alavi, 2020, Pournader et al., 2020). Most companies faced tremendous challenges at every section of their SCs. Suppliers could not meet their delivery obligations, stricter hygiene standards up to complete plant closures affected manufacturing, and customer demand was highly unpredictable (Ivanov, 2020). These conditions are alarming since SCDs can have severe consequences that directly affect overall company performance (Tang & Nurmaya Musa, 2011). Exemplary outcomes include sales and market share losses, delivery delays, and declines in service level and customer satisfaction that damage reputation (Basole, 2014, Er Kara, Oktay Fırat, & Ghadge, 2020, Tummala and Schoenherr, 2011). Potential negative brand effects are not limited to the directly affected SC members. With the rise of social media, negative experiences from SCDs can promptly be disclosed to a large audience, further damaging a firm’s reputation (Chae, 2015).

Given these severe consequences, supply chain resilience (SCRES) is currently at the center of interest (Reeves & Whitaker, 2020). SCRES’ primary objective is to rapidly recover from unexpected SCDs and regain or even improve an SC’s original performance (Hohenstein et al., 2015, Ponomarov and Holcomb, 2009, Sheffi and Rice, 2005). In a best-case scenario, companies might even achieve competitive advantages when rebounding more successfully than rivals (Dubey et al., 2021, Rajesh, 2016, Sheffi, 2007). Historically, whenever major SCDs hit SC operations, the concept of SCRES gained popularity (Heckmann, Comes, & Nickel, 2015), for instance, during the financial crisis 2009 (Blome and Schoenherr, 2011, Jüttner and Maklan, 2011). The crucial difference between the COVID-19 pandemic and earlier disruptive events is twofold: First, the pandemic and its manifold and severe impacts were completely unforeseen. Companies tend to tolerate low-probability, high-impact events and lack preparedness for extremely uncertain risks (Heckmann et al., 2015, Jüttner and Maklan, 2011). Although regional epidemics have been discussed as a potential source of risk in supply chain risk management (SCRM) literature and have repeatedly disrupted SCs over the last several decades (Anparasan and Lejeune, 2018, Christopher and Peck, 2004, Linton and Vakil, 2020), a global pandemic was considered an improbable event (Hilderink, 2020). Most companies have, therefore, not prepared for the distinct challenges that arise from this risk (Ivanov, 2020), which has led to a research gap in understanding a pandemic’s impacts on commercial SCs (Pournader et al., 2020, Queiroz, Ivanov, Dolgui, & Fosso Wamba, 2020). Second, recent technological advancements have been made to counter SCD consequences. In the past, scholars claimed that legacy information systems are too weak to support SCRES measures effectively (Pettit, Croxton, & Fiksel, 2019); however this might change with industry 4.0 (I4.0), a concept that is based on the idea of connected and autonomously interacting machines, products, and processes within and between firms (Ivanov, Dolgui, & Sokolov, 2019). As Zhang, Wu, Tang, Feng, and Dai (2020, p. 2227) stated, “I4.0 technologies can enable firms to mitigate the risk of disruption so that they can continue their operations.” This condition is especially true for a pandemic scenario where unavailable human labor is one of the most critical factors potentially harming SC operations (Shih, 2020). Many scholars are convinced that I4.0, with its numerous enabler technologies, such as big data analytics (BDA), the internet of things (IoT), and artificial intelligence (AI), can support SCRES and call for research in this area (Birkel and Hartmann, 2020, Dolgui & Ivanov, 2020, Er Kara, Oktay Fırat, & Ghadge, 2020, Gölgeci and Ponomarov, 2015, Ivanov et al., 2019, Koot, Mes, & Iacob, 2021, Queiroz, Pereira, Telles, & Machado, 2021). Research progress in selected sub-areas has been made in recent years. Nevertheless, resilience is considered a particularly complex topic that requires holistic perspectives (Arsovski, Arsovski, Stefanović, Tadić, & Aleksić, 2017), and the literature still lacks a comprehensive review of I4.0 technologies’ potential to support SCRES. To close this gap and create a foundation of the current research state, we conducted a systematic literature review (SLR), and thus evaluated I4.0’s general role in SCRES, developed a comprehensive I4.0 SCRES framework, and paid special attention to application areas to overcome pandemic-related SC challenges.

The paper's remainder is organized as follows: First, in Section 2, we outline and apply the SLR methodology, formulate the research questions (RQs), and analyze the relevant studies. With the synthesized results, we then answer the RQs by introducing an I4.0 SCRES framework that summarizes the relationships between I4.0 enabler technologies, SCRES antecedents, and SCRES phases. Moreover, in Section 3, we apply this framework to a COVID-19 use case to demonstrate its practicality. In Section 4, we derive conclusions and implications for theory and practice before proposing future research directions in Section 5.

2. Systematic literature review (SLR)

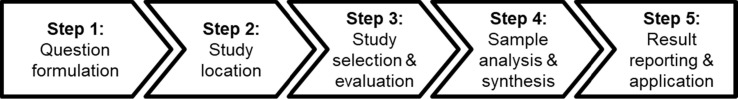

To gain deep and comprehensive insights about previously performed research at the intersections of SCRES and I4.0, this paper follows the SLR method. Knowledge is thus generated using an explicit, reproducible, and transparent approach that enables researchers to identify, analyze, and interpret existing literature effectively and unbiasedly (Cooper, 2017, Fink, 2014, Rousseau et al., 2008). This paper’s SLR is based on the five-stage approach of Denyer and Tranfield (2009) and depicted in Fig. 1 . This procedure has previously been applied in SCRM-related literature (Hohenstein et al., 2015). Furthermore, multiple researchers were involved in this paper to reduce individual bias (Tranfield, Denyer, & Smart, 2003).

Fig. 1.

SLR approach. Source: Adapted from Denyer and Tranfield (2009).

2.1. Question formulation

Formulating RQs guided the entire paper and supported targeted study and data selection (Denyer & Tranfield, 2009). First, we sought to identify applicable I4.0 enabler technologies to boost SCRES. Therefore, we proposed RQ1:

Which I4.0 enabler technologies have the potential to support SCRES?

Second, the literature agrees that SCRES is achieved through mediating antecedents (Chowdhury and Quaddus, 2016, Christopher and Peck, 2004, Hohenstein et al., 2015). Blackhurst, Dunn, and Craighead (2011, p. 375) define these as elements that “increase a firm’s ability to quickly and efficiently recover from a disruptive event.” We thus believe that enabler technologies do not directly affect SCRES but enforce specific antecedents. Identifying these antecedents is therefore a core element when analyzing I4.0’s role in SCRES. Hence, we formulated RQ2:

Which SCRES antecedents benefit from I4.0 enabler technologies?

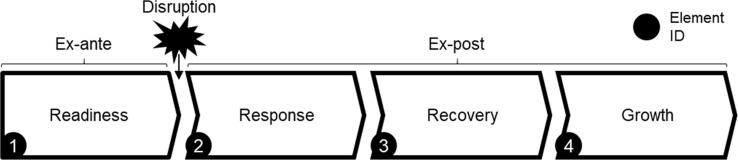

Third, SCRES can be built in four different phases before and after an SCD: readiness, response, recovery, and growth (Hohenstein et al., 2014, Hohenstein et al., 2015). It is thus essential to understand which phases I4.0-enabled SCRES antecedents affect to facilitate a targeted use of I4.0. On this basis, we presented RQ3:

Which SCRES phases do the I4.0-enhanced SCRES antecedents support?

Fourth, scholars have argued that I4.0 has the potential to help mitigate SC risks that result from COVID-19 (Ivanov & Dolgui, 2020a). However, the literature still lacks contributions that holistically describe I4.0 enabler technologies’ application areas to enhance SCRES during a pandemic. Therefore, we built on the previous RQs to answer RQ4:

How can I4.0 enabler technologies enhance SCRES during a pandemic?

2.2. Study location

Consistent with earlier SLRs in supply chain management (SCM) (Fan and Stevenson, 2018, Hohenstein et al., 2014, Hohenstein et al., 2015), four criteria were applied to guarantee a structured and systematic approach for identifying relevant studies: time horizon, database selection, journal selection, and keyword definition.

Time horizon: I4.0 is still a novel research area with its origins in the last decade (Queiroz et al., 2021). The term was introduced at the 2011 Hannover Fair in Germany (Vogel-Heuser & Hess, 2016). We thus applied an 11-year timeline with articles published from 2011 until today.

Database selection: Three distinct online databases were used to minimize bias and ensure completeness. Scopus and Web of Science cover ~95% of published research articles, allowing a broad information base (Rébulade de Oliveira, Souza Espindola, Rocha da Silva, Nostórioda da Silva, & Martins Rocha, 2018). To close potential remaining gaps, we additionally leveraged EBSCO (Business Source Ultimate).

Journal selection: In the academic world, researchers tend to accept that journal reputation varies (McKinnon, 2013). To ensure data quality, we focused on articles published in peer-reviewed academic journals (Light & Pillemer, 1984). Moreover, the 2018 ABS and VHB-JOURQUAL3 quality guides were applied to further limit the selection to renowned scientific journals. Due to SCRM’s high topicality during the COVID-19 pandemic, renowned business-related magazines (e.g., Harvard Business Review) have published popular articles in this paper’s field. These non-peer-reviewed articles that fulfill the journal quality criteria were also included to meet our objective of creating a holistic and state-of-the-art SLR (Durach, Kembro, & Wieland, 2017).

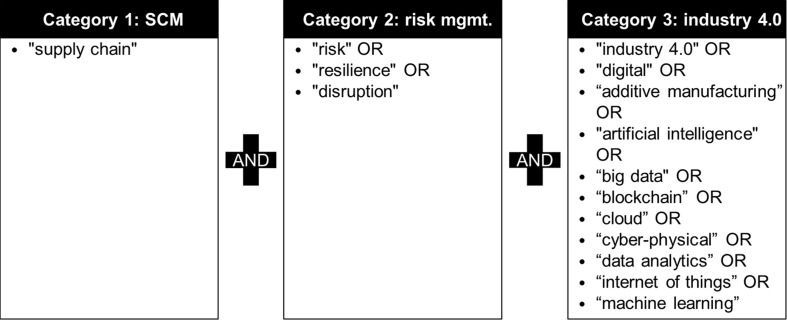

Keywords definition: To identify relevant articles in the stated databases, we identified 15 keywords based on basic literature during brainstorming sessions. The keywords used relate to three areas relevant for this paper: SCM (one keyword), risk management (three keywords) and I4.0 (11 keywords). Combinations with one keyword from each category were formed and applied to articles’ titles, abstracts, and keywords. First, the keyword “supply chain” guaranteed the topical fit of articles with SCM. Following the example of previous SLRs, we applied a unionist perspective so that “logistics” was considered part of SCM and not applied separately (Fan and Stevenson, 2018, Larson and Halldorsson, 2004). Second, the keywords “risk,” “resilience,” and “disruption” added the risk management angle required for this paper. Finally, the I4.0 perspective was added. The keywords “industry 4.0” and “digital” formed the basis for this category. Since not all scholars refer to these general terms when presenting I4.0-related research, the additional keywords “additive manufacturing,” “artificial intelligence,” “big data,” “blockchain,” “cloud,” “cyber-physical,” “data analytics,” “internet of things,” and “machine learning” were derived from current literature that analyzes I4.0’s main technological enablers in an SCRES context (Ivanov et al., 2019, Queiroz, Pereira, Telles, & Machado, 2021, Ramirez-Peña, Sánchez Sotano, Pérez-Fernandez, Abad, & Batista, 2020, Ivanov and Dolgui, 2020a). We did not include a limitation on pandemic-related papers since solutions for other types of risks might also apply to the COVID-19 crisis. Fig. 2 summarizes the applied keywords.

Fig. 2.

Applied keywords.

2.3. Study selection and evaluation

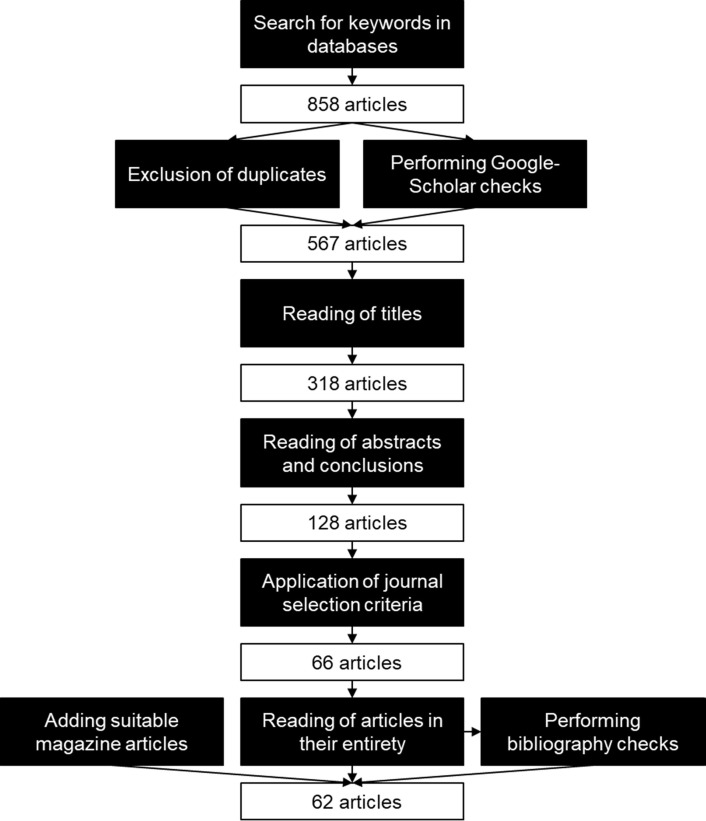

We applied the keywords in the three online databases, which yielded 858 studies (Scopus: 466; Web of Science: 226; EBSCO: 166). When duplicates were removed, 567 articles remained. Double-checks using Google Scholar did not uncover additional suitable articles, proving the selected databases’ completeness. The titles, keywords, abstracts, and conclusions were read with a focus on I4.0 solutions that support SCRES. We focused specifically on contributions that describe the relationship between at least one I4.0 enabler technology and one SCRES antecedent. Afterward, 439 studies were discarded, with 128 remaining in the sample. More than half of the articles fulfilled the journal selection criteria. These 66 articles were read in their entirety. Six unsuitable papers were excluded, resulting in 60 papers. Reviewing these studies’ bibliographies did not uncover additional research contributions that might have been missed, which supports the quality of the chosen approach, including the database and keyword selection. Since two articles recently published in Harvard Business Review were also added, the following analyses are based on a final sample of 62 suitable high-quality papers. Fig. 3 illustrates the study selection and evaluation process. Furthermore, Appendix A presents a table-based summary of all 62 papers.

Fig. 3.

Study selection and evaluation process. Source: Adapted from Hohenstein et al. (2015).

2.4. Sample analysis and synthesis

We meticulously analyzed the identified literature to gain new insights (Denyer & Tranfield, 2009), first, focusing on the individual papers. Intending to find background information on the sample and its research focus at the intersections of SCRES and I4.0, we analyzed five characteristics: the year of publication, venue of publication (both in Section 2.4.1), I4.0 technologies discussed (Section 2.4.2), SCRES antecedents affected (Section 2.4.3), and SCRES phases targeted (Section 2.4.4). Second, we aggregated the individual papers and proposed a generalized I4.0 SCRES framework to unveil the relationships between I4.0 technologies, SCRES antecedents, and SCRES phases (Section 2.4.5).

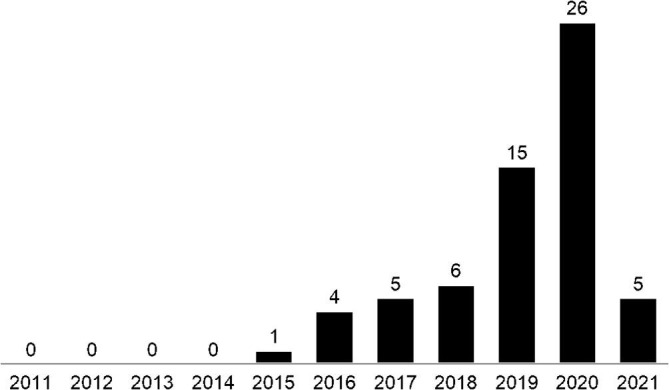

2.4.1. Distribution of studies

Concerning the year of publication, the first relevant contribution dates to 2015. The sample thereafter indicates a steady increase in literature that connects I4.0 and SCRES, as revealed in Fig. 4 . Over two-thirds of the identified papers have been published since 2019, which is consistent with recent contributions that emphasize the growing importance of I4.0 in SCRES (Queiroz, Ivanov, Dolgui, & Fosso Wamba, 2020, Ivanov and Dolgui, 2020a). The reason for this development is twofold: First, SCDs, including natural disasters, Brexit, the US-Chinese trade war, and the COVID-19 outbreak, have intensified over the last few years. This inspires research and industry to find new solutions in SCRM. Second, the maturity and applicability of I4.0 technologies are slowly but steadily increasing (Ivanov et al., 2019), which offers potential solutions to enhance SCRES and counter recurring and increasingly serious SCDs. Due to the COVID-19 pandemic, we are convinced that research in this area will accelerate further in the next several years.

Fig. 4.

Distribution of studies by publication year (as of February 2021).

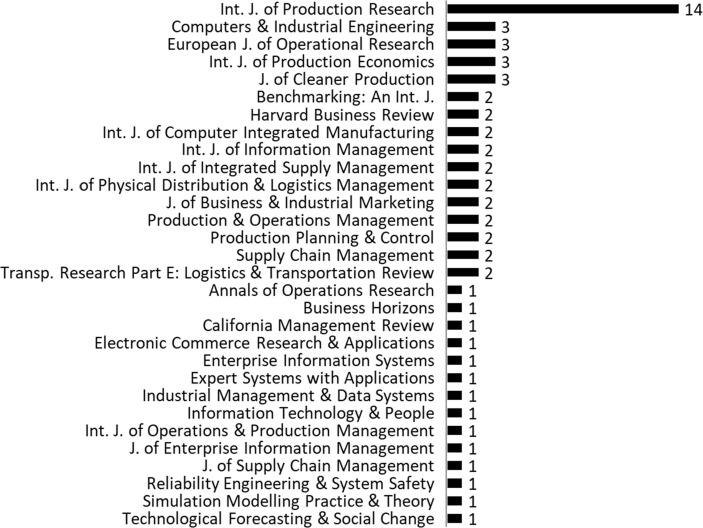

As mentioned in Section 2.2, we focused on peer-reviewed journal articles with an ABS or VHB rating to ensure data quality. Overall, the 62 papers were published in 30 different journals. With 14 publications (~23%), the International Journal of Production Research provides most studies, while Computers & Industrial Engineering, the European Journal of Operational Research, the International Journal of Production Economics, and the Journal of Cleaner Production offer three contributions in this area each. No other venue has published more than two articles on the discussed topic. As expected, most publications relate to production, logistics, and operations journals. Nevertheless, journals that focus on information and communication technologies and general management also provide recent contributions in this field. This emphasizes the topic’s interdisciplinary character. Fig. 5 reveals more details on the journals represented in this sample.

Fig. 5.

Distribution of studies by journal.

2.4.2. Industry 4.0 enabler technologies

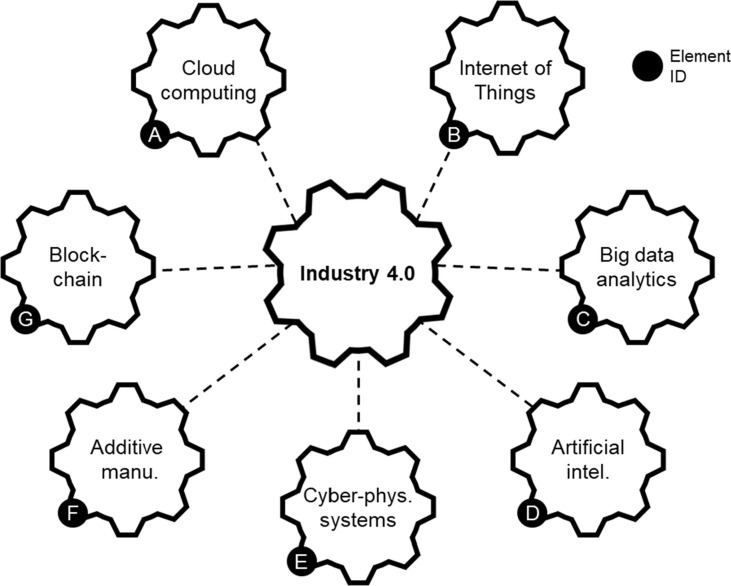

Since I4.0 characteristics and application areas in SCRES literature vary between scholars and studies, no unique I4.0 definition exists (Ivanov et al., 2019). Moreover, “I4.0-related technologies are not consolidated yet” (Queiroz et al., 2021, p. 1766). A complete and mutually exclusive categorization is therefore still missing. For this paper, we reviewed classifications recently presented in the SCRES field. Some papers restrict I4.0 to manufacturing and production functions and focus on cyber-physical systems (CPSs) and the IoT (Er Kara, Oktay Fırat, & Ghadge, 2020, Ivanov et al., 2019). Other scholars take a more comprehensive view and include various digital technologies along the entire SC (Queiroz, Pereira, Telles, & Machado, 2021, Ramirez-Peña, Sánchez Sotano, Pérez-Fernandez, Abad, & Batista, 2020, Zhang, Wu, Tang, Feng, & Dai, 2020). For this study, we followed the latter approach, which supported our ambition to provide a holistic perspective of I4.0 technology use in the entire SC to enhance SCRES. As a starting point, we used the digital SC technology portfolio that Queiroz, Pereira, Telles, and Machado (2021) identified. Based on a literature review of digital SC papers, they established a framework with six technologies: AI, BDA, blockchain (BC), cloud computing (CC), CPSs, and the IoT. As an extension, we considered additive manufacturing (AM), also referred to as 3D printing (Büyüközkan & Göçer, 2018), since many scholars have asserted that this technology clearly belongs to I4.0 (Ivanov and Dolgui, 2019, Ramirez-Peña, Sánchez Sotano, Pérez-Fernandez, Abad, & Batista, 2020, Zhang, Wu, Tang, Feng, & Dai, 2020). Other common digital solutions discussed in the context of I4.0, including machine learning (ML), robotics, and simulation techniques, can be assigned to at least one of the seven categories without information loss. Before identifying the most topical of the seven enabler technologies in SCRES, we briefly introduce each one in an SCRES context. Fig. 6 provides an overview of the seven categories.

Fig. 6.

I4.0 enabler technologies in SCRES.

CC (identifier A) is a shared and permanently available digital resource in three different areas: infrastructure (hardware and servers), platform (operating systems and databases), and software (applications) (Ramirez-Peña, Sánchez Sotano, Pérez-Fernandez, Abad, & Batista, 2020, Subramanian and Abdulrahman, 2017). Its decentralized character enables simple data collection, storing, processing, and exchange between many entities, improving overall data accessibility and data management within and between companies (Biswas and Sen, 2016, Oliveira and Handfield, 2019). Therefore, CC is generally considered to improve SC performance (Queiroz et al., 2021). In an SCRES context, CC is closely linked to other technologies, including BDA, the IoT, and CPSs (Queiroz et al., 2021). Risk data can be gathered, analyzed, and interpreted quicker, enabling more efficient supply, transportation, and demand planning (Arsovski et al., 2017, Ramirez-Peña, Sánchez Sotano, Pérez-Fernandez, Abad, & Batista, 2020). CC’s effectiveness for improving SC performance has been empirically proven. For instance, a study in the automotive industry revealed that cloud-based SMEs are more resilient than their non-cloud competitors (Arsovski et al., 2017).

The IoT (B) is a network of physical objects equipped with digital technology to autonomously interact with one another, human users, or other digital systems within or across company boundaries (Birkel and Hartmann, 2020, Queiroz, Pereira, Telles, & Machado, 2021). Various monitoring devices, such as radio frequency identifiers (RFIDs), global positioning system (GPS) chips, wireless sensors, cameras, microphones, lasers, barcode scanners, and other technologies (e.g., Bluetooth and Near Field Communication) facilitate data collection and connectivity in the network (Dunke et al., 2018, Er Kara, Oktay Fırat, & Ghadge, 2020, Gao et al., 2020, Ivanov and Dolgui, 2020a). For SCRES, the IoT allows tracking items and determining important metrics, including temperature and pressure, along the entire SC (Er Kara et al., 2020). This can improve the process and overall risk knowledge as well as risk strategies (Birkel & Hartmann, 2020). The data generated through the IoT can be used as input parameters for AI, BDA, and CPSs (Engelseth and Wang, 2018, Li et al., 2020, Queiroz, Pereira, Telles, & Machado, 2021).

BDA (C) refers to the combination of tools, techniques, and processes for integrating structured, semi-structured, and unstructured data from different sources into processable information as a basis for decision-making (Biswas and Sen, 2016, Dubey et al., 2021, Er Kara, Oktay Fırat, & Ghadge, 2020, Ivanov et al., 2019). A company’s ERP and CRM systems, machines, and cloud platforms, as well as external sources (e.g., web and social media pages) can therefore be leveraged (Araz et al., 2020, Choi et al., 2018, Meriton, Bhandal, Graham, & Brown, 2020). Scholars have empirically proven that BDA supports SCRES and consider this technology a core element of future I4.0 SCRES initiatives (Dubey et al., 2021, Engelseth and Wang, 2018, Ivanov and Dolgui, 2020a). Specific application areas for BDA in SCRM include predicting risk events, proactive response planning, and reactive real-time control, among others (Bag, Gupta, & Wood, 2020, Ralston and Blackhurst, 2020, Ivanov and Dolgui, 2020a). For instance, BDA can support developing and executing continuity plans in times of SCDs (Zouari, Ruel, & Viale, 2020). Furthermore, BDA can be combined with traditional simulation techniques to generate digital SC twins (Meriton, Bhandal, Graham, & Brown, 2020, Ivanov and Dolgui, 2020a). These models can support understanding complex SCRES problems, determine possible solutions, visualize dynamics, and test alternative scenarios (Vieira et al., 2019a, Vieira et al., 2019b).

AI (D) is an umbrella term for techniques that support a system’s continuous learning and adaptive decision-making capabilities based on large and potentially unstructured data sets (Baryannis et al., 2019, Queiroz, Pereira, Telles, & Machado, 2021). Mathematical optimization, network-based approaches, agent-based modeling, automated reasoning, and machine learning are key approaches in this field (Baryannis et al., 2019, Ivanov and Dolgui, 2020a, Wichmann et al., 2020). Nevertheless, it is important that not every listed approach meets AI's core characteristics, including large datasets, decision-making, prediction, and learning (Baryannis et al., 2019). The link between AI and BDA remains blurry. Some scholars consider BDA part of AI and vice versa (Baryannis et al., 2019, Brintrup et al., 2020, Choi et al., 2018). Although big data can be an input for AI (Hosseini & Ivanov, 2020), we decided to treat both technologies separately, as other scholars do (Ivanov et al., 2019, Ivanov, 2020). BDA has been widely discussed in SCRES papers and increasingly implemented in industry, while research on AI remains in its infancy (Baryannis et al., 2019, Dubey et al., 2021, Ivanov et al., 2019). Therefore, we sought to differentiate between research contributions that address traditional BDA (focused on information generation from big data) and future-oriented AI solutions (focused on autonomous learning and decision-making). As was discussed in the context of BDA, simulation techniques can also be combined with AI (Cavalcante, Frazzon, Forcellini, & Ivanov, 2019). In SCRES, any AI approach can be considered artificially intelligent if it is able to autonomously decide on a course of action that leads to success in a partially unknown SC environment (Baryannis et al., 2019).

CPSs (E) deal “with the physical as well as the informational aspects of processes” (Chen, Dui, & Zhang, 2020, p. 1). Specifically, CPSs integrate physical infrastructure into systems to self-manage operations and regularly communicate and exchange information with the real world (Queiroz et al., 2021), which allows companies to automate, monitor, and control their operations more comprehensively. Autonomous robots and vehicles play an essential role in CPSs since they can facilitate or even undertake personnel’s work to reduce potential risks and errors from human labor, especially during a pandemic (Ramirez-Peña, Sánchez Sotano, Pérez-Fernandez, Abad, & Batista, 2020, Shih, 2020). As a specific SCRES example, an automated system for detecting and transporting testing samples from the assembly line to a laboratory mitigates potential quality risks more reliably and efficiently than human workers ever could (Ralston & Blackhurst, 2020).

AM (F) techniques are the opposite of subtractive manufacturing: materials are successively added layer upon layer instead of cut away from a solid block (International Organization for Standardization, 2018). 3D printers are at the core of AM in SCM, allowing the production of modules, components, and products anywhere in the SC (Ivanov et al., 2019). Potential risk sources in SCs (e.g., the number of production steps, suppliers, and transportation links) can thus be reduced (Ivanov et al., 2019, Shih, 2020).

BC (G) is a decentralized, open, and cryptographic peer-to-peer network that has been discussed in the financial field for many years (Min, 2019). Information on transactions is stored on digital data blocks, reproduced, and distributed to various identical ledgers that all involved parties can access (Choi et al., 2019, Li et al., 2020, Ramirez-Peña, Sánchez Sotano, Pérez-Fernandez, Abad, & Batista, 2020). Decisions on the legitimacy and completion of these transactions are based on a consensus between trade partners, making intermediaries (e.g., banks and governmental entities) increasingly superfluous (Min, 2019, Queiroz, Pereira, Telles, & Machado, 2021). In an SC context, BC can be used to verify information accuracy and track assets’ locations and ownership statuses (Choi et al., 2019, Ivanov and Dolgui, 2020a, Min, 2019). SCRES can significantly benefit from these application areas since BC’s “super audit trails” improve open communication, coordination, and trust across company boundaries (Choi et al., 2020, Dubey et al., 2020, Kshetri, 2018).

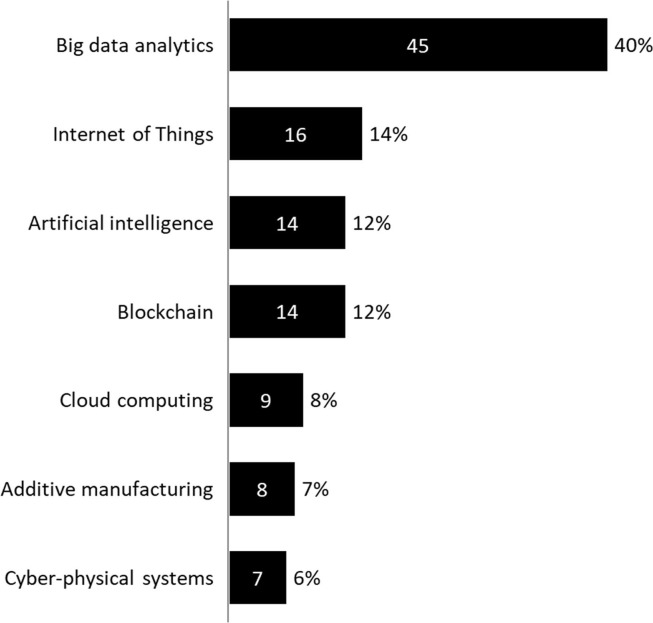

To identify the most topical I4.0 enabler technologies in our sample, we first calculated the absolute number of technology references in our sample. Second, we used an approach that Ramirez-Peña, Sánchez Sotano, Pérez-Fernandez, Abad, and Batista (2020) presented to calculate the relative share of enabler technology references compared to the total number. In some publications, more than one was discussed, resulting in 113 enabler technology references from 62 papers. Fig. 7 displays the results.

Fig. 7.

Absolute total and relative share of I4.0 SCRES enabler technology references.

Most papers identified discuss BDA solutions, which is consistent with our expectations since BDA is considered mature in research and industry (Ivanov et al., 2019, Queiroz, Pereira, Telles, & Machado, 2021). All other enabler technologies lack a high number of contributions. This finding is surprising since many scholars expect major SCRES improvements from I4.0 (Ivanov et al., 2019, Ralston and Blackhurst, 2020, Zhang, Wu, Tang, Feng, & Dai, 2020). This leads to the conclusion that research has not yet fully uncovered the potential and detailed application areas of each I4.0 enabler technology in SCRES. Furthermore, we analyzed the number of papers that present more than one I4.0 enabler technology and discovered 27 contributions. In several cases, scholars discuss them independently. Potential synergies from combining several enabler technologies have therefore largely been missed so far. Exceptions include Li et al. (2020), who proposed an 'enterprise capability evaluation model and sharing system' that leverages AI, BC, and the IoT for appropriate supplier selection, and Engelseth and Wang (2018), who discussed the use of IoT data in BDA.

2.4.3. Supply chain resilience antecedents

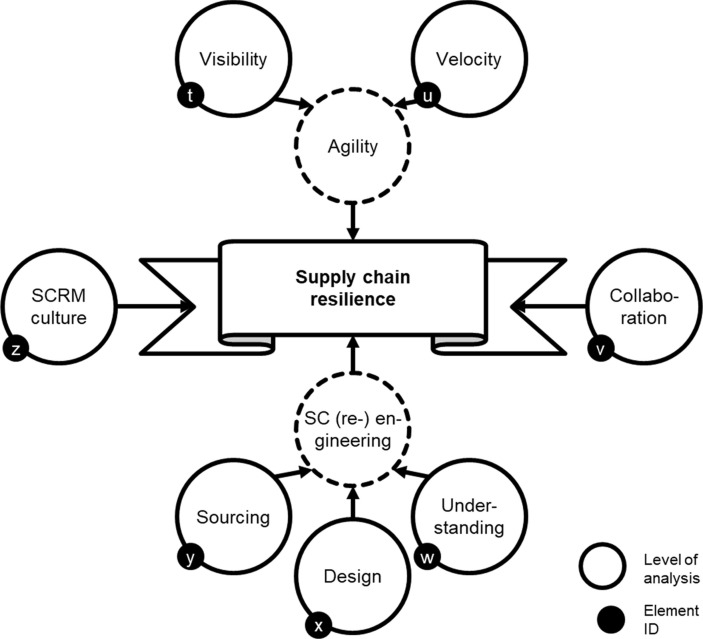

In Section 2.1 we claimed that enabler technologies do not influence SCRES directly; indeed specific antecedents are required as mediating factors. To distinguish SCRES antecedents, we built on Christopher and Peck (2004) SCRES framework, identifying agility, SC (re-)engineering capabilities, collaboration, and a supporting SCRM culture as key enablers. This core concept has been confirmed by many scholars with some sort of variation (Faisal et al., 2007, Jüttner and Maklan, 2011, Kilubi, 2016, Pettit et al., 2013, Tukamuhabwa et al., 2015). We determined that most papers in our sample describe approaches to enhance agility (~76%) and (re-)engineering capabilities (~42%). To understand the relationship between I4.0 and these two antecedents more completely, we decided to divide them further. Agility is generally considered a combined element that includes visibility and velocity (Christopher and Peck, 2004, Hohenstein et al., 2015, Rajesh, 2016), whereas SC (re-)engineering has three different perspectives: sourcing from a reliable supply base, applying SC design principles, and understanding the entire SC’s structure (Cavalcante et al., 2019, Christopher and Peck, 2004, Ivanov, 2017, Ivanov and Dolgui, 2020a). Fig. 8 presents the discussed SCRES antecedents and this study‘s level of analysis.

Fig. 8.

SCRES antecedents. Source: Adapted from Christopher and Peck (2004).

Before evaluating our sample in detail, this subsection briefly introduces all the SCRES antecedents discussed in this paper. Visibility (t), or transparency (Wichmann et al., 2020), concerns the ability to access information on the identities, locations, and statuses of entities transmitting between lower-tier suppliers and customers in the SC (Basole, 2014, Jüttner and Maklan, 2011). This may include inventories, demand, and supply conditions, as well as production and purchasing schedules (Christopher & Peck, 2004).

Velocity (u) focuses on an organization’s speed of performing flexible adaptations, with lead time as a key indicator (Jüttner & Maklan, 2011). This includes firms’ flexibility to quickly react to new environmental conditions, especially when facing disruptions in manufacturing, transportation, sourcing, or labor (Christopher and Peck, 2004, Hosseini et al., 2019, Sheffi and Rice, 2005).

SC collaboration (v) describes independent parties’ attitudes toward aligning forces for risk mitigation (Christopher and Peck, 2004, Jüttner and Maklan, 2011). Some examples of collaborative approaches are joint continuity planning and decision-making, permanent communication infrastructure, and willingness to share information and resources (Jüttner and Maklan, 2011, Scholten et al., 2014, Scholten and Schilder, 2015). In this context, mutual trust is a precondition (Mandal, 2014, Papadopoulos et al., 2017). Some scholars even consider collaboration with competitors productive in times of severe SCDs (Faisal et al., 2007, Scholten and Schilder, 2015).

SC understanding (w) is required to identify critical paths and potential bottlenecks in the SC (Christopher & Peck, 2004), which can be achieved through modeling and mapping techniques (Gardner and Cooper, 2003, Wichmann et al., 2020). Having these kinds of tools when facing SCDs is crucial to enable vulnerability analyses and scenario simulations (Ivanov, 2017, Ivanov and Dolgui, 2020a, Vieira et al., 2019b).

SC design principles (x) in the context of SCRES concern predominantly the trade-off between efficiency and redundancy in a supply network (Christopher & Peck, 2004). Although perceived as helpful to overcome disruptions, redundancy strategies come at a cost (Zsidisin & Wagner, 2010) and must therefore be applied thoughtfully. The three most prominent measures are increased inventory, multiple sourcing, and backup capacity in manufacturing and transportation (Chen, Dui, & Zhang, 2020, Ivanov et al., 2017). Additional design principles include a supply network’s density, complexity, and node criticality (Craighead et al., 2007, Kim et al., 2015).

Sourcing (y) from reliable suppliers is essential since disruptions in lower tiers can affect every company in the SC through the ripple effect (Jüttner, 2005). One study reports that more than half of all SCDs are due to first-tier suppliers (Hosseini et al., 2019), which puts supplier selection at the center of SCRES research (Cavalcante et al., 2019, Hoffmann et al., 2013, Sanders, 2016). Risk assessments during negotiations and regular audits have gained importance; nevertheless, further collaborative activities (e.g., proactive supplier enablement) are recommended since audits on the actual state might not be a predictor for the future (Zsidisin & Wagner, 2010). The role of suppliers is particularly important in an I4.0 context as “an organization cannot truly benefit from disruptive technologies if its other SC partners are still functioning in conventional ways” (Kaur & Prakash Singh, 2021, p. 1).

Establishing an SCRM culture (z) is a very diverse antecedent, that includes a risk awareness mindset, SCRM learning possibilities, and senior management support (Christopher and Peck, 2004, Manuj and Mentzer, 2008, Singh and Singh, 2019). In an I4.0 context, decision-makers must be able to interpret insights from processed data (Grötsch et al., 2013, Oliveira and Handfield, 2019).

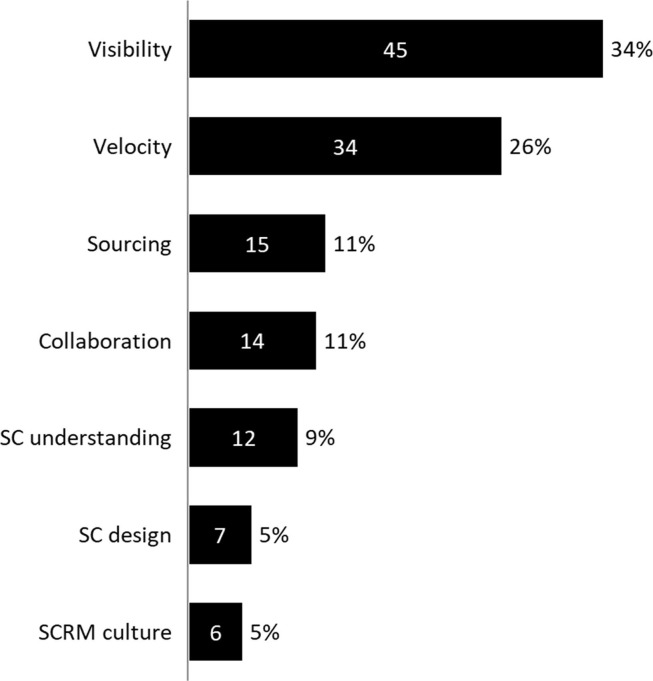

We applied the same logic as in Section 2.4.2 to identify the most topical SCRES antecedents in our sample. We calculated the absolute number and the relative share of SCRES antecedents covered following Hohenstein et al. (2015) . In most publications, more than one was discussed, resulting in 133 SCRES antecedent references from 62 papers. The detailed results are displayed in Fig. 9 .

Fig. 9.

Absolute total and relative share of SCRES antecedent references.

Agility and (re-)engineering elements are at the center of the research, with visibility and velocity leading the field. This finding is coherent since I4.0 enabler technologies in SCRM are considered primarily decision-support tools for managing severe disruptions (Ivanov & Dolgui, 2020a). The restrained treatment of collaboration is somehow remarkable as this SCRES antecedent is described as “the glue that holds organizations together” in crises (Richey, 2009, p. 623). To explain this finding, we refer to Queiroz et al., 2021, who stated that collaboration has considerably benefited from traditional information and communication technologies. We thus believe that I4.0 focuses on other underdeveloped elements. Enhancing an SCRM culture, including discussions whether I4.0 might even be a resilience reducer for this dimension (Ralston & Blackhurst, 2020), has also played a secondary role.

Moreover, we identified two separate research strings. In most cases, SC design and sourcing are discussed separately from other elements, as demonstrated in Appendix A. We believe that the traditionally separated fields of procurement and SCM research are the cause. We are convinced that combining both research streams and considering visibility, velocity, and collaboration aspects straight from I4.0-supported SC planning, including network design and supplier selection, can lead to sustainable improvements in these SCRES antecedents.

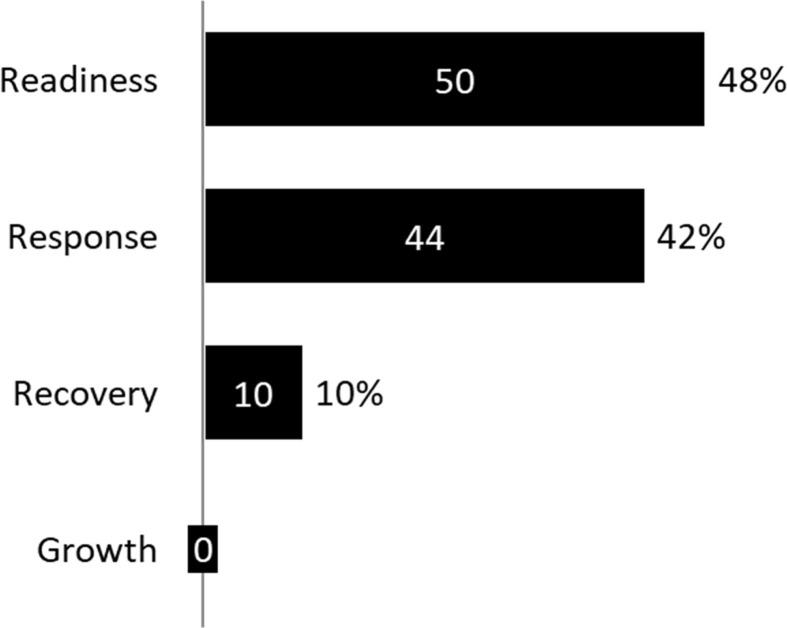

2.4.4. Supply chain resilience phases

Before presenting our I4.0 SCRES framework, this subsection discusses SCRES phases as a final perspective. We based this section on the work of Hohenstein et al. (2015), who introduced four distinct phases: readiness, response, recovery, and growth. Fig. 10 summarizes these phases in chronological order.

Fig. 10.

SCRES phases.

Readiness (1) describes all measures in the pre-disruption state suitable to reduce an SCD’s probability and absorb its negative impact. Response (2) includes countermeasures performed directly after an SCD is detected or experienced. Speed must be of foremost importance at this stage to avoid negative consequences for the SC. All actions during the recovery (3) phase target restoring the SC’s performance level. Finally, growth (4) measures focus on achieving superior SC performance compared to the pre-disruption state.

We calculated the absolute number and the relative share of SCRES phases referred to in our sample. In several publications, more than one was discussed, resulting in 104 SCRES phase references from 62 papers. The detailed results are depicted in Fig. 11 .

Fig. 11.

Absolute total and relative share of SCRES phase references.

Most papers focus on the readiness and response phases, which partially deviates from previous research. Hohenstein et al. (2015) analyzed various SCRES definitions; according to their results, most researchers failed to include aspects of readiness, while response was the most prominent phase. Baryannis et al. (2019), who reported that AI-based SCRM solutions predominantly focus on SCD response, confirmed this finding. However, previous research has revealed that “few studies focused on the potential for growth after being disturbed” (Hohenstein et al., 2015, p. 100). A long-term perspective has often been missed. This circumstance might prevent companies from achieving competitive advantage, which occurs primarily in later SCRES phases (Hohenstein et al., 2015). In this context, it is important to note that a high SCRES in pre- and early-disruption phases also favors a company’s performance in later phases (Reeves & Whitaker, 2020).

Overall, I4.0 SCRES solutions’ focus on the readiness phase was an unexpected finding. Previous research set different priorities since proactive SCRM was considered “rather uncertain yet time and cost intensive” (Grötsch et al., 2013, p. 2855). Nevertheless, our sample indicates that this perception might change with I4.0. The new solutions allow a “certain look-ahead” by generating “near-future data” (Dunke et al., 2018, p. 816), enabling more targeted proactive approaches. Along with utilizing I4.0 enabler technologies’ cost-efficiency (Birkel and Hartmann, 2020, Biswas and Sen, 2016), companies might increasingly leverage digital possibilities and shift their attention from reactive to proactive SCRES measures.

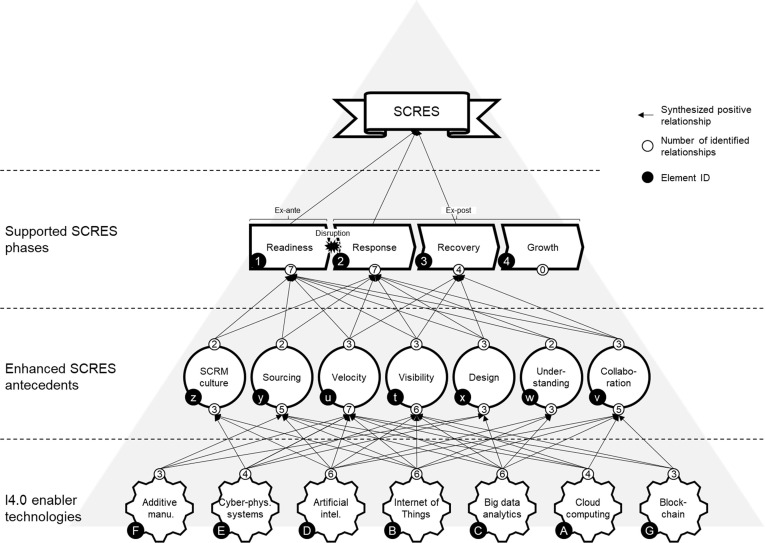

2.4.5. Industry 4.0 supply chain resilience framework

In this subsection, we meticulously analyze our sample, combining insights from previous sections and establishing relationships between I4.0 enabler technologies, SCRES antecedents, and benefited SCRES phases. We also introduce our pyramidal I4.0 SCRES framework (Fig. 12 ), which visualizes the discussed relationships and hierarchical order, with I4.0 enabler technologies as a critical foundation for enhanced SCRES. Furthermore, a detailed table in Appendix B reveals the number of references that describe the detected relationships.

Fig. 12.

I4.0 SCRES framework.

Velocity (u) is the only SCRES antecedent that all I4.0 enabler technologies support. Overall, I4.0 will allow performing work faster, leading to a substantial improvement in lead times (Ivanov et al., 2019, Ralston and Blackhurst, 2020). Regarding BDA (u.C), risks can be detected earlier and mitigation measures executed faster, for instance, when finding alternative transportation routes during infrastructure disruptions (Er Kara, Oktay Fırat, & Ghadge, 2020, Ramirez-Peña, Sánchez Sotano, Pérez-Fernandez, Abad, & Batista, 2020). As a specific example of BDA improving velocity, Chae (2015) leveraged Twitter as an event-monitoring tool; he described how to sense and quickly communicate SCDs to SC partners in real-time. The following is a similar example of AI (u.D): Handfield, Sun, and Rothenberg (2020) developed an ML algorithm to screen news feeds for risk data and rapidly create impact and probability visualizations at a country level. In this context, AI’s ability to replace labor-intensive and time-consuming operations with automatic information processing and interpreting capabilities is a clear enhancer for velocity (Li et al., 2020). BDA and AI applications can also be applied to predict SCDs and identify the optimal state for initiating countermeasures and recovery plans (Brintrup et al., 2020, Paul & Chowdhury, 2020, Singh and Singh, 2019). The required data for AI and BDA can be collected using IoT applications (u.B) and submitted through CC (u.A), allowing quicker, near real-time analyses and counteractions (Birkel and Hartmann, 2020, Biswas and Sen, 2016, Gao et al., 2020, Kaur & Prakash Singh, 2021, Li et al., 2020). The faster data access generally leads to better decisions and performance advantages (Oliveira & Handfield, 2019). The same applies to processes digitized through BC (u.G). Activities are accelerated when the need for interactions with intermediaries is reduced (Kshetri, 2018). AM (u.F) also enhances velocity. Lead times can be accelerated when production steps and supplier levels are reduced (Ivanov et al., 2019, Kaur & Prakash Singh, 2021). Moreover, AM allows more flexibility in choosing production locations, which is an additional velocity enhancer. Finally, CPSs (u.E) that radically affect SC and manufacturing processes enable more responsive and flexible production (Ivanov et al., 2019). Overall, we found references claiming that I4.0-enhanced velocity can improve the first three SCRES phases.

We deduced that all I4.0 enabler technologies except AM might improve visibility (t). The large-scale data gained from various IoT applications (t.B) and CPSs (t.E) significantly favor tracking and tracing the material flow and improving risk transparency in the SC (Birkel and Hartmann, 2020, Ivanov et al., 2019, Kaur & Prakash Singh, 2021, Queiroz, Pereira, Telles, & Machado, 2021). In this context, CC (t.A) helps make the data available to different entities (Oliveira and Handfield, 2019, Rajesh, 2016). Conversely, BDA (t.C) is discussed foremost in the context of digital SC twins. Raw data from different sources are processed and combined with simulation techniques to represent the real-world SC network at any moment in time (Dubey et al., 2021, Hosseini et al., 2019). Such an end-to-end visibility tool highly supports predictive and reactive decision-making (Ivanov and Dolgui, 2020a, Ralston and Blackhurst, 2020). From a marketing and sales perspective, BDA can improve market visibility through predictive analytic techniques, leading to more reliable demand and sales forecasts (Fu and Chien, 2019, Ivanov et al., 2019, Zhang, Wu, Tang, Feng, & Dai, 2020). AI (t.D) can expand such analytical methods. Partially automated evaluation approaches make gaining transparency even easier (Hosseini & Ivanov, 2020, Li et al., 2020). Moreover, BC (t.G) can be used to support supply- and demand-side visibility (Choi et al., 2019). Data stored in the open ledgers can help track the material flow, verify inventory levels, and understand entire order fulfillment processes (Kaur & Prakash Singh, 2021, Min, 2019, Paul & Chowdhury, 2020). In this context, BC can improve visibility creation through real-time data sharing between the integrated parties (Lohmer, Bugert, & Lasch, 2020). Visibility is hence one of the most critical antecedents that supports the first three SCRES phases.

Based on our sample, five I4.0 enabler technologies enhance collaboration (v). BC (v.G) supports building trustful relationships and sharing information through its decentralized, open, and cryptographic nature (Choi et al., 2020, Min, 2019). Trust in existing and newly initiated relationships can be strengthened using BC (Lohmer, Bugert, & Lasch, 2020). Furthermore, BC ensures automated information sharing, thus reducing the possibility of SC partners missing important communication (Li et al., 2020, Lohmer, Bugert, & Lasch, 2020). Certain mechanisms in BDA (v.C) and AI (v.D) applications allow condensing and communicating important findings on risks and SCDs to all relevant SC partners (Chae, 2015, Mandal, 2019, Papadopoulos et al., 2017). In this context, CC (v.A) can play an essential role in sharing and jointly processing the information (Subramanian & Abdulrahman, 2017). Overall, information sharing can be improved by adding detailed data gained from IoT devices (Li et al., 2020). Regarding the affected SCRES phases, we found proof that I4.0 enabled collaboration positively influences readiness, response, and recovery.

Five I4.0 enabler technologies can support sourcing (y) decisions. BDA (y.C) and AI (y.D) can be used for selecting new suppliers and monitoring the current supply base’s SCRES (Cavalcante et al., 2019, Kahiluoto et al., 2020, Sanders, 2016). Multi-criteria decision support applications that consider risk characteristics are increasingly being applied in supplier assessments (Kellner, Lienland, & Utz, 2019); the same is true for mathematical models and combined ML and simulation tools (Cavalcante et al., 2019, Linton and Vakil, 2020, Ocampo et al., 2018). Supplier selection and auditing can be facilitated with data obtained from SC partners’ IoT (y.B) appliances (Birkel & Hartmann, 2020). Nevertheless, more than a supplier’s characteristics is important. For instance, Hosseini et al. (2019) presented an approach for analyzing optimal geographical supplier segregation. Moreover, the ML algorithm that Handfield et al. (2020) introduced can support supplier selections with country-level risk scores. Overall, advances in BDA and AI can help buyers free up time for interpersonal relationship-building instead of performing administrative tasks (Ralston & Blackhurst, 2020). Furthermore, AM (y.F) presents a new option within sourcing, allowing insourcing certain production steps (e.g., injection molding) to avoid unreliable suppliers (Shih, 2020). CC (y.A) supports flexibility in procurement by enabling new opportunities, such as sourcing platforms and crowdsourcing (Zouari et al., 2020). As a side note, it is crucial that suppliers also introduce the I4.0 enabler technologies discussed in this paper to enhance SCRES antecedents (Kaur & Prakash Singh, 2021). This practice should be part of supplier assessments; otherwise, the entire SC’s digitization success can be undermined. Altogether, I4.0-supported sourcing can facilitate achieving SCRES in the readiness and response phases.

Three I4.0 enabler technologies assist with understanding (w) an SC’s key characteristics. AI (w.D) can map existing SC networks to help visualize and analyze them, which allows improving the knowledge on dependencies and potential bottlenecks. Wichmann et al. (2020) presented a solution based on deep learning and natural language processing to generate such maps automatically. Traditional modeling techniques (e.g., Bayesian networks and Petri nets) can also be combined with ML to develop and understand a model’s structure more efficiently (Blos et al., 2018, Hosseini & Ivanov, 2020). In addition, BDA (w.C) supported simulations allow understanding an SC network more numerically, for instance, by analyzing dynamics and testing alternative risk scenarios (Ramirez-Peña et al., 2020). This includes discovering triggering factors, quantifying risks, and evaluating consequences (Er Kara, Oktay Fırat, & Ghadge, 2020, Vieira et al., 2019b). As a third technology, IoT (w.B) data can further enhance the models’ level of detail (Dunke et al., 2018). Generated insights can be used to create business continuity plans or adapt the overall SC design (Dubey et al., 2021), as described in the following paragraph. In our sample, we found evidence that I4.0-enabled SC understanding boosts the first two SCRES phases.

Three I4.0 enabler technologies support SC design (x) principles. BDA (x.C) based simulation and optimization tools enable testing alternative network setups and possible redundancy elements, including supplier quantity, geographical locations, SC inventory levels, and production and transportation capacities (Hosseini et al., 2019, Ivanov, 2017, Ralston and Blackhurst, 2020, Sanders, 2016). In addition, BDA can be applied to existing SC networks to identify, assess, and optimize SCRES attributes (Wu et al., 2017). AM (x.F) enables more flexible SC design planning. Supplier levels, production steps, and locations can be adjusted depending on SCRES favorability (Ivanov et al., 2019, Ivanov and Dolgui, 2019, Shih, 2020). Furthermore, AM solutions can be used as production backup capacities during SCDs (Paul & Chowdhury, 2020). Finally, CPS (x.E) technologization can help achieve the right quantity of inventory and suppliers (Chen, Dui, & Zhang, 2020). Overall, we found that I4.0 supports SC design during the first three SCRES phases.

Three I4.0 enabler technologies help companies improve their SCRM culture (z). Overall, automatizing tasks frees up time for employees to critically scrutinize and improve SCRM maturity levels (Ralston & Blackhurst, 2020). Besides, this allows for more personal interaction with other SC members inside and outside the firm to develop joint solutions. On the one hand, management functions will significantly benefit from AI’s (z.D) information processing and decision-making capabilities. Although the present technological status does not allow automated decision-making for most SCRM problems (Baryannis et al., 2019), AI systems will be the decision-makers in simple situations in the near future. This advancement should enable executives to focus on challenges that require problem-solving and creative thinking skills (Ralston & Blackhurst, 2020). Until then, managers can combine AI insights with their own experience to arrive at optimal SCRM decisions (Baryannis et al., 2019). Advancements in AI should also allow data scientists and programmers to perform SCRM-related analyses better (Queiroz, Pereira, Telles, & Machado, 2021). On the other hand, blue-collar workers are increasingly being relieved of monotonous or even dangerous tasks due to incorporating CPSs (z.E) (Ralston and Blackhurst, 2020, Ramirez-Peña, Sánchez Sotano, Pérez-Fernandez, Abad, & Batista, 2020, Shih, 2020). They can therefore direct their efforts toward developing operational optimization measures that reduce risks. Finally, IoT (z.B) generated data enhances a company’s SCRM knowledge, allowing improvements in overall risk process management (Birkel & Hartmann, 2020). Based on our sample, I4.0-enabled SCRM culture is especially suitable for supporting SCRES in the readiness and response phases.

3. Industry 4.0 and supply chain resilience during the COVID-19 pandemic

Consistent with our SLR approach’s final step, we discuss our I4.0 SCRES framework in a COVID-19 context to prove its practical relevance. This event is a suitable reference frame since scholars consider it one of the most severe SCDs ever (Gölgeci et al., 2020, Pournader et al., 2020). The reason for this assessment is the characteristics of a pandemic compared to those of other SCDs. The individual risk types observed during COVID-19, including supply, operational, and demand risks (Govindan, Mina, & Alavi, 2020, Ivanov, 2020), have been comprehensively discussed in previous research (Christopher and Peck, 2004, Manuj and Mentzer, 2008). However, the risks’ dimensions and simultaneous occurrence during the pandemic have been unique (Ivanov and Dolgui, 2020b, Xu et al., 2020). Craighead and Ketchen, (2020) determined three characteristics (scope, spillover, and shifts) to classify a pandemic. According to them, the COVID-19 pandemic has affected multiple industries (scope), continuously disrupted different geographies and sectors (spillover), and led to high volume and assortment volatility in supply and demand (shifts). Ivanov, 2020, Xu et al., 2020 argued similarly, highlighting the pandemic’s severe and simultaneous impact on multiple SC tiers and geographies, as well as its unprecedented long duration. Pournader et al. (2020) described this prolonged disruption period as a “crisis-as-a-process” rather than a “crisis-as-an-event.”

Although the COVID-19 pandemic’s characteristics differ from those of previous SCDs, scholars agree that established SCRES antecedents have helped companies overcome these challenges. For instance, van Hoek, 2020, Xu et al., 2020 claimed that agility and collaboration have been crucial antecedents to support SCRES during this crisis. In this context, I4.0 technologies have been a valuable enabler (Chamola et al., 2020, Queiroz, Ivanov, Dolgui, & Fosso Wamba, 2020); their advantageous speed and scalability compared to the human workforce have helped firms cope with the previously unknown disruption dimensions during the COVID-19 pandemic (Belhadi et al., 2021, Ivanov and Dolgui, 2020a).

To understand I4.0’s and SCRES antecedents’ role during the COVID-19 pandemic better, we applied our I4.0 SCRES framework to a use case in the automotive industry, specifically to an original equipment manufacturer (OEM). We chose this sector since SCs in the automotive industry are traditionally vulnerable when it comes to SCDs. Automotive supply networks are extremely globalized and thus complex; they also possess high levels of outsourcing, mass customization, and just-in-time and just-in-sequence delivery (Boysen et al., 2015, Sturgeon et al., 2008).

OEMs have faced tremendous challenges through the COVID-19 pandemic. At the beginning of the crisis, several of their plants were shut down for infection prevention reasons (Ivanov & Dolgui, 2020b). In this context, manufacturers were obliged to implement protective measures, including personal protective equipment and social distancing, at their plants. Even if OEMs managed to keep their sites open, suppliers’ worldwide plant closures still affected them (Belhadi et al., 2021, Xu et al., 2020), resulting in a ripple effect that disturbed entire SCs (Ishida, 2020). Border closures in many countries and limited air freight capacities further complicated OEMs’ untransparent supply situation. Furthermore, the general economic conditions deteriorated worldwide, and demand for mobility decreased considerably, leading to sharp drops in sales (Chamola et al., 2020, Craighead and Ketchen, 2020). In the following post-lockdown period, the automotive industry was considered an economic booster with increasing demand (Singh, Kumar, Panchal, & Tiwari, 2021, van Hoek, 2020). These unexpected developments in demand favored a bullwhip effect in automotive SCs. Overall, the automotive sector is a prime example of a pandemic’s simultaneous effect on supply and demand (Ivanov, 2020).

For numerous risks the automotive sector has faced during the COVID-19 pandemic, I4.0 enabler technologies offer mitigation opportunities. In the following paragraphs, we first discuss theoretical options for overcoming OEMs’ SC challenges with I4.0 enabler technologies during the COVID-19 pandemic. Second, we present first evidence from recent research projects on the technologies’ effectiveness during the pandemic.

Visibility plays a vital role during a virus outbreak (Dasaklis, Pappis, & Rachaniotis, 2012). Especially geographically remote facilities can benefit from AI (1.t.D) and BDA (1.t.C) based early warning systems using external data to evaluate the situation at the source of infection and derive proactive measures. Visibility is also a primary antecedent used to respond to supply shortages appropriately. OEMs can leverage BC’s (2.t.G), the IoT’s (2.t.B), and CC’s (2.t.A) full potentials to track the end-to-end flow of materials, parts, and components in the SC. More visibility on safety stocks, production capacities, or ship and truck locations can enable better decision-making and countermeasures. Moreover, AI (2.w.D) and BDA (2.w.C) can be leveraged to understand an OEM’s end-to-end SC network better to improve supply conditions further. Most OEMs do not possess a comprehensive map of their entire SC, leading to a lack of information on potentially affected low-tier suppliers. The first-tier supplier is often the one that informs the OEM of disruptions, resulting in communication delays. In these cases, BC (2.v.G) and CC (2.w.D) can support information dispersion and collaboration. These I4.0 enabler technologies also operate mostly autonomously, which is a clear advantage during a pandemic when human employee capacity might be restricted. Furthermore, AI (2.w.D) and BDA (2.w.C) can be used to rapidly detect other bottlenecks in the SC. As an example, border closures – a common reaction during a pandemic (Dasaklis et al., 2012) – can quickly be detected and corrective actions taken (e.g., by re-routing transports). All these features and information can enable creating a digital SC twin (Ivanov & Dolgui, 2020a), allowing comprehensive and real-time visibility and understanding of an OEM’s SC during a virus outbreak. Further implementing AI (2.w.D) solutions that enable simulations, also allow using the digital SC twin to assess different scenarios, which is an essential feature since occurrences of infections during a pandemic can be very dynamic, requiring regular reevaluations of SC measures.

Moreover, geographical diversification has proven to be critical during a pandemic. To consider this factor in supplier selection, AI (1.y.D) based tools can calculate optimal supplier locations based on specific country risk scores. For certain parts, the probability of supply shortages can also be reduced by proactively implementing AM (1.y.F) solutions directly at the OEM’s production site.

Again, not only supply reliability but also manufacturing continuity and demand forecasting have been challenged during the COVID-19 pandemic. A higher share of automated CPSs in the manufacturing plants and warehouses can enable quicker implementation of infection prevention protocols and potentially prevent site shutdowns (1.u.E). Finally, demand fluctuations can be sensed earlier by analyzing internal and external data using AI (2.t.D), which can help create more reliable forecasts, limit the bullwhip effect, and build trust among SC partners.

Research recently started to empirically prove I4.0 technologies’ effectiveness for increasing SCRES during the COVID-19 pandemic. Belhadi et al. (2021) reported that the automotive sector considers BC, BDA, and the IoT critical enablers to overcome COVID-19-related SC challenges. Industry experts assess leveraging these I4.0 technologies as even more important than applying classical SCRES measures such as safety stocks or continuity plans. For instance, Nandi, Sarkis, Hervani, and Helms (2020) described how an OEM partnered with a service provider to implement BC (2.t.G) material tracking in its complex SC. With this initiative, the company improved its SC visibility. Moreover, automotive firms have successfully used BDA (2.t.C) to determine the right manufacturing capacity and safety stock levels during the crisis (Belhadi et al., 2021). OEMs have also applied BDA (2.y.C) during the pandemic to effectively search for and select reliable suppliers. To overcome market uncertainty, Nikolopoulos, Punia, Schäfers, Tsinopoulos, and Vasilakis (2020) presented a predictive analytics tool (2.t.D) to forecast car demand based on actual infection numbers. It has resolved uncertainty during the COVID-19 pandemic by supporting OEMs’ decision-making in procurement, inventory management, and production planning. Considering these positive experiences during the COVID-19 pandemic, scholars expect that the automotive sector will accelerate I4.0 enabler technology implementation for enhanced SCRES (Belhadi et al., 2021). In this context, particularly upstream suppliers still have a considerable backlog in implementing technology for increasing SCRES (Nandi, Sarkis, Hervani, & Helms, 2020).

The OEM use case underlines I4.0’s extraordinary relevance in the context of SCRES and the enabler technologies’ potentials to mitigate the negative consequences of a pandemic. Since the risks observed during the COVID-19 pandemic can also materialize during other SCDs, we claim that I4.0 enabler technologies should be able to support SCRES in those situations.

4. Conclusion and managerial implications

Following an SLR method, we introduced a complete and mutually exclusive categorization of I4.0 enabler technologies that support SCRES. We can thus answer RQ1: while all technologies discussed have the potential to support SCRES, BDA is the most topical and mature one. Furthermore, we closed an important research gap by analyzing the relationship between enabler technologies and SCRES antecedents. We found clear evidence that I4.0 will become a critical foundation for enhancing SCRES antecedents and present a sophisticated I4.0 SCRES framework. This central finding is consistent with previous contributions stating that an “SC will be as good as the digital technology behind it” (Ivanov et al., 2019, p. 838). Based on our framework, we can also answer RQ2: various I4.0 enabler technologies have the potential to enhance especially visibility and velocity on a broad scale. SC design, SC understanding, sourcing, and an SCRM culture can also be supported, although the number of suitable enabler technologies is more restricted. Regarding RQ3, we discovered that current research at the intersections of I4.0 and SCRES focuses on solutions that support the first two SCRES phases, whereas solutions concerning recovery and growth remain scarce. To answer RQ4, we presented a use case for an automotive OEM and demonstrated I4.0 enabler technologies’ high potentials to mitigate risks from a pandemic.

Our I4.0 SCRES framework leads to some crucial managerial implications. Executives in SCM and related areas are increasingly facing SCDs and seeking new ways to mitigate their effects. These practitioners can leverage our framework to choose appropriate I4.0 enabler technologies when noticing weaknesses in specific SCRES antecedents. Furthermore, SC partners can use this framework during negotiations and as a basis for collaboration. Buyers receive guidance on I4.0’s importance for suppliers’ SCRES and can base their selection decisions, as well as auditing and development efforts, on our findings. In addition, marketing managers and vendors can position themselves as reliable partners when proactively implementing certain technologies. We also identified synergies between different technologies that can help managers build multi-technology SCRES support systems. Finally, we confirmed the importance of employee capabilities in digitization, problem-solving, and creative thinking to leverage I4.0’s full potential, which provides farsighted managers a sound argumentation basis for investing in I4.0 training measures.

5. Limitations and directions for future research

In this final section, we discuss the paper’s limitations and areas for future research. First, SLR results depend on the inclusion criteria applied and databases leveraged. Although we believe that we detected all relevant contributions, it is still possible that some studies may have been missed. However, we are convinced that additional papers would not undermine this study’s clear results.

Second, we identified relationships between I4.0 enabler technologies, SCRES enablers, and SCRES phases from previous literature and derived a framework. Since research at the intersections of I4.0 and SCRES remains mostly conceptional, the relationships have only partially been empirically proven in the current sample. Due to SLRs’ nature, we did not test the relationships’ strengths in this study. Nevertheless, the current framework allows incorporating a performance quantification. We therefore call for empirical validation and believe that the COVID-19 pandemic is an adequate frame for respective evaluations. Research progress will help scholars and managers prioritize and safely choose certain technologies to achieve specific SCRES targets under scarce resources.

Third, the current findings confirm that most I4.0 enabler technologies remain underrepresented in SCRES research. For this reason, we suggest more theoretical and practical application examples for AI, AM, BC, CC, the IoT, and CPSs to unleash I4.0’s full potential. We especially recommend contributions that combine several technologies to achieve synergies by leveraging every technology’s advantages. Research in this direction can also help further develop our framework, which is far from conclusive.

Fourth, we identified a clear lack of long-term orientation when analyzing the intersections of I4.0 and SCRES. This may negatively impact the possibility of achieving competitive advantages after an SCD (Hohenstein et al., 2015). Therefore, we encourage research on I4.0 that specifically supports SCRES in the recovery and growth phases.

Fifth, we focused on SCRES antecedents that act as enhancers. Nevertheless, scholars report that SCRES antecedents can also act as reducers (Blackhurst et al., 2011, Ralston and Blackhurst, 2020). Hence, we recommend research on the relationship between I4.0 and such resilience reducers. In a best-case scenario, I4.0 might help companies overcome them. In a worst-case scenario, I4.0 might exacerbate them and harm SCRES. In this way, not only strengths but also challenges and weaknesses of I4.0 enabler technologies can be analyzed in an SCRES context.

CRediT authorship contribution statement

Alexander Spieske: Conceptualization, Data curation, Investigation, Methodology, Validation, Visualization, Project administration, Writing - original draft. Hendrik Birkel: Conceptualization, Data curation, Investigation, Methodology, Supervision, Validation, Writing - original draft.

Footnotes

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Appendix A. . Identified papers from the SLR selection process

| Industry 4.0 enabler technology | Description | Reference | Discussed SCRES antecedents | Referred SCRES phases | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Visibility | Velocity | Collaboration | SC understanding | SC design | Sourcing | SCRM culture | Readiness | Response | Recovery | Growth | |||

| Cloud computing | Comparison of cloud-based vs. non-cloud automotive SME’s organizational resilience in an uncertain business environment | Arsovski et al. (2017) | x | x | x | ||||||||

| Analysis of the interplay of CC and logistics service providers based on innovation diffusion theory within an SC risk assessment framework | Subramanian and Abdulrahman (2017) | x | x | ||||||||||

| Internet of Things | Assessment of IoT’s effect on SCRM processes, pathways and outcomes based on a multiple case study methodology | Birkel and Hartmann (2020) | x | x | x | x | x | x | |||||

| Discussion of IoT’s impact on internal and external risks under consideration of specific technologies, e.g., 3G, RFID, GPS | Gao et al. (2020) | x | x | x | x | ||||||||

| Big data analytics | Analysis of the barriers successful BDA implementation faces in humanitarian supply chains | Bag et al. (2020) | x | x | x | x | |||||||

| Presentation of a framework to apply Petri Net and Agent Based Model techniques to global SC disruptions | Blos et al. (2018) | x | x | x | |||||||||

| Introduction of an analytical framework (Twitter Analytics) for analyzing tweets with the ambition to generate insights on SCDs and reporting them to SC partners | Chae (2015) | x | x | x | x | ||||||||

| Application of variance-based structural equation modelling to analyze the relationship between data analytics and SCRES | Dubey et al. (2021) | x | x | x | x | x | |||||||

| Presentation of a data-driven, disruption sensitive demand forecast framework | Fu and Chien (2019) | x | x | ||||||||||

| Introduction of an SCM multi-agent-based system with dedicated big data and risk management agents to improve SC agility | Giannakis and Louis (2016) | x | x | x | |||||||||

| Review of literature on quantitative methods, e.g., mathematical models and optimization, for SCRES analysis | Hosseini et al. (2019) | x | x | x | x | x | x | x | |||||

| Development of an SC simulation model for single and dual sourcing under consideration of capacity disruption and big data | Ivanov (2017) | x | x | x | |||||||||

| Discussion of digital SC twins simulating real-world SCs based on the combination of data analytics and model-based decision-support | Ivanov & Dolgui (2020a) | x | x | x | x | x | |||||||

| Assessment of supplier response diversity in case of SC disruptions and the impact on SCRES | Kahiluoto et al. (2020) | x | x | x | |||||||||

| Development of a multi-criteria decision support approach for supplier selection problems under consideration of SC risk | Kellner et al. (2019) | x | x | ||||||||||

| Analysis unveiling the positive influence of BDA planning, BDA coordination and BDA control on SCRES | Mandal (2019) | x | x | x | x | x | |||||||

| Presentation of a SLR on evidence-based, BDA-related papers in SCM | Meriton et al. (2020) | x | x | x | x | x | x | ||||||

| Review of literature on supplier selection including data analytics and mathematical programming approaches to assess individual risk characteristics | Ocampo et al. (2018) | x | x | ||||||||||

| Application of BDA to identify antecedents and propose and test frameworks in the context of SCRES | Papadopoulos et al. (2017) | x | x | x | |||||||||

| Discussion of BDA application in SC inventory management and supplier assessments to mitigate risks in the SC | Sanders (2016) | x | x | x | |||||||||

| Creation of a rule-based resilience support system for collaborative decision-making on the optimal state for initiating production and logistics recovery activities in the network | Singh et al. (2019) | x | x | x | |||||||||

| Analysis on the role of BDA in building SCRES with a special focus on the relationship with organizations’ IT and managerial capabilities | Singh and Singh (2019) | x | x | ||||||||||

| Presentation of a hybrid simulation model using big data and statistical distribution allowing risk scenarios to be analyzed | Vieira et al. (2019a) | x | x | x | |||||||||

| Presentation of a decision-support-system empowered by a big data warehouse and a simulation model, allowing the analysis of risk scenarios | Vieira et al. (2019b) | x | x | x | x | ||||||||

| Identification of key SCRES antecedents through BDA for improved SC design, resource allocation and risk mitigation | Wu et al. (2017) | x | x | ||||||||||

| Artificial intelligence | Presentation of a data-driven ML approach facilitating resilient supplier selection | Cavalcante et al. (2019) | x | x | x | x | |||||||

| Development of a machine-based learning algorithm to convert data from multiple news feeds into risk impact and probability indicators resulting in a visualization of country-level supply base risks | Handfield et al. (2020) | x | x | x | x | ||||||||

| Review of literature on the application of Bayesian networks for supply chain risk, resilience and ripple effect analysis including further development options using ML techniques | Hosseini and Ivanov (2020) | x | x | x | |||||||||

| Recommendation and examples for AI and Natural Language Processing use in supplier monitoring and SC mapping | Linton and Vakil (2020) | x | x | x | |||||||||

| Description of a Natural Language Processing and Deep Learning solution to automatically extract buyer–supplier relationships from newsfeeds and generate supply maps | Wichmann et al. (2020) | x | x | x | |||||||||

| Blockchain | Contribution on how BC can be applied to facilitate the implementation of mean–variance risk analysis for global supply chain operations | Choi et al. (2019) | x | x | x | ||||||||

| Examination of BC application areas in multiple party disaster relief SC operations | Dubey et al. (2020) | x | x | x | |||||||||

| Analysis of resilience strategies in BC-supported SCs through agent-based simulation | Lohmer et al. (2020) | x | x | x | x | x | x | ||||||

| Description of asset and order fulfillment tracking possibilities to mitigate risks associated with intermediaries’ interventions and improve SCRES | Min (2019) | x | x | x | x | ||||||||

| Discussion of BC resources at 24 companies and their role in improving agility and digitalization capabilities | Nandi et al. (2020) | x | x | x | x | x | x | ||||||

| Various technologies | Review of AI and BDA literature in SCRM with a focus on identifying related approaches and application possibilities in the SCRM process | Baryannis et al. (2019) | x | x | x | x | |||||||

| Analysis of SCRES measures in the automotive and airline industries during the COVID-19 pandemic | Belhadi et al. (2021) | x | x | x | x | x | |||||||

| Elaboration of a big data driven SC analytics architecture supported by CC with the goal of mitigating business risks, among others | Biswas and Sen (2016) | x | x | x | |||||||||

| Discussion on the application of BDA and ML in predicting first tier SCDs using historical data | Brintrup et al. (2020) | x | x | x | x | ||||||||

| Development of an analytical-based resilience model for CPSs to facilitate resource allocation decisions between agility, design and sourcing measures in case of SCDs | Chen et al. (2020) | x | x | x | x | x | |||||||

| Presentation of BDA and ML application areas in operations management including potential data sources, commonly used techniques and implications for SCRM | Choi et al. (2018) | x | x | ||||||||||

| Discussion of a new SC typology (“the X-network”) with resilience and digitalization characteristics | Dolgui et al. (2020) | x | x | x | x | x | |||||||

| Application of BDA and IoT approaches in SC planning under causal and temporal uncertainty | Dunke et al. (2018) | x | x | ||||||||||

| Description of possibilities to use BDA in long linked supply chains for risk mitigation under consideration of IoT data provisions | Engelseth and Wang (2018) | x | x | x | x | ||||||||

| Introduction of Data Mining frameworks in an SCRM context including the use of simulation techniques and IoT data | Er Kara et al, (2020) | x | x | x | x | x | |||||||

| Introduction of the I4.0 supported low-certainty-need SC concept ensuring efficient disruption resistance and recovery resource allocation | Ivanov and Dolgui (2019) | x | x | x | x | ||||||||

| Development of a conceptual framework for researching the relationships between SCD risks and digitalization, including AM, BC, BDA, CPSs and IoT | Ivanov et al. (2019) | x | x | x | x | x | |||||||

| Development of a multi-stage hybrid model for supplier selection and order allocation considering disruption risks and several I4.0 technologies | Kaur and Prakash Singh (2021) | x | x | x | x | x | |||||||

| Illustration of BC mechanisms to achieve main SC objectives (including risk reduction) under consideration of IoT | Kshetri (2018) | x | x | x | x | ||||||||

| Introduction of an enterprise capability evaluation model and sharing system using BC, IoT and AI to achieve risk reduction through real-time data collection and automated assessment mechanisms | Li et al. (2020) | x | x | x | x | x | |||||||

| Presentation and application of predictive analytics tools for forecasting demand shifts in various industries based on actual COVID-19 infection cases | Nikolopoulos et al. (2020) | x | x | x | |||||||||

| Investigation on the relationship of real-time data processing, data analytics and managerial capabilities under consideration of supporting technologies, e.g., CC | Oliveira and Handfield (2019) | x | x | ||||||||||

| Presentation of an architectural framework for a cyber-physical logistics system including technical functionalities for a digital SC twin simulation engine | Park, Son, & Noh, 2020 | x | x | ||||||||||

| Presentation of a mathematical production recovery model supported by BC and AM capacities to ensure the provision of essential and high-demand products following SCDs | Paul and Chowdhury (2020) | x | x | x | x | x | |||||||

| Discussion on various digital supply chain capabilities and enabler technologies at the intersection of I4.0 and human resource management to improve SC performance | Queiroz et al. (2021) | x | x | x | x | ||||||||

| Presentation of a CC and IoT supported grey prediction model forecasting key indicators for SCRES performance allowing firms to proactively rearrange SCRM strategies and resources | Rajesh (2016) | x | x | ||||||||||

| Analysis whether I4.0 is a driver of capability enhancement or capability loss including AI, BDA, CPSs and IoT | Ralston and Blackhurst (2020) | x | x | x | x | x | x | x | |||||

| Discussion of several I4.0 enabler technologies to support SCRES in a shipbuilding SC | Ramirez-Peña et al. (2020) | x | x | x | x | x | x | ||||||

| Application of a multi-stage algorithm to assess and improve data quality in supplier selection for risk prevention | Shabani-Naeeni and Ghasemy Yaghin (2021) | x | x | x | |||||||||

| Discussion of SCRES advantages from AM and CPSs | Shih (2020) | x | x | x | |||||||||