Abstract

This review collects a wide range of initiatives and results that expose the potential of the refineries to be converted into waste refineries. Thus, they will use their current units for the valorization of consumer society wastes (waste plastics and end-of-life tires in particular) that are manufactured with petroleum derivatives. The capacity, technological development, and versatility of fluid catalytic cracking (FCC) and hydroprocessing units make them appropriate for achieving this goal. Polyolefinic plastics (polyethylene and polypropylene), the waxes obtained in their fast pyrolysis, and the tire pyrolysis oils can be cofed together with the current streams of the industrial units. Conventional refineries have the opportunity of operating as waste refineries cofeeding these alternative feeds and tailoring the properties of the fuels and raw materials produced to be adapted to commercial requirements within the oil economy frame. This strategy will contribute in a centralized and rational way to the recycling of the consumer society wastes on a large scale. Furthermore, the use of already existing and, especially, depreciated units for the production of fuels and raw materials (such as light olefins and aromatics) promotes the economy of the recycling process.

1. Introduction

Growing population is the root cause of the progressive damage to the environment. The production of waste in the consumer society is directly related to the development and improvement of the standard of living. However, it has also caused one of the greatest environmental issues that paradoxically is a threat to human development. Furthermore, the following factors tend to aggravate the current environmental situation:1 (i) replacement of traditional materials by plastic materials (packaging, building and construction, furniture, utensils, etc.); (ii) increase and concentration of population (7.7 billion in 2020 and a forecast of 9.7 billion in 2050 with a migration rate from the countryside to the cities that has increased from 30% in 1950 to 55% in 2019); (iii) global access to consumer society increasing the use of plastics, together with the acquisition, replacement, and disposal of tires. Different environmental reports that have a great impact on public opinion, such as those that analyze CO2 emissions, global warming, or the presence of microplastics in the oceans, together with the shocking events caused by the COVID-19 pandemic, have brought the conviction that human health care and wellness requires the conservation of the environment. Within this scenario, new agreements and laws are adopted to reduce waste generation and to manage waste, establishing political interventions to strengthen the culture of environmental protection and recycling. Hence, the adoption of 5R principles (reduce, reprocess, reuse, recycle, and recover) and the use of renewable resources has been consolidated in the daily life of the citizens and regulates the actuation of every industrial activity according to the Circular Economy.

The mechanical recycling of tires and plastics and the incorporation of mechanically recycled materials alongside virgin resins into production processes have severe limitations. Thus, the repolymerization process is affected by the lack of stability of the materials leading to a reduction in the quality of the products obtained. Moreover, these solutions cannot be applied on a large scale.2 The valorization routes of highest viability for these wastes are the thermochemical processes. Among them, pyrolysis, either thermal or catalytic, is the one with the highest expectations for the production of fuels and chemicals because of the notable technological development it has undergone.3 Nevertheless, the establishment of new industries for the production of fuels and raw materials from waste plastic and discarded tires has to face technological and economic difficulties, apart from those involving the production of high-quality products suitable to be added to the well-established oil market.

The recycling of end-of-life (EOL) consumer goods, such as the plastics and tires produced from petroleum-derivative chemicals, can be faced by the oil industry. This review gathers different research initiatives that propose the valorization of these wastes in two conventional refinery units, fluid catalytic cracking and hydroprocessing units. Focus has been specifically placed on the valorization of plastics (polyolefins) dissolved in current refinery streams and on the valorization of the liquid products obtained in the fast pyrolysis of polyolefins (plastic pyrolysis oil, PPO) and of EOL tires (tire pyrolysis oil, TPO). The results are evidence of the potential capacity of refinery units (waste refinery) for the large-scale recycling of waste plastics and EOL tires and contribute to solving the severe environmental issues derived from their mismanagement.

Tables 1 and 2 summarize the main items of some of the numerous reviews that can be found in the literature about the different thermochemical routes available for the valorization of waste plastics and EOL tires, respectively. These reviews have mainly focused on the fast pyrolysis of the wastes, and their principal scopes have been the different reactor types, operating conditions, and types of catalysts used, together with their effects on the yields and composition of the obtained products. The product that has attracted most attention in the literature has been the liquid one (PPO and TPO) because of its possible use as a fuel. It is worth noting that the main topics studied in these reviews about the pyrolysis of waste plastics and EOL tires are complementary to those of this review, the originality of which lies on the possible integration of the fast pyrolysis units with conventional refinery units.

Table 1. Reviews about the Thermochemical Routes for the Valorization of Waste Plastics.

| reference | main items |

|---|---|

| Thermal and Catalytic Pyrolysis | |

| Wong et al.4 | different technologies for the production of fuels |

| fuels of single type plastics, mixed and municipal waste plastics | |

| Anuar Sharuddin et al.5 | different technologies and operating conditions |

| composition and properties of the gas the liquids products to be used as fuels | |

| Al-Salem et al.6 | reaction technologies |

| role of the catalyst in the pyrolysis | |

| Lopez et al.3 | technologies and operating conditions for the production of fuels and raw materials from different plastics |

| pros and cons of each technology | |

| Kasar et al.7 | reaction technologies |

| effects of the operating conditions on obtained products | |

| co-pyrolysis of plastics with oil-derived residues | |

| Qureshi et al.8 | opportunities and challenges for the commercialization of the liquid product as a fuel |

| Solis and Silveira9 | pros and cons of the thermochemical routes |

| degree of establishment of different commercial technologies and pilot plants | |

| Catalytic Pyrolysis | |

| Serrano et al.10 | effects of the porous structure and acidity of the catalyst on the product distribution obtained in the cracking of polyolefins |

| Miandad et al.11 | advantages of catalytic pyrolysis |

| catalysts for the pyrolysis of different plastics | |

| effects of the catalyst on the product composition and distribution | |

| Li et al.12 | different catalysts in the pyrolysis of municipal solid wastes (mixtures of plastics, paper, textiles, organic wastes, and others) |

| Mark et al.13 | analysis of the performance of different catalysts for the cracking of plastics |

Table 2. Reviews about the Thermochemical Routes for the Valorization of EOL Tires.

| reference | main items |

|---|---|

| Thermochemical Routes | |

| Rowhani and Rainey14 | management technologies and conditions |

| pyrolysis technologies | |

| effects of the reactor type, operating conditions, and catalyst type on the product distribution | |

| Thermal Pyrolysis | |

| Antoniou et al.15 | policy and legislative issues in the EU |

| reactor configurations (bench, pilot, and industrial scales) | |

| composition of obtained products | |

| economical, energetic, and environmental analysis | |

| Martínez et al.16 | investigations and patents |

| advantages of pyrolysis | |

| effects of the reactor type and operating conditions on the product composition and distribution | |

| Williams17 | reactors and commercial and semicommercial plants |

| effects of the operating conditions on the composition of the liquid product | |

| properties as a fuel of the liquid product | |

| composition of the gas and solid products | |

| Sathiskumar and Karthikeyan18 | valorization routes of the liquid product: as a fuel or as a source of BTX and limonene |

| valorization of the gas and solid products (pyro-gas and pyro-char) | |

| Czajczyńska et al.19 | effects of the operating conditions on the composition of obtained products |

| environmental impact of the composition (nitrogen, sulfur, and metals) | |

| Uses of the Liquid Product | |

| Januszewicz et al.20 | analysis of different reactor types and of the operating conditions for maximizing the yield of limonene |

| Zhang et al.21 | analysis of the composition and properties of the liquid product |

| separation of the limonene | |

| possible use of the liquid product as a fuel | |

| synthesis of carbon material and bitumen | |

| Uses of the Solid Product | |

| Xu et al.22 | rubber manufacture, as activated carbon and as biochar for soil improvement |

| Okoye et al.23 | carbon black production mechanisms |

| perspectives of using pyrolysis liquid product for carbon black manufacturing | |

| Catalytic Pyrolysis | |

| Arabiourrutia et al.24 | different pyrolysis technologies |

| reaction mechanisms | |

| effects of the reactor type, operating conditions, and properties of the catalyst on the product distribution and composition | |

2. Petroleum Derivative Wastes in the Consumer Society

Among the different types of wastes that can be found in the municipal solid waste (MSW), the ones that attract greatest attention are waste plastics and EOL tires, as hydrocarbons and chemicals produced in refineries are used in their manufacturing. Consequently, their recycling is potentially feasible in a refinery.

2.1. Waste Plastics

2.1.1. Generation

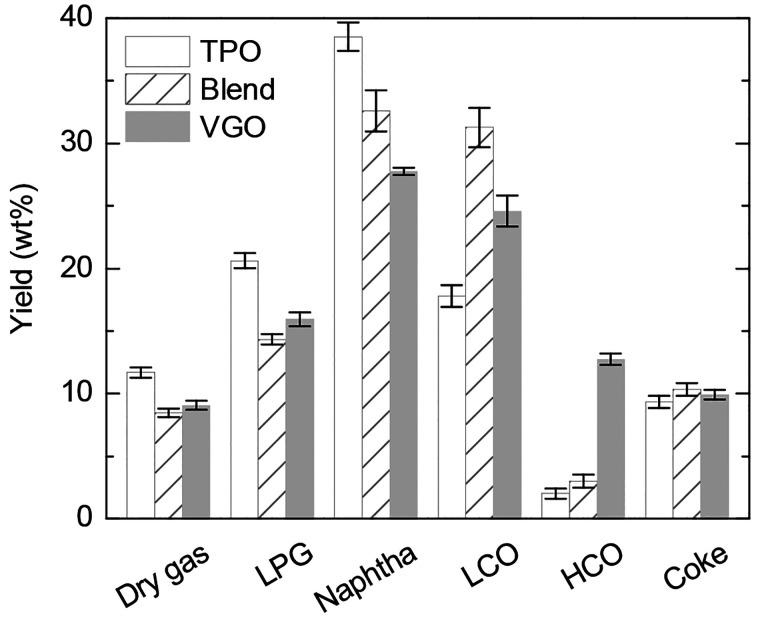

Given the non-biodegradability of plastics and tires and their contribution to the total amount of wastes disposed in landfills, their increasing generation is becoming a serious problem. The production of plastics has increased steadily since their first appearance in the market in the 1930s reaching 359 million tons produced worldwide in 2018 (348 million tons in 2017). Asia is the region that produced the largest amount of plastics, 51% of the total amount (30% China, 4% Japan), whereas North America and the EU produced 18% and 17%, respectively.25 This historical development is explained by their low manufacturing costs and excellent properties for multiple applications in different areas. Postconsumer waste plastics stem from five big sectors: agriculture, automotive, building and construction, distribution, and packaging. A more detailed study shows that agriculture, automotive, building and construction, and distribution sectors account for the generation of 40% of the plastic wastes, whereas the remaining 60% derives from the packaging sector. This last group is the main plastic fraction found within MSW. The average MSW composition in EU is detailed in Figure 1, where it can be seen that plastics only account for 7 wt % of the trash. Polyolefins (PP, HDPE, LDPE, and LLDPE) are the main plastic types (>60 wt %) and PVC, PS, and PET also appear in considerable concentrations.26 However, because of their low density, the volume contribution of the plastics to the MSW increases to 20 vol %. Accordingly, on the basis of 1.35 kg of municipal waste generated per person and day, around 19 million tons of the 270 million tons of MSW collected in the EU in 2019 are plastics.25 Moreover, a fact to be highlighted is the huge increase in the use of health care materials, personal protective equipment, and single-use plastics in 2020 due to the COVID-19 pandemic, which undoubtedly will contribute to increasing the generation of waste plastics.27

Figure 1.

Average composition (wt %) of MSW in the EU and of its plastics fraction.

2.1.2. Management

Even though only 8% of the oil consumed worldwide can be attributed to the plastics industry,28 the interest in their recycling is based on the need to reduce their disposal in landfills. This is a consequence of their low biodegradability, as the lifetime of most of the plastic wastes ranges from 1 to 35 years.29 Geyer et al.30 estimated that the worldwide waste plastics production up to 2015 accounted for 6300 million tons, of which 9% have been recycled, 12% incinerated, and the remaining 79% accumulated in landfills or in natural environments. These authors also estimated that, without significant recycling efforts, 12 000 million tons of waste plastics might be disposed by the year 2050. Furthermore, the waste plastics disposed in landfills undergo gradual fragmentation into microplastics (MPs, particles of <5 mm diameter) through mechanical and microbial decomposition, weathering, photolysis, and abrasion. This phenomenon, together with the release of manufactured MPs contained in various consumer goods (microbeads, capsules, fibers, or pellets in cosmetics, personal care products, cleaning agents, paints, and coatings) are the main contributors to the 243 000 tons of MPs afloat in the oceans.31 The high surface area and hydrophobicity of these materials ease their ingestion by living organisms and promote the risk of adsorption and desorption of toxic chemicals and pathogens in water. Accordingly, it is well established that the presence of MPs in aquatic organisms has negative health effects, such as growth and development inhibition, neurotoxic responses, metabolic disorders, and genotoxicity.32,33 Likewise, the presence of MPs in the soil also affects its properties, plant performance, and microbial activities.34 Moreover, the inhalation of smaller MPs (nanoplastics, NPs) and the ingestion of MP/NP-containing foodstuffs by human beings (ultimate consumers in the food chain) may involve potential risks, whose dependency on the composition and concentration of MPs/NPs is still under study.35

Apart from being landfilled, waste plastics can be also incinerated in order to produce energy or recycled to recover the monomers that they contain. These disposal methods were of low significance before 1980. From 1980 and 1990 onward, incineration and recycling rates have increased an average of 0.7% per year, reaching average values of 28.3% and 19.3%, respectively, in the year 2019.30,36 However, energy recovery or recycling rates greatly change depending on the country or region.37 Incineration of waste plastics is the main disposal method in various countries. Thus, Japan, Sweden, and Denmark incinerate 56, 81.7, and 57.1 wt % of the plastics, respectively, with the aim of recovering energy. This activity is carried out by taking severe measures to control emissions.

As plastics are final petroleum products, it seems logical to associate their recycling with the petrochemical industry and the production of chemicals. Waste plastics could be reintroduced in different manufacturing stages, by means of primary, secondary (mechanical), or tertiary (chemical) recycling. Among the different recycling routes, those with higher prospects to be implemented on a large scale are the thermochemical routes of tertiary recycling. These routes allow the production of fuels and the recovery of the monomers, which may be converted into the original material from which they came. Different reviews of these thermochemical routes have already been reported focusing on the initiatives associated with pyrolysis3 and gasification38 of waste plastics.

2.2. EOL Tires

2.2.1. Generation

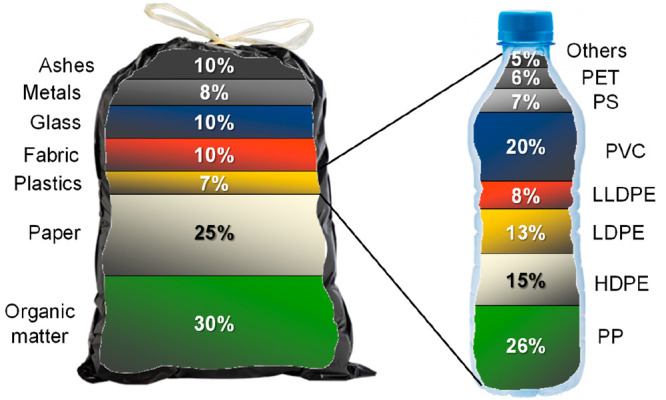

Tires are products of complex engineering. They are the result of the assembly of more than 200 components. Among the components used in the manufacturing of tires, rubber (both natural and synthetic), carbon black, inert fillers (amorphous precipitated silica, alumina), steel, textile and fabric cords (nylon, kevlar), sulfur, zinc oxide, and different antioxidants and antiozonants are the main ones. Figure 2 shows the average composition of passenger tires,39 which depends on the type of vehicle (cars, trucks, buses, planes, etc.) and regional climatology. Because of its complex composition and structure, once a tire reaches the end of its lifespan, it cannot be restored and directly reused. Hence, it becomes an EOL tire. Furthermore, the presence of different components creates difficulties for their recycling.

Figure 2.

Average composition of a passenger tire by weight.

The International Rubber Study Group has estimated that 14.8 million tons of rubber were consumed in 2019 all over the world, with 60% being used for the manufacturing of tires. It should be added that the manufacturing of each tire consumes between 23.5 and 141 L of oil,40 which is evidence of the high usage of resources involved in this industry. Furthermore, estimations account for an average production of 17 million tons of EOL tires per year, which means that about 2800 million tires are disposed every year (assuming that an average tire weights 6 kg).41 Therefore, the notable increase in the worldwide motorization rate and so in tire consumption surpasses the impact of the measures designed to extend their life cycle.42,43 Furthermore, both the dumping and disposal in landfills of EOL tires may cause (i) groundwater pollution, (ii) uncontrolled and hazardous fires with high levels of emissions of carbon monoxide, nitrogen and sulfur oxides, volatile organic compounds (VOCs), polycyclic aromatic hydrocarbons (PAHs), and heavy metals, and (iii) proliferation of rodents, mosquitos, or termites.

2.2.2. Management

The manufacturing of tires involves irreversible vulcanization processes. In these processes, the layers of synthetic and natural rubber, sulfur, and other components are cross-linked conferring elasticity, insolubility, and infusibility upon the tire.44 Consequently, the recovery of materials and chemicals from discarded tires requires energy demanding processes involving mechanical, thermal, or chemical destruction of the rubber.45 The trends observed in the management of EOL tires over the last 20 years have consisted in a slight increase in the routes involving material recovery and a reduction of those for energy recovery, with reuse being steady and gradually reduced.46

Energy recovery is a relevant route for EOL tire management provided that environmental impacts are under control.47,269 Advantages involving the use of this waste in the ovens of ceramic and cement factories are as follows:48,49 (i) saving of raw materials, electricity, and fuels; (ii) mitigation of CO2 emissions due to the high content of rubber in the tires; (iii) the possibility of cofeeding with other wastes without affecting the efficiency of the oven. Similarly, Rowhani and Rainey14 have enumerated some advantages of EOL tire incineration: (i) the possibility of producing electricity and steam and (ii) the recovery of several raw materials used in the manufacturing of the tires, such as steel wires, zinc oxide, and sodium sulfate. Based on these facts, the tire industry approached the incineration of EOL tires in rotary kilns with the aim of producing steam for the vulcanization process and of reducing the environmental impact of this waste.51

According to the European Tire and Rubber Manufacturers’ Association,52 from the 3.5 million tons of EOL tires that were generated in 2018 in the EU, 91% were collected and treated for material recycling and energy recovery. About 1.2 million tons of EOL tires (35% of the amount generated) were treated through energy recovery, especially in cement kilns (75%) and urban heating and power plants (25%). The remaining 2 million tons (53% of total EOL tires generated) were used for material recovery purposes, including granulation (78%) and their use in civil engineering and public works (about 5%). With regard to the USA, just the 72.9% of the EOL tires produced were collected and treated in 2019 according to the U.S. Tire Manufacturers Association.53 Furthermore, the amount of tires treated through energy recovery and recycled were similar, the former being slightly higher (38.2% and 34.7%, respectively). The remaining 27.1% of tires discarded in the USA suffer the worst destiny, as they are legally and illegally land disposed (14.3% and 9.7%, respectively) or exported to other countries (3.1%).

Therefore, in concordance with the aforementioned data about the low recycling level and the low added value of obtained products, the generation of plastic waste and EOL tires far exceeds the capacity of the currently established management routes. This fact promotes the development of new valorization routes suitable to be implemented on large scale with the required economic viability. Accordingly, thermochemical routes are the most promising ones, specially gasification and pyrolysis.

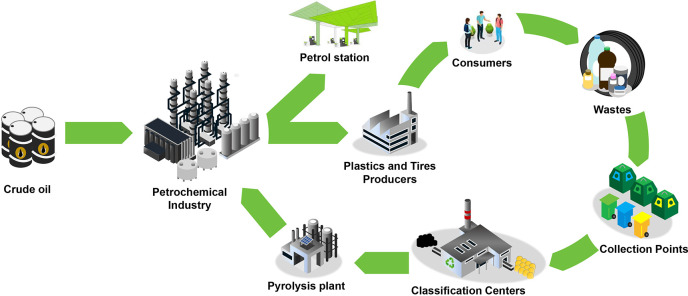

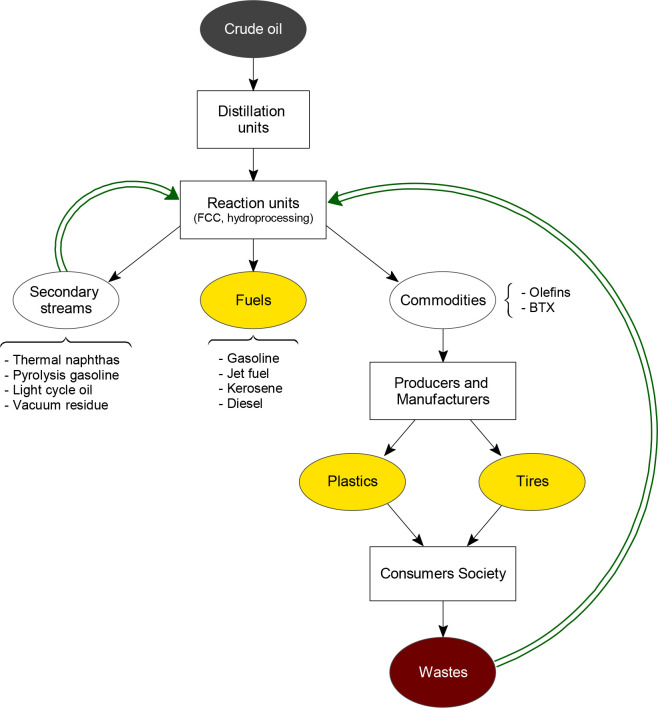

3. The Concept of Waste Refinery

As previously stated, important advances have been made in the technologies for tertiary recycling of waste plastics and EOL tires, with emphasis being placed on the development of pyrolysis technology (Section 4) for the production of fuels and the recovery of monomers. Nonetheless, there is no industrial initiative for the valorization of these wastes with the required capacity to solve the current mismanagement. This situation is strongly affected by the following drawbacks: (i) a big economic investment is required for the implementation of the units required for the integral valorization of these wastes at large scale; (ii) the obtained products must meet severe quality standards established by current legislation; (iii) this new and alternative industry will have to compete with the well-established oil industry. Consequently, the situation suggests the promotion of a large-scale waste valorization industry (waste refinery) by integrating primary waste valorization units within refineries. Accordingly, primary units will produce low-quality streams that will be converted into fuels and commodities (light olefins and aromatics) in the large-scale secondary treatment units available in refineries.

The waste refinery appears as a new concept given the necessity to make technologically and economically viable the large-scale valorization routes of waste plastics and EOL tires. It can be defined as “a plant that integrates conversion processes with units for the production of fuels, energy, and chemicals, either from wastes and their derivatives or from secondary refinery streams”.

Therefore, the numerous activities that a waste refinery brings together can be divided into two series of interrelated actions (Figure 3). The first series corresponds to the initiatives of the petroleum industry itself, as it generates secondary refinery streams as byproducts of distillation and reaction units. The processing of these side streams follows an increasing trend in refineries in order to intensify the valorization of oil by means of increasing the yield of commercial products. Indeed, the FCC unit plays a key role in the cofeeding of vacuum residue54 and of visbreaker and coker heavy naphthas.55−59 Equally, hydroprocessing units can be appropriate for the cofeeding of aromatic streams, such as the pyrolysis gasoline obtained in steam cracker units60 or the light cycle oil (LCO) obtained in FCC units,61−63 with the aim of producing naphtha and medium distillates or BTX aromatics.64 The second series of actions of the waste refinery, which constitutes the interest of this review, focuses on the recycling of consumer society wastes, for example, waste plastics and EOL tires. Recycling activities relate refinery units with other additional units, which will develop the ecoindustry. Among the required additional units, the one for pyrolysis is key for the conversion of waste solids into liquid streams that can be fed into refinery units, either as they are produced or blended with common feeds.

Figure 3.

Scheme that describes the concept of waste refinery, which consists in the recycling of secondary refinery streams and petroleum-derived wastes.

Based on their versatility, the refinery units with higher prospects for managing these feeds (raw plastics, waste plastic pyrolysis oil, and EOL tire pyrolysis oil) are the following ones: catalytic cracking (FCC), hydroprocessing, steam cracking, and coker units.54,65,66 Moreover, taking into account their capacity and technological development, the refinery units that forge ahead in the implementation of the waste refinery are the FCC unit (in the short term, using already depreciated units) and the hydroprocessing unit (in the long term, given its higher complexity and lower implementation). Next, in sections 5 and 6, the main features of these units have been summarized, together with the main research results obtained in the catalytic cracking and hydroprocessing of these wastes. Furthermore, a refinery is equipped with separation, purification, and other units appropriate for the integral valorization of the remaining streams of products obtained in the pyrolysis of waste plastics and EOL tires, such as light olefins and BTX aromatics.

The oil industry is immersed in a big dilemma given the change in the energy model society is demanding and the fluctuations in the availability, quality, and price of crude oil.67 Within this scenario, the involvement of the refineries in waste recycling may be boosted by economic incentives and subsidies provided by public administration, which will undoubtedly help to finance the revamping of the FCC and hydroprocessing units. Moreover, global emissions of CO2 will be notably reduced entailing a reduction in the carbon taxes of the corresponding country. Furthermore, the contribution of the oil industry to resolve an urgent environmental issue as that involving the uncontrolled disposal of these wastes would help to improve the image and projection of oil refineries.

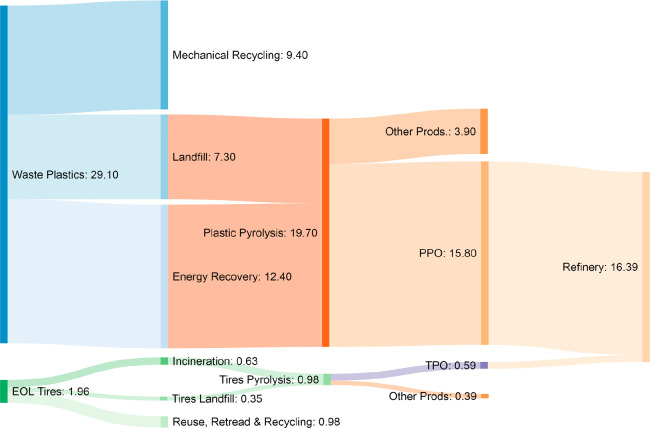

Furthermore, oil refineries may save an important amount of crude oil by recycling the waste plastics and EOL tires. Figure 4 computes the total amount of hydrocarbons that can be obtained from these wastes in the EU. Therefore, analyzing the case of waste plastics first, 29.1 million tons were generated in 2018 in the EU.25 From this amount, 9.4 million tons were mechanically recycled, whereas the remaining 19.7 million tons were landfilled or burned for energy recovery. Thus, assuming that neither landfilling nor combustion are the optimal management routes, these wastes may have been pyrolyzed. Taking into account that waste plastic pyrolysis might lead to liquid yields of 80 wt %,68 an amount of 15.8 million tons of plastic pyrolysis oil (PPO) suitable for treatment in refinery units might have been produced. Note that from the total amount of PPO produced, two-thirds approximately correspond to the PPO obtained from polyolefins. Likewise, the same analysis can be performed for the EOL tires. Thus, 1.96 million tons of EOL tires were produced in the EU in 2018. Half of these were incinerated (0.63 million tons) or landfilled (0.35 million tons). If the 0.98 million tons of mismanaged EOL tires had been submitted to a pyrolysis stage, 0.59 million tons of tire pyrolysis oil (TPO) would have been produced assuming a liquid yield of 60 wt %.69 Consequently, a total amount of 16.39 million tons of hydrocarbons would have been available for European refineries, which means an important source of raw materials considering that 740 million tons of crude oil are processed on average in the EU.70

Figure 4.

Availability of hydrocarbons for refineries (in million tons) if EU waste plastics and EOL tires were managed according to the model proposed by waste refinery.

4. Fast Pyrolysis

The generation of plastic waste and EOL tires far exceeds the capacity of currently established management routes. This fact and the limitations derived from the environmental restrictions on incineration promote the development of new valorization routes suitable to be implemented at large scale with the required economic viability. Thermochemical routes are the most promising ones, specially fast pyrolysis, because the liquid and gaseous products obtained may be valorized in line or in subsequent catalytic stages. Pyrolysis (or thermal cracking) requires high temperatures and is commonly carried out in non-oxidizing atmospheres (in the absence of O2). This process breaks down solid wastes into three different fractions: gas, liquid (oil), and solid (commonly known as char). The ratios of the different fractions obtained depend on the operating conditions, but especially on temperature and residence time of the volatiles. Fast pyrolysis is characterized by high heating rates and short residence time of the volatiles, which maximizes the yield of the oil obtained. Among the advantages of fast pyrolysis, those worth mentioning are as follows:71 (i) versatility, as wastes of different nature (agroforestry wastes, plastics, tires, sewage sludge) can be cofed;72,73 (ii) reduced environmental impact, as pyrolysis produces lower emissions than gasification.74 Moreover, pyrolysis can be performed under vacuum by reducing the gas flow rate,75 but it can be also carried out in autothermal regime by cofeeding O2.76 There are a variety of reactor configurations (moving, fluidized, or spouted beds) for continuous fast pyrolysis.3 Furthermore, their simple design makes feasible the manufacturing of smaller or movable units that may operate nearby waste collection and specific locations where in situ pyrolysis may be conducted. The energy requirements of the pyrolysis unit may be covered by the combustion of the gas fraction produced or a fraction of the input mass flow rate77 (on the order of 5 wt %) or by concentrated solar energy as an alternative.78 Finally, the interest for the waste refinery lies in the possibility of transporting the pyrolysis oil to the refinery and treating it on a large scale in the corresponding refinery unit.3

Even though the reviews summarized in Tables 1 and 2 collect a great part of the studies available in the literature about the pyrolysis of waste plastics and EOL tires, respectively, some works are discussed below, since they can contribute to understanding the state of the art of this thermochemical route. Indeed, the suitability of the refinery units for the valorization of the liquid product obtained from waste plastics and EOL tires (PPO and TPO, respectively) has been stressed.

4.1. Waste Plastics

Pyrolysis is an environmentally friendly option for managing plastic wastes, especially addition polymers, which are the main ones within the MSW. A goal extensively studied in the literature has been recovery of monomers (light olefins) by means of fast pyrolysis in either fluidized bed reactors79 or other reactor types.80,81 The conical spouted bed reactor meets the conditions to fulfill this goal, as its hydrodynamics avoids the defluidization of the bed caused by the agglomeration of the molten plastic.82 Furthermore, the short residence time of the volatiles inhibits the extent of the secondary reactions at the same time as it promotes the production of waxes (C21+) operating at low temperatures (80 and 92 wt % from HDPE and PP, respectively, at 450 °C)68 and the formation of light olefins at high temperatures (39 wt % from HDPE at 700 °C).83 Recently, an innovative cold plasma assisted pyrolysis reactor has been proposed to maximize the production of ethylene from HDPE.84

The study of fast pyrolysis of other non-polyolefinic polymers has also been focused on the recovery of monomers and raw materials. The pyrolysis of polystyrene (PS) in a conical spouted bed reactor allows attainment of 70.6 wt % yield of styrene at 500 °C, together with other commercially interesting fractions, such as fuels and aromatics (benzene and toluene).85 Poly(methyl methacrylate) (PMMA) is thermally degraded from 280 °C, and the yields of the monomer methyl methacrylate (MMA) and of ethyl acrylate (EA) reach values of 86.5 and 6.19 wt %, respectively, at 450 °C.86 Poly(ethylene terephthalate) (PET) is a very thermostable polymer, whose decomposition starts at 300 °C and reaches a significant degradation level above 400 °C. High temperatures increase the yield of gases and slightly that of liquid, whereas the yields of solid and residue are reduced.87 The main compound in the liquid product is acetaldehyde, reaching a yield of 11.1 wt % at 500 °C. In the solid product, in turn, benzoic acid is the main compound with a yield of 27.0 wt % at the same temperature.

4.1.1. Yield and Composition of the Liquid Product and Interest in It as a Fuel

The main goal of many studies has been the production of a liquid product or PPO for its use as a fuel, directly or after being upgraded in refinery units. According to the number of carbon atoms in the molecules within the PPO, it is commonly divided into three different lumps: gasoline (C5–C11), diesel (C12–C21), and waxes (C21+). Within this context, Palos et al.88 have proven that the PPO obtained in the slow pyrolysis of HDPE at 430 °C has a composition similar to that of vacuum gas oil (VGO), which is the common feedstock of FCC units in refineries. Nevertheless, above 460 °C (independently of the reaction time), pyrolysis oil will have a distillation profile similar to that of light cycle oil (LCO), suitable to be fed on its own or cofed into a hydrotreatment unit.

The gasoline fraction obtained by Kumari and Kumar89 in the pyrolysis of HDPE has a suitable composition to be used as a motor fuel. Its low content of olefins and suitable content of aromatic compounds make up a stable gasoline fraction with good octane number. Dobó et al.90 studied the behavior of the gasoline fraction in the PPO obtained with different polymers (HDPE, LDPE, PP, PS) in an internal combustion engine. The fuel consumption was reduced with all the PPOs compared to that with a 95 research octane number (RON) gasoline. Indeed, this effect was maximized with the LDPE-derived gasoline fraction, reaching a reduction of 6.1–7.8 wt %. However, higher emissions were registered with the gasoline fraction obtained from the PPOs. Accordingly, based on the emissions obtained in the combustion of commercial gasoline, the fuels produced from HDPE, LDPE, and PP led to the highest emissions of CO, whereas NOx emissions increased with the PS-derived gasoline.

Owusu et al.,91 in turn, focused their research on the diesel fraction. These researchers obtained their best results with HDPE and PP. However, the PPO obtained with PS requires an additional processing stage prior to be used in diesel engines. The performance in a diesel engine of different blends of commercial diesel and the PPO obtained from a mixture of plastics (mainly composed of styrene–butadiene and polyester) led to a longer ignition delay, higher cylinder peak pressure, and higher heat release rate caused by the lower cetane number of the blend.92,93 Furthermore, the engine thermal efficiency decreased by 3–4 wt % in comparison with that obtained with commercial diesel, and the emissions (including hydrocarbons, CO, and NOx) increased with the content of PPO in the blend. Based on the results reported by other authors, the effects on the thermal efficiency and on the emissions depend on the composition of the PPO and therefore on the type of plastic and operating conditions in the pyrolysis (especially on temperature). Thus, Das et al.94 reported that the suitable content of PPO in the blend with a commercial diesel is 20 wt %. Singh et al.95 determined that blends with contents of up to 50 wt % PPO allowed good performance with a slight decrease in the thermal efficiency compared to that obtained with the commercial diesel. Chintala et al.96 studied the performance and the emissions upon feeding PPO obtained from a mixture of waste plastics into a diesel engine at different brake mean effective pressures (BMEPs). The results showed that the thermal efficiency is comparable to that obtained with the commercial diesel. Furthermore, registered emissions (hydrocarbons, CO, and smoke) were also similar for low values of BMEP (1.8–3.8 bar), but higher emissions were obtained for high values of BMEP (5.8–10.8 bar). However, a notable reduction in the emissions of NOx was observed at 10.8 bar because of the lower in-cylinder temperature. Gala et al.97 have compared the PONA (paraffins, olefins, naphthenes, and aromatics) analysis results (displayed in Table 3) of the PPO resulting from pyrolysis of industrial plastic waste (IPW), postconsumer colored (PCPW) and white plastic (PWPW) film waste in a pilot scale plant (80 kg h–1). As observed, the content of paraffins was higher in the postconsumer plastic films (50.5 and 57.8 wt % in PCPW and PWPW, respectively) than in the industrial one (38.7 wt %). Moreover, the PPOs complied with the hydrocarbons (50 vol %) in the diesel boiling point range (180–380 °C) and a blend of this fraction with the commercial diesel (50/50 vol %) met the requirements for being used in the EU as a fuel in diesel engine vehicles.

Table 3. PONA Analysis Results of the PPO from IPW, PCPW, and PWPW.

| composition (wt

%) |

|||

|---|---|---|---|

| components | IPW | PCPW | PWPW |

| paraffins | 38.7 | 50.5 | 57.8 |

| olefins | 18.4 | 22.5 | 19.3 |

| naphthenes | 16.5 | 19.0 | 14.2 |

| aromatics | 26.4 | 8.0 | 8.7 |

Adapted from the work by Gala et al.97

Arabiourrutia and co-workers98 characterized the waxes obtained in the fast pyrolysis of LDPE, HDPE, and PP by several techniques (gel permeation chromatography, simulated distillation analysis, and high heating value measurements). They divided their products into light and heavy waxes, establishing that overall, all the products obtained were suitable to be used as fuel. Moreover, they have observed that the results obtained with all the addition polymers were quite similar.

An interesting strategy that allows maximizing the selectivity toward certain products lies in the use of acid catalyst in situ in the pyrolysis reactor. Mark et al.13 have reviewed the different catalytic technologies used in the cracking of plastics and emphasized the role of the configuration and porous structure of catalyst particles in the yields and product distribution. The reaction mechanism in the catalytic pyrolysis (catalytic cracking) occurs through intermediate carbocations,99 at low temperatures and with a narrower product distribution. Furthermore, pyrolysis (thermal cracking) mechanism occurs with free radicals as intermediates, which induces random scission and chain-end scission reactions in the cracking of polyolefins.100 Pursuing the goal of maximizing the content of aromatics in the liquid product, Renzini et al.101 reached a selectivity of almost 100% with a Zn-impregnated ZSM-11 catalyst. Elordi et al.102 tested HZSM-5, HY, and H-Beta zeolite-based catalysts in the pyrolysis of HDPE. They observed that HZSM-5 zeolite promoted the formation of light olefins (yield of ca. 58 wt %), whereas HY and H-Beta zeolite-based catalysts allowed high yields (ca. 45 wt %) of nonaromatic C5–C12 hydrocarbons. Studying the effect of the acidity of the HZSM-5 zeolite demonstrated that slightly acidic catalysts with low acid strength promoted the yield both of light olefins (59.8 wt %) and of nonaromatic compounds, with the latter being similar to that of the gasoline fraction (32.1 wt %).103 In these works, emphasis has been placed on the relevance of the porous structure and acidity of the HZSM-5 zeolite for attenuating the deactivation caused by coke deposition. Using HZSM-5 zeolites, Wang et al.104 maximized the production of monocyclic aromatics in the pyrolysis of PC (polycarbonate) and PS.

Kassargy et al.105 extended the pyrolysis experiments to PE and PP using USY zeolites as catalysts. They obtained an average yield of 58.5 and 36 wt % of gasoline and diesel-like fuels, respectively. Elordi el al.106 used an equilibrated FCC catalyst (USY zeolite embedded in a macroporous structure) agglomerated with bentonite (50 wt %). This strategy pursued the aim of extending the life cycle of a refinery waste catalyst that could be obtained at very low price. Indeed, the yields of light olefin and gasoline fractions obtained (28 and 50 wt %, respectively) supported that catalytic pyrolysis of polyolefins could be integrated in a refinery. Additionally, Valanciene et al.107 also used an equilibrated FCC catalyst in the pyrolysis of waste industrial and automotive plastics, intensifying the formation of branched C7–C9 hydrocarbons.

Acid mesoporous catalysts have also been subjects of study. Thus, Li et al.108 compared different mesoporous materials (Kanemite-derived folded silica, Al-MCM41, and Al-SBA15) in the cracking of PE and PP. These catalysts lead to lower yields of gases and higher yields of aliphatic liquid products. Furthermore, Lee and Park109 have used commercial Al-MSU-F and desilicated β-zeolite for the catalytic pyrolysis of PE and PP. These authors observed that the properties of the catalysts strongly affect the results obtained, as higher yields of light and aromatic products are attained with the desilicated β-zeolite.

Carbonates have also been assessed as catalysts in the pyrolysis of polyolefins. MgCO3 was selected by Kunwar and co-workers for the pyrolysis of HDPE81 and of mixtures of PP, HDPE and medicine bottles.110 This catalyst leads to higher yields of diesel-range fraction. Singh et al.111 opted for testing CuCO3 for the pyrolysis of HDPE, obtaining high yields of liquid product (85–92 wt %). In another work, Singh112 performed the pyrolysis of virgin and waste HDPE using CoCO3 as catalyst, and they obtained slight differences in performance, with the liquid yields being very high (91 wt %).

With the aim of going a step further in this research topic, numerous authors have investigated the catalytic pyrolysis of postconsumer plastic mixtures.81,113−119 Among these works, the one by Sangpatch et al.114 is noteworthy. These researches have used local resources to synthesize the catalysts. Specifically, they used cogon grass, which is a native species in their region, as a source of silica for preparing silica–alumina catalysts. In the same line, Eze et al.120 have synthesized Y zeolites from kaolin extracted in their area. Based on the same concept of increasing the sustainability of the process, Li et al.121 have used the biochar produced in the pyrolysis of poplar woodchips as catalyst for the pyrolysis of LDPE and HDPE. They observed that the effect of biochar addition changed depending on the plastic used. Thus, biochar promoted the formation of gases (especially propane) in the pyrolysis of LDPE, while the formation of waxes was promoted in the pyrolysis of HDPE.

Another polyolefin pyrolysis strategy, in which monomer recovery is the aim, consists in using a tandem of two different setups connected in line. Artetxe et al.122 produced in the first stage (using a conical spouted bed reactor at 500 °C) a stream rich in waxes, which was thermally cracked in a second stage (at 850–900 °C). Final products were composed of 77.4 wt % light olefins, in which 40.4%, 19.5%, and 17.5% were ethylene, propylene, and butenes, respectively. The used HZSM-5 zeolite in the second stage causing various effects:123 (i) reduction in cracking temperature to 550 °C; (ii) decrease in the yield of olefins to 62 wt %; (iii) formation of aromatics within the gasoline fraction (C5–C12). The same strategy was used by Muhammad et al.124 in the catalytic pyrolysis of real and simulated mixtures of plastics. Even though the feeds used were different, these authors also observed a shift toward lighter products and the formation of 1-ring aromatics (benzene, toluene, xylenes, ethyl benzene, and styrene) when using HZSM-5 zeolite in the second stage. Akubo et al.,125 in turn, used Y zeolite-based catalysts loaded with Co, Ga, Fe, Mo, Ni, and Ru for cracking the volatiles of the pyrolysis of HDPE. The presence of metallic promoters led to the production of highly aromatic liquid products (between 97 and 99 wt %), at the expense of promoting the coke deposition on the catalysts.

4.1.2. Kinetic Modeling

Most of the kinetic studies about the pyrolysis of plastics have been carried out by means of TG analysis, adjusting the mass loss results to an n order equation (commonly between 0.5 and 1) with activation energies and frequency factors within the 80–280 kJ mol–1 and 1010–1018 s–1 ranges, respectively.126−131 Aguado et al.132 determined that a conical spouted bed reactor is appropriate for kinetic studies. The rapid fusion of the plastics, high heat transmission velocity, and fast volatilization of the waxes obtained as pyrolysis primary products reduce the limitations of the thermogravimetric techniques.

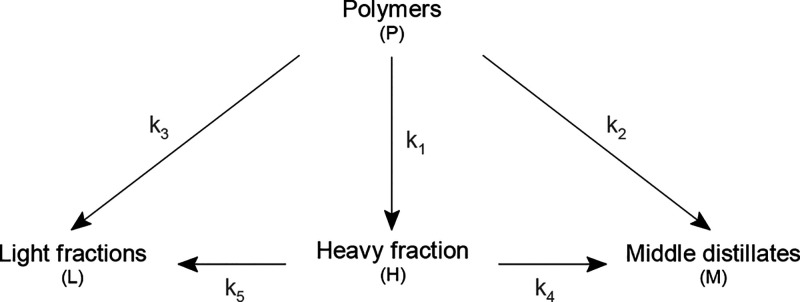

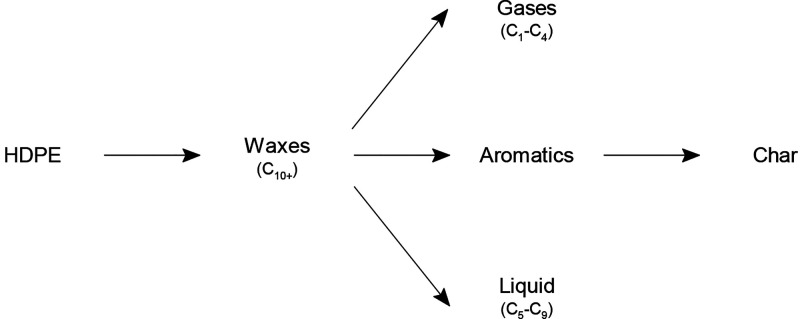

Aiming at the production of fuels and raw materials, the kinetic models that group the different products in lumps are more attractive. Ding et al.133 computed the kinetic parameters of the pyrolysis of HDPE and mixed plastics (scheme shown in Figure 5). Considered lumps were light fraction (L), middle distillates (M), and heavy fraction (H). Aguado et al.134 used Principal Component Analysis methodology to establish the reaction scheme in Figure 6 for the pyrolysis of HDPE. Furthermore, various works have revealed that the presence of zeolite-based catalysts reduces the activation energy of the pyrolysis of plastics reducing, at the same time, the required temperature.135−137 Indeed, the acidity and shape selectivity of the zeolite are key factors for controlling product distribution and for attenuating the deactivation caused by coke deposition.138 The magnitude of the effects of using acid catalysts on the product distribution has been quantified by lump kinetic models.139,140 In this context, Till et al.141 have established a kinetic model composed of 6 lumps and 10 individual kinetic steps to describe the pyrolysis of a HDPE/PP/LDPE mixture.

Figure 5.

Kinetic scheme for the pyrolysis of polyolefins. Adapted from the work by Ding et al.133

Figure 6.

Kinetic scheme proposed for the thermal pyrolysis of HDPE. Adapted from the work by Aguado et al.134

4.2. EOL Tires

4.2.1. Product Distribution

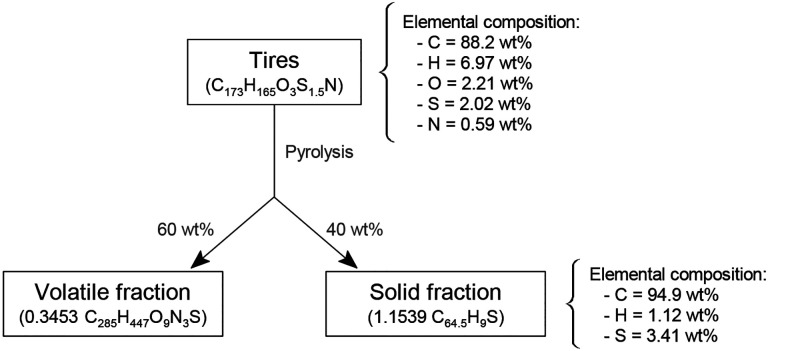

The pyrolysis of EOL tires is considered as a promising route for the valorization of this solid waste, as the products streams (gas, char, and TPO) are of high heat value.142 Martínez et al.16 described the pyrolysis of tires considering the average composition of the products (Figure 7), distinguishing a volatile fraction, which is mainly composed of tire pyrolysis oil (TPO), from a solid fraction (40 wt %), which is basically adulterated carbon black (CBp).

Figure 7.

Product distribution in the pyrolysis of tires. Adapted from the work by Martínez et al.16

However, the composition and the yields of the different product fractions are strongly affected by the operating conditions, tire formulation, reactor type, and the presence of a catalyst. The most interesting reactor types for the continuous pyrolysis of EOL tires are moving-bed, rotatory kiln, fluidized bed, and conical spouted bed reactors.71 The aim of the noncatalytic pyrolysis is the production of the liquid product (TPO) for its use as fuel, even though the economic viability of the process requires the valorization of the CBp and the separation of high-value added chemicals from the TPO (isoprene, d-limonene, o-cymene, o-xylene, toluene, and ethyl-benzene).21 The pyrolysis of EOL tires has a low environmental impact, as the presence of metals in the TPO and in the char is rather low. However, both the TPO and the gas fraction require a subsequent desulfurization stage.19

Lopez et al.143 pyrolyzed two different types of tire materials with different contents of natural rubber and synthetic polymers (polystyrene and polybutadiene, respectively) in a conical spouted bed reactor. They observed that product distribution was barely affected by tire formulation, but strongly influenced product composition. The higher the content of synthetic rubber in the tire formulation, the higher the yields of benzene, toluene, and xylenes (BTX). The yield of limonene followed the same trend; that is, the maximum yield was obtained in the pyrolysis of synthetic rubber. Similar results were obtained by Singh et al.144,145 in the pyrolysis of different automotive waste tires and by Tang and co-workers146 in the pyrolysis of waste rubber and polyurethane bicycle tires.

Pyrolysis under vacuum solves one of the important limitations for the scale up of the process, as the N2 flow required for operating under fluidized or spouted bed regimes is reduced. In the case of the conical spouted bed reactor, operation at 0.25 atm in the 400–600 °C range required a N2 flow rate 3.5 times lower than that required under atmospheric pressure.147 Vacuum has a marked effect on product distribution,75 increasing the yield of the liquid fraction and promoting the formation of less CBp, with average surfaces above 90 m2 g–1. Moreover, the yield of isoprene was increased, to the detriment of the yield of limonene, because vacuum attenuates the dimerization reaction of isoprene to limonene.

The catalytic pyrolysis of waste tires has also been approached in the literature in order to improve product distribution.24 Arabiourrutia et al.148 and Olazar et al.149 studied the in situ catalytic pyrolysis of EOL tires using HZSM-5, HY, and H-Beta zeolites. The HZSM-5 zeolite promoted the formation of gases (increasing the yield of propylene and butadiene over that obtained without catalyst) and of hydrocarbons within the gasoline fraction, with an average content of 20 wt % of BTX aromatics. Conversely, the HY zeolite produced a heavier liquid product, with hydrocarbons prevailing within the diesel fraction. However, in both cases, the HHV of the TPO was lower than that obtained in the thermal pyrolysis.

Williams and Brindle studied the catalytic cracking of the volatiles obtained in the pyrolysis of tires using acid zeolite catalysts (HZSM-5 and HY zeolites).150,151 Based on their tandem strategy, these authors observed that the catalytic treatment reduced the yield of the liquid fraction, which was converted into gas and coke. In spite of this, the concentration of BTX aromatics was significantly increased with the catalysts, especially with the HY zeolite.

Although the pyrolysis of tires aims for the production of the TPO, yield of which reaches values of 58.2 wt % at 475 °C in a conical spouted bed reactor,69 various byproducts are also obtained. Among them, CBp (with an average yield of 35 wt %) is the most interesting one as its surface area and structure are similar to those of commercial CB.152 Therefore, once it has been subjected to atomization dispersion and high temperature sputtering drying, it can be used for the preparation of rubber composites.153 Moreover, the low ash content (<10 wt %) and high volatile matter (>70 wt %) make it appropriate for use as adsorbents in pollution control and as biochar for soil amendment.22,154

4.2.2. Composition and Properties of the Liquid Product as a Fuel

TPO is a brownish liquid with the appearance and smell of petroleum fractions. It is a complex mixture of organic compounds of 5–24 carbon atoms, with a H/C molar ratio of ∼1.4 and a large proportion of aromatics. Its aromaticity and, especially, the content of polyaromatic hydrocarbons (PAHs) (naphthalene, phenanthrene, fluorene, biphenyls, etc.) increases with temperature because aliphatic cyclization reactions are enhanced, together with the combination reactions involving aliphatics and aromatic free radicals.155,156

Additionally, TPO can be the source of various raw materials, such as dl-limonene, dipentene, and isoprene. The concentration of these chemicals in TPO is strongly affected by pyrolysis conditions, especially temperature and heating rate.157−159 In a conical spouted bed reactor, the concentration of dl-limonene may be as high as 26.8 wt %,160 with the concentration of PAHs being low (2.42 wt %), which is a consequence of the short residence time of the volatiles. Moreover, the TPO obtained in this reactor type is very light, as more than 60 wt % of the compounds are within the gasoline fraction (C5–C12), with a notable concentration of BTX. In addition to isoprene, most of the compounds in the C5 fraction are olefins. The C6 and C7 fractions are mainly composed of diolefins, whose yield increases with temperature. The most representative compound in the C8 fraction is styrene, whereas in the C9 fraction, they are indene and benzene derivatives. Finally, 1-methyl-4-(1-methylethyl)benzene and 1-methyl-2-(1-methylethyl)benzene are found in the C10 fraction, which are formed by the dehydrogenation of limonene. Furthermore, the heaviest fraction of the gasoline (C11–C12) contains aromatic compounds, which are benzene, naphthalene, and indene derivatives, as well paraffinic and olefinic compounds.161

Table 4 shows the average fuel properties of TPOs obtained under different conditions, which have been reported by Rowhani and Rainey.14 These authors have compared the average TPO features with those of commercial gasoline and diesel. The similarity between the properties of the TPOs and the commercial diesel has promoted the testing of TPO as an alternative fuel by feeding either on its own or blended with diesel. İlkılıç and Aydin162 tested the behavior of a direct injection engine under different blending ratios of TPO and diesel. These researchers concluded that the engine operated efficiently and without requiring any modification with TPO contents of up to 35 wt %. However, blends with TPO content of ∼50 wt % led to a considerable increase in particulate matter, CO, SO2, and smoke emissions. Similar results were obtained by Murugan et al.163 blending the TPO in ratios of up to 50 wt % with automotive diesel. Other authors164,165 established that the feeding of only TPO into a standard rail diesel engine requires tailored injection strategies for optimum behavior of the engine.

Table 4. Main Properties of an Average TPO, Commercial Gasoline, and Commercial Diesel.

| property | TPO | gasoline | diesel |

|---|---|---|---|

| density (kg m–3) | 830 | 780 | 838 |

| viscosity (cSt) | 4.75 | 2.1 | |

| flash point (°C) | 65 | 43 | 54 |

| HHV (MJ kg–1) | 42.7 | 43.9 | 45.5 |

| elemental analysis (wt %) | |||

| C | 79.96 | 85 | 87.4 |

| H | 10.04 | 14.1 | 12.1 |

| N | 0.94 | 0.02 | 0.04 |

| S | 0.11 | 0.03 | 0.29 |

| O | 9.3 | 0.29 | |

| boiling points (°C) | |||

| IBP | 38.5 | 34 | 171.5 |

| T50 | 174.8 | 92 | 265.6 |

| T90 | 154 | 335.8 | |

| FBP | 382.4 | 218 | 364.6 |

Adapted from the work by Rowhani and Rainey.14

With the aim of improving the ignition of the TPO/diesel blend, Wang et al.166 proved that an increase in the pyrolysis temperature of the tires entailed an increase in the HHV (to the detriment of the yield of TPO). Consequently, the volume of the blend required for ignition was reduced. Additionally, Hariharan et al.167 investigated the effect of adding diethyl ether and concluded that this addition led to a reduction in the emissions of NOx. However, given the high content of aromatic compounds and low H/C ratio, the emissions of unburned hydrocarbons and CO were 38% higher than in the case of the conventional diesel.

Nevertheless, some physicochemical properties of the TPO,71,168 such as low cetane index (∼40), high viscosity (∼6.3 cSt), high content of aromatics (∼65 wt %), and total content of sulfur (∼14000 ppm), are serious disadvantages for its direct use as fuel in internal combustion engines. Depending on the technology used for its production, TPO may contain sand or coal particles or alkali metals that could damage parts of the engine.169 Furthermore, it generates a higher amount of coke in the injectors and higher emissions of unburned hydrocarbons, particulate matter, SOx, and NOx.170 Its direct use in internal combustion engines may delay the ignition of the engine requiring a bigger volume of oil in the cylinders to start ignition. This, in turn, entails pressure increase within the cylinders and therefore a decrease in the engine performance.

Alvarez et al.161 made a detailed analysis of the TPO obtained in a conical spouted bed reactor in the 425–475 °C range. The simulated distillation analysis showed that approximately 70 wt % corresponds to the diesel range. These authors pointed out the need for reducing the content of sulfur, nitrogen, and aromatics for use as fuel. The content of sulfur (up to 1.6 wt %) appears in the form of benzothiazol, dibenzothiophene, and its alkylated derivatives.171 Within this context, some strategies have been tested to obtain a sulfur free liquid product in the pyrolysis stage. They have consisted in using in situ catalysts of CaO, MgCl2, or NaOH, but moderate reductions have been obtained, as the maximum sulfur reduction has only accounted for 35 wt %.162,172,173 Hence, the required sulfur reduction must be carried out by means of a desulfurization or mild hydrotreatment process in order to use TPO as fuel. Furthermore, TPO can be fractionated to obtain different quality fuels,174 and the heaviest fractions can be used as plastifiers in different rubber formulations or as a substitute for asphalt concrete.175

4.2.3. Kinetic Modeling

Conventionally, the EOL tire pyrolysis kinetics has been determined by thermogravimetric means quantifying the evolution of mass loss with time.176−270 The differences between the kinetic parameters, that is, pre-exponential factor, activation energy, and reaction order, are a consequence of the mass and energy transfer limitations during the experiments and of the different composition of the EOL tires used in each work. The use of a fast heating microreactor allowed Aguado et al.178 to obtain kinetic data at higher temperature (within the 500–550 °C range) and under conditions similar to those of a continuous large-scale reactor. Olazar et al.181 used a conical spouted bed reactor to study the kinetics of the pyrolysis of EOL tires because of its isothermicity and high mass and energy transfer velocities between the phases. Some authors considered the heterogeneity of the EOL tires by means of kinetic models that evaluate the independent decomposition of their main compounds. Lopez et al.147 identified by DTG analysis the kinetics for the pyrolysis of individual components of the EOL tires. Those components were volatile components, natural rubber, and styrene–butadiene rubber, and their activation energies computed under vacuum (0.25 atm) were 43.5, 104.7, and 243.0 kJ mol–1, respectively. Lah et al.183 established a kinetic model that identified the kinetics of five different components of the EOL tires: (i) fabric materials, which include rayon, nylon, and aramid; (ii) wire; (iii) natural rubber; (iv) styrene–butadiene rubber; (v) butadiene rubber, together with the heat of reaction and the internal and external mass and heat transport phenomena.

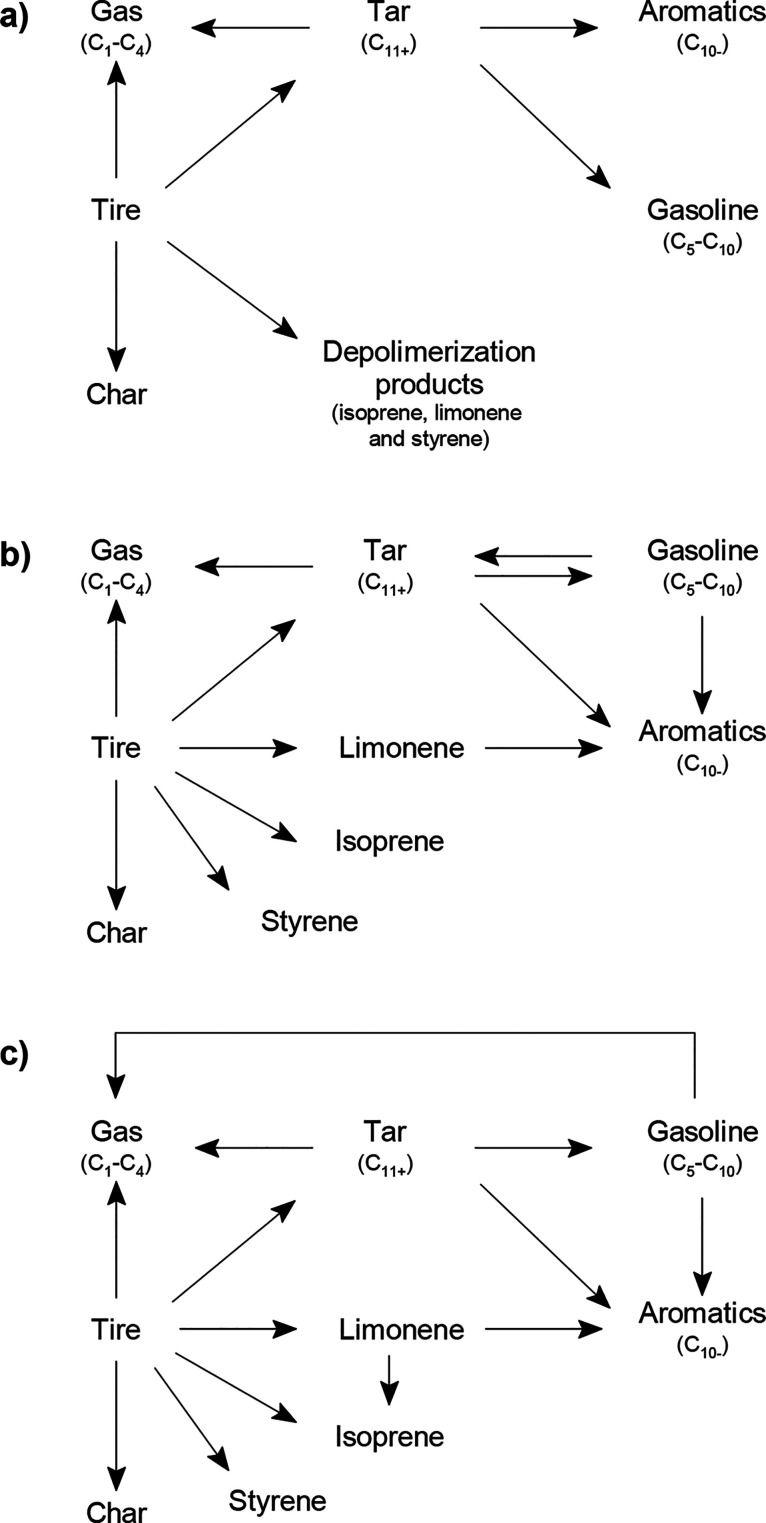

Pursuing the production of fuels and raw materials, the kinetic models that quantify the products distribution are of special interest.184−188 Aguado et al.189 used the Principal Component Analysis methodology for grouping the products into different lumps (Figure 8a): gas (CH4, C2–C4); monoaromatics C10–; nonaromatic gasoline (C5–C10); tar (C11+); char (CBp). The presence of acid catalysts has a strong influence on the kinetic scheme. The HY zeolite promotes the condensation and alkylation reactions that lead to the formation of aliphatic hydrocarbons in the gasoline fraction and of mono- and polyaromatics in the tar (Figure 8b). In contrast, the HZSM-5 zeolite fosters different cracking stages: (i) tar to monoaromatics and gases; (ii) limonene to the monomer isoprene; (iii) C5–C10 aliphatics to gases (Figure 8c).

Figure 8.

Kinetic scheme for the (a) thermal and (b, c) catalytic pyrolysis of tires with (b) HY and (c) HZSM-5 zeolites. Adapted from the work by Aguado et al.189

5. Catalytic Cracking

5.1. FCC Unit

FCC units, which are available in most of the petroleum refineries worldwide, are used to produce high octane gasoline and light olefins from heavy streams obtained in the distillation of crude oil. They are composed of four sections:190 (i) the pneumatic transport reactor (riser); (ii) the stripper; (iii) the gas–solid separator; (iv) the regenerator. The process starts when the preheated feedstock, commonly vacuum gas oil (VGO) with a boiling point above 344 °C, is steam-atomized at 350–425 °C. Afterward, the atomized feedstock is mixed at the base of the riser reactor with the catalyst stream that comes from the regenerator at 650–700 °C. Note that, based on the different temperatures of the feedstock and the catalyst, the mixture ends with an average temperature of 530 °C. The steam-atomized feedstock sweeps the catalyst throughout the riser, which has a length of 25–40 m and a diameter of 0.6–1.2 m. Because of the cracking reactions, the gas stream expands, reaching velocities of 5–15 m s–1. The flow regime corresponds to a dense-phase pneumatic conveying system due to the high catalyst to oil ratio (4–9 gcat gfeed–1) and residence time of the gas and catalyst (3–8 s).

In the upper part of the reactor, cracking reactions reach their end, but in order to avoid undesired secondary reactions, the catalyst is separated from the products by high efficiency (99.995%) cyclones. Products exit through the reactor head and go to fractionation and concentration systems, with the average fractions being commonly as follows: dry gases (C1–C2) 3–5 wt %; liquefied petroleum gases (LPG, C3–C4) 8–20 wt %; gasoline (C5–C12) 36–60 wt %; light cycle oil (LCO, C13–C21) 12–20 wt %; heavy cycle oil (HCO, C21+) 10–15 wt %; coke 3–8 wt %.190 The deactivated catalyst goes to the stripping section, where interstitial and adsorbed hydrocarbons are removed from the catalyst by a counter current stream of steam (2.5 kg of steam per ton of catalyst). Once they have been separated, the hydrocarbons go to a fractionation column, whereas the catalyst goes to the bubbling-bed regenerator (10–15 m in diameter).

The catalyst inventory of an average FCC unit, which treats ca. 50 000 barrels per day (bpd), is 270–300 tons. FCC units perform between 100 and 400 cycles per day, and in each cycle, the catalyst spends most of the time in the regenerator (6–11 min), and only 3–8 s in the riser reactor. The content of coke at the entrance of the regenerator is 0.4–2.5 wt %, and it is removed by combustion at a temperature of 620–745 °C with an air velocity of 0.6–1.2 m s–1. This way, the catalyst is reactivated and acquires the sensitive heat required to satisfy the thermal requirements of the unit.191 Furthermore, the combustion gases that leave the regenerator drag the particles produced by the attrition phenomenon, and they must be retained and replaced by a stream of fresh catalyst.

USY zeolite has a well-defined crystalline structure with a cubic unit cell of 24.5–24.75 Å and a silica/alumina ratio between 3 and 6. The internal cavity of its super cage is 12 Å in diameter, with entries of 7.4 Å (12 oxygen atom rings). Each cavity is connected to the other four cavities, which are, in turn, connected to another four leading to the formation of the characteristic tridimensional structure of the Y zeolite. The crystals of the USY zeolite are embedded in a matrix commonly composed of alumina, silica–alumina and clay. The matrix plays a key role in the behavior of the catalyst within the reactor due to the following aspects: (i) it confers appropriate fluid dynamical properties, mechanical resistance, and thermal conductivity upon the catalyst particles; (ii) the macropores of the matrix (average diameter of 100–600 Å) ease heat and mass transfer and allow the diffusion of the heavy components of the feedstock; (iii) its acidic properties contribute to the cracking of heavy compounds; (iv) it retains poisoning substances (N and S containing molecules and metals, specifically Na) extending the life cycle of the catalyst and reducing their content in the products; (v) the coke formed inside the zeolite crystals flows outward and settles on the matrix attenuating the blockage of the zeolite channels. The main modifications of the USY zeolites lie in the steam ultrastabilization and ion-exchange with rare earth oxides (REO) to attenuate dealuminization and improve the hydrothermal stability required in the regeneration step.

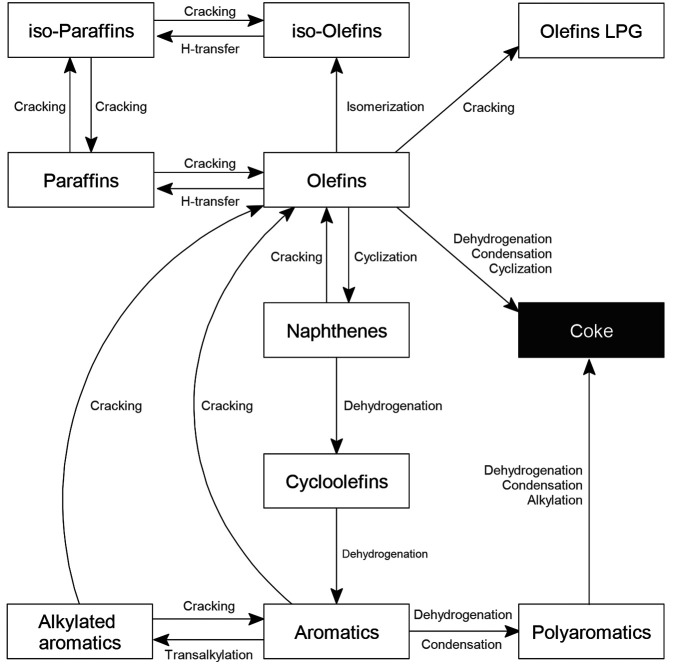

Figure 9 shows a scheme of the main reactions in which each type or family of hydrocarbons is involved in the catalytic cracking in the FCC unit.

Figure 9.

Main reactions occurring in the riser reactor of the FCC unit.

5.2. Cracking of Waste Plastics

The results obtained under experimental conditions similar to those in the industrial FCC unit are detailed in this section. For the cracking of waste plastics, different strategies have been studied for their feed into the unit, such as (i) dissolution in conventional refinery streams and (ii) conversion into PPO, which is fed on its own or blended with the standard FCC unit feedstock.

5.2.1. Plastics Dissolved in Conventional Refinery Streams

The direct cofeeding of plastics dissolved in conventional refinery streams (vacuum gasoil, VGO) has the advantage of not requiring additional pyrolysis facilities. However, this direct strategy shows several drawbacks: (i) a rigorous separation of polyolefinic plastics must be carried out in municipal solid waste collection and segregation points; (ii) plastics must be transported to the refineries, which is not an easy task given their low density; (iii) plastics must be dissolved in refinery streams. In short, a non-normalized and difficult to obtain feedstock would have to be handled in the refinery.

The first reference in the literature about catalytic cracking in a fixed bed MAT type reactor by feeding VGO blended with HDPE (5 and 10 wt %) at 510 °C reports a substantial production of gasoline from the HDPE plastic contained in the feed (10 wt %).192 Later, the cracking of polyolefins and polyaromatics under conditions similar to those of the industrial unit was studied on a riser simulator reactor with different types of catalysts: (i) equilibrated commercial FCC catalysts;193,194 (ii) commercial fresh catalysts and other in-house synthesized HY zeolite-based catalysts with different porous structures and acidities;195,196 (iii) catalysts prepared in the laboratory using HZSM-5 zeolites as additives.195 The solvents used in these studies for dissolving the plastic were VGO, which is the current FCC unit feed, and light cycle oil (LCO), which is a product stream of the FCC unit with a high content of aromatics.

The cofeeding of polyolefins with LCO increased the yield of gasoline and reduced that of coke. The content of aromatics was reduced in the gasoline fraction, at the same time as the contents of isoparaffins and olefins was increased, thereby leading to an increase in the quality of the gasoline fraction obtained. Moreover, the RON increased with temperature from 98.1 to 99.0 when 10 wt % PE was in the feed.193 The results obtained by cofeeding PP were quite similar. Furthermore, the use of HZSM-5 zeolite as an additive of the catalyst significantly affected product distribution. A notable increase in the yield of olefins was obtained, whereas the yields of aromatics, paraffins, and coke were reduced.195 These results were later on ratified by Marcilla et al.197 in a sand fluidized bed reactor and by Odjo et al.198,199 in a FCC pilot plant. Therefore, the viability of cofeeding polyolefins with VGO without affecting the yields and quality of the product streams is evident.

When 10 wt % PS was cofed with LCO, the conversion surpassed that obtained with pure LCO, the yield of gasoline increased to the detriment of that of dry gases, and the fraction of LPG was mostly olefinic, with propylene and isobutene being the main compounds. Additionally, it should be highlighted that 50 wt % of the styrene in the PS was recovered. The RON of the gasoline, between 97.2 and 95.4, was lower than that obtained in the cracking of pure LCO. This drop is a consequence of the lower content of isoparaffins and olefins. The results obtained by cofeeding PS-BD were qualitatively similar, even though the yield of the gasoline fraction obtained was 2 wt % lower.193

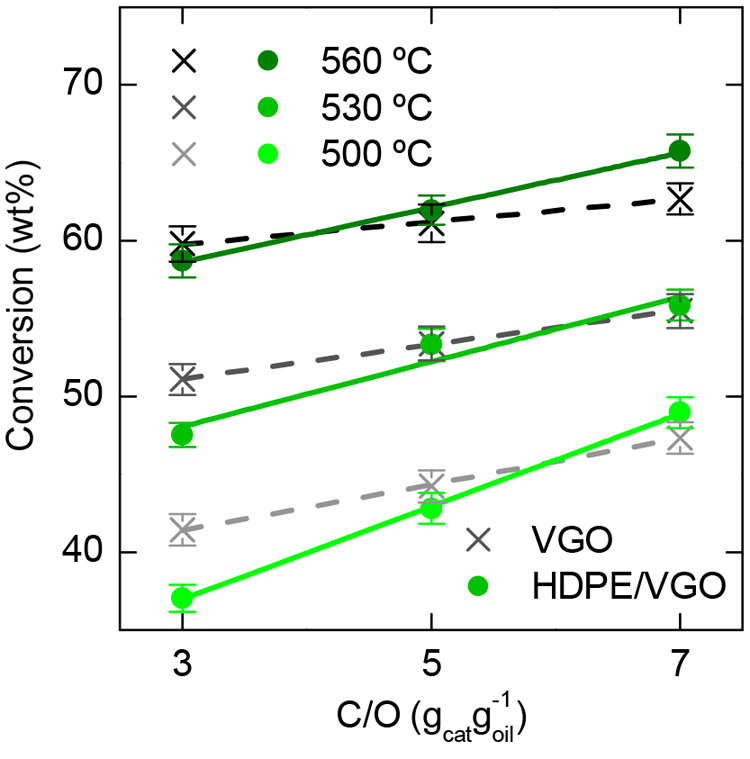

The conversions obtained in the cracking of a HDPE/VGO blend (10 wt % of HDPE) are compared in Figure 10 with those obtained in the cracking of pure VGO. The conversion attained with the blend was in the 37–66 wt % range, whereas with the VGO it was in the 41.4–62.7 wt % range. An increase in the catalyst to feed (C/O) ratio and, especially in temperature, allowed reaching higher conversions in the cracking of the blend.200 For low conversion values, that is low temperature and low C/O ratio, the reactivity of the blend was lower than that of the VGO. However, for a conversion of 58 wt %, the previously mentioned differences disappeared and the crackability of both feeds was similar. Under these conditions, the cofeeding of HDPE promoted the formation of LPG and gasoline fractions, to the detriment of dry gas and coke. The lower formation of coke led to a minor deactivation of the catalyst, which explained the higher yields of LPG and gasoline as well as the lower overcracking observed.200 This work also compared the composition of the gasoline fraction obtained in the cracking of the HDPE/VGO blend with that obtained in the cracking of the VGO, and several differences were observed in the concentration of all the families of hydrocarbons. Nonetheless, the operating conditions lead to similar trends for both feeds. Thus, higher temperatures involve higher concentrations of olefins and lower of the remaining families in the gasoline fraction. Furthermore, these researchers observed subtle differences in the impact of temperature. High temperatures reduced the difference between the concentration of linear and branched paraffins, and the concentration of aromatics reached its maximum value at 530 °C. The effect of increasing the C/O ratio lies in increasing the concentrations of n-paraffins and isoparaffins (especially at 500 °C) in the gasoline fraction and in reducing the concentration of olefins. These modifications in the composition of the gasoline fraction were a consequence of the promotion of hydrogen-transfer reactions. Similarly, the promotion of Diels–Alder reactions led to an increase in the concentration of aromatics in the cracking of the blend. However, the concentration of aromatics increased to a minor extent in the cracking of VGO, because fewer olefins were in this feedstock.

Figure 10.

Evolution of conversion with C/O ratio in the cracking of the HDPE/VGO blend (solid lines) and raw VGO (dashed lines) at different temperatures.200

5.2.2. Plastic Pyrolysis Oil (Waxes)

A previous step of pyrolysis of waste plastics would make much easier their valorization in refinery units. Plastics could be locally converted into liquid or waxy hydrocarbons in small pyrolysis units located near the municipal solid waste collection and sorting points. Accordingly, the subsequent transport of pyrolysis derivatives to the refinery would be easier as a small fleet of tanker trucks would be sufficient to collect all the products of medium-large geographical areas. Furthermore, this feed could be stored and mixed in the refinery oil terminals in order to attain a standard formulation prior to their treatment in the corresponding units.

Iribarren et al.201 determined by life cycle analysis that the combined strategy of pyrolysis and catalytic treatment is the most sustainable management strategy when the perspectives involving energy and environment are considered. Based on these positive points, various authors have approached the catalytic cracking of plastic pyrolysis waxes, either neat202,203 or dissolved.204,205

Rodríguez et al. studied the catalytic cracking of neat HDPE pyrolysis waxes in two different works. First,202 these authors studied the suitability of the FCC unit for the production of fuels from the HDPE pyrolysis waxes. Accordingly, they performed a parametric study where temperature and catalyst to oil ratio were investigated. Moreover, the results were compared with those obtained in the cracking of VGO in order to analyze their trends. Overall, HDPE pyrolysis waxes were less reactive than VGO. Temperatures above 550 °C and C/O ratios of 7 gcat gfeed–1 were required to obtain higher conversions with the waxes. The composition of the gasoline fraction was also different, as it depended on the composition of the feedstock. Thus, the gasoline fraction was more paraffinic and olefinic and less aromatic than that obtained from the VGO. The same authors tested different FCC equilibrated catalysts in the cracking of the waxes203 and concluded that the properties of the catalyst played a significant role in product distribution. In fact, catalysts with low acidity promoted the formation of gasoline with low content of aromatics, suitable to be marketed after a mild hydrotreatment stage, whereas highly acid catalysts were appropriate for the production of commodities, such as C5 and C6 olefins.

Nonetheless, the cofeeding of waste plastic pyrolysis waxes with a benchmark feed provides a more realistic approach concerning the integration of waste plastic valorization into refineries. This strategy was first approached by Lovás et al.,204 as they studied the cocracking of HDPE and PP pyrolysis waxes blended with atmospheric gas oil and hydrotreated gas oil in a MAT experimental apparatus. They concluded that both blends (with HDPE and PP) improved the crackability of the hydrotreated gas oil. Moreover, they observed that the cofeeding of HDPE promoted the formation of light olefins, whereas that of PP increased the formation of the gasoline fraction. Afterward, Rodríguez et al.205 investigated the cocracking of HDPE pyrolysis waxes and VGO in a riser simulator reactor. They determined that the cofeeding of the HDPE pyrolysis waxes had remarkable effects on the process. Thus, the cofeeding inhibited the secondary cracking reactions, which promoted the formation of the dry gas fraction, and increased the yields of LPG and gasoline fractions. Moreover, a reduction in the content of coke was observed because of the higher H/C ratio of the blend. Overall, higher contents of olefins and paraffins and lower contents of aromatics were obtained. Consequently, a LPG fraction rich in ethylene, propylene, and butylenes was obtained with the blend. In addition, a higher quality gasoline fraction was obtained, with values of the octane index being about 103. With regard to coke deposition,206 the cofeeding of HDPE pyrolysis waxes significantly lessened the formation of coke on the catalyst. In addition, its nature was rather different from that obtained in the cracking of neat VGO (Figure 11). Hence, it was less aromatic and more aliphatic and it contained long olefinic chains, which made regeneration easier and could extend the life cycle of the catalyst.

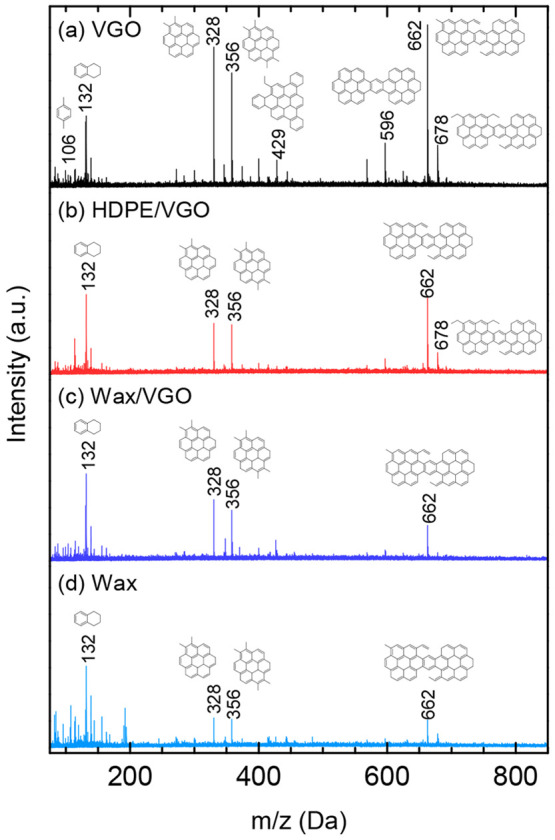

Figure 11.

LDI TOF-MS spectra and main coke species detected in the spent catalyst used in the catalytic cracking of VGO, HDPE/VGO blend, HDPE wax/VGO blend, and neat HDPE wax. Adapted from the work by Rodríguez et al.206

5.3. Cracking of Tire Pyrolysis Oil

Even though the pyrolysis of scrap tires has been extensively analyzed in the literature (section 4.2), the catalytic cracking of TPO has been barely studied. A comparison of the properties of the TPO with those of the streams currently used in the refinery for the production of fuels (Table 5) shows that the TPO could be potentially cofed with these feeds.

Table 5. Properties of the TPO, LCO, and VGO.

| TPO |

||||||

|---|---|---|---|---|---|---|

| properties | stirred tank | rotary kiln | fixed bed | CSBR | LCO | VGO |

| density (kg L–1) | 0.91 | 0.96 | 0.83 | 0.89 | 0.78 | 0.89 |

| viscosity 40 °C (cSt) | 6.30 | 3.30 | 21.0 | |||

| HHV (MJ kg–1) | 42.0 | 41.7 | 42.7 | 44.0 | 44.8 | 46.0 |

| flash point (°C) | 20 | 17 | 65 | 79 | 75 | |

| carbon residue (wt %) | 2.20 | 1.78 | <0.35 | |||

| elemental analysis | ||||||

| C (wt %) | 88.0 | 84.3 | 79.6 | 87.2 | 85.5 | 87.1 |

| H (wt %) | 9.40 | 10.4 | 10.0 | 10.6 | 12.4 | 12.8 |

| N (wt %) | 0.45 | 0.42 | 0.94 | 0.45 | 0.15 | 0.05 |

| S (wt %) | 1.50 | 1.54 | 0.11 | 1.22 | 1.40 | 0.90 |

| proximate analysis | ||||||

| ash content (wt %) | 0.01 | 0.02 | ||||

| moisture (wt %) | 4.60 | 0.88 | 0.05 | 0.10 | ||

| simulated distillation | ||||||

| IBP (°C) | 100 | 38.5 | 129 | 139 | 218 | |

| 90% BP (°C) | 355 | 455 | 352 | 507 | ||

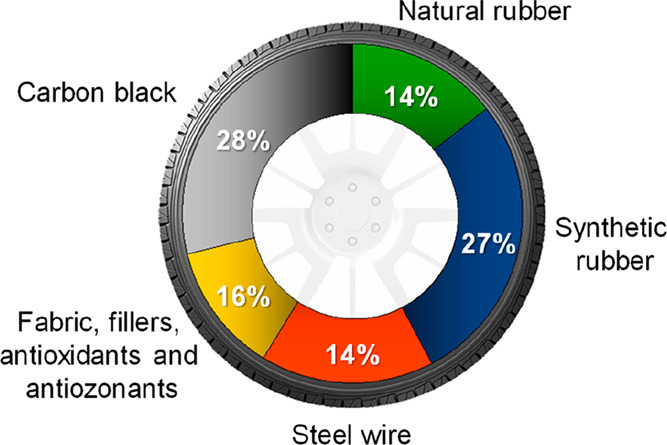

Adapted from the work by Hita et al.71