Abstract

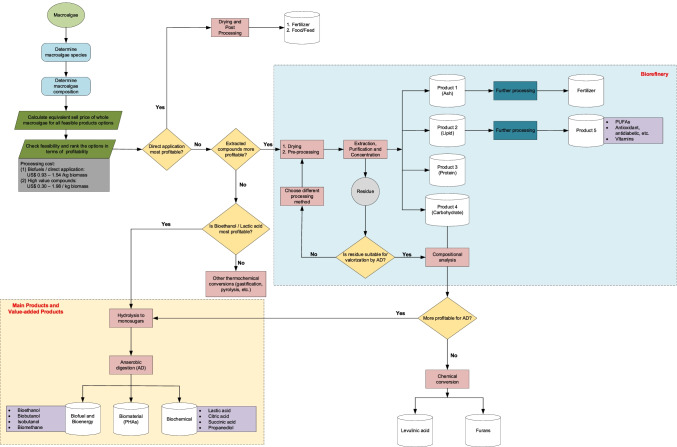

The extensive growth of energy and plastic demand has raised concerns over the depletion of fossil fuels. Moreover, the environmental conundrums worldwide integrated with global warming and improper plastic waste management have led to the development of sustainable and environmentally friendly biofuel (bioethanol) and biopolymer (lactic acid, LA) derived from biomass for fossil fuels replacement and biodegradable plastic production, respectively. However, the high production cost of bioethanol and LA had limited its industrial-scale production. This paper has comprehensively reviewed the potential and development of third-generation feedstock for bioethanol and LA production, including significant technological barriers to be overcome for potential commercialization purposes. Then, an insight into the state-of-the-art hydrolysis and fermentation technologies using macroalgae as feedstock is also deliberated in detail. Lastly, the sustainability aspect and perspective of macroalgae biomass are evaluated economically and environmentally using a developed cascading system associated with techno-economic analysis and life cycle assessment, which represent the highlights of this review paper. Furthermore, this review provides a conceivable picture of macroalgae-based bioethanol and lactic acid biorefinery and future research directions that can be served as an important guideline for scientists, policymakers, and industrial players.

Graphical abstract

Keyword: Bioethanol, High value-added bioproducts, Seaweed, Hydrolysis, Fermentation, Third generation

Introduction

In recent years, skyrocketing global energy demands and limited availability of fossil fuels due to urbanization and progressively growing of the world’s population have escalated renewable energy development. At the same time, due to the COVID-19 pandemic, increment of plastic waste generation is observed as a human propensity towards wearing personal protective equipment (PPE) such as face masks and hand gloves. Besides, the pandemic also slowly shifted human lives to depend on online platforms to get their meals, goods, and groceries delivered. Globally to date, nearly 140-fold of increment of plastic waste had been generated as compared to that produced in 2010 and reached approximately 8.3 billion tons of plastic waste in 2020 [1]. As a result, the interest in developing innovative biorefinery approaches for the production of bioenergies and biopolymers from renewable resources has intensified. The biorefinery concept offers a scheme to facilitate the circular bioeconomy that closes the loop of organic or fresh resources, minerals, carbon, and water. It can be defined as a green and sustainable bioprocess that utilizes the optimum energy potential of organic resources to produce bioenergy and bioproducts through the bioconversion process [2]. From the point of view of circular bioeconomy, the ideas focus on conserving the long-term usage of biomass resources, minimizing contamination on both environment and end-product, and guaranteeing food security while producing jobs for mankind [3]. To this extent, the macroalgae feedstocks tallying with these ideas strengthen the bioeconomy [4].

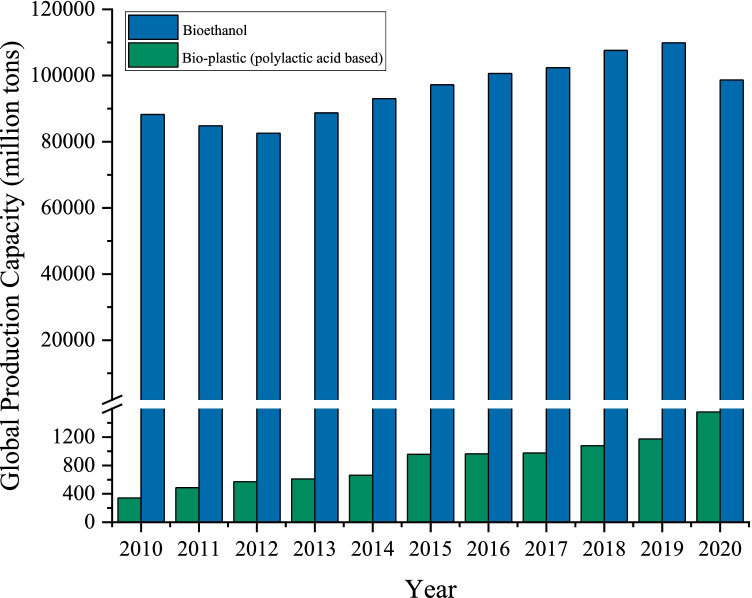

As a consequence, literature related to macroalgal biorefinery showed an increasing trend with expanding research outputs [5, 6]. Macroalgae can be processed towards a variety of rare sugars (glucose, galactose, mannose, and rhamnose) depending on the macroalgae strain, which can then be converted into a wide range of bioproducts by fermentation, including biofuels, biochemicals, biomaterials, and biofertilizer [4]. Among the renewable energies, bioethanol is considered a clean biofuel due to its renewability properties and biodegradability [7]. The global production of bioethanol continues to increase at an average of 5% annually from 2010 to 2019, but production fell worldwide in 2020 due to the pandemic and reached 98.65 billion tons (Fig. 1) [8]. Several nations such as the United States (US), China, India, Turkey, and Brazil have taken the initiative to develop bioethanol production as a commercial fuel [9–11]. Apart from being utilized as a fuel additive, bioethanol can also be converted into various derivatives such as acetic acid and ethylene, which can be further applied as raw material to produce a variety of green solvents and polymers [12].

Fig. 1.

Global production capacities of bioethanol and bioplastic 2010–2020. Adjusted from [8, 15]

In order to achieve sustainable bioeconomic growth, the production of high value-added bioproducts coupled with renewable energies generation in an integrated biorefinery should be prioritized. Apart from bioethanol, biochemical products, especially lactic acid (LA) or 2-hydroxypropionic acid, can also be generated from macroalgae biomass through biotechnological route by using lactic acid bacteria (LAB) to metabolize rare sugars. A large scale of the world’s commercial LA production is currently derived from food-grade sources [13]. On the other hand, large-scale synthesis of LA from edible bioresources may conflict with food and feed availability. Thus, non-edible macroalgae biomass is a better option for biochemical products synthesis due to their high compositional diversity. Moreover, LA is an essential building block for polylactic acid (PLA), a biodegradable and biocompatible aliphatic polyester with various applications. It can be found in the forms of D- and L-enantiomeric, where D( −)-LA and L( +)-LA are outlined as dextro-lactic acid and levo-lactic acid, respectively [14]. In fact, the applications of PLA in different fields have grown enormously in recent years, especially when produced from pure isomers (L( +)- or D( −)-lactic acid) and reached nearly 1.6 billion tons of global production capacity in 2020 [15]. Its applications range from packaging, fibers to foams and biomedical applications such as implants, sutures, bone fixation, scaffold in tissue engineering, and controlled drug delivery [9].

Moreover, the renewability and biodegradability properties of PLA have driven it to become one of the biopolymers that can be utilized as bioplastic. The main advantage of PLA as bioplastic is that the plastic can be degraded in a short time by the action of enzymes and microorganisms such as bacteria and fungi. The microbial degradation of bioplastic occurs with the changes in the chemical structure of the exposed material and normally requires a certain period, which ranges between 11 months and a few years. The degradation period of bioplastic mainly depends on the mechanical (crystallinity and melting temperature) and chemical (molecular weight distribution and chemical structure) properties of PLA and environment conditions (temperature, pH) [16]. Other than biodegradability, the production of plastic by using PLA can save approximately two-thirds of energy consumption compared to the production of petrochemical-based plastic. Furthermore, bioplastic derived from PLA will not increase the net emission of carbon dioxide into the atmosphere since PLA originates from cellulosic and macroalgae biomass. The macroalgae will absorb the carbon dioxide released during degradation [17].

Both bioproducts can be produced through two critical stages of macroalgae biorefinery, including hydrolysis of polysaccharides and fermentation of rare sugars extracted from macroalgae biomass. Thus, it is widely regarded as a superior approach for the sustainable valorization of biomass to meet the future multi-fold demand of commodities [18]. The fermentation process, which metabolize rare sugar to bioproducts, has taken place after the disruption of the cell wall which also can be defined as the hydrolysis process. Tan and Lee [19] reported that bioethanol fermentation could be done by selecting Saccharomyces cerevisiae to ferment the rare sugars from hydrolysates. The robust characteristics of S. cerevisiae that enable it to be used under a wide range of pH have promoted it to become the most commonly employed yeast in bioethanol production [20]. According to Alexandri et al. [21], Bacillus coagulans is favorable in the anaerobic conversion of rare sugars from hydrolysates to LA. Various configurations of hydrolysis and fermentation have been employed in bioethanol and biobased product generation. The configuration for both processes can be categorized into separate hydrolysis and fermentation, simultaneous saccharification and fermentation, and high cell density culture [22, 23].

This paper was systematically designed to critically review the prospects of biorefineries in transforming biomass into value-added products as a strategy for sustainability. Even though extensive reviews on biomass utilization had been published in the past few years, the current study focused on the latest trends and state-of-the-art technological development in this area. In addition, the advantages of different integration scenarios for bioethanol and LA production were also compared extensively. On the basis of the different integration scenarios, some recommendations were pointed out for future research directions on the seamless integration of third-generation bioethanol and LA production from macroalgae-based feedstocks. Therefore, this review provides essential technical information on the contemporary status and future trends of macroalgae biomass utilization to realize the pursuit of a green and sustainable economy.

Limitations and challenges of first and second generations of microbial bioethanol and lactic acid production

Bioethanol is one of the liquid alcohol–based biofuels, while LA is one of the acid- and alcohol-based biochemicals which can be produced by anaerobic conversion of carbohydrates extracted from various types of feedstocks such as food waste, woody biomass, agricultural residual, and edible crops using microorganisms and bacteria [24, 25]. In recent years, L-LA with high enantiomeric purity is displaying great potential for various applications in different industries (e.g. polymer, food, and pharmaceutical industries) as food packaging material, preservative, and flavoring agent [26]. In this section, several restrictions and drawbacks of existing bioethanol and LA production were discussed comprehensively, such as issues of using food carbohydrates as feedstocks for bioproducts synthesis, sensitivity to inhibitory compounds during pretreatment of lignocellulosic biomass, indirect utilization of polymeric sugars (cellulose in all macroalgae and xylan in green macroalgae), and impacts on bioproducts productivity due to the end-product inhibition (Table 1). Being the most demanded biofuel and biopolymer for resolving the energy and environmental issues, bioethanol and LA production have passed through several technological advancements to increase global productivity due to the technical and economic challenges with respect to first-generation feedstocks (edible crops, corn husk) and second-generation feedstocks (woody biomass, agricultural residual) in bioethanol and LA production [27].

Table 1.

Differences among bioethanol and lactic acid generations

| Generation | Feedstocks | Advantages | Limitations | Reference |

|---|---|---|---|---|

| First | Cereal crops (wheat, oats, grain sorghum) Edible oil seed (sunflower, cucumber, soybeans) Sugar crops (sugar beet, sugarcane, sweet sorghum) | Low production cost; Fairly simple conversion technology; Availability of industrial and commercial-scale equipment | Fluctuation of bioethanol selling price Food security Increasing global food price; Extensive demand on agricultural land and water consumption in cultivation phase; Bioethanol quality depends on environmental condition Massive usage of fertilizers and pesticides; Required laborious harvesting process | [28, 29] |

| Second | Energy crops (maize, sudan grass, millet) Lignocellulosic biomass (LCB) (corncobs, corn stover, wheat straw, grasses) Non-edible oil seed Waste stream | No food vs. energy competition; Abundancy of feedstocks at lower costs compared to edible crops; Availability of industrial and commercial-scale equipment; Lesser amount of fertilizers and pesticides compared to first-generation feedstocks | Extensive demand on agricultural land and water consumption in cultivation phase; Bioethanol quality depends on environmental condition Delignification is required for LCB; Complex and costly manufacturing, upgrading, and development process; Need for novel and emerging technologies to reduce the conversion costs | [30–32] |

| Third | Algae (microalgae, macroalgae, water hyacinth) | No food vs. energy competition; Fast growth rate; Producing algal biomass with high amounts of carbohydrates, proteins, and lipids Capable of yielding high amount of bioethanol per unit land area compared with terrestrial biomass; Contain lower amount of lignin compared to LCB; Capable of algal biomass to be cultivated in non-arable land and wastewater; Feasibility of algae-based wastewater treatment to eliminate the harmful components mainly phosphorus and nitrogen; Reduction of greenhouse gas emission level by fixation of carbon dioxide in the algae cultivation; Compatibility with co-production of multiple products by biorefinery process | Large-scale cultivation lead to change of nutrient content and water hydrology characteristics of marine ecosystem; Expensive algae harvesting process; Difficult scaling up of lab-scale production rate to industrial and commercial quantities; Lack of research and technological development for commercial and industrial-scale equipment | [4, 33] |

1G microbial bioethanol and lactic acid production

The feedstocks for first-generation (1G) bioethanol and LA are generally classified into food-based, starch-based (corn, barley, grain sorghum, wheat, and oats), and sugar-based crops (sugar beet, sugarcane juice, and sweet sorghum) [28, 34, 35]. The 1G bioethanol and LA can be produced from direct fermentation of hexose sugars or polysaccharides converted into rare sugars without pretreatment [36]. 1G bioethanol processing technologies in the US, Brazil, Turkey, and several countries in Europe have been commercialized for over two decades [29]. However, several studies reported that 1G bioethanol encounters economic issues such as fluctuating prices for commercial bioethanol production and inconsistent feed supply, which caused global food security as bioethanol is derived from food crops [34]. Renewable Fuels Association [37] had reported that maize was primarily used for 1G bioethanol and LA production in the US, which raised the conflict between bioethanol production and food consumption. The usage of edible food as feedstock poses a considerable ethical dilemma and strongly polarized debate, generally referred to as the “food vs. biofuel.” The supply of edible food as feedstock can also become a potential limiting factor due to the potential increased demand.

2G microbial bioethanol and lactic acid production

Second-generation (2G) biorefinery, also known as lignocellulosic biorefinery, is introduced to replace the 1G biorefinery approach for both bioethanol and LA production as its feedstocks are based on non-food raw materials that do not compete with the food supplies. One of the most common raw materials for 2G biorefinery is lignocellulosic biomass (LCB), which can be classified into woody biomass, agricultural residues (rice straw, grasses, and corncobs), forest residual, and energy crops [30–32]. Lignocellulosic waste contains three major chemical compositions: cellulose, hemicellulose, and lignin which can be processed into biofuels, biochemicals, and reinforcement agents for biopolymer, respectively [32]. The chemical compositions of different biomass can vary greatly from each other. However, several works of literature have reported that lignin is strongly bounded with cellulose-hemicellulose complex via hydrogen and covalent bonds, which render the structures to be highly stable and recalcitrant for depolymerization [38–40]. Thereby, delignification process is introduced with the usage of chemicals to remove the lignin complex and ensure the optimum yield of rare sugars can be attained [41]. Moreover, LCB requires a large scale of land for cultivations, which caused the issue of land-use competition [29]. Recently, European Parliament had raised a vote to phase out the usage of oil palm–based bioethanol as transport fuels from 2030 due to the European Union (EU) aimed to make the EU climate neutral by 2050. Owing to the cultivation of oil palm offers the highest indirect greenhouse gas (GHG) emissions, which is caused by the drainage of peatlands and deforestation [37]. Thus, lignocellulosic-derived bioethanol and LA are commercially limited due to the high production cost and environmentally unfavorable biorefinery processes [42].

Exploitation of macroalgae as a potential feedstock for 3G bioethanol and lactic acid production: a sustainable approach

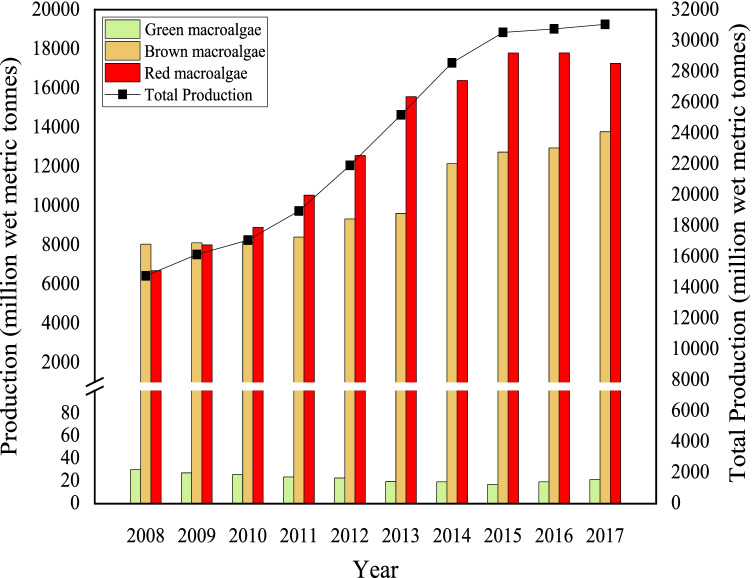

The development of a sustainable feedstock is needed to overcome the limitations encountered by 1G and 2G bioethanol and LA production. In view of this, algal biomass is a promising alternative feedstock as the third-generation (3G) energy and polymer resources. Saccharification of macroalgal polysaccharides to fermentable sugar and LA production is still yet to be studied. In this context, clarification on the algal biorefineries concept is paramount to attract the attention of researchers on the perspectives of algal-based bioethanol and LA production. Macroalgae have shown significant potential as feedstocks for bioethanol and LA production. Macroalgae, also known as seaweed, are photosynthetic and multicellular eukaryotic organisms present abundantly in oceans [4]. Red algae (Rhodophyta), green algae (Chlorophyta), and brown algae (Phaeophyta) are the main types of macroalgae that derive their colors based on chlorophyll and natural pigment synthesis. The carbohydrate-rich strain of macroalgae has driven it to become the most sustainable resource for the production of high rare sugar yield [43]. The world production of macroalgae had increased dramatically at an average increment rate of 10% annually over the past 10 years (2008–2017) and reached 31.05 million tons, which is worth over US$11.3 billion [44]. From Fig. 2, the cultivation of red and brown macroalgae has increased in the last 10 years. In recent years, the drastic growth in macroalgae production is mostly owing to increased demand for macroalgae applications in agricultural and biofuel production. Gajaria et al. [45] reported that green macroalgae were suitable to be applied as a sustainable source of bioactive compounds for biofertilizer production. Moreover, the red and brown species of macroalgae are mainly cultivated for the application of renewable energy production and wastewater treatment processes [19, 22, 46].

Fig. 2.

World production of farmed macroalgae from 2008 to 2017. Adjusted from Adjusted from [44]

Several laboratories work on the utilization of macroalgae for the generation of bioethanol and LA that had been reported in the literature, and the chemical compositions for selected macroalgae are shown in Table 2. These studies revealed that carbohydrates in the form of glucose polysaccharides such as cellulose could be found in macroalgae, laminarin can be found in brown algae, cellulose and starch can be found in both red and green algae, and other polysaccharides such as mannitol and alginate were contained in brown algae, agar, and carrageenan in red macroalgae and ulvan in green macroalgae [47–49]. Hence, macroalgae are generally considered sustainable sources for fermentable sugar. It also addresses the sustainability concerns related to food supplies and land cultivation suffered by the edible crops and LCBs [50, 51]. Unlike terrestrial plants, macroalgae possess many excellent properties such as abundance in supply, ability to grow in seawater (not competing with agricultural land for cultivation), and low lignin content [52]. Enormous quantities of macroalgae can be found in the oceans, so the rigidity conferred by lignin is pointless to the macroalgae. This highlights a major benefit of biorefinery processing because the delignification of the biomass is no longer required. This will further simplify the carbohydrates extraction and the saccharification process. Moreover, the detoxification or neutralization process, which is usually needed to remove the inhibitory compounds (5-HMF, furfural acid, and irreversible salts) produced during the delignification process of LCBs, can be eliminated leads to lower production cost [4]. Thus, macroalgae biomass is a cost-effective feedstock for 3G bioethanol and LA production [53].

Table 2.

Summary of polysaccharides in different macroalgae and major monosaccharides via hydrolysis

| Macroalgae group | Macroalgae | Polysaccharides | Major monosaccharides | Reference |

|---|---|---|---|---|

| Rhotophyta | Gracilaria sp. | Cellulose | Glucose | [22] |

| Agar | Galactose | |||

| Kappaphycus alvarezii | Cellulose | Glucose | [47] | |

| Carrageenan | D-galactose | |||

| Agar | Galactose | |||

| Gelidiopsis variabilis | Cellulose | Glucose | [57] | |

| Agar | Galactose | |||

| Chondrus crispus | Cellulose | Glucose | [58] | |

| Chlorophyta | Enteromorpha intestinalis | Cellulose | Glucose | [59] |

| Xylan | Xylose | |||

| Mannose | D-glucuronic acid | |||

| L-rhamnose | ||||

| Ulva lactuca | Ulvan | Glucose | [48] | |

| Xylose | ||||

| L-rhamnose | ||||

| Glucuronic acid | ||||

| Iduronic acid | ||||

| Cellulose | Glucose | |||

| Phaeophyta | Laminaria digitata | Alginate | Mannuronic acid | [49] |

| Guluronic acid | ||||

| Fucoidan | Frucose | |||

| D-xylose | ||||

| D-galactose | ||||

| D-mannose | ||||

| Glucuronic acid | ||||

| Cellulose | Glucose |

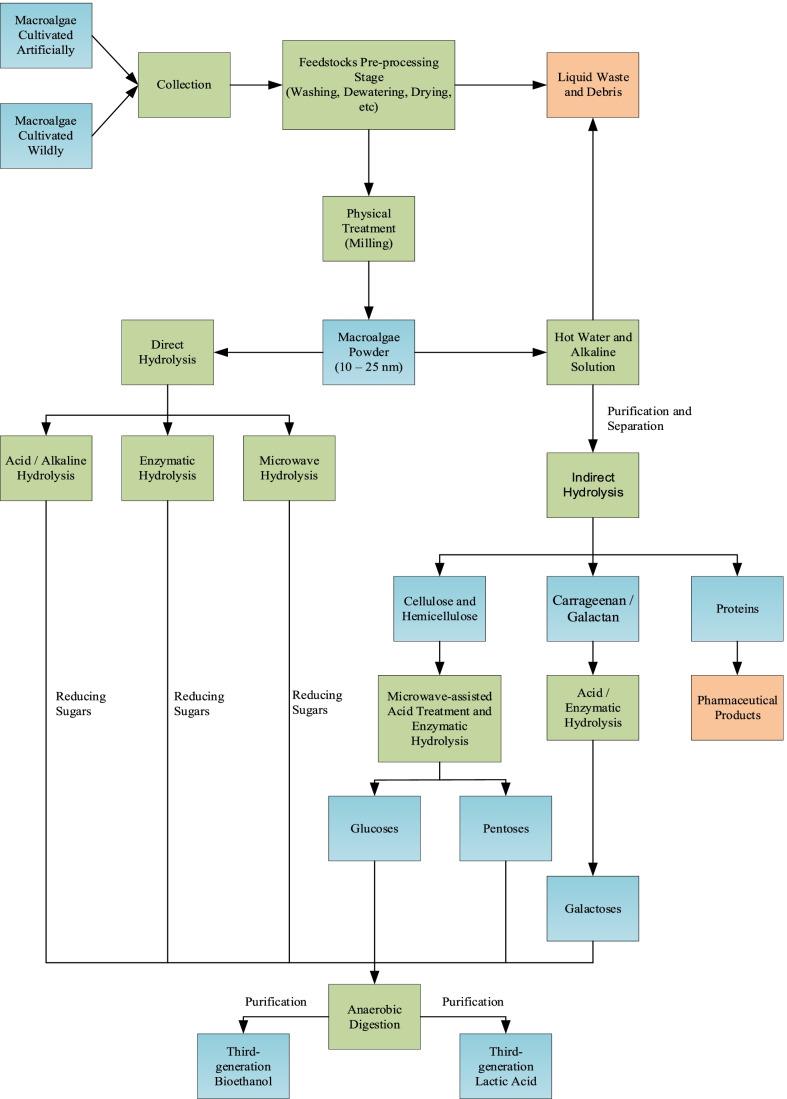

The macroalgae bioethanol and LA production processes include milling, pretreatment, hydrolysis (saccharification), fermentation, and distillation [54]. An overview of all stages for macroalgae-based bioethanol and LA generation is summarized in Fig. 3. Hydrolysis is essential to disintegrate and hydrolyze the cell wall of macroalgae to release the carbohydrates such as cellulose and other rare sugars for fermentative microorganisms [55]. The carbohydrates in the cell wall of macroalgae can be hydrolyzed easily to form monosaccharides via hydrolysis due to the low lignin content in macroalgae. However, in the work by Kostas et al. [49], it was highlighted that hydrolysis of pretreated brown macroalgae Laminaria digitata would yield a higher amount of rare sugars, which is approximately 93.80% as compared to hydrolysis of untreated biomass under the same loading. This was due to the pretreatment on macroalgae increasing the reaction surface area of carbohydrates in macroalgae and thus maximizing the fermentable sugar yield [56]. The fermentation process is followed after the disruption of the cell wall to produce fermentable sugar. The alcoholic fermentation is carried out using yeast under anaerobic conditions along with the hydrolysate [20]. Like 2G LA, 3G LA can be derived from the residual medium, which contains xylose and galactose hydrolyzed from macroalgae using LAB. In contrast, to glucose, which is a priority consumed by yeast strain for bioethanol production, conversion of xylose and galactose is slower due to the slower reaction kinetics [18, 20].

Fig. 3.

Flow chart of macroalgal bioethanol and lactic acid production process

Utilization of macroalgae biomass

Marine macroalgae are composed of different constituents (phycocolloids and celluloses), which could be fractionated into different constituents for refining separately or processed as whole biomass [4].

Extraction of phycocolloids from macroalgae biomass

Macroalgae is considered the natural resource of hydrocolloids which consist of various types of phycocolloid such as alginate, agar, carrageenan, fucoidan, and ulvan [60]. These phycocolloids are heterogeneous polysaccharides other than cellulose derived from macroalgae composed of sugars with unique chemical structures and commercially valued [61]. For instance, carrageenan extracted from red macroalgae consists of ester sulfate D-galactose and 3,6-anhydro-D-galactose (D-AHG). Herein, D-galactose is one of the abundantly used sugars in the carbohydrate-based biorefinery, while D-AHG has practical application for skin whitening and cell generation [62–64]. Meanwhile, sugars like 3,6-anhydro-L-galactose (L-AHG), L-rhamnose, L-fucose, and glucuronic acid can be found in agar from red macroalgae, ulvan from green macroalgae, fucoidan, and alginate from brown macroalgae, respectively [47–49]. Among the phycocolloids, agar, alginate, and carrageenan have been used widely as thickener and emulsifiers in food and textile industries to improve the viscosity of the aqueous solutions and the texture in foods [65]. Besides, the monomer sugars from phycocolloids could be used to generate bioethanol and LA through microbial fermentation [64].

Owing to the variety of macroalgae phycocolloids and their unique monomer sugars, which possess commercial significance for a wide range of applications, the extraction technology for macroalgae phycocolloids has been scarcely explored and upgraded over the years for enhancing the extraction yields. Various solvents, including distilled water, acidic or alkaline solution in stand-alone or in combinations employed for conventional and innovative phycocolloids extraction, are presented in Table 3. These studies revealed that specific approaches had been employed to extract the targeted phycocolloids from the cell wall of the specific macroalgae strain as the phycocolloid composition of macroalgae varies depending on the species. From the studies, the application of distilled water and alkaline in agar extraction is strain-dependent. For instance, an alkali extraction method is required for both Pyropia spp. and Gracilaria spp. to form L-AHG, which is responsible for producing a high-strength gel by eliminating the sulfate groups in agar, whereas this extraction method is not required for Gelidium spp. [66–68]. In contrast, both acidic and alkali extraction methods are required for alginate extraction. Acid such as hydrochloric acid (HCl) is mainly applied in alginate extraction for solubilizing the calcium alginate fraction in the brown macroalgae to alginic acid. To produce a more commercially valued phycocolloid, sodium carbonate (Na2CO3) is employed to transform the alginic acid to sodium alginate, a sodium salt that has a variety of applications, including hydrogels for cell immobilization and dental impression materials [69, 70]. In the case of carrageenan extraction, the alkali extraction method is not prioritized, but chelating agents such as calcium hydroxide (Ca(OH)2) and potassium hydroxide (KOH) can be utilized to improve the carrageenan-gel strength [71, 72].

Table 3.

Summary of pretreatment and extraction approach for macroalgal phycocolloids from macroalgae strain at laboratory and industrial level

| Targeted phycocolloid | Macroalgae strain | Pretreatment | Extraction procedure | Reference |

|---|---|---|---|---|

| Agar | Pyropia yezoensis | Washed with water | Ratio 1:30 algae/4% (v/v) NaOH Oil bath with 4% NaOH (80 °C, 2 h), followed by autoclave with 260 mL distilled water (130 °C, 1 h) | [66] |

| Agar | Gracilaria lemaneiformis | No pretreatment | Ratio 1:20 algae/reaction solution EAE in distilled water with 4 U/mL cellulases (50 °C, 1 h), followed by 3% NaOH (87 °C, 3 h) EAE in distilled water with 8 U/mL cellulases and 26.6 U/mL arylsulfatase (50 °C, 3 h) | [67] |

| Agar | Gelidium sesquipedale | Washed with water and milled into powder form | Ratio 1:10 algae/distilled water Maceration in distilled water (90 °C, 2 h), followed by screened through muslin cloth and freeze-dried (− 25 °C, 24 h) UAE (400 W, 24 kHz, 30 min) | [68] |

| Alginate | Sargassum muticum | Washed with water and oven-dried (65 °C) | Ratio 1: 10 algae/reaction solution Maceration in 0.2% CH2O (RT, 24 h), followed by 0.2 M HCl and washed with 3% Na2CO3 | [70] |

| Alginate | Sargassum binderi | Washed with water and macerated in 80% ethanol (RT, 24 h) | Ratio 1: 100 algae/distilled water Distilled water at pH 11.0, followed by UAE (150 W, 50 °C, 30 min) | [92] |

| Alginate | Sargassum angustifolium | 85% ethanol (1:4 g/mL, RT, 24 h). Rinsed with acetone and dried in fume hood (RT, 24 h) | Ratio 1:8 algae/reaction solution EAE in distilled water with 5% (w/w) alcalase (pH 8, 50 °C, 24 h) | [89] |

| Alginate | Sargassum muticum | Washed with water | Ratio 1:20 algae/distilled water UAE (150 W, 1.5 A, 40 Hz, RT,30 min) | [83] |

| Alginate | Nizamuddinia zanardinii | Washed with water and milled into powder form Pretreated with 0.2 M HCl using high voltage electrode discharge | Ratio 1:32 algae/reaction solution Maceration in 2% CH2O (RT, 200 rpm, 24 h), followed by 0.2 M HCl (60 °C, 150 rpm, 3 h) and 3% Na2CO3 (60 °C, 250 rpm, 2.5 h) | [93] |

| Carrageenan | Hypnea musciformis | Washed with water, oven-dried (60 °C) and milled into powder form | Ratio 1:50 algae/3% (v/v) KOH Macerated in 3% KOH (85 °C, 3.5 h) MAE (105 °C, 10 min, 2450 MHz) | [80] |

| Carrageenan | Kappaphycus alvarezii | Washed with water | Ratio 1:20 algae/0.5% (v/v) Ca(OH)2 Maceration in 0.5% Ca(OH)2 (RT, 2 h), followed by autoclave with 200 mL distilled water (107 °C, 1.5 h) | [71] |

| Carrageenan | Hypnea musciformis | Methanol-acetone mixture with a ratio of 1:1 (RT, 12 h) | Ratio 1:150 algae/3% (v/v) KOH Macerated in 3% KOH (80 °C, 4 h) UAE (500 W, RT, 20 min) | [72] |

| Carrageenan | Eucheuma denticulatum | Washed with water and macerated in 80% ethanol (RT, 24 h) | Ratio 1:100 algae/distilled water Distilled water at pH 7.0, followed by UAE (150 W, 50 °C, 30 min) | [92] |

| Carrageenan | Kappaphycus alvarezii | Washed with water and milled into powder form | Ratio 1:16 algae/1% (v/v) ionic liquid Ionic liquid assisted SWE (180 °C, 5 MPa, 200 rpm, 5 min) | [47] |

| Carrageenan | Eucheuma denticulatum | Washed with water and milled into powder form | Ratio 1:20 algae/distilled water Maceration in distilled water (90 °C, 1 h), followed by screened through 45 µm mesh and oven-dried (80 °C, 72 h) | [62] |

| Fucoidan | Splachnidium rugosum | Washed with water and oven-dried (45 °C, 72 h) | Ratio 1:100 algae/distilled water Maceration in distilled water (70 °C, 24 h), followed by screened through Whatman filter paper and freeze-dried (− 80 °C, 24 h) | [94] |

| Fucoidan | Nizamuddinia zanardinii | 85% ethanol (1:10 g/mL, 2000 rpm, RT, 24 h). Rinsed with acetone and dried in fume hood (RT, 24 h) | Ratio 1: 21 algae/distilled water SWE (150 °C, 7.5 bar, 1500 W, 29 min | [91] |

| Ulvan | Ulva pertusa | 80% ethanol (1:4 g/mL, 85 °C, 2 h), the precipitated was collected and oven-dried (50 °C) | Ratio 1:55.45 algae/distilled water MAE (600 W, 43.63 min, pH 6.57) | [81] |

| Ulvan | Ulva pertusa Kjellm | Milled into powder form and macerated in 80% ethanol (1:4 g/mL, 24 h) | Ratio 1:20 algae/distilled water Maceration in distilled water (90 °C, 3 h), followed by a precipitation of residue with 95% ethanol EAE in distilled water with 5% (w/w) 50,000 U/g cellulases (50 °C, 2.5 h) | [87] |

| Ulvan | Ulva fasciata | Dichloromethane (1:20 g/mL, 250 rpm, RT, 24 h) and ethanol (1:20 g/mL, 250 rpm, RT, 24 h). Rinsed with acetone and dried in a fume hood (RT, 24 h) | Ratio 1:20 algae/distilled water Maceration in distilled water (120 °C, 3 h), followed by screened through the non-woven fabric and dried in RT | [95] |

RT room temperature

Moreover, the extraction method is temperature-dependent based on the targeted phycocolloids. For agar extraction, operation temperatures above 80 °C are required for complete solubilization of agar from red macroalgae [66–68]. Besides, carrageenan is a group of water-soluble anionic sulfated polysaccharides soluble either in cold or hot water but depending on the genus of red macroalgae [73]. Das et al. [71] revealed that the carrageenan from Kappaphycus alvarezii can be solubilized in a 0.5% Ca(OH)2 solution at room temperature without being heated. On the other hand, ulvan from green macroalgae is only soluble in hot water with operation temperatures above 90 °C [74]. However, pH is the main solubilizing parameter for alginate extraction, and thus, the pH should be maintained above the pKa value of alginate (pKa > 3.65) [75]. From Table 3, hot water extraction (HWE) followed by filtration, centrifugation, and purification are the conventional phycocolloid extraction techniques employed by many researchers [62, 68, 71]. However, from the industrial point of view, the conventional extraction technique is constrained by requiring a high extraction temperature, longer extraction time that will cause severe depolymerization of phycocolloid chain, and effluents generated by this technique caused water pollution problems due to the usage of toxic chemicals [76, 77].

To improve the drawbacks of conventional extraction technology, innovative and eco-friendly extraction protocols are increasingly developed, including microwave-assisted extraction (MAE), ultrasound-assisted extraction (UAE), enzyme-assisted extraction (EAE), and subcritical water extraction (SWE) [78]. MAE technology is based on the application of electromagnetic radiation at frequencies and wavelength ranges between 0.3–300 GHz and 0.001–1 m, respectively, to transfer energy for rapid internal heating on the sample matrix and macroalgae cell wall disruption [79]. MAE has been applied successfully to extract carrageenan from Hypnea musciformis under 150 °C with an operation duration of 10 min [80]. MAE demonstrated to achieve higher carrageenan yields which are approximately 16.6% compared to the conventional alkali extraction method (85 °C, 3.5 h) that achieved approximately 3.74% yield per gram of biomass with a reduction of reaction time and volume of KOH used [80]. Ulvans from Ulva pertusa was also extracted by Le et al. [81] using MAE obtaining 41.91% yield at a microwave power of 600 W for 43.63 min.

On the other hand, UAE technology is based on the application of sound frequencies ranging between 0.2 and 10 MHz to treat the samples by applying agitation, pressure, shear force, compression-rarefaction, and radial formation on the sample matrix to enhance the cell wall disruption [82]. Martínez-Sanz et al. [68] concluded that UAE with non-alkali treatment (400 W, 24 kHz) and conventional HWE method achieved similar agar yields (10–12%) extracted from Gelidium sesquipedale; however, UAE successfully reduced the extraction time by fourfold. Alginates from Sargassum muticum were also extracted by Flórez-Fernández et al. [83] using UAE (150 W, 40 Hz, 30 min), obtaining 15% yield with a low mannuronic/guluronic ratio of 0.64 that resulted in a soft gel with high viscosity. Alginate gels with high guluronic acid content are essential in food and cosmetic industries, which are widely used as resistant gels in food and cosmetic products [84]. Besides achieving a higher yield of carrageenans from Hypnea musciformis, Rafiquzzaman et al. [72] also reported that the UAE method possesses specificity to extract pure kappa-carrageenan and eliminate the desulfation on the extracted carrageenan, which can enhance the properties of carrageenans. This is mainly due to carrageenans containing higher than 25% of sulfate groups being reported to have strong antiviral effects on both problematic enveloped and non-enveloped viruses such as hepatitis A, dengue virus, and human immunodeficiency virus [85].

As an emerging and innovative extraction technology, EAE was also explored to obtain phycocolloids from various macroalgae biomass. EAE technology is based on the application of enzymes secreted from microorganisms to disrupt the macroalgae cell wall for releasing the polysaccharides [86]. The use of EAE involving cellulase was explored by Chen et al. [87] to enhance the ulvan extraction from Ulva pertusa Kjellm. The yield of ulvans extracted through EAE was comparable to conventional HWE and UAE methods, in which the yields were 25.3%, 17.8%, and 20.6%, respectively [87]. Compared to the conventional extraction method that involved the use of calcium chelating agents to break the glycosidic bonding between the ulvan and cell wall matrix, EAE is considered as a simplified method that does not require the usage of chelating agents and dialysis process due to enzyme-assisted disruption of the macroalgae cell wall [88]. Borazjani et al. [89] extracted alginates from Sargassum angustifolium by EAE, using alcalase and cellulase. The use of both enzymes showed no significant differences in the alginates yield compared to the conventional HWE method, but the protein and polyphenol contents in the extracted alginates were significantly reduced coupled with enhanced purities. Furthermore, SWE is the advanced extraction method of HWE with the use of pressurized hot water for the isolation of phycocolloids from macroalgae [90]. Alboofetileh et al. [91] concluded that SWE (150 °C, 7.5 bar) successfully increased the fucoidan yields from Nizamuddinia zanardinii by approximately fivefold compared to the conventional HWE method, where the fucoidan yields were 25.98% and 5.2%, respectively. Besides, high temperatures observed in SWE facilitated reducing the extraction time by 12.4-fold compared to HWE [91]. It can be concluded that a considerable reduction in extraction times and increment in extraction yields can be achieved with minimal impact on the quality of phycocolloids extracted. Thus, the innovative extraction methods are considered the facile greener alternative to the conventional extraction methods for separating cellulose from macroalgal phycocolloids prior to being utilized for macroalgae-based bioethanol and LA production.

Synthetic pathway for rare sugars from macroalgae biomass

Besides being fractionated into different constituents and refined separately to high value-added bioproducts, macroalgae can be processed as whole biomass. The extraction of rare sugars such as glucose, galactose, and mannose from macroalgae has been explored extensively. Various hydrolysis techniques and rare sugar yields for bioethanol and LA production from macroalgae are described in Table 4. However, the extraction methods are technically similar to that for producing common sugars (glucose) from 1G- and 2G-based polysaccharides [96]. The main process is disrupting the cell wall and breaking the glycosidic bonds between polysaccharides to release rare sugars as the crystallinity of cellulose has provided greater stability and rigidity to the macroalgae cell wall. Hence, these structures have to be modified either by using chemo-catalytic, biocatalytic, thermal-catalytic, or innovative hydrolysis processes [97]. Before being processed using the chemical or biological hydrolysis method, macroalgae biomass is subjected to physical pretreatment to reduce the cellulose crystallinity in the cell wall matrix [98]. The mechanical comminution technique, which consists of the chipping and milling process, has been widely used to pretreat and reduce the biomass size to 10–25 nm. This will increase the reaction surface area of biomass to other hydrolysis reagents and reduced the crystallinity of cellulose [99].

Table 4.

Comprehensive review of various hydrolysis techniques for macroalgal biomass

| Macroalgae strain | Pretreatment | Hydrolysis technique | Hydrolysis procedure | Rare sugar yield (%) | Reference |

|---|---|---|---|---|---|

| Chemo-catalytic hydrolysis approach | |||||

| Gracilaria verrucosa | Washed with water, oven-dried (60 °C, 48 h), and crushing | Solid acid hydrolysis | S/L ratio of 1:7.5, 15% (w/w) Amberlyst-15 (140 °C, 2.5 h) | 51.90 | [100] |

| Eucheuma cottonii | Washed with water, oven-dried (40 °C), and crushing | Solid acid hydrolysis | 16% (w/v) biomass, 6% (w/v) Dowex™ Dr-G8 (120 °C, 1 h) | 43.20 | [19] |

| Eucheuma cottonii | Washed with water, oven-dried (40 °C), and crushing | Acid hydrolysis | 16% (w/v) biomass, 0.2 M H2SO4 (120 °C, 2.5 h) | 34.60 | [19] |

| Ulva fasciata | Washed with water, oven-dried (60 °C, 24 h), and crushing | Acid hydrolysis | S/L ratio of 0.1:5, 3% (w/w) H2SO4 (121 °C, 15 min) | 70.06 | [101] |

| Kappaphycus alvarezii | Milled into powder form | Hyper thermal acid hydrolysis | 10% (w/v) biomass, 360 mM H2SO4 (140 °C, 10 min) | 60.50 | [102] |

| Ulva rigida | Washed with water, oven-dried (60 °C, 24 h), and crushing | Thermal acid hydrolysis | 10% (w/v) biomass, 4% (v/v) H2SO4 (121 °C, 1 h, pH 7.0) | 60.20 | [103] |

| Ulva rigida | Washed with water, oven-dried (60 °C, 24 h), and crushing | Thermal acid hydrolysis | 15% (w/v) biomass, 5% (v/v) HCl (121 °C, 1 h, pH 7.0) | 30.00 | [103] |

| Gracilaria manilaensis | Washed with water, oven-dried (80 °C, 24 h), and crushing | Acid hydrolysis | S/L ratio of 1:20, 2.5% (w/v) H2SO4 (120 °C, 60 min) | 42.34 | [104] |

| Gelidium elegans | Washed with water, oven-dried (75 °C) | Acid hydrolysis | S/L ratio of 1:20, 2.5% (w/v) H2SO4 (120 °C, 40 min) | 39.42 | [105] |

| Biocatalytic hydrolysis approach | |||||

| Saccharina latissima | Washed with water, oven-dried (30 °C), and crushing | Enzymatic hydrolysis | 25% (w/v) biomass, 6.3 mg/g CellicCTec2 (37 °C, 3 h), 0.7 mg/g alginate lyase (50 °C, 17 h), 100 mM citric acid-sodium phosphate buffer (pH 6.3) | 48.65 | [106] |

| Enteromorpha sp. | Washed with water, air-dried, and crushing | Enzymatic hydrolysis | 3% (w/v) biomass, 10 FPU/g cellulase from Aspergillus niger (~ 0.8 U/g), 0.1 M sodium acetate buffer (50 °C, 96 h, pH 5.0) | 70.48 | [107] |

| Kappaphycus alvarezii | Washed with water, oven-dried (50 °C, 24 h), and crushing | Enzymatic hydrolysis | 1% (w/v) biomass, 60 Unit/g enzyme (Celluclast® + β-glucosidase), 0.1 M citrate buffer (50 °C, 8 h, pH 4.8) | 37.00 | [108] |

| Thermal-catalytic hydrolysis approach | |||||

| Sargassum muticum | Washed with water and crushing | Subcritical water hydrolysis | 14.3% (w/v) biomass, hydrolyzed (170 °C, 25 min) | 34.89 | [109] |

| Gelidium sesquipedale | Washed with water, oven-dried (40 °C), and crushing | Subcritical water hydrolysis | 4% (w/v) biomass, hydrolyzed (170 °C, 40 min) | 38.34 | [110] |

| Ulva intestinalis | Oven-dried (60 °C), and crushing | Steam explosion hydrolysis | 1 g biomass, steam exploded (121 °C, 1.72 bar, 15 min) | 51.70 | [111] |

| Advanced hydrolysis approach | |||||

| Ecklonia radiata | Washed with water, oven-dried (45 °C), and crushing | Microwave-assisted enzymatic hydrolysis | 1% (w/v) biomass, 100 µL enzyme (Ultraflo® L + Flavourzyme® 1000 L), 0.2 M phosphate buffer (50 °C, 3 h, pH 7.0) | 69.50 | [112] |

| Monostroma latissimum | Washed with water, lyophilized, and crushing | Microwave-assisted hydrothermal hydrolysis | 5% (w/v) biomass, microwave hydrolyzed (140 °C, 10 min) | 53.10 | [113] |

| Pyropia yezoensis | Washed with water, freeze-dried (− 20 °C), and crushing | Microwave-assisted enzymatic hydrolysis | S/E ratio of 10:1, amyloglucosidase, 0.1 M phosphate buffer (60 °C, 2 h, pH 4.5, 400 W) | 25.00 | [114] |

| Laminaria digitata | Washed with water, oven-dried (80 °C, 48 h), and crushing | Sequential acid and enzymatic hydrolysis | 25% (w/v) biomass, 1.5 M H2SO4 (121 °C, 24 min), enzymatic hydrolyzed (50 FPU/g CellicCTec2, 0.05 M sodium citrate buffer, 50 °C, 48 h, 120 rpm) | 93.80 | [49] |

| Eucheuma denticulatum | Washed with water, oven-dried (60 °C), and crushing | Microwave-assisted acid hydrolysis | 20% (w/v) biomass, 0.1 M H2SO4 (160 °C, 10 min) | 74.84 | [115] |

| Macrocystis pyrifera | Washed with water and crushing | Sequential acid and enzymatic hydrolysis | 33.3% (w/v) biomass, 2% (v/v) H2SO4 (120 °C, 60 min), enzymatic hydrolyzed (alginate lyases, oligoalginate lyases [25 °C, 12 h], CellicCTec2 [50 °C, 4 h]), 0.45 M McIlvaine buffer (pH 7.5) | 95.10 | [116] |

| Ulva lactuca | Washed with water, oven-dried (50 °C), and crushing | Sequential hydrothermal and enzymatic hydrolysis | 10% (w/v) biomass, hydrolyzed (135 °C, 20 min), enzymatic hydrolyzed (2.5% (w/w) cellulase (~ 2.32 U/g), 45 °C, 48 h) | 79.70 | [48] |

| Gracilaria verrucosa | Washed with water, freeze-dried, and crushing | Sequential acid and enzymatic hydrolysis | 7.5% (w/v) biomass, 0.1 M H2NSO3H (130 °C, 90 min), enzymatic hydrolyzed (CellicCTec2: Viscozyme: CellicHTec2 = 1:1:0.1 v/v/v ratio per dried biomass, 0.02% sodium azide, 50 °C, 72 h, 180 rpm) | 69.10 | [117] |

| Sargassum muticum | Washed with water and crushing | Sequential hydrothermal and enzymatic hydrolysis | 14.3% (w/v) biomass, hydrolyzed (170 °C, 25 min), enzymatic hydrolyzed (20 FPU/g CellicCTec2, 5 U/g Viscozyme, 0.05 M citric acid-sodium citrate buffer, pH 4.85, 48.5 °C, 28.6 h) | 94.40 | [109] |

| Gracilaria lemaneiformis | Washed with water, oven-dried (60 °C, 48 h), and crushing | Microwave-assisted acid hydrolysis | 5% (w/v) biomass, 0.2 M H2SO4 (180 °C, 20 min) | 73.30 | [118] |

| Saccharina latissima | Washed with water, crushing, and freeze-dried | Sequential microwave-assisted hydrothermal and enzymatic hydrolysis | 5% (w/v) biomass, microwave hydrolyzed (190 °C, 5 min), enzymatic hydrolyzed (50 °C, 20 h, 200 rpm, 0.7% (w/v) CellicCTec2) | 87.36 | [119] |

S/L solid-to-liquid ratio, S/E substrate-to-enzyme ratio

Chemo-catalytic hydrolysis approach

Recently, several studies have been conducted to develop chemo-catalytic hydrolysis approaches for the selective production of rare sugars from macroalgae. This process is principally based on the solvolysis in water to release rare sugars from their polymeric chains by using acid reagents as the catalyst, namely acid hydrolysis [120]. For acid hydrolysis, protic acid such as HCl and sulfuric acid (H2SO4) is mostly utilized because these catalysts are more effective in breaking the glycosidic bonding between polysaccharides with the intake of water molecules through nucleophilic substitution reaction [121]. Similar to other biomass, the hydrolytic efficiency of macroalgae through acidolysis is mainly dependent on the acid type used, the acid concentration used, biomass loading, hydrolysis duration, as well as reaction temperature (Table 4). El Harchi et al. [103] performed acidolysis of Ulva rigida under the condition of 121 °C for 1 h with a 1:10 of solid-to-liquid (S/L) ratio and enhanced the total rare sugar (rhamnose and glucose) yield in hydrolysate up to 60.20% when substituting the acid type from HCl to H2SO4 at the same concentration. Mild acid like dilute H2SO4 is preferable over HCl for acidolysis due to H2SO4 contains extra H+ ions, creating a more acidic environment that offers strength to hydrolyze and disrupt the acid-sensitive 1,3-glycosidic bonds, resulting in the generation of monosaccharides from polysaccharides with higher hydrolytic efficiency [115]. Hence, the H2SO4 concentration is a considerable parameter that requires to be optimized to enhance the rare sugar yield. Hessami et al. [105] conducted the acidolysis of Gelidium elegans using various concentrations of H2SO4 and verified that the total rare sugar (galactose and glucose) yield could be significantly enhanced from 5 to 39.42% by increasing the H2SO4 concentration from 0.5 to 2.5% (w/v). Similar research reported that the higher efficiency of acidolysis (70.95%) can be achieved from Gracilaria manilaensis by 2.5% diluted H2SO4 than that by 0.5% with a total rare sugar yield of 42.34% [104].

Notably, unfavorable acid hydrolysis conditions could lead to the formation of undesirable by-products such as acetic acid, formic acid, 5-hydroxymethylfurfural (HMF), and levulinic acid [121]. The by-products can prevent the fermentation of rare sugars by damaging the DNA and hindering RNA and protein synthesis of fermentative microorganisms [122]. These inhibitors are formed from the carbonization or degradation of rare sugars caused by the high reaction temperature, long retention times, and high acid concentration [123]. Ra et al. [102] demonstrated that 34.85 g/L of rare sugar can be released during acidolysis of K. alvarezii using an extremely high temperature of 140 °C with 360 mM H2SO4 for 10 min, which resulting in a hydrolytic yield of 60.50%. However, Ra et al. [102] reported that increasing the temperature up to 200 °C would give rise to the loss of rare sugars from K. alvarezii to 7.20 g/L due to conversion of glucose and galactose to undesirable by-products. In addition, a long hydrolysis duration will increase the interaction between the acid and rare sugars, bringing about a low hydrolytic efficiency and total rare sugar concentration [101, 102, 105]. The degradation of rare sugars is the side reaction of acid hydrolysis, which is unable to suppress or avoid completely. Consequently, a neutralization or detoxification process is necessary to be carried out to minimize the detrimental impacts of by-products on the fermentation performance of the microorganisms [124]. Ra et al. [125] found that 6 g/L of 5-HMF was removed completely from acid-modified Gelidium amansii hydrolysates by using 3% (w/v) activated carbon in a shaking water bath at 100 rpm and 50 °C for 5 min, but activated carbon also removed approximately 5 g/L of total rare sugars present in the hydrolysate. Similar research reported that the higher HMF removal efficiency (41.6%) can be achieved from acid-modified Eucheuma spinosum hydrolysates by filtering through 2.5% (w/v) activated carbon powder in shaking water bath at 100 rpm and 50 °C for 2 min [126]. Alternatively, a bacterial strain, called Burkholderia cepacia H-2, has been found capable of degrading furfural and 5-HMF in acid-modified Chaetomorpha linum hydrolysates to furfuryl alcohol and 2,5-furan-dicarboxylic acid, respectively [127]. These organic acids were found to have no detrimental effect on rare sugars fermentation when accumulated in the fermentation medium [128].

Acid hydrolysis is preferred for rare sugar extraction in terms of high hydrolytic efficiency and mass transfer rate. Nevertheless, the sustainable use of liquid acid catalysts is constrained by the difficulty of catalyst recovery [129]. As an alternative for conventional liquid acid catalyst, solid acid catalyst (SAC) is preferred for dilute acid hydrolysis as it can be easily separated from reaction medium for recycling use, non-corrosive, and environmentally benign [130]. To ensure high hydrolytic efficiency, the SAC should have a high number of Brønsted acid sites, a high surface area, and good thermal stability [131]. Amberlyst™-15 and Dowex™ Dr-G8 resins were the most popular SAC in the organic synthesis process, mainly due to high thermal (up to 280 °C) and chemical stability [120]. Amberlyst™-15 resin is a strongly acidic catalyst that can selectively convert cellulose and other phycocolloids to rare sugars. About 51.90% of total rare sugar yield corresponding to 61 g/L of rare sugars was attained from milled G. verrucosa under acid hydrolysis reaction of 140 °C for 2.5 h with 15% (w/v) Amberlyst™-15 [100]. Besides possessing a microporous pore structure that allows the access of liquid or gaseous reactants to the H + ion sites, Dowex™ Dr-G8 resin also bearing with sulfonic acid sites could offer strength for simultaneous production of rare sugars from biomass and removal of by-products in the hydrolysates [132]. The use of Dowex™ Dr-G8 as SAC has been applied successfully to extract galactose from 16% (w/v) Eucheuma cottonii under the condition of 120 °C with 6% (w/v) catalyst loading for 1 h [19]. Dowex™ Dr-G8 achieved a higher galactose yield, which is approximately 43.20%, and no 5-HMF content in hydrolysate compared to the conventional dilute sulfuric acidolysis (120 °C, 2.5 h) that only achieved 34.60% of galactose yield with a reduction of reaction time [19].

Biocatalytic hydrolysis approach

Besides acid hydrolysis, the biocatalytic approach is an alternative method to hydrolyze macroalgae biomass. This process involves the utilization of enzymes or the direct addition of biological microorganisms (fungi or bacteria) to facilitate the cleavage of glycosidic bonds between the complex macroalgal polysaccharides into rare monomeric sugars generally known as enzymatic hydrolysis [133]. In addition, enzymatic hydrolysis is considered an effective disruption method due to its relatively low temperatures and the formation of minimum inhibitory compounds as compared to the chemo-catalytic hydrolysis method [2]. Similar to terrestrial plants, cellulose is the major component in the macroalgae biomass, but the macroalgae cell wall is composed of cellulose Iα which is different from cellulose Iβ in the plant cell wall. Cellulose Iα is the triclinic crystalline form of cellulose consisting of weaker hydrogen bonds with one cellobiose residue per unit cell, resulting in easy access to cellulolytic enzymes during enzyme hydrolysis [33]. The commonest enzyme utilized in the saccharification of macroalgae is cellulase [117, 134]. Cellulase is a mixture of different enzymes which consists of endocellulase, exocellulase, and β-glucosidase that function synergistically to convert cellulose into β-glucose without being consumed in the reaction [2]. Endocellulase is also known as endoglucanase, which is used to disrupt the cellulose chains and reduce the crystallinity of cellulose to improve hydrolysis efficiency. Exocellulase or cellobiohydrolase is used to break down the straight microfibrils cellulose ends for releasing the cellobiose molecules. Meanwhile, β-glucosidase or cellobiase is used to hydrolyze the glycosidic linkage of each soluble cellobiose molecule to release two molecules of β-glucose as final products [135].

The mechanism of cellulolytic enzymes on celluloses consists of three main stages: (1) adsorption of cellulase on the surface of the cellulose, (2) conversion of cellulose to β-glucose by hydrolysis, and (3) desorption of cellulase [33]. Cellulases are naturally secreted either by cellulolytic bacterial species of Cellulomonas, Clostridium, Bacillus, Erwinia, and Streptomyces or by fungal species of Aspergillus, Fusarium, Humicola, Trichoderma, and Penicillium [136, 137]. The use of cellulase derived from Aspergillus niger was explored by Jmel et al. [107] to enhance the glucose extraction from Enteromorpha sp. They revealed that enzymatic hydrolysis using cellulase from A. niger alone was sufficient to complete the saccharification of Enteromorpha sp. with glucose yields of 70.48%, primarily due to the only glucan was present in the macroalgae [107]. Moreover, Xue et al. [138] reported that the cellulase isolated from A. niger is composed of acidic and thermostable endoglucanase, which shows higher catalytic efficiency on cellulose hydrolysis compared to alkali-tolerant endoglucanase. This is mainly due to the acidic endoglucanase was able to enhance the cleavage of acid-sensitive 1,3-glycosidic bonds between the cellulosic polysaccharides and offers strength to hydrolyze polysaccharides across a wide range of pH conditions (pH 3–6) [139].

Unlike 1G and 2G feedstocks, polysaccharides of macroalgae are different in terms of macroalgae and sugar monomers species; a multiple-enzyme complex or also known as enzyme cocktail is thus needed to enhance the extraction of the rare sugars [140]. The use of enzyme cocktail (CellicCtec2 and alginate lyase) has been applied successfully for the complete hydrolysis of Saccharina latissimi [106]. The optimal total rare sugar (glucose and mannitol) yield of 48.65%, which corresponds to 74 g/L of sugars, was attained after inoculation with CellicCtec2 (37 °C, 3 h) and alginate lyase (50 °C, 17 h) to hydrolyze the cellulose and alginate, respectively. This study also revealed that the character of the enzyme was dependent on its species and could only perform well under their optimum conditions [106]. Besides using an enzyme cocktail for complete hydrolysis of various polysaccharides in the same biomass, an enzyme cocktail could be utilized for optimizing the extraction yield of the specific polysaccharide in the biomass. Rodrigues et al. [108] conducted the hydrolysis of K. alvarezii using cellulase alone and verified that the yield of rare sugars could be significantly enhanced from 31 to 37% by applying β-glucosidase as a supplement enzyme under the same hydrolysis duration and enzyme loading. This is mainly due to the addition of β-glucosidase could facilitate the cleavage of the glycosidic bonds between the cellobiose molecules and resolve the product inhibition setback caused by the single-enzyme process [141]. Although high rare sugar yield can be obtained, this process is constrained by the hydrolysis duration, which requires long residences times ranging between 1 and 4 days [106, 107]. Hence, the use of enzymatic hydrolysis usually implies with chemo-catalytic and thermo-catalytic hydrolysis approach to enhance the rare sugar productivity [133].

Thermo-catalytic hydrolysis approach

The thermo-catalytic hydrolysis approach, commonly known as hydrothermal hydrolysis, is principally based on the nucleophilic substitution in water or steam to release rare sugars from complex macroalgae polysaccharides at elevated levels of temperature and pressure in a closed system by changing their physiochemical properties [142]. Hydrothermal hydrolysis has been considered an environmentally friendly and cost-effective hydrolysis approach as this process possess several benefits on the macroalgal biorefinery route, including (1) the process does not require the addition of chemicals or catalysts as water is the only reagent, (2) limited corrosion problems on equipment, and (3) economical and simple operation [143]. Subcritical water (autohydrolysis) and steam explosion techniques can be considered hydrothermal hydrolysis, depending on the conditions of temperature and pressure employed [144]. In autohydrolysis processing, macroalgal biomass is exposed to water in the liquid state at high temperatures (150–380 °C) and pressure (5–28 MPa) to hydrolyze polysaccharides into a variety of rare monomeric sugars [145]. Autohydrolysis for rare sugar extraction was conducted by del Río et al. [109] with S. muticum in a pressurized batch reactor evaluating the effect of temperature and resistance time. A maximum rare sugar yield of 34.89% was achieved with a 1:7 S/L ratio at 180 °C and a residence time of 25 min. They revealed that temperature was the key factor for maximum rare sugar yield, followed by residence time [109]. Similar results were also found in the study of Gomes-Dias et al. [110] that the higher total rare sugar yield of 38.34% could be released from red macroalgae G. sesquipedale via autohydrolysis at the reaction temperature of 170 °C than that at 127.60 °C and 212.40 °C for 40 min. Moreover, Gomes-Dias et al. [110] concluded that increasing the reaction temperature up to 212.40 °C would give rise to the formation of 5-HMF from 1.04 to 3.23% in the G. sesquipedale hydrolysates. Wang et al. [146] reported that water at high temperatures will weaken the hydrogen bonds in the water molecules, resulting in the autoionization of water molecules into acidic hydronium ions (H3O+), which act as a catalyst to cleave the glycosidic bonds of macroalgal polysaccharides.

In contrast, the steam explosion hydrolysis technique has been widely employed as a lignocellulosic saccharification process. Nevertheless, it is still not highly explored as a thermal-catalytic hydrolysis approach for macroalgae as the macroalgae biomass is less recalcitrant due to the lack of lignin content [147]. The steam explosion technique utilizes high pressures of steam (1–50 bar) to treat the biomass followed by sudden depressurized so that the biomass will undergo explosive decompression. This quick pressure reduction comprises an initial temperature of 160 to 270 °C for a few seconds or minutes in saturated steam before exposure to atmospheric pressure [148]. Diffusion of the saturated steam into the macroalgal cell wall matrix leads to the dispersion of fibers and cleavage of the glycosidic bonds [149]. Compared to LCBs, the operating temperature and pressure for steam exploding of macroalgal biomass will be lower due to macroalgae possess high moisture content that facilitates a quick rise of pressure and temperature within the cells, allowing cell wall rupturing [144]. This aspect makes the steam explosion hydrolysis approach a simpler extraction method for macroalgal biomass. Rare sugar extraction from Ulva intestinalis by steam explosion obtaining yields of 51.70% under 121 °C and 1.75 bar for 15 min with no comparable values for control samples was reported [111].

Advanced hydrolysis approach

Despite the widespread usage of conventional hydrolysis protocols at the industrial level, there is a growing interest in incorporating innovative hydrolysis protocols to enhance rare sugar extraction. The aim of developing innovative hydrolysis processes is to improve the hydrolytic efficiency of the conventional hydrolysis protocols by increasing the sugar recovery from the biomass while decreasing the energy consumption and hydrolysis duration of macroalgal processing [78]. The most potential emerging hydrolysis protocols described in the literature involve the use of microwave irradiation, combined acids and enzymes, and combined hydrothermal process and enzymes [113, 114, 150]. The use of microwave irradiation is regarded to be a promising pretreatment process for macroalgae biomass as it utilized microwave-generated thermal and non-thermal effects in moisture and aqueous environment [151]. The thermal effect generated by microwave refers to the part of the process that generates heat for internal heating, which is dependent on the direct energy absorption by polar molecules or organic polymers [152]. On the other hand, the non-thermal effect refers to the effect caused by the dipole rotation of polar molecules and ionic conduction of dissolved ions [79]. The dipole rotation can be described as the realignment of polar molecules with the poles of the rapidly oscillating electromagnetic field of the microwave, resulting in the cleavage of the hydrogen bonds and glycosidic bonds between transmembrane domains of the cell [153]. Based on the abovementioned heating process, microwave heating offers several advantages over the conventional heating methods (autoclaving or water-bathing): (1) enhance the heat transfer between the biomass and solvent by applying volumetric and rapid internal heating; (2) the reaction temperature can be well controlled and stopped immediately; and (3) provide shorter reaction duration and can heat the biomass evenly in the whole reaction process, which enabled this method to be often utilized in combination with acids, enzymes, and thermal-catalytic hydrolysis approach to increase hydrolytic efficiency [150].

Acid hydrolysis was performed by Teh et al. [115] in an improved microwave oven (800 W) to evaluate the influence of temperature and acid concentration on the sugar recovery and by-product formation from Eucheuma denticulatum. The authors concluded that the red macroalgae E. denticulatum had been hydrolyzed effectively to achieve the sugar recovery rate of 74.84%, which corresponds to 51.47 g/L of sugars accompanied by a low by-product 5-HMF of 0.20 g/L with the involvement of microwave-assisted sulfuric acid (0.1 M) hydrolysis for 10 min [115]. Cao et al. [118] further applied higher microwave power (1900 W) to assist the acidolysis of red macroalgae Gracilaria lemaneiformis under the optimized condition of 180 °C with aided of 0.2 M H2SO4, and the maximum yield of rare sugars reached up to 73.30% using only 20 min of reaction time which is sixfold lesser than the conventional heating method. Boulho et al. [154] concluded that the superficial heat transfer environment offered by microwave heating to the biomass not only improved the sugar recovery rate from the biomass but also limited the formation of 5-HMF. Unlike microwave heating, conventional heating uses conduction and convection heat transfer, in which the heat energies are transferred from the surface to the center of biomass by conduction [155]. Thereby, the heating time of this process is longer than microwave heating for the solvent and biomass to achieve the targeted temperature [156]. As a result, it will lead to a reduction of the rare sugars and an increment of the 5-HMF due to the degradation of monosaccharides during the heating process [157].

The use of autohydrolysis involving microwave heating was studied by Tsubaki et al. [113] to enhance the extraction of rare sugars from Monostroma latissimum. They revealed that the microwave heating could increase the solubilization rate of M. latissimum probably due to the microwaves generate homogenous and uniform heating on the biomass, which allows penetration of subcritical water into the matrix polysaccharides to release the rare sugars, and the maximum total rare sugar yield of 53.10% was achieved under 140 °C for 10 min [113]. Furthermore, enzymatic hydrolysis could be enhanced by microwave irradiation, Charoensiddhi et al. [112] evaluated the production of rare sugars from brown macroalgae Ecklonia radiata by microwave-assisted enzymatic hydrolysis with carbohydrate hydrolytic enzymes: Viscozyme, Cellulast, Ultraflo, Alcalase, Neutrase, and Flavourzyme. The authors investigated different enzyme cocktail configurations in the same volume (100 µL) with microwave operating at 200 W. Enzyme cocktail of Ultraflo and Flavourzyme showed the highest extraction yield (69.50%) under working conditions of 50 °C. In addition, it was observed a synergic effect between microwave and enzyme cocktail, in which it shortens the time of hydrolyzing by eightfold and doubles the extraction yield when compared to conventional enzymatic hydrolysis [112]. A similar conclusion was found in a study by Lee et al. [114] that the rare sugar extraction yield from red macroalgae Pyropia yezoensis was improved from 5 to 25% with the involvement of microwave-assisted amyloglucosidase hydrolysis. This can be clarified by changing direction for the active sites on the enzyme due to the rotation and acceleration of the polysaccharide molecules done by microwave irradiation. Thus, the opportunity for the substrate bounded with the active sites on the enzyme per unit time to release rare sugar will increase, leading to the high productivity of rare sugars [158].

Besides using microwave irradiation as the heating source for the hydrolysis process, the hydrolytic efficiency and duration can be enhanced by employing an efficient pretreatment method. The establishment of the pretreatment method is to facilitate the hydrolytic efficiency to increase the sugar recovery rate and subsequently increase the productivity of bioethanol and LA [159]. Ravanal et al. [116] conducted additional enzymatic hydrolysis with enzyme cocktail (alginate lyase, oligoalginate lyase, and CellicCTec 2) for 17 h on the dilute H2SO4 pretreated green macroalgae Macrocystis pyrifera to increase rare sugars release content yield to 95.10%. Similar results were also achieved in the study of Park et al. [117] that the hydrolysis of red macroalgae G. verrucosa via the diluted sulfamic acid (H2NSO3H) and an enzyme cocktail composing of Viscozyme® L, Cellic® CTec2, and Cellic® HTec2 for 72 h led to a significantly increased production yield of rare sugars from 39.90 to 69.10%. Other than applied acidolysis as a pretreatment step prior to enzymatic hydrolysis, Poespowati et al. [48] added cellulase into the autohydrolyzed green macroalgae Ulva lactuca to achieve a maximal rare sugar yield of 79.70%. Del Río et al. [109] utilized ultrapure water and a mixed enzymatic system composing of Cellic® CTec2 and Viscozyme 1.5L to treat the brown macroalgae S. muticum, which resulted in the increment of total rare sugar yield from 34.89 to 94.40% by comparing with autohydrolysis only. The inorganic acids and subcritical water serve as a proton donor to break the intra- and inter-chain hydrogen bonds of the macroalgal cell wall matrix to release the hydrocolloids results in an increase of accessibility to enzymes for further degradation [160].

Biotechnological route for bioethanol and lactic acid

Fermentation of bioethanol and LA is followed after the pretreatment and hydrolysis of the macroalgae biomass. The overall process of fermentation can be described as the rare sugars that are produced as a result of disruption of the cell wall and depolymerization of phycocolloids and cellulose molecules before being subjected to fermentation by the relevant microorganisms or bacteria and converted into bioethanol and LA [31, 161].

Recommendations of microorganisms’ strain for 3G bioethanol and lactic acid conversion

To optimize the productivity of bioethanol and LA from macroalgal biomass through microbial fermentation, the strain of fermentative microorganisms implemented is considered as a crucial parameter for the fermentation process. This is due to different microbial strains possess different properties and metabolic pathways on the fermentable sugars extracted from the biomass. Furthermore, the derivatives of bioproduct generated by microbial fermentation are mainly dependent on the selected microbial strain [162, 163]. Thus, the selection of appropriate strains of microbial is crucial after deciding the target bioproduct for production. Several reports on the utilization of different fermentative microbial strains for the single production of bioethanol or LA are summarized in Table 5. Although there have been many bacterium and yeast strains utilized for the production of bioethanol from renewable resources, the results shown in Table 4 revealed that S. cerevisiae yeast is the dominant microbial that has been considered the most critical part was contributing to beneficial effects in bioethanol fermentation using reducing sugars as substrate. The eukaryotic microorganism S. cerevisiae is chosen over the other bacterium and yeast strains for bioethanol fermentation due to its offer strength to growth under a wide range of pH, less stringent nutritional requirements, and utmost resistance to contamination [163, 164]. Moreover, S. cerevisiae is also able to metabolize diverse fermentable sugars and possess the ability to produce a high titer of bioethanol as it can resist the contamination caused by high ethanol concentrations produced in the fermentation broth [164].

Table 5.

Summary of fermentative microbial strain utilized in the single production of bioethanol or LA

| Fermentative bacterium | Biomass | Fermentable sugar | Product | Reference |

|---|---|---|---|---|

| Saccharomyces cerevisiae Baker’s yeast | Chaetomorpha linum | Glucose | Bioethanol | [174] |

| Ambrosiozyma angophorae | Laminaria digitata | Glucose Laminarin | Bioethanol | [175] |

| Ethanologenic Escherichia coli | Arundo donax | Arabinose Glucose Xylose | Bioethanol | [176] |

| Saccharomyces cerevisiae KCTC 1126 | Gracilaria verrucosa | Galactose Glucose | Bioethanol | [177] |

| Candida glabrata | Gracilaria fisheri | Galactose Glucose | Bioethanol | [178] |

| Escherichia coli SL100 | Olive tree pruning biomass | Galactose Glucose Xylose | Bioethanol | [179] |

| Saccharomyces cerevisiae YRH400 | Populus deltoides | Glucose Xylose | Bioethanol | [180] |

| Saccharomyces cerevisiae Ethanol Red® | Sargassum muticum | Galactose Glucose Mannose | Bioethanol | [109] |

| Saccharomyces cerevisiae PE-2 | Sargassum spp. | Glucose | Bioethanol | [181] |

| Bacillus coagulans NBRC 12,714 | Corn stover | Glucose Xylose | L-lactic acid | [182] |

| Lactobacillus plantarum | Gracilaria vermiculophylla | Galactose Glucose | L-lactic acid | [183] |

| Bacillus coagulans DSM No. 2314 | Beechwood | Glucose Xylose | L-lactic acid | [184] |

| Bacillus coagulans LA-15–2 | Rice straw | Glucose Xylose | L-lactic acid | [185] |

| Bacillus coagulans DSM ID 14–300 | Sugarcane bagasse hemicellulosic material | Arabinose Glucose Xylose | L-lactic acid | [186] |

| Lactobacillus delbrueckii CECT 286 | Orange peel waste | Fructose Galactose Glucose | D-lactic acid | [187] |

| Bacillus coagulans ATCC 7050 | Eucheuma denticulatum cellulosic residue | Glucose | L-lactic acid | [62] |

| Lactobacillus rhamnosus ATCC 7469 | Brewer’s spent grain | Arabinose Galactose Glucose Mannose Xylose | L-lactic acid | [188] |

| Pediococcus acdilactici ZP26 | Picea abies | Glucose Mannose | D-lactic acid | [189] |

The large-scale production of LA is mostly done by employing the use of LAB as the bacteria for fermentation and the selected bacterium strain can be shown in Table 5. Among thousand types of identified LAB strains, B. coagulans has become one of the most popular bacteria employed in either laboratory- or industrial-scale LA production due to its characteristics and mild operating conditions. A typical superiority of B. coagulans strain for LA fermentation is offered better acid tolerance compared to other LAB strains, resistance to heat up to 50 °C, and less stringent nutritional requirements [21, 165]. Moreover, B. coagulans strain could improve the biorefinery performance and increase fermentable sugar digestibility as it is capable to metabolize both C6 and C5 sugars by secreting several types of thermostable enzymes, including glucokinase, α-galactosidase, and xylanase [166]. As a matter of fact, B. coagulans strains will metabolize C6 and C5 sugars through the homofermentative pathway and pentoses phosphate pathway, respectively, to produce LA as the major end metabolic product of carbohydrate fermentation [167].

By using the microbial fermentation route for LA production, the main concern of this production route is the enantiomer of LA produced is mainly dependent on the lactate dehydrogenase (LDH) specificity of the fermentative strain employed [168]. In this case, B. coagulans strain is considered an excellent producer of L-lactic acid (L-LA) as it contains L-lactate dehydrogenase (L-LDH) enzyme, which promotes the formation of L-LA [169]. As reported in the literature, high crystalline PLA can be prepared either from an optically pure L-LA isomer or D-lactic acid (D-LA) isomer via ring-opening polymerization [170, 171]. However, L-LA isomer was chosen over D-LA isomer as the monomer of PLA due to poly-L-lactic acid (PLLA) possess higher melting temperature (170–200 ) and tensile strength (15.5–150 MPa) as compared to poly-D-lactic acid (PDLA) [172]. Furthermore, PLLA is the material of choice for biomedical applications as D-LA is considered a harmful enantiomer of LA on human health which can cause neurotoxicity on the human body [173]. Thus, given the multiple traits described above, B. coagulans strain is a promising candidate for the production of LA at the industrial level to meet the high demands of PLA as bioplastics.

Synthetic pathway for 3G bioethanol and lactic acid

Bioethanol and LA fermentation can be classified into two methods, which include solid-state fermentation and submerged fermentation. The solid-state fermentation method is the bioconversion of the carbohydrates from macroalgal biomass in its natural state in which the biomass is introduced to the surface of a thin layer of water [190]. Moreover, water is also known as an essential solvent for the submerged fermentation method, where it is used for creating fermentation mash, which is mixed with the hydrolyzed biomass [191]. The solid-state fermentation method is preferred over submerged fermentation methods as the solid-state fermentation method is more energy-efficient due to smaller fermenter volume and requires no excess water in the fermenter, leading to less amount of water needed to be heated [192]. Currently, there are numerous solid-state fermentation approaches employed to convert rare sugars extracted from macroalgae into bioproducts (bioethanol and LA). The processes are denoted as follows: (1) separate hydrolysis and fermentation (SHF); (2) simultaneous saccharification and fermentation (SSF); and (3) high cell density culture (HCDC) [193–195].

Separate hydrolysis and fermentation (SHF)

SHF process is one of the most common combinations of hydrolysis and fermentation methods employed for the bioethanol and LA production process [196]. In the SHF process, the hydrolysis and the fermentation processes are operated separately, in which the carbohydrates of macroalgae biomass are first decomposed into monosaccharides via the hydrolysis process, and the fermentation of rare sugars are carried out later in separate units with different operating conditions [197]. The production of bioethanol and LA by using the SHF method on various types of macroalgae are summarized in Table 6. These studies revealed that the production of bioethanol and LA from macroalgae biomass using the SHF method was operated under batch mode. Batch mode is chosen over the continuous and fed-batch modes for the bioproducts fermentation process due to it offers the highest conversion rate as complete biomass can be utilized [198]. Hessami et al. [104] demonstrated that 18.16 g/L (67.90%) of bioethanol can be achieved during the fermentation of acid-modified G. manilaensis hydrolysates using 5% (v/v) S. cerevisiae Ethanol Red® directly under batch mode at 30 °C for 96 h. Under the same yeast cell volume, the fermentation process for the acid-modified G. elegans hydrolysates was optimized to achieve a bioethanol yield of 63.30%, corresponding to 13.27 g/L of bioethanol [105]. Saravanan et al. [22] also utilized S. cerevisiae yeast cell for fermentation of other red macroalgae Gracilaria sp. hydrolysates, and the maximal bioethanol yield obtained after 96 h fermentation at 30 °C was 28.70 g/L, which corresponded to a 50.98% of the theoretical yield.

Table 6.

Bioethanol and lactic acid production from SHF method on various macroalgae

| Macroalgae strain | Hydrolysis technique | Fermentation conditions | Bioethanol yield | Lactic acid yield | Reference |

|---|---|---|---|---|---|

| Whole macroalgae biomass | |||||

| Gracilaria manilaensis | Acid hydrolysis | 5% (v/v) Saccharomyces cerevisiae Ethanol Red®, 6 g/L yeast extract (30 °C, 150 rpm, pH 5.0, 96 h) | 67.90% | - | [104] |

| Ulva lactuca | Sequential acid and enzymatic hydrolysis | 106 CFU/g Lactobacillus plantarum BCRC 10,069 (37 °C, pH 5.5, 24 h) | - | 0.58 g/g RS | [200] |

| Gracilaria fisheri | Acid hydrolysis | 1% (v/v) Candida glabrata, 3 g/L yeast extract, 5 g/L peptone (37 °C, 120 rpm, pH 6.5, 96 h) | 0.03 g/g RS | - | [178] |