Summary

Many light-based technologies have been developed to manipulate micro/nanoscale objects such as colloidal particles and biological cells for basic research and practical applications. While most approaches such as optical tweezers are best suited for manipulation of objects in fluidic environments, optical manipulation on solid substrates has recently gained research interest for its advantages in constructing, reconfiguring, or powering solid-state devices consisting of colloidal particles as building blocks. Here, we review recent progress in optical technologies that enable versatile manipulation and assembly of micro/nanoscale objects on solid substrates. Diverse technologies based on distinct physical mechanisms, including photophoresis, photochemical isomerization, optothermal phase transition, optothermally induced surface acoustic waves, and optothermal expansion, are discussed. We conclude this review with our perspectives on the opportunities, challenges, and future directions in optical manipulation and assembly on solid substrates.

Subject areas: Molecular self-assembly, Optical physics, Applied physics, Nanotechnology, Biomanipulation

Graphical abstract

Molecular self-assembly; Optical physics; Applied physics; Nanotechnology; Biomanipulation

Introduction

Precise manipulation of micro/nanoscale objects plays an important role in a variety of fields, such as microrobotics (Palima and Glückstad, 2013; Zhang et al., 2019), biomedical engineering (Ding et al., 2012, 2014; Jiang et al., 2021; Zhong et al., 2019), and nanofabrication (Lin et al., 2017b; Ozin et al., 2009). Among the different manipulation methods, such as microfluidic (Farahi et al., 2004), optical (Grier, 2003), acoustic (Ding et al., 2012), electric (Fan et al., 2011), and magnetic manipulation (Snezhko and Aranson, 2011), optical manipulation is appealing for its remote and noninvasive control of objects with nanoscale resolution (Chen et al., 2022). For instance, optical tweezers use optical gradient forces to trap small objects with a focused laser beam (Ashkin, 1970; Ashkin et al., 1986). Since first proposed by Ashkin in 1970, optical tweezers have been widely exploited to trap and manipulate synthetic particles, cells, viruses, and bacteria to advance both fundamentals and applications in different fields (Ashkin, 1997; Ashkin and Dziedzic, 1987; Ashkin et al., 1987; Grier, 2003; Maragò et al., 2013). Many new approaches are developed to enhance the performance and applicability of optical tweezers, such as plasmonic tweezers (Grigorenko et al., 2008; Juan et al., 2011; Yang et al., 2021), optoelectronic tweezers (Chiou et al., 2005; Wu, 2011), and optothermal tweezers (Li et al., 2018, 2021a; Lin et al., 2018). However, most of these optical manipulation techniques operate in liquid environments where the targeted objects are suspended in solvents. The liquid-phase operation poses a challenge for some applications such as directed assembly of micro/nanoparticle into solid-state functional structures and devices, which requires the precise arrangement and immobilization of the particles on the solid substrates. The bottom-up approach is attractive in creating designer materials and devices with their functions tailorable by both particle properties and inter-particle interactions in the particle assemblies. Various optical printing methods have been developed for the immobilization of colloidal particles on the substrates (Li et al., 2019b), such as plasmon-enhanced laser printing (Nedev et al., 2011; Urban et al., 2010), optoelectric printing (Jamshidi et al., 2009), optothermal printing (Lin et al., 2017a; Peng et al., 2018), photochemical printing (Walker et al., 2016), and bubble printing (Lin et al., 2016). Nevertheless, optical printing of colloidal particles from the aqueous solutions onto the substrates could be affected by the strong capillary force, which may cause the arrangement misalignment or pattern collapse (Chini and Amirfazli, 2010; Ni et al., 2016). In addition, the Brownian motion of small objects, especially nanoscale materials, in the colloidal suspensions can decrease the optical manipulation precision (Do et al., 2013; Jones et al., 2018).

An alternative strategy to address these challenges is to manipulate objects and assemble functional structures on the solid substrate. However, in comparison to the free motion of colloidal particles suspended in liquid environments, the adhesion forces (e.g., van der Waals forces and electrostatic forces) between the micro/nanoscale objects and the substrates are much stronger (Gu et al., 2016). In general, the adhesion force for a micrometer-sized object on a solid surface could reach the scale of ∼μN, which exceeds the typical value of optical force in the scale of ∼pN by a factor of >106 (Lu et al., 2019). Owing to the relatively weaker driving forces, common optical techniques such as optical tweezers have difficulty in manipulating micro/nanoscale objects in nonliquid environments. An atomic force microscope (AFM) can be used to manipulate nanoparticles on a flat solid substrate (Junno et al., 1995; Requicha, 2003; Schaefer et al., 1995; Wang et al., 2017). However, AFM uses a sharp tip to physically push the particle, which could result in undesired particle deformation, tip break, and particle adhesion to the tip. In addition, AFM relies on the same tip for both manipulation and imaging purposes, making the real-time tracking of the target objects challenging (Kim et al., 2009). Other manipulation approaches based on acoustic waves (Shigematsu et al., 2003) or piezoelectric actuation (Merry et al., 2010) have been demonstrated. However, these methods require complex designs on the experimental configuration.

In this review, we highlight recent progress in using light to manipulate micro/nanoscale objects and assemble them into desired patterns on solid substrates. The key to optical manipulation on the solid substrate is the optical modulation of interfacial interactions between objects and substrates to reduce the adhesion forces, which has been realized in multiple systems based on four types of working mechanisms. First, photophoretic forces induced by optically heated air molecules provide the possibility to manipulate objects under ambient conditions. Second, the rotation and translation of microparticles on azobenzene-doped liquid crystal substrates are realized based on photochemical isomerization of the azobenzene molecules. Third, optical manipulation of liquid crystal elastomers and azobenzene crystals on solid substrates is achieved through a photoinduced phase transition. Fourth, optothermal shape deformation of either the object or the substrate is exploited to control the interfacial interactions for optical manipulation. Finally, we provide our perspectives on existing challenges and future directions of optical manipulation and assembly on solid substrates.

Optical techniques for manipulation on solid substrates

Among many applications, precise manipulation of micro/nanoscale objects on the solid substrate is instrumental in achieving new materials and devices with precisely controlled configurations and functions (Li and Zheng, 2021). In this section, we discuss different optical manipulation techniques operated on solid substrates, which are categorized based on their distinct physical mechanisms, including photophoresis, photochemical isomerization, optothermal phase transition, optothermally induced surface acoustic waves (SAWs), and optothermal expansion.

Optical manipulation based on photophoresis

Firstly observed by the French physicist M. Tore around 1877, photophoresis denotes the movement of light-absorbing objects in gaseous media (Rohatschek, 2000). Photophoretic forces stem from the collision and momentum transfer between the surrounding gas molecules and the object (Gong et al., 2018). Generally, a net photophoretic force can exist when the object has a different surface temperature (T) or thermal accommodation coefficient (α) at two sides, which can lead to different momentum changes during the molecule-object collision (Jovanovic, 2009). With the existence of a temperature difference (ΔT) at the object surface, the gas molecules around the high-temperature side will exert a larger force on the object than the low-temperature side, resulting in a net force toward the low-temperature side (Shvedov et al., 2010). Alternatively, when one side of the object has a larger thermal accommodation coefficient than the other side, the gas molecules will leave the surface with a higher average velocity after the collision, leading to the net momentum transfer and a photophoretic force pointing to the side with a lower thermal accommodation coefficient (Azadi et al., 2021). Photophoresis has been widely exploited for the manipulation of light-absorbing objects, such as carbon spheres (Porfirev, 2019; Shvedov et al., 2009), carbon nanotube clusters (Pan et al., 2012; Wang et al., 2016), and absorbing plates (Cortes et al., 2020).

In pursuit of photophoretic manipulation on solid substrates, Lu et al. achieved the controlled pulling and pushing of a micrometer-sized gold plate on a tapered optical fiber by coordinating optical and photophoretic forces (Figure 1A) (Lu et al., 2017b). When the gold microplate approached the fiber tip, the outside evanescent field became stronger due to the decreasing diameter of the fiber. Therefore, the light-induced heating was more efficient in the front part of the gold plate, leading to a considerably higher temperature. This temperature difference resulted in a photophoretic force that pulled the gold plate against the light propagation direction. Along with the pulling of the gold plate, the optical force became larger while the temperature difference became smaller, which made the photophoretic force more negligible. The total light-induced force (photophoretic and optical forces) was negative near the fiber tip to pull the gold plate to the light source and positive when the gold plate was away from the fiber tip to push it back. Thus, the gold plate could exhibit a light-driven oscillation behavior on the fiber and move back and forth. Figure 1B shows the optical images of a gold microplate being pulled and pushed along a tapered fiber guided by supercontinuum light. The gold plated was optically manipulated at an average speed of ∼30 μm s−1.

Figure 1.

Photophoretic manipulation on solid substrates

(A) Photophoretic pulling and pushing of a gold microplate on a tapered fiber in the ambient air.

(B) Optical images of a gold microplate moving back and forth on a fiber.

(C) Schematic showing the mechanism behind the photophoretic levitation force due to a difference in the thermal accommodation coefficient of top and bottom surfaces.

(D) Scanning electron microscopic image of the structured carbon nanotube layer.

(E) Photophoretic levitation of a mylar film from the substrate.

Figures reproduced from: (A and B) (Lu et al., 2017b) Copyright 2017, American Physical Society; (D and E) (Azadi et al., 2021) Copyright 2021, American Association for the Advancement of Science.

Azadi et al. demonstrated the optical levitation of mylar thin films from a solid substrate through the photophoretic force resulting from the difference of thermal accommodation coefficients (Azadi et al., 2021). Only one side of the mylar film (bottom side) was coated with a carbon nanotube layer (Figure 1D). Subsequently, the nanostructured surface caused an increasing collision time between the film and the surrounding gas molecules, which led to a larger thermal accommodation coefficient compared to the uncoated side (top side). Thus, the average leaving velocity of gas molecules after the collision was higher at the bottom side, resulting in a larger recoil and a net upward force (Figure 1C). This photophoretic lifting force could levitate the mylar thin film from the solid substrate under a light intensity of 0.5 W cm−2 (Figure 1E). This photophoretic levitation could be powered by a laser beam or sunlight, which showed great potential for the development of microflyers to carry payloads for weather and climate applications.

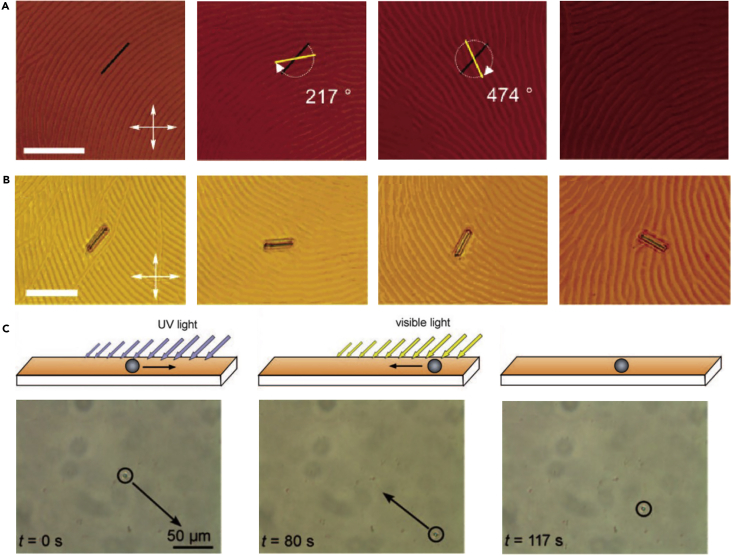

Optical manipulation based on photochemical isomerization of molecules in liquid crystal films

Liquid crystals are ordered soft materials consisting of self-organized molecules, and the orientation of the molecules can be directed by external fields (Tamaoki, 2001). Depending on the type of alignment of the molecules, liquid-crystalline phases can be divided into nematic, cholesteric (or chiral nematic), and smectic mesophases. Cholesteric liquid crystals are characterized by a helical structure, where the chirality is indicated by the sign and magnitude of the cholesteric pitch (Mitov, 2012). For the cholesteric liquid crystals doped with chiral molecular motors, the pitch of the helix is dependent on the concentration and helical twisting power of the molecular motors. Under light irradiation, photochemical isomerization of light-driven molecular motors can alter the helicity of the liquid crystal molecules and result in a change in the cholesteric pitch (Eelkema et al., 2006a). Figure 2A shows the rotational reorganization of the liquid crystal film under ultraviolet (UV) irradiation. The lines of the polygonal texture exhibited a clockwise rotation in response to the UV-induced isomerization of the molecular motors. The reorganization of the liquid crystal film can generate a sufficiently large torque to achieve the rotation of microscale objects on the film surface (Eelkema et al., 2006b). Typically, the microparticle (e.g., microrod) rotated in the same direction following the rotation direction of the cholesteric texture (Figure 2B), which could be controlled by the type of molecular motors and the isomerization processes (Browne and Feringa, 2006; Kausar et al., 2011; Kim and Tamaoki, 2016).

Figure 2.

Optical manipulation of microscale objects on liquid crystalline films driven by photochemical isomerization of the doped molecular motors

(A) Optical images showing the rotational reorganization of a cholesteric liquid crystal film texture. The images were taken at 15 s intervals under irradiation with 365 nm light. Black and yellow reference lines indicate the initial and rotated texture orientations, respectively.

(B) Optical images showing the rotation of a glass microrod on a liquid crystal film. The photos were taken at 15 s intervals under irradiation with 365 nm light. Scale bars: 50 μm.

(C) Schematic and optical images showing the translation of a PS microparticle on a liquid crystal film. Under irradiation with UV or visible light, the particle moved toward or away from the irradiation side, respectively. The diameter of the PS particle was about 5 μm. The intensity of UV and visible light was 45 mW cm−2 and 65 mW cm−2, respectively.

Figures reproduced from: (A and B) (Eelkema et al., 2006a) Copyright 2006, American Chemical Society; (C) (Kausar et al., 2009) Copyright 2009, Wiley-VCH.

Kausar et al. demonstrated the optical translation of polystyrene (PS) microspheres on an azobenzene-doped liquid crystal film (Kausar et al., 2009). The azobenzene molecules undergo reversible trans-cis isomerization upon irradiation of light with different wavelengths. Under the asymmetric UV irradiation (365 nm), a PS microparticle on the liquid crystal film moved consistently toward the irradiation position at a speed of 88 μm min−1 (Figure 2C). The PS particle moved to the opposite direction under visible light irradiation. The directional particle motion was attributed to the reorientation of the liquid crystal molecules, the surface energy gradient, or a combination of both effects, which were induced by the trans-cis isomerization of the azobenzene molecules. The translation speed of the particle could be tuned by the light intensity or the concentration of the doped azobenzene compound.

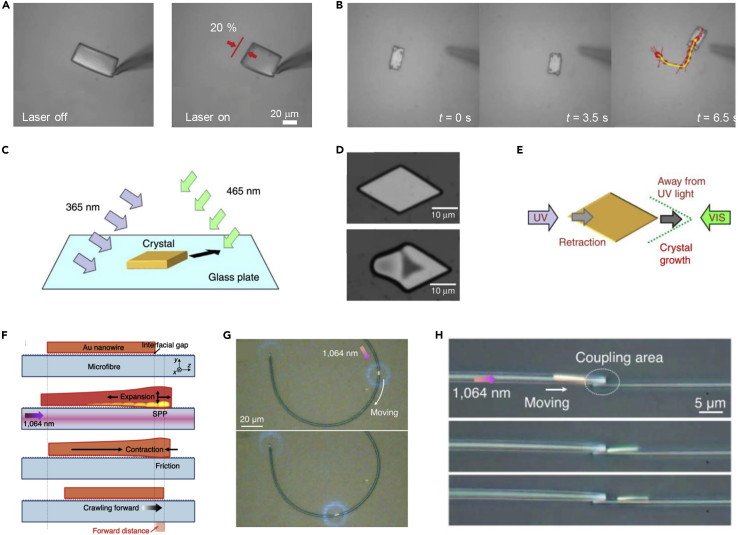

Optical manipulation based on shape deformation of objects

Inspired by soft animals, such as snails and earthworms, which can deform their bodies to navigate on complex solid surfaces, scientists and engineers have proposed a similar strategy to enable optical manipulation of target objects on the solid substrate via their light-induced shape deformation. For instance, liquid crystalline elastomers (LCEs), which combine elastomeric properties with liquid crystalline orientational order, can reversibly deform in response to external stimuli (Ikeda et al., 2007; Ohm et al., 2010). Zeng et al. reported the light-driven locomotion of an LCE microstructure on the solid surface (Zeng et al., 2015). Under 532 nm laser illumination, the intermediate optical heating of the LCE structure induced a nematic-isotropic phase transition, leading to a contraction of ∼20% (Figure 3A). With a chopped laser beam, the LCE body exhibited contraction-expansion cycles following the laser modulation frequency. The resultant elastomeric force could overcome the friction force to drive the walking of the LCE structure on the substrate (Figure 3B). A steady walking direction remained challenging due to the strong friction fluctuation, which could be overcome by the design of a grating surface. Light-driven LCE soft robots of the millimeter-scale have also been developed (Gelebart et al., 2017; Jiang et al., 2019; Palagi et al., 2016; Rogóż et al., 2016; Zeng et al., 2018).

Figure 3.

Optical manipulation via the shape deformation of objects

(A) Optical images showing 20% contraction of the LCE by laser heating.

(B) Locomotion of the LCE microscopic walker on a glass substrate under chopped laser excitation. The size of the LCE walker is 60 μm.

(C) Schematic showing the light-induced crawling of the DMAB crystal.

(D) Optical images showing the position of a DMAB crystal before (top) and after (bottom) light irradiation for 2 min.

(E) Schematic showing the mechanism of the light-induced crystal motion.

(F) The working mechanism of the crawling of Au nanowires.

(G) A Au nanowire moving on a curved fiber.

(H) Transport of a Au nanowire from the left fiber to the right fiber.

Figures reproduced from: (A and B) (Zeng et al., 2015) Copyright 2015, Wiley-VCH; (C–E) (Uchida et al., 2015) Copyright 2015, Nature Publishing Group; (F–H) (Linghu et al., 2021) Copyright 2021, Nature Publishing Group.

Azobenzene-based crystals could exhibit a crystal-liquid phase transition induced by the photochemical trans-cis isomerization (Ito et al., 2018; Kim et al., 2015; Paterson et al., 2016). Uchida et al. demonstrated light-induced crawling of a 3,3′-dimethylazobenzene (DMAB) microcrystal on a glass surface (Uchida et al., 2015). Under irradiation with UV (365 nm) and visible (465 nm) light from opposite incident directions (Figure 3C), the DMAB crystal moved away from the UV light and toward the visible light (Figure 3D). The UV light irradiation facilitated the isomerization of azobenzene to cis-isomer and induced liquefaction, while visible light resulted in the trans-isomer and crystallization. The liquefied portion of the crystal consisted of a mixture of trans- and cis-isomers, where the isomer ratio depended on the position due to the spatially uneven intensity ratio between UV and visible light. Therefore, a non-equilibrium condition occurred at the front and rear edges of the crystal, leading to crystal growth and melting (Figure 3E). The overall phase transitions induced the motion of the crystal toward the visible light.

Shape deformation of objects can also be caused by optothermally induced SAWs, which have been exploited for optical navigation of plasmonic nanoobjects on solid substrates (Li et al., 2019a). Recently, Linghu et al. reported light-induced crawling of gold nanowires (AuNWs) on the silica microfiber (Linghu et al., 2021). When an AuNW was excited by a pulsed 1,064 nm laser beam propagating along with the fiber, the surface plasmon polaritons produced abundant heat at the frontend of the AuNW. This optical heating led to the formation of SAWs and the resultant lattice expansion of the AuNW. The SAWs could drive the earthworm-like crawling motion of the AuNW based on the synergy of expansion, friction, and contraction. Specifically, the lattice expansion at the frontend reduced the interfacial gap between the microfiber and the AuNW, which increased the friction force. When the AuNW began to contract, it was pushed along the direction of light propagation (Figure 3F). In contrast, the illumination of a 532 nm pulsed laser would not excite SAWs but rather induce a thermal expansion at the backend of the AuNW, leading to the crawling of the AuNW along an opposite direction. The translation of AuNWs on the arbitrarily shaped microfibers could be precisely controlled by the repetition rates of the 1,064 nm pulsed laser with a position accuracy of 0.56 nm (Figure 3G). Versatile on-chip manipulation of AuNWs was demonstrated, including selective actuation of individual AuNWs and transport of AuNWs on different fibers (Figure 3H). In addition to the translation of objects on an optical fiber, Qiu and coworkers further demonstrated the complex rotation and actuation of Au microplate around the optical fibers based on optothermal elastic waves (Lu et al., 2017a, 2019; Tang et al., 2021).

Optical manipulation based on optothermal deformation of substrates

Optothermal deformation of the substrates presents another promising strategy to modify the interfacial interactions between the substrates and the target objects, which has been exploited to overcome the object-substrate adhesion force for optical manipulation. In this sub-section, we discuss both out-of-plane and in-plane optical manipulation.

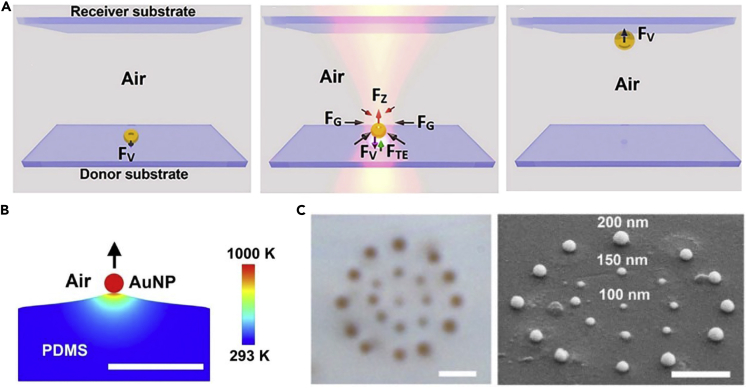

Opto-thermomechanical printing

The out-of-plane optical manipulation of colloidal nanoparticles on a solid substrate has been realized by the light-induced thermal expansion of the substrate. Alam et al. reported opto-thermomechanical nanoprinting of nanoparticles with nanoscale accuracy operated between two solid substrates (Alam et al., 2020; Alam and Zhao, 2018). The target nanoparticles were placed on a donor substrate with a large thermal expansion coefficient, such as polydimethylsiloxane (PDMS). When the laser is off, the nanoparticle is attached to the donor substrate via van der Waals forces (Figure 4A). Optothermal expansion of the substrate can be achieved by optically heating light-absorbing particles (e.g., gold) or absorptive substrates. As shown in Figure 4B, the optical heating of a gold nanoparticle (AuNP) resulted in the deformation of the PDMS film and provided a strong thermal expansion force (FTE). The synergy of FTE and optical forces could overcome the van der Waals adhesion force to nudge the AuNP toward another receiver substrate (Figure 4A). By optimizing the laser focus and the gap between two substrates, individual AuNPs could be nudged away from the donor substrate and printed onto the receiver substrate with sub-100 nm accuracy, as shown in the circular pattern of printed nanoparticles (Figure 4C). In addition, the printed nanoparticles could be released for the correction of printing errors.

Figure 4.

Opto-thermomechanical printing of nanoparticles

(A) Schematic and force analysis for opto-thermomechanical printing of particles operated between two solid substrates, i.e., donor substrate and receiver substrate.

(B) Simulated thermal expansion behavior of the PDMS film under optical heating of a 100 nm AuNP on the PDMS. Scale bar: 500 nm.

(C) Optical and scanning electron microscopic images of a circular pattern printed with AuNPs of different sizes (100, 150, and 200 nm). Scale bars: 1 μm.

Figures reproduced from: (A-C) (Alam et al., 2020) Copyright 2020, American Chemical Society.

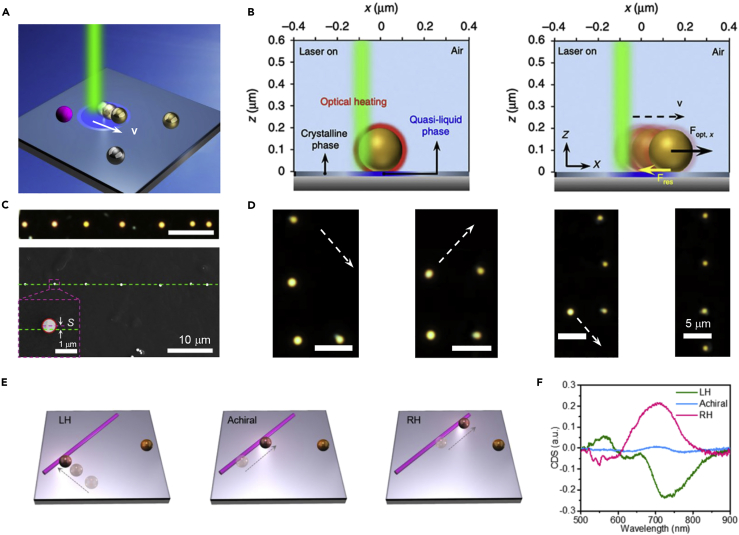

Optothermally gated photon nudging

The in-plane optical manipulation on solid substrates has been demonstrated by coordinating optothermal deformation of the substrate and the in-plane optical scattering forces. For instance, Fedoruk et al. reported the optical nudging of gold nanoparticles inside the polyvinyl alcohol (PVA) film (Fedoruk et al., 2011). The plasmon-enhanced optical heating of the AuNP resulted in the rapid melting of the PVA film, after which the AuNP within the localized melting region was nudged by optical forces. However, this manipulation was irreversible since the PVA film was thermally decomposed. Lately, Li et al. developed optothermally gated photon nudging (OPN) technique to achieve reversible and noninvasive optical manipulation of particles (Figure 5A) (Li et al., 2019c). The key working principle of OPN is the use of a thermoresponsive solid layer (e.g., cetyltrimethylammonium chloride (CTAC)) between the particle and the substrate to optothermally modulate the particle-substrate interfacial interactions. Specifically, when the laser was off, the CTAC layer remained in the solid phase and the AuNP was immobilized on the substrate by van der Waals forces. Under laser irradiation, the optical heating of the AuNP caused a localized phase transition of the CTAC layer from the solid phase to a quasi-liquid structure. Thus, the interfacial friction was considerably reduced, which allowed the AuNP to be nudged by optical scattering forces (Figure 5B). OPN could be applied to manipulate particles of different materials (e.g., Au, Ag, and silicon), sizes (sub-50 nm to a few micrometers), and shapes (spherical and anisotropic). By simply translating the substrate or steering the laser beam, colloidal particles could be nudged to any target positions at the nanoscale accuracy (Figure 5C). After the laser was turned off, the CTAC layer could recover to its solid form to easily immobilize particles on the substrate. In addition, OPN enabled reversible manipulation of colloidal particles and thus reconfigurable patterning of colloidal superstructures (Figure 5D). Li et al. further applied this technique to assemble reconfigurable chiral nanostructures using a silicon nanowire and a silicon nanoparticle as the building blocks (Li et al., 2021b). The optical chirality of the assembled nanostructures could be tailored on-demand by manipulating the silicon nanoparticle along the silicon nanowire (Figures 5E and 5F), which served as a promising platform to develop active chiroptical devices.

Figure 5.

Optothermally gated photon nudging

(A) Schematic of OPN on a solid substrate.

(B) Working principle of OPN.

(C) Optical assembly of randomly dispersed silicon nanoparticles into a straight line with an average position error of 80 nm.

(D) Reconfigurable patterning of four 300 nm AuNPs. The dashed arrows show the reconfigurable patterning sequence.

(E) Schematic showing the assembly of reconfigurable chiral nanostructures via OPN.

(F) Circular differential scattering (CDS) spectra of left-handed (LH), achiral, and right-handed (RH) structures.

Figures reproduced from: (A–D) (Li et al., 2019c) Copyright 2019, Nature Publishing Group; (E and F) (Li et al., 2021b) Copyright 2021, American Chemical Society.

Conclusion and outlook

The state-of-the-art approaches discussed herein show that a variety of physical mechanisms can be exploited for optical manipulation and assembly of micro/nanoscale objects on solid substrates in nonliquid environments. Versatile manipulation of the different objects has been demonstrated, including in-plane rotation, crawling, and translation, as well as out-of-plane nudging and levitation (Table 1). In comparison to the earlier works focusing on manipulating micro/nano-objects in liquid environments, optical manipulation on solid substrates greatly extends the capability of optical tweezers and opens many new opportunities in broad applications. Some possible directions include bottom-up assembly of functional materials and devices such as optical waveguides (Gür et al., 2018), development of complex micro-gratings (Nedev et al., 2011), assembly and reconfiguration of optical nanocircuits (Shi et al., 2014), and integration of topological nanodevices (Kruk et al., 2019). The capability to reversibly manipulate and assemble colloidal particles on solid substrates with light, along with in situ optical measurements, also leads to an ideal platform for fundamental studies in a broad range of fields such as materials science, colloidal science, and nanophotonics. Still, more efforts are needed to improve optical manipulation technologies on solid substrates. On the one hand, many of the existing manipulation techniques are only applicable to specific objects or working environments. For instance, photophoretic manipulation relies on the difference of temperature or thermal accommodation coefficients, which requires the nonuniform light illumination or special sample configuration (Azadi et al., 2021; Lu et al., 2017b). Similarly, for certain optical manipulation based on photochemical isomerization, specific liquid-crystal substrates are required (Eelkema et al., 2006a). To improve the applicability, a general optical technique that can manipulate all kinds of materials on any solid substrates is highly preferred. Optical manipulation of objects on solid substrates based on shape deformation is more general since many physical mechanisms can be exploited, such as optothermal deformation and surface acoustic waves. However, in comparison to optical manipulation in liquids, current optical manipulation methods on solid substrates suffer from relatively low efficiency and speed (Li et al., 2019c; Linghu et al., 2021; Uchida et al., 2015). One would explore new working mechanisms and advanced optical engineering (e.g., use of spatial light modulators for parallel manipulation) to improve the manipulation and assembly throughput. With the continuous efforts from researchers in multidisciplinary fields, we are optimistic that the evolution of optical manipulation from liquid to solid environments will lead to broader impacts.

Table 1.

Summary of the reviewed techniques for optical manipulation on solid substrates

| General mechanism | Manipulation mode | Specific mechanism | Light source | Applicable objects | Applicable substrates | References |

|---|---|---|---|---|---|---|

| Photophoresis | Pulling and pushing | Photophoresis induced by temperature difference | Fiber laser | Light-absorbing objects | Tapered fiber | (Lu et al., 2017b) |

| Levitation | Photophoresis induced by the difference of thermal accommodation coefficient | Laser or sunlight | Light-absorbing objects | Any | (Azadi et al., 2021) | |

| Light-driven reorganization of liquid crystal films | In-plane rotation and translation | Photothermal isomerization | UV or visible light | Any | Liquid crystal films | (Eelkema et al., 2006a; Kausar et al., 2009) |

| Shape deformation of objects | Crawling | Optothermally induced phase transition | Laser | Liquid crystalline elastomers | Any | (Zeng et al., 2015) |

| Crawling | Photothermal isomerization | UV or visible light | Azobenzene-based crystals | Any | (Uchida et al., 2015) | |

| Crawling | Optothermally induced surface acoustic waves | Fiber laser | Plasmonic nano-objects | Optical fiber | (Lu et al., 2019; Linghu et al., 2021) | |

| Shape deformation of substrates | Out-of-plane nudging | Optothermal expansion | Laser | Light-absorbing objects | Substrates with large thermal expansion | (Alam et al., 2020) |

| In-plane nudging | Optothermally induced phase transition | Laser | Objects with strong light scattering | Substrates with the thermally induced solid-liquid transition | (Li et al., 2019c, 2021b) |

Acknowledgments

Y.Z. and J.L. acknowledge the financial supports of the National Institute of General Medical Sciences of the National Institutes of Health (DP2GM128446) and the National Science Foundation (NSF-ECCS-2001650). J.L. also acknowledges the financial support of the University Graduate Continuing Fellowship from The University of Texas at Austin.

Author contributions

J.L. and Y.Z. conceived the idea, designed the frame, and wrote the manuscript. A.A. assisted with the manuscript revision. Y.Z. supervised the project.

Declaration of interests

The authors declare no competing interests.

References

- Alam M.S., Zhao C. Nondestructive approach for additive nanomanufacturing of metallic nanostructures in the air. ACS Omega. 2018;3:1213–1219. doi: 10.1021/acsomega.7b01907. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Alam M.S., Zhan Q., Zhao C. Additive opto-thermomechanical nanoprinting and nanorepairing under ambient conditions. Nano Lett. 2020;20:5057–5064. doi: 10.1021/acs.nanolett.0c01261. [DOI] [PubMed] [Google Scholar]

- Ashkin A. Acceleration and trapping of particles by radiation pressure. Phys. Rev. Lett. 1970;24:156–159. [Google Scholar]

- Ashkin A. Optical trapping and manipulation of neutral particles using lasers. Proc. Natl. Acad. Sci. U S A. 1997;94:4853–4860. doi: 10.1073/pnas.94.10.4853. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ashkin A., Dziedzic J.M. Optical trapping and manipulation of viruses and bacteria. Science. 1987;235:1517–1520. doi: 10.1126/science.3547653. [DOI] [PubMed] [Google Scholar]

- Ashkin A., Dziedzic J.M., Bjorkholm J.E., Chu S. Observation of a single-beam gradient force optical trap for dielectric particles. Opt. Lett. 1986;11:288. doi: 10.1364/ol.11.000288. [DOI] [PubMed] [Google Scholar]

- Ashkin A., Dziedzic J.M., Yamane T. Optical trapping and manipulation of single cells using infrared laser beams. Nature. 1987;330:769–771. doi: 10.1038/330769a0. [DOI] [PubMed] [Google Scholar]

- Azadi M., Popov G.A., Lu Z., Eskenazi A.G., Bang A.J.W., Campbell M.F., Hu H., Bargatin I. Controlled levitation of nanostructured thin films for sun-powered near-space flight. Sci. Adv. 2021;7:eabe1127. doi: 10.1126/sciadv.abe1127. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Browne W.R., Feringa B.L. Making molecular machines work. Nat. Nanotechnol. 2006;1:25–35. doi: 10.1038/nnano.2006.45. [DOI] [PubMed] [Google Scholar]

- Chen Z., Li J., Zheng Y. Heat-mediated optical manipulation. Chem. Rev. 2022;122:3122–3179. doi: 10.1021/acs.chemrev.1c00626. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chini S.F., Amirfazli A. Understanding pattern collapse in photolithography process due to capillary forces. Langmuir. 2010;26:13707–13714. doi: 10.1021/la101521k. [DOI] [PubMed] [Google Scholar]

- Chiou P.Y., Ohta A.T., Wu M.C. Massively parallel manipulation of single cells and microparticles using optical images. Nature. 2005;436:370–372. doi: 10.1038/nature03831. [DOI] [PubMed] [Google Scholar]

- Cortes J., Stanczak C., Azadi M., Narula M., Nicaise S.M., Hu H., Bargatin I. Photophoretic levitation of macroscopic nanocardboard plates. Adv. Mater. 2020;32:1906878. doi: 10.1002/adma.201906878. [DOI] [PubMed] [Google Scholar]

- Ding X., Lin S.-C.S., Kiraly B., Yue H., Li S., Chiang I.-K., Shi J., Benkovic S.J., Huang T.J. On-chip manipulation of single microparticles, cells, and organisms using surface acoustic waves. Proc. Natl. Acad. Sci. U S A. 2012;109:11105–11109. doi: 10.1073/pnas.1209288109. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ding X., Peng Z., Lin S.-C.S., Geri M., Li S., Li P., Chen Y., Dao M., Suresh S., Huang T.J. Cell separation using tilted-angle standing surface acoustic waves. Proc. Natl. Acad. Sci. U S A. 2014;111:12992–12997. doi: 10.1073/pnas.1413325111. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Do J., Fedoruk M., Jackel F., Feldmann J. Two-color laser printing of individual gold nanorods. Nano Lett. 2013;13:4164–4168. doi: 10.1021/nl401788w. [DOI] [PubMed] [Google Scholar]

- Eelkema R., Pollard M.M., Katsonis N., Vicario J., Broer D.J., Feringa B.L. Rotational reorganization of doped cholesteric liquid crystalline films. J. Am. Chem. Soc. 2006;128:14397–14407. doi: 10.1021/ja065334o. [DOI] [PubMed] [Google Scholar]

- Eelkema R., Pollard M.M., Vicario J., Katsonis N., Ramon B.S., Bastiaansen C.W.M., Broer D.J., Feringa B.L. Nanomotor rotates microscale objects. Nature. 2006;440:163. doi: 10.1038/440163a. [DOI] [PubMed] [Google Scholar]

- Fan D.L., Zhu F.Q., Cammarata R.C., Chien C.L. Electric tweezers. Nano Today. 2011;6:339–354. doi: 10.1016/j.nantod.2011.05.003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Farahi R.H., Passian A., Ferrell T.L., Thundat T. Microfluidic manipulation via Marangoni forces. Appl. Phys. Lett. 2004;85:4237–4239. [Google Scholar]

- Fedoruk M., Lutich A.A., Feldmann J. Subdiffraction-limited milling by an optically driven single gold nanoparticle. ACS Nano. 2011;5:7377–7382. doi: 10.1021/nn2023045. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gelebart A.H., Jan Mulder D., Varga M., Konya A., Vantomme G., Meijer E.W., Selinger R.L.B., Broer D.J. Making waves in a photoactive polymer film. Nature. 2017;546:632–636. doi: 10.1038/nature22987. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gong Z., Pan Y.-L., Videen G., Wang C. Optical trapping and manipulation of single particles in air: principles, technical details, and applications. J. Quant. Spectrosc. Radiat. Transf. 2018;214:94–119. [Google Scholar]

- Grier D.G. A revolution in optical manipulation. Nature. 2003;424:810–816. doi: 10.1038/nature01935. [DOI] [PubMed] [Google Scholar]

- Grigorenko A.N., Roberts N.W., Dickinson M.R., Zhang Y. Nanometric optical tweezers based on nanostructured substrates. Nat. Photon. 2008;2:365–370. [Google Scholar]

- Gu Z., Li S., Zhang F., Wang S. Understanding surface adhesion in nature: a peeling model. Adv. Sci. 2016;3:1500327. doi: 10.1002/advs.201500327. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gür F.N., McPolin C.P.T., Raza S., Mayer M., Roth D.J., Steiner A.M., Löffler M., Fery A., Brongersma M.L., Zayats A.V., et al. DNA-assembled plasmonic waveguides for nanoscale light propagation to a fluorescent nanodiamond. Nano Lett. 2018;18:7323–7329. doi: 10.1021/acs.nanolett.8b03524. [DOI] [PubMed] [Google Scholar]

- Ikeda T., Mamiya J.-i., Yu Y. Photomechanics of liquid-crystalline elastomers and other polymers. Angew. Chem. Int. Ed. 2007;46:506–528. doi: 10.1002/anie.200602372. [DOI] [PubMed] [Google Scholar]

- Ito S., Yamashita A., Akiyama H., Kihara H., Yoshida M. Azobenzene-based (meth)acrylates: controlled radical polymerization, photoresponsive solid–liquid phase transition behavior, and application to reworkable adhesives. Macromolecules. 2018;51:3243–3253. [Google Scholar]

- Jamshidi A., Neale S.L., Yu K., Pauzauskie P.J., Schuck P.J., Valley J.K., Hsu H.Y., Ohta A.T., Wu M.C. NanoPen: dynamic, low-power, and light-actuated patterning of nanoparticles. Nano Lett. 2009;9:2921–2925. doi: 10.1021/nl901239a. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jiang Z.-C., Xiao Y.-Y., Tong X., Zhao Y. Selective decrosslinking in liquid crystal polymer actuators for optical reconfiguration of origami and light-fueled locomotion. Angew. Chem. Int. Ed. 2019;58:5332–5337. doi: 10.1002/anie.201900470. [DOI] [PubMed] [Google Scholar]

- Jiang K., Liang L., Lim C.T. Engineering confining microenvironment for studying cancer metastasis. iScience. 2021;24:102098. doi: 10.1016/j.isci.2021.102098. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jones S., Andren D., Karpinski P., Kall M. Photothermal heating of plasmonic nanoantennas: influence on trapped particle dynamics and colloid distribution. ACS Photon. 2018;5:2878–2887. [Google Scholar]

- Jovanovic O. Photophoresis—light induced motion of particles suspended in gas. J. Quant. Spectrosc. Radiat. Transf. 2009;110:889–901. [Google Scholar]

- Juan M.L., Righini M., Quidant R. Plasmon nano-optical tweezers. Nat. Photon. 2011;5:349–356. [Google Scholar]

- Junno T., Deppert K., Montelius L., Samuelson L. Controlled manipulation of nanoparticles with an atomic-force microscope. Appl. Phys. Lett. 1995;66:3627–3629. [Google Scholar]

- Kausar A., Nagano H., Ogata T., Nonaka T., Kurihara S. Photocontrolled translational motion of a microscale solid object on azobenzene-doped liquid-crystalline films. Angew. Chem. Int. Ed. 2009;48:2144–2147. doi: 10.1002/anie.200804762. [DOI] [PubMed] [Google Scholar]

- Kausar A., Nagano H., Kuwahara Y., Ogata T., Kurihara S. Photocontrolled manipulation of a microscale object: a rotational or translational mechanism. Chem. Eur. J. 2011;17:508–515. doi: 10.1002/chem.201001238. [DOI] [PubMed] [Google Scholar]

- Kim Y., Tamaoki N. Asymmetric dimers of chiral azobenzene dopants exhibiting unusual helical twisting power upon photoswitching in cholesteric liquid crystals. ACS Appl. Mater. Interfaces. 2016;8:4918–4926. doi: 10.1021/acsami.5b11888. [DOI] [PubMed] [Google Scholar]

- Kim S., Ratchford D.C., Li X. Atomic force microscope nanomanipulation with simultaneous visual guidance. ACS Nano. 2009;3:2989–2994. doi: 10.1021/nn900606s. [DOI] [PubMed] [Google Scholar]

- Kim D.-Y., Lee S.-A., Kim H., Min Kim S., Kim N., Jeong K.-U. An azobenzene-based photochromic liquid crystalline amphiphile for a remote-controllable light shutter. Chem. Commun. 2015;51:11080–11083. doi: 10.1039/c5cc02834e. [DOI] [PubMed] [Google Scholar]

- Kruk S., Poddubny A., Smirnova D., Wang L., Slobozhanyuk A., Shorokhov A., Kravchenko I., Luther-Davies B., Kivshar Y. Nonlinear light generation in topological nanostructures. Nat. Nanotechnol. 2019;14:126–130. doi: 10.1038/s41565-018-0324-7. [DOI] [PubMed] [Google Scholar]

- Li J., Lin L., Inoue Y., Zheng Y. Opto-thermophoretic tweezers and assembly. J. Micro Nanomanuf. 2018;6:040801. doi: 10.1115/1.4041615. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li F., Pei C., Jiang L., Jin S. Detaching and moving of adhered particles with a photoacoustic micro-resonator. Appl. Phys. Lett. 2019;114:081905. [Google Scholar]

- Li J., Hill E.H., Lin L., Zheng Y. Optical nanoprinting of colloidal particles and functional structures. ACS Nano. 2019;13:3783–3795. doi: 10.1021/acsnano.9b01034. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li J., Liu Y., Lin L., Wang M., Jiang T., Guo J., Ding H., Kollipara P.S., Inoue Y., Fan D., et al. Optical nanomanipulation on solid substrates via optothermally-gated photon nudging. Nat. Commun. 2019;10:5672. doi: 10.1038/s41467-019-13676-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li J., Zheng Y. Optothermally assembled nanostructures. Acc. Mater. Res. 2021;2:352–363. doi: 10.1021/accountsmr.1c00033. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li J., Chen Z., Liu Y., Kollipara P.S., Feng Y., Zhang Z., Zheng Y. Opto-refrigerative tweezers. Sci. Adv. 2021;7:eabh1101. doi: 10.1126/sciadv.abh1101. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li J., Wang M., Wu Z., Li H., Hu G., Jiang T., Guo J., Liu Y., Yao K., Chen Z., et al. Tunable chiral optics in all-solid-phase reconfigurable dielectric nanostructures. Nano Lett. 2021;21:973–979. doi: 10.1021/acs.nanolett.0c03957. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lin L., Peng X., Mao Z., Li W., Yogeesh M.N., Rajeeva B.B., Perillo E.P., Dunn A.K., Akinwande D., Zheng Y. Bubble-pen lithography. Nano Lett. 2016;16:701–708. doi: 10.1021/acs.nanolett.5b04524. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lin L., Peng X., Zheng Y. Reconfigurable opto-thermoelectric printing of colloidal particles. Chem. Commun. 2017;53:7357–7360. doi: 10.1039/c7cc03530f. [DOI] [PubMed] [Google Scholar]

- Lin L., Zhang J., Peng X., Wu Z., Coughlan A.C.H., Mao Z., Bevan M.A., Zheng Y. Opto-thermophoretic assembly of colloidal matter. Sci. Adv. 2017;3:e1700458. doi: 10.1126/sciadv.1700458. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lin L., Hill E.H., Peng X., Zheng Y. Optothermal manipulations of colloidal particles and living cells. Acc. Chem. Res. 2018;51:1465–1474. doi: 10.1021/acs.accounts.8b00102. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Linghu S., Gu Z., Lu J., Fang W., Yang Z., Yu H., Li Z., Zhu R., Peng J., Zhan Q., et al. Plasmon-driven nanowire actuators for on-chip manipulation. Nat. Commun. 2021;12:385. doi: 10.1038/s41467-020-20683-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lu J., Hong Y., Li Q., Xu Y., Fang W., Qiu M. Light-induced reversible expansion of individual gold nanoplates. AIP Adv. 2017;7:105025. [Google Scholar]

- Lu J., Yang H., Zhou L., Yang Y., Luo S., Li Q., Qiu M. Light-induced pulling and pushing by the synergic effect of optical force and photophoretic force. Phys. Rev. Lett. 2017;118:043601. doi: 10.1103/PhysRevLett.118.043601. [DOI] [PubMed] [Google Scholar]

- Lu J., Li Q., Qiu C.W., Hong Y., Ghosh P., Qiu M. Nanoscale Lamb wave–driven motors in nonliquid environments. Sci. Adv. 2019;5:eaau8271. doi: 10.1126/sciadv.aau8271. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Maragò O.M., Jones P.H., Gucciardi P.G., Volpe G., Ferrari A.C. Optical trapping and manipulation of nanostructures. Nat. Nanotechnol. 2013;8:807. doi: 10.1038/nnano.2013.208. [DOI] [PubMed] [Google Scholar]

- Merry R., van de Molengraft R., Steinbuch M. Modeling of a walking piezo actuator. Sens. Actuator A Phys. 2010;162:51–60. [Google Scholar]

- Mitov M. Cholesteric liquid crystals with a broad light reflection band. Adv. Mater. 2012;24:6260–6276. doi: 10.1002/adma.201202913. [DOI] [PubMed] [Google Scholar]

- Nedev S., Urban A.S., Lutich A.A., Feldmann J. Optical force stamping lithography. Nano Lett. 2011;11:5066–5070. doi: 10.1021/nl203214n. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ni S., Leemann J., Buttinoni I., Isa L., Wolf H. Programmable colloidal molecules from sequential capillarity-assisted particle assembly. Sci. Adv. 2016;2:e1501779. doi: 10.1126/sciadv.1501779. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ohm C., Brehmer M., Zentel R. Liquid crystalline elastomers as actuators and sensors. Adv. Mater. 2010;22:3366–3387. doi: 10.1002/adma.200904059. [DOI] [PubMed] [Google Scholar]

- Ozin G.A., Hou K., Lotsch B.V., Cademartiri L., Puzzo D.P., Scotognella F., Ghadimi A., Thomson J. Nanofabrication by self-assembly. Mater. Today. 2009;12:12–23. [Google Scholar]

- Palagi S., Mark A.G., Reigh S.Y., Melde K., Qiu T., Zeng H., Parmeggiani C., Martella D., Sanchez-Castillo A., Kapernaum N., et al. Structured light enables biomimetic swimming and versatile locomotion of photoresponsive soft microrobots. Nat. Mater. 2016;15:647–653. doi: 10.1038/nmat4569. [DOI] [PubMed] [Google Scholar]

- Palima D., Glückstad J. Gearing up for optical microrobotics: micromanipulation and actuation of synthetic microstructures by optical forces. Laser Photon. Rev. 2013;7:478–494. [Google Scholar]

- Pan Y.-L., Hill S.C., Coleman M. Photophoretic trapping of absorbing particles in air and measurement of their single-particle Raman spectra. Opt. Express. 2012;20:5325–5334. doi: 10.1364/OE.20.005325. [DOI] [PubMed] [Google Scholar]

- Paterson D.A., Xiang J., Singh G., Walker R., Agra-Kooijman D.M., Martínez-Felipe A., Gao M., Storey J.M.D., Kumar S., Lavrentovich O.D., et al. Reversible isothermal twist–bend nematic–nematic phase transition driven by the photoisomerization of an azobenzene-based nonsymmetric liquid crystal dimer. J. Am. Chem. Soc. 2016;138:5283–5289. doi: 10.1021/jacs.5b13331. [DOI] [PubMed] [Google Scholar]

- Peng X.L., Li J.G., Lin L.H., Liu Y.R., Zheng Y.B. Opto-Thermophoretic manipulation and construction of colloidal superstructures in photocurable hydrogels. ACS Appl. Nano Mater. 2018;1:3998–4004. doi: 10.1021/acsanm.8b00766. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Porfirev A. “Optical mill”—a tool for the massive transfer of airborne light-absorbing particles. Appl. Phys. Lett. 2019;115:201103. [Google Scholar]

- Requicha A.A.G. Nanorobots, NEMS, and nanoassembly. Proc. IEEE. 2003;91:1922–1933. [Google Scholar]

- Rogóż M., Zeng H., Xuan C., Wiersma D.S., Wasylczyk P. Light-driven soft robot mimics caterpillar locomotion in natural scale. Adv. Opt. Mater. 2016;4:1689–1694. [Google Scholar]

- Rohatschek H. History of photophoresis. In: Preining O, James Davis E, editors, History of aerosol science; 2000. p. 118–127 chapter VIII. https://www.aaar.org/bookstore/history-of-aerosol-science/

- Schaefer D.M., Reifenberger R., Patil A., Andres R.P. Fabrication of two-dimensional arrays of nanometer-size clusters with the atomic force microscope. Appl. Phys. Lett. 1995;66:1012–1014. [Google Scholar]

- Shi J., Monticone F., Elias S., Wu Y., Ratchford D., Li X., Alu A. Modular assembly of optical nanocircuits. Nat. Commun. 2014;5:3896. doi: 10.1038/ncomms4896. [DOI] [PubMed] [Google Scholar]

- Shigematsu T., Kurosawa M.K., Asai K. Nanometer stepping drives of surface acoustic wave motor. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2003;50:376–385. doi: 10.1109/tuffc.2003.1197960. [DOI] [PubMed] [Google Scholar]

- Shvedov V.G., Desyatnikov A.S., Rode A.V., Krolikowski W., Kivshar Y.S. Optical guiding of absorbing nanoclusters in air. Opt. Express. 2009;17:5743–5757. doi: 10.1364/oe.17.005743. [DOI] [PubMed] [Google Scholar]

- Shvedov V.G., Rode A.V., Izdebskaya Y.V., Desyatnikov A.S., Krolikowski W., Kivshar Y.S. Giant optical manipulation. Phys. Rev. Lett. 2010;105:118103. doi: 10.1103/PhysRevLett.105.118103. [DOI] [PubMed] [Google Scholar]

- Snezhko A., Aranson I.S. Magnetic manipulation of self-assembled colloidal asters. Nat. Mater. 2011;10:698–703. doi: 10.1038/nmat3083. [DOI] [PubMed] [Google Scholar]

- Tamaoki N. Cholesteric liquid crystals for color information technology. Adv. Mater. 2001;13:1135–1147. [Google Scholar]

- Tang W., Lyu W., Lu J., Liu F., Wang J., Yan W., Qiu M. Micro-scale opto-thermo-mechanical actuation in the dry adhesive regime. Light: Sci. Appl. 2021;10:193. doi: 10.1038/s41377-021-00622-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Uchida E., Azumi R., Norikane Y. Light-induced crawling of crystals on a glass surface. Nat. Commun. 2015;6:7310. doi: 10.1038/ncomms8310. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Urban A.S., Lutich A.A., Stefani F.D., Feldmann J. Laser printing single gold nanoparticles. Nano Lett. 2010;10:4794–4798. doi: 10.1021/nl1030425. [DOI] [PubMed] [Google Scholar]

- Walker D., Singh D.P., Fischer P. Capture of 2D microparticle arrays via a UV-triggered thiol-yne “click” reaction. Adv. Mater. 2016;28:9846–9850. doi: 10.1002/adma.201603586. [DOI] [PubMed] [Google Scholar]

- Wang C., Gong Z., Pan Y.-L., Videen G. Laser pushing or pulling of absorbing airborne particles. Appl. Phys. Lett. 2016;109:011905. [Google Scholar]

- Wang Y.R., Zheng R.Q., Ding Y.F., Fan W.J., Liu D.H., Zhou J., Shi J.W. Resolving the bond angle of a plasmonic metamolecule. Optica. 2017;4:1092–1097. [Google Scholar]

- Wu M.C. Optoelectronic tweezers. Nat. Photon. 2011;5:322–324. [Google Scholar]

- Yang W., van Dijk M., Primavera C., Dekker C. FIB-milled plasmonic nanoapertures allow for long trapping times of individual proteins. iScience. 2021;24:103237. doi: 10.1016/j.isci.2021.103237. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zeng H., Wasylczyk P., Parmeggiani C., Martella D., Burresi M., Wiersma D.S. Light-fueled microscopic walkers. Adv. Mater. 2015;27:3883–3887. doi: 10.1002/adma.201501446. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zeng H., Wani O.M., Wasylczyk P., Priimagi A. Light-driven, caterpillar-inspired miniature inching robot. Macromol. Rapid Commun. 2018;39:1700224. doi: 10.1002/marc.201700224. [DOI] [PubMed] [Google Scholar]

- Zhang S., Scott E.Y., Singh J., Chen Y., Zhang Y., Elsayed M., Chamberlain M.D., Shakiba N., Adams K., Yu S., et al. The optoelectronic microrobot: a versatile toolbox for micromanipulation. Proc. Natl. Acad. Sci. U S A. 2019;116:14823–14828. doi: 10.1073/pnas.1903406116. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhong Q., Ding H., Gao B., He Z., Gu Z. Advances of microfluidics in biomedical engineering. Adv. Mater. Technol. 2019;4:1800663. [Google Scholar]