Abstract

Objective:

The force moment providing rotation of the tooth around the x-axis (buccal-lingual) is referred to as torque expression in orthodontic literature. Many factors affect torque expression, including the wire material characteristics. This investigation aims to provide an experimental study into and comparison of the torque expression between wire types.

Materials and Methods:

With a worm-gear–driven torquing apparatus, wire was torqued while a bracket mounted on a six-axis load cell was engaged. Three 0.019 × 0.0195 inch wire (stainless steel, titanium molybdenum alloy [TMA], copper nickel titanium [CuNiTi]), and three 0.022 inch slot bracket combinations (Damon 3MX, In-Ovation-R, SPEED) were compared.

Results:

At low twist angles (<12 degrees), the differences in torque expression between wires were not statistically significant. At twist angles over 24 degrees, stainless steel wire yielded 1.5 to 2 times the torque expression of TMA and 2.5 to 3 times that of nickel titanium (NiTi). At high angles of torsion (over 40 degrees) with a stiff wire material, loss of linear torque expression sometimes occurred.

Conclusions:

Stainless steel has the largest torque expression, followed by TMA and then NiTi.

Keywords: Torque expression, Orthodontic biomechanics, Self-ligating brackets, Stainless Steel, TMA, NiTi wire

INTRODUCTION

To correct malocclusions associated with irregular axial inclination of teeth, controlled root movement is required. This movement is commonly referred to as third order movement, root torque, or root uprighting.1 The twisting of an edgewise wire in a bracket slot generates a torsional load.2 The force moment providing rotation of the tooth around the x-axis (buccal-lingual) is sometimes referred to in orthodontic literature as torque expression. For the purposes of this paper, torque is defined as the physical moment applied to the bracket slot, measured in N•mm or in a dimensionless form. In addition, angle or torque angle is the angle to which the wire has been twisted in degrees, and torque expression is defined as the torque at a given angle or set of angles.

Torque expression is the result of the interaction of many factors. Bracket design, wire/slot play (engagement angle), mode of ligation,3 bracket deformation,4 wire stiffness,3,5 magnitude of wire torsion and dimension,4,6,7 and wire edge beveling,8–10 all have been suggested as factors that affect torque expression. Clinical factors such as initial tooth inclination,4 bracket position,11 and tooth anatomy12,13 are also determinants of torque expression. Orthodontic bracket manufacturers have sought to address these factors by preangulating the bracket slot relative to the bracket base. The prescription of slot angulations varies between manufacturers, and some manufacturers offer a range of slot angulations.

The relative contribution of wire type to torque expression has not been well defined. Alloys with a low modulus of elasticity, such as nickel titanium (NiTi), result in decreased torque expression relative to stainless steel.5 A recent publication suggested that reduced modulus alloys such as NiTi and beta-titanium (β-Ti), with only a fraction of the stiffness of stainless steel wire, may be ineffective in transmitting a torque moment within a bracket slot.3 Although no published studies have evaluated torque expression with NiTi and β-Ti archwires with self-ligating orthodontic brackets, manufacturers have introduced 20 degree “pretorqued” NiTi wire.

The objective of this study was to compare torque expression between three commonly employed wire alloys: stainless steel, β-Ti, and NiTi.

MATERIALS AND METHODS

The orthodontic torque measurement device previously described by Badawi et al.14 was utilized to measure torque expression in N•mm. This apparatus consists of an orthodontic bracket mounted on a multiaxis force/torque transducer (Nano 17 Multi-Axis Force/Torque Transducer, ATI Industrial Automation, Apex, NC) capable of measuring forces and torques in three dimensions. The error of measurement of the force/torque transducer is 1.5% (manufacturer specification). The load cell was used with a data acquisition card, which imported the transducer signal to a personal computer (DAC 16-Bit E Series NI PCI-6033E, National Instruments, Austin, Tex). LabView data acquisition software (National Instruments) was used to acquire the signal from the transducer and to log the force and torque data in the x-dimension to file, along with the mean angle of torsion of the wire segment. A digital inclinometer was used to measure the angle of torsion of the wire segment (Model T2-7200-1N, US Digital, Vancouver, Wash). The wire was rotated by turning worm-gear. The wire subassembly turned 3 degrees for every full turn of the worm-gear.14 To be consistent with data previously reported by Badawi et al.,14 torque data were recorded every 3 degrees from 0 to 51 degrees.

One-hundred fifty maxillary right central incisor brackets of each of three types of self-ligating brackets (total: 450 brackets, In-Ovation-R, GAC, Bohemia, NY; SPEED, Strite Industries, Cambridge, Ontario, Canada; Damon 3MX, Ormco, Orange, Calif) were included in the study. Straight lengths of 0.019 × 0.025 inch stainless steel, titanium molybdenum alloy (TMA, a type of β-Ti), and copper nickel titanium (CuNiTi) wire were tested in torsion, with a new segment used for each experiment (300 Series Stainless Steel lot #07J2J and #05A8A; TMA lot #06E22E and #04B16B; 35 degree CuNiTi Custom Order; Ormco, Glendora, Calif). The torque prescription of the brackets was assumed to have no effect on the method of study because each data set was adjusted to the estimated true zero position of that bracket during the data analysis.

The orthodontic torque measurement device was placed in an incubator (Air-Shields Isolette Infant Incubator, Model C100/200-2, Series 00, Serial DT 9290, Draeger Medical Systems Inc., Telford, Pa), where all tests were conducted at an average temperature of 37.92°C. All 450 experiments were individually randomized to keep differences in temperature and calibration of the device from confounding the results. The device was calibrated before data collection was begun (ATI Industrial Automation). Data were collected by one investigator during an average of two sessions per week for 14 weeks.

Statistical analysis was carried out at four angles (12, 24, 36, and 48 degrees) to compare between wires within brackets using multivariate analysis (MANOVA), with the Bonferroni corrected significance level (P < .017 is statistically significant).

RESULTS

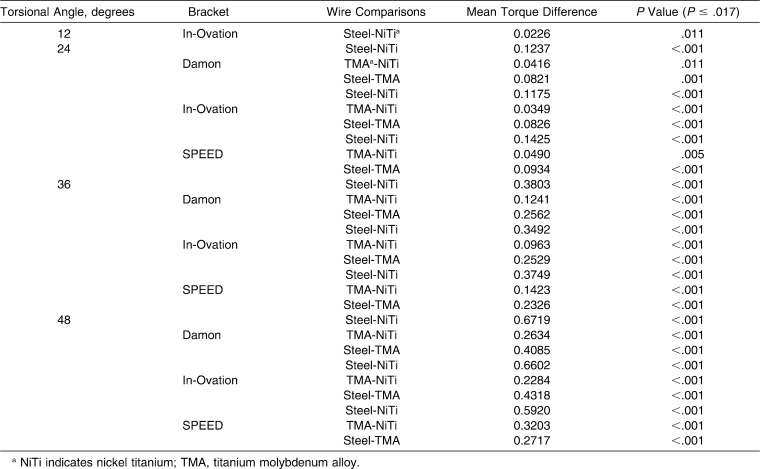

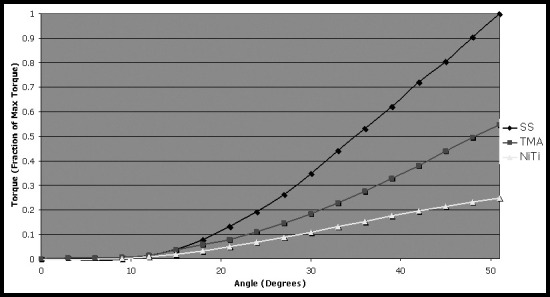

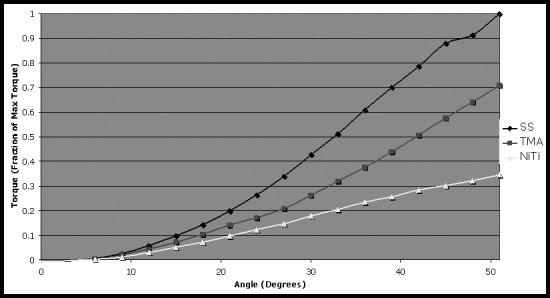

Figures 1 to 3 show plotted comparisons of the wires for each of the three bracket types by plotting measured torque vs the angle of torque. Because this was intended to be a comparative study between wires, all torque values were expressed as a dimensionless fraction of the maximum measured torque for each bracket. Therefore, the maximum torque value within each figure was set to be exactly one. The remainder of this paper uses these nondimensionalized units whenever quantifying torque. For each of the three brackets, stainless steel wire produced the greatest torque, followed by TMA, and then NiTi.

Figure 1.

Relative average torque expression in Damon brackets.

Figure 3.

Relative average torque expression in SPEED brackets.

Figure 2.

Relative average torque expression in In-Ovation brackets.

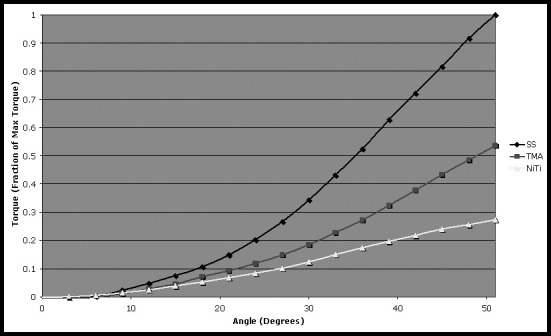

Statistical results for comparison of torque results are shown in Table 1. At 12 degrees, the only statistically significant difference was noted between stainless steel and NiTi wires in In-Ovation brackets. At all higher angles of torque (24, 36, and 48 degrees), a statistically significant difference between wires was seen for all types of brackets. The mean torque difference is the difference in average torque for each wire comparison. For example, at 12 degrees, the steel wire in the In-Ovation brackets produced an average torque of 0.0467, whereas the NiTi produced an average torque of 0.0240. Subtracting gives a mean torque difference of 0.0226. Statistically irrelevant results were excluded, which was particularly notable at 12 degrees.

Table 1.

Statistical Comparisons

DISCUSSION

The maximum torque application angle (wire twist relative to bracket slot) in the present study was arbitrarily set at 51 degrees. Other researchers such as Morina et al.3 have chosen to record only up to 20 degrees of torque angle. The typical bracket prescription is less than 20 degrees, and use of straight wire would limit torque “angulations” to the bracket prescription. However, it is common clinical practice to “pretwist” SS and TMA arch wires to add torque expression. To account for the orthodontist bending a “twist” into the archwire, the present study evaluated torque angle to 51 degrees. It is unlikely that a clinician would introduce more than 51 degrees of twist into a segment of archwire before engagement into the bracket. Ormco recently introduced pretorque NiTi wire to add to the torque expression provided by the bracket prescription. The amount of preset angular twist provided by the manufacturer could easily be altered to increase the range of torque expression in resilient archwires.

All brackets yielded a similar result in that steel produced the largest torque expression, followed by TMA and then NiTi. This is not unexpected, given that stainless steel is the stiffest material, followed by TMA and then NiTi.5 The angle at which torque expression began was between 10 and 12 degrees in the Damon brackets, whereas the In-Ovation and SPEED brackets began to express torque at approximately 5 degrees. This discrepancy is likely due to the effects of active self-ligation in the In-Ovation and SPEED brackets, which reduced the torque play. All three bracket types took until approximately 25 degrees to display fully linear torque expression results (when the wire was fully engaging the slot). From the initial torque expression angle until approximately 25 degrees, the slot was “partially engaged.” At 48 degrees, the stainless steel wire deviated from the linear trend in the SPEED bracket, which could be attributed to opening or partial opening of the door.

At 12 degrees, less statistically significant differences occurred than at higher angles. In fact, only one of nine wire-bracket comparisons was statistically relevant according to the Bonferroni corrected significance level. This may be so because at 12 degrees of wire torsion, the wire was near the end of the torque play region and the beginning of the partially engaged region. At 24 degrees, which occurred at the end of the partially engaged region, all nine comparisons resulted in statistically significant differences. In all cases, steel expressed torque better than NiTi and TMA. The mean torque difference was within approximately 10% between all three brackets when steel was compared with either NiTi or TMA. The mean torque difference between NiTi and TMA displayed up to 40% variation (In-Ovation: 0.0349, SPEED: 0.0490). This could have produced less predictable torque expression. In general, steel wires produced 1.5 to 1.8 times the torque of TMA and approximately 2.5 times the torque of NiTi at 24 degrees.

At 36 degrees, one would intuitively expect to see the best comparison between wires because the wire is fully engaged in the bracket slot. All three brackets appeared to have a linearly rising torque, which indicated that the wire was fully engaged. The mean torque difference was within about 5% between all brackets when steel was compared with either NiTi or TMA, but when NiTi was compared with TMA, a large variation between brackets (up to 45%) was observed. In general, steel wires produced approximately two times the torque of TMA and three times the torque of NiTi at 36 degrees.

At 48 degrees, the steel wire in the SPEED bracket was no longer following the linear trend, as seen in Figure 3, possibly because the slot door had started to open. The clinician should be aware that with SPEED brackets at higher angles of torque, particularly with steel wire, the bracket is no longer giving a reliable or predictable linear torque expression.

CONCLUSIONS

At low angles of twist, when the wire is not engaged and is not “partially engaged” in the bracket slot, the differences in torque expression between wires are generally not statistically significant. This is particularly notable at angles of torsion of 12 degrees or less.

At any angle of significant torque expression (24 degrees or greater), stainless steel wire yields approximately 1.5 to 2 times the torque expression of TMA and 2.5 to 3 times that of NiTi.

At very high angles of torsion (over 40 degrees) with a stiff wire material, such as stainless steel, there is a risk of losing linear torque expression in certain bracket types. In this experiment, the SPEED brackets lost linear torque at very high angles of torque.

Acknowledgments

Funding for this research was provided by the Dr Reyburn McIntyre Fund and the Natural Sciences and Engineering Research Council of Canada (NSERC).

REFERENCES

- 1.Lee B. W. The force requirements for tooth movement. Part II: Uprighting and root torque. Aust Orthod J. 1995;14:34–39. [PubMed] [Google Scholar]

- 2.Rauch E. Torque and its application to orthodontics. Am J Orthod. 1959;45:817–830. [Google Scholar]

- 3.Morina E, Eliades T, Pandis N, Jäger A, Bourauel C. Torque expression of self-ligating brackets compared with conventional metallic, ceramic, and plastic brackets. Eur J Orthod. 2008;30:233–238. doi: 10.1093/ejo/cjn005. [DOI] [PubMed] [Google Scholar]

- 4.Odegaard J, Meling T, Meling E. An evaluation of the torsional moments developed in orthodontic applications: an in vitro study. Am J Orthod Dentofacial Orthop. 1994;105:392–400. doi: 10.1016/S0889-5406(94)70134-2. [DOI] [PubMed] [Google Scholar]

- 5.Gioka C, Eliades T. Materials-induced variation in the torque expression of preadjusted appliances. Am J Orthod Dentofacial Orthop. 2004;125:323–328. doi: 10.1016/j.ajodo.2003.02.007. [DOI] [PubMed] [Google Scholar]

- 6.Meling T, Odegaard J. On the variability of cross-sectional dimensions and torsional properties of rectangular nickel-titanium arch wires. Am J Orthod Dentofacial Orthop. 1998;113:546–557. [PubMed] [Google Scholar]

- 7.Siatkowski R. E. Loss of anterior torque control due to variations in bracket slot and archwire dimensions. J Clin Orthod. 1999;33:508–510. [PubMed] [Google Scholar]

- 8.Sebanc J, Brantley W. A, Pincsak J. J, Conover J. P. Variability of effective root torque as a function of edge bevel on orthodontic arch wires. Am J Orthod. 1984;86:43–51. doi: 10.1016/0002-9416(84)90275-6. [DOI] [PubMed] [Google Scholar]

- 9.Meling T. R, Odegaard J, Meling E. On mechanical properties of square and rectangular stainless steel wires tested in torsion. Am J Orthod Dentofacial Orthop. 1997;111:310–320. doi: 10.1016/s0889-5406(97)70190-2. [DOI] [PubMed] [Google Scholar]

- 10.Hixson M. E, Brantley W. A, Pincsak J. J, Conover J. P. Changes in bracket slot tolerance following recycling of direct-bond metallic orthodontic appliances. Am J Orthod. 1982;81:447–454. doi: 10.1016/0002-9416(82)90422-5. [DOI] [PubMed] [Google Scholar]

- 11.Balut N, Klapper L, Sandrik J. L, Bowman D. Variations in bracket placement in the preadjusted orthodontic appliance. Am J Orthod Dentofacial Orthop. 1992;102:62–67. doi: 10.1016/0889-5406(92)70015-3. [DOI] [PubMed] [Google Scholar]

- 12.Germane N, Bentley B. E, Jr, Isaacson R. J. Three biologic variables modifying faciolingual tooth angulation by straight-wire appliances. Am J Orthod Dentofacial Orthop. 1989;96:312–319. doi: 10.1016/0889-5406(89)90350-8. [DOI] [PubMed] [Google Scholar]

- 13.Miethke R. R, Melsen B. Effect of variation in tooth morphology and bracket position on first and third order correction with preadjusted appliances. Am J Orthod Dentofacial Orthop. 1999;116:329–335. doi: 10.1016/s0889-5406(99)70246-5. [DOI] [PubMed] [Google Scholar]

- 14.Badawi H. M, Toogood R. W, Carey J. P, Heo G, Major P. W. Torque expression of self-ligating brackets. Am J Orthod Dentofacial Orthop. 2008;133:721–728. doi: 10.1016/j.ajodo.2006.01.051. [DOI] [PubMed] [Google Scholar]