Abstract

As a type of elastomeric polymers, non-degradable polyurethanes (PUs) have a long history of being used in clinics, whereas biodegradable PUs have been developed in recent decades, primarily for tissue repair and regeneration. Biodegradable thermoplastic (linear) PUs are soft and elastic polymeric biomaterials with high mechanical strength, which mimics the mechanical properties of soft and elastic tissues. Therefore, biodegradable thermoplastic polyurethanes are promising scaffolding materials for soft and elastic tissue repair and regeneration. Generally, PUs are synthesized by linking three types of changeable blocks: diisocyanates, diols, and chain extenders. Alternating the combination of these three blocks can finely tailor the physio-chemical properties and generate new functional PUs. These PUs have excellent processing flexibilities and can be fabricated into three-dimensional (3D) constructs using conventional and/or advanced technologies, which is a great advantage compared with cross-linked thermoset elastomers. Additionally, they can be combined with biomolecules to incorporate desired bioactivities to broaden their biomedical applications. In this review, we comprehensively summarized the synthesis, structures, and properties of biodegradable thermoplastic PUs, and introduced their multiple applications in tissue repair and regeneration. A whole picture of their design and applications along with discussions and perspectives of future directions would provide theoretical and technical supports to inspire new PU development and novel applications.

Keywords: Biodegradable polyurethane, Thermoplastic, Elastic, Synthesis, Tissue repair

Graphical abstract

Highlights

-

•

Linear biodegradable polyurethanes with high elasticity and good biocompatibility have been utilized for soft and elastic tissue repair.

-

•

The biofunctions and characteristics of biodegradable polyurethanes can be effectively offered and tuned through designing and altering chemical structures, and they also can be easily processed into desirable architectures.

-

•

New chemistry and further evaluations are expected for future development and applications of biodegradable elastic polyurethanes in tissue repair.

1. Introduction

Tissue engineering is an interdisciplinary field dedicated to replacing or regenerating the biological functions of human tissues or organs, relying on the combination of scaffolds, cells, and bioactive signal molecules [1]. The classic tissue engineering method can construct tissue-like implants based on biomaterial matrices in a simulated physiological environment in vitro for implantation into a patient. In vivo or in situ tissue engineering directly implants an acellular biomaterial into a patient to utilize endogenous cells for tissue repair in vivo. In above tissue repair methods, biodegradable scaffolds play an important role by providing a 3D porous space, mechanical support, and microenvironment. In general, an ideal biodegradable scaffold should meet the following criteria: (i) be biocompatible to support cell adhesion, migration, and proliferation and elicit a negligible immune reaction; (ii) be biodegradable at a comparable rate to that of new tissue growth at the implanted site, and its degradation products are nontoxic and absorbable; (iii) have mechanical properties matching the native tissue, and effectively transmits forces from the environment to the growing tissue over a long period of time; and (iv) have an interconnected pore structure and high porosity to allow cell penetration and nutrient and oxygen transportation [2,3]. Synthetic biodegradable polymers are versatile biomaterials that can be processed into scaffolds with a wide range of physical, thermo, and mechanical properties [2].

Elastic polyurethanes (PUs) are a class of important synthetic elastomeric polymers with broad biomedical applications [4]. The earliest biomedical application of non-degradable PUs dates back to the 1960s. Biomer® is the first biostable PU product for cardiovascular applications because of its durability and good mechanical properties and biocompatibility [5]. To meet the need for tissue repair and regeneration, biodegradable PUs have drawn significant interests since the 1990s. The biodegradable PU exhibits high mechanical strength, softness, and high elasticity to mimetic biomechanical behaviors of soft and elastic tissues. The flexible chemistry of PU synthesis also can generate varieties of biodegradable PUs to meet the specific needs for different tissues. Biodegradable PUs are generated by incorporating hydrolyzable bonds (e.g., ester, amide, anhydride, and carbonate) into polymer backbones [6,7]. Thermoplastic PUs are linear and can be processed into three dimensional (3D) scaffolds through a variety of fabrication techniques, and have been widely used in the biomedical field [8]. They are known as elastomers for their high elasticity and softness which make them stand out from those commonly used biodegradable polymers, such as poly(glycolide) (PGA) [9], poly(lactide) (PLA) [10], and poly(ε-caprolactone) (PCL) [11,12]. Thermoplastic PU also has numerous diversities of chemical compositions and physical-mechanical properties through alteration of its segmented blocks, which makes PU more versatile than other thermoplastic polyester based elastomers, such as polyhydroxyalkanoates (PHA) [13] and polyester-based copolymers (e.g., PLA-co-PCL (PLCL) [14], PLA-co-poly(trimethylene carbonate) (PLA-co-PTMC) [15]). Furthermore, compared with common chemically cross-linked polyester elastomers, such as poly(glycerol sebacate) (PGS) [16] and poly(1,8-octanediol-co-citric acid) [17], one important advantage of thermoplastic PUs is their good processability because the chemically cross-linked polyester elastomers are hardly re-processed [18,19]. The high elasticity, great processability, good biocompatibility, and biodegradability make the thermoplastic biodegradable PU an excellent matrix candidate for tissue repair and regeneration. In this review, we introduce the synthesis of thermoplastic biodegradable PUs and summarize and discuss the current functional biodegradable PUs and their applications in tissue repair and regeneration (Fig. 1).

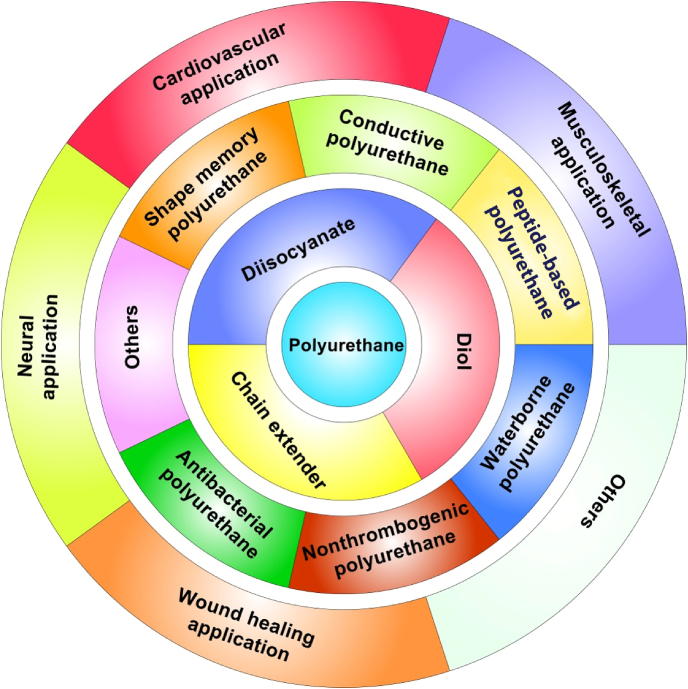

Fig. 1.

Biodegradable polyurethanes: chemistry, functionalization, and tissue repair applications.

2. Biodegradable thermoplastic polyurethane synthesis

The synthesis of thermoplastic biodegradable PUs includes three Lego-block like components: a diisocyanate, a biodegradable polymer diol, and a chain extender of diol or diamine [8]. The polymer diol and chain extender are linked by a diisocyanate to form linear segmented PUs. The PUs consist hard and soft segments, which results in microphase separation [20]. The formation of the microphase-separated structure causes the PU to have high elasticity. Generally, the diisocyanate and chain extender comprise the hard segment (hard phase), and the long, linear chain of polymer diol comprises the soft segment (soft phase). In general, there exist one glass-transition temperatures (Tg) and one melting temperatures (Tm). When a crystalline soft segment is used, two TMs may be observed. The hard segment functions as a physical cross-linking element, which leads to a Tm, and a high modulus and strength of PU [21,22]. The soft segment contributes to a low Tg, and to the softness of PU [22,23]. The thermal and mechanical properties are dependent on the properties and interactions of both soft and hard segments. To achieve the degradability of the PUs, polymer diols containing hydrolyzable bonds, such as ester and amide bonds, are generally used as the soft segments [24]. Varying the three blocks and their ratios in the PU backbone can tailor its thermal and mechanical properties, and degradation profiles.

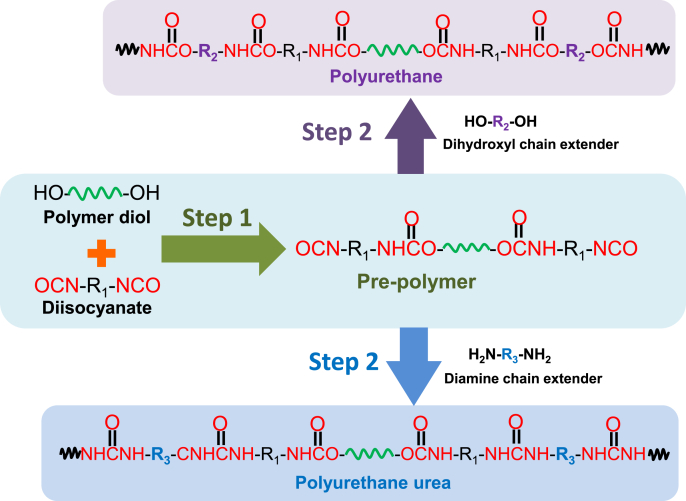

Thermoplastic PUs can be chemically synthesized via the one- or two-step method. In the one-step method, all reactants (a diisocyanate, a polymer diol, a chain extender, and catalyst) are mixed and reacted in one pot, which makes it hard to control the chemical structure of the PU [8]. The two-step solution polymerization is a popular method to synthesize thermoplastic/linear PUs (Fig. 2). The diol and excessive diisocyanate react first (first step) to form a prepolymer with two isocyanate end groups, followed by the addition of the chain extender (second step) to increase the molecular weight. The two-step method, compared with the one-pot synthesis, is more effective in controlling the structure and property of the PU [25]. To achieve a high molecular weight PU, the molar ratio of isocyanate groups to total hydroxyl or amine groups must be equivalent. Additionally, another key factor to achieve high molecular weight PUs is the absence of water, especially for small-scale synthesis, in the reaction system. To achieve a linear structure, only bifunctional monomers can be used.

Fig. 2.

Typical synthesis routine of biodegradable polyurethane and polyurethane urea via a two-step method.

Isocyanates can actively react with hydroxyls or amines to form urethane or urea bonds via a nucleophilic addition, separately. The diisocyanates for biodegradable PU synthesis are listed in Table 1. The first generation of degradable PUs is synthesized using aromatic diisocyanates, such as 4,4′-methylenebis(phenyl isocyanate) (MDI) and toluene-2, 4-diisocyanate (TDI), to link the biodegradable soft segments [26,27]. Because the potential degradation products (aromatic diamines) are toxic and carcinogenic, their usages in biodegradable PU synthesis are limited [28]. The second generation of biodegradable PUs is based on aliphatic diisocyanates (e.g., 1,4-butane diisocyanate (BDI), 1,6-hexamethylene diisocyanate (HDI), and lysine-based diisocyanate (LDI)) or cycloaliphatic diisocyanates (e.g., isophorone diisocyanate (IPDI) and 4,4′-methylene bis(cyclohexyl isocyanate) (HMDI)). HDI, BDI, and LDI are the three most used aliphatic and linear diisocyanates because of their nontoxic biodegradation products (1,4-butanediamine, 1,6-hexanediamine, and lysine) [22,[29], [30], [31], [32], [33]]. The symmetric chemical structures of HDI and BDI can result in well-ordered hard segments through hydrogen bonds, resulting in high strength and elasticity [8]. In a study of comparing HDI and BDI, biodegradable PUs were synthesized using HDI or BDI with a soft segment of PCL diol (MW = 2000) and a chain extender of butanediamine (BDA) [34]. The HDI-based PU showed higher tensile strength and breaking strain and larger plastic deformation than the BDI-based PU because of its less-ordered hard segments. The cyclohexane rings in cycloaliphatic diisocyanates, such as IPDI and HMDI, limit the flexibility of the polymer chains, and results in stiffer PUs compared with those based on aliphatic linear diisocyanates [35,36]. Furthermore, the introduction of LDI can result in a high hydrolytic degradation rate because it may affect the aggregation and hydrophilicity of hard segments due to the side group containing a hydrolyzable ester bond [32,[37], [38], [39]].

Table 1.

List of diisocyanates for biodegradable thermoplastic polyurethane synthesis.

| Chemical name | Structure | Refs |

|---|---|---|

| 1,4-butane diisocyanate (BDI) | [33,34,49,213,214,238] | |

| 1,6-hexamethylene diisocyanate (HDI) | [31,34,51,81,87,235] | |

| isophorone diisocyanate (IPDI) |  |

[35,122,132,133] |

| 4,4′- methylenebis(cyclohexyl isocyanate) (HMDI) | [36] | |

| Lysine ethyl ester diisocyanate (LDI) |  |

[32,[37], [38], [39]] |

| 4,4′-Methylenebis(phenyl isocyanate) (MDI) | [26] | |

| Tolylene-2,4-diisocyanate (TDI) |  |

[27] |

The biodegradable polymer diols are commonly polyester based and used as soft segments in biodegradable PUs (Table 2). The degradation of the biodegradable PUs is majorly attributed to the hydrolytic and enzymatic degradation of these polymer diols. Most homopolymer polyester diols (e.g., PCL, poly(D,l-lactide) (PDLLA), and PGA) are synthesized via ring-opening polymerization [8,21,40]. The semicrystalline PCL diol is widely investigated in biodegradable PU synthesis because of its good biocompatibility and low Tg (−60 °C), which can result in a high flexibility of PU [41,42]. The random copolymers, such as poly(δ-valerolactone-co-ε-caprolactone) (PVCL) and poly(3-hydroxybutyrate-co-4-hydroxybutyrate) (P3/4HB), and block polymers, such as PLA-PCL-PLA, are used as soft segments [30,[43], [44], [45]]. The PUs synthesized from polyether diols, such as poly(ethylene glycol) (PEG)/poly(ethylene oxide) (PEO), poly(propylene oxide) (PPO) and PEO-PPO-PEO, are generally considered as non-degradable PUs [[46], [47], [48]]. However, the polyether is often co-polymerized with polyester or polycarbonate to form triblock copolymers, such as PCL-PEG-PCL and PTMC-PEO-PPO-PEO-PTMC [12,46,47,[49], [50], [51]]. The introduction of a hydrophilic polyether can increase the hydrophilicity of the PU, accelerate its degradation, and change its mechanical properties. Additionally, a mixed soft segment from various biodegradable polymer diols is often used [52].

Table 2.

List of polymer diols for biodegradable thermoplastic polyurethane synthesis.

| Chemical name | Structure | Refs |

|---|---|---|

| Poly(D,l-lactide) (PDLLA) | [200,201] | |

| Poly(ε-caprolactone) (PCL) | [31,33,34,81,86,109,214] | |

| Poly(1,6-hexamethylene carbonate) (PHC) | [52,235,238] | |

| Poly(trimethylene carbonate) (PTMC) | [30] | |

| Poly[(R)-3-hydroxybutyrate] (PHB) |  |

[61,62] |

| Poly(δ-valerolactone-co-ε-caprolactone) (PVCL) | [30,51] | |

| PVCL-PEG-PVCL | [51] | |

| Poly(ε-caprolactone)-co-poly(ethylene glycol)-co-poly(ε-caprolactone) (PCL-PEG-PCL) | [49] | |

| Polyethylene butylenenbutylene adipate (PEB) diol | [122] | |

| Poly(trimethylene carbonate)-co-poly(ethylene oxide)-co-poly(propylene oxide)-co-poly(ethylene oxide)-co-poly(trimethylene carbonate) (PTMC-PEO-PPO-PEO-PTMC) |

[47] | |

| Poly(3-hydroxybutyrate-co-4-hydroxybutyrate) (P3/4HB) | [12,43] |

Altering the components and the molecular weight of the soft segments can significantly affect the properties of the PUs, particularly the mechanical properties and degradation. For example, a PVCL copolymer diol reached minimal crystallinity when the feeding ratio of valerolactone (VL) to caprolactone (CL) was 50/50. It resulted in a polyurethane with lower initial modulus and tensile strength than a polyurethane based on a semi-crystalline PCL diol [30,51]. In addition, increasing the block length of the amorphous PVCL diol (VL/CL = 50/50) from 2000 to 6000 significantly decreased the initial modulus and tensile strength of the PU by reducing the hard segment density. This observation is consistent with the rubber thermodynamic theory because the initial modulus of elastomers increases with the decrease of average molecular weight between the physical cross-link points [53]. Because the optimal degradation period for the implanted scaffold is unclear, the degradation rate of the tissue-engineered scaffold should be tunable to meet different requirements [52]. Slowly degradable soft segments, such as polycarbonate diol, can be introduced into the soft segment to achieve a PU with a slow degradation rate [30,47,52,54]. A blended soft segment of slowly degradable poly(1,6-hexamethylene carbonate) (PHC) and PCL would markedly reduce the hydrolytic degradation rate of the PU [52]. To reach a fast degradation rate, hydrophilic moieties (e.g., PEG) can be introduced into the soft segment in a PU backbone [49,51]. The incorporation of PEG into a PCL soft segment (PCL-PEG-PCL) significantly increased the hydrolytic degradation rate of PU [49]. However, PEG incorporation may not be able to accelerate the enzymatic degradation of the PU in a lipase/PBS solution in vitro [51,55], although the lipase can accelerate the in vitro enzymatic degradation of polymers containing ester, amide, carbonate, urea, and urethane groups [30,56,57]. One reason is that the ether groups of PEG are less susceptible to lipase than ester groups [58,59]. The other reason is that the PEG segment can lead to the increase of PU surface hydrophilicity, which reduces protein adsorption and compromises polymer enzymatic degradation [59,60]. Additionally, the crystalline degree of the soft segment may affect degradation rates of PUs. Regarding soft segments with the same chemical structures, the crystalline soft segment would lead to a slow degradation compared to amorphous soft segments. On the other hand, it is interesting to use a stiff polyester as a hard segment. For example, Li group developed a family of multi-block poly(ester urethane)s with poly[(R)-3-hydroxybutyrate] (PHB) as a hard and hydrophobic segment and PEG as a soft and hydrophilic segment [61,62].

The chain extenders are generally small molecular diols or diamines, such as 1,4-butanediol (BDO), ethylene glycol (EG), ethylenediamine (ED), 1,4-butanediamine (BDA), and peptides (Table 3). BDO and BDA are popular chain extenders [23,34,63]. One important function of the chain extender is to promote the formation of highly ordered hard segments in the PU backbone [64]. Hence, the chain extenders are usually short chains with a symmetrical structure to favor the order of hard segments. The diamine reacts with diisocyanate to form urea bonds, which, compared with urethane bonds, can significantly strengthen the PUs because of increased hydrogen bonding. The length of the chain extender also has a significant effect on the mechanical properties of PU because it directly affects the formation and strength of the hard phase in the PU. Chain extenders with hydrolyzable bonds (e.g., ester and phosphate ester) can also accelerate hard segment degradation [65,66]. A degradable ester chain extender based on lactic acid and ethylene glycol was introduced into a PU backbone, which contributed to the accelerated hydrolytic degradation of the PU in vitro [65]. Moreover, peptide-based chain extenders have been used to improve the enzyme-mediated degradation and biocompatibility of PUs [64,67]. The degradation of PU containing elastase sensitive AAK can be accelerated in an elastase solution [67].

Table 3.

List of chain extenders for biodegradable thermoplastic polyurethane synthesis.

| Chemical name | Structure | Refs |

|---|---|---|

| 1,4-Butanediol (BDO) | [121,235] | |

| Ethylene glycol (EG) |  |

[65] |

| 1,4-Butanediamine (BDA) | [33,49,51,52,67,213,214,226] | |

| Ethylenediamine (ED) |  |

[122,200,201] |

| 2-hydroxyethyl lactate |  |

[65] |

| Ala-Ala-Lys (AAK) | [67] | |

| Aniline trimer | [81,86] | |

| 2-Hydroxyethyl disulfide (HDS) | [31] | |

| Sulfobetaine (SB) diol |  |

[167] |

| Diazeniumdiolate NO donor | SGG[K[N(O)NO-]4GGS | [183,184] |

| Collagenase sensitive peptide | GGGLGPAGGK-NH2 | [145] |

| Gemini quaternary ammonium salts (GQAS) |  |

[166] |

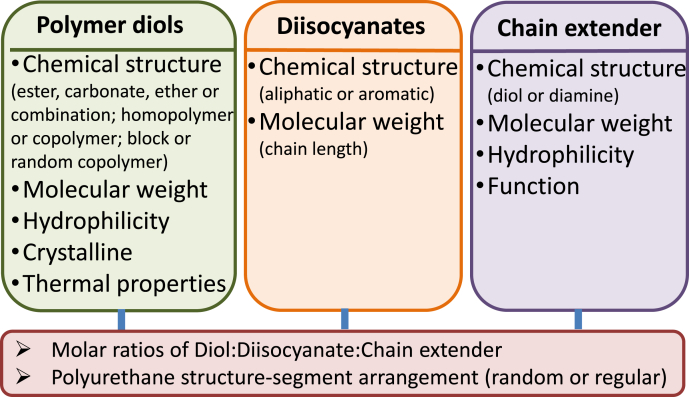

Based on these findings, we summarized the major parameters of three components, which affect the properties of biodegradable PUs (Fig. 3). Altering a single parameter, such as a component and feeding ratio, may affect synthesis and some characteristics of a biodegradable PU. As discussed above, mechanical properties and degradation of PUs are dependent on many factors including chemical structure, molecular weight, and physic microstructure (phase separation, hydrogen bonding, and crystalline et al.). Thus, to design a PU with desirable properties, it is necessary to comprehensively consider all the possible factors. Such complexity also creates opportunities to develop many attractive PUs for broad biomedical applications.

Fig. 3.

List of component parameters that affect mechanical properties and degradation of biodegradable polyurethanes.

3. Functional biodegradable thermoplastic polyurethanes

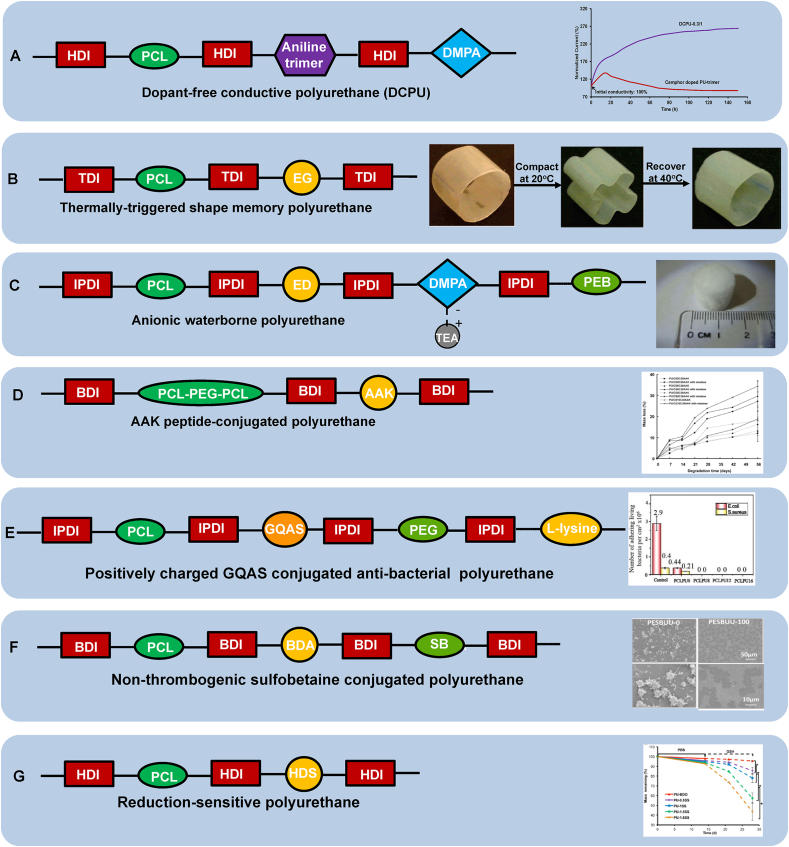

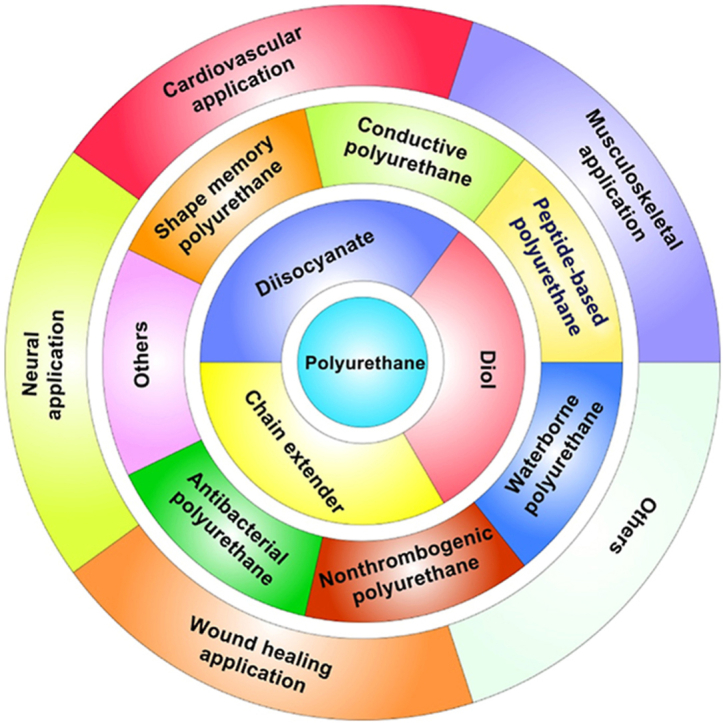

PU can be endowed with unique functions to meet the specific requirements relevant to tissue repair and regeneration. Their functions can be achieved by altering soft segments or chain extenders. According to recently published works, we primarily summarized the PUs with functions of conductivity, shape memory, and non-thrombogenicity, and peptide incorporating PUs, waterborne PUs, and antibacterial PUs (Fig. 4).

Fig. 4.

Functional biodegradable polyurethane design. (A) Dopant-free conductive polyurethane. Structural design (left); Electrical stability (right): Relationship between electrical current and incubation time in the electrical stability test of DCPU-0.3/1 film in cell culture medium. Camphor doped PU-trimer film was used as a control. Reprinted with permission from [87]. Copyright 2016 Springer Nature. (B) Thermally triggered shape-memory polyurethane. Structural design (left); Shape memory behavior (right): Polyurethane cylinder was compacted into a flower shape at 40 °C and then cooled to room temperature immediately, and it returned to the original shape when immersed in 40 °C water. Adapted with permission from [109]. Copyright 2005 American Chemical Society. (C) Anionic waterborne polyurethane. Structural design (left); Porous polyurethane sponge fabricated from polyurethane/water dispersion via freeze-drying (right). Reproduced with permission from [122]. Copyright 2014 Elsevier B.V. (D) AAK-peptide conjugated polyurethane. Structural design (left); Polyurethane enzymatic degradation manipulation by introducing elastase sensitive AAK sequence and varying the feeding ratio of polyether/polyester (PEG/PCL) in the soft segment (right). Reprinted with permission from [67]. Copyright 2005 American Chemical Society. (E) Positively charged GQAS conjugated anti-bacterial polyurethane. Structural design (left); Antibacterial activities (right): live bacteria attached on surfaces with and without GQAS and PEG. No live E. coli or S. aureus cells detected on all surfaces of the polyurethanes containing different GQASs compared with the PCLPU0 without GQAS, indicating the antibacterial property of GQAS. Reprinted with the permission from [167]. Copyright 2017 Royal Society of Chemistry. (F) Non-thrombogenic polyurethane. Structural design (left); Ovine blood platelet deposition on polyurethane films observed by scanning electron microscopy after blood contact for 2 h (right): PSBUU-0 was control group without SB content which had relatively high platelet deposition, while PSBUU-100 contained the highest SB content showing sparse platelet deposition. Reprinted with the permission from [176]. Copyright 2014 American Chemical Society. (G) Reduction sensitive polyurethane. Structural design (left); Electrospun polyurethane scaffold controllable degradation (right): Scaffolds were immersed in PBS for 14 d and then in 10 mM GSH for another 14 d, where the scaffold degradation rate increased obviously after transferring from PBS to GSH solution. * represents significantly different groups (p < 0.05). Reprinted with the permission from [31]. Copyright 2015 American Chemical Society.

3.1. Conductive polyurethanes

Conductive biomaterials, including conductive composites and polymers, have gained significant interest as smart tissue-engineered scaffolds because of their impressive performance in regulating cell behavior (e.g., adhesion, migration, proliferation, and differentiation) and in promoting electrically responsive tissue repair and regeneration (e.g., myocardium, nerve, muscle, skin, and bone) [[68], [69], [70], [71], [72]]. Conductive composites are a combination of biodegradable polymers (e.g., PLA, PCL, and PU) and non-degradable conductive polymers (e.g., polyaniline, polypyrrole, and poly(3,4-ethylenedioxythiophene (PEDOT)), or a combination of biodegradable polymers and inorganic additives (e.g., metals, carbon nanotube, or graphene). The biodegradable polymers provide mechanical behavior, and the additives provide electrical conductivity [69,[73], [74], [75]]. Biodegradable PUs have great potential to be used as conductive composite matrices because of their tunable mechanical properties, elasticity, biodegradability, biocompatibility, and ease of processing into scaffolds for tissue-engineering applications [30,51,52]. Therefore, blends of biodegradable PUs and conductive additives have been investigated [[76], [77], [78], [79], [80]]. The conductivity of the electrospun composites of biodegradable PUs and carbon black increased nearly six orders of magnitude as the carbon black amount increased from 0% to 40%. This scaffold exhibited improved PC12 neural cell proliferation and inter-cellular communication and interaction [78]. A patterned conductive PU with gold or titanium coating promoted myogenic differentiation and maturation of skeletal cells (C2C12) because of the upregulation of the myogenic regulatory factors Myf5, MyoD, and myogenin (MyoG) [79]. Although it is exciting to see positive results in cell functions on conductive composites, some concerns should be considered for clinic use. Conductive additives with PUs without covalent bonding may lead to poor controllability in mechanics and conductivity because of the immiscibility of the two materials. The residual non-degradable conductive additives may cause chronic inflammation and infection and even implant failure.

Covalently incorporating conductive oligomers (e.g., aniline oligomers) into the PU backbone to achieve a conductive polymer with the desired degradable, electrical, and mechanical properties may address these concerns from the conductive composites [[81], [82], [83], [84], [85]]. Short conductive segments, such as aniline pentamer and aniline trimer, can be introduced as chain extenders into the PU backbone. However, it is necessary to add a dopant, camphor sulfonic acid (CSA) to achieve a conductive biodegradable PU [74,75]. The polymer conductivity is dependent on conductive segment types and amounts, as well as dopant amounts [82]. A linear conductive, biodegradable PU based on PCL, HDI, and aniline trimer with CSA dopant was fabricated [81]. The conductivity of the conductive PU increased from 1.8 ± 0.6 × 10−7 S/cm to 7.3 ± 1.5 × 10−5 S/cm in a wet state (24-h of PBS immersion) with an increasing amount of CSA dopant (CSA/aniline trimer = 0.5/1–1.5/1). Although the value was relatively low, it was sufficient to conduct electrical signals in vivo [86]. Regarding these two conductive PUs, the polymer conductivity for pentamer (longer) is higher than that for trimer (shorter). However, the addition of CSA dopant significantly increased the stiffness of PU, and it also deteriorated the electrical properties (e.g., conductivity and electrical stability) and cytotoxicity of PU because the dopant leaches out with time or charging. To address this concern, a new generation of conductive PUs was designed by covalently linking the soft segment (PCL), diisocyanate (HDI), the conductive segment (aniline trimer), and a doping molecule (dimethylol propionic acid (DMPA)) into one polymer chain (Fig. 4A) [87]. This PU does not require the addition of an extra dopant and is called a dopant-free conductive PU (DCPU). The DCPU presented enhanced conductivities from 4.4 ± 0.4 × 10−7 S/cm to 4.7 ± 0.8 × 10−3 S/cm in a wet state with increasing DMPA contents (10–30%), compared with the CSA-doped PU. It is important that the chemical structure of the DCPU can markedly improve the conductivity stability compared to the CSA-doped PU because of its limited dopant mobility. The DCPU also exhibited higher tensile strength and better elasticity than the CSA-doped PU. A porous DCPU scaffold fabricated by salt leaching exhibited good tissue compatibility in vivo with extensive cell infiltration over 4 weeks in a mouse subcutaneous implantation model.

3.2. Shape-memory polyurethanes

Shape-memory polymers (SMPs) are a group of smart adaptive materials and can recover their permanent shape from their temporary shape via exposure to stimuli. These stimuli include temperature [[88], [89], [90]], magnetic field [91,92], light [93,94], pH [95], solution [[96], [97], [98]], and ultrasound [99,100]. The potential of SMP has been explored for various biomedical applications, such as self-tightening sutures [89], cardiovascular stents [90,101], dialysis needle adapters [102], and thrombectomy devices for clot removal [103]. SMPs are attractive as tissue-engineered scaffolds because of their ability to allow for minimally invasive implantation and to adapt themselves to the native physiological environment to regulate cell behavior [78].

PU-based SMPs have been developed for tissue engineering because of their good biocompatibility and elasticity and tailorable transition temperatures (Tg and Tm) [104]. Most reported tissue-engineered scaffolds based on SMPs are triggered by a thermal stimulus, in which their shape recovery temperatures are near or slightly higher than body temperature [[105], [106], [107], [108]]. The shape memory function of the PU-based SMP is majorly attributed to soft segment alteration. A SMP foam based on a PU synthesized from PCL, hydroxyapatite, castor oil, and HDI was fabricated to induce bone regeneration [105]. The SMP foam was implanted into a rabbit femoral defect with a compact shape for a minimally invasive delivery. Subsequently, the compacted SMP foam self-matched the bone defect after thermal stimulation (40 °C saline). Fast bone ingrowth and neovascularization were observed at 12-weeks post-surgery. The PU shape transition temperature, which is mainly determined by Tg or Tm, can be tuned by changing the component and the block length of the soft segments and modifying the soft-to-hard segment ratio in the PU backbone [[109], [110], [111]]. In a PCL-based PU, after changing the PCL block length from 2000 to 10,000, the lowest shape transition temperature increased from 23.5 to 48.2 °C because of different PCL crystalline statuses (Fig. 4B) [109].

Recently, interests in water-induced shape-memory PUs has grown because their shape transition can be easily triggered through body fluid (mainly water) in humans [112]. The water-actuated shape-memory PUs are commonly synthesized through combining a PU matrix with hydrophilic particles, such as PU-cellulose nanocrystals [113,114], PU-clay particles [115], and PU-poly(vinyl alcohol) particles [116]. Their shape-memory behaviors are attributed to the formation and dissociation of the hydrophilic particle network in the PU matrix upon removal of and exposure to water, respectively [113].

A multi-responsive shape-memory PU is more attractive, and it can be developed through linking multiple stimuli components using diisocyanates [117], such as thermo-photo responsive shape-memory PUs and thermo-water responsive shape-memory PUs [[118], [119], [120]]. A thermo-water responsive PU was synthesized from HDI, PEG, PHA, and BDO [121]. The hydrophilic PEG and PHA components contributed to the water-triggered shape-memory response, and the melting and formation of soft segment crystalline resulted in a thermo-triggered shape-memory response.

3.3. Waterborne polyurethanes

Waterborne PU (WBPU) is a unique category of PUs that are dispersed in water. Compared with conventional PUs, their green- and water-based synthetic process avoids the possible toxicity resulting from residual organic solvents and residual isocyanates, thus making them more biocompatible [[122], [123], [124], [125]]. The WBPU is treated as a functional PU in this article because other types of PUs are generally solid and the WBPU is rarely used in tissue repair and regeneration. WBPUs are synthesized by introducing hydrophilic ionic groups, such as carboxylic acid or tertiary amine, into the backbone [125]. In terms of the types of these ionic groups, WBPUs can be categorized as cationic, anionic, or nonionic. N-methyl diethanolamine is the most used cationic component for the synthesis of cationic WBPUs [126,127]. Anionic WBPU usually contains hydrophilic anionic moieties with ionized carboxylic acid [128]. The nonionic WBPUs normally contain nonionic hydrophilic segments, such as PEG [129]. Because of the mild polymerization condition and high emulsifying capacity of anionic hydrophilic moieties, the anionic WBPU becomes a practical choice for biomedical application [122,123,126,130,131]. A family of anionic WBPUs was synthesized from soft segments of PCL and PEG, IPDI, and a chain extender of l-lysine with a carboxyl group [132,133], and they were processed into a porous scaffold through freeze-drying. Another anionic WBPU was synthesized from PCL, polyethylene butylene adipate (PEB) diol, IPDI, 2,2-bis(hydroxymethyl)propionic acid (DMPA), ethylenediamine, and triethylamine (TEA; neutralizer), which was then processed into a porous scaffold via freeze-drying or a particulate-leaching method (Fig. 4C) [122]. Its waterborne ability is attributed to PEB diol and DMPA. This scaffold induced the chondrogenic differentiation of human-bone-marrow-derived mesenchymal stem cells (MSCs) within 7 days after induction.

3.4. Peptide-based functional polyurethanes

Peptides have been explored for various biomedical applications because of their unique physical, chemical, and biological properties [134,135]. Thus, combining peptide with the synthetic polymers is an attractive approach for biofunctional polymers. Peptide-based PUs can be classified into two main categories: PUs surface-modified with peptides and PUs containing peptides in the backbone or the pendant peptides. Many groups have reported grafting an RGD peptide, a common peptide for cell attachment to the extracellular matrix (ECM), onto the PU surface to improve cell adhesion [[136], [137], [138]]. For example, an RGD peptide was first conjugated with a PEO-MDI-PEO copolymer via sulfonyl chloride activation, and then the RGD containing polymer was physically blended with the PU to promote human umbilical vein endothelial cell (HUVEC) growth [136].

Incorporation of peptides into a PU backbone can endow the PU with improved biocompatibility and biodegradability, and create a specific biological function, such as enzyme liability or enhanced cell attachment [67,[139], [140], [141], [142], [143], [144]]. A YIGSR peptide as a chain extender was introduced into a PU backbone to enhance the endothelialization of the PU as a small-diameter vascular graft [139]. l-tyrosine-based and lysine-based chain extenders have been introduced into the PU backbone to promote polymer biocompatibility and biodegradability [64,140,141]. An Ala-Ala-Lys (AAK) peptide, which can be specifically cleaved by elastase, was used as a chain extender for PU synthesis to improve the polymer's enzymatic degradation (Fig. 4D) [67]. Furthermore, a collagenase-sensitive peptide, GGGLGPAGGK-NH2, was introduced into the PU backbone as a chain extender to obtain a collagenase labile biodegradable polymer for wound healing [145]. A dipeptide of Gly–Leu linkage is the cleavage site of various matrix metalloproteinases (MMPs), and a Gly–Leu-based chain extender was introduced into a PU to support mouse embryonic fibroblasts growth [146]. Considering above peptide-containing PUs, their functions mainly focus on degradation control and cell affinity. It is essential to expand peptide use in the PU synthesis because the peptide family has many unique biofunctions, not limited to the degradation sensitivity and cell compatibility improvement.

3.5. Antibacterial polyurethanes

A bacterial infection significantly impedes wound healing, results in disfiguration, and can be life threatening [147]. Antibacterial wound dressings can inhibit bacterial growth within the wound and on the dressing itself. PU is a promising wound dressing material because of its effective barrier properties and oxygen permeability [148,149]. Various antibacterial agents, such as silver [[150], [151], [152], [153]], gold [154], ZnO [155], quaternary ammonium salts [156], curcumin [157], N-halamine [158], chitosan [159] and antibiotics [160,161], can improve the antibacterial efficiency of PU wound dressings. These antibacterial agents can be physically blended with the PU or covalently anchored onto or conjugated with the PU.

Physical blending is an easy way to achieve the antibacterial function. An antibacterial composite scaffold of PU and nano-gold was fabricated through salt leaching [154], which showed a 99% inhibition against both S. epidermidis and Klebsiella spp. A blend of PU and mupirocin (Mu), a commonly used antibiotic for wound care, were co-electrospun into a patch, and this patch demonstrated effective antibacterial activity against Staphylococcus aureus [160]. However, the released antibacterial agents may kill healthy cells exposed in the wounded area. Furthermore, with the leaching of these agents, the material will lose antibacterial function, and the bacteria may become resistant to the diluted antibacterial agents [162,163].

To address these concerns, covalent incorporation of antibacterial agents, such as cationic components, into PU is an effective approach [[164], [165], [166], [167], [168]]. An epoxy-terminated PU prepolymer (EPU) with a soft segment of antibacterial castor oil was synthesized first, and then a mixture of EPU, a reactive bactericidal agent of glycidyltriethylammonium chloride (GTEAC), and BDA were co-cured to form a PU membrane [164]. The obtained PU membrane with 50% GTEAC demonstrated effective antibacterial activity with acceptable cell compatibility. Additionally, a family of WBPUs with gemini quaternary ammonium salt (GQAS) also showed promising antibacterial function [[166], [167], [168]]. Chitin based PUs with a chain extender curcumin also exhibited potential against selected strains of bacteria [169]. Lysine-derivative GQAS chain extenders were incorporated with PCL, PEG, IPDI and lysine to form antibacterial waterborne biodegradable PUs (Fig. 4E) [167]. Covalently introducing cationic and hydrophobic amino acids into a PU can prevent surface attachment of both Gram-positive and Gram-negative bacteria at subinhibitory concentrations and disrupt their biofilm formation without toxicity to mammalian cells [170]. In another approach, chitooligosaccharide (COS), a low-molecular-weight chitosan with antibacterial properties, was grafted onto the PU surface through the self-polymerization of dopamine [165]. The antibacterial activity of the PU membrane against Escherichia coli and Staphylococcus aureus significantly increased. However, these cationic PUs may not be good for cell growth and may induce relatively high inflammation in vivo because of its high positive charge. It is necessary to seek a balance between charge intensity for antibacterial function and cell/tissue compatibility for tissue repair.

It is notable that directly conjugating antibacterial drug into the polyurethane structure is feasible for antibacterial function [171,172]. Ciprofloxacin, a fluoroquinolone antibiotic was covalently conjugated into a polyurethane as a chain extender with 1,12-dodecane diisocyanate (DDI) and PCL (MW = 2000). The enzyme-degraded polyurethane demonstrated antibacterial activity against P. aeruginosa and E. coli [171].

3.6. Non-thrombogenic polyurethanes

Biodegradable PUs have been investigated for their use in blood-contact devices because of their attractive mechanical properties, and good biocompatibility and processability. However, common PUs easily trigger material-induced thrombosis. To enhance their nonthrombogenicity for blood contact implant use, nonthrombogenic moieties were physically or chemically combined with biodegradable PUs, such as phosphorylcholine (PC) [[173], [174], [175]], sulfobetaine [176,177], sulfate [[178], [179], [180]], PEG [181], and antithrombogenic drugs (e.g., clopidogrel, aspirin, and dipyridamole) [182]. In addition to physical blending and surface modification by nonthrombogenic moieties [175,177], these nonthrombogenic moieties can be covalently incorporated into the PU backbone or grafted onto the polymer chain as pendants. For example, biodegradable PU with pendant carboxyl groups were first synthesized by DMPA incorporation, and then PC or sulfate groups were conjugated with these pendant carboxyl groups [174,178]. The PC- or sulfate-containing PUs had effective thromboresistance in vitro. Directly incorporating those moieties into a PU backbone is also an effective way to amplify the capacity of grafted nonthrombogenic moieties. A sulfobetaine diol was introduced into the PU backbone to achieve a nonthrombogenic polymer for cardiovascular applications (Fig. 4F) [176].

Nitric oxide (NO) release also improves blood compatibility of the PU, and a NO donor can mix with the PU or can be conjugated with a PU chain [[183], [184], [185]]. NO is a natural mediator of vascular homeostasis [186]. The NO donors, N-diazeniumdiolates and S-nitrosothiols, have been used to release NO [183]. Because the leach-out and/or degradation of NO donors may cause the potential toxicity, covalently conjugating NO donors with a PU chain is a better method [183]. A nonthrombogenic polyurethane with a chain extender of a diazeniumdiolate NO donor, a lysine peptide, inhibited platelet deposition and promoted endothelial cell proliferation [187].

3.7. Others

In addition to the aforementioned PUs, other functional PUs are also interesting and attractive. The degradation rate of PUs is expected to be tunable to match the rate of new tissue growth through biological response. Poly(thioketal)urethane (PTK-UR) was synthesized by introducing thioketal bonds into the PU chain, and its degradation accelerated with a specific cell-generated reactive oxygen species (ROS) [[188], [189], [190]]. Additionally, our group developed reduction-sensitive polyurethanes containing disulfide bonds (PU-SS) that can be selectively degraded through the natural compound, glutathione (GSH) (Fig. 4G) [31]. The degradation of the PU-SS scaffold sped up on demand with the addition of GSH. Additionally, bio-adhesive PU is worth mentioning here. The chemical strategy is to synthesize the PU in the form of a prepolymer with free isocyanate end-groups, which can react with the amino groups in the biological molecules [191,192]. Another strategy is to incorporate adhesive moieties into the PU backbone. Xylose can provide four hydroxyl groups and a formyl-functional group. It reacted with 4,4-methylenebis(cyclohexyl isocyanate) (MCI) and PEG (MW = 200) to form an adhesive PU, which helped wound closure [193].

In short, the functions of the biodegradable PUs are generally gifted from functional chain extender introduction. Soft segments of biodegradable polyesters (e.g., PCL) and hydrophilic polymers (e.g., PEG) are often used to manipulate mechanical properties, degradation, and hydrophilicity, and they are hard to be replaced using a new polymer because of their recognized biosafety. The diisocyanate option is limited to aliphatic diisocyanates, such as HDI, LDI, and BDI, in terms of biosafety. Thus, their libraries are very limited compared with small molecular chain extenders. There is a huge library for chain extenders from organic diols and diamines to peptides, and it is easy to find a safe and functional molecule as a functional chain extender. Thus, utilizing or synthesizing a new chain extender is still a highly effective and efficient way to develop functional PUs.

4. Biodegradable thermoplastic polyurethane scaffolds for tissue repair

4.1. Polyurethane scaffold fabrication methods

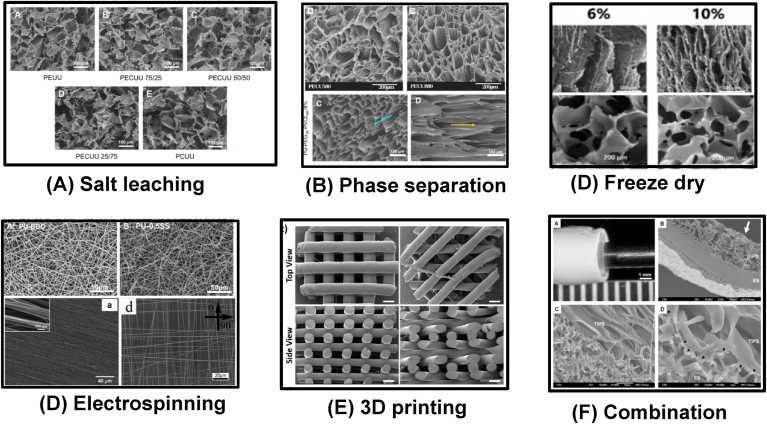

Biodegradable thermoplastic PUs can dissolve in organic solvents. This advantage allows the PUs to be processed into scaffolds by applying various techniques, such as particle leaching [52,87,194,195], thermally induced phase separation (TIPS) [49,51,196,197], freeze-drying [122,130,131,133,198,199], electrospinning [31,[200], [201], [202]], 3D printing [[203], [204], [205], [206], [207]], and their combinations [208,209]. Because of high hydrogen binding, the organic solvents for these biodegradable polyurethanes are polarized solvents, such as dimethyl sulfoxide (DMSO), dimethylformamide (DMF), and hexafluoro-2-propanol (HFIP). Six methods of PU scaffold fabrication are briefly introduced as below. (1) The particle leach is a common way to fabricate a porous PU scaffold with uniform pore size distribution (Fig. 5A). The particle is generally salt crystal and sugar. The PU solution is firstly blended with particles, and after solvent evaporation, the particles are removed through immersion in water. The pore size is easily tuned by altering the particle size, and the porosity can be tailored by changing the polymer/particle ratio. (2) The TIPS technique utilizes the changes of polymer solubility in the solvent with temperature to induce phase separation (polymer-rich phase and solvent-rich phase) and generate pores (solvent-rich phase). For example, the PU/DMSO solution at 80 °C was frozen at −80 °C to induce phase separation, and the frozen product was immersed in ethanol or water at 4 °C to remove the DMSO [196]. After freeze-drying, a porous PU scaffold can be obtained (Fig. 5B top). The pore size can be controlled by altering polymer type and concentration, temperature, coalescence time, and solvents. The polymer concentration and temperature are the most effective to control pore sizes. Because the pore formation of the TIPS scaffold is influenced by heat transition, the pore size distribution may not be uniform, and a dense outer layer may appear. Controlling heat transition from one direction can produce a porous polyurethane scaffold with aligned pores (Fig. 5B bottom) [197]. (3) Freeze-drying is not often used for PU scaffold fabrication. The WBPUs in water can be directly freeze-dried and form a porous structure [122,131,133,198,199,210]. The pore size can be tuned through altering PU concentration and temperature (Fig. 5C) [198,210], and the pore alignment also can be controlled by heat transition (Fig. 5C) [210]. (4) Three-dimension (3D) printing is an advanced manufacturing approach. Because PUs are difficult to melt, extrusion printing of biodegradable PUs is rarely reported. Recently, printable biodegradable PUs synthesized from a soft segment of a random copolymer of PLA and PCL (50/50) and a hard segment of BDI-BDO-BDI-BDO-BDI (Fig. 5D) [206,207], and WBPUs [205,211,212] exhibited promise in 3D extrusion printing. (5) Electrospinning is a popular technique to generate microscale and nanoscale fibrous scaffolds. The linear thermoplastic PU is easily dissolved in highly evaporated HFIP, thus HFIP is often used for electrospinning. The fiber diameter can be tuned by altering the polymer concentration, infuse rate, charge, distance between tips and collector, and other. Random fibers are easily achieved (Fig. 5E top). Using a high-speed rotating collector or altering the electric field of the collector can achieve aligned fibers to generate an anisotropic matrix (Fig. 5E bottom left) [213,214], and orthogonally aligned fibers (Fig. 5E bottom right) [214]. (6) The combination of multiple fabrication methods is an effective and attractive approach to generating a scaffold with new architecture and to improving properties in mechanics and functions. For example, a combination of electrospinning and TIPS was used to generate a bilayer tubular scaffold, which combined the mechanical enhancement from electrospinning and the cell loading from large porous TIPS scaffold (Fig. 5F) [208]. The selection of a fabrication technique is based on the requirement in structures and properties from the specific tissue repair of the scaffolds.

Fig. 5.

Typical morphologies of biodegradable thermoplastic polyurethane scaffolds fabricated by various methods. (A) Salt leaching. Reprinted with permission from [52]. Copyright 2010 Elsevier B.V (B) Phase separation. Top: random pores. Reprinted with permission from [196]. Copyright 2005 Elsevier B.V.; Bottom: aligned pores Reprinted with permission from [197]. Copyright 2020 American Chemical Society. (C) Freeze drying. The aligned (top) and random (bottom) scaffolds were prepared using WBPU emulsion by freeze-drying at different concentrations. Reprinted with permission from [210]. Copyright 2019 Oxford University Press. (D) Electrospinning. Top: random fibers. Reprinted with permission from [31]. Copyright 2015 American Chemical Society. Bottom left. Aligned fibers. Reprinted with permission from [213]. Copyright 2012 Elsevier B.V. Bottom right: orthogonally aligned fibers. Reprinted with permission from [214]. Copyright 2015 Wiley. (E) 3D printing. Melt extrusion printing. Reprinted with permission from [206]. Copyright 2020 Elsevier B.V. (F) Combination. A bilayer scaffold from phase separation and electrospinning. Reprinted with permission from [208]. Copyright 2010 Elsevier B.V.

4.2. Polyurethane scaffolds for cardiovascular repair

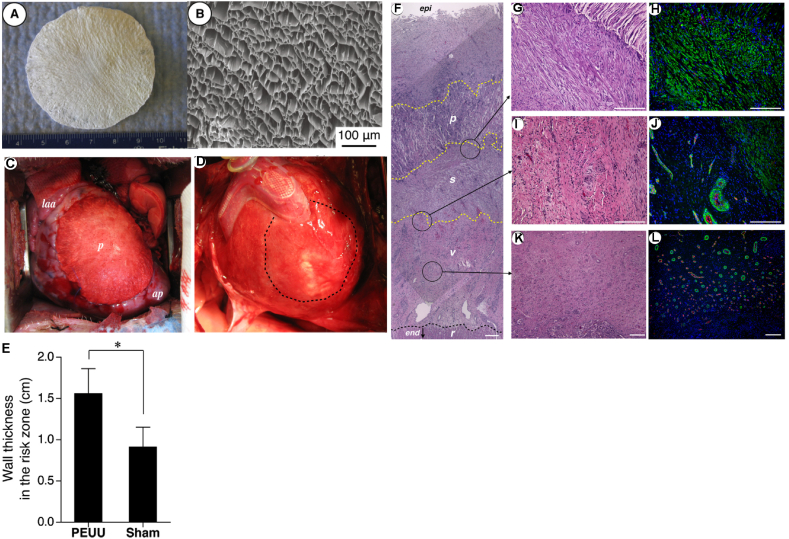

Biodegradable PUs are attractive for cardiovascular regeneration because they have good biocompatibility, and also have strong mechanical properties and high elasticity mimicking with the mechanical behaviors of heart muscle and blood vessels [[215], [216], [217]]. Biodegradable PU cardiac patches have been implanted into myocardial infarct (MI) animal models (e.g., mice, rat, and porcine) for heart repair and function restoration [[218], [219], [220], [221], [222]]. Biodegradable PUs synthesized from BDI, PCL, and BDA was fabricated into porous scaffolds by TIPS, and the scaffold was placed on a surgical defect in the right ventricular outflow tract of adult rats [222]. The PU patch allowed host fibroblast penetration and ingrowth, endocardial endothelialization, and minimal inflammation, indicating its potential for infarct heart repair. Furthermore, in a 2-week postinfarction rat model, the PU porous patches increased infarcted heart left ventricular wall thickness and smooth muscle bundles with mature contractile phenotype were observed in the infarcted area [218]. In addition (Fig. 6), a porcine MI model was used to further validate the biodegradable PU (based on BDI, PCL, and BDA) cardiac patch by observing its prevention of left ventricle dilation, preservation of contractile ability, and improvement of the retention of wall thickness of the infarcted left ventricle wall [221].

Fig. 6.

Biodegradable polyurethane cardiac patch implanted in a porcine MI model. Digital (A) and SEM (B) images of biodegradable polyurethane cardiac patch. (C) The polyurethane patched left ventricle wall (n = 7) was significantly thicker than the sham surgery wall (n = 8). *p < 0.01. (F) Hematoxylin and eosin staining and immunostaining for a-smooth muscle actin (αSMA) and CD31. The polyurethane patched wall exhibited an aSMA rich layer (s) beneath the implanted PEUU patch (p). Below the αSMA rich layer was a vascular rich layer (v) and then a myocardial remnant (r) region at the endocardial side. A higher magnification of the boundary area between the polyurethane patch and αSMA rich layer showed that the PEUU partially degraded and cellular infiltration occurred with αSMA-positive cells (G and H). (I and J) are the junction between αSMA and vascular rich layers, and (K and L) are the center of the vascular rich layer. Reprinted with permission from [221]. Copyright 2013 American Association for Thoracic Surgery.

Conductive PUs have recently become attractive options for use as cardiac patches because native cardiac muscle is an electroactive tissue that can transfer electrical signals and allows the heart to beat [223,224]. Conductive materials may support the electrical signal transfer process and improve cardiac patch contractibility. Electroactive PUs based on PCL, PEG, IPDI, and aniline pentamer were processed into porous scaffolds using a particulate leaching method [225,226]. The obtained scaffold had a conductivity at 1 ± 0.09 × 10−5 S/cm and supported neonatal cardiomyocyte adhesion and growth. Additionally, higher expressions of the cardiac genes related to muscle contraction, relaxation, and cytoskeleton alignment were observed on the electroactive PU scaffold than those on a PCL film or scaffold and a tissue culture plate.

Vascular graft is another major application of biodegradable PUs in the cardiovascular system [227,228]. Vectra® graft (Thoratec Corp, the United States) is a poly(ether urethane) urea vascular graft that obtained clearance from the United States Food and Drug Administration (FDA) in 2000 [227]. In regard to an ideal small diameter vascular graft (inner diameter <6 mm), anti-thrombosis, intimal hyperplasia inhibition, and rapid and adequate endothelialization on a graft lumen are expected. Many approaches have been used to reduce thrombogenicity and improve the intimal hyperplasia inhibition of biodegradable PUs based small diameter vascular grafts, such as surface/compositional modification with nonthrombogenic moieties [[173], [174], [175]], NO release [186,187], drug release [229,230], and endothelialization [231,232]. PUs modified with nonthrombogenic moieties such as PC, sulfate, PEG, and sulfobetaine or NO donors, are good candidates for small-diameter vascular grafts. Hong's group mixed a clinically used antithrombogenic drug dipyridamole (DPA) with a biodegradable PU, and then electrospun it into a fibrous tubular scaffold [229]. The DPA-loaded PU scaffold reduced human platelet deposition, inhibited proliferation of human aortic smooth muscle cells, and improved endothelial cell proliferation. To improve endothelialization, heparin and vascular endothelial growth factor (vEGF) were immobilized on a PU electrospun fibrous scaffold via self-polymerization and the deposition of polydopamine [231]. The result demonstrated that surface heparinization significantly inhibited platelet deposition, and vEGF immobilization markedly increased endothelialization. Additionally, stem cells, such as muscle derived stem cells and human pericytes, can be loaded into biodegradable PU based tubular bilayer scaffolds (inner layer: porous scaffold, and outer layer: electrospun fibers) as cellularized vascular grafts and have exhibited great patency and tissue remodeling in a rat aorta model [233,234]. Particularly, human pericyte loaded PU vascular grafts exhibited 100% patency and similar components with native artery after 8 week implantation in a rat aorta replacement model [233]. Another interesting work is that the biodegradable PU was electrospun simultaneously with electrosprayed smooth muscle cells to generate a cellularized vascular graft [235].

In recent years, scaffold mechanical matches with native cardiovascular tissues have gained attention because a mechanical mismatch between an implanted scaffold and a native tissue may trigger high foreign body reactions or even implant failure [236,237]. A bilayer PU scaffold was fabricated as a small diameter vascular graft with a highly porous inner layer, using a TIPS technique to allow cell penetration, and a fibrous-reinforcing outer layer by electrospinning to provide mechanical support [208]. Both layers were made of PU synthesized from PCL diol, BDI, and BDA. The resulting bilayer PU scaffold possessed mechanical properties (compliance = 4.6 ± 0.5 × 10−4 mmHg−1, β stiffness = ∼20, elastic modulus = 1.4 ± 0.4 MPa) comparable to those of healthy human coronary arteries (compliance = 14.1 ± 5.9 × 10−4 mmHg−1, β stiffness = 16.9 ± 7.1, elastic modulus = 1.4 ± 0.7 MPa) [238]. Additionally, the scaffolds were able to load muscle-derived stem cells prior to implantation in an animal model. Our group also developed relatively low-initial-modulus biodegradable PUs by varying the block length and hydrophilicity of the soft segments (PVCL or PVCL-PEG-PVCL) in the PU backbone [51]. A porous scaffold made of an optimal PU fabricated by TIPS exhibited an initial modulus (0.60 ± 0.14 MPa) similar to that of the human myocardium (0.02–0.50 MPa) [239], demonstrating its potential as a tissue-engineered cardiac patch for heart repair.

To further improve the bioactivity of PU scaffolds, natural materials, such as collagen, elastin, or elastin-like peptides (ELP), laminin, fibrin, and decellularized ECM, can be combined with PU to form a synthetic/natural material composite for cardiovascular repair and regeneration [200,217,[240], [241], [242], [243]]. A poly(carbonate urethane) synthesized from PHC, HDI, and BDO was electrospun into a fibrous scaffold [240]. ELP-4 was grafted onto the fibrous scaffold surface to enhance vascular smooth muscle cell adhesion. A PU synthesized from BDI, PCL, PHC, and BDA was co-electrospun with decellularized porcine heart ECM (hECM) into a bi-layered cardiac patch, which was implanted in a rat MI model [243]. Compared to the pure polyurethane group, this hECM-incorporated PU cardiac patch improved cardiac remodeling and function with reduced scar tissue formation and left ventricle global mechanical compliance and increased left ventricle wall thickness and vascularization.

PU is one of the most common materials used in generating tissue engineered valvular scaffold because of its good biocompatibility and high elasticity to endure repeated loading and unloading cycles. In terms of soft segment types, PUs for cardiac valve use can be categorized into three groups: poly(ether urethane), poly(ester urethane), and poly(carbonate urethane). Some commercial polyether-based PUs such as Biomer® [244], Estane® [245], and Angioflex® [246], exhibited high durability for heart valve use. However, those poly(ether urethane)s are hard to degrade with potential cracking failure [247]. Poly(ester urethane)s are biodegradable in vivo and highly elastic [248]. A biodegradable polyurethane from a soft segment of PCL-PEG-PCL triblock diol was electrospun and then combined with a PEG based hydrogel to form a composite scaffold for aortic valve tissue engineering [249]. There existed concerns about fast hydrolysis in vivo. Poly(carbonate urethane)s possess lower degradation rate in vivo compared with other biodegradable polyurethanes [52,250,251]. Mitral and aortic prosthesis made from poly(carbonate urethane)s (from Adiam Life Science, Erkelenz, Germany) exhibited high durability in vitro (up to 20 years) and advanced in vivo durability and hemodynamics but they had mild (mitral) or moderate (aortic) calcifications [252]. Wagner's group has developed a series of poly(ester urethane)s (PCL diol, BDI, and putrescine), poly(carbonate urethane)s (PHC diol, BDI and putrescine) and poly(ester carbonate) urethane (PCL/PHC diols (50/50), BDI and putrescine) and electrospun them into fibrous scaffolds with tunable degradation and mechanical properties for heart valve replacement [202,253,254]. Particularly, tricuspid valves made from the biodegradable poly(carbonate urethane) showed good acute functions in a swine model after 24 h implantation [255].

4.3. Polyurethane scaffolds for musculoskeletal applications

Several factors are important in designing skeletal-muscle-tissue-engineered scaffolds. First, scaffold stiffness plays an important role in skeletal muscle regeneration. Generally, PU scaffolds with moduli similar to healthy muscle tissue (∼12 kPa) are optimal for skeletal muscle cell growth and differentiation [[256], [257], [258]]. However, Andriani et al. hypothesized that a biomaterial with modulus in the range of tendons and bones (hundreds of MPa to several GPa) is acceptable to be used as human muscle cell culture substrates [259]. A synthesized PU with tendon-like surface modulus ranging from 150 MPa to 2.4 GPa supported the long-term in vitro culture of human myoblasts (proliferation, differentiation, and sustenance beyond 35 days). PU scaffolds with electroactivity promoted myoblast adhesion, proliferation, and differentiation [82,83,260]. Additionally, microscale and nano-scale topography of the scaffold has a major influence on skeletal muscle cell behaviors. The skeletal muscle structure is highly organized and consists of long, parallel bundles of multinucleated myotubes that formed through the differentiation and fusion of myoblast satellite cells [261]. A highly oriented fibrous PU scaffold produced by electrospinning enabled skeletal myogenesis in vitro by aiding in myoblast adhesion, myotube alignment, and noncoplanar arrangement of cells [262]. Micropatterned polyurethane films with microchannels via ultra-violet micro-embossing showed that the dimensions of the channel and wall significantly affected skeletal muscle cell elongation [263].

Biodegradable PU scaffolds were also used to manage meniscus defects in the clinic [[264], [265], [266], [267]]. A biodegradable PU scaffold implant was used for a treatment of painful irreparable partial meniscal defects with a minimum 5-year follow-up [265]. The PU meniscal implant improved knee joint function and reduced pain. However, the chondroprotective ability of the implant was questionable, and a relatively high implantation failure rate (∼40%) was noticed during the follow-up period. Schüttler et al. and Monllau et al. confirmed a functional outcome of biodegradable PU meniscal scaffolds with a 4-year and 5-year follow-up, respectively [266,267]. In Monllau's study, PU scaffold resorption and the incomplete in-growth of new meniscus-like tissue was observed [267]. Recently, the first clinical report of PU meniscal scaffolds with MSCs was published [268]. Seventeen patients (18–50 years old) with past meniscectomies were separated into two groups: acellular PU scaffold and MSC-enriched PU scaffold. After 12 months of implantation, the acellular PU scaffold maintained normal T2 mapping values in the adjacent cartilage, while the addition of MSCs did not show additional clinical benefit in articular cartilage protection.

Biodegradable PU scaffolds also show great potential for bone regeneration because of their high elasticity, enhanced calcium phosphate crystal formation (calcification) in vivo, and effective processability [269]. It was reported that scaffold hydrophilicity significantly affected calcification [270]. A poly((R)-3-hydroxybutyrate) (PHB)-based PU with improved hydrophilicity, achieved by incorporating a hydrophilic PEG segment into the soft segments, showed enhanced mineralization capability [61]. Gogolewski et al. found similar results, in which the newly formed bone in the PU scaffold with higher hydrophilicity had more bone mineral than for the scaffolds with less hydrophilicity [271]. Another way to promote calcification is the incorporation of carbon nanotubes into scaffolds to induce the nucleation of hydroxyapatite [272]. A PU foam with a surface deposition of carbon nanotubes accelerated the precipitation of calcium phosphate [273].

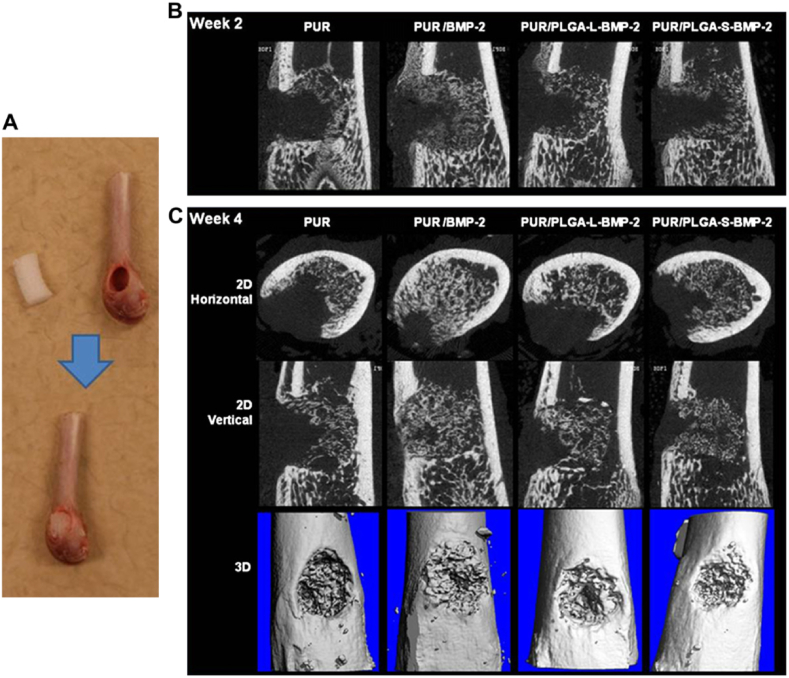

To further enhance the bioactivity of a PU scaffold for bone regeneration, bioactive materials such as native ECM [274], bioactive ceramics [275,276], and growth factors [277] can be incorporated with the PU. An electrospun PU/hydroxyapatite scaffold enhanced the viability of osteoblasts and human embryonic mesenchymal progenitor cells, calcification, and collagen deposition [275]. Recombinant human bone morphogenetic protein-2 (rhBMP-2), an osteoinductive growth factor, was physically combined with a PU scaffold (Fig. 7), and it supported bone ingrowth after 2 weeks implantation into a rat femoral plug defect [277]. New bone formation in the PU scaffold incorporating rhBMP-2 powder was more than that in the scaffold incorporating rhBMP-2 loaded PLGA microspheres at 4 weeks. Besides the above physical combination, an amino-terminated bis(l-arginine) alkylene diester extender could be covalently incorporated into a PU to promote the adhesion and proliferation of human dental pulp stem cells [278].

Fig. 7.

In vivo evaluation of the effects of polyurethane scaffold encapsulating rhBMP-2 on bone reparation in a rat femoral plug model. Four treatment groups included: PUR control (no rhBMP-2), PUR/rhBMP-2 (no PLGA microspheres), PUR/PLGA-L-rhBMP-2 (rhBMP-2 released from large PLGA microspheres), and PUR/PLGA-S-rhBMP-2 (rhBMP-2 released from small PLGA microspheres). The PUR cylinders (5 mm*3 mm) were implanted into rat femoral plug defects (A) and harvested for mCT imaging at week 2 (B) and 4 (C), respectively. All rhBMP-2 treated groups showed significantly higher new bone formation than the control (PUR) (p < 0.05). Reprinted with permission from [277]. Copyright 2009 Elsevier. Ltd.

The biodegradable PU scaffolds are also used for cartilage repair, although there are limited number of reports. A biodegradable PU from a blend of PCL/PHB (50/50) and lysine methyl ester diisocyanate supported the growth of rat chondrocytes [279]. The porous scaffolds of a Esynthesized from PCL, HDI and isosorbide diol (1,4:3,6-dianhydro-d-sorbitol) was seeded with articular chondrocytes isolated from the fetlock joints of young calves of 3–4 months of age, and up to a 42-day culture, and the scaffold supported the production of extracellular matrix proteins [280]. Bovine chondrocytes on a porous biodegradable PU membrane showed a greater rate of matrix production than on a PLA membrane within the first 10 days [281]. Furthermore, acellular biodegradable PU foam matrixes (Novosorb™, Polynovo Biomaterials Pty Ltd, Port Melbourne, Victoria, Australia) were implanted into pig ears. After 28 days, the matrix showed great integration with the auricular defect [282]. However, the PU itself was not bioactive and did not facilitate cell growth. Natural bioactive materials, such as fibrin and cellulose, were combined with the PU scaffold to support chondrogenesis of mesenchymal stem cells (MSCs) under mechanical stimuli [283,284]. It is notable that WBPUs were recently used for cartilage regeneration using 3D printing technology [205,211,212]. A water dispersed biodegradable PU was synthesized from a mixed soft segment of PCL diol (Mn = 2000) and polyethylene butylene adipate diol (Mn = 2000), IPDI, and two chain extenders of 2,2-bis(hydroxymethyl) propionic acid (DMPA) and ethylenediamine (EDA) (IPDI/oligodiols/DMPA/EDA molar ratio = 3.52:1:1:1.52) [211]. The printed scaffold was generated from a blend of the PU and hyaluronan combining with TGF-beta3 or Y27632 using a low-temperature fused deposition manufacturing (LFDM) system. The MSC-seeded PU/HA/Y27632 scaffold was implanted into a rabbit chondral defects and promoted GAG and collagen II produce at the defected area. Additionally, melt-extrusion printing was used to generate printed scaffolds using a thermoplastic PU [206,207]. The utilization of a soft segment of a random copolymer of PLA and PCL (50/50) and a hard segment of BDI-BDO-BDI-BDO-BDI significantly reduced the hydrogen bonding, which allowed the PU to melt at an appropriate temperature for extrusion printing. A teratocarcinoma derived chondrogenic cell line (ATDC5) was seeded in the printed scaffold and cultured in vitro [206]. The formed neotissue contained a high content of GAG and collagen II rich ECM with a stable chondrogenic cell phenotype.

4.4. Polyurethane scaffolds for neural applications

Biodegradable PUs can be used as nerve conduits because of its excellent elasticity and flexibility [285,286]. A conduit made from a biodegradable PU (HDI, PCL, and dianhydro-D-sorbitol) was coated with fibrin, and implanted into a 8-mm rat sciatic nerve defect model [287]. No significant differences in nerve function between the PU conduit and autologous nerve graft were observed 12 weeks after the implantation. A Y-shaped conduit from a PU (HDI, PCL, and BDA) was used for the molecular guidance cues that mediated motor and sensory neuron regeneration [288]. The common arm was filled with type I/III collagen, and two “Y” compartments were filled with collagen and neurotrophic factors loaded PLGA microspheres. In in vitro dorsal root ganglion (DRG) cultures, Y compartments filled with glial cell line-derived neurotrophic factor (GDNF) and nerve growth factor (NGF) increased the motor and sensory axon content, respectively. The Y-shaped conduit was implanted into a rat 2 mm transected sciatic nerve defect. The sensory-to-motor ratio of the regenerated axons was significantly higher in the pleiotrophin compartment of the Y-conduit when compared with a BDNF + GDNF compartment.

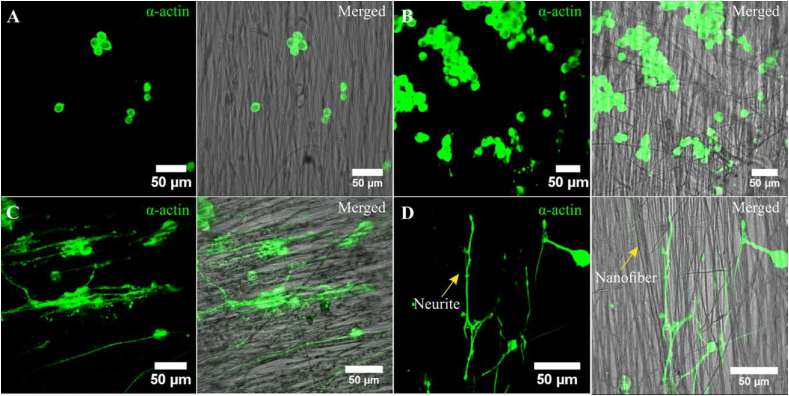

Conductive PU scaffolds have gained great attention for neural tissue engineering because neurons are electrically active cells whose activity originates from the depolarization of the plasma membrane, and scaffold conductivity may support this process [[289], [290], [291], [292]]. Aligned PU nanofibers were fabricated via electrospinning that was infused with gold nanoparticles [293]. Rat pheochromocytoma (PC-12) cells were seeded onto the PU nanofibers. It was found that the incorporation of gold nanoparticles enhanced PC-12 attachment and proliferation. Additionally, by including NGF and electrical stimulation, increased neurite outgrowth and elongation were observed (Fig. 8). Additionally, a conductive composite was prepared by a mixture of PU, poly(3,4-ethylenedioxythiophene) (PEDOT)/poly(4-styrenesulfonate) (PSS) and liquid crystal graphene oxide (LCGO). This composite supported human neural stem cell (NSC) growth and differentiation into neurons as well as neuroglia [294]. Electrical stimulation further enhanced NSC differentiation on the conductive composite.

Fig. 8.

PC12 cells growth on (A) polyurethane nanofibers; (B) gold nanoparticle decorated polyurethane nanofibers; (C) gold nanoparticle decorated aligned polyurethane nanofibers; (D) gold nanoparticle decorated aligned PU nanofibers after NGF and electrical stimulation. The neurite elongation of PC-12 cells was significantly promoted on gold nanoparticle decorated aligned PU nanofibers with the synergistic effect of NGF and electrical stimulation. Reprinted with permission from [293]. Copyright 2018 Wiley Periodicals, INC.

The waterborne biodegradable PU-based scaffolds are also attractive for neural regeneration. A series of biodegradable WBPU hydrogels based on IPDI, oligodiols (e.g., PCL, PLLA, PDLLA), DMPA and ethylenediamine were synthesized for neural regeneration [131,203]. Emulsion of WBPUs based on a blended soft segment of PCL and PLGA was freeze-dried to form porous scaffolds, which showed anti-inflammatory function when cultured with BV2 microglia cells and also promoted PC12 differentiation into neural cells [199]. Another WBPU scaffold showed great expression of the neuronal growth associated protein (GAP43) and synaptophysin, and satisfactory functional recovery in the rat traumatic brain injury model [295].

4.5. Polyurethane scaffolds for wound healing

Biodegradable PUs are promising candidates for wound healing because of their effective barrier properties and oxygen permeability [148]. However, the antibacterial activity and hydrophilicity of PUs need improvement to prevent bacterial infection and enhance cell affinity, respectively [296]. To enhance antibacterial activity, various antibacterial agents (e.g., silver, ZnO, gold, quaternary ammonium salts, curcumin, and antibiotics) can be combined with PUs. A PU scaffold incorporated with a hydrophobic vancomycin, a tricyclic glycopeptide antibiotic, significantly reduced infection in a rat femoral segmental defect model [297]. In another case, a polyurethane with soybean oil as a soft segment showed better progress of wound healing in a rat wound model compared to a non-antimicrobial dressing or a cotton gauze [298]. To improve the hydrophilicity of antibacterial polyurethanes, hydrophilic moieties such as dextran [155,299], cellulose acetate (CA) [296], and COS [165] are incorporated into PUs. PU, dextran, and antibiotic ciprofloxacin were mixed and electrospun into a fibrous scaffold [299]. The composite scaffold presented effective bacterial activity against both gram-positive and gram-negative bacteria and favorable cell-material interaction. Similar results were observed in the development of an antibacterial electrospun scaffold from a combination of PU, highly hydrophilic CA, and an antibacterial protein, zein [296].

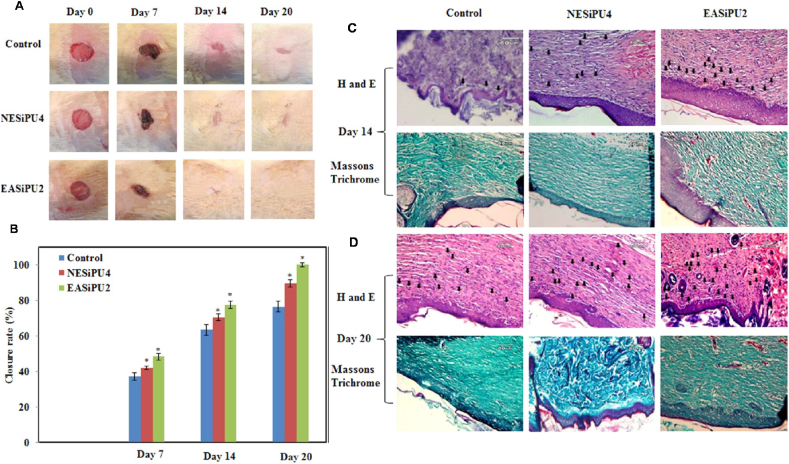

Antioxidant moieties could also be incorporated with PUs to protect the tissue from oxidative stress during the wound healing process. Overproduction of ROS, a hallmark of inflammation and the pathogenesis of various diseases, causes oxidative stress, which may lead to tissue damage, infection, and chronic wound healing [300,301]. Ascorbic acid, an antioxidant moiety, was introduced as a chain extender into the PU backbone, and the resulting antioxidant PU scavenged free radicals and protected cardiomyocytes from oxidative stress-induced cell death [302]. Additionally, conductive PUs were also investigated for wound healing because conductive polymers can scavenge free radicals [303]. An antioxidant PU/siloxane dressing was generated based on castor oil as an antibacterial segment and aniline trimer as a conductive segment [304]. The obtained PU/siloxane dressing membrane showed effective antimicrobial activity and antioxidant efficiency, and it supported fibroblast growth. In a rat model of skin wound healing, the multifunctional dressing promoted wound contraction and collagen deposition, and enhanced vascularization in the wounded area (Fig. 9).

Fig. 9.

In vivo evaluation of effects of polyurethane/siloxane dressing on wound healing in a rat skin wound model. Two treatment groups include: NESiPU4 (no aniline trimer, nonconductive), and EASiPU2 (containing aniline trimer, conductive). Photographs (A) and closure rate (B) of wounds treated with gauze (control), NESiPU4, and EASiPU2 during the wound healing process for 20 days. *p < 0.05. H&E and Masson's Trichrome staining at day 14 (C) and day 20 (D). Scale bars: 60 μm. Arrows indicate capillaries. The results suggested that the electroactive wound dressing could promote fast wound healing by complete re-epithelialization of the wound, enhanced vascularization, and collagen deposition. Reprinted with permission from [304]. Copyright 2015 American Chemical Society.

5. Conclusions and perspectives

Although numerous in vivo and in vitro studies have proved the biocompatibility of biodegradable PUs, there are only a few commercial biodegradable PU products (e.g., Actifit®, Lacthane®, Artelon®, DegraPol®, and Tecoflex®) used in pharmacy or medicine. The Actifit® meniscal implant (Orteq Ltd., the United Kingdom), approved by Conformitè Europeänne (CE), is a biodegradable porous scaffold from a PU synthesized from BDI, PCL, and BDO [305]. Lacthane® (Polyganics, Netherlands), which is synthesized from BDI, polyesters, and polyethers, is applied as a wound and nasal dressing and surgical sealant [306]. Artelon® (Artimplant, Sweden) is a CE- and FDA-approved, biodegradable PU porous scaffold based on MDI, PCL, and 1.3-butanediamine for tendon and ligament reconstruction [307]. Currently, only a few biodegradable PU scaffolds have gained FDA approval in the United States. For many promising biodegradable PU products, there still exists much work prior to FDA approval. Specifically, it is important to obtain substantial evidence of the product's safety and effectiveness in vitro and in vivo. Compared with the common biodegradable polyesters, such as PLA, PCL, and PLGA, it is necessary to pay attention to fundamental research on in vitro cell biology and in vivo toxicology and immune response, and rational design and synthetic routine of biodegradable PUs.

In addition to the linear thermoplastic structure discussed in this review article, cross-linked thermoset structure cannot be neglected for biodegradable functional PU design. These biodegradable cross-linked polyurethanes contain at least one block with more than two functionalities, such as polyisocyanate, polyols, and chain extenders [21]. The cross-linked PUs are also easily integrated with desired biofunctions using appropriate functional components. Our group developed a nonthrombogenic biodegradable PUs from HDI, PCL, and dipyridamole (DPA, an antithrombogenic drug with four hydroxyl groups) via a one-pot/one-step synthesis [308]. A series of crosslinked conductive PUs from PGS and aniline pentamer are also interesting and have been used for neural cell culture [82,85]. Thus, the PU design and synthesis strategy can be flexibly utilized in terms of the required characteristics for the specific applications.

Compared with the mono-functional PUs, interest in multifunctional biodegradable PUs through a combination of multiple functional components or moieties has increased. The conductivity and shape-memory functions were combined to form electroactive shape-memory PUs [78,84,111,309]. A multifunctional PU synthesized from PCL, aniline trimer, and HDI [111] had a tunable shape transition temperature of 31–44 °C from PCL and a conductivity from aniline trimer in the polymer backbone. This polyurethane, compared with an insulated PCL, enhanced C2C12 cell proliferation, myotube formation, and relative myogenic differentiation gene expression. Even triple functions can be involved. An elastomeric poly(citric acid-co-polycaprolactone) based PU with bioactive dopamine and electroactive aniline hexamer exhibited functions of shape memory, conductivity, and bioactivity for C2C12 muscle cells although this PU is a cross-linked structure [84]. These reports can inspire novel PU designs with multiple functions through a combination of approaches, which can meet complex needs in tissue repair and regeneration.

Three-dimensional (3D) printing has become a common technique for fabricating scaffolds and devices with high structural complexity and precision for tissue engineering applications [310]. It is extremely important to design printable biodegradable PUs to meet the urgent needs of the scaffolds with regular, complex, or biomimetic structures. Because a PU has a high melting temperature due to high hydrogen bonding, it is difficult to print using the common melt extrusion printing technique, although some non-degradable PUs has been printed using melt extrusion [311,312]. As a solution, the WBPU may be a good option for printing. Hsu group developed a series of printable water-dispersible WBPUs [130,[203], [204], [205],211,212,313]. In their report [204], a WBPU based on PCL, PDLLA, IPDI, DMPA, and ethylenediamine was used for extrusion-based 3D bioprinting. It can be combined with gelatin to form a double network hydrogel utilizing chelation and thermal gelation [205]. On the other hand, new chemical structure of the biodegradable polyurethane is helpful. Recently, the PU from a random copolymer of PLA and PCL (50/50) and BDI-BDO-BDI-BDO-BDI was melted and extrusion-printed [206,207]. These cases provide evidence that it is achievable to develop printable, biodegradable PUs through molecular design.