Abstract

The strength–ductility trade-off is an eminent factor in deciding the mechanical performance of a material with regard to specific applications. The strength–ductility synergy is generally inadequate in as-synthesized high entropy alloys (HEAs); however, it can be tailored owing to its tunable microstructure and phase stability. Thermo-mechanical processing (TMP) allows the microstructure to be tailored to achieve desired strength–ductility combination. The additional attribute is evolution of texture, which also significantly influences the mechanical properties. This review presents a critical insight into the role of TMP to achieve superior strength–ductility symbiosis at room temperature in single-phase (FCC, BCC) and multiphase HEA. The role of overall processing strategy of HEAs encompassing rolling and subsequent annealing in relation to the evolution of microstructure and texture in have been discussed. Recently practiced severe plastic deformation processes have also shown promise in improving the strength–ductility combination. The relevance of these processes in the processing of HEAs has also been analysed. At the end, futuristic approaches have been elaborated to enable efficient as well as hassle-free process towards achieving the proficiency of strength–ductility in HEAs.

Keywords: High entropy alloy, Rolling, Thermo-mechanical processing, Strength–ductility synergy, Microstructure, Texture

Introduction

High Entropy Alloys (HEA) are the class of alloys having minimum of five principal elements with a concentration of constituent elements between 5 and 35 at%1–4. The microstructure, properties, and performance of HEA are driven by four core effects, i.e., high configurational entropy1,5, lattice distortion3, sluggish diffusion6, and cocktail effect7. Owing to these effects, HEA exhibit excellent tensile ductility, fracture toughness, corrosion resistance, and many other important properties of relevance8–13. The combination of desirable property attributes in HEAs makes these materials a perfect candidate for numerous applications, like in gas storage, in ion irradiation plants, and for biomedical implants13–15. The lower yield strength of many HEA, in as-synthesized condition, restricts their use in structural applications such as automobile sector16. Hence, enhancing the strength while maintaining ductility of HEA is a crucial factor to become potential structural material to compete with conventionally used materials in automobile and other sectors.

The HEA are synthesized conventionally through various routes such as melting and casting17, powder metallurgy by mechanical alloying (MA) and sintering18–21, surface deposition22, etc. Techniques like additive manufacturing (AM)23 and carbothermal shock synthesis (CTS)24 have also been utilized widely in recent times. The HEA manufactured through these routes have inherent limitations including gas porosity, shrinkage porosity, un-melted particles and detrimental microstructural features, etc.25–27. These defects in the specimens create inhomogeneous stress distribution which limit the optimum strength–ductility combination. The strength–ductility synergy is quantified as a product of strength and ductility (PSD in GPa × %) defined elsewhere28. Since the strength and ductility specifications for many room-temperature structural applications are critical, the synthesized HEA need to be engineered further to imbibe the desirable properties.

Thermo-mechanical processing (TMP) constitutes of a series of plastic deformation and thermal operations to tune the microstructure consequentially enhancing the strength–ductility synergy of as-synthesized components. The plastic deformation processes, like rolling, combined with a post-deformation annealing constitute the most commonly used sequence of a TMP schedule. A combination of rolling and heat treatment process (RHP) has been effectively utilized for aluminium, steel, and titanium alloys for enhancing room-temperature mechanical properties29–31. The rolling process, apart from changing the shape, is known to strengthen the as-cast or PM processed materials through various mechanisms such as dislocation strengthening, grain and twin boundary strengthening32,33, etc. A subsequently optimized heat treatment facilitates the tailoring of the strength–ductility combination34, leading to mechanical properties superior to as-cast or PM processed specimens.

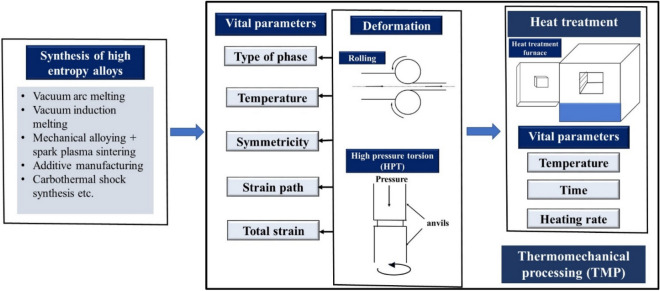

The schematic Fig. 1 depicts three major modes of HEA processing along with key factors in individual stages. First step of HEA synthesis routes render characteristic microstructural features, e.g., type and fraction of phases, grain size, etc. All these parameters play a vital role in deciding post RHP properties35,36. During secondary processing, i.e., deformation through rolling or HPT, the working temperature along with recrystallization temperature governs the microstructural evolution. Rolling at various temperatures exhibits different strengthening mechanisms and hence influences the properties of HEA37–39. The rolling processes can be differentiated based on operating temperature which includes cryo-rolling (CR), room-temperature rolling (RTR), hot rolling above the recrystallization temperature (HR), and warm rolling (WR) (around average temperature of hot rolling and RTR). In addition to temperature, the parameters like amount of total strain, strain path, symmetricity of rolling (symmetric/asymmetric rolling), etc. also play an important role in ascertaining the final properties of an HEA40–42. During the heat treatment of the HEA, the annealing temperature primarily dictates microstructural evolution43. Additionally, the duration of annealing44 and heating rate to achieve temperature of interest45 also can be used to tune the strength–ductility synergy. Taken together, there are various parameters associated with different stages of TMP which decides the enhancement in tensile room-temperature mechanical properties of HEA.

Figure 1:

Schematic mentioning the various parameters of thermo-mechanical processing of high entropy alloys affecting the final mechanical properties.

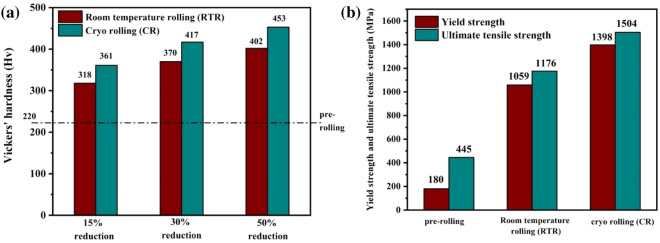

There are a substantial number of journal papers on RHP of HEA starting from the year 2009. Figure 2 highlights the rapid increasing trends in number of publications in TMP starting from its inception. Review on evaluation of mechanical properties of HEA through tensile and compressive behaviour has also been undertaken46,47. However, any of the reviews does not deal with the generic aspects of thermo-mechanical processing involving the rolling and annealing process. In summary, the focus of this review is to establish the role of variety of parameters in RHP process.

Figure 2:

Graph indicating the number of journal publications on rolling annealing process of high entropy alloys.

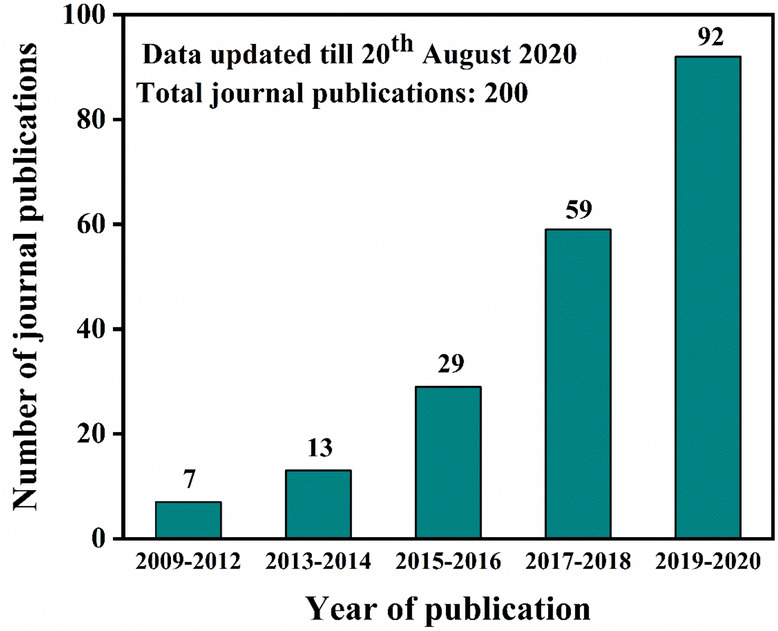

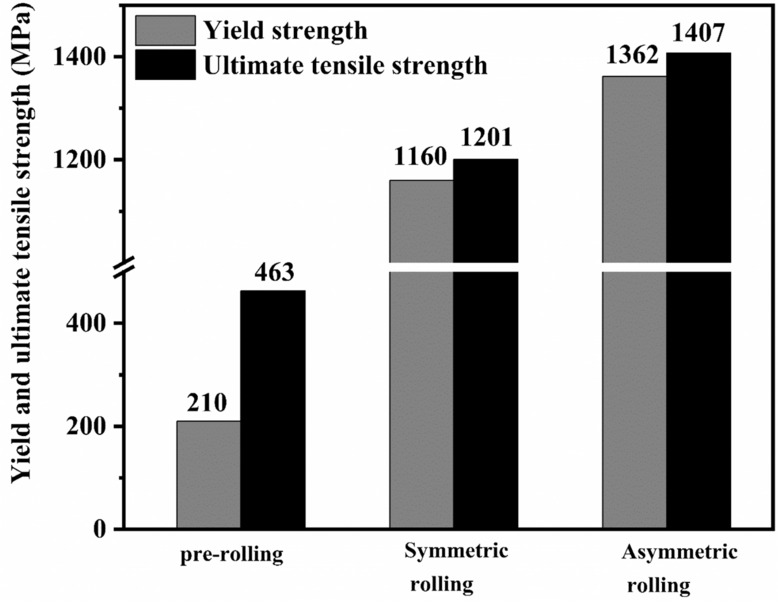

Strengthening HEA by Rolling

The rolling process in TMP has been effectively employed in the strengthening of as-synthesized HEA48–53. Figure 3 clearly indicates significant strengthening of HEA due to rolling. The compositions of HEA, rolling parameters, and percentage increase in the strength values after rolling have been given in Table 1. The primary strengthening mechanisms in HEA operative during rolling are associated with increased dislocation density54, twin boundaries37, kink bands40, shear bands55, grain refinement56, transformation-induced plasticity57,58, back stress hardening due to accumulation of dislocations59–61, etc. In the following section, the tuning of various factors such as pre-rolling microstructural features, temperature of rolling, total strain, strain path, symmetricity, etc. and their corresponding strengthening mechanisms will be discussed.

Figure 3:

Ultimate tensile strength vs. yield strength graph implying the significant strengthening after rolling.

Table 1:

Strengthening of as-synthesized high entropy alloys after rolling.

| Composition of HEA | No. of phases | Structure of phases present | Rolling details (rolling temperature/reduction in thickness) | Yield strength (MPa) | Ultimate tensile strength (MPa) | Increase in yield strength (%) | Increase in ultimate tensile strength (%) | Reference | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Before rolling | After rolling | Before rolling | After rolling | |||||||

| Al0.1CoCrFeNi | Single | FCC | RTR/ 75% | 200 | 1198 | 850 | 1230 | 499 | 45 | 137 |

| Al0.25CoCrFeNi | Single | FCC | RTR/ 90% | 126 | 1292 | 491 | 1481 | 925 | 202 | 48 |

| Al0.25CoCrFeNi | Single | FCC | RTR / 60% | 173 | 1080 | 428 | 1088 | 524 | 154 | 50 |

| Al0.25CoCrFeNi | Single | FCC | RTR / 60% | 260 | 1150 | 644 | 1160 | 342 | 80 | 50 |

| Al0.25CoCrFe1.25Ni1.25 | Single | FCC | RTR/ 80% | 92 | 616 | 433 | 702 | 570 | 62 | 39 |

| Al0.3FeCoCrNiMn | Single | FCC | RTR / 96% | 275 | 1459 | 443 | 1534 | 431 | 246 | 51 |

| Al0.3CoCrFeNi | Single | FCC | RTR/ 70% | 207 | 420 | 335 | 1325 | 103 | 296 | 41 |

| Al0.3CoCrFeNi | Single | FCC | RTR/ 90% | 175 | 1283 | 325 | 1380 | 633 | 325 | 169 |

| Al0.45CoCrFeNi | Single | FCC | RTR / 70% | 209 | 1100 | 608 | 1137 | 426 | 87 | 52 |

| Al0.5CoCrFeNi | Dual | FCC + BCC | RTR/ 50% | 402 | 1396 | 568 | 1461 | 247 | 157 | 43 |

| Al0.5CoCrFeNi | Dual | FCC + BCC | RTR/ 20% | 402 | 755 | 616 | 842 | 88 | 37 | 21 |

| Al0.5CrCuFeNi2 | Single | FCC | RTR/ 50% | 402 | 1132 | 560 | 1200 | 182 | 114 | 154 |

| AlCoCrFeNi2.1 | Dual | L12 + B2 | Cryo-rolling/ 45% | 600 | 1600 | 1100 | 1750 | 167 | 59 | 55 |

| AlCoCrFeNi2.1 | Dual | L12 + B2 | Cryo-rolling + warm rolling/ 90% | 600 | 1900 | 1100 | 2000 | 217 | 82 | 55 |

| AlCoCrFeNi2.1 | Dual | L12 + B2 | Cryo-rolling/ 90% | 615 | 1699 | 1105 | 1773 | 176 | 60 | 65 |

| AlCoCrFeNi2.1 | Dual | L12 + B2 | RTR/ 90% | 620 | 1625 | 1050 | 1800 | 162 | 71 | 168 |

| AlCoCrFeNi2.1 | Dual | L12 + B2 | Warm rolling/ 90% | 510 | 1390 | 1009 | 1940 | 173 | 92 | 41 |

| AlCoCrFeNi2.1 | Dual | L12 + B2 | RTR/ 90% | 615 | 1731 | 1105 | 1813 | 181 | 64 | 22 |

| Al3.4C0.7CoCrFeNiMn | Single | FCC | RTR/ 80% | 210 | 1310 | 445 | 1500 | 524 | 237 | 111 |

| CoCrFeMnNi | Single | FCC | RTR / 60% | 184 | 854 | 346 | 901 | 364 | 160 | 70 |

| 1 at% N- CoCrFeMnNi | Single | FCC | RTR / 60% | 280 | 1043 | 554 | 1068 | 273 | 93 | 70 |

| CrMnFeCoNi | Single | FCC | RTR / 90% | 210 | 1150 | 463 | 1152 | 448 | 149 | 140 |

| CrMnFeCoNi | Single | FCC | RTR/ 50% | 210 | 1250 | 463 | 1327 | 495 | 187 | 140 |

| 0.69 at% C-CoCrFeNiMn | Single | FCC | RTR / 80% | 275 | 1310 | 580 | 1500 | 376 | 159 | 136 |

| FeCoCrNiMn-1 at % C | Single | FCC | RTR/ 80% | 400 | 1360 | 750 | 1470 | 240 | 96 | 79 |

| CoCrFeNiMn | Single | FCC | RTR/ 80% | 160 | 1120 | 445 | 1175 | 600 | 164 | 42 |

| FeCrCoMnNi | Single | FCC | RTR / 90% | 210 | 1150 | 447 | 1164 | 448 | 160 | 140 |

| CoCrFeNiMo0.2 | Single | FCC | RTR/ 80% | 280 | 1392 | 610 | 1589 | 397 | 160 | 170 |

| CoCrFeNiNb0.1 | Single | FCC | RTR/ 25% | 250 | 650 | 475 | 694 | 160 | 46 | 92 |

| CoCrFeNi2.1Nb0.2 | Dual | FCC + Laves | Cryo-rolling/ 90% | 178 | 1150 | 598 | 1758 | 546 | 194 | 49 |

| CoCrFeMnNi | Single | FCC | RTR/ 80% | 356 | 1292 | 690 | 1352 | 263 | 96 | 132 |

| CoCrFeNiNb0.1 | Single | FCC | Cryo-rolling/ 25% | 250 | 600 | 475 | 685 | 140 | 44 | 92 |

| CoCrFeNiMn | Single | FCC | RTR/ 80% | 180 | 1059 | 445 | 1176 | 488 | 164 | 37 |

| CoCrFeNiMn | Single | FCC | Cryo-rolling/ 80% | 180 | 1398 | 445 | 1504 | 677 | 238 | 37 |

| FeCrCuMnNi | Single | FCC | Cryo-rolling/ 85% | 336 | 1176 | 499 | 1294 | 250 | 159 | 108 |

| Fe28.2Ni18.8Mn32.9Al14.1Cr6 | Single | FCC | RTR/ 65% | 679 | 1442 | 931 | 1521 | 112 | 63 | 37 |

| CoCrFeNi2.1Nb0.2 | Dual | FCC + Laves | RTR/90% | 160 | 1380 | 600 | 1530 | 763 | 155 | 60 |

| CoCrFeNi2.1Nb0.4 | Dual | FCC + Laves | RTR/90% | 480 | 1500 | 730 | 1680 | 213 | 130 | 60 |

Evolution of Deformed Microstructure Based on Phases

The various types of as-synthesized alloys with different phases can be classified as: (i) single-phase alloys: face-centered cubic (FCC)50, body centered cubic (BCC)40, B2 phase62, etc.; (ii) multiphase alloys: FCC + BCC63, FCC + hexagonal closed packed (HCP)64, L12 + B265, etc. The deformation mechanisms active in these two types of alloys leading to strengthening will be elaborated in this section.

Single-Phase Alloys

During the initial stages, the single-phase FCC HEA undergo strengthening through dislocation activities leading to cell formation66–68, deformation twins69, microbands70,71, shear bands due to heavy deformation72,73, etc. At constant deformation temperature, the deformation of FCC HEA is primarily controlled by stacking fault energy (SFE)74. The nucleation of deformation twins is directly proportional to SFE75,76. Hence, the HEA with lower SFE exhibit deformation twinning as their deformation mechanism77. Additionally, with reduction in the SFE by tuning of composition of alloy, the deformation twin thickness can also be reduced76. This reduction of twin thickness will provide higher strengthening in FCC HEA78. In contrast, the increase in SFE (lowering the distance between Shockley partials) leads to easier cross-slip. Hence, at higher SFE values, microband formation was found to be dominant mechanism for deformation79. The deformation mechanism changes from twinning to microband formation with increasing nitrogen content70. The SFE increases by alloying elements like nitrogen leading to change in the deformation mechanism80. To sum up, in the initial and intermediate stages of deformation, the microstructural evolution and strengthening in FCC HEA is influenced by SFE.

In BCC HEA, the deformation is driven by mechanisms such as increase in dislocation density40, kink bands81, deformation bands82,83, microbands84, shear bands40, etc. The misorientation of boundaries was found to be related to kink bands40,81,85 after rolling which was lower compared to the misorientation of twin boundary in BCC HEA40,81,86. Along with BCC alloys, the partially ordered single-phase B2 also deforms primarily by dislocation microbands formation62. The formation of microbands in B2 has been attributed to the preference of deformation via planar slip over other mechanisms71, wherein the leading Shockley partially destroys the barrier for ordering of B2 phase making it easy for trailing Shockley partial to continue planar slip leading to formation of microbands62,87. At larger plastic strains, the shear band formation is the dominant mechanism for most of the HEAs irrespective of initial phase40,72. The shear band formation represents plastic instability88 and occurs irrespective of crystallography of sample at sufficiently larger rolling deformation89. Taken together, there are variations in deformation mechanisms possible in single phases based on type of phase and SFE.

Multiphase Alloys

The deformation mechanisms of multiphase alloys include most of the mechanisms applicable to single-phase alloys, such as dislocation cell formation43,60, deformation twinning73,90, shear banding65,73, etc. In addition, the multiphase alloys have additional strengthening mechanisms such as back stress strengthening due to accumulation of dislocations at phase boundaries59–61, strain-induced martensitic transformation73,90, etc. The major strain partitions to soft FCC phase compared to hard phases like carbides, ordered phase B2, etc. For maintaining continuity, the geometrically necessary dislocations (GNDs) participate in the deformation, which provides additional strengthening in dual-phase alloys compared to single-phase alloys59. The mechanism of strain-induced FCC-to-HCP martensite transformation in the dual-phase alloy containing FCC and thermally stabilized HCP phase has also been reported64. The stacking fault generated in the initial stages of deformation in FCC phase acts as nuclei for transformation of FCC phase to HCP martensite91. Hence, in general, the strengthening effect is higher in dual-phase HEA compared to single-phase HEA.

Development of Microstructure at Different Rolling Temperatures

As described in previous section, the active strengthening mechanisms in HEA are dislocation activity50, microbands71, stacking fault (SF)92, deformation twinning70, shear bands93, etc. depending on pre-rolling phases and SFE. The selection and evolution of any of the above-mentioned mechanisms, however, depends on the rolling temperature37. During cryo-rolling (CR) and room-temperature rolling (RTR), the evolution of microstructure is governed by dislocation activity and twinning depending on SFE of HEA. The SFE of the conventional alloys and HEA is directly proportional to temperature92,94. Hence, during CR and RTR, the microstructural evolution will change according to SFE. However, at higher temperature regime (near or above the recrystallization temperature of alloy), the microstructural changes will get affected by thermal activation. The effect of rolling temperature at elevated temperatures on properties can be explained through change in Zener–Hollomon (Z–H) parameter95. At constant strain rate, lowering the rolling temperature increases the Z–H parameter and the strength thereof. In this section, the difference in mechanisms of strengthening and their effect on properties after rolling at different temperatures will be discussed.

Deformation at Room Temperature and Cryogenic Temperature

The difference in the mechanical properties with change in the rolling temperature in the temperature regime spanning from room temperature to cryogenic temperature is shown in Fig. 4. Figure 4a describes the difference in hardening at two rolling temperatures of CoCrFeNiMo0.15 HEA71 and Fig. 4b highlights the effect of rolling temperature on strengthening in CoCrFeNiMn alloy37. The cryo-rolled (CR) specimens exhibited more strengthening than room-temperature rolled (RTR) specimens. The difference between RTR and CR is that the microstructural evolution kinetics is faster in the latter37,71,92,96. The initial stages of deformation in RTR are dominated by dislocation activity and SFs, and with increasing strain, the deformation twins become dominant. The SFE of the studied alloy is low, and hence, deformation twining is favorable over microbands at room temperature75. Compared to RTR specimens the activation of deformation twinning for CR specimens happened at earlier stages. This is explained with the fact that the SFE at liquid nitrogen temperature is further less compared to SFE at room temperature92. With increasing strain in CR, the multiple twin systems get activated and distortion of nanotwins occurs later. The shear bands were also found post CR after imparting high strain37,71,96. The enhanced dislocation density was also observed in the conventional FCC alloys after deforming at cryo-temperature in comparison with room temperature97. The deformation-driven FCC-to-HCP transformation-induced plasticity (TRIP) was observed after CR. The SFs present in the initial stages acted as nucleating sites for FCC-to-HCP transformation64. The texture after CR and RTR was brass-type texture which is typical for low SFE material93. Hence, there is little role of texture in additional strengthening after CR than RTR. Hence, the HEA exhibits the enhanced strengthening at cryo-temperature compared to room temperature (Fig. 4a, b) due to higher dislocation density, intersection of twins from non-parallel systems, TRIP, and more shear banding.

Figure 4:

The different amount of strengthening achieved through rolling at cryo and room temperature in high entropy alloys: a CoCrFeNiMo0.1571; b CoCrFeNiMn37.

Warm and Hot Deformation

The influence of rolling in high-temperature regime at intermediate as well as at high temperatures, namely warm rolling (WR)98 and hot rolling99–102, has been investigated for HEAs. In general, hot working refers to rolling at temperatures above the recrystallization temperature103, while warm rolling is performed at intermediate temperatures of cold and hot rolling55. For the HEAs that are less workable, hot working is preferred35. Another associated attribute of deformation at high temperature is associate control of microstructures55,100. The hot rolling of HEAs involves dynamic recovery, dynamic recrystallization, grain growth, etc. as other micro-mechanisms like phase evolution and transformation depending on rolling temperature100,104. Mostly recovery and partial recrystallization is prevalent in the FCC HEA rolled at temperatures below recrystallization temperature of HEA100. This recovery-to-recrystallization ratio is strongly dependent on temperature and SFE of the material. Recovery is dominant at lower rolling temperatures and in high SFE alloys, while at higher rolling temperatures and for low SFE alloys, recrystallization is more prevalent105. For HEAs, increased degree of recrystallization is observed at higher rolling temperatures100. For much higher rolling temperatures, grain growth has also been observed100 due to increased mobility of grain boundary at higher temperature105. The microstructural transformation through any of these routes led to specific strength–ductility synergy in the HEA.

The deformation mechanisms during the warm rolling of AlCoCrFeNi2.1 eutectic HEA were found to be function of rolling temperature55. The shear banding and disordering of L12 phase was influenced by rolling temperature. In the dual-phase (FCC + BCC) Al0.5CoCrFeMn HEA, the FCC phase underwent deformation, while the harder BCC phase underwent grain fragmentation instead of deformation35. Another influence of temperature was noticed in terms of propensity of twinning. Twinning was reported to be suppressed with increase in temperature in warm working regime due to increase in SFE in the HEAs that exhibit twinning induced plasticity (TWIP)106.

In general, the strength–ductility combination has been tailored by a combination of deformation in multiple temperature domains, for example, a combination of cryo-rolling and warm rolling. This combination results in generation of heterogeneous microstructure to enhance the strength–ductility synergy53. Such a processing is sometimes referred to as hybrid processing or hybrid rolling. To summarize, a broad range of micro-mechanisms act to play, depending on the working temperature. Hence, by varying the rolling temperature, hence by tailoring the microstructure optimally, the strength–ductility combination can be fine-tuned.

Total Plastic Strain

The evolution of microstructure in various HEA with increasing rolling reductions (plastic strains) and its effect on mechanical properties thereof has been evaluated extensively107–109. The evolution of strength after cold rolling in FCC HEA Al0.25CoCrFeNi with increasing total plastic strain Fig. 548. The increase in % thickness reduction led to increase in strength at the cost of ductility (Fig. 5a). The strain hardening analysis has been carried out on results presented in Fig. 5a. The strain hardening regime of stress–strain curve (between yield strength and ultimate tensile strength) was considered for the calculations of specimens rolled to different reductions. The Hollomon analysis plot (ln (true uniform plastic stress) vs. ln (true uniform plastic strain)) after various rolling reductions is presented in Fig. 5b. The details of the Hollomon calculation can be found elsewhere110. The slope of the curve after applying linear regression (R2 > 0.8) is the strain hardening exponent (n). Figure 5b highlights the decrease in ‘n’ (early necking) after increasing the rolling reduction. Similar behavior was observed for some HEA111,112 and conventional aluminium alloys110. The decrease in strain hardening capacity in Al0.25CoCrFeNi HEA with increasing rolling reduction can be explained based on deformation mechanisms. The mechanisms of deformation in various phases are different at different temperatures, and dislocation activity and cell formation are the dominant mechanism of deformation in the initial stages43,60. As the deformation proceeds, the multiplication of dislocations and sub-grain size refinement take place which makes it difficult for further strain hardening and non-uniform deformation leads to necking110. Taken together, the strength evolution as a function of plastic strain has been observed and increased strengthening can be achieved with increasing plastic strain.

Figure 5:

a The engineering stress–strain curve of Al0.25CoCrFeNi high entropy alloy before and after various reduction in thickness48; b the corresponding ln (true uniform plastic stress) vs. ln (true uniform plastic strain) plot for strain hardening analysis with values of strain hardening exponent(n) mentioned.

Tuning the Strain Path

The effect of varying strain path during rolling on microstructure evolution and final properties in the conventional alloys containing different phases has been well studied113–115. The elongated grain structure is developed by virtue of unidirectional rolling (UDR), whereas the lamellar structure fragmentation occurs by cross rolling. There are a few reports on difference in microstructure due to strain path change in HEA41,117,118. The variation in deformation microstructure gives rise to difference in the mechanical properties post-annealing. In the case of the HEA AlCoCrFeNi2.1, the UDR sample resulted in heterogeneous microstructure with lamellar and recrystallized grains in contrast to cross-rolled specimens which exhibited duplex recrystallized grains. Subgrains are well developed in UDR specimen, whereas it gets distorted during cross rolling. The destabilization of dislocation structure during cross rolling is also reported in the case of cold rolling of CoCrFeMnNi FCC alloy117. This destabilization effect has also been reported in the conventional FCC alloys114,119, and the distortion in development of misorientation provides lesser nucleating sites for recrystallization leading to coarse grain size in cross-rolled specimens in comparison to UDR117. The difference in the grain size affects the strength–ductility synergy120. The increase in the volume fraction of intersecting twins in low SFE HEA after cross rolling and intermittent annealing due to destabilization of substructure has also been reported118. Therefore, it is clear that changing the strain path during rolling could enable the microstructure and strength–ductility combination to be tuned.

Symmetricity of Rolling

The symmetricity of rolling can be varied by varying the (a) diameter of the rolls, (b) friction conditions at the roll and sample surface, and (c) the speed of the roll121,122. Along with plain strain compressive stress (as in conventional rolling), asymmetric rolling imparts additional shear stress during deformation122. The equivalent strains in asymmetric rolling were also found to be slightly higher compared to the conventional rolling123. Researchers have utilized asymmetric rolling for refining the microstructure and enhancing the mechanical properties of conventional aluminium, magnesium alloys123–125, etc. The process of asymmetric rolling (ASR) at room temperature using different roll speeds (speed ratio 1.5) for FCC CoCrFeMnNi alloy was also performed42. Asymmetrical rolling strengthened the HEA by 96% more in comparison with symmetric rolling (SR) (Fig. 6). As discussed earlier, the deformation mechanisms dominant in FCC HEA are dislocation cell formation, deformation twinning, shear bands, etc.43,65,90. The CoCrFeMnNi alloy exhibited a higher number of dislocation cell formation in ASR compared with SR specimens. The asymmetrically rolled FCC metals like aluminium exhibited higher percentage of low-angle grain boundaries (LAGBs) converted to high-angle grain boundaries (HAGBs) due to higher dislocation activity. This conversion was promoted by additional shear stress123. In addition to dislocation activity, SR specimens showed parallel set of deformation twins in contrast to intersecting twins in ASR specimens. These intersecting twins exhibit additional hardening in ASR specimens126. Higher volume fraction of shear bands formation was seen in ASR as compared to conventionally rolled specimens. The complex strain distribution in ASR is reported to be the plausible reason for higher fraction of intersecting twins and shear bands124,126. Owing to the above-mentioned discussion, ASR displays additional strengthening in comparison with SR specimens. Similar kind of additional strengthening in FCC HEA has been reported with different roll speeds127. The dislocation density is found to be twice in ASR specimens compared to SR. Asymmetric rolling is proven to be effective way to attain the additional strengthening compared to symmetric rolling for HEA.

Figure 6:

The difference in strengthening with symmetric and asymmetric rolling at room temperature in CoCrFeMnNi alloy42.

Deformation Texture

The generation of texture during TMP of HEA significantly influences the strength of the material. Orientation of grains in HEA post TMP is decided by the strain path, working temperature, and the recrystallization parameters. Texture evolution in HEA post-deformation in HEA is discussed here based on phases present in the alloy. Table. 2 shows the deformation and annealing texture components of common HEA.

Table 2:

Deformation and annealing texture components of HEA.

| Rolling conditions | Composition | Phase | Deformation texture | Recrystallization texture | Recrystallization temperature (°C) | Ref. no |

|---|---|---|---|---|---|---|

| RTR | CoFeNi | FCC | Bs, S | Cube | 700–1000 | 38 |

| CoCrFeNi | S, Bs | Random | ||||

| CoCrFeMnNi | Bs | Random | ||||

| RTR | CoCrFeMnNi | FCC | Bs, Cu, cube, S | K{142} < 2 >, M{13 6 25} < 20 15 > | 650–1000 | 129 |

| WR | AlFeCrCoNi2.1 | L12 | Bs, G, G/B | Bs, G, G/B | 800–1200 | 130 |

| B2 | {112} < 110 > | {112} < 110 > | 800 | |||

| {111} < 110 > | 1200 | |||||

| CR | AlFeCrCoNi2.1 | L12 | Bs, Goss, Rt-Goss | Bs, Goss, Rt-Goss | 800–1200 | 49 |

| B2 | {001} < 110 > | ND fibre | ||||

| RTR | HfZrTiTaNb | BCC | ND, RD fibre | {111} < 110 > | 1400 | 131 |

HEA like Cantor alloy contain typical rolling components post-room-temperature rolling (RTR) such as Bs, Cu, cube, and S components. The S component strengthens up to 80% RTR reduction, beyond which it decreases129. The brass component strengthens beyond 80% and keeps on increasing till 90% reduction. Slip planes at low RTR reduction and fine lamellae with deformation bands co-existing at high RTR reduction are responsible for the texture development. The Goss and Bs components show up in the FCC phase of FeCrCuMnNi in 90% RTR alloy109. Twins present in the Cantor alloy promote the transition of Cu to brass type of texture to during RTR126. Al0.5CoCrFeNi HEA shows {110} < 112 > and {111} < 110 > components on RTR possessing FCC with trace BCC phase, which on recrystallization become weak43. Cryo-rolling of Cantor alloy shows a similar texture as after cold rolling93. Multistage cross cold rolling of Cantor alloy shows stronger Bs component than unidirectional rolled specimen117.

The L12 phase in the eutectic HEA AlFeCrCoNi2.1 possesses Bs type of texture post-warm rolling along with α-fibre (Goss, Bs, G/B); whereas the B2 phase shows {112} < 110 > type of texture along with RD||110 and ND||111 fibres post-warm rolling130. Different strain paths imparted at cryo-temperature on EHEA generate Bs along with Goss, Rt-Goss in L12 phase, and {001} < 110 > in B2 phase after multistep cross rolling41. HfZrTiTaNb HEA with BCC phase, when cold rolled, exhibits strong ND fibre (ND// < 111 >), and RD fibre (RD// < 110 >) along with cube and Rt-cube components131.

Post-rolling Heat Treatments: Annealing

Rolling leads to strengthening of HEAs, compromising on the ductility factor132,133. The strength–ductility combination has been optimized by designing different heat treatment regimens post-rolling, which is plotted and highlighted in Fig. 7128,134,135. The composition of the alloys with respective RHP and properties are presented in Table 3. The quantification of strength–ductility synergy which is realised by the parameter PSD (GPa × %) displays that RHP has significantly enhanced the strength–ductility combination of as-synthesized HEA (Table 3). This improvement is dependent on the cascade of events taking place (microstructural evolution) during annealing heat treatments, which depends on various parameters such as annealing temperature56, annealing time136, heating rate during annealing45, etc. In this section, the role of various annealing parameters in microstructure evolution will be discussed in detail.

Figure 7:

Yield strength vs. product of ultimate tensile strength and ductility graph highlighting the enhancement in strength–ductility synergy through RHP of high entropy.

Table 3:

Strength—ductility combination in high entropy alloys after RHP.

| Composition | Phases present | Details of RHP (rolling type/annealing temperature/annealing time) | Yield strength (MPa) | Tensile strength (MPa) | Ductility (% elongation) | Product of tensile strength and ductility (PSD) (GPa × %) | Increase in PSD (%) | References | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pre-TMP | Post-TMP | Pre-TMP | Post-TMP | Pre-TMP | Post-TMP | Pre-TMP | Post-TMP | |||||

| Al0.25CoCrFeNi | FCC | RTR / 650 °C/ 48 h | 173 | 470 | 428 | 879 | 79.3 | 48.23 | 33.94 | 42.39 | 24.9 | 50 |

| Al0.3CoCrFeNi | FCC | RTR /1050 °C/ 1440 min | 207 | 204 | 335 | 588 | 40 | 69 | 13.40 | 40.57 | 202.8 | 51 |

| Al0.3CoCrFeNi | FCC | RTR /1050 °C/ 1440 min | 207 | 204 | 335 | 588 | 40 | 69 | 13.40 | 40.57 | 202.8 | 51 |

| Al0.3CoCrFeNi | FCC | RTR / 1100 °C/1 h | 175 | 188 | 325 | 553 | 60 | 95 | 19.50 | 52.54 | 169.4 | 51 |

| Al0.45CoCrFeNi | FCC | RTR / 1000 °C/1 h | 298 | 667 | 591 | 923 | 30 | 30 | 17.73 | 27.69 | 56.2 | 52 |

| Al0.5CoCrCuFeNi | FCC + BCC | RTR /900 °C/ 300 min | 578 | 612 | 884 | 750 | 10.7 | 28 | 9.46 | 21.00 | 122.0 | 43 |

| Al0.5CoCrFeNi | FCC + BCC | RTR /1200 °C /1 h | 402 | 328 | 568 | 725 | 33.68 | 47.8 | 19.13 | 34.66 | 81.2 | 43 |

| Al0.6CoCrFeNi | FCC | RTR /1000 °C/ 1 h | 561 | 795 | 750 | 1112 | 32 | 29.83 | 24.00 | 33.17 | 38.2 | 63 |

| AlCoCrFeNi2.1 | L12 + B2 | cryo-rolling/ 800 °C/ 1 h | 615 | 1437 | 1105 | 1562 | 17 | 14 | 18.79 | 21.87 | 16.4 | 55 |

| AlCoCrFeNi2.1 | L12 + B2 | RTR / 700 °C/12 h | 741 | 1110 | 1065 | 1340 | 7.5 | 11 | 7.99 | 14.74 | 84.5 | 65 |

| AlCoCrFeNi2.1 | L12 + B2 | warm rolling /1000 °C/1 h | 510 | 705 | 1009 | 1194 | 17 | 31 | 17.15 | 37.01 | 115.8 | 68 |

| AlCoCrFeNi2.1 | L12 + B2 | RTR / 1100 °C/1 h | 620 | 648 | 1050 | 1075 | 17 | 27 | 17.85 | 29.02 | 62.6 | 168 |

| Al3.37-C0.69-Co22.35-Cr19.67-Fe22.85-Ni22.44Mn8.62 | FCC | RTR / 1000 °C/1 h | 209 | 429 | 451 | 825 | 74 | 44 | 33.38 | 36.30 | 8.7 | 96 |

| CrMnFeCoNi | FCC | RTR / 800 °C/1 h | 210 | 700 | 463 | 930 | 57 | 54 | 26.39 | 50.22 | 90.3 | 70 |

| FeCrCoMnNi | FCC | RTR / 650 °C /1 h | 210 | 534 | 447 | 832 | 57 | 50 | 25.48 | 41.60 | 63.3 | 70 |

| CrMnFeCoNi | FCC | RTR / 650 °C/1 h | 210 | 625 | 463 | 855 | 57 | 51 | 26.39 | 43.60 | 65.2 | 140 |

| CoCrFeMnNi | FCC | RTR /900 °C/ 1 h | 168 | 328 | 346 | 670 | 43 | 52 | 14.88 | 34.84 | 134.1 | 140 |

| CrMnFeCoNi | FCC | RTR / 920 °C/1 h | 210 | 280 | 463 | 632 | 57 | 64 | 26.39 | 40.45 | 53.3 | 140 |

| FeCoCrNiMn | FCC | RTR / 800 °C/1 h | 195 | 378 | 491 | 700 | 70 | 54 | 34.37 | 37.80 | 10.0 | 79 |

| CoCrFeMnNiN0.01 | FCC | RTR /900 °C/ 1 h | 280 | 407 | 554 | 766 | 42 | 50 | 23.27 | 38.30 | 64.6 | 70 |

| FeCoCrNiMn-0.5 at % C | FCC | RTR / 800 °C/1 h | 262 | 517 | 572 | 790 | 50 | 40 | 28.60 | 31.60 | 10.5 | 79 |

| FeCoCrNiMn-1 at % C | FCC | RTR / 800 °C/1 h | 400 | 690 | 750 | 840 | 32 | 31 | 24.00 | 26.04 | 8.5 | 79 |

| FeCoCrNiMn-1 at % C | FCC | RTR /1100 °C/ 30 min | 400 | 380 | 750 | 810 | 32 | 74 | 24.00 | 59.94 | 149.8 | 79 |

| FeCoCrNiMn-0.6 at % C | FCC | RTR / 900 °C/1 h | 275 | 530 | 580 | 875 | 46.4 | 47 | 26.91 | 41.13 | 52.8 | 111 |

| FeCoCrNiMn-2 at % C | FCC | RTR / 900 °C/6 h | 446 | 581 | 723 | 857 | 15 | 33 | 10.85 | 28.28 | 160.6 | 49 |

| CoCrFeNi2.1Nb0.2 | FCC + Laves | cryo-rolling/800 °C/ 1 h | 178 | 1219 | 598 | 1272 | 38.4 | 22 | 22.96 | 27.98 | 21.9 | 60 |

| Fe24Co23Ni24Cr23Ti2Al4 | FCC | RTR /1000 °C/ 2 h | 293 | 709 | 418 | 861 | 22 | 17 | 9.19 | 14.64 | 59.3 | 45 |

| Fe40.4Ni11.3Mn34.8Al7.5Cr6 | ||||||||||||

| - 1 at % C | FCC | Room temperature rolling (RTR) /1100 °C/4 h | 355 | 405 | 734 | 914 | 46 | 46 | 33.76 | 42.04 | 24.5 | 99 |

| Fe41Mn25Ni24Co8Cr2 | FCC | RTR / 800 °C/1 h | 175 | 330 | 432 | 566 | 43 | 34 | 18.58 | 19.24 | 3.6 | 127 |

| Nb25Ti25Hf25Zr25 | FCC | RTR / 1000 °C/1 h | 636 | 769 | 652 | 941 | 12 | 30 | 7.82 | 28.23 | 261.0 | 139 |

Annealing Temperature

The different mechanisms of microstructure evolution during heat treatments reported in literature are as follows: recovery126,137, precipitation138,139, recrystallization140–142, grain growth143–145, and annealing twins146,147, etc. The mechanism in play triggering the microstructural change for HEA is dictated by annealing temperature148. The strong dependence on annealing temperature can be attributed to microstructural changes occurring, which in turn is strongly influenced by diffusion149 which is exponentially related (Arrhenius dependence) to temperature150. Before annealing, rolling enhances the yield strength of FCC HEA manifold with considerable reduction in ductility148. Hence, the product of strength and ductility value reduced marginally, as shown in Fig. 8a148. However, annealing at different temperatures increases the PSD parameter significantly in comparison to both pre- and post-rolled HEA. Annealing renders higher yield strength values compared to pre-rolled status of HEA (Fig. 8a). The plausible reasons behind the enhanced mechanical properties post-annealing at different temperatures will be discussed vis-à-vis microstructural changes.

Figure 8:

Enhancement in product of ultimate tensile strength and ductility (PSD in GPa × %) for high entropy alloys: a FeCoCrNiMn-0.6 at % carbon FCC alloy; annealed for 1 h at different temperatures148; b Al0.5CoCrCuFeNi FCC alloy; annealed at 900 °C for various time176.

Recovery

The driving force for recovery during annealing post-deformation (static recovery) is the stored energy in the rolled specimens151. The static recovery in HEA involves steps such as dislocation interaction leading to formation of dislocation cells68, reduction of dislocation density inside cell152–154, intensification of texture126, formation of subgrains81, etc. The recovery temperature regime is dependent on compositional complexity and SFE of the material155, etc. The higher is the SFE, more is the recovery as discussed earlier in hot rolling section. Static recovery is found to be dominant for FCC72,98,137, BCC81, and dual-phase153,156 HEA after annealing below recrystallization temperature. The activation energy required for static recovery in conventional alloys is same as that of dislocation annihilation by climb and cross-slip, which is lower compared to that of recrystallization157,158. In terms of mechanical property evolution during recovery, the decrease in hardness of rolled FCC HEA is insignificant72,148,156, whereas increase in ductility is notable137. The strength decrease during recovery was reported to be logarithmic and not as drastic as recrystallization159. This is the probable reason for increase in PSD after annealing below recrystallization temperatures of HEA (Fig. 8a).

Recrystallization

The mechanism of recrystallization involves the migration of HAGBs105. Hence, recrystallization needs higher thermal energy compared to recovery157,158. Above the recrystallization temperature, the recrystallization starts to dominate recovery. Similarly, the recrystallized fraction increased with increase in temperature in different HEA having various phases62,72,81,160 possibly due to increase in HAGBs’ mobility161. The HAGBs’ mobility impeding elements such as carbon increase the recrystallization onset temperature162. The recrystallization activation energy in FCC HEA (549 kJ/mol)163 is significantly higher compared to high manganese steel (230 kJ/mol)164 and TWIP steel (229 kJ/mol)165 due to precipitates pinning the grain boundaries in addition to solute drag effect. Hence, the nucleation of recrystallization in HEA requires higher annealing temperature compared to the conventional high-performance alloys. The recrystallization nucleation sources in HEA are deformation bands52, grain boundaries43, shear bands98, second-phase particles160, etc. The regions such as deformation bands, shear bands, etc. exhibited recrystallization initialization due to large driving force of stored energy52,98. The particle stimulated nucleation (PSN) is also prevalent in multiphase HEA. The harder phase deform less compared to softer phase and dislocation pile-up at the phase interface causes formation of deformation zone leading to nucleation of recrystallized grains160. The ductility is enhanced after recrystallization, and hence, the PSD value also gets enhanced with annealing for various HEA140,166–169 which is shown in Fig. 8a148.

Grain Growth Inhibition

As the HEA gets fully recrystallized, the grain growth starts dominating significantly at higher annealing temperatures compared to recrystallization temperature152. The excessive grain growth can deteriorate the strength of HEA162. The strategy of controlled precipitation in single-phase HEA is effectively employed in HEA to inhibit the excessive grain growth significantly166. The calculation of phase diagrams (CALPHAD) is used as tool to optimally tune the precipitation depending on annealing temperatures61,170. This temperature has a significant role in deciding the size67,171, distribution167, and volume fraction of precipitates139,172. With increase in the annealing temperature, the coarsening of precipitates occurs by Oswald ripening mechanism166. Along with coarsening of precipitates, the volume fraction of precipitates reduces with increase in the annealing temperature172. Hence, annealing temperature plays a vital role in optimizing the precipitation and controlling grain growth thereof in single-phase HEA. Similar effect of grain boundary pinning is observed in multiphase alloys where harder phase inhibits the grain growth35,166,173. The volume fraction of harder second phase decreases with increase in annealing temperature. Hence, grain growth dominates with increasing annealing temperature35,173. In addition to this, the annealing twin fraction varies proportionally to grain size143,146, and hence, annealing twinning increases as annealing temperature rises142,173. These microstructural changes result in higher activation energy for grain growth in HEA compared to the conventional alloys163. The yield strength and PSD are also higher than pre-rolling HEA even after annealing at temperatures significantly higher than recrystallization temperature (Fig. 8a). The excessive grain growth has been successfully inhibited with precipitates in single-phase HEA or with harder phase in multiphase alloys and the strength ductility synergy has been enhanced compared with pre-rolling HEA.

Annealing Time

After the microstructural evolution mechanism is ascertained by the annealing temperature, the microstructure can be tailored by varying the annealing time to enhance the PSD further149,172,174,175. The increasing trend in strength–ductility combination with increasing annealing time with respect to pre-rolled specimens was observed in Al0.5CoCrCuFeNi HEA176,177 (Fig. 8b). The specimens heat treated for different times exhibit higher yield strength values in comparison with pre-rolled HEA (Fig. 8b). The enhancement in the properties in relation to change in the microstructural features will be elaborated here.

The recrystallization kinetics in HEA is formulated with Johnson–Mehl–Avrami–Kolmogorov (JMAK) equation160. The recrystallization kinetics in HEA is slower90 compared to other conventional high-performance alloys such as high manganese steel164, TWIP steel178, micro-alloyed steel179 etc. The sluggish diffusion, severe lattice distortion effect and precipitates in HEA, results in delaying the recrystallization6,90,163. The sluggish diffusion renders restrictions on HAGBs’ movement for recrystallization90. The severe lattice distortion leads to generation of local concentration fluctuation (LCF) regions which restricts the dislocation motion during the softening90. The precipitates formed during annealing in FCC HEA impede the mobility of HAGBs, and hence, the recrystallization requires higher thermal energy to occur163.

The evolution of precipitates in HEA with increase in annealing time at particular temperature has been studied extensively134,175. The precipitate growth exponent (n) reported in various HEA is 3148,169,180. The significance of n = 3 lies in the fact that the coarsening of precipitates is via Oswald ripening mechanism166 and volume diffusion82,148. The volume fraction of precipitates remains constant up to a specific annealing time and reduces drastically with further increase in the annealing time172. The grain boundary precipitates are stable, but the precipitates inside the grain start to dissolve in the matrix leading to overall decrease in volume fraction of precipitates169.

The precipitates also slow down the kinetics of grain growth in FCC136,169, BCC81,145, and multiphase HEA166,180. The grain growth is described with modified Zener–Smith model (Z–S) model describing the pinning pressure exerted by the precipitates to restrict the grain growth169. Abnormal grain growth is also observed in FCC HEA due to heterogeneous distribution of precipitates in the initial stages of annealing181. Hence, the discussed microstructural evolution leads to achieving higher PSD values compared to pre-rolled HEA.

Heating Rate

The heating rate to reach annealing temperature also decides the microstructural evolution during annealing182 and mechanical properties of conventional alloys183. The difference in grain size after annealing due to variation of heating rate in FCC HEA is represented in Fig. 945. At high heating rates, HEA specimens exhibited lower grain size at two different annealing times than a lower heating rate (0.013 °C/s) of HEA specimens (Fig. 9). In lower heating rate specimens, the early nucleation and growth of recrystallized grains at preferred sites takes place45,184. Hence, larger grain size is achieved in low heating rate compared to high heating rate. This difference in final grain size leads to difference in the yield strength according to Hall–Petch relationship162. Hence, high heating rate achieves better yield strength and PSD compared to low heating rate183.

Figure 9:

Significant finer grain size achieved in high heating rate sample compared with low heating rate samples after annealing at two different time at 1000 °C45

Recrystallization Texture

The annealing of ternary medium entropy alloy leads to a strong cube recrystallization texture, similar to high SFE alloys. Quaternary and quinary medium entropy alloys retain some deformed texture components indicating delayed recovery phase128. Sluggish diffusion of grain boundaries in quaternary and quinary alloys hinders preferential texture growth, leading to randomisation of the texture. First-order annealing twins give rise to new annealing texture components such as K and M component apart from retained CR components129. No significant change in texture was observed with the annealing temperature. Bs, Goss, and S texture components appear post-cold rolling–annealing at 800 °C in CoCrFeMnNi (FCC) alloy with 1 atom % of carbon content elevating the strength185. Annealing twinning in Cantor alloy aids strong texture modification post-recrystallisation126. Randomisation of texture post-annealing was corroborated with Cellular Automata simulation results. Another study on annealing texture analysis of Cantor alloy showed S component dominant compared to brass and Goss components, and became stronger with annealing temperature142.

Annealing of EHEA post-warm rolling at 800, 1000, and 1200 °C renders the FCC phase with retained deformed texture components. {112} < 110 > components are present post-annealing at 800 °C in B2 phase, and {111} < 110 > component shows up at 1200 °C130. {111} < 110 > component predominates along with ND fibre post-annealing of the HfZrTiTaNb HEA131.

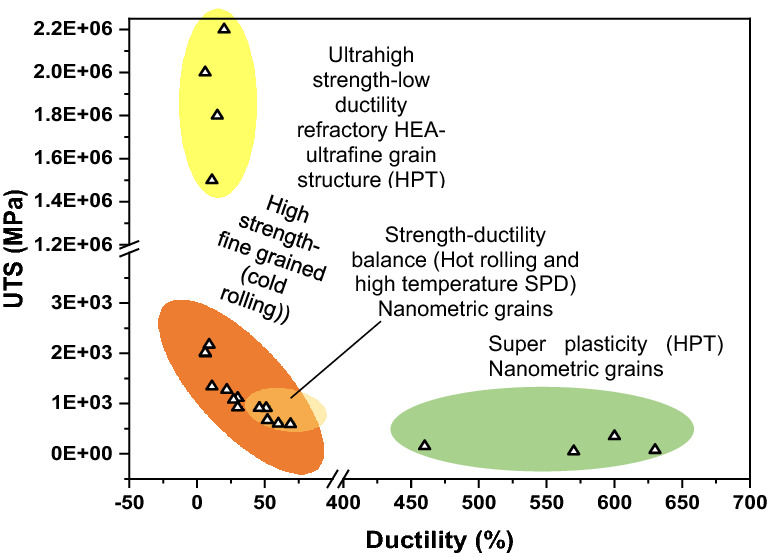

Severe Plastic Deformation

HEA have been processed and engineered using high-pressure torsion (HPT) to improve the strength, hardness, ductility, and superplasticity. The studies performed on HEA, out of which some significant cases will be discussed here. HPT combined with thermal annealing imparts 400% increase in hardness to Al0.3CoCrFeNi HEA. Formation of ordered BCC phase at high-temperature (500–700 °C) annealing as well as heterostructure promotes the elevation in hardness186. A grain size of 25 nm was achieved by HPT performed on AlNbTiVZr0.5 alloy which had an initial coarse-grained structure with B2 matrix embedded with C14 Laves phase (rich in aluminium and Zirconium). Increase in nano-hardness (550–665 HV) was observed in the B2 phase, whereas the C14 Laves phase becomes softer post-HPT187. Betterment in hardness in HPT processed HfNbTiZr BCC alloy from 2600 to 4450 MPa was realised by the aid of friction stress, possessing dislocation density of the order of 1016 m−2188. Chromium oxide precipitates of size 7–10 nm in a matrix of CoCrFeMnNi alloy consisting of FCC + BCC solid solutions show hardness of 6700 MPa which is a staggering improvement in this kind of alloys189. Hardness improvement of 910 HV by forming a multiphase nanostructured microstructure obtained after long time (100 h) annealing of HPT processed Cantor alloy is reported by Schuh et al.190. Cyclic HPT (changes in strain path) creates unstable dislocation structure and fine grains which is responsible for high hardness of CoCuFeMnNi alloy191. Room temperature and cryo-HPT led to high hardness and fine grain morphology in Cantor alloy192.

The synergy of tensile strength and ductility was demonstrated in case of HPT followed by annealing in V10Cr15Mn5Fe35Co10Ni2 alloy, possessing 1.54 GPa UTS and 6% of ductility194. V10Cr15Mn5Fe35Co10Ni25 alloy showcased a hardness of 505 MPa and tensile strength of 2 GPa with elongation failure of ~ 6%, post-HPT of coarse- and fine-grained starting material195. This was assisted by dislocation substructure formation along with twinning in the HEA. The Ashby plot for HPT processed and rolled HEAs is compared and shown in Fig. 10. The properties of fine and nanometer size grains post-HPT as well as rolling have been depicted in the plot. Nanometer size grain formation in HPT processed CoCrFeMnNi alloy improved the superplasticity behaviour (> 600% total elongation) at high temperatures; grain boundary sliding being instrumental for the former behaviour198,199. Addition of 2 atom % titanium in CoCrFeMnNi alloy followed by HPT showed 830% total elongation at 700 °C defining a new benchmark of superplasticity in HEA. This is possible due to grain size of 30 nm and retention of equiaxed nature of grains as titanium triggers sluggish diffusion200.

Figure 10:

Ultimate tensile strength vs. ductility of SPD processed HEAs showing different properties post-HPT and rolling.

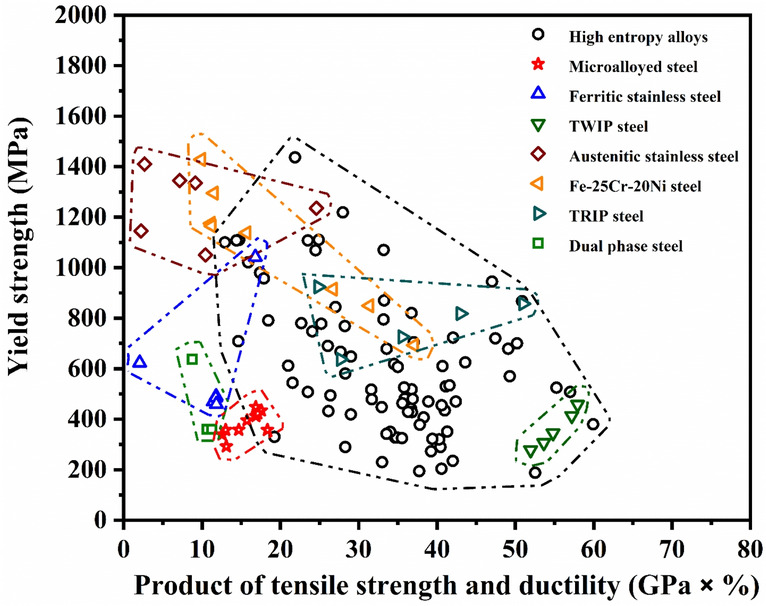

Comparison of HEA Properties with High-Performance Materials Post-RHP

The comparison of tensile mechanical properties at room temperature of HEA with high-performance materials after RHP is presented in Fig. 10201–209. The best strength ductility combination (PSD) of RHPed HEA (maximum PSD of 60 GPa × % FeCoCrNiMn-1 at % C) is in the same range of TWIP steel (PSD: 58 GPa × %)204, TRIP steel (PSD: 51 GPa × %)208. The highest yield strength (YS) values of RHPed HEA (maximum YS: 1437 MPa AlCoCrFeNi2.1) are close to that of Fe-20 Cr-20 Ni steel (YS: 1428 MPa)207, austenitic stainless steel (YS: 1410 MPa)206, etc. The strength–ductility combination for many RHP HEA is also higher compared to micro-alloyed steel (PSD: 18.4 GPa × %)201, dual-phase steel (PSD: 11.2 GPa × %)209, and ferritic stainless steel (PSD: 16.8 GPa × %)203 (Fig. 11). The microstructural evolution in the above-mentioned alloys include precipitations inhibiting grain growth203, twinning204, grain refinement207, etc. The role of various parameters during rolling and heat treatment processes is significant in these high-performance materials also in deciding final strength–ductility combination201. Figure 10 shows compilation of various yield strength and PSD values of the RHPed HEA and their comparison with conventional RHP high-performance materials201–209.

Figure 11:

The comparison of post-rolling and annealing room-temperature tensile properties of high entropy alloys with other high performance.

Summary and Futuristic Approaches

In this review, the role of processing has been emphasized on room-temperature mechanical properties of a wide range of HEAs. The key variables of rolling and heat treatment process (RHP) that can be tuned to enhance the performance of synthesized HEA have been elaborated and debated. The strengthening mechanisms in HEA which operate during the deformation are explained in terms of metamorphosis of the microstructure. These changes are dependent on the nature of phases, working temperature along with SFE of the HEA. Tuning the total strain, strain path, and symmetricity of rolling optimally could impart additional strengthening. Further in the processing, the annealing temperature primarily dictates the microstructure evolution. The optimization of annealing time, heating rate, etc. enhances the strength–ductility synergy further. Following the evaluation of the role of possible parameters in influencing the microstructure evolution and room-temperature tensile properties during RHP in HEA, some futuristic ideas are enlisted below:

The strength–ductility combination can be enhanced to a desirable magnitude by combination of the advantages of multiple RHP domains in terms of temperature and, e.g., combination of cryo-rolling and warm rolling as well as asymmetric and symmetric rolling (hybrid rolling). This combination will enable the generation of hierarchical heterostructures with gradient microstructures which will help to promote the above-mentioned synergy.

Integrated Computational Materials Engineering (ICME) approach could find a solution for predicting processing–property correlation of HEA, by conducting lesser number of experiments. These simulation models can be used for better design of selective experiments to achieve optimal performance of HEA. The better design of experiments will promote energy efficiency and hassle-free methods to scale up the methods.

Microstructure and crystallographic texture simulation studies on HEA can be carried out to enable better maneuvering of microstructure–property correlation.

SPD techniques such as accumulative roll bonding can be performed to develop multilayers which inherently develop hierarchical microstructure (responsible for strength–ductility alliance) owing to the non-uniform strain-induced during the process. Along with developing the above properties and microstructures, the scale up of these processes is highly possible which could be undertaken to compete with the conventional materials in the market.

Acknowledgements

The authors are thankful to the online resources provided by Indian Institute of Technology, Madras in remote mode in the COVID-19 pandemic situation.

Biographies

Mr. Rushikesh Sabban

is a research scholar in Indian Institute of Technology, Madras. He has obtained his MTech (Research) degree from Indian Institute of Science, Bangalore, where he worked in the laboratory of Prof. Satyam Suwas. He works in the area of high entropy alloys, 3D printing of Titanium alloys, and their thermomechanical processing. He has authored research papers and presented his work in conferences. He has been awarded the prestigious Prime Minister Research Fund to pursue Ph.D.

Dr. Khushbu Dash

is a postdoctoral scholar in Indian Institute of Technology, Madras. She works with the group of Prof. B.S. Murty at IIT, Madras. She obtained her Ph.D. from the National Institute of Technology, Rourkela. She has worked with world renowned scientists in Charles University, Prague, and the University of Oxford. Her research interests span from metal matrix composites and their microstructural engineering to texture studies on severely plastically deformed metallic multilayers. She has authored many research papers published in prestigious journals. She has also been awarded national postdoctoral fellowship by SERB. She is a life member of EMSI.

Dr. Satyam Suwas

is a professor and currently the Chair of Materials Engineering at Indian Institute of Science, Bangalore, India. He obtained his Ph.D. in Materials and Metallurgical Engineering from IIT Kanpur and worked at Defence Metallurgical Research Laboratory, Hyderabad; University of Lorraine, France; and RWTH Aachen, Germany, before joining Indian Institute of Science. His specialization includes materials processing, crystallographic texture, and mechanical behaviour of materials. He is the author of more than 300 research papers and has co-authored/co-edited three books. He is a Humboldt fellow and has also been conferred with the Friedrich Wilhelm Bessel Award by the Humboldt foundation, Germany. He was awarded Metallurgist of the year 2012 by Ministry of Steel, Govt. of India, and was conferred eminent engineering personality in the year 2014 by the Institution of Engineers, India, and G D Birla Gold Medal in 2020 by Indian Institute of Metals. He is a fellow of EMSI, INAE, and NASI.

Prof. B.S. Murty

is the Director of IIT Hyderabad from August 26, 2019. He obtained his Ph.D. (1992) from IISc, Bangalore. He is an Institute Professor and Girija & R. Muralidharan Chair Professor at IIT Madras. He is also an Adjunct Professor at Ryerson University, Toronto, Canada, since 2011 and an associate faculty of school of engineering, University of British Columbia, Kelowna, Canada, since 2016. He has authored about 450 journal publications and 4 books. He has supervised 44 PhDs and 16 PhDs are ongoing. He has completed about 65 sponsored research projects and currently handling about 8 projects and filed 20 patents. He is a recipient of numerous awards including Shanti Swarup Bhatnagar Award (2007), JC Bose Fellowship award (2018-2023), Distinguished Alumnus Award of IISc Bangalore (2020), INAE Outstanding Teacher award (2019), Professor Extraordinarius from University of South Africa (2021), Honorary Doctorate from Deakin University, Australia (2017), Life time Achievement Award of IIT Madras (2016), GD Birla Gold Medal (2015), Eminent Materials Engineer Award (2011), Distinguished Alumnus Award of VNIT (2010), Metallurgist of the Year Award (2004), MRSI Medal (2004), INAE Young Engineer Award (1997), INSA Young Scientist Award (1995), Young Metallurgist Award (1994), and ISCA Young Scientists Award (1992). His is a fellow of TWAS, APAM, ASM, NAE, NA, NASc.

Declarations

Conflict of Interest

Authors declare that they have no potential conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Murty BS, Yeh J-W, Ranganathan S, Bhattacharjee P. High-entropy alloys. Amsterdam: Elsevier; 2019. [Google Scholar]

- 2.Jien-Wei Y. Recent progress in high entropy alloys. Ann Chim Sci Mat. 2006;31(6):633–648. doi: 10.3166/acsm.31.633-648. [DOI] [Google Scholar]

- 3.Yeh JW, Chen YL, Lin SJ, Chen SK. High-entropy alloys–a new era of exploitation. Materials Science Forum: Trans Tech Publ; 2007. pp. 1–9. [Google Scholar]

- 4.Cantor B. Multicomponent and high entropy alloys. Entropy. 2014;16(9):4749–4768. doi: 10.3390/e16094749. [DOI] [Google Scholar]

- 5.Yeh J-W. Alloy design strategies and future trends in high-entropy alloys. Jom. 2013;65(12):1759–1771. doi: 10.1007/s11837-013-0761-6. [DOI] [Google Scholar]

- 6.Tsai K-Y, Tsai M-H, Yeh J-W. Sluggish diffusion in Co–Cr–Fe–Mn–Ni high-entropy alloys. Acta Mater. 2013;61(13):4887–4897. doi: 10.1016/j.actamat.2013.04.058. [DOI] [Google Scholar]

- 7.Ranganathan S. Alloyed pleasures: multimetallic cocktails. Curr Sci. 2003;85(10):1404–1406. [Google Scholar]

- 8.Raman L, Karthick G, Guruvidyathri K, Fabijanic D, Murty SN, Murty BS, Kottada RS. Influence of processing route on the alloying behavior, microstructural evolution and thermal stability of CrMoNbTiW refractory high-entropy alloy. J Mater Res. 2020;35(12):1556–1571. doi: 10.1557/jmr.2020.128. [DOI] [Google Scholar]

- 9.Jalbuena A, Logier J, Nava J, Ravi V, Adil S, Murty BS (2018) Corrosion of High Entropy Alloys in Molten Salts, CORROSION 2018, NACE International

- 10.Fabijanic D, Bhattacharya R, Murty BS (2020) Enhancing the oxidation resistance of AlCrCoNiFe high entropy alloy by introducing nanocrystalline grain structure. In: International conference on nanostructured materials (NANO 2020), Engineers Australia, 2020, p 402

- 11.Miracle DB, Miller JD, Senkov ON, Woodward C, Uchic MD, Tiley J. Exploration and development of high entropy alloys for structural applications. Entropy. 2014;16(1):494–525. doi: 10.3390/e16010494. [DOI] [Google Scholar]

- 12.Gludovatz B, Hohenwarter A, Catoor D, Chang EH, George EP, Ritchie RO. A fracture-resistant high-entropy alloy for cryogenic applications. Science. 2014;345(6201):1153–1158. doi: 10.1126/science.1254581. [DOI] [PubMed] [Google Scholar]

- 13.Yang L, Ge H, Zhang J, Xiong T, Jin Q, Zhou Y, Shao X, Zhang B, Zhu Z, Zheng S. High He-ion irradiation resistance of CrMnFeCoNi high-entropy alloy revealed by comparison study with Ni and 304SS. J Mater Sci Technol. 2019;35(3):300–305. doi: 10.1016/j.jmst.2018.09.050. [DOI] [Google Scholar]

- 14.Edalati P, Floriano R, Mohammadi A, Li Y, Zepon G, Li H-W, Edalati K. Reversible room temperature hydrogen storage in high-entropy alloy TiZrCrMnFeNi. Script Mater. 2020;178:387–390. doi: 10.1016/j.scriptamat.2019.12.009. [DOI] [Google Scholar]

- 15.Todai M, Nagase T, Hori T, Matsugaki A, Sekita A, Nakano T. Novel TiNbTaZrMo high-entropy alloys for metallic biomaterials. Scripta Mater. 2017;129:65–68. doi: 10.1016/j.scriptamat.2016.10.028. [DOI] [Google Scholar]

- 16.He J, Wang H, Huang H, Xu X, Chen M, Wu Y, Liu X, Nieh T, An K, Lu Z. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016;102:187–196. doi: 10.1016/j.actamat.2015.08.076. [DOI] [Google Scholar]

- 17.Karati A, Guruvidyathri K, Hariharan V, Murty BS. Thermal stability of AlCoFeMnNi high-entropy alloy. Script Mater. 2019;162:465–467. doi: 10.1016/j.scriptamat.2018.12.017. [DOI] [Google Scholar]

- 18.Murty BS, Ranganathan S. Novel materials synthesis by mechanical alloying/milling. Int Mater Rev. 1998;43(3):101–141. doi: 10.1179/imr.1998.43.3.101. [DOI] [Google Scholar]

- 19.Varalakshmi S, Kamaraj M, Murty BS. Synthesis and characterization of nanocrystalline AlFeTiCrZnCu high entropy solid solution by mechanical alloying. J Alloy Compd. 2008;460(1–2):253–257. doi: 10.1016/j.jallcom.2007.05.104. [DOI] [Google Scholar]

- 20.Praveen S, Basu J, Kashyap S, Kottada RS. Exceptional resistance to grain growth in nanocrystalline CoCrFeNi high entropy alloy at high homologous temperatures. J Alloy Compd. 2016;662:361–367. doi: 10.1016/j.jallcom.2015.12.020. [DOI] [Google Scholar]

- 21.Vaidya M, Muralikrishna GM, Murty BS. High-entropy alloys by mechanical alloying: a review. J Mater Res. 2019;34(5):664–686. doi: 10.1557/jmr.2019.37. [DOI] [Google Scholar]

- 22.Anupam A, Kottada RS, Kashyap S, Meghwal A, Murty BS, Berndt C, Ang A. Understanding the microstructural evolution of high entropy alloy coatings manufactured by atmospheric plasma spray processing. Appl Surface Sci. 2020;505:144117. doi: 10.1016/j.apsusc.2019.144117. [DOI] [Google Scholar]

- 23.Vikram R, Murty BS, Fabijanic D, Suwas S (2020) Insights into micro-mechanical and texture response of additively manufactured eutectic high entropy alloy (AlCoCrFeNi2. 1). J Alloys Compounds 154034

- 24.Yao Y, Huang Z, Xie P, Lacey SD, Jacob RJ, Xie H, Chen F, Nie A, Pu T, Rehwoldt M. Carbothermal shock synthesis of high-entropy-alloy nanoparticles. Science. 2018;359(6383):1489–1494. doi: 10.1126/science.aan5412. [DOI] [PubMed] [Google Scholar]

- 25.Van Den Avyle JA, Brooks JA, Powell AC. Reducing defects in remelting processes for high-performance alloys. Jom. 1998;50(3):22–25. doi: 10.1007/s11837-998-0374-7. [DOI] [Google Scholar]

- 26.Miner R, Dreshfield R. Effects of fine porosity on the fatigue behavior of a powder metallurgy superalloy. Metall Trans A. 1981;12(2):261. doi: 10.1007/BF02655199. [DOI] [Google Scholar]

- 27.Gong H, Rafi K, Gu H, Ram GJ, Starr T, Stucker B. Influence of defects on mechanical properties of Ti–6Al–4 V components produced by selective laser melting and electron beam melting. Mater Des. 2015;86:545–554. doi: 10.1016/j.matdes.2015.07.147. [DOI] [Google Scholar]

- 28.Chen L, Wei R, Tang K, Zhang J, Jiang F, He L, Sun J. Heavy carbon alloyed FCC-structured high entropy alloy with excellent combination of strength and ductility. Mater Sci Eng A. 2018;716:150–156. doi: 10.1016/j.msea.2018.01.045. [DOI] [Google Scholar]

- 29.Bahl S, Krishnamurthy AS, Suwas S, Chatterjee K. Controlled nanoscale precipitation to enhance the mechanical and biological performances of a metastable β Ti-Nb-Sn alloy for orthopedic applications. Mater Des. 2017;126:226–237. doi: 10.1016/j.matdes.2017.04.014. [DOI] [Google Scholar]

- 30.Kalsar R, Ghosh P, Kundu S, Suwas S (2016) Effects of deformation texture and microstructure on recrystallization and grain growth in Twip steels. In: Proceedings of the 6th international conference on recrystallization and grain growth (ReX&GG 2016), Springer, New York, pp 137–145

- 31.Venkateswarlu K, Murty BS, Chakraborty M. Effect of hot rolling and heat treatment of Al–5Ti–1B master alloy on the grain refining efficiency of aluminium. Mater Sci Eng A. 2001;301(2):180–186. doi: 10.1016/S0921-5093(00)01422-2. [DOI] [Google Scholar]

- 32.Gurao N, Suwas S. Texture evolution and operative mechanisms during large-strain deformation of nanocrystalline nickel. Philos Magn. 2011;91(5):798–817. doi: 10.1080/14786435.2010.530621. [DOI] [Google Scholar]

- 33.Kusakin P, Belyakov A, Haase C, Kaibyshev R, Molodov DA (2014) Microstructure evolution and strengthening mechanisms of Fe–23Mn–0.3 C–1.5 Al TWIP steel during cold rolling. Mater Sci Eng A 617:52–60

- 34.An X, Wu S, Zhang Z, Figueiredo R, Gao N, Langdon T. Enhanced strength–ductility synergy in nanostructured Cu and Cu–Al alloys processed by high-pressure torsion and subsequent annealing. Script Mater. 2012;66(5):227–230. doi: 10.1016/j.scriptamat.2011.10.043. [DOI] [Google Scholar]

- 35.Wani I, Sathiaraj GD, Ahmed M, Reddy S, Bhattacharjee PP (2016) Evolution of microstructure and texture during thermo-mechanical processing of a two phase Al0. 5CoCrFeMnNi high entropy alloy. Mater Char 118:417–424

- 36.Sathiaraj G, Bhattacharjee PP. Effect of starting grain size on the evolution of microstructure and texture during thermo-mechanical processing of CoCrFeMnNi high entropy alloy. J Alloy Compd. 2015;647:82–96. doi: 10.1016/j.jallcom.2015.06.009. [DOI] [Google Scholar]

- 37.Stepanov N, Tikhonovsky M, Yurchenko N, Zyabkin D, Klimova M, Zherebtsov S, Efimov A, Salishchev G. Effect of cryo-deformation on structure and properties of CoCrFeNiMn high-entropy alloy. Intermetallics. 2015;59:8–17. doi: 10.1016/j.intermet.2014.12.004. [DOI] [Google Scholar]

- 38.Sathiaraj GD, Bhattacharjee PP. Effect of cold-rolling strain on the evolution of annealing texture of equiatomic CoCrFeMnNi high entropy alloy. Mater Charact. 2015;109:189–197. doi: 10.1016/j.matchar.2015.09.027. [DOI] [Google Scholar]

- 39.Eleti RR, Bhattacharjee T, Zhao L, Bhattacharjee PP, Tsuji N. Hot deformation behavior of CoCrFeMnNi FCC high entropy alloy. Mater Chem Phys. 2018;210:176–186. doi: 10.1016/j.matchemphys.2017.06.062. [DOI] [Google Scholar]

- 40.Zherebtsov S, Yurchenko N, Shaysultanov D, Tikhonovsky M, Salishchev G, Stepanov N (2020) Microstructure and mechanical properties evolution in HfNbTaTiZr refractory high‐entropy alloy during cold rolling. Adv Eng Mater 2000105 [DOI] [PMC free article] [PubMed]

- 41.Patel A, Wani I, Reddy S, Narayanaswamy S, Lozinko A, Saha R, Guo S, Bhattacharjee PP (2018) Strain-path controlled microstructure, texture and hardness evolution in cryo-deformed AlCoCrFeNi2. 1 eutectic high entropy alloy. Intermetallics 97:12–21

- 42.Han Z, Liang S, Yang J, Wei R, Zhang C. A superior combination of strength–ductility in CoCrFeNiMn high-entropy alloy induced by asymmetric rolling and subsequent annealing treatment. Mater Charact. 2018;145:619–626. doi: 10.1016/j.matchar.2018.09.029. [DOI] [Google Scholar]

- 43.Guo T, Li J, Wang J, Wang WY, Liu Y, Luo X, Kou H, Beaugnon E (2018) Microstructure and properties of bulk Al0. 5CoCrFeNi high-entropy alloy by cold rolling and subsequent annealing. Mater Sci Eng A 729:141–148

- 44.Tsai C-W, Chen Y-L, Tsai M-H, Yeh J-W, Shun T-T, Chen S-K (2009) Deformation and annealing behaviors of high-entropy alloy Al0. 5CoCrCuFeNi. J Alloys Compounds 486(1–2):427–435

- 45.Sathiaraj G, Tsai C, Yeh J, Jahazi M, Bhattacharjee PP. The effect of heating rate on microstructure and texture formation during annealing of heavily cold-rolled equiatomic CoCrFeMnNi high entropy alloy. J Alloy Compd. 2016;688:752–761. doi: 10.1016/j.jallcom.2016.07.155. [DOI] [Google Scholar]

- 46.George EP, Curtin W, Tasan CC. High entropy alloys: a focused review of mechanical properties and deformation mechanisms. Acta Mater. 2020;188:435–474. doi: 10.1016/j.actamat.2019.12.015. [DOI] [Google Scholar]

- 47.Diao H, Feng R, Dahmen K, Liaw P. Fundamental deformation behavior in high-entropy alloys: an overview. Curr Opin Solid State Mater Sci. 2017;21(5):252–266. doi: 10.1016/j.cossms.2017.08.003. [DOI] [Google Scholar]

- 48.Hou J, Zhang M, Ma S, Liaw PK, Zhang Y, Qiao J (2017) Strengthening in Al0. 25CoCrFeNi high-entropy alloys by cold rolling. Mater Sci Eng A 707:593–601

- 49.Sunkari U, Reddy S, Rathod B, Kumar SS, Saha R, Chatterjee S, Bhattacharjee P (2020) Heterogeneous precipitation mediated heterogeneous nanostructure enhances strength–ductility synergy in severely cryo-rolled and annealed CoCrFeNi 2.1 Nb 0.2 high entropy alloy. Sci Rep 10(1):1–9. [DOI] [PMC free article] [PubMed]

- 50.He Y, Yang H, Zhao C, Zhang Y, Pan X, Li J, Wang J (2020) Enhancing mechanical properties of Al0. 25CoCrFeNi high-entropy alloy via cold rolling and subsequent annealing, J Alloys Compounds 154645

- 51.Li Z, Fu L, Peng J, Zheng H, Shan A (2020) Effect of annealing on microstructure and mechanical properties of an ultrafine-structured Al-containing FeCoCrNiMn high-entropy alloy produced by severe cold rolling. Mater Sci Eng A 139446

- 52.Hou J, Wang Z, Shi X, Wang Z, Qiao J, Wu Y () Strengthening of an Al 0.45 CoCrFeNi high-entropy alloy via in situ fabricated duplex-structured composites. J Mater Sci 1–16

- 53.Reddy S, Yoshida S, Bhattacharjee T, Sake N, Lozinko A, Guo S, Bhattacharjee P, Tsuji N. Nanostructuring with structural-compositional dual heterogeneities enhances strength–ductility synergy in eutectic high entropy alloy. Sci Rep. 2019;9(1):1–9. doi: 10.1038/s41598-019-47983-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 54.Chen L, Cao T, Wei R, Tang K, Xin C, Jiang F, Sun J (2020) Gradient structure design to strengthen carbon interstitial Fe40Mn40Co10Cr10 high entropy alloys. Mater Sci Eng A 772:138661

- 55.Reddy S, Sunkari U, Lozinko A, Saha R, Guo S, Bhattacharjee P (2019) Microstructural design by severe warm-rolling for tuning mechanical properties of AlCoCrFeNi2. 1 eutectic high entropy alloy. Intermetallics 114:106601

- 56.Mehranpour MS, Shahmir H, Nili-ahmadabadi M (2020) Microstructure and excess free volume of severely cold shape rolled CoCrFeNiMn high entropy alloy. J Alloys Compounds 155672

- 57.Liu Y, Tu J, Tang Y, Zhu H, Huang C, Zhang Y-B, Tan L, Zhou Z-M (2020) Deformation substructural evolution in transformation-induced plasticity high-entropy alloy during cold rolling. Mater Lett 127885

- 58.Wang M, Li Z, Raabe D. In-situ SEM observation of phase transformation and twinning mechanisms in an interstitial high-entropy alloy. Acta Mater. 2018;147:236–246. doi: 10.1016/j.actamat.2018.01.036. [DOI] [Google Scholar]

- 59.Reddy T, Wani I, Bhattacharjee T, Reddy S, Saha R, Bhattacharjee PP (2017) Severe plastic deformation driven nanostructure and phase evolution in a Al0. 5CoCrFeMnNi dual phase high entropy alloy. Intermetallics 91:150–157

- 60.Sunkari U, Reddy S, Rathod B, Kumar D, Saha R, Chatterjee S, Bhattacharjee P (2020) Tuning nanostructure using thermo-mechanical processing for enhancing mechanical properties of complex intermetallic containing CoCrFeNi2. 1Nbx high entropy alloys. Mater Sci Eng A 769:138489

- 61.Stepanov N, Shaysultanov D, Chernichenko R, Ikornikov D, Sanin V, Zherebtsov S. Mechanical properties of a new high entropy alloy with a duplex ultra-fine grained structure. Mater Sci Eng A. 2018;728:54–62. doi: 10.1016/j.msea.2018.04.118. [DOI] [Google Scholar]

- 62.S. Zherebtsov, N. Yurchenko, E. Panina, A. Tojibaev, M. Tikhonovsky, G. Salishchev, N. Stepanov, Microband-induced plasticity in a Ti-rich high-entropy alloy. J Alloys Compds (2020) 155868.

- 63.Li Q, Zhang T, Qiao J, Ma S, Zhao D, Lu P, Wang Z. Mechanical properties and deformation behavior of dual-phase Al0. 6CoCrFeNi high-entropy alloys with heterogeneous structure at room and cryogenic temperatures. J Alloys Compds. 2020;816:152663. doi: 10.1016/j.jallcom.2019.152663. [DOI] [Google Scholar]

- 64.Li Z, Tasan CC, Pradeep KG, Raabe D. A TRIP-assisted dual-phase high-entropy alloy: grain size and phase fraction effects on deformation behavior. Acta Mater. 2017;131:323–335. doi: 10.1016/j.actamat.2017.03.069. [DOI] [Google Scholar]

- 65.Wani I, Bhattacharjee T, Sheikh S, Bhattacharjee PP, Guo S, Tsuji N. Tailoring nanostructures and mechanical properties of AlCoCrFeNi2. 1 eutectic high entropy alloy using thermo-mechanical processing. Mater Sci Eng A. 2016;675:99–109. doi: 10.1016/j.msea.2016.08.048. [DOI] [Google Scholar]

- 66.Singh A, Basha D, Matsushita Y, Tsuchiya K, Lu Z, Nieh T-G, Mukai T. Domain structure and lattice effects in a severely plastically deformed CoCrFeMnNi high entropy alloy. J Alloys Compd. 2020;812:152028. doi: 10.1016/j.jallcom.2019.152028. [DOI] [Google Scholar]

- 67.Peng J, Li Z, Fu L, Ji X, Pang Z, Shan A. Carbide precipitation strengthening in fine-grained carbon-doped FeCoCrNiMn high entropy alloy. J Alloy Compd. 2019;803:491–498. doi: 10.1016/j.jallcom.2019.06.204. [DOI] [Google Scholar]

- 68.Zhou W, Fu L, Liu P, Xu X, Chen B, Zhu G, Wang X, Shan A, Chen M. Deformation stimulated precipitation of a single-phase CoCrFeMnNi high entropy alloy. Intermetallics. 2017;85:90–97. doi: 10.1016/j.intermet.2017.02.010. [DOI] [Google Scholar]

- 69.Li L, Li Z (2020) Aging induced segregation and nanoprecipitation in a severely deformed equiatomic high-entropy alloy. Mater Char 110369

- 70.Xiong F, Fu R, Li Y, Xu B, Qi X (2020) Influences of nitrogen alloying on microstructural evolution and tensile properties of CoCrFeMnNi high-entropy alloy treated by cold-rolling and subsequent annealing. Mater Sci Eng A 139472

- 71.Wu W, Guo L, Guo B, Liu Y, Song M. Altered microstructural evolution and mechanical properties of CoCrFeNiMo0. 15 high-entropy alloy by cryogenic rolling. Mater Sci Eng A. 2019;759:574–582. doi: 10.1016/j.msea.2019.05.078. [DOI] [Google Scholar]

- 72.Santos LA, Singh S, Rollett AD. Microstructure and texture evolution during thermomechanical processing of Al 0.25 CoCrFeNi high-entropy alloy. Metall Mater Trans A. 2019;50(11):5433–5444. doi: 10.1007/s11661-019-05399-3. [DOI] [Google Scholar]

- 73.Su J, Raabe D, Li Z. Hierarchical microstructure design to tune the mechanical behavior of an interstitial TRIP-TWIP high-entropy alloy. Acta Mater. 2019;163:40–54. doi: 10.1016/j.actamat.2018.10.017. [DOI] [Google Scholar]

- 74.Okamoto NL, Fujimoto S, Kambara Y, Kawamura M, Chen ZM, Matsunoshita H, Tanaka K, Inui H, George EP. Size effect, critical resolved shear stress, stacking fault energy, and solid solution strengthening in the CrMnFeCoNi high-entropy alloy. Sci Rep. 2016;6:35863. doi: 10.1038/srep35863. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 75.Gwalani B, Gorsse S, Choudhuri D, Styles M, Zheng Y, Mishra RS, Banerjee R. Modifying transformation pathways in high entropy alloys or complex concentrated alloys via thermo-mechanical processing. Acta Mater. 2018;153:169–185. doi: 10.1016/j.actamat.2018.05.009. [DOI] [Google Scholar]

- 76.Zhang Y, Tao N, Lu K. Effect of stacking-fault energy on deformation twin thickness in Cu–Al alloys. Scripta Mater. 2009;60(4):211–213. doi: 10.1016/j.scriptamat.2008.10.005. [DOI] [Google Scholar]

- 77.Deng Y, Tasan CC, Pradeep KG, Springer H, Kostka A, Raabe D. Design of a twinning-induced plasticity high entropy alloy. Acta Mater. 2015;94:124–133. doi: 10.1016/j.actamat.2015.04.014. [DOI] [Google Scholar]

- 78.Shen Y, Lu L, Lu Q, Jin Z, Lu K. Tensile properties of copper with nano-scale twins. Scripta Mater. 2005;52(10):989–994. doi: 10.1016/j.scriptamat.2005.01.033. [DOI] [Google Scholar]

- 79.Guo L, Ou X, Ni S, Liu Y, Song M. Effects of carbon on the microstructures and mechanical properties of FeCoCrNiMn high entropy alloys. Mater Sci Eng A. 2019;746:356–362. doi: 10.1016/j.msea.2019.01.050. [DOI] [Google Scholar]

- 80.Moravcik I, Hadraba H, Li L, Dlouhy I, Raabe D, Li Z. Yield strength increase of a CoCrNi medium entropy alloy by interstitial nitrogen doping at maintained ductility. Scripta Mater. 2020;178:391–397. doi: 10.1016/j.scriptamat.2019.12.007. [DOI] [Google Scholar]

- 81.Yurchenko NY, Panina E, Zherebtsov S, Tikhonovsky M, Salishchev G, Stepanov N. Microstructure evolution of a novel low-density Ti–Cr–Nb–V refractory high entropy alloy during cold rolling and subsequent annealing. Mater Charact. 2019;158:109980. doi: 10.1016/j.matchar.2019.109980. [DOI] [Google Scholar]