Abstract

Biopolymers are natural polymers sourced from plants and animals, which include a variety of polysaccharides and polypeptides. The inclusion of biopolymers into biomedical hydrogels is of great interest due to their inherent biochemical and biophysical properties, such as cellular adhesion, degradation, and viscoelasticity. The objective of this review is to provide a detailed overview of the design and development of biopolymer hydrogels for biomedical applications, with an emphasis on biopolymer chemical modifications and crosslinking methods. First, the fundamentals of biopolymers and chemical conjugation methods to introduce crosslinking groups are described. Crosslinking methods to form biopolymer networks are then discussed in detail, including i) covalent crosslinking (e.g., free radical chain polymerization, click crosslinking, crosslinking due to oxidation of phenolic groups), ii) dynamic covalent crosslinking (e.g., Schiff base formation, disulfide formation, reversible Diels-Alder reactions), and iii) physical crosslinking (e.g., guest-host interactions, hydrogen bonding, metal-ligand coordination, grafted biopolymers). Finally, recent advances in the use of chemically-modified biopolymer hydrogels for the biofabrication of tissue scaffolds, therapeutic delivery, tissue adhesives and sealants, as well as the formation of interpenetrating network biopolymer hydrogels, are highlighted.

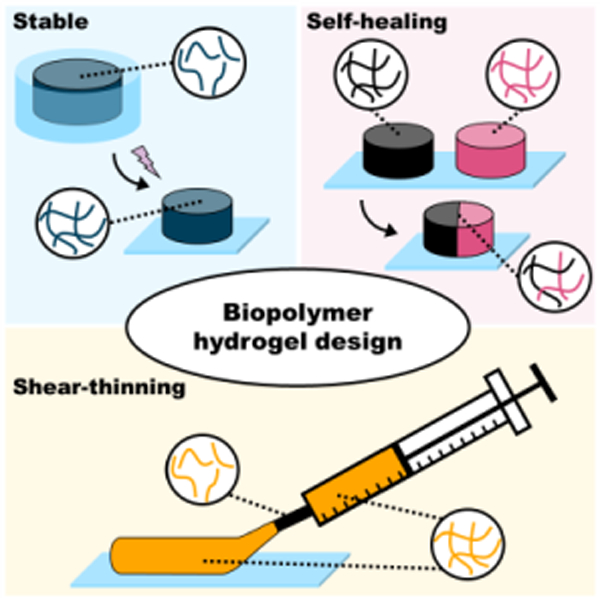

Graphical Abstract

1. Introduction

Hydrogels are water-swollen polymer networks that have great utility for biomedical applications.1 Hydrogels can mimic features of many tissues, and there have been great advances in the tailoring of hydrogel properties (e.g., mechanics, degradation) for widespread biomedical applications. Many important advances have been made with the use of synthetic polymers to construct hydrogels due to precise control over chemical structures, low batch variability, and ease of sourcing.2 However, recent trends have included the fabrication of hydrogels from biological molecules, such as biopolymers, to introduce specific inherent biofunctionality to hydrogels.3

Biopolymers are natural polymers that are sourced from animals and plants, including a wide range of polysaccharides (e.g., sugars) and polypeptides (e.g., proteins). Representative examples of polysaccharides include hyaluronic acid, chondroitin sulfate, heparin, dextran, alginate, cellulose, chitin, and chitosan. Representative examples of polypeptides include gelatin, silk fibroin, albumin, elastin, keratin, and unique polypeptides engineered for specific functionality. The selection of specific polysaccharides or polypeptides introduces inherent properties to hydrogels, such as cell adhesion and degradability.

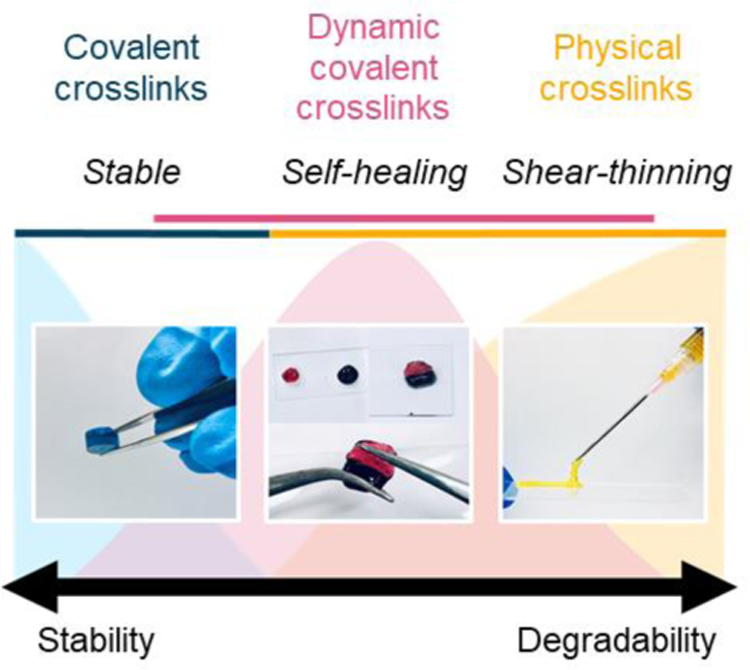

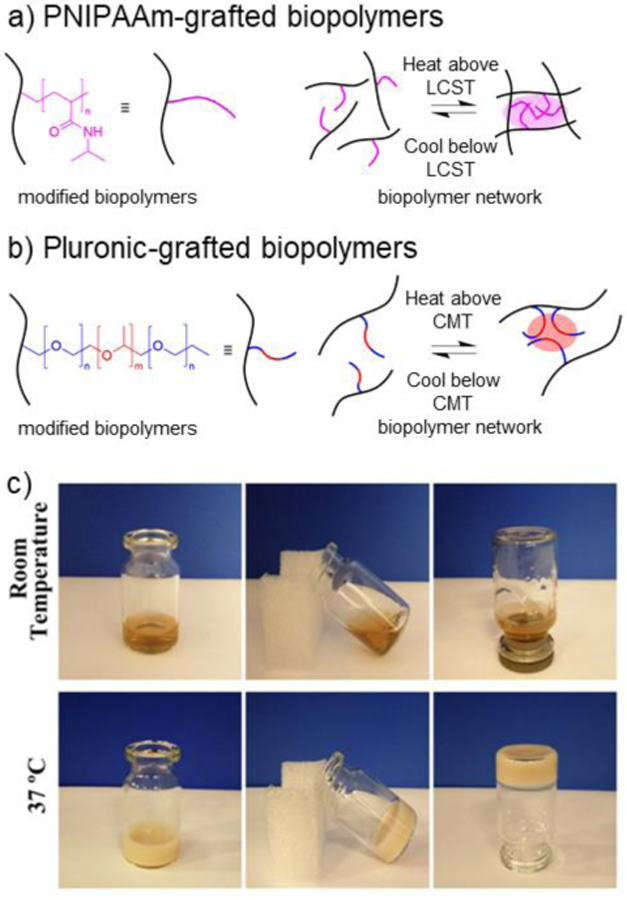

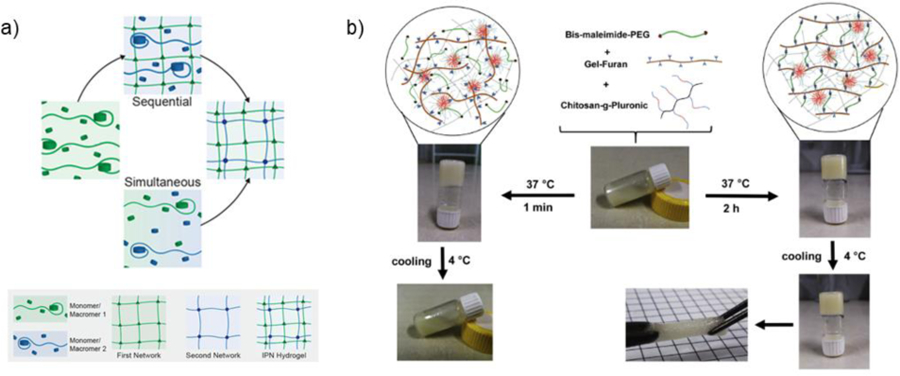

It is often necessary to chemically modify biopolymers to facilitate hydrogel formation. These modifications are performed on various chemical groups within the biopolymer repeat units (e.g., amines, hydroxyl groups, carboxylic acids) to allow for diverse methods of crosslinking (e.g., mixing, light, redox, thermal). The mechanical properties of formed hydrogels are generally driven by the extent of biopolymer modification, the degree of crosslinking, the biopolymer concentration, and the type of crosslinking chemistry used. If a very stable hydrogel is desired, chemical groups that permit covalent crosslinking (e.g., free radical chain polymerization, click reactions) are often used (Figure 1). However, dynamic covalent crosslinking (e.g., Schiff base, disulfides) can also be implemented to combine hydrogel stability with features such as self-healing behavior (Figure 1). If a less-stable hydrogel is desired, physical crosslinking (e.g., hydrogen bonding, metal-ligand coordination) is typically used, which exhibits properties such as shear-thinning and disassembly over time (Figure 1). Various biopolymer networks can also be combined (e.g., interpenetrating networks) to further vary hydrogel properties to match the needs of specific applications.

Figure 1. General hydrogel properties as a function of crosslink type.

Schematic illustrating representative images of hydrogels formed from different crosslinking mechanisms (i.e., covalent [blue], dynamic covalent [pink], physical [yellow]).

The overall objective of this review is to provide the reader with an introduction to the use of biopolymers for the formation of biomedical hydrogels, with an emphasis on chemical modifications that facilitate hydrogel formation and control over hydrogel properties. There is great diversity in the modifications and resulting hydrogels properties, which is a strength to the use of biopolymers in hydrogel formation. Furthermore, specific examples of where biopolymer-based hydrogels are being used in biomedical applications of tissue engineering, biofabrication, and drug delivery are introduced, particularly where the use of a biopolymer and chemical modification was important to the hydrogel function.

2. Overview of biopolymers

Biopolymers are natural polymers that are derived from animals and plants. Biopolymers used for hydrogel formation generally fall into two classes of molecules: polysaccharides and polypeptides. Their repeat units consist of sugars or peptides, which guide the various biopolymer properties. Biopolymers inherently incorporate features that may be attractive in their use as biomaterials, including chemical compositions for cell interactions and degradation. Biopolymer hydrogels can be formed by polymer entanglement due to high molecular weight or high polymer concentration, by assembly (e.g., charge) due to the specific functionality of certain biopolymers, or by inter-polymer crosslinking due to chemical modifications of the biopolymer. In this section, we discuss the various biopolymers that are often chemically modified for hydrogel formation in the biomaterials field, including their general properties (e.g., molecular weight, adhesion to cells, degradability) and past use in commercial products.

2.1. Polysaccharides

Polysaccharides consist of monosaccharide or disaccharide repeat units and have important structural and biological functionality in living organisms (Table 1). For biomaterial applications, polysaccharides are often isolated from renewable sources such as plants and microorganisms. They may also be sourced from animal byproducts in the meat and fish industries. Many polysaccharides have been chemically modified to obtain natural hydrogels with a wide range of mechanical and biological properties.

Table 1. Polysaccharide-based biopolymers.

Representative chemical structures, function, and sources of various polysaccharide biopolymers that have been modified to form biomedical hydrogels.

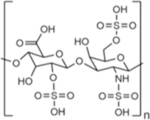

| Polysaccharides | ||||

|---|---|---|---|---|

| Name | Hyaluronic Acid (HA) | Chondroitin Sulfate (CS) | Heparin Sulfate (HS) | Dextran |

| Chemical structure |

|

|

|

|

| Type | Linear GAG | Linear GAG | Linear GAG | Branched |

| Native function | Major component of ECM in human connective tissue | Major component of ECM in human connective tissue | Stored in mast cells in humans and secreted into vasculature upon injury | Component of some bacterial ECM |

| Source for biomedical applications | Bacterial culture; rooster comb19 | Animal sources (e.g., bovine trachea, porcine nasal septa)29 | Animal sources (e.g., porcine intestines)34 | Bacterial culture39 |

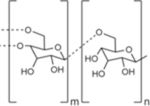

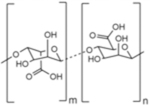

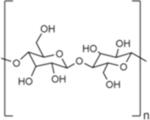

| Name | Alginate | Cellulose | Chitin | Chitosan |

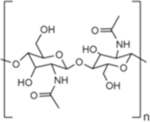

| Chemical structure |

|

|

|

|

| Type | Linear | Linear | Linear | Linear |

| Native function | Structural support in seaweed | Structural support in plant cell walls; component in some bacterial ECM | Structural support in insect and crustacean exoskeletons | n/a |

| Source for biomedical applications | Brown algae42 | Bacterial culture49 | Shrimp and crab shells from food industry waste products56 | Deacetylated derivative of chitin57 |

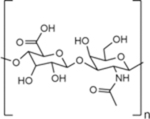

2.1.1. Hyaluronic acid

Hyaluronic acid (HA) is a linear glycosaminoglycan (GAG) consisting of alternating D-glucuronic acid and N-acetyl-D-glucosamine repeat units that are linked together by alternating β-1,4 and β-1,3 glycosidic bonds.4,5 HA is a native component of the extracellular matrix (ECM) and is found throughout multiple tissues in the body, including cartilage, muscle, skin, and vocal folds.6,7 In its naturally occurring state, the size of HA can range from ~100 kDa in serum to ~8000 kDa in vitreous fluid.8 Through its structure and chemical properties, HA influences the mechanical and biological functionality of native tissues, as well as cellular responses in wound healing.9 HA is very hydrophilic, and one of its major roles is the maintenance of viscoelasticity and low-friction tissue interfaces, such as in synovial and vitreous fluids.5,10 Cells bind to HA through surface receptors such as the glycoprotein CD44.11 HA-CD44 binding interactions are very important in many cellular processes, such as chondrocyte proliferation and matrix production in cartilage tissue.12 HA can be degraded by oxidative species or enzymes such as hyaluronidase, glucuronidase, and hexosaminidase.5

Since the 1960s, HA has been utilized for many clinical applications including dermal fillers for soft-tissue augmentation,13–15 wound dressings,16 and intra-articular injections to manage symptoms of osteoarthritis.17 For research and clinical use, HA is either derived from streptococcal fermentation cultures or from animal sources, such as rooster combs.18,19 Unmodified HA can be crosslinked with 1,4-butanediol diglycidal ether (BDDE) or divinyl sulfone (DVS), either loosely to increase HA solution viscosity or more extensively to increase the mechanical integrity of HA hydrogels.13 To increase the diversity in properties of HA hydrogels for biomedical applications, a range of chemical modifications have been introduced to HA.4,20

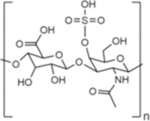

2.1.2. Chondroitin sulfate

Chondroitin sulfate (CS) is a linear sulfated GAG consisting of ~40–100 repeat units of alternating β-1,3-linked-N-acetyl-galactosamine and β-1,4-linked-glucuronic acid sugar residues.21 CS is the main GAG found in aggrecan, a proteoglycan (PG) consisting of a protein core with GAG side chains.22 Aggrecan, and thus CS, plays an important role in cartilage mechanics by influencing tissue hydration, swelling, and lubrication.23 CS and PGs in general also play an important role in injury and disease recovery in the central nervous system.24 PGs formed with CS interact with ECM and cell adhesion molecules.25 CS can be degraded by enzymes such as chondroitinase ABC.26 Clinically, CS has been delivered orally for management of pain in knee and hip osteoarthritis, as CS stimulates PG synthesis in the joint space, as well as exhibits anti-inflammatory properties.27,28 For use in biomedical applications, CS is isolated from animal sources including bovine trachea, chicken keel, shark fins, and pig nasal septa.29

2.1.3. Heparin

Heparin is a linear GAG consisting of repeat units of uronic acid and D-glucosamine that are linked together by β-1,4 glycosidic bonds.30 Heparin is found on the cell surface and in the ECM, and is known to play essential roles in tissue development, angiogenesis, and anticoagulation.31 Heparin and heparan sulfate (HS), a sulfated derivative of heparin polysaccharides, interact with proteins to form PG coatings around cells,31 which enable cells to interact with many signaling molecules.31 Heparin binds to many biomolecules such as growth factors, cytokines, and adhesion proteins, including fibronectin.32 The molecular weight of naturally occurring heparin can range from 5 to 1000 kDa.30 Endothelial cells and macrophages preferentially bind to higher molecular weight heparin.33 Enzymes such as heparinase can degrade heparin and HS, which is important in ECM maintenance and remodeling.32

Clinically, heparin is used as a blood thinner to prevent the formation of blood clots. Heparin is one of only a few clinically approved polysaccharide drugs, and it is one of the oldest drugs still in clinical use.34 The World Health Organization (WHO) identifies heparin as one of the world’s Essential Medicines.35 For biomedical use, heparin is isolated from animal sources, most often porcine intestine.34 Heparin is often classified as either unfractionated heparin (UFH) or purified low molecular weight heparin (LMWH). As an anticoagulant, clinical use has shifted from UFH to LMWH for increased efficacy, as higher molecular weight heparin can adhere to endothelial cells and macrophages, and impede their anticoagulant ability.33 As a tissue engineering scaffold, higher molecular weight heparin may be of interest due to its increased affinity for endothelial cell adhesion.

2.1.4. Dextran

Dextran is a highly branched polysaccharide consisting of α-1,6-linked-glucose monomers and α-1,3 branching.36 Dextran is a major component of bacterial ECM, allowing for surface adhesion and biofilm formation.37 Dextran has been extensively researched in the dental field, as streptococci bacteria secrete dextran to form gelatinous plaques on teeth.38 Dextran can vary from molecular weights of ~10–150 kDa and ~5–30% degree of branching, depending on the bacteria and purification process used.36,39 Most dextran in commercial use is produced from Leuconostoc mesenteroides bacteria with ~5% degree of branching.39 Dextran can be degraded enzymatically by dextranase.40

Due to the ease of manufacturing and its biocompatibility, dextran has been widely used in many industries. Clinically, dextran is used as an antithrombotic agent to decrease vascular thrombosis by binding to erythrocytes, platelets, and vascular endothelium to reduce aggregation and make clots more easy to lyse.36 Dextran is also used as a lubricant in eye drops and as an additive in intravenous fluids to solubilize other factors.36 The clinical grades of dextran most often used include Dex-40 (40 kDa MW) and Dex-70 (70 kDa MW). The WHO includes Dex-70 on its List of Essential Medicines.35 In addition to its uses in medicine, dextran is extensively used in food and cosmetic products, as well as in waste water treatment processes.36 Due to the widespread availability and history of success in clinical use, dextran is a promising material for tissue engineering.

2.1.5. Alginate

Alginate is a linear polysaccharide consisting of repeat units of 1,4-linked β-D-mannuronic acid (M) and α-L-guluronic acid (G) residues.41 Alginate is found in the cell walls of brown algae (Phaeophysceae), providing a flexible mechanical structure to protect seaweed from damage due to strong water motion.42 Alginate rapidly crosslinks in the presence of divalent cations (e.g., Ca2+) due to ionic interactions with G residues. This ionic crosslinking mechanism has been used as a method to encapsulate biomolecules and cells for decades. For biomedical applications, alginate is frequently explored due to its biocompatible ionic gelation mechanisms, as well as its low cost and low toxicity.43

Purified alginate can be derived from brown algae cell walls as well as some bacterial strains, though commercially available alginate is derived exclusively from algal sources.44 Alginate is available across a range of molecular weights from ~30–400 kDa.43 Alginate has been used in many products for clinical applications, including reduction of gastrointestinal reflux, accelerated wound healing, and defect filling in musculoskeletal tissues.44 In addition to biomedical applications, alginate has been extensively used in the food industry as a thickening and gelation additive, colloid stabilizer, and sausage casing material.45

2.1.6. Cellulose

Cellulose is a linear polysaccharide consisting of repeating D-glucose units linked together by β-1,4 glycosidic bonds.46 Cellulose is considered to be the most abundant organic polymer on Earth.47 In plants, cellulose is a major component of the cell wall, where it forms strong microfibril crystal structures, leading to impressive mechanical properties.48 Cellulose derived from plant sources is used extensively for the production of paper, lumber, and cotton textiles.48 For biomedical applications, cellulose is typically derived from bacterial sources.49 Some bacteria produce cellulose to form flocs and create a mechanically robust microenvironment.48 Microbial-derived cellulose has been used in therapies for burns and ulcers, as well as in dental implants.49 Cellulose is also commonly utilized as an emulsion stabilizer in cosmetic and food products.49 Water-soluble derivatives of cellulose are manufactured by etherification reactions for use in food and medical industries.50 The most common cellulose derivatives used in hydrogel formation are carboxymethyl cellulose (CMC) and hydroxypropyl cellulose (HPC).50,51

2.1.7. Chitin and Chitosan

Chitin is a linear polysaccharide with similar structure to cellulose, except the hydroxyl group is replaced with an acetamide group, resulting in N-acetyl-D-glucosamine repeat units.52 Like cellulose, chitin monomers are linked by β-1,4 glycosidic bonds. The acetamide group allows for increased hydrogen bonding, resulting in increased strength in the chitin fibrillar matrix when compared to cellulose alone. Chitin is the primary component of exoskeletons of crustaceans and insects, and it is also found in fish scales, fungi cell walls, and cephalopod beaks.53 Behind cellulose, chitin is the second most abundant natural biopolymer on Earth.54 For biomedical applications, chitin is mostly sourced from shrimp and crab shells, which are waste products of the food industry.55,56 In its native form, chitin is hydrophobic, which can be utilized to form hard materials for tissue engineering applications.54 The electrical properties of chitin have also been explored for biomedical materials that benefit from electrical conductance.54 For hydrogel formation, water-soluble derivatives of chitin are often used.

Chitosan is produced by either chemical or enzymatic deacetylation of chitin isolated from crustaceans.57 It consists of glucosamine and N-acetyl-D-glucosamine repeat units.58 The degradation rate and hydrophilicity of chitosan is influenced by the degree of deacetylation, which may range from 30–95%.58 Lysozyme is the main enzyme that degrades chitosan in humans.58 Clinically, chitosan has been used in chitosan-based hemostatic dressings,59 as well as explored for use as a vaccine adjuvant.60

2.2. Polypeptides

Polypeptides are biopolymers consisting of amino acid repeat units, which are considered proteins when they consist of more than 50 amino acids (Table 2). Polypeptide- and protein-based hydrogels are of great interest in biomedical applications due to their potential to incorporate numerous cell interaction sites and to mimic native functions of the ECM. Polypeptides may be isolated from human, animal, or plant sources, or synthetically engineered using recombinant protein production or peptide synthesizers. The precision and diversity in polypeptide materials are attractive for many biomedical applications.

Table 2. Polypeptide-based biopolymers.

Representative structures, function, and sources of various polypeptide biopolymers that have been modified to form biomedical hydrogels.

| Polypeptides | |||||

|---|---|---|---|---|---|

| Name | Gelatin | Silk Fibroin | Albumin | Elastin | Keratin |

| Structure |

|

|

|

|

|

| Contains RGD motif for cell adhesion | Contains sequences that form crystalline β-sheets | Heart shaped, globular protein | Contains hydrophobic domains (i.e., VPGXG) for mechanical resilience | Contains high cysteine content for disulfide bond formation | |

| Native function | Denatured derivative of collagen (structural component of mammalian ECM) | Structural component of silk fibers produced by some arthropods | Modulates fluid distribution and provides oncotic pressure in blood plasma | Responsible for recoiling response when stress is applied in vertebrate connective tissue | Structural and protective component of hard tissues such as skin, hair, nails, horns, wool, feathers, and hooves |

| Source for biomedical applications | Animal sources (e.g., porcine skin)63 | Bombyx mori (silkworm)73 | Human (HSA) or bovine (BSA) blood plasma82 | Human donors or animal sources (e.g., bovine, murine)91 | Human hair,98 animal sources (e.g., feathers, wool)99,100 |

2.2.1. Gelatin

Gelatin is a hydrolyzed and denatured form of collagen, which is the main structural protein in mammalian connective tissue ECM.61 Collagen is the most abundant protein in mammals, making up 25–35% of the total protein content.61 To produce gelatin, collagen proteins are extracted from the skin and bones of animal sources (most often porcine skin) by acid or alkaline treatments, followed by a thermal-driven process of protein separation.62,63 Due to the heterogeneity in animal sources and gelatin isolation methods, the molecular weight of commercially available clinical-grade gelatin can range from ~103-106 Da.64 Much of the triple-helix structure of native collagen is denatured in gelatin production; however, the chemical structure of gelatin remains similar to collagen.63 Gelatin contains Gly-X-Y amino acid repeat sequences, where X is usually proline and Y is usually hydroxyproline.65 Gelatin also contains the RGD sequence (Arg-Gly-Asp), which is a cell adhesion site and binds to integrins.66 Adding gelatin (and thus RGD) to biomaterials has been shown to improve cell integration and tissue repair in many applications.66 In the body, gelatin can be degraded by proteases such as collagenase and metallo-proteases.67

Gelatin has been widely used in many industries, including those related to food, photography, and pharmaceuticals. For example, in food science, gelatin is used as a stabilizer, thickener, texturizer, and emulsifier,68 whereas in photography gelatin is used as a medium for making emulsions.68 In clinical use, gelatin is a major ingredient in hard and soft capsules, as well as tablet preparation,63,68 and gelatin sponges and particles have been widely used as hemostatic agents and to fill cartilage and bone defects.69 Towards tissue engineering, a major advantage to using gelatin is that it has biological functionality (RGD sequence) and thus mimics native ECM functions.70 Crosslinkers such as glutaraldehyde (GTA) and genipin can be used to directly form hydrogels with gelatin.71 To improve mechanical performance and increase the range of possible mechanical properties, gelatin can also be chemically modified with functional groups to undergo hydrogel formation.

2.2.2. Silk fibroin

Silk is produced through a series of proteins found in the glands of some arthropods including silkworms, spiders, scorpions, and bees.72 Silk is composed of two major proteins: silk fibroin, a semi-crystalline protein which provides structural stiffness and strength, and sericin, a glue-like protein that wraps around silk fibroin to hold fibers together.72 In biomedical applications, silk fibroin is of interest due to its excellent mechanical strength, biodegradability, and widespread availability. Silk fibroin consists of semi-crystalline polypeptides that have a heavy chain (MW ~390 kDa) and a light chain (MW ~26 kDa) linked together via a single disulfide bond.72 For clinical applications, silk fibroin is extracted from the Bombyx mori silkworm73 and consists mainly of Gly (43%), Ala (30%), and Ser (12%) amino acids.72 Silk fibroin contains hydrophobic domains that allow for the formation of stable anti-parallel β-sheet crystallites.72

Silk fibroin has been used in the textile industry for thousands of years.74 Towards clinical applications, silk has been used as a suture material for centuries.75,76 FDA-approved silk fibroin-based products include surgical meshes and ligament grafts.76 It has been shown that silk fibroin can be engineered for attachment and growth of human and animal cells.77 In vivo, silk fibroin scaffolds can be degraded by enzymes and hydrolysis,77 and the β-sheet crystalline content can be reduced in silk fibroin scaffolds to increase degradation rates.78 Chemically-modified silk fibroin scaffolds are being widely explored for applications in tissue repair and regeneration.

2.2.3. Albumin

Albumin is an endogenous protein produced mainly by the liver and secreted into the blood plasma.79 Human serum albumin (HSA) is the most abundant protein in blood plasma, accounting for 50–60% of total protein content.80 The primary role of HSA is the regulation of fluid distribution by providing ~80% of the total blood plasma oncotic pressure.81 HSA is a globular protein consisting of 585 amino acids with a molecular weight of 66 kDa.81 As determined by X-ray crystallography, the tertiary structure of HSA is a heart-shaped protein that is stabilized by 17 disulfide bridges formed between amino acids.82 Clinically, HSA has been used as a plasma expander for decades to restore and maintain circulating blood volume in response to trauma, surgery, and blood loss.81,83 HSA can be isolated from human blood plasma by many methods, including plasma fractionation followed by liquid chromatography.82 For biomedical research, albumin may be sourced from human blood plasma; however, bovine serum albumin (BSA) is also being widely explored as a cheaper and more abundant alternative.82

2.2.4. Elastin

Elastic fibers are an important ECM structural component and are responsible for the resilience and elasticity in many vertebrate connective tissues, including skin and cartilage.84,85 Elastic fibers are composed of ~90% elastin protein and a complex microfibrillar structure made of numerous other macromolecules.84 Elastin is composed of tropoelastin precursors that accumulate on the microfibrillar skeleton.86 The half-life of human elastin is around 70 years, making it an extremely durable biopolymer with low turn-over in healthy tissue.87 Elastic fibers can be degraded with disease or age due to proteolytic elastase enzymes.88 Many cell types interact with elastin, including through elastin receptors and integrins.84 Elastin is insoluble in water due to the presence of multiple hydrophobic domains; however, for hydrogel formation, water-soluble elastin-based materials have been explored.84

Various elastin formulations have been developed that include α-Elastin, a water-soluble elastin derivative that has been solubilized with oxalic acid,89 and tropoelastin, which is water soluble at low temperatures.90 Elastin-containing materials may be isolated from animal sources or human cadavers and processed into water-soluble derivatives for hydrogel formation.91 Using synthetic protein engineering, Elastin-like polypeptides (ELPs) have also been engineered for biomedical applications.92 ELPs contain the hydrophobic motif Val-Pro-Gly-X-Gly (VPGXG), where X is any amino acid except for Pro.93 VPGXG is one of the main hydrophobic motifs present in natural elastin that contributes to its unique mechanical properties. Elastin-based biopolymers can be crosslinked without chemical modification using crosslinkers such as GTA, disuccinimidyl suberate, and disuccinimidyl glutarate.89 Towards forming hydrogel scaffolds for tissue engineering applications, elastin-based materials are of particular interest due to their diverse biological and mechanical properties, which arise from the unique resilient behavior of elastin polypeptides.84

2.2.5. Keratin

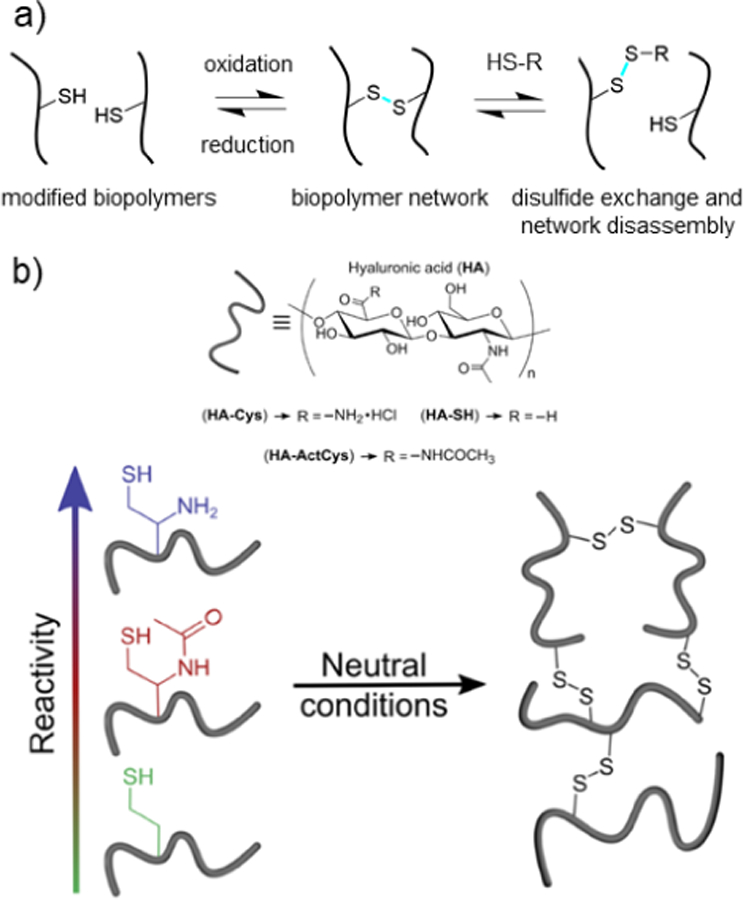

Keratin is a fibrous protein rich in cysteine residues and is naturally found in hard integuments of animals, including in skin, hair, nails, wool, feathers, scales, and horns.94,95 Keratinous tissues serve structural and protective functions in a variety of animals.95 In humans, keratin is found in many epithelial tissues, including the epidermis and corneal epithelium, contributing to their role as a protective barrier.96 Keratin contains multiple cell adhesion sites, including RGD.97 The rich cysteine content allows for the formation of disulfide bonds, giving keratinous tissue strong and resilient mechanical properties.94 Keratins are often classified as either α-keratins (forming α-helices) or β-keratins (forming β-sheets).94 In the textile industry, keratin has been used as a raw material for centuries.94 For biomedical purposes, keratin may be extracted from numerous sources, including human hair,98 wool,99 and feathers.100 Keratin is of growing interest for use as a sustainable and cheap raw material in the biomedical field, as it can be easily sourced from the millions of tons of wool and feathers that are produced annually as by-products in livestock industries.94 In its native state, keratin is insoluble in most solvents, including water.101 Post-processing must be used to form water-soluble keratin for hydrogel formation, often involving the breaking of disulfide bonds with the addition of a reducing agent.98 Such a process results in free thiol groups on keratins that can be used for crosslinking or further functionalization.98,99

2.2.6. Engineered polypeptides

Advances in recombinant protein production and peptide synthesis have allowed for the design of engineered polypeptides that can be fabricated into hydrogels.102 Engineered polypeptides can be designed to mimic biological functions of naturally occurring peptides. For example, resilin-like polypeptides (RLPs) have been recombinantly engineered to fabricate hydrogel scaffolds that mimic the highly resilient mechanical properties of resilin protein found in arthropods.103 Using RLPs instead of native resilin allows for control over incorporation of other bioactive motifs into the polypeptide, such as MMP-sensitive and cell-binding sites.103 As another example, the engineered peptide poly(γ-propargyl-L-glutamate) (PPLG) has been used in combination with poly(ethylene glycol) (PEG) to form hydrogels.104 PPLG introduces cell-adhesion sites as well as nanoscale stiffness due to PPLG’s rod-like tertiary folding structure.104 Furthermore, self-assembling peptide hydrogels have been designed that result in nanofibrillar structures due to β-sheet formation.105 Other examples of hydrogels formed from engineered polypeptides include the use of novel pH-responsive engineered peptide amphiphiles for the formation of injectable nanofibrous scaffolds,106 and the use of engineered PEG-peptide copolymers for the formation of “Shear-thinning Hydrogels for Injectable Encapsulation and Long-term Delivery” (SHIELD).107 While engineered polypeptides may be designed for self-assembly, chemical modification of the engineered polypeptides may also be utilized for hydrogel formation, such as for crosslinking by azide-alkyne cycloaddition.108,109 Ultimately, the engineering of polypeptides expands potential hydrogel components well beyond those that are found in natural tissues and structures.

3. Conjugation reactions to modify biopolymers

As stated above, although many biopolymers have inherent inter-molecular interactions that can be used to form hydrogels, chemical modification is often needed for hydrogel formation or to improve upon formed hydrogel properties. Fortunately, biopolymers possess various chemical groups (e.g., hydroxyl, carboxyl, amine, thiol) available for modification through standard conjugation procedures. For example, all polysaccharides have hydroxyl groups (-OH), as do the amino acids serine and tyrosine, which often contribute to the hydrophilicity and hydrogen-bonding capabilities of biopolymers. The carboxyl group (-COOH) is found on two amino acids, aspartic acid and glutamic acid,110 and in numerous polysaccharides such as HA, alginate, and CS. Amines (-NH2 or -NR2) are common on biopolymers such as chitosan and within the amino acid lysine as a component of proteins and polypeptides.110 Lastly, thiols (-SH) are found in the amino acid cysteine, and the oxidation of thiols can lead to formation of a disulfide bond, which is commonly used in biopolymer hydrogel formation and fabrication.110

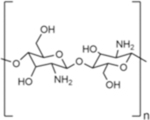

The most common conjugation reactions to chemically modify biopolymers include the formation of esters, amides, ethers, and carbamates, which involve hydroxyl, carboxyl, amine, and thiol groups on biopolymers (Figure 2). Ester formation is accomplished via the condensation of hydroxyl and carboxyl groups, usually in the presence of dehydrating reagents and appropriate catalysts. A common bioconjugation method is to use a carbodiimide such as 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDC) to activate a carboxylic acid group for esterification, in combination with a catalyst, such as 4-dimethylaminopyridine (DMAP). Esterification can also be achieved by combining a carboxylic acid with an epoxy, resulting in a hydroxyester. In bioconjugation, it is also common to combine acid anhydrides with functional hydroxyl groups on biopolymers to form esters. For example, methacrylic anhydride can be used to chemically modify biopolymers containing an aliphatic hydroxyl group with a methacrylate.111 Di-tert-butyl decarbonate (i.e., Boc anhydride, Boc2O) combined with DMAP can also be used to accomplish esterification.112

Figure 2. Common chemical reactions for modification of biopolymers.

Schematic representation of chemically modifying biopolymers using common mechanisms. From top to bottom: esterification, amidation, etherification, and carbamate formation. The green circle denotes various chemical groups introduced onto biopolymers for potential use in hydrogel formation.

Amide formation can be achieved by condensing a carboxylic acid with an amine group. To accomplish this, the carboxylic acid group is usually first converted into an activated ester compound. Carbodiimides such as EDC activate the carboxylate group, and molecules like N-hydroxysuccinimide (NHS),113,114 hydroxybenzotriazole (HOBt),115,116 or benzotriazol-1-yloxytris (dimethylamino)phosphonium hexafluorophosphate (BOP)117 form activated ester compounds. The activated esters then readily form stable amide bonds with amine functional groups present in the reaction. Ethers can be formed by combining epoxide and hydroxyl functional groups under basic conditions. For example, this method is used to conjugate glycidyl methacrylate (which has an epoxide functional group) to biopolymers containing free hydroxyl groups,118–120 often in the presence of DMAP as a base. Lastly, compounds containing isocyanate functional groups can form carbamate bonds (also referred to as urethane bonds) with hydroxyl groups or can combine with thiols to form thiocarbamate bonds.121,122

There are numerous other examples of modifications directly to biopolymers for hydrogel formation. For example, Michael addition reactions can be used to chemically modify thiols on biopolymers, as well as to crosslink modified biopolymers for hydrogel formation (as described later in Section 4).123 Specifically, under basic conditions, thiolated molecules (Michael donors) can be combined with electron-deficient unsaturated compounds (Michael acceptors, such as maleimides, vinyl sulfones, acrylates, and acrylamides) via thiol-Michael addition, leading to the formation of a thioether bond.124 Polysaccharides can also be modified using ring-opening oxidation, resulting in free aldehyde groups on the biopolymer backbone, which can change degradation rates or be used for crosslinking (e.g., Schiff base formation).125,126 A common method to introduce aldehydes is to use sodium periodate as the oxidizing agent.127 Lastly, biopolymers such as keratin that have multiple disulfide bridges can be exposed to a reducing agent such as dithiothreitol (DTT) or mercaptoethanol to functionalize with free thiol groups,128 allowing for further biopolymer modification or crosslinking.

4. Covalent crosslinking

Hydrogels can be formed by the covalent crosslinking of functional groups attached to biopolymers. Covalent crosslinking mechanisms often require catalysts or initiators to induce covalent bond formation. Due to the general stability of covalent bonds, covalently crosslinked hydrogels have the potential to remain stable over long timescales both in vitro and in vivo, although this may be dependent on the ability of the network to undergo degradation. Both the mechanical and biological properties of the hydrogel formed are influenced by various components of the biopolymer and hydrogel design, such as the concentration of biopolymer, the type of crosslinking group introduced, and the degree of modification of the biopolymer. While there are many methods to form covalently crosslinked hydrogels, this review will focus on the most common approaches utilized in biopolymer hydrogel formation, including free radical chain polymerization, click chemistry, and oxidation of phenolic groups.

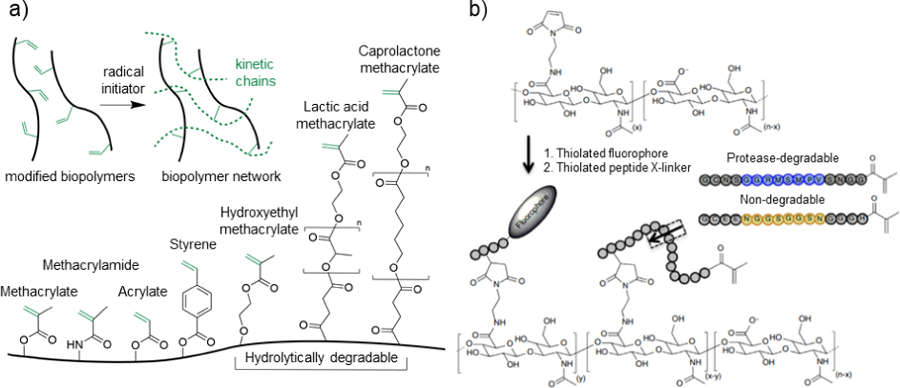

4.1. Crosslinking via free radical chain polymerization

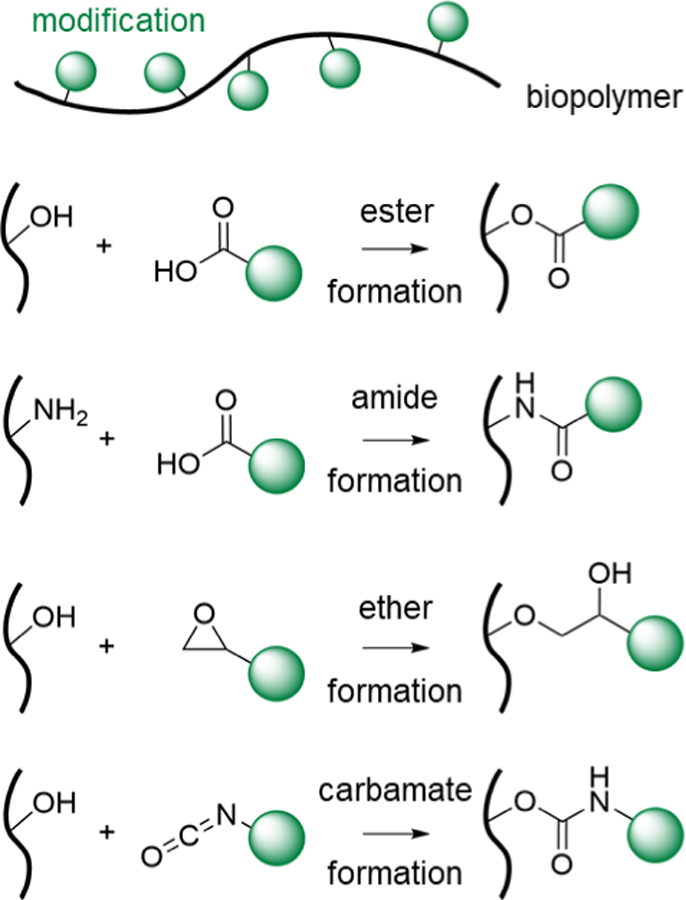

Free radical chain polymerization consists of three steps: 1) initiation, 2) propagation, and 3) termination. During the initiation step, free radicals are generated from initiators, typically with changes in temperature, light, or redox conditions. During propagation, free radicals interact with unsaturated double bonds, and the free radical active center is transferred to propagate the kinetic chain, leading to crosslinking of the modified biopolymers (Figure 3a). The crosslinking reaction is terminated by either combination, disproportionation, or chain transfer events that stop the radical from propagating further. There are a wide range of functional groups that are used for the crosslinking of biopolymers in free radical chain polymerization (Figure 3a).

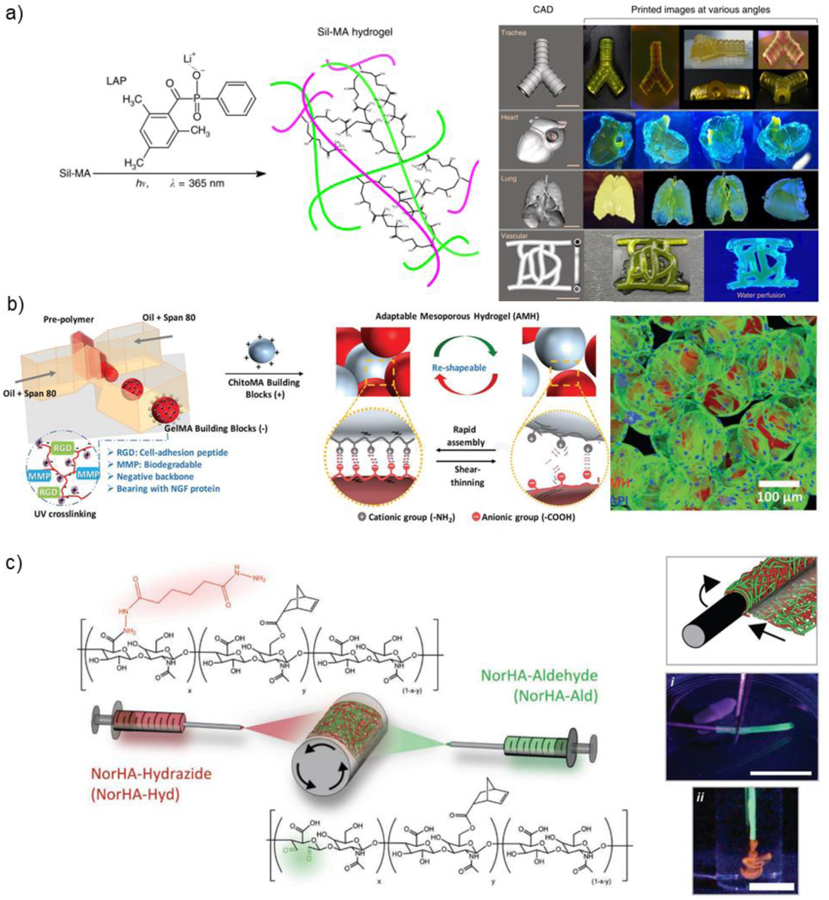

Figure 3. Crosslinking via free radical chain polymerization.

a) Schematic representation of the general crosslinking of modified biopolymers in the presence of an initiator to induce the formation of kinetic chains through the propagation of radical species (top), as well as common reactive groups used for biopolymer modification and hydrogel formation (bottom). b) Hyaluronic acid (HA) modified with maleimide groups to react with thiolated fluorophores and thiolated protease-degradable peptides capped with methacrylate groups for free radical chain polymerization. Peptide sequences are designed to be either protease degradable (blue) or non-degradable (yellow). Adapted with permission from Wade, et al.167 Copyright, 2015 Springer Nature.

Photoinitiation is a common method to generate free radicals in hydrogel formation.129 In this approach, a photoinitiator molecule cleaves in response to certain wavelengths of light, resulting in the generation of free radicals. Examples of water-soluble, biocompatible photoinitiators used in crosslinking include ultraviolet (UV) light-responsive molecules such as 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiophenone (e.g., Irgacure, I2959)120,130 and visible light-responsive molecules such as lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP).131 Parameters such as light intensity and exposure time, as well as initiator and biopolymer concentrations, will affect the rates of polymerization and the resulting hydrogel properties. Oxidative-reductive (redox) mechanisms may also be used to generate free radicals. One of the most used redox initiators in biomedical applications is ammonium persulfate (APS) in combination with tetramethylethylenediamine (TEMED). Since radicals are generated upon mixing, injectable, in situ-forming hydrogels with tunable mechanical properties are possible with redox systems.132 Lastly, there are a number of thermal initiators in which a change in temperature is used to generate free radicals.133 Free radical chain polymerizations form stable hydrogels, as the kinetic chains formed are non-degradable, although degradable groups (e.g., hydrolytically degradable, enzymatically degradable) can be incorporated into the network to tailor erosion behaviors.

4.1.1. Meth(acrylates) and methacrylamides

To functionalize biopolymers for free radical chain polymerization, methacrylate groups are often conjugated to biopolymers. This can be accomplished through various reactions, including esterification with methacrylic anhydride134 and etherification with glycidyl methacrylate (GMA).135 Dextran was first modified with methacrylate groups by etherification between GMA and hydroxyl groups on the dextran backbone, forming GMA-Dex.118 GMA-Dex hydrogels were crosslinked in situ in the presence of APS/TEMED redox radical initiators.118 Kim et al. synthesized methacrylated dextran by esterification with methacrylic anhydride under basic conditions.136 It was demonstrated that model drugs such as fluorescently-labeled dextran and doxorubicin could be released in a sustained fashion from methacrylated dextran hydrogels crosslinked with UV light in vitro.137 To introduce micro- and macro-porous structures, PEG has been mixed into methacrylated dextran hydrogels, and liquid-liquid phase separation created different morphologies and porosities.119 In a similar approach, Ferreira et al. modified dextran with acrylate groups to form hydrogels containing tethered RGD and vascular endothelial growth factor (VEGF) encapsulated in poly(lactic-co-glycolic acid) (PLGA) microspheres for use as a scaffold for human embryonic stem cell vascular differentiation.138

HA modified with methacrylate moieties has been widely used in tissue engineering and drug delivery. Smeds et al. demonstrated that HA could be methacrylated (MeHA) using esterification with methacrylic anhydride and subsequently photocrosslinked to form HA hydrogels for sustained release of model drugs.134 Stiffness, swelling ratio, and degradation rates can be varied in HA hydrogels formed from MeHA as a function of the degree of substitution, polymer concentration, and photoinitiation conditions.111 In another chemical modification approach, Leach et al. showed that HA could be modified through etherification between hydroxyl groups on the polymer backbone and GMA (GMA-HA), and subsequently photocrosslinked using UV light.120 Furthermore, BSA was released as a model drug in a sustained fashion from GMA-HA for several weeks.139 Hydrogels from methacrylated HA have been used for a wide range of applications, including vocal fold tissue engineering,140 controlled human embryonic stem cell differentiation,141 and bioprinting.142

Numerous other polysaccharides have been modified with methacrylates for free radical chain polymerization, including cellulose,143 alginate,144 and CS.145 By altering reaction conditions, such as reagent concentrations and temperature, the degree of substitution of methacrylate groups on cellulose could be controlled, which later influenced hydrogel mechanical properties.143 HPC has been modified with methacrylates through reaction with methacrylic anhydride146 and processed with photolithography to create patterned hydrogel structures for diagnostics and tissue engineering applications.147 Towards cartilage tissue engineering, methacrylated alginate, methacrylated HA, and methacrylated CS have been used for chondrocyte encapsulation and proliferation.148–154

Chitin has been modified with methacrylate groups via esterification between methacrylic anhydride and free hydroxyl groups on water-soluble carboxymethyl chitin, resulting in a photocrosslinkable hydrogel.155 In another approach, chitin has been functionalized with methacrylate groups by carbamate bond formation between hydroxyl moieties on chitin and 2-isocyanatoethyl methacrylate.156 The modification resulted in a photocrosslinkable chitin hydrogel that could be micropatterned for controlled guidance of cells.

Beyond methacrylates, reactive methacrylamide groups have been used for free radical chain polymerization of modified biopolymers. For example, HA was modified with methacrylamides using amidation reactions in the presence of EDC.157 Park et al. showed that diacrylated PEG (PEGDA) could be incorporated into these methacrylamide-HA hydrogels to increase mechanical properties, and RGD could be tethered to the hydrogels to allow for cell adhesion and proliferation.157 Gelatin has also been used extensively after modification for free radical chain polymerization, mostly commonly through esterification with methacrylic anhydride,158 or by amidation with methacrylamide to form GelMA.159 GelMA has been shown to be a useful material for photopatterned, cell-laden microtissues and microfluidic devices.160 While GelMA has been a widely explored polypeptide for hydrogel formation, other polypeptides have also been explored. Kim et al. demonstrated that hydrolyzed silk fibroin could be methacrylated to form photocrosslinked hydrogels in the presence of UV light and LAP photoinitiator, where crosslinking is aided by β-sheet formation.161

4.1.2. Styrene

Although not used extensively, styrene moieties contain alkene groups that can be used for free radical chain polymerization. Styrene has been introduced to gelatin, HA, heparin, and albumin by either esterification with 4-vinylbenzoic acid or amidation with 4-vinylaniline.162 Styrenated gelatin has been explored for cartilage tissue engineering as a hydrogel for chondrocyte delivery.163 Furthermore, styrenated gelatin microspheres have been fabricated in a batch emulsion and subsequently explored for adipose tissue engineering.164

4.1.3. Degradable hydrogels from free radical chain polymerization

For some applications, hydrogels with high mechanical properties and low degradability may be preferred; however, more rapid hydrogel degradation may be desired for other applications. To introduce control over hydrogel degradation, hydrolytically degradable groups (e.g., esters) can be incorporated in between the biopolymer backbone and conjugated reactive groups. For example, hydroxyethyl methacrylate (HEMA) has been conjugated to many biopolymers, including dextran130 and HA,132 to modulate hydrogel degradation behavior. To increase hydrogel degradation rates, multiple lactic acid groups can be introduced.135 Sahoo et al. demonstrated that this could be achieved with HA, and that ECM distribution increases when mesenchymal stromal cells (MSCs) were cultured in these hydrolytically degradable hydrogels.165 The incorporation of lactic acid can result in hydrogels that degrade too quickly, resulting in cell clustering and altered cell morphology.166 To overcome this, caprolactone can be used instead as a hydrolytically degradable group with slower degradation rates. It has been shown that incorporating caprolactone groups between the HA backbone and methacrylate moieties allows for the tuning of hydrogel degradation rates to match the ECM deposition rates of MSC-laden hydrogels towards superior neocartilage formation in vitro.166 Beyond hydrolysis as a method of degradation, Wade et al. introduced protease-degradable peptides between the HA backbone and methacrylates, so that formed hydrogels respond to proteases (Figure 3b).167 These modified HA biopolymers were processed into degradable electrospun fibrous scaffolds, where degradation was dependent on the protease-sensitivity of the peptide sequence and the protease concentration.

4.2. Crosslinking via click chemistry

Click chemistry refers to a set of often biocompatible chemical reactions that result in the rapid formation of covalent bonds. Click chemistry reactions occur in a one-pot system, have a high thermodynamic driving force (greater than 20 kcal/mol), are not disturbed by water, have high specificity, and generate minimal byproducts.168 Due to the biocompatibility, reliability, and specificity of click chemistry reactions, they are often used in biomedical applications such as drug discovery and biomaterials engineering.169,170 Herein, we review some of the most common click chemistry reactions used for crosslinking of biopolymer hydrogels, including thiol-ene radical additions, thiol-ene Michael additions, azide-alkyne reactions, and tetrazine-norbornene cycloaddition.

4.2.1. Thiol-ene radical addition

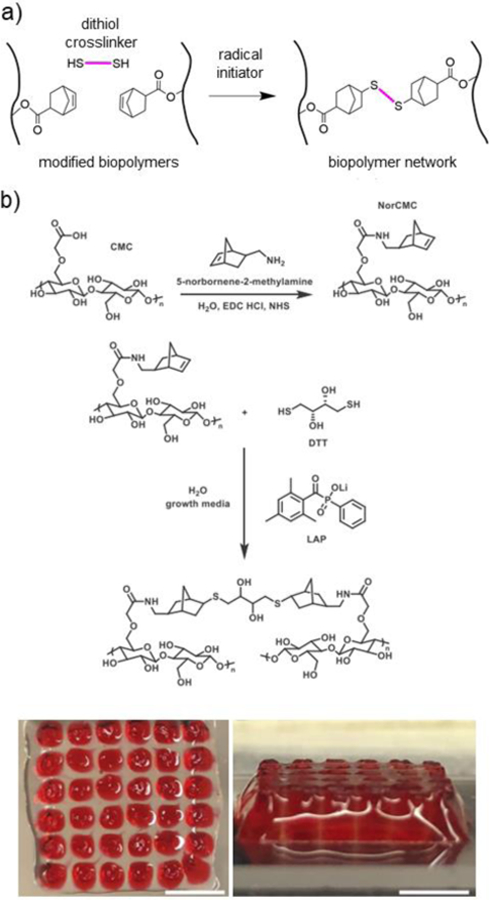

Thiol-ene radical additions form a covalent thioether bond between an alkene and a thiol in the presence of a radical initiator. This click reaction is a powerful biomaterials tool due to its high yield, mild reaction conditions, regiospecificity and stereospecificity, and biorthogonality.171 Radical initiators convert thiols into thiyl radicals, which subsequently form thioether bonds with electron-deficient or strained enes (e.g., norbornene) and can be used to form hydrogels (Figure 4a). Although methacrylates, acrylates, styrenes, and maleimides can undergo both thiol-ene step growth and radical chain growth homopolymerization, norbornenes and vinyl ethers only undergo thiol-ene step growth, which permits better control over hydrogel formation.171 Thus, towards biopolymer hydrogel formation, the thiol-ene radical addition of thiols and norbornenes is most commonly used.

Figure 4. Crosslinking via a thiol-ene radical addition.

a) Schematic representation of norbornene-modified biopolymers (black) crosslinked with a dithiol crosslinker (pink) in the presence of a radical initiator. b) Thiol-norbornene crosslinked CMC hydrogels for bioprinting, showing (top) schematic representation of amidation reaction to synthesize norbornene-modified CMC (NorCMC), (middle) schematic representation of photocrosslinking reaction, and (bottom) bioprinted NorCMC scaffolds (clear) filled with Pluronic (red). Scale bars represent 5mm. Adapted with permission from Ji, et al.182 Copyright, 2020 Elsevier.

Norbornene is a bridged cyclic hydrocarbon with a strained carbon-carbon double bond. Many biopolymers have been functionalized with norbornene groups to undergo thiol-norbornene radical addition crosslinking, including HA,112,117,131,172 alginate,173,174 cellulose,114,175,176 gelatin,177–180 and silk fibroin.181 Biopolymers can be functionalized with norbornene derivatives using esterification112,177 or amidation117,174 reactions. DTT,112,181 multi-functional PEG dithiols,178 and enzymatically degradable dithiols114,173 have been explored as crosslinkers. While photoinitiator systems are commonly employed, redox-mediated radical initiators such as APS/TEMED can also be utilized for radical generation and thiol-norbornene crosslinking.176 Biopolymer, crosslinker, and initiator concentrations can be used to tune hydrogel mechanical properties across orders of magnitudes (~1–100kPa);112,114 however, the range of hydrogel stiffnesses that can be achieved may be hindered by limited chain mobility as the reaction progresses, resulting in “maximum possible” stiffnesses despite increased polymer or crosslinker concentrations.175

Gramlich, et al. demonstrated that HA could be functionalized with norbornene (NorHA) using esterification between 5-norbornene-2-carboxylic acid and the secondary alcohol group on HA.112 NorHA hydrogels could be spatiotemporally patterned by conjugating thiolated peptides to remaining free norbornenes using photomasks, demonstrating the ability to independently tune biochemical and mechanical properties.112 Vega, et al. further demonstrated the photopatterning capabilities of NorHA (synthesized through BOP coupling of 5-norbornene-2-methalamine to carboxylic acid via amidation) by encapsulating MSCs in a NorHA hydrogel with photopatterned gradients of thiolated- RGD and other peptides created using a sliding opaque photomask.117 In a single hydrogel, over 100 distinct biochemical formulations could be formed and screened for cartilage formation, demonstrating the promising application of thiol-norbornene radical addition in screening potential hydrogel formulations for tissue engineering.117 NorHA can also be utilized with other scaffold biofabrication techniques, including bioprinting131 and microgel formation.172

Other biopolymers have been modified with norbornenes for hydrogel formation. For example, norbornene-functionalized alginate hydrogels have been explored for many applications, including tissue engineered implantable constructs. Leuckgen et al. showed that norbornene-modified alginate hydrogels crosslinked with dithiolated enzymatically degradable crosslinkers allowed for cell and tissue infiltration in vivo after 8 weeks in a subcutaneous mouse study.173 Furthermore, Ooi, et al. demonstrated that norbornene-functionalized alginate could be used as a cell-laden bioink for bioprinting of tissue engineering scaffolds.174 CMC functionalized with norbornenes for thiol-ene radical addition crosslinking has also been explored for tissue engineering applications.114,175,176,182 Ji et al. showed that CMC can be modified with norbornene groups using either amidation or esterification reactions.182 Norbornene-modified CMC was combined with DTT to undergo thiol-ene photocrosslinking, and subsequently used as a cell-laden bioprinting ink (Figure 4b). Furthermore, Dadoo et al. showed that norbornene-modified CMC could be crosslinked with a thermally responsive dithiol-terminated poly(N-isopropyl acrylamide) crosslinker for spatiotemporal control over hydrogel swelling upon targeted temperature regulation.114 In another strategy, cellulose nanofibrils could be functionalized with norbornene to allow for conjugation with different thiolated molecules to create nanofibril hydrogel suspensions with a wide range mechanical properties.176 Lastly, Ryu, et al. demonstrated that silk fibroin modified with norbornenes could be combined with 4-arm PEG norbornene and DTT to create PEG hydrogels with embedded silk fibroin microgels, including with adenocarcinomic human alveolar basal epithelial cells.181

Gelatin can also be functionalized with norbornene groups using amidation between amines on the collagen backbone and carbic anhydride.177–179 Munoz, et al. demonstrated that norbornene-modified gelatin hydrogels supported more rapid and extensive cell spreading of encapsulated human MSCs (hMSCs) when compared to GelMA.177 This may be due to radical-mediated damage to proteins and cells due to kinetic chain growth in GelMA hydrogels, as well as the limited control over mesh size and molecular transport within GelMA hydrogels.177 Greene et al. demonstrated temporal control over crosslinking and thus mechanical properties of norbornene-modified gelatin hydrogels using intermittent light exposure, which was used to study hepatocellular carcinoma cell fate as a function of hydrogel matrix properties in vitro.178 While functionalizing biopolymers with norbornene groups is a common approach, biopolymers can also be functionalized with thiols and subsequently crosslinked with multi-arm norbornene crosslinkers. Holmes, et al. functionalized amine groups on collagen with thiols using 2-iminothiolane in the presence of DTT as a reducing agent.180 Thiolated collagen was then crosslinked with a multi-arm norbornene crosslinker for hydrogel formation. In another example, Yue et al. used thiol-modified keratin, along with a multi-arm PEG norbornene and Eosin Y photoinitiator, to create hydrogel constructs upon exposure to visible light.98 The keratin hydrogels could encapsulate cells with high viability and exhibited tunable compressive moduli up to 45 kPa.

In addition to norbornene modification, biopolymers including gelatin,183 chitosan,184 and starch185 have been modified with allyl groups through reaction with allyl glycidyl ether (AGE) or allyl chloride186 for thiol-ene radical addition crosslinking. AGE-modified gelatin (Gel-AGE) hydrogels crosslinked with DTT have been explored for bioprinting tissue engineered scaffolds for the encapsulation of chondrocytes.187 Kiliona et al. demonstrated that chitin nanocrystals and nanofibrils (nanochitin) could be functionalized with allyl groups by reaction with 10-undecenoyl chloride.188 When mixed with thiolated PEG, allyl-modified nanochitin was used to form organogels in the presence of UV light and photoinitiators.188 Hilderbrand et al. demonstrated that allyl-functionalized collagen mimetic peptides (CMPs) can be combined with thiolated PEG to fabricate a photocrosslinkable hydrogel for 3D cell culture.189 In another approach, biopolymers can be modified with pentenoate to functionalize with ene groups in order to undergo thiol-ene radical addition. For example, Mergy et al. modified both dextran and HA with pentenoate groups via esterification with pentenoic anhydride to undergo thiol-ene photocrosslinking in the presence of thiol crosslinkers.190 Further, pentenoate-modified gelatin and thiolated gelatin have been combined to form a photocrosslinkable hydrogel for cell encaulstion.191

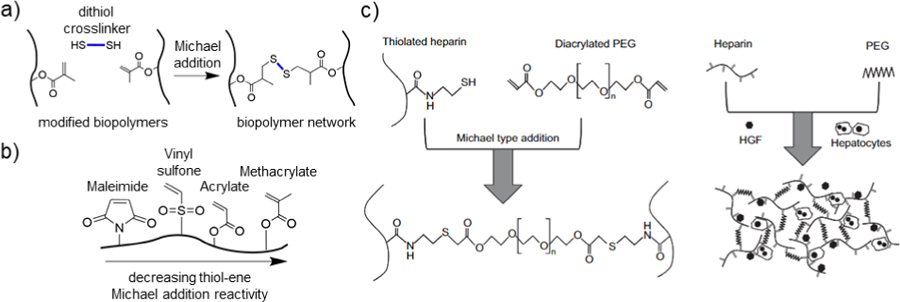

4.2.2. Thiol-ene Michael addition

In Michael addition crosslinking, thiol-ene reactions can occur readily between thiols (Michael donors) and electron-deficient enes (Michael acceptors) without the need for radical initiators (Figure 5a).171 Thiol-ene Michael addition reactions can be either base-catalyzed or nucleophile-catalyzed.124 Common ene groups used for hydrogel crosslinking include maleimides, vinyl sulfones, acrylates, and methacrylates, in order of decreasing reactivity towards thiol-ene Michael addition (Figure 5b).124 Variations in the ene group, the pH, and the biopolymer and crosslinker concentrations allow for tuning of gelation times from a few seconds to several hours. Biopolymers may be functionalized with ene or thiol groups for crosslinking using esterification or amidation reactions. Biopolymer hydrogels crosslinked using Michael addition reactions are commonly utilized as injectable, in situ forming hydrogels due to the ability to tune gelation kinetics to clinically relevant timescales.

Figure 5. Crosslinking via thiol-ene Michael addition.

a) Schematic representation of methacrylate-modified biopolymers (black) crosslinked with a dithiol crosslinker (blue) under Michael addition conditions. b) Schematic representation of a biopolymer modified with multiple ene groups that can undergo thiol-ene Michael addition. From left to right, in decreasing order of Michael addition reactivity: maleimide, vinyl sulfone, acrylate, and methacrylate. c) Thiolated heparin is crosslinked with diacrylated PEG (PEGDA) via a thiol-ene Michael addition reaction, which was used for the culture of primary rat hepatocytes and hepatocyte growth factor (HGF). Adapted with permission from Kim, et al.205 Copyright, 2010 Elsevier.

Thiol-ene Michael addition reactions have been used for in situ crosslinking of injectable HA hydrogels for drug delivery and tissue engineering applications.192–194 Hahn et al. showed that MeHA crosslinked through Michael addition with DTT could be used as an injectable hydrogel for sustained release of erythropoietin.192 Gelation time varied from 30 minutes to 3 hours, and erythropoietin could be released over a 7 day period in a rat in vivo model.192 Vanderhooft et al. also demonstrated a wide range of gelation times (30 seconds – 2 hours) for hydrogels consisting of thiolated HA, thiolated gelatin, and various ene-functionalized PEG crosslinkers, including PEGDA and PEG-dimaleimide.193 Furthermore, the storage modulus of thiolated HA hydrogels crosslinked with PEGDA by Michael addition ranged from tens to thousands of Pa.195 Forgoing the need for small molecules or synthetic polymer crosslinkers, HA has been modified with methacrylates, acrylates, vinyl sulfones, and maleimides, and subsequently mixed with thiolated HA to crosslink via a Michael addition reaction, with gelation times ranging from instantaneous (maleimide) to ~45 minutes (methacrylate) as a function of the ene group present, pH, and polymer concentration.196 Towards cardiac tissue engineering, MeHA and thiolated HA were selected as an in situ crosslinking, injectable hydrogel formulation for mechanical stabilization of myocardial tissue after infarction.196 Michael addition crosslinking in HA hydrogels has been used for numerous applications, including cartilage tissue engineering197,198 and neural tissue engineering.199,200

A range of chemical modifications have been applied to dextran hydrogels for thiol-ene Michael addition hydrogel formation. Injectable, in situ crosslinking hydrogels consisting of thiolated dextran and either acrylated PEG or vinyl-sulfonated dextran have been developed with a wide range of mechanical and degradation properties.201 Degradation timescales can vary significantly (days to weeks) as a function of polymer concentration, Michael donors and acceptors selected, and spacing between conjugated functional groups and biopolymer backbone.201,202 For spatiotemporal control over degradation, Peng et al. chemically modified dextran with an acrylate functional group that contained a photolyzable o-nitro-benzyl moiety between the acrylate and dextran backbone.203 The hydrogel was crosslinked with a dithiolated PEG crosslinker using Michael addition, and subsequent exposure to UV light resulted in controlled degradation and release of model drugs.203

Many other biopolymers have been modified with thiols and/or ene functional groups for thiol-ene Michael addition crosslinking. For example, an injectable, thiolated chitosan hydrogel was developed by crosslinking with an acrylated PEG, resulting in tunable gelation times between ~10 seconds to 20 minutes.204 Cell attachment and spreading was demonstrated in vitro upon addition of an RGD peptide.204 Kim et al. showed that thiolated heparin could be mixed with PEGDA for Michael addition crosslinking to form a hydrogel useful for the encapsulation and in vitro culture of primary hepatocytes (Figure 5c).205 Furthermore, thiolated gelatin hydrogels mixed with PEGDA are promising for the rapid encapsulation of MSCs for wound repair applications.206 Xu et al. showed that, when applied to a full thickness wound rat model, these hydrogels supported accelerated wound closure, re-epithelialization, and vascularization.206 In another example, Zhang et al showed that thiolated keratin can be mixed with 4-arm PEG-vinyl sulfone (PEG-VS) to undergo Michael Addition crosslinking.99 The keratin hydrogel showed promise as a flexible strain sensor for future applications in wearable electronics.

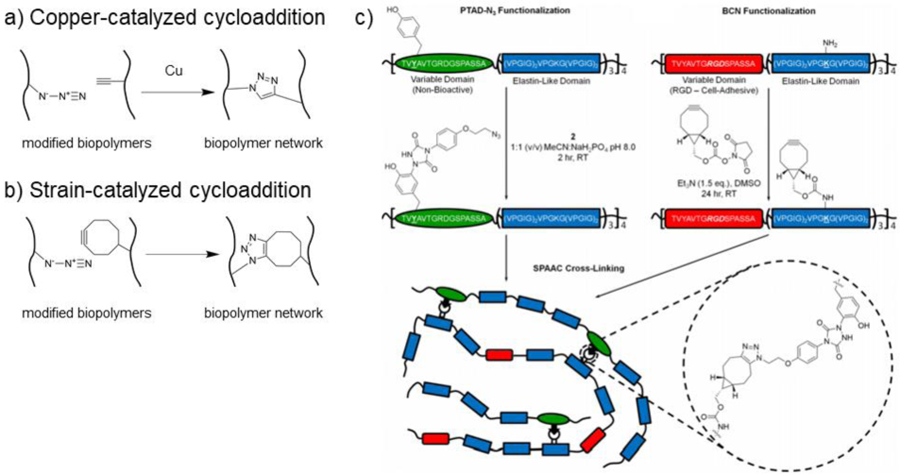

4.2.3. Azide-alkyne [3+2] cycloaddition

Azide-alkyne [3+2] cycloaddition, also called Huisgen 1,3-dipolar cycloaddition, is a powerful click chemistry tool that is widely used in bioconjugation to form strong covalent bonds in a one-pot reaction.207 To perform the reaction under physiologically relevant conditions, the reaction is often catalyzed by Cu(I) or Cu(II).208 Towards hydrogel formation, biopolymers can be modified with azide or alkyne moieties to undergo [3+2] cycloaddition crosslinking, potentially in the presence of copper catalysts (Figure 6a). Li et al. fabricated a thermo-responsive albumin hydrogel by conjugating propargyl maleimide to thiol groups on BSA cysteine residues.209 The combination of alkyne-functionalized BSA with poly(N-isopropylacrylamide) (PNIPAAm) end-terminated with azide groups in the presence of Cu(II) catalysts yielded an azide-alkyne hydrogel.209 Gelatin hydrogels formed via azide-alkyne reactions have been engineered by conjugating propolic acid to lysine residues to add azide functionality and crosslinking with either 4,4′-diazido-2,2′stilbenedisulfonic acid or 1,8-diazidooctane, both of which are di-functionalized with alkyne groups.210 Upon exposure to Cu(II) catalysts, the gelatin hydrogels reached compressive moduli between 50 and 390 kPa.210 Other biopolymers that have been crosslinked by copper-catalyzed azide-alkyne cycloaddition reactions include HA,170,211,212 cellulose,213 and alginate.214

Figure 6. Crosslinking via azide-alkyne cycloaddition.

a) Schematic representation of copper-catalyzed azide-alkyne cycloaddition crosslinking of biopolymers. Biopolymers are modified with either azide or alkyne functional groups and upon combination in the presence of a copper catalyst, crosslinks form by azide-alkyne cycloaddition. b) Schematic representation of strain-catalyzed azide-alkyne cycloaddition crosslinking of biopolymers. Biopolymers are modified with either azide or strained alkyne (i.e., cyclooctyne) groups and upon combination, crosslinks form by azide-alkyne cycloaddition. c) Elastin-like polypeptides (ELPs) functionalized with either azide or bicyclononyne (BCN) groups for bio-orthogonal crosslinking due to the strain-promoted [3+2] azide-alkyne cycloaddition (SPAAC) reaction. Adapted with permission from Madl, et al.109 Copyright, 2017 American Chemical Society.

Copper-catalyzed azide-alkyne cycloadditions allows for rapid gelation; however, copper catalysts are often cytotoxic, limiting the ability for copper-catalyzed reactions to be used in cellular systems.215 To overcome this, strain-promoted [3+2] azide-alkyne cycloaddition (SPAAC) can be utilized by combining azides with strained cyclooctynes (Figure 6b).215 Wang et al. engineered metal-free, azide-alkyne crosslinked, injectable dextran hydrogels by modifying dextran with either azadibenzocyclooctyne (ADIBO-Dex) or azides (Dex-N3).216 Upon mixing the two components, gelation occurred within 1 to 10 minutes, resulting in hydrogels with storage moduli between 2 and 6 kPa.216 The hydrogels supported chondrocyte growth and cartilaginous tissue formation in vitro.216 In another approach to fabricate metal-free azide-alkyne hydrogels, chitosan was functionalized with azides by modification with azidopentanoic acid and subsequently mixed with 3-arm PEG-propiolate, a multifunctional alkyne crosslinker.217 The resulting hydrogel formed crosslinks within 5 to 60 minutes and reached compressive moduli between ~40 and 80 kPa.217 Lastly, ELPs have been functionalized with either azide or bicyclononyne moieties to undergo SPAAC crosslinking (Figure 6c).109 SPAAC-ELP hydrogels crosslinked within minutes.108,109 These hydrogels were used to rapidly encapsulate hMSCs and murine neural progenitor cells in vitro with high viability and phenotypic maintenance.

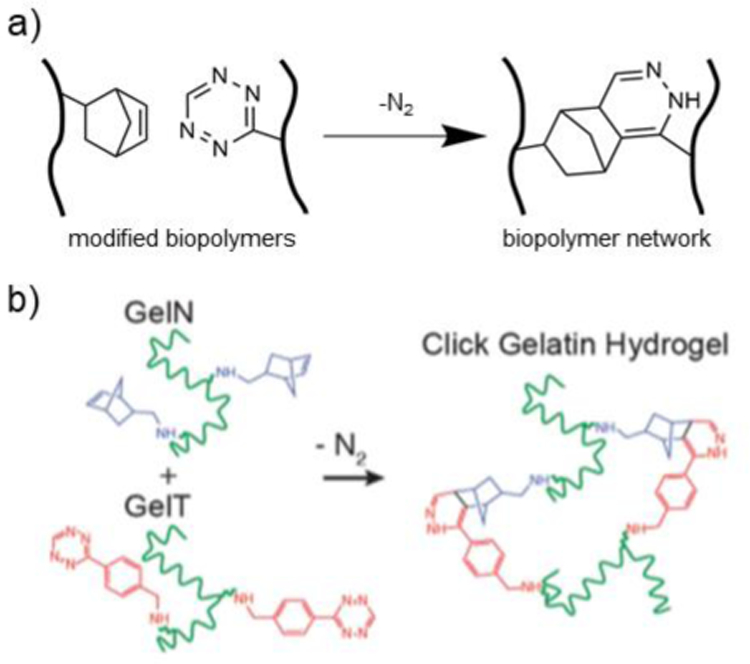

4.2.4. Tetrazine-norbornene

Tetrazine-norbornene reactions are useful to rapidly form irreversible covalent bonds. Hydrogels can be crosslinked by tetrazine-norbornene mechanisms for the encapsulation of cells and therapeutics (Figure 7a).218 Tetrazine-norbornene click chemistry offers similar advantages to metal-free azide-alkyne cycloaddition without the burden of the high cost of strained cyclooctyne groups.218 Biopolymers can be functionalized with tetrazine and norbornene groups to engineer injectable hydrogels that undergo in situ crosslinking.219,220 Desai et al. demonstrated that alginate could be functionalized with either benzylamino tetrazine or norbornene methylamine groups by EDC/NHS amidation.221 Cytocompatible alginate hydrogels could then be formed via tetrazine-norbornene click chemistry, with gelation times of approximately a few minutes and storage moduli between ~0.5 and 3 kPa.221,222 Furthermore, Lueckgen et al. showed that tetrazine-norbornene biopolymer networks containing oxidized alginate allowed for cell infiltration in an in vivo subcutaneous injection mouse model.222 HA has also been modified with tetrazine and norbornene moieties using EDC/NHS amidation mechanisms.219 The resulting HA hydrogels were engineered as an injectable delivery vehicle for the sustained release of protein therapeutics.219 Gelatin modified with tetrazine and norbornene groups has been explored for tissue engineered scaffold formation and as a delivery vehicle for contrast agents.220,223 For example, Koshy et al. developed a tetrazine-norbornene crosslinked gelatin hydrogel that supported cell growth and matrix remodeling in vitro, as well as cell infiltration in an in vivo subcutaneous mouse model (Figure 7b).223

Figure 7. Crosslinking via tetrazine-norbornene reactions.

a) Schematic representation of biopolymers modified with either norbornene or tetrazine groups. Upon combination, crosslinks form by a tetrazine-norbornene reaction. b) Gelatin modified with either norbornene (GelN) or tetrazine (GelT) are mixed to form a tetrazine-norbornene click biopolymer network, which was cell-adhesive and degradable for use in cell encapsulation. Adapted with permission from Koshy, et al.223 Copyright 2016, Wiley.

4.3. Crosslinking via oxidation of phenolic groups

Phenols are aromatic hydrocarbons that contain one or more hydroxyl groups. Oxidative environments lead to the generation of phenolate radicals that form covalently bonded phenol dimers.224 This mechanism can be used to form crosslinks between biopolymers modified with phenolic moieties. Two of the most common approaches for hydrogel formation include the enzymatically driven crosslinking of tyramine and oxidation of catechol groups.

4.3.1. Tyramine

Tyramine is a naturally occurring amine derived from the tyrosine amino acid. In the presence of horse radish peroxidase (HRP) and hydrogen peroxide (H2O2), tyramine groups are converted into phenolate radicals that form either carbon-carbon bonds or di-tyramine adducts which can be used for hydrogel crosslinking. For example, radical photoinitiators can be combined with keratin, which contains tyrosine amino acids, to form a photocrosslinkable hydrogel upon exposure to UV light.225

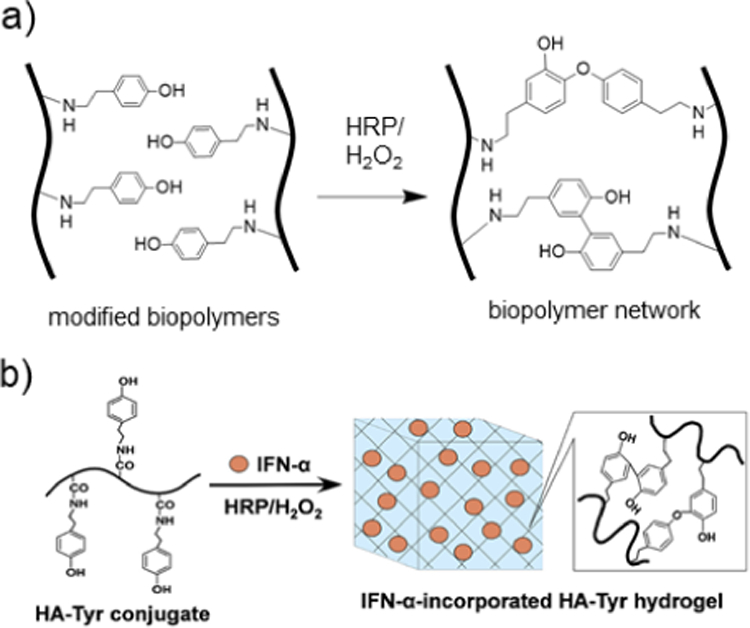

Biopolymers can be modified with tyramine functional groups, usually by amidation between tyramine and carboxyl groups on biopolymer backbones, and subsequently covalently crosslinked by the addition of HRP and H2O2. (Figure 8a). Tyramine-based enzymatic crosslinking occurs rapidly within a few seconds to minutes, but can be tuned by varying concentrations of tyramine, HRP, and H2O2 in solution.116,226 While enzymatic crosslinking of tyramine moieties is most common, it has also been shown that tyramine can be crosslinked using visible light and a photoinitiator.227,228

Figure 8. Crosslinking via tyramine enzymatic reactions.

a) Schematic representation of biopolymers modified with tyramine that crosslink in the presence of HRP and H2O2 to form dityramine adducts. b) HA is modified with tyramine and subsequently exposed to horse radish peroxidase (HRP) and H2O2 to undergo enzymatic crosslinking by oxidation of tyramine groups, forming covalent dityramine adducts. Interferon-α (IFN-α) is encapsulated in the hydrogel for use as a prolonged-release delivery vehicle for renal carcinoma treatment. Adapted with permission from Ueda, et al.231 Copyright, 2016 Elsevier.

Using carbodiimide chemistry, tyramine groups can be conjugated to HA (HA-Tyr) by amidation with free carboxyl groups.116,229 Simultaneous injection of two solutions, one containing HA-Tyr and H2O2 and one containing HRP, can be used for rapid gelation in vivo upon mixing.116 It has been demonstrated that HA-Tyr hydrogels can be used for sustained delivery of proteins and anticancer therapeutics.230,231 For example, Ueda, et al. showed that HA-Tyr hydrogels could be used to rapidly encapsulate interferon-alpha (IFN-α) for sustained release as an immunotherapy treatment (Figure 8b).231 The HA-Tyr hydrogel was able to prolong the biological half-life of IFN-α and improve anticancer effects in vivo when evaluated in a human renal cell carcinoma xenograft mouse study.

Towards tissue engineering applications, Loebel et al. demonstrated the versatility of HA-Tyr hydrogels, comparing the influence of enzymatic crosslinking and visible light photocrosslinking on encapsulated MSCs.227 It was found that when HA-Tyr hydrogel stiffness was constant, enzymatically crosslinked biopolymer networks resulted in increased cell spreading and greater focal adhesion strength when compared to photocrosslinked hydrogels; however, photocrosslinked hydrogels resulted in increased cellular tractions.227 This highlights the importance of considering how crosslinking methods influence cell behavior. Furthermore, it has been shown that additional biopolymers, such as silk fibroin232 and tyramine-modified CS,233 can be added to enzymatically crosslinked HA-Tyr hydrogels to create multifunctional hydrogels for tissue engineering.

Using amidation, alginate can also be modified with tyramine groups (Alg-Tyr) for enzymatic crosslinking.234 It has been shown that enzymatically crosslinked Alg-Tyr hydrogels can retain their ability to undergo additional ionic crosslinking upon exposure to calcium (Ca2+).234,235 Furthermore, enzymatic crosslinking of Alg-Tyr hydrogels results in more stable hydrogels, overcoming the potential dissolution that occurs with ionic crosslinking during long-term cultures. In addition to Alg-Tyr, alginate modified with catechol moieties allow for HRP/H2O2 enzymatic crosslinking.236 Hou et al. showed that enzymatically crosslinked alginate hydrogels with catechol moieties results in improved tissue adhesiveness when compared to Alg-Tyr hydrogels.236

One method to functionalize dextran with tyramine groups is to first modify dextran with p-nitrophenyl chloroformate and to subsequently conjugate tyramines by urethane bond formation.121,226 In an alternative strategy, dextran can be modified with di-glycolic anhydride and subsequently functionalized with tyramine groups by amidation.121 Both synthesis methods result in tyramine-modified dextran hydrogels that can undergo enzymatic crosslinking; however, the latter method results in a hydrogel with increased hydrolytic degradability.121 Tyramine-modified dextran hydrogels have been promising towards cartilage repair, especially when combined with tyramine-modified heparin.226,237,238

Many other biopolymers have been modified with tyramine groups for enzymatic crosslinking, including cellulose derivatives,228,239 CS,240 pullulan,240 and chitin.241 Many polypeptides, such as silk fibroin, contain tyrosine residues for HRP/H2O2 enzymatic crosslinking.232,242 However, polypeptides can also be further modified with additional tyramine groups for increased enzymatic crosslinking in hydrogel formation.243,244

4.3.2. Catechol

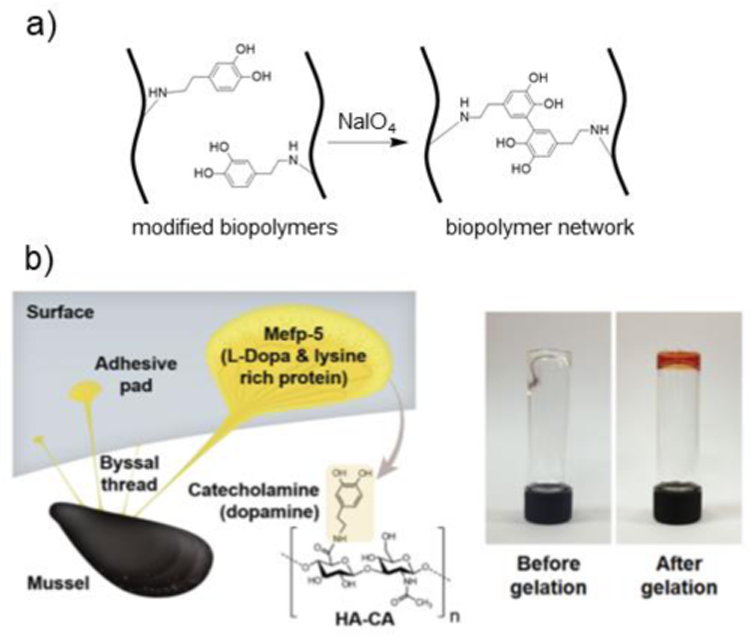

Catechol, the ortho isomer of benzene diol, is a versatile functional group that can undergo crosslinking by the formation of covalent bonds, metal-ligand coordination, and hydrogen bonding.245 Catechol moieties occur widely in nature, with the famous example being mussel adhesion to dynamic wet surfaces due to the secretion of fluids rich in catechol groups.245,246 Inspired by mussels, tissue adhesive hydrogels containing catechol groups have been explored.246,247 Under oxidative conditions, catechol groups can form covalently crosslinked catechol dimers, which have been widely used in hydrogel formation (Figure 9a).245 Dopamine contains a catecholic moiety and has been conjugated to many biopolymers by EDC/NHS amidation reactions.248,249

Figure 9. Crosslinking via catechol reactions.

a) Schematic representation of biopolymers modified with catechol and crosslinking in the presence of NaIO4 to form dicatechol adducts. b) A mussel-inspired, HA hydrogel is formed by modifying HA with catechol moieties (HA-CA). HA-CA is covalently crosslinked in the presence of sodium periodate (NaIO4). Image shows HA-CA hydrogel before (clear) and after (red) gelation. Adapted with permission from Shin, et al.251 Copyright, 2015 Wiley.

Alginate,247 chitosan,250 and HA249 have all been modified with dopamine functional groups for hydrogel formation and tissue-adhesive applications. Lee et al. developed a catechol-modified alginate hydrogel that covalently crosslinks upon exposure to sodium periodate (NaIO4).248 The storage modulus could be tuned from 300 to 6000 Pa, depending on polymer concentration and degree of substitution.248 Furthermore, catechol-alginate hydrogels exhibited increased cytocompatibility when compared to ionically crosslinked alginate.248 Hong et al. demonstrated that catechol-modified HA (HA-CA) hydrogels exhibited strong adhesion to wet surfaces in acidic environments and increased mechanical stability due to the formation of covalent crosslinks in basic environments.249 Covalently crosslinked HA-CA hydrogels have been shown to adhere to both wet and beating tissues in vivo.251 Shin et al. engineered an HA-CA hydrogel for tissue adhesion applications (Figure 9b).251 The hydrogel adhered to liver and heart tissue for at least 1 month in an in vivo rat model. While exposing catechol-modified biopolymers to basic conditions yields rapid covalent crosslinking, Sato et al. showed that HA-CA hydrogels can undergo auto-oxidation and covalent crosslinking under physiological conditions (pH ~7.4) over a period of a few hours.252

5. Dynamic covalent crosslinking

Dynamic covalent crosslinking consists of a subset of reactions that allow for the formation of reversible covalent crosslinks between biopolymers. The dynamic nature of the covalent bonds may introduce shear-thinning and self-healing properties into the hydrogel while maintaining high mechanical moduli for structural integrity. Furthermore, dynamic covalent bonds can introduce stimuli-responsiveness in hydrogel assembly and disassembly. Gelation via dynamic covalent crosslinking may be achieved by one-pot mixing of reactive components. When compared to covalently crosslinked biopolymer networks, biopolymer networks crosslinked via dynamic covalent chemistries may experience faster degradation times and increased cell infiltration both in vitro and in vivo. Mechanical and biological properties of dynamic covalent biopolymer networks will be influenced by biopolymer and crosslinking group concentrations, as well as bond strength and bond formation kinetics. Dynamic covalent crosslinking in hydrogels has been explored for many applications, including tissue engineered scaffolds, drug delivery vehicles, and bioprinting inks. This review will focus on dynamic covalent crosslinking mechanisms commonly used towards biomedical applications, including Schiff base reactions, disulfide formation, and reversible Diels-Alder reactions.

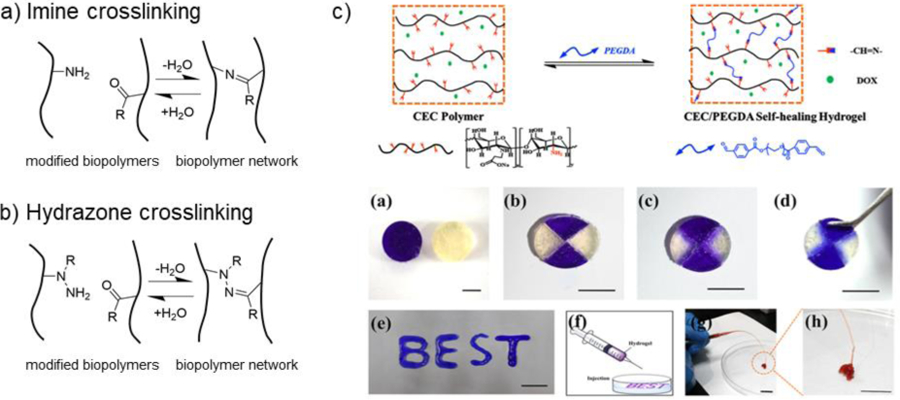

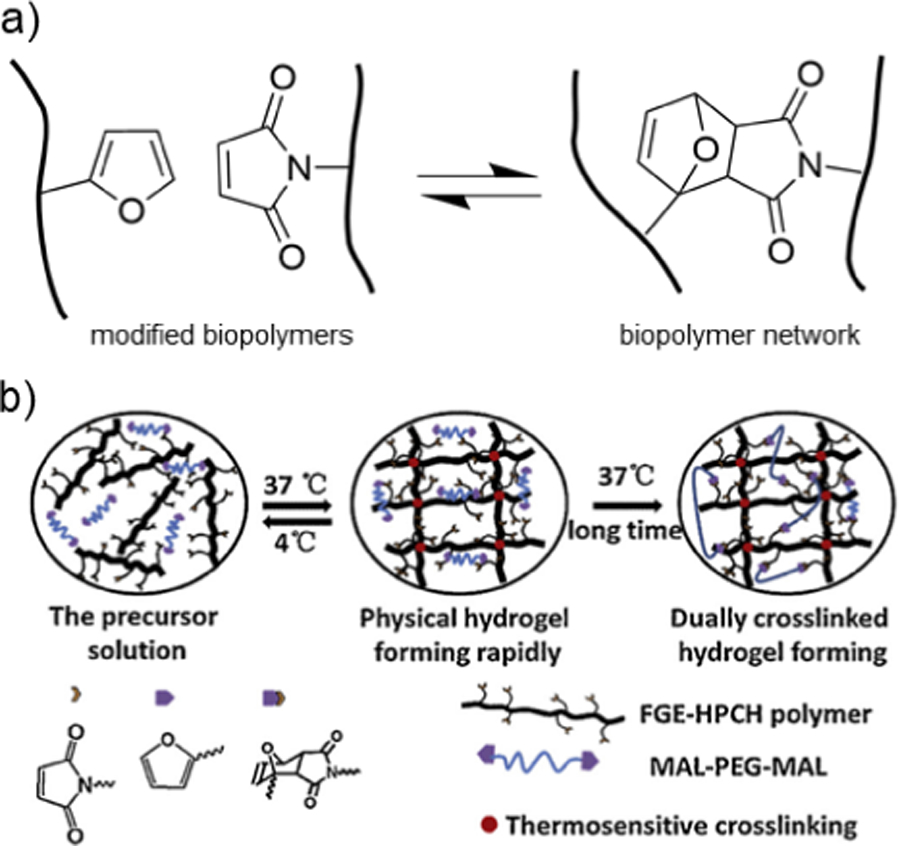

5.1. Schiff base crosslinking