Abstract

Successful regeneration of cartilage tissue at a clinical scale has been a tremendous challenge in the past decades. Microcarriers (MCs), usually used for cell and drug delivery, have been studied broadly across a wide range of medical fields, especially the cartilage tissue engineering (TE). Notably, microcarrier systems provide an attractive method for regulating cell phenotype and microtissue maturations, they also serve as powerful injectable carriers and are combined with new technologies for cartilage regeneration. In this review, we introduced the typical methods to fabricate various types of microcarriers and discussed the appropriate materials for microcarriers. Furthermore, we highlighted recent progress of applications and general design principle for microcarriers. Finally, we summarized the current challenges and promising prospects of microcarrier-based systems for medical applications. Overall, this review provides comprehensive and systematic guidelines for the rational design and applications of microcarriers in cartilage TE.

Keywords: Cartilage tissue engineering, Cartilage regeneration, Microcarriers, Cargo delivery, Bioprinting

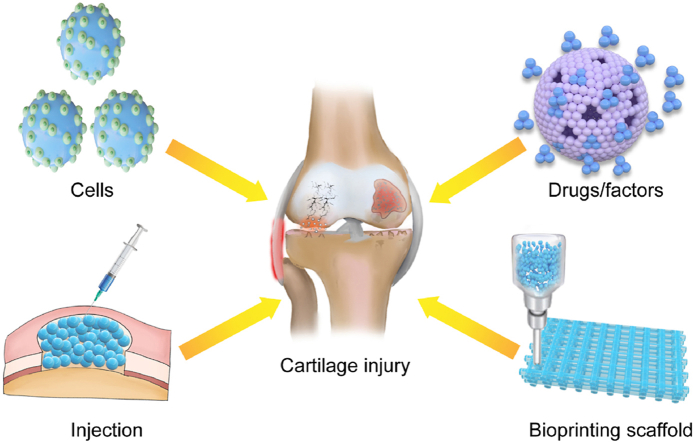

Graphical abstract

Microcarriers applied in joints for the repair of cartilage defects and cartilage regeneration. Microcarriers are three-dimensional culture platform that have been applied as scaffolds in biological and biomedical applications such as cell culture, expansion, delivery, modeling for biological studies, and medical implants, and can be combined with injection and bioprinting techniques for potential clinical application.

Highlights

-

•

This review summarized fabrication techniques and cartilage repaired application of microcarriers.

-

•

The appropriate materials and design principle for microcarriers in cartilage tissue engineering are discussed.

-

•

Promising future perspectives and challenges in microcarriers fields are outlined.

Abbreviations

- 3D

Three-dimensional

- ADSCs

Adipose-derived stem cells

- BMSCs

Bone marrow-derived mesenchymal stem cells

- BMP

Bone morphogenetic proteins

- ECM

Extracellular matrix

- EMM

Electromagnetic manipulation

- GAG

Glycosaminoglycan

- GelMA

Gelatin-methacryloyl

- HA

Hyaluronic acid

- iPSC

Induced pluripotent stem cell

- IGF

Insulin-like growth factor

- MCs

Microcarriers

- MSC

Mesenchymal stem cell

- MA

Methacrylic anhydride

- OPMs

Open-porous PLGA microspheres

- PLGA

Poly Lactic-co-Glycolic Acid

- PCL:

Poly (ε-caprolactone)

- PLA

Poly (lactic acid)

- PLLA

Poly (l-Lactide)

- RGD

Arginine-glycine-aspartic acid

- SF

Silk fibroin

- TNF-α:

Tumor necrosis factor-α

- TE

Tissue engineering

- TGF-β:

Transforming growth factor beta

1. Introduction

Tremendous progress has been achieved in the field of cartilage tissue engineering (TE), which mainly involves transplanting cell-scaffold complexes into a cartilage defect site to repair and improve the structure and function of the damaged tissue [[1], [2], [3]]. Here we review the advancements and enlightenments of microcarriers in cartilage regeneration from the perspective of cartilage TE development, and envision directions for future development. The aim of TE is to develop tissue and organ substitutes that can be transplanted into the diseased or injured counterparts to maintain, or recover their in vivo functions [4]. Based on the classic cartilage TE theory [5], in author's opinions, the key points for successful regeneration include the following: first, renewable sources of function cells and/or signaling factors. Second, scaffold with tunable desired properties (mechanical, chemical and biological properties). Third, implanted substitutes that can easily integrate into the host native tissues with immunocompatibility and biocompatibility. During the past decade, we have witnessed advanced progress in the field of cartilage TE, embodied by the following changes: (i) sufficient seed cell selection for applications (mesenchymal stem cells, induced pluripotent stem cells) [[6], [7], [8]]; (ii) precise patterning of biomaterials and novel biomaterials with advanced chemistries (more efficient and versatile biomaterial conjugations) [1,9,10]; (iii) active modulation of cellular biological functions and behaviors via structure and properties (e.g., stiffness, viscoelasticity, porosity and degradability) of biomaterials [[11], [12], [13]]; (iv) combination of biological drugs and factors are combined to improve bioavailability and bioactivity [[14], [15], [16]]; (v) rapid development of biofabrication technologies including programmed self-assembly and three-dimensional (3D) bioprinting [[17], [18], [19], [20], [21], [22], [23]].

Cartilage consists of a dense extracellular matrix and embedded chondrocytes (the only cell type in the cartilage). According to the composition of the matrix especially the fibers, cartilage can be classified into three main types: hyaline cartilage, elastic cartilage and fibrocartilage. This review mainly discusses knee articular cartilage, which is the most common type of cartilage in the human body and has a semitransparent appearance. As a tough and durable supporting connective tissue, articular cartilage plays supportive and protective roles in the musculoskeletal system. The main components of articular cartilage are water (60–85% of total wet weight), collagen type II (15–22% of dry weight), proteoglycan (15–40% of dry weight), and chondrocytes (2–5% of total cartilage volume) [24,25]. From its surface to its lowest depth, articular cartilage consists of the superficial/tangential zone, the middle/transitional zone and the deep/radial zone. In the superficial zone, type II collagen fibrils are parallel to the articular surface with flattened shape chondrocytes, and this layout confers cartilage with high-tensile stiffness and strength because of the low content of proteoglycans and the low permeability. This zone maintains the function of joint lubrication [26]. Notably, the collagen fibrils are thick and randomly oriented, and the cells are rounder, in the meddle zone, which provides the first defense in resisting compressive forces. In the deep zone, the collagen tough fibrils are perpendicular to the cartilage surface and contain hydroxyapatite, and the interstitial chondrocytes are aligned with collagen fibers [2].

The high stiffness of cartilage is attributed to the viscoelastic and poroelastic dissipation of the tissue networks [27,28]. Abundant strong collagen fibers interpenetrate with proteoglycan macromolecules in the articular cartilage, which provides viscoelasticity and poroelasticity for mechanical dissipation [29,30]. The viscoelasticity of articular cartilage is mainly due to its rearrangement of aggrecan and the reconfiguration of collagen, whereas the poroelasticity is mainly associated with the interstitial fluid movement. Furthermore, articular cartilage is superficially lubricated and presents the most efficiently-lubricated surface known in nature. Such low friction is indeed essential for cartilage well-being. Lubrication minimizes the cartilage degradation associated with osteoarthritis by reducing shear stress on the mechanotransductive, cartilage-embedded chondrocytes [31]. Despite so many protective mechanisms, degenerated articular cartilage, an avascular and aneural tissue, has a very limited capacity for regeneration after damage. Additionally, the hypocellular structure (chondrocytes and stem cells) may also underlie an intrinsic inability to repair [32]. Without appropriate and timely intervention, the chondral defect may extend deep into the subchondral bone [2]. Understanding such composition, structure and characteristics of articular cartilage, therefore, is of major importance to slow or even reverse its breakdown by cartilage TE.

Microcarriers are generally described as microparticles made from natural or synthetic materials with sizes ranging from 1 μm to 1000 μm, that are widely used in drug/cell delivery, regenerative medicine, and TE [33,34]. Moreover, microcarriers have been applied as microspherical scaffolds in biological and biomedical applications such as cell culture, expansion, delivery, modeling for biological studies, biosensor, and medical implants [[35], [36], [37], [38]]. To date, a variety of biomaterials have been developed to fabricate microcarriers using various techniques and methods, such as bioactive inorganic materials, natural/synthetic polymers, and their composites [[39], [40], [41]]. A significant advantage of microcarriers versus bulk scaffolds, hydrogels, or films is that they offer a large specific surface area for cell growth, facilitation of adhesions and maintenance of cell differentiation phenotypes. For example, a study compared cell pellets, collagen hydrogel bulk and collagen hydrogel MCs with regard to the chondrogenic phenotype and matrix synthesis of mesenchymal stem cells (MSCs) in vitro, it demonstrated the advantages of collagen hydrogel MCs microenvironments compared with those of collagen hydrogel bulk and pellets via an improved mimicking of the natural MSC proliferation process and enhanced mass exchange [42]. Microcarriers can be divided into solid and porous microcarriers according to the surface properties. In the solid MCs, cells only adhere on the surface of microcarriers as a monolayer, which limits the amplification of cell numbers, whereas porous microcarriers can offer a larger specific surface area and greater volume [43,44]. Furthermore, the open pore structure facilitates interactions between cells, excretion of metabolic waste, and exchange of nutrients.

Recently, microcarriers have been developed with distinct techniques as candidate materials for cartilage regeneration and have become research focus. The unique histological characteristics of articular cartilage result in its limited self-repair ability, to summarize: (i) cartilage is an avascular and aneural tissue with hypocellular structure (progenitor cells and chondrocytes); (ii) cartilage possesses a dense extracellular matrix (ECM) that limits the ability of chondrocytes to migrate quickly and gather at the damaged site for self-repair; and (iii) the wet and dynamic mechanical environment affects the therapeutic efficacy of drugs and implants in the joint cavity [[45], [46], [47]]. Therefore, the repair of damaged or degenerated cartilage tissue caused by arthritis, injuries, and many other types of damage remains a challenging obstacle in clinical medicine. A sufficient quantity of seeded cells is essential for cartilage regeneration, furthermore, few cell expansion methods are without problems of differentiation and/or loss of potency, that can be met by microcarriers. A study showed that monolayer expanded chondrocytes lost their native morphology within 1 week. Conversely, the use of 3D microcarriers can lead to large cellular yields, preserving of the chondrogenic phenotype for synthesis of cartilaginous tissue in 3 weeks of expansion [48]. Microcarriers can also be used as injectable carriers to directly deliver cells to the defect site, combinated with hydrogel scaffolds, or embedded in bioinks for 3D bioprinting. With such variety, microcarriers have been widely used in cartilage TE.

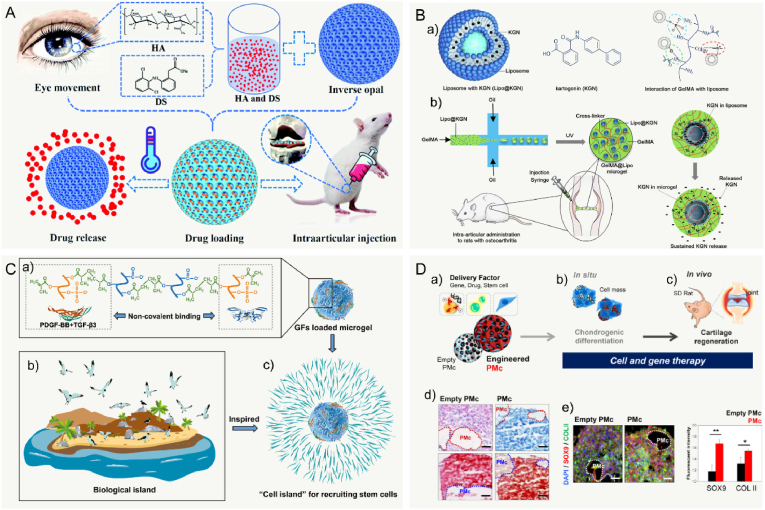

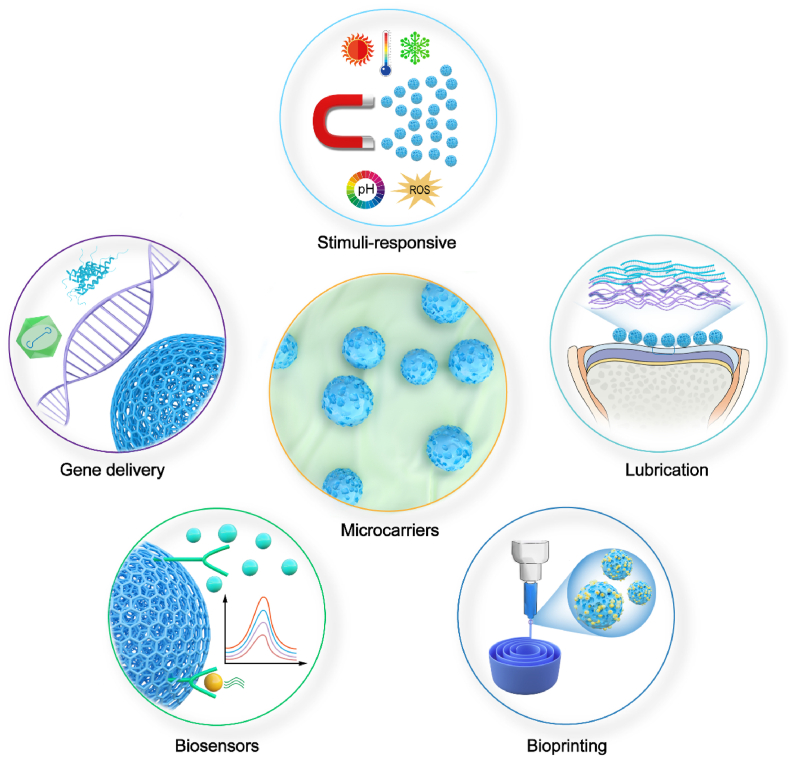

In this review, we concisely outlined the corresponding advantages and fabrication methods of various types of microcarriers that can be customized to fulfil different needs of cartilage regeneration. We then highlighted the recent progress in application of microcarriers in cartilage TE, including the carriers for seed cells or cargo, combination biological scaffold, injectable/bioprinting microcarriers, and bioresponsive microcarriers (Fig. 1). Finally, we summarized the current challenges and promising directions of microcarrier-based systems for cartilage TE. We hope this review can provide comprehensive information and inspire new thoughts to researchers.

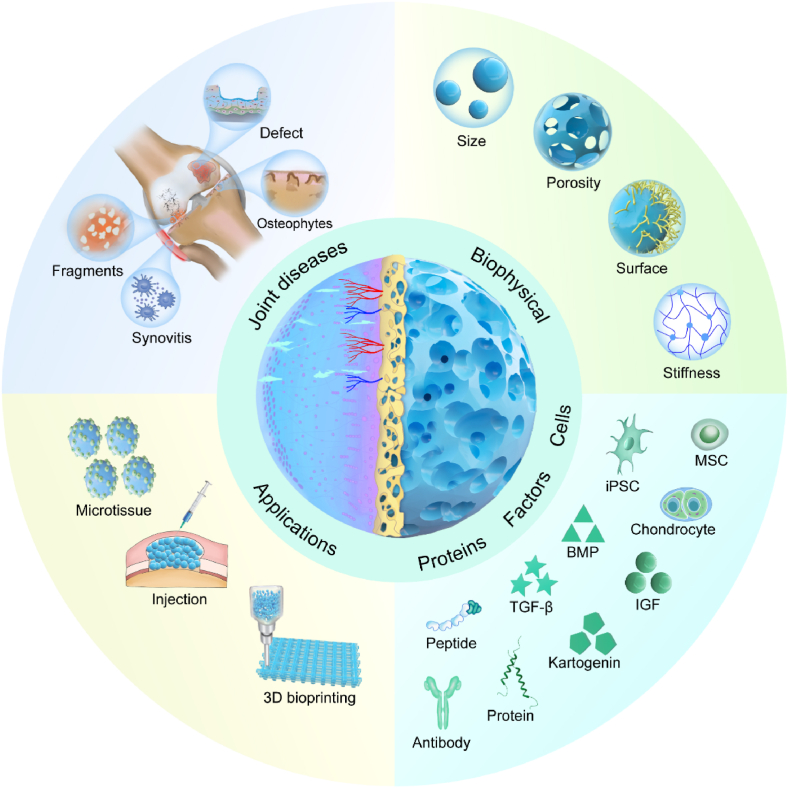

Fig. 1.

A schematic illustration of the microcarrier-based therapeutical platforms, utilizing various methodologies for numerous applications in joint diseases. MSC: Mesenchymal stem cells; iPSC: induced pluripotent stem cell; BMP: bone morphogenetic proteins; TGF-β: transforming growth factor beta; IGF:insulin-like growth factor.

2. Fabrication techniques of microcarriers

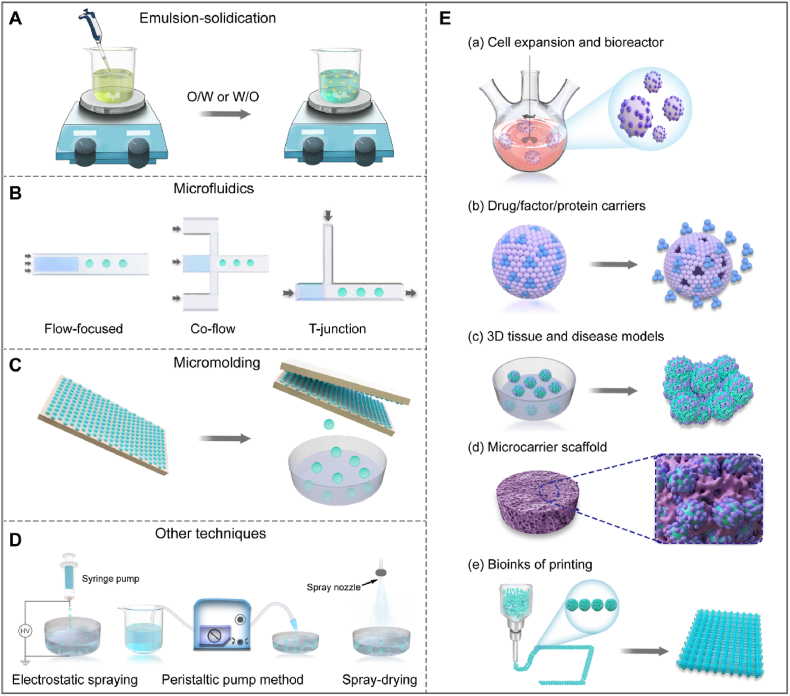

Microcarriers, which have recently attracted much attention in TE, are a class of microspherical scaffolds with biofunctional capabilities in cell culture, delivery and expansion. To date, several methods have been developed for the fabrication of microcarriers. Here we focus on several promising techniques, including emulsion-solidication, microfluidics, the mold method, and more (Table 1). It is extremely important to choose the appropriate preparation methods, balancing polymerization conditions and devices as well as low price, and efficiency to meet different needs. Fig. 2A–D shows typical examples of these microcarriers preparation strategies.

Table 1.

Selected processing techniques for the fabrication of microcarriers.

| Technique | Advantages | Disadvantages | Refs. |

|---|---|---|---|

| Emulsion-solidication | Easily scaled-up, simple and convenient, low cost, | Limited to low viscosity solutions, suffers from a wide particle size distribution. | [37,[49], [50], [51]] |

| Microfluidics | Well adapted to produce monodispersed particles with narrow distribution of particle size | Low production rate, costly and tedious device preparation | [[56], [57], [58],62,63,66] |

| Mold methods | Easily scaled-up, simple and convenient, low cost | Low production rate, costly and tedious device preparation | [68,69] |

| Spray-drying | Easily scaled-up, low cost | Limited polymer range | [73,74] |

| Electrostatic spraying | Small particle size | Very low production rate | [76] |

Fig. 2.

Schematic diagram of fabrication techniques and application of microcarriers. A: emulsion-solidication, O/W: oil-in water; W/O: water-in-oil; B: microfluidics. C: Mold method. D: other techniques, including electrostatic spraying, peristatic pump, and spray-drying. E: The application of microcarriers, including large-scale cell culture (a); drugs/factors delivery platform (b); microtissue construction in vitro (c); combination with scaffolds (d); and injectable and three-dimensional (3D) bioprinting microcarriers (e).

2.1. Emulsion-solidication

The emulsion-solidification technique is the most commonly employed method to fabricate microcarriers from different polymers, various natural biopolymers, including chitosan, alginate, collagen, hyaluronic acid, and gelatin, and synthetic materials such as poly (ethylene glycol), inorganic ceramics, and Poly Lactic-co-Glycolic Acid (PLGA) [[49], [50], [51], [52]]. Polymers usually are classified into two types according to their solubility: oil-soluble polymers and water-soluble polymers. This technique has been described in the literature [37,38,53]. Briefly, the polymer is made into an emulsion of O/W (oil-in water), W/O (water-in-oil), W1/O/W2 (water-in-oil-in-water) or O/W/O (oil-in-water-in-oil) using different emulsification processes (Fig. 2A). The solvent then is removed via different routes depending on the solvent properties for solidification of the polymer to obtain microcarriers; simultaneously, MCs also may be synthesized via physical or chemical cross-linking [54]. In this approach, the stirring speed and emulsifying speed, significantly affects the particle size distribution of the microcarriers (ranging from nanometer to millimeter). Sprio et al. described biomimetic hybrid MCs made of collagen type I-like peptide matrix mineralized with Fe2+/Fe3+ doping hydroxyapatite by emulsification of the hybrid slurries in the presence of citrate ions with a surface functionalization and dispersion ability [55]. The emulsification method is suitable for large-scale production of microcarriers, but limitations exist. The method suffers from a wide particle size distribution, so it is necessary to screen out MCs with the same particle size. In addition, irritating chemical solvents are used in the emulsification process, hence such solvent should be taken into consideration with regard to the cell compatibility.

2.2. Microfluidics

Microfluidics, inspired by an extrusion-solidification technique, perfectly overcome the problem of large particle size caused by injection needles. The microfluidics technique is based on the operation, and control of micro-fluids at the micro-scale using micro-pipes [[56], [57], [58]]. In these techniques, an aqueous polymer solution and typically a nonpolar oil or other fluids are co-extruded to produce consistently-sized droplets [59]. Therefore, the microfluidic device produces MCs with high monodispersity and a controllable size and shape, the operation is simple and superior over conventional emulsification techniques. The production rate of microcarriers can be adjusted by controlling the size of the orifice of the microfluidic channel, the viscosity of the immiscible phases, the hydrophilicity or hydrophobicity of the channel surface, and the velocity ratio of the continuous phase to discrete phase [60]. Currently, three channel designs exist in microfluidics to prepare microcarriers: T-junction [61], co-flow [62], and flow-focused geometries (Fig. 2B) [63,64]. The microfluidics-based procedure typically involves two steps, the formation of emulsion droplets and the solidification of emulsion droplets.

By coupling to photo-crosslinking, the microfluidics can generate cell-laden microparticles with varying sizes and shapes. Lee et al. fabricated macrophage-laden droplets containing methacrylic gelatin using a double a microfluidic flow-focusing device, which was developed a co-culture tissue model to study the mutual effects between macrophages in different stages of differentiation and the surrounding cells [65]. Furthermore, drugs and cells can be loaded at the same time to achieve a sustained release effect. For example, Zhao et al. presented a strategy of microfluidics-assisted technology that entrapped cells and growth factors to generate photo-crosslinkable gelatin (GelMA) MCs [66]. Similarly, photopolymerizable hydrogels from methacrylated laminarin were also been proposed as an enabling platform combination of microfluidics technology [67]. Additionally, microcarriers with superior sophisticated structure can be prepared by microfluidics to mimic the cell adhesive microenvironment (e.g., stem cell niche) [57]. The preparation of polymer MCs by microfluidics is influenced by many factors, including the properties of the fluids and materials, the geometric size and shape of micro-channels, and absolute ratio of liquid velocity to flow rate. Microfluidics can be well adapted to produce monodispersed particles with narrow distribution of particle size; however, the microcarrier production rate is very slow.

2.3. Mold method

In 2014, Liu et al. integrated microfabrication technology with cryogel preparation to develop a microcryogel array chip containing arrayed microscale PEG-derived cryogels with predefined sizes and shapes (Fig. 2C) [68]. The microscale and macroporosity of the novel microcryogels allowed automatic and homogeneous loading of cellular niche components on the array chip using a simple scraping approach. The array chip was generally fabricated with a mold that had many microunits and photo-lithography methods, and the microcarriers with desired shapes were stripped using a matched ejector chip or other techniques [69,70]. However, the application of mold methods may be limited by their low yield and cumbersome steps.

2.4. Other techniques

In addition to the above-mentioned widely used techniques, many other techniques are available, such as the spray-solidification technique [71,72], electrostatic spraying [[73], [74], [75]], and the use of electrostatic microdroplets [76]. Recently, Costantini et al. reported a highly efficient method, pulsed electrodripping, to form porous microbeads with tailorable dimensions, and modeled the process to predict the size of the template droplets [56]. Moreover, Zhang et al. designed a simple and low-cost acid-dissolved/alkali-solidified self-sphering shaping for rapid and facile production of chitosan/graphene oxide hybrid MCs via a peristatic pump method (Fig. 2D) [77]. Generally, most fabrication processes need organic solvents, photoinitiators, chemical crosslinkers, ultraviolet irradiation, and/or cytotoxic reagents, which may be hindered to their medical application. Herein, Tang and coworker presented a simple, flexible, biocompatible technique using gas-shearing strategy to fabricating multifaced MCs [78,79].

The specific surface area and the available cell concentration of solid microcarriers are low. The cells can be easily damaged by dynamic factors such as stirring, collision between MCs, and flow shear force. Macroporous microcarriers can be used widely in a stirred tank biochemical reactor. In the emulsification process, porous microcarriers can be prepared by combinatining with porogens, such as sodium chloride, bicarbonate, ammonium, sodium bicarbonate, gelatin and water [80,81]. The porogen is usually removed by filtration [81], gas-foaming [53,82], or other means according to the porogen properties to desynthesize the porous microcarriers. Huang et al. reported the formation of highly porous chitosan MCs via an emulsion-based, thermally induced phase separation without the use of toxic crosslinkers and chemical porogenic agents other than ice [39]. Furthermore, a novel strategy was presented by Zhang and coworkers that the porogen could be uniformly distributed using microfluidic technique, and subsequent removal lead to the formation of porous architectures [44,83,84]. In summary, the microstructures of microcarriers can be controlled by altering the preparation conditions during the emulsification stage. Functionally, Microcarriers are widely used in medical regeneration, including use in cell expansion/bioreactors, cargo delivery, micro-tissue and disease models, scaffold combinations, and injectable/bioprinting (Fig. 2E). Collectively, each of these preparation methods has its own features and requirements, and each polymer material has its own specific properties and characteristics. Specific requirements should be considered when selecting any of these techniques to fabricate microcarriers for the application of TE.

3. Appropriate materials for microcarriers in cartilage TE

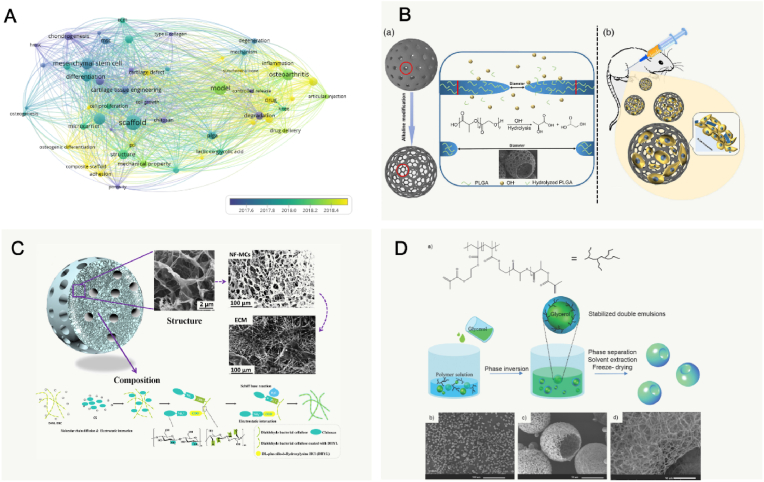

Choosing appropriate materials with desirable physical and chemical properties for fabrication of microcarriers is crucial in microcarrier cultures, because the porosity, mechanical strength, size, density, and shape highly affects the cell phenotypes. Notably, the visualized co-occurrence networks of keywords (VOSviewer version 1.6) indicated that research focus has changed from cells loading systems to applications such as tissue engineering, drug delivery, injectable and controllable degradation in recent years (Fig. 3A). Various sources of materials, including the synthetic polymers, polysaccharides, proteins, and an acellular matrix, can be made into microcarriers (Table 2). Details are described in the following sections.

Fig. 3.

Appropriate composition and structure of microcarriers for cartilage tissue engineering. A: Summary of the published articles of microcarriers of keywords evolution over time in cartilage TE (2015–2021). Its research focus changes (keywords of articles) from cells loading systems in the earlier period to applications such as tissue engineering, drug delivery, injectable and controllable degradation etc. in recent years. B: Schematic illustration for the fabrication and application of open-porous PLGA MCs in cartilage regeneration. Reproduced with permission [86]. 2021, Wiley Periodicals LLC. C: Schematic illustration of nanofibrous microcarriers were designed to structurally and functionally mimic extracellular matrix. Reproduced with permission [166]. 2018, Elsevier Ltd. D: Schematic illustration the emulsification and phase separation techniques to fabricate functional nanofibrous hollow MCs (a) and SEM graphs (b) of functional nanofibrous hollow MCs fabricated from poly (l-lactic acid)-graft-poly (hydroxyethyl methacrylate)-acrylic. Reproduced with permission [167]. 2014, WILEY‐VCH Verlag GmbH & Co. KGaA, Weinheim.

Table 2.

Biocompatible polymer used in microcarriers for cartilage tissue engineering.

| Polymer type | Polymer name | Targeted diseases | Fabrication techniques | Advantages | Limitations | Refs. |

|---|---|---|---|---|---|---|

| Synthetic polymers Polysaccharides |

PLGA | Osteochondral defect Osteoarthritis Acute arthritis |

|

|

|

[[85], [86], [87], [88],92,[212], [213], [214], [215], [216], [217], [218], [219], [220], [221], [222], [223], [224]] |

| PCL | Endochondral defect Osteochondral Defects |

|

|

|

[93,95,225,226] | |

| PLA | Osteochondral defect Cartilage defects Osteoarthritis Degeneration of articular cartilage |

|

|

|

[144,167,[227], [228], [229], [230], [231]] | |

| Alginate | Intra-articular injection Osteochondral defect Osteoarthritis |

|

|

|

[[232], [233], [234], [235], [236], [237], [238]] | |

| Hyaluronic Acid | Cartilage defects Osteoarthritis |

|

|

|

[95,128,239,240] | |

| Chitosan | Cartilage defects Osteoarthritis |

|

|

|

[[241], [242], [243], [244]] | |

| Agarose | Cartilage defects |

|

|

|

[151,164,245] | |

| Cellulose | Osteochondral defect |

|

|

|

[166] | |

| Fibrin | Osteoarthritis |

|

|

|

[246] | |

| Proteins | Gelatin | Osteoarthritis Cartilage defects |

|

|

|

[123,181,183,[247], [248], [249]] |

| Collagen | Articular cartilage defects Osteoarthritis Osteochondral defect |

|

|

|

[168,169] | |

| Silk fibroin | Osteochondral defect Cartilage defects osteoarthritis |

|

|

|

[250] | |

| ECM-based materials | – | Cartilage defects |

|

|

|

[197,199,200,251,252] |

3.1. Synthetic polymers

Synthetic polymers, such as poly PLGA [[85], [86], [87], [88], [89], [90], [91], [92]], poly (ε-caprolactone) (PCL) [[93], [94], [95], [96], [97]], and poly (lactic acid) (PLA) [[98], [99], [100]] are promising materials for cartilage TE. Generally, synthetic polymers can be processed via many techniques with good physical, mechanical, and chemical properties that can be modified to improve the parameters of the microcarriers. Most of these polymers are biocompatible as they can degrade into components that are metabolizable in the body.

PLGA is a reliable and high-performance copolymer owing to its biodegradability and biocompatibility. The PLGA matrices ultimately degrade into lactic acid and glycolic acids by hydrolysis of the ester linkages, and the acids are then eliminated as carbon dioxide and water [101]. A suitable degradation that matches the rate neotissue formation is necessary for tissue regeneration. A recent study demonstrated that PLGA-rapamycin MCs could be used successfully not only for sustained release of rapamycin (more than 3 months) but also be used as cell carriers for cellular therapy [35]. Another study developed an acellular agarose hydrogel carrier with embedded dexamethasone-loaded PLGA MCs to provide sustained release for at least 99 days, which indicated a better histological score compared with an osteochondral autograft transfer in a pre-clinical canine model [88]. Apart from the superior biocompatibility of PLGA, surface structures of opened pores could enhance metabolic activities and improve tissue regeneration. Qu et al. modified traditional porous PLGA MCs with NaOH to obtain open-porous PLGA MCs (OPMs), in which pore sizes could be large enough for cellular infiltration and migration into the inner space (Fig. 3B) [86]. Together, MCs made of PLGA have been extensively used as cell and/or drug carriers in cartilage TE with excellent performance as a result of their larger pores, controllable degradation, and increased surface roughness. However, it has been reported that the acidic degradation of PLGA can reduce the local pH low enough to create an autocatalytic environment [102].

PCL is also known as a robust biocompatible and biodegradable material. It is one of the most commonly used polymers for cartilage repair and has initial mechanical stability tailored to mechanical properties [103]. Remarkably, chondrogenic and osteogenic cells have been successfully co-cultured on porous PCL scaffolds. However, chondrocyte seeding onto macroporous PCL results in uneven cell distribution, cell loss, and initial dedifferentiation due to the monolayer-like cell attachment [104]. Lam et al. reported that porous PCL microcarriers coated with extracellular matrices can be used to efficiently expand a variety of MSC lines in a cost-effective manner while maintaining surface markers expression and differentiation capability [97]. Osteochondral defects involve multiple tissues, and a biphasic scaffold model that combines a cartilaginous phase and a bony phase is the most common strategy for cartilage TE. A novel strategy for constructing the hydroxyapatite (HA)/PCL MCs using a selective laser sintering technique, demonstrated that the multilayer scaffolds could induce articular cartilage formation by accelerating the early subchondral bone regeneration [97]. The PCL polymer has been widely used in cartilage TE; however, its application is limited by hydrophobicity and the lack of active functional groups.

PLA is approved by the U.S. Food and Drug Administration as a biodegradable polyester that is used to produce MCs, and it has been proposed as a support matrix for cartilage TE [105]. Notably, PLA possesses chirality, which enable the mid-chain residues to exist in three enantiomeric states, l-Lactide, d-Lactide, and meso-lactide. The most widely used PLA is the poly (l-Lactide) (PLLA) [106]. Using star-shaped PLA technology, Liu et al. have fabricated nanofibrous biodegradable hollow MCs as injectable chondrocyte carriers for knee cartilage repair. The self-assembled MCs were designed to mimic the structure of collagen fibers in the ECM, and the study showed that MCs are an excellent cell carrier for chondrocytes to facilitate high-quality hyaline cartilage regeneration [107]. An advantage of PLA-based biomaterials is their ability of well-established processing technologies with the appropriate mechanical properties such as injection molding and 3D printing [108]. For example, it was shown recently by Ghosh et al. that PLA MCs contained decellularized cartilage matrix, and they successfully fabricated a hybrid PCL filament containing MC encapsulating ALP enzyme as a surrogate via melt extrusion [98].

In summary, the synthetic polymers discussed in this section have been widely studied for cartilage TE. Despite the high mechanical strength of these polymers, most are biologically inert. Thus, increasing works combined natural biological macromolecules with synthetic polymers to simultaneously provide good mechanical strength and support biological functions.

3.2. Polysaccharides

Alginates, as anionic natural polysaccharides, are derivated from bacteria or the cell walls of brown marine algae and possess biocompatibility, solubility and hydrophilicity, but do not readily degrade in-vivo [109]. As per the degradation rate consideration, one study showed that the degradation rate of alginate microbeads can be controlled by incorporating alginate-lyase in the hydrogel at 4 °C [110]. Consequently, the controlled degradation MCs could affect cell release rates and growth factor production [110]. Another experiment with alginate demonstrated that decreasing alginate molecular weight can also promote the degradation of alginate MCs [111]. Despite these credentials, alginates biofunctionality is challenged by the absence of arginine-glycine-aspartic acid (RGD) molecules, which affects interactions with proteins and cells (e.g., adhesion of cells). In 2014, RGD-modified alginate MCs were prepared by Woo et al. using an emulsion method, and results indicated that the MCs formed an aggregate in the presence of chondrocytes and effectively regenerated cartilage tissues in vivo [112]. The application of alginate is limited by its mechanical strength. A recent research study using a novel strategy showed that calcium alginate Janus MCs were made with MSCs in one compartment and iron oxide magnetic nanoparticles or drug-loading ability in the other compartment, which showed proper formation of calcium alginate and displayed mechanical integrity lasting up to 30 days, targeting was controlled using an electromagnetic manipulation (EMM) device [113]. Alginate can be used in various biofabrication techniques, including molding, spraying, and 3D bioprinting due to the ability of physically crosslinks via divalent cations (e.g., Ca2+) [114,115]. Despite these successes, alginate hydrogels have some limitations. For example, the alginate microcarrier with physical crosslink lacks long-term stability. Furthermore, alginate lacks a cell adhesive site and cellular interaction ability, resulting in alginate MCs that are generally modified with cell adhesion peptide, polymer modifiers, and oppositely charged polysaccharides [116,117].

Hyaluronic acid (HA), as the most abundant glycosaminoglycan (GAG) in native cartilage, is a linear biomacromolecule and the component of articular cartilage in the extracellular matrix (ECM), and is composed of repeating units of β−1,4-d-glucuronic acid-β−1,3-N-acetyl-Dglucosamine residues that can maintain cartilage homeostasis [118]. HA is involved in some key cellular processes of chondrocytes (including morphogenesis and proliferation) and has stimulatory effects on chondrocyte metabolism in vitro, which could significantly increase the synthesis of collagen type II, hydroxyproline, and glycosaminoglycan [[119], [120], [121]]. HA is also well known for interacting with specific receptors such as CD44, to regulate signal transduction, cell migration, and differentiation [122]. Therefore, tissue-mimetic pellets composed of chondrocytes and HA-graft-amphiphilic gelatin microcapsules can serve as biomimetic chondrocyte ECM environments with targeting on CD44 receptors, and these MCs can stimulate chondrogenesis and sulfated glycosaminoglycan synthesis [123]. The injectability of hydrogels broadens the clinical applications for drug delivery and regenerative cell therapies. HA has abundant carboxyl and hydroxyl groups that can be modified by various chemical reactions to control the mechanical properties of HA, including degradation resistance and elasticity [124]. Additionally, the multifunctionality (e.g., self-healing and shear-thinning properties) of HA can be obtained by introducing biofunctional molecules or reactive moieties to provide ease of injectability [125]. HA-based hydrogel particulates have been developed by incorporating bioactive ceramic nanoparticles to enhance the structural stability of HA under enzymatic degradation. However, a high injection force resulting from the presence of nanosized ceramic fillers and nonuniform shapes and sizes of gel granules is unavoidable [126]. To address this challenge, the injectable HA-based hybrid hydrogel MCs with nanosized calcium phosphate were fabricated using a W/O emulsion process and in situ precipitation process [127]. In clinical practice, uncross-linked HA is generally mixed as a lubricant. A more recent study developed an inverse opal-structured MC scaffold for osteoarthritis treatment, and used the HA microcarrier as a lubricant vehicle to deliver drugs when the temperature increased in the joint cavity during exercise or osteoarthritis [128]. In addition, HA can be modified by chemical reaction of carboxylic group and photo-crosslinkable functional groups such as methacrylate and glycidyl methacrylate. As a result, a variety of HA-based microcarriers can be fabricated towards controllable biodegradability and improve mechanical properties.

Chitosan is a naturally linear polysaccharide composed of N-glucosamine and N-acetylglucosamine units from the shells of shrimp and other crustaceans and the molecule cationic was obtained from the amino/acetamido group in chitosan [129]. Chitosan has been known as a promising candidate material in cartilage TE due to its excellent biological functions, including antibacterial properties, biodegradable, affordability, lack of immunogenicity, and biocompatibility that promote cell adhesion, proliferation, and differentiation [[130], [131], [132], [133]]. Moreover, Chitosan is a repeating glucosamine unit, which is an essential ingredient for the synthesis of glycoproteins [134,135]. For example, Sheehy et al. reported that chitosan constructs accumulated the highest levels of sulfated glycosaminoglycan and collagen compared with alginate and fibrin [136]. In addition, chitosan has a hydrophilic surface that it may maintain and attract fluid and cells to defective sites [137]. Ma and coworker prepared chitosan microcarriers that impregnated with soybean protein isolate, their outcomes show that composite microcarriers better-supported cell adhesion and proliferation than chitosan microcarriers [138]. Several chitosan-based scaffolds have demonstrated good results because of the structural similarities between sGAG in the articular cartilage and chitosan. These scaffolds can provide a suitable microenvironment for chondrocytes to maintain the correct phenotype, to sustain chondrogenesis, and to repair cartilage tissue defects [[139], [140], [141]]. On the whole, the porous structures in chitosan can be prepared by freeze-drying acidic solutions or gels. Specifically, Lu et al. fabricated porous chitosan microcarriers with sizes ranging from 180 μm to 280 μm using an emulsion-solidification technique combined with freeze-drying [142].

Nevertheless, the mechanical stability of the chitosan scaffold is inadequate hindering the production of MCs with stable structures and controlled sizes, thus, the scaffold cannot easily be applied in clinical cases. To address this limitation, an appropriate strategy for combining the chitosan hydrogel and solid-state bio-matrix could overtop the inadequate mechanical stability of chitosan [132,143]. Subsequently, a novel kind of porous PLGA/chitosan polyelectrolyte complex MC was developed by electrostatic interaction using the emulsion-solidification technique combined with freeze-drying for its simple operation and easy scalability [144]. Another study that attempted to address the poor mechanical properties of chitosan, involved preparation of size-controllable chitosan/PEGDA hydrogel MCs using a water-in-oil approach after photo-crosslinking and physical-crosslinking, results showed that these cell-laden MCs were self-assembled into a 3D cartilage-like scaffold [145]. Furthermore, many studies have indicated that the physical properties of chitosan were mainly affected by the molecular weight, the sequence of the acetamido/amino groups, and the purity of the product [146,147]. The poor solubility in water, the low cellular interaction, and the allergenicity of chitosan may limit extensive translation of chitosan into clinical use [148,149].

Agarose is extracted from marine red algae composed of alternating units of 3,6-anhydro-α-l-galactopyranosyl and β-d-galactopyranosyl units, which is a thermosetting hydrogel that undergoes gelation in response to a reduction in temperature [150,151]. Specially, agarose forms a gel when cooled to below an upper critical solution temperature (UCST), and this process is related to the agarose molecule twisting [152]. Various factors such as concentration, molecular weight, and lateral groups significantly affect the melting and gelling temperature [153]. Therefore. The agarose polymer can be transformed into microcarriers by extrusion of droplets hardened when the temperature is lower than UCST. Furthermore, other preparing methods (e.g., water-in-oil emulsion, microfluidics) are also followed by a reduction in the temperature to allow gelation of the agarose droplets. For example, Sakai et al. developed agarose microcapsules with a single hollow core templated by alginate microcarriers, and subsequently the vascular endothelial cells grew and formed embryoid body-like spherical tissue in the core [154]. Moreover, agarose is also successfully used as a biocompatible substrate combined with ceramic contents for augmentation, such as bioactive ceramics or glasses [155]. Composite microspheres were prepared for the first time by agarose enforcement with combination of biphasic calcium phosphate and calcium sulfate dehydrate [156]. In more recent study, Zhao et al. prepared agarose microcarriers with a controllable pore structure by varying agarose types and crosslinking degrees. Various agarose could tailor the gel formation of microspheres matrix and thus affect the final pore structures [157]. Agarose hydrogel, along with proper biocompatibility and biodegradability, can offer a suitable microenvironment for chondrocytes, and stabilize the chondrocyte phenotype and enhanced the proteoglycan and glycosaminoglycans precipitation [158]. Particularly, low concentration agarose increased the deposition of the extracellular matrix, which improved the mechanical properties [159]. Therefore, the distinctive advantage of agarose hydrogels is the encapsulation of chondrocytes which enables 3D culture maintaining the cellular phenotype or morphology. Collectively, agarose and its composites presented a conspicuous role in the cartilage TE due to the excellent characteristics, such as mechanical properties, biocompatibility, nontoxicity, and high cell interaction.

Cellulose is a linear chain polysaccharide consisting of d-glucose units. Notably, bacterial nanocellulose is nanofibrillar material that combines high flexibility and tensile strength, and it has a nano-network structure similar to the collagen fibrils in tissue ECM. Cellulose has various advantages as a nanoscale structure and is available in different formats for cartilage regeneration [[160], [161], [162], [163]]. Moreover, the production of cellulose is more economically practicable due to the reasonable cost, yet approaches are application-dependent and vastly diverse. For example, porous bacterial cellulose scaffolds, as described by Yin et al., were prepared by cultivating Acetobacter xylinum in the presence of agarose microparticles, which could control the physical dimensions of the pore network [164]. However, an intrinsic limitation of TE is the compact structure with the 0.02–10 μm in the fibril network, resulting in slow biodegradation and limiting cell penetration and migration [162,165]. To address these concerns, bacterial nanocellulose has been modified by chemical and physical methods, including modification of chemical structure and functionalities, changes in porosity, crystallinity, and fiber density, respectively [161]. In a more recent study, Wang et al. fabricated the bionic nanofibrous microcarriers to mimic collagen microfibers, and hydroxylysine and chitosan by crosslinking dialdehyde bacterial cellulose through electrostatic interactions (Fig. 3C). The biodegradation rate as well as mechanical properties and porosity could be regulated by the orthogonal design [166]. Collectively, fibrous microcarriers may represent real progress in the development of biomimetic MCs. However, it is a challenge to control fiber diameter and micro-nano structure as well as pore geometry to affect cell attachment and cell–cell interactions.

Overall, polysaccharides have been used in the field of cartilage TE because of their high biocompatibility and resemblance to the glycan constituent of the ECM. However, the presently available polysaccharide microcarriers exhibit limitations, including the lack of active functional groups, the low mechanical strength, and fast degradation rate. Therefore, a reasonable strategy involves combining these polysaccharides with another category of polymers.

3.3. Protein

Collagen is a type of ECM protein that has low immunogenicity in native cartilage and can support the proliferation and maturation of chondrocytes. One study that established 3D collagen MCs, demonstrated the phenotypic changes of primary human osteoarthritic chondrocytes in collagen MCs when exposed to a few external factors [168]. In another study, Yu et al. prepared type I collagen MCs seeded with chondrocytes for 14 days, which showed the formation of cartilage particulates in vitro [169]. Notably, another study found that type II collagen could convert auricular chondrocytes into articular cartilage after dedifferentiation by a two-step protocol [170]. Collagen reduce the risk of immune response by ECM formation, and can be used as a coating material for microcarriers to improve cell adhesion. In natural ECM, collagen nanofibers are found to improve stem cell attachment, proliferation, and differentiation along various lineages. Zhang et al. successfully synthesized a novel functionalized graft copolymer that can self-assemble into functional nanofibrous hollow MCs (Fig. 3D). The results showed the nanofibrous structure could enhance the efficacy of GF signals in stem cell differentiation [167]. Moreover, collagen can be combined with other polymers to form hybrid hydrogel scaffolds that have enhanced properties compared with those of the individual components. For instance, collagen-coated PLA microcarriers have been successfully fabricated, the results indicated that the mechanical properties of scaffold were substantially enhanced, and formed cell attachment [171]. Type I collagen is widely employed as scaffolds products for cartilage TE in clinical treatment. Nonetheless, the pure type I collagen suffers its limited biological activity and weak mechanical properties. Compared with type I collagen, type II collagen shows better chondrogenic performance. However, type II collagen is not an ideal polymer for cartilage TE due to its arthritogenic potency [172].

Gelatin, as a hydrolyzed form of collagen, is famously used for various medical diseases due to its biocompatibility, proteolytic degradability, and controlled delivery system advantages [173,174]. The gelatin microcarriers can provide a surface for cellular adhesion and proliferation, while simultaneously allowing control over the release of drugs or biological agents [175]. The biodegradability of gelatin microcarriers can be achieved by collagenase. For instance, Ng et al. fabricated dissolvable gelatin-based microcarriers for MSC expansion [176]. Another study showed that the gelatin microcarriers could enhance the efficiency of chondrogenesis in bone marrow stromal cells (BMSCs) in vitro [177]. In term of safety, gelatin microcarriers were seemed to be non-cytotoxic and noninflammatory because of low immunogenic properties. In terms of efficacy, the gelatin microcarriers can maintain drug levels in the plasma for more than 48h [178]. Generally, the content and the degree of crosslinking of gelatin could influence the biodegradation of gelatin microcarrier, resulting in the rate of drug release. These studies demonstrated that the controlled release of biologics is vital to ensuring success in tissue regeneration. Besides, methacrylic anhydride (MA) can be easily modified with gelatin to form photo-crosslinkable GelMA. Several studies have prepared GelMA MCs via ultraviolet cross-linking [[179], [180], [181], [182], [183]]. The gelatin MC has been endorsed for its potential in cartilage TE applications. However, the major disadvantage of poor mechanical properties limits its application for medical purposes [184]. Taken together, the gelatin microcarrier not only can provide a platform for cellular and drug delivery, but also serve as a building block to form a more complex tissue construct.

Silk fibroin (SF), as a natural fibrous protein, exhibits non-toxicity, excellent biocompatibility and biodegradability, self-assembly, and mechanical stability for the development of microcarriers [185,186]. The silk of silkworm cocoons consists of fibroin (a semicrystalline fibrillar protein) and sericin (a water-soluble glue-like protein) [187]. Singh et al. fabricated an agarose/silk fibroin hydrogel via minimal secretion of tumor necrosis factor-α (TNF-α) by murine macrophages. The results demonstrated that silk is an alternative biomaterial with good immunocompatibility for cartilage TE. Pure silk fibroin-based microcarriers were fabricated by Wang et al. using a high voltage electrostatic field [188]. Fang et al. prepared silk fibroin porous microcarriers containing strontium for injectable bone TE [189]. In addition, various biopolymers have been combined with silk fibroin to improve its mechanical and biological properties. For instance, Perteghella et al. innovatively developed composite microcarriers containing SF and alginate to realize cell delivery [190]. Conventionally, the SF of composite microcarriers is induced into the β-sheet conformation, which could provide a more stable, insoluble homogeneous structure by immersion with ethanol [[190], [191], [192]]. Furthermore, the SF could be combined with positively charged polymers, such as chitosan and collagen, to provide an adhesive microenvironment [193,194]. It is worth noting that pure SF is difficult to degrade in vivo, and its poor thermal stability also limits its biological application. Although few studies about SF-based microcarriers have been reported for cartilage TE, this type of biomaterial has a great potential biomedical application prospect. Interestingly, there is still no study to develop serin-based microcarriers owing to its water solubility and weak mechanical properties [195].

Proteins are denatured by high temperature, physical stress, or exposure to strong organic solvents. Furthermore, protein-based microcarriers may be hampered by its weak mechanical strength, and shrinkage, which could be optimized through blending with other materials. Considering the aforementioned works, proteins served as essential polymers for the next generation of cartilage TE due to their excellent biocompatibility and biodegradability.

3.4. ECM-based materials

Polymers derived from the cartilage ECM are widely used in cartilage tissue regeneration, because they can provide a highly biocompatible environment for proliferation of chondrocytes and MSCs. In a previous study, cartilage ECM/peptide coating microcarriers could improve MSC expression of CXCR4, and trigger MSC migration from microcarriers for cell therapy [196]. Yin et al. proposed a novel cell carrier derived from natural cartilage ECM, which can support proliferation of MSCs and facilitate their chondrogenic differentiation without the exogenous growth factors [197]. ECM not only offers a complex 3D microenvironment for the survival, organization and differentiation of the cells, but also accelerates the formation of tissue-engineered cartilage because of simulating the native osteochondral tissue. In addition, ECM plays a key role in the transmission of mechanical forces, growth factor release and signaling [198]. The decellularized extracellular matrix (dECM) can be termed by all cells and genetic material while maintaining the physical and biochemical characteristics. Sivandzade et al. introduced porous injectable microcarriers composed of dECM of cartilage tissue, which could be a potential candidate to be used in cartilage tissue engineering applications [199]. A more recent study, the bionic cartilage acellular matrix MCs were prepared for chondrogenic differentiation of bone marrow cells and combination with microfracture [200]. These study support that the ECM proteins from cartilage acellular matric may provide favorable conditions for cells toward chondrogenesis. However, the disadvantages of using dECM are also obvious, like weak mechanical properties rapid in vivo degradation, limited source. Hence, standardized decellularization procedures and guidelines primarily need to be provided in the future.

As mentioned previously, various synthetic and natural biopolymers have been used for the fabrication of microcarriers. Synthetic materials provide high reproducibility and tailorability. However, synthetic biopolymers exhibit disadvantages that include poor hydrophilicity, cytocompatibility, and low biodegradability. Although natural biopolymers have excellent biocompatibility, there are also limitations such as poor mechanical properties, low cell adhesiveness and cellular interaction, uncontrollable degradation, and the inconsistency of source batches. Therefore, selecting a desirable biomaterial in microcarrier development to that will improve the biological properties. The ideal biomaterial will provide microcarriers that are similar to native cartilage in composition and structure.

3.5. Surface biological modification of microcarriers

The interaction between the microcarrier surface, surrounding medium, and cells are critical for the cell cultures, and cell attachment involves interaction between cell adhesion molecules and various substrates on the surface of the microcarrier [201]. There are a number of adhesion factors, such as fibroblast growth factor, bone morphogenetic protein, endothelium, glass fibronectin, which need first be absorbed before the adhesion of cells to the MC surfaces [202]. Notably, some protein like collagen, laminin, and fibronectin, can also improve the cell attachment on microcarriers [203]. For example, Lu et al. modified the surface of porous carboxymethyl chitosan microcarriers with collagen for application in cartilage TE [204]. Moreover, the introduction of collagen can enhance the proliferation, and differentiation of cells in MCs. Surface modification of MCs with short peptide sequences or growth factors is an attractive approach to guiding the spatially and temporally complex multicellular processes. Dandekar et al. illustrated the procedure for expansion of human BMSCs on collagen-I-based recombinant peptide-based microcarriers [205]. The growth factors paly crucial roles in situ cell recruitment and attachment. Gelatin microspheres have been used as a method of releasing TGF-β1, which is a secreted protein to create 3D pieces of cartilage tissue [206]. The growth factor TGF-β3 has also been explored for cartilage regeneration, other growth factors, such as bone morphogenetic protein (BMP)-2, have been utilized in similar degradable microspheres to stimulate chondrocyte development [207]. One can add surface moieties to the MCs that will improve cell attachment by tailoring the surface chemistry or functional molecular. Functional groups such as hydroxyl, carboxyl, and amino groups can be introduced to the surface modification to obtain hydrophilicity and positive surface charge [208]. Besides, surface charge and hydrophilicity can be achieved by incorporating chemical groups, e.g., amino groups (-NH2) or carboxyl groups (-COOH), which can also significantly affect cell attachment and behavior [209]. And several studies have shown that a better attachment on positively charged compared to negatively charged microcarriers [210,211]. However, the charge on the surface of the microcarrier will affect the dispersion between the MCs and easily adsorb surrounding impurities. The ability of adhesion and proliferation of cells was clearly improved by modifying the surface hydrophilicity. It is well-established that slightly hydrophilic surfaces lead to better cell attachment than hydrophobic (>90°) and superhydrophobic (>150° contact angle) surfaces [211]. Therefore, these functional molecules are a common route to improve cell adhesion, proliferation, and differentiation. However, these bioactive moieties are often expensive, and the process of chemically linking them to microcarriers is very complicated. It is worth considering that cell-surface, protein-cell interactions as well as protein-surface should be carefully investigated.

4. Microcarriers design application in cartilage TE

In cartilage TE, two main ways have been proposed for the regeneration of cartilage (including at the osteochondral interface and full-thickness). One method involves preparation of complex scaffolds to mimic the architectural features, mechanical properties, and biological functions of native cartilage tissues. The other approach is to develop the appropriate biomaterials that serve as a temporary 3D microenvironment for chondrogenic cell growth, proliferation, and differentiation to generate cartilage tissue [253]. To produce desirable engineered cartilage, we still need to prioritize three elements of TE: cells, scaffolds, and growth factors [254,255]. MCs are mainly applied as the form of hydrogels or sponge scaffolds in drug delivery or cell carriage. In this section, we summarize advantages of microcarriers as cell/drug/factor-laden delivery platform, and in combination with biological scaffolds to achieve efficient chondrogenesis for cartilage regeneration. Furthermore, we highlight recent advances in biomanufacturing technologies (e.g., 3D bioprinting) for the fabrication of MC-based scaffolds to mimic the native cartilage counterpart. Understanding these methods affect MC and scaffold properties, thereby serving as a valuable guide for the design of microcarriers or MC-based scaffold for diverse clinical needs.

4.1. Delivery vehicles and scaffold for cargo/cells

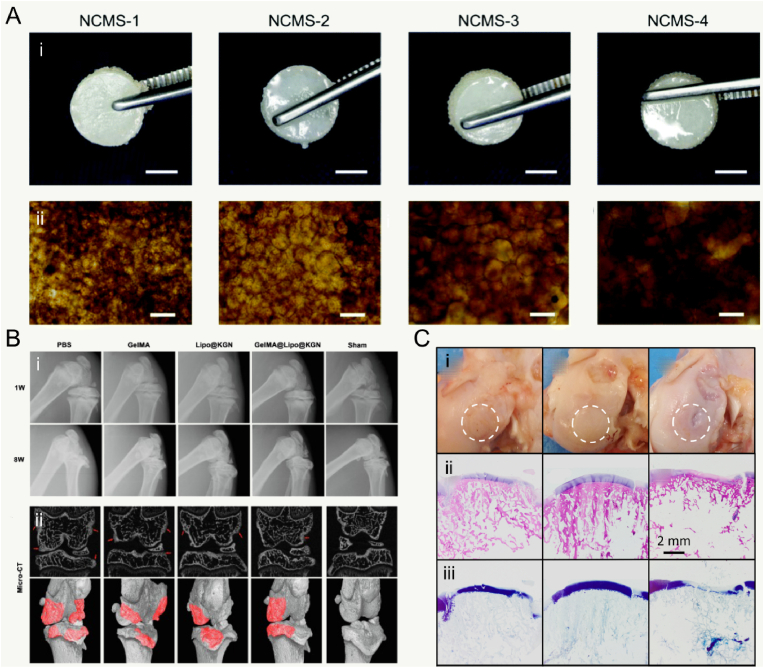

Many clinical therapeutics like intra-articular drug injection have been widely used for treating joint diseases. But some shortcomings still need to be overcome. First, drugs need to be administered frequently and repeatedly to reach the therapeutic dose, which may cause the increasing of drug level. Second, some existing drug delivery systems released the drugs rapidly and exceed the therapeutic concentration and the maximum safe level. In past decades, various microcarriers have been developed for controlled drug delivery to reduce dosing frequency and to improve the therapeutic effects by minimally invasive Injection. In general, drug delivery microcarriers are often prepared by natural or synthetic polymers. The cargo (e.g., drug and factor) is encapsulated in MCs to increase the bioavailability and provide a long release period with constant drug plasma concentration [256]. Moreover, Controllable MC porosity and pore structure are important properties. In one recent study, Yang et al. prepared the smart microcarriers that could shrink or swell to release the drugs with pathological response switches for treating osteoarthritis [128] (Fig. 4A). Therefore, the release rate of the delivered drugs can be precisely regulated by controlling the porosity of the MCs. Similarly, Han et al. successfully developed lubricating MCs encapsulated with an anti-inflammatory drug of diclofenac sodium [181]. The result showed that these MCs possessed lubrication and controllable drug release for the treatment of osteoarthritis. With regard of releasing drug for a long period, the Immobilizing liposomes, interacted with GelMA microgels by the physical network, were designed to protect Kartogenin against rapid clearance in the joint cavity [183]. These microgels could extend Kartogenin release for over five weeks (Fig. 4B). The flowability and flexibility of microcarriers allow them to disperse adequately in the solution and fulfill the requirement of joint loading. Additionally, more researchers believe that the functional microcarriers should be combined with bioactive factors to promote the growth and differentiation of seeded cells. In more recent study, inspired by the recruiting of seabirds home to nesting, Lei et al. fabricated cell island” microgels that encapsulated platelet-derived growth factor-BB and transforming growth factor-beta3 to recruit stem cells [257] (Fig. 4C). Collectively, microcarriers, as a carrier for drug delivery, can be prepared to provide excellent encapsulation performance and advanced controlled release performance.

Fig. 4.

Microcarriers served as cargo/cells delivery platform in application of cartilage TE. A: Schematic diagram of the generation of the bio-inspired lubricant drug delivery particle derived from HA with pathological-state responsive switches for the treatment of osteoarthritis. HA: hyaluronic acid and DS: diclofenac sodium. Reproduced with permission [128]. 2020, the Royal Society of Chemistry. B: Schematic of kartogenin-loaded liposomes, chemical structures of kartogenin, and non-covalent interactions between GelMA and liposomes, the kartogenin-loaded GelMA@Lipo hybrid microgels were used for treatment in a rat osteoarthritis via intraarticular injection. Reproduced with permission [183]. 2020, Elsevier B.V. C: Inspired by the phenomenon where islands can recruit seabirds for nesting, the “cell island” microgels were employed for recruiting the stem cells. The injectable porous microgel was fabricated by photopolymerization of methacrylated hyaluronic acid and heparin (HAMA@HepMA) blend pregel droplets generated via microfluidic technology. Subsequently, PDGF-BB and TGF-β3 were non-covalently incorporated within the microgels by binding heparin. Reproduced with permission [257]. 2021, Wiley‐VCH GmbH. D: Brief illustration of the preparation and analysis of histology by Alcian blue staining and Safranin-O staining of stem cells mixed with pocket-type microcarrier. Scale bar: 500 μm. Reproduced with permission [258]. 2021, The Authors.

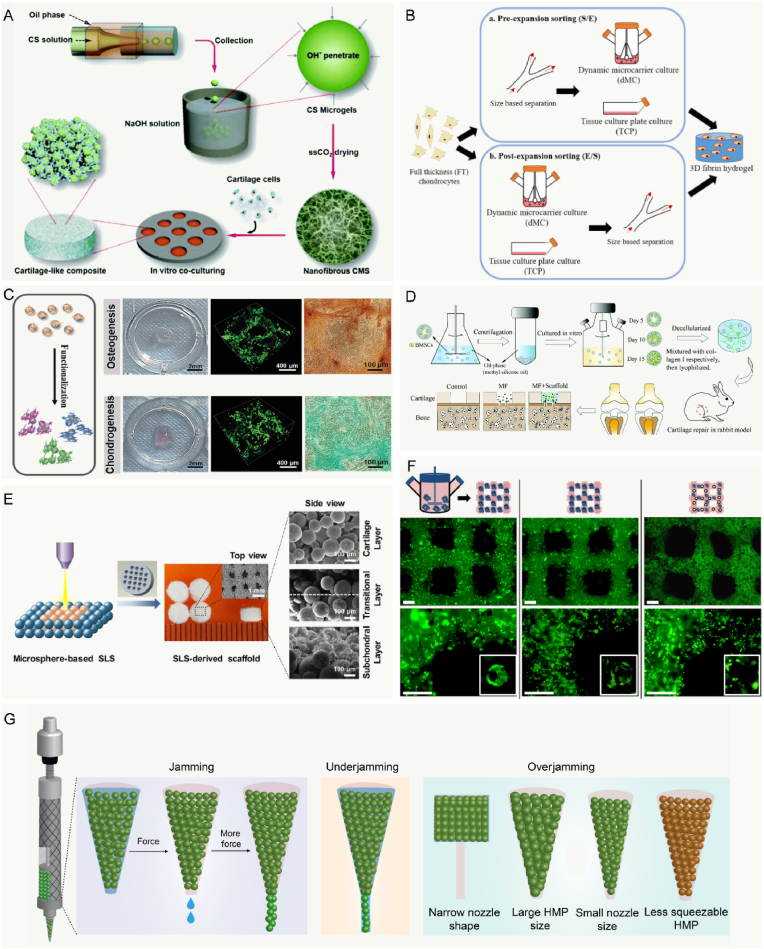

The cell delivery efficiency can be adjusted by controlling the structure and pore size of the microcarrier. For instance, Kim et al. prepared pocket-type biodegradable PLGA microcarriers with pores larger than 30 μm for use in cell delivery [258]. The results in this study indicated that the pocket-type MCs produced differentiation of stem cells in combination with containing SOX9 pDNA (Fig. 4D). Various stem cells, such as adipose-derived stem cells (ADSCs), embryonic stem cells, and bone marrow-derived mesenchymal stem cells (BMSCs), have been demonstrated pre-clinical or clinical efficacy to improve the outcomes of cartilage repair [259,260]. However, limitations based on MSC therapeutic strategies still exist. In particular, results of clinical study have shown fibrous cartilage formation in repaired joint defects implanted with MSCs. The most advanced cartilage TE is the matrices seeded with chondrocytes, which might tend to lose their phenotype, with dedifferentiation after long term culture in vitro, producing fibroblastic type I and III collagens [261,262]. Understanding the suitable microenvironment for cell-cell and cell-matrix interactions is essential [51]. In one study, researchers investigated the influence of microenvironment on chondrocytes by comparing the collagen hydrogel in bulk and microspherical forms, the results suggested that chondrocyte phenotype could be maintained in MCs at an early stage of the in vitro culture [263]. Zhou et al. reported chitosan microcarriers with an ECM-mimicking nanofibrous structure that could easily develop a macroscopic 3D geometrically shaped cartilage-like composite [264]. Furthermore, the chitosan microcarriers provided researchers with bottom-up cell-carrier components for repairing cartilage defects (Fig. 5A).

Fig. 5.

Combination microcarriers with technologies application for cartilage regeneration. A: Schematic representation of the nanofibrous chitosanwith an ECM-mimicking nanofibrous structure based on physical hydrogels of chitosan through the direct alkaline induced gelation of chitosan MCs emulsions. Reproduced with permission [264]. 2016, The Royal Society of Chemistry. B: Illustration of expansion and sorting strategy. Sorted small and medium/large were expanded for 1 passage in tissue culture plate, then further expanded in dynamic microcarrier condition or TCP for 2 passages. Reproduced with permission [267]. 2019, Elsevier Ltd. C: Schematic diagram of the printed GelMA MCs for macrotissues construction through a “bottom-up” method, and macroscopic images of the osteogenic macrotissue and chondrogenic macrotissue. Reproduced with permission [268]. 2020, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. D: Preparation and in vivo implantation of bionic cartilage acellular matrix MCs scaffolds in comparison with microfracture. Reproduced with permission [200]. 2021, The Royal Society of Chemistry. E: The PCL MCs and hydroxyapatite/PCL composite MCs were used as building blocks to fabricate bio-inspired multilayer scaffolds via selective laser sintering technique. Reproduced with permission [95]. 2017, Elsevier Ltd. F: Immunofluorescence staining for actin cytoskeleton (green) on bioprinted GelMA-Gellan Gum hydrogels with encapsulated cells and microcarriers. Scale bar: 500 μm. Reproduced with permission [301]. 2014, IOP Publishing Ltd. G: Schematic of the HMP extrusion process under varying conditions. Jamming: Interstitial water was extruded first, and HMPs were packed closer before yielding to flow. Underjamming: Due to less resistance, HMPs were extruded with interstitial water in these scenarios. Overjamming: Due to more resistance, HMPs were not extruded until rupture of the beads. Reproduced with permission [302]. Copyright 2021, the Authors.

Scaffold with microcarriers, including MC-incorporating scaffolds and MC-based scaffolds, can serve as TE treatment strategy. Microcarriers can be assembled into MC-based scaffolds in three main packing strategies: random packing, directed assembly, and rapid prototyping [265]. As described previous studies, articular cartilage is composed of three layers that have distinct characteristics in terms of cell density, cell shape, collagen organization and ECM content [266]. The shearing force and compressional loading could be withstood by the zonal property of articular cartilage with biphasic mechanical properties. Therefore, restoration in the zonal hierarchy of natural articular cartilage is extremely important. Lee et al. has developed a sorting protocol in expanding chondrocytes and showed that post-expansion size-based sorting can be applied on microcarriers-expanded chondrocytes, generating enriched zonal subpopulations that form phenotypically distinct cartilage constructs in the 3D hydrogel, these constructs could support the stratified zonal repair of articular cartilage (Fig. 5B) [267]. The interaction between the biologics and microcarriers can be achieved by physical encapsulation, physical or chemical immobilization, and electrostatic interaction [128,182,212]. In addition, the adjacent ECM that produced by cells on the microcarriers can be able to assemble and stick MCs together. Traditionally, the majority of studies have followed a top-down approach by taking a bulk material and degrading sections of it to create pores scaffolds. Recently, hADSC-loaded GelMA microcarriers were induced to form osteogenic and chondrogenic microtissues through a “bottom-up” method, which presented the capability to achieve the construction of macrotissues [268] (Fig. 5C). Microfracture surgery is still considered as the gold standard method for articular cartilage repair due to its cost-effectiveness, minimally invasive nature, and technical simplicity, which could trigger the release of BMSCs [269]. There are tremendous challenges in developing a scaffold with homogenous materials to work with microfracture for researchers. Recently, Liu and coworkers have fabricated a biofunctionalized scaffold with cartilage acellular matrix microcarriers to improve the outcome of microfracture surgery [200]. This study showed that the cell-free MCs scaffolds exhibited enhanced both articular cartilage regeneration and subchondral bone repair (Fig. 5D). Overall, biological scaffold, as a temporary 3D construct to fill the osteochondral defect, can offer mechanical support, promote cell infiltration, and encapsulate drugs/factors to form an appropriate microenvironment for cartilage regeneration.

4.2. Scale-up cell expansion using microcarriers

Cell therapeutic strategies have been proven to be a well-tolerated, safe therapy for a variety of indications, which need a target production lot size of ∼100B cells [270]. Microcarriers have a 3D culture area that could rapidly expand cells for a sufficient amount and maintain the phenotype of cells, which have been used commonly in cell-line production with oscillating and multiplate bioreactors [271]. Therefore, a robust suspension bioreactor process that can be scaled-up is crucial to meet this demand for clinical manufacturing of seeded cells [272]. Furthermore, during the bioreactor manufacturing process, cell quality and phenotype may be influenced by the key parameters of bioreactor, such as oxygen concentration (pO2), temperature, cell concentration, pH, agitation and pressure (Table 3). Oxygen is one of the most critical nutrients for cell expansion, and is continuously added into the bioreactor via the sparger. Most mammalian cell expansion are performed with a dissolved oxygen of around 20–50% of the saturation with air. It is important to maintain a homogenous constant temperature in the bioreactor. When the temperature is above 38 °C, cellular viability was significantly reduced. The pH is usually set between 7 and 7.5 and the pH can be controlled by diluted base, diluted acid and CO2 [273]. It is needed to get a homogenous distribution of the culture, temperature, pH, nutrients, and oxygen in the bioreactor and prevent settling, but on the other hand, high-speed agitation has demonstrated significantly higher shear stress, which is the most severe potential damage to cells [274]. It may be the case that a small percentage of cells (e.g., chondrocytes, endothelial cells) need a high shear stress, but the average shear stress of most bioreactor remains low [275]. Collectively, these key parameters are very important for the designing of bioreactor that aims to successfully manufacture a large number of adherent cells.

Table 3.

Key parameters of scale-up bioreactors.

| Key parameters | Recommended range | Refs. |

|---|---|---|

| pO2 | Dissolved oxygen of 20–50% of the saturation with air. | [[280], [281], [282]] |

| Temperature | 30 °C–37 °C, it must be tightly controlled to within about 1 °C. | [282,283] |

| Cell concentration | 104–107 cells/cm3, it needs to reach the minimum inoculation density. | [284,285] |

| pH | 7.0–7.5, it is maintained in the range naturally with correct buffers. | [286,287] |

| Agitation | 10–150 rpm, it depends on the type of cell and bioreactor. | [[288], [289], [290]] |

| Hydrostatic pressure | 30–90 mmHg, cell production can be enhanced by the moderate hydrostatic pressure. | [291] |

This way of culturing cells raises additional challenges on the bioprocessing side. These challenges include the separation of cells and MCs, establishment of the minimum agitation level required, optimization of the feeding regime and the optimization of the gassing strategy [276]. The main strategies to separate cells from microcarriers are enzymatic dissociation combined with high stirring speed or using non continuous mixing [277]. Moreover, the use of magnetic microcarriers to separate cells is also an alternative way during culture harvest. Monitoring seed cell state after expansion whilst maintaining cell quality presents a key process step. Quality control tests include e purity, viability, genetic stability and, immunophenotype characterization [278]. Recently, Gong et al. reported a novel microfluidic approach that label-free and continuous-flow monitoring of single microcarrier using co-planar Field's metal electrodes and can be integrated into bioreactors for long-term [279]. Taken together, by employing bioreactors and microcarriers, it is expected that production costs would decrease due to improved process monitoring and quality control leading to better consistency and process efficiency, and enabling economies of scale.

4.3. Injectable and 3D bioprinting microcarriers

In general, the direct transplantation of cells sometimes may be ineffective. Because transplanted cells may be killed by the variable mechanical pressure, limited nutrient supplies, and shearing force [292]. It is estimated that only 1–20% of transplanted cells survive or remain at the site of injection, limiting the cell therapeutic potential [293]. Microcarriers have proven to be useful method as delivery vehicles through injectable methods due to their small size and spherical shape [207]. Furthermore, the injectable microcarriers could improve the delivery of cells with excellent properties, like the physical support. In addition, they can be performed in a minimally invasive fashion at the site of the defect and easily conform to any shapes, especially in joint diseases. This malleability provides a 3D platform for releasing agents, cell proliferation, and increasing lubricity [294]. In these MCs systems, viscosity decreases when shear strain is increased, allowing the possibility that MCs could flow during the injection [295,296]. Due to the limitations of injectable techniques, the issues of layer separation and weak interface bonding frequently exist. Therefore, Du et al. prepared a bio-inspired multilayer scaffold with PCL microcarriers for osteochondral repair using an advanced selective laser sintering (SLS) [95]. Compared with the powder form used in conventional SLS strategies, MC-based SLS technique is utilized to enhance micro-scale porosity during the sintering process (Fig. 5E).

Microcarrier-based osteochondral and cartilage constructs with microarchitectures can be achieved with biomanufacturing technologies (e.g., 3D printing). Various bioprinting techniques were developed, the most preferred deposition technique is extrusion because of its convenience, flexibility, precision, and high levels of cell compatibility [297,298]. However, challenges in fabrication of microcarrier-based inks include sufficient cells with high cell viability, the ability of extrusion molding, the stability and resolution of printed constructs and restrictions. In bioprinting, these inks should have controlled rheological properties (e.g., shear-thinning) that can be stabilized after deposition with both nontoxic and compatible [22,299]. Furthermore, the filamentous inks need rapidly stabilize to preserve fidelity of the printed structure from a reservoir onto a print surface [300]. Few studies have reported on bio-inks based on microcarriers so far, especially application of cartilage repair. In 2014, Levato et al. fabricated bilayer osteochondral models using microcarrier-laden bioink for bone and osteochondral constructs [301]. In this study, 3D bioprinting of cell-laden microcarriers showed the powerful ability to create a precisely-designed 3D architecture with high cell concentration and viability. Moreover, these PLA microcarriers provide a mechanical reinforcement to the inks (Fig. 5F). The result in this study also demonstrated that it is not advisable to solely use MSCs in MCs-based hydrogels for the cartilage region, since they can easily differentiate towards osteoblastic lineage.

As a whole, the large aggregates can easily block the injection nozzle [301]. Microcarriers flow is largely different from the liquid flow of common continuous bioinks during 3D printing. Unlike traditional hydrogel boinks, MCs-based inks are usually packed closely together in a jammed state, they look like a solid, hence their rheological properties need to be adjusted by chemical or physical modification and a secondary crosslinking is often required. Besides, the wall of the syringe and nozzle provide resistance and confine the MC-inks flow because of the considerable size of microcarriers. And then MCs may present closer packing to remove the aqueous solutions in the interstitial spaces, further deforming, squeezing, or sometimes rupturing themselves before yielding to flow. Moreover, the physicochemical properties of MCs-inks, like the size and modulus, can influence the dissipation process (Fig. 5G). The research results of Xin et al. revealed a large enough opening was required for smooth printing of MCs bioinks, but the shape and size of the syringe and nozzle as well as the size and polydispersity of the HMPs must also be considered [302]. Furthermore, the jamming process within the syringes also affected the printing stability and cytocompatibility. For instance, Highley et al. developed jammed microgels inks from norbornene-modified hyaluronic acid with shear-thinning behavior and short-term stability, and cell viability within the microgel was generally high (≈70%) [303]. Notably, it is worthwhile to consider that the post-cross-linking should be tested between the microcarrier. Nevertheless, the tissue defects usually feature curved surfaces or even more intricate geometries, where the mismatch of the shapes may be further worsened by the possible deformation of the local tissues [304,305]. Therefore, in situ MCs based-bioprinting address this dilemma to reconstruction of defective tissues in a clinical setting by handheld approaches. Taken together, extrusion-based bioprinting technology has progressed substantially and has paved the way during the last decade for bioprinting of cells and microtissues. The microcarriers could be performed via the extrusion-based bioprinting technology, while the orifice could easily be blocked.

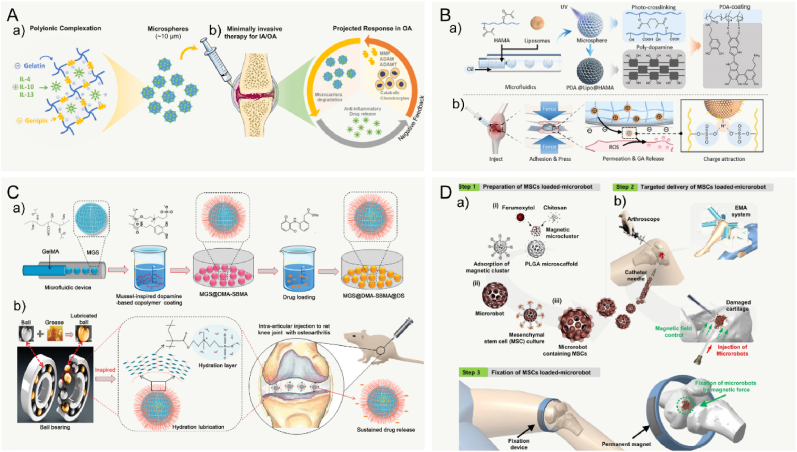

4.4. Stimuli-responsive microcarriers

Recently, stimuli responsive microcarriers have attracted particular interest, which offer great advantages for its nanostructured features and rapid transitions by the small alterations in the environment. These smart hydrogels can undergo reversible transitions of chemical/physical properties in response to various external factors such as physical stimuli like the magnetic field, temperature, light, and mechanical force, and the chemical or biochemical stimuli including the pH, solvent composition, or chemical triggers like reactive oxygen species and inflammatory environment [306]. The drug-releases process in stimuli responsive microcarrier is activated by external environmental changes, which not only reduces drug waste and improve drug utilization, but also improves the safety of treatment as well.