Abstract

Objective:

To compare porcelain surfaces at debonding after use of two surface preparation methods and to evaluate a method for restoring the surface.

Materials and Methods:

Lava Ceram feldspathic porcelain discs (n = 40) underwent one of two surface treatments prior to bonding orthodontic brackets. Half the discs had sandblasting, hydrofluoric acid, and silane (SB + HF + S), and the other half, phosphoric acid and silane (PA + S). Brackets were debonded using bracket removing pliers, and resin was removed with a 12-fluted carbide bur. The surface was refinished using a porcelain polishing kit, followed by diamond polishing paste. Measurements for surface roughness (Ra), gloss, and color were made before bonding (baseline), after debonding, and after each step of refinishing. Surfaces were also examined by scanning electron microscopy (SEM). Data was analyzed with 2-way ANOVA followed by Tukey HSD tests (α = 0.05).

Results:

The SB + HF + S bonding method increased Ra (0.160 to 1.121 µm), decreased gloss (41.3 to 3.7) and altered color (ΔE = 4.37; P < .001). The PA + S method increased Ra (0.173 to 0.341 µm; P < .001), but the increase in Ra was significantly less than that caused by the SB + HF + S bonding method (P < . 001). The PA + S method caused insignificant changes in gloss (41.7 to 38.0) and color (ΔE = 0.50). The measurements and SEM observations showed that changes were fully restored to baseline with refinishing.

Conclusions:

The PA + S method caused significantly less damage to porcelain than the SB + HF + S method. The refinishing protocol fully restored the porcelain surfaces.

Keywords: Porcelain, Orthodontic bonding, Debonding, Refinishing, Polishing, Surface roughness

INTRODUCTION

Bonding orthodontic brackets to porcelain and subsequent debonding has been shown to result in significant damage to the porcelain.1–8 While some laboratory studies have concluded that mechanical or chemical abrasion to deglaze the porcelain surface is necessary for enhanced bond strength,3,5 others report no advantage to deglazing and suggest silane bonding.1,2,4 Reports have also been mixed regarding various porcelain refinishing methods after orthodontic bracket debonding. Some investigators, using porcelain adjustment kits and diamond polishing paste, showed that surfaces can be restored to the original,2,4 while others, testing Sof-Lex discs (3M ESPE, St. Paul. MN), porcelain polishing kits, wheels, and paste, found that polishing methods were deficient.6–8 Further investigation is needed into the effects of preparing porcelain for bonding and outcomes of refinishing.

The purpose of this study was to compare the damage to porcelain surfaces at debonding following the use of two orthodontic bracket bonding methods, and to evaluate a porcelain refinishing procedure. Specific objectives were to (1) quantify changes in surface roughness, gloss, and color; (2) evaluate a porcelain polishing method and determine if surface roughness, gloss, and color can be fully restored; and (3) develop for the orthodontist a protocol recommendation for refinishing porcelain.

It was hypothesized that relative to the prebonding measurements, porcelain bonded with orthodontic brackets and then debonded would exhibit significant surface alterations, but that the surface could be restored using a porcelain polishing kit and diamond polishing paste.

MATERIALS AND METHODS

Lava Ceram feldspathic porcelain discs (n = 40, 20/bonding method; shade A3, 25 µm grain size; 3 M ESPE, St Paul, Minn), 10 mm in diameter and 2 mm thick, were fabricated with firing starting under vacuum at 500°C, increasing to 925°C with a heat rate of 75°C per minute, and then air firing at 925°C for 30 seconds for an autoglaze. Before starting bonding procedures (baseline), the discs were rinsed with water; air dried; and measured for surface roughness, gloss, and color. These measurements were repeated after various surface treatments as indicated below.

Bonding Method 1: Sandblasting, Hydrofluoric Acid, and Silane

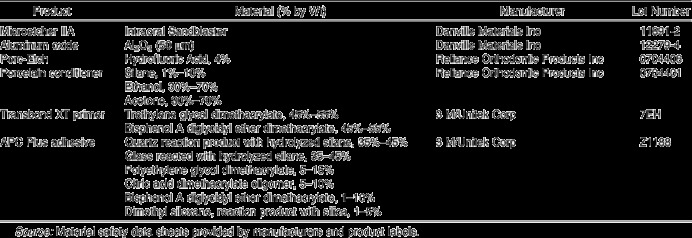

After the work of Zachrisson,3,9,10 20 discs were sandblasted for 3 seconds using an intraoral Microetcher IIA (Danville Materials Inc, San Ramon, Calif) with 50 µm alumina. The surfaces were then rinsed, dried, and etched for 4 minutes with Porc-Etch 4% hydrofluoric acid gel (Reliance Orthodontic Products Inc, Itasca, Ill). After the gel was removed and the surfaces were rinsed and dried, Porcelain Conditioner silane coupling agent (Reliance) was applied for 60 seconds followed by Transbond XT Light Cure Adhesive Primer (3 M/Unitek Corp, Monrovia, Calif). (This group will be referred to as the sandblasting, hydrofluoric acid, and silane [SB + HF + S] group.) Upper right central incisor stainless steel brackets (Victory Series, MBT .022″ slot; 3 M/Unitek) with APC Plus composite (3 M/Unitek) were centered and firmly seated with a force of 12–14 N. The force was measured with the disc seated on a calibrated load cell. After excess adhesive was removed, specimens were cured 20 seconds to the mesial and distal of the brackets using an Ortholux LED unit (3 M/Unitek) operating at 800 mW/cm2 (Table 1).

Table 1.

Materials Used in Sandblasting, Hydrofluoric Acid, and Silane (SB + HF + S) Bonding Group

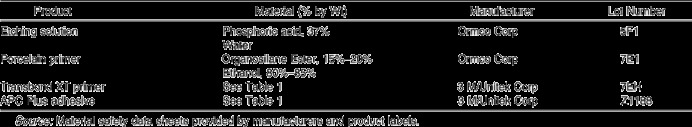

Bonding Method 2: Phosphoric Acid and Silane

Twenty discs were treated in accordance with the manufacturer's instructions (Ormco Corp, Glendora, Calif) by applying phosphoric acid etching solution for 60 seconds and then adding porcelain primer silane coupling agent. (This group will be referred to as the phosphoric acid and silane [PA + S] group.) After 1 minute, the surfaces were rinsed and dried, and brackets were bonded as above. Bonded porcelain samples from both groups were stored in water at 37°C for 24 hours before debonding (Table 2).

Table 2.

Materials Used in Phosphoric Acid and Silane (PA + S) Bonding Group

Orthodontic Bracket Debonding, Adhesive Removal, and Porcelain Refinishing

In order to simulate clinical procedures, brackets were debonded by hand rather than using a testing machine in shear or tension. Bond strength was not investigated, as multiple laboratory studies had previously found clinically adequate bond strengths (6–8 MPa or greater11) using SB + HF + S3–5 and PA + S.4,5,12 One operator debonded the brackets using bracket removing pliers (#098-SL; Orthopli Corp, Philadelphia, Pa). Each porcelain disc was held firmly against the bench top with finger pressure and a gentle peeling force was applied to the bracket while squeezing the tie-wings and distorting it.10 Resin was removed from the surface with a 12-fluted tungsten carbide bur (replaced every 10 samples; US# 7404 Football; Brasseler, Savannah, Ga) in a high-speed handpiece and the surface was measured. The samples were then polished with the Intra-Oral Dialite Porcelain Adjustment Polishing Kit (Brasseler) series of Reduce Polish (blue), Pre-Polish (pink), and High Gloss (gray) polishing wheels using a slow-speed handpiece. All polishing was performed until the porcelain surface appeared smooth to the eye,6–8,13 then the surface was measured. Final refinishing consisted of diamond polishing paste (Truluster Polishing System for Porcelain; grain size, 2–5 µm; Brasseler) applied with a small felt wheel in a slow-speed handpiece (3000 rpm) with moderate pressure until a smooth surface was observed, followed by a higher speed (10,000–15,000 rpm) with light pressure to produce a glossy surface. Measurements were then repeated (Table 3).

Table 3.

Materials Used in the Refinishing Procedure

Surface Roughness Measurements

Surface roughness (Ra) was measured using a surface profilometer (TR200 Surface Roughness Tester; TIME Group Inc, Beijing, China) set to five cutoffs of 0.25 mm each for a total measured length of 1.25 mm. Calibration was checked with a standard (Ra = 1.61 µm) after every 10 samples. Each sample was oriented consistently, measured three times (length, width, diagonal) and the average value recorded.

Gloss Measurements

Gloss values were measured with a gloss meter (Novo-Curve; Rhopoint Instrumentation, East Sussex, UK) where the percentage of incident light (60°; 2 × 2 mm area) reflected from the surface is recorded as gloss units (gu = 0 to 100). Calibration was checked with a standard (93.9 gu) after every 10 samples. Five gloss measurements were made for each disc and the highest value recorded.

Color Measurements

Color was analyzed using a chromameter (ChromaMeter CR-221; Minolta Co, Osaka, Japan) calibrated with a standard measuring L* = 99.66, a* = −0.41, b* = 2.89, and rechecked after every 10 samples. Measurements were made on a scale of −100 to +100 using the CIE L*a*b* color system,14 where L* measures lightness (black, −L*, to white, +L*), a* measures green (−a*) to red (+a*), and b* measures blue (−b*) to yellow (+b*).15,16 Color differences (ΔE) were calculated as follows:15,16 ΔE = [(ΔL*)2 + (Δa*)2 + (Δb*)2]½.

Scanning Electron Microscopy

To qualitatively compare surface roughness, uncoated representative porcelain specimens from each bonding group and at each polishing stage were examined at 500× by scanning electron microscopy (SEM) operating at 12.5 kV (Quanta 200; FEI Company, Hillsboro, Ore).

Statistical Analysis

Data were analyzed with 2-way ANOVA followed by Tukey HSD tests (α = 0.05). The variables included bonding method and polishing stage.

RESULTS

At debonding, one sample in the PA + S group had a fragment of porcelain the size of the bracket base separate from the disc and thus the sample size for the group was reduced to 19. Two way analysis of variance showed significant differences between bonding method groups (P < .001) and polishing stages (P < .001), as well as significant interaction between bonding and polishing; (P < .001) for surface roughness, gloss, and color change.

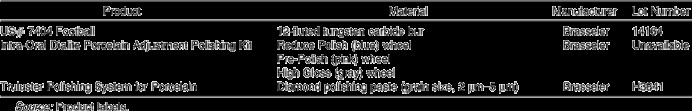

Ra

Compared with the baseline surface, the SB + HF + S group showed a large increase in Ra after debonding and residual resin removal (P < .001). The polishing kit failed to fully restore Ra (P < .05), but this was achieved with the polishing paste. Relative to baseline, the PA + S group showed a significant increase in surface roughness after resin removal (P < .001), but less than that found in the SB + HF + S group (P < .001). In the PA + S group, the polishing kit restored the Ra to control level, a result that was unchanged by the polishing paste (Figure 1).

Figure 1.

Mean surface roughness values with standard deviation bars. * Statistically different from baseline; P < .05.

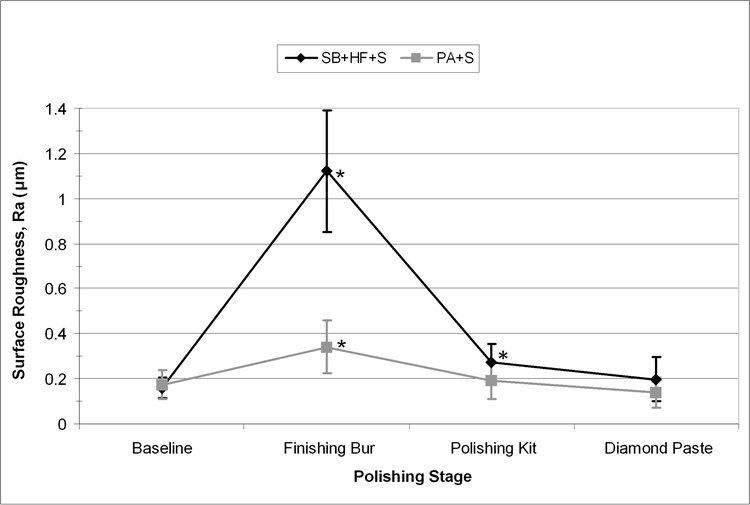

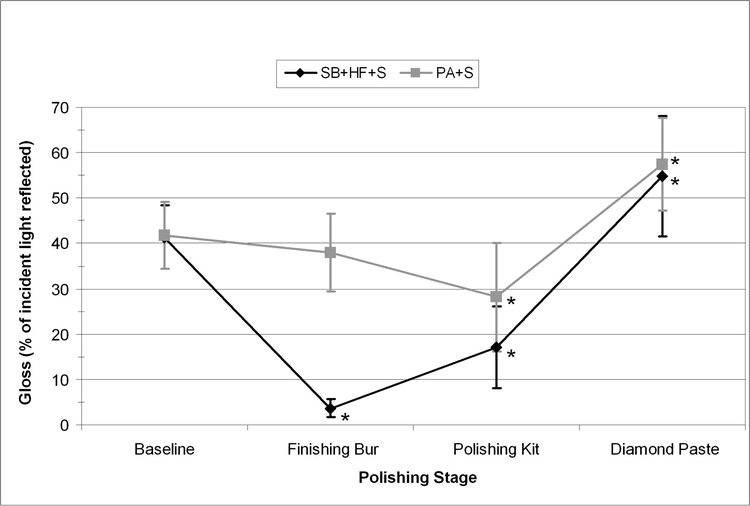

Gloss

The SB + HF + S group showed a large decrease in gloss after residual resin removal (P < .001). The polishing kit did not restore gloss values (P < .001), but after application of polishing paste, the values exceeded baseline (P < .001). After resin removal in the PA + S group, there was no difference in values compared with baseline. The polishing kit resulted in a decrease in gloss relative to baseline (P < .001), but after paste polishing, values exceeded baseline (P < .001) (Figure 2).

Figure 2.

Mean gloss values with standard deviation bars. * Statistically different from baseline; P < .05.

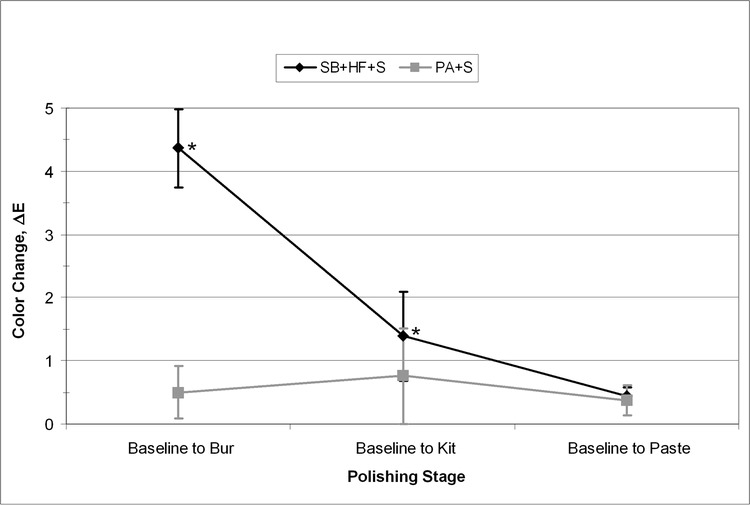

ΔE

After residual resin removal in the SB + HF + S group, ΔE was increased (P < .001). In general, the samples became lighter (increased L*) and less yellow (decreased b*) with an average ΔE of 4.37. The polishing kit improved ΔE to a mean of 1.39, which still differed from baseline (P < .001). Diamond paste polishing reduced ΔE to a mean of 0.44, equivalent to baseline. In the PA + S group, no significant change in color was found at any stage of the debonding or refinishing procedures (Figure 3).

Figure 3.

Mean color change (ΔE) values with standard deviation bars. * Statistically different from baseline; P < .05.

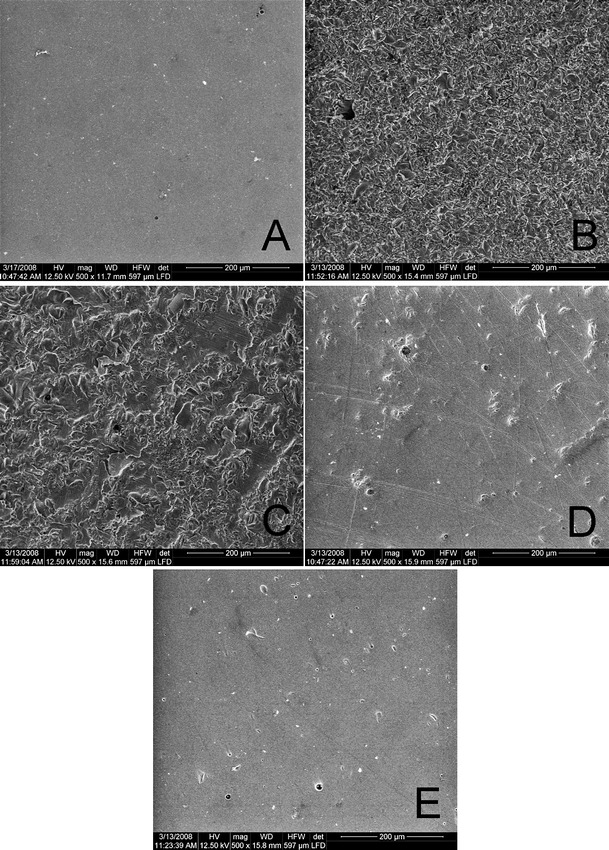

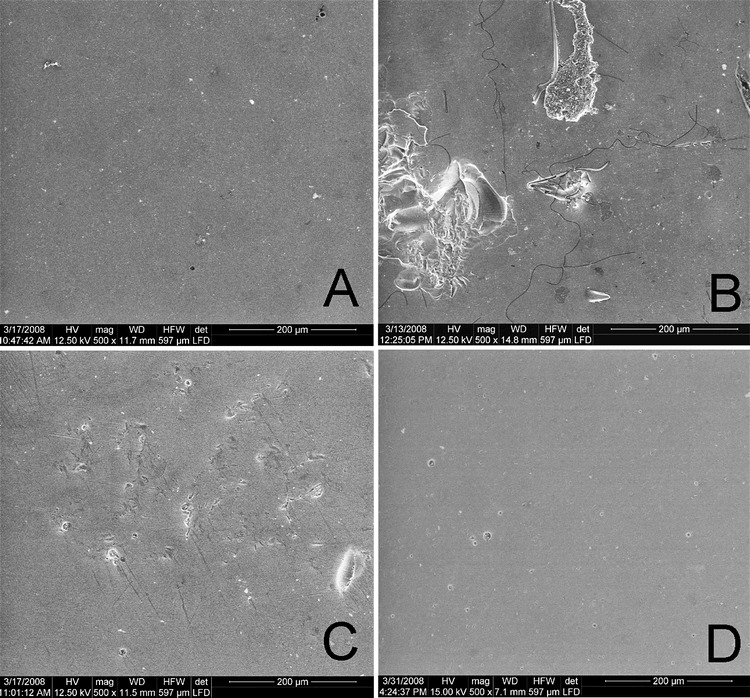

SEM analysis corroborated the measurements for surface roughness. The glazed surface at baseline appeared smooth with a few random small pits and irregularities. The prebond SB + HF + S etched surface appeared very rough with small chips, pits, and fissures (Figure 4), and the surface had a similar appearance after resin removal. After the polishing kit stage, the surface appeared smooth but with occasional scratch marks and pits, while after paste polishing, the appearance was similar to the glazed surface. The PA + S group images showed a mildly altered surface after debonding (Figure 5), where the surface was mostly smooth with some scuff marks from the bur, resin remnants, and cracks. The surface appeared progressively smoother after refinishing with the polishing kit followed by diamond polishing paste.

Figure 4.

SEM images from the SB + HF + S group. (A) Autoglazed (baseline). (B) After SB + HF. (C) After resin removal. (D) After porcelain polishing kit. (E) After diamond polishing paste.

Figure 5.

SEM images from the PA + S group. (A) Autoglazed (baseline). (B) After resin removal. (C) After porcelain polishing kit. (D) After diamond polishing paste.

DISCUSSION

In support of our hypothesis, results of this study showed that bonding and debonding orthodontic brackets significantly damaged porcelain surfaces, and that the refinishing method tested restored the surfaces to their original condition. Selection of a porcelain bonding method that delivers adequate strength but minimizes damage and selection of a refinishing procedure that restores the porcelain surface are important clinical considerations. Increased surface roughness decreases the porcelain's flexural strength because surface flaws can lead to fracture at a lower stress.17,18 Rougher porcelain surfaces can also lead to increased dental plaque accumulation.19 Surface roughness affects gloss20 and color,15 and it can attract staining factors.6 Thus, the aesthetics of the porcelain dental restoration can be adversely affected.

The SB + HF + S technique resulted in large changes in Ra, gloss, and color. Several recent studies have tested bonding methods that included either SB or HF etching. They concluded that refinishing procedures such as carbide burs and Sof-Lex discs,6 an adjustment kit and diamond polishing paste,7 and Sof-Lex discs and a polishing wheel with polishing paste8 could improve Ra, but the porcelain surface could not be restored to its original condition.6–8 In contrast, other studies show that significant damage inflicted by SB, HF etching, or burs can be fully restored with polishing kits and paste.4,13,16 Results of the current study suggest that porcelain surfaces treated with SB + HF + S prior to bracket bonding can be restored to the original Ra, gloss, and color by refinishing with an intraoral porcelain polishing kit followed by diamond polishing paste. The polishing kit and paste re-create the smooth surface through the action of abrasive particles that reduce irregularities on the porcelain surface.7,16 The polishing process begins with larger, rougher particles and gradually progresses to the very fine particles found in diamond polishing paste.

In contrast to SB and HF etching, phosphoric acid etching of porcelain is not designed to roughen the surface but to clean and neutralize its alkalinity, thereby enhancing the chemical activity of the silane primer.4,12,21 We found that the PA + S method caused much less damage to the porcelain surface than the SB + HF + S technique, in agreement with other studies.4,5 While the PA + S method caused insignificant change in gloss and color, it resulted in a significant change in Ra that was restorable. Previous laboratory experiments concluded that treating the porcelain surface with PA + S results in sufficient bond strength.4,5,12 However, we found subjectively that relative to the PA + S, the SB + HF + S samples were more difficult to debond and much of the adhesive was left bonded to the porcelain (data not shown). These observations coincide with data of Bourke and Rock wherein SB + HF + S promoted high bond strength and increased adhesive remnant index scores and porcelain fracture index scores.4 Zachrisson3,9 contends that SB + HF are essential for adequate clinical bonding. In the clinic, a prudent course might be to begin with the PA + S method to minimize porcelain damage, and if the bracket bond fails, the clinician could progress to the SB + HF + S bonding method, or band the tooth. Interestingly, the one sample that experienced fracture on debonding was in the PA + S group, suggesting appreciable bond strength. The porcelain sample may have been defective, perhaps with an air bubble below the surface.

Surface roughness strongly influences both gloss and color of the porcelain surface. A rough surface results in diffuse reflection and a less glossy appearance, whereas a smooth surface results in specular reflection and exhibits higher gloss.20 In a clinical situation, the rough porcelain surface is usually wet. Moisture can fill the crevices of a rough surface, increasing the amount of specular reflection and thereby improving the gloss.22 With regard to color, white light is reflected directly off the surface and is mixed with light reflected from the body of the porcelain.15 On a rough surface, more white light is reflected, resulting in a lighter appearance.15 This explains why porcelain surfaces severely roughened with SB + HF + S concurrently experienced large decreases in gloss and color changes, and why polishing restored them. According to previous studies, a ΔE between 1 and 3.3 may be observable clinically, but it is acceptable, while a value at or above 3.3 is considered unacceptable.15,16 Thus, our final ΔE of 0.44 would not be noticeable clinically. In summary, we found that both the polishing kit and the diamond paste are necessary to fully restore the Ra, gloss, and color of the porcelain to its original condition.

This study had several limitations. In order to simulate clinical procedures, brackets were debonded by hand using bracket-removing pliers rather than a testing machine in shear or tension,3,10 and polishing was performed without artificial time constraints until the porcelain surface appeared smooth and glossy.6–8,13 Thus, bond strengths were not investigated, and polishing times varied with need. The porcelain samples had slightly varying convex surfaces, accounting in part for the range in gloss measurements. Polishing might have flattened the porcelain surfaces, explaining why gloss values exceeded baseline after use of polishing paste. Only one porcelain refinishing method was tested. Future research could compare the effectiveness and efficiency of multiple refinishing systems. In addition, various types of porcelain, porcelain conditioning methods, bonding systems, and composite adhesives could be tested and compared.

CONCLUSIONS

The SB + HF + S method significantly increased porcelain surface roughness, decreased gloss, and altered color.

The PA + S method caused insignificant changes in gloss and color, but significantly increased porcelain surface roughness, although less than with SB + HF + S.

Alterations in the porcelain surface were fully restorable with the refinishing procedure tested, regardless of bonding method.

The recommended protocol for refinishing porcelain surfaces after orthodontic bracket debonding is (1) careful removal of residual resin adhesive with a carbide finishing bur, (2) polishing with an intraoral porcelain polishing kit until the surface appears smooth; and (3) polish with diamond polishing paste on a small felt wheel until the surface appears glossy.

Acknowledgments

The authors thank David May, Juliana da Costa, Jerry Adey, Lucas Ferracane, and Tracy Herion for helping with the project, and Dahlin/Fernandez/Fritz Dental Laboratory Inc for manufacturing the porcelain discs. In addition, we thank 3 M/Unitek Corp, Brasseler USA, Danville Materials Inc, Ormco Corp, and Reliance Orthodontic Products Inc for donating materials used in this study.

REFERENCES

- 1.Eustaquio R, Garner L. D, Moore B. K. Comparative tensile strengths of brackets bonded to porcelain with orthodontic adhesive and porcelain repair systems. Am J Orthod Dentofacial Orthop. 1988;94:421–425. doi: 10.1016/0889-5406(88)90132-1. [DOI] [PubMed] [Google Scholar]

- 2.Zelos L, Bevis R. R, Keenan K. M. Evaluation of the ceramic/ceramic interface. Am J Orthod Dentofacial Orthop. 1994;106:10–21. doi: 10.1016/S0889-5406(94)70016-8. [DOI] [PubMed] [Google Scholar]

- 3.Zachrisson Y. O, Zachrisson B. U, Buyukyilmaz T. Surface preparation for orthodontic bonding to porcelain. Am J Orthod Dentofacial Orthop. 1996;109:420–430. doi: 10.1016/s0889-5406(96)70124-5. [DOI] [PubMed] [Google Scholar]

- 4.Bourke B. M, Rock W. P. Factors affecting the shear bond strength of orthodontic brackets to porcelain. Br J Orthod. 1999;26:285–290. doi: 10.1093/ortho/26.4.285. [DOI] [PubMed] [Google Scholar]

- 5.Ajlouni R, Bishara S. E, Oonsombat C, Soliman M, Laffoon J. The effect of porcelain surface conditioning on bonding orthodontic brackets. Angle Orthod. 2005;75:858–864. doi: 10.1043/0003-3219(2005)75[858:TEOPSC]2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 6.Jarvis J, Zinelis S, Eliades T, Bradley T. G. Porcelain surface roughness, color and gloss changes after orthodontic bonding. Angle Orthod. 2006;76:274–277. doi: 10.1043/0003-3219(2006)076[0274:PSRCAG]2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 7.Sarac Y. S, Elekdag-Turk S, Sarac D, Turk T. Surface conditioning methods and polishing techniques effect on surface roughness of feldspar ceramic. Angle Orthod. 2007;77:723–728. doi: 10.2319/062206-256.1. [DOI] [PubMed] [Google Scholar]

- 8.Karan S, Toroglu M. S. Porcelain refinishing with two different polishing systems after orthodontic debonding. Angle Orthod. 2008;78:947–953. doi: 10.2319/081307-374.1. [DOI] [PubMed] [Google Scholar]

- 9.Zachrisson B. U. Orthodontic bonding to artificial tooth surfaces: clinical versus laboratory findings. Am J Orthod Dentofacial Orthop. 2000;117:592–594. doi: 10.1016/s0889-5406(00)70211-3. [DOI] [PubMed] [Google Scholar]

- 10.Zachrisson B. U. Bonding in orthodontics. In: Graber T. M, Vanarsdall R. L, Vig K. W. L, editors. Orthodontics Current Principles and Techniques 4th ed. St Louis, Mo: Elsevier Mosby; 2005. pp. 579–659. [Google Scholar]

- 11.Reynolds I. R. A review of orthodontic bonding. Br J Orthod. 1975;2:171–178. [Google Scholar]

- 12.Nebbe B, Stein E. Orthodontic brackets bonded to glazed and deglazed porcelain surfaces. Am J Orthod Dentofacial Orthop. 1996;109:431–436. doi: 10.1016/s0889-5406(96)70125-7. [DOI] [PubMed] [Google Scholar]

- 13.Wright M. D, Masri R, Driscoll C. F, Romberg E, Thompson G. A, Runyan D. A. Comparison of three systems for the polishing of an ultra-low fusing dental porcelain. J Prosthet Dent. 2004;92:486–490. doi: 10.1016/j.prosdent.2004.07.021. [DOI] [PubMed] [Google Scholar]

- 14.Commission Internationale l'Eclairage Colorimetry. CIE Publication No. 15.2; 1986. p. 74. [Google Scholar]

- 15.Powers J. M. Optical properties. In: Craig R. G, Powers J. M, editors. Restorative Dental Materials 11th ed. St Louis, Mo: Mosby; 2002. pp. 38–47. [Google Scholar]

- 16.Sarac D, Sarac Y. S, Yuzbasioglu E, Bal S. The effects of porcelain polishing systems on the color and surface texture of feldspathic porcelain. J Prosthet Dent. 2006;96:122–128. doi: 10.1016/j.prosdent.2006.05.009. [DOI] [PubMed] [Google Scholar]

- 17.de Jager N, Feilzer A. J, Davidson C. L. The influence of surface roughness on porcelain strength. Dent Mater. 2000;16:381–388. doi: 10.1016/s0109-5641(00)00030-0. [DOI] [PubMed] [Google Scholar]

- 18.Fischer H, Schafer M, Marx R. Effect of surface roughness on flexural strength of veneer ceramics. J Dent Res. 2003;82:972–975. doi: 10.1177/154405910308201207. [DOI] [PubMed] [Google Scholar]

- 19.Kawai K, Urano M, Ebisu S. Effect of surface roughness of porcelain on adhesion of bacteria and their synthesizing glucans. J Prosthet Dent. 2000;83:664–667. [PubMed] [Google Scholar]

- 20.Shackleford J. F. Introduction to Materials Science for Engineers 3rd ed. New York, NY: Macmillan; 1992. Ceramics and glasses: Major optical properties; pp. 413–423. [Google Scholar]

- 21.Wolf D. M, Powers J. M, O'Keefe K. L. Bond strength of composite to etched and sandblasted porcelain. Am J Dent. 1993;6:155–158. [PubMed] [Google Scholar]

- 22.Tanaka T, Kunishi T, Wakeshima H. Relation between gloss and wetting of a matte surface. Optics Letters. 1985;10:170–172. doi: 10.1364/ol.10.000170. [DOI] [PubMed] [Google Scholar]