Abstract

Objective:

To investigate the degree of debris, roughness, and friction of stainless steel orthodontic archwires before and after clinical use.

Materials and Methods:

For eight individuals, two sets of three brackets (n = 16) each were bonded from the first molar to the first premolar. A passive segment of 0.019- × 0.025-inch stainless steel archwire was inserted into the brackets and tied by elastomeric ligature. Debris level (via scanning electron microscopy), roughness, and frictional force were evaluated as-received and after 8 weeks of intraoral exposure. Mann-Whitney, Wilcoxon signed-rank, and Spearman correlation tests were used for statistical analysis at the .05 level of significance.

Results:

There were significant increases in the level of debris (P = .0004), roughness of orthodontic wires (P = .002), and friction (P = .0001) after intraoral exposure. Significant positive correlations (P < .05) were observed between these three variables.

Conclusion:

Stainless steel rectangular wires, when exposed to the intraoral environment for 8 weeks, showed a significant increase in the degree of debris and surface roughness, causing an increase in friction between the wire and bracket during the mechanics of sliding.

Keywords: Orthodontic archwire, Roughness, Friction

INTRODUCTION

Several mechanical and biological factors may modify the frictional force generated during orthodontic sliding mechanics.1,2 Studies examining wires as-received from the manufacturer have shown an inverse relationship between the force loss caused by friction, the slot size, and the interbracket distance.2,3 Direct relationships between the frictional force and the wire section diameter,2,4–7 as well as the angulation between the bracket and the wire,2,8 have been reported. Despite some inconsistency in the literature, studies have demonstrated that stainless steel (SS) wires produce less friction than other materials.2,9–11 SS ligatures create less friction when compared with elastic ligatures.4,5 More recently, studies have demonstrated less friction when self-ligating brackets are used during initial sliding mechanics.5–7,12,13 However, when loosened steel ligatures are used, the friction of conventional and self-ligating brackets is more or less similar.6,13

Biological variables causing friction include the presence of saliva,9,12,14,15 acquired pellicles, corrosion, and plaque.9 Studies have shown that when SS wires are used, saliva may not act as a lubricant.11,16 Instead, saliva may increase the friction and present an adhesive interference, caused by increased surface tension in the archwire. An analysis of the surface roughness of different archwires materials suggests that these results could be related to the coefficient of friction of the material analyzed.17

Dental material science has paid more attention to archwire mechanical properties of as-received materials than to changes produced after intraoral exposure.17,18 Only one investigation has evaluated the effect of clinical use on nickel-titanium (NiTi) orthodontic wires (0.016- × 0.022-inch) in terms of surface roughness of wires and friction during the sliding between bracket and wire.19 The NiTi archwires showed higher coefficients of friction and roughness after four weeks of clinical use, but no significant relationship was observed between the increasing roughness of the wire and the friction level.

However, although orthodontic NiTi archwires are more commonly used, SS archwires are more frequently indicated for sliding mechanics because of their lower friction coefficients.2,9–11 Also, rectangular SS archwires used during sliding mechanics may need to stay in the oral environment for several months. Thus, it is necessary to examine the changes produced by the oral environment in the mechanical properties of SS orthodontic archwires.

The aim of this investigation was to evaluate the changes that occur in SS orthodontic archwires before and just after clinical use for 8 weeks. Specifically, the changes in the degree of debris impregnated on the orthodontic wire, the wire surface roughness, and the friction produced during sliding were evaluated before and after exposure to the oral environment.

MATERIALS AND METHODS

This study was approved by the Commission of Bioethics, Faculty of Dentistry of the Brazilian Federal University, Pará State 025/2008. Consent was also sought by asking subjects to sign a form that explained the nature and purpose of the present investigation.

The sample size was calculated assuming a normal distribution of the tested parameters, allowing use of the Student t test for statistical analysis of the differences between as-received (T0) archwires and archwires after 8 weeks of clinical use (T1). We also assumed a power of 80% to detect a difference of 0.5 N of force and standard deviations of 0.3 (T0) and 0.6 (T1) and a bilateral alpha level of 5%. Standard deviations were determined in a pilot study involving six unused wires and six wires (from three patients) examined after 8 weeks of intraoral exposure. The sample sizes were determined to be n = 8 (T0) and n = 16 (T1), since the variance was doubled for the wires after clinical use.

Eight pieces of straight segments of as-received SS wire, 0.019 × 0.025 inch (3M Unitek, St Paul, Minn), were examined. The effects of intraoral exposure were examined in eight adult individuals (four men and four women), who received a bonding consisting of a set of three edgewise brackets, slot 0.022- × 0.030-inch (Morelli, São Paulo, Brazil) in each hemiarch (n = 16), from the first molar to the first premolar. A straight segment of the same SS wire (0.019- × 0.025-inch) was inserted into each of the 16 sets of brackets at a distance corresponding to the first molar to first premolar of each patient. The wires were carefully tied to the brackets with elastic ligatures (diameter 0.120 inch; Unicycles, Masel, Carlsbad, Calif). The sets of brackets and wires remained in the oral environment for 8 weeks (Figure 1).

Figure 1.

Bracket wire set after 8 weeks of intraoral exposure.

After being removed from the oral cavity, the wires were stored in four closed containers, with a layer of utility wax, that were set upright. The tips of the wires that maintained contact with the wax were not used in the examinations. Debris level and roughness were evaluated before (T0, n = 16) and after 8 weeks of intraoral exposure (T1, n = 16) in paired analyses. Frictional force was evaluated in as-received wires (n = 8) and after 8 weeks of intra-oral exposure (n = 16). All examinations were performed within 48 hours of removal of the wires from the oral environment.

Microscopic and Roughness Analysis

For the microscopic debris and roughness analyses, the upper tip of each segment of the wire was fixed on a glass slide. A mark in the central area of the wire was determined previously in order to standardize the reading. The central area (0.025 inch) of the wires was observed by scanning electron microscopy (SEM) using a LEO 1430. Images were obtained from secondary electrons, with magnifications of 18× and 200×.

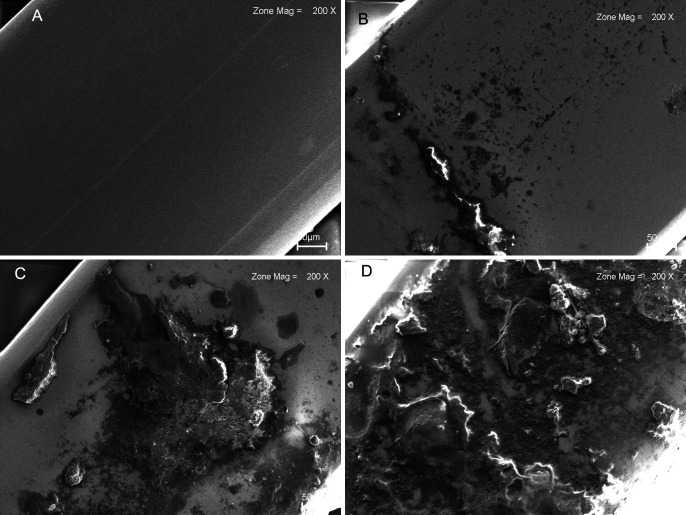

Assessment of the amount of debris on the surface of the wires was performed by a single examiner. The following scores were used, according to previous published methods used in endodontics (Figure 2): 0 = total absence of debris; 1 = some debris, involving less than one-fourth of the image analyzed; 2 = moderate presence of debris involving one-fourth to three-fourths of the image; 3 = presence of a large amount of debris involving more than three-fourths of the image examined.

Figure 2.

SEM images (200×) showing debris on the wires. (A) Score 0. (B) Score 1. (C) Score 2. (D) Score 3.

For analysis of error associated with the debris score, two readings for all segments of wire used before (n = 16) and after clinical use (n = 16) were made in a blinded fashion with an interval of one week between them. The Spearman correlation was used to check the reproducibility.

The surface roughness of the wire was examined with a rugosimeter (Mitutoyo SJ-201). An average roughness was obtained by reading the standard Ra through three readings of 0.8 cm on the surface of the central area of the rectangular wire.

The analysis of debris and roughness before and after clinical use was performed for all 16 segments of the wire used in this experiment. The distribution of roughness was checked with the Shapiro-Wilk test. Because roughness was not distributed normally at T0 (P = .009), the Wilcoxon signed-rank test was used to examine differences in roughness and debris scores. The alpha level was established at 5% (P < .05).

Friction Testing

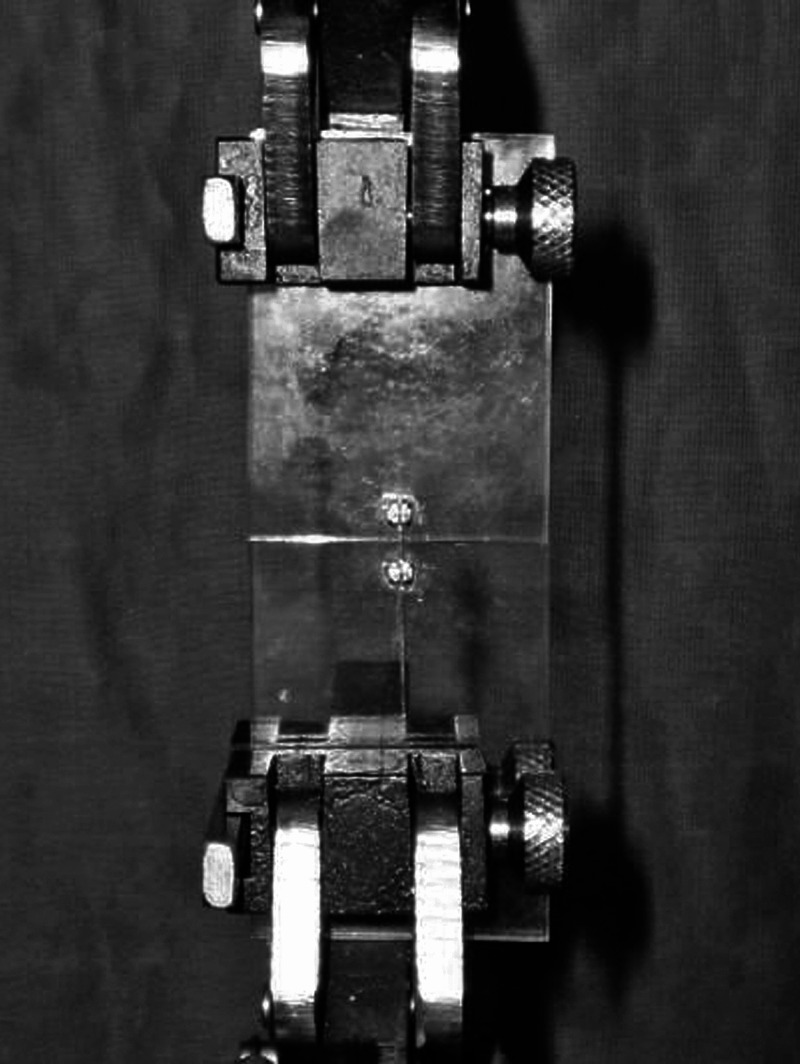

Friction testing was done using two rectangular acrylic plates (area = 4 × 5.5 cm and thicknesses = 0.5 cm). Two SS edgewise brackets (0.022- × 0.030-inch, Morelli, São Paulo, Brazil) were bonded on each plate. Each bracket was bonded with 4 mm between and 2 mm from the extremities of the plate. One SS wire (0.021- × 0.025-inch) was placed in the bracket slot, providing a full filling for the bracket alignment, and was removed after the composite had cured.

Before the friction test, each wire segment had one end bent. Then, the wire was tied to the brackets using a 0.120-inch-diameter elastic ligature (Unicycles, Masel). The plates of acrylic containing the wire segments were fixed in the universal testing machine (EMIC DL 2000) and positioned at a 90° angle relative to the ground (Figure 3). The plate containing the bent wire end was set at the upper grip. The machine was enabled and the upper grip slid at a speed of 0.5 mm/minute for a distance of 5 mm. The test model was the same for all friction tests, so only the wire segments and elastic ligatures were changed. After each friction test, the brackets bonded to the plate were cleaned with gauze soaked in alcohol (96%) to eliminate possible debris from the previous wire. Kinetic frictional force was measured in Newtons (N), using the mean force exerted from the beginning of the movement until the end of the test.

Figure 3.

Acrylic plate model used to examine friction.

Because of the surface changes produced in the orthodontic wires after the friction test, eight segments of as-received wires were used to perform the control friction test (T0). Thus, these wires were not used clinically. The other 16 wires were subjected to friction evaluation after 8 weeks of intraoral exposure (T1).

The normal distribution assumption was tested with the Shapiro-Wilk test. Because the intraorally exposed wires (T1) displayed a nonnormal distribution (P = .009), the Mann-Whitney nonparametric statistical test was used to examine the differences. Correlations between the degree of debris, roughness, and kinetic friction were examined with the Spearman correlation test. For correlation analysis, all the wires (T0 + T1, n = 24) were examined. The alpha level was established at 5% (P < .05).

RESULTS

Scanning Electron Microscopy

The Spearman correlation showed excellent reproducibility (P < .0001) for the debris scores obtained in this study (r = 0.96, 18× magnification, and r = 0.99, 200× magnification). Analysis of debris on the as-received wires (T0) using SEM showed a complete absence of debris (zero score) for all segments of wire at 18× and 200× magnification. However, the degree of debris was significantly increased for wires that had remained in the oral environment for 8 weeks (T1). The median score after clinical use was 2 (moderate debris) at 18× magnification (P = .0004), and 3 (large amount of debris) at 200× magnification (P = .0004) (Table 1).

Table 1.

Descriptive Statistics for Debris, Roughness, and Friction and P Values for Comparisons of As-Received SS Archwires (T0) and Clinically Used SS Archwires (T1)

Roughness

Before exposure to the oral environment (T0), the wires showed homogeneity (SD = 0.02) and very low values of roughness, with an average Ra of 0.02. Eight weeks of intraoral exposure (T1) caused a significant increase in the degree of roughness of the wires (P = .0022) (Table 1). The segments of the wire at T1 showed a mean value of Ra = 1.09 (SD = 0.9) (Table 1).

Friction

There was a significant increase in frictional force from T0 to T1 (P = .0001), with an average increase of 1.48 N (Table 1), corresponding to a 20.8% increase in the friction level.

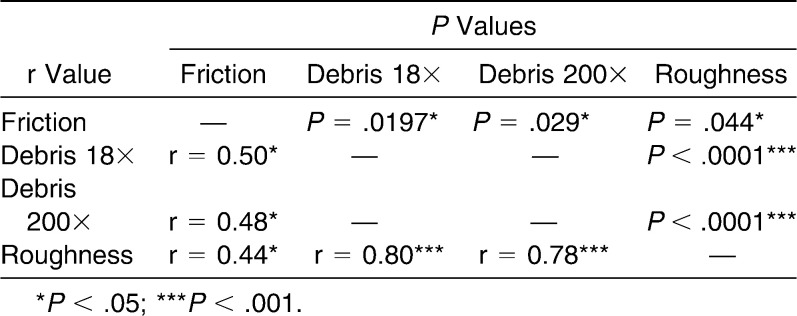

Correlation Between Frictional Force, Amount of Debris, and Roughness

Spearman correlation analysis showed a significant association between kinetic friction and the degree of debris measured using 18× magnification (r = 0.50, P = .019) and 200× magnification (r = 0.46, P = .029), as well as between kinetic friction and roughness (r = 0.44, P = .044). A greater degree of correlation was observed in the association between roughness and debris (P < .0001; r = 0.80 for 18× and r = 0.78 for 200×) (Table 2).

Table 2.

Correlation Coefficients (r) and P Values for the Variables Examined

DISCUSSION

The friction of brackets, ligatures, and archwires as received from manufacturers has been studied extensively.2–10,12–17 The effect of aging in the oral environment is an important factor to consider with regard to the efficacy of orthodontic mechanics. Aging effects on surface archwire roughness,19 surface topography,20 fracture,21 and friction19 have been examined in only a few investigations on NiTi archwires. SS wire has not been evaluated recently. Our choice of rectangular SS wires was motivated by the fact that these wires are very useful during mechanical sliding because of their lower coefficient of friction2,9,11 and lower surface roughness.17 Also, during mechanical incisor retractions, a rectangular SS archwire needs to remain in the oral environment for several months. Edgewise brackets were used in the present study because the slots are flat and they can be assembled without any angles or inclinations.

This test setup used linear unidirectional sliding mechanics, while orthodontic tooth movement is dynamic. Debris in archwire can potentially increase friction, but it is only one of the factors involved in the resistant force system.22 It is also important to consider the different normal forces that can change during active orthodontic movement and the influence of the debris on this phenomenon. Although it is quite hard to simulate in vitro the dynamic relation between archwire and bracket slots, this issue should be investigated further.

The choice of elastic ligatures was made because they are the first choice for most clinical orthodontists. Furthermore, it is more difficult to standardize the tying strength when using SS ligatures.23

In the present study, the as-received SS wire showed very low values of roughness, with an average of 0.02 µm. After intraoral exposure for 8 weeks, there was a significant increase in roughness (Table 1). A previous study19 demonstrated an increase in roughness for four different NiTi wires as a result of 4 weeks of intraoral exposure. The values reported previously seem to differ from those of the present study, probably because of differences between the materials used to manufacture the wires and the duration of intraoral exposure.

There is little information in the literature regarding increased debris on orthodontic wires after clinical use, a very common measure in endodontics studies for evaluating methods of cleaning endodontic files.24–26 In this study, using SEM, a debris score of 0 was obtained for as-received wires, but after 8 weeks of intraoral exposure, the scores were significantly higher (P < .001). Increases in roughness19 and significant deterioration in topography and structure20 in retrieved NiTi archwires have been previously demonstrated.

Comparison of the frictional force of SS before and after clinical use showed an average increase of 1.48 N (20.8%) after 8 weeks of intraoral exposure. Resistance to sliding of orthodontic appliances in the dry state may not correspond to actual friction in the oral environment. However, the presence of saliva seems to cause an increase in friction.14 The samples were analyzed until 48 hours after removal from the oral environment, which might have caused the drying of residues on the archwire surface. This might have influenced the friction level; however, this dryness can also occur during the clinical use of orthodontic wire, since the orthodontist usually removes the archwire from the mouth and replaces it after a short period of time.

The difference of 1.48 N (20.8%) in the magnitude of force loss caused by friction generated by the presence of debris seems to be an important factor to be considered when the force to be applied is calculated. It seems evident that the force used to move a canine, usually around 1 N, is insufficient to generate appropriate movement under the conditions observed in rectangular arches after 2 months of clinical use. This study defends the importance of cleaning the archwires at every clinical appointment to remove plaque and debris from the archwire surface and prevent an increase in friction during mechanical sliding.

No data were found for SS wires in the literature, but increased friction after intraoral exposure for 4 weeks was previously reported for NiTi wires, with increases ranging from 7% to 137%.19 The authors did not find any correlation between friction and roughness and attributed the increased friction to the loss of ions implanted in the wire to reduce roughness and friction. Clinically, surface roughness is a property of the wires that affects corrosion and biocompatibility, as it allows a greater accumulation of plaque.18 According to the present findings, surface roughness is also significantly related to higher levels of frictional force.

Correlation analyses showed significant positive correlations between the degree of debris on the archwire surface, surface roughness, and friction (Table 2). However, the correlation between friction and debris was less significant than the correlation between debris scores and roughness. In this study, changes in structural characteristics of the archwire surface were not examined. It is possible that other factors, in addition to the accumulation of debris on the surface of the archwire, may have contributed to the higher level of friction. Further research using levels of debris, roughness, and friction to evaluate the efficiency of methods employed to clean orthodontic archwires is needed.

CONCLUSIONS

SS rectangular wires exposed to the intraoral environment for 8 weeks show a significant increase in the amount of debris and degree of surface roughness.

An increase in friction between the wire and bracket occurs during the mechanics of sliding. This change is correlated to the degree of debris and roughness on the archwire surface.

REFERENCES

- 1.Rossouw P. E. Friction: An Overview. Semin Orthod. 2003;9:218–222. [Google Scholar]

- 2.Kapila S, Angolkar P. V, Duncanson M. G, Nanda R. S. Evaluation of friction between edgewise stainless steel brackets and orthodontic wires of four alloys. Am J Orthod Dentofacial Orthop. 1990;98:117–126. doi: 10.1016/0889-5406(90)70005-W. [DOI] [PubMed] [Google Scholar]

- 3.Whitley J. Q, Kusy R. P. Influence of interbracket distances on the resistance to sliding of orthodontic appliances. Am J Orthod Dentofacial Orthop. 2007;32:360–372. doi: 10.1016/j.ajodo.2006.04.032. [DOI] [PubMed] [Google Scholar]

- 4.Kuramae M. Evaluation of Frictional Forces In Vitro Between Brackets and Orthodontic Wires in Upper Cusp Distalization According to the TweedMerrifield Sequential Directional Force Technique [thesis] São Paulo, Brazil: Faculdade de Odontologia de Piracicaba, Universidade Estadual de Campinas; 2006. [Google Scholar]

- 5.Bednar J. R, Gruendeman G. W, Sandrik J. L. A comparative study of frictional forces between orthodontic brackets and archwires. Am J Orthod Dentofacial Orthop. 1991;100:513–522. doi: 10.1016/0889-5406(91)70091-A. [DOI] [PubMed] [Google Scholar]

- 6.Tecco S, Di Iorio D, Cordasco G, Verrocchi I, Festa F. An in vitro investigation of the influence of self-ligating brackets, low friction ligatures, and archwire on frictional resistance. Eur J Orthod. 2007;29:390–397. doi: 10.1093/ejo/cjm007. [DOI] [PubMed] [Google Scholar]

- 7.Kim T. K, Kim K. D, Baek S. H. Comparison of frictional forces during the initial leveling stage in various combinations of self-ligation brackets and archwires with custom-designed typodont system. Am J Orthod Dentofacial Orthop. 2008;133:15–24. doi: 10.1016/j.ajodo.2007.08.013. [DOI] [PubMed] [Google Scholar]

- 8.Frank C. A, Nikolai R. J. A comparative study of frictional resistances between orthodontic bracket and arch wire. Am J Orthod Dentofacial Orthop. 1980;78:593–609. doi: 10.1016/0002-9416(80)90199-2. [DOI] [PubMed] [Google Scholar]

- 9.Drescher D, Bourauel C, Schumacher H. Frictional forces between bracket and arch wire. Am J Orthod Dentofacial Orthop. 1989;96:397–404. doi: 10.1016/0889-5406(89)90324-7. [DOI] [PubMed] [Google Scholar]

- 10.Kusy R. P, Whitley J. Q. Coefficients of friction for arch wires in stainless steel and polycrystalline alumina brackets slots. I. The dry states. Am J Orthod Dentofacial Orthop. 1990;98:300–312. doi: 10.1016/S0889-5406(05)81487-8. [DOI] [PubMed] [Google Scholar]

- 11.Mendes K, Rossouw P. E. Friction: validation of manufacturer's claim. Semin Orthod. 2003;9:236–250. [Google Scholar]

- 12.Thorstenson G. A, Kusy R. P. Resistance to sliding of self-ligating brackets versus conventional stainless steel twin brackets with second-order angulation in the dry and wet (saliva) states. Am J Orthod Dentofacial Orthop. 2001;120:361–370. doi: 10.1067/mod.2001.116090. [DOI] [PubMed] [Google Scholar]

- 13.Franchi L, Baccetti T, Camporesi M, Barbato E. Forces released during sliding mechanics with passive self-ligating brackets or nonconventional elastomeric ligatures. Am J Orthod Dentofacial Orthop. 2008;133:87–90. doi: 10.1016/j.ajodo.2007.08.011. [DOI] [PubMed] [Google Scholar]

- 14.Kusy R. P, Whitley J. Q. Resistance to sliding of orthodontic appliances in the dry and wet states: influence of archwire alloy, interbracket distance, and bracket engagement. J Biomed Mater Res. 2000;52:797–811. doi: 10.1002/1097-4636(20001215)52:4<797::aid-jbm25>3.0.co;2-9. [DOI] [PubMed] [Google Scholar]

- 15.Thorstenson G. A, Kusy R. P. Comparison of resistance to sliding between different self-ligating brackets with second-order angulation in dry and saliva states. Am J Orthod Dentofacial Orthop. 2002;121:472–482. doi: 10.1067/mod.2002.121562. [DOI] [PubMed] [Google Scholar]

- 16.Smith D. V, Rossouw P. E, Watson P. Quantified simulation of canine retraction: evaluation of frictional resistance. Semin Orthod. 2003;9:262–280. [Google Scholar]

- 17.Kusy R. P, Whitley J. Q, Mayhew M. J, Buckthal J. E. Surface roughness of orthodontic archwires—via laser spectroscopy. Angle Orthod. 1988;58:33–45. doi: 10.1043/0003-3219(1988)058<0033:SROOA>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 18.Eliades T, Bourauel C. Intraoral aging of orthodontic materials: the picture we miss and its clinical relevance. Am J Orthod Dentofacial Orthop. 127:403–412. doi: 10.1016/j.ajodo.2004.09.015. 2005 Apr. [DOI] [PubMed] [Google Scholar]

- 19.Wichelhaus A, Geserick M, Hibst R, Sander F. G. The effect of surface treatment and clinical use on friction in NiTi orthodontic wires. Dent Mater. 2005;21:938–945. doi: 10.1016/j.dental.2004.11.011. [DOI] [PubMed] [Google Scholar]

- 20.Eliades T, Eliades G, Athanasiou A. E, Bradley T. G. Surface characterization of retrieved NiTi orthodontic archwires. Eur J Orthod. 2000;22:317–326. doi: 10.1093/ejo/22.3.317. [DOI] [PubMed] [Google Scholar]

- 21.Bourauel C, Scharold W, Jäger A, Eliades T. Fatigue failure of as-received and retrieved NiTi orthodontic archwires. Dent Mater. 2008;24:1095–1101. doi: 10.1016/j.dental.2007.12.007. [DOI] [PubMed] [Google Scholar]

- 22.Burrow S. J. Friction and resistance to sliding in orthodontics: a critical review. Am J Orthod Dentofacial Orthop. 2009;135(4):442–447. doi: 10.1016/j.ajodo.2008.09.023. [DOI] [PubMed] [Google Scholar]

- 23.Iwasaki L. R, Beatty M. W, Randall C. J, Nickel J. C. Clinical ligation forces and intraoral friction during sliding on a stainless steel archwire. Am J Orthod Dentofacial Orthop. 2003;123:408–415. doi: 10.1067/mod.2003.61. [DOI] [PubMed] [Google Scholar]

- 24.Van Eldik D. A, Zilm P. S, Rogers A. H, Marin P. D. A SEM evaluation of debris removal from endodontic files after cleaning and steam sterilization procedures. Aust Dent J. 2004;49:128–135. doi: 10.1111/j.1834-7819.2004.tb00061.x. [DOI] [PubMed] [Google Scholar]

- 25.Drukteinis S, Balciuniene I. A scanning electron microscopic study of debris and smear layer remaining following use of AET instruments and K-flexofiles. Stomatologija. 2006;8:70–75. [PubMed] [Google Scholar]

- 26.Perakaki K, Mellor A. C, Qualtrough A. J. Comparison of an ultrasonic cleaner and washer disinfector in the cleaning of endodontic files. J Hosp Infect. 2007;67:355–359. doi: 10.1016/j.jhin.2007.09.009. [DOI] [PubMed] [Google Scholar]