Highlights

Fundamental rationalisation for high-energy batteries.

Newly emerging and the state-of-the-art high-energy batteries vs. incumbent lithium-ion batteries: performance, cost and safety.

Closing the gap between academic research and commercialisation of emerging high-energy batteries, and examination of the remaining challenges.

Keywords: High energy density, Beyond lithium-ion batteries, Multivalent-ion batteries, Conversion electrode materials, Electrolyte

Abstract

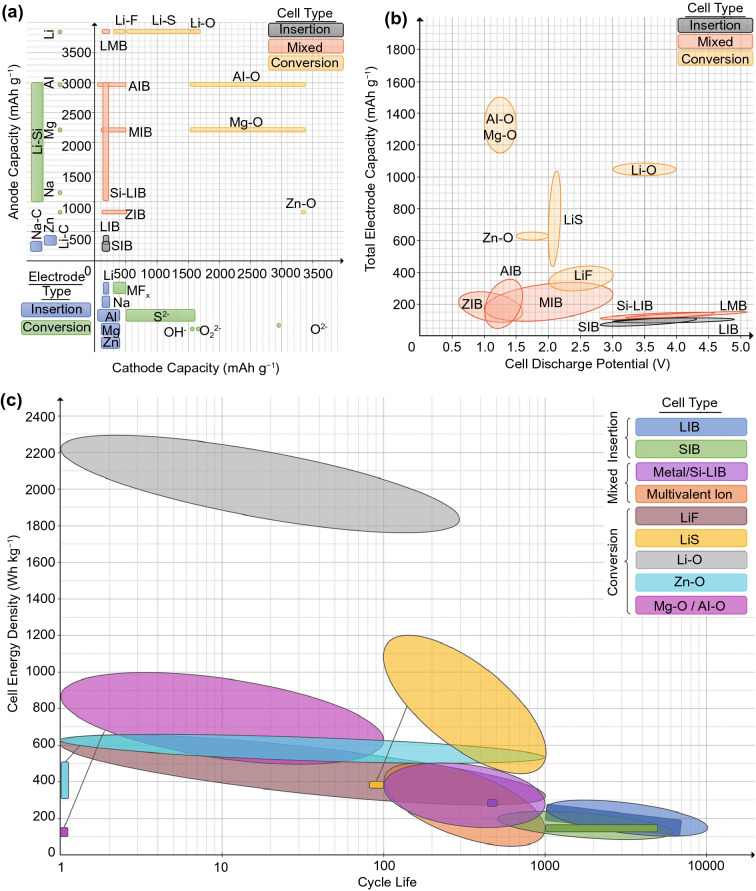

Rechargeable batteries of high energy density and overall performance are becoming a critically important technology in the rapidly changing society of the twenty-first century. While lithium-ion batteries have so far been the dominant choice, numerous emerging applications call for higher capacity, better safety and lower costs while maintaining sufficient cyclability. The design space for potentially better alternatives is extremely large, with numerous new chemistries and architectures being simultaneously explored. These include other insertion ions (e.g. sodium and numerous multivalent ions), conversion electrode materials (e.g. silicon, metallic anodes, halides and chalcogens) and aqueous and solid electrolytes. However, each of these potential “beyond lithium-ion” alternatives faces numerous challenges that often lead to very poor cyclability, especially at the commercial cell level, while lithium-ion batteries continue to improve in performance and decrease in cost. This review examines fundamental principles to rationalise these numerous developments, and in each case, a brief overview is given on the advantages, advances, remaining challenges preventing cell-level implementation and the state-of-the-art of the solutions to these challenges. Finally, research and development results obtained in academia are compared to emerging commercial examples, as a commentary on the current and near-future viability of these “beyond lithium-ion” alternatives.

Introduction

Background

The battery, famously invented by Alessandro Volta in 1800 [1], is an electrochemical device that converts chemical energy to electrical energy. Redox reactants are stored in the electrodes, separated by an electronically insulating but ionically conducting electrolyte, with their reaction driving electrons through an external circuit during discharge. In a rechargeable system, simply applying a sufficient potential to the electrodes reverses the reaction and converts electrical energy to chemical energy. Rechargeable batteries have changed substantially in architecture, chemistry and performance since the initial invention. Regardless of these changes, the ability to reversibly store and release electrical energy on demand in a mobile package has had an undeniably significant impact on society, with off-the-grid electrical devices being ubiquitous all around the world. The role that they play is becoming even more important, as the depletion of fossil fuels and rapid climate change urgently call for clean, renewable sources of energy that will need to be stored in various electrical energy storage devices, including batteries, and especially so for mobile applications.

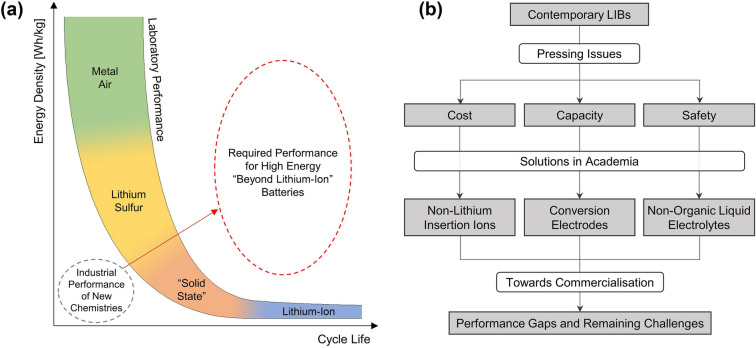

While other factors such as power capacity, cyclability, price and operating temperature are important, the perennial problem that batteries face is insufficient energy density,1 where battery designers are often engaged in an unwitting arms race with device designers that introduce ever more powerful devices to take advantage of ever more energy-dense batteries. Over the past few decades, lithium-ion batteries (LIBs) have emerged as the dominant high-energy chemistry due to their uniquely high energy density while maintaining high power and cyclability at acceptable prices. However, issues with cost and safety remain, and their energy densities are becoming insufficient with the rapid trend towards electrification of the transport and energy industries. There is thus an increasingly urgent need for better LIBs and “beyond lithium-ion” alternatives that are safer, cheaper and higher capacity while maintaining sufficient longevity and power capacity to address new application demands. A large variety of potential candidates have emerged as a result, including sodium and multivalent ion, lithium–sulphur, metal–air and solid-state batteries among others. While many of them have demonstrated potentially higher capacities or lower costs, this often comes at a large expense in cyclability. A large gap also remains between academia and industry, and emerging commercially available examples of these new alternatives are generally falling short of their laboratory counterparts in all performance aspects (Fig. 1a). As a result, despite encouraging academic progress, LIBs currently still account for nearly the entire high-energy battery market [2].

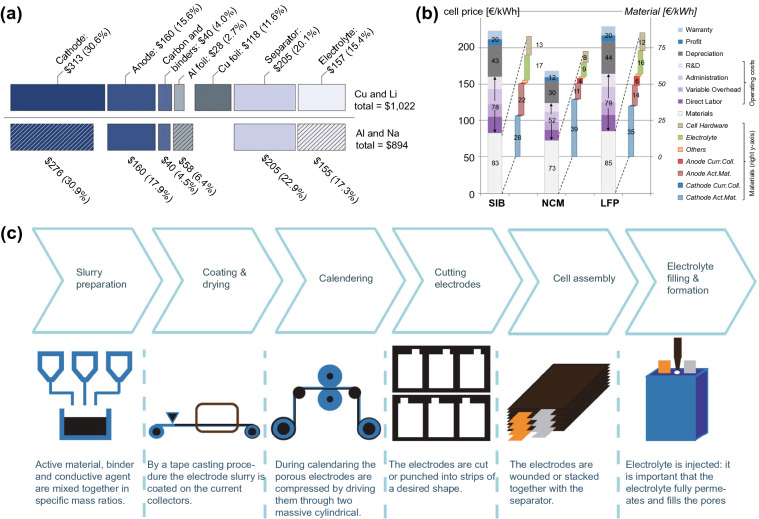

Fig. 1.

a General performance for LIBs and popular new chemistries along with emerging commercial examples of the latter, compared with the region of performance required by future applications. b Flowchart describing the sequence of content for this review

Nonetheless, recent progress in the field has been undeniably rapid, with an average of nearly 30,000 papers published globally per year for the past decade, covering a wide variety of different chemistries, architectures and applications. However, while numerous excellent reviews have been published on individual aspects of the field (e.g. on different battery types), holistic considerations of the entire field in the context of high-energy “beyond lithium-ion” batteries, including industrial developments, are absent. This review thus aims to rationalise and deconvolute these developments by returning to fundamental principles and examining the material characteristics that make a good high-energy battery, through which notable candidates are identified and correlated with trends in both academia and industry. A brief overview is then given regarding the main challenges of each system, strategies that are being adopted to tackle them and the extent of positive impact that these strategies have had on battery performance. Finally, cell performance in academia is compared to emerging industrial examples, where the differences are illustrative of the remaining barriers to successful commercialisation (Fig. 1b).

Material Choices: Returning to Elements

Fundamental design of a high-energy battery begins with electrode material selection. In general, there are two types of electrode materials for batteries: insertion and conversion. Redox reactions occur in insertion electrodes via the insertion or removal of an active ion into or from an inactive host framework, with no change in the structure of the host beyond the inclusion or removal of the active ions and an associated volume change. This is also referred to as intercalation when it occurs in layered materials, and active ions are stored between layers. In contrast, conversion electrodes involve bond breakage and significant structural changes of the electrode materials during redox reactions. While distinctions are often made between the different types of bond-breaking reactions (e.g. dissolution, displacement, alloying and true-conversion reactions), these will broadly be referred to as conversion reactions for this review, as the challenges they face for use as batteries are largely similar.

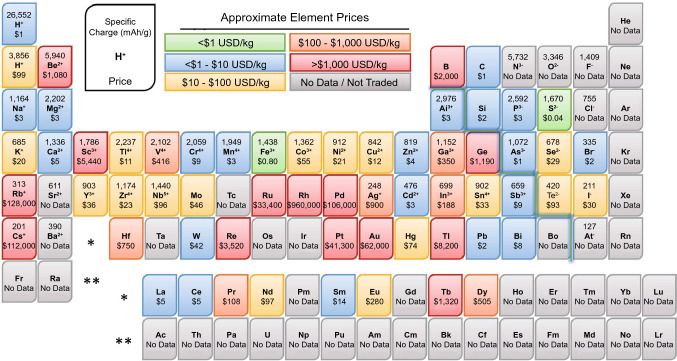

The energy density of an electrode is directly correlated with the charge capacity2 and redox potential of the active species involved. Thus, the suitability of an element for use as a battery electrode material can be, to some extent, assessed with the periodic table (Fig. 2). Within the same group, elements positioned higher on the periodic table possess higher charge capacities as their ion charges are the same, but atomic mass decreases. Within the same period, ion charges increase more than proportionately to increases in atomic mass, likewise leading to higher charge capacity, although this trend is slightly tenuous at high atomic numbers as electronic structures become more complex. Changes in redox potential within a period are less systematic and are also dependent on the counter-electrode, but a general trend of increasing theoretical energy density towards the top and centre of the periodic table can nonetheless be observed. It is also clear that elements, rather than their compounds, should be used as the active species whenever possible, as compounds necessarily have higher molecular weights than elements, but usually without the benefit of higher charge or redox potentials.

Fig. 2.

Periodic table of elements with price and charge capacity of each element at the indicated oxidation state. Price data retrieved from Shanghai Metals Market [3] (June 2021 spot price), Preismonitor [4] USGS Mineral Commodity Summaries [5], Institute of Rare Earths and Strategic Metals [6] and others [7, 8]. Gas prices vary substantially with location and storage method and are thus excluded

Other factors are also important for industrially relevant battery chemistries. First, the element should preferably be non-gaseous at operational temperatures for ease of handling and cell design. While gaseous batteries do exist in the form of fuel cells, the need to store the reacting gases in high-pressure vessels can substantially decrease the energy density of the energy storage system as a whole. The element should also be not overwhelmingly expensive or toxic to humans or the environment. It should be noted that the actual fabrication cost of an electrode can differ substantially from the element prices shown in Fig. 2, as the electrodes are usually not synthesised from the pure element, and element prices can also vary significantly with time, quantity and purity. Nonetheless, Fig. 2 offers an order-of-magnitude price gauge and a comparison of relative costs between the elements and their compounds.

By examining the periodic table with these factors in mind, one can have some ideas on good candidate materials for battery electrodes. Among the metallic cationic species, which are commonly used as both insertion ions and conversion anodes, lithium stands out as the only suitable element in Period 2. Beryllium, despite its high theoretical energy density, is unsuitable due to its high cost and toxicity. In Period 3, sodium, magnesium and aluminium are notable, and while their theoretical energy density is lower than lithium, they are considerably cheaper and thus have received substantial research interest [9–11]. A much larger number of cationic elements is available from Period 4. However, the high atomic masses of these elements results in lower theoretical energy densities than their Period 3 counterparts without significant cost benefits. The transition metal elements, despite their high charge capacities, also generally suffer from low redox potentials. Nonetheless, they do see use, but mostly in systems that are gradually facing obsolescence, such as the various nickel- and zinc-based batteries, or as insertion compounds for higher energy ions. They are also important for redox flow batteries [12], which will not be covered presently as energy density is usually not their primary goal.

Anionic species are rarely used as insertion ions due to them having higher atomic masses than cationic species of the same charge, as well as being generally more difficult to handle owing to their tendency to be gaseous at room temperature. Nonetheless, fluorine has been explored as a potential insertion ion [13]. For use as conversion cathodes, the monovalent halogen ions are gaseous and toxic, unlike their cationic analogue, the alkali metals. As a result, the light halogens like fluoride and chlorine are used as more benign, solid compounds instead, such as transition metal halides. However, the inclusion of inactive ions substantially reduces the theoretical charge capacity, resulting in halogens having substantially lower energy densities than those of chalcogens of the same period despite possessing higher redox potentials [14].

The chalcogens are generally more popular than the halogens. Oxygen can be used as a gaseous conversion cathode without storage issues, due to its unique combination of abundance in the atmosphere and high reactivity, allowing it to be harvested directly from ambient air [15]. Oxygen compounds are also commonly used as insertion electrodes due to their high stability [16]. Sulphur is the highest energy solid cathode material and thus also has received substantial research interest [17]. The pnictogens, despite having higher charge capacities than their chalcogen counterparts of the same period, are generally too stable to be used as conversion cathodes and are generally used as compounds in the form of insertion frameworks or conversion anodes instead [18, 19].

Lithium-Ion Batteries: The Current Workhorse

The dominance of LIBs for high-energy applications can in part be explained by lithium’s position in the periodic table, which gives it the highest charge capacity among suitable elements as previously shown, second only to hydrogen and beryllium. This, combined with the most negative standard reduction potential among all cationic elements of − 3.04 V, gives lithium an extremely high theoretical energy density, making it the obvious choice for a high-energy anode material. While the first rechargeable lithium batteries used lithium metal anodes with transition metal sulphide insertion cathodes, apparent safety issues prevented the commercial use of lithium metal anodes, and sulphide cathodes were gradually superseded by higher energy oxide cathodes [20]. The electrolyte is usually a lithium salt, such as LiPF6, dissolved in an organic solvent, the latter being necessary due to the typical operating potentials of lithium batteries far exceeding the electrochemical stability window of water.

Anodes

Commercial LIBs nearly invariably employ a graphite intercalation anode, with lithium ions being stored between individual graphite layers. The fully lithiated state is of the composition LiC6, leading to a theoretical charge capacity of 339 mAh g−1 including lithium mass (372 mAh g–1 excluding lithium mass). Graphite is suitable for this application due to both sufficiently high electronic and lithium ionic conductivities that lead to low redox overpotentials. In addition, the volume expansion upon lithiation is fairly modest at around 10% [21], limiting electrode damage and allowing cycle lives of up to several thousand. Finally, its potential against metallic lithium is only 0.2 V [22], allowing for high energy densities at the cell level due to high cell voltages. However, this small potential difference also limits the charge rate, as lithium metal plating and associated dendritic growth can easily occur [23].

Lithium titanate (LTO), in the form of Li4Ti5O12, is another insertion anode material that has been commercialised. The fully lithiated state is of the composition Li7Ti5O12 [24], leading to a theoretical charge capacity of 167 mAh g−1 including lithium mass (175 mAh g−1 excluding lithium mass), which is substantially lower than carbon. LTO has a potential of approximately 1.55 V against metallic lithium, allowing for higher charge/discharge rates compared to graphite anodes due to the avoidance of lithium metal plating. It also has a lower tendency to form insulating solid electrolyte interphases, allowing the usage of higher surface area electrodes that further increase current capabilities. In addition, it produces nearly no volume change upon lithiation, improving cyclability [25]. However, the higher cost of LTO, as well as the higher reduction potential and lower theoretical charge capacity, which together lead to a significantly lower energy density, results in LTO usually being reserved for applications that require rapid charging or very long cycle lives.

Cathodes

A fairly large number of different insertion cathodes have been explored for LIBs, most of which are transition metal chalcogenides. However, over the past few decades, three main types have emerged as the frontrunners, all of which are oxygen-containing transition metal compounds. In general, insertion and removal of the lithium ion is balanced by reduction and oxidation of the transition metal ion, meaning the remaining ions in the compound are inactive and present only as structural stabilisers.

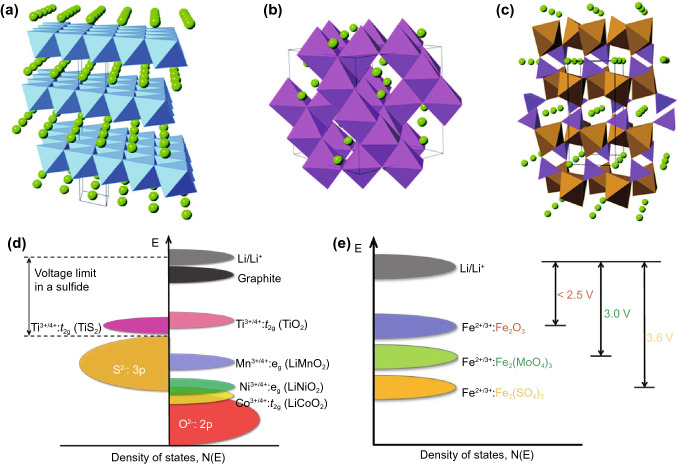

The first among these are layered transition metal oxides of the formula LiMO2, where the structure is idealised as close-packed planes of oxygen atoms between alternating layers of lithium and the transition metal. LiCoO2 (LCO, Fig. 3a) was the first to see widespread commercial use; however, its energy capacity is limited by the tendency for oxygen release above approximately 50% lithiation, due to the substantial overlap between the Co3+/Co4+ and O2- densities of states. This means that only ~140 mAh g−1 out of the 273 mAh g−1 theoretical capacity can be accessed [16].

Fig. 3.

Schematics of the common LIB cathodes, a layered LiCoO2, b spinel LiMn2O4 and c olivine LiFePO4, with green atoms representing lithium [34]. Creative Commons License (CC BY 3.0). d Relative positions of the energy bands of different elements in LIB, showing the higher stability of Mn and Ni with oxygen compared to Co. e Illustration of the inductive effect of polyanions in increasing the cell voltage relative to lithium metal [16]. Creative Commons License (CC BY 4.0)

Other transition metal ions such nickel and manganese do not face the same issue to such an extent (Fig. 3d). However, LiMnO2 suffers from poor structural stability in the form of a layered-to-spinel transition during the charge/discharge process [26], and while LiNiO2 is stable during operation, it is unstable during the synthesis process into a well-ordered layered oxide [27]. Hence, state-of-the-art layered oxide cathodes are of the form LiNixCoyMnzO2 (NCM), where x + y + z = 1 and the three transition metal ions stabilise each other through d-band interactions. NCM cathodes are typically 60–80% nickel, with approximately equal remaining proportions of cobalt and manganese, and the general trend is to continue increasing the nickel content to improve energy capacity as well as minimise the use of expensive cobalt [16]. Replacing Mn with Al, resulting in LiNixCoyAlzO2 (NCA) cathodes, can also achieve a similar stabilisation effect [28]. NCA cathodes are generally more resistant to phase transformations and dissolution than NCM, but more susceptible to mechanical pulverisation [29].

The second type of oxide cathodes are spinel oxides, for which LiMn2O4 (LMO, Fig. 3b) is the exemplary composition. Lithium-ion mobility in LMO is high, due to the presence of open channels for ion diffusion in all three dimensions, allowing for good current capabilities but not significantly superior to layered oxides [30]. However, the higher inactive mass compared to layered oxides gives rise to a lower charge capacity, and the tendency for the cathode to dissolve in the electrolyte due to acid disproportionation of Mn3+ [31] leads to limited cycle life. As a result, the main advantage of LMO over NCM is a slightly lower cost arising from the avoidance of cobalt, and does not see as much commercial use.

The final type of oxide cathodes are the polyanion oxides, which were first investigated due to an inductive effect resulting in higher redox potentials compared to simple oxides (Fig. 3e) [16]. While there are a large number of possible compositions, the emergent one in industry has been olivine LiFePO4 (LFP, Fig. 3c). However, LFP actually shows a lower redox potential than LCO, NCM and LMO due to the usage of iron. In addition, it has both low electronic and lithium ionic conductivity, resulting in the necessity for practical cathodes to be manufactured as small particles and contain a greater proportion of inactive conductive carbon [25]. These factors lead to LFP having the lowest practical energy densities among the three common cathode types. Nonetheless, LFP has higher thermal stability than layered and spinel oxides, leading to higher thermal runaway temperatures, and thus is prioritised for use in safety-critical applications [32]. They can also demonstrate higher cycle lives than layered oxide LIBs [33], making them popular for grid energy storage.

Challenges Faced by LIBs

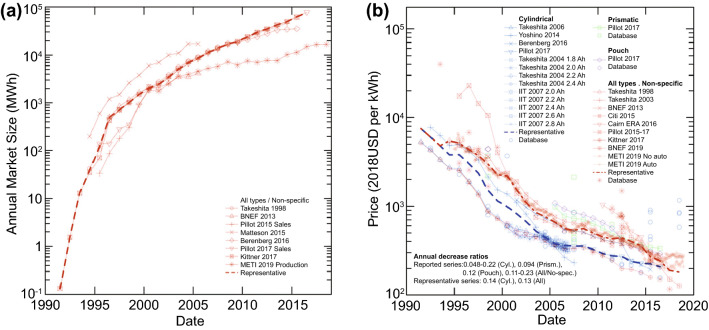

Commercial LIBs based on the aforementioned chemistries are capable of remarkably good performance compared to their nickel- and lead-based predecessors. NCM/Graphite cells can discharge at rates of up to 10C with energy densities of around 200 Wh kg−1 [35]. Under deep, slow discharge, energy densities can be as high as 280 Wh kg−1 [36]. Cycle life is also excellent, reaching as high as 6000 with 80% capacity retention [37] if cycled within a limited voltage window. LTO cells are capable of even higher cycle lives that can exceed 10,000 [38, 39]. These characteristics have propelled LIBs to significant popularity over the past three decades, with the market size in terms of total energy increasing by close to 6 orders of magnitude since their first introduction in 1991 (Fig. 4a) [40]. As of 2019, nearly the entire market for high-energy batteries is dominated by LIBs [2], with this rise apparently continuing as governments around the world increasingly encourage the adoption of electric vehicles and clean energy.

Fig. 4.

The change in a annual market size, and b price of LIBs since their introduction in 1991 [40]. Creative Commons License (CC BY-NC 3.0)

Nonetheless, a few issues remain to be addressed for these workhorse LIBs. Firstly, despite steadily decreasing in cost by 97% since 1991 (Fig. 4b) [40], LIBs remain fairly expensive as compared to the $80/kWh target set by the US Department of Energy’s Energy Storage Grand Challenge [41]. Additionally, as of 2021, the consumption of lithium by battery applications has already exceeded 70% of all global lithium consumption [5], and constantly rising demand has raised concerns on rising costs in the future due to potential resource depletion [42]. In addition to lithium, cobalt, frequently used in LIB cathodes, also faces a similar issue, with more than half of all global cobalt consumption being attributed to batteries [43].

Secondly, energy capacity also remains insufficient. Despite the relatively high energy densities already achieved by LIBs, which have played a part in enabling many applications including powerful mobile devices and a new wave of consumer electric vehicles, they remain substantially inferior to internal combustion engines and fuel cells. This is true even for small vehicles where the weight of the engines and fuel tanks would be more significant [44], making their usage in power-hungry or weight-critical applications such as heavy vehicles or aircraft highly challenging.

Finally, safety is also a critical issue for both mobile and stationary storage applications. LIBs notably contain all necessary components of the fire triangle once thermal runaway temperatures are reached. Rapid cathode decomposition releases heat and oxygen, while the flammable organic electrolyte and graphitic anode act as fuel [45, 46]. Further, the initial source of heat is often a short circuit, which will continue to act as a heat source until the battery is fully discharged. These factors lead to LIB fires being extremely difficult to extinguish. While external cooling and fire suppression mechanisms can be adopted, these will add further cost and weight to the energy storage system as a whole.

Addressing Cost: Beyond Lithium Active Ions

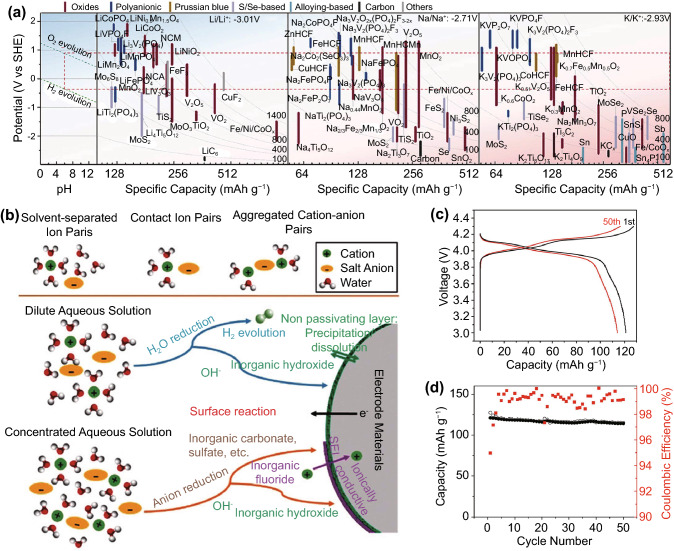

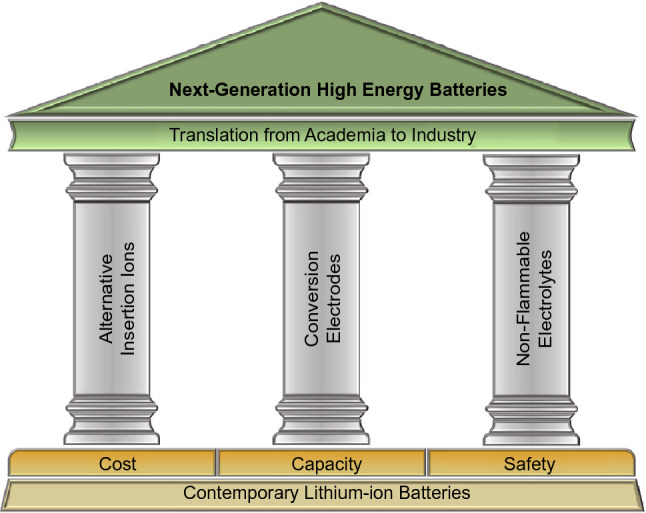

An obvious solution to the issue of lithium cost and resource depletion is to use an alternative insertion ion. Although the mass of the active ion is only a small portion of the total mass of insertion electrodes, ion energy density is nonetheless important, especially for high-capacity electrodes (Fig. 5). Of the many potentially suitable ions identified previously through the periodic table, magnesium and aluminium stand out due to their high theoretical energy densities, second only to lithium. Sodium and zinc are also popular alternative ions, the former due to its very similar chemistry to lithium, and the latter due to its less negative standard reduction potential allowing it to be used more easily with aqueous electrolytes.

Fig. 5.

Theoretical charge capacity of an electrode calculated with both ion and electrode mass, plotted as a function of the charge capacity calculated with just the electrode mass (CEM), showing the detrimental effect of high ion mass on the charge capacity of an insertion electrode

Several other ions have also been explored, which have plenty of academic novelty, but which are disadvantaged compared to the aforementioned four ions for industrial relevance. Potassium [47] and calcium [48] are popular, but currently offer uncertain benefits over their Period 3 counterparts. Fluorine has received attention due to its high redox potential and relatively low atomic weight. However, the theoretical energy density of the fluoride ion remains inferior to lithium, magnesium and aluminium, and the system faces significant difficulties in finding suitable electrolytes [13].

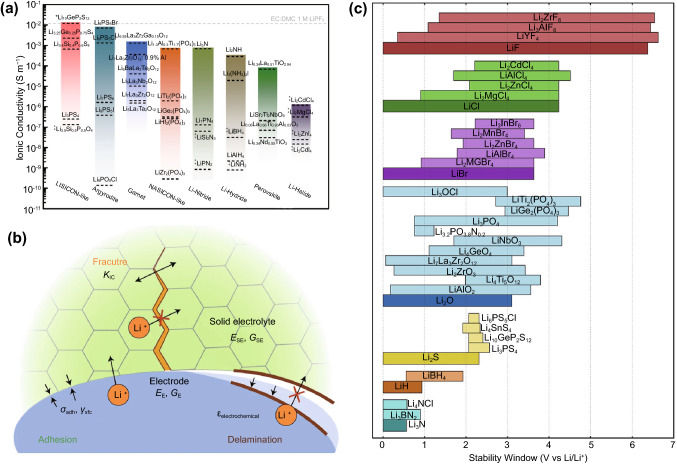

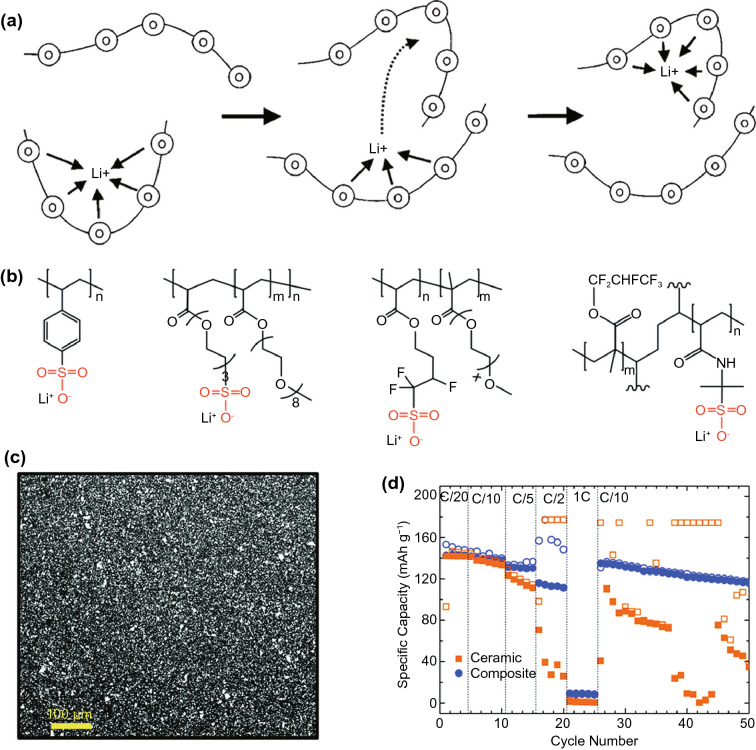

Sodium-Ion Batteries

The popularity of sodium as an insertion ion, aside from its low cost and high elemental abundance in the earth’s crust, also arises from it being an alkali metal like lithium, resulting in very similar chemical behaviour. In fact, sodium ion electrolytes (Fig. 6c), typically a sodium salt such as NaPF6 dissolved in an organic solvent, are nearly identical to lithium-ion electrolytes aside from the change from lithium to analogous sodium salts [49]. Anode and cathode compositions are also highly similar to those in LIBs, leading to rapid developments that have propelled sodium-ion batteries (SIBs) to near-commercial viability.

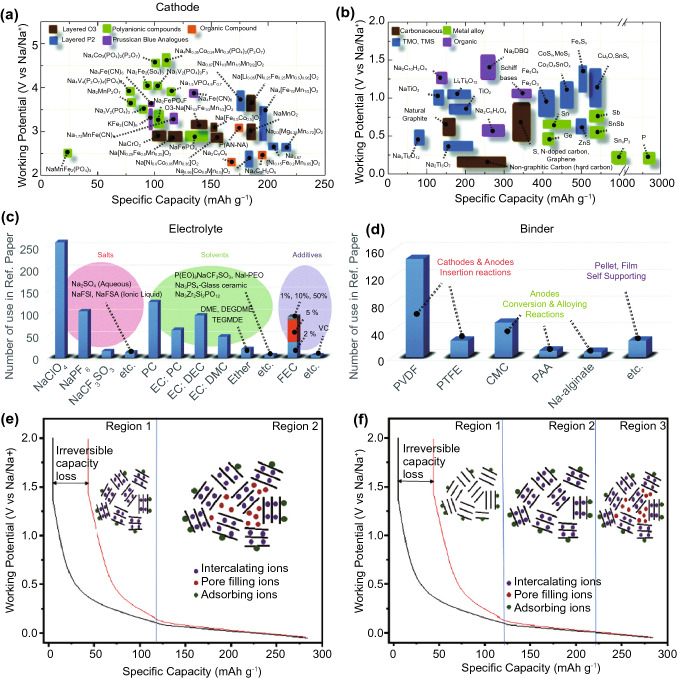

Fig. 6.

A non-exhaustive visual summary of selected a cathodes, b anodes, c electrolytes and d binders that have been explored for sodium-ion batteries [9]. Creative Commons License (CC BY 3.0). e Initial model for sodium ion insertion into hard carbon, attributing the sloping region to intercalation and low potential plateau to pore-filling. f A more recent model for sodium insertion into hard carbon, attributing the sloping region with defect binding, and the low potential plateau to intercalation and pore-filling [50].

Copyright 2020, Elsevier

While oxide insertion anodes such as TiO2 exist (Fig. 6b), the dominant anodes for SIBs are carbon-based, like LIBs [50, 51]. However, unlike lithium, regular graphite is a very poor anode for sodium due to its larger ionic radius, resulting in negligible reversible capacity in typical organic solvents [52, 53]. Expanded graphite shows better results, which can be achieved either by direct synthesis for capacities as high as 284 mAh g−1 [54] or by co-intercalation of non-standard organic solvent molecules such as diglyme [55] for capacities in the region of 100–200 mAh g−1. Nonetheless, most of the explored carbon anodes for SIBs are based on non-graphitic carbon such as hard carbon. Sodium ion insertion proceeds first along a high potential, sloping region, followed by a low potential plateau. Initially, the sloping region was attributed to intercalation between graphene sheets in turbostratic domains in the hard carbon, while the low potential plateau was attributed to the filling of nano-pores located among these domains (Fig. 6e) [56]. However, more recent evidence points towards the sloping region being due to sodium ion binding with defect sites instead, with the low potential plateau being attributed to both turbostratic domain intercalation and nano-pore filling (Fig. 6f) [50]. Regardless of the mechanism, the more disordered structure of hard carbon compared to graphite allows it to achieve higher charge capacities, generally in the region of 200–300 mAh g−1. The charge capacity can be further increased to some extent by appropriate heteroatom doping, which increases the turbostratic interlayer spacing [57]. Soft carbons, with mixed graphitic and disordered domains, are able to achieve similar charge capacities as hard carbon, but with substantially higher current capabilities due to higher electronic conductivity.

SIB cathodes are likewise very similar to LIBs, with the majority consisting of layered and polyanion oxides with similar insertion mechanisms (Fig. 6a). It is then perhaps no surprise that one of the more promising full-cell SIBs recently reported is based on the familiar layered NCM chemistry [58]. However, the larger ionic radii of sodium ions mean they cannot be stored in the same lattice sites in layered oxides as lithium, resulting in phase transformations during sodium insertion and extraction that lead to stepped charge/discharge curves [59]. Remarkably, the larger ionic radius and higher atomic mass does not appear to affect the charge storage capacity as much as in anodes, and layered sodium oxides are able to achieve charge capacities similar to layered lithium oxides at around 200 mAh g−1 [60–62].

Polyanion oxides show greater differences between sodium and lithium analogues. Most notably, NaFePO4 is unstable in the olivine structure that is so popular for LFP batteries. Although the olivine phase can be synthesised in laboratories, it remains susceptible to phase transformations [63, 64] during charge/discharge and sodium diffusion coefficients are substantially lower than lithium due to the larger ion size [65]. As a result, many other types of polyanion oxides have been explored, including phosphates, fluorophosphates, pyrophosphates and sulphates. Among these, NASICON-type compounds are notable due to their high sodium ionic conductivity. Nonetheless, polyanion oxide cathode capacities are typically in the region of 100 mAh g−1, and no dominant composition appears to have emerged yet [9, 60, 61].

Other than the oxides, Prussian Blue Analogues (PBAs) are also popular sodium insertion cathodes by virtue of their open structures. The usage of PBAs as cathodes is complicated by the large amount of vacancies and coordinated water that arise from their synthesis processes, detrimentally affecting electrochemical performance. Nonetheless, these synthesis processes have since been refined sufficiently to allow cathode capacities generally in the region of 150 mAh g−1 [66], with exceptional examples exceeding 200 mAh g−1 [67]. Nonetheless, these charge capacities, along with generally similar redox potentials, means energy density remains lower than those of layered oxides. However, PBAs do not suffer from phase transitions the during charge/discharge process, leading to the possibility of longer cycle lives [68].

Unfortunately, the strong chemical similarities between sodium and lithium that have driven the rapid recent developments of SIBs is also a major disadvantage. As the electrodes and electrolytes are so similar, the lower redox potential and charge capacity of sodium ions mean the energy density of SIBs are invariably lower than their LIB analogues [69]. Hence, the only significant advantage the former can currently claim over the latter is potentially lower cell costs arising from the use of a lower cost active ion. Further cost savings can be achieved with the use of cheaper aluminium as anode current collectors in SIBs, as opposed to copper in LIBs. This is due to a low-potential reaction that occurs for aluminium with lithium, but not with sodium [42]. However, even this advantage is threatened by the constantly falling costs of LIBs.

Aluminium-Ion Batteries

The attractiveness of aluminium-ion batteries (AIBs) stems from the very high charge capacity of the trivalent aluminium ion. At 2976 mAh g−1, it is second only to lithium among the relatively low-cost elements that are solid at room temperature. This, in combination with a decent standard reduction potential of – 1.66 V, results in a very high theoretical energy density. However, the trivalency also results in a very high surface charge density and thus high stability of compounds formed. This results in generally lower salt solubility and ion mobility, and more difficult insertion into and extraction from electrodes than monovalent and divalent ions. Notably, the low salt solubility means sufficient ionic conductivity generally cannot be achieved for the salt-in-solvent type organic electrolytes used in SIBs and LIBs [11].

Research and development of AIBs is far less mature than SIBs and LIBs, and most efforts have been focused on finding suitable electrolytes and characterisation of the insertion process in general. The latter is especially important in AIBs as the aluminium ion can insert into an electrode in three different valence states, with only the trivalent ion able to approach the theoretical charge capacity. Hence, while the potential difference against metallic aluminium of some insertion compounds such as TiO2 [70, 71] is small enough for them to be used as anodes, the vast majority of AIBs in literature simply use metallic aluminium as the anode.

With the difficulty of utilising organic electrolytes, an obvious substitute is aqueous electrolytes. However, aside from the usual issue of electrochemical breakdown of water, aqueous electrolytes also cause the formation of an impermeable layer of Al2O3 on the surface of the metallic aluminium anode, passivating it from the redox reactions necessary for battery operation. While this can be avoided with basic electrolytes, the aluminium anode corrodes in a basic environment instead, leading to continuous self-discharge [72]. As a result, the majority of AIBs use room temperature ionic liquid electrolytes, usually AlCl3 mixed with 1-ethyl-3-methylimidazolium chloride ([EMIm]Cl), which appears to facilitate the formation of an ionic-liquid-rich solid electrolyte interphase (SEI) that simultaneously erodes Al2O3 and prevents its re-formation. Interestingly, this interphase has been found to persist even if the aluminium anode is subsequently transferred into aqueous electrolytes, allowing their use [73]. It should be noted that aluminium does not dissolve into AlCl3-based electrolytes as the trivalent Al3+ ion, but as AlCl4− and Al2Cl7− [74]. However, the numerous reports of Al3+ cathodic insertion (Fig. 7c) in AlCl3 electrolytes [75–79] imply that these monovalent anions are subsequently converted back into Al3+ at the cathode in a process that appears to be neither very well studied nor understood at the moment.

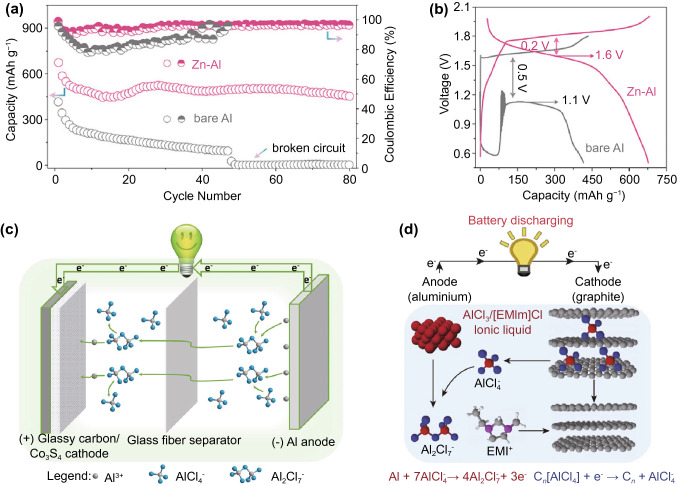

Fig. 7.

a Galvanostatic discharge curve of a high performance MnO2 cathode with Zn-Al anode, with the high energy density arising from both high charge capacity and b high discharge voltage [80].

Copyright 2020, American Chemical Society. c Schematic of the insertion of the high capacity Al3+ ion [81]. Copyright 2019, Elsevier. d As a comparison, schematic of the insertion of heavy AlCl4− ion, commonly seen in carbon cathodes [82]. Copyright 2015, Springer Nature

Most AIB cathodes reported so far are based on a variety of different transition metal chalcogenides, including oxides, sulphides and selenides, although PBA cathodes are also known. A common issue that plagues the majority of these cathodes is a low redox potential against the aluminium anode, with average cell discharge voltages of 1 V or even less, severely limiting the energy density [11, 72, 74, 83]. This is an issue that will be further exacerbated if insertion anodes are used. The highest energy densities achieved so far, as high as 736 Wh kg−1 for cathode mass only with a zinc/aluminium alloy anode [80], are with MnO2 cathodes (Fig. 7a, b). However, while the generally accepted mechanism is aluminium ion insertion, recent evidence points towards a conversion reaction involving soluble Mn2+ instead [84]. Conversion reactions are generally less reversible, and could contribute towards the reported cycle lives of MnO2 cathodes not exceeding 100, echoing the challenges faced by LiMnO2 due to structural instabilities.

Overall, AIBs remain in the early stages of development. While ionic liquid electrolytes work in a laboratory environment, they are highly corrosive and expensive, and thus difficult to commercialise. A sufficiently stable, high voltage cathode also needs to be found before a commercially useful battery with acceptable energy density and cycle life can be realised.

While not strictly AIBs, chloroaluminate batteries based upon the insertion of AlCl4- ions into usually carbon-based cathodes (Fig. 7d) have also seen rising popularity in recent years, taking advantage of the presence of these ions in AlCl3-[EMIm]Cl electrolytes. High cell voltages of around 2 V and respectable cathodic charge capacities of around 200 mAh g−1 have been reported [85, 86]. However, it must be noted that the charge capacities do not usually consider the mass of the heavy AlCl4− ion, which has a theoretical charge capacity of only 159 mAh g−1. As such, the viability of these chloroaluminate ion chemistries as high-energy batteries remains unclear [87].

Magnesium-Ion Batteries

Like aluminium, the attractiveness of magnesium-ion batteries (MIBs) arises from a high theoretical energy density. The lower charge capacity of 2202 mAh g−1 is compensated by a substantially more negative standard reduction potential of − 2.37 V, resulting in a theoretical energy density against the standard hydrogen electrode (SHE) that is actually slightly higher than aluminium. The MIB anode scene is somewhat more vibrant than for AIBs, with a large number of group 14 and 15 alloying anodes, primarily tin and bismuth, having been explored [88]. Nonetheless, at the cell level, most MIBs use magnesium metal anodes. This is in part due to magnesium metal showing a lower propensity for dendrite growth than other metals by virtue of its high self-diffusion rates. However, despite common claims on the contrary, magnesium metal is not in fact immune to dendritic growth, which can occur in unfavourable electrolytes or at high current densities [89].

The lower surface charge of the Mg2+ ion means it does not face as large of a solubility issue as Al3+, and salt-in-solvent type organic electrolytes are viable. However, unlike LIBs, where reactions between the electrodes and organic electrolytes form an SEI that protects against further reaction but still allows lithium-ion conduction, the SEIs formed between MIB electrodes and simple magnesium salts in conventional organic solvents insulate against magnesium ion conduction due to the higher ionic charge density [90]. Instead, magnesium organohaloaluminate electrolytes are typically used, formed by the reaction of a Lewis acid, commonly an aluminium chloride, with an alkyl or aryl Grignard reagent in an organic solvent (Fig. 8a). Grignard reagents alone can also be used, but they show a relatively small electrochemical stability window, and reactions with the chloride Lewis acid improves stability. However, these electrolytes are often corrosive to typical battery housing materials, and halogen-free electrolytes are being explored to address this issue [91–93].

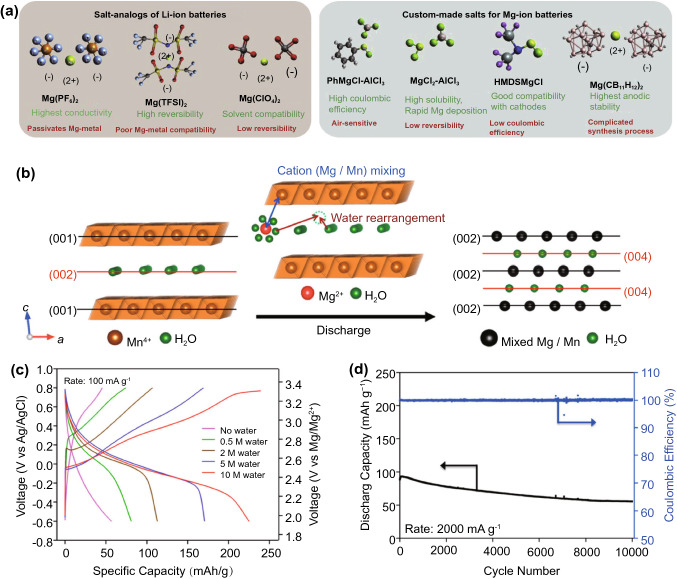

Fig. 8.

a Illustration and comparison of a selection of magnesium salts used in organic MIB electrolytes [92].

Copyright 2019, Elsevier. b Schematic of the co-insertion of water and Mg2+ ions into a birnessite MnO2 cathode, and electrochemical performance showing c improved capacity with higher water concentration and d excellent cycle stability of the cathode [94]. Copyright 2015, American Chemical Society

The first rechargeable MIBs were demonstrated with Chevrel phase molybdenum sulphide cathodes [95]; however, they suffer from both low charge capacities and low redox potentials against the magnesium anode. Since then, similar to AIBs, a variety of different transition metal chalcogenides and PBAs have been explored [10, 96–99]. While no dominant chemistry has yet emerged, vanadium [100] and manganese oxides [101] have received comparatively more attention than others. Energy densities of as high as 800 and 650 Wh kg−1 based on cathode mass only have been reported in layered V2O5 [102] and MnO2 [94], respectively, with high discharge voltages of around 3 V. Interestingly, in both cases, the high performance is attributed to the incorporation of crystal water into the layered structure, which shields the high charge of the Mg2+ ion that normally results in poor ionic mobility [96]. In the case of MnO2, the crystal water also appears to stabilise the cathode against the commonly faced dissolution issue, allowing a remarkably high cycle life of 60% capacity retention after 10,000 cycles, although at a high current that leads to substantially lower capacity (Fig. 8b–d). Unfortunately, most high-energy cathodes reported for MIBs were characterised with three-electrode cells, and it is unclear if the high potentials measured with Ag/Ag+ reference electrodes can be maintained in the two-electrode configuration of a conventional cell.

Overall, MIBs continue to suffer from generally the same issues as AIBs. Electrolytes suitable for laboratory cells are now fairly commonplace, but examples suitable for commercialisation remain elusive. Gaps remain with the electrodes as well, as a sufficiently stable and energy-dense combination has yet to be demonstrated at the cell level.

Zinc-Ion Batteries

Zinc may at first appear to be a puzzling choice for an active ion due to its low energy density of 622 Wh kg−1 against the SHE, an order of magnitude less than lithium, aluminium and magnesium, due to both its low charge capacity and standard reduction potential. However, decent potentials can in fact be achieved at the cell level with appropriate cathode selection, and the low standard reduction potential makes it attractive for use with aqueous electrolytes, as far less stabilisation is required at the anode than the higher energy elements. Metallic zinc anodes also have a history as long as the entire field of batteries, dating back to Alessandro Volta’s invention of the voltaic pile, allowing researchers a large body of prior work from which to draw inspiration. Hence, while non-aqueous zinc-ion batteries (ZIBs) [103] and insertion anodes are known [104], ZIBs typically use metallic zinc anodes and aqueous electrolytes, consisting of various zinc salts dissolved in water, with most variations occurring at the cathode.

Popular ZIB cathodes can be classified into three familiar categories: manganese oxides, vanadium oxides and PBAs (Fig. 9b, c) [105–107]. The highest energy densities are again achieved with MnO2 of various structures, with charge capacities generally in the region of 200–400 mAh g−1 and operating voltages of around 1.3 V. However, like with aluminium ions, recent evidence points towards a dissolution conversion reaction rather than Zn2+ insertion [108–110]. The same structural instabilities and dissolution issues as with other active ions also remain present, leading to short cycle lives of less than 100 cycles in general. Nonetheless, a remarkably high cycle lives of more than 90% capacity retention after more than 1000 cycles have been achieved with hollandite-MnO2, enabled by reduced graphene oxide coatings [111], or the suppression of MnO2 dissolution via Mn-salt inclusion in the electrolyte [112]. However, there is some debate on whether the salt inclusion truly suppresses dissolution, or instead improves cyclability by providing buffer ions for the Mn2+ conversion reaction [84].

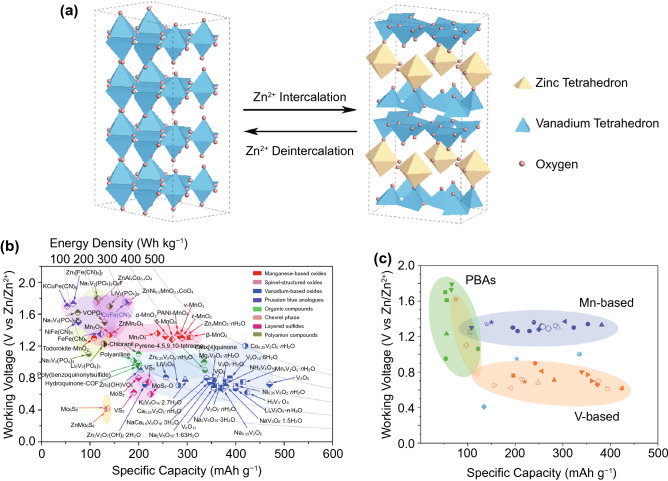

Fig. 9.

a Schematic of Zn ion insertion into a representative V2O5 cathode framework. b, c Cell voltages and charge capacity of various cathodes for ZIBs. Reproduced with permission [105, 107].

Copyright 2021, Elsevier. Copyright 2020, Royal Society of Chemistry

The charge capacities of vanadium oxide cathodes are likewise around the region of 200–400 mAh g−1, but energy density is limited by a generally low cell voltage of less than 1 V against metallic zinc. However, cyclability is generally superior to manganese oxides, with cycle lives frequently exceeding 1000 with more than 80% capacity retention, owing to the high reversibility of zinc insertion reactions (Fig. 9a). Similar to MIBs, incorporation of water into the vanadium oxide framework is often beneficial for performance [105, 107]. PBA cathodes have the highest operating voltages of up to 1.8 V [113] against metallic zinc, but charge capacity is low, at generally less than 100 mAh g−1 due to the same defect and coordinated water issues faced in SIBs.

Compared to MIBs and AIBs, ZIBs are closer to commercialisation, due to the more stable zinc anode allowing for the use of a wider variety of aqueous electrolytes along with the encouraging progress made with various cathodes. Nonetheless, the use of aqueous electrolytes limits the achievable voltages at the cell level, which will be discussed in greater detail in Sect. 5.1. The apparently attractive charge capacities achieved are also usually evaluated with cathode mass only, and inclusion of the mass of the heavy zinc ions can lower charge capacity by more than 30% (Fig. 5). This is far greater than the higher energy elements covered previously, and results in severely compromised energy densities of full cells.

Other Metal-Ion Batteries

Potassium-Ion Batteries

Potassium-ion batteries (PIBs) have also been actively pursued as alternatives to LIBs and SIBs by virtue of their similar chemical behaviour. The potassium ion has a theoretical charge capacity of only 685 mAh g−1, substantially lower than that of sodium ion (1165 mAh g−1), putting it at a distinct disadvantage for high-energy applications. However, potassium does have two important redeeming features, the first being a significantly more negative standard reduction potential of − 2.93 V compared to the − 2.71 V of sodium, which may partially compensate for its lower charge capacity to high energy densities. Secondly, unlike sodium, potassium can intercalate into graphite to form KC8 [114]. Therefore, the anode can be made highly similar to those in commercial LIBs, which would be a merit for eventual commercialisation. Like SIBs, the dominant electrolytes in PIBs use potassium salts that are analogous to those used in LIBs, such as KF6, dissolved in an organic solvent [115], which is another boon for commercialisation.

Nonetheless, PIBs continue to face several challenges. For example, potassium ion insertion onto graphite is associated with a volume expansion of ~ 61% [116], substantially larger than lithium and which severely hinders cycle performance. Although some alternative anodes are available, such as hard and soft carbons, as well as non-carbonaceous materials, the cycle performance is generally in the hundreds rather than thousands achievable by LIBs and SIBs. The initial Coulombic efficiency also tends to be low, at less than 60%, due to the formation of undesirable SEIs that require electrolyte modification to resolve [115, 117, 118]. There are difficulties with the cathode as well. Although several SIB and LIB cathodes are useable in KIBs, such as PBAs and transition metal oxides, both the cyclability and charge capacity tend to be lower, due to the larger size and lower charge capacity of the potassium ion. In particular, the layered oxide cathode materials that have seen so much success in SIBs and LIBs can only achieve capacities in the region of 150 mAh g−1 when used in KIBs [119, 120], as compared to ~ 200 mAh g−1 in the former two. Although this can be partially compensated for by higher cell voltages than SIBs, they remain lower than those of LIBs. Finally, while cheaper than lithium, potassium is substantially more expensive than sodium. This means that the advantage of lower costs, which applies to SIBs over LIBs, is significantly diminished in the case of PIBs.

Calcium-Ion Batteries

Calcium is an alkaline earth metal, and like potassium, trades a slightly more negative standard reduction potential (− 2.84 vs. − 2.37 V) for a substantially lower ion charge density (1336 vs 2202 mAh g−1) as compared to its Period 2 counterpart, magnesium. This results in a significantly lower theoretical energy density against the SHE.

Calcium-ion batteries (CIBs) share many similar challenges with the other non-aqueous multivalent batteries, MIBs and AIBs, but are the least mature. The compatibility of calcium metal anodes with electrolytes is an issue, with several known organic electrolytes causing either undesirable side reactions or the formation of insulating SEIs. An effective solution, such as organohaloaluminates for MIBs and ionic liquids for AIBs, has yet to be found for CIBs. Various transition metal chalcogenides and PBAs have been explored as potential cathodes, but charge capacities remain generally less than 100 mAh g−1, and cathode discovery remains an ongoing challenge [48, 121, 122]. Calcium is also slightly more expensive than sodium, aluminium, magnesium and zinc. These issues present CIBs with significant developmental roadblocks in the near future, especially in the presence of potentially cheaper, more mature and more energy-dense alternatives like MIBs and AIBs.

Dual-Ion Batteries

Unlike conventional ion batteries, which involve the insertion of the same ion into both the anode and cathode, dual-ion batteries (DIBs) involve the insertion of a cation into the anode and an anion into the cathode. This cation can be any of the aforementioned metal ions, while the anion is usually the counterion in the salt containing the cation, such as PF6− or TFSI−. As the anodes insert cations, they are usually of the same design and composition as conventional ion batteries, and DIB efforts are mainly focused on the anion-inserting cathode [123–125].

It is notable that as the anode and cation are the same as in conventional ion batteries, DIB cost-savings must arise from the cathode. Among the earliest DIBs achieved was by the insertion of lithium salt anions into graphite cathodes. It avoided the use of expensive transition metal oxide cathodes and also had the additional benefit of potentially higher cell energy densities due to the higher cathode insertion potentials. However, these graphite cathodes suffered from very poor cyclability due to both the large volume expansion in association with the large anions, and the higher working voltages encouraging electrolyte decomposition. More recent efforts have thus been focused on novel cathodes such as various non-graphitic carbons, organic compounds and metal–organic frameworks [123–125]. While the cycle stability can be excellent, achieving several thousand cycles to 80% capacity [126, 127], voltages are generally reduced compared to graphite cathodes. This, in combination with generally low charge capacities, removes the potentially higher energy densities of DIBs. More importantly, most of these novel cathode materials are synthesised only at small scales and remain very expensive, making cost-effective commercialisation highly challenging.

Addressing Capacity: Beyond Insertion Electrodes

Limits of Insertion Electrodes

An obvious approach to increasing the energy density of an ion battery is to use insertion cathodes with higher potential or charge capacity. High voltage cathodes for LIBs have been a popular research topic over the past couple of decades as a result, most of which are based on polyanion oxides due to the inductive effect, such as LiCoPO4 having a discharge voltage against metallic lithium of 4.8 V [128], instead of ~ 4.3 V for LiCoO2. However, these polyanion oxides suffer from the same low conductivity issues as LiFePO4, sometimes to an even larger extent [129]. The increase in voltage also causes issues with electrolyte decomposition like in DIBs, leading to low cycle life, and the desired resultant higher energy capacity is partially offset by a decrease in theoretical charge capacity due to the inclusion of the additional anions. Spinel LiNi0.5Mn1.5O4 has shown the greatest promise among high voltage cathodes, with a discharge voltage of ~ 4.7 V against metallic lithium along with high electronic and ionic conductivity. However, it suffers the same Mn dissolution issues as spinel LiMn2O4 and an associated structural instability, leading to poor cycle life [130]. Higher charge capacity is achieved using lithium-rich layered oxides of the general form LixMO2, where x > 1, but such cathodes suffer from voltage fade during charge/discharge for which the mechanism remains unclear, leading to poor cycle life [131].

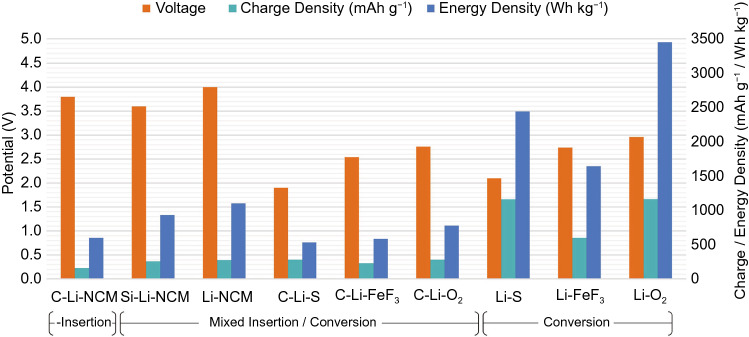

Despite the promises and interest in high voltage and high charge capacity insertion cathodes, it is clear upon examination of the common LIB chemistries, C6-LiCoO2, C6-LiMn2O4 and C6-LiFePO4, that more than 90% of the electrodes’ mass arises from the insertion frameworks. As only a small proportion of these frameworks actively participate in the redox reaction, this places a limit on the theoretical charge capacities of insertion electrodes. The situation does not substantially improve even with highly lithium-rich systems such as C6-Li2MnO3. Instead, the next frontier in high-energy batteries is likely to lie in conversion electrodes. Unlike insertion electrodes, conversion electrodes do not require a framework to insert and remove active ions from, hence the proportion of active material in the electrodes can be close to 100%, leading to substantially higher charge capacities. Although the cell voltage is often lower, this is usually outweighed by the increase in charge capacity, leading to substantially higher energy densities overall (Fig. 10).

Fig. 10.

Theoretical charge capacity, voltage, and energy density of different lithium battery systems

Conversion Anodes

The high theoretical capacities of conversion anodes have attracted substantial research interest, and a large number of different anodes have been explored with several different mechanisms, including true conversion, alloying and active metal anodes. The so-called true conversion anodes (TCAs) are those that obey the most conventional definition of a conversion electrode, that is one that stores charge via cation replacement in an ionic compound by the active ion. Such systems are most commonly explored for alkali-ion batteries such as lithium and sodium, and the general reaction is depicted in Eq. 1, where M represents a cation, X represents an anion, and A represents the active ion [132].

| 1 |

A very large number of possible compounds have been explored, including various transition metal oxides, sulphides, nitrides and phosphides [132–134]. However, TCAs typically suffer from poor reversibility, high charge/discharge voltage hysteresis and low current capabilities, arising from poor electronic conductivity of both the original MαXβ and β·AnX reaction product [135]. In addition, the average reaction potentials often exceed 1.0 V against metallic lithium, reducing the achievable cell potentials and limiting the cell energy density. Both practical and theoretical capacities are also generally limited to the region of 1000 mAh g−1 or less. This, while substantially higher than insertion anodes, pales in comparison to the several thousand achievable by alloying and active metal anodes, which will be the main discussion focus of Sect. 4.2.

Also of note are anodes with both insertion and conversion mechanisms, such as graphite intercalation compounds (GICs) [136]. For example, transition metal chloride-intercalated graphite has been shown to store lithium first through intercalation into the remaining space between graphite sheets, followed by a conversion reaction with the pre-intercalated metal chloride according to Eq. 1. In this case, the intercalation and conversion species are symbiotic. Presence of the metal chloride between graphite sheets expands the interlayer spacing, increasing ionic conductivity, while the graphite enhances the electronic conductivity of the metal chloride and provides a buffer matrix for the volume expansion during lithiation [137]. Nonetheless, GIC reversible charge capacities remain in the region of 1000 mAh g−1 for lithium, and reaction potentials remain fairly high compared to metallic lithium. Hence, like TCAs, they appear to be less attractive than the high capacity, low potential alloying and active metal anodes.

Alloying Anodes

Alloying anodes are similar to insertion anodes in that they both store charge in the form of active ions, but a phase change usually occurs in the former that allows a substantially higher ion capacity. However, this higher ion capacity coincides and correlates with a substantially larger volume expansion during storage, which may lead to disintegration of the anode during cycling [138]. While a large number of different alloying anodes have been explored for various active ions, the issues faced such as the aforementioned volume expansion are often very similar and will be presently illustrated in by far the most popular example, lithium-silicon.

Silicon is known to be the highest energy alloying anode for lithium due to its very high charge capacity of 2009 mAh g−1 for the most highly lithiated Li22Si5 phase, including lithium mass, coupled with a redox potential of ~ 0.4 V against metallic lithium, allowing for high cell potentials. While the low electronic and lithium ionic conductivity is an issue, the main barrier to commercial adoption is the extremely high volume expansion of ~ 400% during lithiation [139], 40 times that of graphite. This enormous volume change during cycling can cause fracturing of the silicon anode, at first disrupting electronic conduction and eventually leading to disintegration of the entire anode. Fracturing of the SEI also occurs, resulting in continuous conversion of active lithium to inactive compounds and electrolyte consumption due to the re-formation of the SEI. Both of these effects lead to very poor cyclability of the anode [140, 141].

The general strategy to address volume expansion is to reduce feature sizes of the silicon anode, as smaller structures generally show lower tendencies to be damaged when subjected to mechanical stress [142, 143]. Conveniently, this simultaneously addresses the conductivity issue as diffusion lengths are reduced. 0D nanostructures in the form of nanoparticles require a conducting matrix that physically and electronically anchors them to the current collector. Carbon is a popular matrix due to its simultaneous ability to store lithium ions, forming silicon carbon composite anodes. The matrix also buffers the volume expansion of the anode as a whole, aiding in the structural preservation of the SEI during cycling [144]. While addition of small amounts of silicon to primarily graphite matrices is already sufficient to substantially improve charge capacities [145, 146], the usage of more complex structures like core-shell nanoparticles [147] (Fig. 11a) or the anchoring of silicon to highly conductive graphene scaffolds [148, 149] (Fig. 11b) can allow charge capacities much closer to theoretical limits.

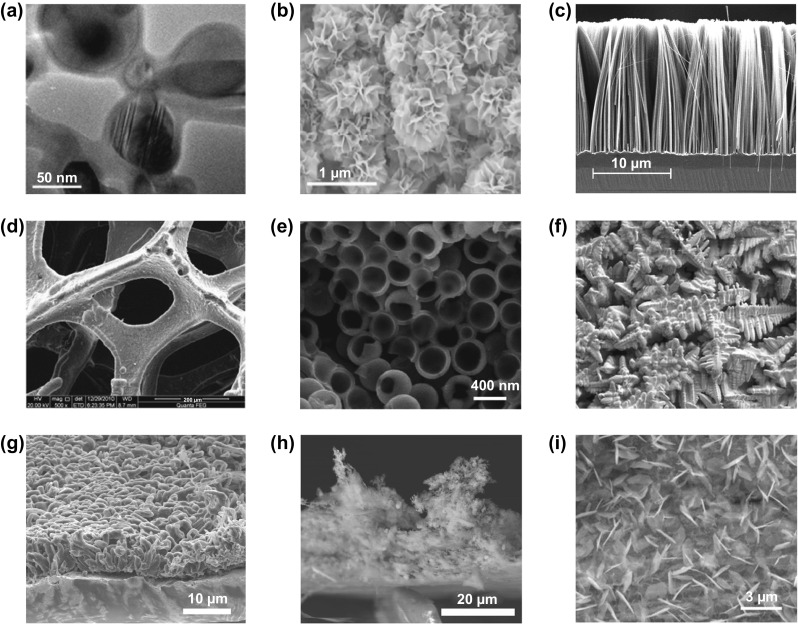

Fig. 11.

Scanning electron micrographs showing various, selected nanostructured silicon anodes. a core–shell silicon-carbon nanoparticles [147].

Copyright 2012, Elsevier. b Spongy nanographene encapsulating silicon nanoparticles [149]. Copyright 2017, Springer Nature. c Aligned silicon nanowires [152]. Copyright 2008, AIP Publishing. d Silicon thin film deposited on nickel foam [153]. Copyright 2012, Elsevier. e 3D porous anode formed from hollow silicon nanospheres permission [154]. Copyright 2011, American Chemical Society. Scanning electron micrographs showing various dendrite morphologies. f Melt-grown crystal dendrites [155]. Creative Commons License (CC BY). g Electrochemically grown lithium dendrites [156]. Copyright 2016, American Chemical Society. h Electrochemically grown aluminium dendrites [157]. Copyright 2017, American Chemical Society. i Electrochemically grown zinc dendrites [158]. Copyright 2020, John Wiley and Sons

1D, 2D and 3D nanostructured silicons have all been explored extensively as means to reduce feature sizes. For example, 1D structures in the form of nanowire forests (Fig. 11c) can resist cracking due to the relative ease of strain relaxation inherent in their morphology [150]. Adopting nanotubes instead of nanowires can further improve performance due to their hollow structure allowing more room for volume expansion, as well as a greater surface area for electrolyte access. 2D structures in the form of thin films (Fig. 11d) likewise resist cracking, with mechanical stabilisation arising from good adhesion to the current collector substrate. However, the effect only persists over film thicknesses on the order of one micron or less [140]. Hence, increasing film thickness requires the incorporation of pores to provide space for volume expansion, forming 3D porous nanostructures (Fig. 11e). Nonetheless, while these approaches are effective in preserving the structural integrity of the silicon, they do not address the SEI fracturing issue, which is tackled by the simultaneous addition of carbon coatings or matrices, as is the case with silicon nanoparticles.

Generally, the strategy of reducing feature size in silicon anodes has been fairly successful for both nanoparticulate and nanostructured anodes. Charge capacities routinely fall within the range of 1000–3000 mAh g−1 (excluding lithium mass), accompanied by cycle lives of several hundred [140, 141]. Remaining challenges lie in the translation of laboratory-scale set-ups to practical commercial cells instead. While nanostructured anodes generally achieve higher charge capacities than nanoparticulate anodes due to higher silicon content, fabrication methods are also generally far more complicated and expensive. Nanostructured anodes, especially in 1D and 2D forms, also suffer from low areal mass loading, resulting in low practical cell capacity as the anode mass becomes dominated by the current collector. Nanoparticulate anodes thus remain popular, especially from the perspective of industrial adoption [144, 151].

Active Metal Anodes

Active metal anodes have the highest theoretical energy densities for each cationic species, as they consist of 100% active material, and have been in use for far longer than insertion or alloying anodes in primary batteries. However, recharging remains a major challenge despite decades of research and development. Reactions with the electrolyte is a common issue, causing corrosion of the anode, decomposition of the electrolyte or the formation of passivating SEIs. The exact causes and consequences of these reactions differ greatly among different metals, as has been covered in the earlier section on alternative insertion ions for various multivalent metal species, and the general solution is to alter the electrolyte composition.

The more challenging barrier for rechargeable metal anodes is the tendency for non-uniform plating during the charging process, usually in the form of high aspect ratio protrusions that are commonly referred to as dendrites. It should be noted that despite the name, metal anode dendrites share very little similarities with the more well-known crystal dendrites formed during melt solidification, and can exhibit various different morphologies depending on the metal and electrolyte combination (Fig. 11f–i). In many cases, they are not even strictly dendritic, but are nonetheless referred to as dendrites [158]. Nonetheless, regardless of morphology, the effect on cell performance is similar. Uncontrolled dendritic growth over repeated charge/discharge cycles can eventually cause piercing of the separator and physical contact between the anode and cathode, short-circuiting the cell. Repeated non-uniform dissolution and growth at the anode can also gradually reduce the amount of anodic active material due to dendrites physically breaking off, or the formation of insulating SEI-coated deposits [159]. Both of these effects are responsible for the characteristically short cycle life of metal anodes. Most investigations into dendritic growth mechanisms and solutions are focused on zinc and lithium anodes in aqueous and organic electrolytes, respectively, due to their relative maturity at the cell level. However, the general strategies to address dendritic growth are fairly similar, and can be carried over to other multivalent aqueous and monovalent organic systems.

The general mechanism of dendritic growth occurs via initial nucleation, occurring due to inhomogeneities on the anode surface or regions of damaged SEI, followed by self-promoting growth due to the intensification of the local electric field at dendrite tips facilitating further metal deposition on the tips [160, 161]. Strategies against dendritic growth can tackle the issue at either the nucleation or growth stage. A common approach is to deposit an artificial SEI ex-situ, that is more stable that the SEI that would normally form, on the surface of the anode. This artificial SEI is usually designed to be ionically conductive, allowing ions to pass through and deposit in-between itself and the current collector, but suppressing dendritic growth via physical confinement. Ionically insulating artificial SEIs can also be used, which encourage uniform plating via the provision of uniformly distributed nucleation sites rather than physical confinement, although the effect is limited to thin layers of metallic lithium which restricts active material loading [158, 162, 163].

Nanostructured current collectors, such as porous copper or carbon scaffolds, is another possible approach [158, 162, 163]. Dendritic growth is addressed by confining them to within the scaffold, where they are less likely to grow towards the cathode and more likely to maintain electrical contact with the current collector after structural damage. Scaffolds can be combined with artificial SEIs to further control dendritic growth within the scaffold. In the case of ionically insulating SEIs, the scaffold also provides a greater surface area for active material loading. However, this approach dramatically increases the cost and weight of the current collector, negatively affecting performance at the practical cell level.

Electrolytes can also be modified to control dendritic growth. Reactive additives can be used to facilitate the in-situ generation of SEIs that play the same role as the aforementioned artificial SEIs. On the other hand, highly polar non-reactive additives can selectively adsorb themselves onto dendrite tips due to the intensified electric field, shielding them from the active cations and disrupting the self-promoting growth mechanism [158, 162, 163]. A more direct approach is to use solid electrolytes that mechanically suppress dendritic growth. However, challenges remain with this approach as well, as the effectiveness of suppression is dependent on the stiffness of the electrolyte, and dendritic growth is still possible through defects in the solid electrolyte such as voids and grain boundaries [164]. Solid electrolytes also face their own set of issues, such as poor interfacial stability with the electrode, that need to be separately addressed.

In general, the various strategies for suppressing dendritic growth have shown successful suppression over several hundred cycles [158, 162, 163]. However, the effect on cell-level performance is poorly documented. This is as failure due to dendritic growth is highly dependent on the cell geometry, and cell-level performance recorded in typical laboratory cells, which generally have physically further separated electrodes than tightly packed commercial cells, is not very useful in predicting the performance of the latter.

Conversion Cathodes

Negative ions occupy far less space on the periodic table than positive ions, reflecting a smaller selection of elements, concentrated in Groups 5, 6 and 7, to choose from. This is further complicated by the fact that most light anionic elements are gaseous at around room temperature. By far the most popular conversion cathodes are based on the light chalcogens, sulphur and oxygen, although halogen cathodes also exist. Pnictogens, despite high theoretical charge capacities, are generally too stable to be used as conversion cathodes at normal battery operating temperatures.

Halide Cathodes

Fluorine is an especially attractive element due to its very high standard reduction potential of + 2.87 V coupled with a high charge capacity of 1409 mAh g−1 for the F- ion, leading to very high theoretical energy density. However, fluorine is a toxic gas at room temperature, a property of nearly all stable halogens except iodine, which has an energy density less than 10% of fluorine against the SHE due to its low redox potential and charge capacity. Halide cathodes are thus usually made solid by utilising them as metal halides, with transition metal fluorides being the most popular.

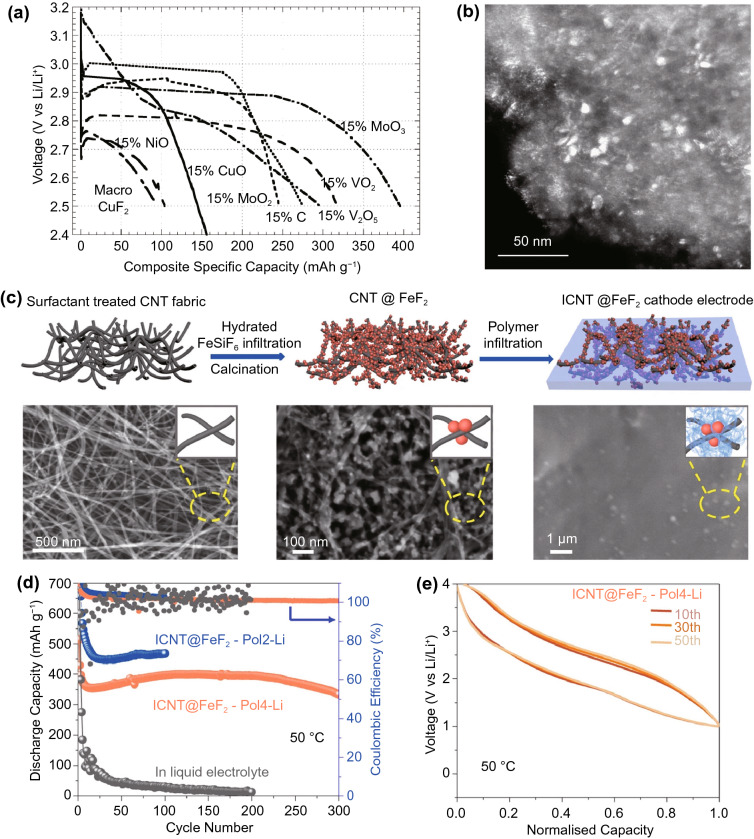

While the incorporation of the inactive transition metal reduces both the charge capacity and redox potential of fluorine, theoretical energy density remains high due to the high ionicity of the fluoride bond leading to generally higher redox potentials than other solid conversion cathodes. However, like TCAs, the same high ionicity also leads to very low electronic and ionic conductivity of both the transition metal fluoride and the conversion reaction product, such as lithium fluoride, in the case of pairing with a lithium anode [14, 25]. Aside from causing generally high overpotentials and low current capabilities [165], this also results in generally poor practical capacities due to rapid passivation of the cathode during discharge, requiring dispersion as nanoparticles in conductive matrices to resolve (Fig. 12a, b) [166, 167].

Fig. 12.

a Discharge capacity of CuF2 composite cathodes with different conductive matrices, and b a transmission electron micrograph depicting CuF2 nanoparticles within a conductive matrix [167].

Copyright 2007, American Chemical Society. c Schematic of a FeF2 cathode on a conductive carbon nanotube scaffold that provides good electronic access, while the polymer electrolyte controls dissolution, leading to a d high capacity, e high cycle life cathode [170]. Copyright 2019, Springer Nature

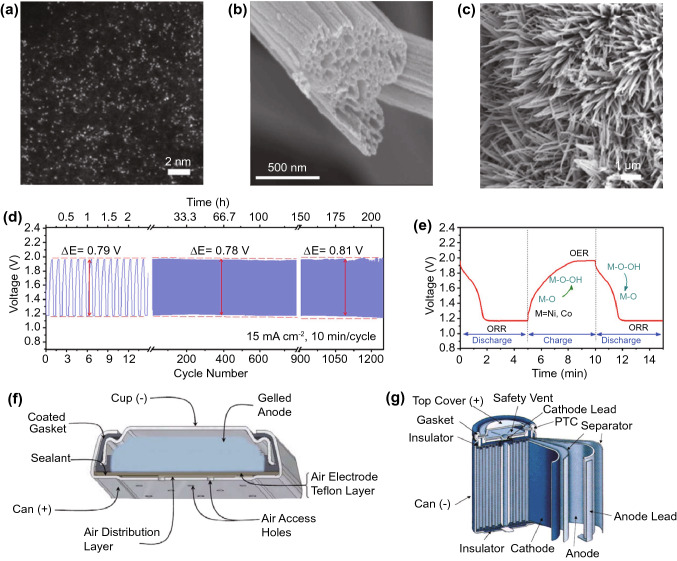

The discharge products of transition metal fluoride cathodes are the anodic metal fluoride and the transition metal. This substantially complicates recharging as the charging reaction involves two species that have to be kept in electrical contact with the current collector in order to regenerate the transition metal fluoride and anodic metal. CuF2 cathodes paired with lithium anodes had received ample early attention due to the high energy density enabled by a remarkably high potential of ~ 3.55 V against metallic lithium [14]. However, recharging is very difficult due to the tendency for the copper reaction product to agglomerate into nanoparticles insulated from the current collector by a matrix of lithium fluoride [168]. FeF3 has similar theoretical energy density to CuF2, but suffers less from this issue due to the lower diffusivity of the higher charge density Fe3+ ion, facilitating the formation of percolating conductive iron networks upon discharge [169]. However, reversibility remains generally limited. This, in combination with the generally high solubility of transition metal halides in common organic electrolytes [165] and their tendency to form structurally unstable SEIs [170], results in generally very low cycle lives.

Furthermore, the FeF3 reaction occurs via a complex mechanism involving both insertion and conversion. The latter is responsible for most of the charge capacity, but is disabled by the absorption of water, which occurs very easily due to the generally high hygroscopicity of metal fluorides. This complicates fabrication processes for batteries hoping to utilise the conversion reaction, even at the laboratory scale [171]. Despite these challenges, some encouraging results of around 1000 Wh kg−1 (Fig. 12c–e) cathodic energy densities with cycle lives of 300–1000 have been achieved [170, 172]. Nonetheless, the poorer theoretical energy density of metal halides compared to the elemental chalcogens contribute to generally lower research interest. As a result, overall progress is substantially slower than the chalcogens.

Sulphur Cathodes

Sulphur and phosphorus are the two lightest solid anionic elements in the periodic table; however, the latter generally cannot undergo conversion reactions with metallic cations at around room temperature, and has instead been investigated for use as an insertion anode [19]. Hence, sulphur can boast the highest charge capacity among solid conversion cathodes, at 1670 mAh g−1 for the S2− ion. Although the main discharge plateau occurs at ~ 2.1 V against metallic lithium, substantially lower than in transition metal fluorides, the very high charge capacity allows sulphur to have the highest theoretical energy density among all solid conversion cathodes of ~ 2500 Wh kg−1 in the form of Li2S. Sulphur is also extremely cheap. While sulphur cathodes can be paired with a large number of different cationic species [17], the challenges faced at the cathode are largely similar. By far the highest capacities have been achieved in and the greatest amount of research has been focused on the lithium–sulphur couple, which is the archetypal system used presently to discuss sulphur cathodes.

The challenges faced by sulphur cathodes are somewhat similar to other solid conversion electrode materials [173–175], including a large volume expansion of ~ 80% upon discharge leading to structural damage and very low electronic and ionic conductivity. Active material dissolution is also an issue, like metal fluorides, but through a different mechanism. Elemental S8 is gradually reduced to S2- during the conversion through S82−, S62−, S42− and S22− polysulphide intermediates. While S22− and S2− form insoluble Li2S2 and Li2S when paired with lithium, and S8 itself is also insoluble, the longer chain polysulphide compounds are soluble in typical organic solvents. These soluble polysulphides can be beneficial to cell performance by aiding uniform sulphur dispersion in the cathode and acting as redox mediators [176, 177], but they also diffuse to the anode and form short-circuited lithium–sulphur couples, generating insoluble Li2S and leading to active material loss from the cathode. Although some of this Li2S can be oxidised back to soluble polysulphides during charging and redeposited at the cathode, this often leads to morphological changes that generate insulated, inactive sulphur. This so-called polysulphide shuttle effect is responsible for the main practical challenge faced by sulphur cathodes, appreciable self-discharge and a generally low cycle life.

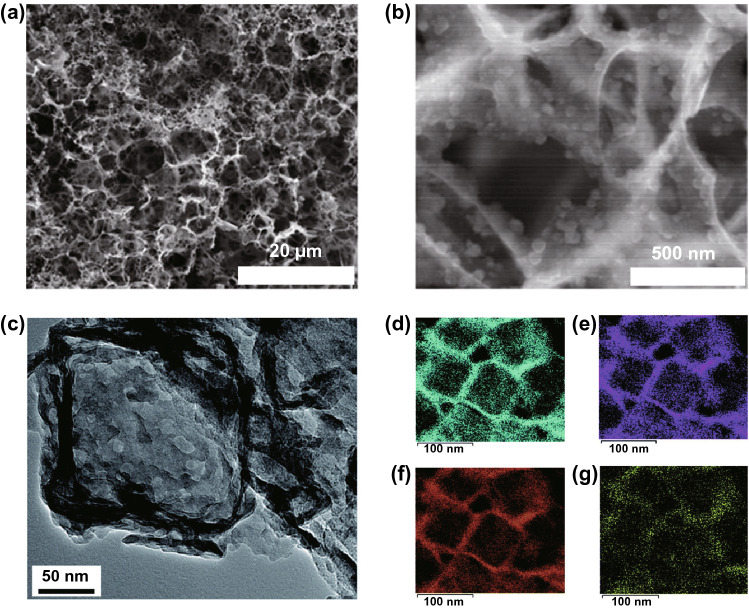

Like silicon, the main approach adopted to address the conductivity and volume expansion issues of sulphur is by reducing feature sizes. However, rather than being grown directly as nanostructures, a porous scaffold is usually synthesised instead, followed by infiltration of molten sulphur. Carbon scaffolds are popular in a variety of different forms, including nanotubes, graphene, nanofibers and porous 3D carbon (Fig. 13a, b). Polysulphide shuttle in carbon is generally addressed simply by more tortuous diffusion paths out of the scaffold, which has shown encouraging results in laboratory environments, where cycling rates exceed the time scale at which polysulphide diffusion occurs. This may not be the case in practical cells as they undergo intermittent use accompanied by long storage times, resulting in more stringent requirements on polysulphide diffusion rates and echoing similar challenges in LIB testing [178]. In the case of extremely small pores of less than 1 nm, polysulphide shuttle can also be reduced by sterically preventing the formation of the soluble long-chain polysulphides [179]. Carbon-scaffold sulphur cathodes are generally able to achieve charge capacities of around 1000 mAh g−1 with cycle lives in the region of 100–300 [17, 173, 174].

Fig. 13.

Scanning electron micrographs of a 3D porous carbon scaffold onto which sulphur nanoparticles are deposited, at a low magnification and b high magnification [180]. Creative Commons License (CC BY 4.0). c Transmission electron micrograph of a polysulphide-adsorbing TiO2-MnO nanobox cathode infiltrated with sulphur, and associated energy-dispersive X-ray spectroscopy maps for d Ti, e Mn, f O and g S [181].

Copyright 2021, Royal Society of Chemistry

A more sophisticated approach of preventing polysulphide shuttle involves using scaffolds that are able to chemically coordinate with the soluble polysulphides through polar interactions (Fig. 13c–g), which has been observed in a variety of compounds including chalcogenides, oxides, nitrides and organic compounds. This can also be achieved on carbon scaffolds through the addition of heteroatoms. The coordination strength between such scaffolds and the soluble polysulphides must be finely controlled so that it is strong enough for good adsorption, yet not so strong that it is favoured over the lithium–sulphur bond, which would make the sulphide inactive. Such compounds also generally have lower conductivities, so a portion of the scaffold often remains carbon-based. Nonetheless, cathode scaffolds based on polysulphide coordination are generally able to achieve similar charge capacities as carbon scaffolds of around 1000 mAh g−1, with slightly improved cycle lives in the region of 200–500 [17, 174].

A separate approach involves the elimination of the soluble polysulphides from the conversion process with catalysts, nonetheless deposited on porous scaffolds, that can facilitate fast reactions directly to the solid sulphides. The catalytic mechanism relies on strong adsorption of long-chain polysulphides, while maintaining a sufficiently high sulphide diffusion coefficient for efficient surface nucleation and growth of the solid sulphides. High electronic conductivity is also important for electrons to access the insulating sulphides [182]. A large number of catalysts have been explored including noble metals, chalcogenides, nitrides, various metal-free materials, as well as heterostructure combinations of these materials. It is notable that many of these are also used in the desulphurising industry [183]. While the performance of catalysed lithium–sulphur batteries is highly variable, remarkable results of around 80% capacity retention at 2000 cycles with a 600–800 mAh g−1 initial capacity have been achieved with TiO2-TiN heterostructures [184].