Abstract

The April 2010 Deepwater Horizon drilling unit explosion at the Macondo oil well resulted in the release of approximately 779 million l of oil into the Gulf of Mexico. As part of the response effort to break up oil slicks on the water’s surface, 6.81 million l of chemical dispersants COREXIT™ EC9500A and COREXIT™ EC9527A were applied by plane or vessel or injected near the seabed. The GuLF Long-term Follow-up Study is investigating possible adverse health effects of workers involved in the oil spill response and clean-up (OSRC). In this paper, we describe potential dispersant-related air concentrations generated from aerial spraying of dispersants to provide insight as to what concentrations OSRC workers may have been exposed under worst-case conditions. Personal exposure measurement data were not collected. Modeling, therefore, was conducted to estimate airborne concentrations of total aerosol to COREXIT™ EC9527A and EC9500A. Using the AgDISP model, we estimated air concentrations to dispersant total aerosols, defined as all components of the dispersant including active ingredients, surfactants, and water, resulting from aerial and vessel applications, as average 1-h and 2-min concentrations. For comparison, 1-h air concentrations associated with aerial spraying were estimated using another model, AERMOD. At 152 m horizontal to the flight path, average 1-h total aerosol concentrations associated with aerial applications were estimated to be as high as 49.3 µg m−3 (9527A) and 45.4 µg m−3 (9500A), and both decreased with increased distance from the flight line. The estimates for spraying 9500A from vessels indicated that total aerosol concentrations were potentially as high as 0.33 µg m−3 at 10 m from the nozzles. These results suggest that personal exposures to dispersant aerosols were negligible.

Keywords: aerosol, chemical dispersant, Deepwater Horizon Oil Spill, exposure assessment

Introduction

The Deepwater Horizon (DWH) drilling rig explosion at the Macondo oil prospect on 20 April 2010 caused the release of approximately 779 million l (4.9 million barrels) of crude oil into the Gulf of Mexico (Lehr et al., 2010). The wellhead was located at a water depth of 5000 ft (1525 m) and, as buoyant oil reached the water’s surface, large oil slicks formed and spread by currents, winds, and tides. At its peak, the oil slicks covered 40 000 km2, and oil was detected over more than 112 100 km2 of water, impacting shoreline environments, marine animals, and humans (Westerholm and Rauch, 2016).

Chemical dispersants were applied to the slicks through both spraying the water surface and injecting at the source of the leak close to seabed as part of a larger oil spill response and clean-up (OSRC) effort. Dispersants are typically used to reduce the interfacial tension between crude oil and water and facilitate the breakdown of oil slicks into smaller droplets that are thought to be more easily degraded by natural processes such as evaporation, dispersion, emulsification, dissolution, photo-oxidation, sedimentation, and bioremediation to prevent the oil from accumulating on the beaches and shoreline. OSRC workers were potentially exposed to the dispersant aerosol if they were in the vicinity when spraying dispersant. We are unaware of any measurement data collected to evaluate exposures arising from the conditions described in this paper.

A total of 6.81 million l (1.84 million gal) of COREXIT™ EC9527A (9527A) (COREXIT™ EC9527A (2020)) and COREXIT™ EC9500A (9500A) (COREXIT™ EC9500A (2020)) was applied to the water surface by plane (9527A and 9500A) or marine vessel (9500A) or into the water subsurface by injection (9500A) (Westerholm and Rauch, 2016). This unprecedented amount of dispersants raised concerns about hazards associated with their use. The GuLF Long-term Follow-up (GuLF) Study, conducted by the National Institute of Environmental Health Sciences, is investigating possible adverse health effects among workers involved in the OSRC (Kwok et al., 2017). A recent investigation from that event found that respiratory symptoms were more prevalent among participants reporting potential dispersant-related tasks than those who did not (McGowan et al., 2017). In studies conducted in animal models, transient cardiovascular, peripheral vascular functions (Krajnak et al., 2011; Roberts et al., 2014) and potential neurotoxicity (Sriram, Jefferson et al., 2011, and Sriram, Lin, et al. 2011.) were observed. Atmospheric dispersion models incorporating dispersant use and meteorological data collected during the OSRC can be used to develop air concentration estimates.

The Responsible Party (RP) for the spill (as designated by the US government) did not collect dispersant aerosol personal or area measurements. The goals of this paper are to: (i) apply mathematical modeling to obtain a point estimate of potential dispersant-related aerosol concentrations at various locations relative to the area of application considering the ambient conditions at the time; and (ii) relate these concentrations to the study participants in the GuLF Study through the areas they worked. The paper covers a separate discussion of the three types of dispersant application (spraying water surfaces by planes, spraying water surfaces by marine vessels, and injection into the subsurface water). We estimated concentrations perpendicular to the flight path both direct (from the flight path) and indirect (from spray drift) sources. Stenzel, Arnold et al. (2021) address air concentrations of vapors associated with handling dispersant-related equipment and being in dispersant sprayed areas.

An overview of the study’s entire exposure assessment is presented by Stewart, Groth et al. (2021). The strategy for developing exposure groups for the GuLF Study is described in Stenzel, Groth et al. (2021b). Inhalation exposures of workers to total hydrocarbons, benzene, toluene, ethylbenzene, xylene, and n-hexane (Huynh et al., 2021a, b, c; Groth, Banerjee et al., 2021; Groth, Huynh et al., 2021; Ramachandran et al., 2021) and air concentrations of other substances [i.e. PM2.5 (Pratt et al., 2021), dispersant vapors (Stenzel, Arnold et al., 2021), and oil mist (Stewart, Groth et al., 2021)] are presented elsewhere. Estimation of dermal exposures has also been described (Gorman Ng et al., 2021; Stewart, Groth et al., 2021).

Background

Dispersants have been used in the past to mitigate the environmental impact of offshore oil spills in the Gulf of Mexico. The chemical dispersants used and the distribution size of the spray in the DWH response were selected in accordance with the Federal On-Scene Coordinator (FOSC) Dispersant Pre-Approval Guidelines and Checklist (40 CFR, 1991). The Safety Data Sheet for 9527A indicates that it contains 2-butoxyethanol (2-BE) (30.0–60.0%, w/w), a proprietary organic sulfonic acid salt (10.0–30.0%, w/w), and propylene glycol (PG) (1.0–5.0%, w/w) (COREXIT™ EC9527A, 2020). 9500A contains petroleum distillates, hydrotreated light (10.0–30.0%, w/w), PG (1.0–5.0%, w/w), and a proprietary organic sulfonic acid salt (10.0–30.0%, w/w) (COREXIT™ EC9500A, 2020). Spraying results in aerosolization of these particles. Exposure can occur directly from being directly in the field of the spray nozzle or indirectly from spray drift. Given the low vapor pressure of the dispersant components (at 25°C the total vapor pressure attributed to the non-aqueous volatiles is <1 mm of Hg in 9527A and <1.5 mm of Hg in 9500A), we do not address differential evaporation of the aerosol components in this paper, but only total aerosols. We define total aerosol as all components of the dispersant including active ingredients, surfactants, and water.

Aerial application of dispersants

Across the Gulf of Mexico a total of 812 611 l (214 669 gal) of dispersant 9527A and 2 882 848 l (761 568 gal) of dispersant 9500A was applied to oil slicks by planes (412 sorties) flying 15–30 m (50–100 ft) above the water surface on 16 of 29 days, 22 April to 31 May 2010 (9527A) and on 58 of 84 days, 27 April to 19 July 2010 (9500A). Aerial applications of dispersants were carried out using five plane types: Lockheed C-130, Douglas DC-3, Beechcraft King Air 9500, Air Tractor AT-802, and ASI BT-67. Dedicated aerial dispersant planes were deployed out of the Stennis Space Center Airport in Mississippi and the Houma-Terrebonne Airport in Louisiana. Each plane was equipped with a geographic positioning system (GPS) that provided a record of the time and track of the spray sorties (Gass et al., 2011). During a spray sortie, each spray aircraft was accompanied by spotter aircraft to aid in the positioning of the spray aircraft. Once the spraying was completed, the spotter plane flew several hundred feet above the slick to verify that the spray aircraft effectively hit its target, remaining in the spray area for approximately 30 min postspray application to ensure no reentry of vessels to the sprayed area. Each spray plane typically flew up to six sorties per day. Accounting for the payload application time, transit time to and from the oil slick, filling the dispersant tanks, and refueling time, we estimate the duration for a sortie was, on average, about 1½ h. For example, if an aircraft had a 5000 gal payload and a 150 ft swath width and traveled at 180 knots (207 mph, 333 kmph) with an application rate of 5 gal acres−1 (46.8 l/ha), and the slick required only one pass (55 mi, 88 km), the entire payload would be applied in 15–16 min. US government criteria prohibited aerial dispersant spraying: (i) <3 nautical miles (nmi) (3.45 mi, 5.56 km) of the coastline; (ii) where water depths were <10 m (32.8 ft); (iii) <5 nmi (5.75 mi, 9.26 km) of the wellhead; (iv) <2 nmi (2.30 mi, 3.70 km) of any maritime vessels and drilling rig platforms; (v) <3 nmi (3.45 mi, 5.56 km) of visible marine mammals; or (vi) when wind speeds >64 km h−1 (40 mph). In practice, however, sorties were not flown when winds exceeded 46 kmph (28.7 mph) (On scene coordinator report: Deepwater Horizon oil spill, 2011).

Many activities were performed by OSRC workers, but most were presumed to result in negligible inhalation exposure to dispersant aerosols. Potentially exposed OSRC jobs to the sprayed dispersant aerosol were pilots and crew on the planes that sprayed the dispersant and did spotting and reconnaissance; and OSRC workers who were on the water in the spray area during or immediately after the dispersant was applied. Prior to 6 May 2010, the US government prohibited any vessel from being <1 nmi (1.15 mi, 1.85 km) of the plane spray path; after that date, the minimum allowable distance was increased to 2 nmi (2.3 mi, 3.7 km). Vessels were allowed to return to the sprayed area 30 min after spraying had been completed.

Surface vessel application of dispersants

The RP set up a monitoring program that required certain actions to occur if volatile organic compounds (VOCs) or benzene levels, as measured by direct-reading instruments on 38 marine and drilling rig vessels in the wellhead area, exceeded for more than 15 min 100 ppm for VOCs or 0.5 ppm for benzene (calibrated with isobutylene). The actual mitigation action was left to the discretion of the captain of the vessel with the exceeded measurements. One of the actions was to spray 9500A dispersant on the water surface in the area of the vessel by a second vessel equipped with a spray boom. A total of 117 vessel surface applications of 364 448 l (96 277 gal) of dispersant 9500A occurred over 41 days, 15 May to 13 July 2010, for an estimated average duration of 3 h. Additionally, one marine vessel sprayed 189 l (50 gal) or less of 9500A dispersant on 28 July 2010 and 4 September 2010. Workers were potentially exposed to dispersant aerosol indirectly from vessel spraying (i.e. through spray drift) on the spray vessels and on the decks of nearby vessels.

Subsurface injection of dispersant

Subsurface injection was conducted by a single marine vessel equipped with underwater remote operation vehicles (ROVs). Between 30 April and 14 May 2010 three subsea injection tests over 6 days, consuming approximately 113 562 l (30 000 gal) of 9500A, were conducted to establish appropriate operating conditions and procedures and determine effectiveness of the dispersant application. Starting 15 May 2010, daily injection was done until the well was mechanically capped on 15 July 2010. Approximately 2 919 000 l (771 000 gal) of dispersant was used at a continuous rate of approximately 37.8 l (10 gal) per min, resulting in approximately 45 425 l (12 000 gal) of dispersant applied per day. A wand on the end of a hose connected to a manifold was positioned into the leaking oil stream 1524 m (5000 ft) below the water surface by an ROV. Because the marine vessel piping system was completely closed and the release of dispersant occurred 1524 m under water, negligible aerosol exposure would likely have occurred during this operation and so is not discussed further.

Methods

Estimation modeling

Airborne concentrations of dispersants potentially occurring from aerial and vessel spraying were modeled using AgDISP (Teske et al., 2009). This model was originally designed for the prediction of surface deposition patterns and air concentrations of pesticides sprayed aerially at various horizontal distances from the aircraft flight line and on the ground using spray booms. It accounted for the larger droplets in a spray, released through spray nozzles, that were expected to fall to the ground relatively quickly and for fine droplets from spray drift to reflect the entire spray volume from its point of release to the final location downwind.

Aerial spraying of dispersants

The models used in this work include many assumptions. While a full discussion of the models’ assumptions is beyond the scope of this paper, the reader is directed to the following references for AgDISP (Bird et al., 2002; Teske et al., 2002; Teske, 2003) and AERMOD (United States Environmental Protection Agency (EPA), 2015). Input assumptions are identified in the relevant tables in Supplementary Materials (available at Annals of Work Exposures and Health online). For aerial applications, AgDISP considers aircraft design factors such as the wingspan, type, and number of nozzles; fluid characteristics such as weight fraction of ingredients and volatility; weather conditions such as air temperature and wind speed; and topographic characteristics such as canopy density and surface roughness. The characteristics of the aircraft used in aerial dispersant spraying operations were identified in the AgDISP database for each aircraft type (BP Gulf Science Data, 2016). Model input values both specific to the plane type and default values are shown in Supplementary Table S1 (available at Annals of Work Exposures and Health online).

Deposition velocities for aerosol particles were estimated using AgDISP, based on the specific gravity of the dispersant aerosols with a coarse–very coarse particle distribution (volume median diameter [VMD] = 439.3 µm, as defined by the FOSC Dispersant Pre-Approval Guidelines and Checklist) (40 CFR, 1991). For this particle size distribution, AgDISP estimated the maximum settling time for the smallest 10% of the volume fraction (Dv0.1, identified as 95–200 µm depending on the plane’s nozzles) to be 2.28 min for the C-130 plane. Larger volume fractions and other planes resulted in even shorter settling times (Supplementary Table S2, available at Annals of Work Exposures and Health online).

Spray input parameters of the dispersant characteristics were defined to reflect application at the concentrations used in the aerial applications (Supplementary Table S3, available at Annals of Work Exposures and Health online). We conservatively assumed no evaporation of volatiles from either 9527A or 9500A, as the droplets rapidly descended toward the ocean surface and because of the low vapor pressures of the dispersant components.

We used meteorological data from the buoy marker closest to the response area (site 42040) of the National Data Buoy Center (NOAA, 2010), located 64.4 km (40 mi) north of the DWH wellhead (NOAA, 2010). Daily average temperature, humidity, and wind speed were calculated from the hourly measurements at this marker between sunrise and sunset (Gass et al., 2011; Supplementary Table S4, available at Annals of Work Exposures and Health online). Topographical (tree height, upslope angle, etc.) model inputs were defined to reflect the water surface where the dispersant droplets settled, specifically, we assumed a relatively level area without vegetation that would otherwise reduce surface deposition (Supplementary Table S3, available at Annals of Work Exposures and Health online).

Pilots spraying and spotting would have experienced dispersant aerosol exposure only indirectly, i.e. from spray drift. Even this would have been minimal as nozzle design and the rapid settling of the dispersant would have quickly propelled the aerosol away from the plane, minimizing the likelihood of re-entrainment. Spotters maintained flying altitudes of 305–457 m (1000–1500 ft), dropping down to several hundred feet during postapplication inspection (Gass et al., 2011), and so should not have been exposed directly to the aerosol. We also considered that direct exposure could have occurred if a vessel on the water had inadvertently, in violation of policies and practices, transected the spray application zone during the critical spray period. As reentry into the zone was prohibited within 30 min of spraying, and the maximum settling time of the dispersant was rapid (2.28 min) even for small particles comprising only 10% of the volume fraction (i.e. <200 µm in size), we deemed any potential exposure to the individuals on the water surface was more likely from spray drift from this low end of the droplet size distribution, which does not settle as quickly as the larger droplets (Caldwell, 2006).

The shortest period that AgDISP calculates concentrations is 1 h. Thus, although workers may have violated procedures and entered the spray area within the restricted period, the shortest time duration available from the model is 1 h. Thus, average airborne concentrations of total aerosolized 9527A and 9500A were estimated on OSRC vessels as 1-h concentrations in µg m−3 from spray drift across all spray days by plane type. We report these average concentrations at 3 vertical m (10 ft) above the ocean water surface to reflect the deck height above the water of smaller vessels at five horizontal (perpendicular) distances downwind from the flight path: 152, 305, 457, 610, and 752 m (500, 1000, 1500, 2000, and 2500 ft, the furthest distance AgDISP allows). The concept of the horizontal perpendicular distance downwind is demonstrated in Supplementary Fig. S1 (available at Annals of Work Exposures and Health online). Concentrations estimated at 6 m (20 ft) and 9 m (30 ft) above the water surface, representing deck heights of larger vessels, resulted in nearly identical concentrations and are not presented. We estimated the average total aerosol concentrations over the approximately 3-month period of dispersant application. In the unlikely scenario that vessels entered the spray zone within less than ½ h after spraying had been completed, potential air concentrations would have been higher. For completeness, we estimated hypothetical average air concentrations resulting from a vessel entering the spray area prior to 1 h and 2 min; see Supplementary Fig. S2, available at Annals of Work Exposures and Health online for details).

Exposures to vapors of 2-BE, a major constituent of 9527A, and PG, a constituent of both 9527A and 9500A, are not the focus of this paper (see Stenzel, Arnold et al., 2021, for vapor evaluations). Possible aerosolized concentrations of the dispersants’ volatile chemical constituents can be estimated, however, based on their respective weight fractions in the dispersants by multiplying the total aerosol concentration by the corresponding weight fraction (Supplementary Table S7, available at Annals of Work Exposures and Health online). For 9500A (COREXIT™ EC9500A) the corresponding upper bound fraction for PG is 0.05, based on the upper bound percent weight values presented on the safety data sheet. Similarly, for 9527A (COREXIT™ EC9527A), the corresponding upper bound fractions for 2-BE and PG are 0.6 and 0.05.

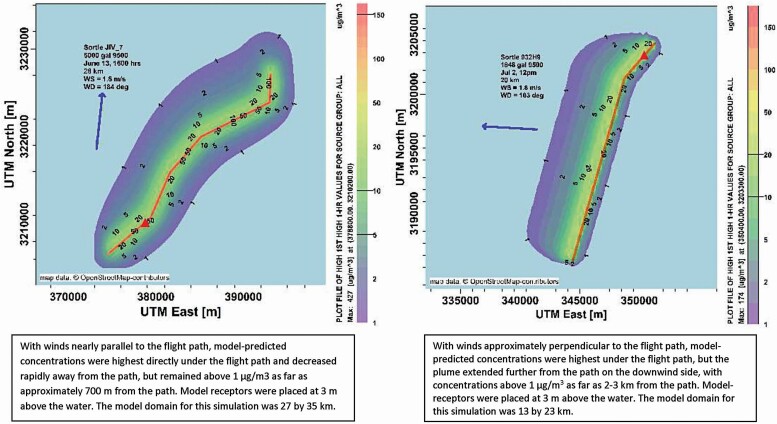

Comparison of AgDISP and AERMOD predictions

A second model, the U.S. Environmental Protection Agency recommended guideline model, AERMOD (Cimorelli et al., 2005), was used to compare air concentration results generated from AgDISP for two plane sorties included in the aerial applications estimated above. The two sorties modeled were JIV 7 (C-130) (13 June 2010, 1600 h) and 932H9 (BT-67) (2 July 2010, 1200 h), representing light crosswinds (932H9) and winds parallel (JIV 7) to the flight paths, respectively. Sortie JIV 7 consisted of three complete passes and one partial pass over an entire distance of 28 km (17 mi), during which 18 927 l (5000 gal) of dispersant 9500A were applied. Sortie 932H9 comprised three passes over an entire distance of 20 km (12 mi) with 6995 l (1848 gal) of 9500A applied.

AERMOD requires input of meteorological data, source emissions, surface land use data, and source characterization. AERMOD was applied using the same hourly surface buoy meteorological data as were used with AgDISP, along with upper air data from Lake Charles, Louisiana. Source emissions were described as 21 particle size fractions (Supplementary Table S5, available at Annals of Work Exposures and Health online) by the nozzle manufacturer data. Since the meteorological data were available as 1-h values, emissions were assumed to have occurred over a 1-h period starting with the dispersant application and thus were equivalent to the AgDISP concentrations. Surface land use was characterized as ‘water’. The flight path for each sortie was characterized as a series of volume sources that were each assigned a release height of 25 m (82 ft) corresponding to the release height of the C-130s, and a plume height and width of 5 m (16 ft) and 20 m (66 ft), respectively. These volume sources were arranged adjacently to represent a line source along the flight path, and emissions were apportioned evenly across the volumes. The AERMOD model developed ranges of estimates for the same conditions as AGDISP and are reported as horizontal values up to 2 km (1.2 mi) (the maximum AERMOD distance allowed) perpendicular to the flight path.

Vessel spraying of dispersants

As indicated above, vessel spraying was initiated when the VOCs or benzene concentration threshold was exceeded for more than 15 min near the wellhead. It ceased when the VOC or benzene level was below this threshold (Curd, 2011). Surface application of dispersant was most effective when it was sprayed forward of the vessel bow wave, which maximized mixing, as the dispersant was caught up by the turbulence caused by the ensuing prop wash (water that is pushed toward the stern by the marine vessel’s propeller). Vessels sprayed the dispersant starting upwind of the stationary vessel and moved perpendicular to the wind following a ‘ladder’ pattern to minimize spray drift.

Workers would not have been located under the vessel-mounted boom spray nozzles. Workers on the spraying vessel would not have been in the path of any spray drift because the nozzles reached out 6–9 m (20–30 ft) from the vessel’s bow to direct the spray ahead of the ship and were only 2–3 m (6–9 ft) above the water surface, while the vessel decks were upwind from the spray and about 10 m (30 ft) above the water surface. Exposures to OSRC workers on nearby stationary vessels that were downwind of the spraying could have occurred from spray drift if the released dispersant drifted upward rather than settling. Air concentrations were estimated using AgDISP for ground applications. This model accounts for spray characteristics [boom pressure, nozzle design, vessel position relative to the wind, nozzle type, and boom positioning (relative to the deck surface)] (Supplementary Tables S6, available at Annals of Work Exposures and Health online); spray composition (Supplementary Table S3, available at Annals of Work Exposures and Health online); and meteorological conditions (Supplementary Table S4, available at Annals of Work Exposures and Health online). The meteorological data and spray composition input values were the same as for aerial spraying. We developed two sets of estimates to represent drift originating from the 2 vessels (‘large vessels’) with a larger spray swath (swath width = 21.9 m, 72 ft) and the vessels with a smaller spray swath (swath width = 12.8 m, 42 ft) (‘small vessels’). Air concentrations were estimated at vertical distances of 2 m (6.6 ft) and 3 m (10 ft) to reflect vertical difference between the height of the nozzles and the deck height of other OSRC vessels that might have received the spray drift. Three horizontal distances of 10, 100, and 500 m (32.8, 328, and 1640 ft) were evaluated to cover possible distances of nearby OSRC vessels.

Hypothetical average air concentrations were developed for periods of 2 min and 1 h over the 2-month period of application (Supplementary Table S9, available at Annals of Work Exposures and Health online).

Results

Aerial spraying

The arithmetic means (AMs), geometric means (GMs), geometric standard deviations (GSDs), and the 5th and 95th percentiles of the 1-h averages for each plane type across all application days are provided in Table 1. AM estimates ranged from 49.3 µg m−3 for C-130 sorties to 23.2 µg m−3 for BT-67 sorties at a distance 152 m downwind and perpendicular from the flight path and from 3.6 µg m−3 for C-130 sorties to 1.5 µg m−3 for BT-67 sorties 762 m downwind, for 9527A. For 9500A, the estimated AM concentrations ranged from 45.4 µg m−3 for C-130 sorties to 12.3 µg m−3 for AT-802 sorties 152 m downwind and from 4.2 µg m−3 for C-130 sorties to 0.4 µg m−3 for AT-802 sorties 762 m downwind.

Table 1.

AgDISP generated 1-h average total aerosol concentrations (µg m−3) at horizontal distances downwind, perpendicular to flight path.a

| Aircraft | Aerosol | Horizontal distances perpendicular from flight path (m) | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 152 | 305 | 457 | 610 | 762 | ||||||||||||||||||||||

| AM | GM | GSD | 5% | 95% | AM | GM | GSD | 5% | 95% | AM | GM | GSD | 5% | 95% | AM | GM | GSD | 5% | 95% | AM | GM | GSD | 5% | 95% | ||

| A-802a,e | 9500A | 12.30 | 10.80 | 1.93 | 2.89 | 40.29 | 3.60 | 3.30 | 1.51 | 1.45 | 7.50 | 1.80 | 1.40 | 2.14 | 0.31 | 6.43 | 0.60 | 0.50 | 2.52 | 0.08 | 3.17 | 0.40 | 0.20 | 3.04 | 0.02 | 1.85 |

| DC-30b | 9527A | 39.94 | 35.95 | 1.66 | 21.64 | 99.18 | 4.48 | 3.46 | 2.41 | 1.44 | 20.11 | 4.60 | 3.94 | 1.82 | 2.17 | 13.02 | 2.80 | 2.20 | 2.12 | 1.04 | 9.84 | 1.74 | 1.25 | 2.40 | 0.52 | 7.20 |

| 9500A | 18.44 | 16.05 | 1.71 | 9.39 | 46.83 | 4.12 | 3.41 | 1.93 | 1.77 | 12.70 | 1.61 | 1.20 | 2.24 | 0.54 | 6.03 | 1.11 | 0.60 | 2.89 | 0.21 | 5.06 | 0.45 | 0.28 | 2.70 | 0.10 | 2.07 | |

| BT-67c | 9527A | 23.20 | 22.30 | 1.40 | 11.37 | 43.75 | 7.80 | 7.70 | 1.19 | 5.44 | 10.91 | 4.00 | 3.90 | 1.20 | 2.71 | 5.61 | 2.20 | 2.20 | 1.20 | 1.51 | 3.16 | 1.50 | 1.50 | 1.19 | 1.06 | 2.13 |

| 9500A | 15.40 | 13.16 | 1.82 | 3.99 | 43.39 | 6.60 | 4.54 | 1.95 | 1.19 | 17.32 | 2.40 | 2.16 | 1.68 | 0.77 | 6.10 | 1.70 | 1.20 | 2.38 | 0.21 | 6.79 | 0.90 | 0.67 | 2.39 | 0.12 | 3.84 | |

| King Aird | 9527A | 37.50 | 36.80 | 1.24 | 23.93 | 56.58 | 10.70 | 10.68 | 1.14 | 8.22 | 13.88 | 5.50 | 5.42 | 1.22 | 3.64 | 8.07 | 3.30 | 3.30 | 1.18 | 2.37 | 4.50 | 2.00 | 2.00 | 1.00 | 2.00 | 2.00 |

| 9500A | 36.22 | 33.50 | 1.52 | 14.41 | 77.86 | 10.56 | 10.30 | 1.27 | 6.40 | 16.58 | 4.84 | 4.70 | 1.28 | 2.86 | 7.73 | 2.58 | 2.50 | 1.37 | 1.34 | 4.68 | 1.58 | 1.40 | 1.65 | 0.51 | 3.83 | |

| C-130c | 9527A | 49.30 | 43.20 | 1.70 | 14.91 | 125.20 | 15.70 | 14.90 | 1.42 | 7.34 | 30.20 | 8.60 | 8.20 | 1.43 | 4.01 | 16.76 | 5.50 | 5.00 | 1.71 | 1.71 | 14.57 | 3.60 | 3.30 | 1.63 | 1.24 | 8.81 |

| 9500A | 45.38 | 40.00 | 1.64 | 14.86 | 107.70 | 16.03 | 14.70 | 1.42 | 7.25 | 29.81 | 9.39 | 8.30 | 1.53 | 3.55 | 19.42 | 5.32 | 5.00 | 1.51 | 2.08 | 11.33 | 4.20 | 3.30 | 1.84 | 0.97 | 11.18 | |

9527A: COREXIT™ EC9527A. 9500A: COREXIT™ EC9500A. a: swath width 24.4 m. b: swath width 36.6 m. c: swath width 45.7 m. d: swath width 22.9 m. e: did not conduct any sorties using 9527A. 5 and 95% represent the 5th and 95th percentiles of the estimates.

aThe concept of the horizontal perpendicular distance downwind is demonstrated in Supplementary Fig. S1 (available at Annals of Work Exposures and Health online).

Air concentrations near the water surface were most influenced by the height at which the planes sprayed the dispersant and wind speed. The average 1-h 9500A total aerosol concentration following spraying by an AT-802 from a release height of 4.6–15.2 m on 23 May 2010 was estimated to be 9 µg m−3 at 152 m, when the daily average wind speed was 6.39 mph (10 km h−1) falling to 0.1 µg m−3 at 762 m. These concentrations can be compared with average 1-h 9500A total aerosol concentrations of 23 µg m−3 at 152 m and 2 µg m−3 at 762 m from a C-130 with a release height of 22.9–30.5 m, twice that of the AT-802. Similarly for wind speed, the average 1-h 9500A total aerosol concentration following spraying by an AT-802 on 3 June 2010, when the daily average wind speed was 15.35 mph (24.7 km h−1), was 19 µg m−3 at 152 m (1 µg m−3 at 762 m).

Modeled concentration estimates at the five distances downwind suggested that the dispersant aerosol settled on the water surface quickly (min) with minimal drift. From AgDISP, we estimated the GM deposition velocity for the aerosol (with VMD 439.3 µm) to be 0.65 m s−1, with a maximum velocity of 7 m s−1. This is comparable to a mean settling time of 46 s for an aerosol released from 30.5 m (100 ft).

The dispersant 9500 1-h average total aerosol concentration predicted by AERMOD from spray drift was 427 µg m−3 (420 µg m−3 for AgDISP) up to 20 m from the flight path (Table 2). The distances were slightly offset from the flight path since the winds were not exactly parallel to the flight path on 13 June 2010 (Fig. 1a, concentrations at 20 m not visible on the figure). At ~100 m, concentrations were estimated to be in the range of 100–200 µg m−3 (80 µg m−3 for AgDISP) and at 500–1000 m, the estimate was <1 µg m−3 (4 µg m−3 for AgDISP). For the 2 July 2010 sortie, which occurred under light crosswinds conditions, AERMOD-predicted concentrations of 174 µg m−3 (365 µg m−3 for AgDISP) for 0–20 m of the flight path, which were offset to the west of the flight path (Fig. 1b, concentrations at 50–500 m not visible on the figure), and 30–50 µg m−3 (30 µg m−3 for AgDISP) up to about 500 m downwind (Fig. 1b). The estimated concentration on 2 July at 500–1000 m downwind was 10.0 µg m−3 (4 µg m−3 for AgDISP), but beyond 1000 m concentrations were mostly <2.0 µg m−3. The spray drift distance was affected by the orientation of the flight path in relation to the wind direction, which changed as the plane tracked the oil slick, and by the model’s accounting for low wind speed turbulence. The concentrations were on the order of 2.5 times higher for 13 June when the application rate was about twice as high as the concentrations estimated for 2 July, suggesting that concentrations were more likely to build up with parallel winds.

Table 2.

Comparison of AERMOD and AgDISP generated 1-h average total 9500A aerosol concentrations (µg m−3) at 3 m deck height, downwind from flight path.

| Date | Wind conditions | Model | Horizontal distances perpendicular from flight path (m) | ||

|---|---|---|---|---|---|

| 0–20 | 100 | 500–1000 | |||

| 13 June | Approximately parallel to flight path | AERMOD | 427 | 100–200 | 1 |

| AgDISP | 420 | 80 | 4 | ||

| 2 July | Approximately perpendicular to flight path | AERMOD | 174 | 30–50 | 1–10 |

| AgDISP | 365 | 30 | 4 | ||

Figure 1.

AERMOD-predicted air concentrations of dispersant when wind speed (WS) was light and wind direction (WD) was approximately parallel (13 June, a) or perpendicular (2 July, b) to the flight path. Flight paths are shown as contiguous volume sources that appear as red lines. The axes are in units of meters in Universal Transverse Mercator (UTM) coordinates. Arrows indicate the simulated wind direction.

The average 1-h airborne concentrations estimated by the model were the best available estimates of the average 1-h total aerosol concentrations that could have been experienced by the study participants over the 3-month application period from spray drift. We also calculated hypothetical air concentrations of shorter duration (2 min) (Supplementary Table S9, available at Annals of Work Exposures and Health online).

Surface vessel spraying application of dispersants

One-hour average descriptive statistics (AM, GM, GSD, and 5th and 95th percentiles) for the marine vessel applications are presented in Table 3. Predicted average total aerosol concentrations from vessel spraying were approximately 160 times lower than those associated with aerial spraying, and swath size made little difference. For example, the average 1-h total aerosol concentrations were about 0.30 µg m−3 at 10 m and 0.001 µg m−3 at 500 m downwind of the nozzles for both swath sizes (Table 3). Hypothetical 1-h average total aerosol concentrations based on shorter durations of 2 min were 30× higher, compared with the 1-h average concentration (Supplementary Table S9, available at Annals of Work Exposures and Health online).

Table 3.

AgDISP generated 1-h average total aerosol concentrations (µg m−3) of 9500A at distances downwind following surface spraying.a

| Marine vessel | Horizontal distances downwind from vessel spray nozzles (m) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 100 | 500 | |||||||||||||

| AM | GM | GSD | 5% | 95% | AM | GM | GSD | 5% | 95% | AM | GM | GSD | 5% | 95% | |

| Small | 0.293 | 0.170 | 2.653 | 0.024 | 1.197 | 0.016 | 0.014 | 1.630 | 0.005 | 0.037 | 0.001 | 0.001 | 2.765 | 0.0001 | 0.004 |

| Large | 0.330 | 0.242 | 2.122 | 0.054 | 1.091 | 0.042 | 0.034 | 1.992 | 0.009 | 0.135 | 0.004 | 0.003 | 2.556 | 0.001 | 0.021 |

9500A: COREXIT™ EC9500A. Small: swath width 12.8 m; large: swath width 21.9 m. 5 and 95% represent the 5th and 95th percentiles of the estimates.

aOnly 9500A was applied by vessel. Estimates do not include the applications on 28 July 2010 and 4 September 2010 because they were so small and occurred weeks after the routine applications had been terminated.

Discussion

In this paper, we modeled air concentrations of aerosols from two dispersants to inform the exposure assessment for the GuLF Study. The use of dispersants to mitigate the oil spill raised concerns among the public, some of whom reported nausea and headaches after exposure (Deep Water Horizon: The Gulf Oil Disaster and the Future of Offshore Drilling Report to the President, 2011). Anecdotal reports indicated workers on fishing vessels were sprayed while being in an area where planes were applying dispersant. Also, respiratory symptoms were reported by our study participants performing dispersant-related tasks (McGowan et al., 2017). Due to these concerns, we investigated use and possible aerosol air concentrations from the spraying of dispersants (vapor air concentrations are described in Stenzel, Arnold et al., 2021).

The modeled 1-h average total aerosol concentrations resulting from aerial spraying followed a logical pattern of higher predicted concentrations at the nearest estimated horizontal distance downwind, perpendicular to the flight path (152 m), whereas lower concentrations were predicted further away on days for which the minimum wind speed was observed, suggesting a lower dispersion rate and minimal drift. In contrast, the highest predicted 1-h average concentrations farthest from the flight path occurred on days during which the maximum daily average wind speeds were observed, suggesting a higher dispersion rate. Furthermore, concentrations dropped off quickly; we found that concentrations at 762 m were <10% of concentrations at 152 m under the same conditions. This finding was supported by our AgDISP model predictions both for the maximum settling time of 2.28 min modeled from the Federal guidelines (40 CFR 300, 1991) for the particle size distribution and for the deposition velocities (e.g. GM = 0.65 m s−1; maximum of 7 m s−1, equivalent to a GM of 46 sec at a flying height of 30 m). In addition, the AgDISP-predicted total aerosol concentrations associated with aerial spraying are in good agreement with the AERMOD predictions, with most estimates within a factor of ±2×, increasing our confidence that the AgDISP model results reflect reasonable estimates of the concentrations resulting from aerial spraying.

There are several reasons to suggest that being on a vessel near a plane spraying would not have resulted in direct exposure. First, a policy was developed to ensure that dispersants were not sprayed when vessels were within 2 nmi. The location of each application was precisely known because planes were equipped with a GPS that logged the time and track of each sortie, confirming each plane’s flight path, which allowed postevent verification that no plane violated the spray requirements (Gass et al., 2011). Additionally every sortie had a spotter plane, with one of its duties being to verify that there were no vessels or marine animals within the restricted area of 2 nmi within ½ h of spraying. Also, it is highly unlikely that a plane flying low above the water (15–30 m) would have done so with a vessel under or close to the flight path. We assume that planes flew only under conditions specified in the guidance plan [including spraying only when winds were <30 mph (48 km h−1)]. Given these conditions, it is unlikely that workers on vessels were exposed to aerosolized dispersants directly from aerial spraying.

There is a somewhat greater possibility that exposures could have occurred through spray drift. With wind speeds <46 kmph and a GM deposition velocity of 0.65 m s−1 (maximum = 7 m s−1) at a plane height of 15–30 m above the water, the larger (>200 µm) particles of the dispersant would have settled on the water surface within a minute, after accounting for the trajectory associated with the plane and the wind speed. These large particles are governed primarily by gravity, are less susceptible to wind, and tend to settle quickly with minimal drift (Parkin and Merritt, 1988). Exposure to these larger particles was, therefore, highly unlikely. Horizontal drift from aerial spraying of smaller particles, in contrast, exhibit considerably greater (3×) drift (Yates et al., 1974). Even for the smallest fraction of particles corresponding to the FOSC Dispersant Pre-Approval Guidelines and Checklist of coarse–very coarse aerosols (Dv0.1 = 209.03 µm) (40 CFR, 1991), however, we estimated the maximum settling time would have been 2.28 min (C-130 for fraction size 0.1, Supplementary Table S2, available at Annals of Work Exposures and Health online). For dispersant sprays in the designated FOSC size range, approximately 95.3% of the spray volume is contained in droplets >200 µm, leaving only a small fraction (4.7%, fraction <141 µm, Supplementary Table S1, available at Annals of Work Exposures and Health online) of the spray volume susceptible to substantial drift. The estimated concentrations of total aerosol in the air at 762 m (the furthest distance allowed by AgDISP, which is one-half the allowable distance originally specified and one-quarter of the final specified distance) were low (95 %ile concentrations <10 µg m−3). The small fraction of droplets <200 µm that might drift beyond this distance, although probably comprising a larger percentage of the concentration by weight, would have been at a much lower concentration and therefore would not likely be of consequence if the vessel remained outside the 1–2 nmi, (1–2 km) distance for the required ½ h. This is further supported by our estimates of the distance the aerosol would settle given different wind speeds (Table 4). Even with a wind speed of 536 m min−1, we estimated the aerosol would settle onto the water in a little over 1 km.

Table 4.

Distance an aerosol particle would likely settle at various wind speeds.

| Wind speed (mph) | Wind speed (m min−1) | Distance a particle would settle on the water, given a maximum deposition time of 2.28 min (m) | Distance a particle would settle on the water, given a maximum deposition time of 2.28 min (ft) | Distance a particle would settle on the water, given a maximum deposition time of 2.28 min (mi) | Distance a particle would settle on the water, given a maximum deposition time of 2.28 min (nmi) |

|---|---|---|---|---|---|

| 1 | 26.8 | 53 | 164 | 0.03 | 0.03 |

| 5 | 134 | 268 | 830 | 0.16 | 0.15 |

| 20 | 536 | 1072 | 3323 | 0.63 | 0.58 |

Similarly, if the plane was flying 150 mph (240 km h−1), the plane crew probably had only minimal exposure when the plane returned in the opposite direction to spray an adjacent swath, because the >200 µm particles of dispersant, being the vast majority of spray particles, would generally have settled by that time. Further, with the vast majority of spray particles >200 µm, exposure to suspended small particles also was likely minimal because of the short time to deposition under the conditions of application. For <200 µm, the maximum time to deposition was ~137 s (see Supplementary Table S5, available at Annals of Work Exposures and Health online).

Air concentrations to which workers on nearby vessels during vessel spraying potentially experienced were substantially lower (<0.1 µg m−3 at 100 m) than predicted for workers near aerial spraying, likely due to the force that the aerosol leaves the nozzle and the small distance between the nozzle and the water surface. Spraying lasted on average 3 h day−1 and only occurred 41 days over a 2-month period. Thus, we considered these exposures to be negligible.

Limitations of the work are that AgDISP is a deterministic model that allows single value model inputs to produce single value concentration estimates rather than distributions of predicted concentrations, so the predicted concentrations do not reflect the inherently high run-to-run variability (Bird et al., 2002). Another limitation was the incomplete input data, requiring the use of default values and the need to make assumptions when data were incomplete or missing. The strengths include the use of recognized, credible models in use over 20 years. AgDISP was recently identified as ‘the most suitable of the existing tools for determining the extent of the dispersant drift’ due to aerial application (AMOG, 2016). Bird et al. (2002) compared simulated field deposition and drift of three pesticides using AgDISP to field trial data from 161 agricultural application trials under similar environmental conditions (temperature, relative humidity, and wind speed) using a slightly finer aerosol (VMD 238 µm). They found a slight tendency of AgDISP to overestimate mean deposition levels of pesticide aerosols >100 m. Those authors found that relative bias, defined as the difference between expected and measured concentrations divided by the measured concentration, was reported to be generally <20%. In addition, we used a recognized air dispersant model that found good agreement when compared with our results for two aerial sorties.

The purpose of this evaluation was to estimate potential air concentrations experienced by workers possibly exposed to dispersants in response to the DWH OSRC. The goal of an exposure assessment for an epidemiologic study is to allow investigation of exposure–response relationships. For such an investigation, workers with different potential for exposure or different exposure levels must be discriminated. Study participants were identified as having possible dispersant exposure from questions specifically asking about dispersants (flying a plane spraying dispersants or working on a vessel spraying dispersants on the water) (Supplementary Table S10, available at Annals of Work Exposures and Health online). Possible dispersant-exposed participants were also identified by responding positively to being in an area in the Gulf of Mexico where dispersants were applied (seeing a plane spraying a chemical in your immediate area, seeing individual vessels in the wellhead area, working on a vessel that injected or pumped dispersant below the water surface and identifying the name of a vessel known to work within 5 nmi of the wellhead).

We have presented reasons as to why we believe no study participant was likely to have had direct exposure to total dispersant aerosols. We have also indicated why the flight crews and the workers on the planes and vessels spraying dispersants and the workers on vessels near to a spraying vessel were likely to have negligible aerosol exposures from spray drift.

The remaining scenario was that of accidental exposure to workers on vessels in the area when an aerial application was occurring. Although we developed estimates of 1-h total aerosol concentrations for each spray sortie, these results should not be interpreted as suggesting the estimates represent long-term exposures of the study participants for several reasons. First, only 412 spraying sorties were performed on 61 days over an 89-day period. The large C-130 aircraft required 12–16 min to spray a full payload while the smaller aircraft required 3–7 min. Thus, considering the gal of dispersant sprayed in each sortie, we calculated the total number of spray hours over the entire spray period to be about 58 h over 61 days, an average of <1 h day−1 across the entire Gulf. Second, a total of 771 272 gal of dispersant was sprayed aerially at a rate of 5 gal acre−1, resulting in the spraying of 154 254 acres (~182 nmi2, 241 mi2, or 624 km2), a small fraction of the peak oil slick coverage of 40 000 nmi2 (140 000 km2). It is difficult to imagine any single vessel being regularly in a spray area when only 412 sorties occurred for 58 h over <1% of the 40 000 nmi2 oiled area. Third, even if a plane had been violating the policies and spraying within the 1–2 nmi of a vessel, because it is difficult to imagine a plane spraying 15–30 m directly over a vessel, it is more likely a vessel would have been further away, resulting in workers on the vessel getting exposure from spray drift. Only the smaller particles (<200 µm), however, were affected by spray drift, but even they were expected to settle onto the water surface within 3 min or about 1 km of spraying. Moreover, these smaller particles comprised only about 4% of the total aerosol concentration. Thus, even at 150 m from the flight path, the maximum AM air concentration over 30 min would have been, on average, 4 µg m−3 for dispersant aerosols sprayed by a C-130 plane. Air concentrations of shorter duration (2 min) were also presented to reflect a ‘worst-case’ scenario where workers had entered an area 2 min after spraying had occurred before the ½ h reentry restriction had elapsed. All of the estimates, however, would have resulted in exposures to the participants only for the seconds that the plane was in the immediate area of the vessel; seconds later, the plane would have traveled beyond the vessel, even if the vessel were moving in the same direction as the plane, because the plane was flying much faster than the boat could have traveled. Thus, we estimate the total exposure duration would generally be <1 min. Fourth, the vessel would have had to have been downwind of the flight path; upwind of the flight path, little exposure would have occurred (Fig. 1a,b).

Thus, cumulative exposure is probably not relevant to these workers given the unlikeliness of any vessel being subjected to spray drift for any appreciable time. Although conceptually, peak exposures may be more appropriate, the likelihood of any of our thousands of study participants being exposed more than once or twice seems highly unlikely. Finally, it is unclear how to identify which study participants in the epidemiologic study had lower and which had higher exposures, as we have incomplete information to determine which participants were on any particular vessel or where particular vessels were located on a daily basis, much less for a few minutes in relation to a spray application. In addition, we have no evidence that violations of procedures occurred. Given these reasons, assigning a single peak exposure level to all water workers would not provide useful information to the epidemiologic analyses.

Conclusions

The quantity of dispersant used in the response to the DWH response and clean-up effort was unprecedented, and no quantitative air measurements of dispersant aerosols exposures existed. The use of publicly available and widely accepted exposure assessment models provided a mechanism to approximate air concentrations of dispersant aerosols generated by the spray application process. Exposures were likely to have been extremely low to negligible if policies were followed and our estimates based on spray drift and settling velocity were accurate, although there are no guidelines on acceptable exposure limits to specific total dispersant aerosols. Even if a vessel had violated the rules, because the plane would have been flying faster than the vessel could move in the water, within less than a minute or two the plane would have been out of range from the vessel getting spray either directly or from drift. Thus, the 2-min concentrations estimated within 150 m are likely to be substantial overestimates. Due to the limitations of no measurement data, the application of a model developed for pesticide application and no validation of that model for dispersant application, the assumptions we had to make for use of the model and the study-participant data resulting in our inability to estimate the potential for differential exposures among the study population or the frequency of possible policy violations, we recommend using these data with caution in any epidemiologic analyses.

Supplementary Material

Funding

This study was supported by the National Institutes of Health Common Fund and the Intramural Research Program of the National Institutes of Health, National Institute of Environmental Health Sciences (ZO1 ES 102945).

Conflict of interest

The authors declare no conflict of interest relating to the material presented in this article. Its contents, including any opinions and/or conclusions expressed, are solely those of the authors.

Data availability

The data underlying this article will be shared on reasonable request, consistent with protections for the privacy of study participants and existing multiparty agreements. Requests should be made following instructions on the study website https://gulfstudy.nih.gov.

References

- AMOG Consulting, Inc . (2016) OSSR program develop an innovative dispersant spray drift model. Houston, TX: AMOG Consulting, Inc. p. 224. [Google Scholar]

- Bird SL, Perry SG, Ray SLet al. (2002) Evaluation of the AgDISP aerial spray algorithms in the AgDRIFT model. Environ Toxicol Chem; 21: 672–81. [DOI] [PubMed] [Google Scholar]

- BP Gulf Science Data . (2016) Application of dispersants to surface oil slicks by aircraft and by boat in approved areas of the Gulf of Mexico from April 22, 2010 to final application on July 19, 2010. Distributed by: Gulf of Mexico Research Initiative Information and Data Cooperative (GRIIDC), Harte Research Institute, Texas A&M University–Corpus Christi. doi: 10.7266/N70G3HK6 [DOI] [Google Scholar]

- Caldwell DM. (2006) Quantification of spray drift from aerial applications of pesticide. Canada: M.S. University of Saskatchewan. [Google Scholar]

- Cimorelli A, Perry S, Venkatram Aet al. (2005) AERMOD: a dispersion model for industrial source applications. Part I: General model formulation and boundary layer characterization. J Appl Meteorol; 44: 682–93. [Google Scholar]

- Code of Federal Regulations [40 CFR 300] Subpart J . (1991) National Oil and Hazardous Substances Pollution Contingency Plan. USA: Government Printing Office. [Google Scholar]

- COREXIT™ EC9500A . (2020) 11177 S. Stadium Drive Sugar Land, TX 77478: C. E. S. LLC. Available at https://www.restorethegulf.gov/sites/default/files/imported_pdfs/external/content/document/2931/539287/1/Corexit%20EC9500A%20MSDS.pdf. Accessed 31 August 2020. [Google Scholar]

- COREXIT™ EC9527A . (2020) 11177 S. Stadium Drive Sugar Land, TX 77478: COREXIT Environmental Solutions LLC. Available at https://www.restorethegulf.gov/sites/default/files/imported_pdfs/external/content/document/2931/539295/1/Corexit%20EC9527A%20MSDS.pdf. Accessed 31 August 2020. [Google Scholar]

- Curd H. (2011) The use of dispersant for the control of volatile organic compounds. In 2011 International Oil Spill Conference. Portland, OR: American Petroleum Institute. doi: 10.7901/2169-3358-2011-1-359 [DOI] [Google Scholar]

- Gass M, Albert VE, Huber Cet al. (2011) Aerial dispersant operations in the Deepwater Horizon spill response—a framework for safely mounting a large scale complex dispersant operation. In 2011 International Oil Spill Conference. Portland, OR: American Petroleum Institute. doi: 10.7901/2169-3358-2011-1-262 [DOI] [Google Scholar]

- Gorman Ng M, Cherrie JW, Sleeuwenhoek Aet al. (2021) GuLF DREAM: a model to estimate dermal exposure among oil spill response and clean-up workers. Ann Work Expo Health; 66: i218–i233. [DOI] [PMC free article] [PubMed]

- Groth CP, Banerjee S, Ramachandran Get al. (2021) Methods for the analysis of 26 million VOC area measurements during the Deepwater Horizon oil spill clean-up. Ann Work Expo Health; 66: i140–i155. [DOI] [PMC free article] [PubMed]

- Groth CP, Huynh TB, Banerjee Set al. (2021) Linear relationships between total hydrocarbons and benzene, toluene, ethylbenzene, xylene, and n-hexane during the Deepwater Horizon response and clean-up. Ann Work Expo Health; 66: i71–i88. [DOI] [PMC free article] [PubMed]

- Huynh TB, Groth CP, Ramachandran Get al. (2021a) Estimates of occupational inhalation exposures to six oil-related compounds on the four rig vessels responding to the Deepwater Horizon oil spill. Ann Work Expo Health; 66: i89–i110. [DOI] [PMC free article] [PubMed]

- Huynh TB, Groth CP, Ramachandran Get al. (2021b) Estimates of inhalation exposures to oil-related components on the supporting vessels during the Deepwater Horizon oil spill. Ann Work Expo Health; 66: i111–i123. [DOI] [PMC free article] [PubMed]

- Huynh TB, Groth CP, Ramachandran Get al. (2021c) Estimates of inhalation exposures among land workers during the Deepwater Horizon oil spill clean-up operations. Ann Work Expo Health; 66: i124–i139. [DOI] [PMC free article] [PubMed]

- Krajnak K, Kan H, Waugh Set al. (2011) Acute effects of COREXIT EC9500A on cardiovascular functions in rats. J Toxicol Environ Health Part A; 74: 1397–404. [DOI] [PubMed] [Google Scholar]

- Kwok RK, Engel LS, Miller AKet al. (2017) The GuLF STUDY: a prospective study of persons involved in the Deepwater Horizon oil spill response and clean-up. Environ Health Perspect; 125: 570–8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lehr B, Bristol S, Possolo A. (2010) Oil budget calculator, Deepwater Horizon. Technical report. Available at : https://www.restorethegulf.gov/sites/default/files/documents/pdf/OilBudgetCalc_Full_HQ-Print_111110.pdf. Accessed 14 October 2020. [Google Scholar]

- McGowan CJ, Engel L, Stenzel MRet al. (2017) Respiratory, dermal, and eye irritation symptoms associated with Corexit™ EC9527A/EC9500A following the Deepwater Horizon oil spill: findings from the GuLF STUDY. Environ Health Perspect; 125: 097015. doi: 10.1289/EHP1677. PMID: 28934097. PMCID: PMC5915187. [DOI] [PMC free article] [PubMed] [Google Scholar]

- National Commission on the BP Deepwater Horizon Oil Spill and Offshore Drilling (U.S.). Deep water: the gulf oil disaster and the future of offshore drilling, book . 2011; Washington, DC: University of North Texas Libraries, UNT Digital Library, https://digital.library.unt.edu; crediting UNT Libraries Government Documents Department. Available at https://digital.library.unt.edu/ark:/67531/metadc123527/. Accessed October 18, 2021.

- NOAA . (2010) National Data Buoy Center. Available at https://www.ndbc.noaa.gov/download_data.php?filename=42040h2010.txt.gz&dir=data/historical/stdmet/. Accessed 24 August 2020.

- On scene coordinator report: Deepwater Horizon oil spill . (2011) Washington, DC: U.S. Dept. of Homeland Security, U.S. Coast Guard. Accessed 24 August 2020. [Google Scholar]

- Parkin CS, Merritt CR. (1988) Measurement and prediction of spray drift. Asp Appl Biol; 351–61. [Google Scholar]

- Pratt GC, Stenzel MR, Kwok RKet al. (2021) Modeled air pollution from in situ burning and flaring of oil and gas released following the Deepwater Horizon disaster. Ann Work Expo Health; 66: i172–i187. [DOI] [PMC free article] [PubMed]

- Ramachandran G, Groth CP, Huynh TBet al. (2021) Using real-time area VOC measurements to estimate total hydrocarbons exposures to workers involved in the Deepwater Horizon oil spill. Ann Work Expo Health; 66: i156–i171. [DOI] [PMC free article] [PubMed]

- Roberts JR, Anderson SE, Kan Het al. (2014) Evaluation of pulmonary and systemic toxicity of oil dispersant (COREXIT EC9500A®) following acute repeated inhalation exposure. Environ Health Insights; 2014: 63–74. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sriram K, Jefferson AM, Lin GXet al. (2011) Neuronal synaptic and cytoskeletal protein aberration following acute inhalation exposure to the oil dispersant COREXIT® EC9500A. FASEB J; 25: 1016.4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sriram K, Lin GX, Jefferson AMet al. (2011) Neurotoxicity following acute inhalation exposure to the oil dispersant COREXIT EC9500A. J Toxicol Environ Health Part A; 74: 1405–18. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stenzel MR, Arnold SF, Ramachandran Get al. (2021). Estimation of airborne concentrations of oil dispersants COREXIT™ EC9527A and EC9500A, volatile components associated with the Deepwater Horizon oil spill response and clean-up operations. Ann Work Expo Health; 66: i202–i217. [DOI] [PMC free article] [PubMed]

- Stenzel MR, Groth CP, Huynh TBet al. (2021) Exposure group development in support of the NIEHS GuLF Study. Ann Work Expo Health; 66: i23–i55. [DOI] [PMC free article] [PubMed]

- Stewart PA, Gorman Ng M, Cherrie JWet al. (2021) Estimation of dermal exposure to oil spill response and clean-up workers after the Deepwater Horizon disaster. Ann Work Expo Health; 66: i234–i246. [DOI] [PMC free article] [PubMed]

- Stewart PA, Groth CP, Huynh TBet al. (2021) Assessing exposures from the Deepwater Horizon oil spill response and clean-up. Ann Work Expo Health; 66: i3–i22. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Teske E, Miller M, Thistle Het al. (2009) Initial development and validation of a mechanistic spray drift model for ground boom sprayers. Trans ASABE; 52: 1089–97. [Google Scholar]

- Teske ME, Thistle HW, Ice GG.(2003) Technical advances in modeling aerially applied sprays. Transactions of the ASAE; 985–96. [Google Scholar]

- Teske ME, Bird SL, Esterly DMet al. (2002) AgDRIFT: a model for estimating near-field spray drift from aerial applications. Environ Toxicol Chem; 21: 659–71. [DOI] [PubMed] [Google Scholar]

- United States Environmental Protection Agency (EPA, U.S.). 2015. (2015) Combined WRF/MMIF/ AERCOARE/AERMOD overwater modeling approach for offshore emission sources. In: Region 10. Seattle, WA. [Google Scholar]

- Westerholm DA, Rauch SD. (2016) Deepwater Horizon oil spill: final programmatic damage assessment and restoration plan and final programmatic environmental impact statement. Available at https://repository.library.noaa.gov/view/noaa/18084. Accessed 28 September 2020.

- Yates EW, Akesson BN, Cowden ER (1974) Criteria for minimizing drift residues on crops downwind from aerial applications. Trans ASAE; 17: 627–32. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The data underlying this article will be shared on reasonable request, consistent with protections for the privacy of study participants and existing multiparty agreements. Requests should be made following instructions on the study website https://gulfstudy.nih.gov.